Ion-type rare-earth ore ammonium-free environment-friendly exploitation technique

An ion-type rare earth mine, green and environmentally friendly technology, applied in the direction of improving process efficiency, etc., can solve the problems of low comprehensive recovery rate of rare earth resources, soil and water environmental pollution, low precipitation efficiency, etc., to reduce the loss of rare earth resources and avoid ammonia nitrogen Pollution, the effect of high comprehensive recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention. Apparently, what has been described is only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

[0035] Adopt the ore leaching agent, impurity removal agent, precipitation agent of each embodiment in table 1 and table 2, carry out ore leaching according to following process steps respectively:

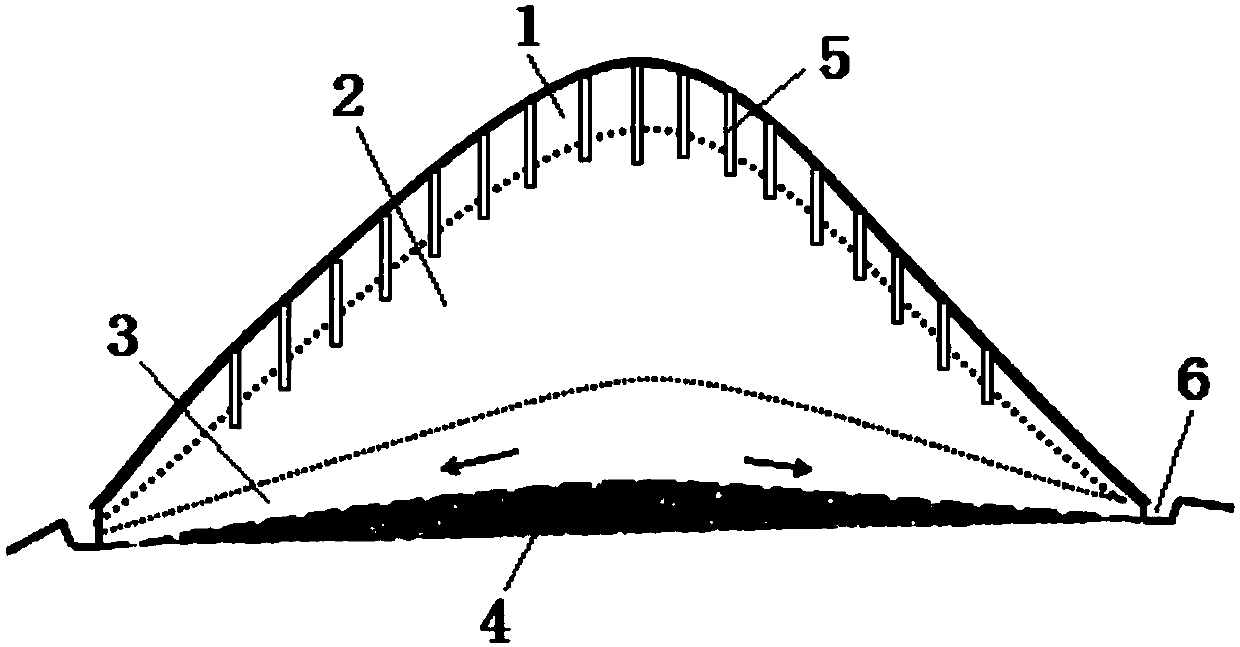

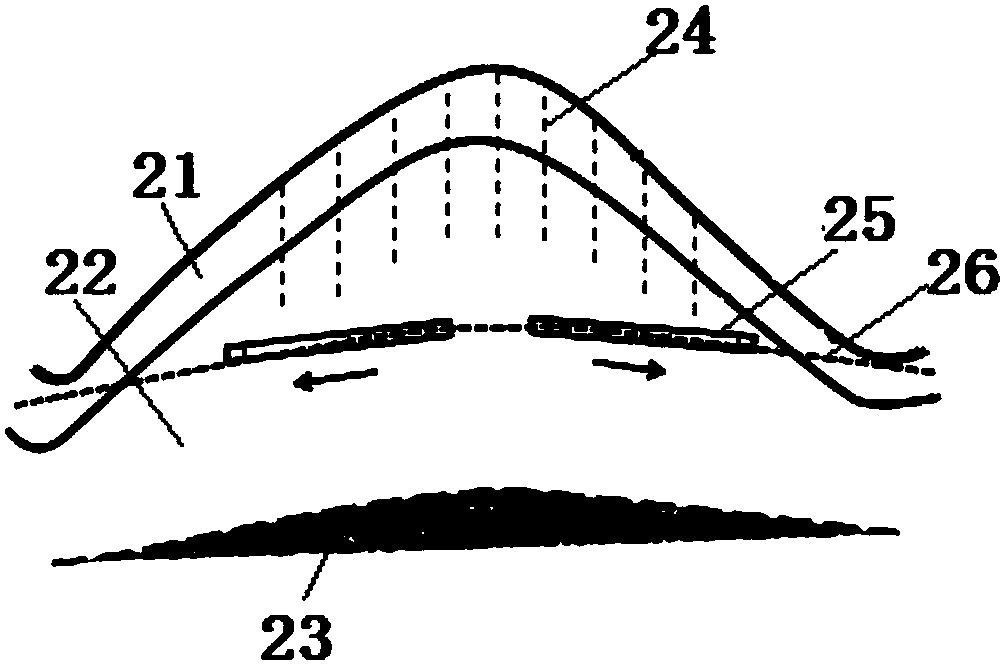

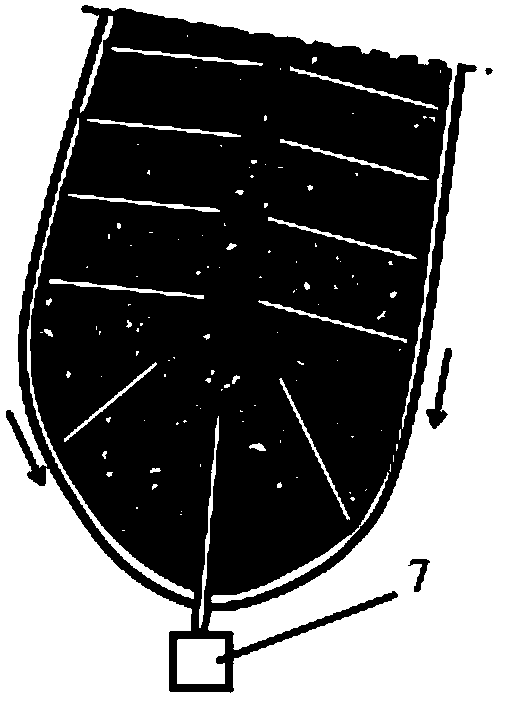

[0036] (1) Arrange liquid injection holes according to a certain grid in the selected stope, use the natural water-proof floor of the mine layer or arrange artificial liquid collection roadways at a certain distance, and match liquid collection and diversion holes of a certain size, that is, water drills for liquid coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com