Novel power tool holder for machine tool machining

A technology of driven tool holders and machine tools, which is applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of reducing work efficiency and the effective utilization rate of tools, and achieve simple structure, effective work efficiency and reasonable design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

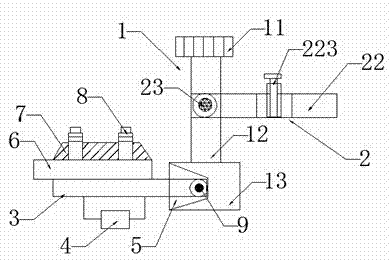

[0017] A new type of power tool holder for machine tool processing, including: a tool holder main body 1, a clamping mechanism 2, a tool support seat 3, an angle adjuster 4 and a locking screw 9;

[0018] The tool seat main body 1 is composed of a nut 11, a connecting rod 12 and a tool seat head 13, wherein the nut 11 and the tool seat head 13 are respectively fixedly installed at both ends of the connecting rod 12;

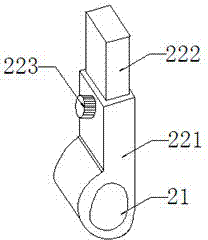

[0019] The clamping mechanism 2 is composed of a clamping sleeve 21 and a clamping handle 22, and the clamping sleeve 21 is movably sleeved on the connecting rod 12 through a fastening screw 23, so that the clamping mechanism 2 is positioned on the knife. Fixing and moving up and down on the seat main body 1, that is, by loosening the fastening screw 23, the clamping mechanism 2 moves up and down along the connecting rod 12 to change the cutting position of the cutter body in the vertical direction. When the fastening screw is tightened After 23, the holding mech...

Embodiment 2

[0023] The difference from Embodiment 1 is that an isosceles trapezoidal groove 5 is provided on the other side of the tool seat head 13 adjacent to the connecting rod 12 .

Embodiment 3

[0025] The difference from Embodiment 1 is that an isosceles trapezoidal groove 5 is provided on the side of the tool seat head 13 opposite to the connecting rod 12 .

[0026] The invention discloses a new type of power tool seat for machine tool processing, which has a simple structure and a reasonable design. Through the design of the position and structure of the clamping mechanism, the cutting position of the tool body in the vertical direction and the cutting depth in the horizontal direction are changed; The design of the structure and connection method between the tool support seat and the tool seat main body changes the cutting angle of the tool body; the invention can quickly and conveniently adjust the cutting of the tool body without changing the tool or readjusting the position of the tool seat. Position, cutting depth and cutting angle, effectively improving work efficiency and tool utilization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com