High-speed aircraft empennage underwater laser processing device

A high-speed aircraft, underwater laser technology, used in laser welding equipment, metal processing equipment, instruments and other directions, can solve the problems of low material utilization, low processing efficiency, low processing accuracy, etc., to improve cutting quality, avoid underwater Operation, the effect of reducing the heat affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

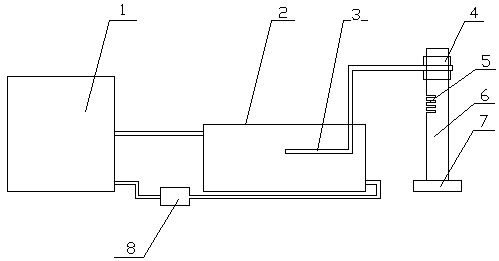

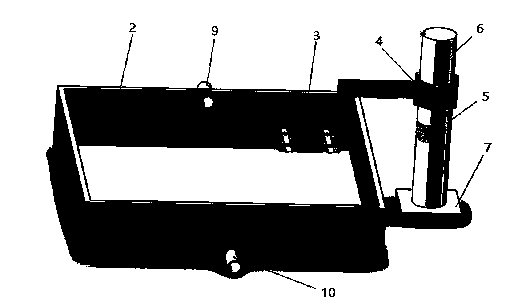

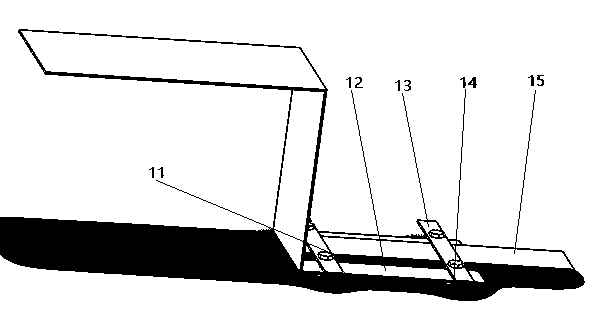

[0020] The high-speed aircraft empennage underwater laser processing device provided by the present invention includes: 9-water inlet, which is set on the upper end of 2-liquid tank side, so that the working fluid flows into the 2-liquid tank; 2-liquid tank, used to store the working fluid , to provide the necessary environment for the processing of the empennage sample; 10-water outlet is set at the lower end of 2-liquid tank, so that the working fluid can be discharged smoothly from the tank; 8-filter is connected to 10-water outlet through one end of the pipe, and the other One end is connected to the 1-chiller, which is used to filter the residue and debris in the working fluid to ensure the cleanliness of the working fluid in the entire circuit; the 1-chiller is connected to the 8-filter at one end of the pipeline, and the other end is connected to the 9-water inlet , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com