Rapidly assembled bamboo wood barrack

A prefabricated, bamboo-wood technology, applied in the field of buildings, can solve the problems of anti-seismic performance, poor thermal insulation effect, slow construction speed, high production cost, etc., and achieve the effect of fast assembly speed, simple shape and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

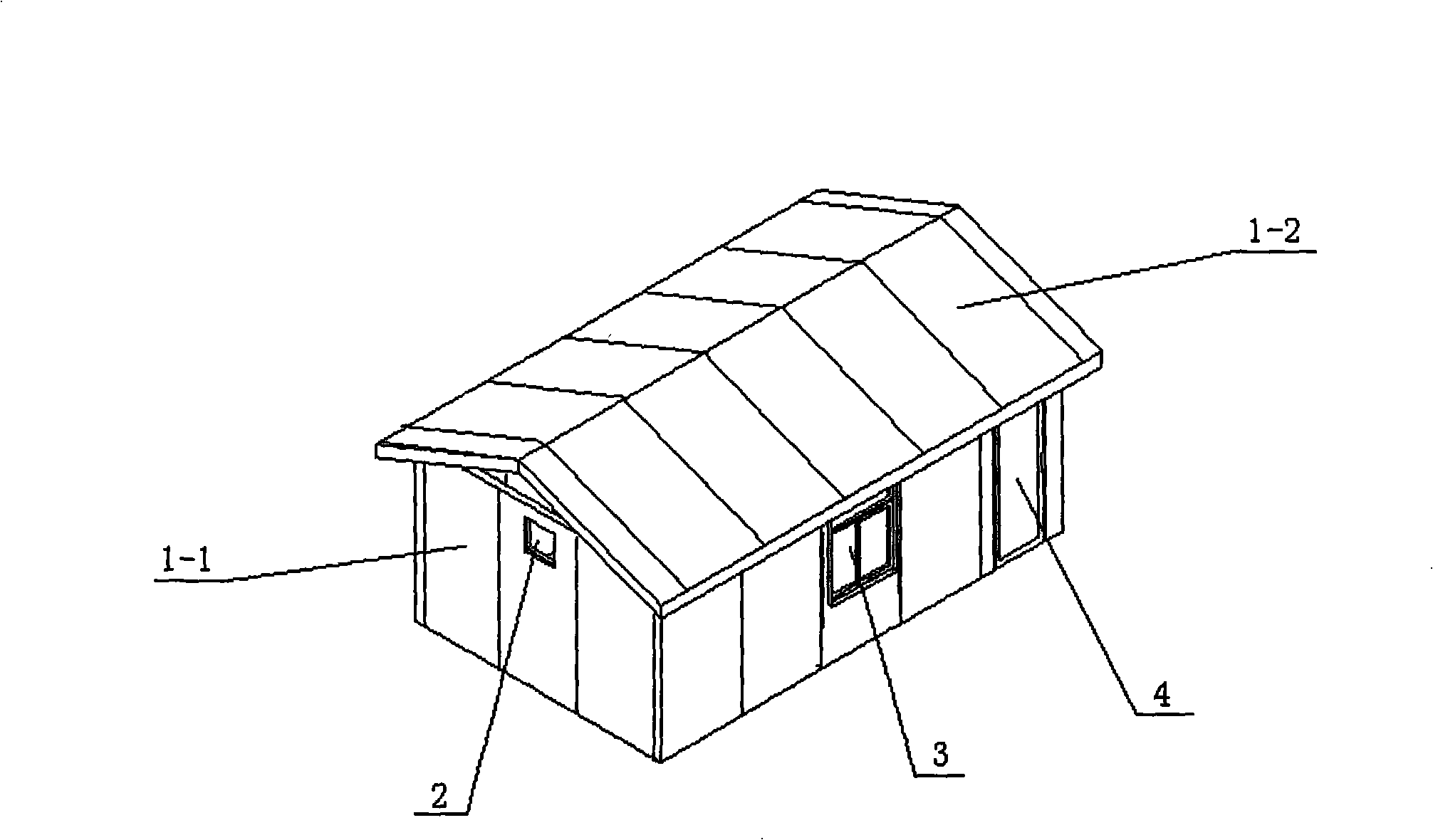

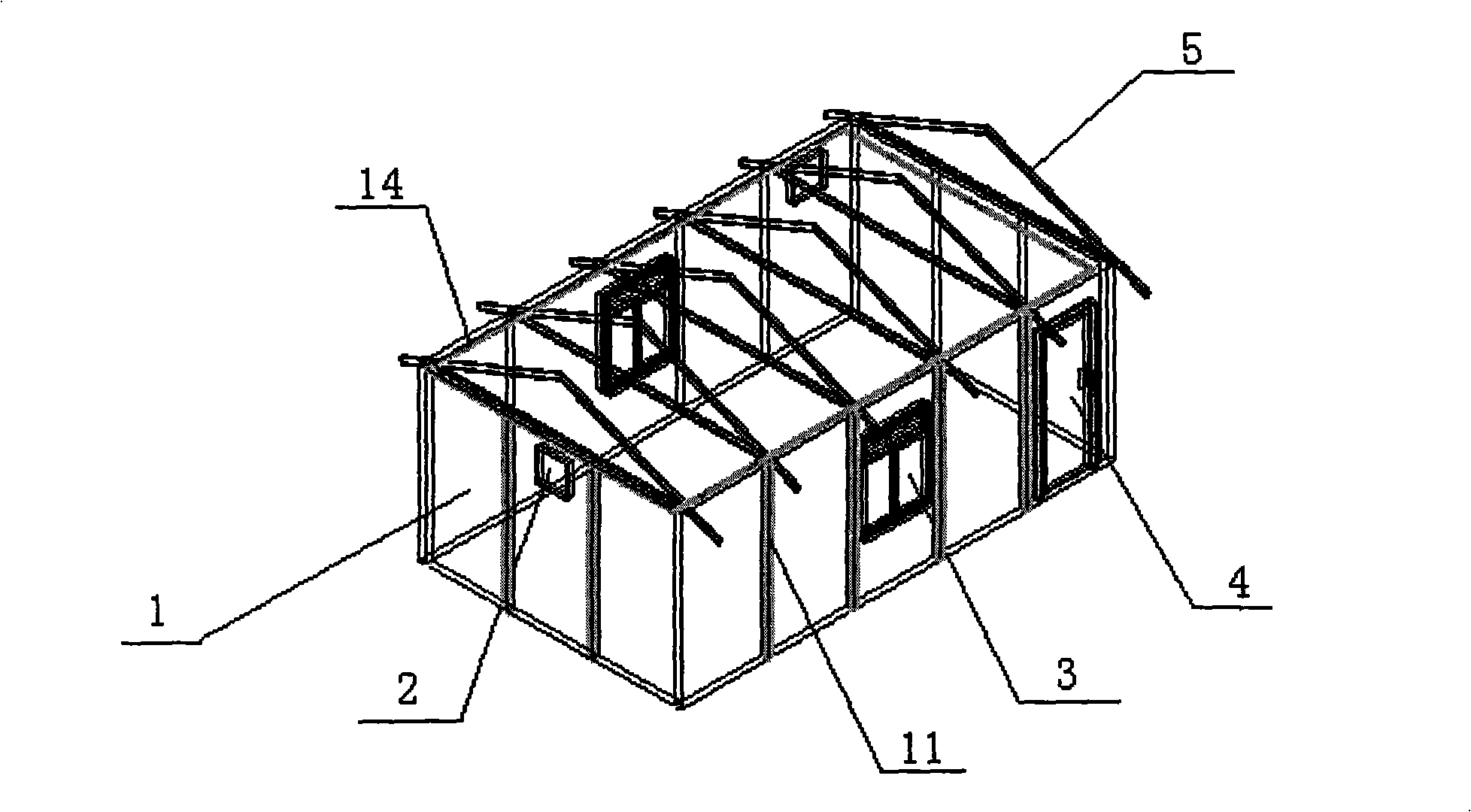

[0024] refer to figure 1 , 2 , this embodiment includes a wall panel unit 1-1, a roof panel unit 1-2, a bamboo roof truss 5, a connecting column 11, and a connecting beam 14. The wall panel unit is provided with an exhaust hole 2, a window 3, and a door 4 ;

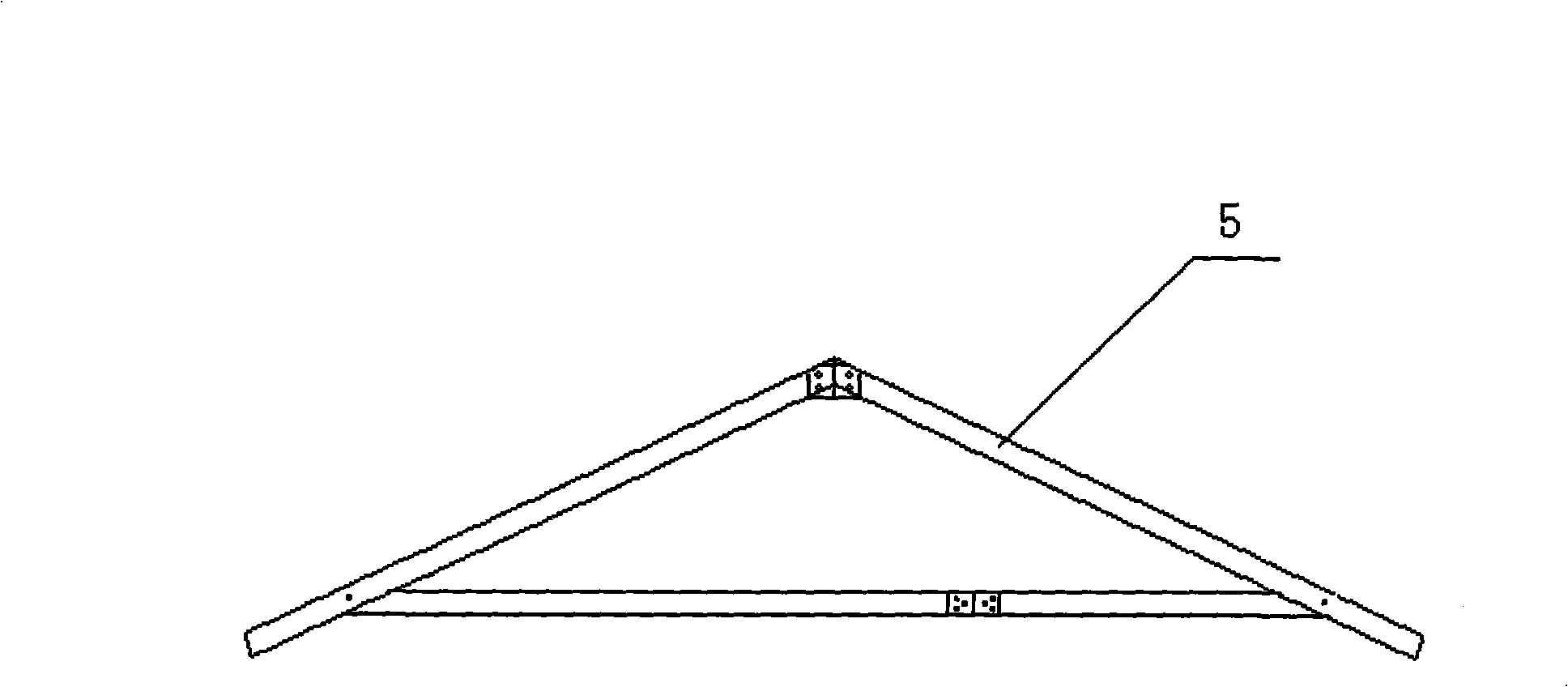

[0025] refer to image 3 , the bamboo roof truss 5 is made of the upper and lower chord members of the roof truss cut from bamboo plywood and the splicing panels made of bamboo plywood, and the upper and lower chords of the roof truss are connected by bolts or nails;

[0026] refer to Figure 4 , the skeleton 6 of the panel unit is made of bamboo plywood or wood, the outer panel of the panel unit is bamboo plywood 10, the inner panel of the wall panel unit 1-1 is a fireproof veneer gypsum board 7, and the roof panel unit 1-2 The inner panel is a gypsum board, and the inner and outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com