Patents

Literature

297 results about "Coal preparation plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A coal preparation plant (CPP; also known as a coal handling and preparation plant (CHPP), coal handling plant, prep plant, tipple or wash plant) is a facility that washes coal of soil and rock, crushes it into graded sized chunks (sorting), stockpiles grades preparing it for transport to market, and more often than not, also loads coal into rail cars, barges, or ships.

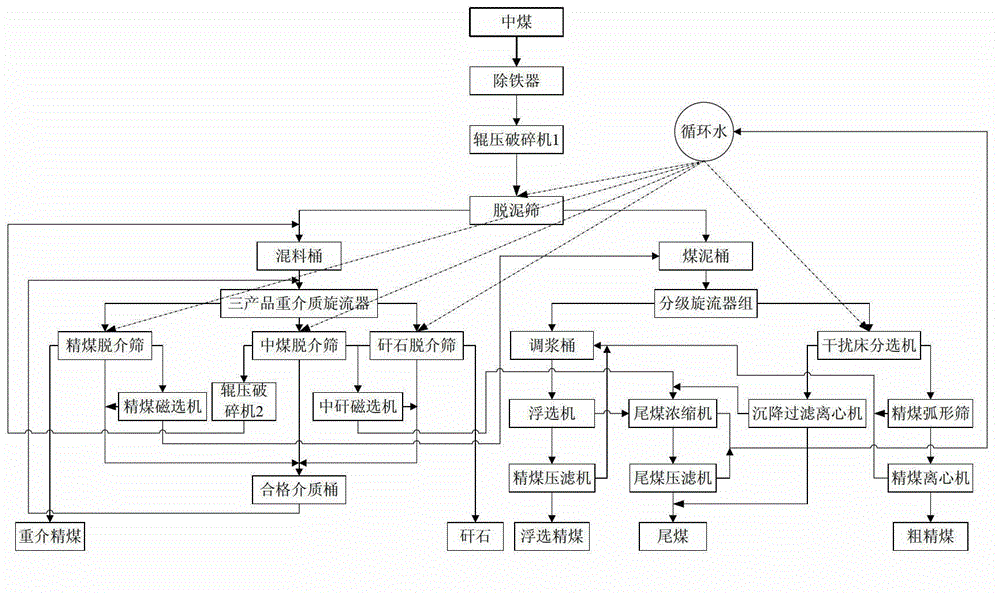

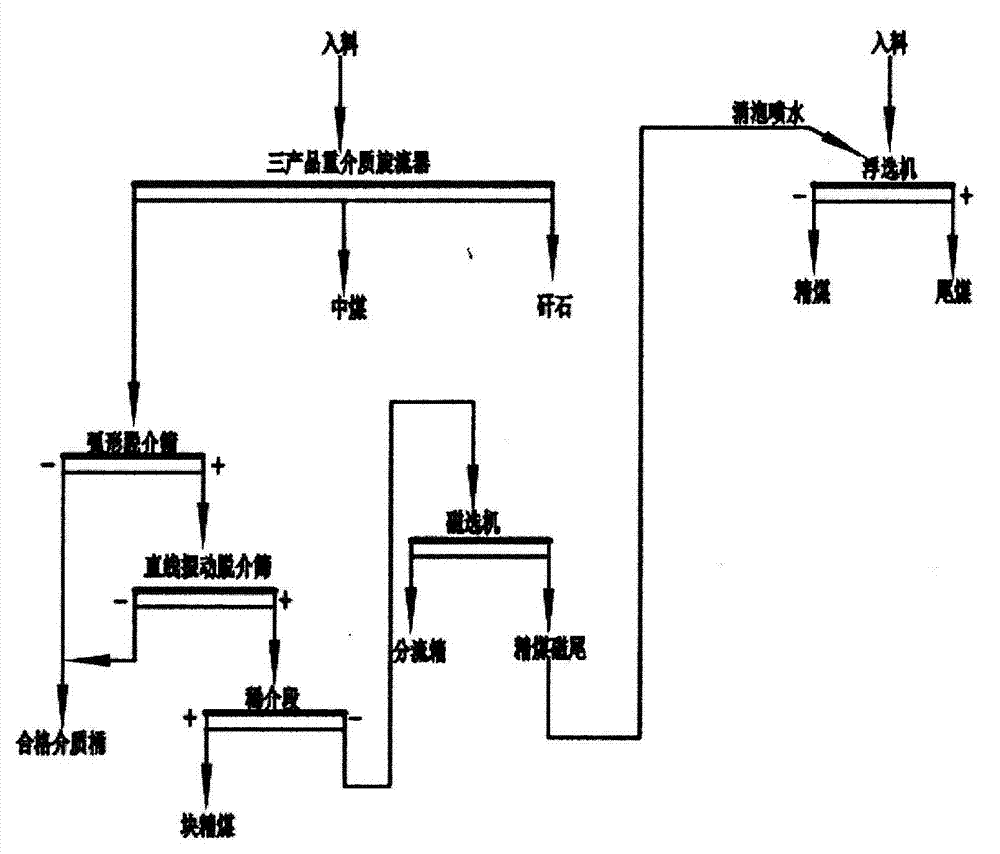

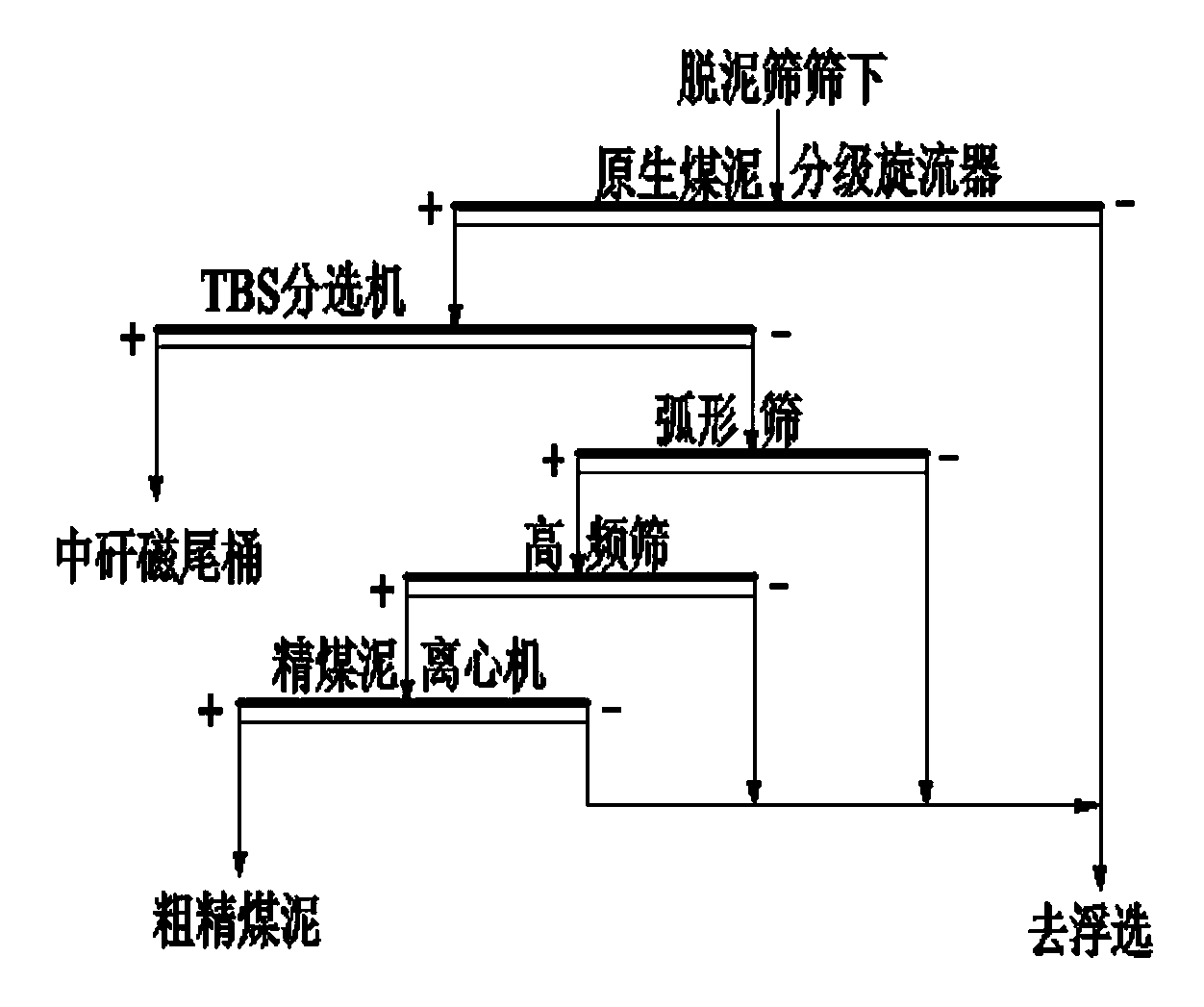

Efficient crushing and three-section type screening method of coking coal gravity middings

An efficient crushing and three-section type screening method of coking coal gravity middings belongs to coal crushing, dissociating and screening processes. Gravity middings in a coking coal preparation plant are taken as a raw material to be crushed through rolling to the fraction being below 6 mm or 3 mm; a desliming screen is used to deslime a material with the fraction being 1 mm, a material with the fraction being 6 to 1 mm or 3 to 1 mm enters into a three-product dense medium cyclone, and clean coal, middings and gangues are respectively obtained after two sections are subjected to medium drainage; the material with the fraction being 1 mm is mixed with tailings in a clean coal magnetic separator, fine coal slimes with the fraction being 0.25 mm are deslimed by a classifying cyclone; coarse coal slimes with the fractions being 1 to 0.25 mm enter into a teetered bed separator for screening, light products are dewatered by a sieve bend and a coal slime centrifuge to obtain coarse clean coal, and heavy products are dewatered by a screen bowl centrifuge to obtain tailings; the fine coal slimes with the fractions being 0.25 mm enter into a flotation machine for flotation, and foamed clean coal and the tailings are sequentially subjected to concentration and pressure filtration dewatering to obtain flotation clean coal and the tailing product; and after the gravity middings are crushed through rolling, the product returns to a mixing barrel. The method has the advantages that the graded screening is carried out on the preselected coal slimes with coarse fraction and fine fraction, and the equipment screening precision is improved.

Owner:CHINA UNIV OF MINING & TECH

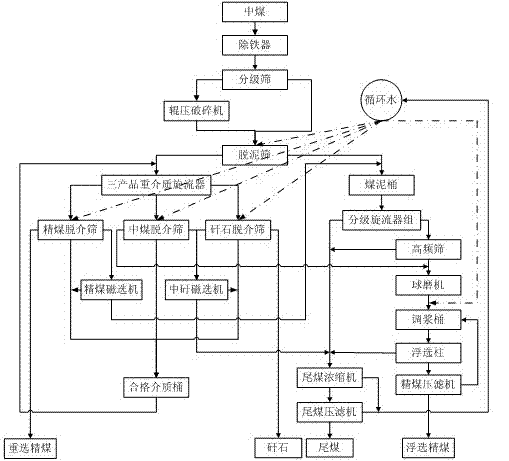

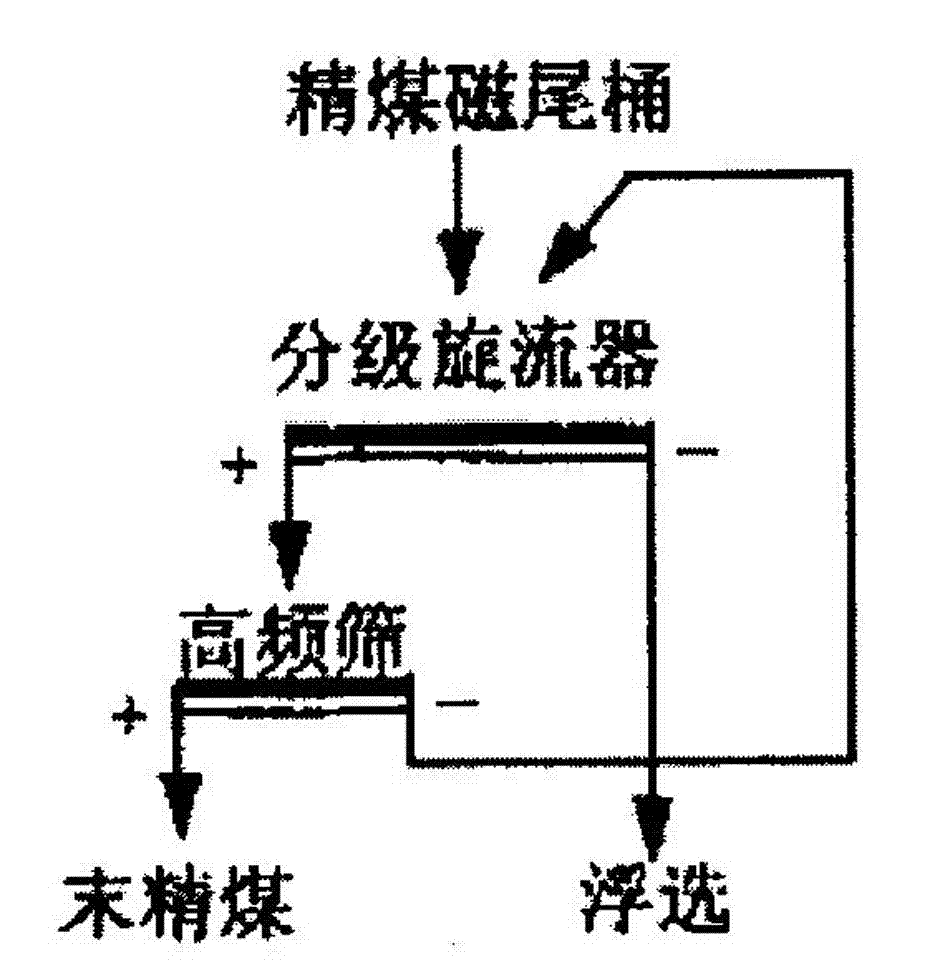

Breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking

A breaking grinding dissociation and re-flotation two-stage recovery process of coal in scarce coking belongs to a coal breaking dissociation flotation process. (1) coal products in a coal preparation plant serve as raw materials, and the coal which is larger than 6mm is rolled and broke into size smaller than 6mm; (2) a desliming screen is used for desliming on middings smaller than 6mm, middings which is 6-0.5mm enters a three-product dense medium cyclone, and dense medium, middings and gangue are obtained after two-stage medium separation is carried out; (3) the middings smaller than 0.5mm is mixed with clean coal magnetic separation gangue, a grading hydrocyclones group is adopted to conduct high frequency screening to obtain high ash fine silt contained slurry water, and coarse particle are mixed with middings on the midding sculping screen to enter a ball mill for wet grinding; and (4) products after grinding enter a flotation column to conduct flotation, foam clean coal and tailing are respectively concentrated, filtered and dewatered to obtain flotation clean coal and tailing products. The breaking grinding dissociation and re-flotation two-stage recovery process has the advantages that the high ash fine silt in fine fraction is pre-selected, pollution of the high ash fine silt is reduced, equipment separation particle size range is reduced, separation accuracy of equipment is improved, and scarce coking coal resources are recovered as far as possible.

Owner:CHINA UNIV OF MINING & TECH

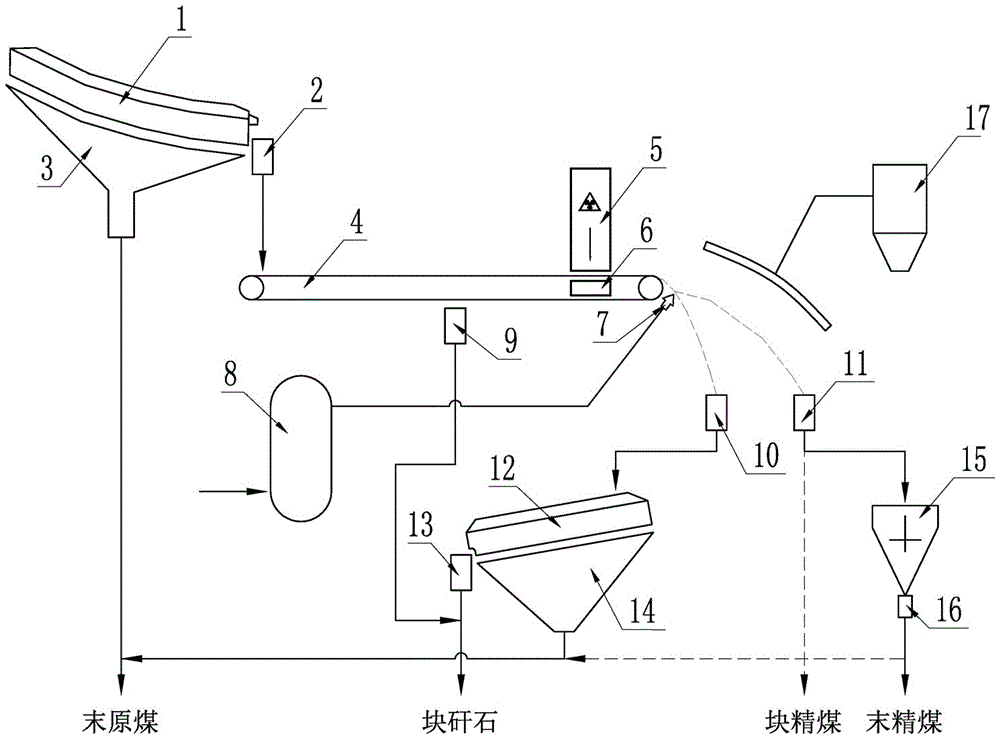

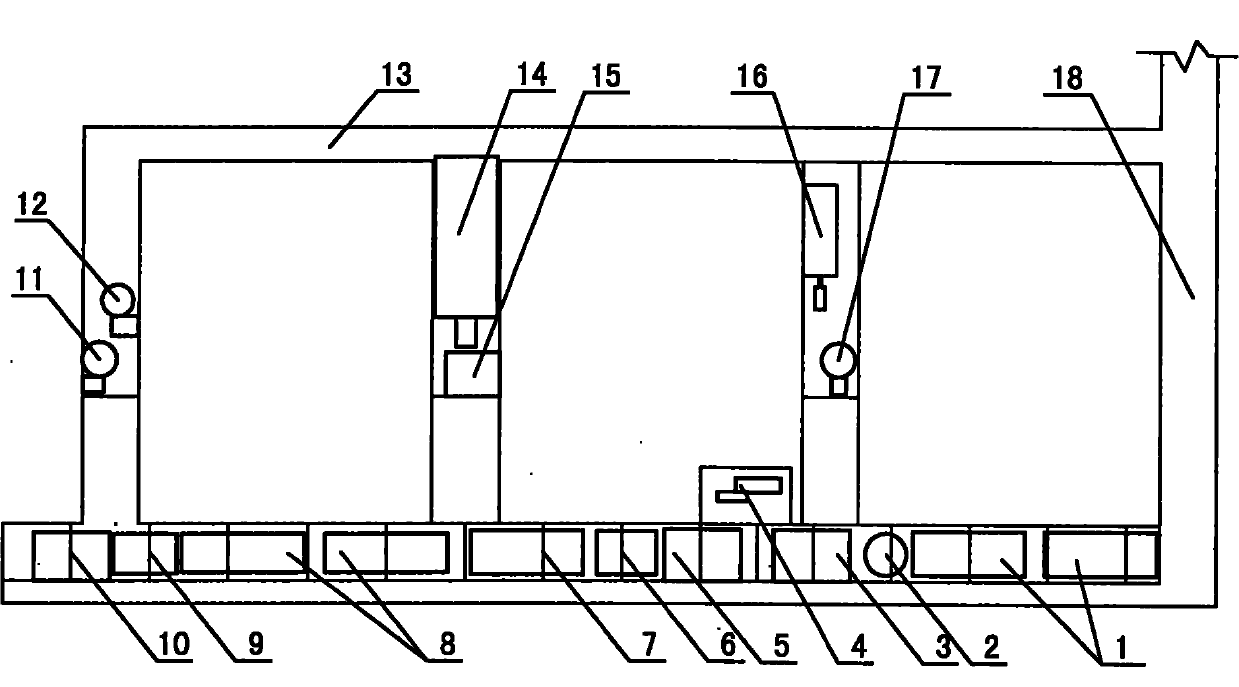

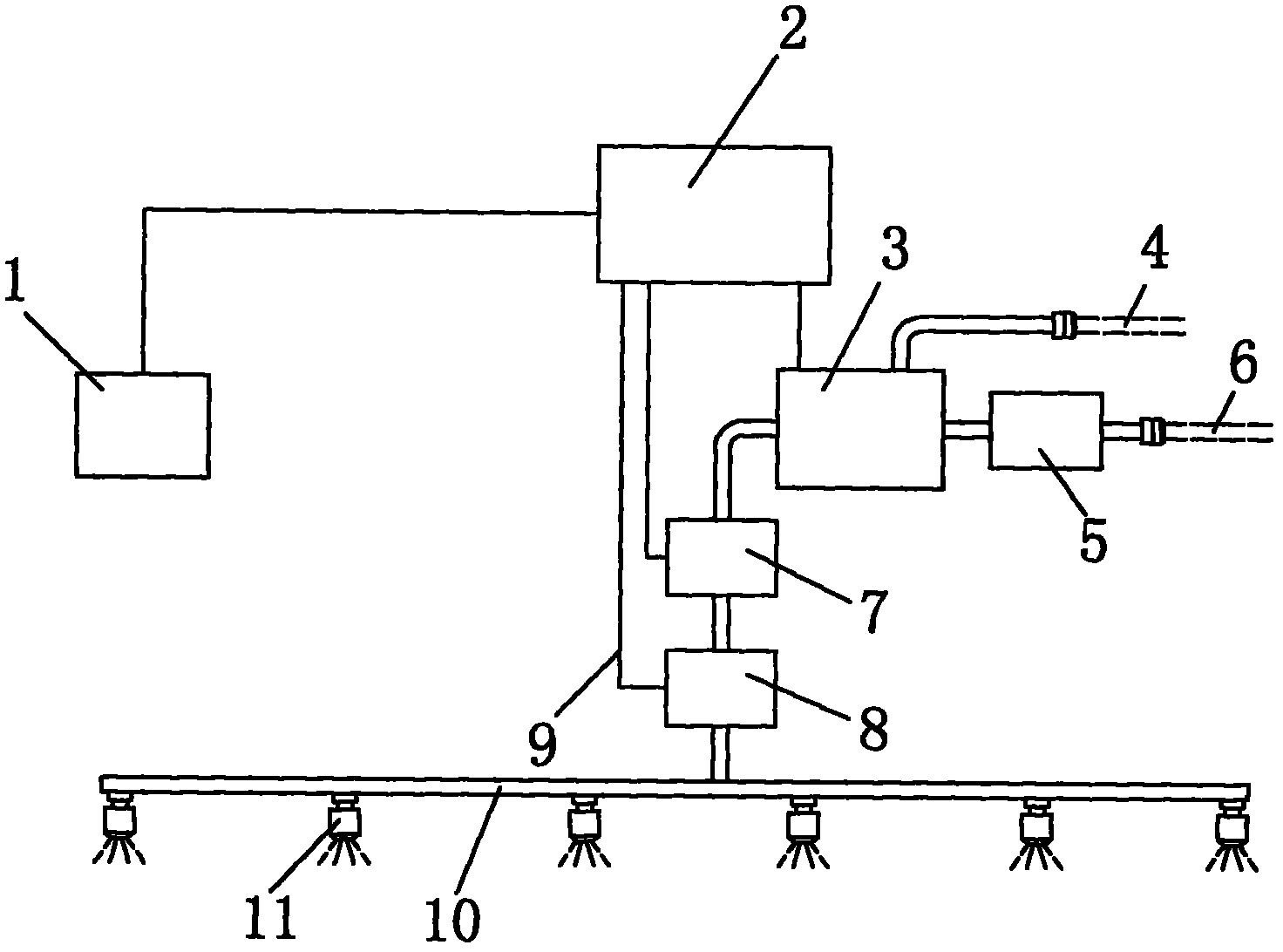

Intelligent lump coal dry method inverted separation system

InactiveCN105537145AAvoid the problem that the force surface is small and it is difficult to blow through the high-frequency solenoid valveAvoid the problem that it is difficult to blow through the high-frequency solenoid valveSortingSolenoid valveSpray nozzle

The invention aims to provide an intelligent lump coal dry method inverted separation system. After supplied raw coal materials are screened through a raw coal classifying screen, raw lump coal enters an intelligent dry separation machine, and are identified by X-rays as clean coal, gangue and other things. The intelligent lump coal dry method inverted separation system is characterized in that conventional gangue blowing operation of intelligent dry separation is turned into coal blowing operation, and the intelligent dry separation machine enables an air spray nozzle which corresponds to the clean coal and is controlled by a high-frequency solenoid valve to be opened according to identifying information of the X-rays, so that the clean coal deviates from the raw coal movement trail, and the clean coal is separated from the gangue and the other things. The intelligent dry separation machine is a dry method separation device which utilizes the rays to conduct intelligent identifying separation on minerals, the clean coal and the gangue are identified according to the difference of the capacities of the clean coal and the gangue for absorbing the rays, and the air spray nozzle serves as an execution mechanism. According to the invention, the intelligent lump coal dry method inverted separation system can be applied to coal preparation plants with a large amount of gangue and a plurality of overlarge blocks and other things so that the problem that an existing conventional intelligent dry method gangue removal system is difficult to handle with overlarge blocks and other things can be solved, and the air consumption and the energy consumption can be reduced.

Owner:TIANJIN MEITENG TECH CO LTD

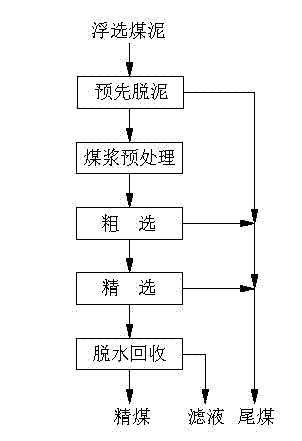

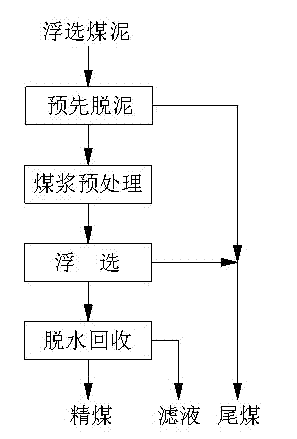

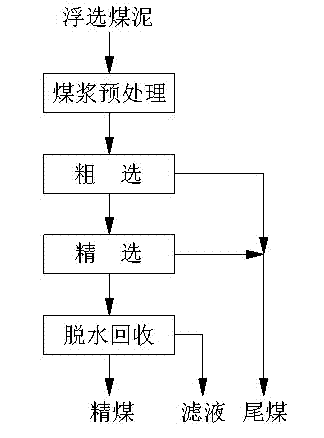

Flotation process method of high-ash-content fine coal slime

The invention relates to a flotation process method of high-ash-content fine coal slime. According to the method, pre-desliming is carried out by using a flotation coal slime flotation feeding desliming pond invented by Tangshan Guohua Technology International Engineering Co., Ltd., preprocessing is carried out by using a pulverization drop-type coal slurry preprocessor, and rough flotation and fine flotation are carried out by using an air jet flotation machine. The method comprises the following steps of: pre-desliming; preprocessing of the coal slurry; controlling of the feeding concentration of the flotation machine; and dehydration and recycling. According to the flotation process method of the high-ash-content fine coal slime, coking clean coal is sorted from inferior coal slime, the flotation process method is scientific and optimized, perfect indexes of sorting are substantially improved, the outward discharging of slime water is thoroughly avoided, the closed cycle of washing water of a coal cleaning plant is realized, and the method is scientific and environment-friendly.

Owner:唐山国华科技国际工程有限公司

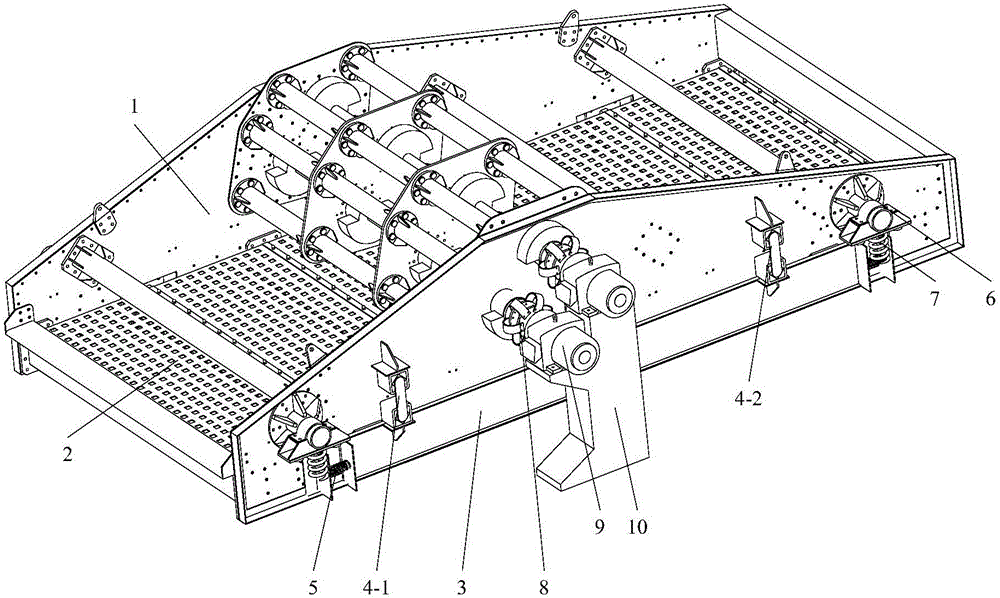

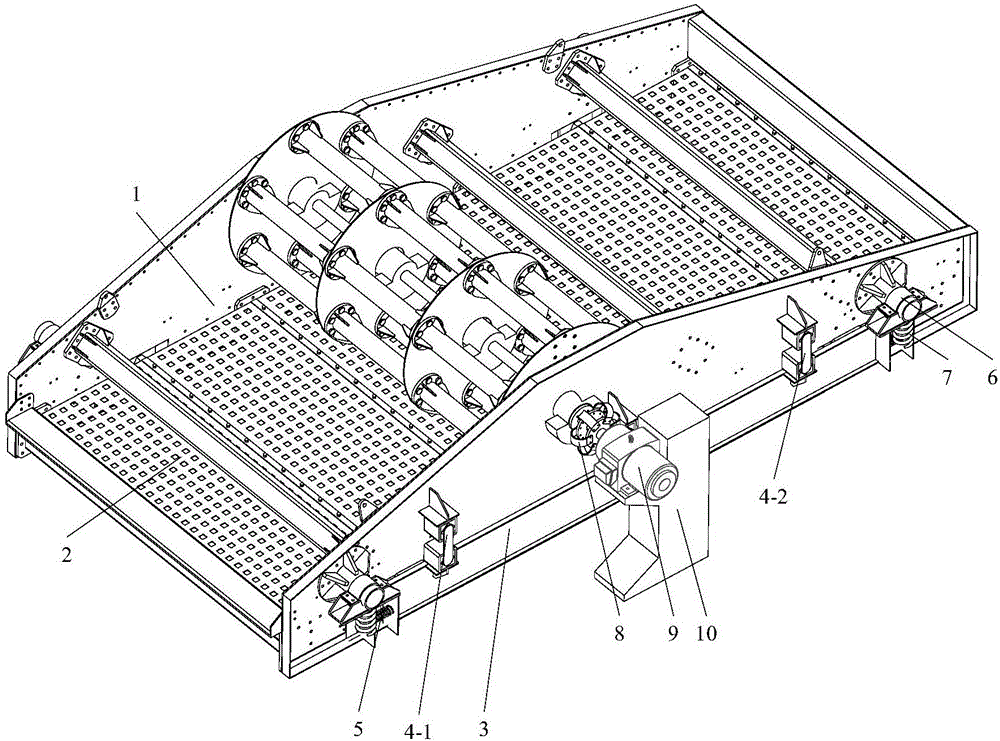

Statically indeterminate modular main beam amplitude adjustable low-frequency vibration tension and relaxation screen

ActiveCN106423834AGood for adapting to large-scale requirementsReduce volumeSievingScreeningStatically indeterminateClassical mechanics

The invention discloses a statically indeterminate modular main beam amplitude adjustable low-frequency vibration tension and relaxation screen. The screen comprises a screen body, a spring support base, a vibration reducing spring, a motor, a bracket, and a statically indeterminate excitation main beam consisting of a pipe beam and a fixed plate; a floating screen frame is arranged on the screen body; elastic screen surfaces are arranged on the screen body and the flowing screen frame; the floating screen frame is hung and mounted at the lower part of the screen body through a rubber hinge; the flowing screen frame can enable the polyurethane elastic screen surfaces to swing up and down under the effect of materials to accelerate the operation speed of the materials to prevent the load concentration; the polyurethane elastic screen surfaces are connected by multiple rectangular screen plates; and two ends of each screen plate are respectively mounted on a fixed cross beam of the screen body and a floating cross beam of the floating screen frame. The floating screen frame and the screen body are in hanging connection by the rubber hinge; and an amplitude adjusting spring is mounted between the two. Vibration exciters are arranged in a side plate and the statically indeterminate main beam. The screen is compact in structure, high in reliability, convenient to adjust the motion mode and the working amplitude and suitable for dry deep screening of wet fine-particle coals in coal preparation plants.

Owner:CHINA UNIV OF MINING & TECH

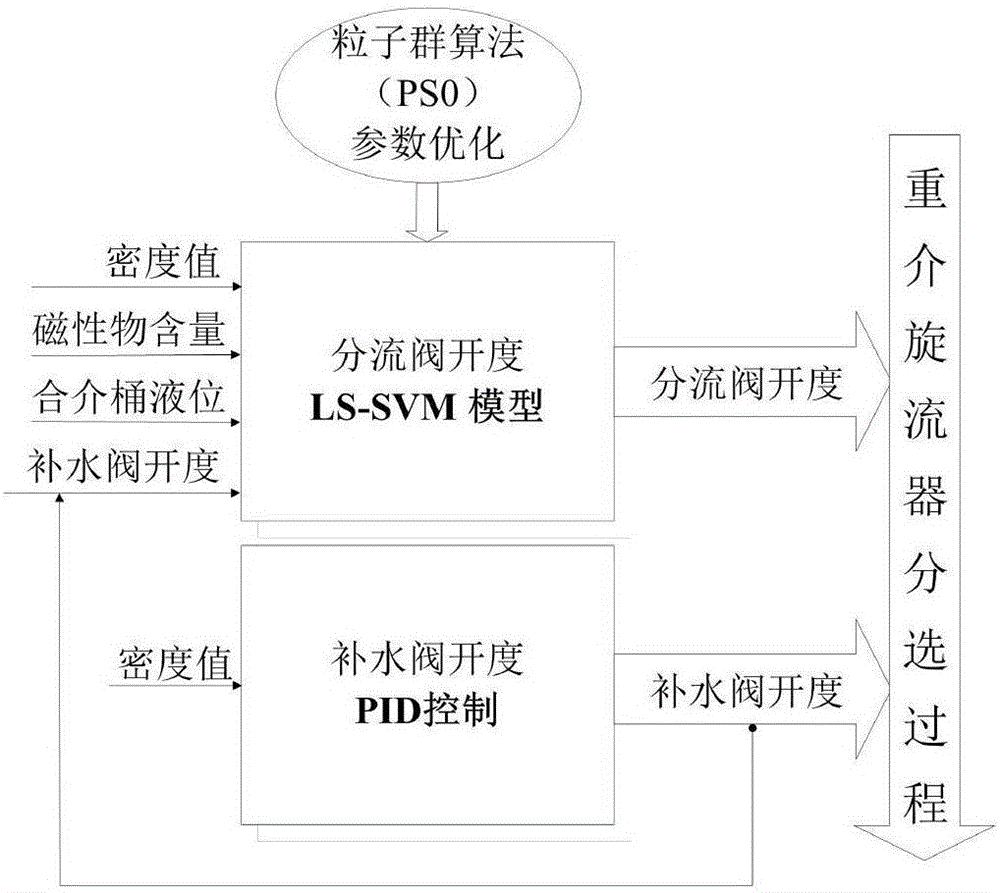

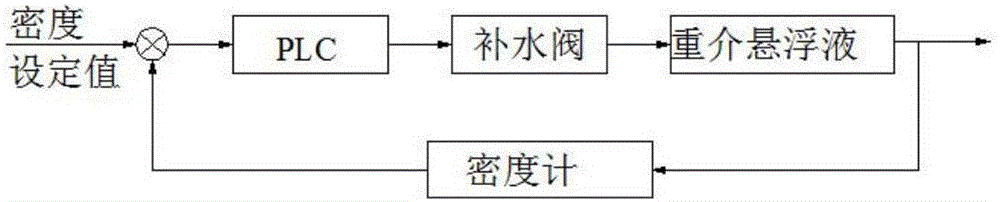

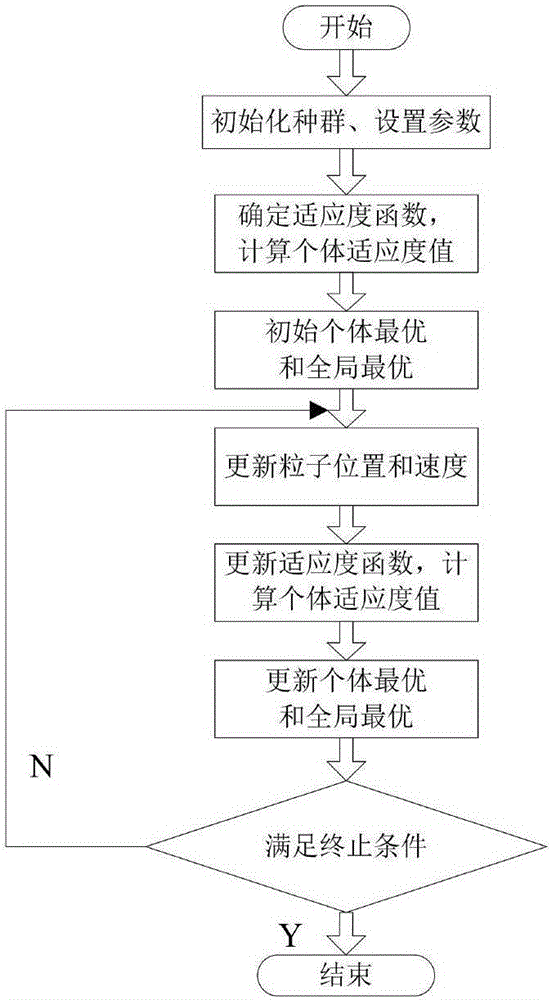

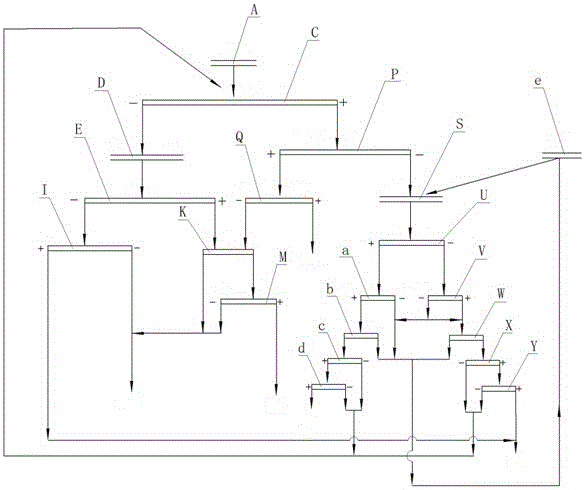

Automatic control system for suspension density in separation process of dense medium cyclone

The invention mainly belongs to the field of dense medium cyclones of coal preparation plants and particularly relates to an automatic control system for the suspension density in a separation process of a dense medium cyclone. The control system comprises a controller and an actuator. The actuator comprises a water replenishing valve and a diverter valve which are mounted on the dense medium cyclone. The controller controls the opening of the valves of the actuator in real time for automatically controlling the suspension density in the separation process of the dense medium cyclone. The controller controls the opening of the diverter valve according to an LSSVM model, and the opening of the water replenishing valve is controlled through a PID control method, and the precision and stability of the dense-medium suspension density are guaranteed; and a diverter main valve, a diverter bypass butterfly valve and an anti-blocking butterfly valve are designed for a diverter, and the stability and reliability of the system are guaranteed.

Owner:山西理工智联科技有限公司

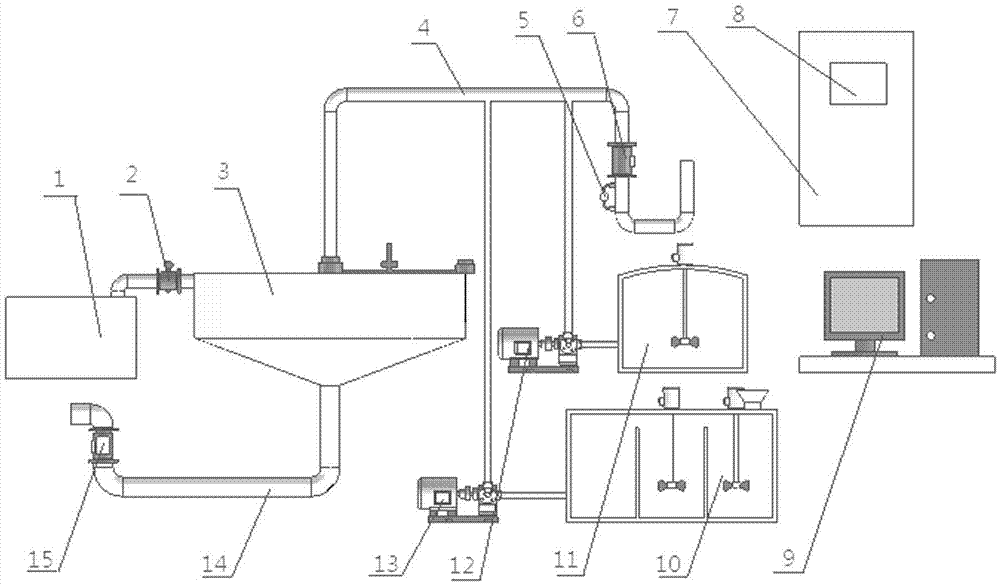

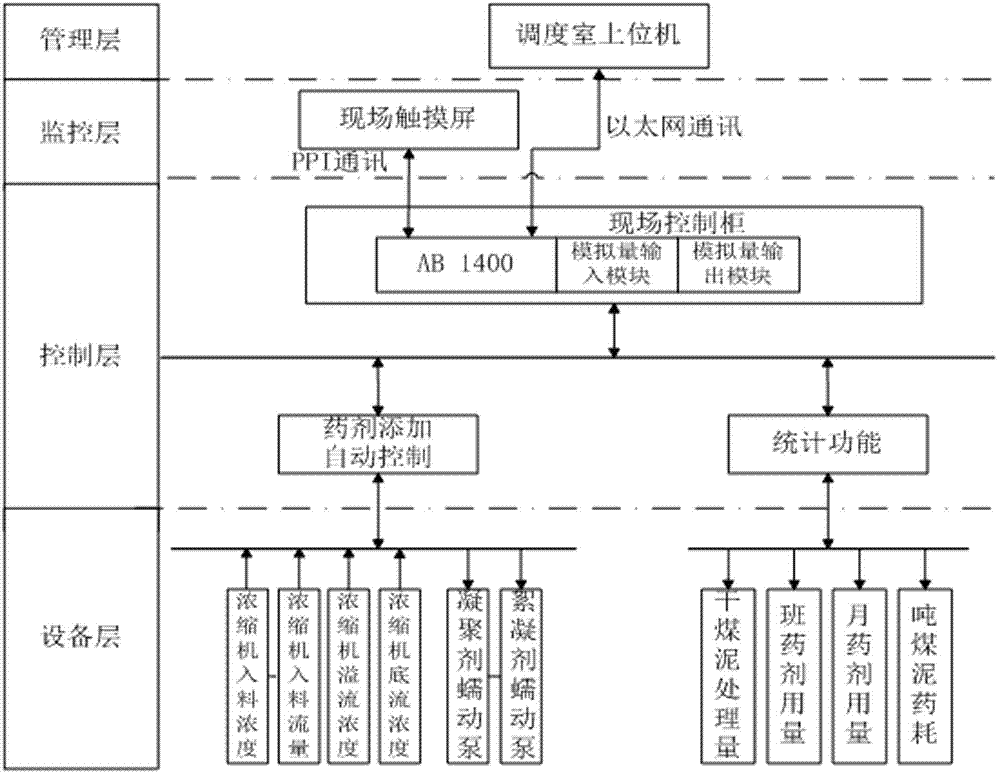

Thickener automatic drug dosing system and method thereof

ActiveCN105435494AQuality improvementImprove efficiencySedimentation separationWater/sewage treatment by flocculation/precipitationAutomatic controlLag

The invention belongs to the technical field of coal preparation plant's slime water treatment link and mainly relates to an automatic addition system and a method of slime water treatment equipment thickener drugs. According to the thickener automatic drug dosing system and the method and mainly in the coal preparation plant's slime water treatment link, a PLC, a reasonable sensor and an execution mechanism and a feedforward+feedback control strategy based on case-based reasoning are adopted. dosage can be modified and optimized in advance through thickener feed concentration and flow signals monitored at real time, and thickener overflow and underflow concentration signals are utilized reasonably. System destabilization caused by feedback signal lag is avoided; problems, such as quality reduction of circulating water from a coal preparation plant, high drug consumption, high water consumption, etc., which are caused by inaccurate measurement of thickener overflow and underflow concentration during slime water treatment process in an existing coal preparation plant, poor reliability of a drug dosing execution mechanism, backward automatic control strategy, etc., are solved; and product quality and benefit of the coal preparation plant are enhanced.

Owner:SHANXI JINMEI GRP TECH RESEACH INST +2

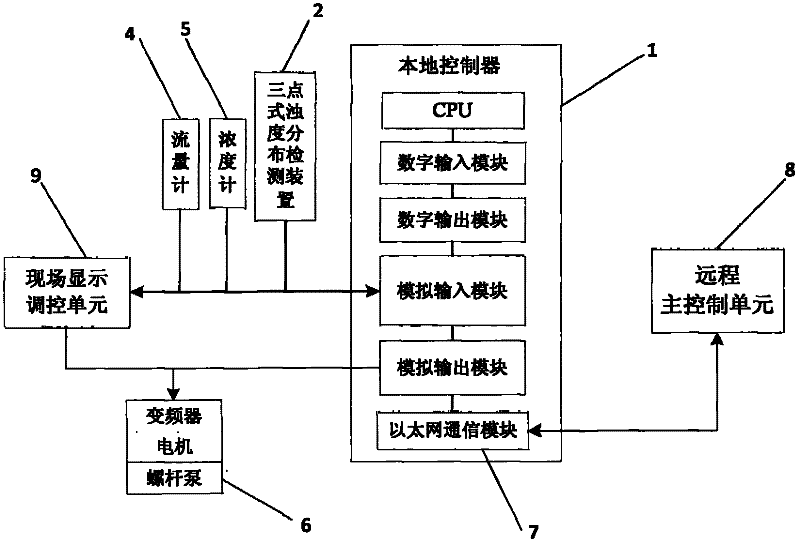

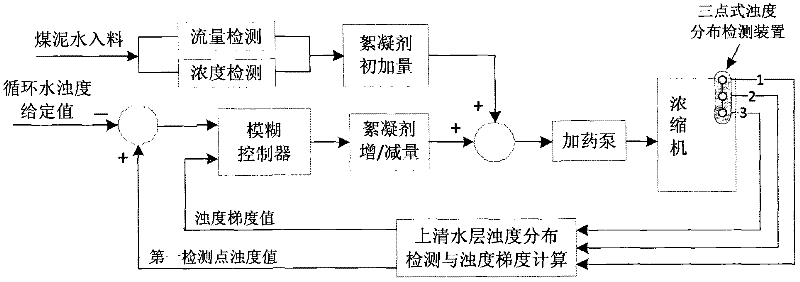

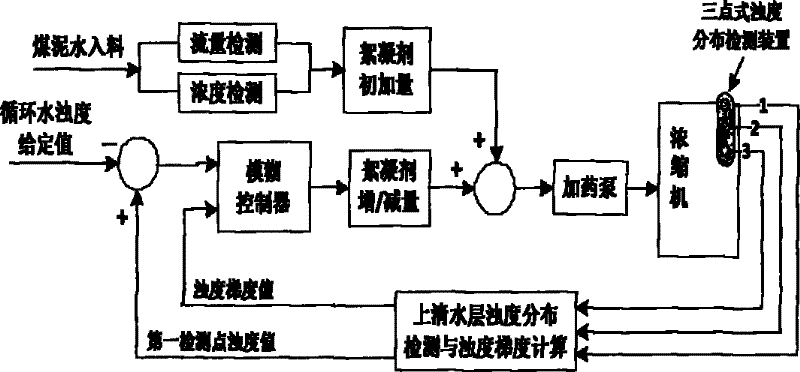

Automatic control system and method for coal slime flocculation settling

InactiveCN102385357AInhibit deteriorationImprove stabilityWater/sewage treatment by flocculation/precipitationTotal factory controlFlocculationAutomatic control

The invention discloses an automatic control system and method for coal slime flocculation settling, which belongs to the technical field of mechatronics and control of mechatronics and particularly relates to a control system and a fuzzy control technology for coal slime flocculation settling on the basis of turbidity gradient detection of a thickener supernate layer. The invention provides an automatic control system and method for coal slime flocculation settling, which can be used for controlling overflow water turbidity to be stable and reach the standard and have the advantage of reducing flocculant consumption. According to the system, a three-point turbidity distribution detection device is used for detecting the turbidity distribution of the thickener supernate layer along the depth direction. According to the turbidity distribution condition, the turbidity space change rate along the supernate layer depth direction can be obtained; the change tendency of flocculation settling is predicted in an early stage; then, by taking the change tendency as one of the inputs of the fuzzy controller, fuzzy logic reasoning and in-time reasonable control can be implemented; and the problem that control effect is unstable, even out of control, because an overflow water turbidity feedback signal is seriously lagged can be overcome, and circulating water turbidity can be prevented from deteriorating. The system and the method disclosed by the invention are suitable for the coal slime flocculation settling processing of various coal preparation plants.

Owner:TAIYUAN UNIV OF TECH

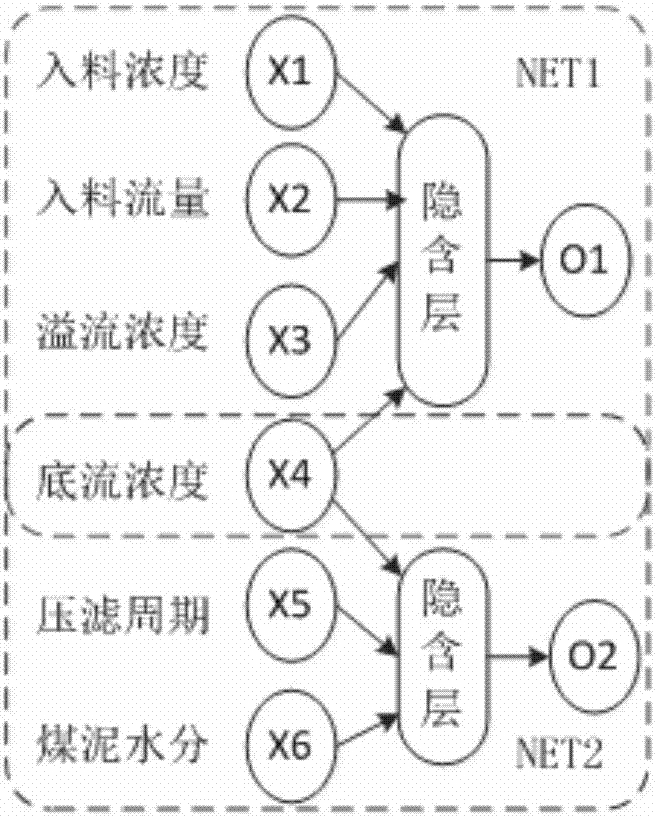

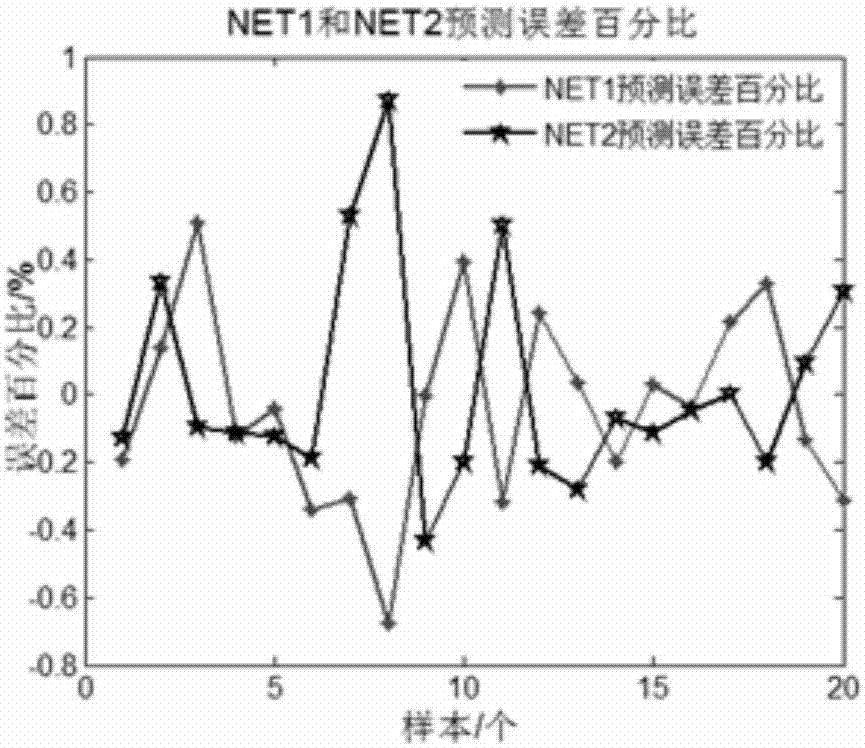

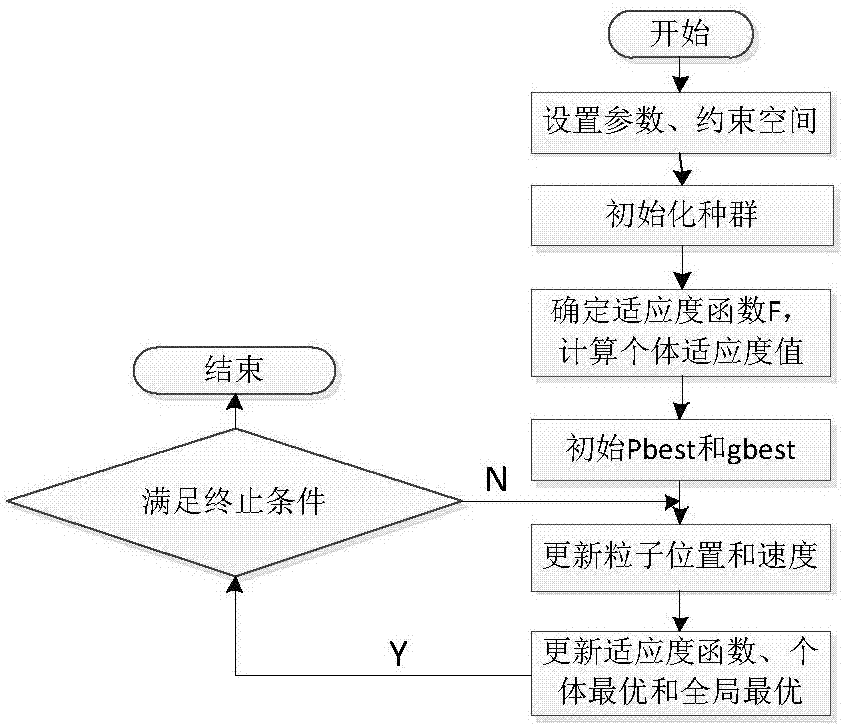

Coal preparation plant thickener and filter press pharmacy adding cooperation control system

ActiveCN106933099AReduce consumptionGuaranteed processing rateWater treatment parameter controlFiltration separationPharmacyControl system

The invention belongs to the field of slime water processing, and particularly relates to a coal preparation plant thickener and filter press pharmacy adding cooperation control system. A cooperative and automatic pharmacy adding system which is based on an adaptive particle swarm optimization (APSO) algorithm for solving the optimal cooperation amount is provided. A BP neural network is selected for model prediction, an APSO algorithm fitness function is used for optimal solution, joint pharmacy adding is realized, and on the premise of ensuring the slime water processing speed and the processing effects, the pharmacy consumption is the lowest and the economic benefits are the best.

Owner:山西理工智联科技有限公司

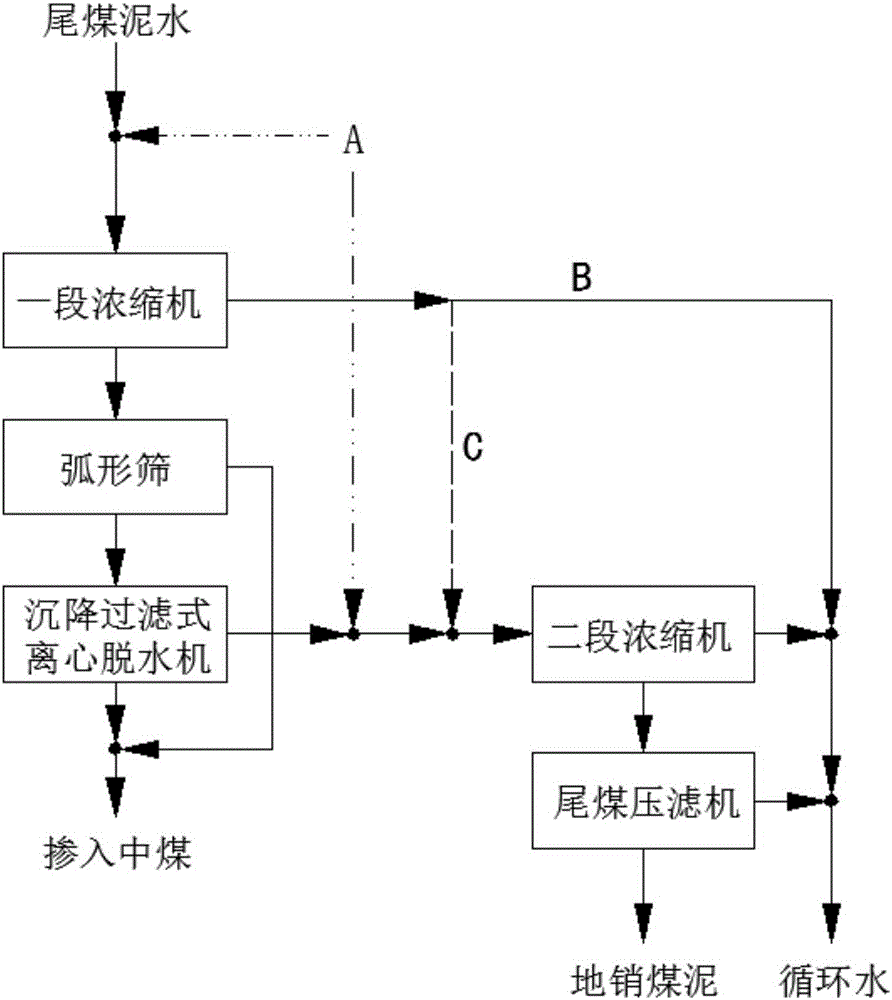

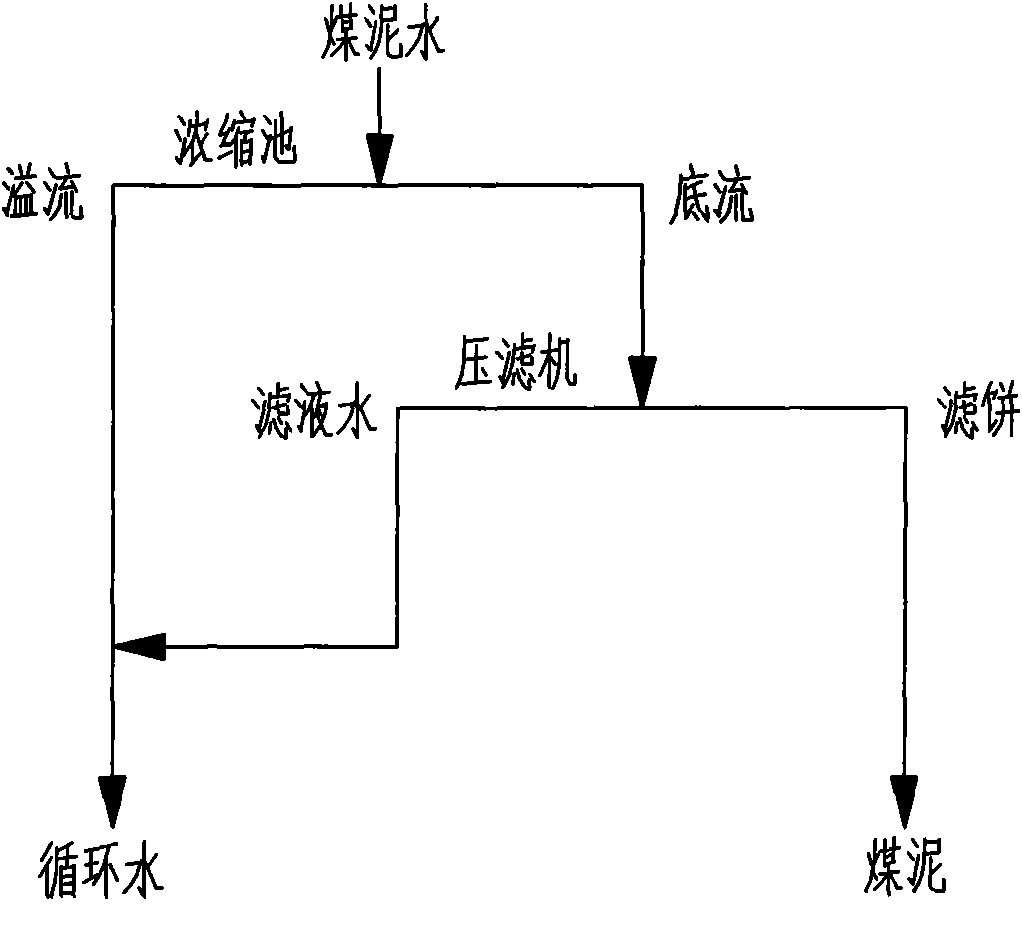

Tailing mud water treatment method for wet coal preparation plant

ActiveCN105858964AReduce moistureReduce the amount of feedWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningRecovery methodFiltration

The invention discloses a tailing mud water treatment method for a wet coal preparation plant. A two-stage concentration and two-stage recycling method for tailing mud water is involved in the method, and the method comprises the following steps: acquiring a hardness value of the tailing mud water; when the hardness value of the tailing mud water is lower than a first threshold value, adding a flocculating agent into a first-stage concentrator; acquiring an overflow concentration value of a first-stage concentrator; when the overflow concentration value of the first-stage concentrator is higher than a second threshold value, adding the flocculating agent into the first-stage concentrator; when the overflow concentration value of the first-stage concentrator is not higher than the second threshold value, reusing the overflow of the first-stage concentrator as circulating water. According to the method, the charging rate of a sedimentation-filtration centrifugal dehydrator can be maximally increased, the charging rate of a tailing mud filter press and the charging rate of the second-stage concentrator can be correspondingly decreased, and the aims of reducing the factory construction investment, improving the tailing mud recycling efficiency and saving coal and water resources can be fulfilled.

Owner:唐山国华科技国际工程有限公司

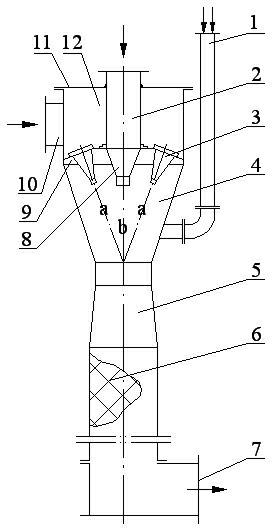

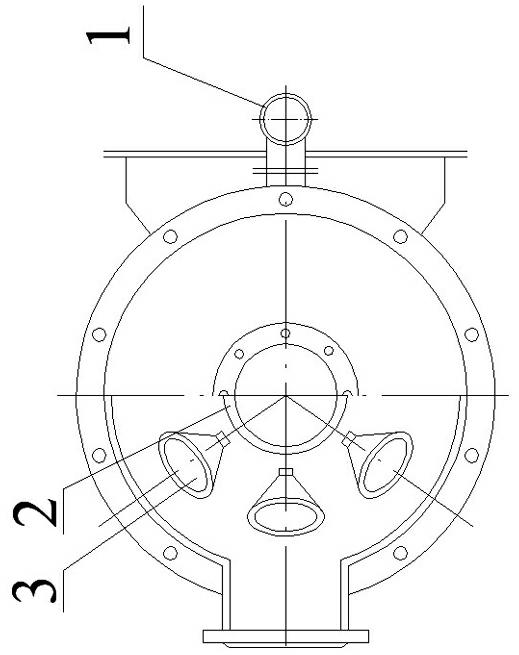

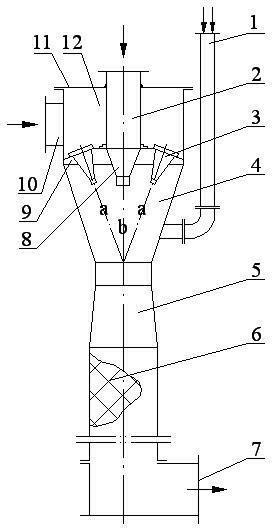

Flotation feed pretreatment device

InactiveCN102600960AImprove sorting selectivityReduce consumptionSolid separationThermodynamicsEmulsion

Disclosed is a flotation feed pretreatment device. Flotation feed and dilute water form jet flow respectively through a feed nozzle and a dilute water nozzle of a multi-nozzle jet device, negative pressure is formed in a mixing chamber, air and flotation reagents enter the mixing chamber through an air suction pipe and are cut and crushed at a high speed by the jet flow, the air is scattered into bubbles, the flotation reagents are emulsified into microfine oil droplets, and the flotation feed, the bubbles, flotation reagent emulsion and the dilute water enter a choke and a mixing mechanism, are sufficiently mixed to complete pretreatment of coal slurry inflation and bubble mineralization, and then enter a flotator tank through a discharging port. The flotation feed pretreatment device integrates pre-flotation concentration dilution, pre-mineralization, flotation reagent emulsification and even mixing of the flotation feed, the dilute water, the flotation reagent emulsion and the bubbles, achieves the purposes of improving flotation feed separation selectivity, reducing flotation cleans ash, improving clean coal yield and reducing consumption of the flotation reagents, and is fine in mixing effect, low in manufacturing cost and suitable for coal preparation plants on various scales.

Owner:唐山国华科技国际工程有限公司

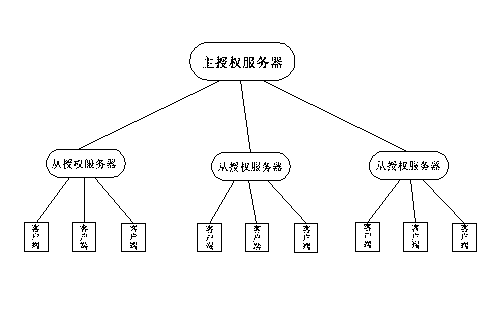

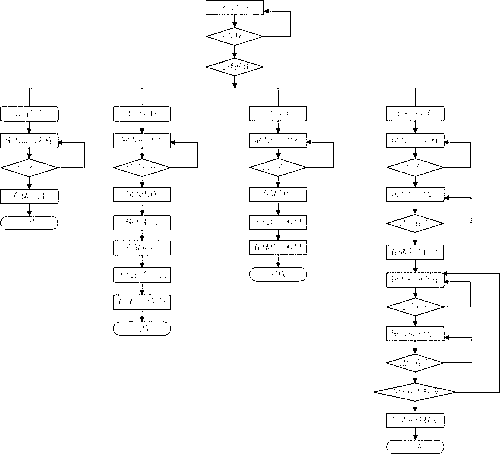

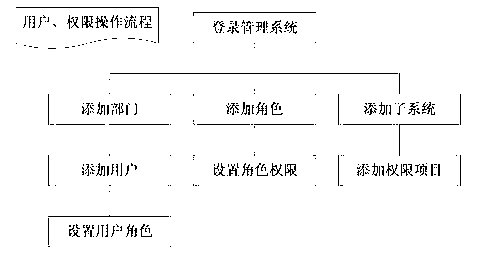

Role-based distributed authority management method for manufacturing execution system (MES) for coal preparation plant

ActiveCN102843261ASuitable for production needsFlexible configurationData switching networksManufacture execution systemSoftware system

The invention relates to a role-based distributed authority management method for a manufacturing execution system (MES) for a coal preparation plant. In the method, a hardware system and a software system installed in the hardware system are provided; the hardware system comprises a primary authorization server installed with a primary service program and a plurality of secondary authorization servers installed with secondary service programs; each secondary authorization server corresponds to one independent department or mechanism in a group; and the secondary authorization servers are communicated with the primary authorization server through data transmission lines. The invention provides a method applied to role-based distributed authority management of the MES for the coal preparation plant. The method is simple to operate, adopts a web management mode, is reasonable in design, can realize distributed expansion, can design the corresponding subsystem, role and authority according to the actual condition of the coal preparation plant, is suitable for production requirement of the coal preparation plant, is high in practicability, realizes flexible allocation on different production management modules and personnel authorities of the MES for the coal preparation plant, and contributes to sequential operation of production management of the coal preparation plant.

Owner:PINGDINGSHAN ZHONGXUAN AUTOMATIC CONTROL SYST

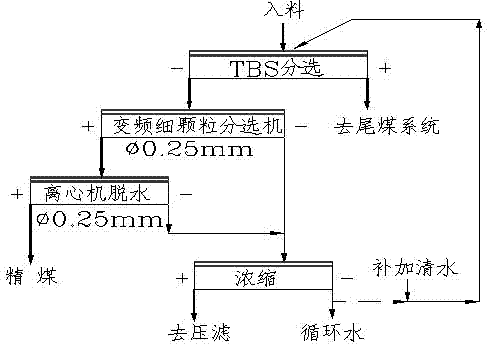

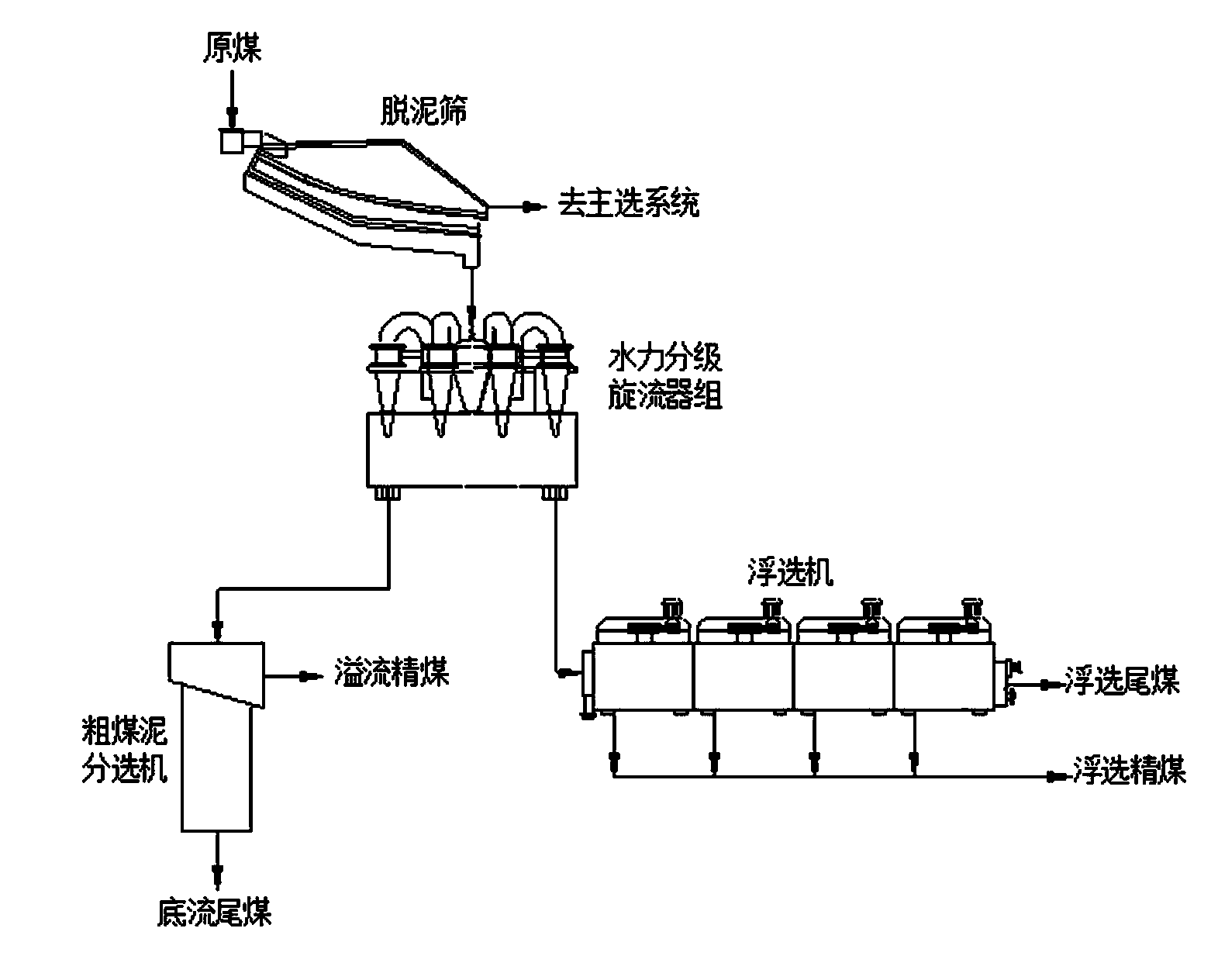

Separation method for roughing slime through teetered bed separator (TBS) and concentrating coarse slime difficult to separate through slime dense medium cyclone

InactiveCN105080701ASolve the accuracy problemSolve the shortcomings of poor sorting effectFlotationWet separationCycloneWater velocity

The invention discloses a separation method for roughing slime through a teetered bed separator (TBS) and concentrating coarse slime difficult to separate through a slime dense medium cyclone. Slime of a slime water system is pumped to a hydraulic classification cyclone to be classified, and overflows into flotation equipment to be separated; and underflow enters the TBS, high-ash tailings and coarse clean coal with a high ash content are obtained at a high ascending water velocity under a high bed density, the coarse clean coal enters the slime dense medium cyclone to be concentrated, and finally clean coal and middling products are obtained. According to the method, the advantages of the TBS and the advantages of the slime dense medium cyclone are combined, the advantages are enhanced, and disadvantages are avoided; the coarse slime difficult to separate is roughed through the TBS to obtain the high-ash tailings and the coarse clean coal; by making use of the characteristic that the separation precision of the slime dense medium cyclone is high, the coarse clean coal is concentrated, and the high-quality clean coal meeting the requirements of a low ash content and a high recovery rate is obtained. Not only are the common problems of 'coarse coal running', 'ash carrying' and the like in coal preparation plants solved, but also the technological problems of high-precision separation of the high-ash coarse slime difficult to separate are solved.

Owner:CHINA UNIV OF MINING & TECH

Apparatus and method for dewatering slime through competitive absorption

InactiveCN104017625AReduce moistureHigh calorific valueSolid fuelsDrying machines with non-progressive movementsPulp and paper industryCoal preparation plant

The invention discloses an apparatus and a method for dewatering slime through competitive absorption. The apparatus comprises a slime concentrating machine, a first slurry pump, a buffering barrel, a second slurry pump, a drum-type mixer, a vibrating screen, a first belt transporter, a dryer, a cyclone dust collector, an induced draught fan, a second belt transporter, a buffering bin, a feeder and a third belt transporter. According to the method, strong-viscosity high-mud-content slurry, which is underflow of the slime concentrating machine, and a crowd of container bags filled with a drying medium are fully mixed, so that water in slime is competitively absorbed by the drying medium, and slime is indirectly dried; the mixture of water-reduced slime and the container-bag crowd is separated by the vibrating screen, the container-bag crowd is sent to a dryer for drying, and after regeneration, the container-bag crowd is sent to the buffering bin and is sent to the drum-type mixer by the feeder for recycling; and the dryer is connected with the cyclone dust collector for preparing a dewatered slime product. The dewatering efficiency of slime in coal preparation plants is effectively improved, and the economic value of low-rank slime is improved. The apparatus and the method are especially suitable for dewatering of strong-viscosity high-mud-content slime. The structure of the apparatus and the method are simple, easy to realize, good in dewatering effect, high in safety and low in operation cost.

Owner:CHINA UNIV OF MINING & TECH

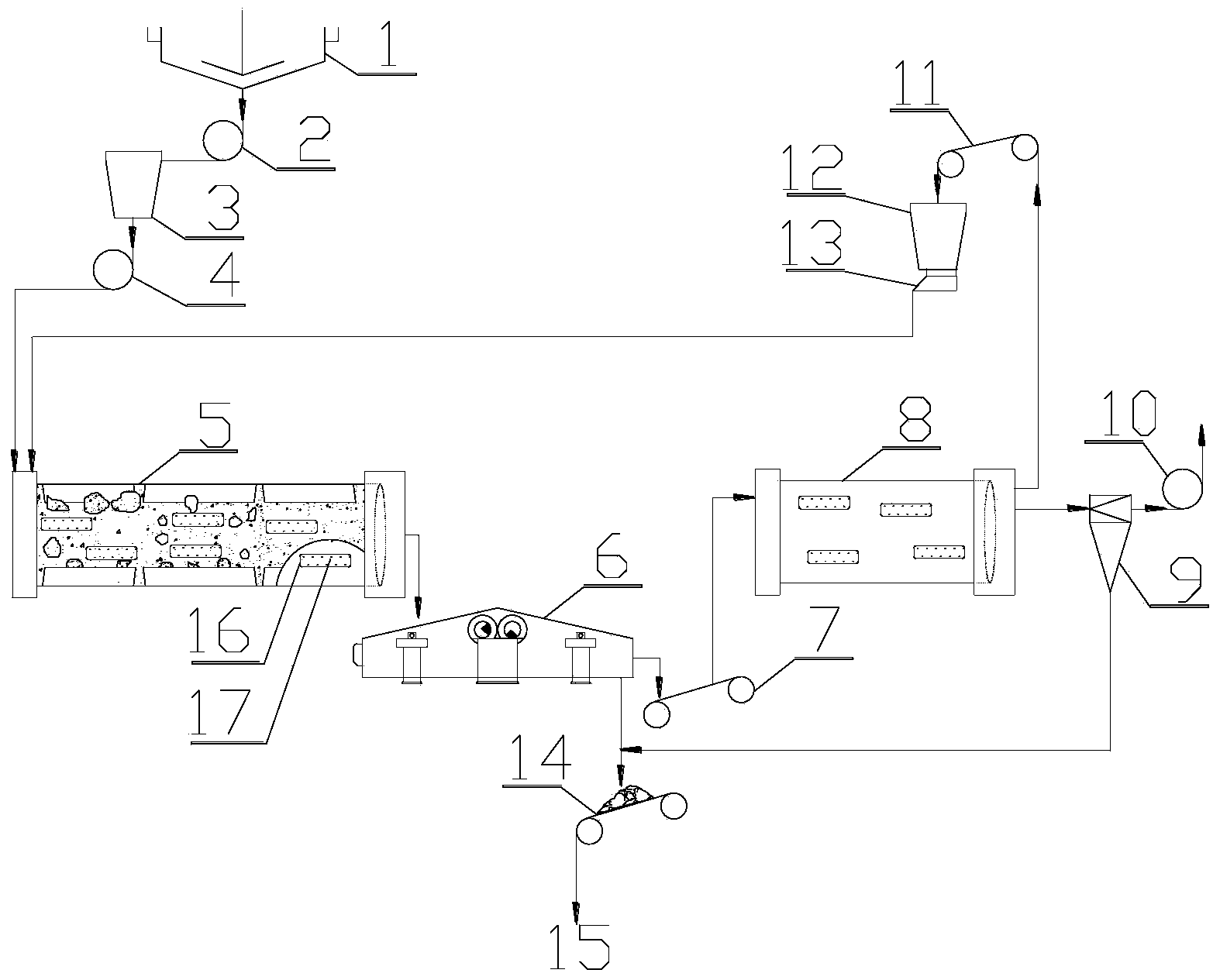

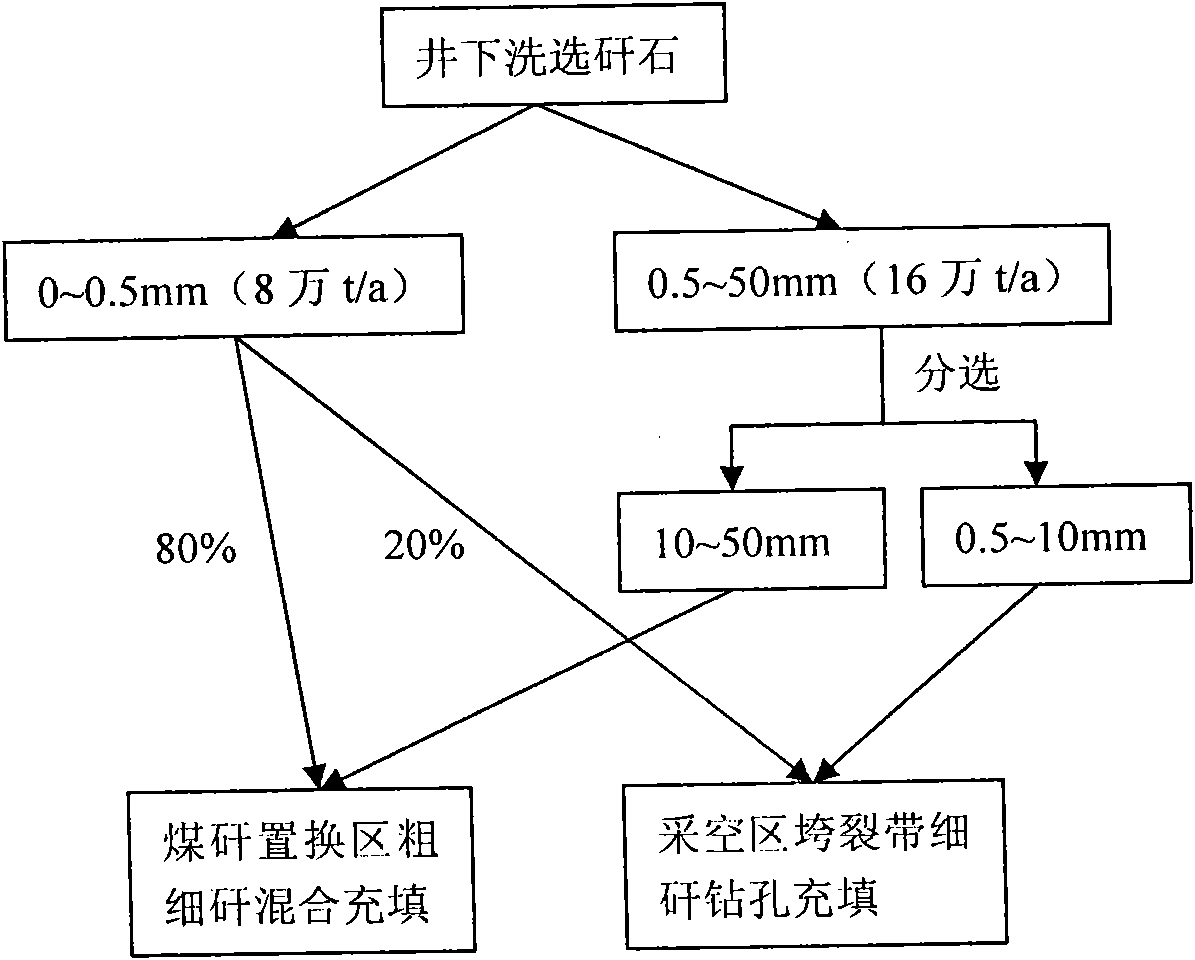

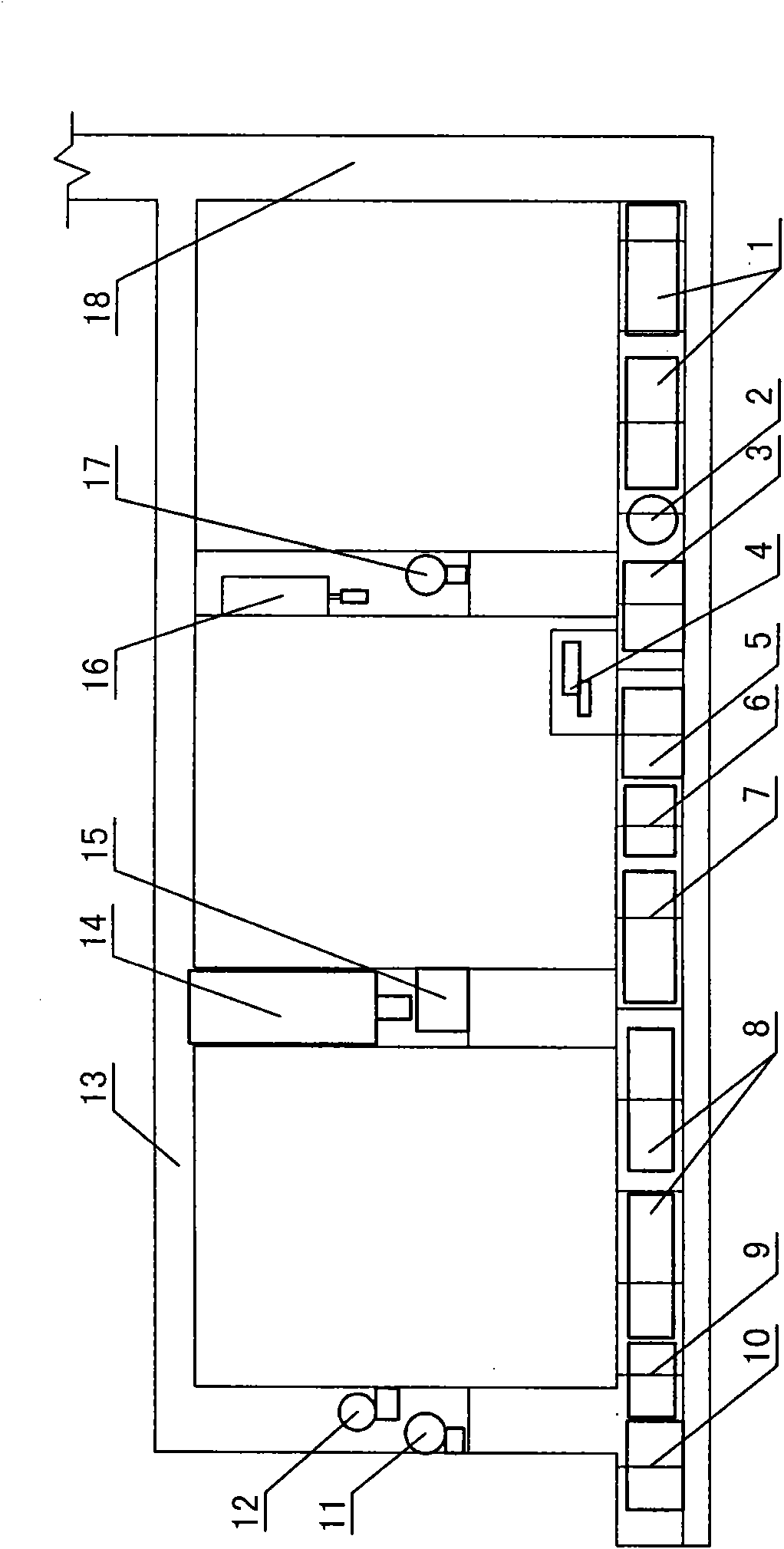

Method for realizing underground separation of raw coal

ActiveCN101905189ASmall footprintReduce the impactWet separationSocial benefitsCoal preparation plant

The invention relates to a method for realizing underground separation of raw coal. The method specifically comprises the following steps of: (a) formulating an underground coal separation process; (b) selecting the type of equipment; (c) timbering an underground chamber; (d) arranging the equipment; (e) backfilling waste rocks; (f) setting an automatic system; (g) arranging cables; and (h) setting a safety system. The invention not only can reduce the ground occupation, but also can discharge the waste rocks in the raw coal before ascending the well, directly uses the separated waste rocks as underground sprayed concrete and backfilling materials of a mined out space and has great economic and social benefits; because underground mining causes serious ground mining damages, the waste rocks are directly backfilled to the mined out space after the waste rocks are separated underground, thus the influences of mining on the ground can be greatly reduced, and the environmental pollution is reduced; and the cost of constructional engineering is about 40 percent in the investment composition of a coal separating plant, thus the investment of the constructional engineering can be reduced if the coal separating plant is built in the underground chamber.

Owner:BEIJING YZH COAL ENG DESIGN

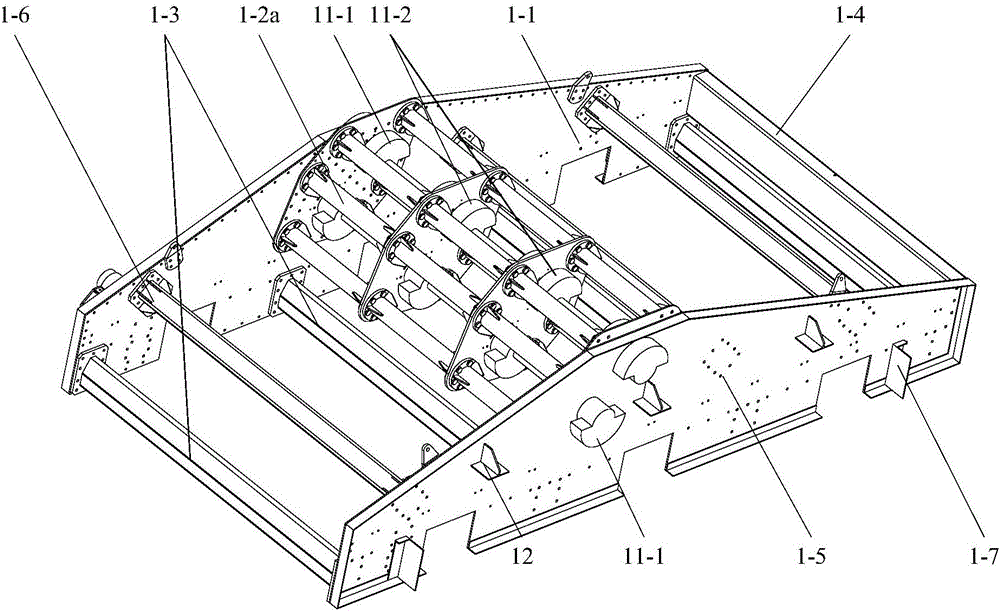

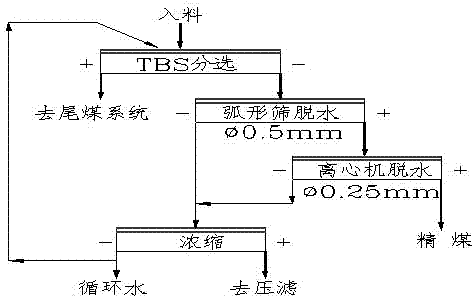

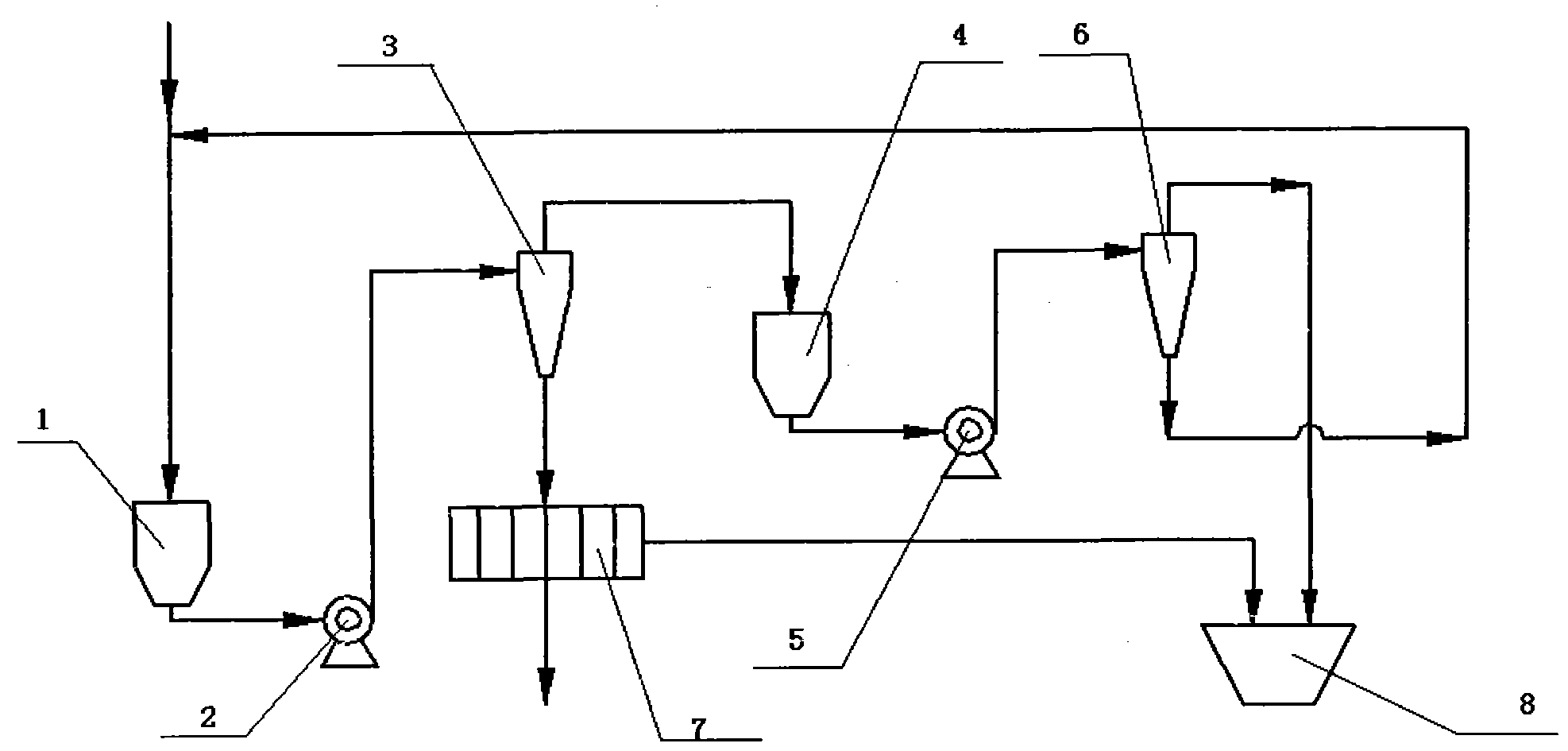

Coarse coal slime sorting equipment and technology of coarse coal slime sorting equipment

ActiveCN103495494AHigh recovery rateSolve the problem of high scoreWet separationThermodynamicsCoal plant

The invention relate to a sorting technology of coarse coal slime of a coal plant, in particular to coarse coal slime sorting equipment and a technology of the coarse coal slime sorting equipment. The coarse coal slime sorting equipment is characterized by comprising a TBS coal slime sorting machine which comprises a tank body, a feeding well, a turbulent flow plate, a density sensor, an actuator, a discharging valve and an overflow weir. Therefore, the coarse coal slime sorting equipment and the technology are reasonable in design and easy to achieve.

Owner:COAL IND JINAN DESIGN & RES

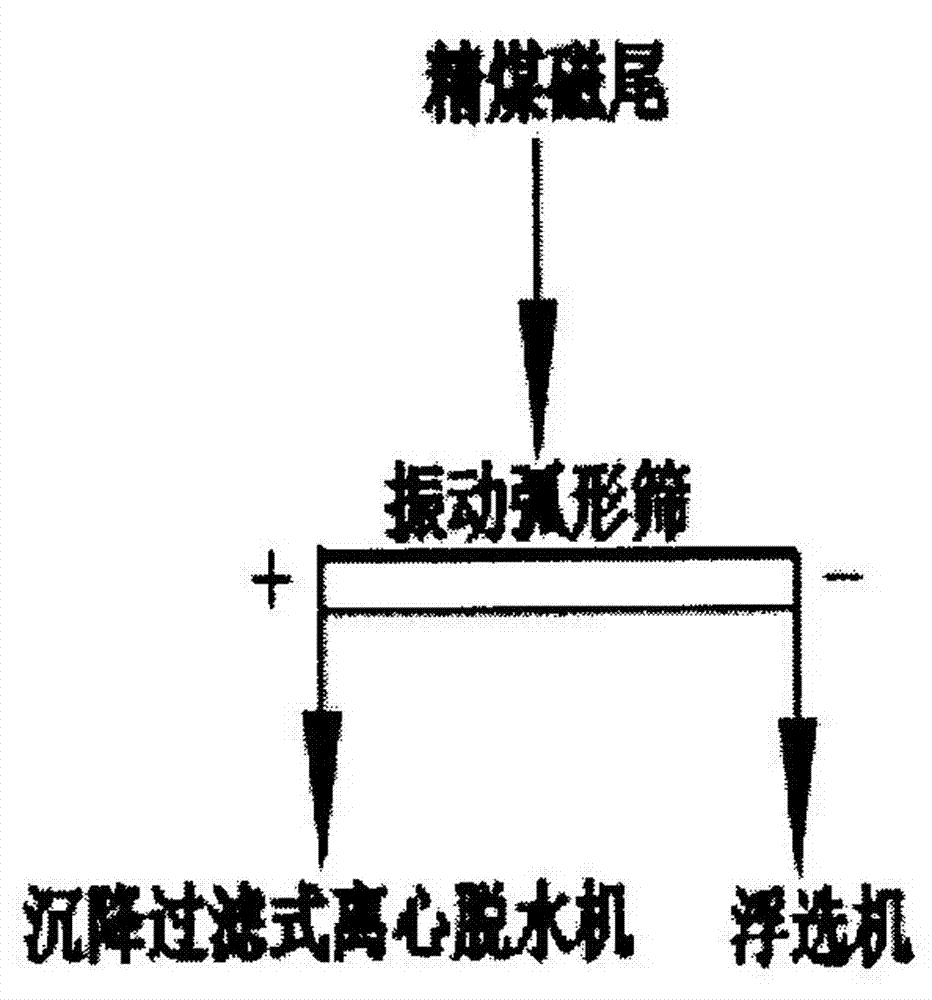

Method for using refined coal magnetic separator tailings for flotation water-spraying foam removal

InactiveCN102824955ALess investment in infrastructureImprove reliabilityWet separationCycloneMagnetic separator

The invention discloses a method for using refined-coal magnetic separator tailings for flotation water-spraying foam removal. The method provides an improvement method aiming at characteristic of first-section overflowing refined coal products of a three-product heavy-medium cyclone, which comprises the following steps of: separating, removing the medium, recycling the medium, and using the refined-coal magnetic separator tailings for the flotation water-spraying foam removal. Therefore, the method is suitable for the characteristic of the refined-coal magnetic separator tailings of the first-section overflowing refined coal products of the three-product heavy-medium cyclone, and is particularly suitable for the technical reform of the refined-coal magnetic separator tailings in a coal preparation plant in which the content of fine granular materials (-0.5mm) is high.

Owner:HENAN POLYTECHNIC UNIV

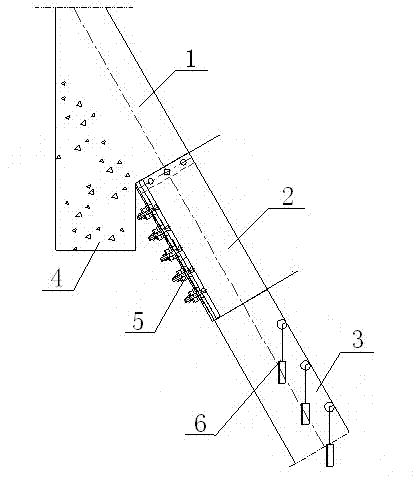

Large-fall vibration absorption and noise reduction buffering device

The invention relates to non-standard equipment for coal mines and coal preparation plants, and particularly relates to a large-fall vibration absorption and noise reduction buffering device. The large-fall vibration absorption and noise reduction buffering device comprises an upper sliding chute section, a middle sliding chute section and a lower sliding chute section which are sequentially connected with one another, and is characterized in that a buffering box is arranged at the upper sliding chute section; a plurality of buffering structures are arranged at the bottom of the middle sliding chute section; and a plurality of ring hammers are suspended at the tail end of the lower sliding chute section. The large-fall vibration absorption and noise reduction buffering device has the beneficial effects that the impact of the device to the device body and subsequent equipment is greatly weakened, the service life of the device and the service life of the subsequent equipment are prolonged, the maintenance for the equipment is greatly reduced, the material cost and the maintenance cost are saved, the labor intensity of workers is alleviated, the stability of a system is improved, and the working environment of the workers is also improved.

Owner:COAL IND JINAN DESIGN & RES

Light-weight aggregate produced by using coal gangue

The invention aims to provide a production method of a light-weight aggregate used for industrial and civil buildings, and in particular relates to the light-weight aggregate produced by using coal gangue. The light-weight aggregate is characterized in that a production raw material of the coal gangue light-weight aggregate is unburned coal gangue; the coal gangue is selected from mining gangue or washing gangue of a coal preparation plant; the particle size range of the coal gangue light-weight aggregate is 0.16-40mm; the coal gangue has a certain heating power, and the caloric value is 1-6276KJ / Kg; the coal gangue is crushed into particles with the particle size of 0.16-40mm, is put into a rotary kiln, and then is subjected to thermal activation at the thermal activation temperature of 650-1250 DEG C.

Owner:李荣怀

Hydrophobic agglomeration, sedimentation and clarification method for slime water

InactiveCN104261538AReduce typesThere are few types of useWater/sewage treatment by flocculation/precipitationSolid particleFilter press

The invention discloses a hydrophobic agglomeration, sedimentation and clarification method for slime water, and the method is applicable to slime water treatment in a coal preparation plant. The hydrophobic agglomeration, sedimentation and clarification method comprises the following steps: measuring concentration of the slime water, regulating the pH value of the slime water to a reasonable range; adding a cationic hydrophobic surfactant into the slime water, mixing the cationic hydrophobic surfactant with slime water to enable the surfaces of coal slime particles to be subjected to hydrophobization sufficiently by the hydrophobic surfactant so as to form a hydrophobic agglomerate; naturally sedimentating the pretreated slime water, detecting concentration of solid particles in clarified water, and if the concentration of the clarified water is larger than 1 g / L, adding an anionic flocculant until the concentration of the clarified water is smaller than 1 g / L. By adopting the hydrophobic agglomeration, sedimentation and clarification method, coal in the coal preparation plant can be cleaned by clear water, subsequent filter pressing and dewatering on coal slime can be easily performed, the coal slime recycling rate and the utilization ratio of recycled water are increased, and outward discharge of the slime water and mining area pollution are avoided; the hydrophobic agglomeration, sedimentation and clarification method is simple and convenient and easy to implement.

Owner:ANHUI UNIV OF SCI & TECH

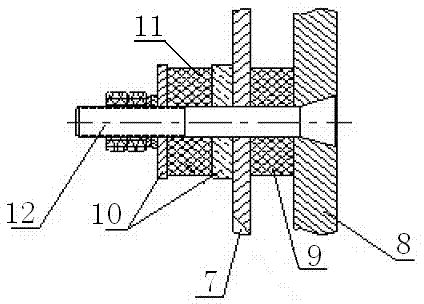

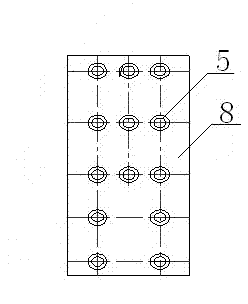

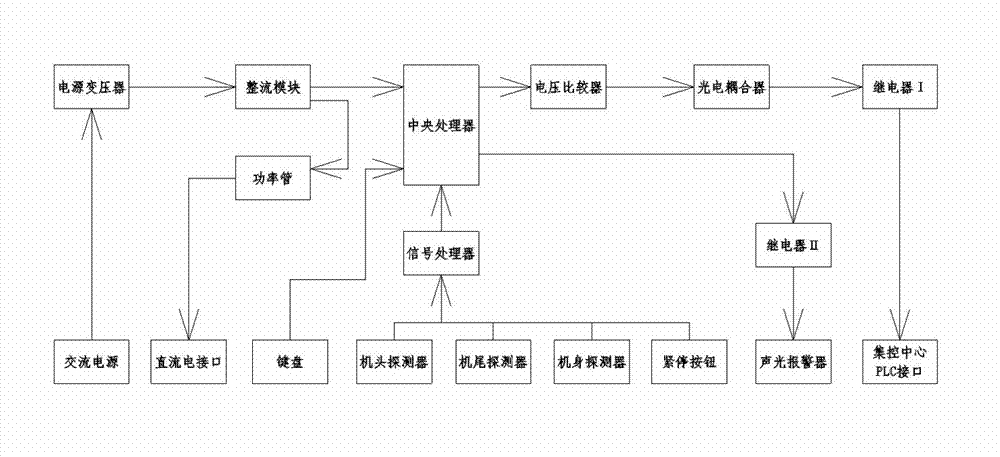

Safety protection system with function of preventing belt conveyor from hurting people for coal preparation plant

InactiveCN102765592AImprove compatibilityMeet the protection requirementsControl devices for conveyorsTransformerEngineering

The invention particularly relates to a safety protection system with function of preventing belt conveyor from hurting people for a coal preparation plant. The safety protection system solves the problem that an existing protection device of a belt conveyor cannot effectively protect people from being hurt by the belt conveyor. An alternating current power supply is connected with a power transformer which is connected with a central processing unit and a power tube respectively, the power tube is connected with a direct current port which is connected with a headpiece, a tail, a tail detector and an audible and visual alarm respectively, the headpiece, the tail and the tail detector are all connected with the central processing unit, a keyboard is connected with the central processing unit connected with the audible and visual alarm and a voltage comparator, the voltage comparator is connected with a PLC (programmable logic controller) port of a concentrated control center, and an emergency button is connected with the central processing unit. The safety protection system with function of preventing belt conveyor from hurting people for the coal preparation plant is reasonable and reliable in structure, can realize spot alarming and shutdown protection, and degree of automation of monitoring protection of the belt conveyor is improved.

Owner:DATONG COAL MINE GRP

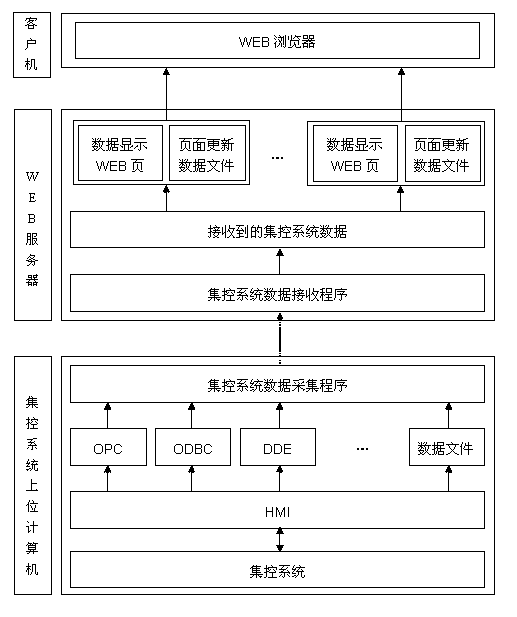

Method for monitoring centralized control system data by manufacturing execution system (MES) of coal preparation plant

ActiveCN102930359AMeet monitoring needsEasy to integrateResourcesTransmissionManufacture execution systemData display

The invention discloses a method for monitoring centralized control system data by a manufacturing execution system (MES) of a coal preparation plant and relates to the technical field of computers. The method comprises the following steps of: connecting a monitoring layer network and a management layer network in an enterprise; erecting an IISweb server on the management layer network and deploying a data receiving program on the IISweb server; acquiring the required centralized control system data and sending the required centralized control system data to the IISweb server by a data acquisition program on an upper computer in the monitoring layer network; processing the received data and then storing the processed data in a shared memory space of the IISweb server by the data receiving program; allowing the content of a data display web page to change along with the data content of the shared memory space; and finally sending a request to the IISweb server by a client in the management layer network through a web browser to browse the data display web page of a centralized control system. By the method, the requirement of monitoring production process data of the coal preparation plant by an enterprise manager can be met, special human-computer interface software is not needed to be installed on each computer of managers, or special human-computer interface web page publishing software is not needed to be purchased, so that many troubles are avoided.

Owner:PINGDINGSHAN ZHONGXUAN AUTOMATIC CONTROL SYST

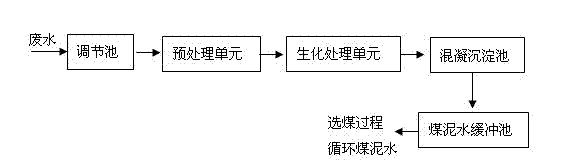

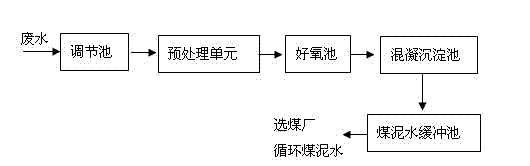

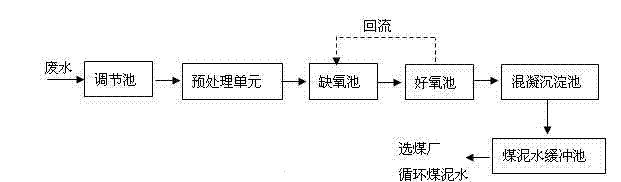

Coal chemical industrial wastewater treating and recycling method combined with coal dressing process

InactiveCN102887612AAchieving zero emissionsRealize resource utilizationMultistage water/sewage treatmentRefractoryWater resources

The invention discloses a coal chemical industrial wastewater treating and recycling method combined with a coal dressing process, belonging to a wastewater treating and recycling method. Wastewater is subjected to pretreatment, biochemical treatment and coagulation treatment to be finally used as coal dressing water. The coal chemical industrial wastewater treating and recycling method specifically comprises the steps of: 1, introducing coal chemical industrial wastewater in a wastewater regulating tank into a pretreatment unit for being pretreated; 2, introducing the pretreated wastewater into a biochemical unit for being biochemically treated; 3, introducing the biochemically treated wastewater into a coagulative precipitation tank for being subjected to coagulative precipitation; and 4, introducing the wastewater subjected to the coagulative precipitation into a coal slime water buffer tank of a coal dressing plant to be used as the coal dressing water. Residual refractory organics in the coal dressing process are absorbed on surfaces of coal particles; and water is recycled in the closed cycle of the coal dressing plant. According to the coal chemical industrial wastewater treating and recycling method, coal chemical industrial wastewater is efficiently and economically treated and recycled, zero emission and recycling of the wastewater and organic pollutants in the wastewater are realized, the treatment cost is lowered, the environment is protected, and water resources are saved.

Owner:CHINA UNIV OF MINING & TECH

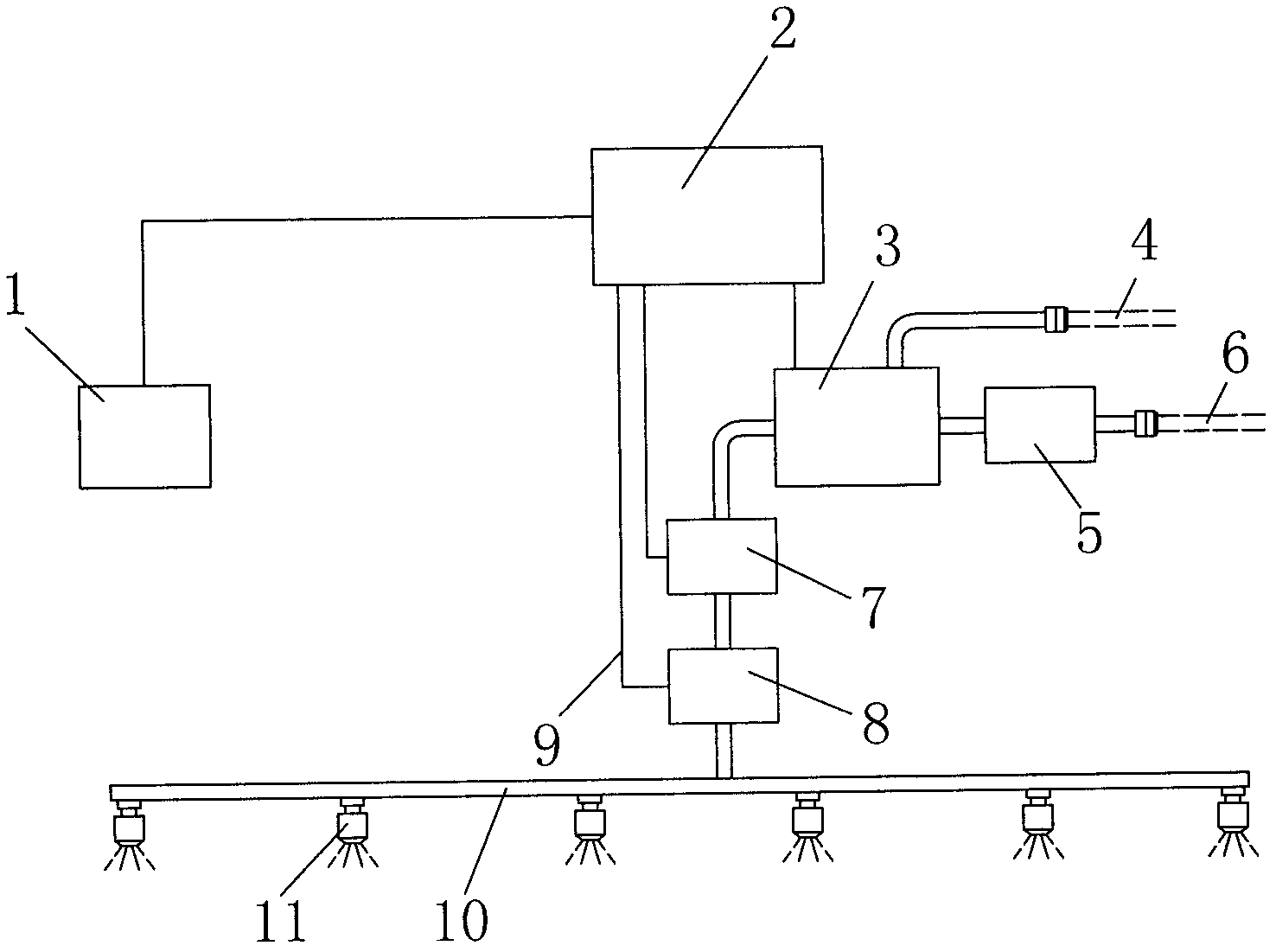

Spraying device capable of automatically adjusting yield

ActiveCN102489424ASpray adjustment in real timeReduce volumeDust removalFire preventionDiaphragm pumpWater source

The invention discloses a spraying device capable of automatically adjusting yield. The spraying device capable of automatically adjusting the yield consists of a yield measurement sensor, a controller, a pneumatic diaphragm pump, a filter, an electromagnetic valve, a flow control valve, a pipeline and a nozzle, wherein the yield measurement sensor is arranged in a carrier roller of a belt conveyor; the controller is connected with the yield measurement sensor, the pneumatic diaphragm pump, the electromagnetic valve and the flow control valve through wires; the pneumatic diaphragm pump provides high-pressure water for the spraying device; the filter is arranged at the water inlet end of the pneumatic diaphragm pump; the electromagnetic valve and the flow control valve are used for controlling on and off of the spraying device and adjusting the spraying flow; and the nozzle is connected with the flow control valve through the pipeline. The spraying device capable of automatically adjusting the yield is applicable to the occasions needing to spray to reduce dust generated when coal mine underground tunnels, coal preparation plants and the like adopt belt conveyors to convey coal, can adjust the spraying quantity according to the conveying quantity of the coal, can save water source and can also avoid excessive spraying quantity, so that the water content of the coal is not ultrahigh and sieve pores are not blocked by the coal during sieving.

Owner:NANTONG ZHONGYI BOILER EQUIP

Settling method of solid substances in carboniferous system coal slurry water

InactiveCN102755766AReduce dosageEasy to handleSedimentation separationWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateHydrolysis

The invention provides a settling method of solid substances in carboniferous system coal slurry water, and solves the problems that great influence is caused to production of a coal preparation plant due to poor carboniferous system coal slurry water treatment effect. The settling method is characterized in that flocculant and polycoagulant are added in the carboniferous system coal slurry water, the flocculant adopts polyacrylamide with the molecular weight of more than 23 million and the degree of hydrolysis of 20% to 27%, the polycoagulant adopts polyaluminum cloride, the use level of the polyacrylamide is 3 to 4.4g / m<3>, the use level of the aluminium polychlorid is 40g / m<3>, the configuration concentration of the polyacrylamide is 100 ppm, and the configuration concentration of the polyaluminum cloride is 1,000 ppm. According to the settling method, the use level of the flocculant is greatly reduced, so that the thickness of the clear water layer in a thickener is larger than 1.5 m, the processing capacity of a pressurizing filter is increased by about 33%, the cost of the flocculant can be saved by 912,200 yuan every year, not only is the drug cost saved, but also the processing capacity of the pressurizing filter is increased, and the moisture of a filter cake is reduced.

Owner:DATONG COAL MINE GRP

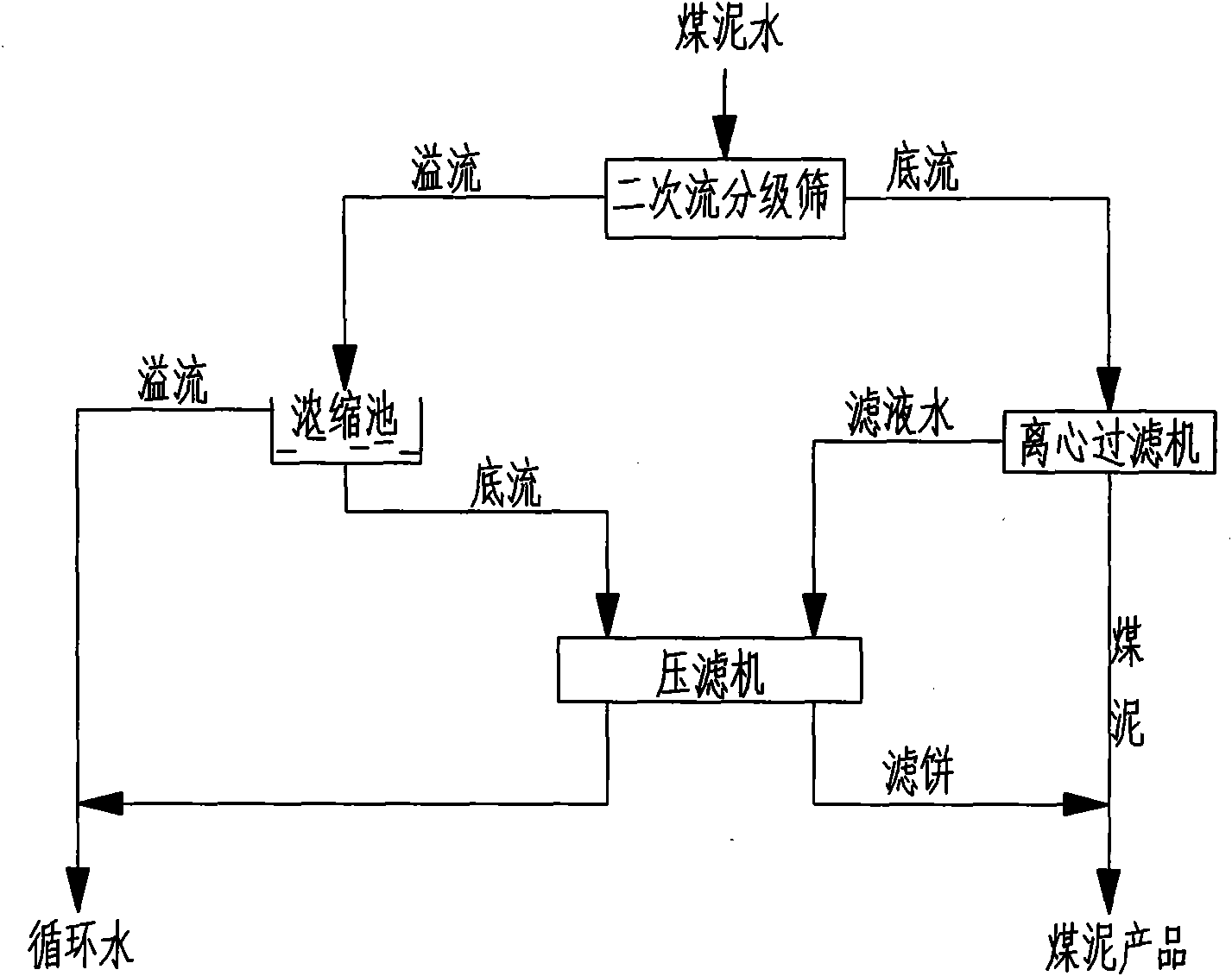

Technology for treating coal slime water through secondary flow and settlement filtering centrifuge

InactiveCN102399028ASmall footprintReduce labor intensityMultistage water/sewage treatmentWater flowFilter press

The invention discloses a technology for treating coal slime water through a secondary flow and a settlement filtering centrifuge, and belongs to the technical field of coal slime water treatment. The technology comprises the following steps that 1, coal slime water flows into a secondary flow classifying screen and is classified; 2, an underflow comprising coarse particles is fed into a filtering centrifuge and then is treated and an overflow comprising fine particles is fed into a condensation tank and then is concentrated; 3, the overflow concentrated by the condensation tank is utilized as circulating water for recycle and an underflow is fed into a filter press and then is treated; 4, filtrate obtained by the filtering centrifuge is fed into the filter press and then is treated and coal slime obtained by the filtering centrifuge is utilized as a product and is sold; And 5, filter cakes obtained by the filter press is coal slime, is utilized as a product and is sold, and filtrate obtained by the filter press is utilized as circulating water for recycle. In the invention, a settlement filtering centrifuge is utilized as a centrifugal hydroextractor. The technology provided by the invention reduces a floor space of a coal preparation plant, saves production time and reduces repairer labor intensity.

Owner:YONGCHENG COAL & ELECTRICITY HLDG GRP

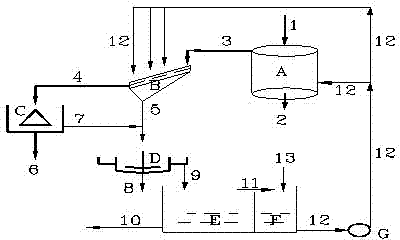

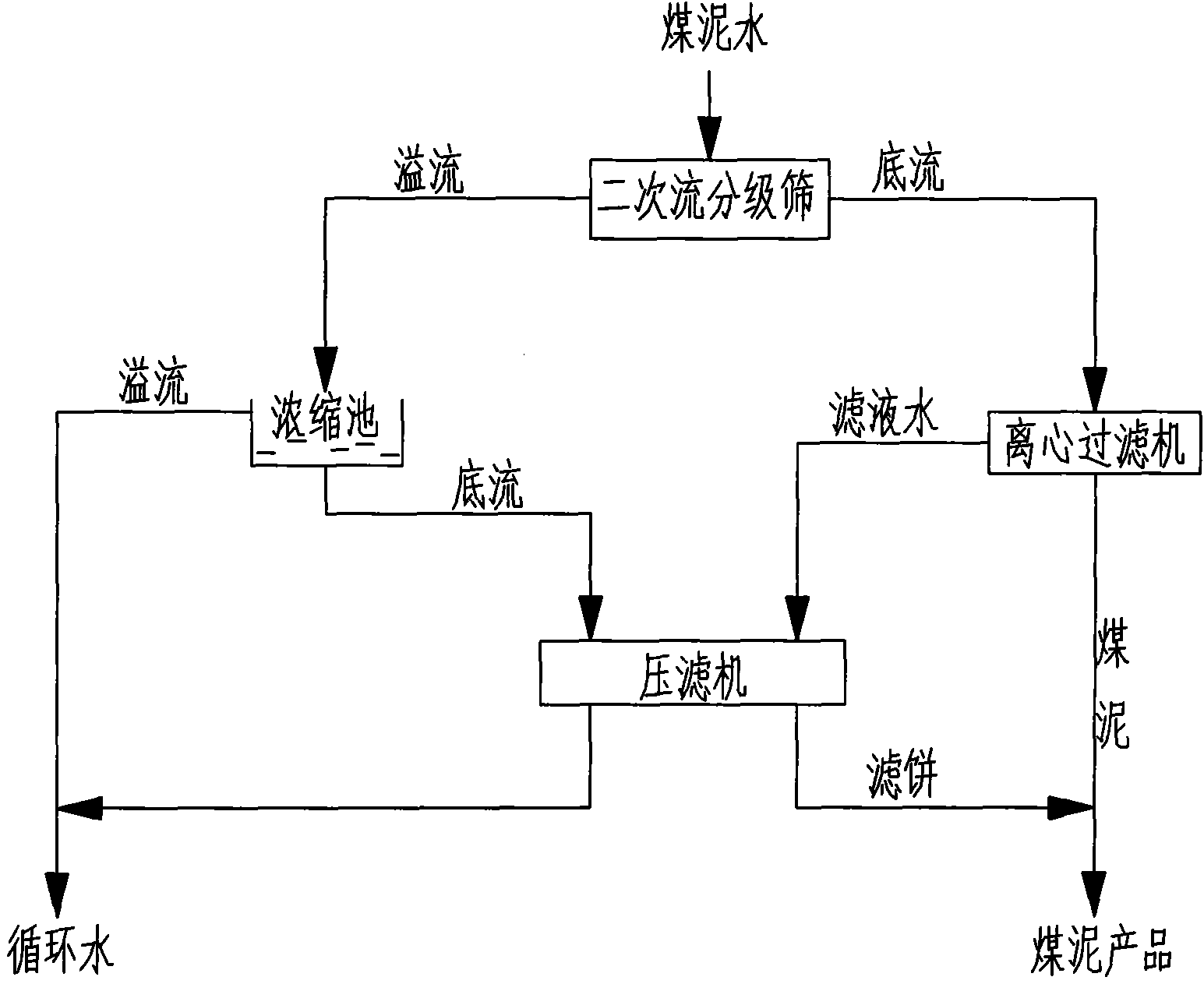

Treatment and recovery process of slime water

InactiveCN102616903AReduce accident rateWater/sewage treatment by centrifugal separationSludge treatment by de-watering/drying/thickeningFilter pressCoal preparation plant

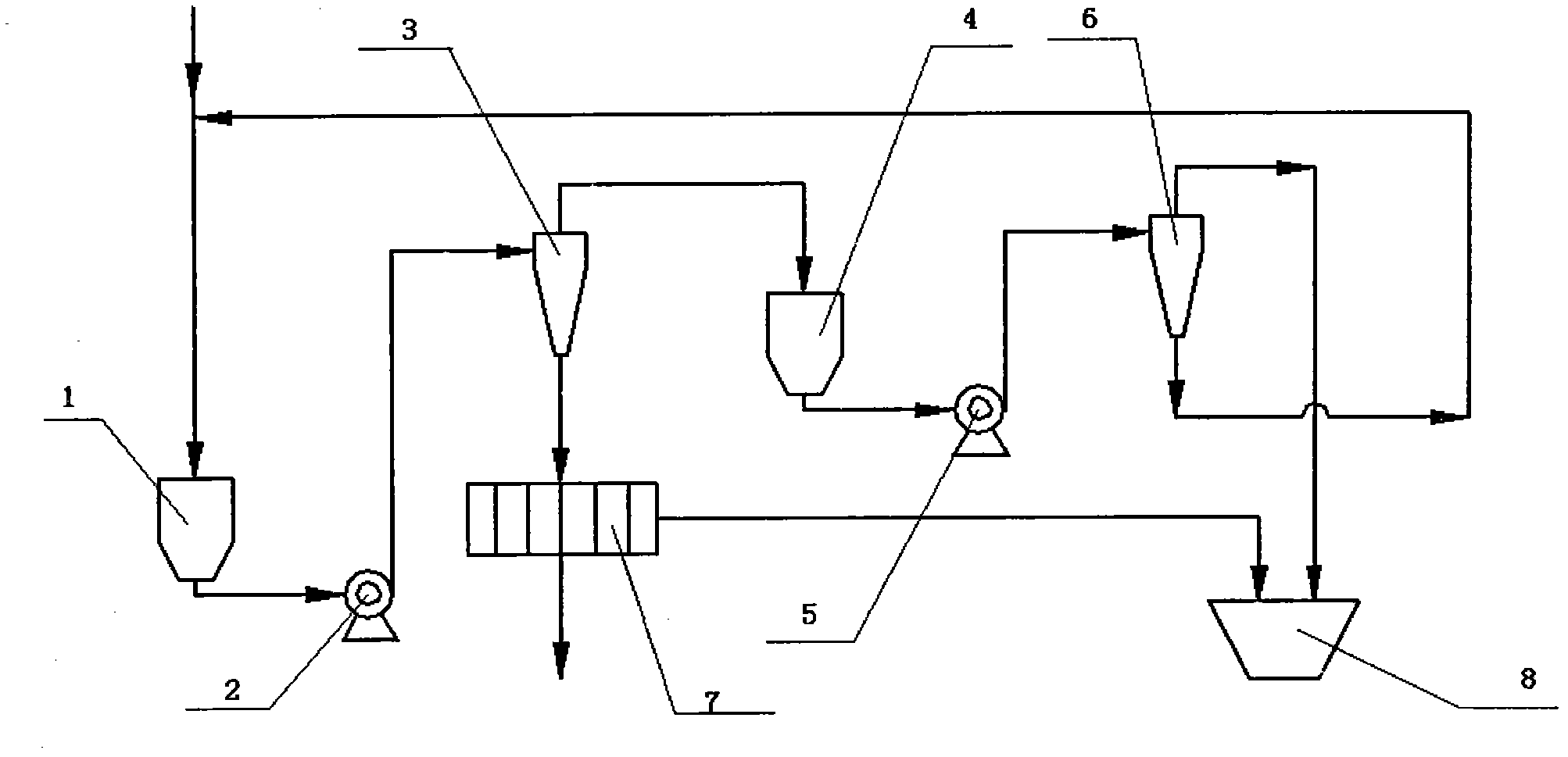

The invention discloses a treatment and recovery process of slime water, which comprises a primary slime water agitating vessel (1), a primary slime water pump (2), a primary swirler (3), a secondary slime water agitating vessel (4), a secondary slime water pump (5), a secondary swirler (6), a filter press (7) and a circulating water tank (8). The process comprises the steps that slime water enters the primary slime water agitating vessel (1) and then is fed into the primary swirler (3) through the primary slime water pump (2) during the production of a coal preparation plant; products at the bottom of the primary swirler (3) enter the filter press (7), so that coal slime is recovered; overflow products of the primary swirler (3) enters the secondary slime water agitating vessel (4) and then are fed into the secondary swirler (6) through the secondary slime water pump (5); products at the bottom of the secondary swirler (6) enter the primary slime water agitating vessel (1); and overflow products of the secondary swirler (6) enter the circulating water tank (8) to be used for producing circulating water in the coal preparation plant.

Owner:拜城县众泰煤焦化有限公司

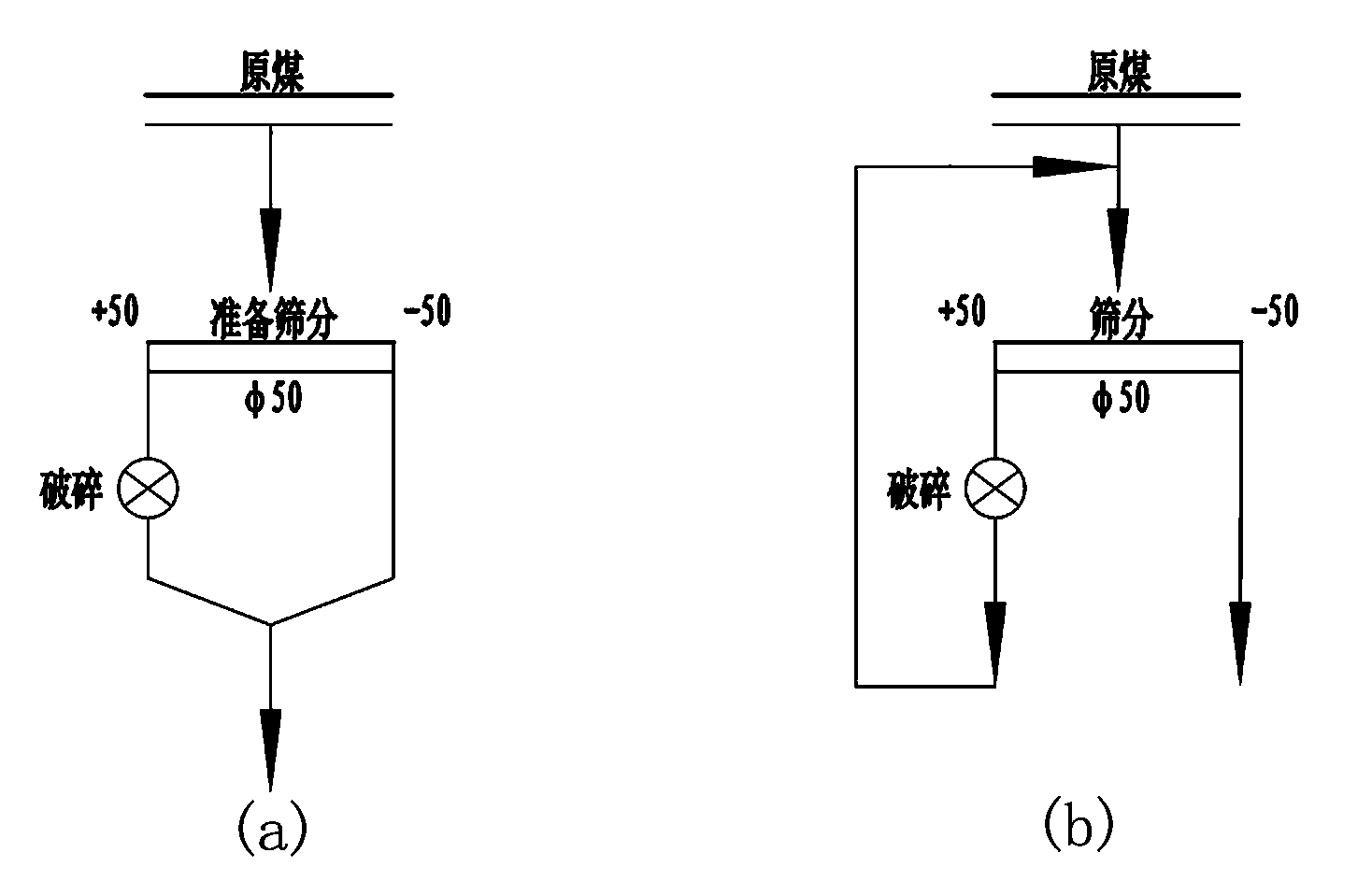

Closed-path grading technology suitable for fine pea coal grading

InactiveCN103920582AEnsure particle sizeGuaranteed GranularityWet separationEngineeringCoal preparation plant

The invention discloses a closed-path grading technology suitable for fine pea coal grading. The closed-path grading technology is established according to characteristics of hydraulic classification hydrocyclone overflow products and underflow products, is adopted to improve a traditional fine pea coal hydraulic classification hydrocyclone technology to make the traditional fine pea coal hydraulic classification hydrocyclone technology suitable for the characteristics of the hydraulic classification hydrocyclone products, and is particularly suitable for the technological transformation of a fine pea coal classifying technology in coal preparation plants with extremely high fine particle material (<=1 mm) content.

Owner:HENAN POLYTECHNIC UNIV

Pre-separation process of coal slime flotation

Owner:LIAONING TECHNICAL UNIVERSITY

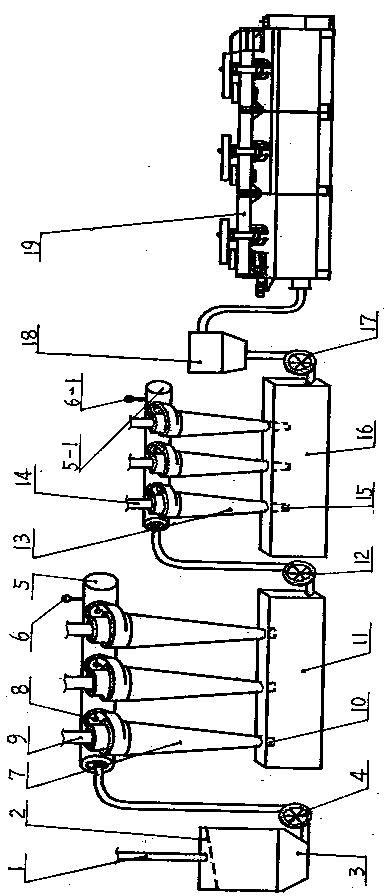

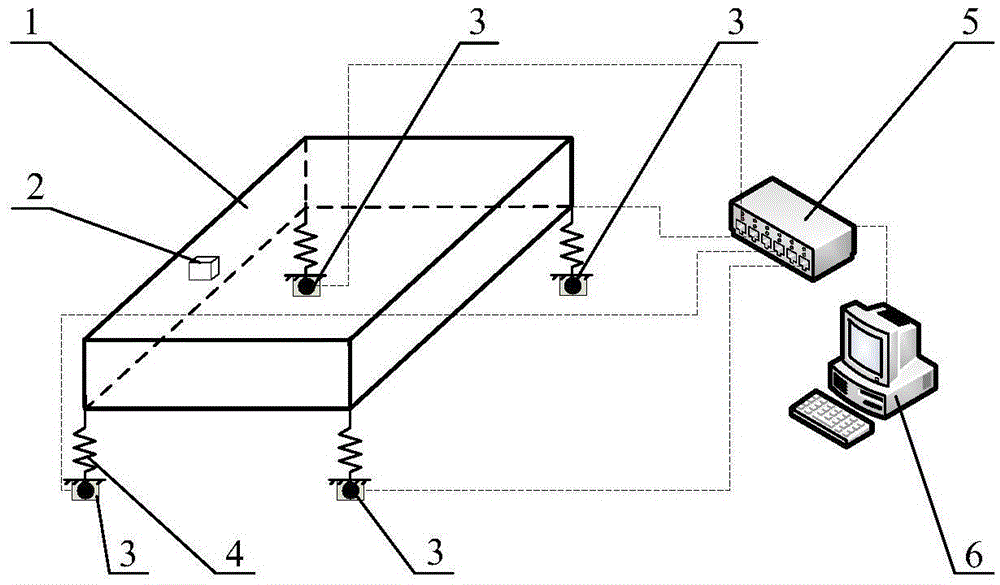

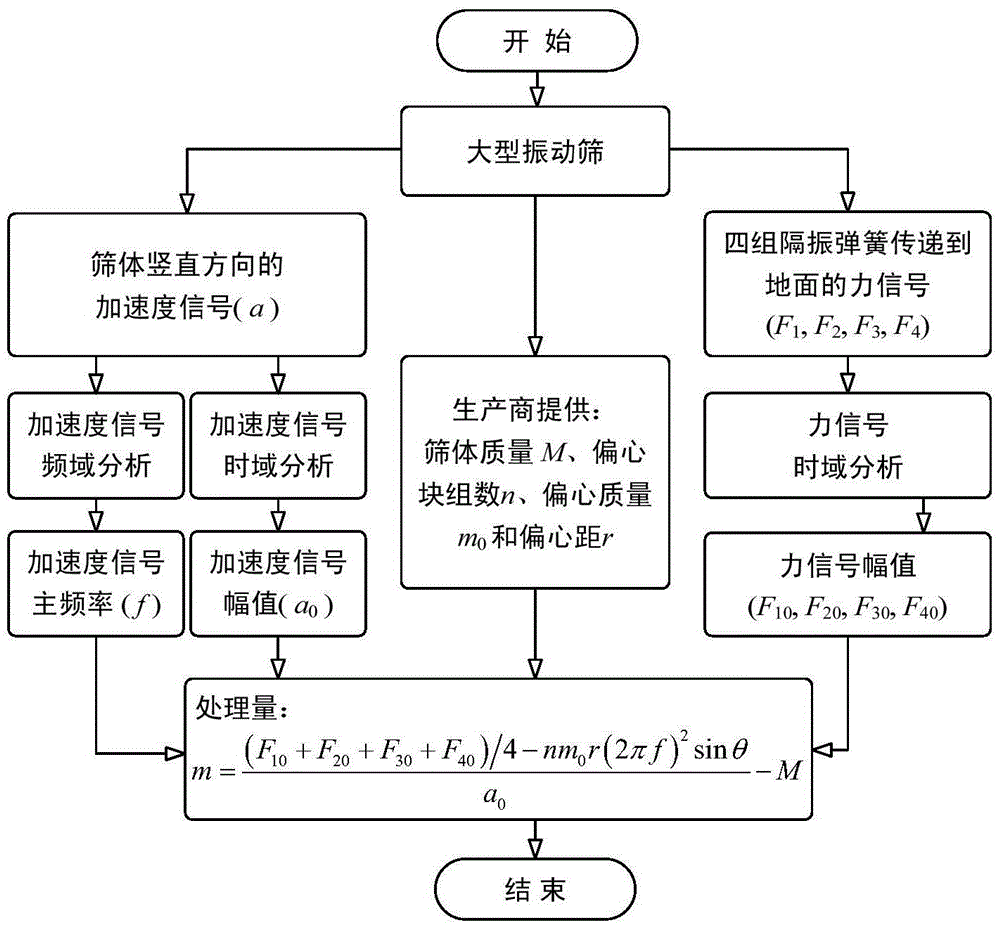

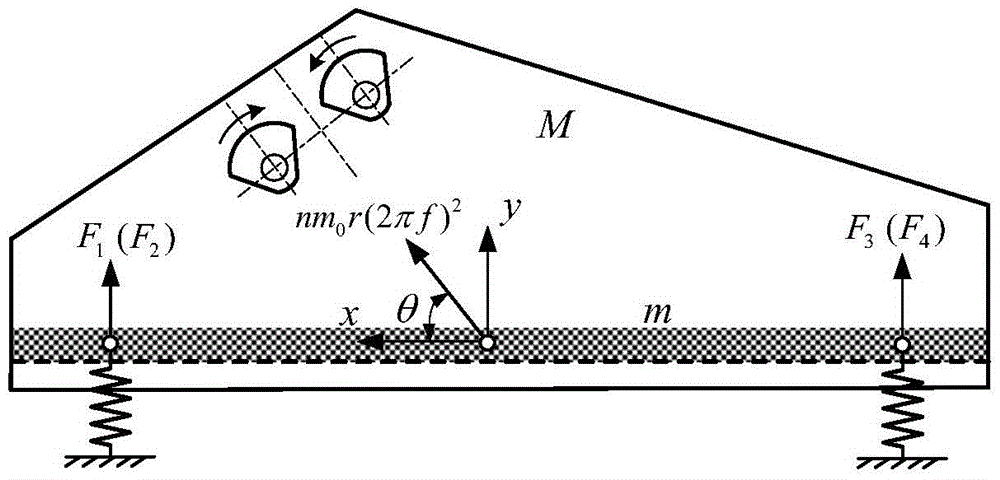

Real-time detecting system and method for vibration screen treatment amount

InactiveCN105478351ASolve the problem of inaccurate processing volume estimationReduce the impactSievingScreeningTime domainProduction line

The invention discloses a real-time detecting system for the vibration screen treatment amount. An acceleration sensor is used for detecting acceleration signals in the middle of a screen body in the vertical direction in real time, force sensors are used for detecting force signals of a vibration screen in the vertical direction in real time, and a signal collecting card collects the acceleration signals and the force signals in real time and uploads the acceleration signals and the force signals to a computer for treatment. The invention further discloses a real-time detecting method for the vibration screen treatment amount. The method comprises the steps that firstly, acceleration time domain signals and force time domain signals are detected in real time; secondly, the time domain analysis is carried out on the acceleration time domain signals and the force time domain signals, and corresponding amplitudes are obtained; thirdly, the Fourier transform is carried out on the acceleration time domain signals, and work frequency is obtained; fourthly, a stress model of the vibration screen in the working process is analyzed; and fifthly, the real-time treatment amount of the vibration screen is worked out. The treatment amount of the vibration screen can be accurately detected in real time, and the real-time detecting system and method have the advantages of being high in automation degree, economical efficiency and precision and can be used for guiding the technology parameter optimization or adjustment of a coal preparation plant production line.

Owner:HOHAI UNIV CHANGZHOU +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com