Metallized iron powder core and preparation method thereof

A technology for metallizing iron powder and iron powder core, which is applied in chemical instruments and methods, metal layered products, metal material coating processes, etc. Expensive and other problems, to achieve the effect of good weldability, fast sputtering film formation speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

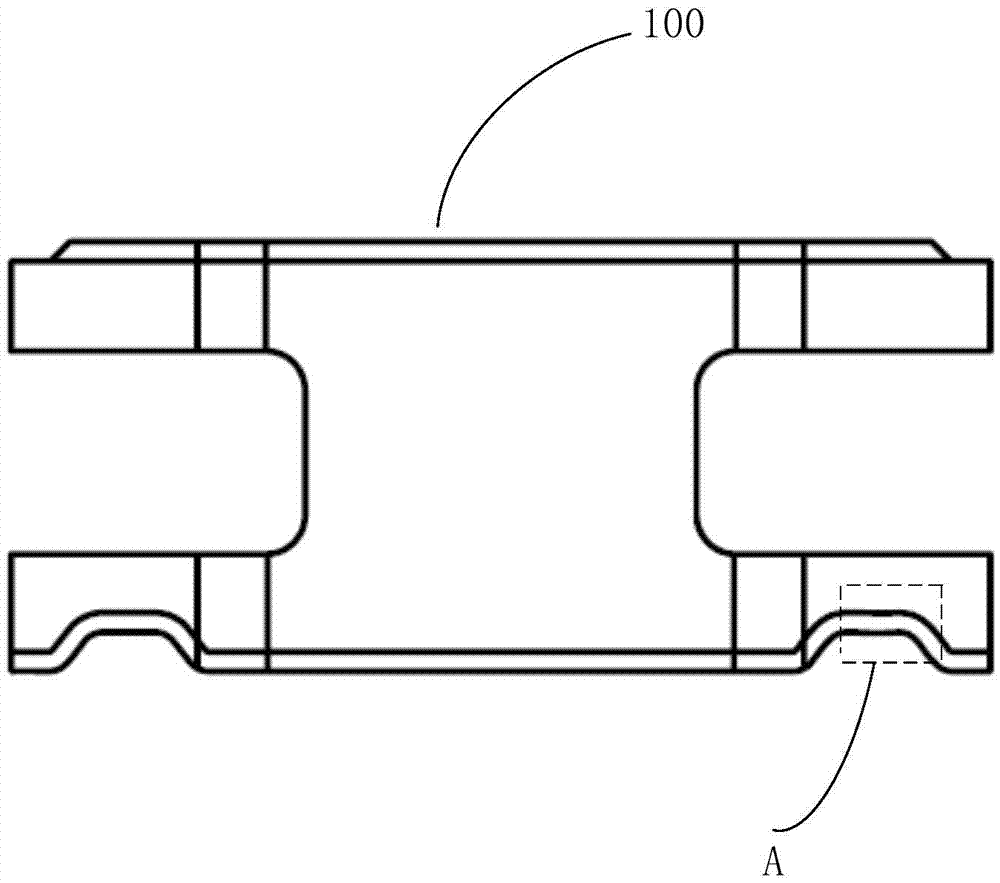

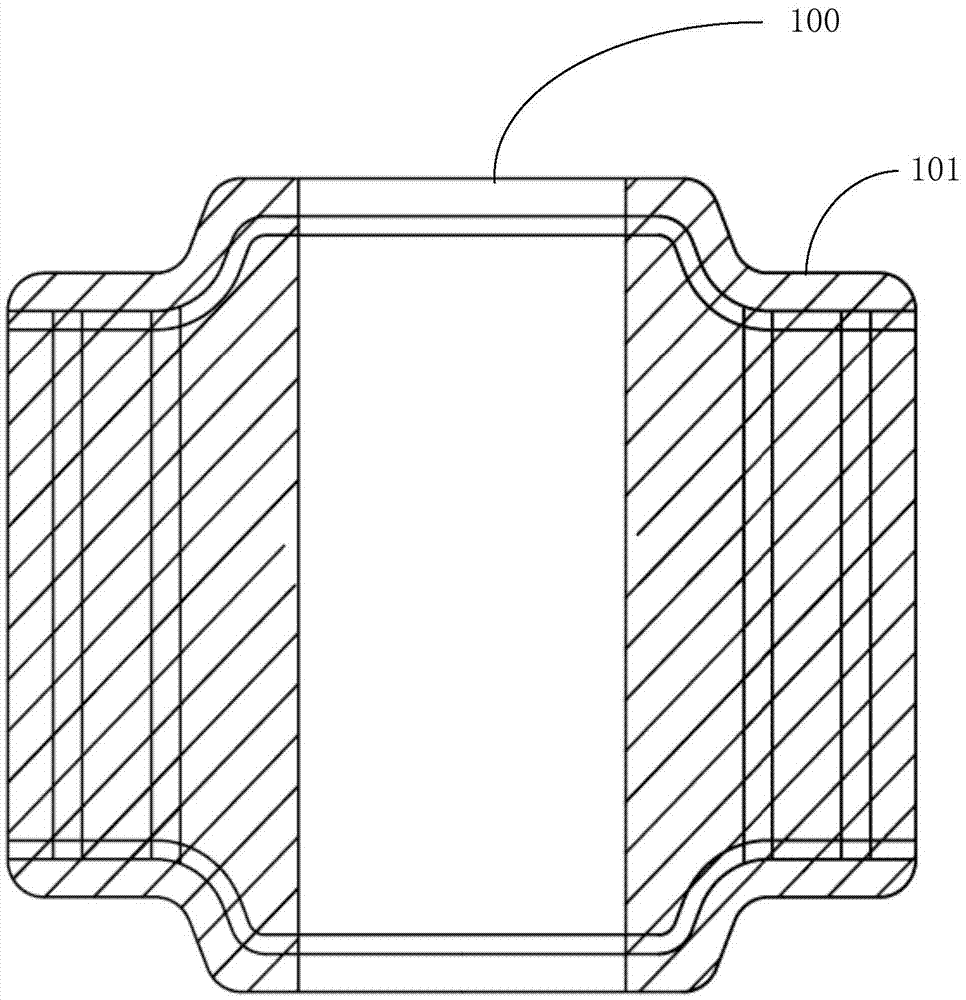

[0033] see Figure 4 , the embodiment of the present invention provides a method for preparing the metallized iron powder core magnetic core, comprising the following steps:

[0034] (1) Take the iron powder core, install it on the substrate frame through the mask tooling, and only expose the electrode area, then push it into the vacuum sputtering equipment to evacuate; then input argon gas into the vacuum chamber, And maintain the pressure of argon in the vacuum chamber at 2×10 -1 Pa-8×10 -1 Pa range;

[0035] The purpose of using the mask is to prevent short circuit caused by metal sputtering on the edge of the magnetic core during the sputtering process;

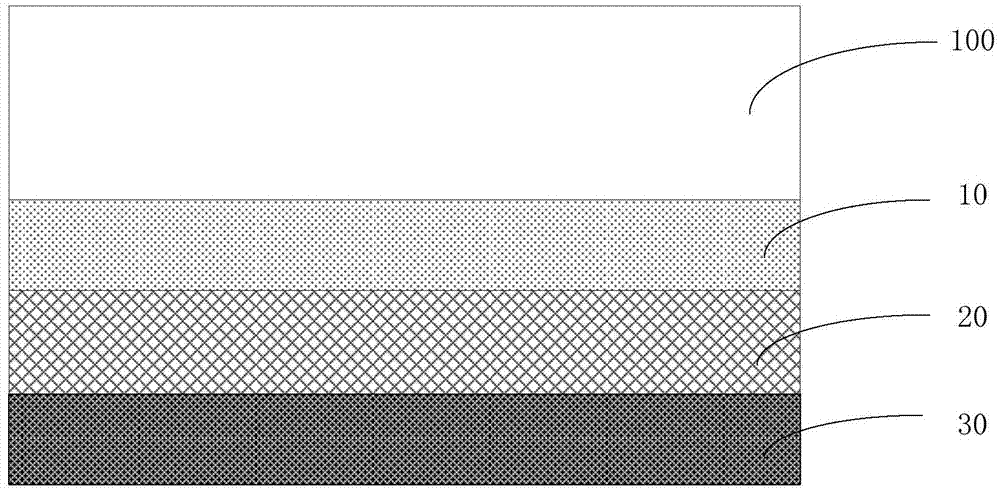

[0036] (2) The iron powder core magnetic core is provided with an electrode area; the metal coating layer is prepared on the surface of the electrode area by magnetron sputtering to obtain a metallized iron powder core magnetic core, and the metal coating layer includes sequentially stacked and formed A chromium layer...

Embodiment 1

[0045] A method for preparing a metallized iron powder core magnetic core, comprising the following steps:

[0046] Take an iron powder core magnetic core, the iron powder core magnetic core is provided with an electrode area; adopt the mode of magnetron sputtering to prepare a metal coating on the surface of the electrode area, and obtain a metallized iron powder core magnetic core, and the metal coating It includes a chromium layer, a nickel-copper alloy layer and a silver layer formed sequentially on the surface of the electrode region.

[0047] (1) Sputtering chromium layer: Arrange the magnetic cores and place them in a special jig, fix them, and only expose the electrode area, then install them on the film rack for vacuum coating, push the vacuum machine, vacuum, and the background The vacuum degree is greater than 5×10 -3 Pa turns on the power supply of the metal chromium target, fills it with argon gas, and starts sputtering. The current of the chromium target is set to...

Embodiment 2

[0052] A method for preparing a metallized iron powder core magnetic core, comprising the following steps:

[0053] Take an iron powder core magnetic core, the iron powder core magnetic core is provided with an electrode area; adopt the mode of magnetron sputtering to prepare a metal coating on the surface of the electrode area, and obtain a metallized iron powder core magnetic core, and the metal coating It includes a chromium layer, a nickel-copper alloy layer and a silver layer formed sequentially on the surface of the electrode region.

[0054] (1) Sputtering chromium layer: Arrange the magnetic cores and place them in a special jig, fix them, and only expose the electrode area, then install them on the film rack for vacuum coating, push the vacuum machine, vacuum, and the background The vacuum degree is greater than 5×10 -3 Pa turns on the power supply of the metal chromium target, fills it with argon gas, and starts sputtering. The current of the chromium target is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com