H20 plasma and h20 vapor methods for releasing charges and use thereof

A plasma and charge technology, applied in the manufacture of circuits, electrical components, semiconductor/solid-state devices, etc., can solve the problems of general products without structure and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

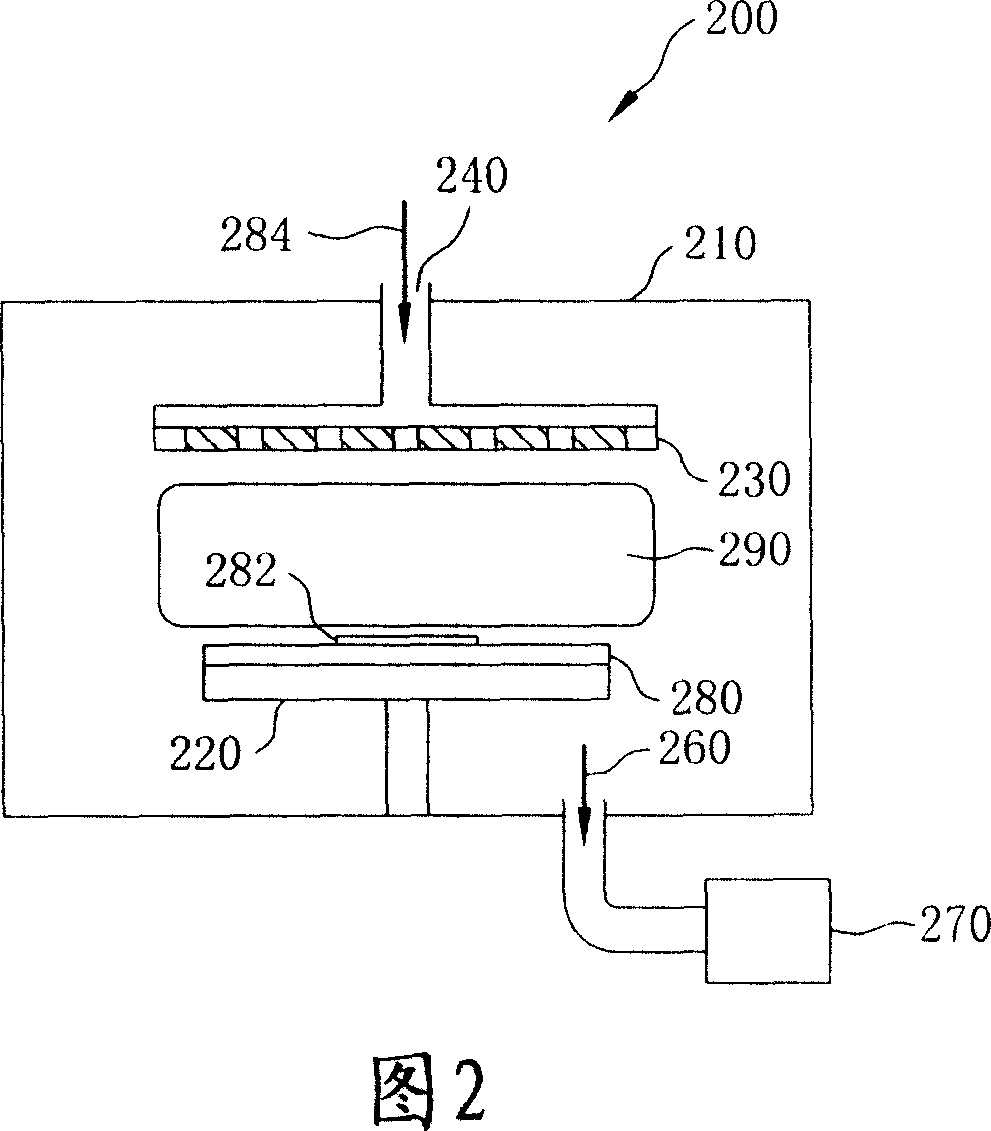

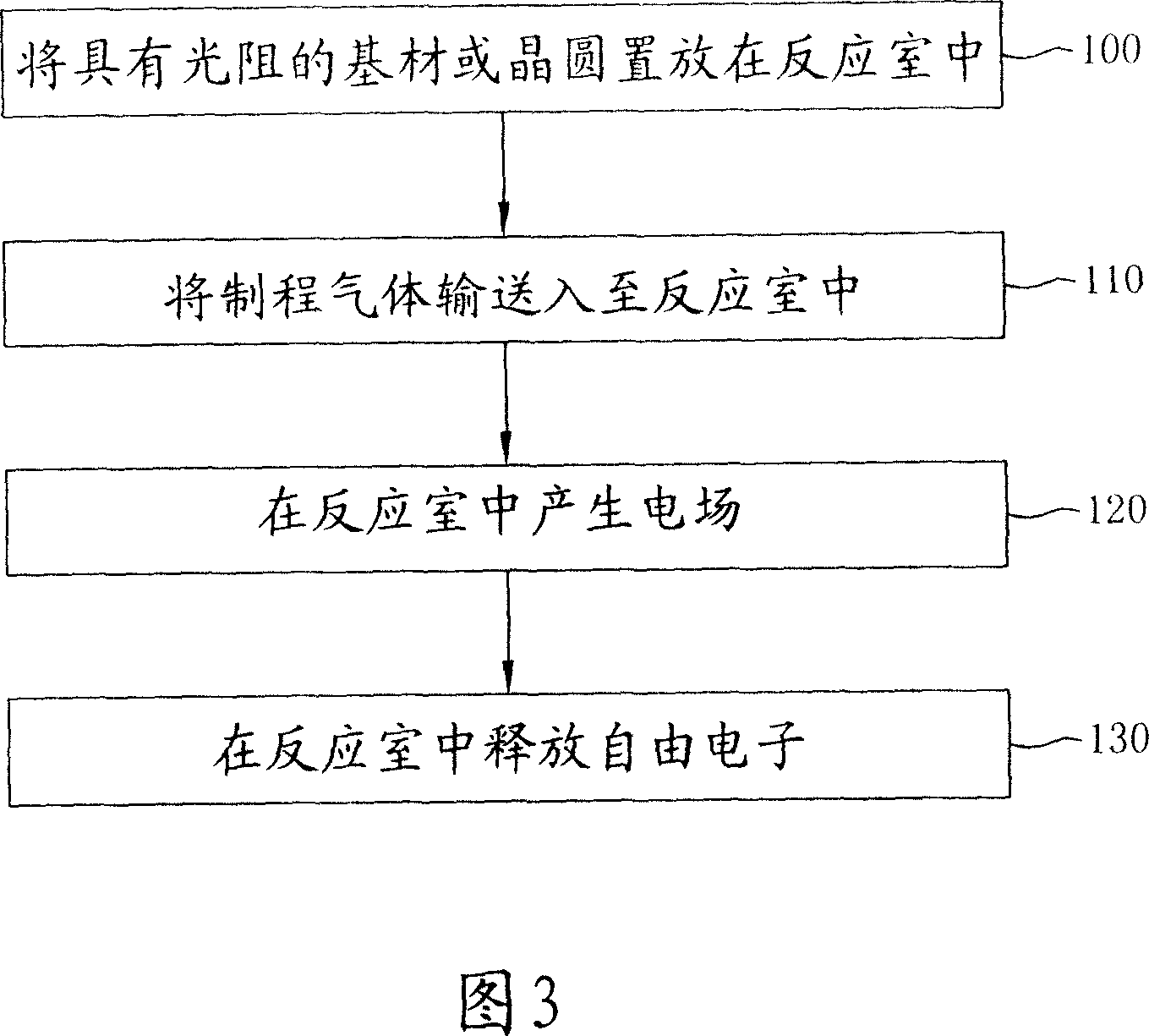

[0074] In order to further illustrate the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the use H proposed according to the present invention 2 O plasma and H 2 The method for releasing charge by O vapor and its application, its specific implementation, structure, characteristics and efficacy are described in detail below.

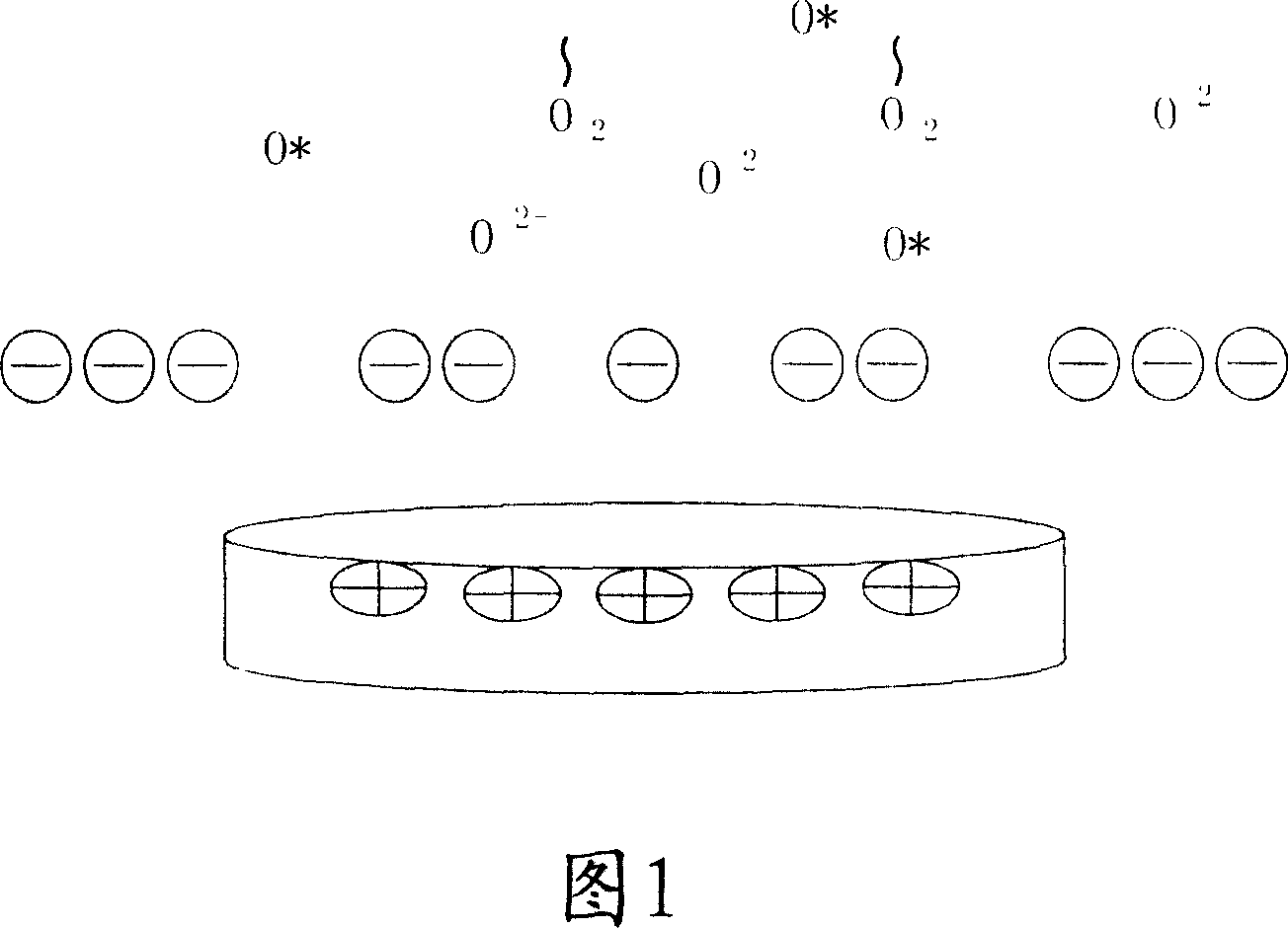

[0075] The disclosed in-situ methods are used to remove photoresist layers from a substrate or wafer without accumulating charge on the substrate or wafer and / or removing Or release charge accumulated by one or more integrated circuit construction processes. This approach eliminates or substantially reduces charges that can exacerbate electrochemical problems. Electrochemical issues include pad pitting, galvanic metal corrosion, tungsten corrosion, low-quality gate oxide, and other electrochemical issues.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com