Cast metal cutting high wear-resistant industrial tool

A technology of casting metal and high wear resistance, applied in the field of cutting tools, can solve the problems of poor bending strength and thermal shock resistance, insufficient fracture toughness, easy to produce cracks, etc., to achieve high production efficiency, good wear resistance, friction force small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

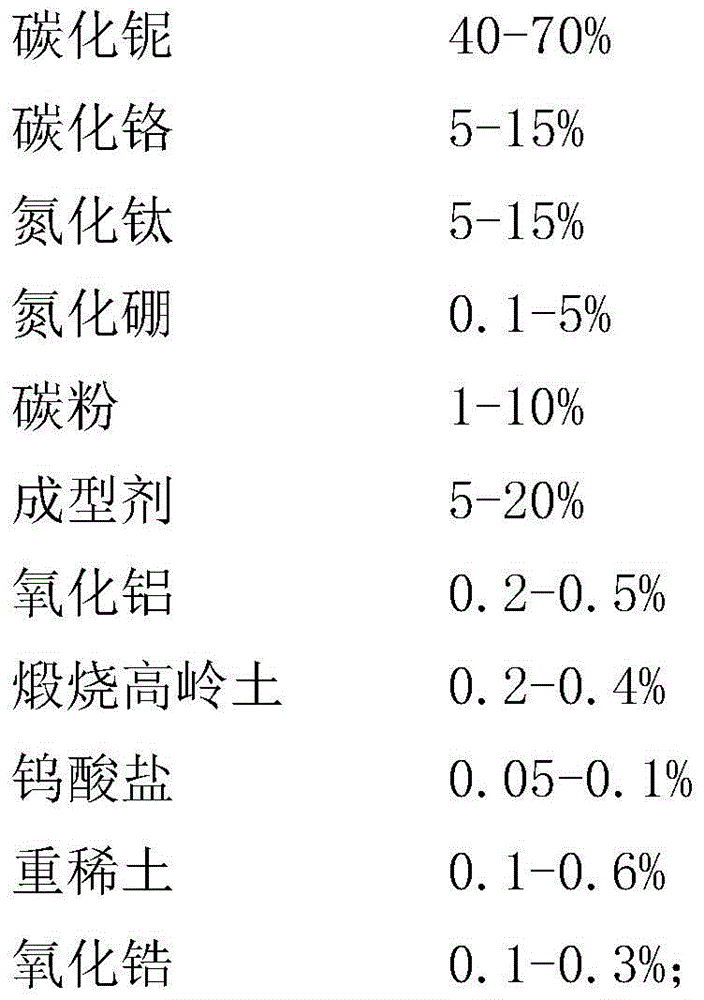

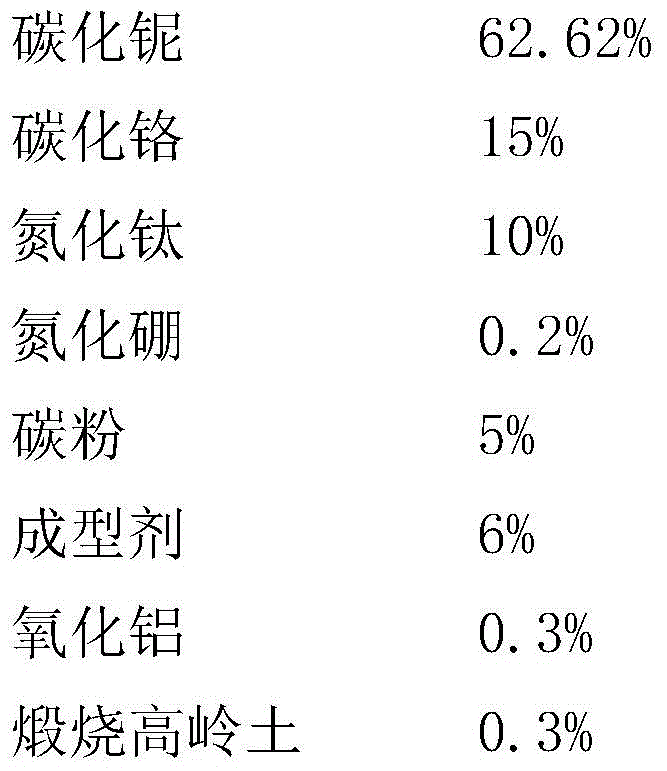

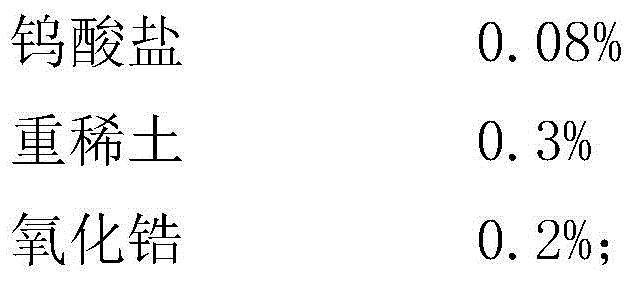

[0023] A cast metal cutting high wear-resistant industrial cutting tool is composed of the following components by weight percentage,

[0024]

[0025]

[0026] The cemented carbide forming agent is a cemented carbide forming agent SD-A;

[0027] The preparation method is as follows:

[0028] 1) Weighing the raw materials according to the weight ratio of each raw material in the component, mixing the raw materials evenly to make a billet for use;

[0029] 2) Add alcohol to the billet, by weight, the billet and alcohol are added in a ratio of 1.2:2.1, and grind in a grinder for 6 hours, thoroughly mix the billet and alcohol to make a mixture;

[0030] 3) Put the mixed material into the container for precipitation for 2 hours, and remove the clarified alcohol above;

[0031] 4) Put the mixture in step 3) into a drying cabinet for drying, and volatilize the remaining alcohol in the mixture to make the mixture into a powder;

[0032] 5) Pass the powdery material through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com