Patents

Literature

31results about How to "Change cutting angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

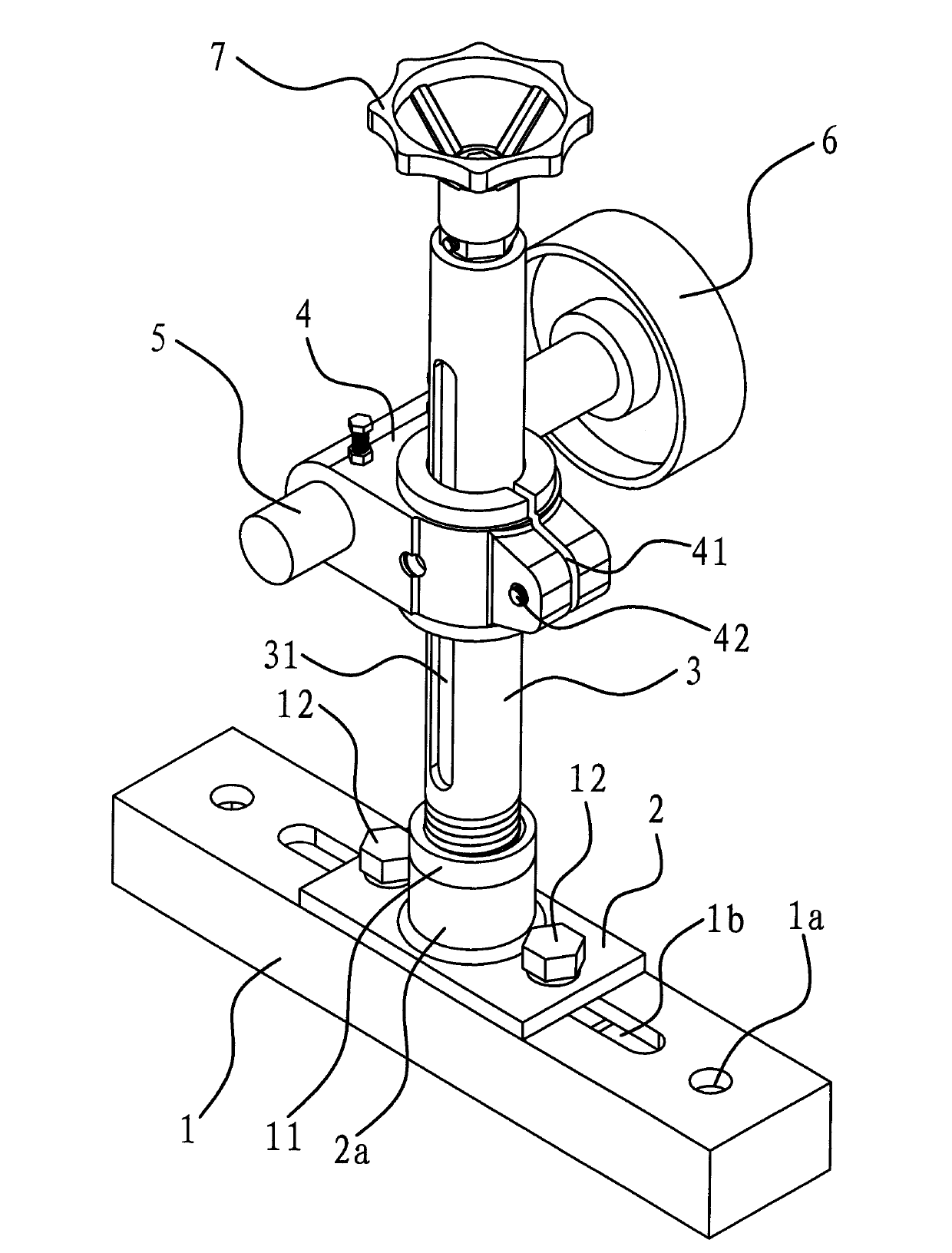

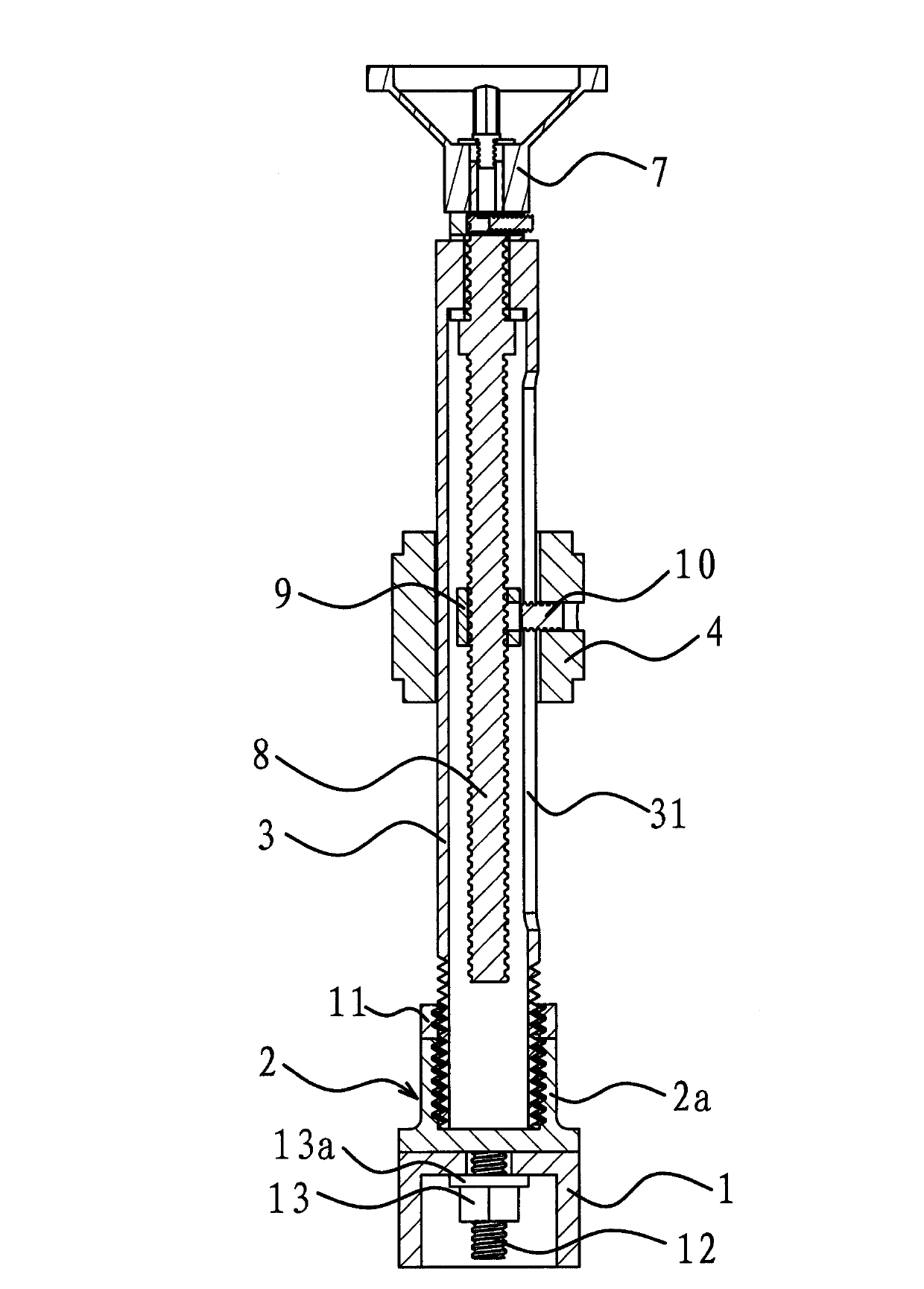

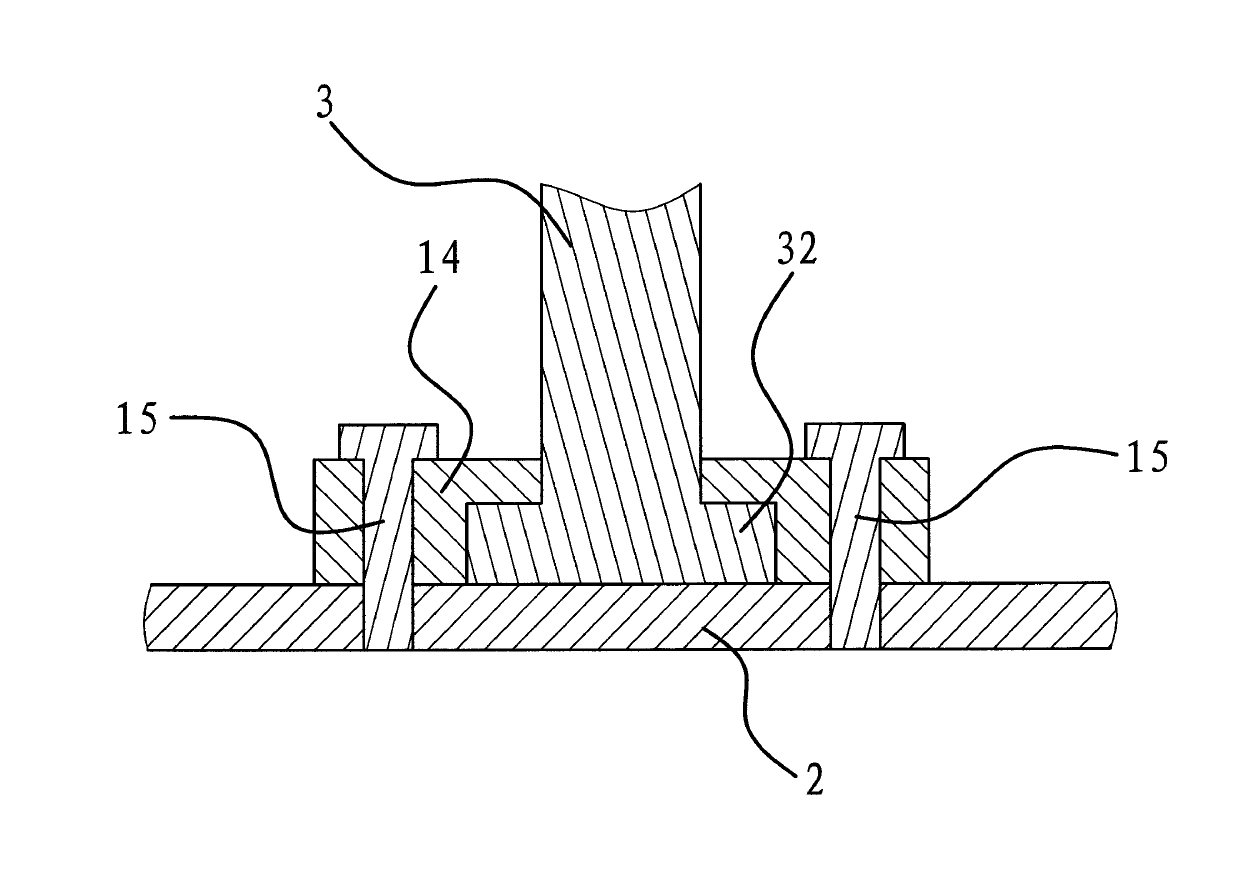

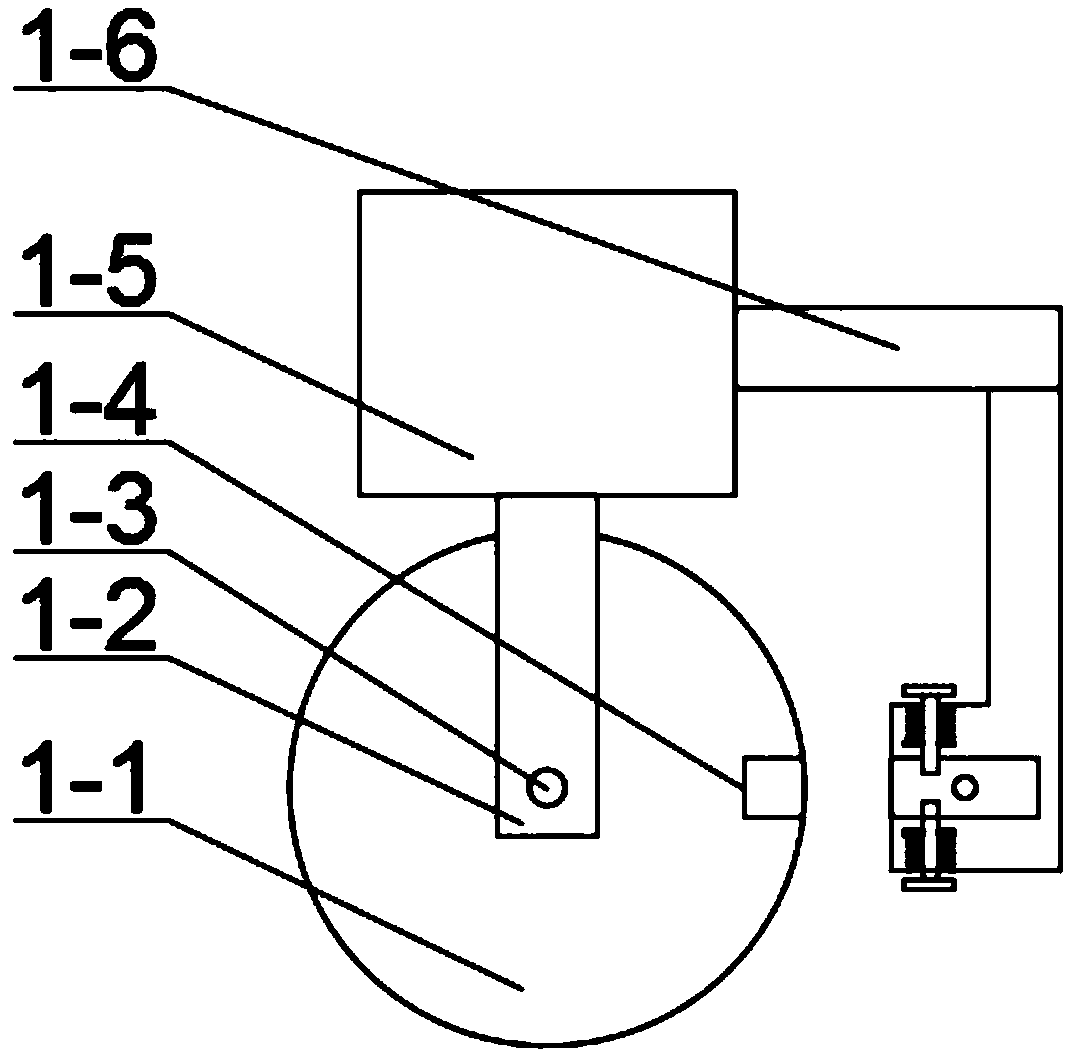

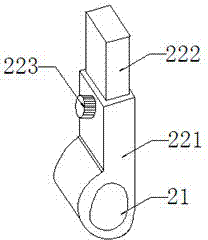

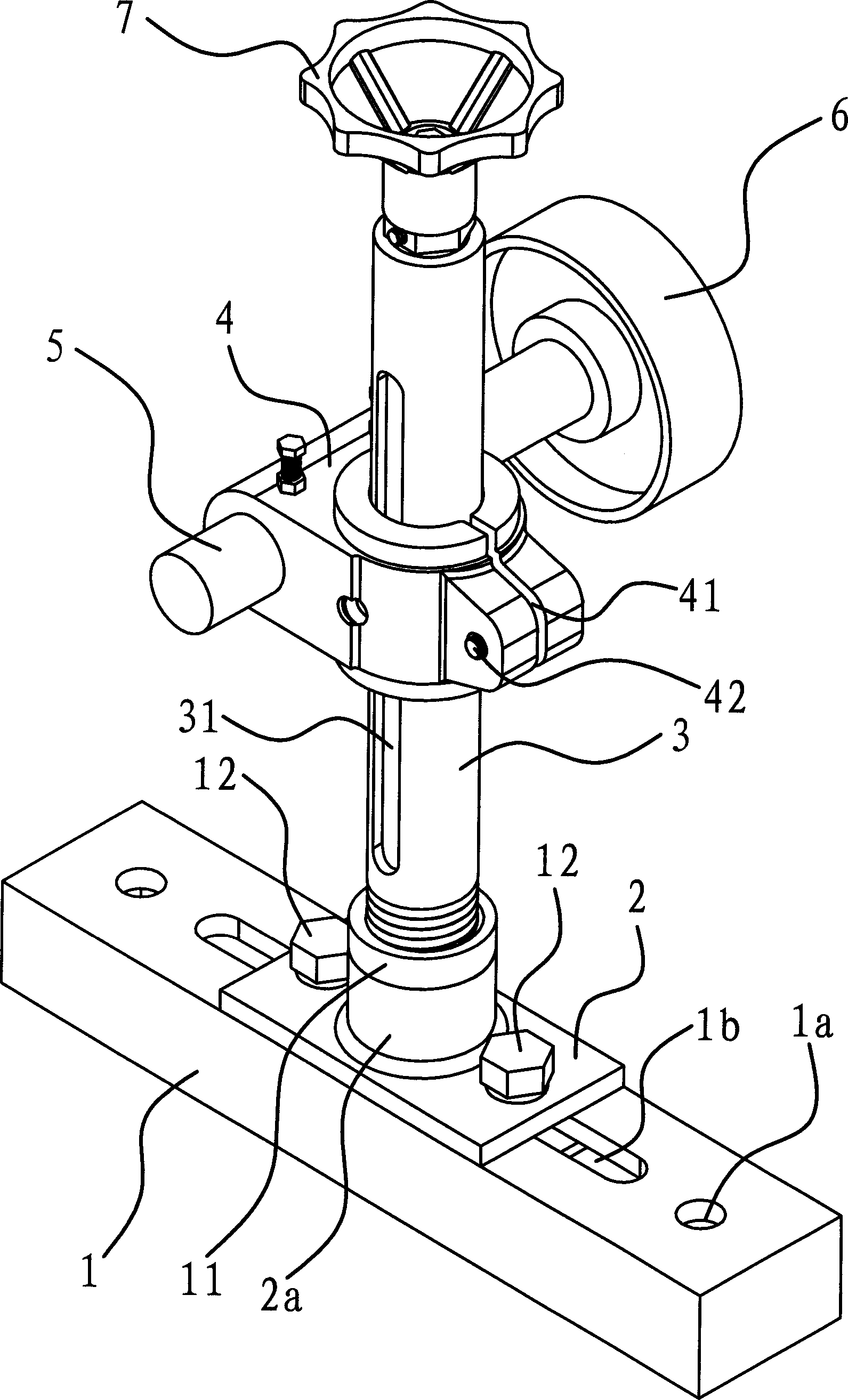

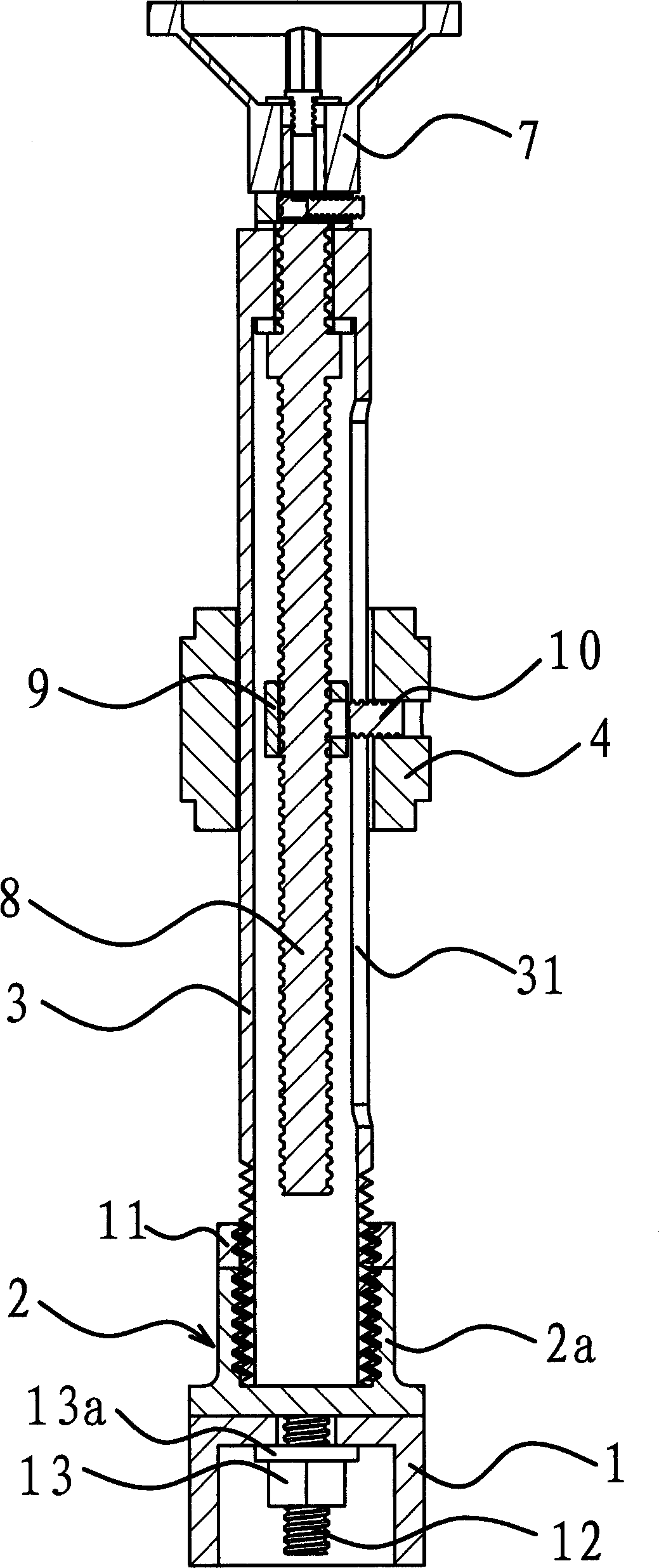

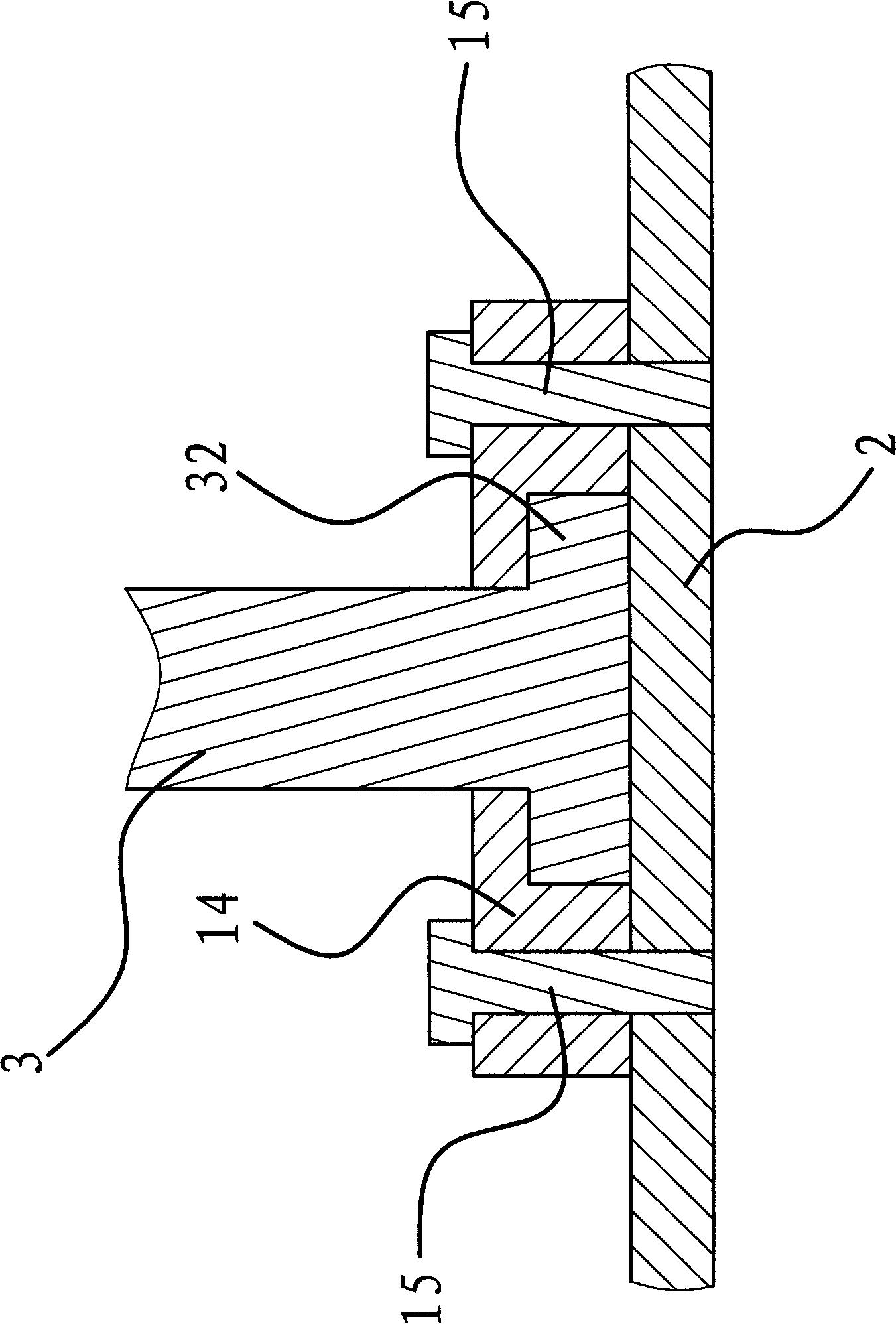

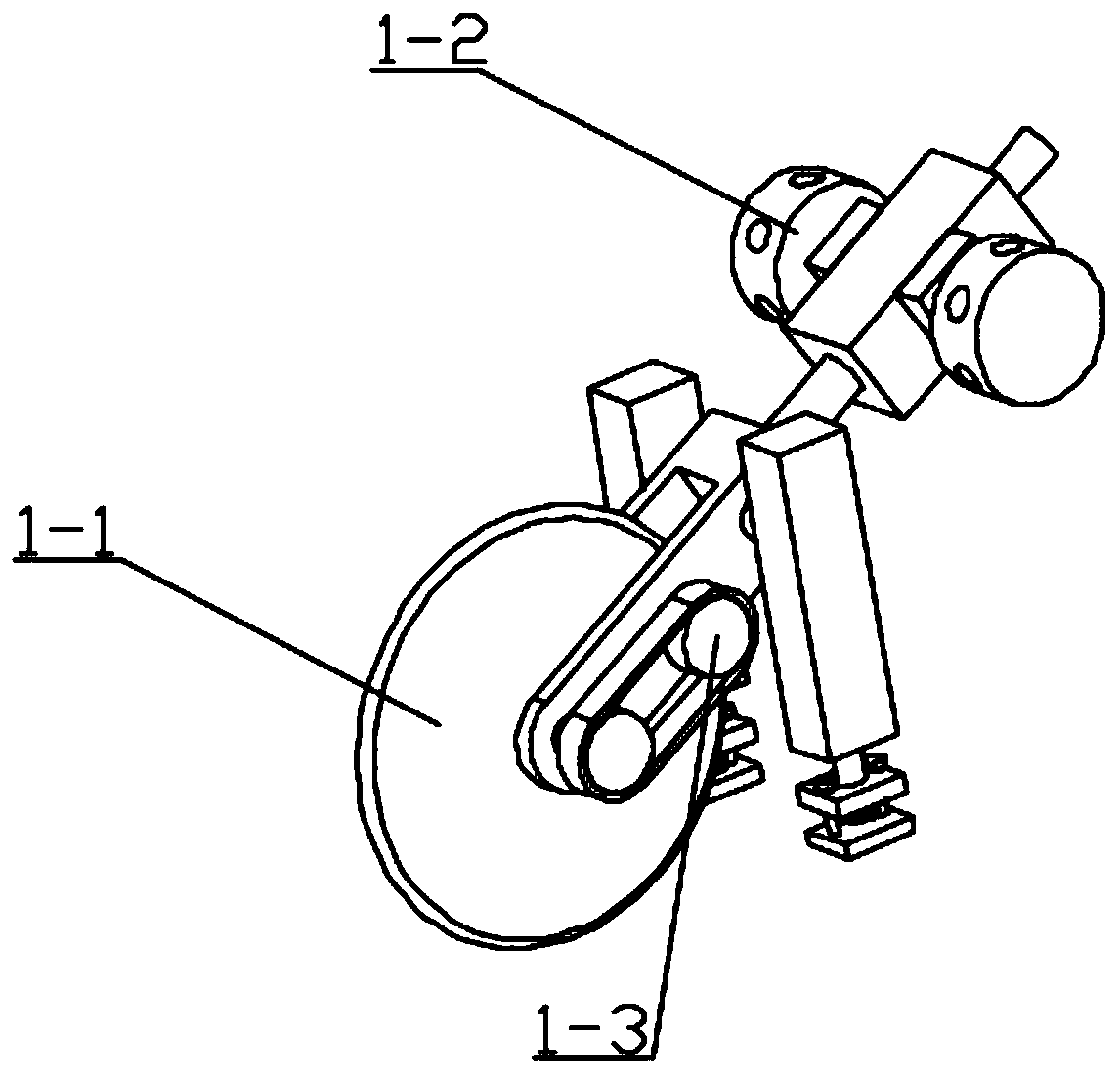

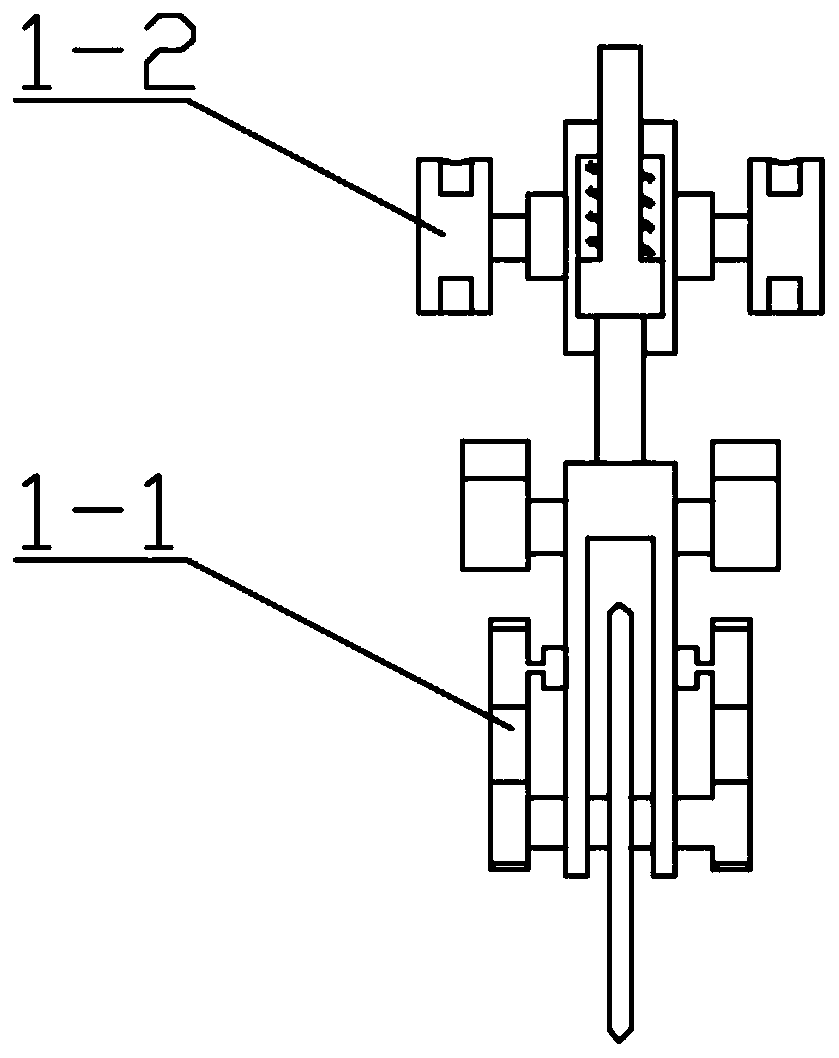

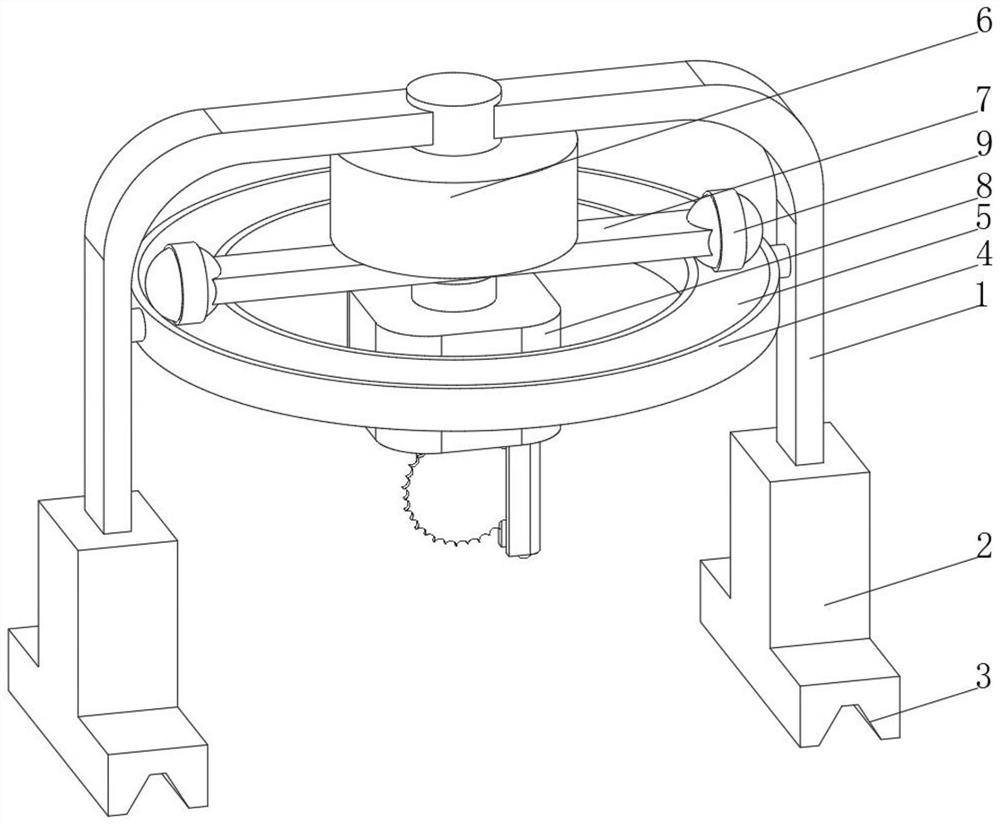

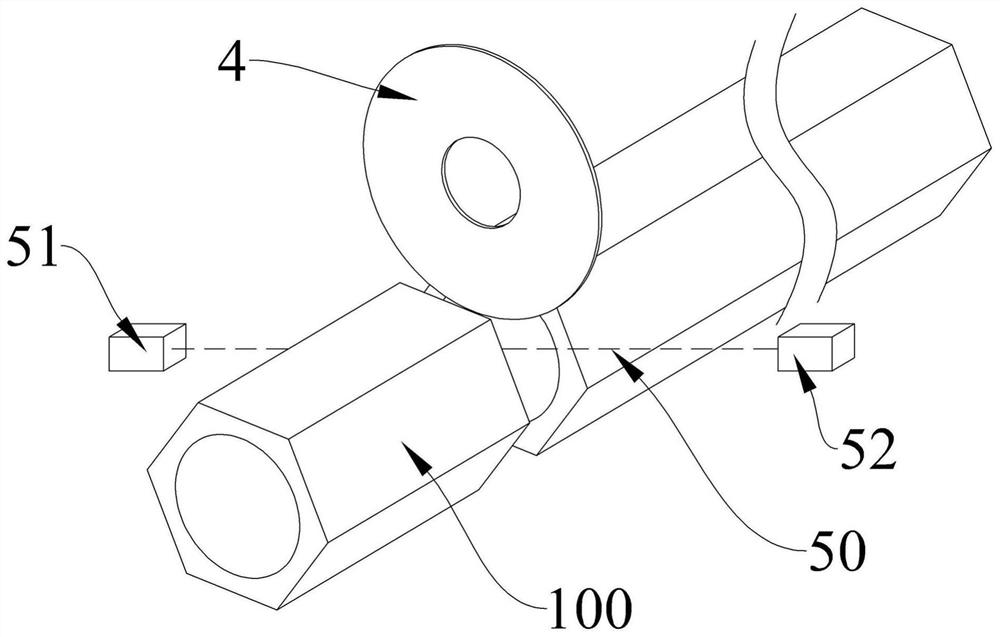

Regulating device of belt wheel

The invention provides a regulating device of belt wheel, belonging to the technical field of machinery, and solving the problem that the existing regulating device of belt wheel is not provided with a mechanism for regulating a driven wheel to rotate circumferentially. The regulating device of belt wheel comprises a seat and a vertical shaft vertically arranged on the seat, a spindle is arranged on the vertical shaft perpendicular to the vertical shaft, a belt wheel is sheathed on the spindle, and a positioning mechanism capable of causing the vertical shaft to do rectilinear translation and / or rotation regulation along the seat and positioning the vertical shaft after regulation is finished. The vertical shaft of the regulating device of belt wheel does rectilinear translation and / or rotation regulation and the spindle can move along the axial direction of the vertical shaft, the spindle, the vertical shaft and the regulating device can be regulated individually or jointly to drive the belt wheel to move to regulate the belt wheel to a proper position more conveniently, and the invention has the advantage of convenient, exact and stable regulating.

Owner:陈文满

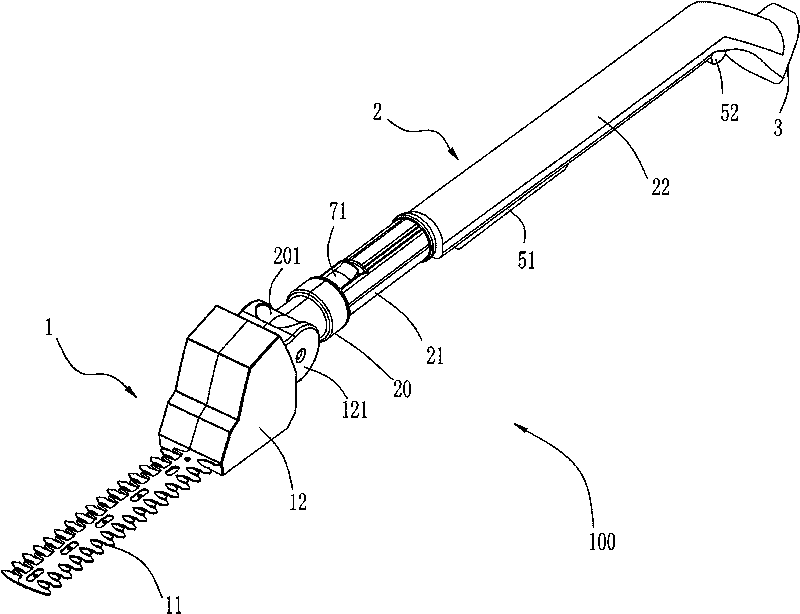

Power tool

ActiveCN101722505ASimple internal structureEasy to operateHedge trimming apparatusCuttersEngineeringPower tool

Owner:NANJING CHERVON IND

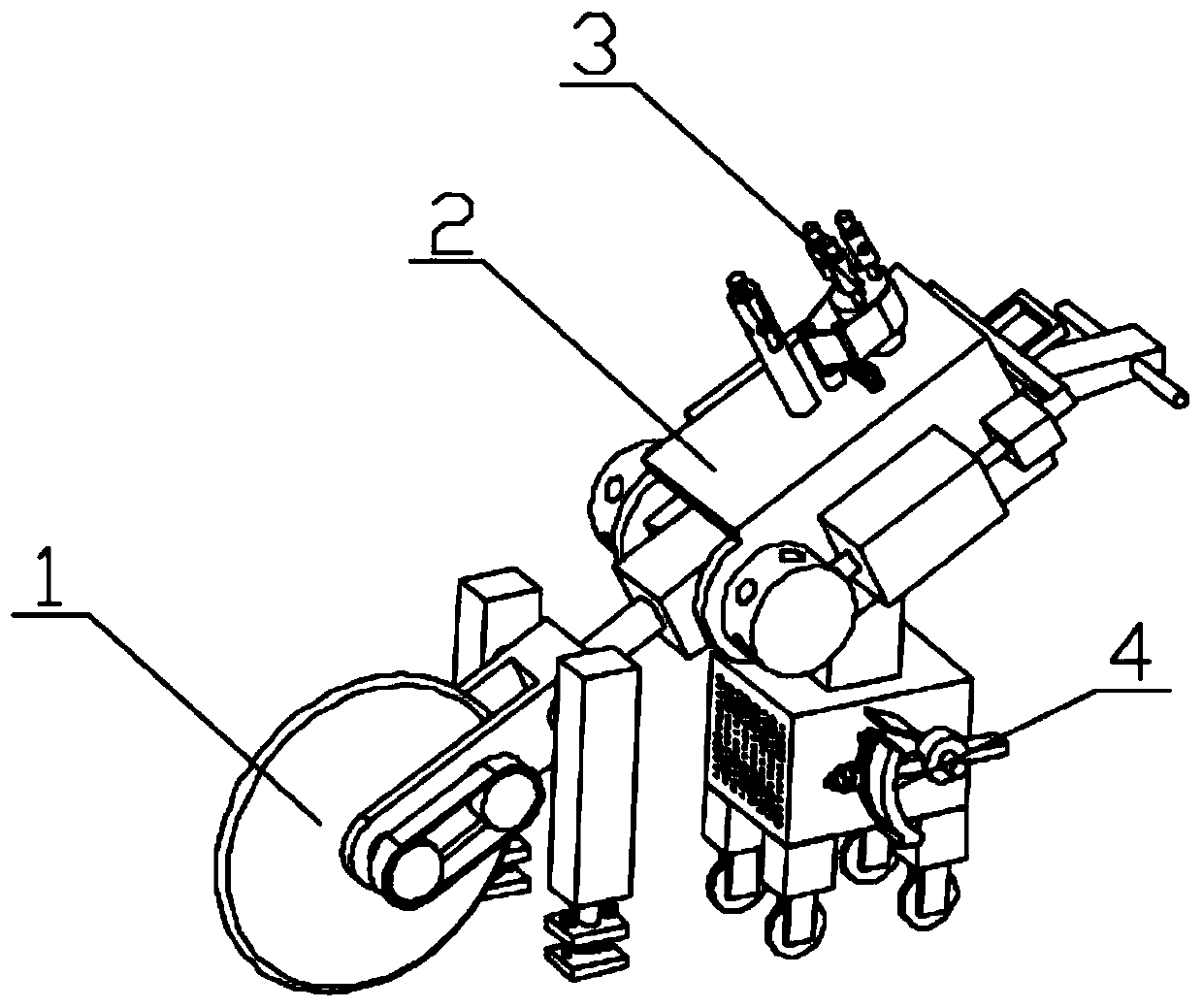

Multifunctional road cutting device

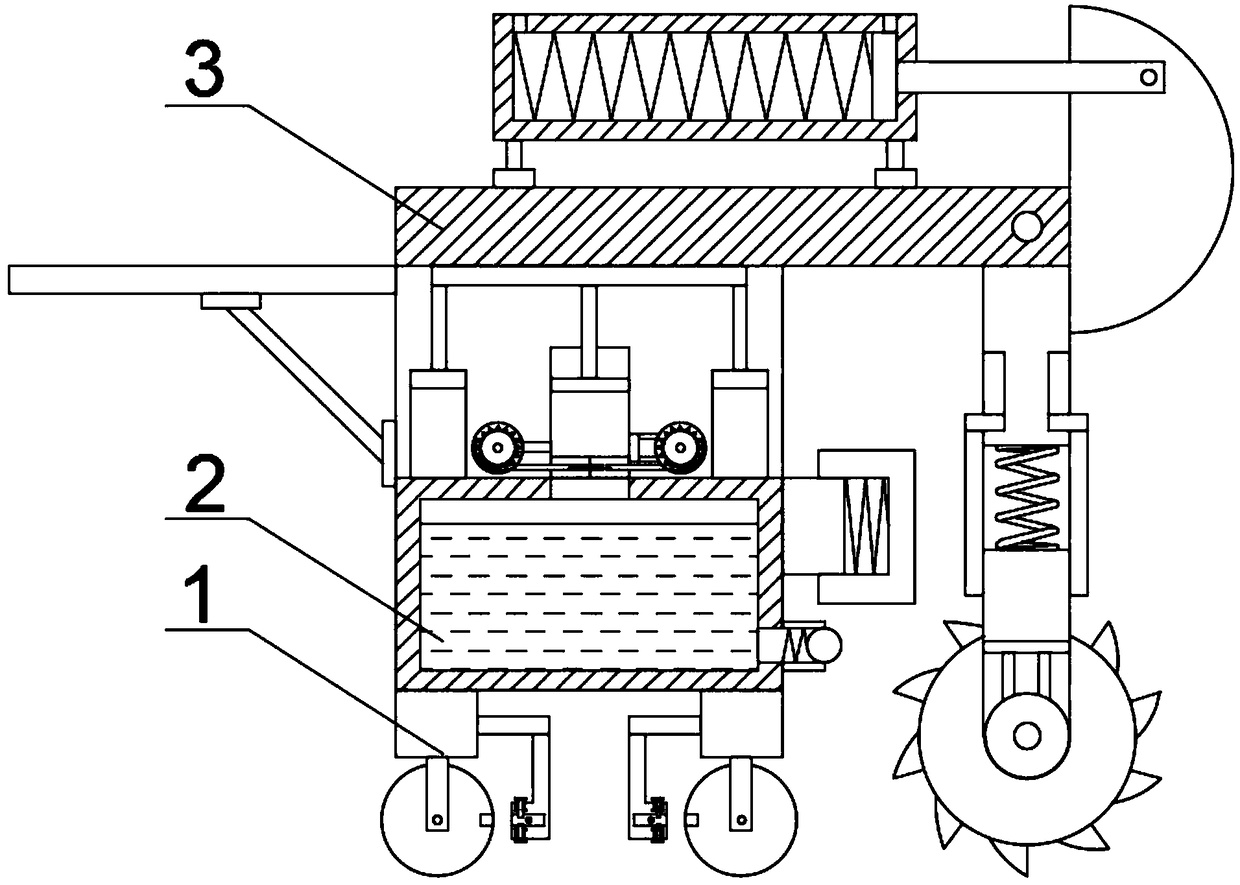

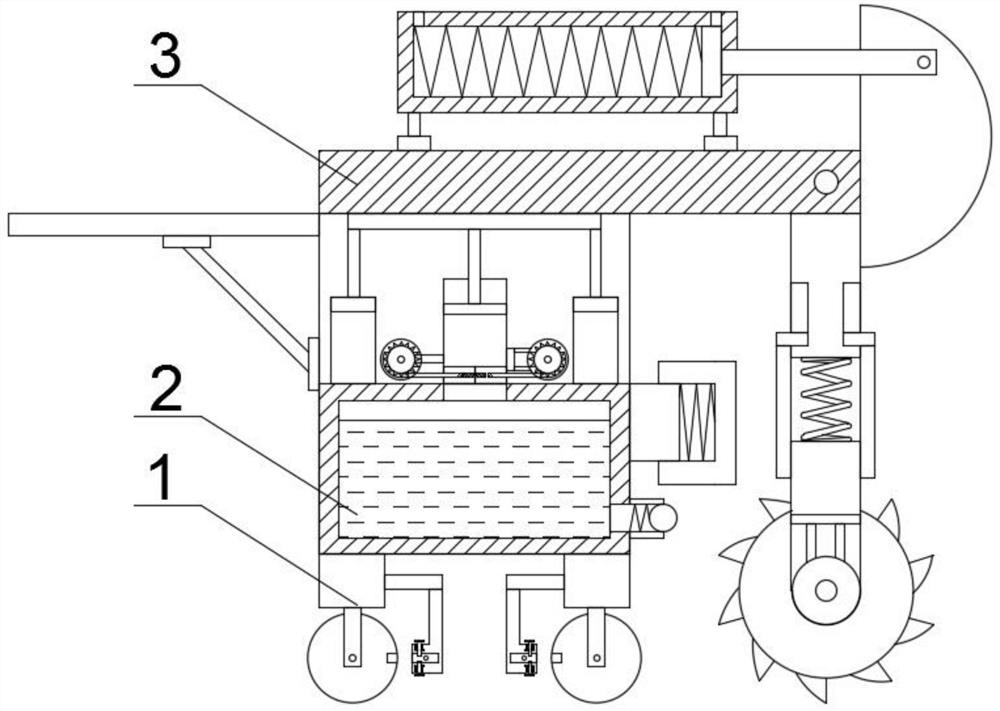

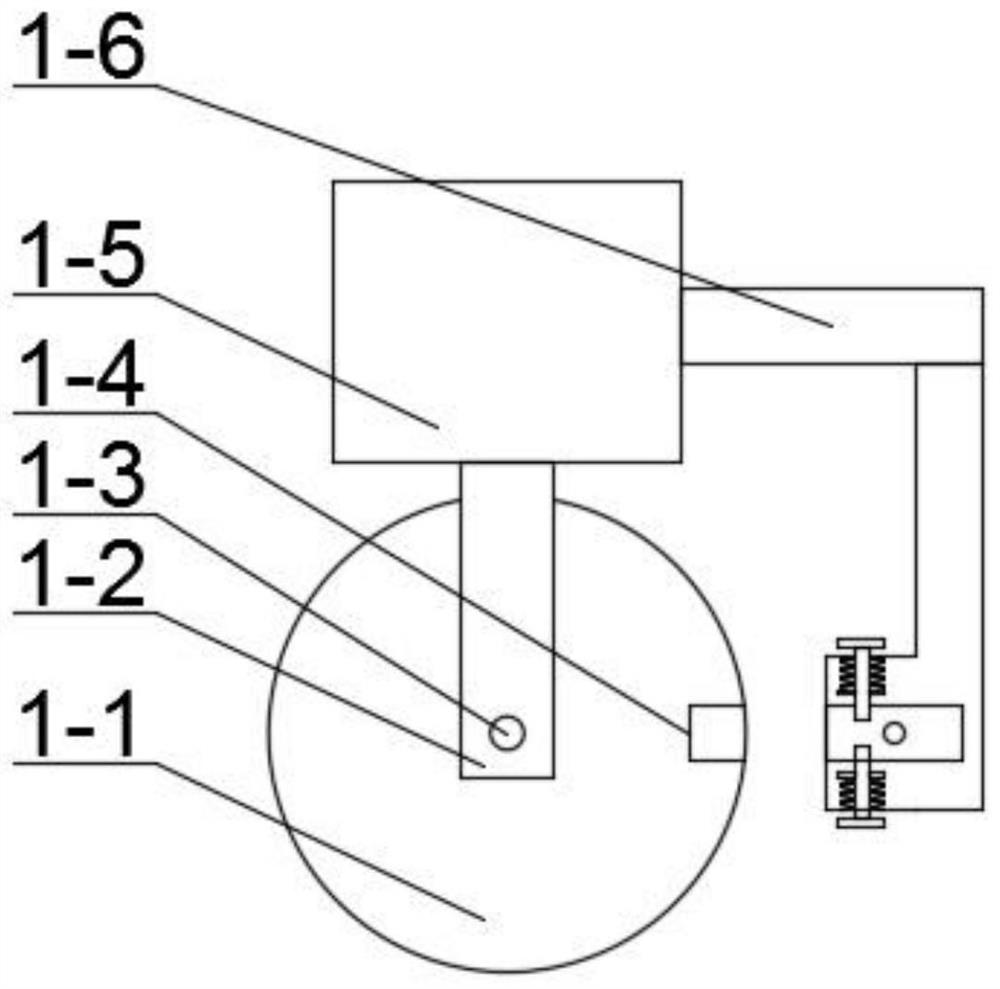

The invention relates to a cutting device, in particular to a multifunctional road cutting device. A moving parking wheel mechanism, a water spraying cooling mechanism and a rotating cutter mechanismare included. The device can cut the ground, change the cutting angle and guarantee certain buffering allowance, and cutter damage is prevented. The device can automatically spray water to cool a cutter. The device can move and can achieve the parking function. The device can safely run. The long usage year limit of the device can be guaranteed. The moving parking wheel mechanism is located belowthe water spraying cooling mechanism, and the connecting manner of the moving parking wheel mechanism and the water spraying cooling mechanism is welding. The rotating cutter mechanism is located above the water spraying cooling mechanism, and the connecting manner of the rotating cutter mechanism and the water spraying cooling mechanism is welding.

Owner:青海省交控建设工程集团有限公司

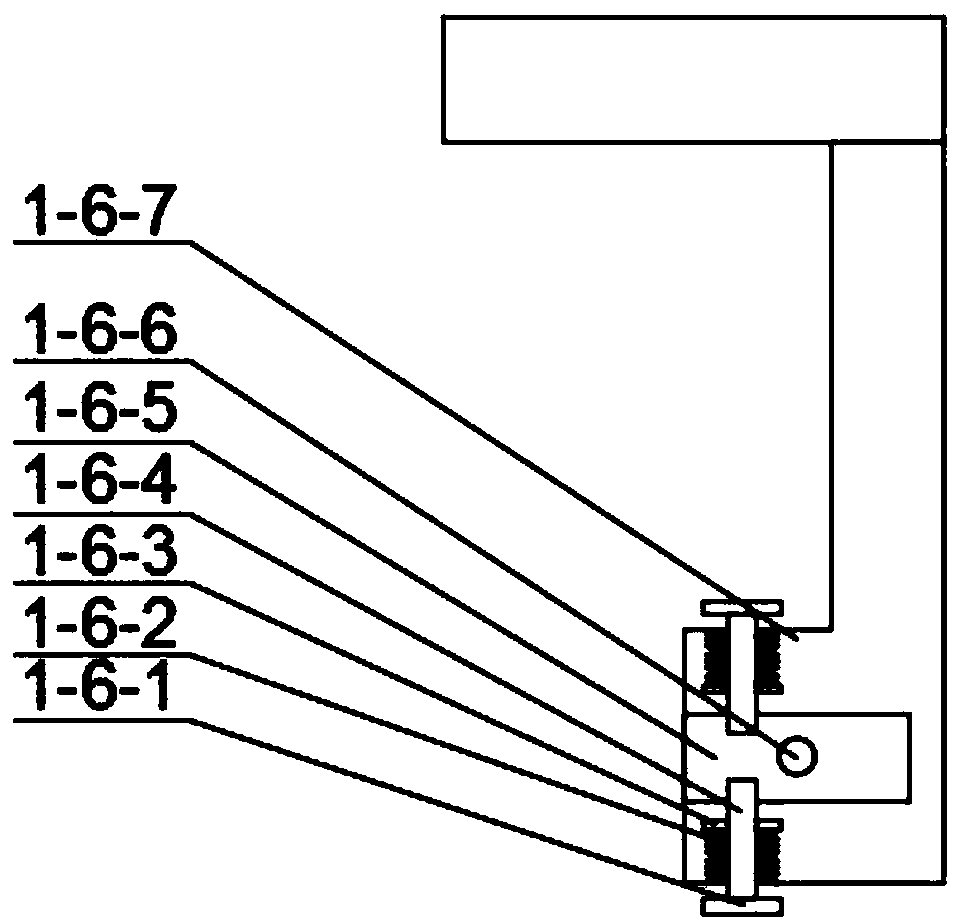

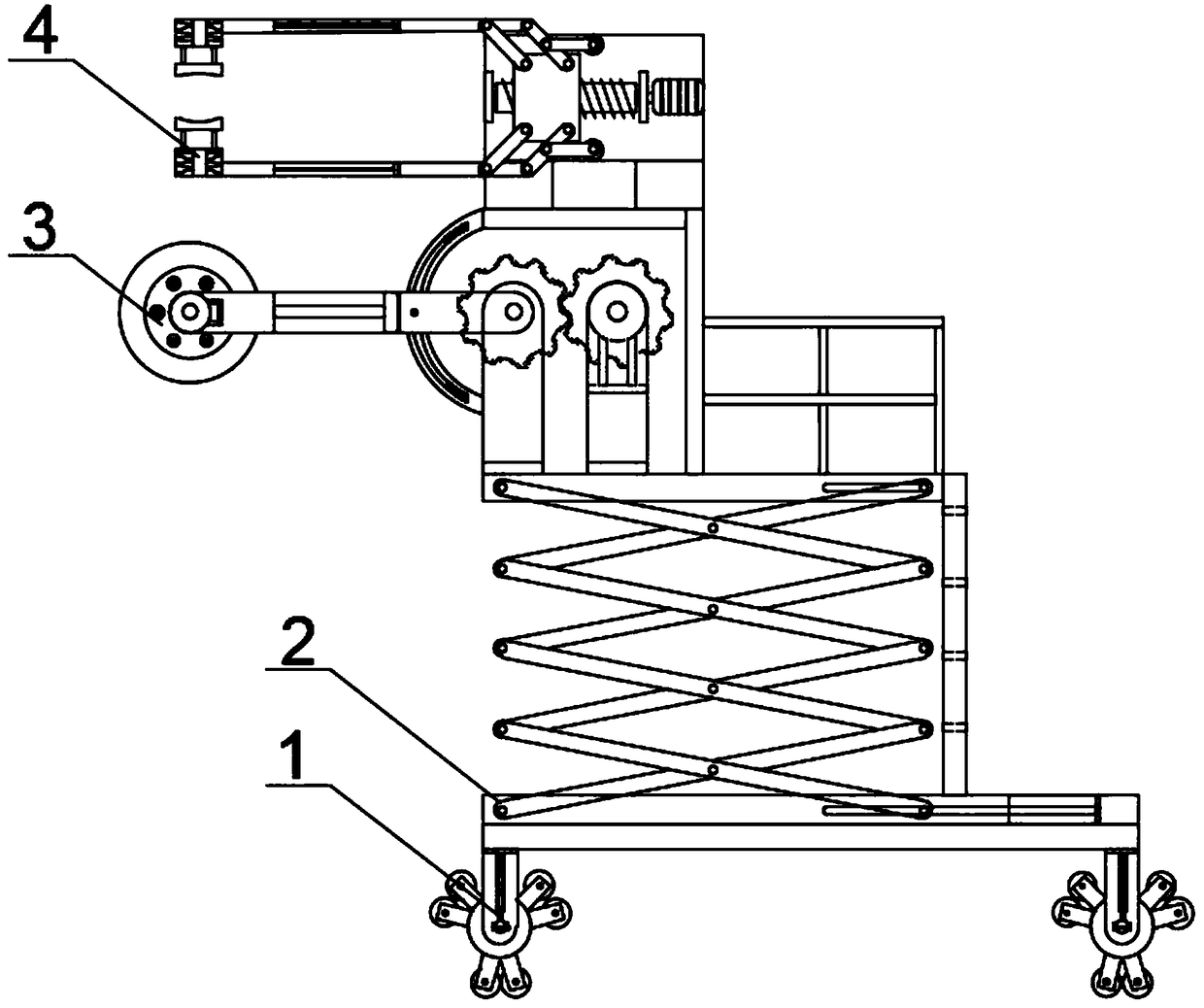

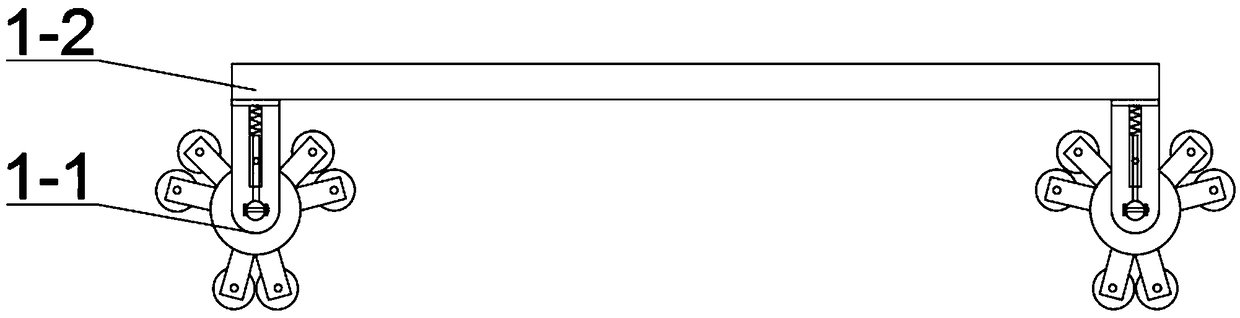

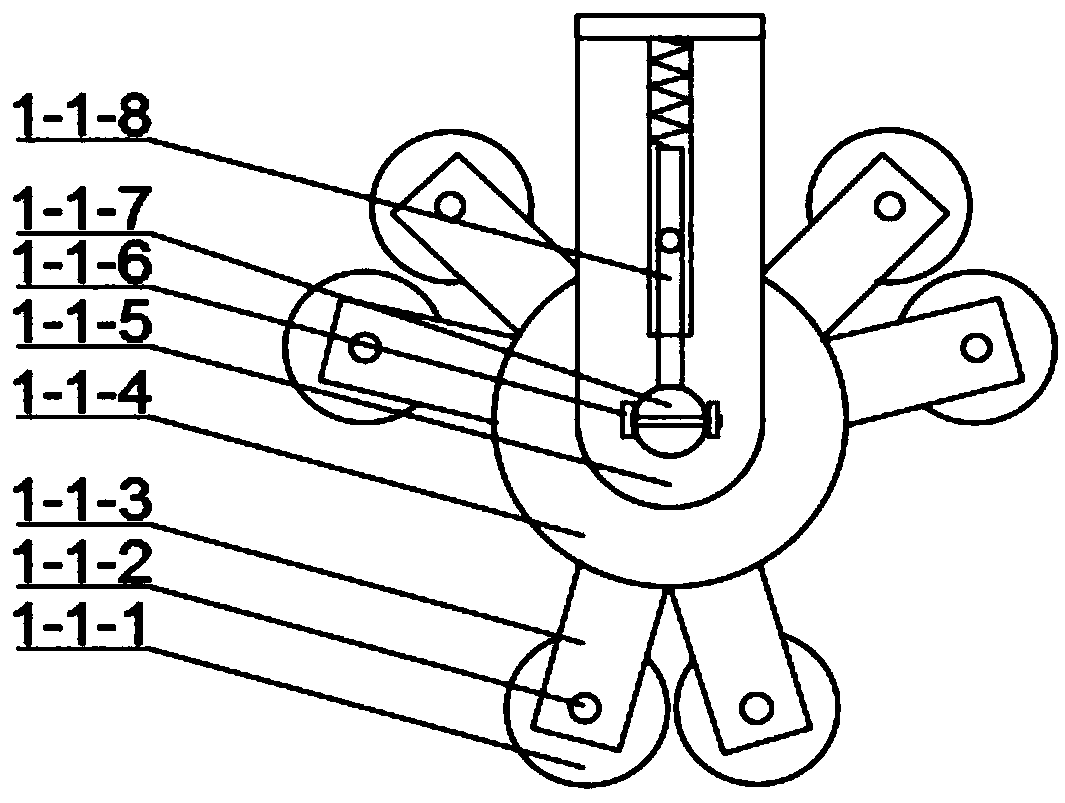

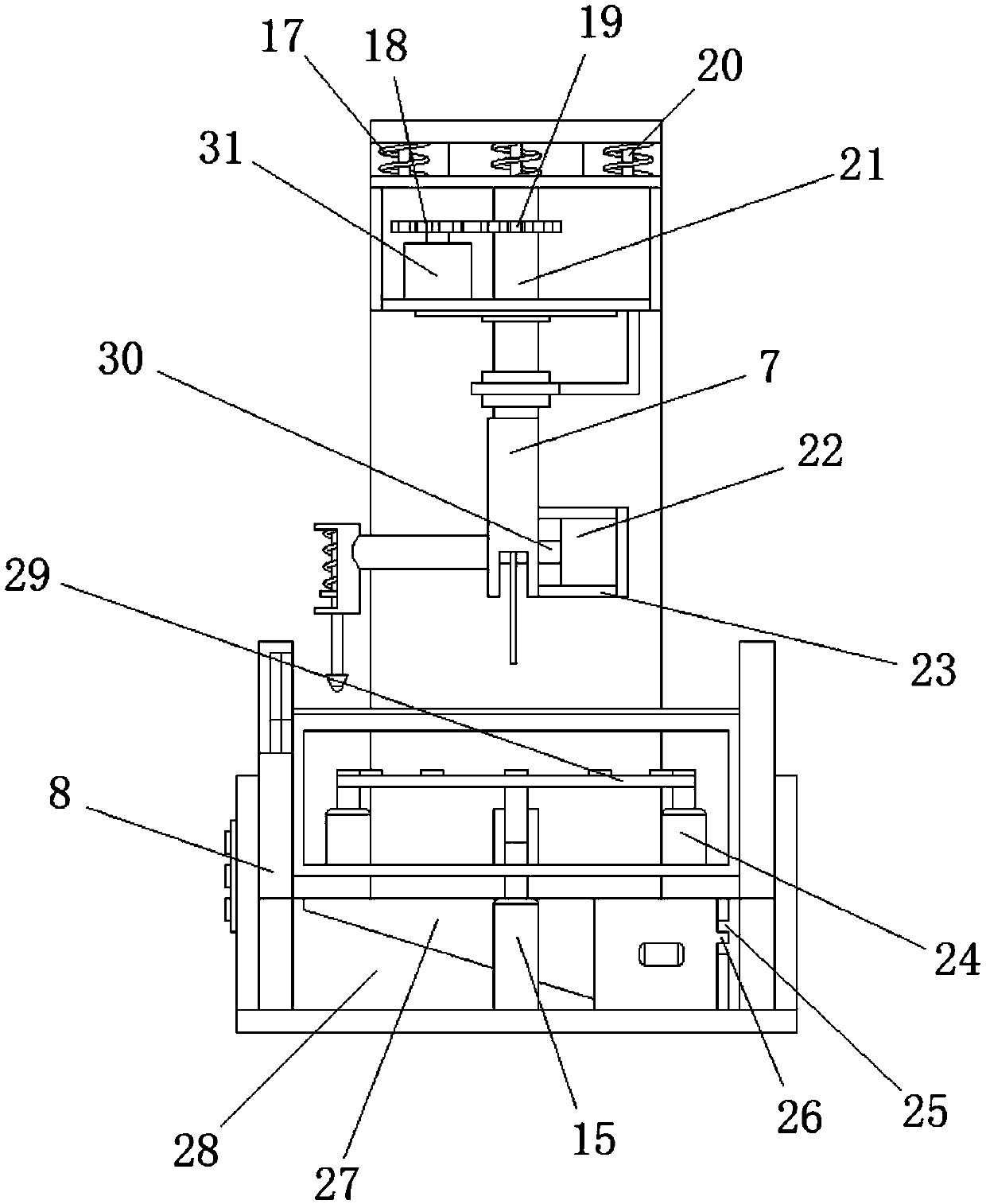

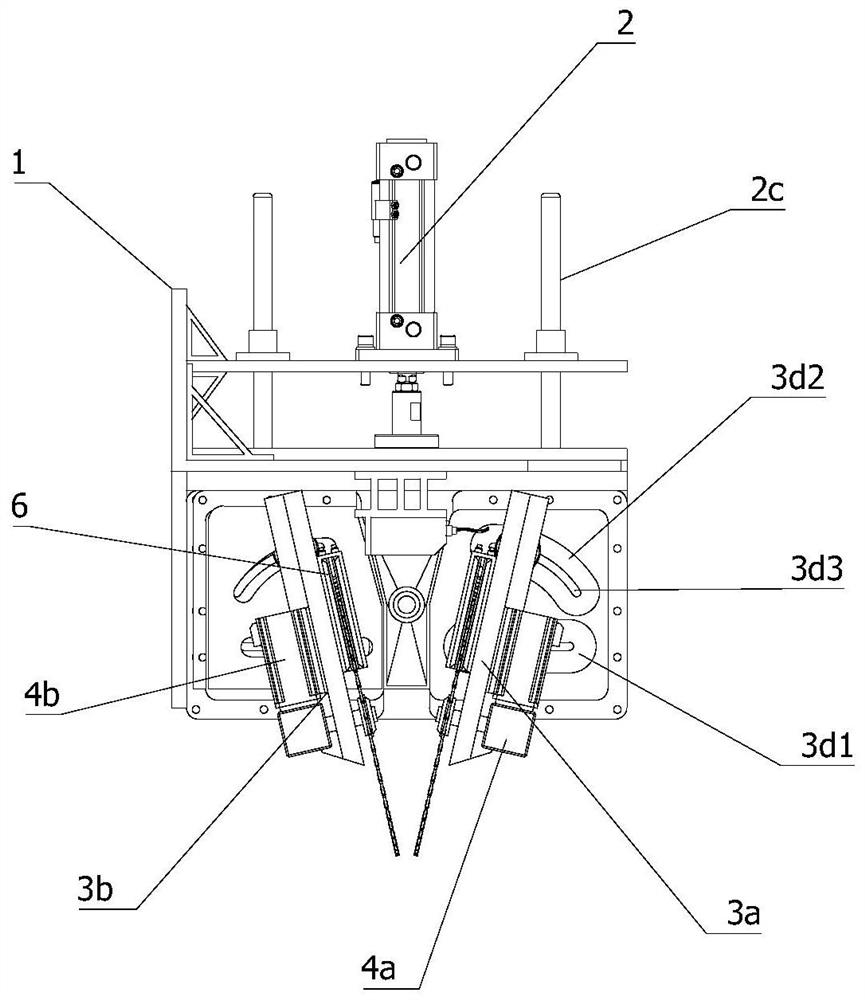

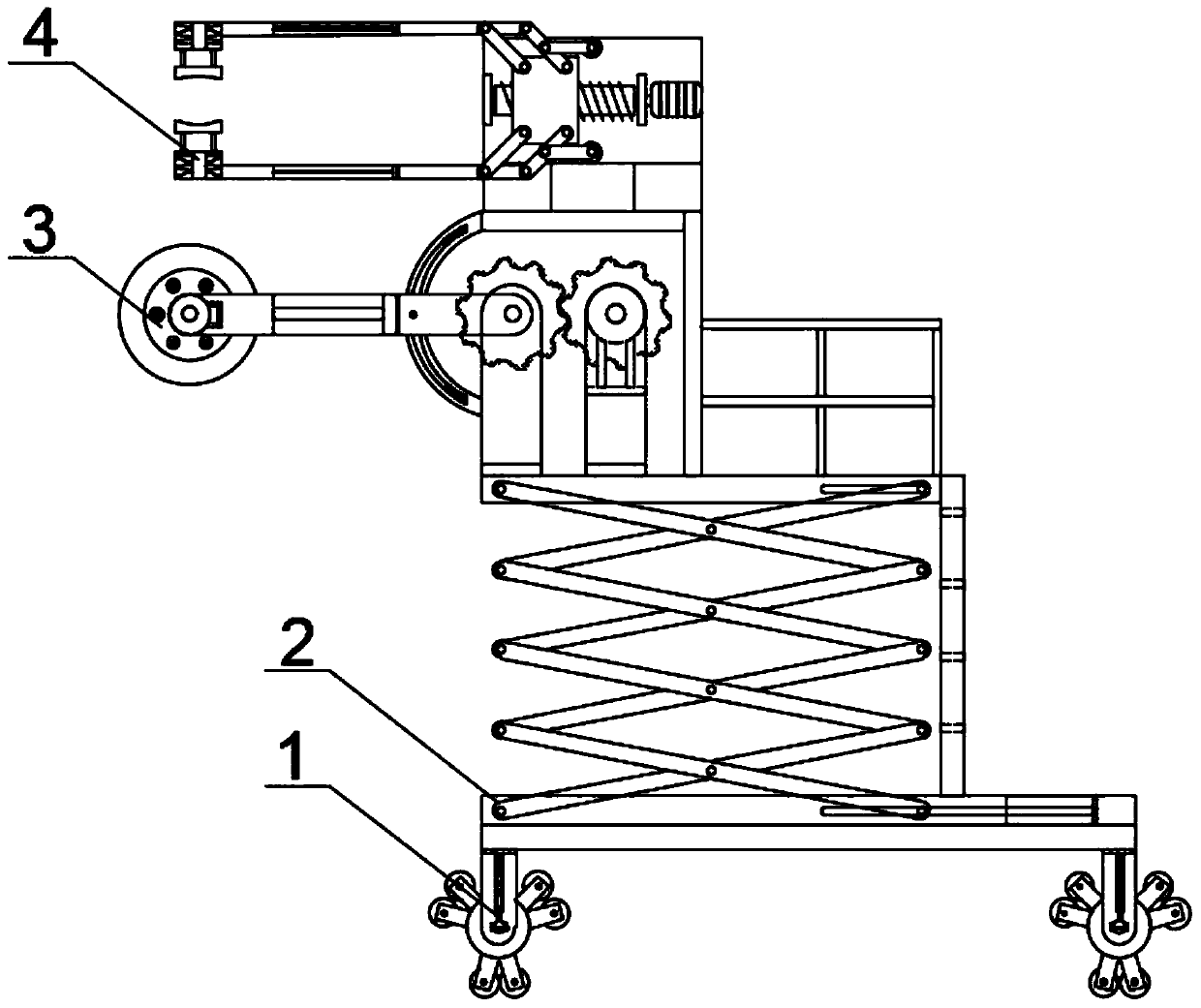

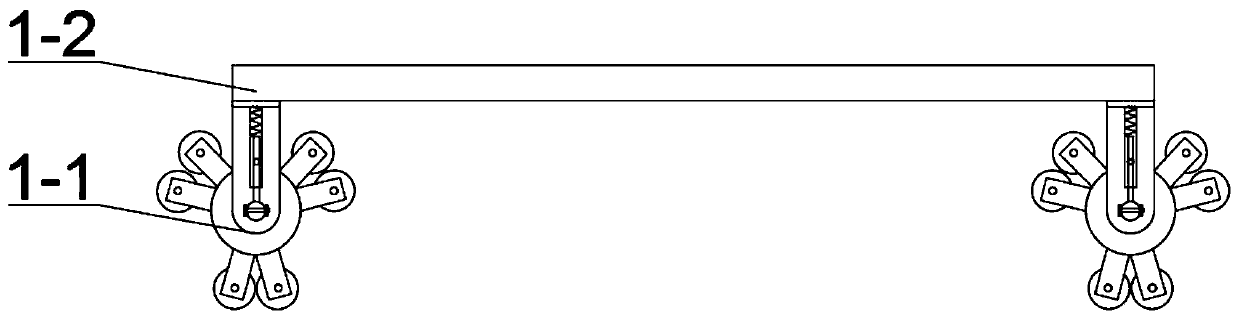

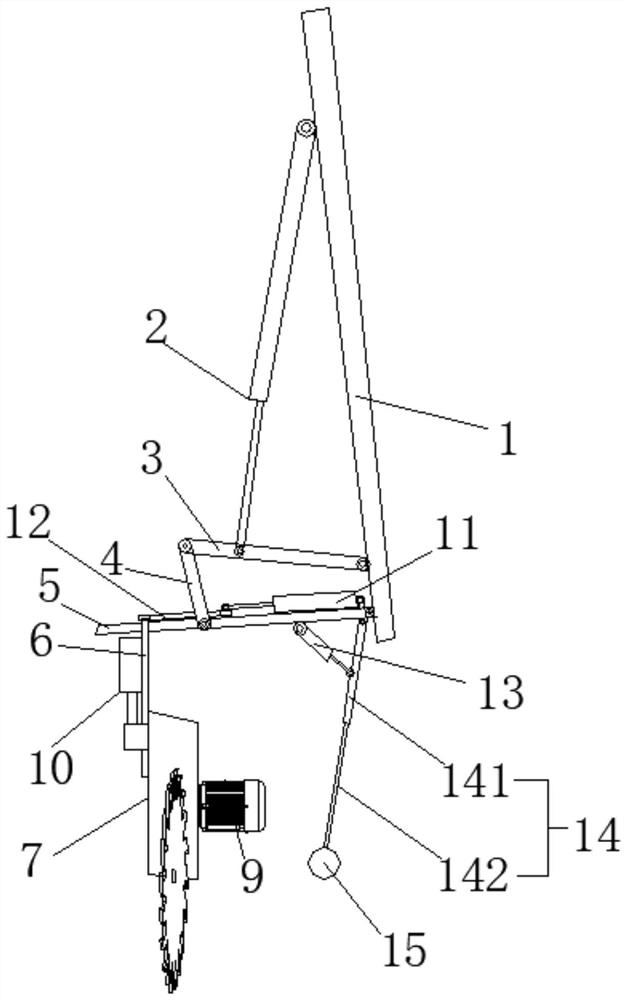

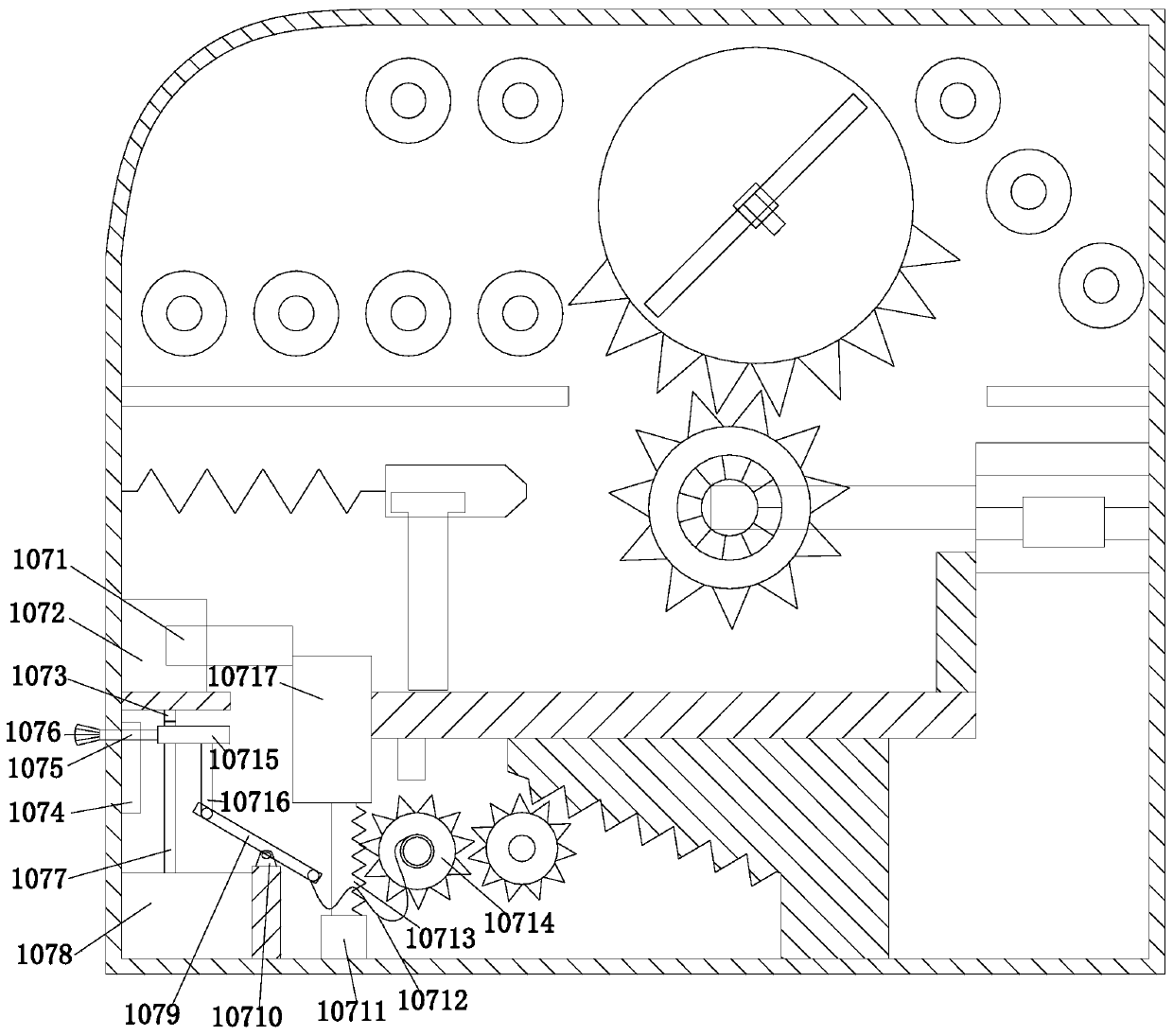

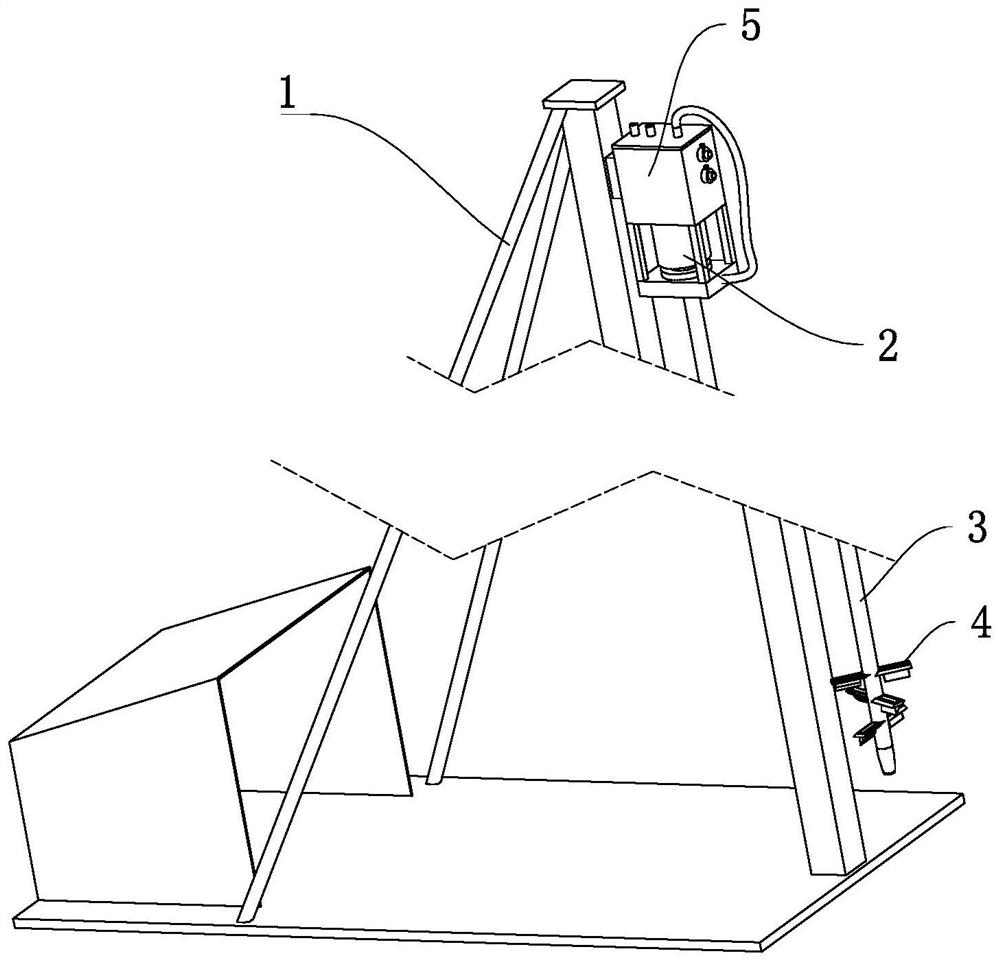

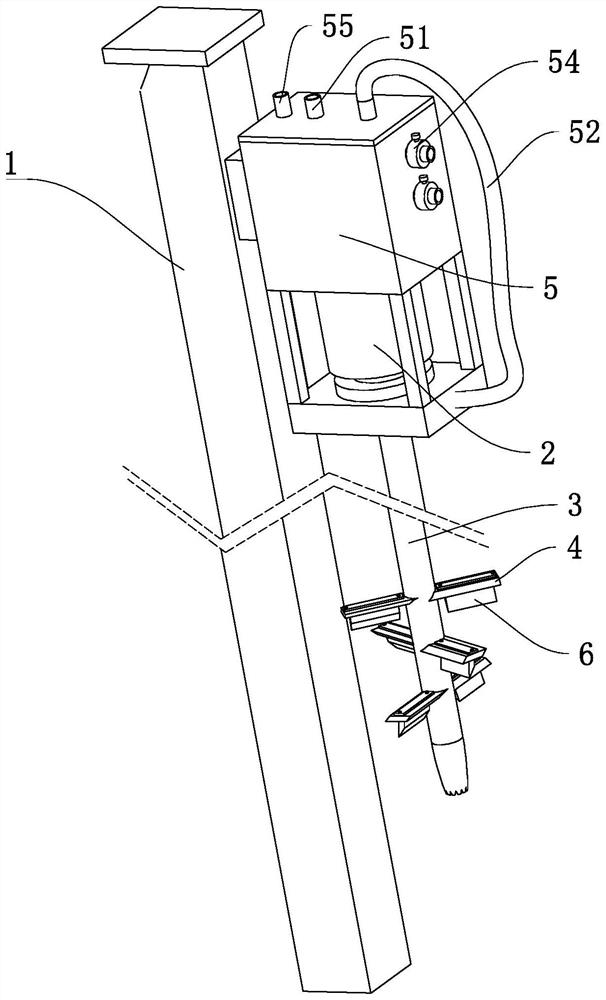

Multifunctional lifting cutting device for fire fighting

ActiveCN109277624AChange the stick out lengthChange cutting angleShearing machinesLarge fixed membersEngineeringClimbing stairs

The invention relates to a cutting device, in particular to a multifunctional lifting cutting device for fire fighting. The device comprises a moving bottom frame mechanism, a lifting mechanism, a cutting mechanism and a clamping and protecting mechanism; and the device can perform cutting operation, change the cutting angle, change the extending length of a cutting knife, clamp an obstacle needing to be cut, lift, move, climb stairs, and run safely. The moving bottom frame mechanism is located below the lifting mechanism, the moving bottom frame mechanism is connected with the lifting mechanism in a welding mode, the cutting mechanism is located above the lifting mechanism, the cutting mechanism is connected with the lifting mechanism through bolts, the clamping and protecting mechanism is located above the cutting mechanism, and the clamping and protecting mechanism and the cutting mechanism are connected in a welding mode.

Owner:西安鸿致信宇科技有限公司

Angle adjustable cutting device for plastic-steel door and window machining

The invention discloses an angle adjustable cutting device for plastic-steel door and window machining. The angle adjustable cutting device for plastic-steel door and window machining comprises a base. The sides, close to each other, of vertical extending plates at the left end and the right end of the base are both provided with T-shaped sliding rails. The front end and the rear end of the top ofthe base are connected with fixed ends of two parallel first electric extensible and retractable rods correspondingly. The extensible and retractable ends of the two first electric extensible and retractable rods are connected with the front end and the rear end of the bottom of a fixing chamber correspondingly. The left side and the right side of the fixing chamber are provided with T-shaped sliding strips which are vertically distributed. The two T-shaped sliding strips are in sliding connection with the two T-shaped sliding rails correspondingly. According to the angle adjusting cutting device, the situation that a plastic-steel door and window deviates during machining, and the cutting angle is changed can be prevented, meanwhile, a pointer rotates, the rotation angle can be determined, angle contrasting can be carried out, defective materials can be prevented from dropping out and are cleaned conveniently, the stability of the device is improved, buffering is carried out, a cutting piece can be prevented from excessively cutting into the plastic-steel door and window, and then the situation the cutting device is fractured and clamped on the plastic-steel door and window is prevented.

Owner:安徽名特玻璃有限公司

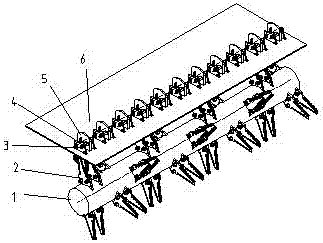

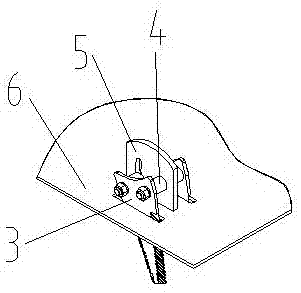

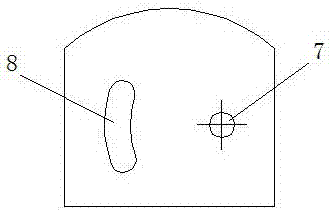

Detachable adjustable fixed cutter device applicable to sugarcane leaf shattering and returning machine

The invention relates to a crushing device, and in particular to a detachable adjustable fixed cutter device applicable to a sugarcane leaf shattering and returning machine. The detachable adjustable fixed cutter device comprises a rack, a fixed cutter device and a moving cutter device, wherein the fixed cutter device is arranged on the rack; the moving cutter device cooperates with the fixed cutter device to achieve a cutting function; a detachable adjustable fixed cutter is arranged on the fixed cutter device; and the fixed cutter device comprises a fixed cutter roller and a moving cutter mounted on the fixed cutter roller. The detachable adjustable fixed cutter device is simple in structure, and due to arrangement of the detachable and adjustable fixed cutter, an optimal cutting angle between the fixed cutter and the moving cutter is achieved, so that the cutting effect of a shattering machine is improved, the working efficiency of the shattering machine is improved, and meanwhile the fixed cutter can be conveniently replaced and maintained.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

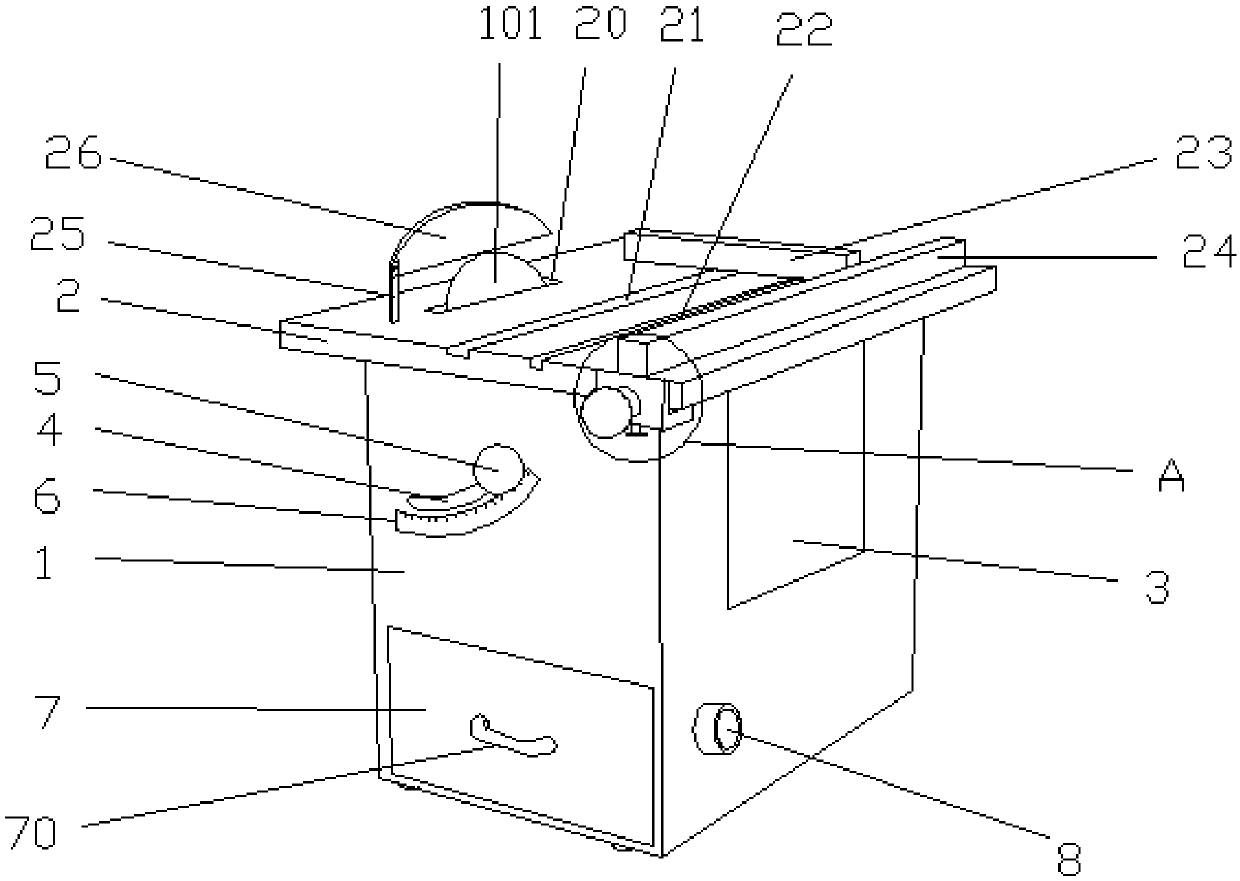

Convenient cutting machine for wood floor laying

InactiveCN109648653AReduce volumeEasy to carryProfiling/shaping machinesBark-zones/chip/dust/waste removalEngineeringBody size

The invention discloses a convenient cutting machine for wood floor laying. The cutting machine comprises a cutting machine main body, a worktable, an air vent, an arc groove, an angle adjusting handle, an angle scale line, a movable bin door, a dust suction pipeline connector, gaskets, a cutting mechanism and a dust removal mechanism. Compared with the prior art, the cutting machine has the advantages of reasonable design, simple structure, small machine body size, light weight and convenience for workers to carry. In addition, the cutting machine also has the functions of changing the cutting angle and cleaning cuttings.

Owner:嘉兴洛可可实业有限公司

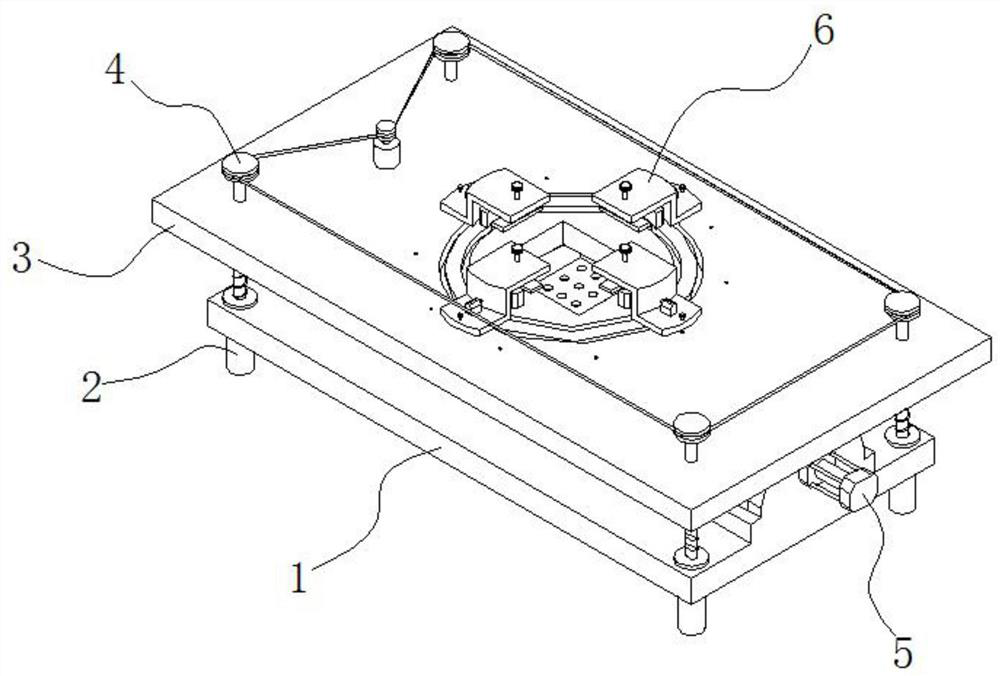

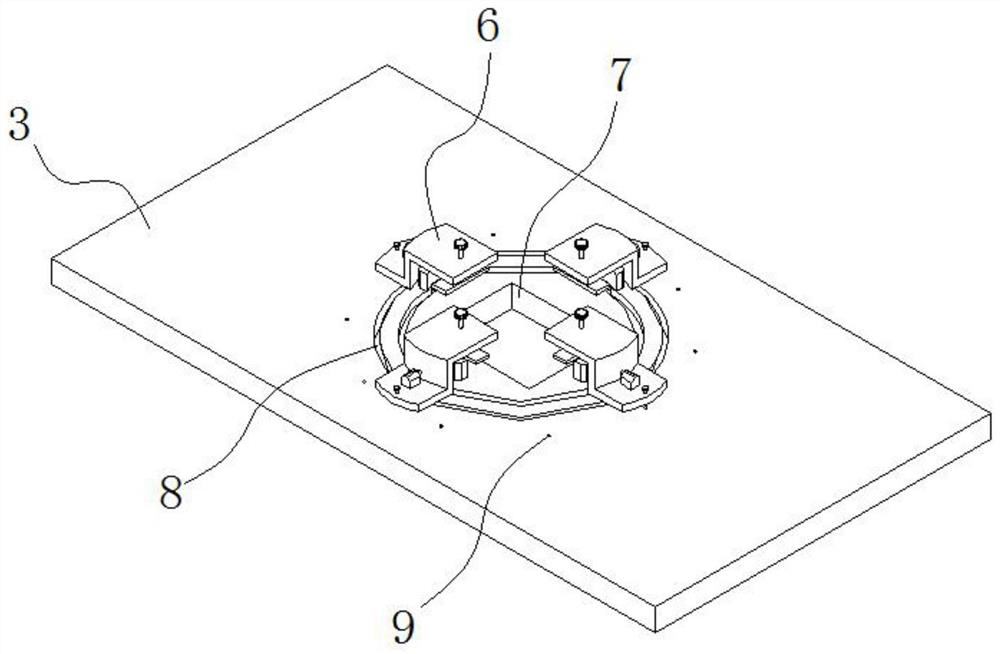

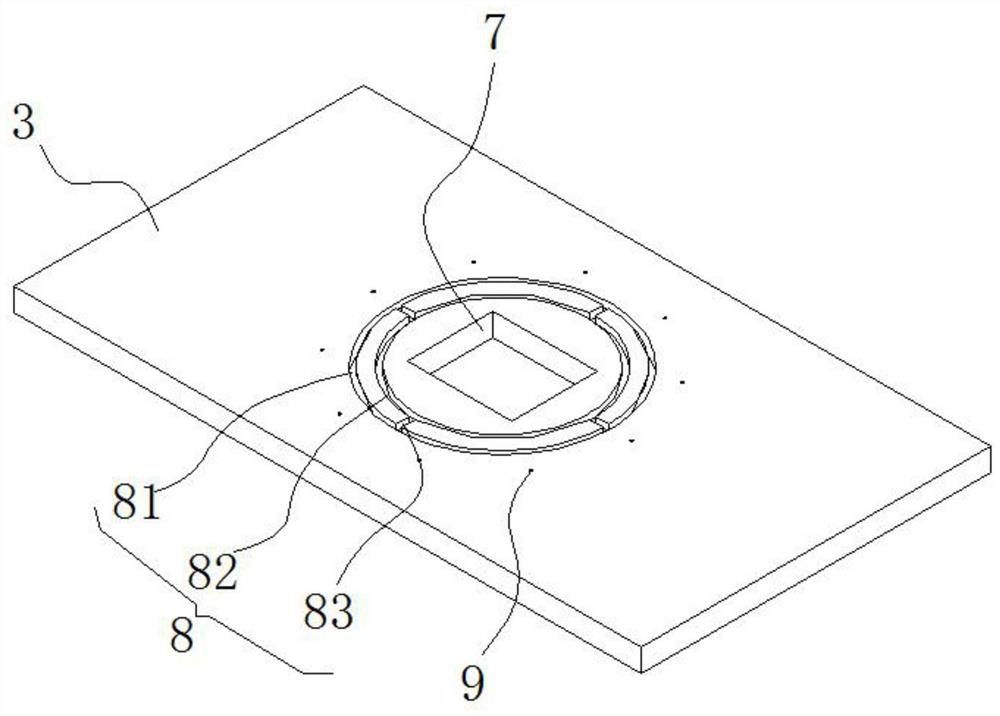

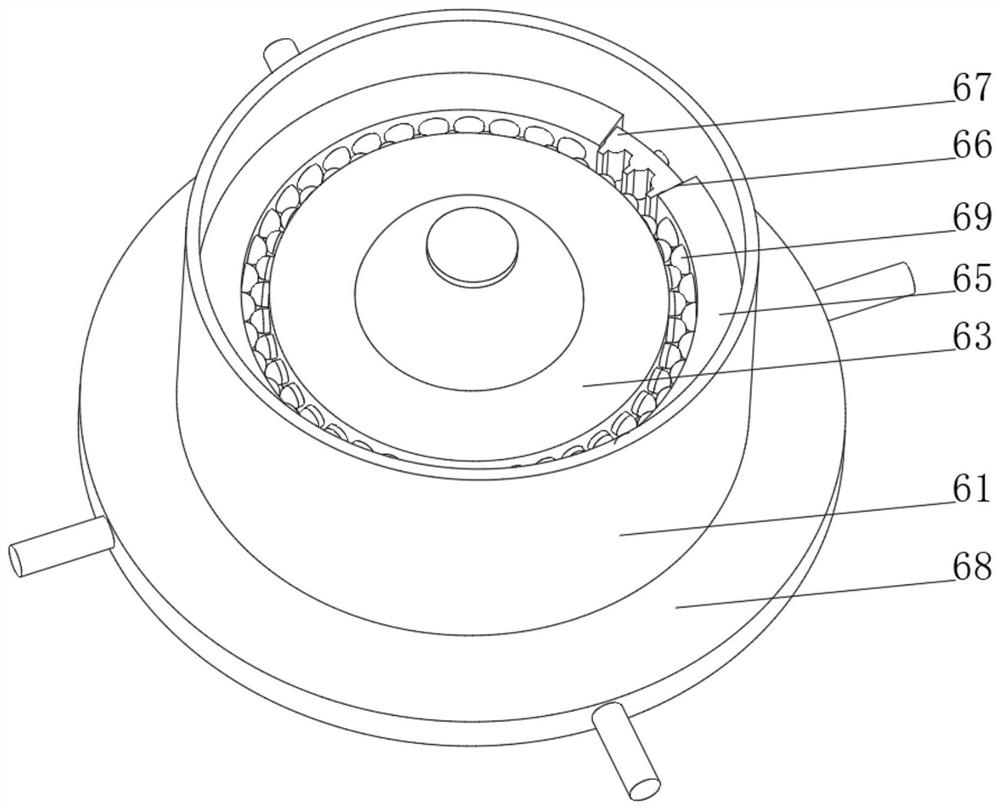

Circuit board processing and clamping treating device in production process of electronic parts

InactiveCN111660019AChange cutting angleWelding/cutting auxillary devicesAuxillary welding devicesBackplaneManufacturing engineering

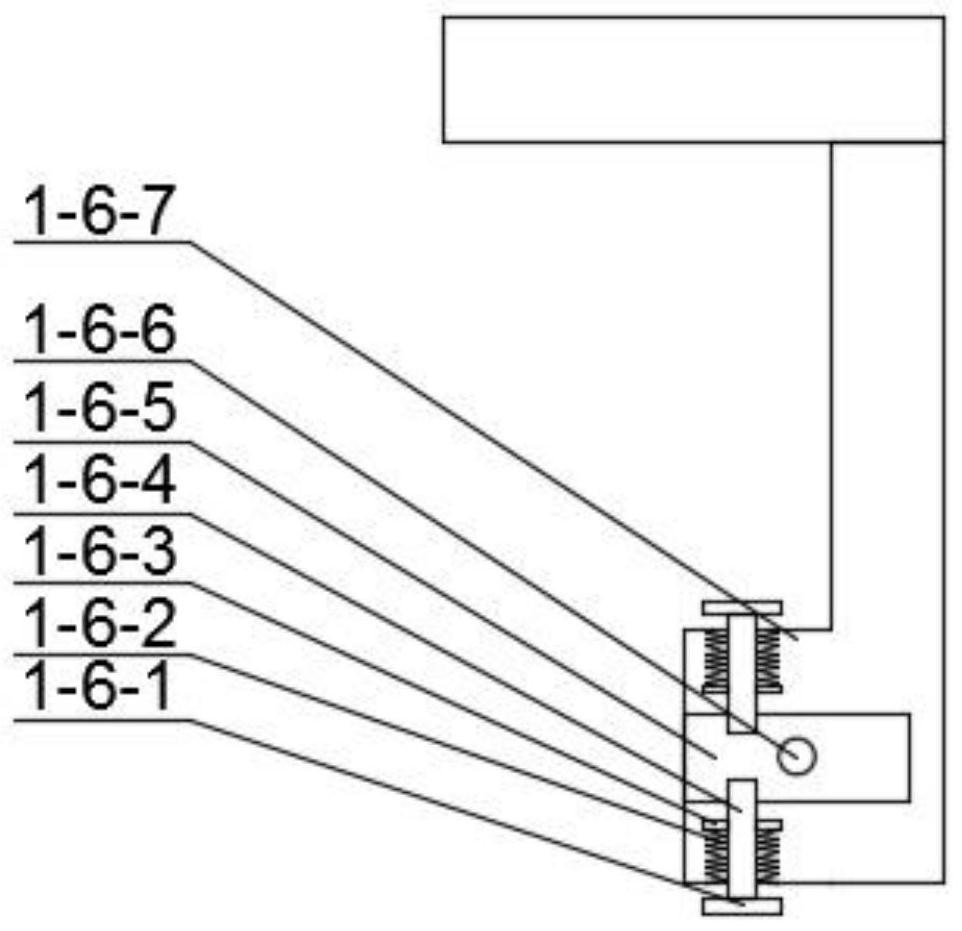

The invention relates to the technical field of processing equipment of electronic parts, in particular to a circuit board processing and clamping treating device in the production process of the electronic parts. The circuit board processing and clamping treating device comprises a bottom plate, supporting mechanisms are correspondingly installed at four corners of the bottom plate, a processingplate is fixedly installed at the top ends of the supporting mechanisms, a processing hole is formed in the middle of the processing plate, a guiding mechanism is arranged on the outer side of the processing hole, and the guiding mechanism comprises a first annular groove, a second annular groove and a straight mouth groove; and a plurality of clamping mechanisms are installed in the first annulargroove, the clamping mechanisms comprise arc-shaped guiding blocks, sliding plates are fixedly installed at the tops of the arc-shaped guiding plates, installation plates are fixedly installed at oneends of the sliding plates, fixing bolts are installed at the other ends of the sliding plates in a threaded mode, adjusting bolts are connected to the tops of the installation plates in a threaded mode, pressing plates are fixedly installed at the bottoms of the adjusting bolts, and springs are arranged on the extension of the bottom ends of the adjusting bolts in a sleeving mode. According to the circuit board processing and clamping treating device, the cutting angle of parts can be adjusted, and waste materials are cleaned more conveniently.

Owner:江西福昌发电路科技有限公司

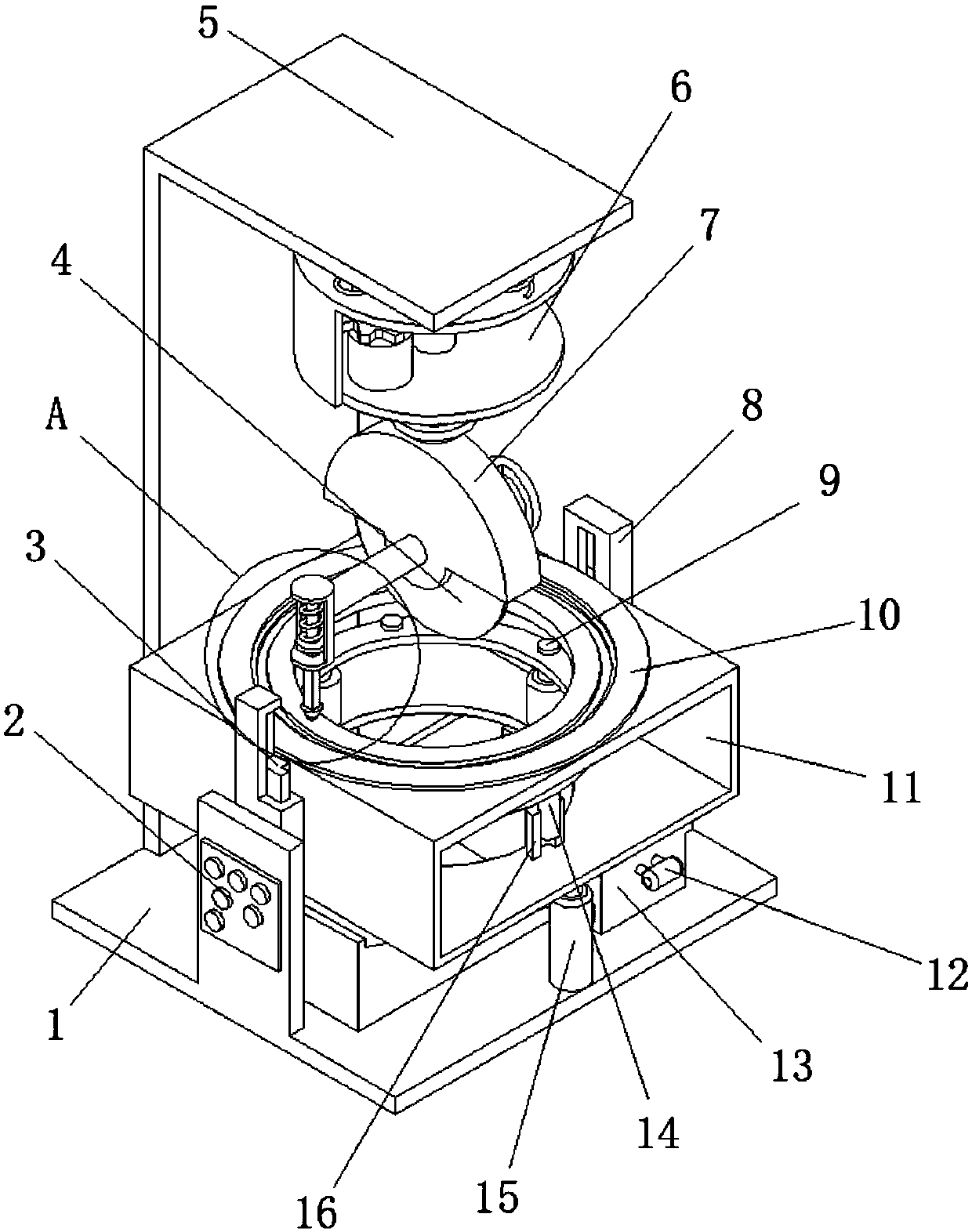

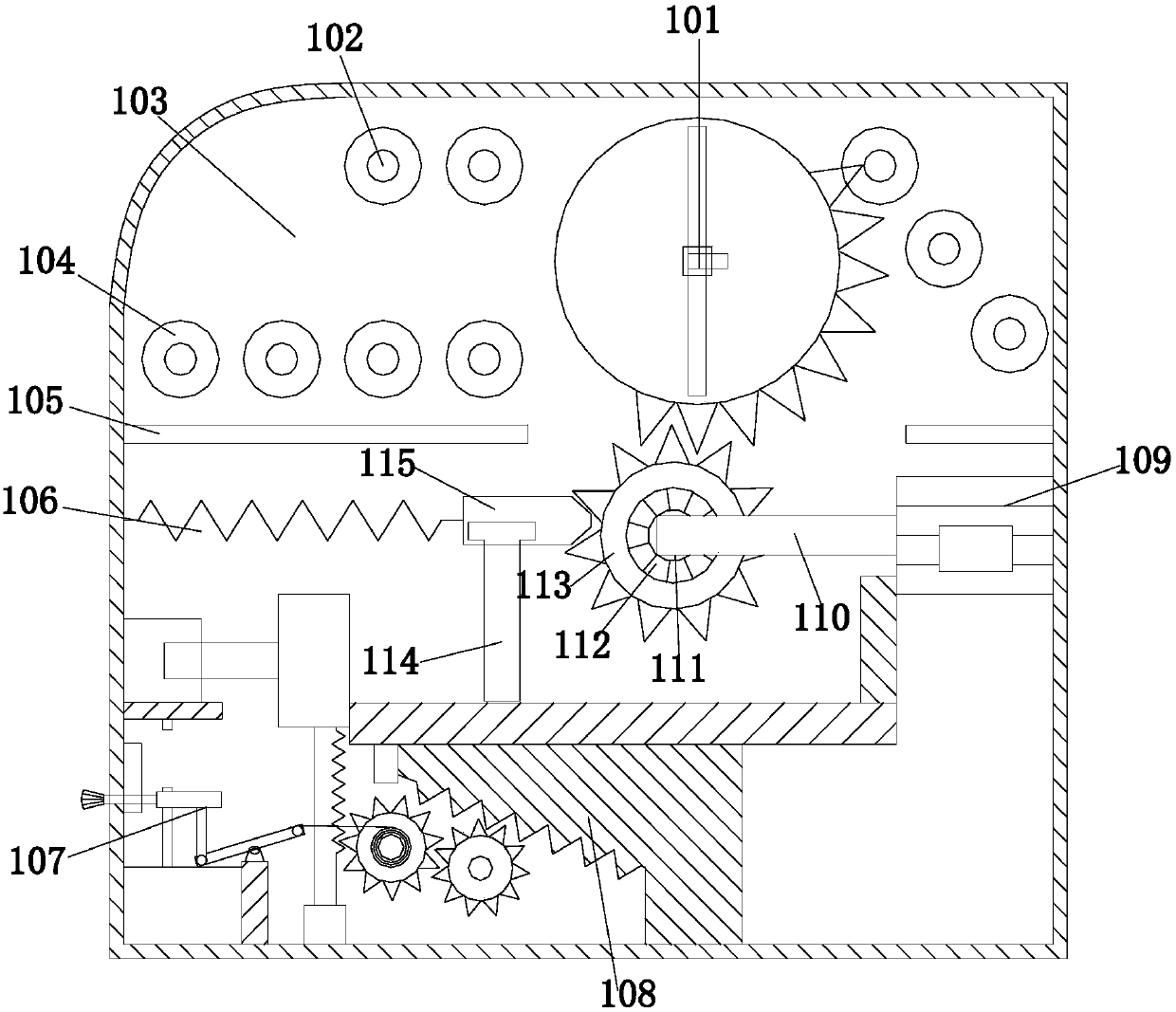

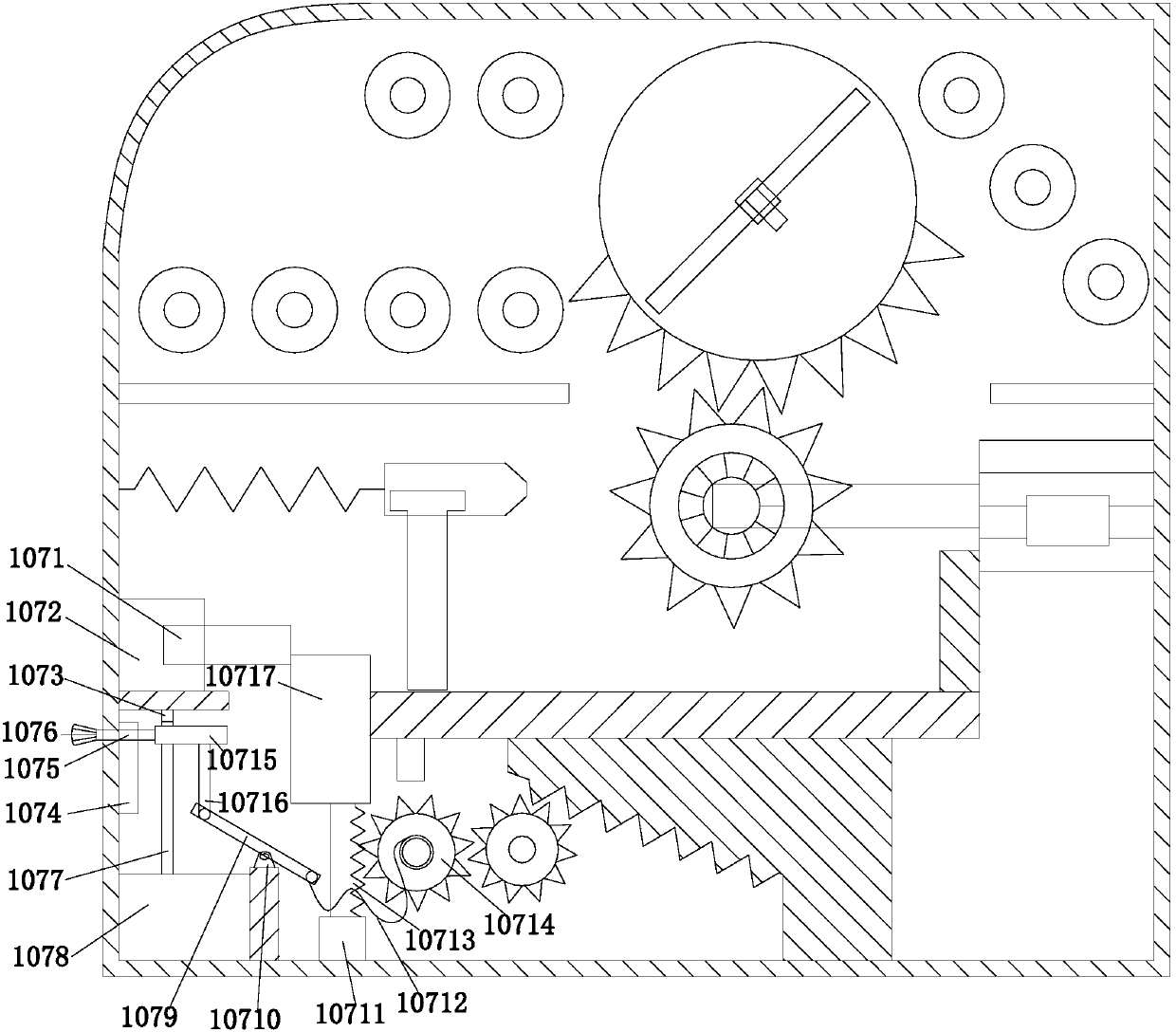

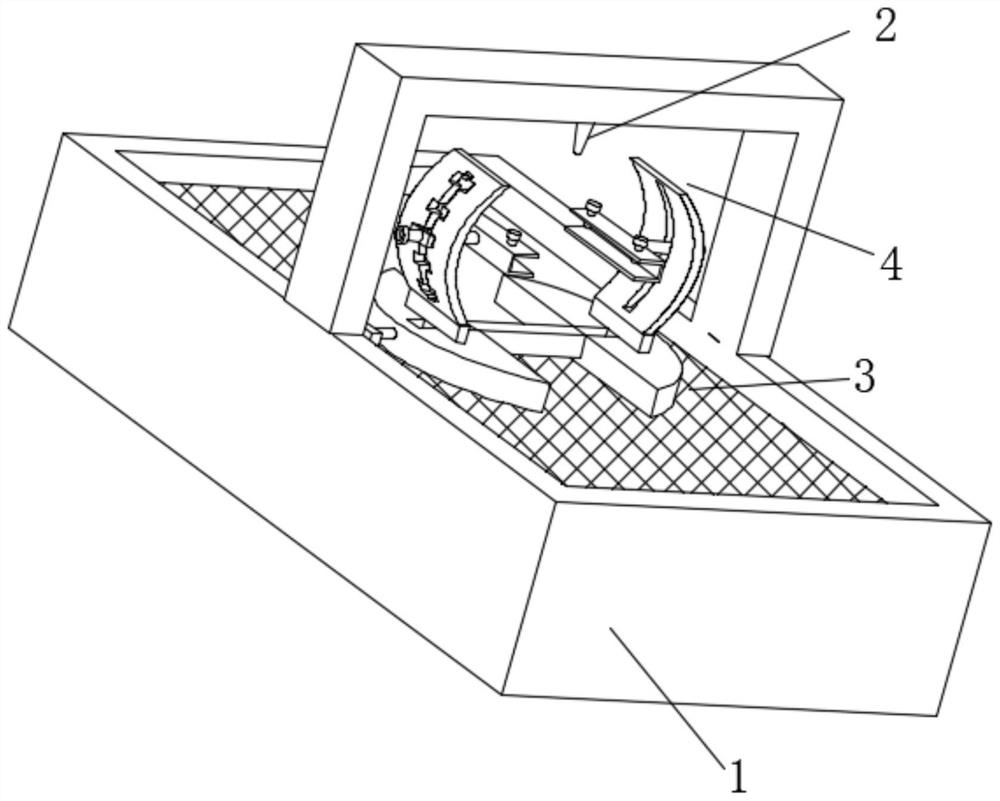

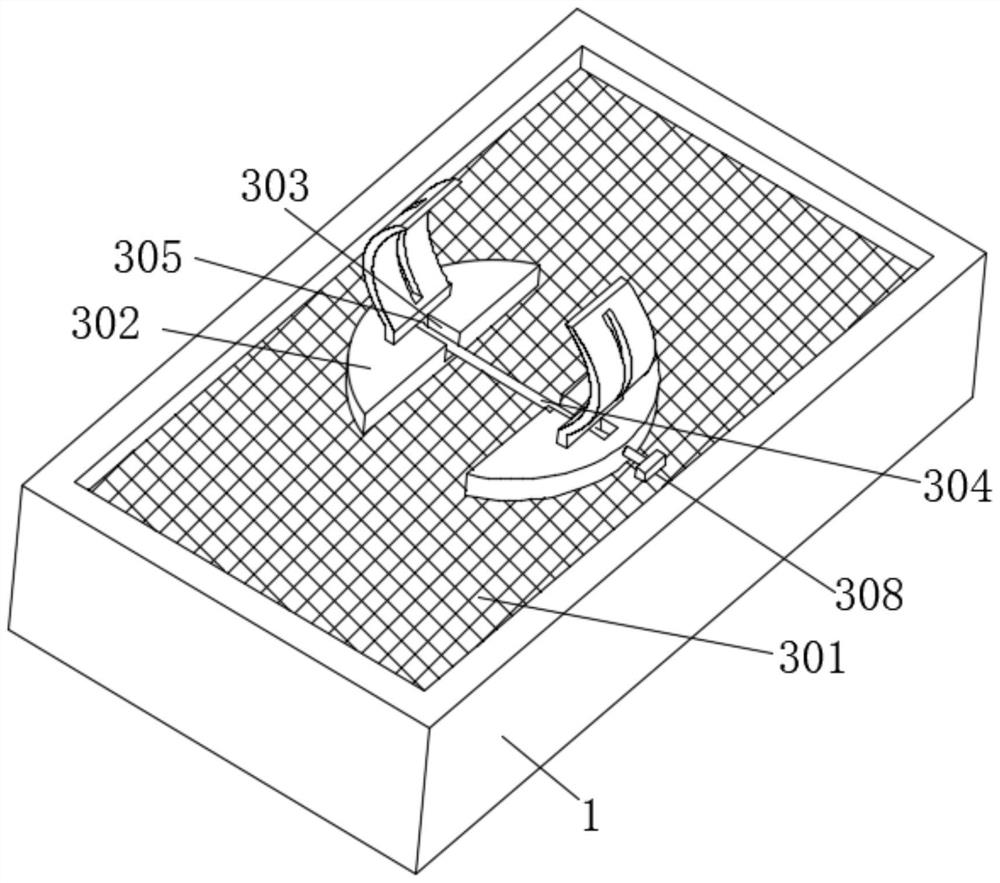

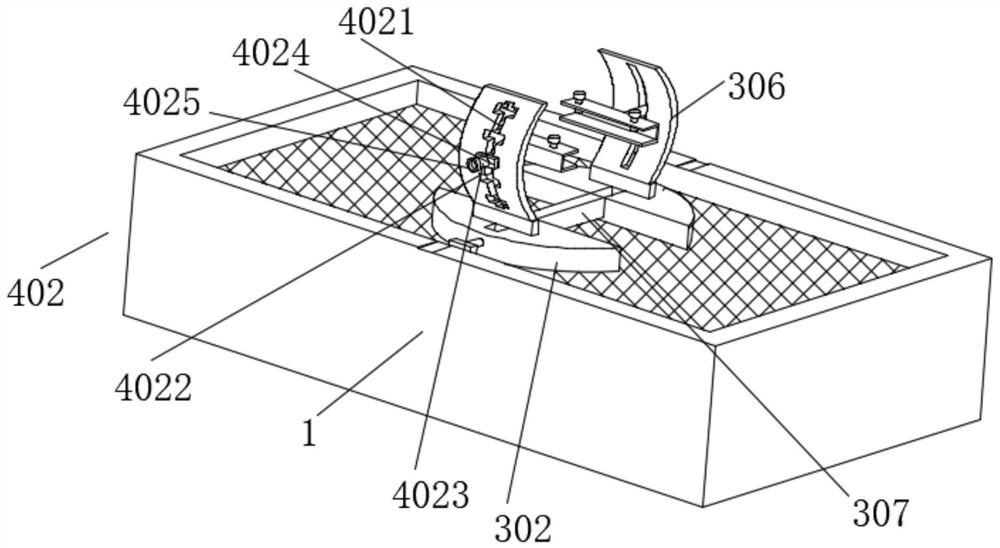

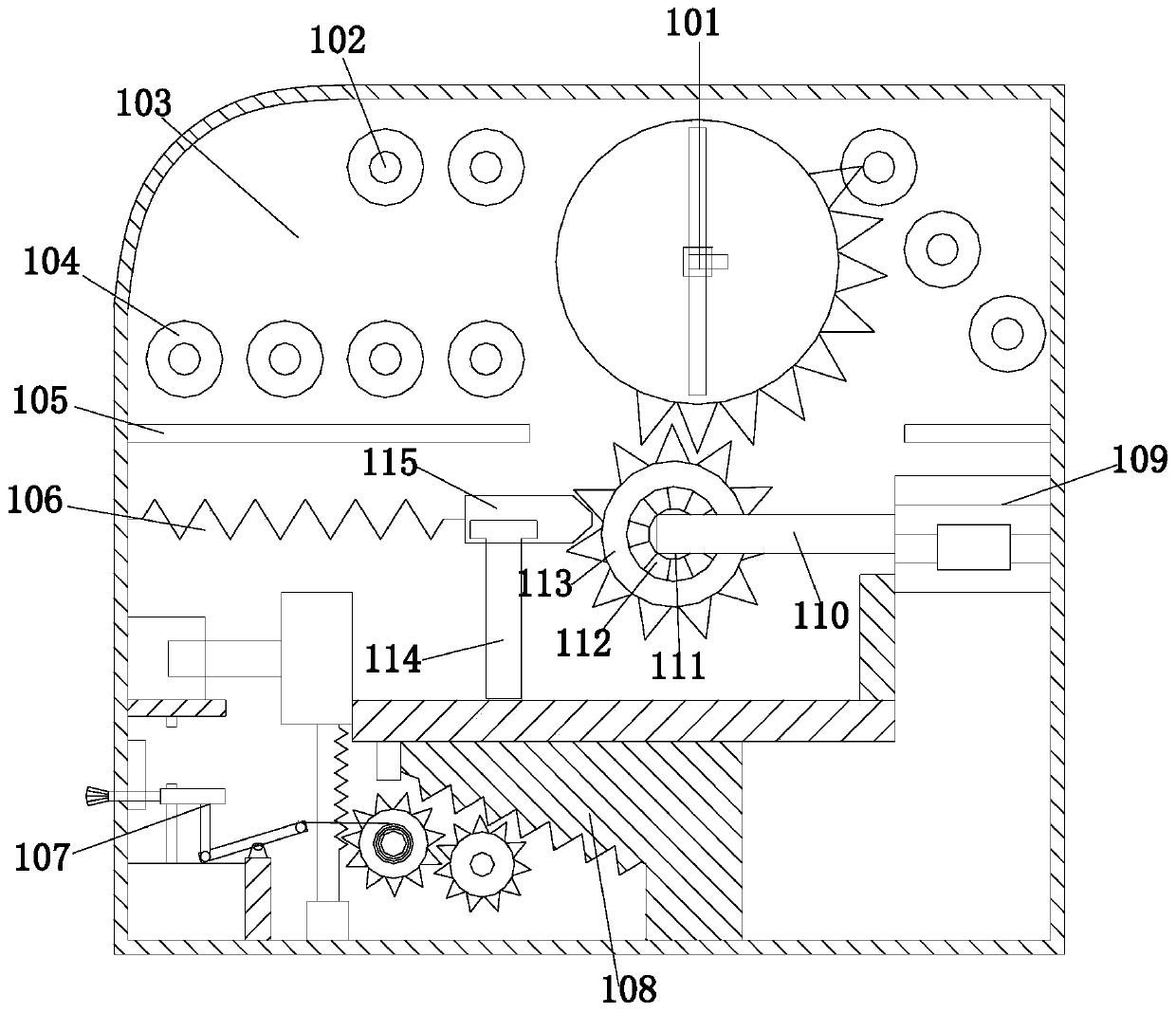

Multifunctional window frame cutting and polishing device

ActiveCN110103030AChange cutting positionChange cutting angleOther manufacturing equipments/toolsEngineeringMechanical engineering

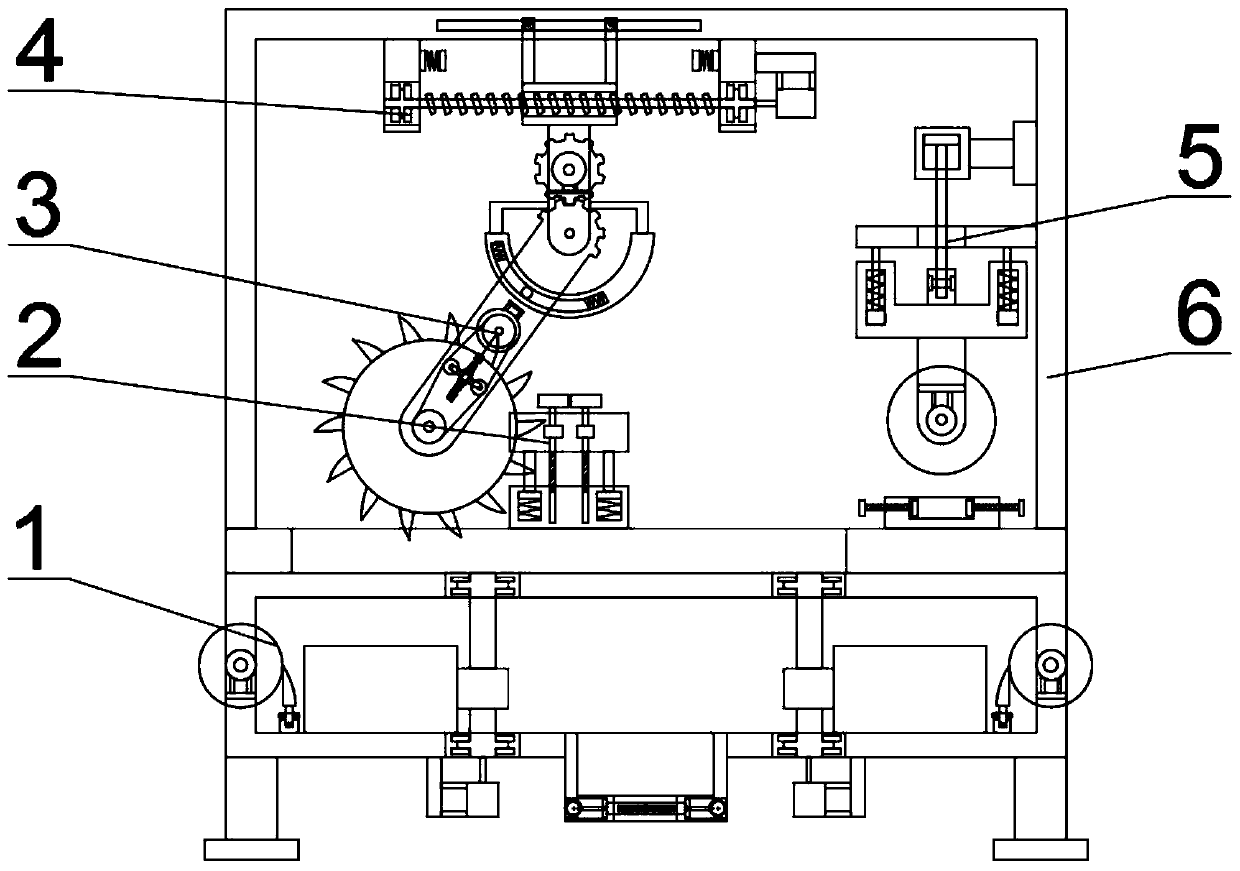

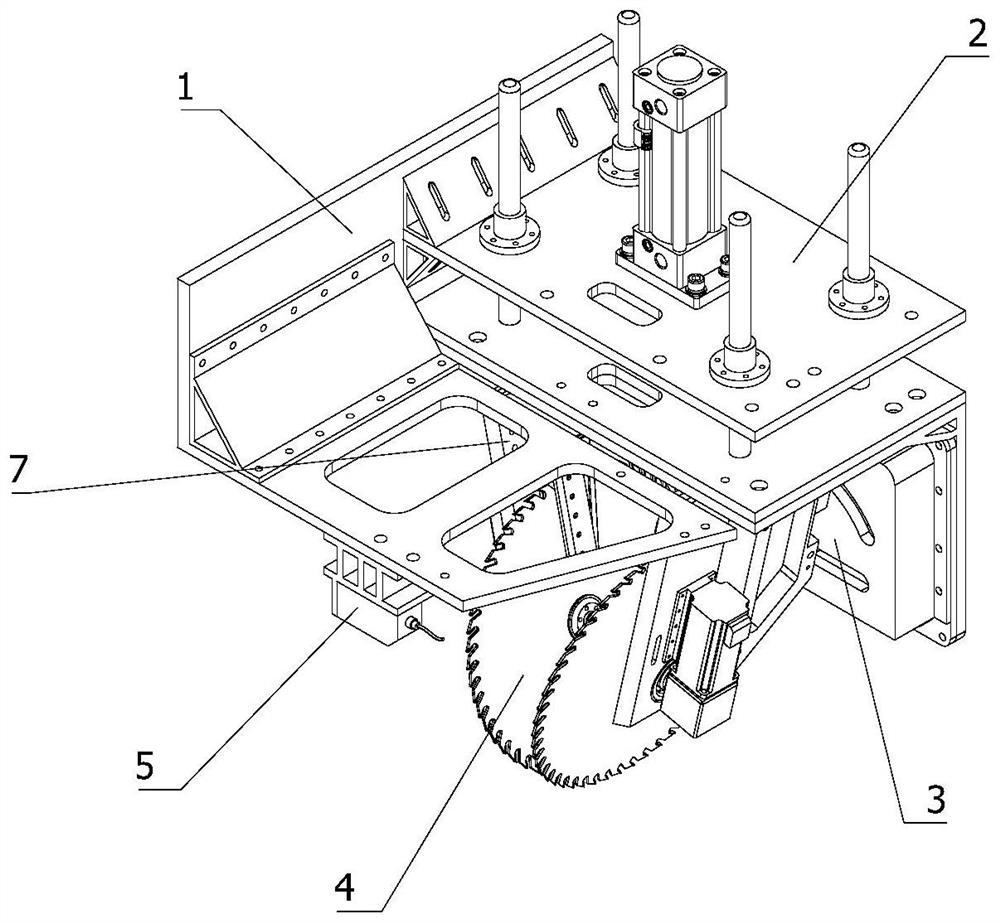

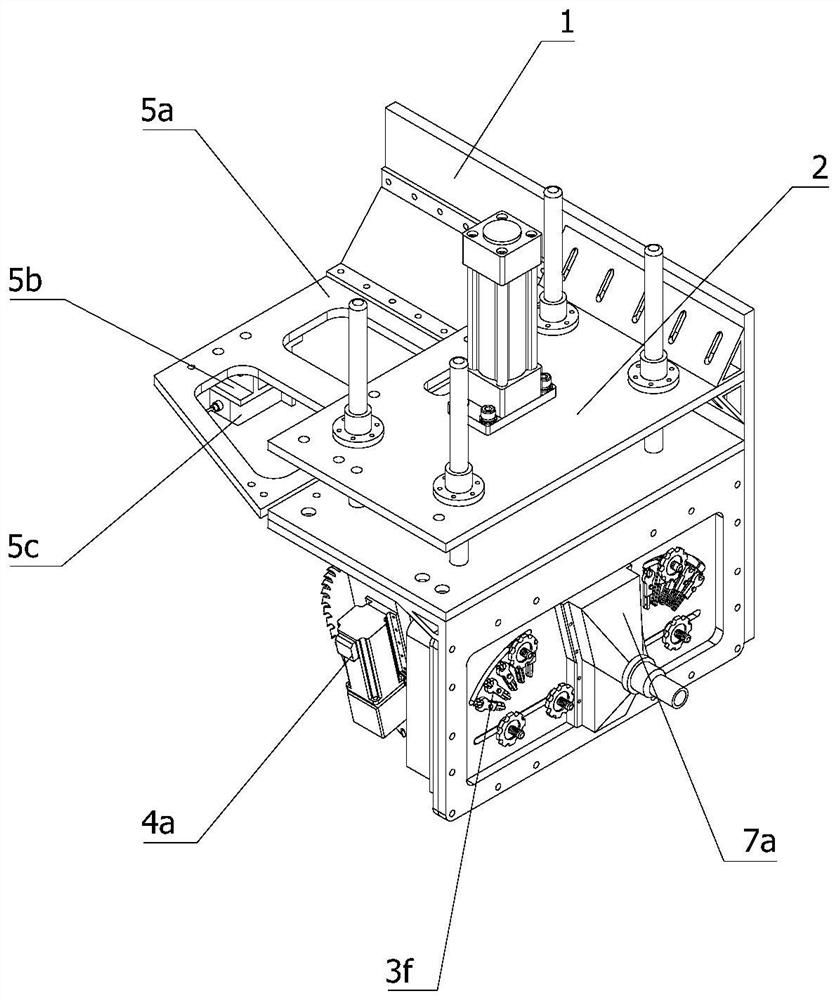

The invention relates to a cutting and polishing device and more particularly relates to a multifunctional window frame cutting and polishing device. The multifunctional window frame cutting and polishing device comprises an iron scrap collecting mechanism, a clamping mechanism, a cutting and executing mechanism, a cutting and moving mechanism, a polishing mechanism and a body frame mechanism. Thedevice is capable of cutting, tightening a belt, changing cutting positions, changing cutting angles, clamping door and window frames, polishing and collecting the iron scraps; the iron scrap collecting mechanism is located under the body frame mechanism; the clamping mechanism is connected with the body frame mechanism; the cutting and executing mechanism is connected with the cutting and movingmechanism; the cutting and moving mechanism is connected with the body frame mechanism; and the polishing mechanism is connected with the body frame mechanism.

Owner:重庆巨耀精密电子有限公司

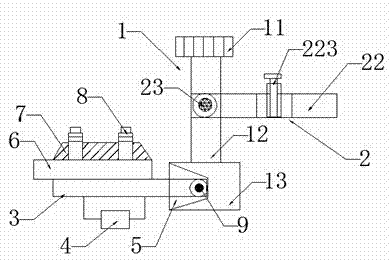

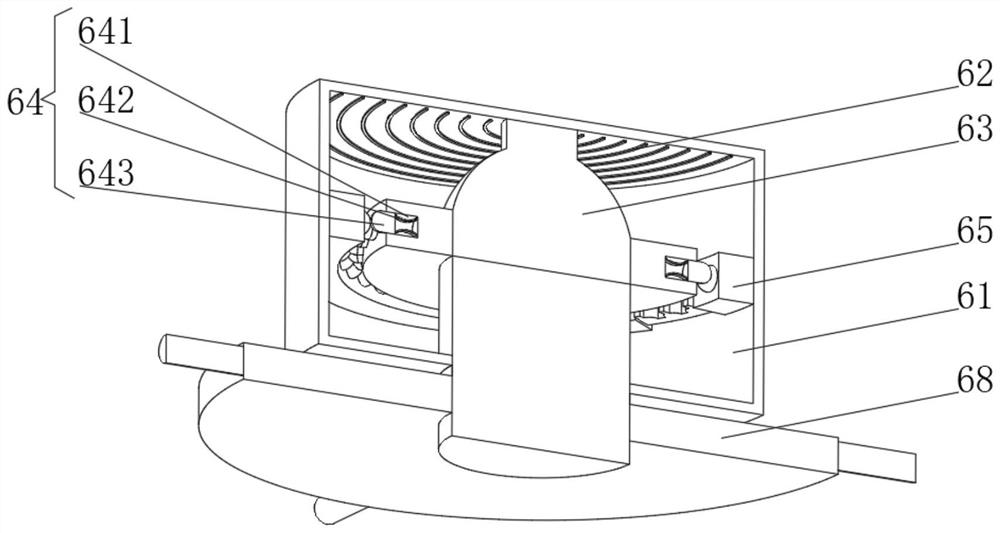

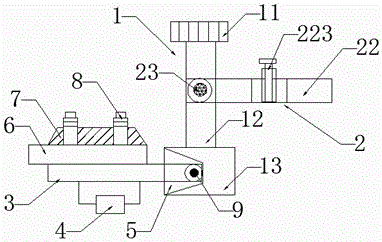

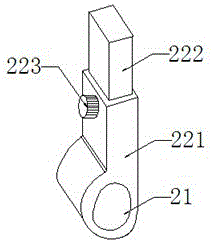

Novel power tool holder for machine tool machining

ActiveCN104325308ASimple structureReasonable designPositioning apparatusMetal-working holdersEngineeringPower tool

The invention discloses a novel power tool holder for machine tool machining. The novel power tool holder comprises a tool holder main body, a clamping mechanism, a cutting tool bearing seat, an angle adjuster and a locking screw, wherein the tool holder main body consists of a nut, a connecting rod and a tool holder head, and the nut and the tool holder head are fixed at the two ends of the connecting rod; the clamping mechanism consists of a clamping sleeve and a clamping handle, and the clamping sleeve is movably arranged on the connecting rod through a fastening screw in a sleeving mode; a trapezoidal groove is formed in one side of the tool holder head, one end of the cutting tool bearing seat is inserted in the trapezoidal groove, a cutter body and a cutter body pressing plate are fixedly mounted above the cutting tool bearing seat in sequence, the angle adjuster is arranged below the cutting tool bearing seat, the angle adjuster is used for adjusting and controlling the cutting tool bearing seat to perform a rotary motion along the axis of the cutting tool bearing seat so as to change the cutting angle of the cutter body. The novel power tool holder is simple in structure and reasonable in design; under the precondition that a cutting tool is not changed or the position of the tool holder is not readjusted, the cutting position, cutting depth and cutting angle of the cutter body can be quickly and conveniently adjusted, and the work efficiency and the utilization rate of the cutting tool are effectively improved.

Owner:统弘自动化科技(苏州)有限公司

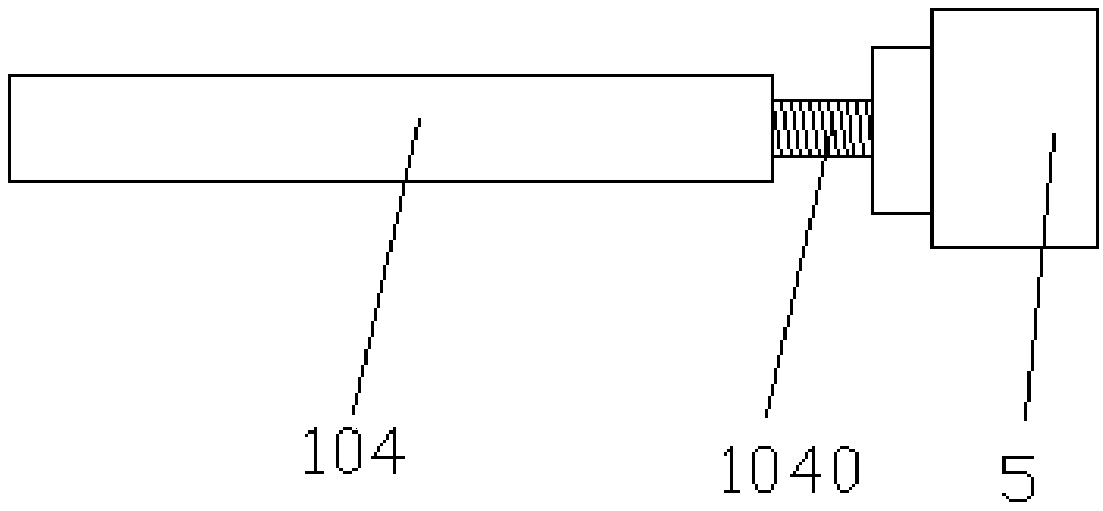

Regulating device of belt wheel

The invention provides a regulating device of belt wheel, belonging to the technical field of machinery, and solving the problem that the existing regulating device of belt wheel is not provided with a mechanism for regulating a driven wheel to rotate circumferentially. The regulating device of belt wheel comprises a seat and a vertical shaft vertically arranged on the seat, a spindle is arranged on the vertical shaft perpendicular to the vertical shaft, a belt wheel is sheathed on the spindle, and a positioning mechanism capable of causing the vertical shaft to do rectilinear translation and / or rotation regulation along the seat and positioning the vertical shaft after regulation is finished. The vertical shaft of the regulating device of belt wheel does rectilinear translation and / or rotation regulation and the spindle can move along the axial direction of the vertical shaft, the spindle, the vertical shaft and the regulating device can be regulated individually or jointly to drive the belt wheel to move to regulate the belt wheel to a proper position more conveniently, and the invention has the advantage of convenient, exact and stable regulating.

Owner:陈文满

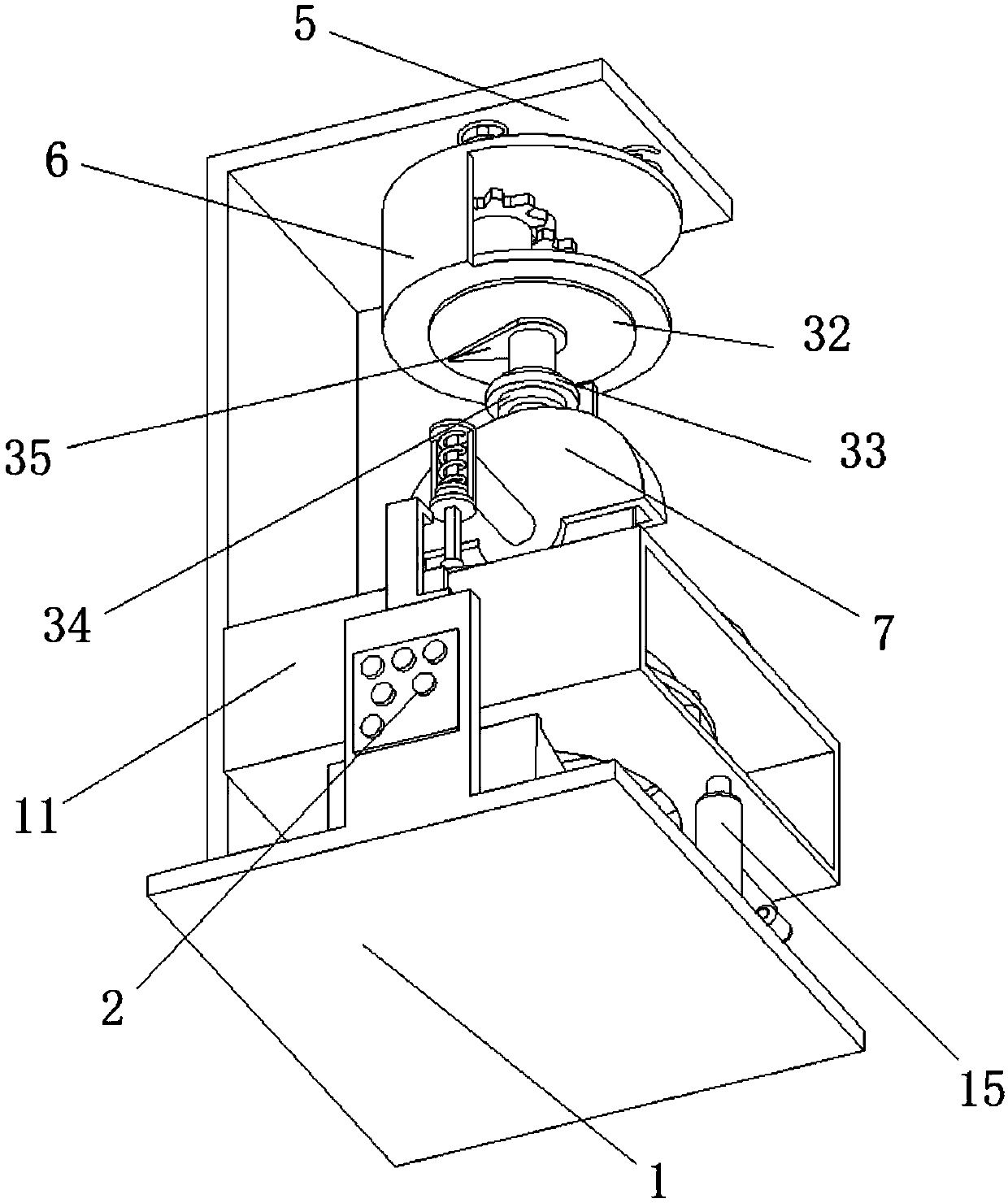

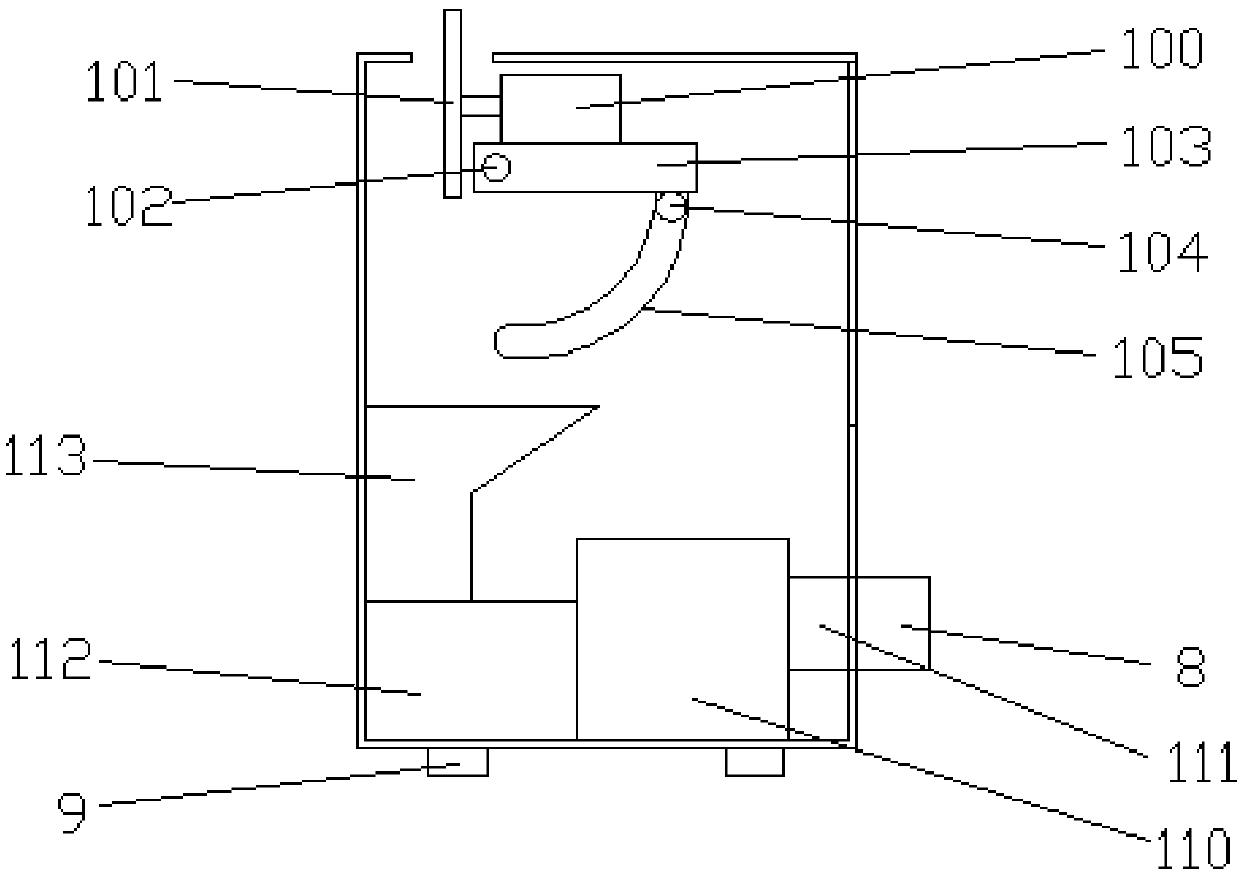

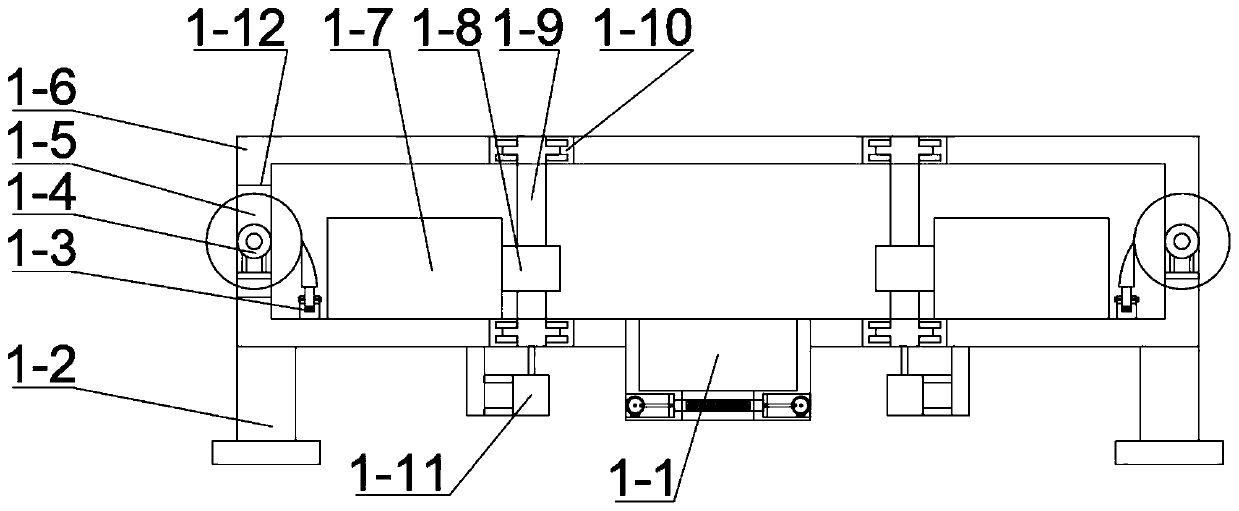

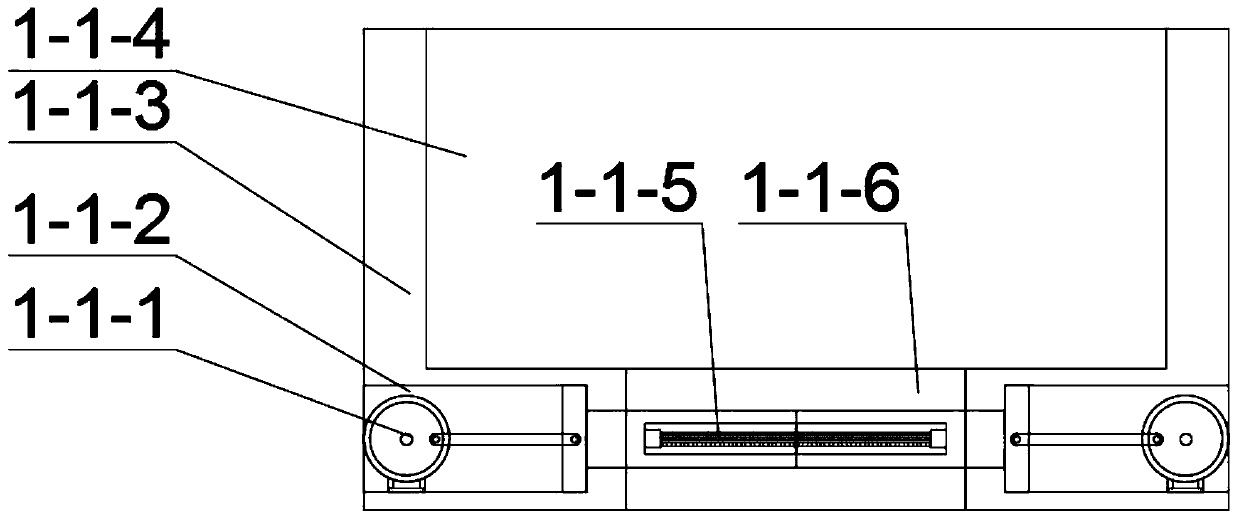

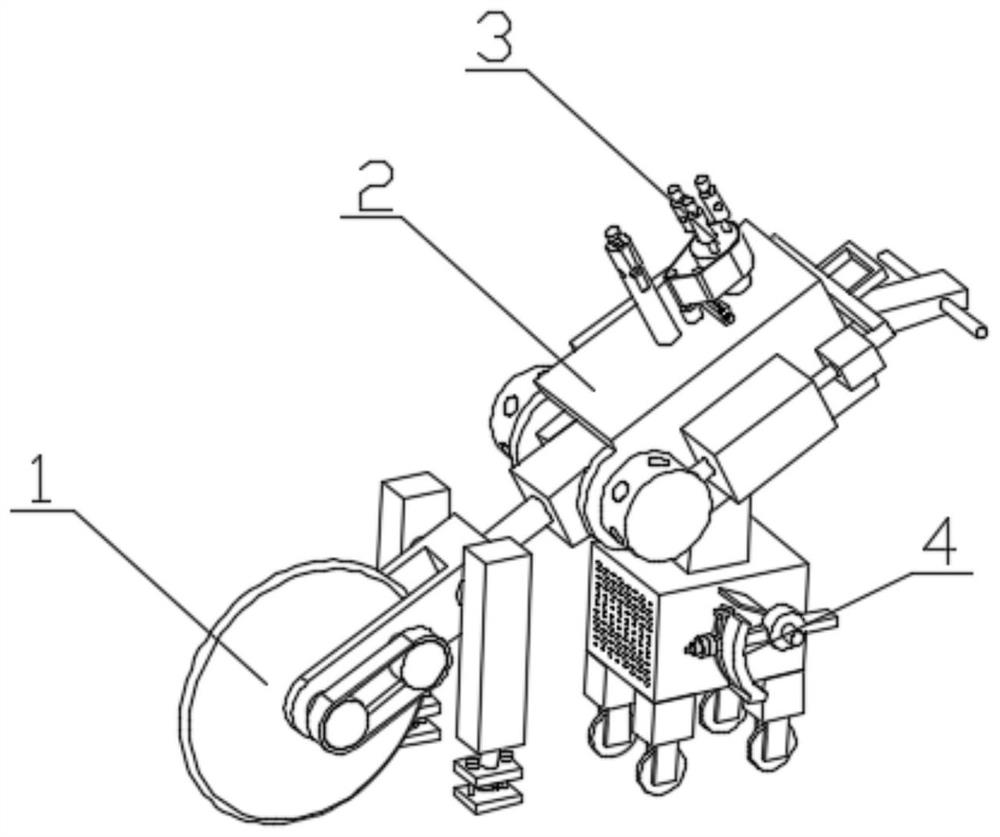

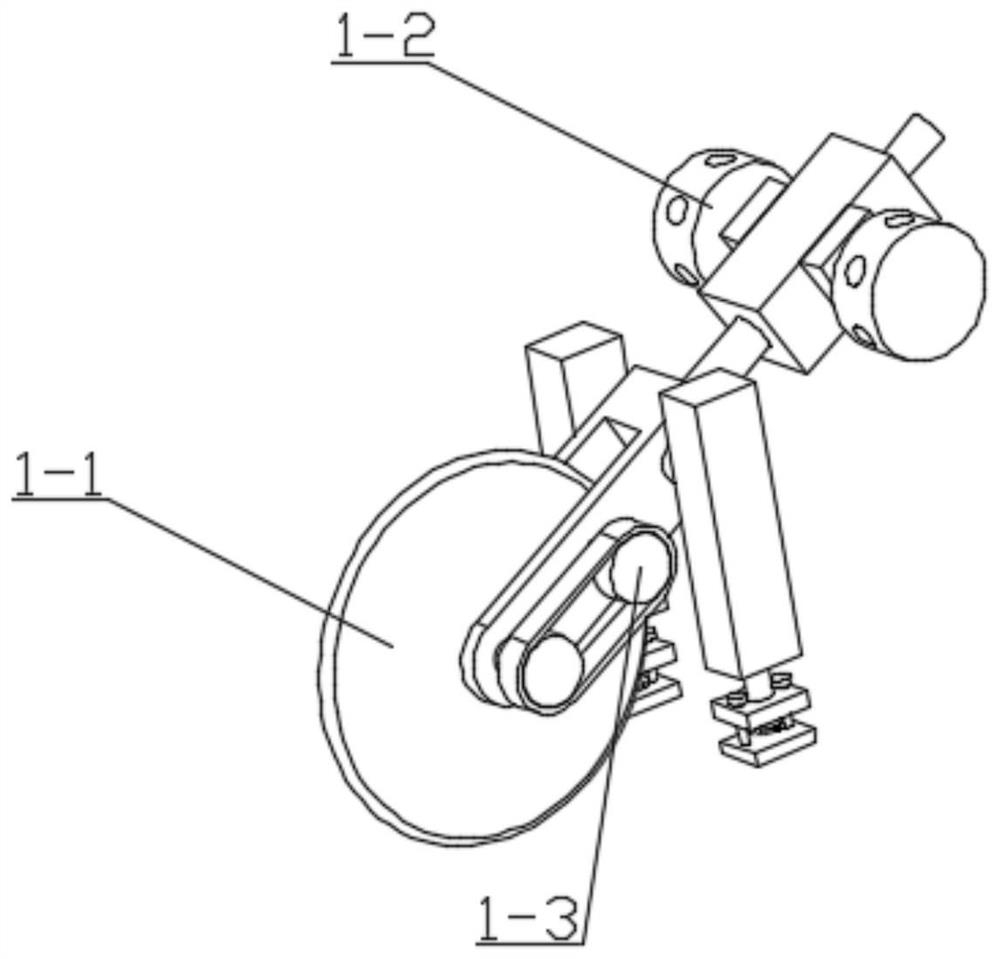

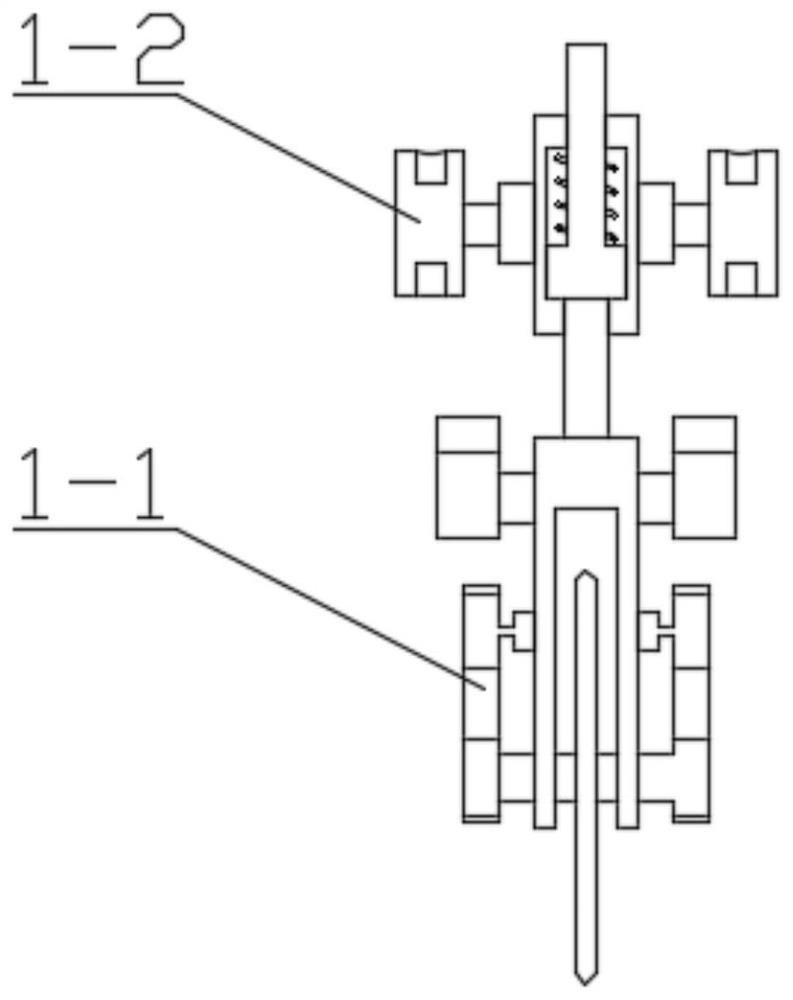

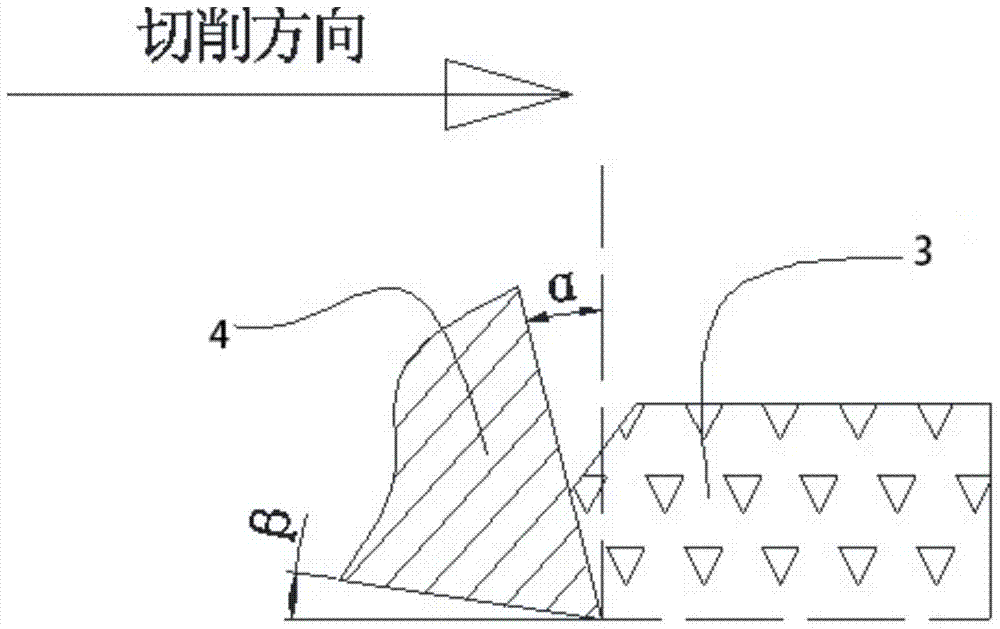

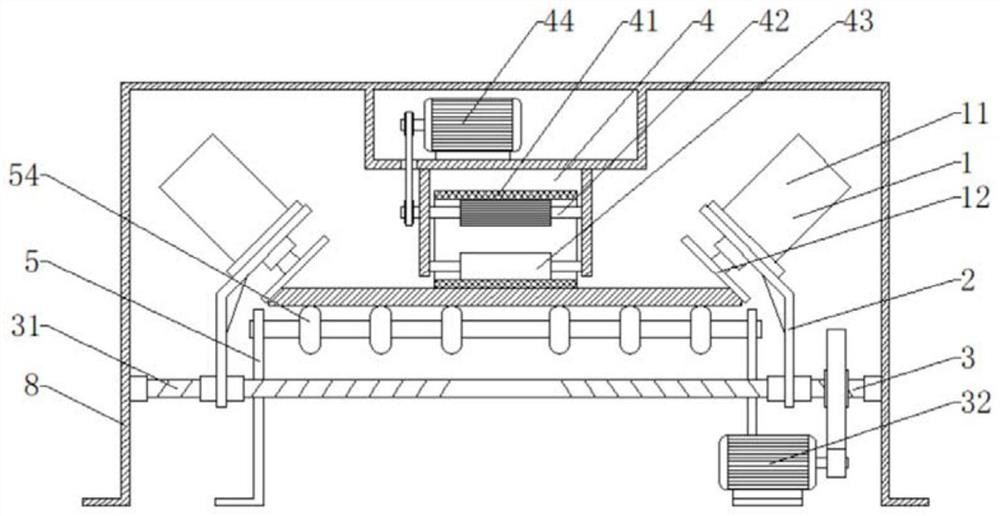

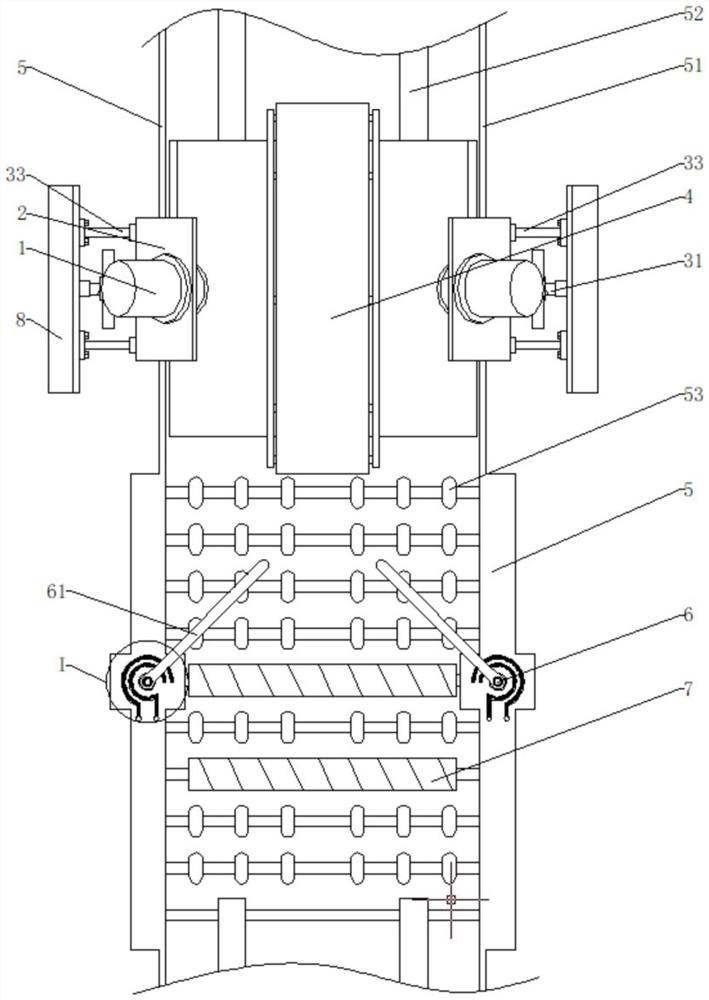

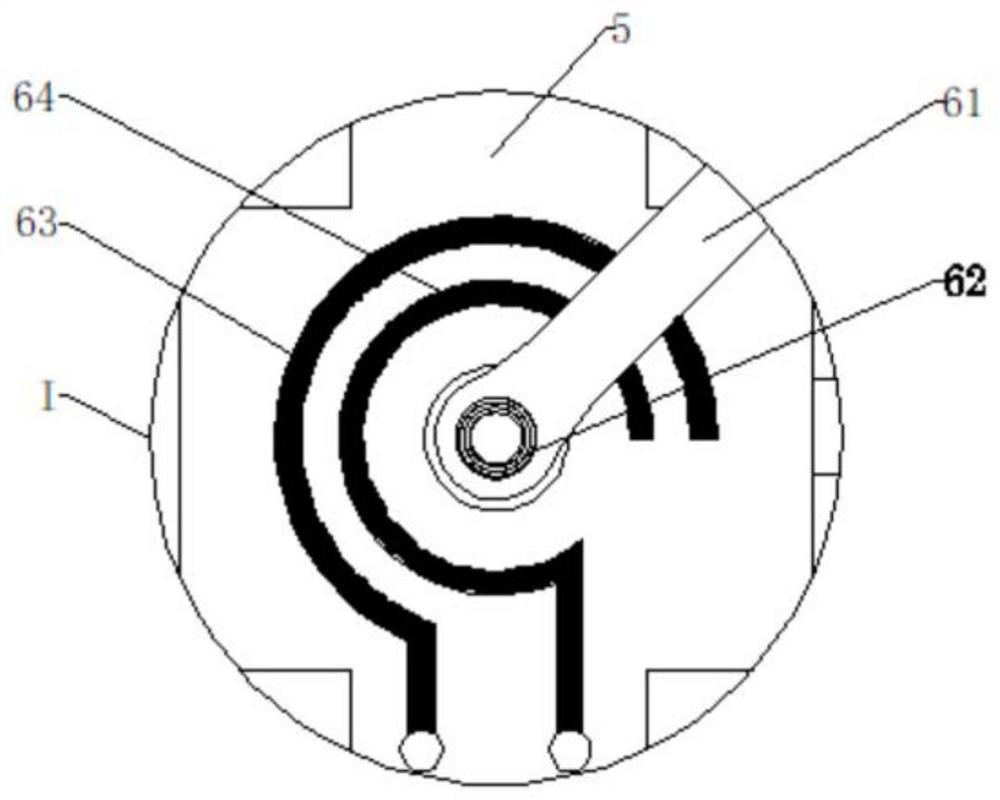

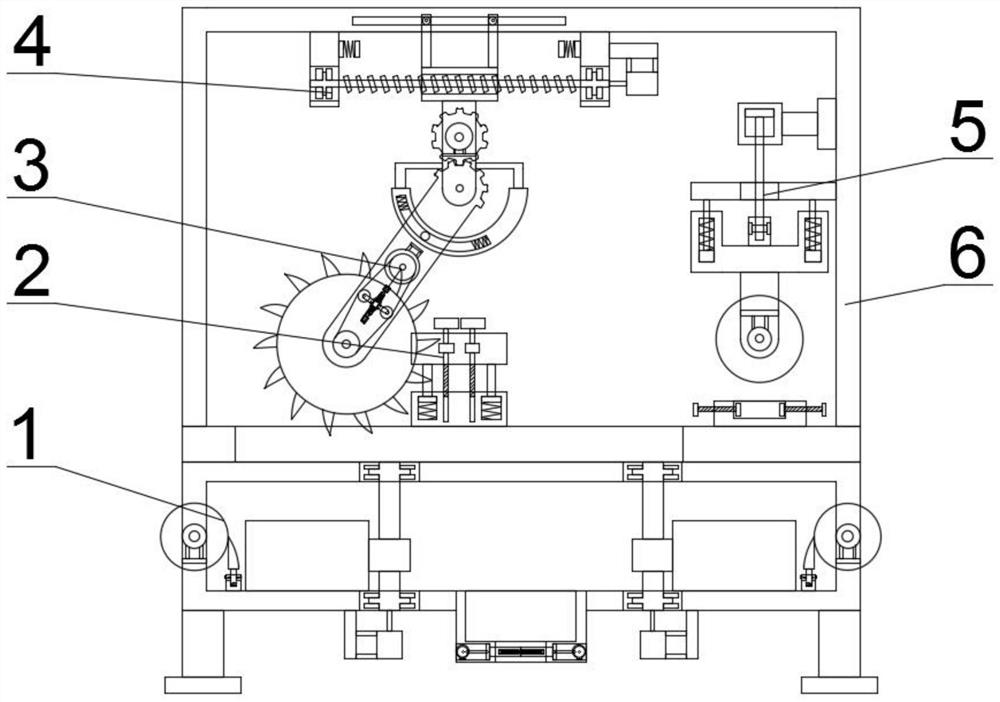

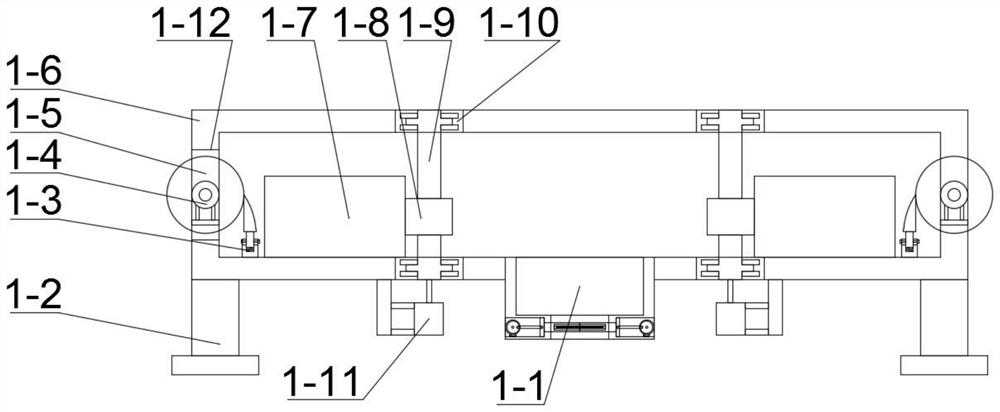

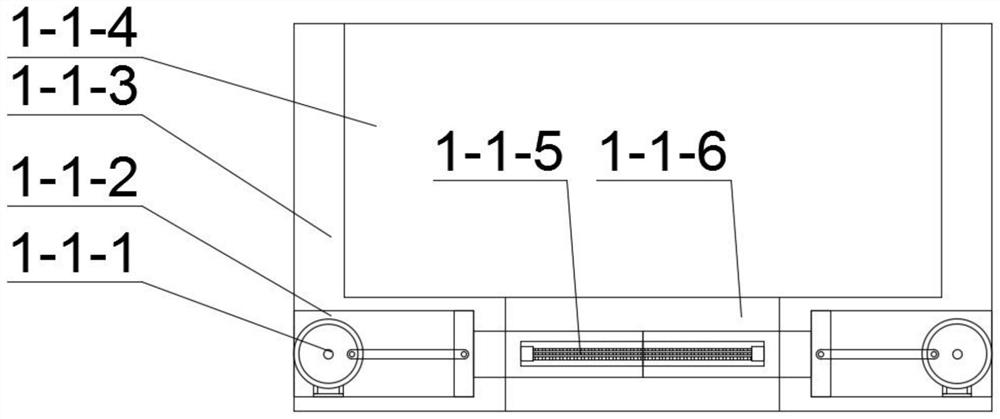

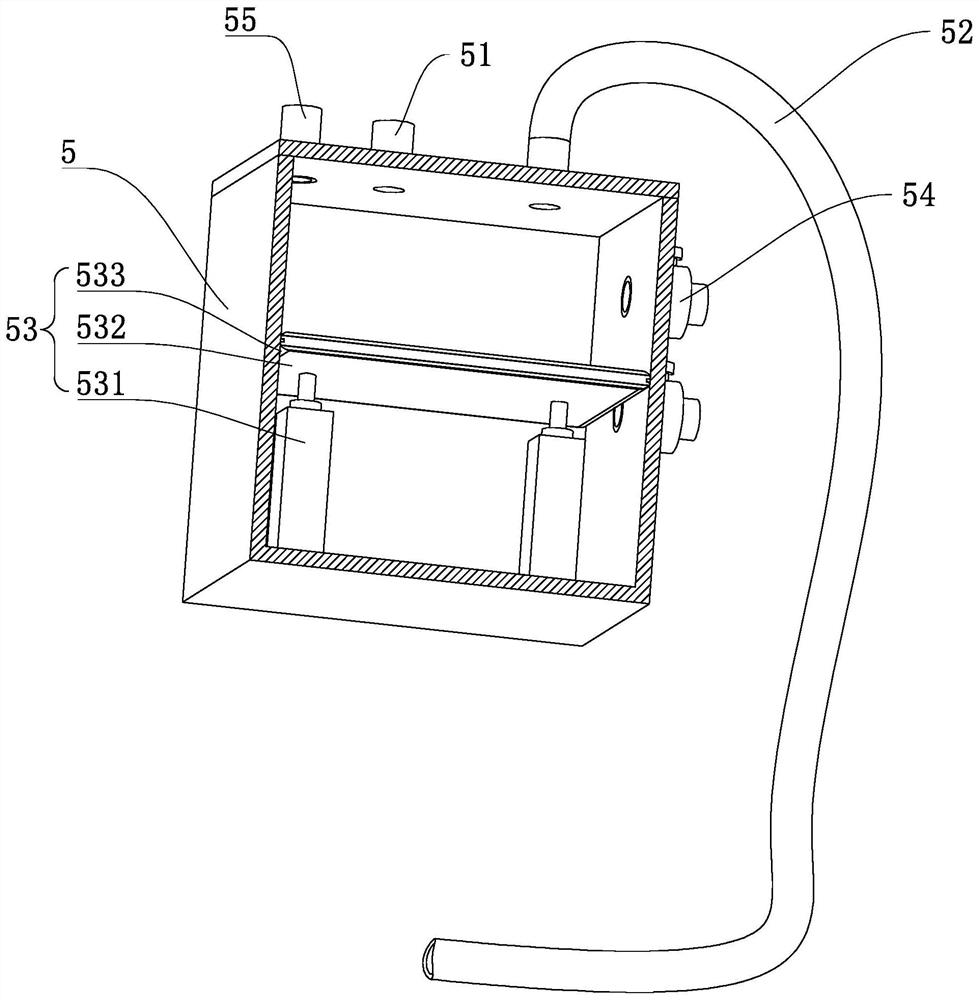

Bridge road surface multifunctional cutting equipment

ActiveCN110409274AOptimize the extraction processChange cutting angleRoads maintainenceRoad surfaceMechanical engineering

The invention relates to cutting equipment, to be specific, relates to bridge road surface multifunctional cutting equipment comprising a cutting execution mechanism, a limiting machine body mechanism, a winding mechanism, and a dust cleaning mechanism. The equipment can be used for cutting, and can be used to pull out a locked cutter easily, and the equipment is capable of changing a cutting angle, and the equipment can be used for winding and cutting wires, and also can be used to clean the dust generated during the cutting, and the equipment can be used to clean the dust conveniently. The cutting execution mechanism is connected with the limiting machine body, and the winding mechanism is connected with the limiting machine body, and the dust cleaning mechanism is connected with the limiting machine body.

Owner:临沂高新置业有限公司

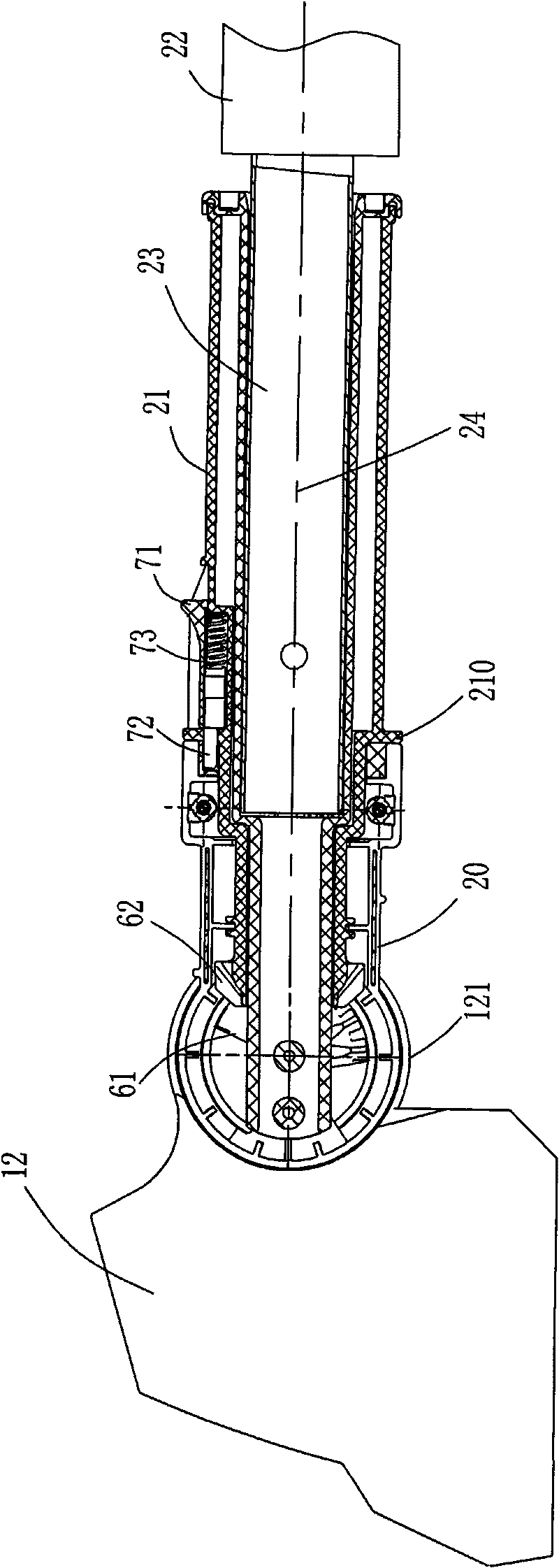

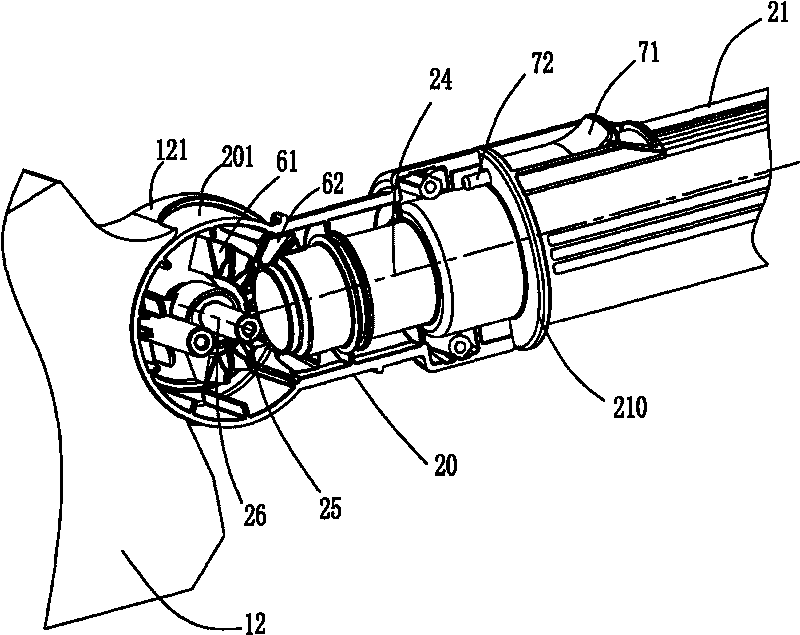

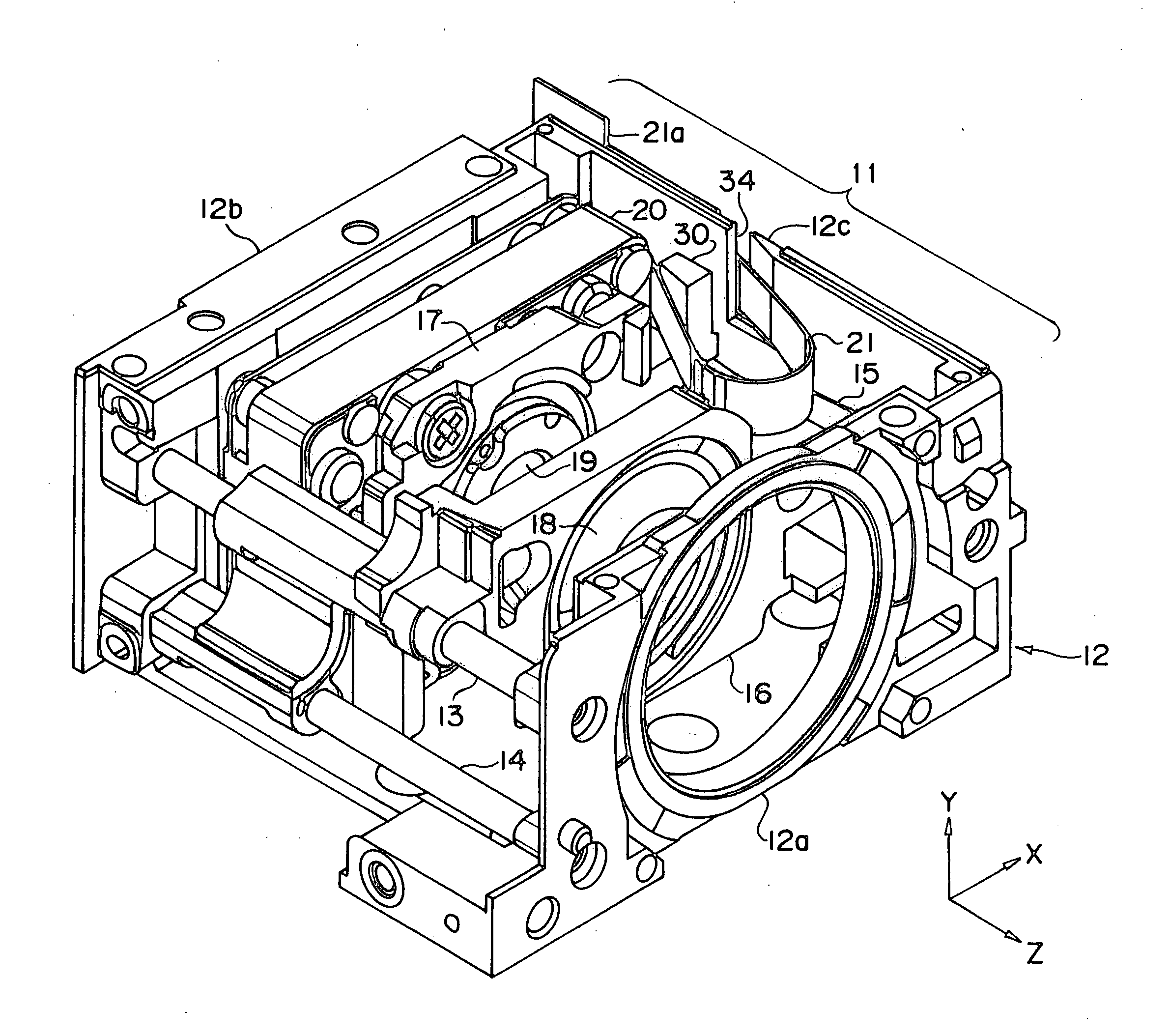

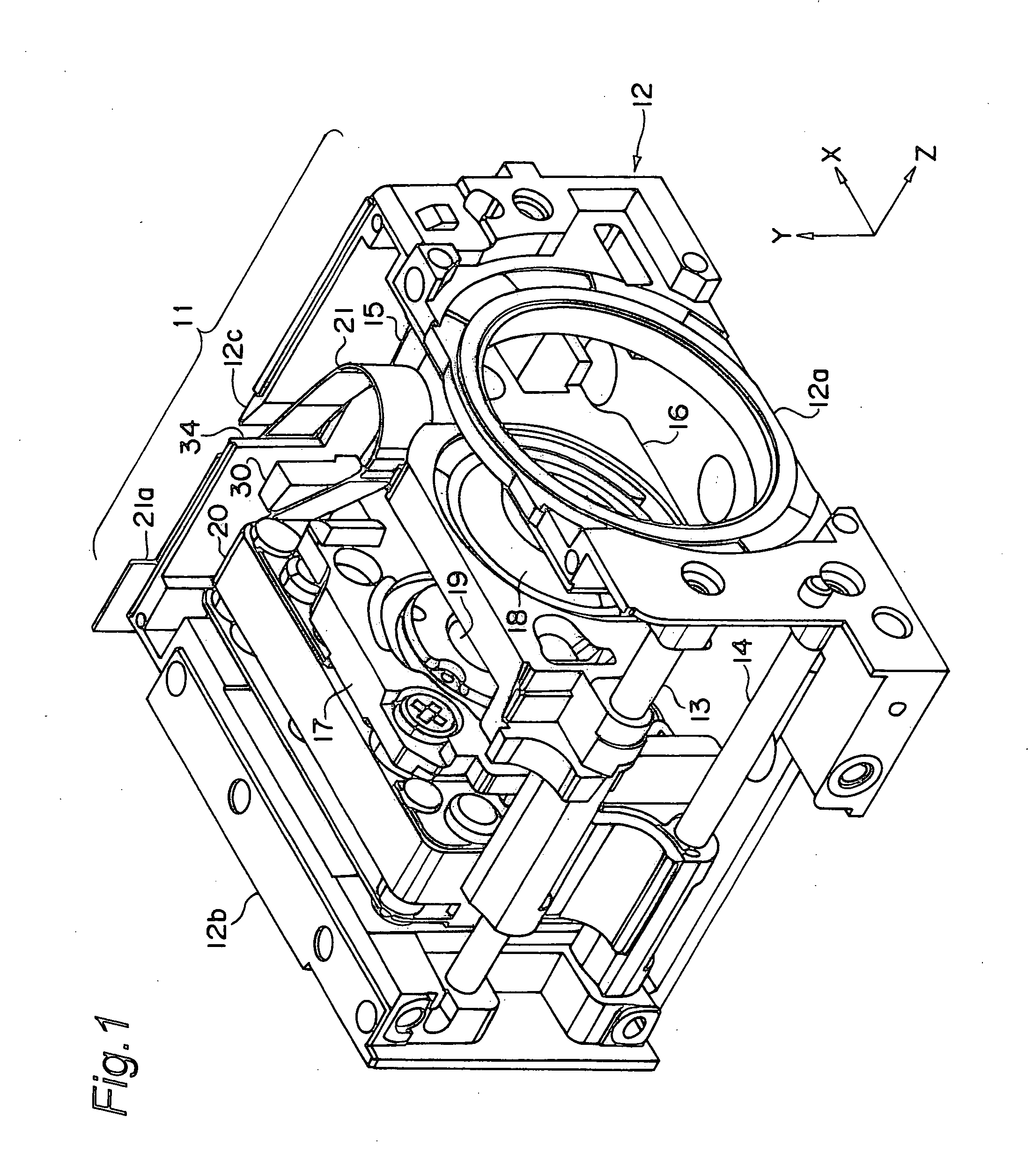

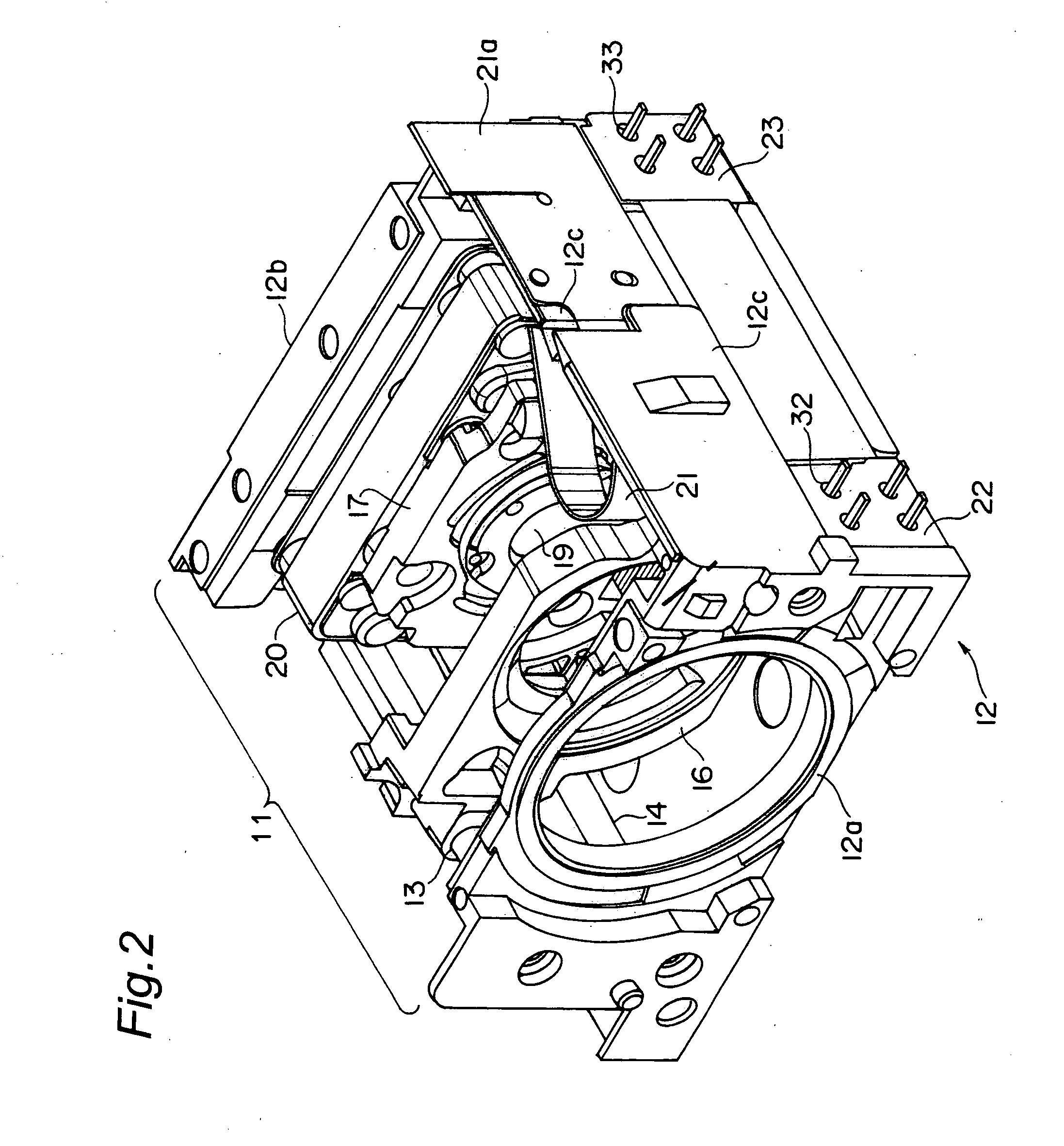

Lens unit

One end of an FPC (21) for supplying power to the driving section of a light amount control section provided in a shutter unit (20) is disposed between a second lens holder (17) and the shutter unit (20) secured to this second lens holder (17) and is held between the second lens holder (17) and the shutter unit (20). Thus, the FPC (21) is prevented from being spaced apart from the shutter unit (20), and a member for securing the FPC (21) to the shutter unit (20) is eliminated, reducing the number of part items. Further, the second lens holder (17) and the shutter unit (20) blocks unwanted light toward the FPC (21), so that a ghost image is prevented from appearing on an image due to unwanted light reflected on the FPC (21).

Owner:SHARP KK

Metal plate cutting device

ActiveCN113798576AChange placementChange cutting angleAutomatic control devicesShearing machinesEngineeringStructural engineering

The invention discloses a metal plate cutting device which specifically comprises a support, a supporting ring, a rotating device and sliding supporting devices. Lifting tables are arranged at the bottoms of the two ends of the support, and fixing grooves are formed in the bottoms of the lifting tables. A sliding groove is formed in the top of the supporting ring, and the two ends of the supporting ring are fixed to the support through fixing rods. The top of the rotating device is fixedly connected with the center position of the top of the support, a transverse sliding way is arranged at the bottom of the rotating device, and a cutting device is slidably connected to the bottom of the transverse sliding way. The sliding supporting devices are arranged at the two ends of the transverse sliding way, and the bottoms of the sliding supporting devices extend into the sliding groove and are in sliding connection with the inner wall of the sliding groove. The rotating device comprises a rotating shell, and the top of the rotating shell is fixedly connected with the support. The invention relates to the technical field of metal cutting. According to the metal plate cutting device, the placement position of a plate is prevented from being changed, time and labor are saved, and the machining efficiency is high.

Owner:梅州展龙五金加工有限公司

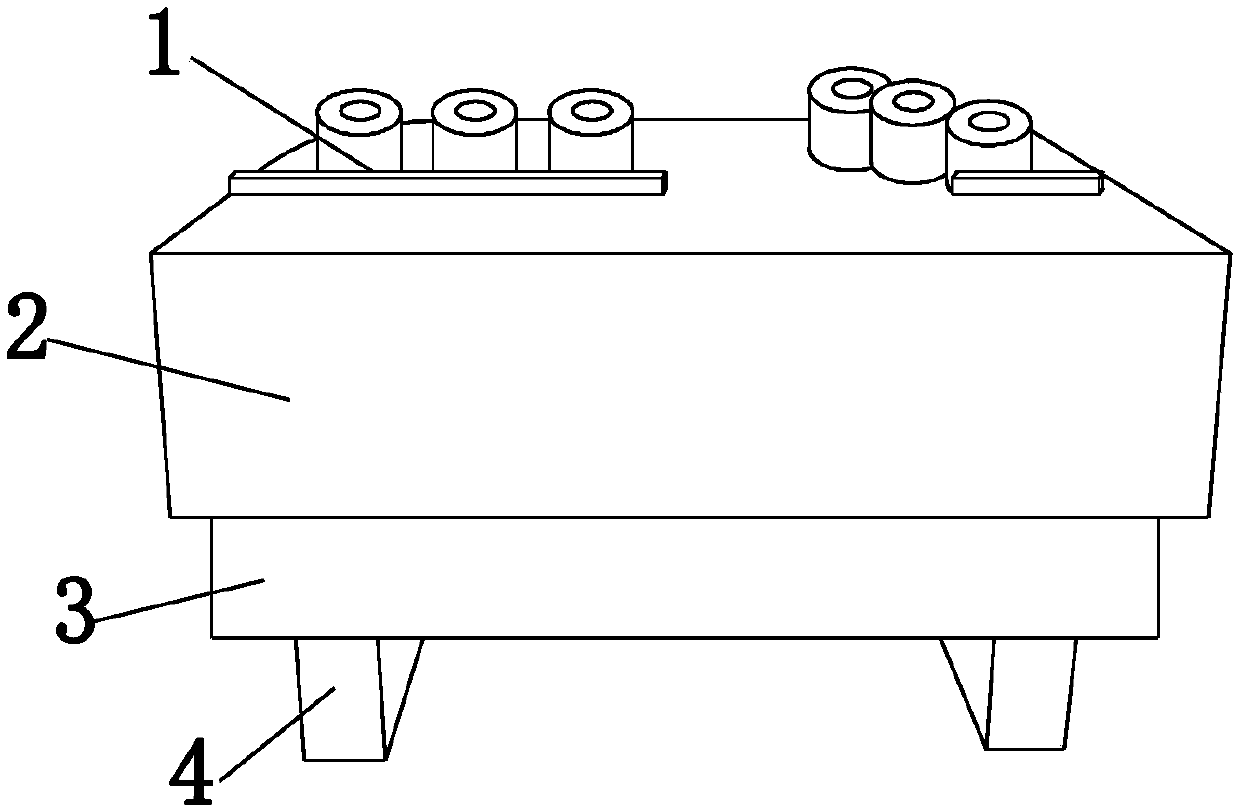

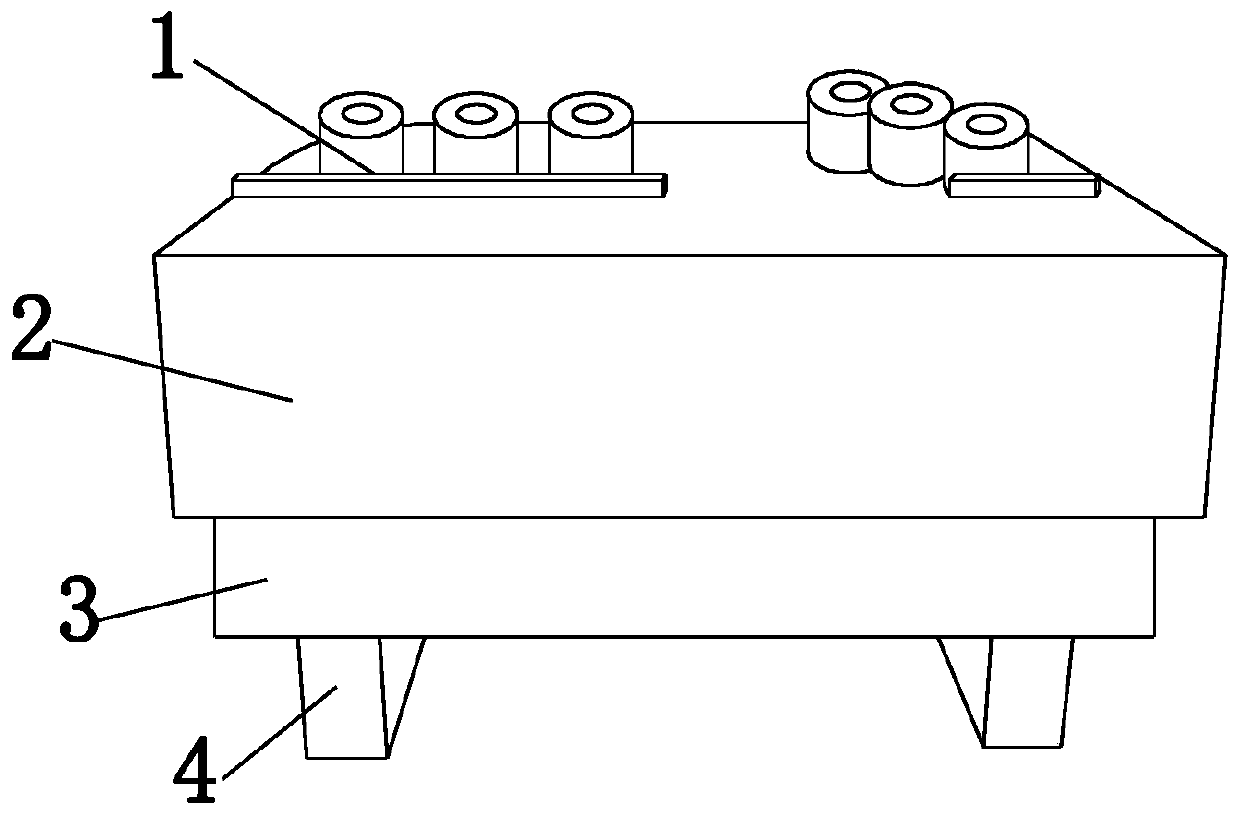

Building timber cutting mechanical device

ActiveCN108015861AImprove magnetismChange cutting angleProfiling/shaping machinesWood working safety devicesEngineering

The invention discloses a building timber cutting mechanical device which structurally comprises a cutting device, a housing, a base and two supporting legs, wherein the cutting device is mounted on the housing; the base is mounted at the bottom of the housing; the base is fixedly connected with the housing; the two supporting legs are symmetrically arranged at the bottom of the base in parallel;the base is fixedly connected with the two supporting legs; according to the building timber cutting mechanical device provided by the invention, through combined action of the cutting device, a cutting mechanism and a heat dissipation mechanism, adjustment on the cutting angle of the device is achieved, the degree of mechanization is high, heat produced in the work of the device can be dissipatedin time, and the service life of the device is prolonged.

Owner:ANHUI SOYA DECORATIVE MATERIALS

A multifunctional cutting equipment for bridge pavement

ActiveCN110409274BOptimize the extraction processChange cutting angleRoads maintainenceStructural engineeringRoad surface

The invention relates to a cutting device, more specifically a multifunctional cutting device for bridge pavement, which includes a cutting actuator, a position limiting body mechanism, a wire winding mechanism, and a dust cleaning mechanism. The equipment can be cut and the equipment can be easily pulled out Out of the locked cutting knife, the equipment can change the cutting angle, the equipment can wrap the thread, the equipment can cut the thread, the equipment can purify the dust generated during cutting, and the equipment can clean dust more conveniently. The cutting actuator and limiter The body mechanism is connected, the thread winding mechanism is connected with the limit body mechanism, and the dust cleaning mechanism is connected with the limit body mechanism.

Owner:临沂高新置业有限公司

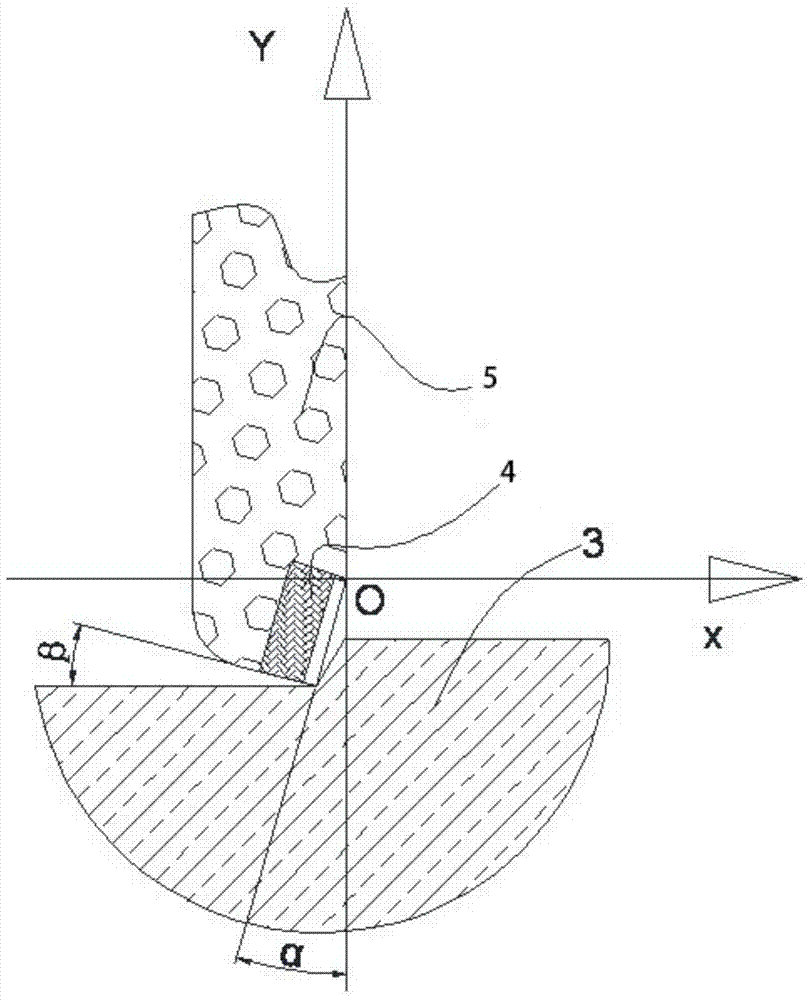

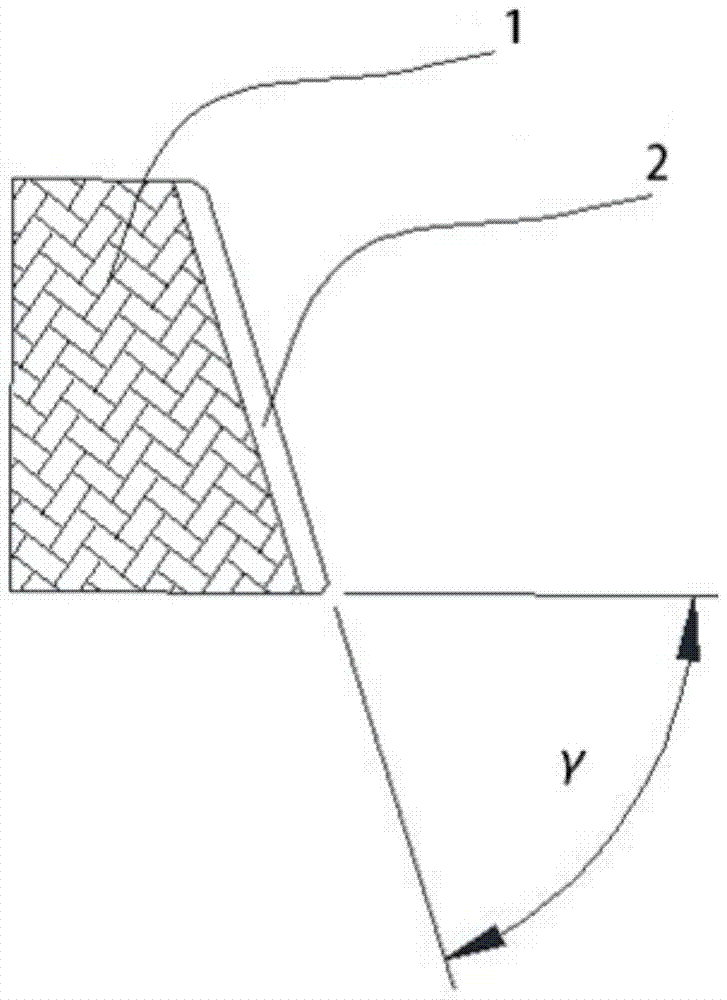

A kind of polycrystalline diamond composite sheet and its application

ActiveCN105041224BThe cutting angle can be changed arbitrarilyRegular shapeDrill bitsElevation anglePolycrystalline diamond

The invention provides a polycrystalline diamond composite sheet and an application thereof. The polycrystalline diamond composite sheet includes a polycrystalline diamond layer and a hard alloy layer, and the plane of the polycrystalline diamond layer forms an included angle of 20°-88° with the bus bar of the polycrystalline diamond compact sheet. The present invention also provides the application of the above-mentioned polycrystalline diamond compact in a PDC drill bit. The polycrystalline diamond composite sheet of the present invention can arbitrarily change the cutting angle of the polycrystalline diamond composite sheet under the condition of maintaining the optimum back angle, so as to achieve more efficient cutting efficiency or higher durability. When the polycrystalline diamond composite sheet is used in the PDC drill bit, the drilling speed can be increased. At the same time, the polycrystalline diamond composite sheet has regular shape, is easy to weld, and has reliable strength; it can also simplify the manufacturing process of the PDC drill bit.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

A multifunctional road cutting device

ActiveCN109371793BAvoid damageChange cutting angleRoads maintainenceStructural engineeringMechanical engineering

Owner:青海省交控建设工程集团有限公司

Highway pavement joint cutting device with automatic adjusting function for monitoring line installation

PendingCN114575229AChange cutting angleChange kerf widthRoads maintainenceAuto regulationDistance detection

The invention relates to the technical field of municipal engineering equipment, in particular to a highway pavement joint cutting device with an automatic adjusting function for monitoring line installation, which comprises a longitudinal posture adjusting device fixedly installed on a rack in a vertical state, and an angle adjusting device vertically and fixedly installed at the output end of the longitudinal posture adjusting device. The angle adjusting device is composed of a first angle adjusting mechanism and a second angle adjusting mechanism. A first joint cutting mechanism and a second joint cutting mechanism are fixedly mounted at the output ends of the first angle adjusting mechanism and the second angle adjusting mechanism respectively; the distance detection unit is fixedly mounted on the rack in a horizontal state; the cooling unit is detachably and fixedly mounted on the angle adjusting device; the cleaning unit is detachably mounted on one side of the cooling unit; the depth and the width of the pre-buried pit can be automatically changed according to the specification of the monitoring cable, self-adaption can be carried out according to the road condition of the cut joint, and it is ensured that the depth and the size of the cut pre-buried pit in the road surface are consistent.

Owner:中铁二十局集团第二工程有限公司 +1

Environment-friendly high-pressure water cutting machine for automobile parts

PendingCN114871949AChange cutting angleMeet different cutting needsAbrasive machine appurtenancesMotor vehicle partStructural engineering

The invention relates to the technical field of water cutting, and discloses an environment-friendly automobile part high-pressure water cutting machine which comprises a cutting table and a water jet cutter body, the water jet cutter body is arranged at the top of the cutting table, an adjusting mechanism is arranged at the top of the cutting table, a fixing mechanism is installed in the adjusting mechanism, and the adjusting mechanism comprises a grating table. Two half-moon-shaped plates are installed at the top of the grating table, sliding grooves are formed in the tops of the two half-moon-shaped plates, a two-way lead screw is movably connected between the two sliding grooves, sliding blocks are installed at the positions, close to the two sliding grooves, of the outer side wall of the two-way lead screw, and arc-shaped surrounding plates are fixedly connected to the tops of the two sliding blocks. The environment-friendly high-pressure water cutting machine for the automobile parts has the advantages that the horizontal cutting face can be adjusted, and special-shaped parts can be conveniently cut, and the problem that an existing horizontal water cutting platform cannot meet the cutting requirements of some special-shaped automobile parts is solved.

Owner:陈平辉

Adjustable cutting device for wall brick production

InactiveCN113858450AAutomatic distance changeImprove cutting efficiencyWorking accessoriesStone-like material working toolsBrickStructural engineering

The invention belongs to the technical field of wall brick production, and provides an adjustable cutting device for wall brick production, which comprises two oppositely arranged cutting assemblies for cutting two sides of a wall brick correspondingly, a distance adjusting unit, a wall brick conveying unit, and a width measuring unit, wherein the distance adjusting unit is connected with the cutting assemblies and used for adjusting the distance between the two cutting assemblies, the wall brick conveying unit passes through the space between the two cutting assemblies and is used for driving the wall brick to move and conveying the wall brick to the next station after the wall brick is cut, the width measuring unit is arranged on the wall brick conveying unit and used for detecting the width of the wall brick and controlling the distance adjusting unit to adjust the distance between the two cutting assemblies, and the width measuring unit is arranged on the upstream side of the cutting assemblies. By arranging the distance adjusting unit, the cutting assemblies can automatically change the distance between the two cutting assemblies 1 according to the wall brick width measured by the width measuring unit, and the cutting efficiency is improved.

Owner:重庆御光新材料股份有限公司

A multi-functional fire-fighting lifting and cutting device

ActiveCN109277624BChange the stick out lengthChange cutting angleShearing machinesLarge fixed membersClassical mechanicsMechanical engineering

The invention relates to a cutting device, in particular to a multifunctional lifting cutting device for fire fighting. The device comprises a moving bottom frame mechanism, a lifting mechanism, a cutting mechanism and a clamping and protecting mechanism; and the device can perform cutting operation, change the cutting angle, change the extending length of a cutting knife, clamp an obstacle needing to be cut, lift, move, climb stairs, and run safely. The moving bottom frame mechanism is located below the lifting mechanism, the moving bottom frame mechanism is connected with the lifting mechanism in a welding mode, the cutting mechanism is located above the lifting mechanism, the cutting mechanism is connected with the lifting mechanism through bolts, the clamping and protecting mechanism is located above the cutting mechanism, and the clamping and protecting mechanism and the cutting mechanism are connected in a welding mode.

Owner:西安鸿致信宇科技有限公司

A multifunctional window frame cutting and grinding device

ActiveCN110103030BChange cutting positionChange cutting angleOther manufacturing equipments/toolsPolishingBody frame

The invention relates to a cutting and polishing device and more particularly relates to a multifunctional window frame cutting and polishing device. The multifunctional window frame cutting and polishing device comprises an iron scrap collecting mechanism, a clamping mechanism, a cutting and executing mechanism, a cutting and moving mechanism, a polishing mechanism and a body frame mechanism. Thedevice is capable of cutting, tightening a belt, changing cutting positions, changing cutting angles, clamping door and window frames, polishing and collecting the iron scraps; the iron scrap collecting mechanism is located under the body frame mechanism; the clamping mechanism is connected with the body frame mechanism; the cutting and executing mechanism is connected with the cutting and movingmechanism; the cutting and moving mechanism is connected with the body frame mechanism; and the polishing mechanism is connected with the body frame mechanism.

Owner:重庆巨耀精密电子有限公司

Cutting type foundation pit expanding excavation device

PendingCN113250258AChange cutting angleEasy to useSoil-shifting machines/dredgersArchitectural engineeringCylinder block

The invention provides a cutting type foundation pit expanding excavation device. The cutting type foundation pit expanding excavation device comprises an excavator arm, a driving oil cylinder, a driving arm, a linkage arm and an installation arm. A cylinder body of the driving oil cylinder is rotationally connected to the excavator arm, a piston of the driving oil cylinder is rotationally connected with one end of the driving arm, the other end of the driving arm is rotationally connected to the excavator arm, one end of the linkage arm is rotationally connected with the driving arm, and the other end of the linkage arm is rotationally connected with the installation arm. One end of the installation arm is rotationally connected with the excavator arm, a cutting device is arranged on the installation arm, the cutting device is rotationally connected with the installation arm, a transposition oil cylinder and a transposition arm are arranged on the installation arm, a cylinder body of the transposition oil cylinder is rotationally connected to the installation arm, a piston of the transposition oil cylinder is rotationally connected with one end of the transposition arm, the other end of the transposition arm is fixed to the cutting device, and a cooling device is installed on the cutting device and comprises a connector, a water pipe and a water tank. The cutting type foundation pit expanding excavation device can adjust the cutting position, depth and angle without moving the excavator, and is more convenient to use.

Owner:江苏创威电子有限公司

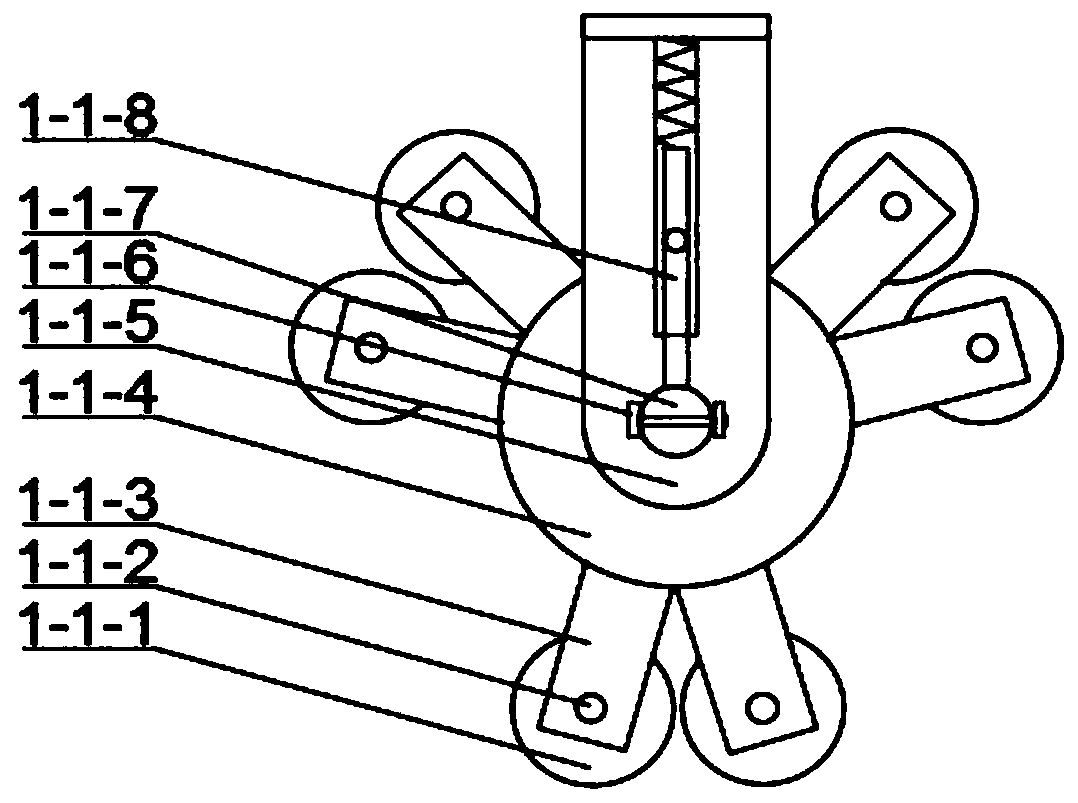

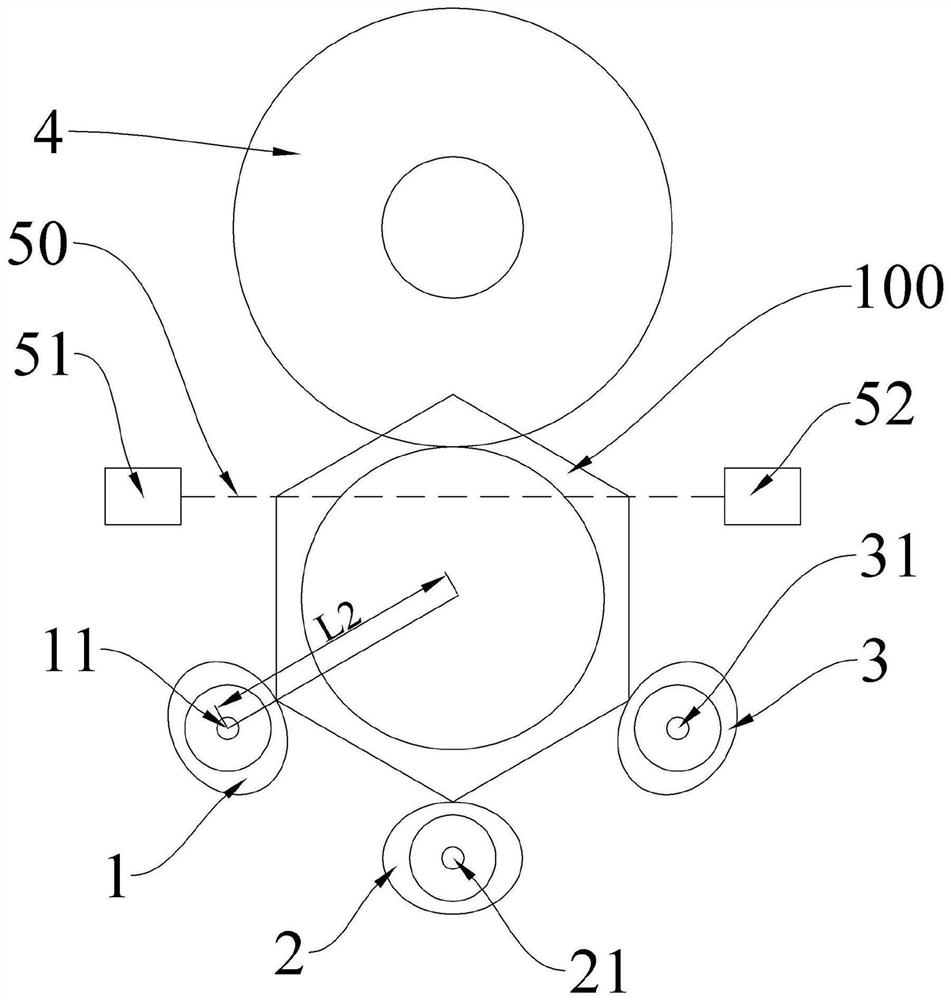

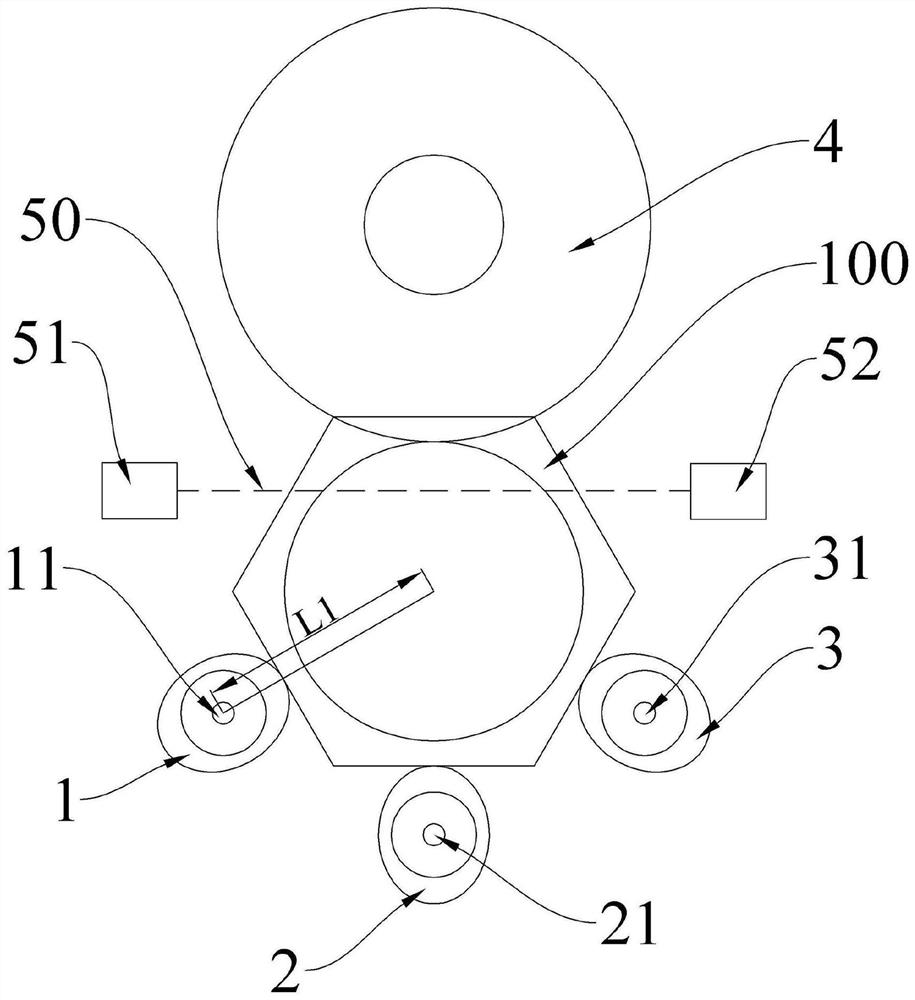

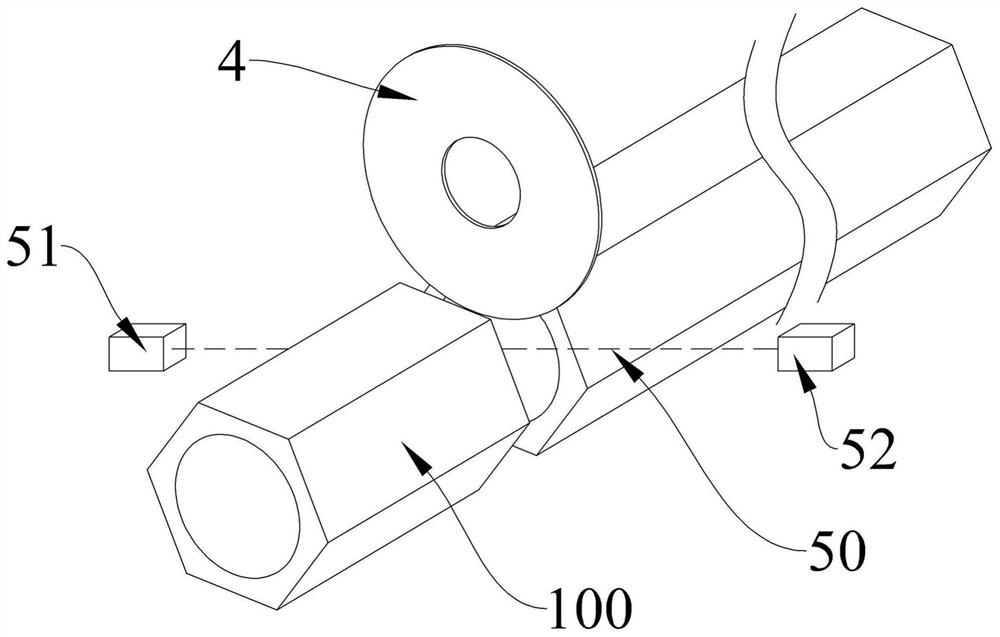

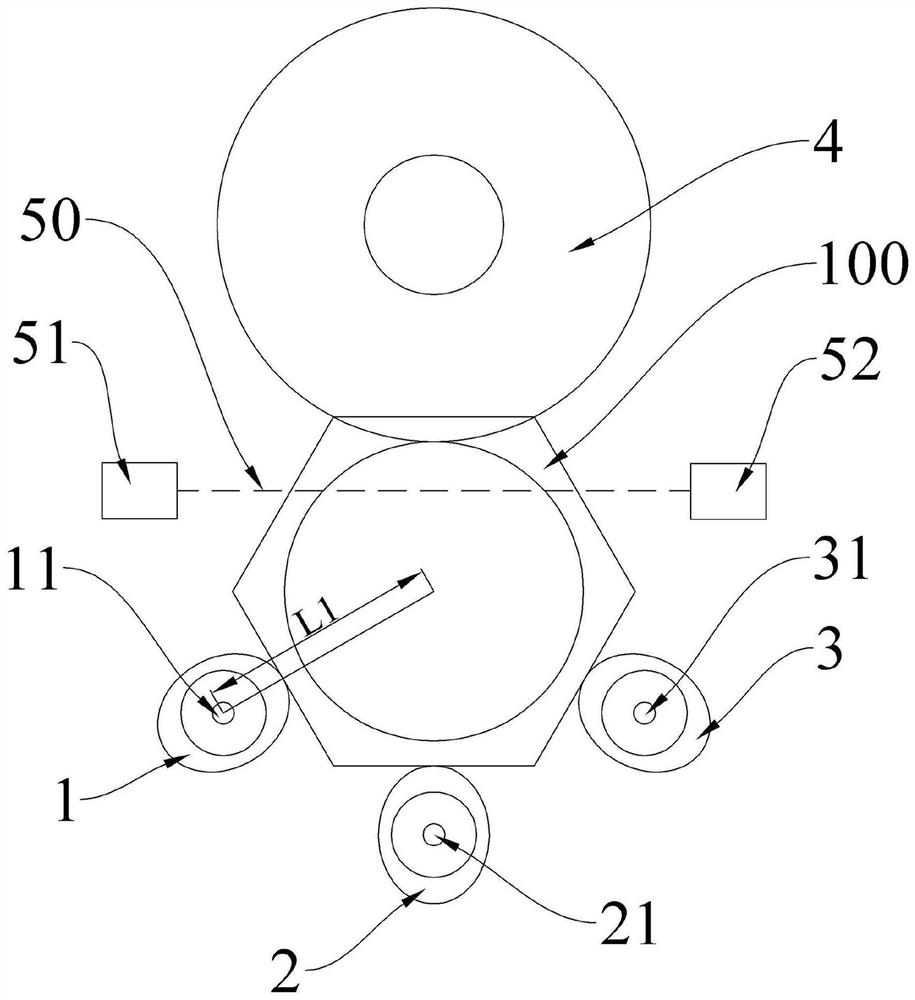

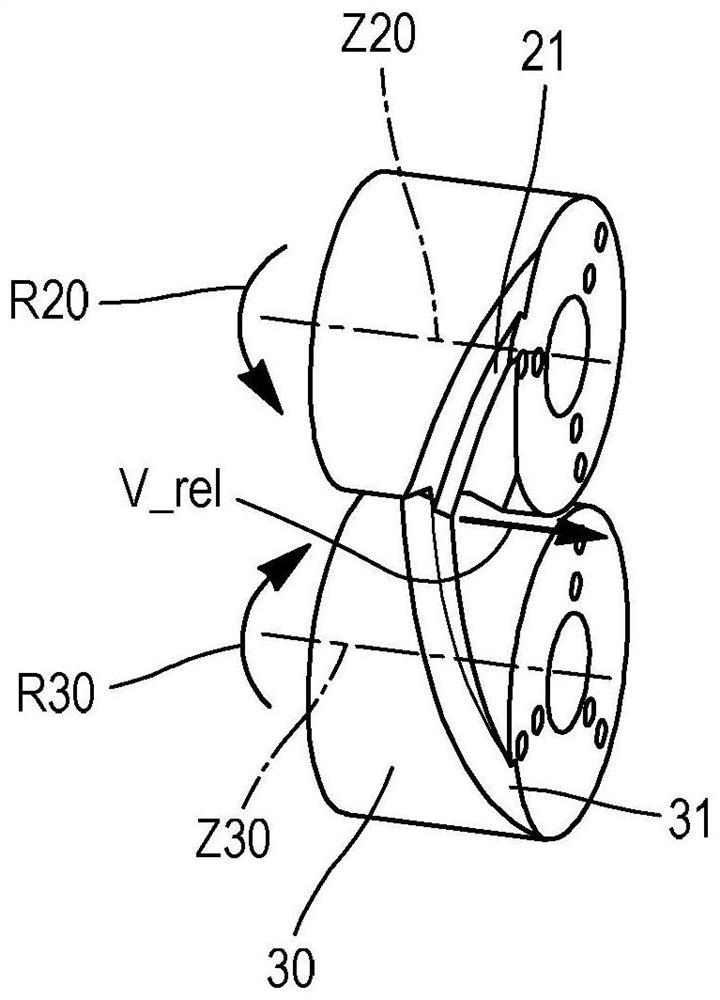

Multifunctional special-shaped nuclear industrial pipe running fit device

ActiveCN112620785AAvoid damageImprove stabilityTube shearing machinesShearing machine accessoriesRotational axisGravity center

The invention relates to a multifunctional special-shaped nuclear industrial pipe running fit device. The device comprises a first roller, a second roller, a third roller and an infrared photoelectric sensor. The first roller rotates around a first rotating shaft, the second roller rotates around a second rotating shaft, and the third roller rotates around a third rotating shaft. The first rotating shaft and the third rotating shaft are symmetrically arranged on the two sides of the second rotating shaft, and the first rotating shaft, the second rotating shaft and the third rotating shaft support three different faces of a special-shaped nuclear industrial pipe correspondingly. The distances from the axis of the first rotating shaft, the axis of the second rotating shaft and the axis of the third rotating shaft to the center point of the section of the special-shaped nuclear industrial pipe are equal and are kept unchanged, it is guaranteed that the gravity center of the special-shaped nuclear industrial pipe is kept unchanged all the time in the rotating process, and the stability of the special-shaped nuclear industrial pipe in the rotating cutting process is effectively improved. The cutting angle is prevented from being changed due to shaking in the cutting process of the special-shaped nuclear industrial pipe, and the cutting quality of the special-shaped nuclear industrial pipe is improved.

Owner:杭州智行远机器人技术有限公司

Mechanical device for cutting wood for construction

ActiveCN108015861BImprove magnetismChange cutting angleProfiling/shaping machinesWood working safety devicesEngineeringWood cutting

The invention discloses a building timber cutting mechanical device which structurally comprises a cutting device, a housing, a base and two supporting legs, wherein the cutting device is mounted on the housing; the base is mounted at the bottom of the housing; the base is fixedly connected with the housing; the two supporting legs are symmetrically arranged at the bottom of the base in parallel;the base is fixedly connected with the two supporting legs; according to the building timber cutting mechanical device provided by the invention, through combined action of the cutting device, a cutting mechanism and a heat dissipation mechanism, adjustment on the cutting angle of the device is achieved, the degree of mechanization is high, heat produced in the work of the device can be dissipatedin time, and the service life of the device is prolonged.

Owner:ANHUI SOYA DECORATIVE MATERIALS

A multi-functional special-shaped nuclear industry pipe rotation matching device

ActiveCN112620785BAvoid damageImprove stabilityTube shearing machinesShearing machine accessoriesRotational axisEngineering

The invention relates to a multi-functional special-shaped nuclear industry pipe rotation matching device, which includes a first roller, a second roller, a third roller and an infrared photoelectric sensor. The first roller rotates around the first rotation axis, the second roller rotates around the second rotation axis, and the third roller rotates around the third rotation axis. The first rotating shaft and the third rotating shaft are arranged symmetrically on both sides of the second rotating shaft, and the first rotating shaft, the second rotating shaft and the third rotating shaft respectively support three different surfaces of the special-shaped nuclear industry pipe. Among them, the distances from the axis of the first rotating shaft, the axis of the second rotating shaft and the axis of the third rotating shaft to the center point of the cross-section of the special-shaped nuclear industry pipe are all equal and remain unchanged, which ensures that the special-shaped nuclear industry pipe can be rotated during the rotation process. The center of gravity is always kept unchanged, which effectively improves the stability during the rotary cutting process of special-shaped nuclear industrial tubes, avoids shaking during the cutting process of special-shaped nuclear industrial tubes and changes the cutting angle, and improves the cutting quality of special-shaped nuclear industrial tubes.

Owner:杭州智行远机器人技术有限公司

Self-pressurization drilling and slurry-making integrated deep mixing pile machine and construction method

ActiveCN114673145ADrilling kinetic energy is largeReduce work intensityBulkheads/pilesStructural engineeringSlurry

The invention relates to a self-pressurization drilling and slurry making integrated deep mixing pile machine and a construction method. The stirring device comprises a rack stably fixed on the ground, a driving mechanism slidably connected to the rack in the vertical direction, a stirring shaft connected to the driving mechanism, stirring blades fixedly connected to the outer bottom of the stirring shaft, a pressure tank fixedly connected to the driving mechanism and additional blades fixedly connected to the stirring blades. Included angles are formed between the axes of the additional blades and the axes of the stirring blades. The device has the effects of reducing the working strength of the driving mechanism and improving the soil layer cutting efficiency.

Owner:北京市地质工程有限责任公司

A kind of driving tool seat for machine tool processing

ActiveCN104325308BSimple structureReasonable designPositioning apparatusMetal-working holdersEngineeringPower tool

The invention discloses a novel power tool holder for machine tool machining. The novel power tool holder comprises a tool holder main body, a clamping mechanism, a cutting tool bearing seat, an angle adjuster and a locking screw, wherein the tool holder main body consists of a nut, a connecting rod and a tool holder head, and the nut and the tool holder head are fixed at the two ends of the connecting rod; the clamping mechanism consists of a clamping sleeve and a clamping handle, and the clamping sleeve is movably arranged on the connecting rod through a fastening screw in a sleeving mode; a trapezoidal groove is formed in one side of the tool holder head, one end of the cutting tool bearing seat is inserted in the trapezoidal groove, a cutter body and a cutter body pressing plate are fixedly mounted above the cutting tool bearing seat in sequence, the angle adjuster is arranged below the cutting tool bearing seat, the angle adjuster is used for adjusting and controlling the cutting tool bearing seat to perform a rotary motion along the axis of the cutting tool bearing seat so as to change the cutting angle of the cutter body. The novel power tool holder is simple in structure and reasonable in design; under the precondition that a cutting tool is not changed or the position of the tool holder is not readjusted, the cutting position, cutting depth and cutting angle of the cutter body can be quickly and conveniently adjusted, and the work efficiency and the utilization rate of the cutting tool are effectively improved.

Owner:统弘自动化科技(苏州)有限公司

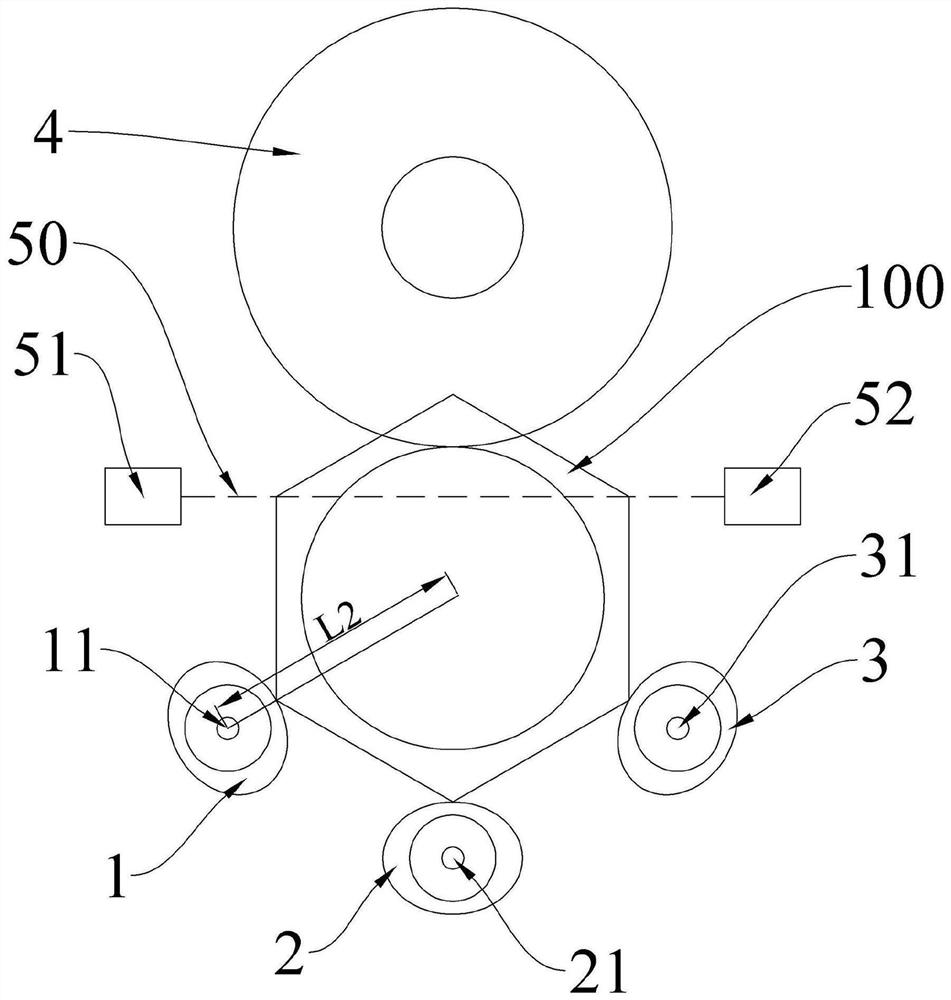

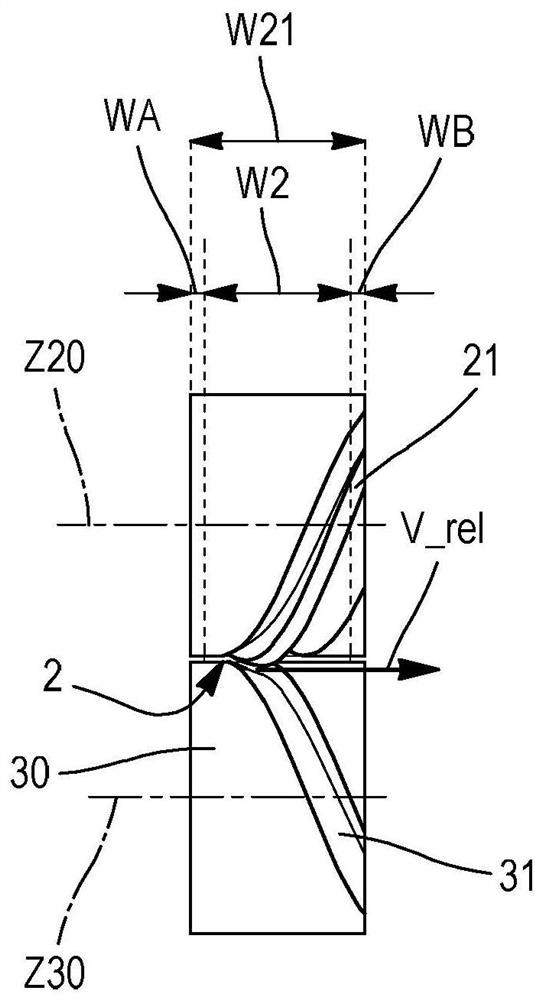

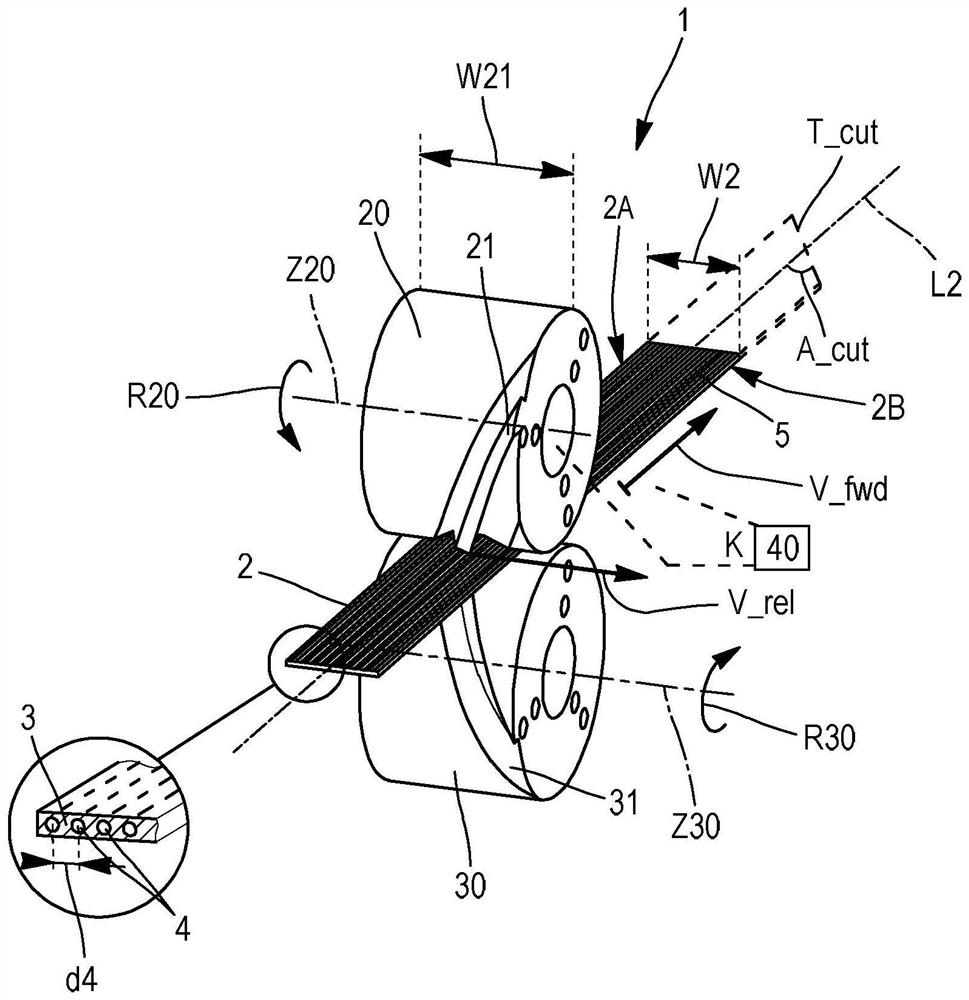

System for cutting strips using helical knives and corresponding cutting method

ActiveCN113039061ASharp cuttingChange cutting angleTyresMetal working apparatusHelical bladeClassical mechanics

The invention relates to a cutting system (1) for cutting into strips (5) a continuous strip (2) which extends lengthwise in a longitudinal direction (L2) and widthwise (W2) between a first edge (2A) and a second edge (2B), said cutting system comprising a drive device (10) which imparts on the continuous strip (2) a feed speed (V_fwd), a first cutting roller (20) and a second cutting roller (30) which are counter-rotating and cooperate to cut the continuous strip (2) across its full width (W2), said first cutting roller (20) being provided for this purpose with a first helical blade (21) and being driven in rotation (R20), and a variable synchronizer (40), which makes it possible to select and modify the synchronization ratio (K) between the rotational speed (R20) of the first cutting roller and the non-zero feed speed (V_fwd) of the continuous strip in such a way as to be able to adjust the so-called cutting angle (A_cut) according to which the cross-section of the continuous strip (2) is oriented with respect to the longitudinal direction (L2) of said continuous strip (2).

Owner:MICHELIN & CO (CIE GEN DES ESTAB MICHELIN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com