meat processing unit

A technology of meat processing and transmission mechanism, which is applied in the direction of meat processing equipment, processed meat, meat processing/transportation/packaging, etc. It can solve the problems of blade sticking to meat, uneven seasoning, etc., and achieve the effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

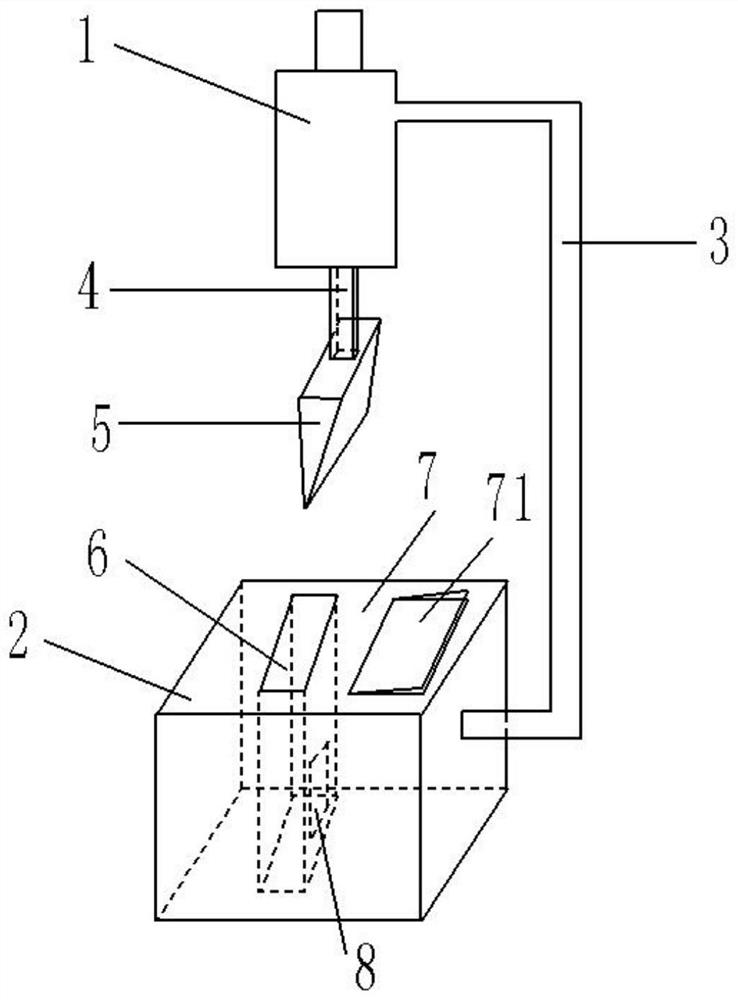

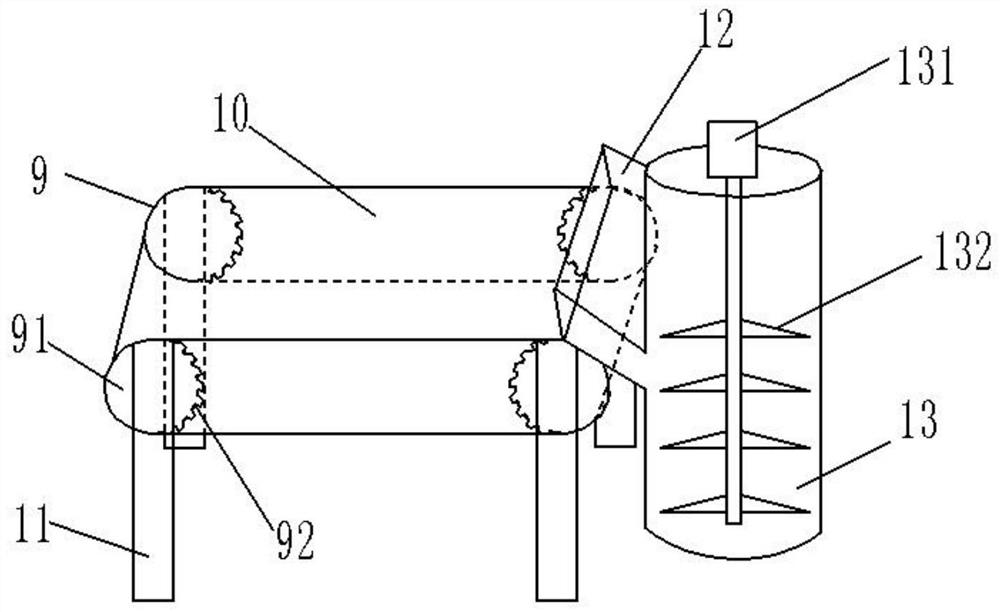

[0029] The reference signs in the drawings of Embodiment 1 include: one-way cylinder 1, seasoning box 2, air outlet pipe 3, telescopic shaft 4, cutter 5, knife groove 6, material storage chamber 7, material inlet 71, material outlet 8. Sprocket 9, smooth part 91, toothed part 92, conveyor belt 10, support 11, outlet pipe 12, pulverizer 13, motor 131, crushing blade 132.

[0030] like figure 1 The shown meat processing device includes a cutting part, the cutting part includes a one-way cylinder 1, a seasoning box 2 and an air outlet pipe 3, the one-way cylinder 1 is provided with a first air inlet and an air outlet, and the first air inlet is provided with an air inlet. Air cover, the air outlet is provided with an air outlet cover, and the air outlet is connected with an end of the air outlet pipe 3, and the lower end of the one-way cylinder 1 is connected with a telescopic rod 4, and the lower end of the telescopic rod 4 is welded with a cutter 5. The seasoning box 2 include...

Embodiment 2

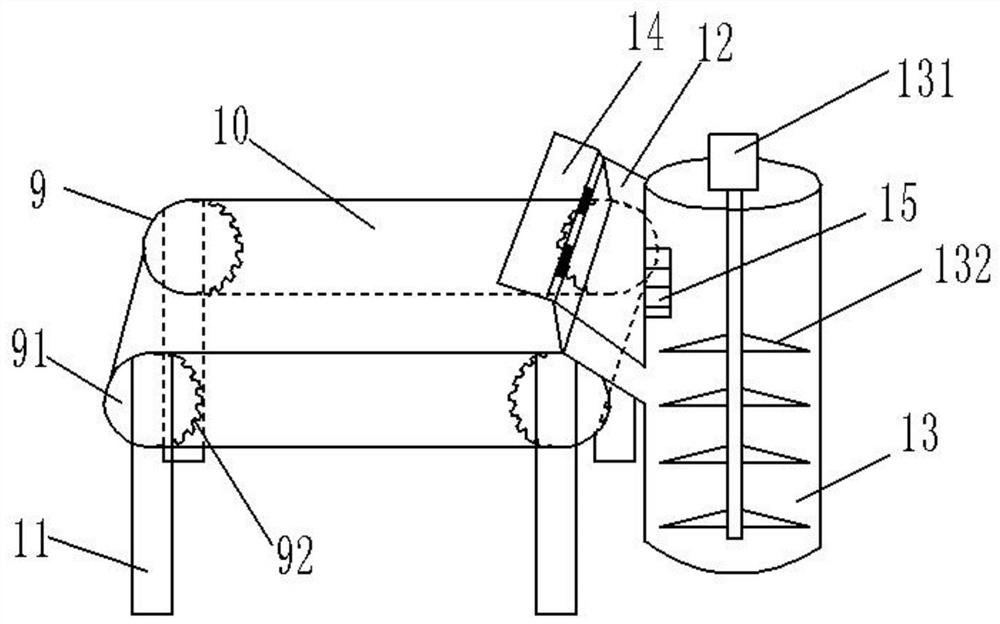

[0034] The reference signs in the drawings of Embodiment 2 include: partitions 14 and ultraviolet germicidal lamps 15 .

[0035] like image 3 As shown, the difference between the present embodiment and the second embodiment is: the meat processing device, wherein the upper edge of one end of the outlet pipe 12 connected to the bottom plate 9 is hinged with a partition 14, and the width of the partition 14 can just block the outlet pipe 12 and the bottom plate 9. At the connection between the supports 11, the dividing plate 14 can be used to resist the meat from entering the grinder 13. When the meat only needs to be cut and does not need to be broken, the dividing plate 14 is rotated to block the connection between the outlet pipe 12 and the transmission mechanism. Junction. An ultraviolet germicidal lamp 15 is fixedly installed on the inner wall of the pulverizer 13, and the bottom end of the pulverizer 13 is a detachable structure. The ultraviolet sterilizing lamp 15 is u...

Embodiment 3

[0037] like Figure 4 As shown, the difference between the present embodiment and the third embodiment is: the meat processing device, the left and right sides of the knife groove 6 of the seasoning box 2 are provided with a material storage cavity 7, and the material storage cavity 7 passes through the air outlet pipe 3 and the one-way cylinder 1 respectively. connect. Wherein, a plurality of discharge openings 8 of the same size and evenly distributed are provided on the left and right side walls of the sipe 6 . When the gas in the cylinder is blown into the storage chamber 7, the seasoning will be evenly distributed on both sides of the cutter 5, and the storage chamber 7 is arranged on both sides of the knife groove 6, and the both sides of the cutter 5 will be stained. There are seasonings, so that the meat is added with seasoning at the cut, which increases the taste of the meat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com