Flotation process method of high-ash-content fine coal slime

A process method and technology for fine coal slime, applied in flotation, solid separation and other directions, can solve the problems of lack of good flotation process, difficult flotation, and reporting, and achieve scientific optimization of flotation process methods, scientific and environmental protection, The effect of improving the sorting index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

[0048] The key point of the present invention is to change the flotation process of the prior art. Before the coal slurry pretreatment, it first deslimes in advance, and adopts the process flow of the combination of pre-desliming and coal slime selection. The whole process is developed by Guohua Technology. The equipment is operated, and the qualified high-quality coking clean coal is separated from the high-ash low-quality coal.

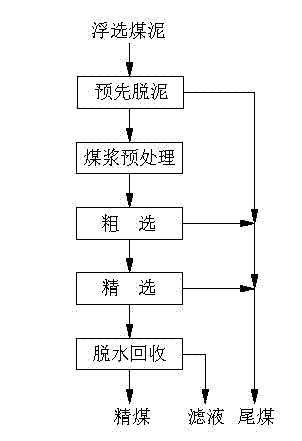

[0049] See the specific process steps figure 1

[0050] The process method of the present invention selects the flotation feed desliming tank (patent application number: 201210099180.4) invented by Tangshan Guohua Technology Co., Ltd. No.: ZL201010033384.9) for pretreatment, and then use a jet flotation machine (patent No.: ZL200810054981.2) for roughing and refining. The operation steps of this method are shown in figure 1 : It consist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com