Coagulant for treating fine-grain high-viscosity soil coal slime water

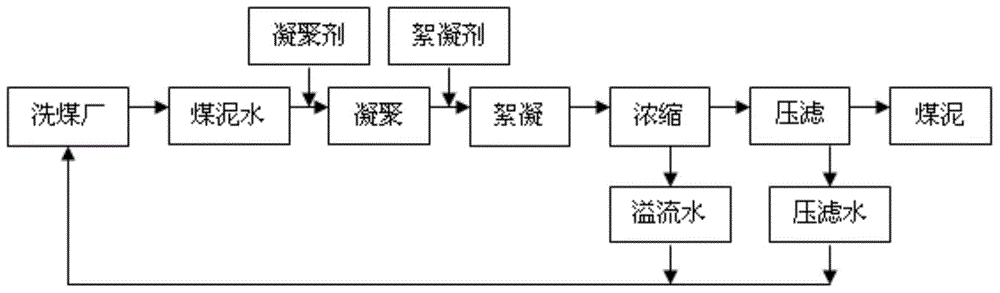

A technology of coal slime water and high clay, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve various problems such as coal slime loss, huge concentration equipment, etc., to improve the quality and output of clean coal, easy to flocculate and settle, and coagulate Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The coagulant in this embodiment is made by uniformly mixing barite powder, calcite powder, dolomite powder and medical stone powder according to the mass ratio of 3:2:1:2.

Embodiment 2~ Embodiment 14

[0028] The preparation method of Example 2 to Example 14 is the same as that of Example 1, and the ratio of raw materials in Example 2 to Example 14 is shown in Table 1 below.

[0029] The coagulant proportioning of table 1 embodiment 2 to embodiment 14

[0030] Example

[0031] Taking the fine-grained high-clay slime water from a coal preparation plant in Shaanxi as the test object, the coagulants of Examples 1 to 14 were used to treat the slime water.

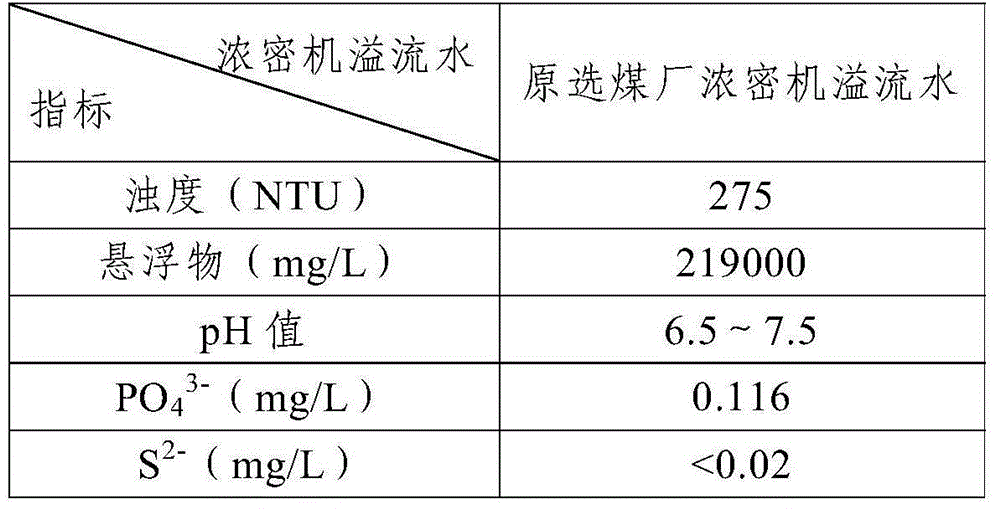

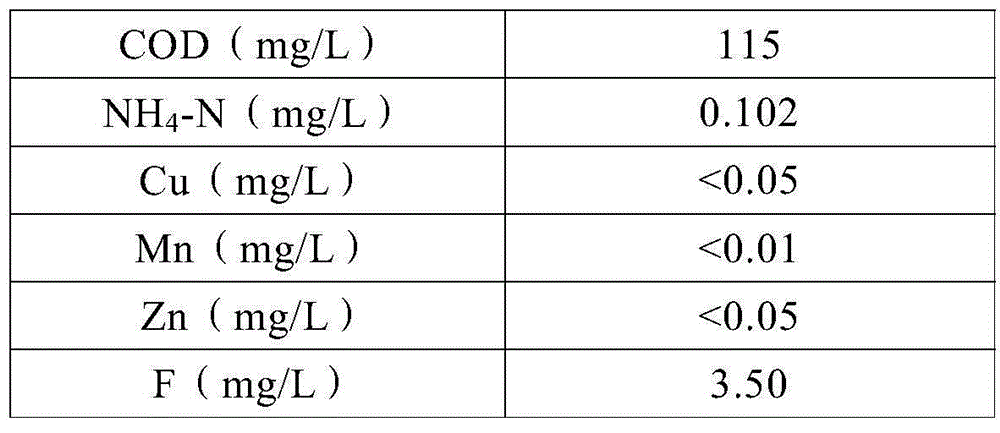

[0032] After testing, the coal slime water of a coal preparation plant in Shaanxi contains clay minerals such as kaolin, illite, chlorite and talc. greater than 0.5mm), and coal slime with a particle size below 38 μm accounts for about 90%. The overflow water indicators of the thickener in the coal preparation plant are shown in Table 2 below.

[0033] Table 2 The overflow water index of the thickener in the coal preparation plant without coagulant treatment

[0034]

[0035]

[0036] Adopt the coagulant of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com