Treatment and recovery process of slime water

A technology of coal slime water and coal slime, which is applied in the direction of centrifugal separation water/sewage treatment, flocculation/sedimentation water/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of increasing equipment and increasing costs, and achieve reduction Effect on accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

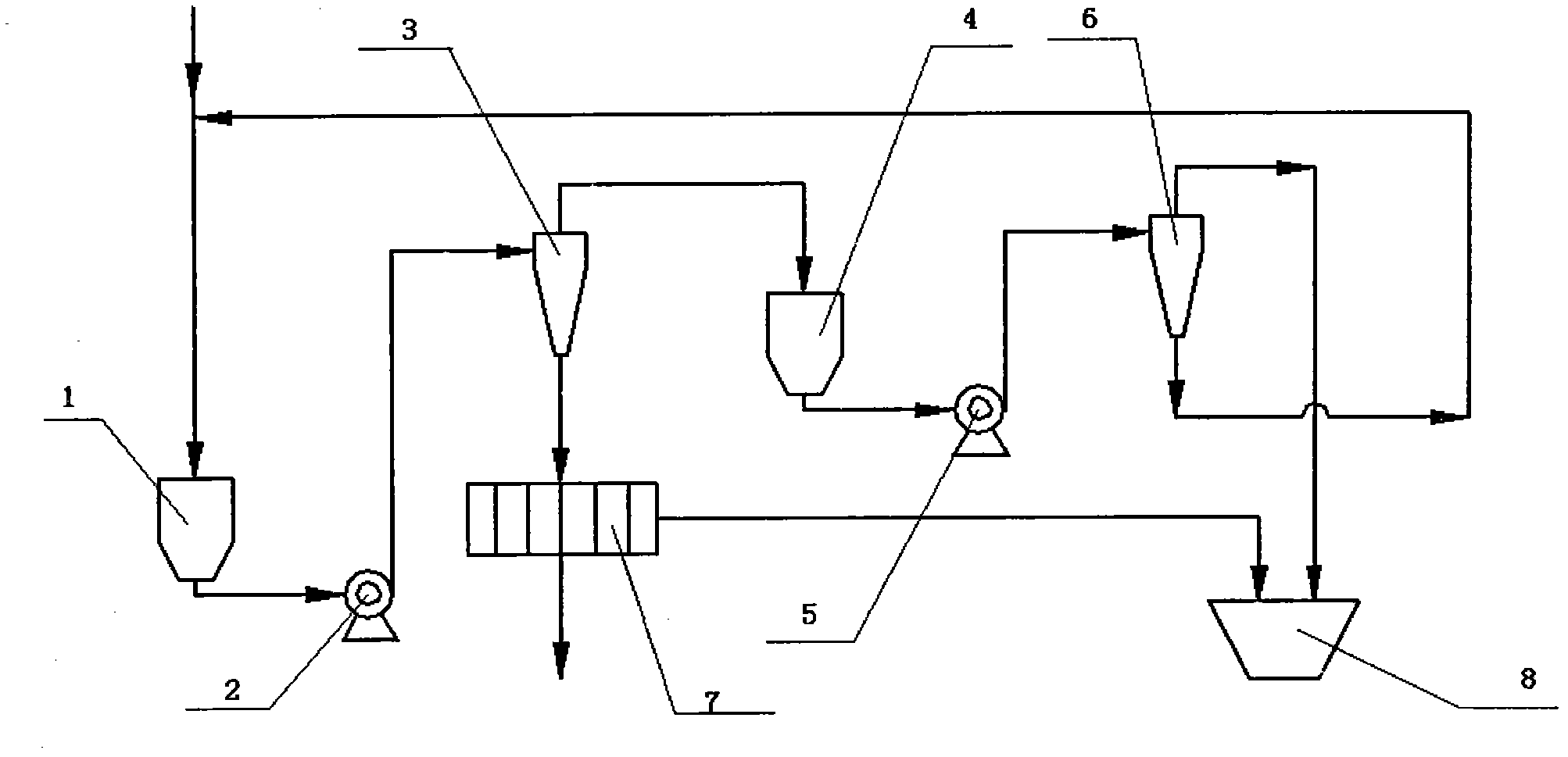

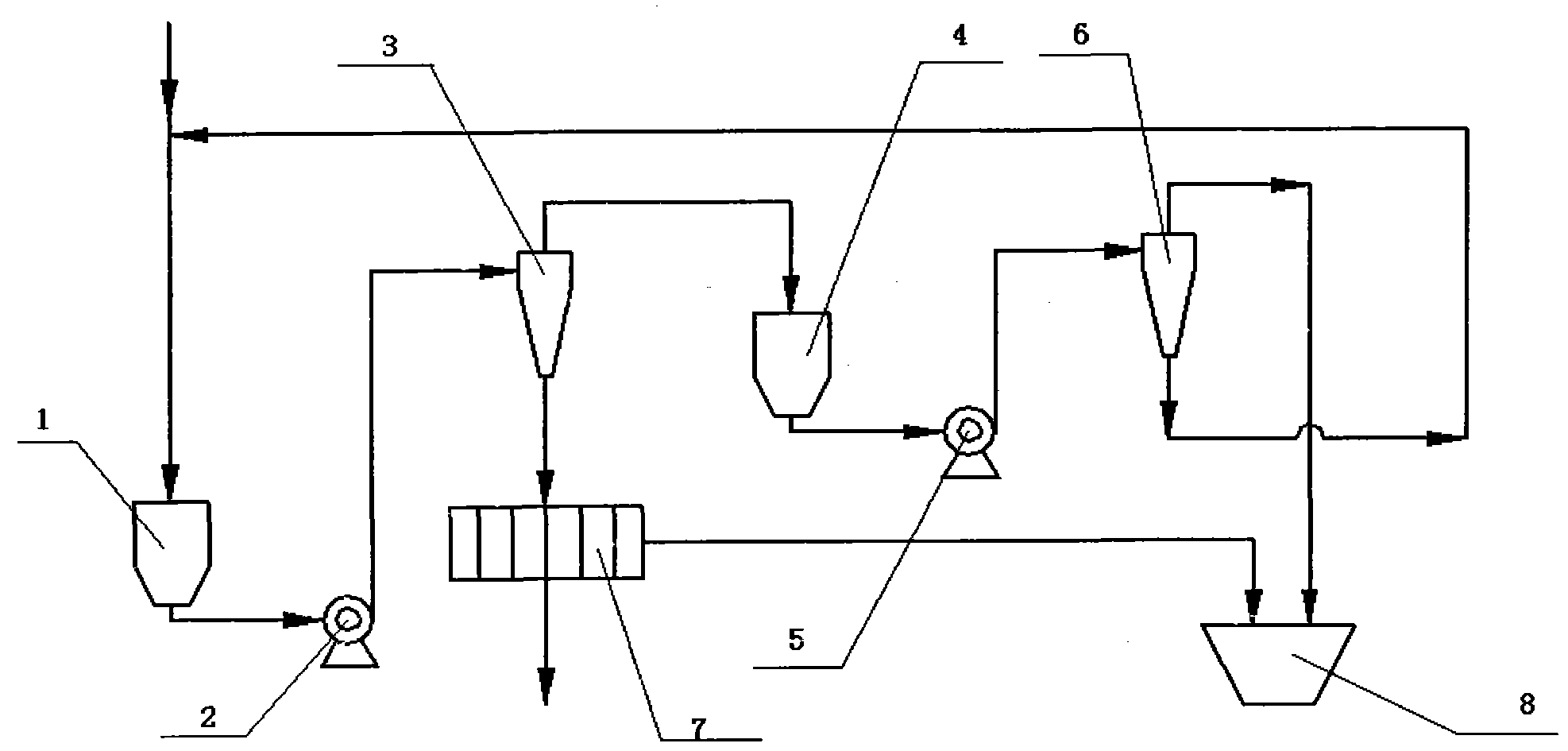

[0007] A kind of coal slime water treatment recovery process of the present invention comprises a first-level coal slime water mixing tank (1), a first-level coal water pump (2), a first-level cyclone (3), a second-level coal slime water mixing tank (4), two A first-level slime water pump (5), a second-level cyclone (6), a filter press (7), and a circulating pool (8). The coal slime water in the production process of the coal preparation plant enters the first-stage coal slime water mixing tank (1), and is pumped to the first-stage cyclone (3) by the first-stage coal slime water pump (2), and the underflow of the first-stage cyclone (3) The product enters the filter press (7) to recover the coal slime, and the overflow product of the primary cyclone (3) enters the secondary coal slime mixing tank (4), and then is beaten to the secondary cyclone by the secondary coal slime water pump (5). flow device (6), the underflow product of the secondary cyclone (6) enters the primary coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com