Patents

Literature

161results about How to "Avoid efflux" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

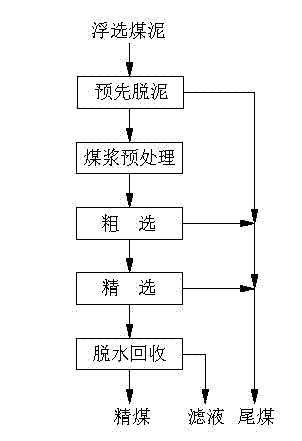

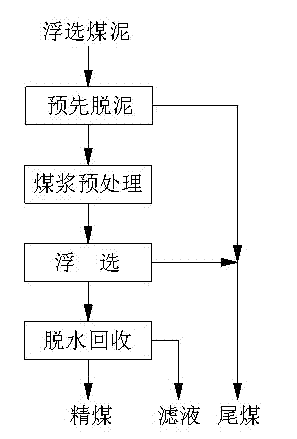

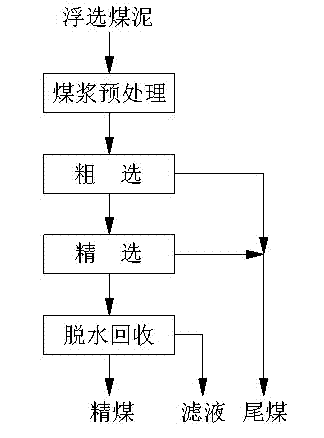

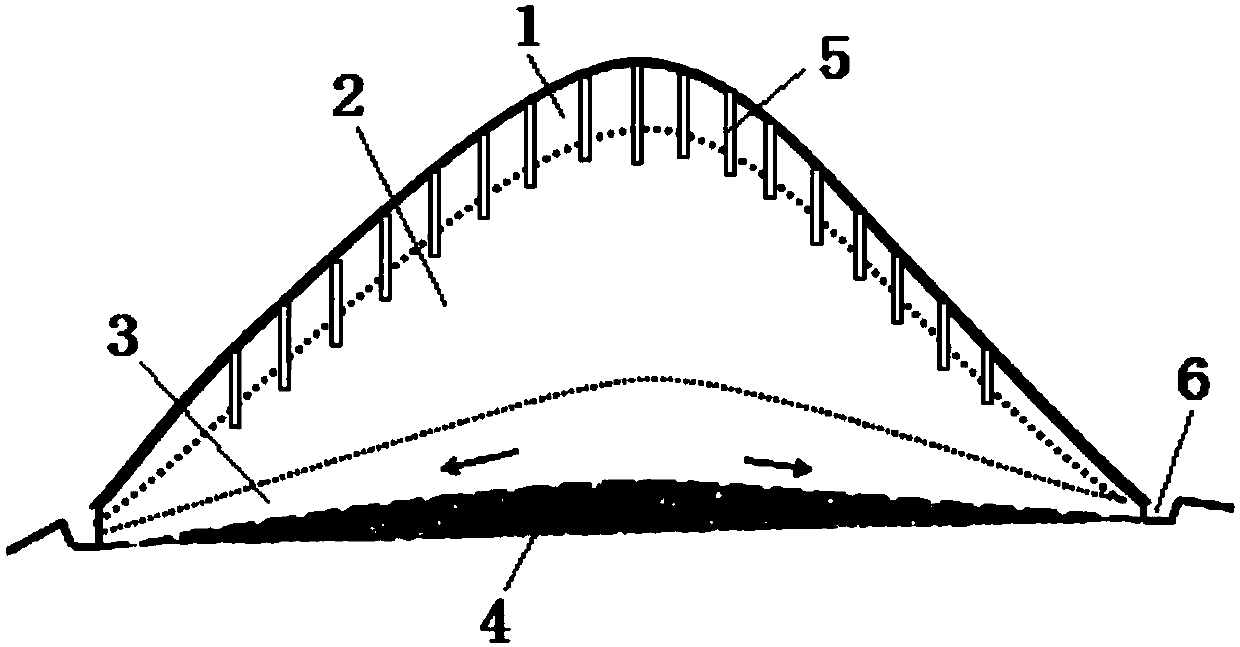

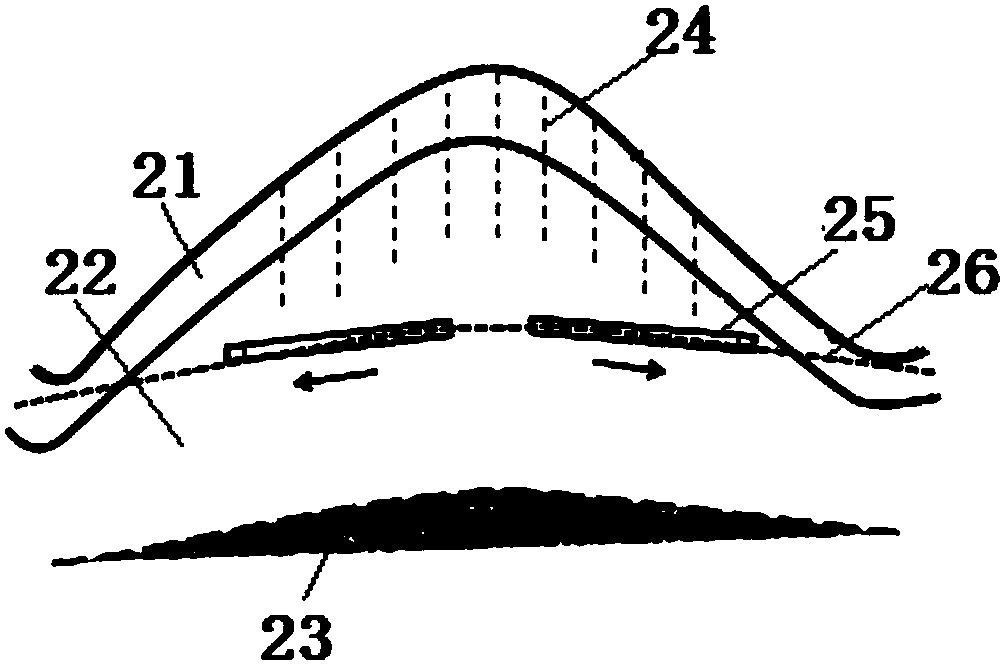

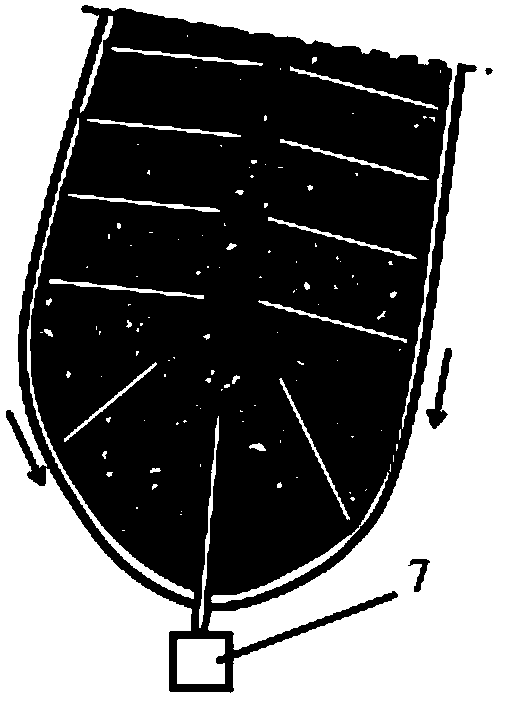

Flotation process method of high-ash-content fine coal slime

The invention relates to a flotation process method of high-ash-content fine coal slime. According to the method, pre-desliming is carried out by using a flotation coal slime flotation feeding desliming pond invented by Tangshan Guohua Technology International Engineering Co., Ltd., preprocessing is carried out by using a pulverization drop-type coal slurry preprocessor, and rough flotation and fine flotation are carried out by using an air jet flotation machine. The method comprises the following steps of: pre-desliming; preprocessing of the coal slurry; controlling of the feeding concentration of the flotation machine; and dehydration and recycling. According to the flotation process method of the high-ash-content fine coal slime, coking clean coal is sorted from inferior coal slime, the flotation process method is scientific and optimized, perfect indexes of sorting are substantially improved, the outward discharging of slime water is thoroughly avoided, the closed cycle of washing water of a coal cleaning plant is realized, and the method is scientific and environment-friendly.

Owner:唐山国华科技国际工程有限公司

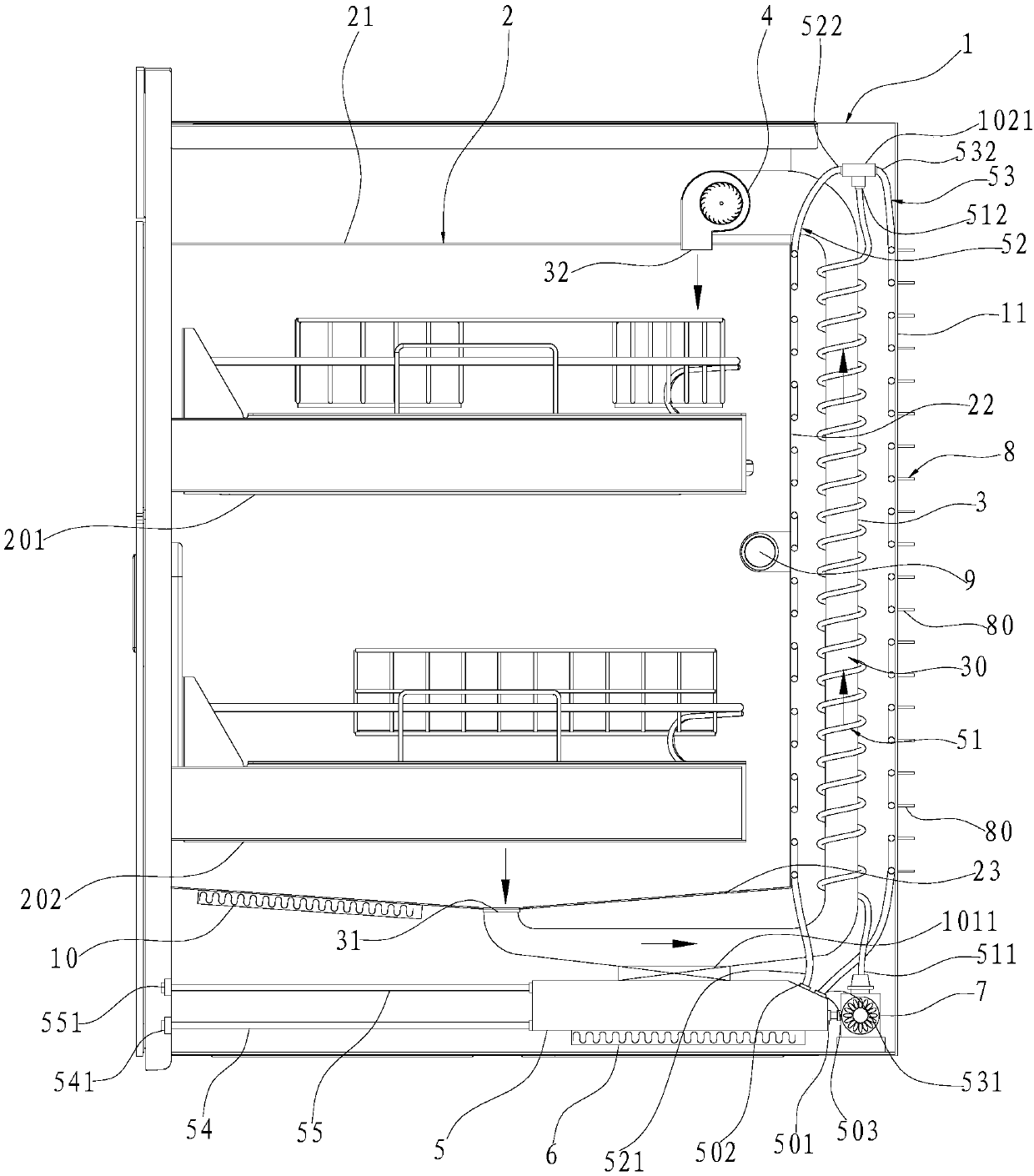

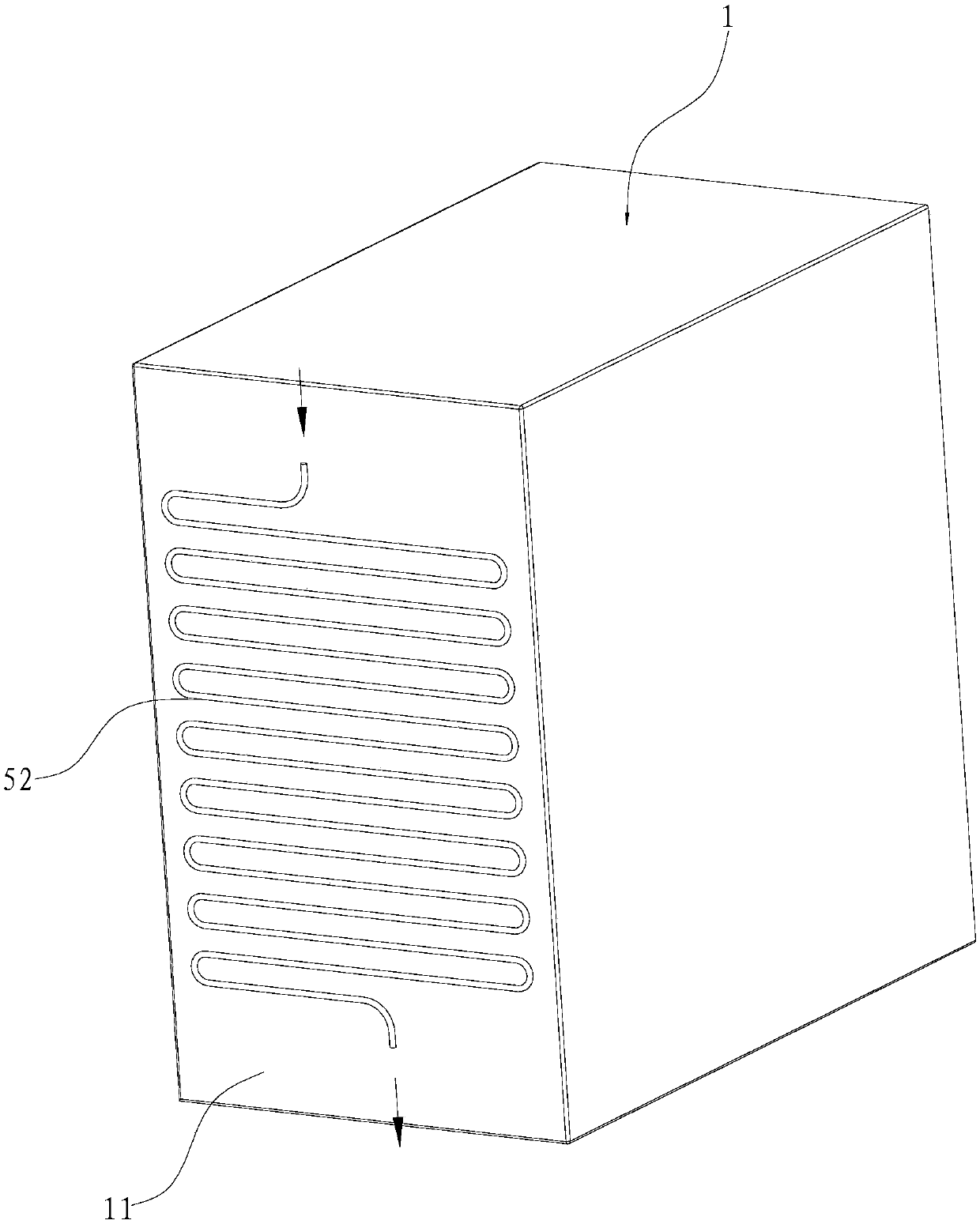

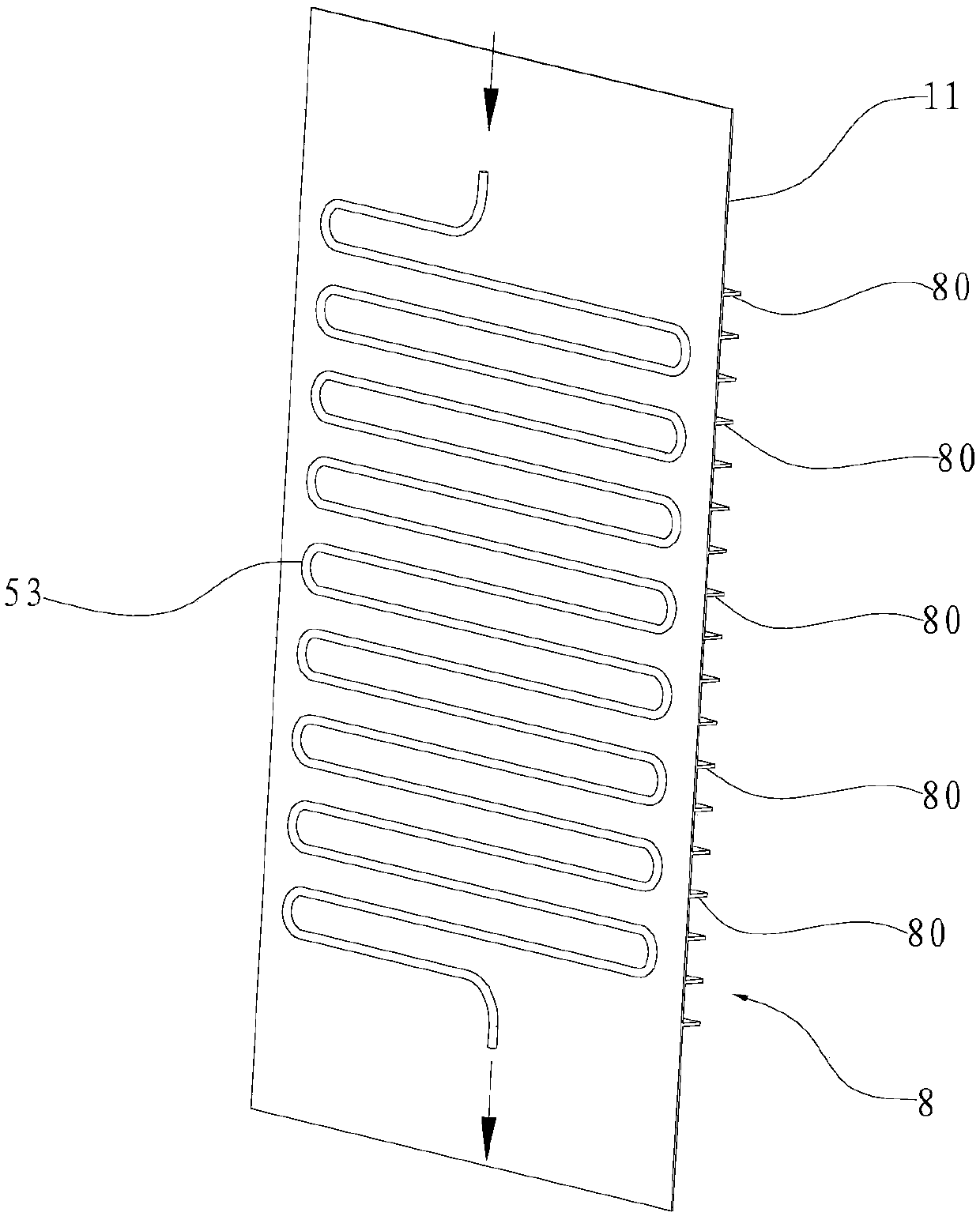

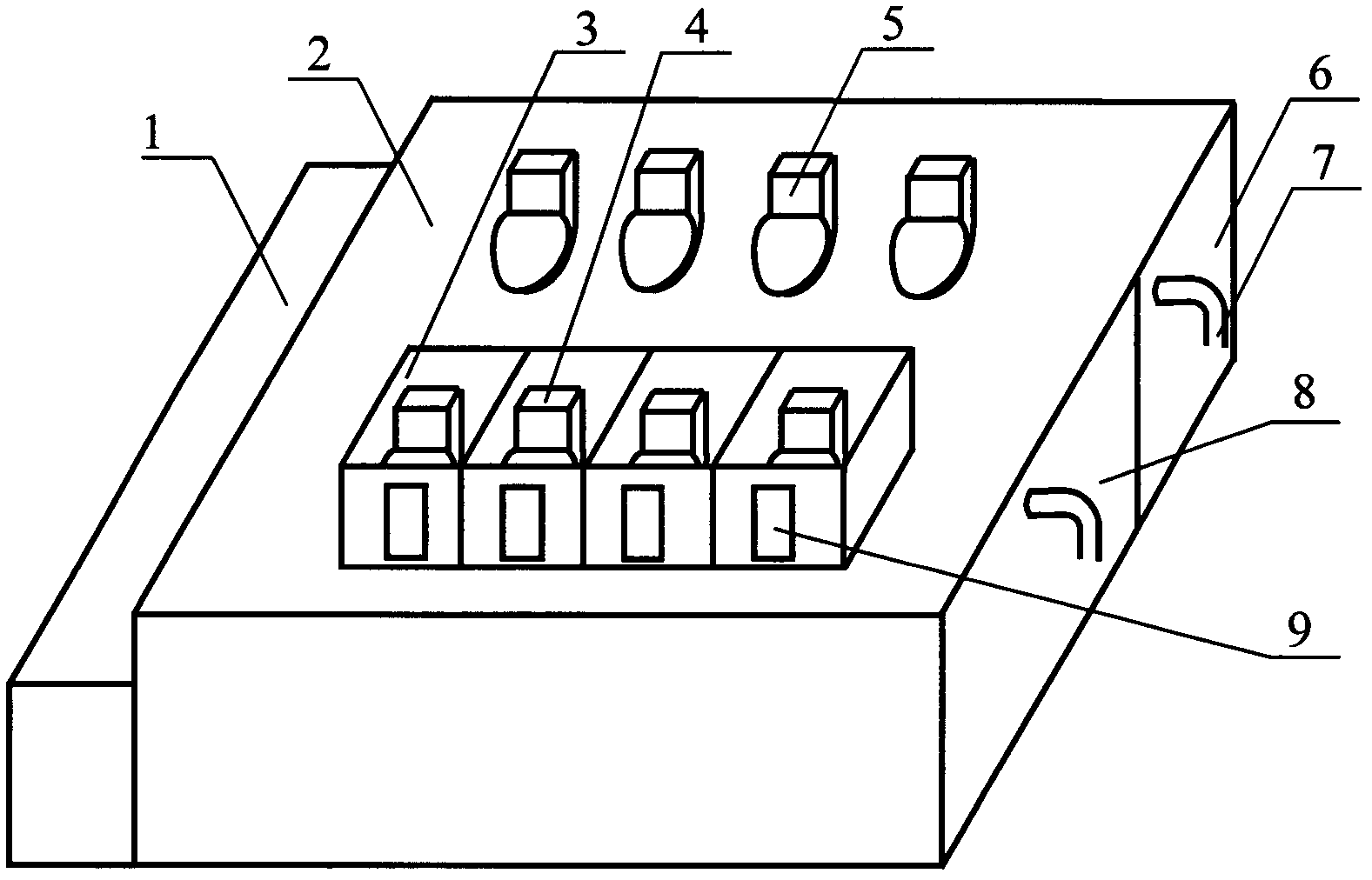

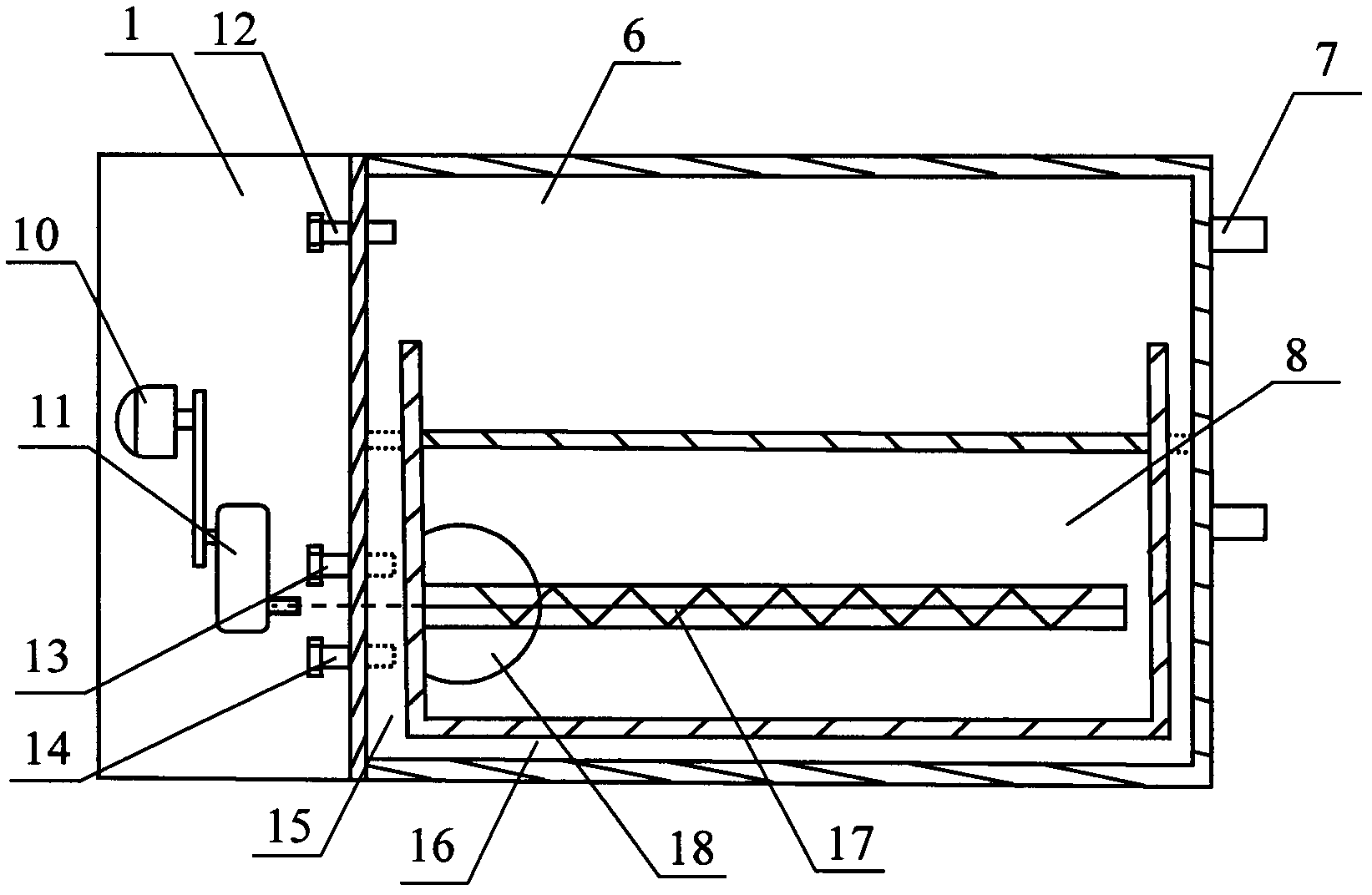

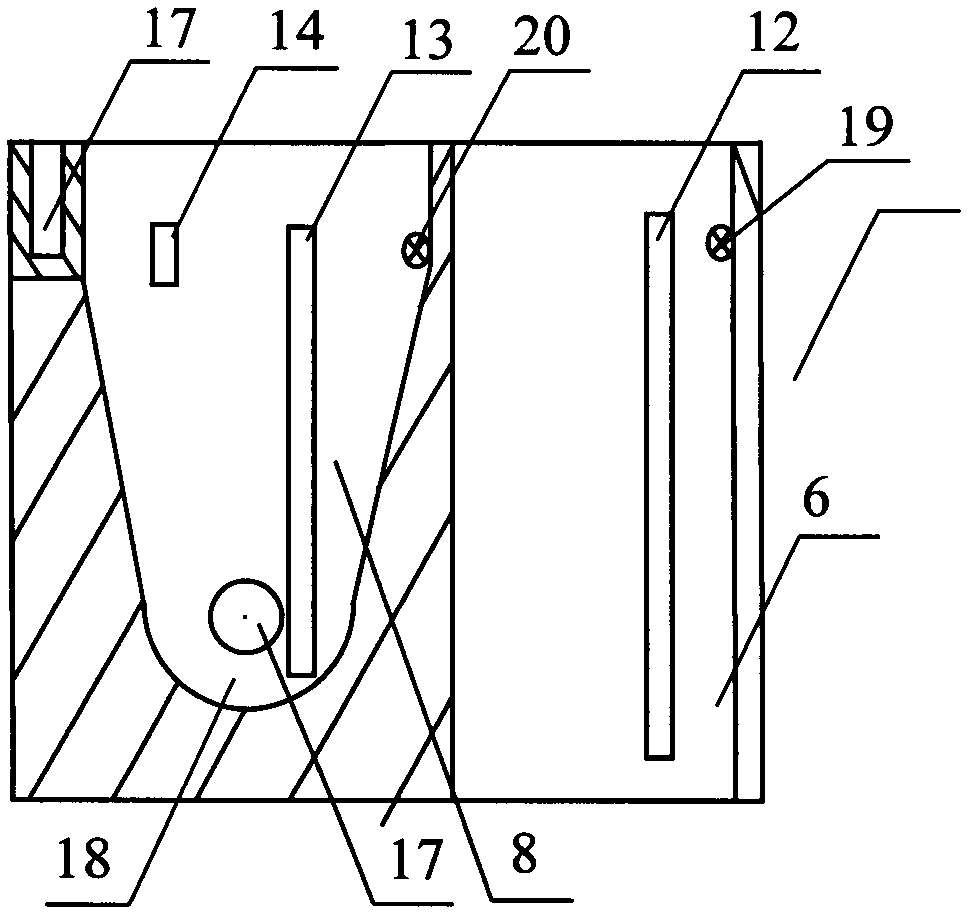

High-efficiency disinfection cabinet

ActiveCN111214671AImprove sterilization efficiencyAvoid bulkLavatory sanitoryHeatEnvironmental engineeringMildew

The invention relates to a high-efficiency disinfection cabinet. The high-efficiency disinfection cabinet comprises a tank body and a liner arranged in the tank body, wherein an air current channel isformed in the tank body, and is provided with an air inlet and an air outlet; the air inlet and the air outlet respectively communicate with the liner; a steam outlet which can emit steam is formed in the side wall of the air current channel; steam emitted from the steam outlet can enter the liner from the air inlet; and a first control valve which can be used for opening and closing the steam outlet is arranged on the steam outlet. Compared with the prior art, the high-efficiency disinfection cabinet has the advantages that the humidity of the liner can be increased in a disinfecting processto enhance the sterilizing performance, and steam can be uniformly distributed in the liner through the air current channel, so that the sterilization effect of the steam can be improved; the steam forms circulating flow in the liner through the air current channel to avoid steam escape, and the problems of conventional mildew and rot caused by steam escape can be solved; and the steam outlet isformed in the side wall of the air current channel and has a compact structure, and the problem of overlarge size of the disinfection cabinet can be avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

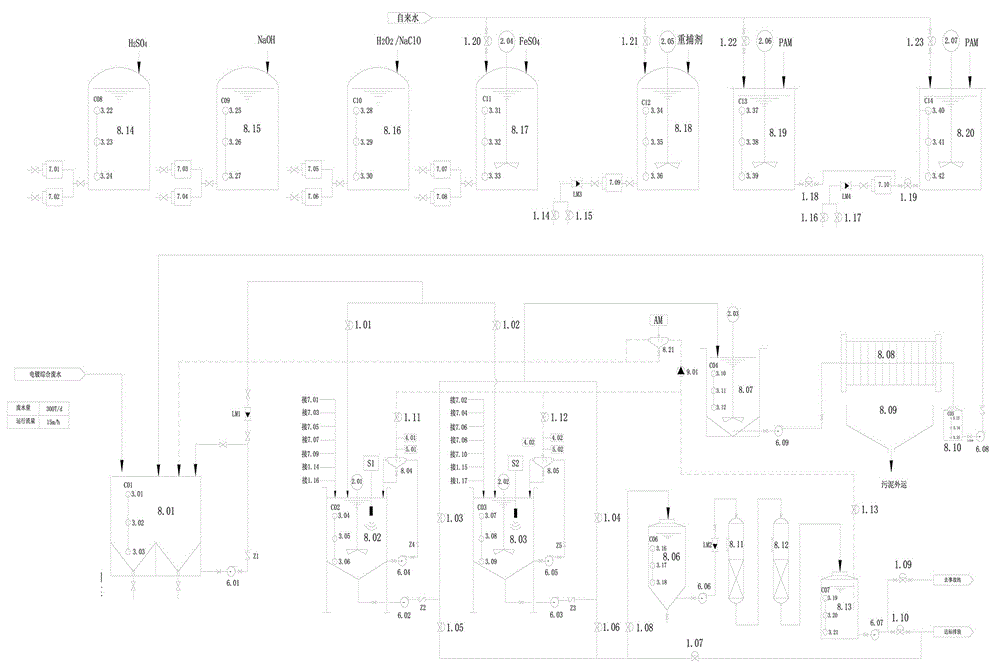

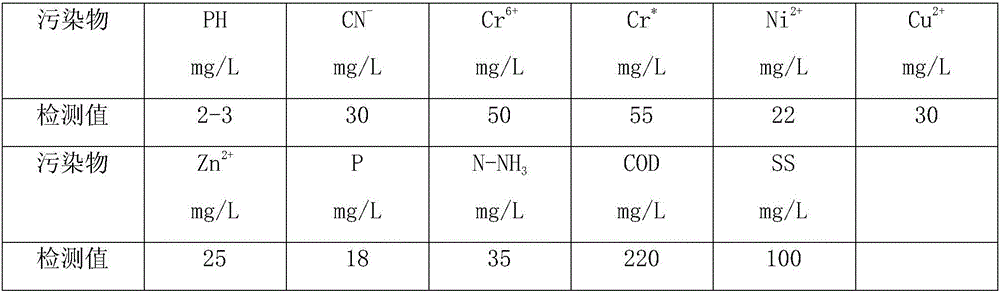

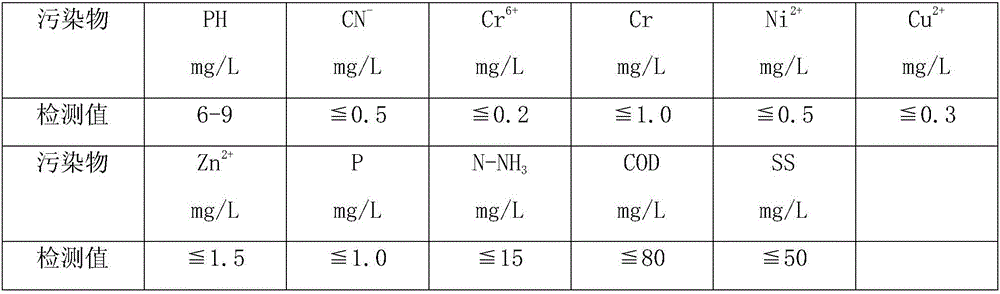

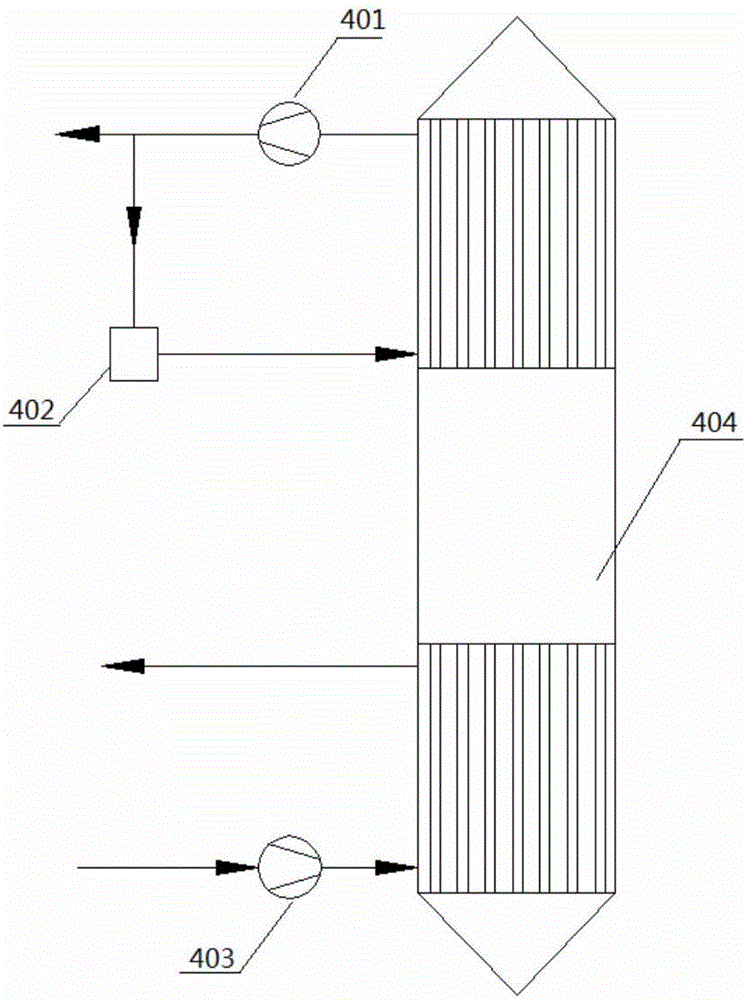

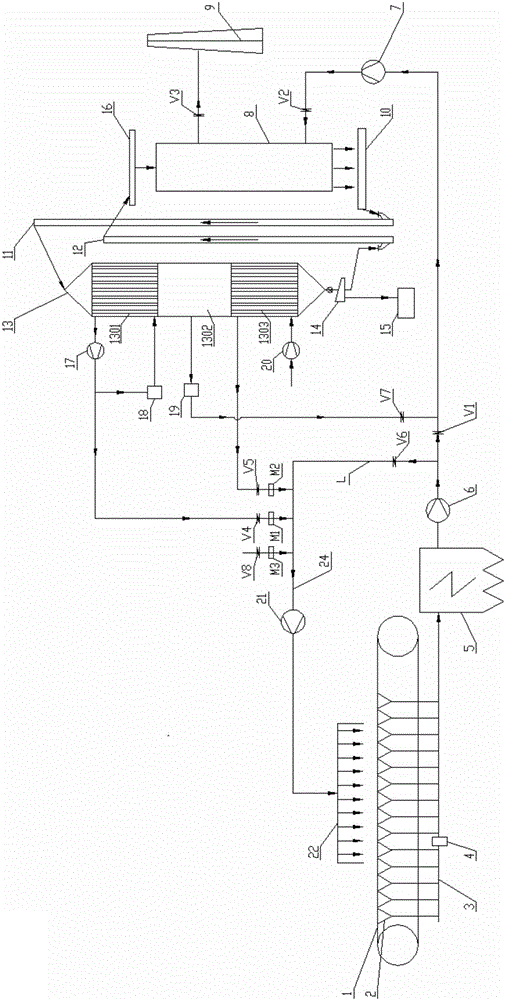

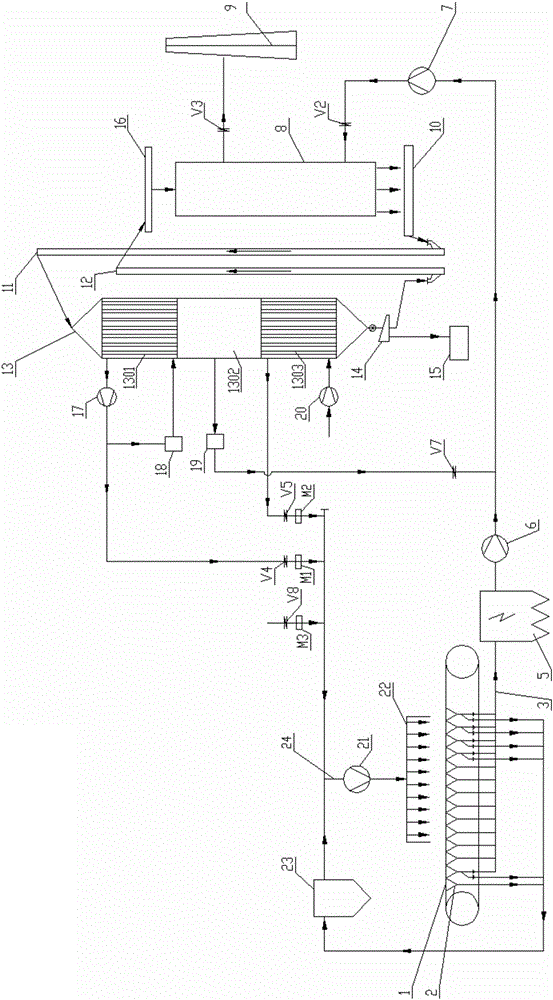

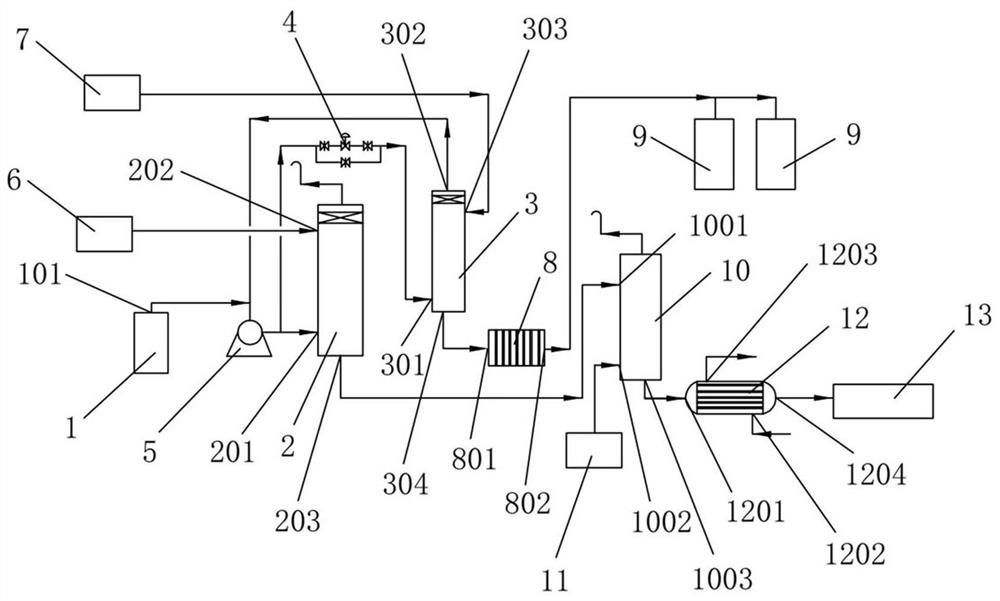

Intelligent treatment device for electroplating synthetical wastewater and control method thereof

ActiveCN106277427AEnter in time automaticallyShorten water intake timeWater treatment parameter controlWater contaminantsTreatment effectPh regulation

The invention relates to an intelligent control technology for electroplating synthetical wastewater, wherein through the steps of pH regulation of wastewater, oxidation, reduction, Cr<6+> filtering, heavy metal capture, settling of suspended solids, ion exchange and sludge treatment, the intelligent synthetical treatment of electroplating wastewater is realized, and the technology has the characteristics of high automation degree and good treatment effect. In the invention, the treatment process is finished by a sequencing bath method in a reactor, two or more reactors alternate to realize timely accurate dosing in the wastewater treatment process as well as real-time detection and control before discharge, the stability, reliability and economy of the wastewater treatment quality are guaranteed, and the wastewater treatment stably meets the requirements of the Discharge Standard for Electroplating Pollutants (GB21900-2008); furthermore, the intelligent unmanned operation can accurately control the wastewater treatment time, the drug adding amount and the wastewater treatment quality, so that the volume of the wastewater treatment equipment is reduced, and the treatment cost is lowered.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Sintering flue gas purification system and method achieving energy conservation and emission reduction

ActiveCN105698550ALow investment and operating costsReduce consumptionNitrous oxide captureGas treatmentFlueExhaust gas

The invention belongs to the technical field of sintering flue gas purification technologies, and provides a sintering flue gas purification system and method achieving energy conservation and emission reduction in order to solve the problems existing in the prior sintering flue gas purification technology. The system comprises a sintering machine, a flue gas distributor, a sintering machine bottom bellows, a sintering machine large gas duct, an electric dust remover, a sintering main exhaust fan, a first fan, a second fan, an adsorption tower, a chimney, a material conveyor and a regeneration tower. Besides, a heat exchanger is arranged in the sintering machine large gas duct of the system, or the system is further provided with a dust remover, and all the devices are connected sequentially through pipelines. The method includes the steps of utilization of flue gas heat of the sintering machine, adsorption of the adsorption tower and regeneration of active coke. According to the system and method, on the basis of effectively controlling the temperature of flue gas, fully utilizing heat-contained exhaust gas, reducing the scale of an active coke flue gas purification device, avoiding secondary pollution and realizing recycling of resources, the investment and operation expenses are lowered.

Owner:中冶北方(大连)工程技术有限公司

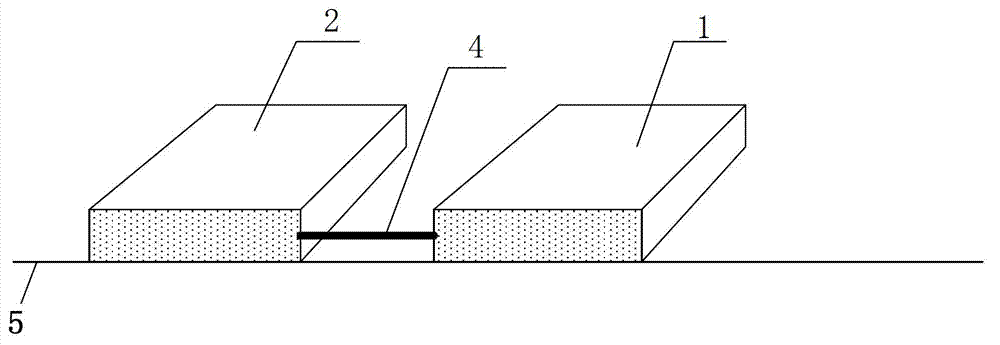

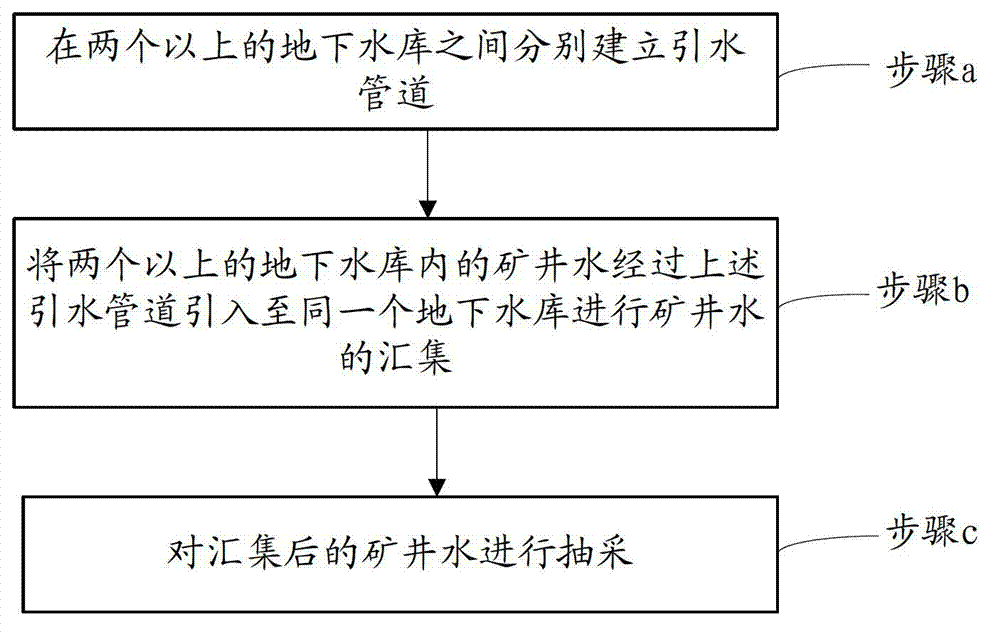

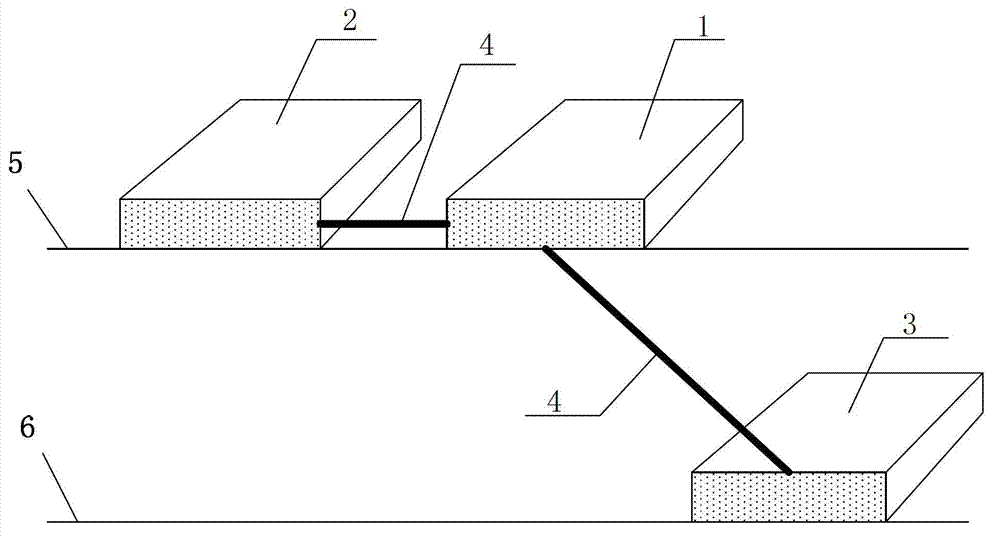

Distributed underground reservoir group and transfer method for mine water in distributed underground reservoir group

The invention discloses a distributed underground reservoir group and a transfer method for mine water in the distributed underground reservoir group. The distributed underground reservoir group comprises more than two underground reservoirs; and the underground reservoirs are respectively connected through water conduit pipelines. According to the distributed underground reservoir group and the transfer method for the mine water in the distributed underground reservoir group, which are provided by the invention, the water conduit pipelines are established among the underground reservoirs and are used for transferring, controlling and centrally draining the mine water in the underground reservoirs, and thus underground water is effectively utilized. Meanwhile, as for the underground reservoirs in different coal seams, the underground mine water is transferred during exploitation, and thus the outside drainage of the mine water during exploitation is avoided and the waste is reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +2

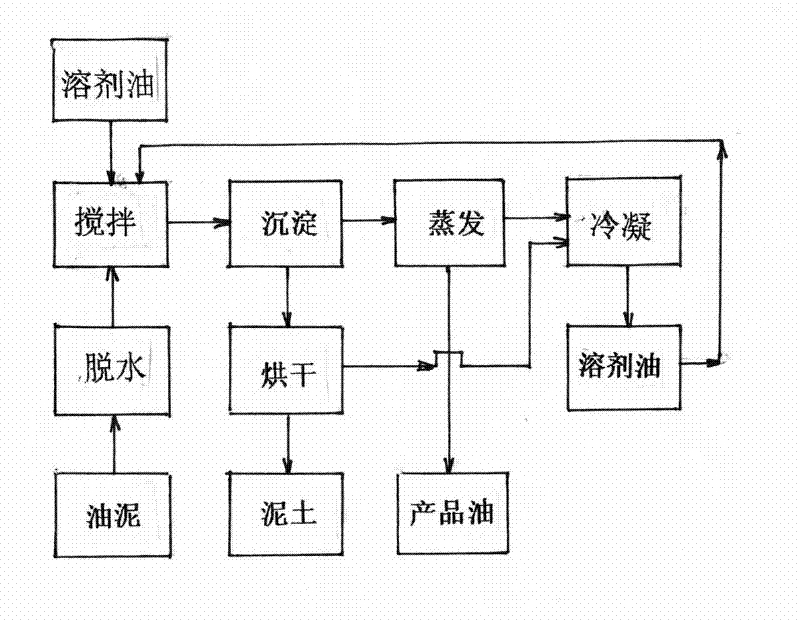

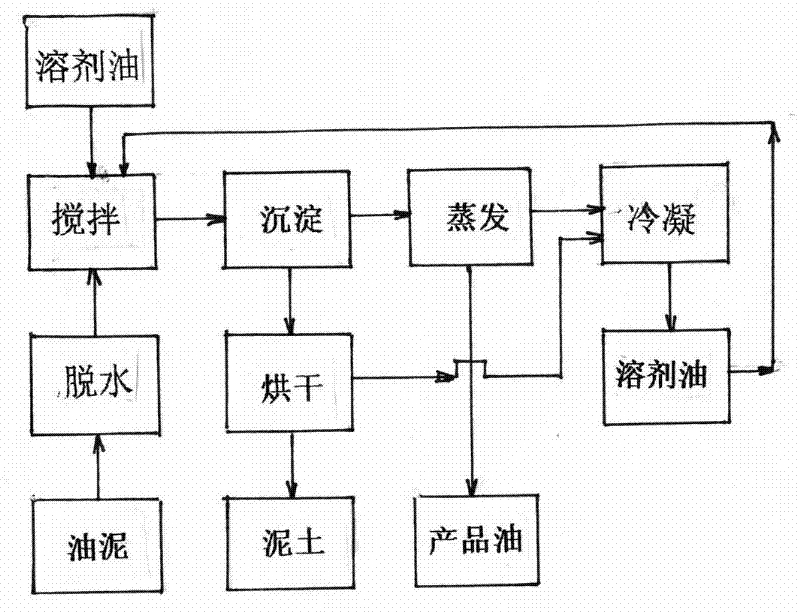

New technology for oil sludge processing

InactiveCN102381821AHigh recovery rateImprove qualityFatty oils/acids recovery from wasteSludge treatment by de-watering/drying/thickeningOil processingFiltration

The invention which belongs to the dangerous waste processing field relates to oil sludge processing and provides a new technology for the oil sludge processing. The technology is mainly characterized in that: after the oil sludge is processed with steps of dehydration, extraction, deposition, evaporation, extraction, pumping filtration, drying and the like, the content of oil in soil is 1% and accords with discharge standards, the total loss of solvent oil is about 1%, the recovery rate of product oil is more than 99%, and no waste gases and no wastewater are discharged. The technology whichhas the advantages of scientific method, mature process, simple equipment and large investment-output benefit and allows great technical problems, environmental protection problems and production safety problems which are difficult to solve for a long time in the dangerous waste processing field to be well solved deserves to be popularized and applied to broad petroleum enterprises, petroleum byproduct enterprises, and plant oil processing and oil product storage and transportation enterprises.

Owner:李廷安

Method for leakage detecting and handling of blast furnace soft water closed circulating cooling system

InactiveCN103031396AAvoid freezing and other vicious accidentsSave time at workCooling devicesExpansion tankTerra firma

The invention provides a method for the leakage detecting and handling of a blast furnace soft water closed circulating cooling system. Through the liquid level difference variation of an expansion tank of a soft water system, the coal gas pressure direction in the expansion tank or a degassing tank can be detected, the phenomenon of bubbles or white turbidity is generated in water flow in a flap flowmeter on a cooling wall of the closed circulating cooling system; during the process that the pH value is continuously and slowly reduced, seepages of water stain and mirabilite can be judged to be generated on an eye plate of a blast furnace shell, so that the judgment shows that the cooling wall or an inner wall of a pipeline is damaged; the flap flowmeter is then utilized, the damage point location of a cooling wall water pipe is determined, and longitudinal treatment is carried out; and a pressure gauge installation pressing leakage detection method is utilized to determine the damage point location of the cooling water pipe, and the lateral treatment is carried out. By the method, the working efficiency is increased, the labor intensity is reduced, leakage points can be found out and treated in real time, and solid foundation is laid for the safety, success production and stable production of a blast furnace.

Owner:BAOSTEEL GROUP XINJIANG BAYI IRON & STEEL

Environment-friendly public toilet without consuming water, having no odor and separating excrement from urine

InactiveCN102160767ALow costAvoid spreadingBathroom accessoriesAgainst vector-borne diseasesAdditive ingredientLatrine

The invention discloses an environment-friendly public toilet without consuming water, having no odor and separating excrement from urine, and the public toilet provided by the invention is used for solving the problems of the existing public toilet that a great amount of water is consumed, and the excrement and urine are mixed. The environment-friendly public toilet is characterized in that a urinal and a closet pan are arranged on a foundation surface, the bottom surface of the closet pan and the foundation surface are in the same horizontal plane, an excrement pool and a urine pool are arranged below the foundation surface, and the closet pan comprises a urine hole, an excrement hole, an inclined plate, a fan, an air absorbing duct, an air exhausting duct and the like. The environment-friendly public toilet ensures that the consumption of a great amount of water for flushing is avoided, is good in sealing property, and can thoroughly eliminate the discharge of odor by virtue of the running of the fan; and the closet pan can be used for realizing the separation of excrement and urine, so as to prevent the excrement from containing excessive water, be beneficial to subsequent treatment on the excrement and provide organic ingredients for agricultural production. In addition, the environment-friendly public toilet can be used for greatly improving the toile grade and social environment quality, and providing a good toilet environment for people.

Owner:黄思华

Ion-type rare-earth ore ammonium-free environment-friendly exploitation technique

InactiveCN108034842ANo pollution in the processPollution meetsProcess efficiency improvementEnvironmental resistanceIon exchange

The invention discloses an ion-type rare-earth ore ammonium-free environment-friendly exploitation technique. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique comprises the following steps that an ammonium-free ore leaching agent with a certain concentration is injected through liquid injecting holes distributed in a stope to be subjected to an ion exchanging reaction with rare-earth ores so as to obtain mother liquid enriched in rare-earth positive ions; the mother liquid seeps and gathers into liquid collecting engineering such as matching of ore-layer natural water partition bottom plates or artificial liquid collecting roadways with liquid collecting flow guiding holes; and then the mother liquid is conveyed to a hydrometallurgy workshop through a main conveying pipeline, ammonium-free agents are used for impurity removal and precipitation to obtain rare-earth carbonate, and supernatant liquid is circulated back to a liquid preparation pool andthen subjected to pH valve adjustment and agent adding, and returns to the stope to serve as a new ammonium-free ore leaching agent. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique has the advantages that ammonium is avoided in the overall process, and environmental friendliness is achieved on soil and water bodies; production waste water is circularly and comprehensively utilized, and harmful waste discharging is avoided; and the leaching rate, liquid collecting rate and precipitating rate of the rare-earth ions are high, and the resource mining comprehensive recovery rate is increased.

Owner:五矿勘查开发有限公司

Recovering treatment method of electrolytic manganese metal anode slime

ActiveCN103436914ATake advantage ofAvoid effluxPhotography auxillary processesProcess efficiency improvementOxalateElectrolysis

The invention discloses a recovering treatment method of electrolytic manganese metal anode slime, and relates to a treatment method of electrolytic manganese metal anode slime in processing manganese metal with a wet process. The recovering treatment method is characterized in that during the recovering treatment, oxalic acid is used as a reducing agent, concentrated sulfuric acid and oxalic acid are used for reducing and leaching manganese in the anode slime, filter pressing is performed, and then leachate is neutralized, oxidized and sulfidized to obtain a manganese electrolyte. According to the recovering treatment method of the electrolytic manganese metal anode slime, oxalic acid is used as a reducing agent and concentrated sulfuric acid and oxalic acid are used for reducing and leaching the manganese in the anode slime, so that the anode slime is utilized fully and prevented from being discharged outside, the aim of recycling the anode slime is achieved, the pollution caused to environment is reduced, the use amount of ore is lowered and the production cost is saved.

Owner:NINGXIA TIANYUAN MANGANESE LIMITED

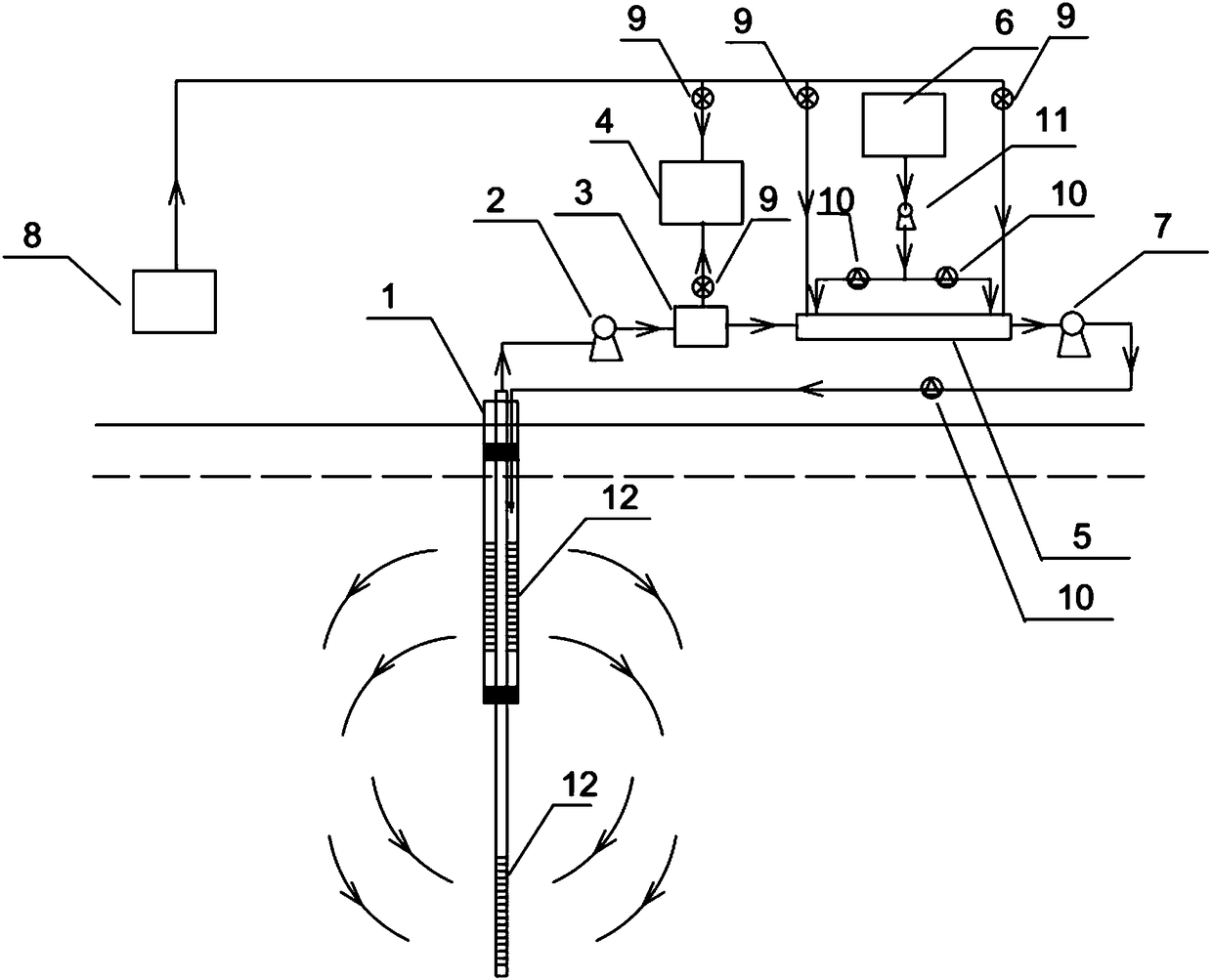

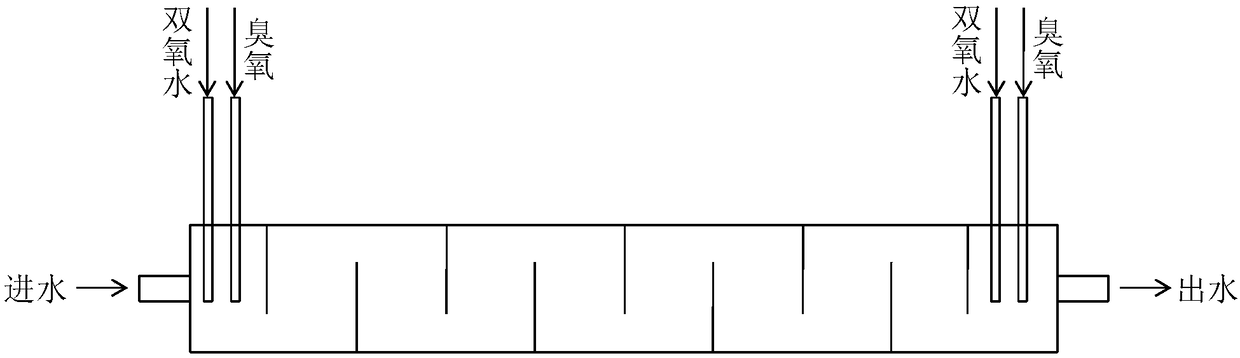

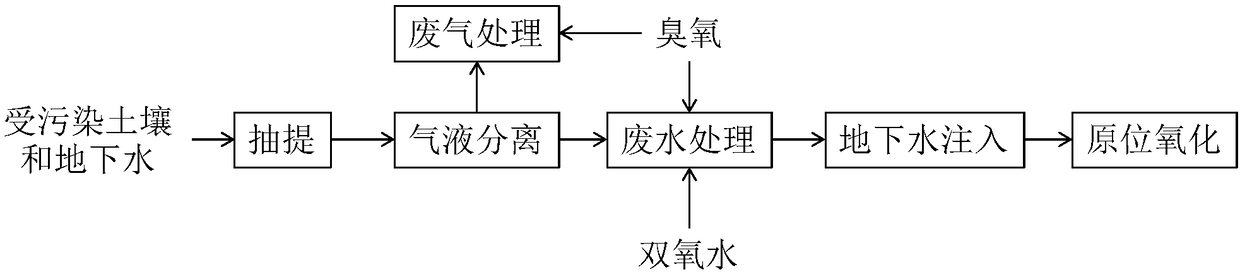

In-situ soil and underground water integrated remediation system and remediation method

PendingCN108435765AEasy to operateImprove repair effectContaminated soil reclamationUnderwaterTreated water

The invention relates to the field of environmental protection, in particular to an in-situ soil and underground water integrated remediation system and remediation method. The system comprises an extraction-injection system, an ozone generation system, a wastewater treatment system, a waste gas treatment system and a hydrogen peroxide configuration system. The extraction-injection system, the ozone generation system, the wastewater treatment system, the waste gas treatment system and the hydrogen peroxide configuration system are connected through corresponding pipelines and are equipped withcorresponding liquid flow meters and gas flow meters. According to the method, through combination with the advantages of extraction-treatment, extraction-injection integration, an underwater circulating well, gas-liquid pollutant treatment, ozone-hydrogen peroxide combined oxidation and in-situ oxidation, polluted underground water is extracted and then is subjected to oxidation treatment through ozone and hydrogen peroxide; and then the treated water containing the ozone and hydrogen peroxide is injected underground to conduct in-situ oxidation remediation. By means of the method, organic polluted soil and underwater can be restored simultaneously. Moreover, the remediation range is wide, the remediation period is short, the cost is low, and operation is convenient.

Owner:内蒙古睿达鑫科技有限责任公司

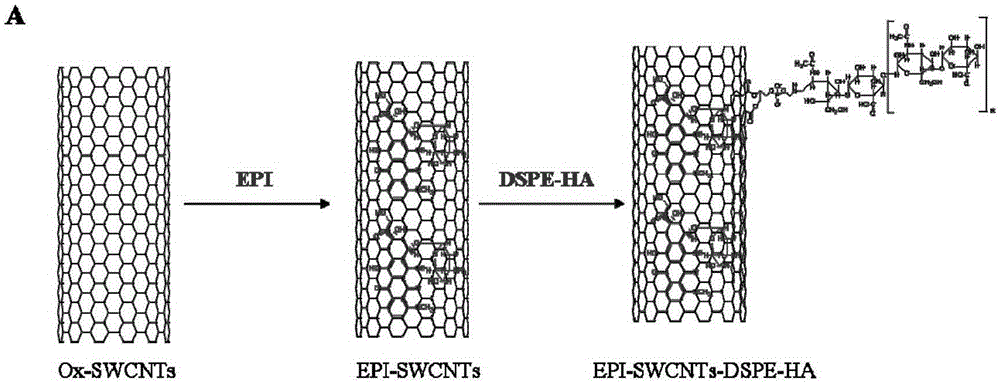

Targeting carbon nanotube drug delivery system, and preparation method and applications thereof

ActiveCN106552268AIncrease intakeLong retention timeOrganic active ingredientsPharmaceutical non-active ingredientsSolubilityExocytosis

The invention provides a targeting carbon nanotube drug delivery system, and a preparation method and applications thereof. The drug delivery system comprises a conjugate and a drug carrying carbon nanotube that is combined with the conjugate in a non-covalent mode; wherein the conjugate comprises a modifying material that can enhance the water solubility and biocompatibility of the drug delivery system and a targeting molecule that is combined with the modifying material in a covalent mode; and the drug carrying carbon nanotube is composed of carbon nanotubes and drug molecules that adsorb on the surface of the carbon nanotubes. One step modification technology is adopted, the problems on purification and yield caused by multi-step modification are avoided; at the same time, the carbon nanotube and drug delivery system are enable to have water solubility, biocompatibility, and multi-functions; the exocytosis of drug resistant tumor cells on drug molecules is effectively overcome, a novel strategy is provided for overcoming multi-drug resistance of tumor cells, and thus the provided drug delivery system has a wide application prospect in the field of drug resistant tumor treatment.

Owner:INST OF PHARMACOLOGY & TOXICOLOGY ACAD OF MILITARY MEDICAL SCI P L A

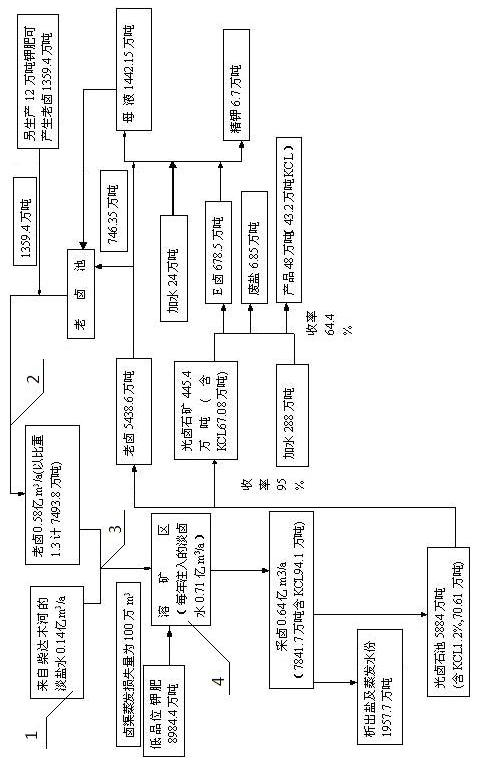

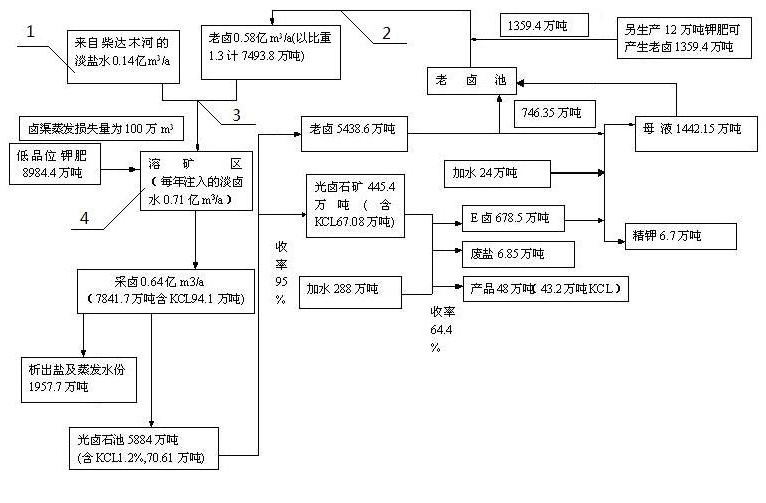

Low-grade solid potassium chloride ore solid-to-liquid method

InactiveCN102583449AHigh reuse rateExtended service lifeAlkali metal chloridesPotassium fertilisersChloride potassiumEnvironmental chemistry

The invention relates to the technical field of salt chemical industry, in particular to a low-grade solid potassium chloride ore solid-to-liquid method for producing low-grade solid potassium chloride ores after dissolving old brine and fresh water according to a certain ratio by utilizing a surface ore dissolving method. The method disclosed by the invention comprises the following steps: 1, a step of introducing the fresh water; 2, a step of introducing the old brine; 3, a step of blending the brine; and 4, a step of conveying the brine to prepare into a potash fertilizer. According to the invention, the flow direction of water in original rivers and lakes to the east of the Qarhan Salt Lake Railway is changed to dissolve the low-grade potassium ores in a mining area, which cannot be directly mined and utilized. Therefore, not only is the repeated utilization rate of the water improved and the service life of a mine is prolonged by dissolving the ores, but also the brine obtained after ore dissolving is returned to the salt lake mining area, the old brine generated after producing the potash fertilizer by mining is all discharged into the ore dissolving engineering to be recycled, the reuse rate of the river is greatly improved, a closed cycle of water resources is formed, the water is furthest saved and the drainage of wastewater is avoided, so that the natural ecological environment of the water resources and the mine resources in the salt lake mining area is protected.

Owner:格尔木藏格钾肥有限公司

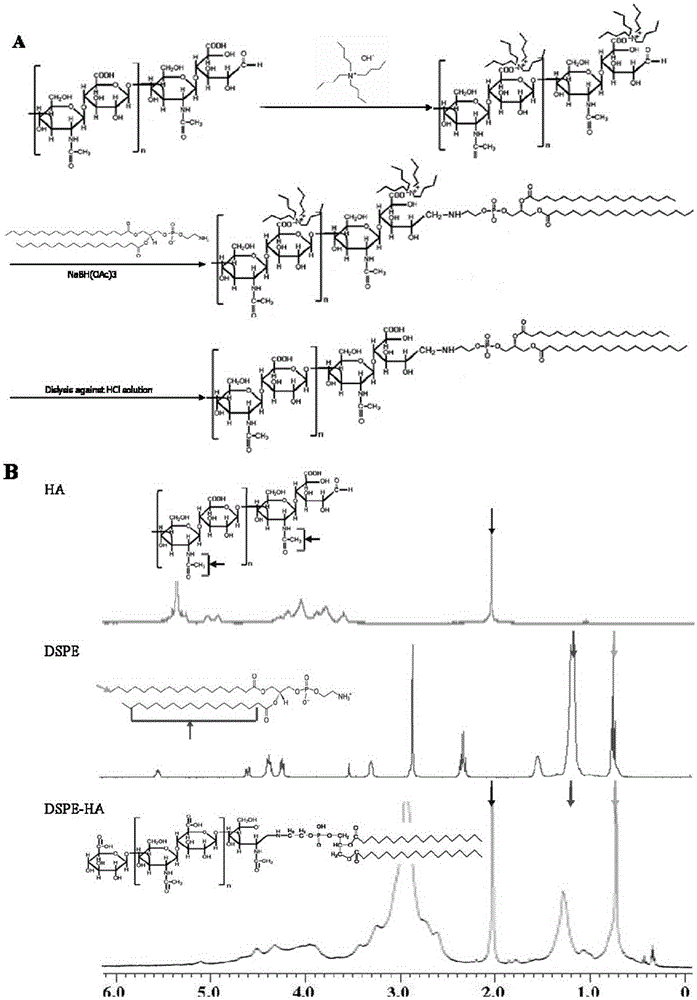

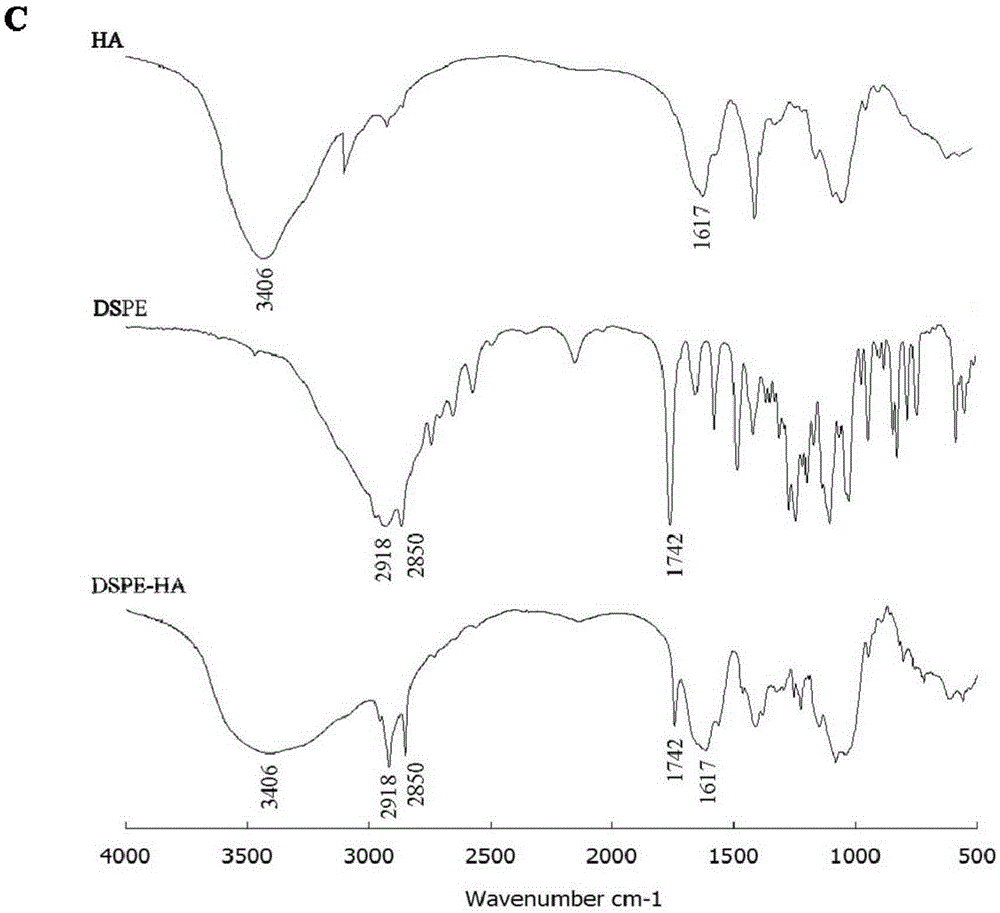

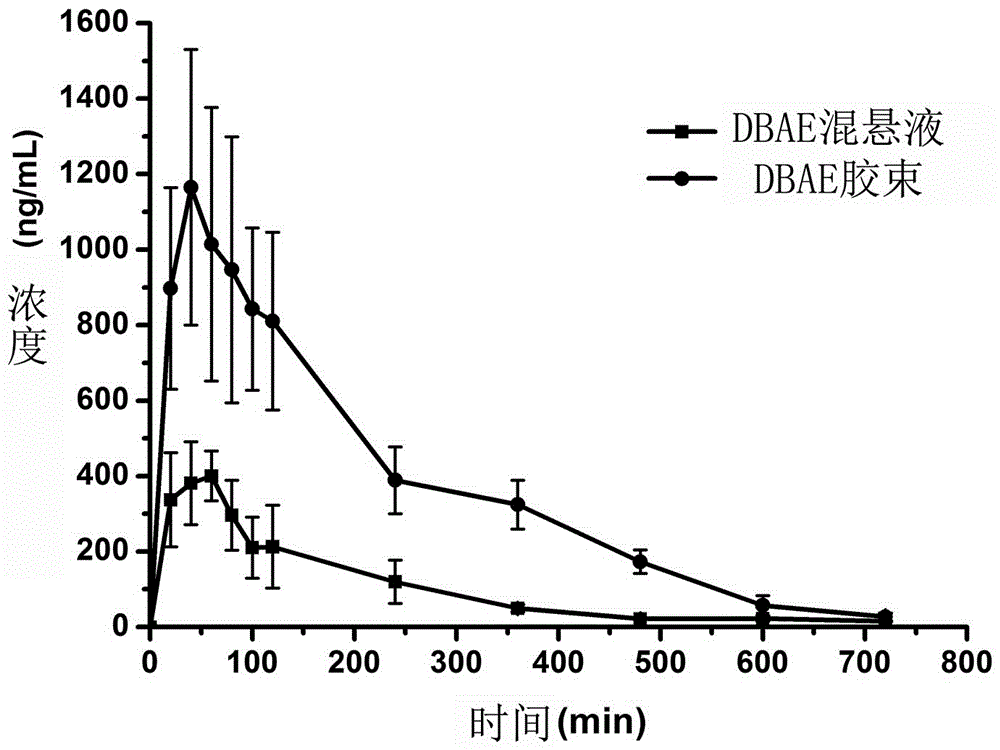

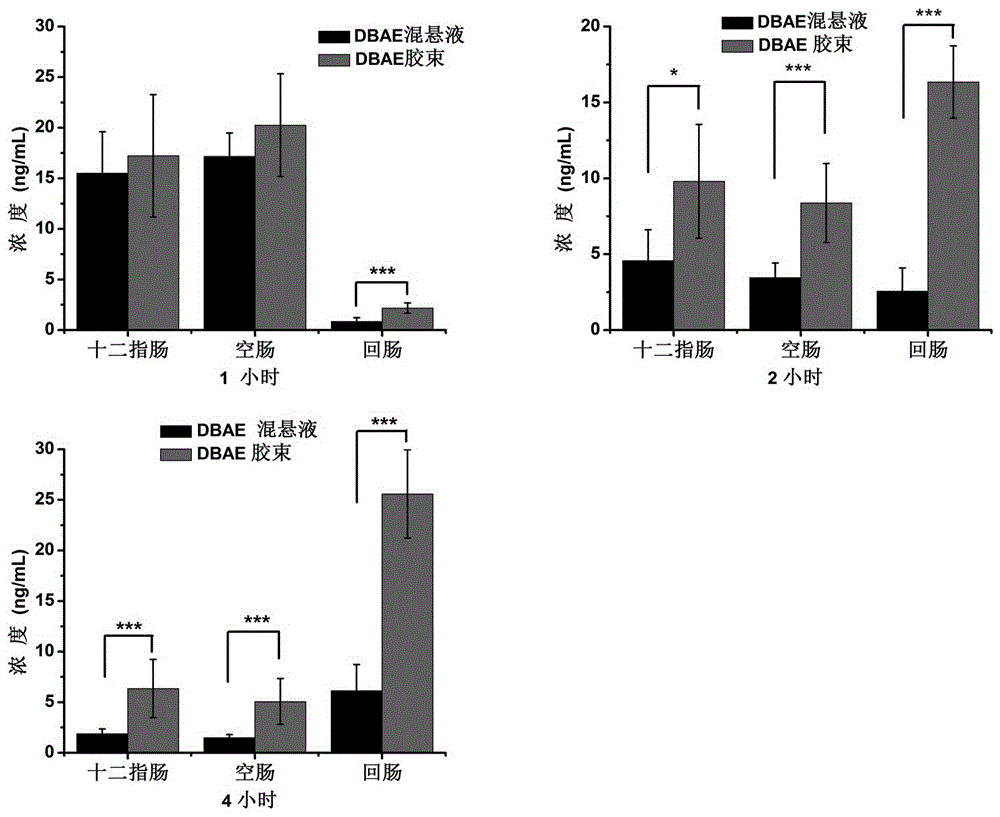

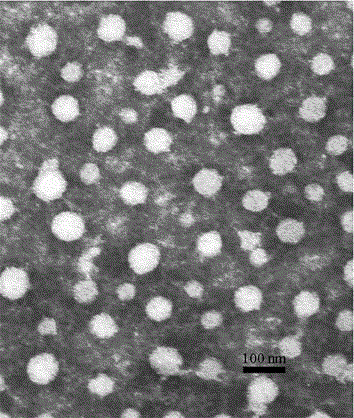

Dabigatran etexilate nano mixed micelle and preparation method thereof

ActiveCN105997868AImprove solubilityPromote dissolutionOrganic active ingredientsPharmaceutical non-active ingredientsMixed micelleDabigatran ethyl ester

The invention provides dabigatran etexilate nano mixed micelle and a preparation method thereof. A film dispersion method is adopted for preparing the soluplus / VitaminE-TPGS nano mixed micelle of the dabigatran etexilate, and the particle size is within 70-100 nm.

Owner:SICHUAN UNIV

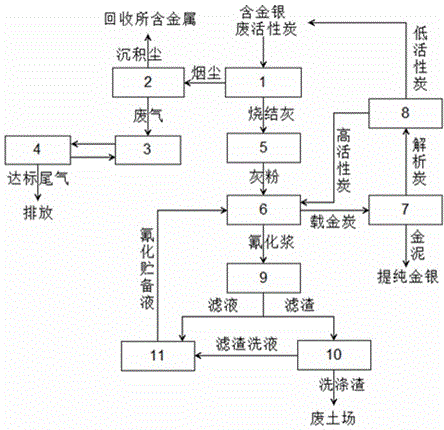

Method for recovering gold and silver from waste gold/silver-containing activated carbon

ActiveCN104357664AEmission reductionPut an end to effluxProcess efficiency improvementGas emission reductionActivated carbonCombustion

Owner:芒市海华开发有限公司

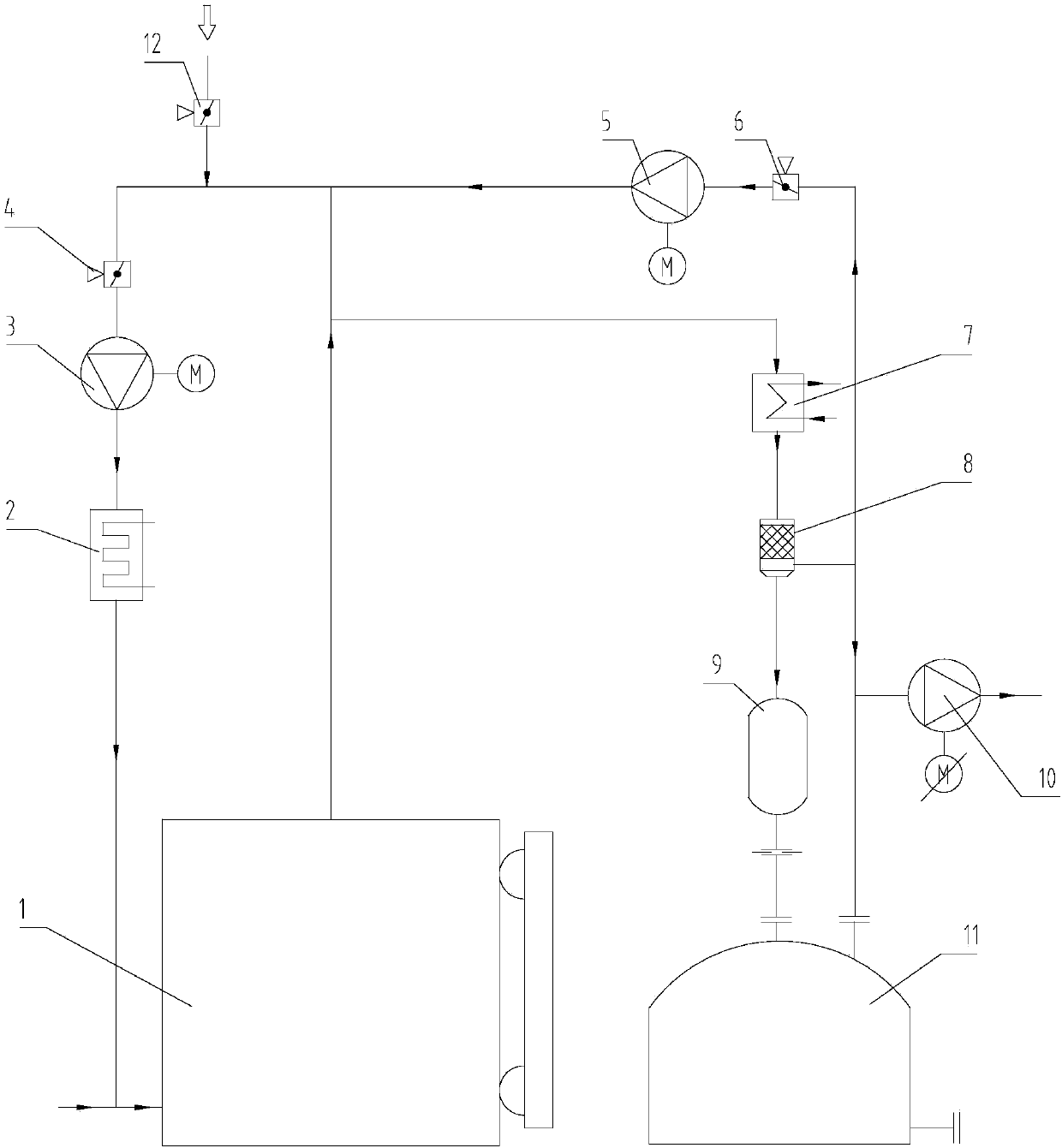

Drying system in radioactive solid waste furnace and drying method

InactiveCN107830698APrevent leakageAvoid effluxDrying solid materials without heatDrying gas arrangementsRadioactive gasVacuum pumping

The invention relates to a drying system in a radioactive solid waste furnace, meanwhile relates to a corresponding drying method, and belongs to the technical field of radioactive waste treatment. The system comprises a drying furnace and a condensate box; the drying furnace is provided with a main circulation loop and a flow dividing pipeline, wherein the top of the main circulation loop is connected to one side of the drying furnace through a heating draught fan and a heater which are in series connection, and the flow dividing pipeline is connected to the condensate box through a cooler, asteam and water separator and a metering device, a gas outlet of the steam and water separator is connected to the main circulation loop through a cooling draught fan to form an air returning pipeline, the cooling draught and the heating draught fan are each provided with a corresponding adjusting valve, and the condensate box and a gas outlet of the gas and water separator are connected with a vacuum pumping device to form a vacuum generation passage. Discharging of radioactive gas in the drying process can be effectively avoided, air utilization rate is improved, energy consumption is saved, and secondary pollutions can be obviously reduced.

Owner:AEROSUN CORP +1

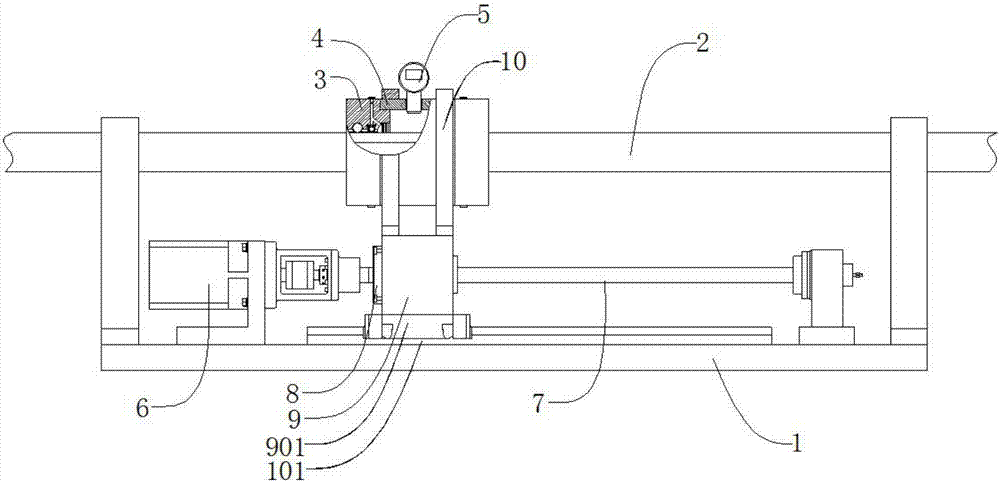

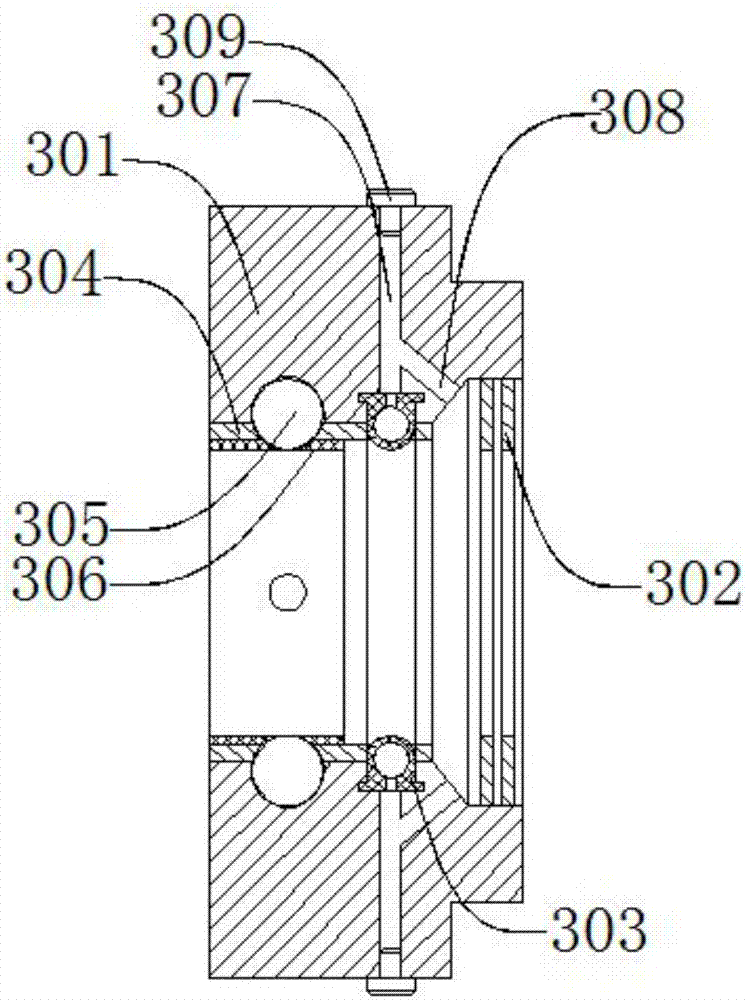

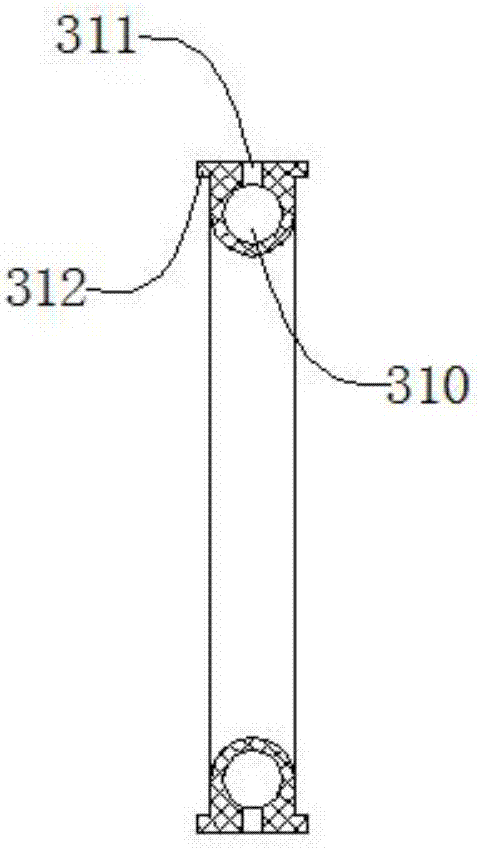

Scanning type pipeline leakage detecting mechanism

The invention discloses a scanning type pipeline leakage detecting mechanism which comprises a base, a pipeline, two sealing mechanisms symmetrically arranged along the pipeline, a connecting pipe, a pressure gage, a servo motor, a lead screw, a feeding nut, a sliding seat and a supporting frame; each of the sealing mechanisms comprises a sealing seat, sealing rings, a sealing rubber ring, a check ring, a steel ball, a rubber sleeve, a first air inlet passage, a second air inlet passage and an end cap, wherein the sealing rings are uniformly distributed along the sealing seat and are more than 3; the servo motor works to drive the connecting pipe to move, so that scanning type detection is carried out on the pipeline; and when the pressure detected by the pressure gage exceeds a set value, the servo motor stops, and the leaked part is sealed. The scanning type pipeline leakage detecting mechanism is simple in structure, detects the whole pipeline in real time through scanning type detection to improve the safety performance, and adopts a floating design to effectively prevent the leaked gas from emission through three stages of sealing so as to enable the leaked gas to be full of the connecting pipe and to effectively improve the detection precision.

Owner:马鞍山英维爱生态科技有限公司

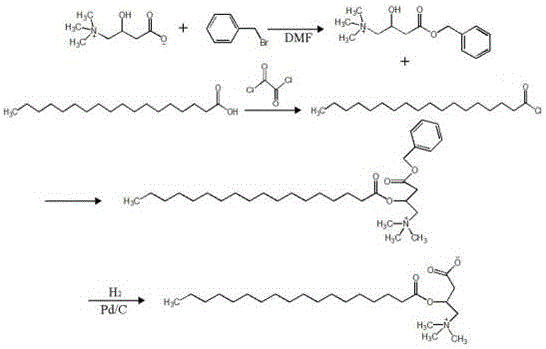

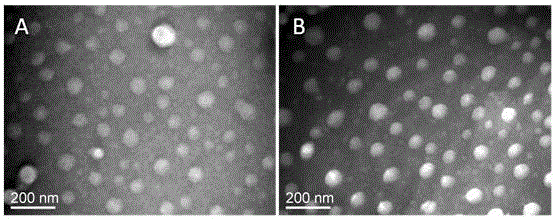

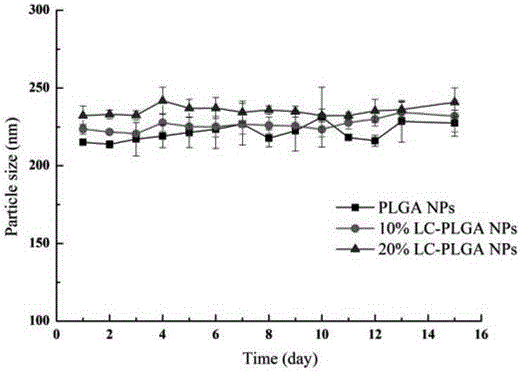

Oral targeting nanoparticles based on intestinal epithelial cell apical OCTN2 transporter

ActiveCN107176911AUniform particle sizeHigh encapsulation efficiencyOrganic active ingredientsOrganic compound preparationStructural formulaStearic acid

The invention belongs to the field of new auxiliary materials and new dosage forms of pharmaceutic preparations, and relates to preparation of a derivative of L-carnitine as a substrate of an intestinal epithelial cell apical OCTN2 transporter and corresponding targeting nanoparticles, and application of the targeting nanoparticles as oral drug carriers in the aspect of drug delivery. Stearoyl-L carnitine is an amphipathic compound consisting L-carnitine as the substrate of the OCTN2 transporter and stearic acid, and is a targeting ligand which is good in stability and is used for constructing an OCTN2 targeting nano drug delivery system. The stearic acid can be long-chain fatty acids such as octadecanoic acid, palmitic acid and tetradecanoic acid. The structural formula of the amphipathic compound is as shown in the specification.

Owner:SHENYANG PHARMA UNIVERSITY

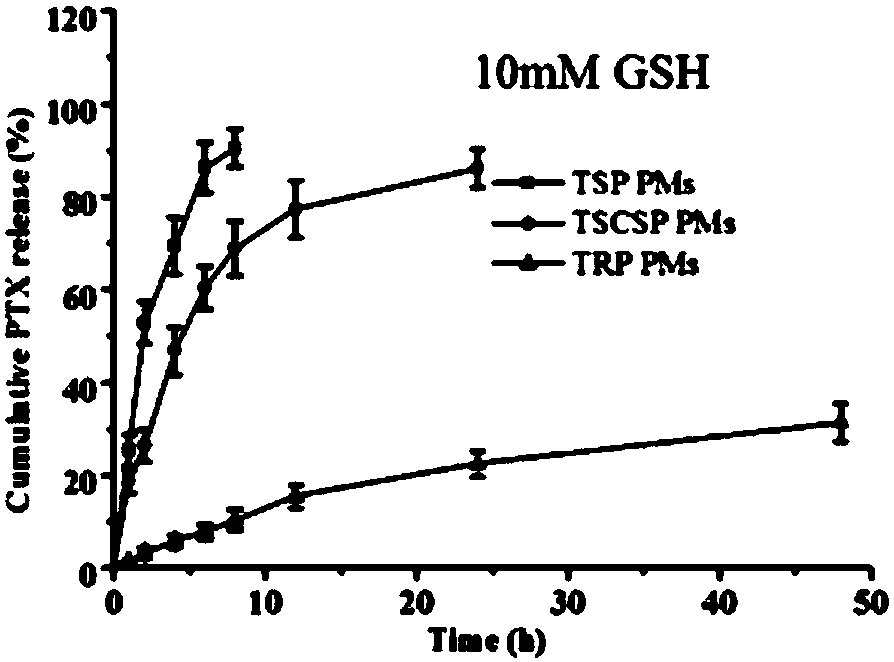

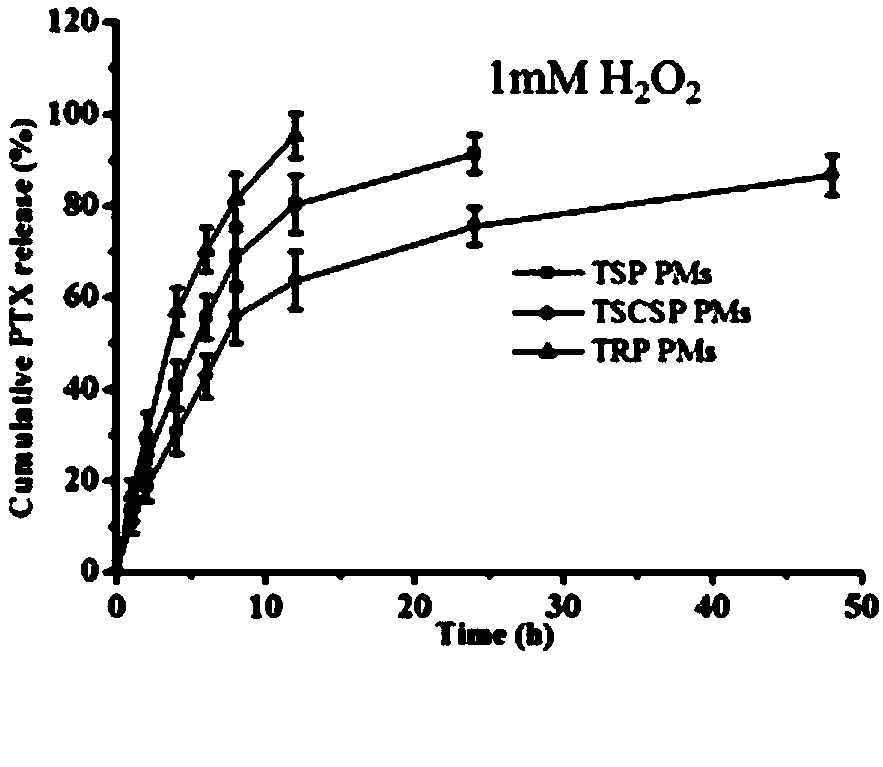

Anti-tumor prodrug with P-glycoprotein inhibition function and preparation method

ActiveCN108245683AImprove solubilityAvoid effluxOrganic active ingredientsPharmaceutical non-active ingredientsPolyethylene glycolTumor cells

The invention discloses an anti-tumor prodrug with a P-glycoprotein inhibition function and a preparation method. The prodrug comprises a part formed by covalently connecting an anti-tumor drug and polyethylene glycol vitamin E succinate through a connecting arm, wherein the connecting arm comprises a sensitive bond; the sensitive bond is a chemical bond which is broken in an oxidization or reduction environment. The free polyethylene glycol vitamin E succinate and the active anti-tumor drug are dissociated; the polyethylene glycol vitamin E succinate is combined with P-glycoprotein; the expression of a P-glycoprotein efflux pump is inhibited, the activity of the P-glycoprotein is inhibited, the excretion of the anti-tumor drug is reduced and the intracellular concentration of the drug isimproved, so that the multi-drug drug resisting property of tumor cells is inhibited, the intracellular concentration of the active anti-tumor drug is greatly improved and a remarkable anti-tumor effect is obtained. The released active drug can be combined with a specific target spot in the cells and the growth of the tumor cells is inhibited.

Owner:HUAZHONG UNIV OF SCI & TECH

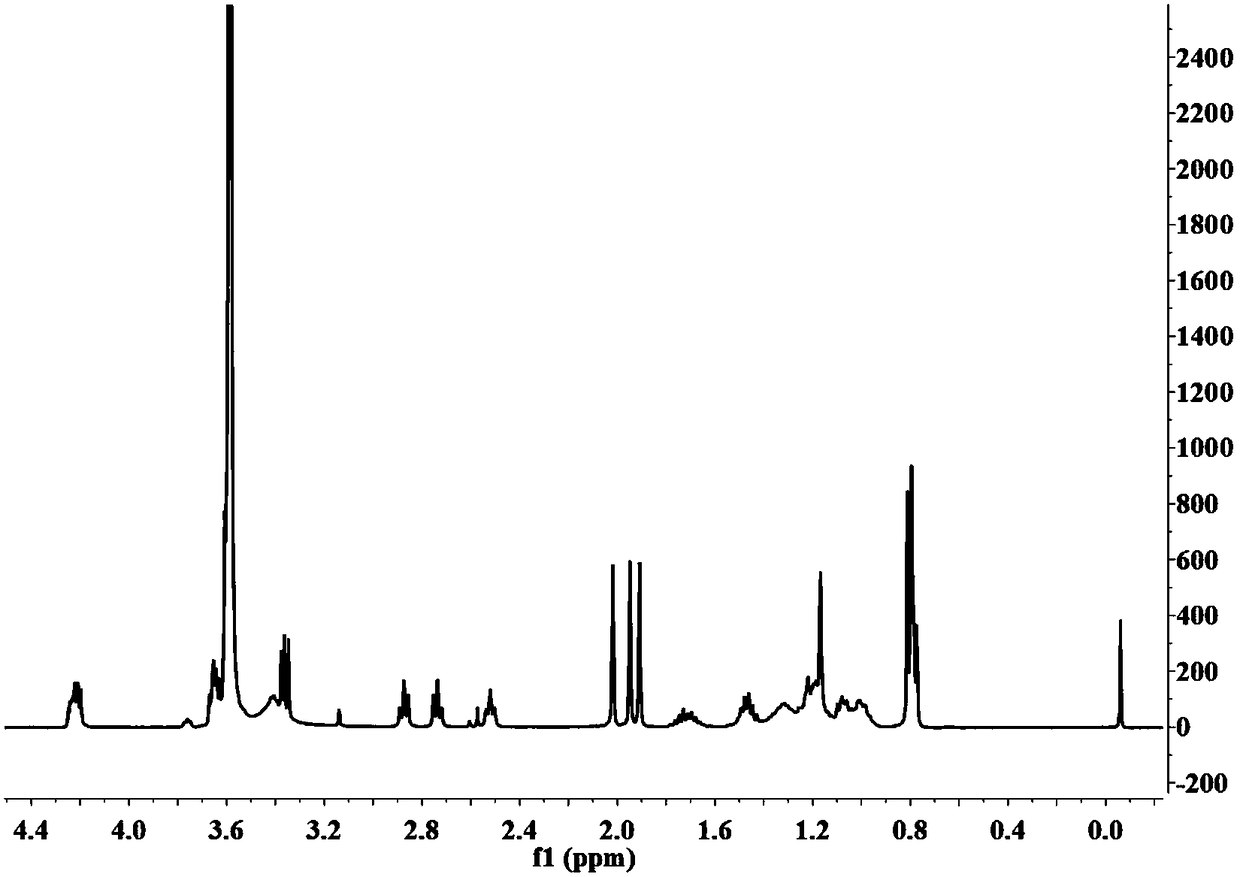

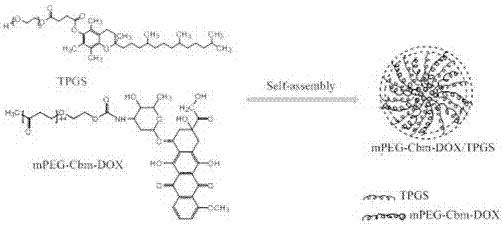

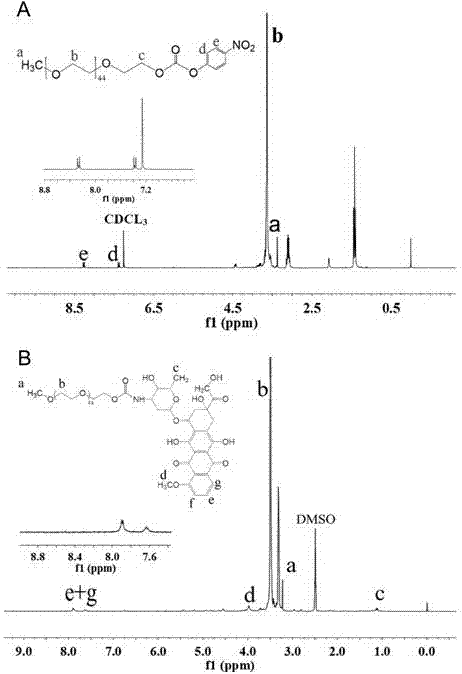

PH-sensitive mixed micelle as well as preparation method and application thereof

ActiveCN107441043APromote accumulationAvoid effluxOrganic active ingredientsPharmaceutical non-active ingredientsMixed micelleCancer drugs

The invention relates to a preparation method and an application of a pH-sensitive mixed micelle. An anti-cancer drug, namely DOX, is in covalent linkage with mPEG by virtue of acid-sensitive Cbm, an obtained material, as a polymer prodrug, is mixed with TPGS, and self-assembling is conducted in a water solution, so that the mixed micelle, which is of a core-shell structure, is formed. The pH-sensitive mixed micelle provided by the invention can, in response to a special low-pH environment of tumor tissues, can achieve specific release of the DOX, so that the excretion of the drug can be effectively inhibited and the multi-drug resistance of tumor cells can be reversed; and the mixed micelle is good in biocompatibility and long in drug circulating time, and the preparation method is convenient for operation and popularization and has a good development prospect.

Owner:NANKAI UNIV

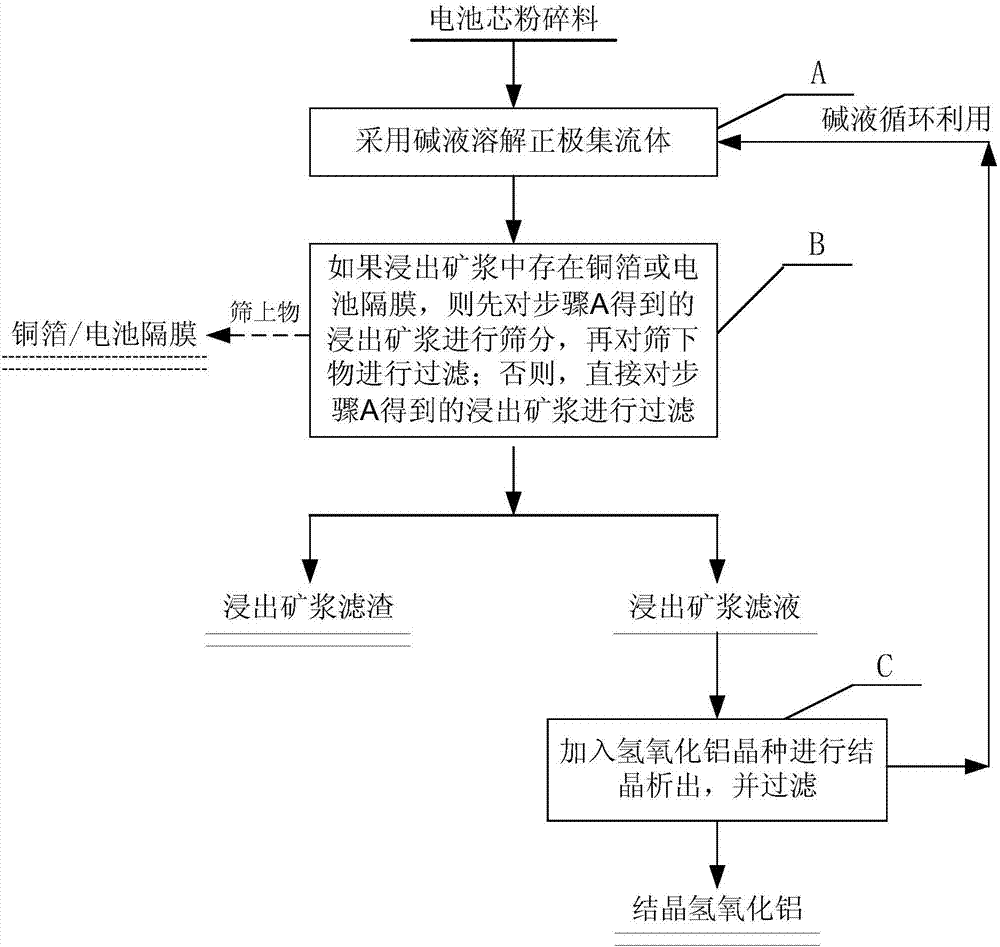

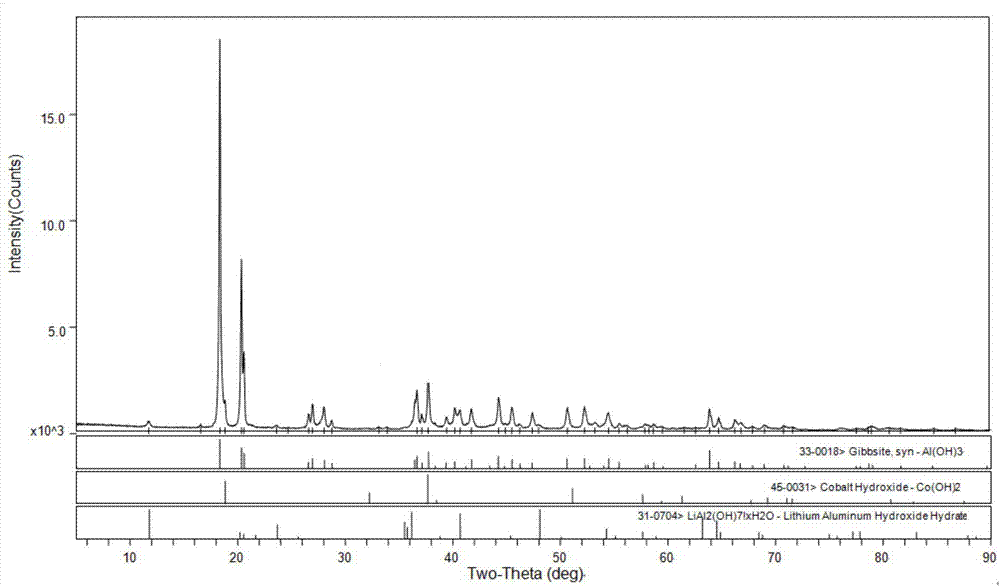

Positive electrode collector recycling treatment method of waste lithium ion battery

InactiveCN107196006AAvoid effluxReduce processingWaste accumulators reclaimingBattery recyclingWastewaterSlurry

The invention discloses a positive electrode collector recycling treatment method of a waste lithium ion battery. The method comprises the following steps: adding battery cell powder particles in an alkali liquor to dissolve the positive electrode collector, thereby obtaining the leach slurry; if a piece of copper foil or a battery diaphragm is existent in the leach slurry, firstly screening the leach slurry, and then filtering the screen underflow, thereby obtaining the leach slurry filtrate and the leach slurry filter residue; otherwise, directly filtering the leach slurry, thereby obtaining the leach slurry filtrate and the leach slurry filter residue; adding aluminum hydroxide seed crystal in the leach slurry filtrate to perform the separation by crystallization, and filtering to obtain the crystallized aluminum hydroxide and the alkali liquor, wherein the alkali liquor is recycled as the alkali liquor for dissolving the positive electrode collector. The treatment method disclosed by the invention is less in reagent consumption, low in energy consumption, small in wastewater treatment amount, and capable of effectively separating the collector adhered with the positive electrode material in the waste lithium ion battery.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Sassafras tsumu seed dormancy breaking and germination accelerating method suitable for Shandong region

InactiveCN103477754AImprove stabilityReduced number of reaction pointsGerminating apparatusSeed dormancyPrawn

The invention discloses a Sassafras tsumu seed dormancy breaking and germination accelerating method suitable for the Shandong region, and belongs to the tree planting field. The method is characterized in that the method comprises the steps of seed soaking treatment, oscillation pressure reduction treatment and germination accelerating treatment; and a seed soaking liquid is prepared by adding 0.6g of NaCl, 0.98g of KCl, 0.17g of CaCl2.2H2O, 0.11g of MgCl2.6H2O, 15mg of polyoxyethylene polyoxypropylene ether, 40mg of gamma-aminobutyric acid and 0.2g of astaxanthin to 1000ml of distilled water to prepare a solution. Compared with the prior art, the method has the advantages of acceleration of the Sassafras tsumu seed germination, improvement of the cold resistance of seedlings, and enhancement of the adaptation of Sassafras tsumu seeds to poor surroundings, so a high germination percentage and a high seedling survival rate can be obtained.

Owner:韩庆军

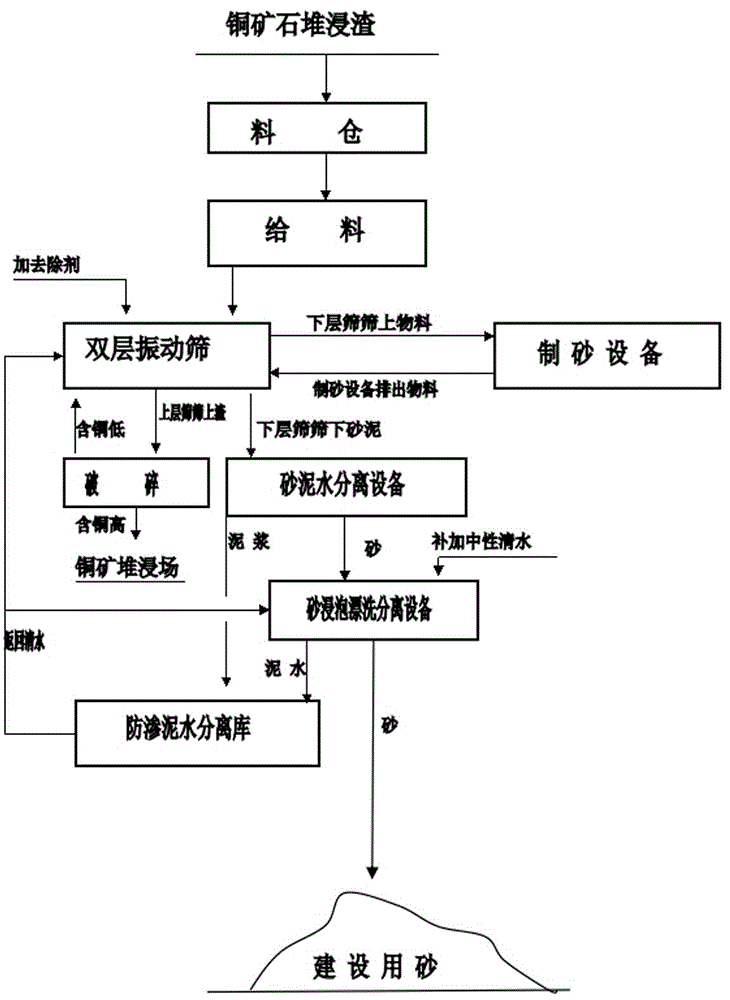

Method for manufacturing construction sand by virtue of copper ore dump leaching slag

ActiveCN104084292AEasy to handleIncrease the soaking and rinsing processWet separationSlagMining engineering

The invention discloses a method for manufacturing construction sand by virtue of copper ore dump leaching slag. The method comprises the following steps of: using the copper ore dump leaching slag as a sand manufacturing raw material, controlling the granularity of ore slag entering a sand manufacturing flow by sieving, adding a remover in the sand manufacturing process to remove trace sulphuric acid and copper sulphate in the copper ore dump leaching slag, removing muddy water from the sand after mud removal in the sand manufacturing process through a neutral clear water soaking and rinsing procedure link, and then producing the construction sand. According to the method disclosed by the invention, the construction sand is produced by virtue of the copper ore dump leaching slag, thus the waste copper ore dump leaching slag is effectively utilized, high-quality engineering construction sand is provided, the damages of construction sand exploitation to river rapids, lakes, beaches, mountain forests and lands are reduced, land occupancy for stacking the copper ore dump leaching slag is reduced, and water and soil loss and environmental pollution are reduced. The method disclosed by the invention has a great popularization and application prospect for districts with the copper ore dump leaching slag and construction sand needs.

Owner:罗光臣

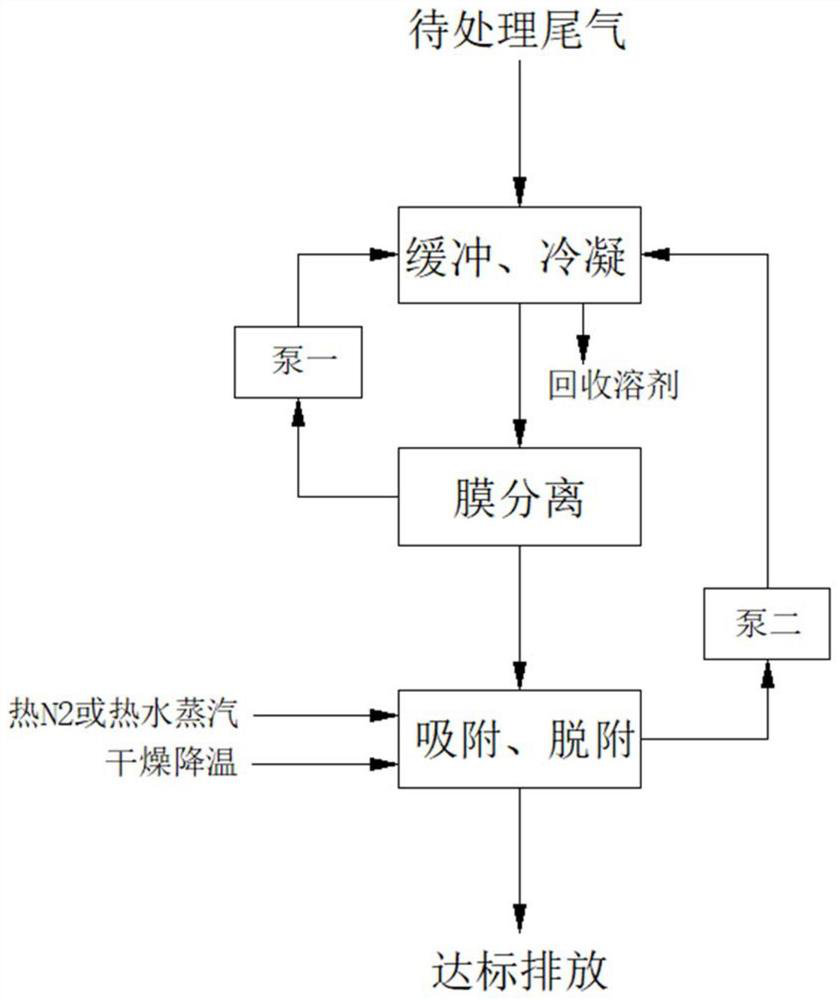

Effective organic waste gas recovery device and process

PendingCN112755719APlay a protective effectImprove efficiencyGas treatmentDispersed particle separationThermodynamicsExhaust fumes

The invention provides an organic waste gas recovery device and process, and belongs to the technical field of organic waste gas treatment. The device comprises a condensation system, a membrane separation system, an adsorption system and a vacuum system, the vacuum system comprises a first vacuum pump and a second vacuum pump which operate independently, an inlet and an outlet of the first vacuum pump are connected with the membrane separation system and the condensation system respectively, and organic gas separated from the membrane separation system is circulated back to the condensation system through the first vacuum pump; an inlet and an outlet of the second vacuum pump are respectively connected with the adsorption system and the condensation system; and desorbed organic gas in the adsorption system is circulated back to the condensation system through the second vacuum pump. According to the invention, the membrane separation system and the adsorption system respectively carry out organic gas and air separation and organic matter desorption through independent vacuum pumps, so that the two systems do not interfere with each other, the intermittent vacuum operation of the adsorption system does not influence the continuous vacuum operation of the membrane separation system, and the working stability of the membrane separation system is effectively guaranteed.

Owner:浙江同善环保科技有限公司

Coal mud water clarifying and controlling method based on water quality adjustment

InactiveCN101186368AIncrease profitAvoid effluxWater/sewage treatment by flocculation/precipitationCoal waterCoal slurry

The invention relates to a coal slurry clarification and control method based on water quality regulation, which is suitable for the treatment of the circulating coal slurry of a coal preparation plant. Firstly, the feeding concentration and water hardness are measured to determine the nature of and classify the coal slurry according the water hardness value and a water quality regulating agent is added according to the water hardness to regulate the water hardness; the water quality hardness value is real time monitored to control the adding quantity of the water quality regulating agent to regulate the water quality of the coal slurry to a total hardness of larger than 50 German degrees, thus changing the hard settled coal slurry into an easy settled coal slurry firstly. The hardness and the concentration of the overflow water of a thickener are measured, and if the total hardness of the coal slurry is less than 50 German degrees, the water quality regulating agent should be continuously added until the total hardness of the coal slurry is larger than 50 German degree; the concentration value of the overflow water is also referred to, if the concentration value is more than 1g / l, the flocculant is further added until the concentration value is less than 1g / l. The method of the invention can prepare coal with fresh water, thus enhancing the utilization rate of water, preventing the outflow of the coal slurry and the environmental pollution of the mining area reducing the running off and the waste of coal resources and having small loss of coal. The total expenses of the invention is lowered by 20 to 80 percent than the prior art, with simple and easy operated method.

Owner:CHINA UNIV OF MINING & TECH

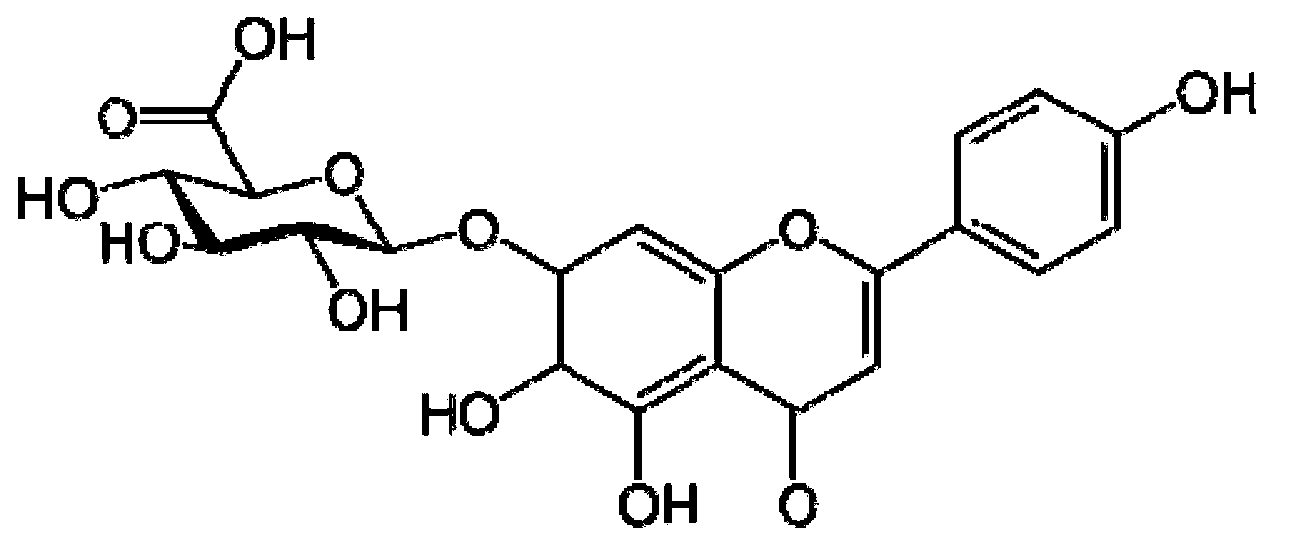

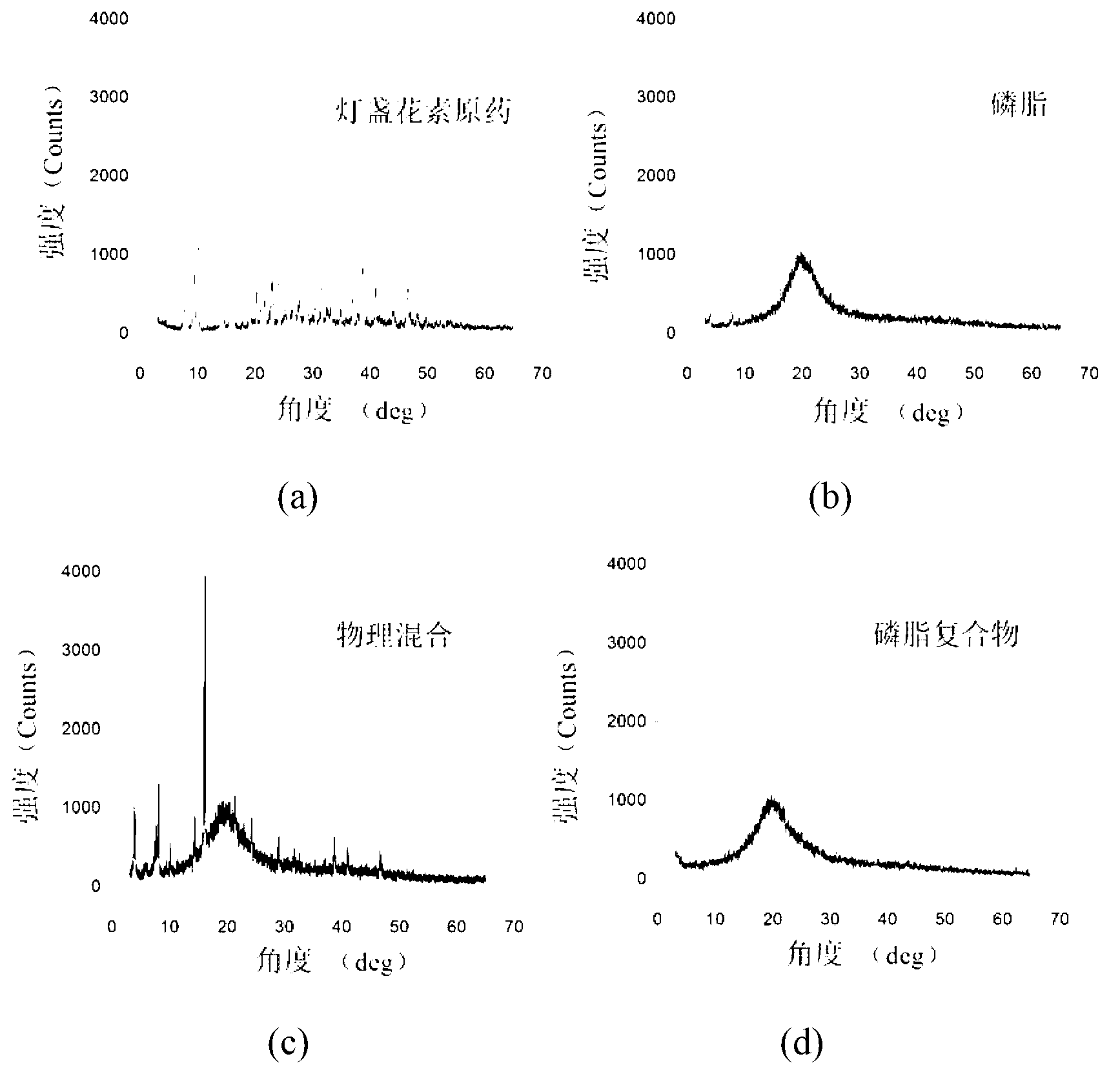

Self-emulsifier containing breviscapine phosphatidylcholine complex, and preparation method and use thereof

InactiveCN103169657AHigh drug loadingSolve the problem of poor fat solubilityPowder deliveryOrganic active ingredientsOral medicationBioavailability

The invention discloses a self-emulsifier containing a breviscapine phosphatidylcholine complex, and a preparation method and a use thereof. The self-emulsifier comprises the following components, by mass, 0.1-16% of breviscapine, 0.1-32% of phosphatidylcholine, 20-70% of an oily phase, 10-50% of a surfactant, and 0-40% of a cosurfactant. An insoluble dug breviscapine is processed to prepare a breviscapine phosphatidylcholine complex, and the breviscapine phosphatidylcholine complex is treated as an intermediate carrier to prepare the self-emulsifier containing the breviscapine phosphatidylcholine complex. The breviscapine phosphatidylcholine complex can effectively solve a bad fat solubility problem of breviscapine and substantially improve the drug loading capability of the self-emulsifier; and the self-emulsifier can increase the dissolution rate of breviscapine, promote breviscapine to penetrate epithelial cells, promote the lymphatic transport of drugs to a certain degree, reduce the hepatic first pass metabolism of the drugs and improve the oral bioavailability of breviscapine. Oral administration tests of rats show that the self-emulsifier containing the breviscapine phosphatidylcholine complex can substantially improve the absorption of breviscapine and improve the oral bioavailability of breviscapine.

Owner:HUAZHONG UNIV OF SCI & TECH

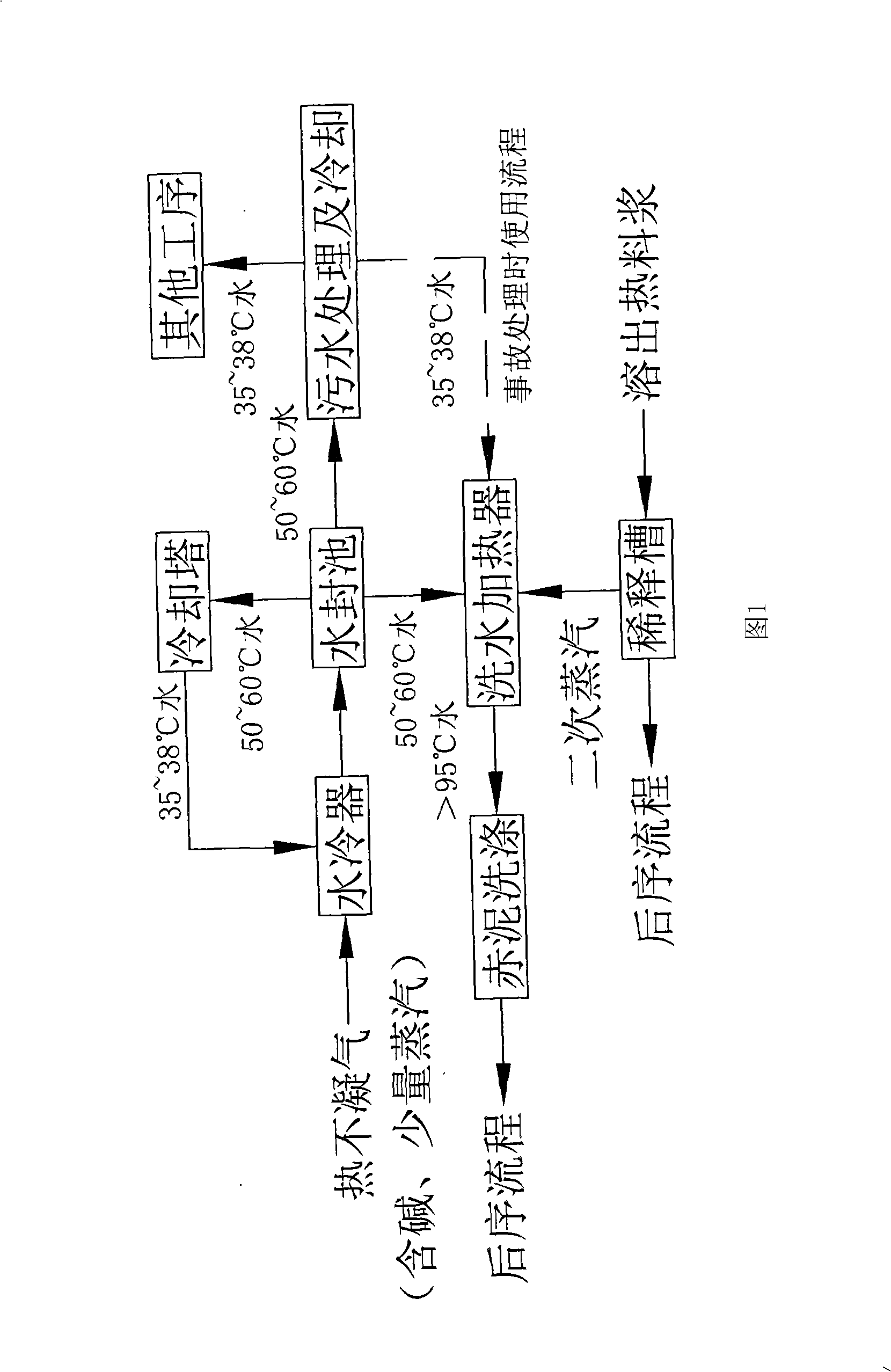

Method for utilizing circulation water in aluminum hydroxide or aluminum oxide production process

InactiveCN101264907ARelieve pressureImprove the heating effectAluminium oxides/hydroxidesCooling towerRed mud

The invention relates to a method for utilizing the recycled water during the production process of aluminum hydroxide or aluminum oxide, which comprises the following steps: the recycled water produced from a mother liquor evaporating system is directly sent to a washing heater for heating, when the temperature of the recycled water reaches 95- 100 DEG C, the recycled water can be used for washing red mud. The utilization method of the recycled water has the advantages that: the pressure of a cooling tower is reduced, as the recycled water with a speed of approximately 60 m<3> need not be cooled down to 35-38 DEG C from 50-60 DEG C, but is instead directly conveyed to the washing heater for use; due to the new recycle water line, the pressure of a wastewater treatment system is eased, the wastewater can be treated in a timely manner and all enter the flow path, thus realizing zero discharge and avoiding environmental pollution; the consumption quantity of fresh water is accordingly reduced by avoiding the discharge of sewage; the alkali taken from a water cooler returns to the flow path and gradually enter the flow path, therefore, the alkali consumption is lowered and the cost is accordingly saved; due to the adequate utilization of the heat, the heating of recycled water in the washing heater is facilitated with sufficient heat, no new steam is necessary, thus economizing the use of heat energy and greatly reducing the labor intensity and danger of the working staff.

Owner:河南未来铝业(集团)有限公司

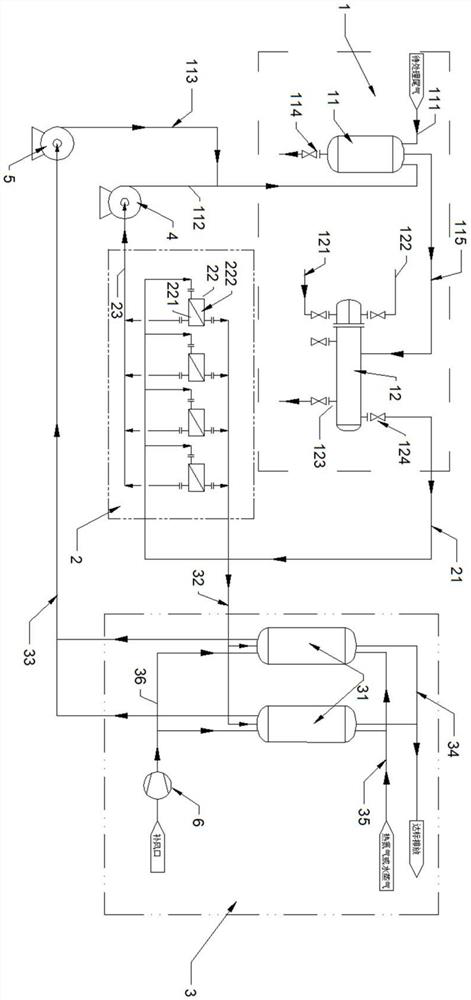

Production system and process for co-production of industrial-grade nitric acid and electronic-grade nitric acid

ActiveCN112279225ASolve the cumbersomeReduce consumptionChemical industryNitric acidProcess engineeringUltrafiltration

The invention discloses a production system and process for co-production of industrial-grade nitric acid and electronic-grade nitric acid. The production system comprises an NOX separator; a materialoutlet of the NOX separator is communicated with a material inlet of a tail gas absorption tower and a material inlet of an electronic-grade nitric acid preparation tower; a first material outlet ofthe electronic-grade nitric acid preparation tower is communicated with the material inlet of the tail gas absorption tower; a second material outlet of the electronic-grade nitric acid preparation tower is communicated with a material inlet of the ultrafiltration device; a material outlet of the ultrafiltration device is communicated with a material inlet of an intermediate storage tank; a material outlet of the tail gas absorption tower is communicated with a material inlet of a bleaching tower; a material outlet of the bleaching tower is communicated with a material inlet of a cooling device; a material outlet of the cooling device is communicated with a material inlet of an industrial nitric acid tank. The production system is low in energy consumption, convenient to use, safe, efficient, simple in production process and high in production efficiency.

Owner:HENAN JUNHUA DEV

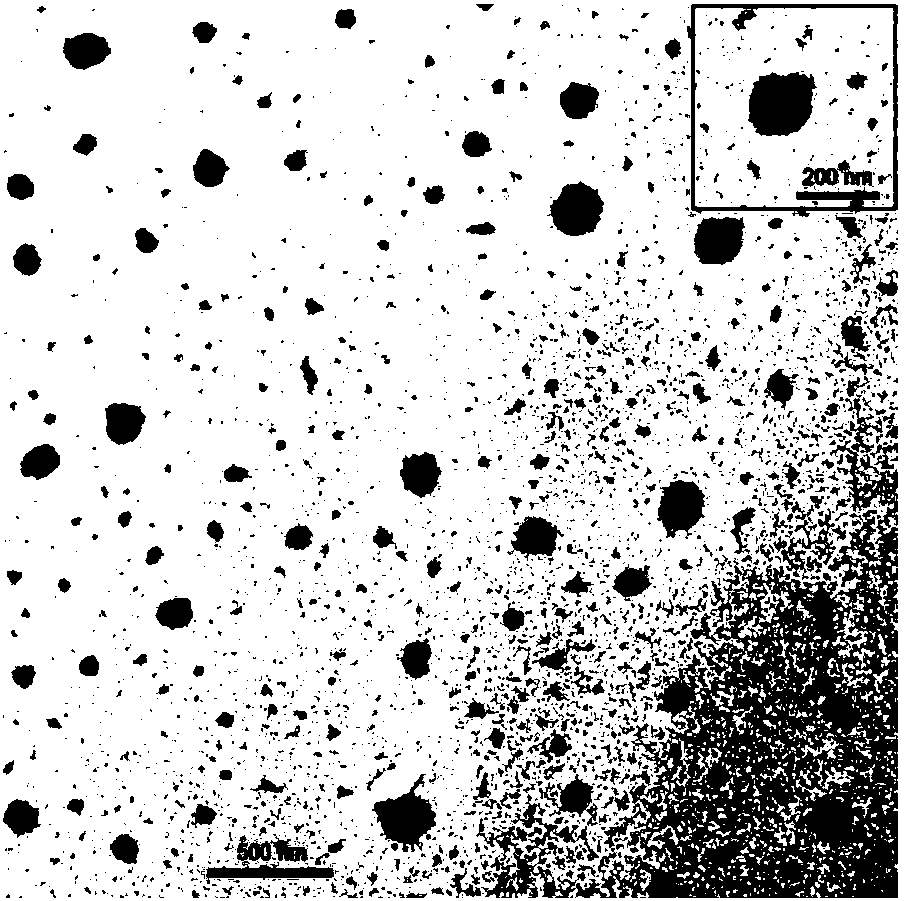

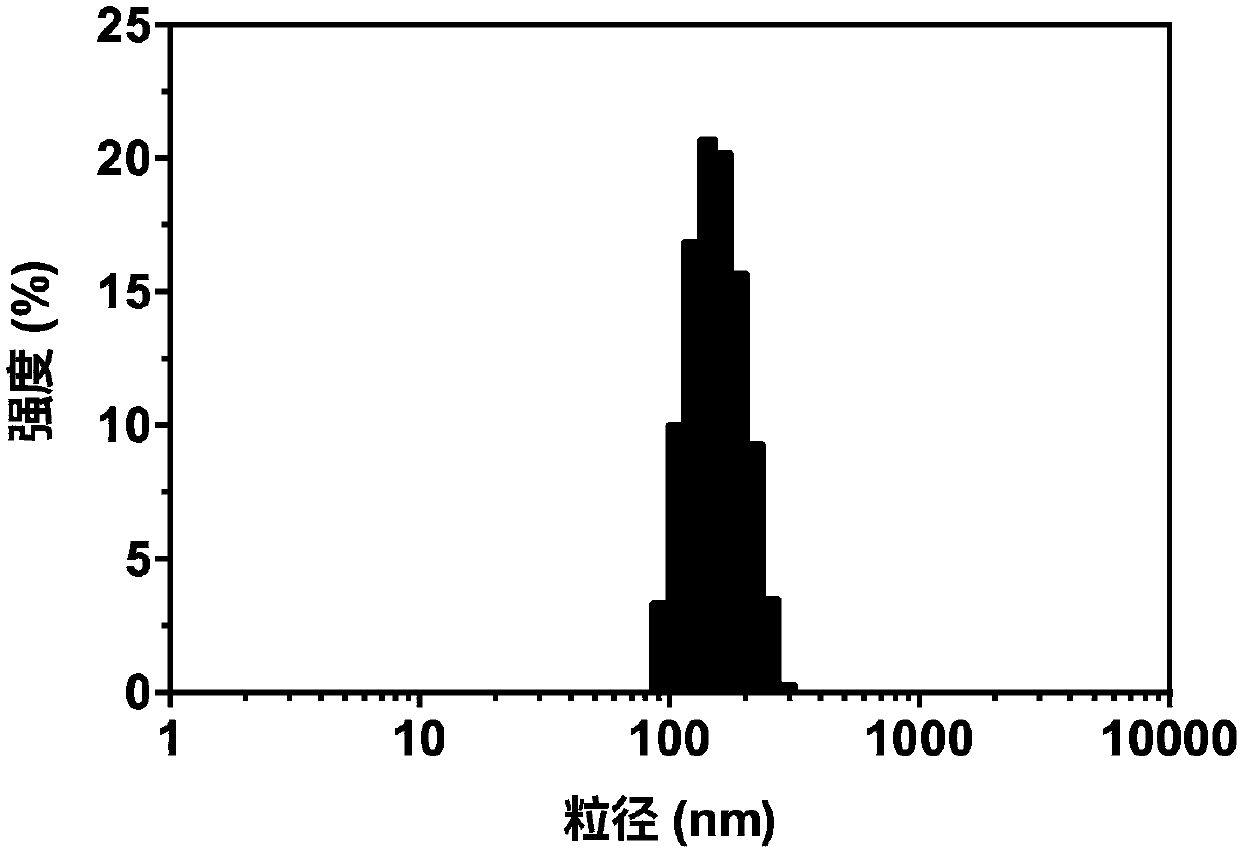

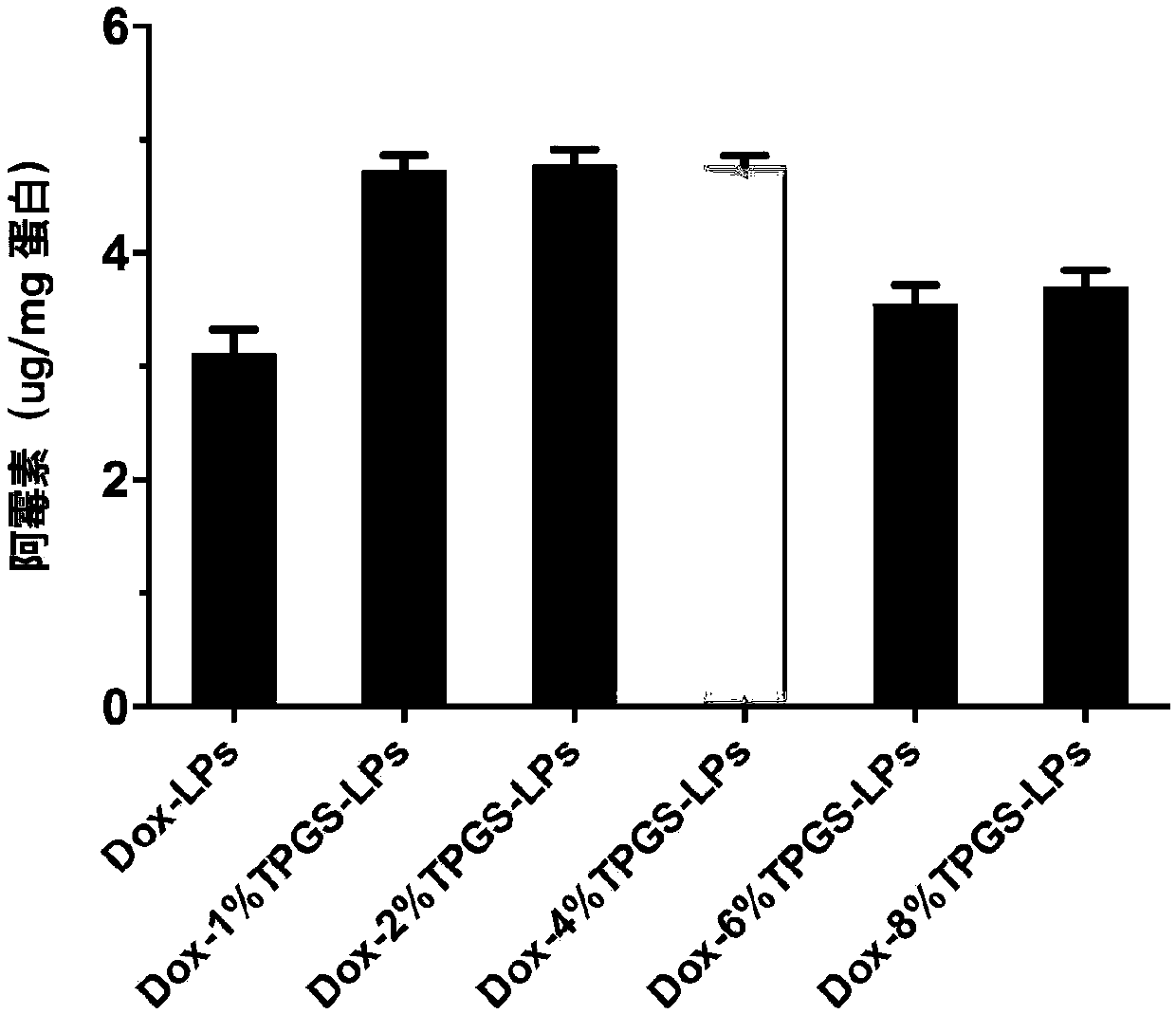

Adriamycin and gene medicine co-transporting nano medicine carrying system and preparation method

ActiveCN107811972ATo achieve co-loadingInhibition of effluxOrganic active ingredientsGenetic material ingredientsCholesterolLiposome

The invention provides an adriamycin and gene medicine co-transporting nano medicine carrying system and a preparation method. The co-transporting nano medicine carrying system is TPGS modified cationic liposome for co-carrying adriamycin and gene medicine, wherein a membrane material of the cationic liposome is prepared from 1,2-dioleoyl-3-trimethylammonio-propane or chlorate of the 1,2-dioleoyl-3-trimethylammonio-propane, dipalmitoyl phosphatidylcholine, TPGS and cholesterol. The prepared co-transporting nano medicine carrying system disclosed by the invention has a higher adriamycin encapsulating efficiency, stability of the co-transporting nano liposome is improved; meanwhile, complete inhibition on a tumor cell efflux pump can be achieved by only adjusting a formula, the purposes of two drug resistance mechanisms of inhibiting tumor medicine efflux and resisting apopotosis are achieved at the same time, and tumor multidrug resistance can be more completely and more effectively reversed.

Owner:HUAZHONG UNIV OF SCI & TECH

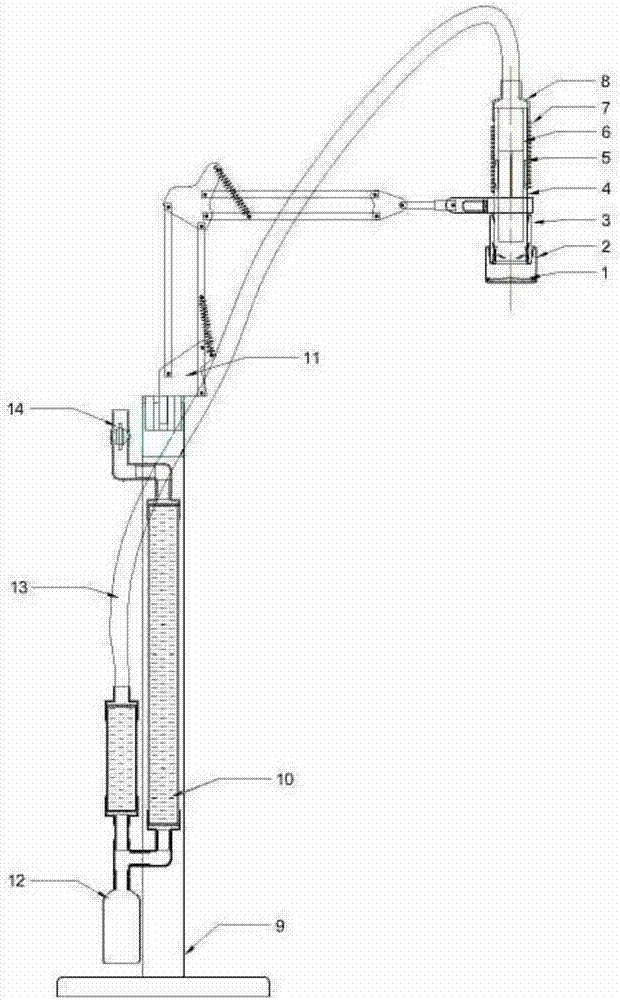

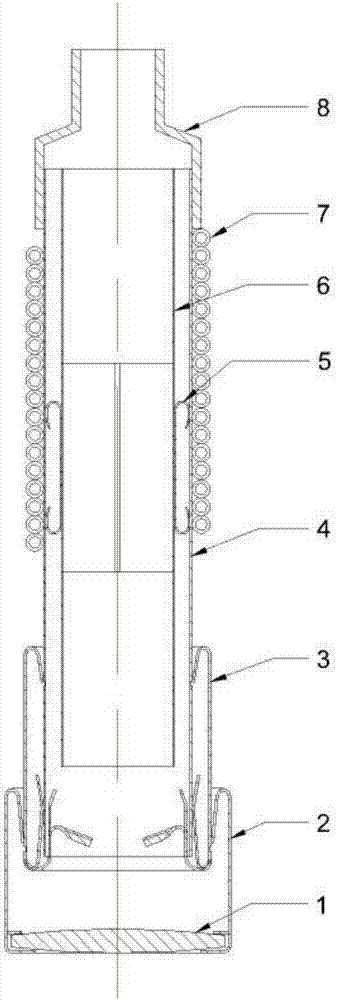

Moxibustion instrument

InactiveCN106994099AControl burning rateNo damageDevices for heating/cooling reflex pointsHuman bodyCombustion chamber

The invention relates to a moxibustion instrument, mainly aiming at solving the problem that existing moxibustion instruments are not significant in treatment effect, and large in damage to patient bodies. The moxibustion instrument is characterized in that a rotary support (11) is fixed on a pedestal (9), a moxibustion head is connected with the upper end of the support (11), the moxibustion head comprises a combustion chamber (4) and a moxa holding chamber (6), the moxa holding chamber (6) is positioned in a combustion chamber (4), a moxa holding chamber clamping spring (5) is arranged between the combustion chamber (4) and the moxa holding chamber (6), an ash removing device (3) is connected with the outer part of the lower end of the combustion chamber (4), an ash storage box (2) is connected with the bottom of the ash removing device (3), and a lens (1) is fixed on a lower end face of the ash storage box (2); a smoke exhaust joint (8) is connected with the upper end of the combustion chamber (4), and the smoke exhaust joint (8) is connected with a smoke abatement device (10) via a smoke exhaust pipe (13). The moxibustion instrument has the functions of directional energy gathering and focusing, and is significant in treatment effect, non-damage to human bodies, and free of smoke emission.

Owner:李安平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com