Self-pressurization drilling and slurry-making integrated deep mixing pile machine and construction method

A deep mixing pile, integrated technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of short service life of the driving mechanism, large damage of the driving mechanism, etc., to improve efficiency, reduce work intensity, change cutting The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

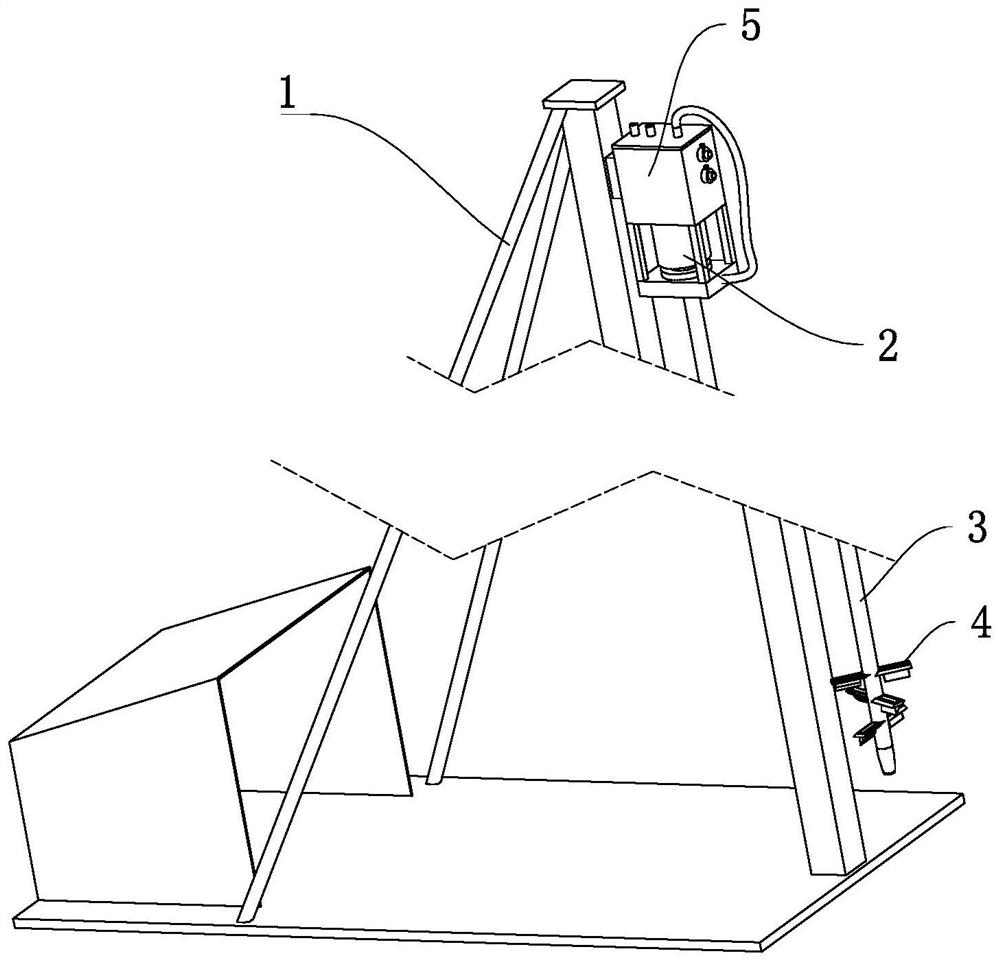

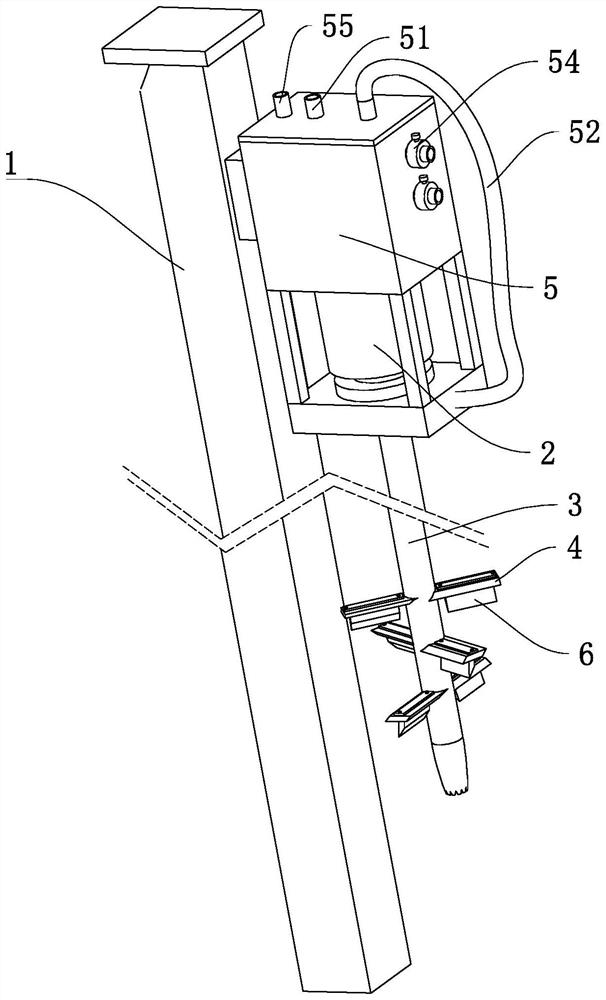

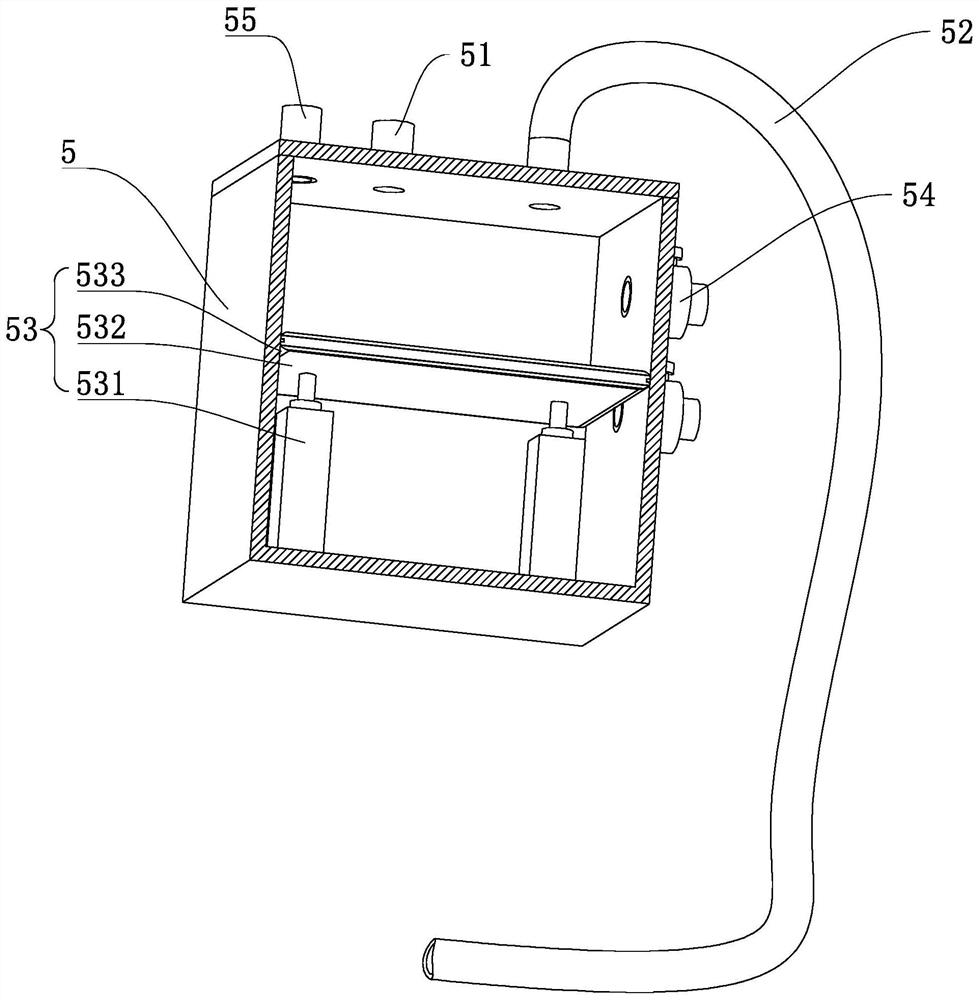

[0036] Attached to the following Figure 1-5 This application will be described in further detail.

[0037] The embodiment of the present application discloses a self-pressurized drilling and slurry-making integrated deep stirring pile driver. refer to Figure 1-5 , Self-pressurized drilling and pulping integrated deep mixing pile driver, including a frame 1 fixed on the ground, a driving mechanism 2 slidably connected to the frame 1 in the vertical direction, a stirring shaft 3 connected to the driving mechanism 2, fixed The stirring blade 4 connected to the outer bottom of the stirring shaft 3, the pressure tank 5 fixedly connected to the driving mechanism 2, and the additional blade 6 fixedly connected to the stirring blade 4, the axis of the additional blade 6 and the axis of the stirring blade 4 have an included angle.

[0038] When the deep pile mixer is working, the driving mechanism 2 provides drilling kinetic energy for the stirring shaft 3 and the stirring blade 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com