Apparatus and method for dewatering slime through competitive absorption

A dehydration device, a competitive technology, applied in the field of coal slime dehydration device, can solve the problems that affect the economic and social benefits of thermal coal preparation plants, waste of coal resources, cultivated land and water resources, and difficulty in transportation by vehicles or belts. To achieve a wide range of practicability, eliminate potential safety hazards, good dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

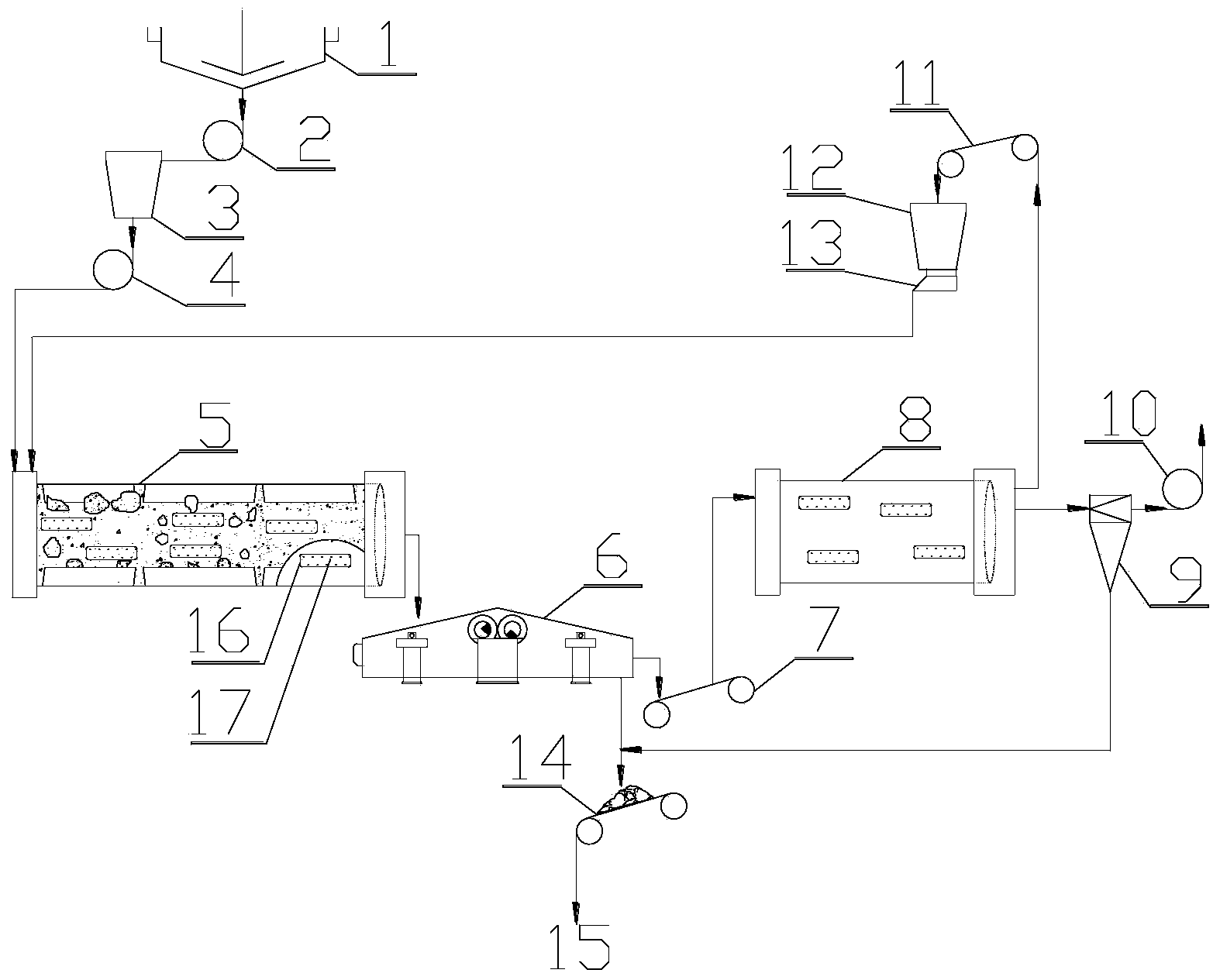

[0014] Such as figure 1 Shown, the coal slime dewatering device of competitive adsorption of the present invention mainly consists of coal slime thickener 1, the first slurry pump 2, buffer barrel 3, the second slurry pump 4, drum mixer 5, Vibrating screen 6, first belt conveyor 7, dryer 8, cyclone dust collector 9, induced draft fan 10, second belt conveyor 11, buffer bin 12, feeder 13, third belt conveyor 14, dehydrated coal slime The product 15 constitutes; the output end of the described coal slime thickener 1 is connected with the input port of the first slurry pump 2, the output end of the first slurry pump 2 is connected with the input port of the buffer tank 3, and the output port of the buffer tank 3 The end is connected with the input port of the second slurry pump 4, and the output end of the second slurry pump 4 is connected with the input port...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com