Cutting machine

A technology of cutting machine and locking mechanism, which is applied in the direction of metal sawing equipment, sawing machine, metal processing equipment, etc., can solve the problems of limited adjustment distance, cutting machine cannot meet the cutting requirements, and the thickness range of the workpiece can be processed is small, etc., to achieve The effect of meeting cutting needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

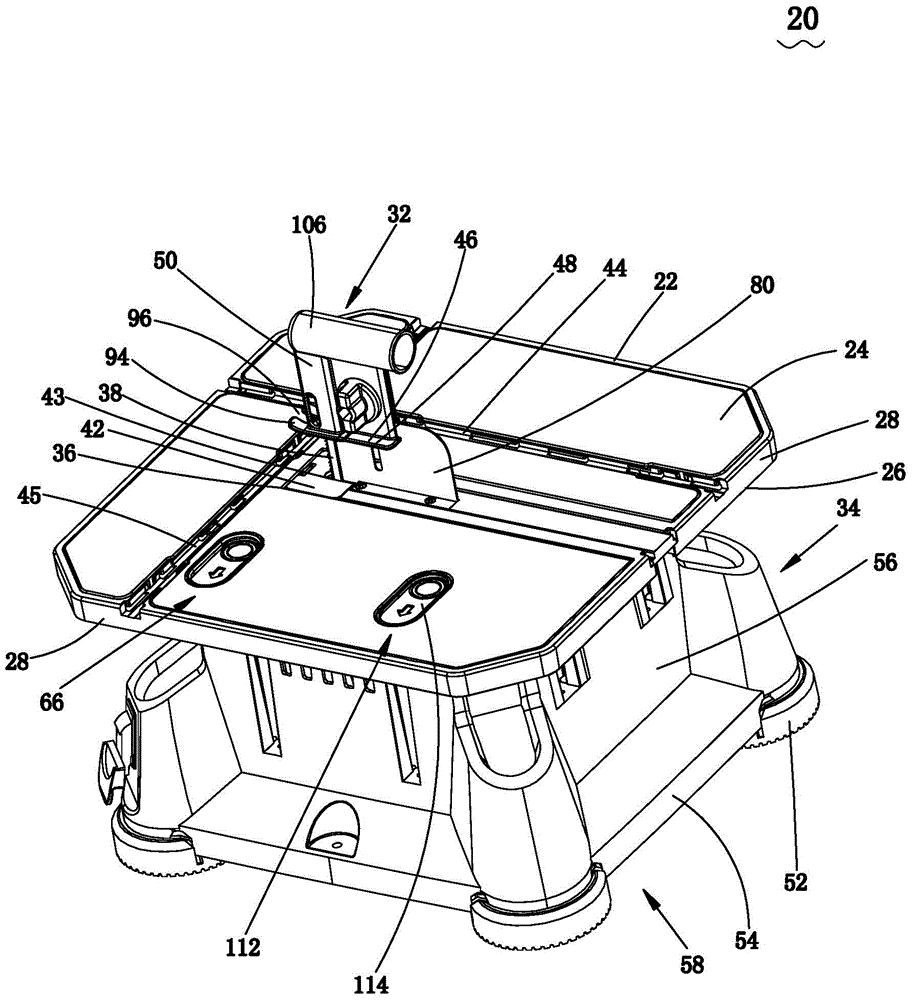

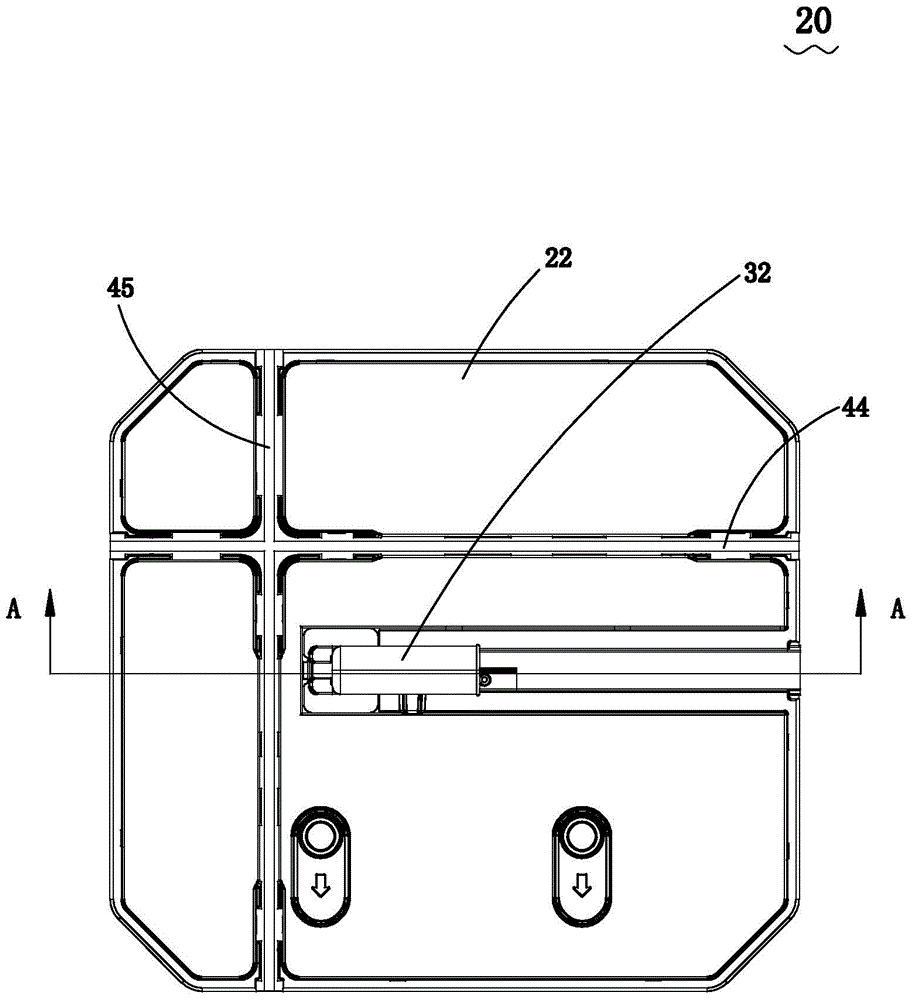

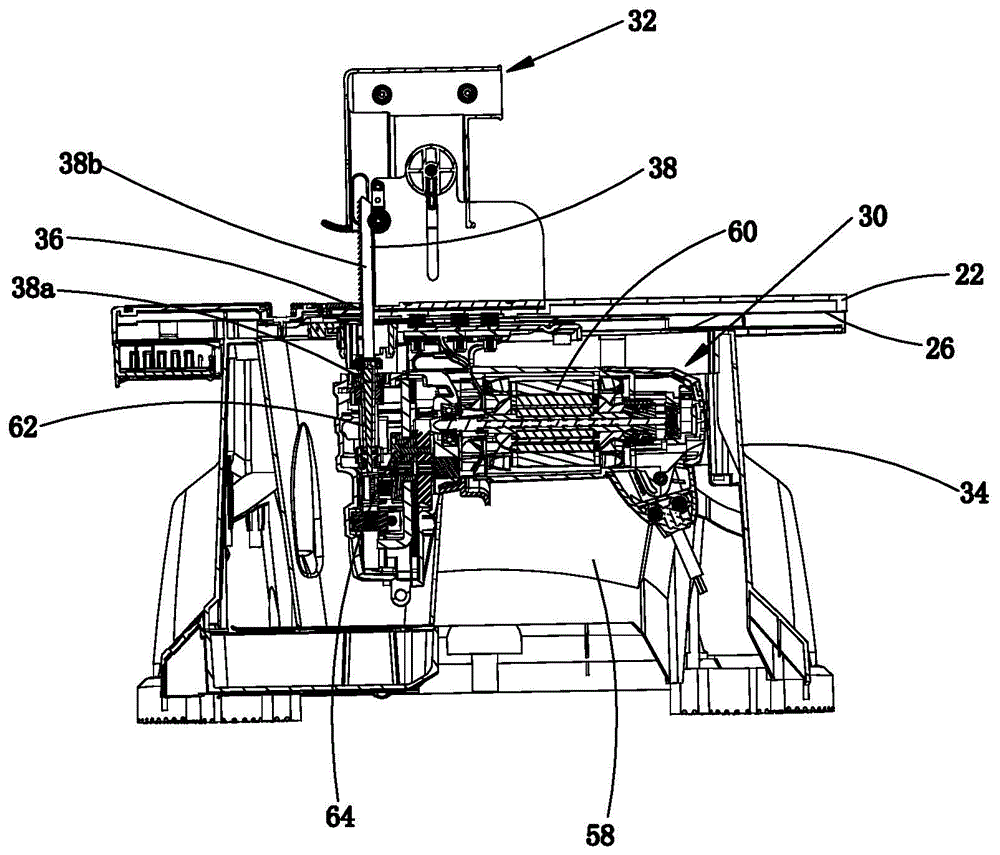

[0068] See attached Figure 1-3 , a cutting machine 20, including a table 22, the table 22 has an upper surface 24, a lower surface 26, and a side wall 28 extending vertically relative to the upper and lower surfaces 24,26. The upper surface 24 is used to support the workpiece.

[0069] The cutting machine 20 also includes a cutting mechanism 30 fixed on the lower surface 26 of the table 22, and a first platen assembly 32 disposed on the table 22, the first platen assembly 32 is used to exert a certain pressure on the workpiece. The support 34 is disposed under the workbench 22 for supporting the workbench 22 .

[0070] The opening 36 is defined on the workbench 22 and penetrates from the upper surface 24 to the lower surface 26 . The saw blade 38 passes through the opening 36 from bottom to top. A workpiece (not shown) may be placed on the upper surface 24 of the table 22 along which the workpiece is moved past the saw blade 38 to be cut by the saw blade 38 . The shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com