Circuit board processing and clamping treating device in production process of electronic parts

A production process, technology of electronic parts, applied in the field of circuit board processing clamping device, can solve the problem of unable to adjust the cutting angle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

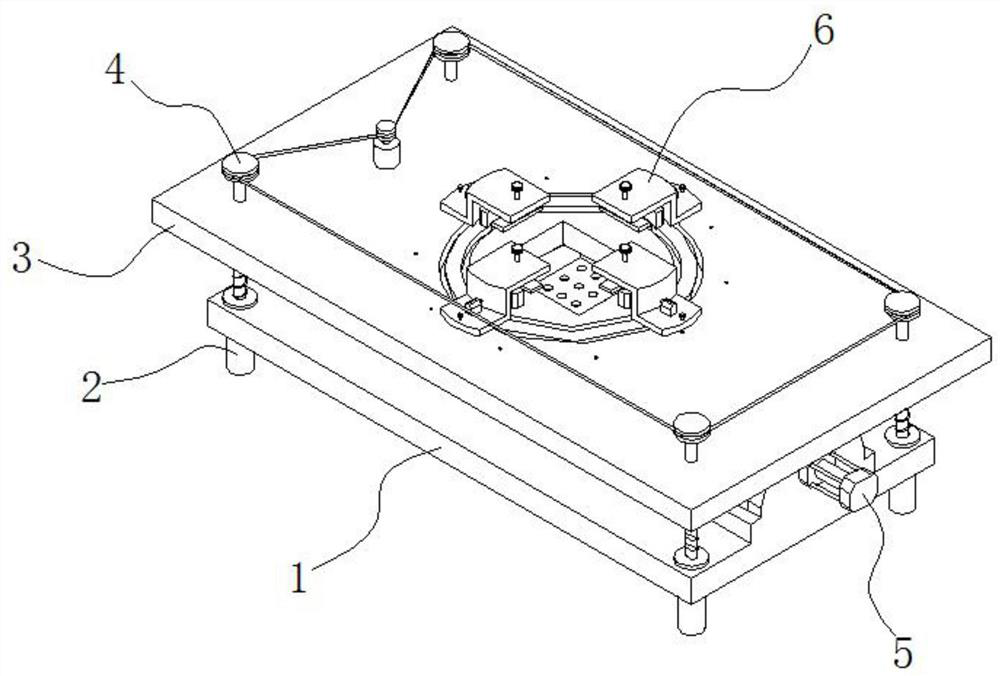

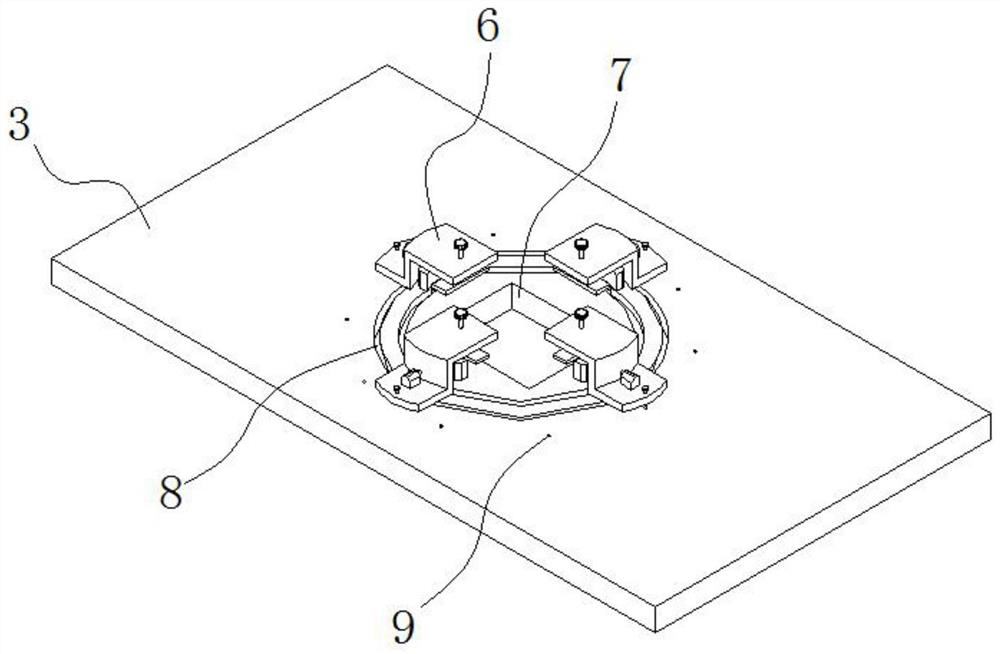

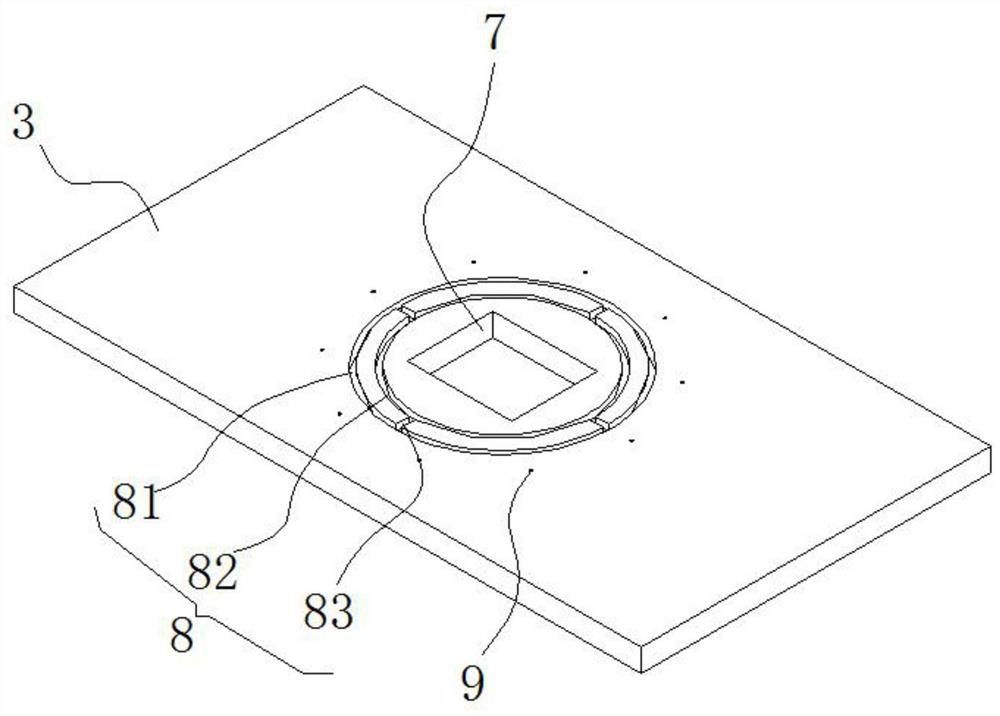

[0029] refer to Figure 1-4 , a circuit board processing and clamping device in the production process of electronic parts, including a base plate 1, a support mechanism 2 is installed at the four corners of the base plate 1, a processing plate 3 is fixedly installed on the top of the support mechanism 2, and a processing plate 3 is provided in the middle of the processing plate 3. The machining hole 7 is provided with a guide mechanism 8 outside the machining hole 7. The guide mechanism 8 includes a first annular groove 81, a second annular groove 82 and a straight groove 83. The second annular groove 82 is located at the inner ring of the first annular groove 81. , The straight groove 83 is opened between the first annular groove 81 and the second annular groove 82 .

[0030] Several clamping mechanisms 6 are installed in the first annular groove 81, and clamping mechanism 6 comprises arc-shaped guide block 62, and arc-shaped guide block 62 is installed in the first annular ...

Embodiment 2

[0034] refer to Figure 1-6 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the support mechanism 2 includes a sleeve 21, the sleeve 21 is fixedly installed on the bottom of the bottom plate 1, and the top of the sleeve 21 is fixedly installed with a threaded sleeve 22, The inner thread of the threaded sleeve 22 is threaded with a threaded shaft 23, the threaded shaft 23 runs through the base plate 1, and extends to the inside of the sleeve seat 21; the top of the processing plate 3 is equipped with a transmission mechanism 4 corresponding to the threaded shaft 23, and the transmission mechanism 4 includes Four first pulleys 41, four first pulleys 41 are respectively fixedly installed on the top of the corresponding threaded shaft 23, the top of the threaded shaft 23 is fixedly installed with the processing plate 3, and one side of the first pulley 41 is provided with Motor 42, motor 42 is fixed on the top of processing plat...

Embodiment 3

[0037] refer to Figure 1-7 , as another preferred embodiment of the present invention, the difference from Embodiment 1 or Embodiment 2 is that a waste guide mechanism 5 is installed on the top of the bottom plate 1, and the waste guide mechanism 5 includes two parallel slide rails 51, and the two slide rails On the rail 51, a slide block 52 is slidably installed, a waste box 53 is fixedly installed on the top of the slide block 52, a fixed plate 54 is fixedly installed on one end of the slide rail 51, and a first cylinder 55 is fixedly installed on the outside of the fixed plate 54. The output end of the cylinder 55 is fixedly connected with the side wall of the waste box 53 .

[0038] By controlling the first cylinder 55, the waste box 53 slides outward along the slide rail 51, thereby leading out the waste inside the waste box 53, which is convenient for manual processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com