System for cutting strips using helical knives and corresponding cutting method

A cutting system and strip technology, used in household appliances, other household appliances, applications, etc., can solve problems such as high energy, high cutting force, and limited throughput of cutters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

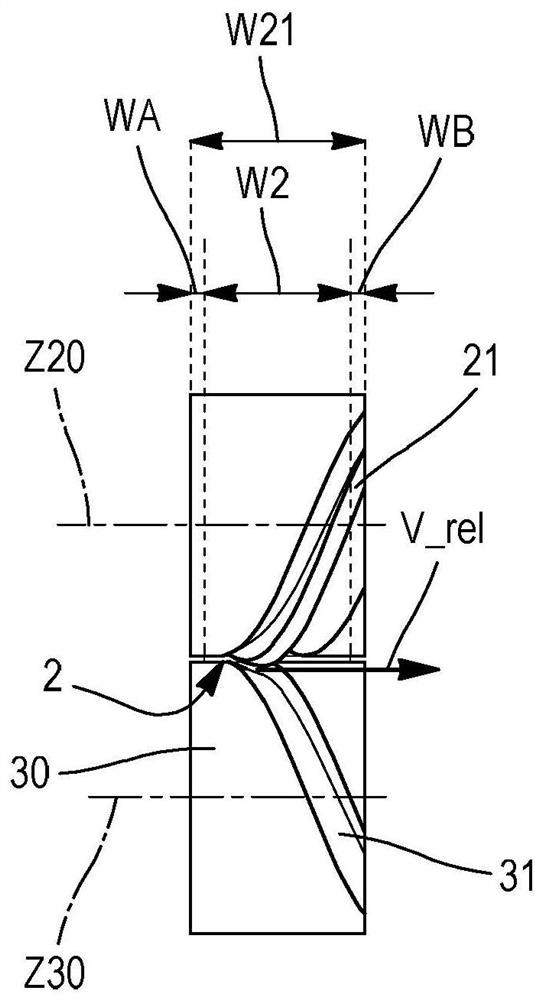

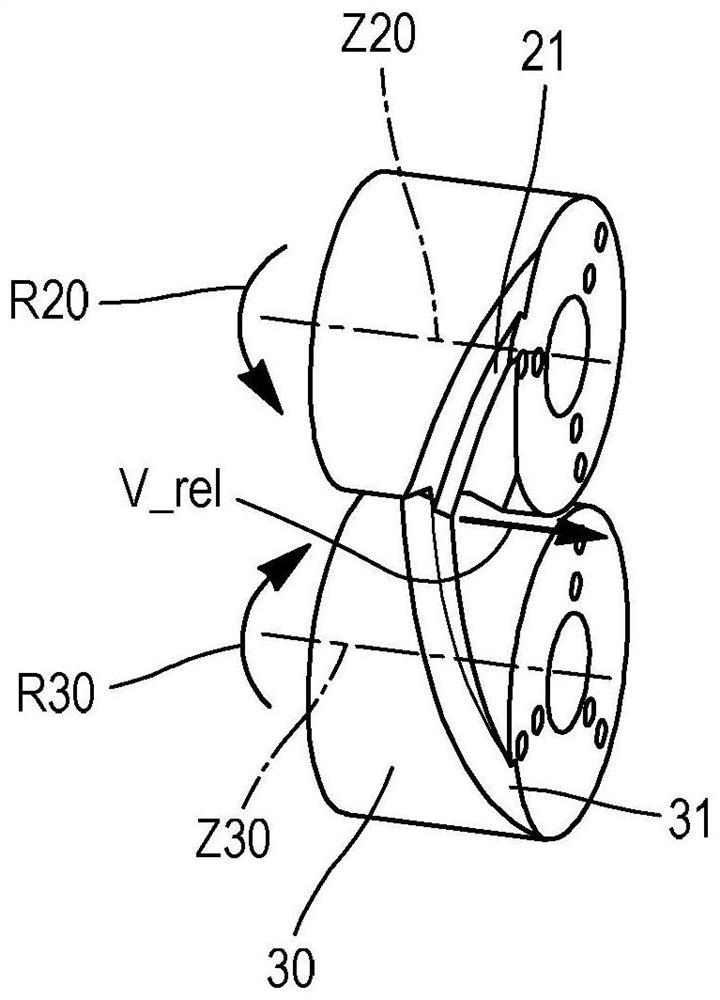

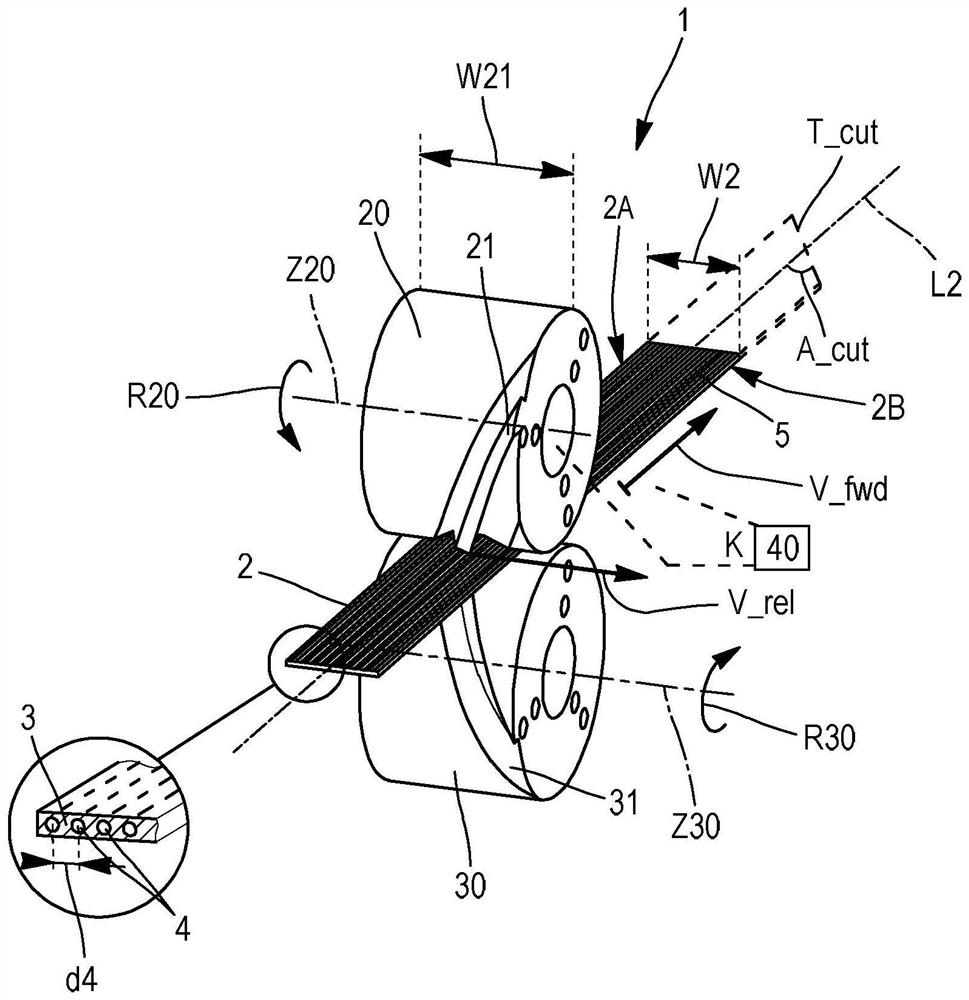

[0036] The present invention relates to a cutting system 1 aimed at cutting a strip 2 called "continuous strip" 2.

[0037] The continuous strip 2 extends in the longitudinal direction in a direction called "longitudinal direction" L2 and extends in the width direction W2 between the first edge 2a and the second edge 2b.

[0038] In image 3 As can be seen from the continuous strip 2, the continuous strip 2 preferably consists of a "zero-degree belt layer" formed by at least one rubber layer 3, the rubber layer 3, which extends parallel to each other on the longitudinal direction L2 of the continuous strip 2. The reinforcing cord 4 (which is preferably metal) is enhanced.

[0039] The reinforcing cord 4 can be multi-wire stocks, i.e., each of the components of the interleaving line stock, or preferably a single strand, i.e., each of which is formed only by one integrated strand.

[0040]The reinforcing cord 4 can be made of any material that is not so sensitive to elongation compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com