Patents

Literature

190results about How to "Pollution meets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

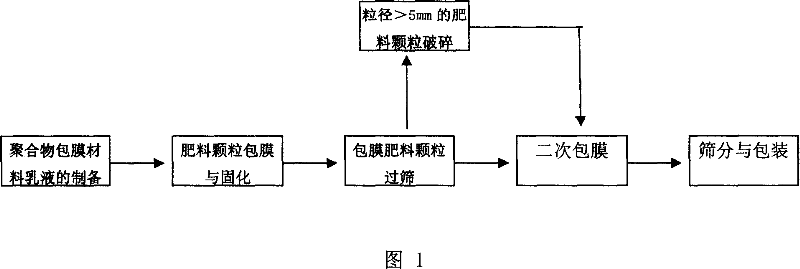

Biological biodegradable self-control slow-releasing fertilizer and preparation method thereof

ActiveCN101037368AImprove controllabilityGuaranteed degradabilityAgriculture gas emission reductionUrea compound fertilisersEpoxyPolymer science

The invention discloses a biodegradable self-controlling slow-release fertilizer which is produced by uniformly coating a layer of controlled-release layer of water soluble macromolecule polymer at the surface of the urea or complex fertilizer grain. The weight ratio of the complex fertilizer grain to macromolecule polymer is 0.3-0.4:9.7-9.6. The macromolecule polymer is produced in proportion of fibrin, oxidized starch, polyvinyl alcohol, polyurethane prepolyme, epoxide resin, epoxide resin solidified agent, cross linker, emolsifier, ignition primer, deionized water. The invention adopts glue and latex crosslinking with a biodegradable material to improve the controlled-release capability of the fertilizer and conquer the ''white pollution'', increase the usage ratio of nitrogen of 20-35%, and satisfy the crop need in a whole growth period.

Owner:格瑞昊尔斯生物科技(山东)有限公司

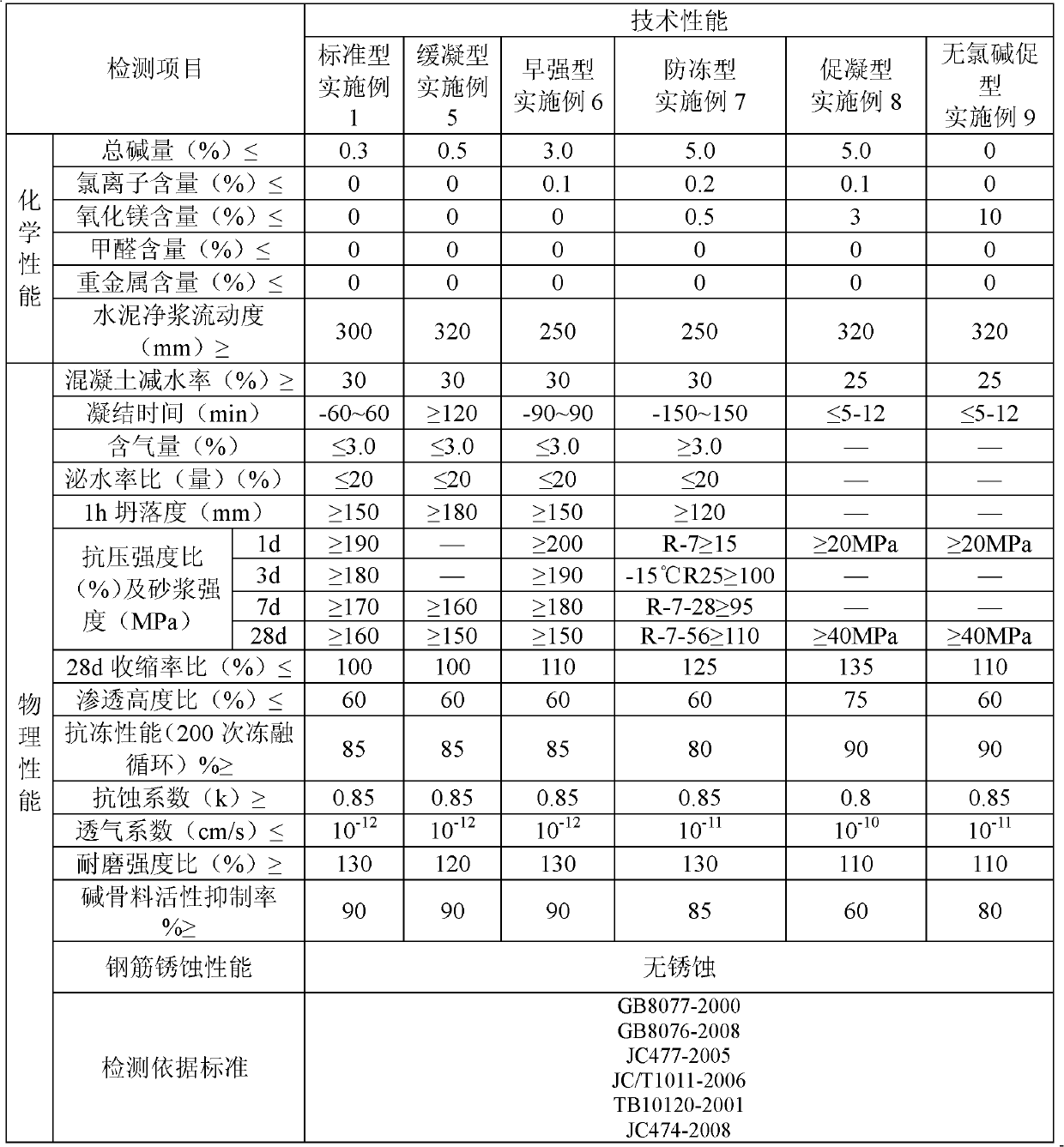

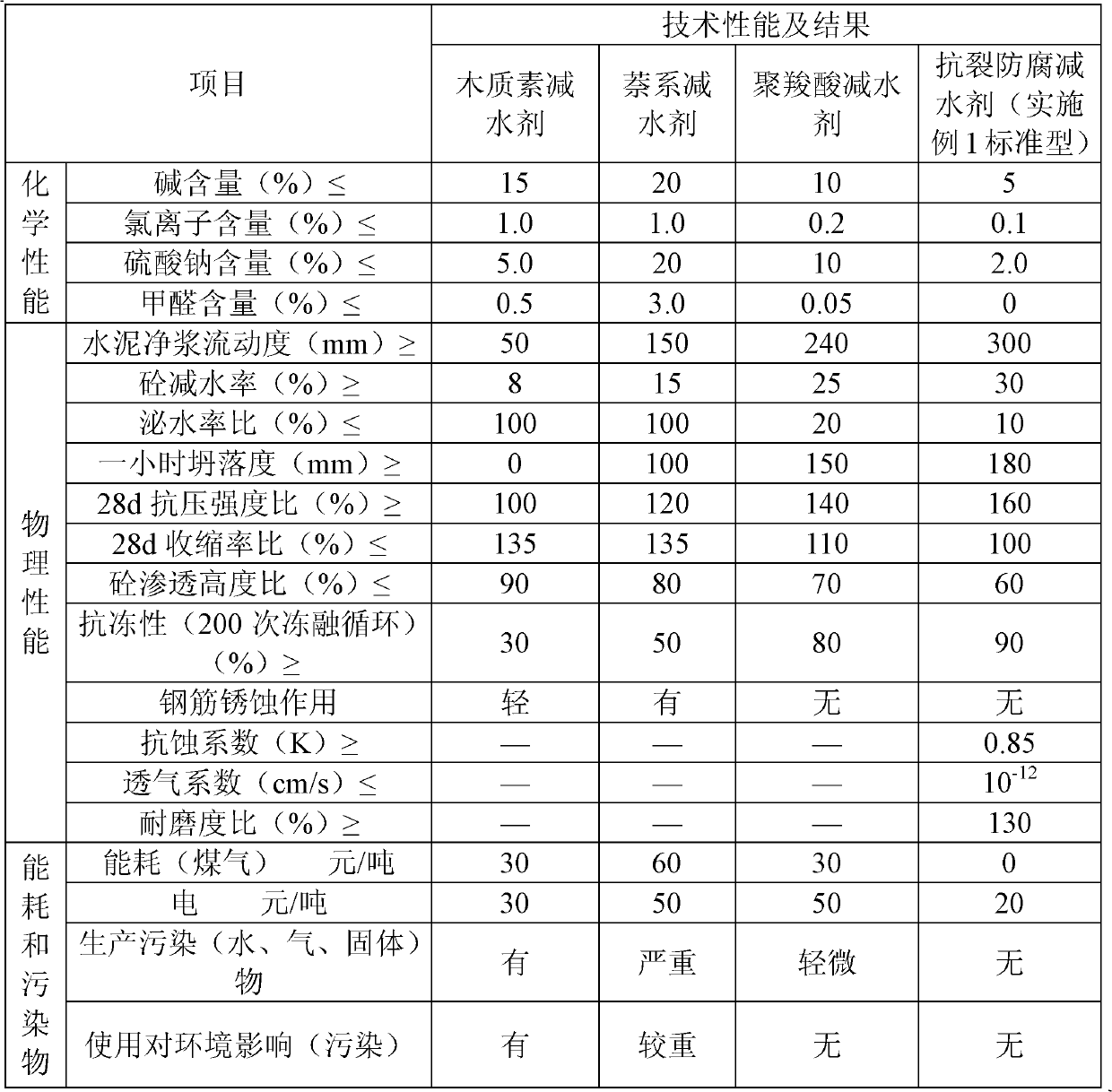

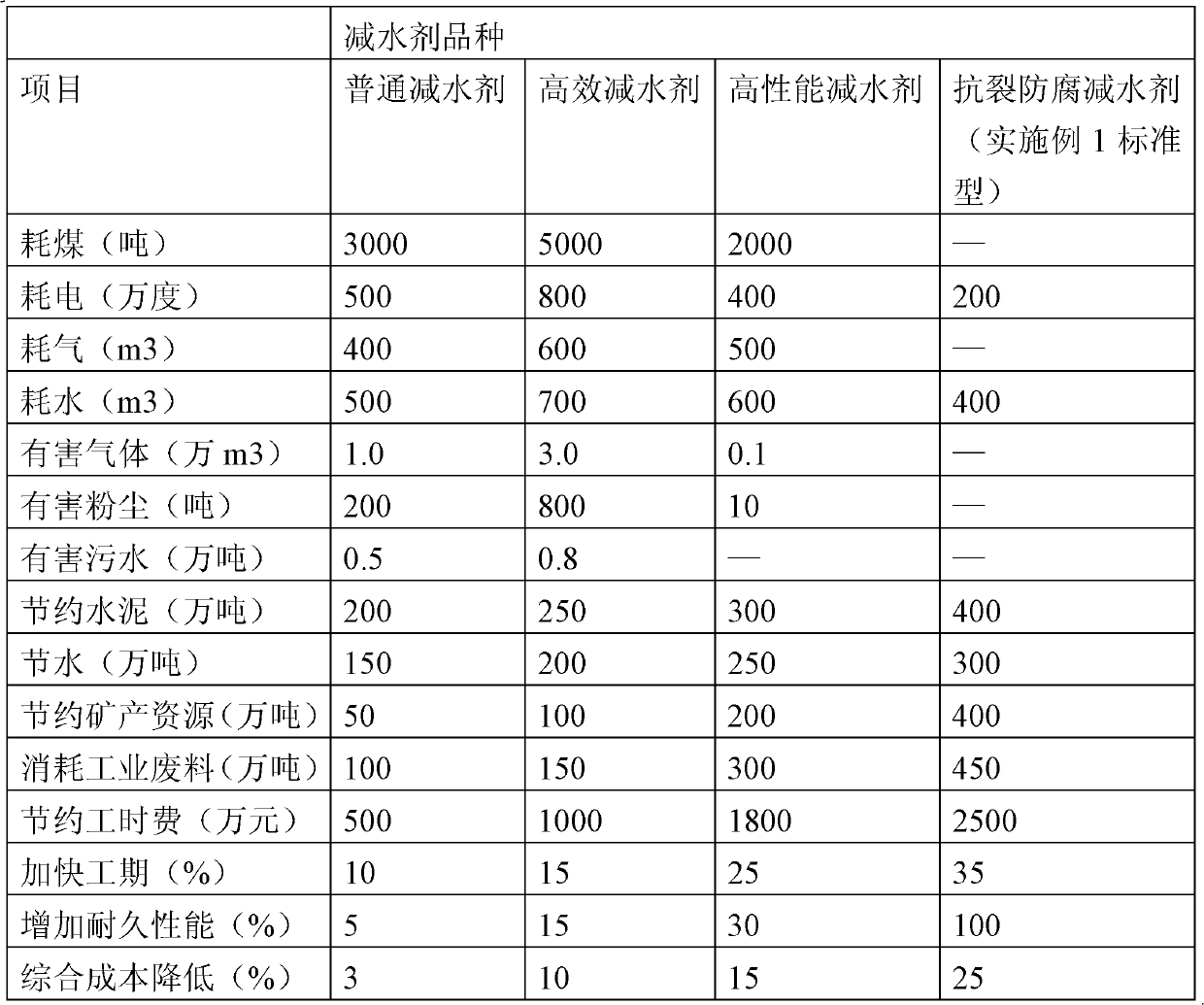

High-performance anti-cracking anticorrosive water reducing agent composition and preparation method thereof

The invention relates to a high-performance anti-cracking anticorrosive water reducing agent composition and a preparation method thereof. The anti-cracking anticorrosive waterproof anti-frost property of the water reducing agent composition is improved while the water-reducing rate of the water reducing agent composition is increased. Compared with a water reducing agent in the prior art, the water reducing agent composition has excellent combination property and an anti-cracking anticorrosion effect. When the water reducing agent composition is prepared, low energy is consumed, and when the water reducing agent composition is used, little pollution is caused.

Owner:苏琳

Foam concrete

The invention discloses a foam concrete, which comprises admixture, cementing material and chemical auxiliary agent, wherein the weight percentage of the admixture in the foam concrete is 25-40%, the weight percentage of the cementing material in the foam concrete is 45-75%, the weight percentage of the chemical auxiliary agent in the foam concrete is 5-25%, the cementing material comprises cement clinker, calcium oxide and bone gelatin powder, and the mass ratio of the three ingredients in the cementing material is 2: 2: 1. The invention further discloses a preparation method of the foam concrete. The preparation method comprises the following steps: foam technology, slurry processing, chemical auxiliary agent processing, mixing, shaping and curing. The foam concrete has the advantages that the cementing material is made of cement clinker, calcium oxide and bone gelatin powder and the use of a great amount of cement is avoided, so that the coal resources required for producing cement is reduced, which not only relieves the tension of energy utilization, but also can improve the compressive strength, leakage resistance, sound insulation effect of the foam concrete.

Owner:王寿光

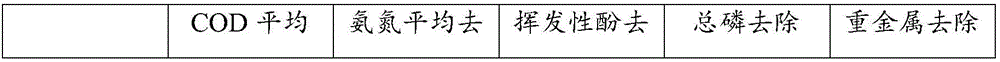

Compound bactericide for treating sewage and sewage treatment method thereof

ActiveCN106701633AGood removal effectFunction increaseFungiBacteriaOperabilityBULK ACTIVE INGREDIENT

The invention discloses compound bactericide for treating sewage and a sewage treatment method thereof, and belongs to the technical field of sewage treatment. The compound bactericide comprises the following active ingredients from following strains: rhodopseudomonas, anaerobic ammonium oxidation bacteria, candida utilis, thiobacillus denitrificans, white-rot fungi, lactobacillus plantarum, bifidobacterium, lactobacillus acidophilus, green nonsulfur bacteria, phosphorus-accumulating bacteria, aspergillus oryzae, nitrosomas, streptomyces, bacillus subtilis and propionibacterium acidipropionici. The invention also provides the method using the compound bactericide to treat the sewage. The compound bactericide and the sewage treatment method have the advantages that the effect of treating sewage is better, the technology is simple, the implementing is easy, the operability is strong, the pollution to environment is avoided, the industrial requirements are met, and the application prospect is better.

Owner:哈尔滨明慧生物技术开发有限公司

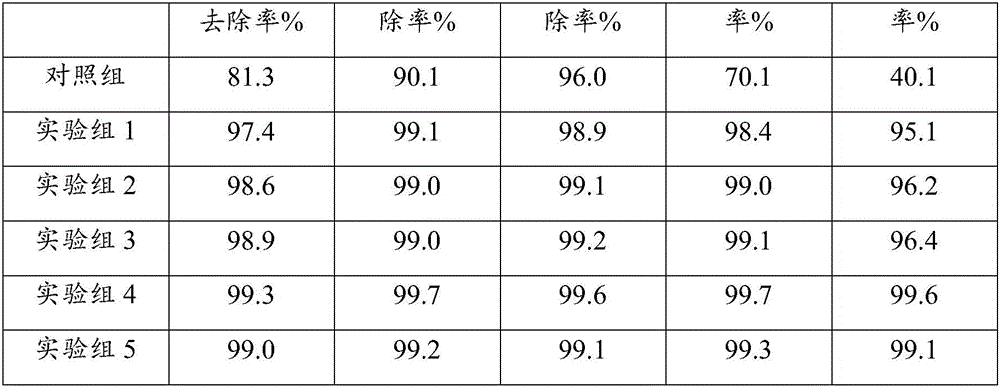

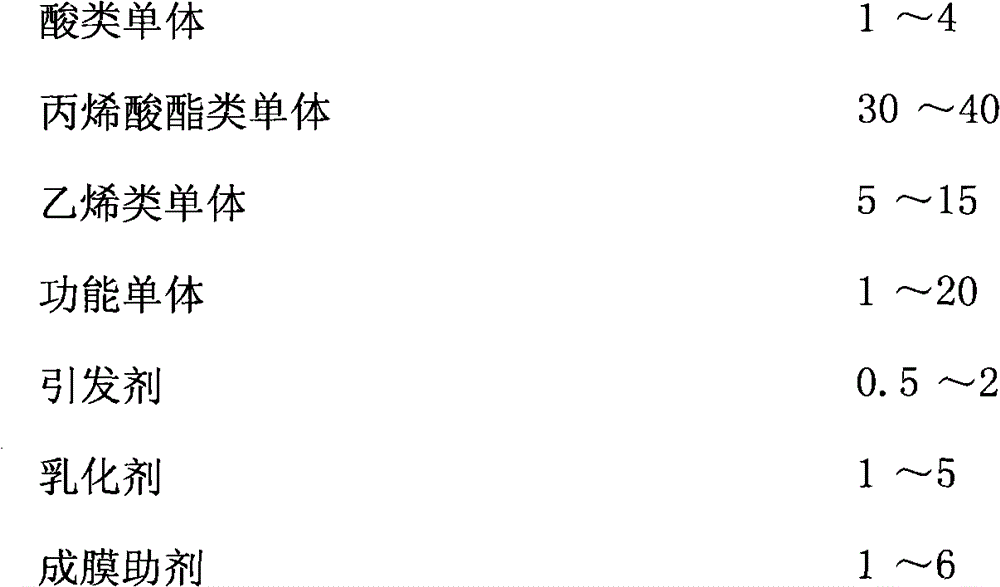

Water-based quick-drying externally-crosslinked functional paint and preparation method thereof

The invention relates to a water-based quick-drying externally-crosslinked functional paint and a preparation method thereof. The preparation method comprises the following steps: adding certain amounts of acid monomer, acrylate monomer, vinyl monomer, functional monomer and deionized water into the reaction kettle to obtain a pre-emulsion (comprising a core emulsion and a shell emulsion); adding part of pre-emulsion into the reaction kettle, and heating; when the emulsion becomes blue and produces reflux, starting dropwisely adding the rest of pre-emulsion, cooling to 50 DEG C, and dropwisely adding a pH regulator until the pH value of the system is 8 or so; and sequentially adding proper amounts of film-forming assistant, emulsifier and external crosslinking and curing agent, and adding a certain amount of corrosion inhibitor if necessary, thereby obtaining the water-based quick-drying externally-crosslinked functional paint. The paint provided by the invention has the advantages of low VOC (volatile organic compound) content, strong adhesive force, high hardness, favorable chemical resistance, energy saving and no air pollution.

Owner:青岛中科煜成安全技术有限公司

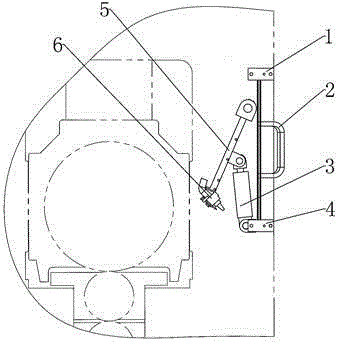

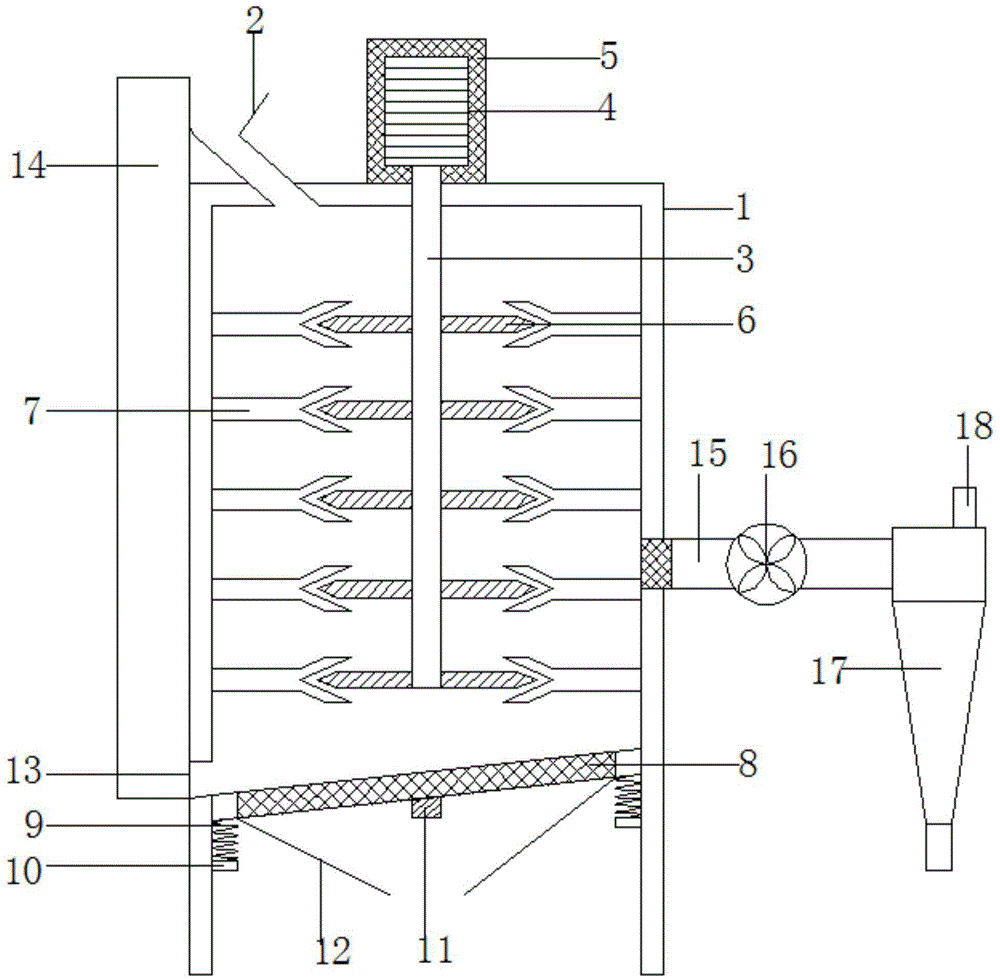

Efficient pulverizer for producing ceramics

The invention discloses an efficient pulverizer for producing ceramics. The efficient pulverizer comprises a pulverizer body, sharp edge movable blades and Y-shaped fixed blades. The upper segment of the left side of the pulverizer body is provided with a feeding pipe. The lower side of the feeding pipe is provided with an inclined pipe, and the upper side of the feeding pipe is in a hopper shape. A rotating shaft is vertically arranged on the axis in the pulverizer body. The top end of the rotating shaft stretches out of the pulverizer body and is connected with a rotating motor. The outer side of the rotating motor is provided with a sound attenuation cover. The outer wall of the rotating shaft is vertically and evenly provided with the sharp edge movable blades. The inner wall of the pulverizer body is provided with the Y-shaped fixed blades. According to the efficient pulverizer for producing the ceramics, the Y-shaped fixed blades and the sharp edge movable blades are vertically arranged and used for pulverizing materials, the pulverizing effect is good, the pulverizing efficiency is high, pulverized materials are thin and fine, the crushed materials are screened, the larger materials are pumped into the pulverizer through an elevator to be pulverized in a circulation mode, the pulverizing effect is guaranteed, dust generated in the pulverizing process is recycled by a cloth dedusting device, pollution is avoided, and raw materials are saved.

Owner:顾马飞

Synthetic method for aromatic[a]carbazole compounds

The invention discloses a synthetic method for aromatic[a]carbazole compounds, belonging to the technical field of organic synthesis. According to a technical scheme in the invention, the synthetic method comprises the following steps: dissolving a 2-phenylindole compound, 2-(naphth-1-yl)indole compound or 2-(thiazol-1-yl)indole compound and a diazo compound in a solvent together; then adding a catalyst and an additive; and carrying out a reaction at 100 to 140 DEG C so as to prepare a benzo[a]carbazole compound, naphtho[a]carbazole compound or thiazolo[a]carbazole compound. According to the invention, 2-substituted indole compounds and the diazo compound are used as raw materials and subjected to a one-pot cascade reaction so as to directly obtain the aromatic[a]carbazole compounds; and the synthetic method is simple and convenient in process, mild in conditions, wide in a substrate adaptability range and suitable for industrial production.

Owner:HENAN NORMAL UNIV

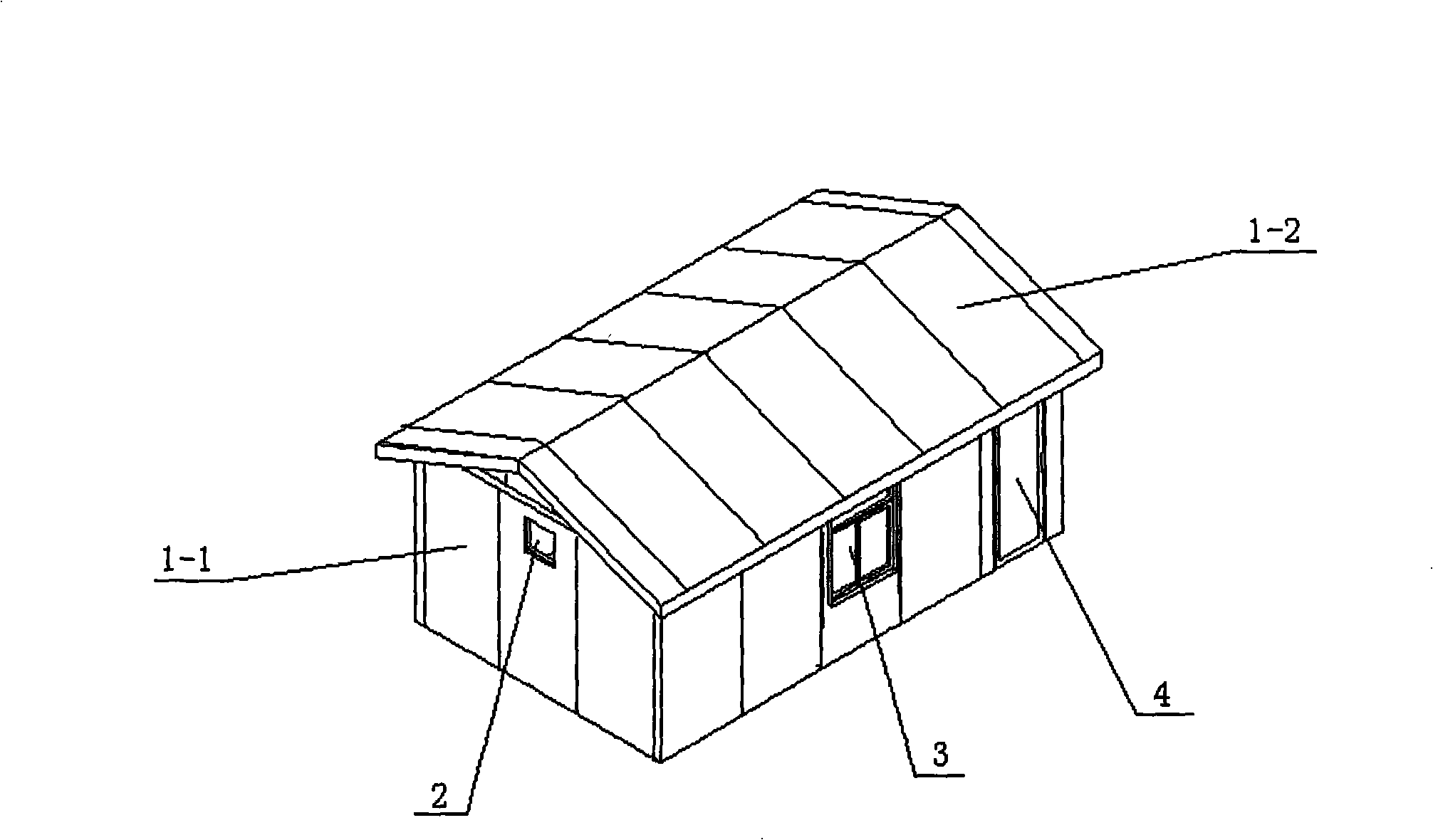

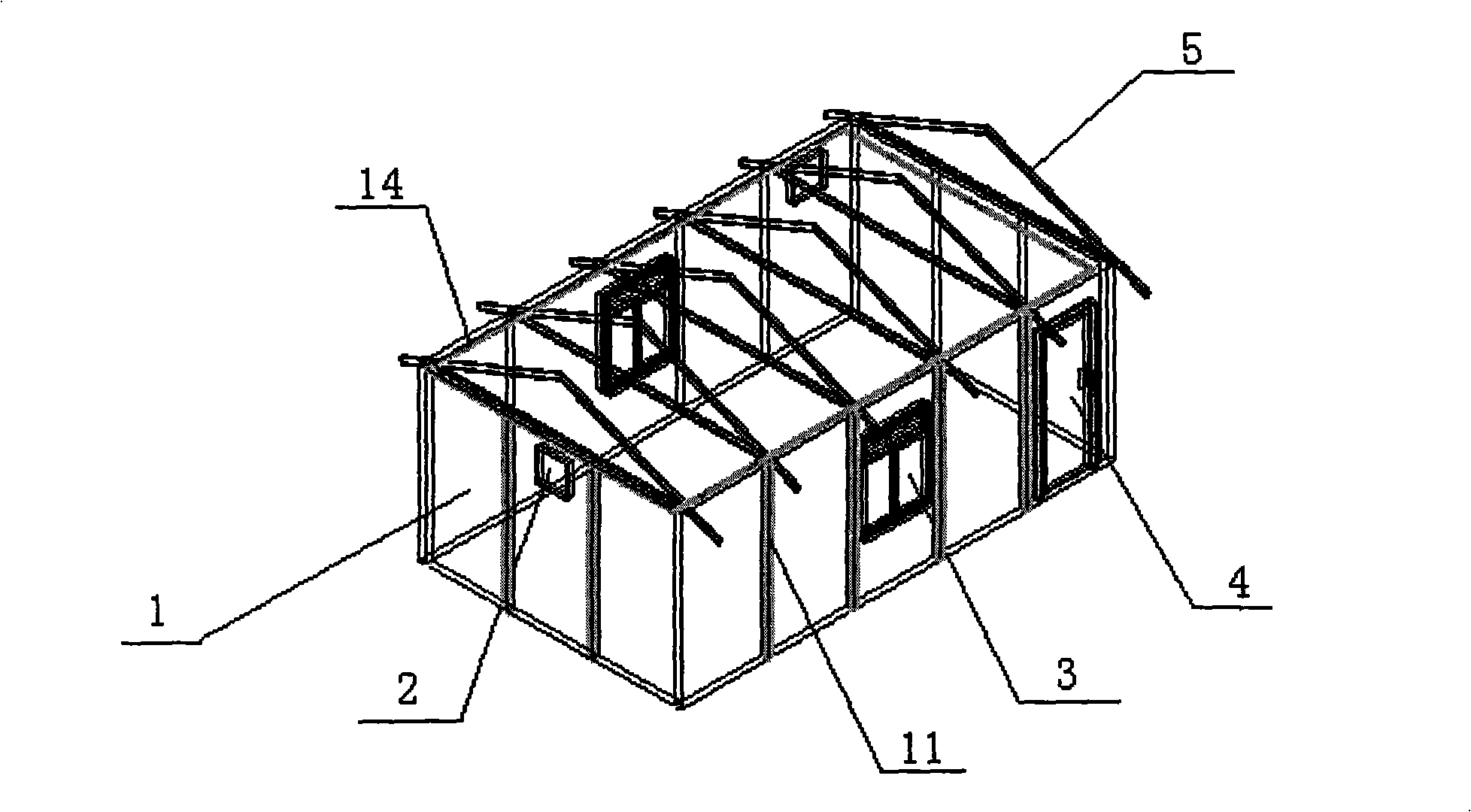

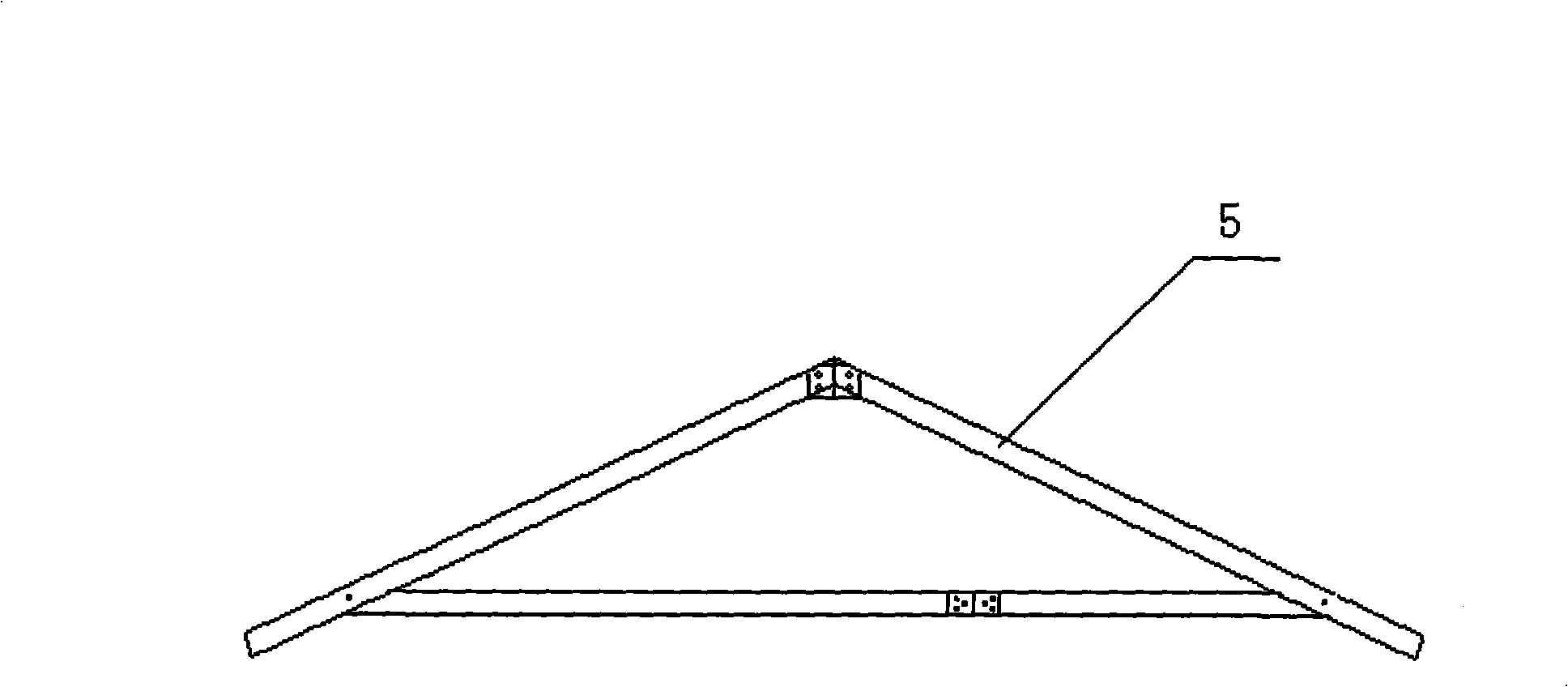

Rapidly assembled bamboo wood barrack

InactiveCN101338622AFast growthCorrosion resistanceBuilding constructionsProtective buildings/sheltersThermal insulationEngineering

The invention relates to a quickly assembled bamboo frame house which comprises plate units, bamboo house frames, connecting pillars and connecting beams; wherein, the frame of the plate unit is made of bamboo veneers or wood beams; the external plate of the plate unit is made of bamboo veneers; the internal plate of a wall plate unit is made of gypsum plates or bamboo veneers or light wooden plates; the internal plate of a house plate unit is made of gypsum plates; and thermal-insulation material or sound-insulation material is filled between the external plate and the internal plate. The connecting pillars and the connecting beams are made of bamboo veneers; the connecting beam is connected with the side of the wall plate unit by bolts; and the wall plate units are connected with each other by the connecting pillars and bolts. The wall plate units at the corners of a house are connected with each other by bolts and angle steel. With excellent quakeproof performance and good thermal-insulation effect, the frame house provided by the invention can be processed and assembled quickly and can be dismounted and reused; moreover, the main construction material is environmental friendly and the material source is wide; therefore, the frame house has low manufacturing cost.

Owner:HUNAN UNIV

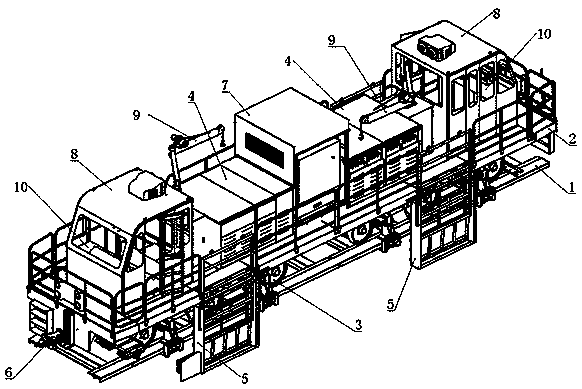

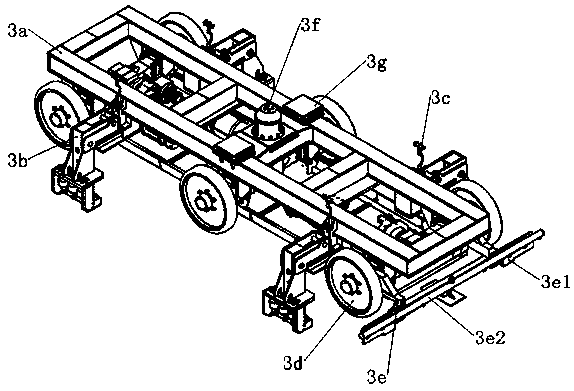

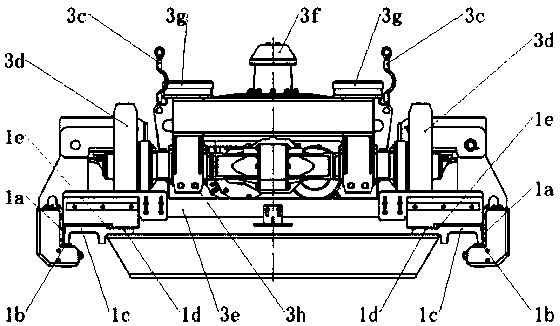

Maglev train traction maintenance engineering vehicle

ActiveCN109094586AWith fault self-diagnosis functionImprove battery lifeElectric locomotivesRailway braking systemsBogieSnow removal

The invention relates to a traction and maintenance engineering vehicle of a maglev train, which is important necessary equipment for the maintenance of a maglev line. Battery is used as power sourceand AC motor is controlled by inverter system to drive running system. 3-axle power bogies and guide device are used to ensure that wheels of the engineering truck run on the non-inductive plate partof the F-type rail surface, so as to ensure the safety of the engineering truck overhaul operation and the traction rescue maglev train; And reliably connecting or releasing the connecting state withthe medium-low speed maglev train by the traction connecting device; And through the electrical control system to accurately control the driving, braking, traction and other operations. The engineering vehicle is suitable for the operation of maglev depot, comprehensive base and line, undertaking maglev train traction and rescue, regular patrol inspection of track / contact rail, spare parts repairand replacement, auxiliary staff and material transportation, as well as dust and snow removal under special weather conditions.

Owner:大连铁丰轨道交通装备有限责任公司 +1

Disperse dye digital printing technology

InactiveCN106149403AMeet the requirements of personalized clothingLess investmentFibre treatmentTransfer printing processDisperse dyePrinting ink

The invention relates to a disperse dye digital printing technology. The disperse dye digital printing technology comprises the following steps that 1, fabric is divided into polyester fabric and non-polyester fabric, wherein the polyester fabric comprises blended fabric taking polyester as the main material, and the non-polyester fabric needs to be subjected to pretreatment to obtain the pretreated non-polyester fabric; 2, disperse dye ink or printing ink for printing is prepared, and the color base is a printing colorant formed by blending the disperse dye; 3, color ink obtained in the second step is printed on transfer paper, namely stained paper through a printing or digital printing method; 4, the front face of the stained paper in the third step is tightly attached to the printed fabric, wherein the printed fabric is the polyester fabric or the pretreated non-polyester fabric; 5, the disperse dye in the color ink sublimates through high temperature pressing to be adsorbed on the surface of the fabric, fixation is conducted on fiber, and patterns with corresponding colors are displayed. The disperse dye digital printing technology has the advantages of being simple in equipment, small in investment, short in technological process, environmentally friendly, good in quality, high in flexibility and the like.

Owner:任旭丹

Method for preparing 2, 4-dichloroacetophenone

InactiveCN102675073AImprove securityThe operation process is safe and controllableCarbonyl compound preparation by condensationAcetic anhydrideDistillation

The invention discloses a method for producing 2, 4-dichloroacetophenone. The method mainly includes acylation, hydrolysis, washing, distillation and crystallization, and m-dichlorobenzene and acetic anhydride are in acylation reaction under the effects of anhydrous aluminum trichloride. The method has the advantages that the m-dichlorobenzene is used as a raw material, the acetic anhydride is used as an acylating agent, A1C13 is used as a catalyst to prepare the 2, 4-dichloroacetophenone by means of reaction, and yield of obtained products is higher than that of products prepared by using acetyl chloride as an acylating agent; as the acetic anhydride is used as the acylating agent, the A1C13 is used as the catalyst and the m-dichlorobenzene which is extracted from chlorinated aromatics waste is comprehensively used as the raw material to prepare the 2, 4-dichloroacetophenone, by-products in a benzene chlorination process are disposed, reusing rate of chlorinated aromatics is increased, and the method has high economical and economical benefits.

Owner:JIANGSU LONGCHANG CHEM

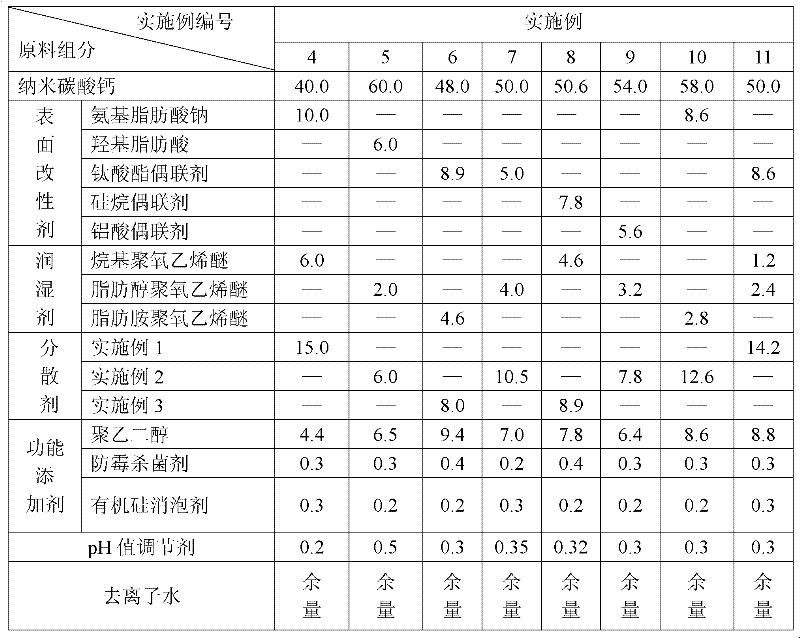

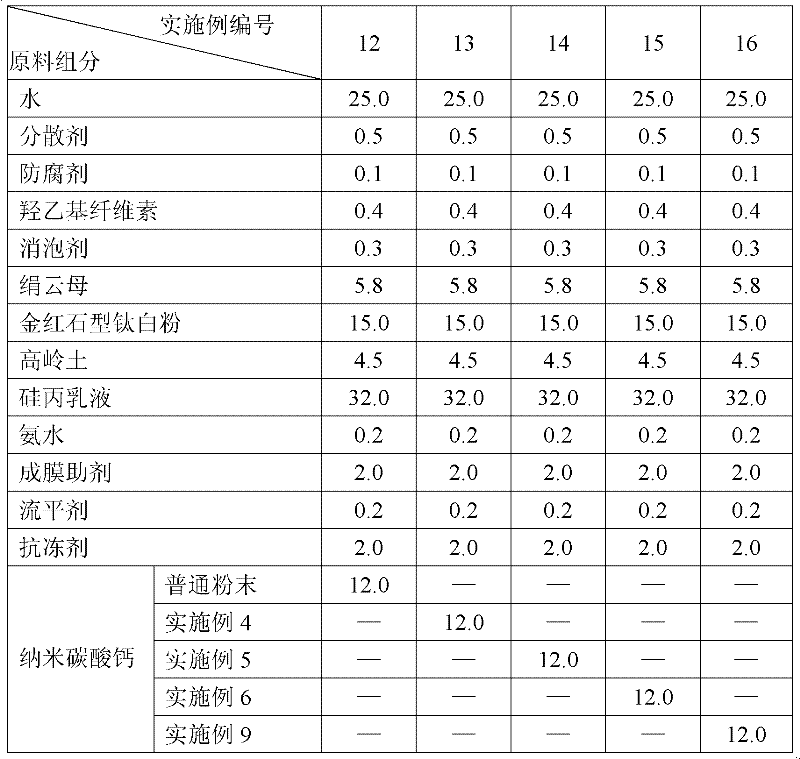

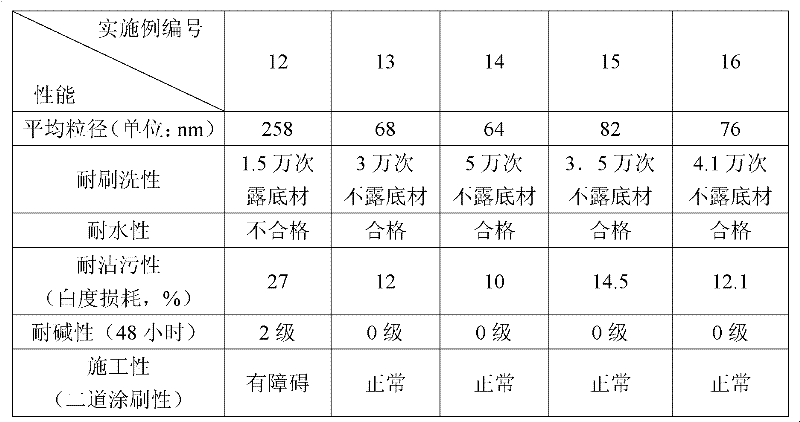

Aqueous high-content nanometer calcium carbonate dispersoid and preparation method thereof

InactiveCN102532976AImprove wettability and dispersibilityAvoid dust pollutionAntifouling/underwater paintsPaints with biocidesNanometreCalcium carbonate

The invention discloses an aqueous high-content nanometer calcium carbonate dispersoid and a preparation method of the aqueous high-content nanometer calcium carbonate dispersoid. The aqueous high-content nanometer calcium carbonate dispersoid comprises the following ingredients through being metered by the total mass percentage: 40.0 to 60.0 weight percent of nanometer calcium carbonate, 5.0 to 10.0 weight percent of surface modifying agents, 2.0 to 6.0 weight percent of wetting agents, 6.0 to 15.0 weight percent of dispersing agents, 5.0 to 10.0 weight percent of functional additives, 0.2 to 0.5 weight percent of pH value conditioning agents and the balance de-ionized water, wherein the dispersing agents are formed by the self preparation of three polymerizable monomers through reaction. The aqueous high-content nanometer calcium carbonate dispersoid can replace nanometer calcium carbonate powder of the same quantity in the paint preparation process, in addition, the calcium carbonate dispersoid is easily dispersed, and the performance of the paint in multiple aspects of water resistance, washing resistance, stain resistance, construction performance and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

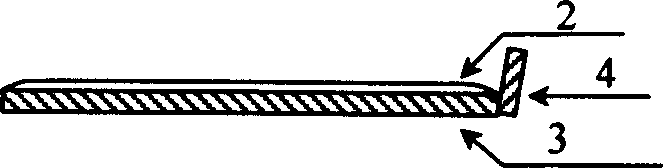

Preparation method of polyimide fiber insulating paper

InactiveCN102587217AImprove performanceImprove insulation performancePlastic/resin/waxes insulatorsImidePolymer science

The invention discloses a preparation method of polyimide fiber insulating paper. The preparation method comprises the following steps of: adopting a polyimide fiber with a length of 20-78 mm and a fiber number of 0.7-8.0 dtex as a raw material, and obtaining a polyimide fiber net through conventional opening, carding and lapping; and then, impregnating the fiber net into a polyamic acid adhesive solution for 10-30 minutes, passing the fiber net through a mangle with a mangle expression of 100-300%, and then, drying the fiber net, and finally, preparing the polyimide fiber insulating paper through a mould pressing process, wherein the adhesive solution is prepared from polyamic acid resin with the same components as the polyimide fiber and a solvent according to a requirement that the volume concentration is 0.3-30%; the solvent is selected from one or two of DMF (dimethyl formamide), DMAc (dimethyl acetamide ) and NMP (N-methyl pyrrolidone) mixed in any proportion; the drying temperature is 40-130 DEG C and the drying time is 0.5-6 hours; and the mould pressing process is that the mould pressing temperature is 150-350 DEG C, the mould pressing pressure is 2-25 MPa, and the mould pressing time is 5-90 minutes.

Owner:TIANJIN POLYTECHNIC UNIV

Novel method for preparing composite organic calcium with high water solubility by using acid fruit juice and eggshell

A new preparing high dissolved complex organic calcium method using acid fruit juice and eggshell as raw materials which is that cleaning, triturating and drying the eggshell, then calcining to eggshell powder, preparing and getting fruit juice by fruits flayed, enucleated, extracted and filtrated; dissolving eggshell powder into fruit juice with mixing at some temperate to make fruit juice of neutrality from acid, where the most suitable quality is 1~5g per fruit juice 100g; putting reacted resultant into petri dish, heating and drying to get calcium preparation at 80 deg.C, or packaging to liquid product directly without drying. The method uses natural fruit juice in place of lactic acid, acetic acid, gluconic acid, citric acid and malic acid artificial composed or fermentation, from which the product can solved in water very easy, contains mass calcium and many kinds natural benefit ingredient, and is propitious to absorb and take for long time.

Owner:李理

An air cleaning device for a pharmaceutical workshop

InactiveCN105521678ASimple structureEasy to useCombination devicesGaseous substancesVertical barBristle

An air cleaning device for a pharmaceutical workshop is disclosed. The air cleaning device comprises an air inlet device, a connecting device, a heating and disinfecting device, a pipeline device, a mixing device and an air outlet device. The air inlet device comprises an air inlet pipe, a first draught fan, an air inlet frame, a block, a first vertical bar, a first cross bar, a first rotating shaft, first bristles, a first filter screen and a first support. The connecting device comprises a first pipe, a second filter screen, a second vertical bar, a second cross bar and a second support. The heating and disinfecting device comprises a heating frame, a heat insulating plate, second fixing rings, a centralizing hopper, a heating bar, a thermal conductive plate, first fixing rings, a third filter screen, a fourth filter screen and a fifth filter screen. The pipeline device comprises a second pipeline, a first valve, a third vertical bar and a third cross bar. The mixing device comprises a mixing tank, a water inlet pipe, a water feeding hopper, a second valve, a second rotating shaft, second bristles, a sponge mat, a fifth filter screen and supporting bars. The air cleaning device can subject air in the pharmaceutical workshop to sufficient cleaning and disinfection, and can prevent pollution to the environment.

Owner:薛彩霞

Ion-type rare-earth ore ammonium-free environment-friendly exploitation technique

InactiveCN108034842ANo pollution in the processPollution meetsProcess efficiency improvementEnvironmental resistanceIon exchange

The invention discloses an ion-type rare-earth ore ammonium-free environment-friendly exploitation technique. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique comprises the following steps that an ammonium-free ore leaching agent with a certain concentration is injected through liquid injecting holes distributed in a stope to be subjected to an ion exchanging reaction with rare-earth ores so as to obtain mother liquid enriched in rare-earth positive ions; the mother liquid seeps and gathers into liquid collecting engineering such as matching of ore-layer natural water partition bottom plates or artificial liquid collecting roadways with liquid collecting flow guiding holes; and then the mother liquid is conveyed to a hydrometallurgy workshop through a main conveying pipeline, ammonium-free agents are used for impurity removal and precipitation to obtain rare-earth carbonate, and supernatant liquid is circulated back to a liquid preparation pool andthen subjected to pH valve adjustment and agent adding, and returns to the stope to serve as a new ammonium-free ore leaching agent. The ion-type rare-earth ore ammonium-free environment-friendly exploitation technique has the advantages that ammonium is avoided in the overall process, and environmental friendliness is achieved on soil and water bodies; production waste water is circularly and comprehensively utilized, and harmful waste discharging is avoided; and the leaching rate, liquid collecting rate and precipitating rate of the rare-earth ions are high, and the resource mining comprehensive recovery rate is increased.

Owner:五矿勘查开发有限公司

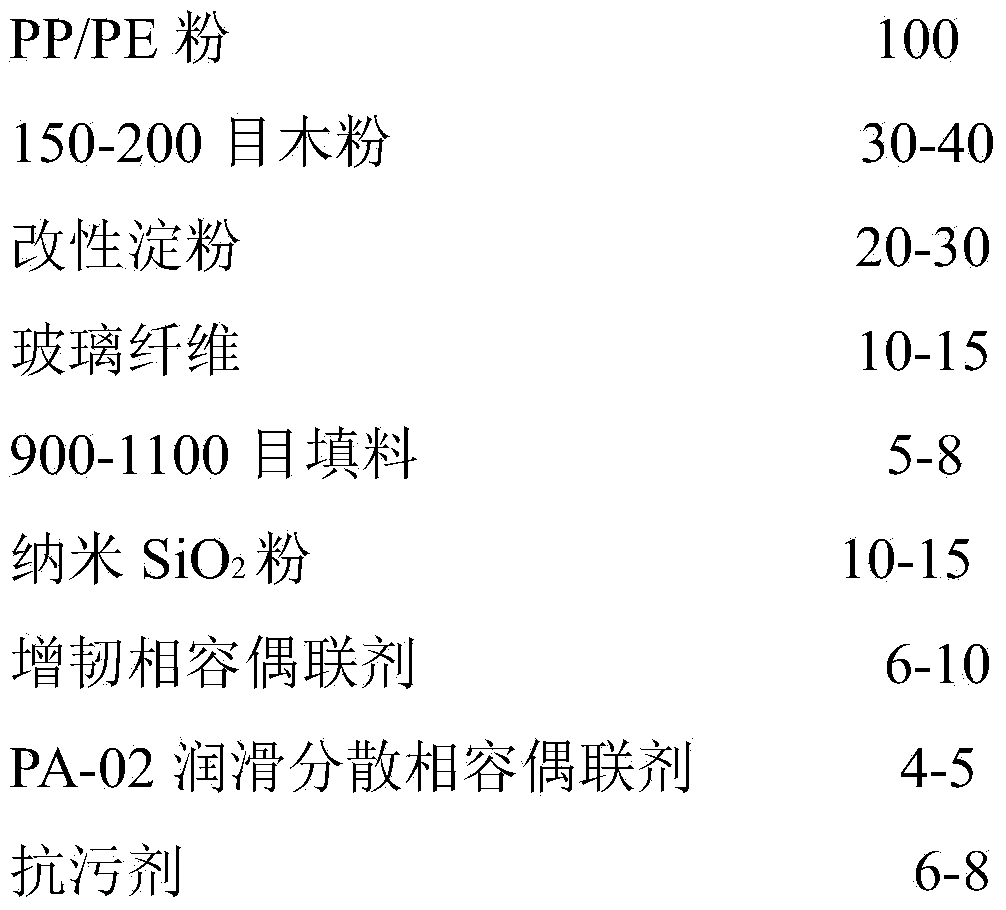

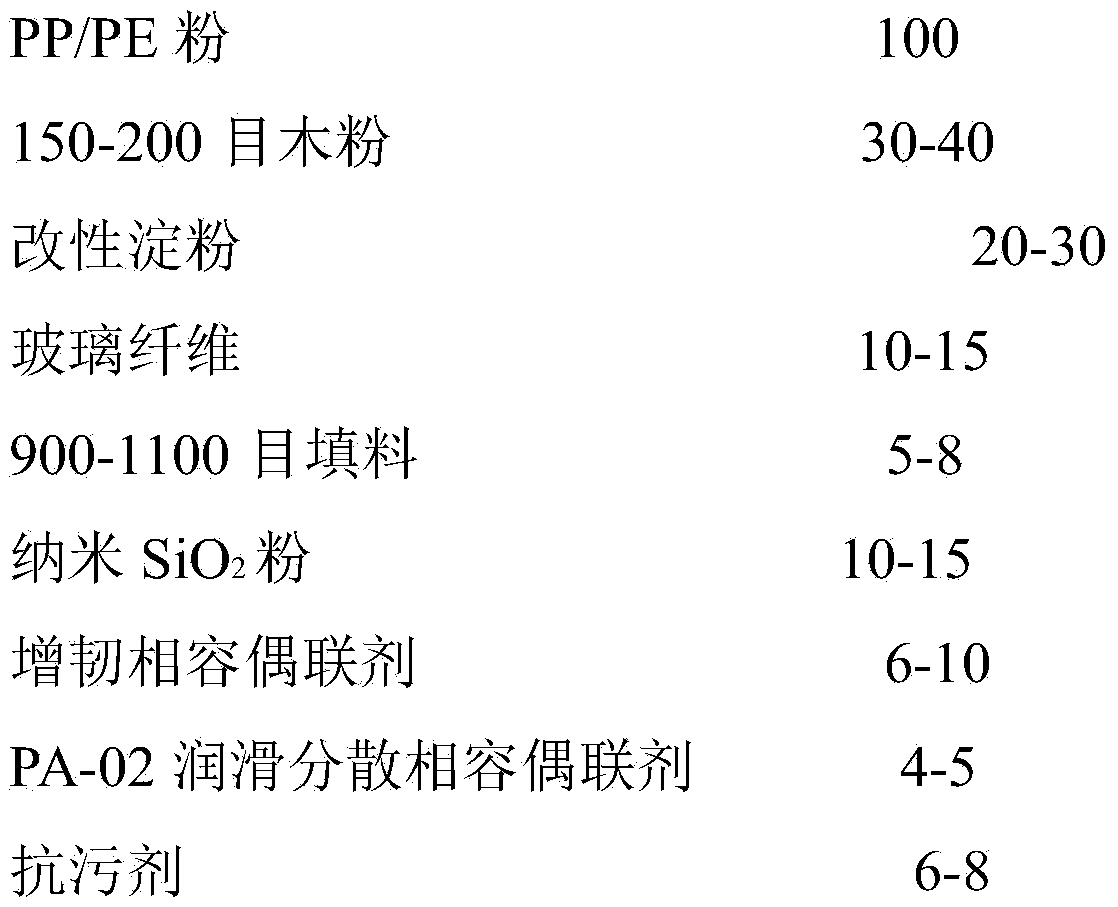

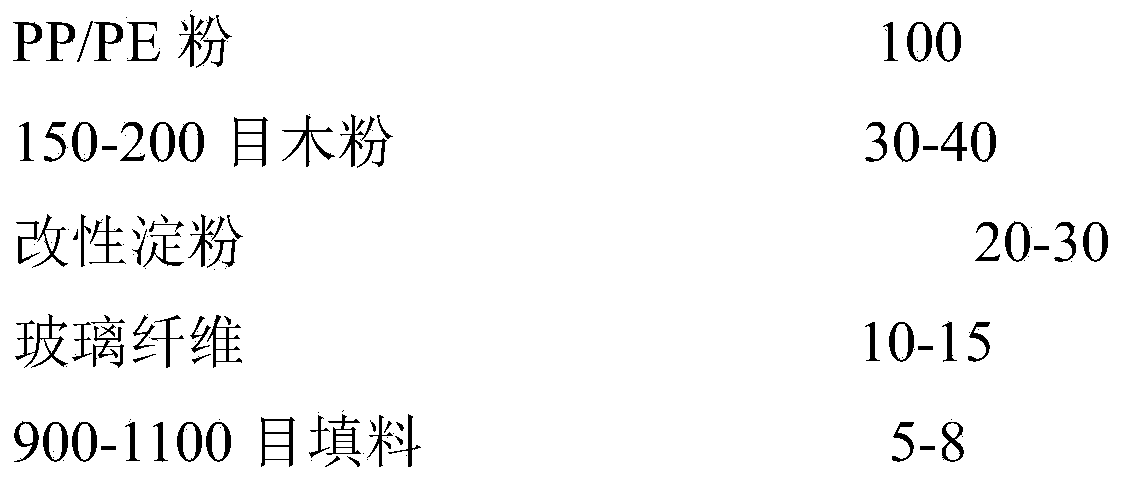

Preparation method of degradable anti-pollution wood plastic material and product

The invention discloses a preparation method of a degradable anti-pollution wood plastic material. The preparation method comprises the following steps: 1) preparing the components in parts by weight: 100 parts of PP / PE powder, 30-40 parts of (150-200)-mesh wood flour, 20-30 parts of modified starch, 10-15 parts of glass fibers, 5-8 parts of (900-1100)-mesh filler, 10-15 parts of nano SiO2 powder, 6-10 parts of toughening compatible coupling agent, 4-5 parts of PA-02 lubricative dispersing compatible coupling agent and 6-8 parts of anti-pollution agent; and 2) highly mixing the PP / PE powder, the (150-200)-mesh wood flour, the modified starch, the glass fibers, the (900-1100)-mesh filler and the nano SiO2 powder to 100-120 DEG C; after fully mixing, adding the PA-02 lubricative dispersing compatible coupling agent, the toughening compatible coupling agent and the anti-pollution agent and mixing to 120-140 DEG C; and after fully mixing, cooling to 30-50 DEG C and granulating to form the degradable anti-pollution wood plastic material. The mechanical properties of the material disclosed by the invention are adjusted by virtue of proportion of the glass fibers and the filler, the degradable environment-friendliness is adjusted by virtue of proportion of the plastic, the modified starch and the wood flour, and finally, the anti-pollution performance is enhanced by virtue of the nanoscale silicon dioxide and anti-pollution agent.

Owner:GUANGDONG HONGYUN FURNITURE CO LTD +3

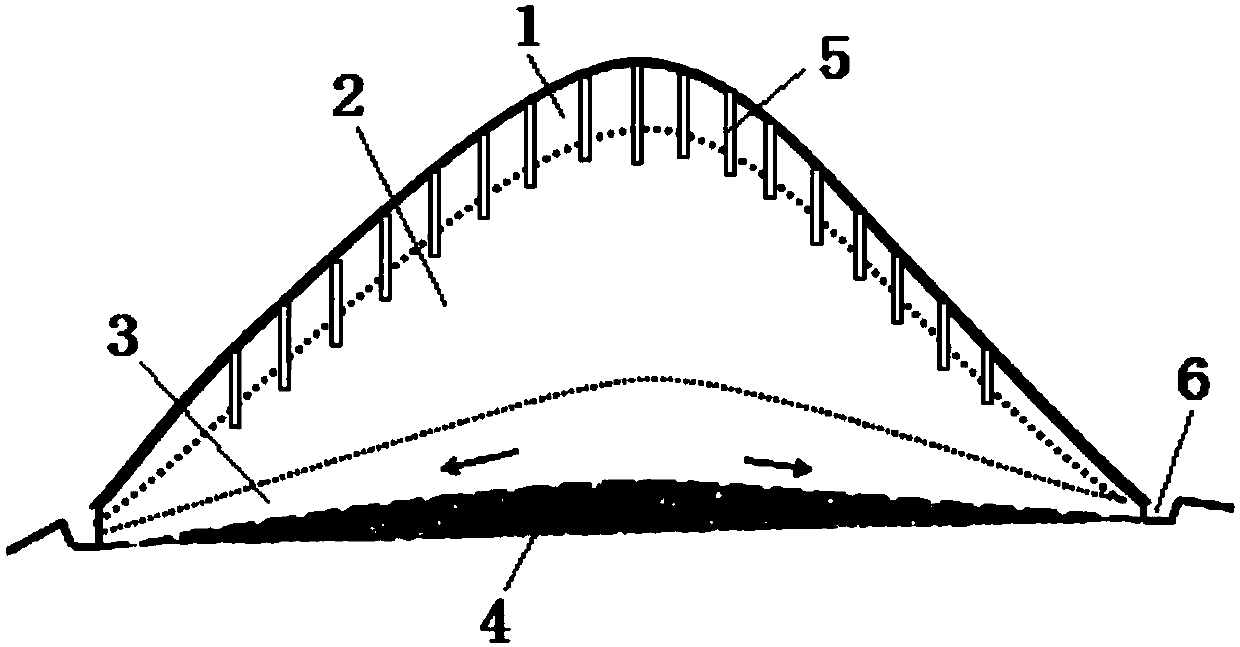

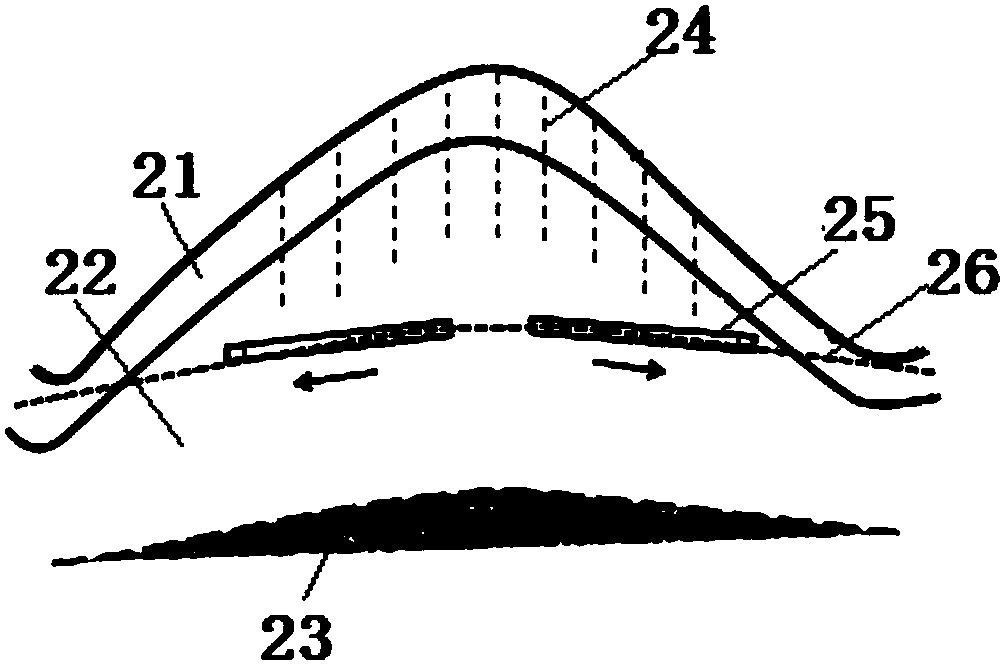

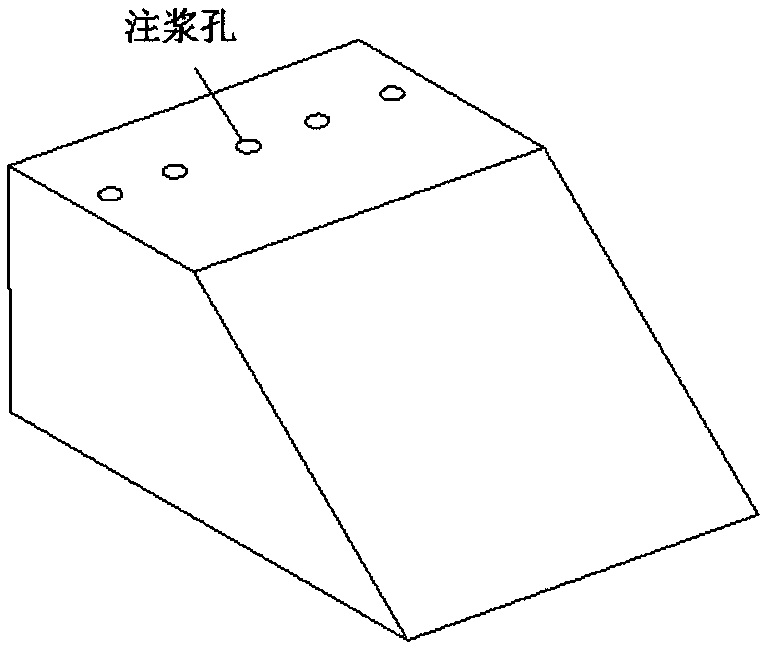

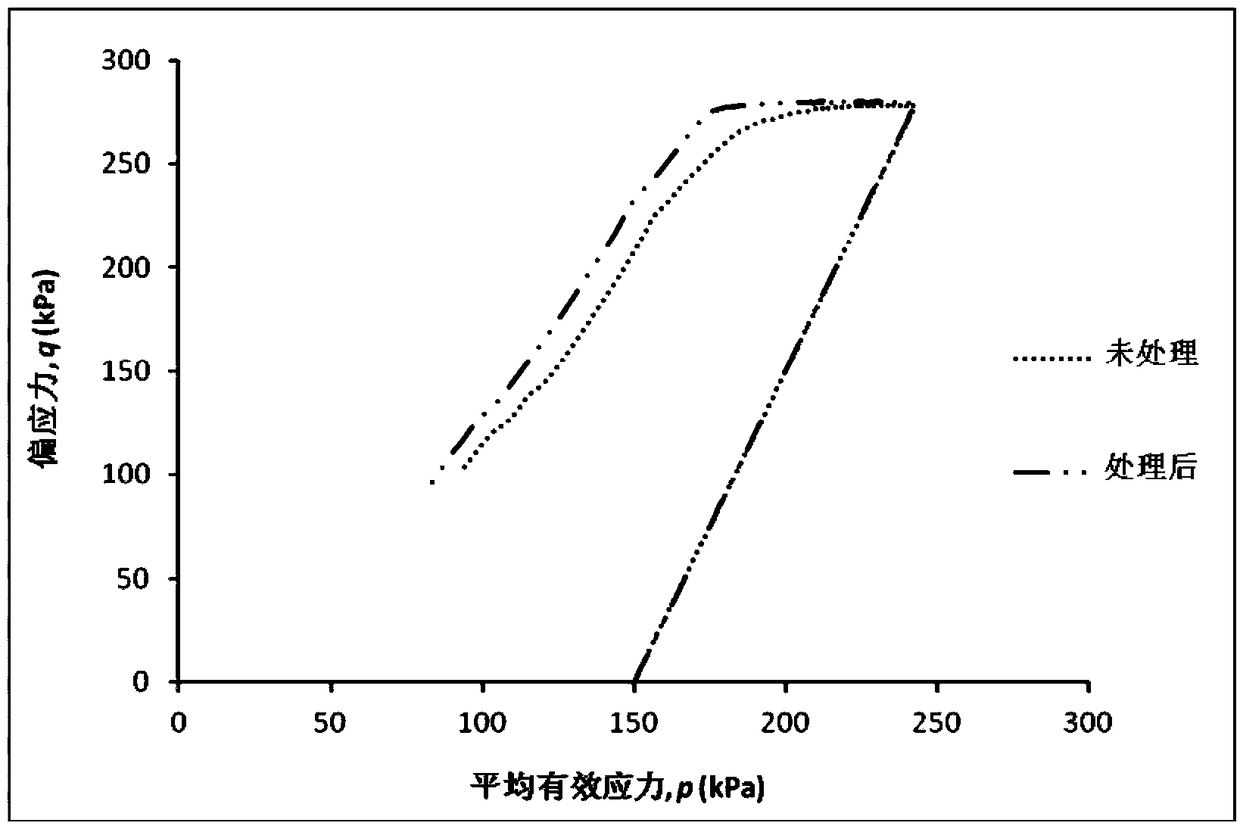

Slope strengthening method based on plant urease reinforcing liquid

The invention discloses a slope strengthening method based on plant urease reinforcing liquid. Grouting treatment is carried out on the interior of a slope through the plant urease reinforcing liquid,and spraying treatment is carried out on the surface layer of the slope. The plant urease reinforcing liquid is prepared from bean flour rich in urease, processing powder and water, and constituentsof the processing powder include urea and calcium salt, wherein the mass ratio of the bean powder to the processing powder is 1:1-1:2, and the mass ratio of the bean powder to the water is 1:10-1:20.The plant urease reinforcing liquid obtained by adding the water into the bean powder and the processing powder is fed into the slope and sprayed onto the surface of the slope, crystallization of calcite is promoted through carbonate generated in a urea hydrolysis reaction and the rising of ph in the reaction process, low-carbon and environment-friendly crystal matter high in strength and adhesivestrength is formed and is filled and adhered among soil particles of the slope, the soil strength can be remarkably improved, the effect that the slope is strengthened is achieved, and the overall stability of the slope is improved.

Owner:HOHAI UNIV

Water-based coating and preparation method thereof

ActiveCN101942256AReduce pollutionPollution meetsAnti-corrosive paintsPotassium persulfateSodium acetate

The invention relates to a water-based coating. The water-based coating is prepared form the following raw materials in percentage by weight: 52 to 55 percent of water, 0.5 to 0.7 percent of sodium dodecyl sulfate, 20 to 25 percent of methyl methacrylate, 3 to 4.5 percent of butyl acrylate, 0 to 2 percent of ethyl hexyl acrylate, 1 to 1.5 percent of acrylic acid, 10 to 15 percent of butyl methacrylate, 1 to 2 percent of butyl maleate, 0.6 to 1 percent of ethyl acrylate, 0.4 to 1 percent of itaconic acid, 0.8 to 1 percent of ammonia water, 0.1 to 0.2 percent of antifoaming agent, 0.05 to 0.1 percent of sodium acetate, 0.1 to 0.2 percent of preservative and 0.1 to 0.2 percent of potassium persulfate. The invention also provides a method for preparing the water-based coating. The water-based coating of the invention is innoxious and has a small amount of environmental pollution; and a coating layer formed by coating has the advantages of high brightness, toughness, excellent anti-explosion performance, excellent subsequent processing performance, capability of stamping gold rapidly and efficiently and good gold stamping effect.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

Safe-type plant washing liquid and preparation method therefor

InactiveCN103361208ARaise the level of full serviceHumanized use effectSurface-active non-soap compounds and soap mixture detergentsSodium bicarbonateWarm water

The invention relates to a safe-type plant washing liquid, especially relates to a safe-type plant washing liquid used for washing of tableware and a preparation method, belongs to the field of civil environmentally-friendly-type washing products, aims to provide a safe-type plant washing liquid and a preparation method therefor. Cassia seeds, ginkgo leaves, soybeans, tea seeds and loofah sponge are crushed, placed into warm water with the temperature of 40-50 DEG C at certain ratios, soaked for hours, and filtered to obtain a mixing liquid. The mixing liquid is added with appropriate amounts of salt and sodium bicarbonate to form a safe-type plant washing liquid. The safe-type plant washing liquid can be used to wash tableware and wipe cooker. The safe-type plant washing liquid not only has strong washing and degreasing abilities, but also has hand-caring functions.

Owner:杨月滢

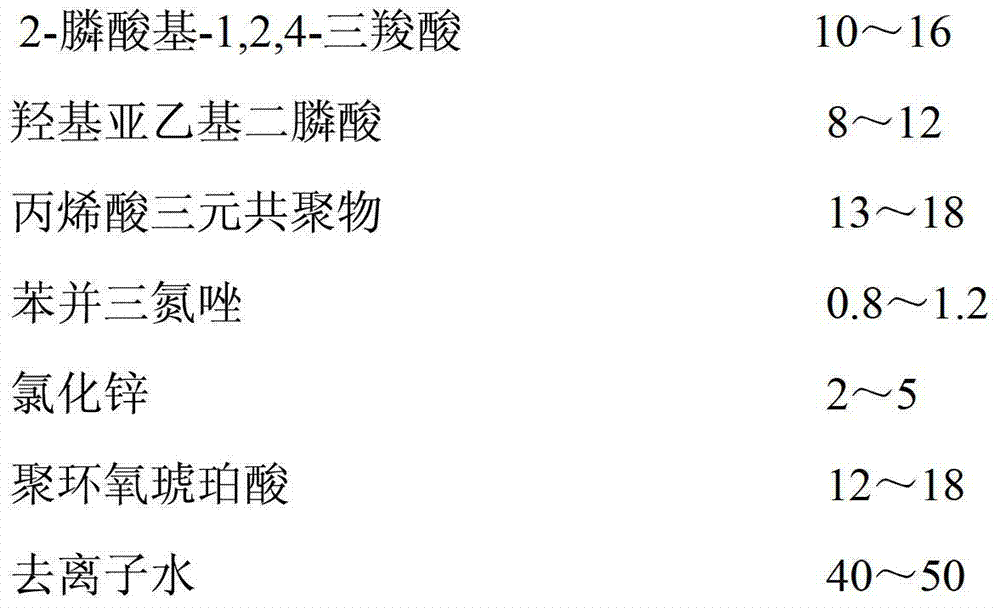

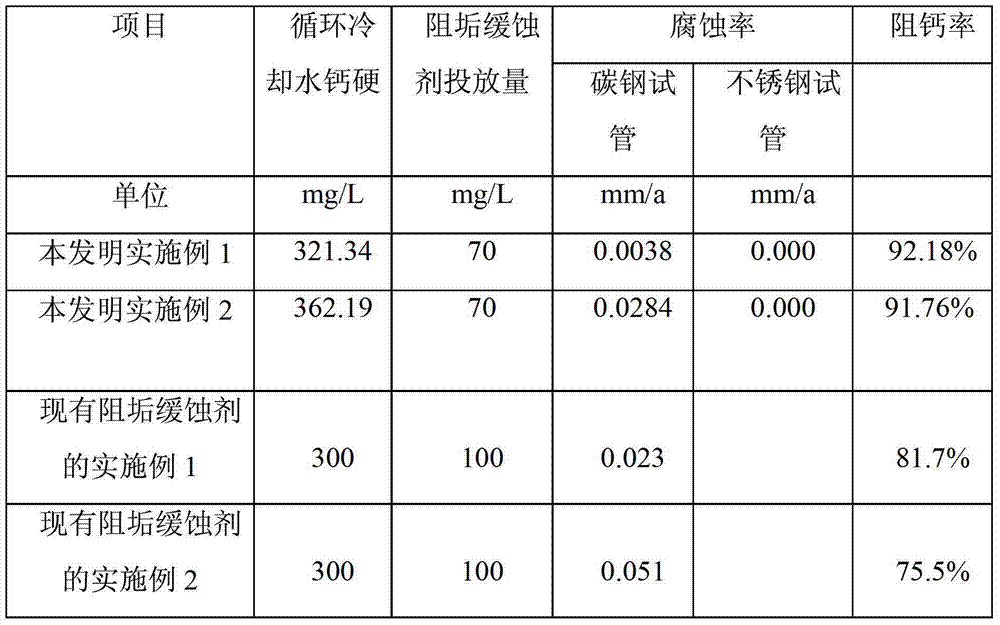

Composite scale and corrosion inhibitor

InactiveCN103241846AGood scale and corrosion inhibitionImprove complexation effectTreatment using complexing/solubilising chemicalsTricarboxylic acidCopolymer

The invention discloses a composite scale and corrosion inhibitor. The inhibitor is characterized by comprising the following main ingredients: 2-phosphono-1,2,4-tricarboxylic acid, hydroxyethylidene-1,1-diphosphonic acid, an acrylic copolymer, benzotriazole, zinc chloride, polyepoxysuccinic acid and deionized water. The inhibitor disclosed by the invention has the following beneficial effects that 2-phosphono-1,2,4-tricarboxylic acid, the hydroxyethylidene-1,1-diphosphonic acid, the acrylic copolymer, benzotriazole, zinc chloride and the polyepoxysuccinic acid of the inhibitor all have good scale and corrosion resistance; and after the above ingredients are compounded according to the weight parts in the formulation of the inhibitor disclosed by the invention, the scale and corrosion resistance effect of the inhibitor is obviously enhanced. The inhibitor disclosed by the invention is suitable for high hardness and high base, and has extremely strong complexing function on carbonate scale. The composite sale and corrosion inhibitor is good in scale and corrosion resistance, low in phosphorus content, and therefore is capable of meeting environment protection requirements. The inhibitor disclosed by the invention not only is suitable for circulating cooling water in a natural gas purification treatment plant, but also is suitable for circuiting cooling water systems in other industries of chemical fertilizer, power, textile and the like, as well as is wide in application range; and acid does not need to be added for regulating PH (Potential of Hydrogen) value.

Owner:北京市龙源科创石油技术有限公司

Method for manufacturing outer bag paper of fruit raising bags by using adherography

InactiveCN102660890ASimple production processFastReinforcing agents additionWax additionPaper productionPrinting ink

A method for manufacturing outer bag paper of fruit raising bags by using adherography comprises repulping, slurry matching, net portion shaping, dehydrating by squeezing, stoving, rolling and separately cutting body paper products obtained by rewinding. Offset printing comprises mixing black printing ink and printing on a machine. The outer bag paper of the fruit raising bags produced by the method can be separated into body paper and an ink layer, shading performance is achieved by printing the black ink layer on the body paper, and the method has the advantages of being simple in body paper production process, capable of producing by using a long net paper machine, rapid in speed, low in cost, less in pollution and the like, and simultaneously solves the problem that carbon black in a lamination method and used in the liquid for dying causes pollution, use ratio is low, a circular net paper machine is slow in speed and the like. The black printing ink is used for printing, anti-liquid-permeation performance of the paper can be improved, simultaneously the paper has good opaqueness, is not prone to fade, keeps high compliance and air permeability.

Owner:SHAANXI UNIV OF SCI & TECH

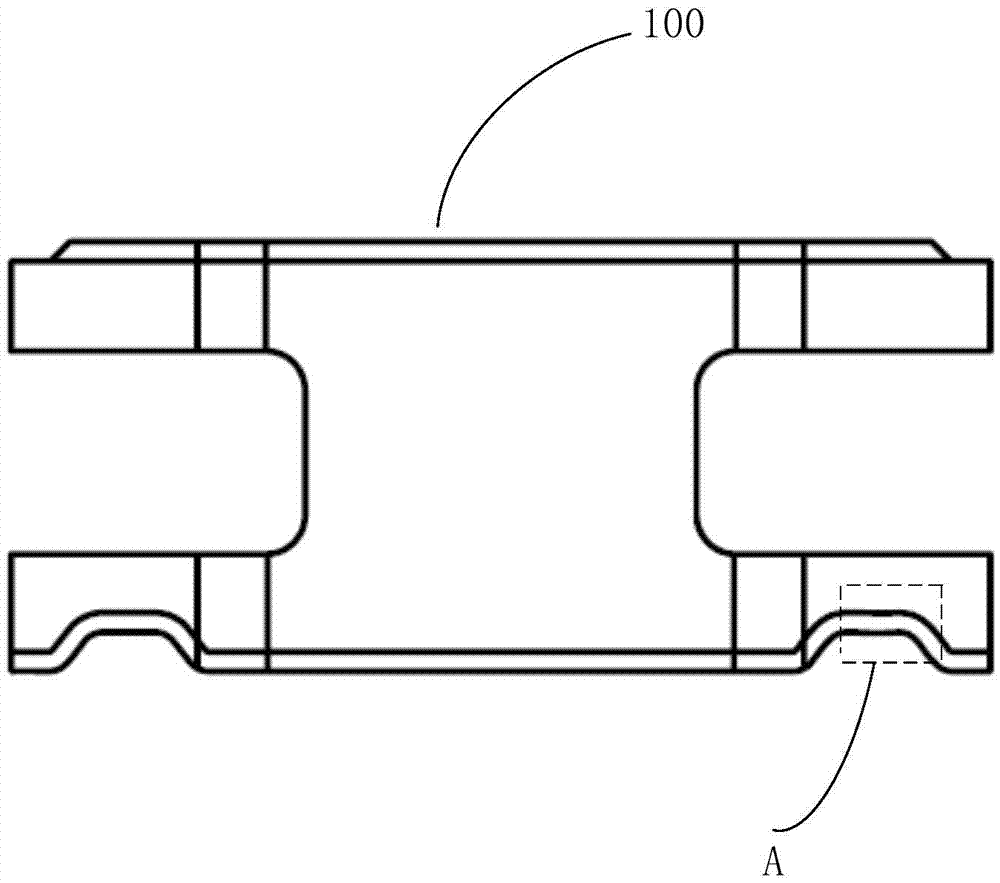

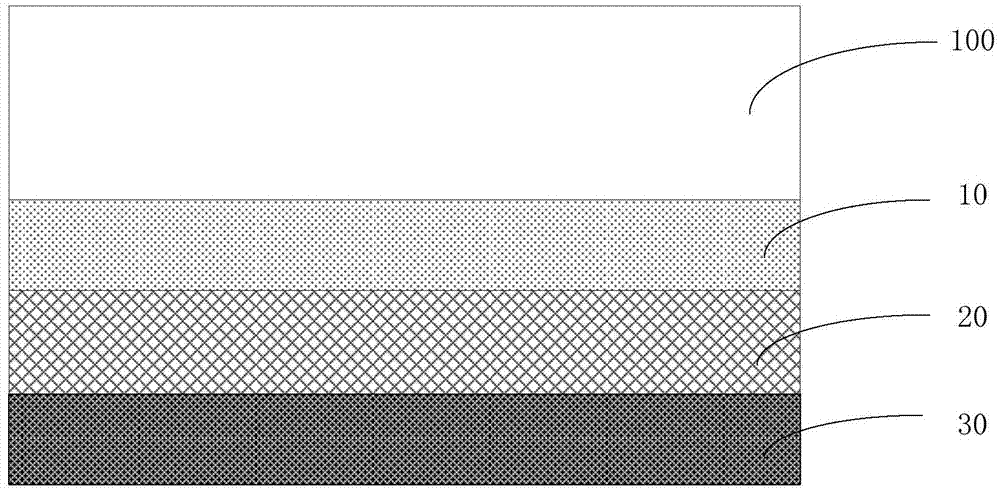

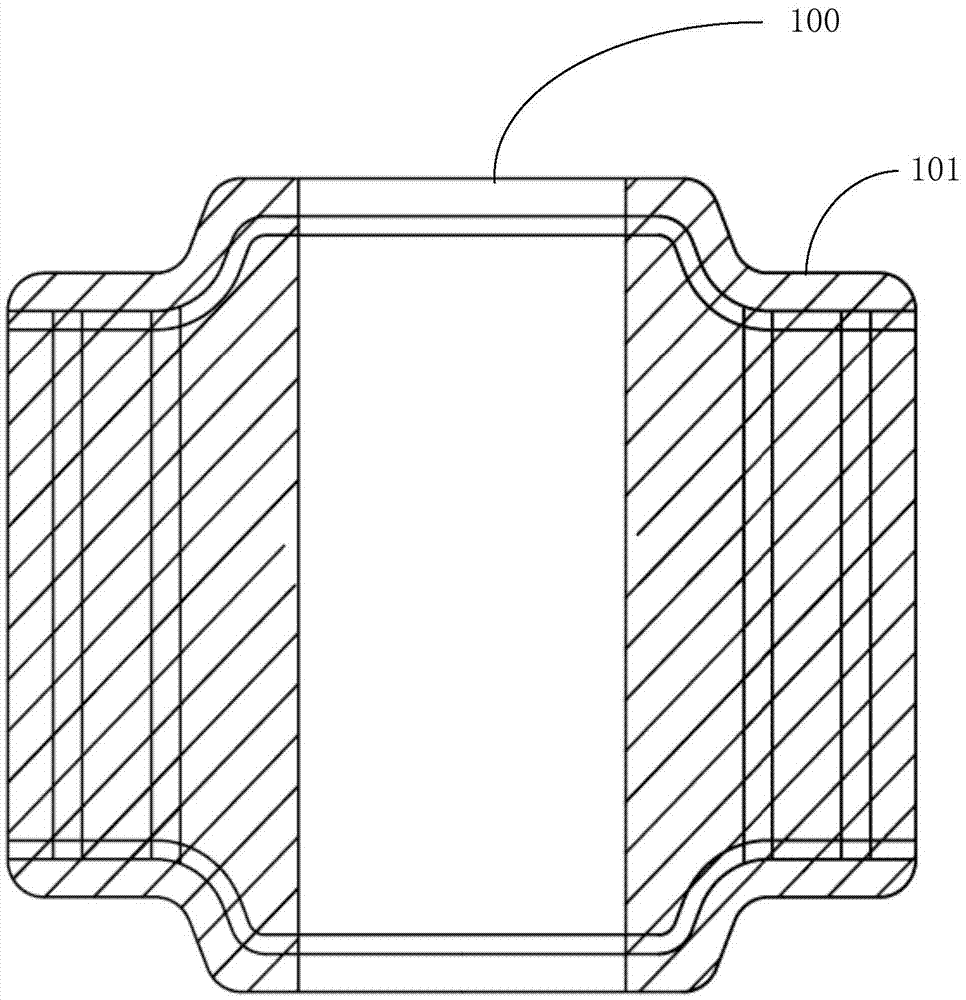

Metallized iron powder core and preparation method thereof

ActiveCN105448466AImprove adhesionGood compatibilityVacuum evaporation coatingSputtering coatingMagnetic coreChromium

The embodiment of the invention provides a metallized iron powder core, comprising an iron powder core, wherein an electrode area is arranged on the iron powder core; a metal coating connected with other devices is formed on the electrode area; the metal coating comprises a chromium layer, a nickel-copper alloy layer and a silver layer sequentially stacked on the electrode area; the chromium layer, the nickel-copper alloy layer and the silver layer are prepared by magnetron sputtering. The metal coating of the metallized iron powder core provided by the invention has the advantages of high adhesive force, strong heat resistance, good weldability and low cost. The embodiment of the invention also provides a preparation method of the metallized iron powder core, which is rapid in film forming speed, free of pollution during whole technical process, and low in cost.

Owner:SHENZHEN KANGCI ELECTRONICS CO LTD

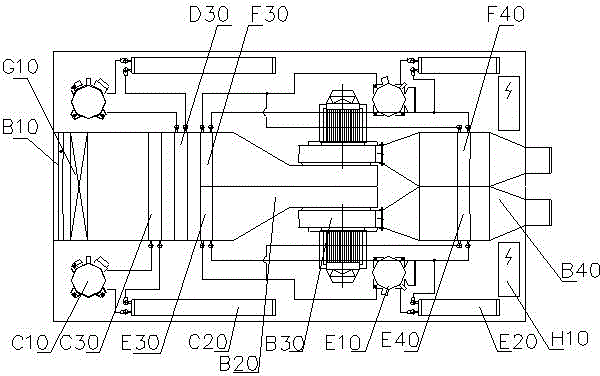

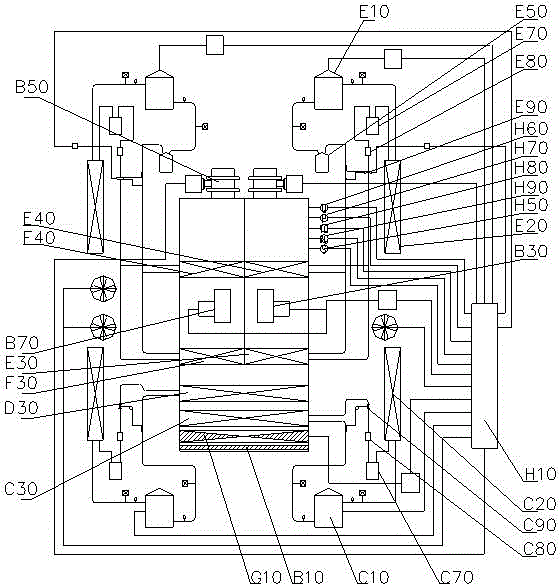

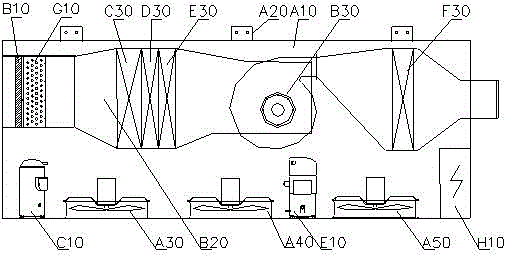

Variable frequency high-precision aircraft ground air conditioning unit and control method thereof

ActiveCN103332298AReasonable designHigh adjustment accuracyMechanical apparatusSpace heating and ventilation safety systemsAutomatic controlControl system

The invention discloses a variable frequency high-precision aircraft ground air conditioning unit and a control method of the aircraft ground air conditioning unit. The aircraft ground air conditioning unit comprises a frame structure, an air conditioning air supply system, a first refrigerating system, a second refrigerating system, a third variable frequency refrigerating system, a fourth variable frequency refrigerating system, a heating system and an automatic control system, wherein the frame structure comprises an air conditioning box, and a first axial flow fan, a second axial flow fan and a third axial flow fan which are arranged on the air conditioning box; all the systems are arranged in the frame structure; and the first axial flow fan, the second axial flow fan, the third axial flow fan, the air conditioning air supply system, all the refrigerating systems and the heating system are respectively connected with the automatic control system. The variable frequency high-precision aircraft ground air conditioning unit is reasonable in design, high in efficiency, energy-saving, high in adjustment accuracy, high in intelligence degree, compact in structure, small in volume, light in weight, high in safety performance and stable and reliable in running, saves the energy, reduces the environmental pollution, and is high in outlet air temperature adjustment accuracy.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

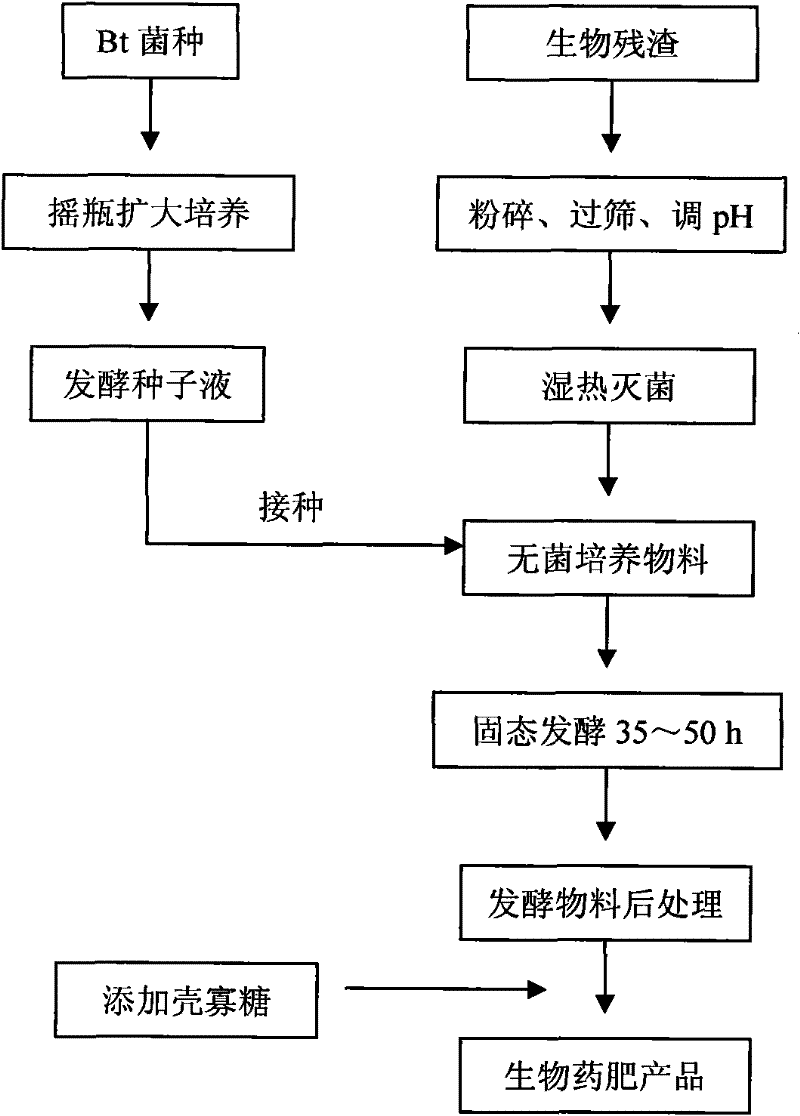

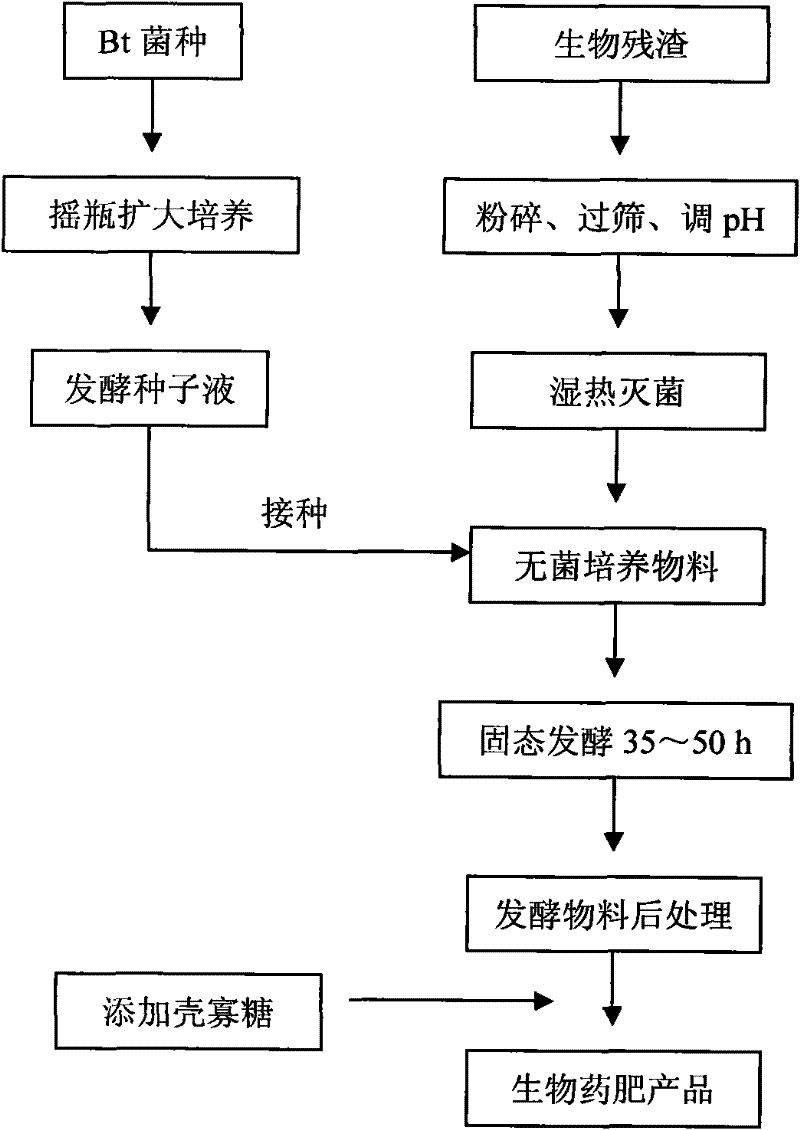

Method for producing biological medicament fertilizer product through solid state fermentation of biological residue

ActiveCN102190534AEvenly distributedTake advantage ofFertilizer mixturesAureobasidium sp.Bacillus thuringiensis

The invention relates to the technical field of biological pesticides, in particular to a method for producing a biological medicament fertilizer product through solid state fermentation of biological residue. The method comprises the following steps of: 1) pretreating the biological residue; 2) performing solid state fermentation, namely inoculating bacillus thuringiensis seed liquor into a sterile culture material for solid state fermentation, wherein temperature-changing fermentation that the initial fermentation temperature is reduced by 2-5DEG C is adopted in the 8 to 11 hours of fermentation; and 3) adding chitosan oligosaccharide powder to obtain the biological medicament fertilizer product. The method has the advantages of low cost, simple process, low equipment investment, environment-friendly production process and the like; moreover, in the method, the chitosan oligosaccharide powder is added into a fermentation product, and the obtained biological medicament fertilizer has effects of killing insects in a broad spectrum and inhibiting viruses, has the functions of regulating plant metabolism and promoting plant growth, has the fertilizer efficiency integrating effect, and combines a biological pesticide and a biological fertilizer.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

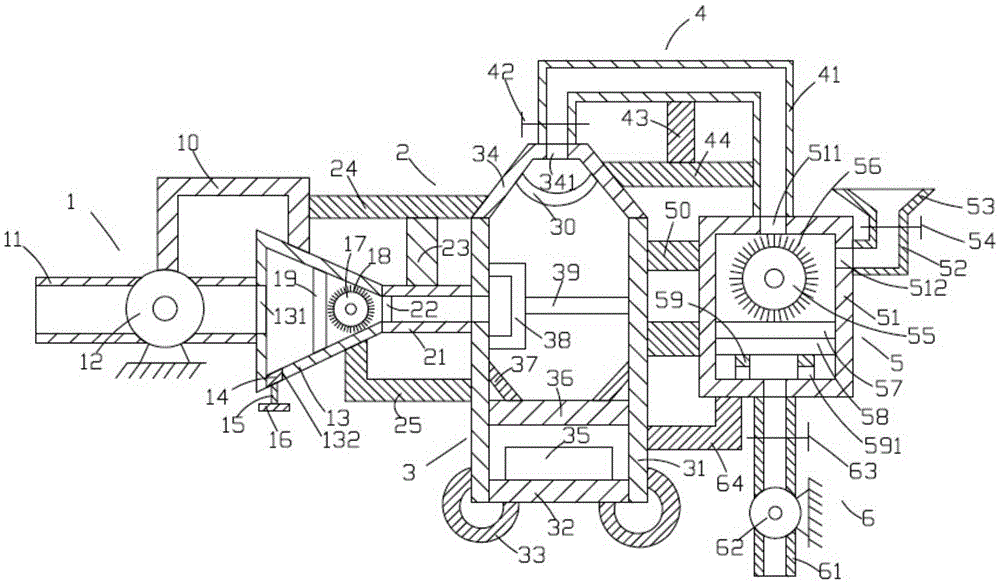

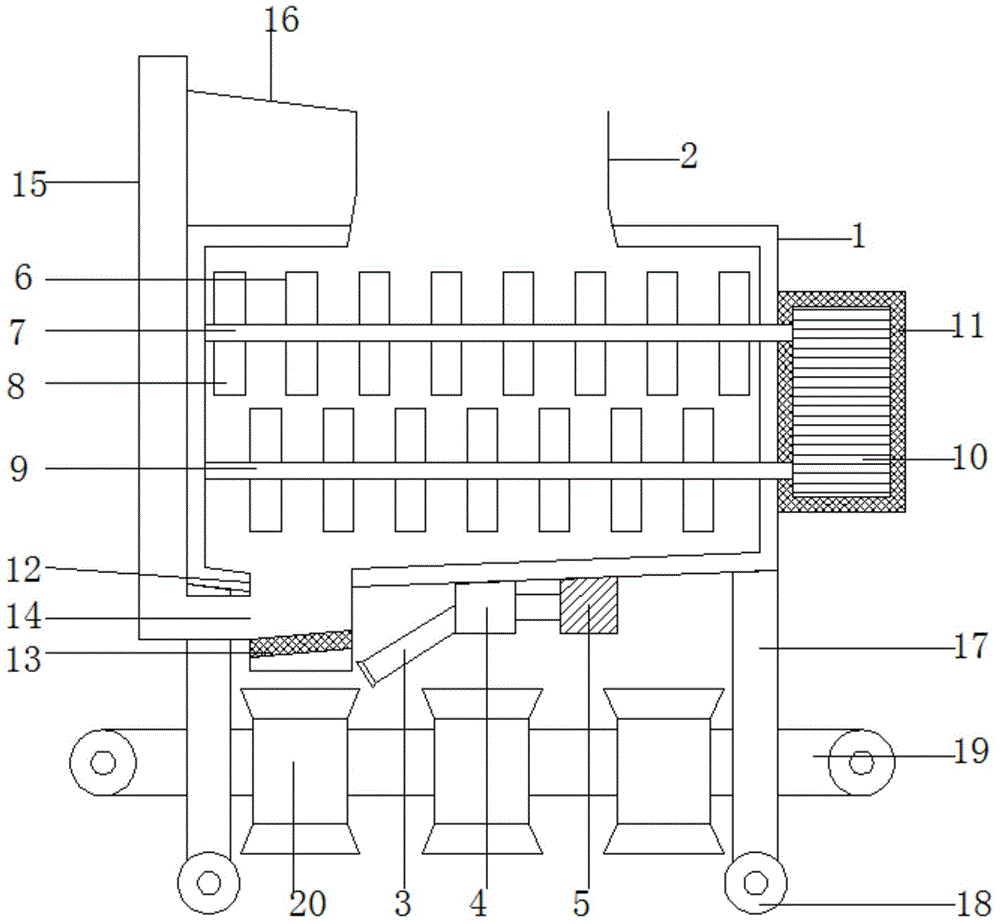

Movable type environment-friendly pulverizer for ceramic production

InactiveCN104923359AImprove work efficiencyReduce noiseGrain treatmentsDischarge efficiencyEngineering

The invention discloses a movable type environment-friendly pulverizer for ceramic production. The movable type environment-friendly pulverizer comprises a pulverizer body, a recycling pipe and a dust collecting device, wherein a feeding funnel is disposed on the upper side of the pulverizer body, a first pulverizing mechanism is horizontally disposed on the upper side inside the pulverizer body, and each of the first pulverizing mechanism and a second pulverizing mechanism comprises a horizontal pulverizing rotary shaft and a plurality of pairs of pulverizing blades disposed on the outer wall of the pulverizing rotary shaft in an up-down symmetry manner. The movable type environment-friendly pulverizer has the advantages that materials are sufficiently pulverized by the two staggered pulverizing mechanisms, the pulverized materials are screened, the materials which do not satisfy the size requirement are elevated into the pulverizer body by an elevator in a circulation manner for pulverizing, pulverizing effect is guaranteed, pulverizing efficiency is increased, discharging is driven by a conveying belt, manual discharging is not needed, discharging efficiency is increased, convenience and quickness are achieved, dust generated during discharging can be collected, environments are protected, and raw material waste is reduced.

Owner:苏晓玲

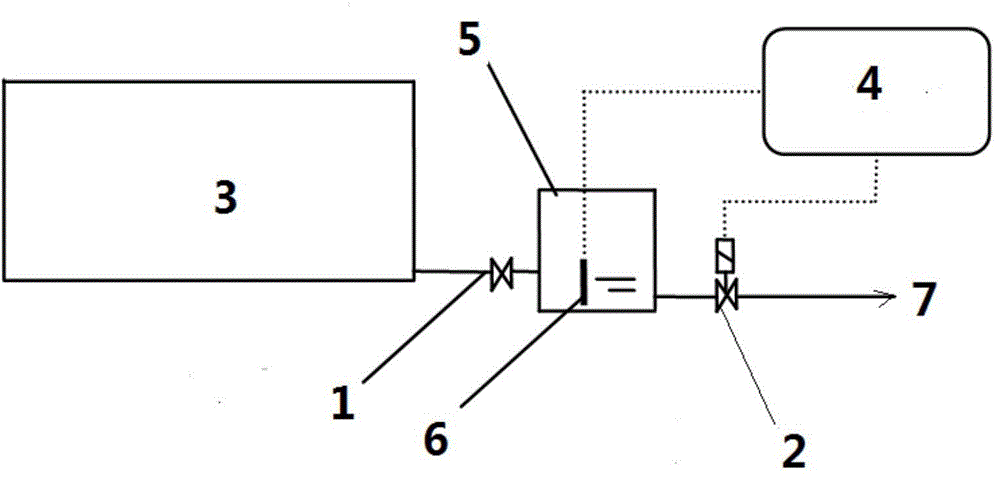

Automatic oil tank water draining method

The invention relates to an automatic oil tank water draining method and aims to solve the problems of high manual operation strength, incapability of achieving strict control of oil-water separation, high oil content quantity of drained water, environmental pollution and low safety factor. According to the automatic oil tank water draining method, a pipeline is arranged at the bottom of at least one oil tank to be communicated with a water draining tank, an oil-water interface monitoring sensor is arranged in the water draining tank, an electromagnetic valve is arranged on a pipeline at an outlet of the water draining tank, and a controller is connected with the oil-water interface monitoring sensor and the electromagnetic valve through signal wires. When the water level in the water draining tank reaches or exceeds a set high limit value, the oil-water interface monitoring sensor sends a signal to the controller, the controller outputs a signal to the electromagnetic valve, the electromagnetic valve is turned on, and water in the water draining tank is drained out; When the water level in the water draining tank declines to the set high limit value, the electromagnetic valve is turned off and draining is terminated. The automatic oil tank water draining method solves the problems effectively and can be used or automatic oil tank water draining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing organic fertilizer by using rice straws and livestock and poultry manures

InactiveCN102746041AHelps dehydration efficiencyImprove dehydration efficiencyBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAnimal feces

The invention provides a method for producing an organic fertilizer by using rice straws and livestock and poultry manures, and relates to the technical field of an organic fertilizer production process. According to the method, livestock and poultry manures and crushed straws are stirred, and subjected to stacking anaerobic fermentation, crushing, and packaging to prepare the organic fertilizer. According to the present invention, characteristics of water absorption, deterioration, and the like of the waste rice straws are mainly adopted; during the organic fertilizer production process, a large amount of the waste rice straws can be added before the livestock and poultry manures are subjected to dewatering and fermentation so as to increase dewatering efficiency, accelerate deterioration process, and further increase organic matter content after humic improving; and the method of the present invention has characteristics of relatively available raw material, low energy consumption, and low investment, and provides an important means for sustainable agriculture development.

Owner:YANGZHOU ZHANPENG FERTILIZER

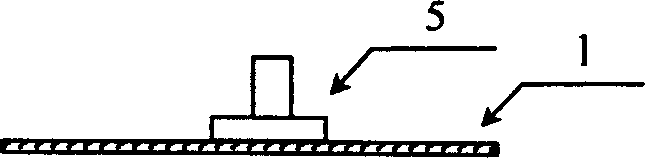

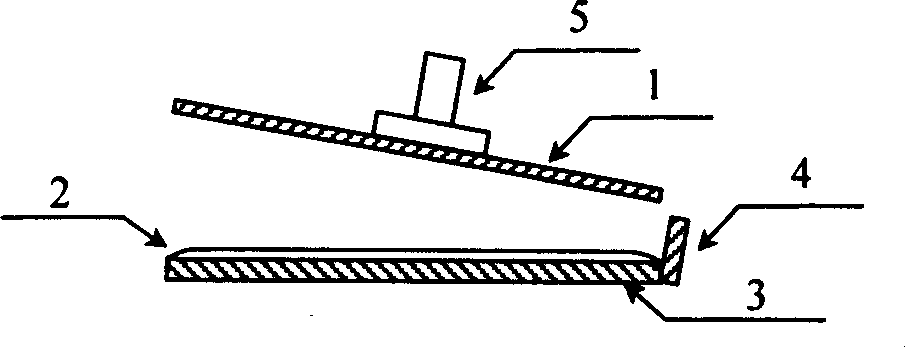

Automatic package method for solar battery sheet and anti-ratiation glass cover

InactiveCN1440083AControl spilloverAvoid pollutionFinal product manufactureSemiconductor devicesFree fallingOrthogonal coordinates

A method for automatically packaging a solar cell piece and a glass covering piece resistant against radiation is used for the solar cell in certain shapes and sizes. The method has the following steps: selecting the inclined packaging angle between the glass covering piece and the solar cell piece through an experiment, programming the moving traces of a packaging unit using a computer, determining the attitude of an absorbing disk which absorbs the glass covering piece, then downloading the documents of the moving traces and the controlling commands into the controller of a robot in orthogonal coordinate of three degrees of freedom so as to meet the specified requirements of the amount and size of the air bubbles using the packaging manner of free-falling body or inclined falling and ensure the relative positions between

Owner:SHANGHAI JIAO TONG UNIV

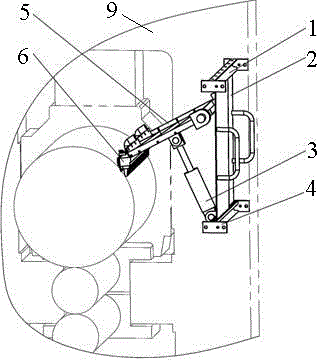

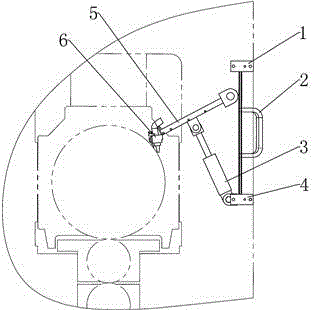

Supporting roller surface deoiling system

ActiveCN106583458AWill not polluteWill not switch freelyRolling equipment maintainenceDirt cleaningCylinder blockPiston rod

The invention provides a supporting roller surface deoiling system which comprises a deoiling cross beam, an oil blocking plate frame, a swinging oil cylinder, a lower track beam, a protective door and an upper track beam. The upper track beam and the lower track beam are horizontally and fixedly arranged on a memorial archway located on the two sides of a rack. The end of a piston rod of the swinging oil cylinder is hinged to the lower surface of the oil blocking plate frame. A cylinder block of the swinging oil cylinder is hinged to the lower track beam through a hinge hole. The protective door is slidably connected between the upper track beam and the lower track beam. One end of the oil blocking plate frame is connected with the deoiling cross beam, and the other end of the oil blocking plate frame is hinged to the memorial archway on the two sides of the rack and connected with the protective door. According to the supporting roller surface deoiling system, an airtight space is formed through the oil blocking plate frame, the roller, rolling pieces and the protective door, rolling oil splashing in the rack can be blocked, it is guaranteed that the blocked rolling oil is sealed on the rolling inlet side, and the surrounding environment of a rolling mill is not polluted; and the stretching and retracting positions of the swinging oil cylinder determine the two working positions of the oil blocking plate frame, and free switching between a deoiling state and a roller changing state is achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthetic method for aromatic[a]carbazole compounds Synthetic method for aromatic[a]carbazole compounds](https://images-eureka.patsnap.com/patent_img/1ceef379-c79e-4323-87be-5b6f2e922b79/BDA0001160801260000011.png)

![Synthetic method for aromatic[a]carbazole compounds Synthetic method for aromatic[a]carbazole compounds](https://images-eureka.patsnap.com/patent_img/1ceef379-c79e-4323-87be-5b6f2e922b79/BDA0001160801260000021.png)

![Synthetic method for aromatic[a]carbazole compounds Synthetic method for aromatic[a]carbazole compounds](https://images-eureka.patsnap.com/patent_img/1ceef379-c79e-4323-87be-5b6f2e922b79/BDA0001160801260000022.png)