Automatic material collecting equipment for slitting large-opening-diameter thick-wall pipe and working method thereof

A technology for automatic material collection and thick-walled pipes, which is applied in the direction of shearing machine equipment, metal processing equipment, pipe shearing devices, etc., can solve the problems of not meeting the cutting requirements, consuming a lot of manpower and material resources, and small cutting range, so as to improve the practicality and richness, improve the scope of application, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0035] see Figure 1-9 , the present invention provides a technical solution:

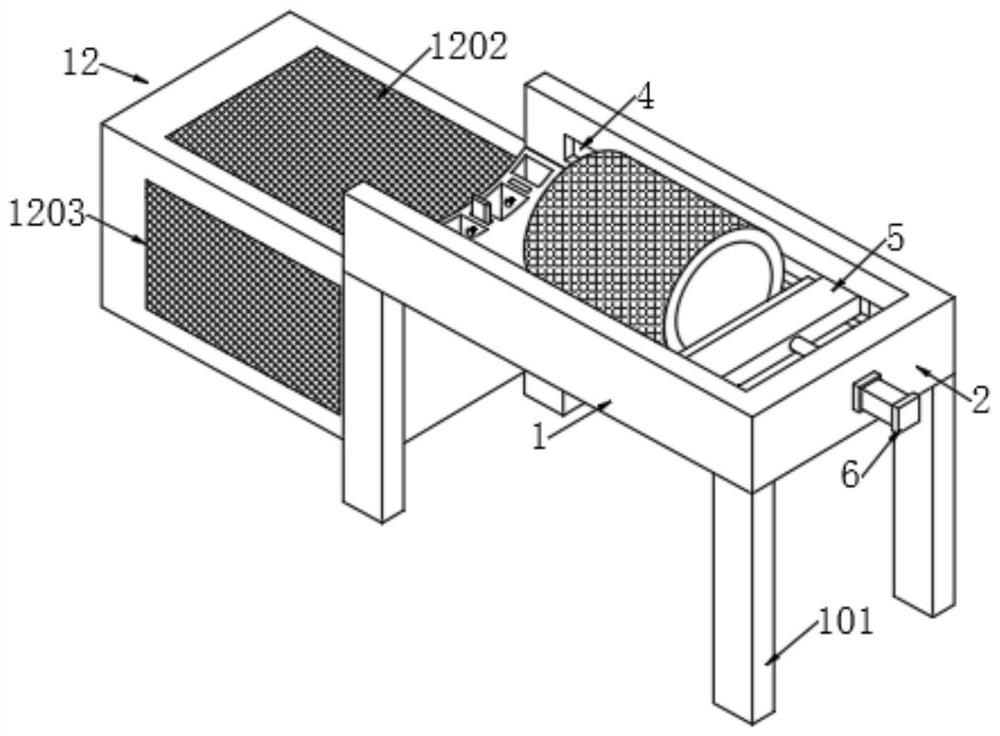

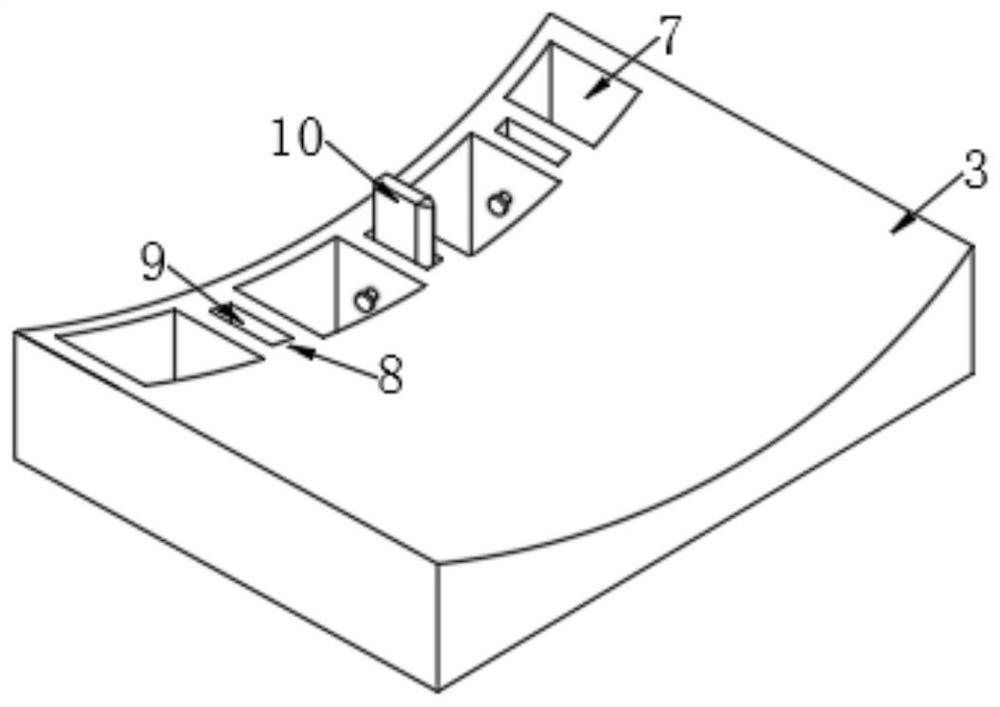

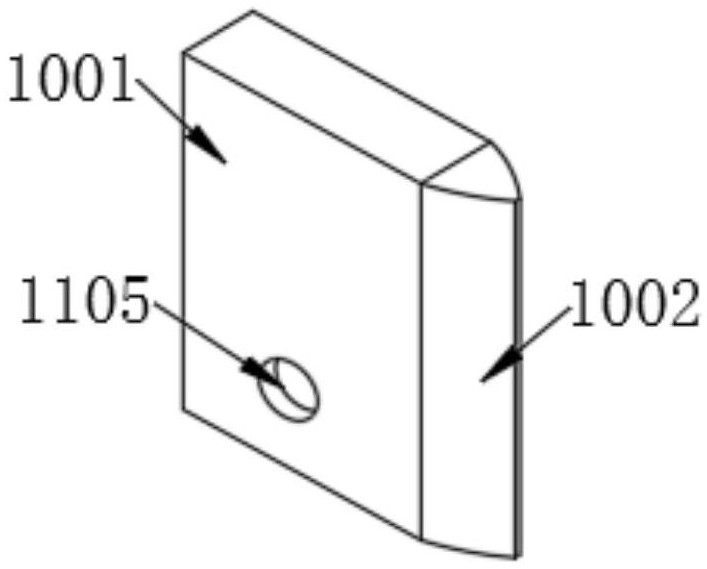

[0036] An automatic material receiving equipment for large-diameter thick-walled pipe slitting, including two symmetrically distributed first support plates 1, a second support plate 2 is fixed between one end of the two first support plates 1, and two first support plates 1 A placing platform 3 is fixed between the bottom ends of the supporting plates 1, and the upper surface of the placing platform 3 is provided with a first annular placing groove, and a large-diameter thick-walled pipe is placed in the first placing groove, and the first first annular placing groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com