Production system and process for co-production of industrial-grade nitric acid and electronic-grade nitric acid

A technology of production system and production process, which is applied in the direction of nitric acid, nitrogen oxides/oxo acids, etc., can solve the problems of production capacity, low yield, material loss, environmental pollution, etc., and achieve high production efficiency, low production cost, and saving The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

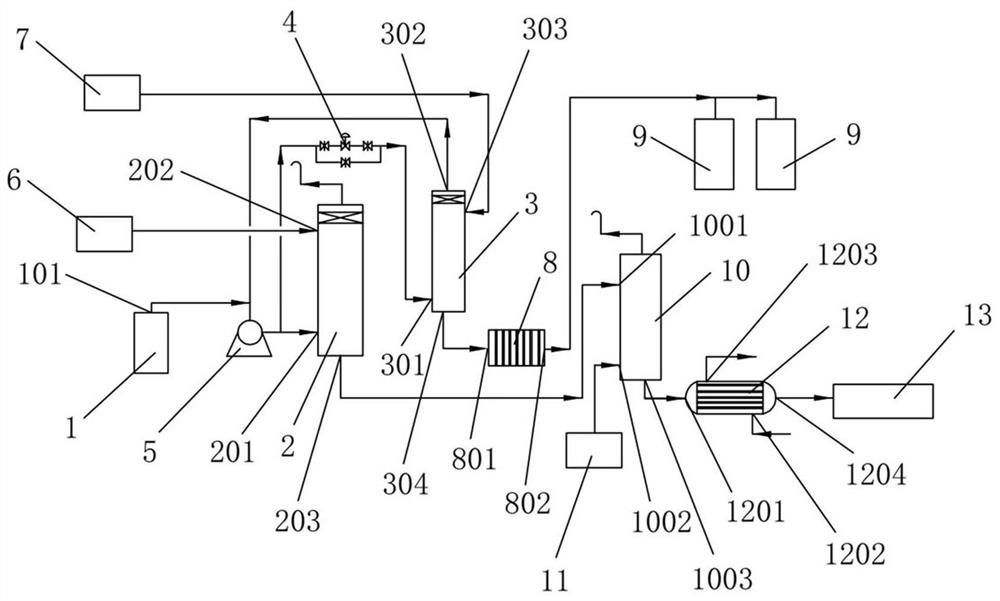

[0024] Such as figure 1 As shown, the invention discloses a production system for co-producing electronic grade nitric acid with industrial grade nitric acid, including NO X Separator 1, NO X The material outlet 101 of the separator is respectively connected to the material inlet 201 of the tail gas absorption tower and the material inlet 301 of the electronic grade nitric acid preparation tower. The tail gas absorption tower 2 is a sieve plate tower with 20-60 trays. The top of the tail gas absorption tower 2 is equipped with a high-efficiency coating device, which can reduce the water vapor content of the tower. The electronic grade nitric acid preparation tower 3 is a packed tower or a sieve plate tower, and the inner wall of the tower and the packing or sieve plate are all lined with fluoropolymers of special specifications. NO X A valve 4 is installed between the material outlet 101 of the separator and the material inlet 301 of the electronic grade nitric acid prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com