Patents

Literature

51results about How to "Reduce production costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance anti-cracking anticorrosive water reducing agent composition and preparation method thereof

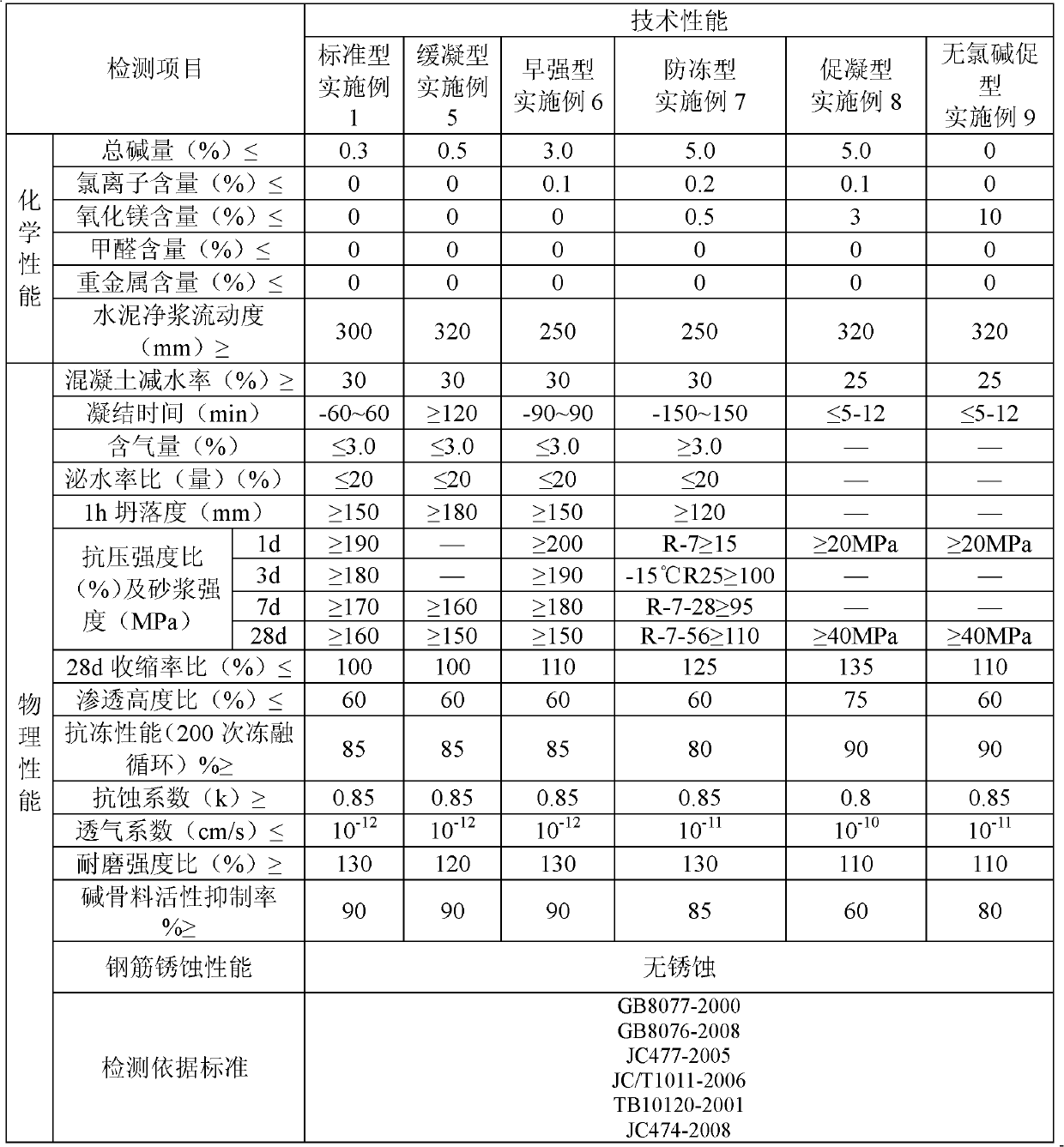

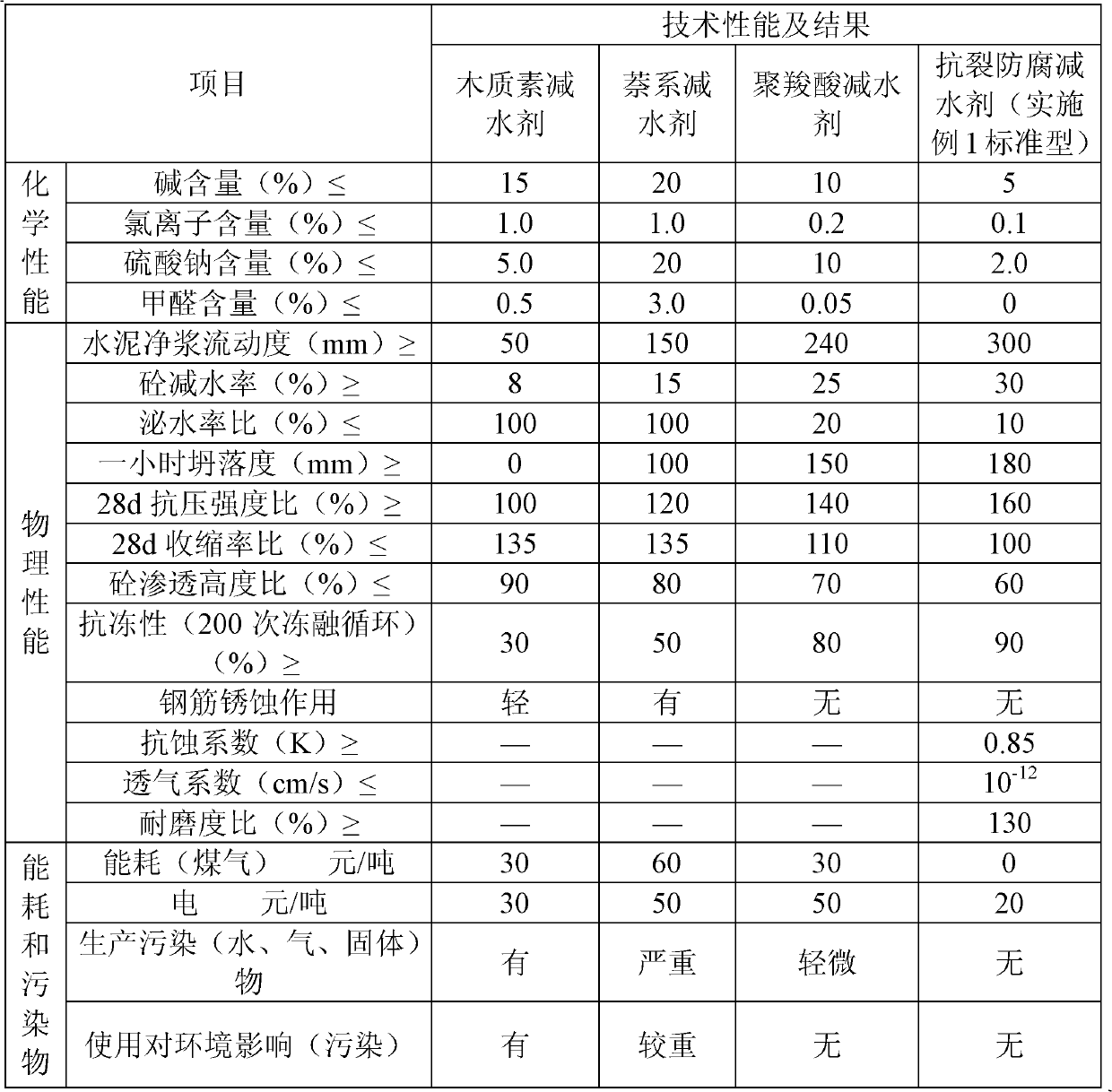

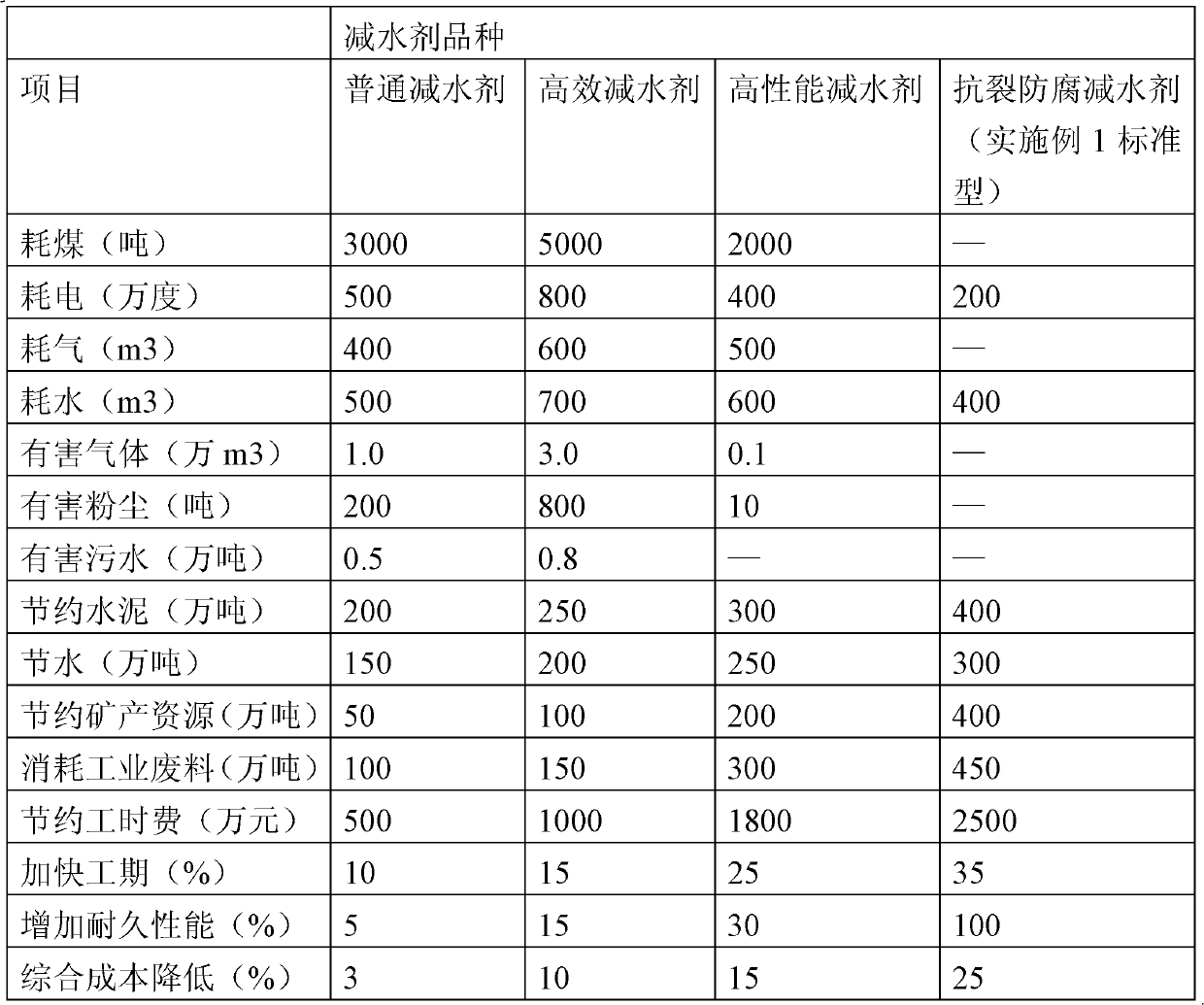

The invention relates to a high-performance anti-cracking anticorrosive water reducing agent composition and a preparation method thereof. The anti-cracking anticorrosive waterproof anti-frost property of the water reducing agent composition is improved while the water-reducing rate of the water reducing agent composition is increased. Compared with a water reducing agent in the prior art, the water reducing agent composition has excellent combination property and an anti-cracking anticorrosion effect. When the water reducing agent composition is prepared, low energy is consumed, and when the water reducing agent composition is used, little pollution is caused.

Owner:苏琳

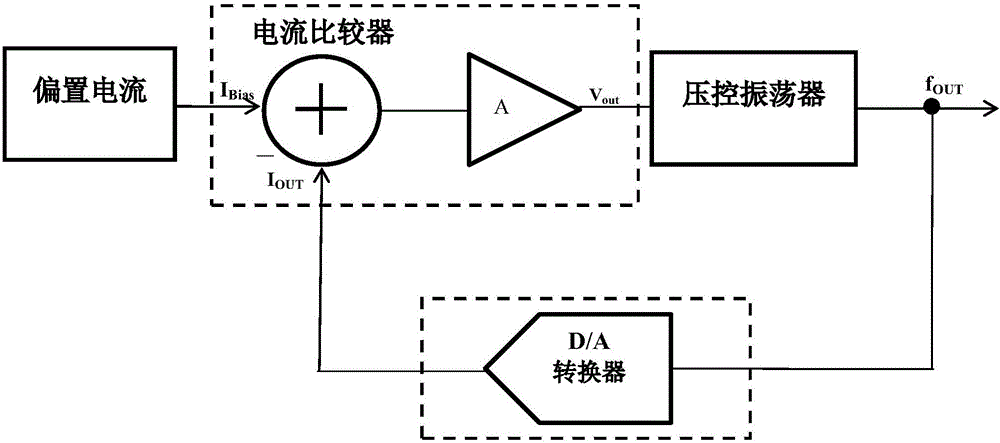

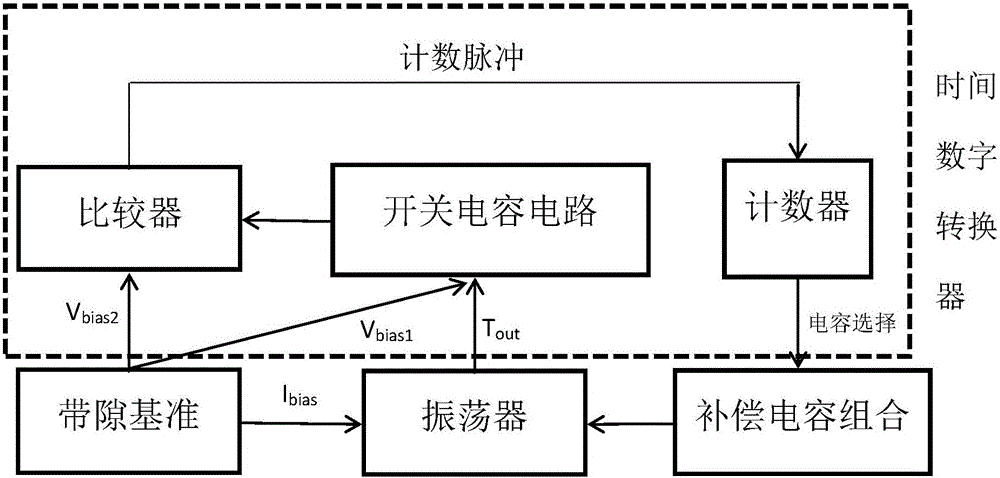

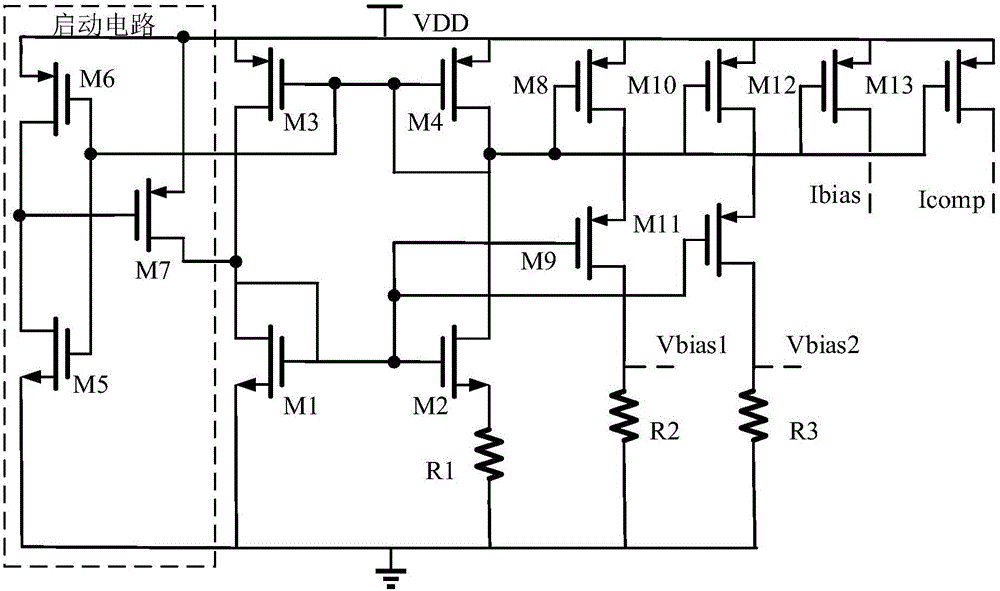

Relaxation oscillator with process deviation calibration function

ActiveCN106059538AReduce mistakesReduce production costsElectric pulse generatorCapacitanceRelaxation oscillator

The invention discloses a relaxation oscillator with a process deviation calibration function. The relaxation oscillator comprises a reference signal generator, an intrinsic oscillator, a time digital converter and a compensation capacitor array. The time digital converter comprises a comparator, a switched capacity circuit and a counter. The reference signal generator provides a first reference voltage to the switched capacity circuit and provides a second reference voltage to the comparator. An output frequency of the intrinsic oscillator controls the switched capacity circuit, an output voltage of the switched capacity circuit is connected with the comparator, and an output end of the comparator is connected with the counter. An output end of the counter is connected with the compensation capacitor array, the output of the counter automatically adjusts the capacitance of the compensation capacitor array and correspondingly changes the frequency of the intrinsic oscillator. According to the invention, the relaxation oscillator is provided with the on-chip calibration function, the error among chips is relatively small, the chip manufacturing cost is lowered, and the precision of chips is improved.

Owner:SHENZHEN UNIV

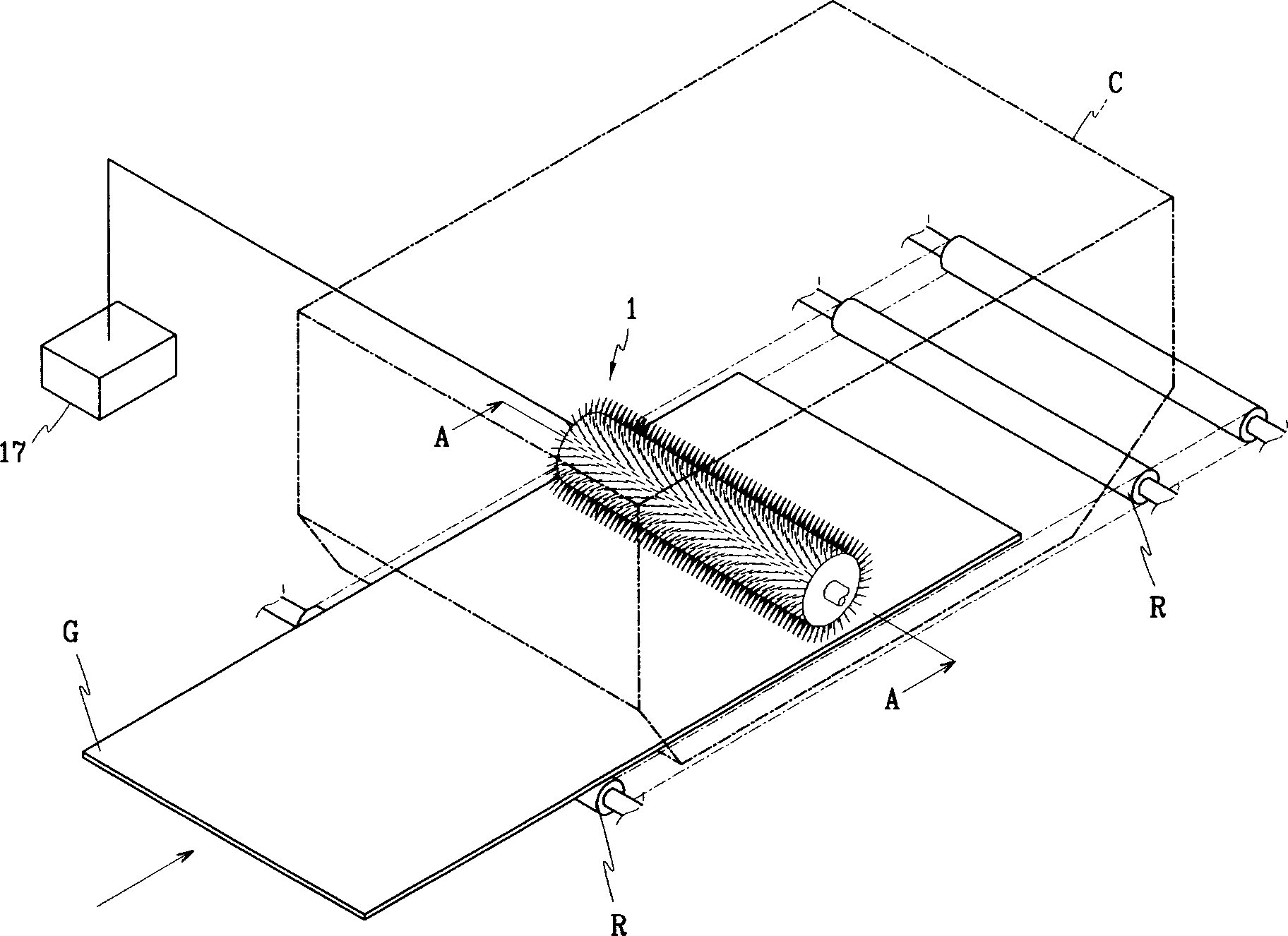

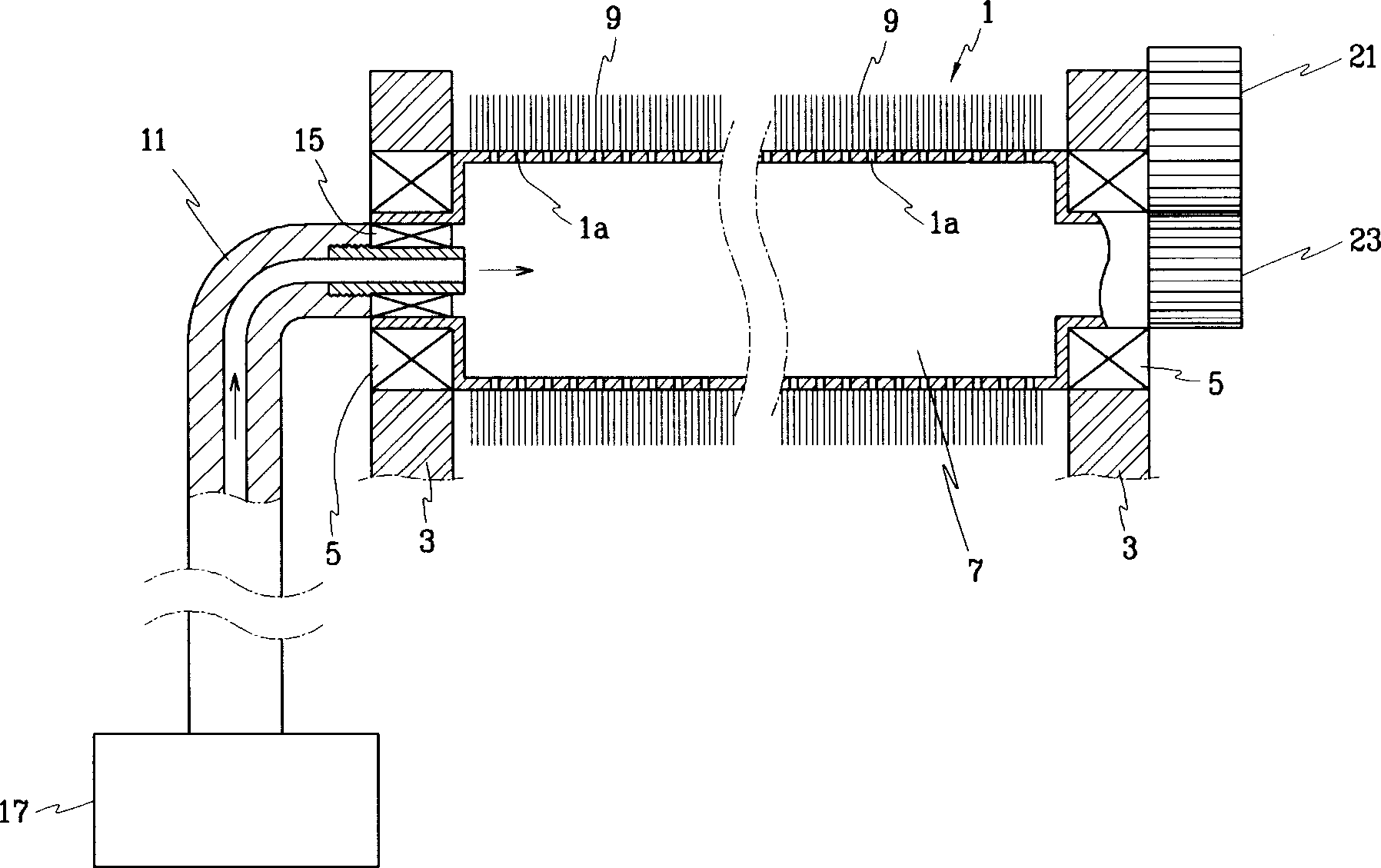

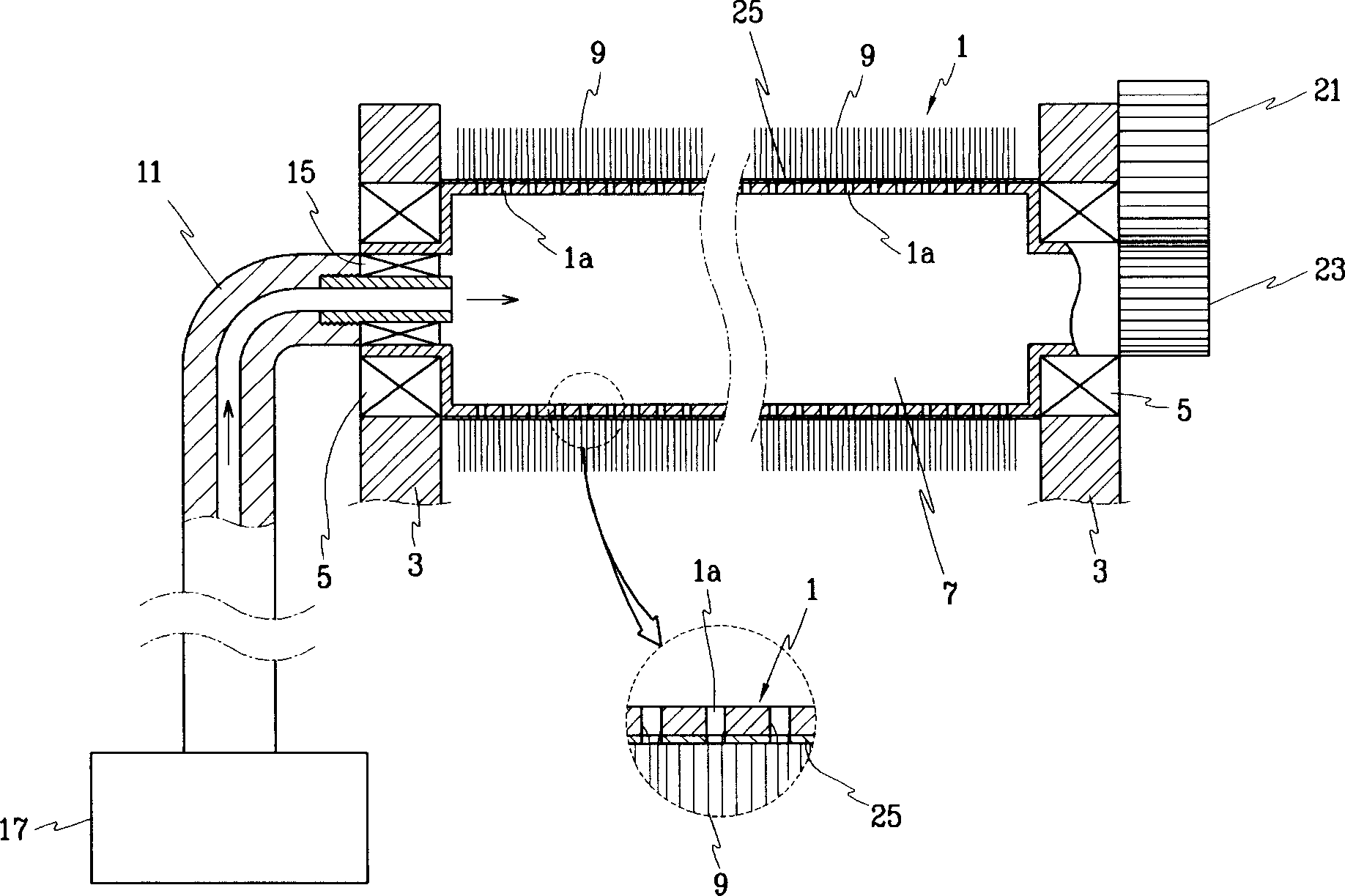

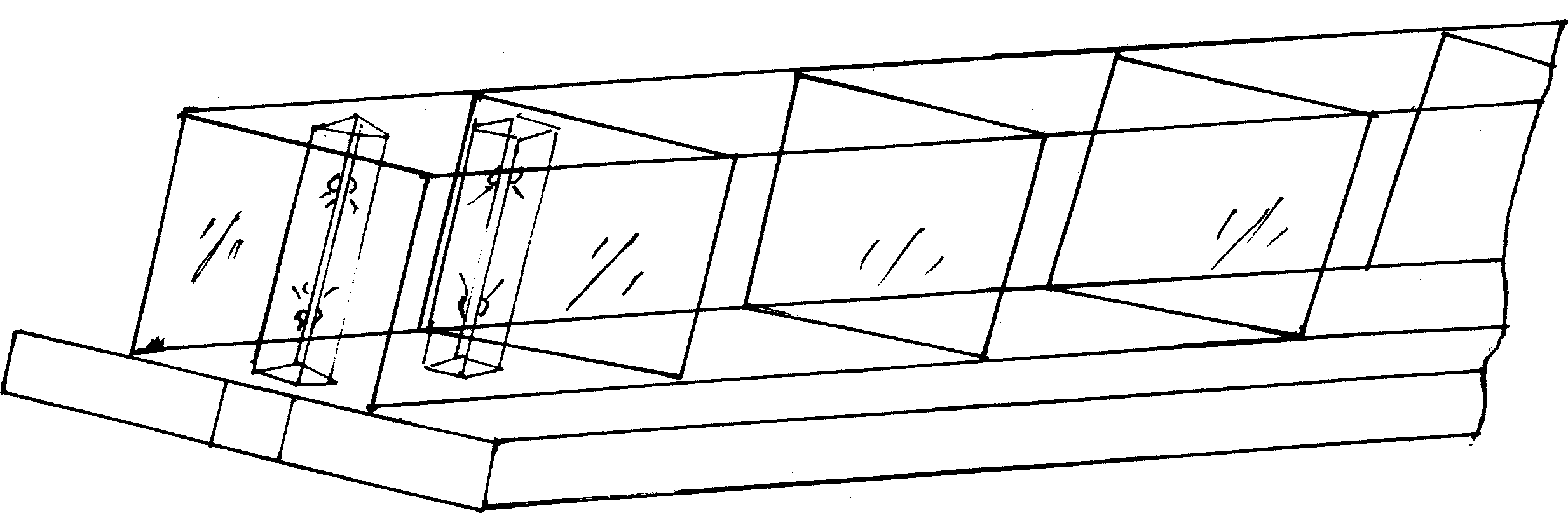

Glass panel cleaning device for flat panel display

InactiveCN1899711AReduce dosageReduce production costsFlexible article cleaningInterior spaceEngineering

The present invention is a method adapted to cleaning glass plate using roller brush and provides a glass plate cleaning device for panel display capable of enabling the cleaning effect of the glass plate achieving optimization. The glass plate cleaning device for panel display of the present invention comprises a cleaning room; a glass plate conveyer for conveying glass plate into the cleaning room; a rotational parts installed in the cleaning room for cleaning the glass plate and is rotatablely supported in the cleaning room, wherein the inside of the rotational parts is provided with a space, the circumferential surface of the rotational parts is provided with a number of cleaning liquid nozzles, and the outer circumferential surface of the rotational parts is provided with a number of brushings; a dynamic force ransferring device for transferring turning effort to turn the rotational parts; pipes for supplying cleaning liquid to the inner space of the rotational parts; a cleaning liquid supplying device connected to the pipes for supplying cleaning liquid.

Owner:DMS CO LTD

Air supplementing and stirring device for biological fertilizer

ActiveCN106747748AGood linkageReduce production costsBio-organic fraction processingOrganic fertiliser apparatusFertilizerPiston

The invention discloses an air supplementing, fermenting and stirring device for biological fertilizer. The device comprises a stirring tank, a stirring rod is arranged in the stirring tank, a seal cover is arranged at the upper end of the seal cover, a first one-way air inlet valve is arranged on the seal cover, a first piston plate is connected to the inner wall of the stirring tank in a threaded mode, a through hole is formed in the upper portion of the stirring cavity, a stirring blade is located in the stirring cavity, the stirring rod is a spline shaft and is of a hollow structure, a spline sleeve is connected to the upper end of the stirring rod, and a stepping motor is fixedly connected to he upper end of the spline sleeve; the non-sleeved portion of the stirring rod is provided with a second one-way air inlet valve, and the portion, in the stirring cavity, of the stirring rod is provided with a one-way air outlet valve; an annular groove is formed in the portion, between the seal cover and the spline sleeve, a lantern ring is in clearance fit with the interior of the annular groove, a connecting rod is connected to the lantern ring, a water bag is attached to the outer wall of the stirring tank, a piston water pumper is connected to the upper end of the water bag and driven by the connecting rod, and a water band is communicated with a water tank. Compared with the prior art, the device has the advantages of being capable of conducting cooling and air supplementing on the biological fertilizer during stirring and lower in production cost.

Owner:北京天葡庄园农业科技发展有限公司

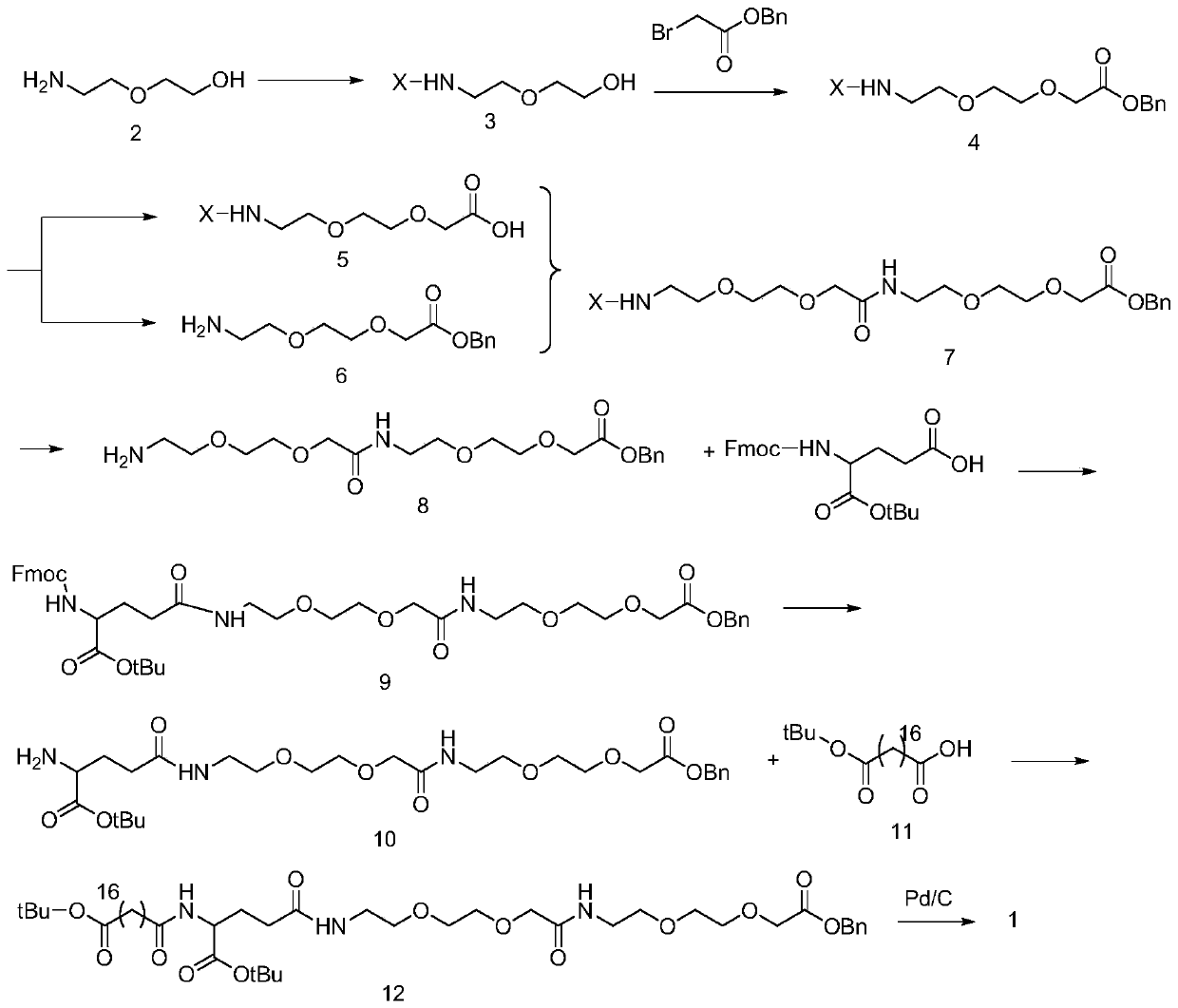

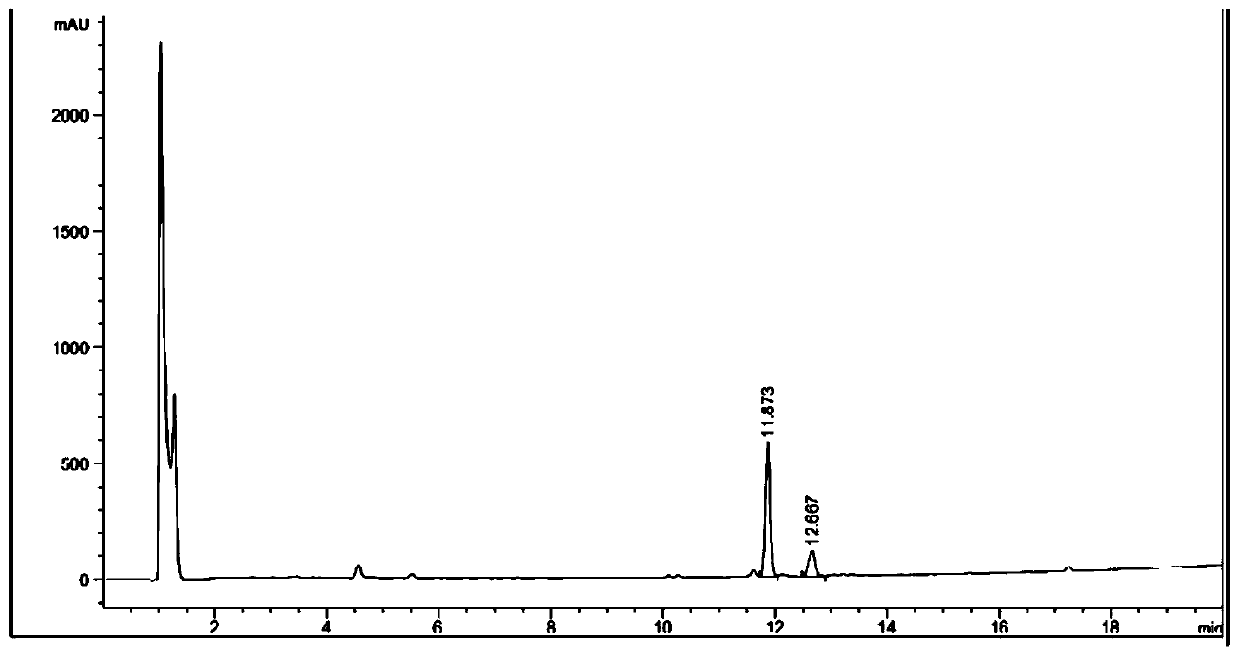

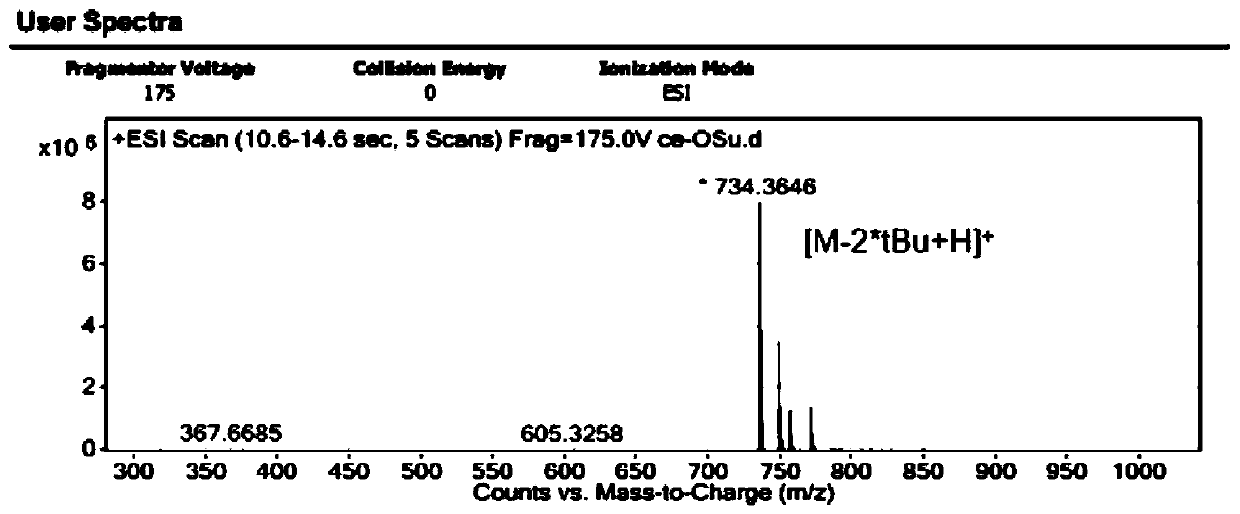

Liquid-phase synthesis method of semaglutide side chain

ActiveCN110041219ALow priceReduce production costsCarbamic acid derivatives preparationOrganic compound preparationAmino terminalSide chain

The invention discloses a liquid-phase synthesis method of a semaglutide side chain. The liquid-phase synthesis method comprises the following steps: taking diglycolamine and an X radical to react, soas to protect an amino terminal of the diglycolamine through the X radical; then realizing hydroxyl protection through the amino terminal and a reaction carboxyl terminal of benzyl bromoacetate, so as to remove benzyl and the X radical; after coupling two products without the radical, removing the X radical; then coupling with an Fmoc-glutamic acid and removing Fmoc; finally coupling with 18-(tert-butoxy)-18oxooctadecanoic acid and then removing the benzyl to obtain the semaglutide side chain. The method disclosed by the invention has the advantages that a synthesis method process is feasible, controllable, low in cost and high in yield; the synthesis method is applicable to large-scale production; the semaglutide side chain is finally prepared and can be directly assembled to a semaglutide main chain in a liquid phase after being modified into OSu ester.

Owner:NANJING UNIV OF TECH

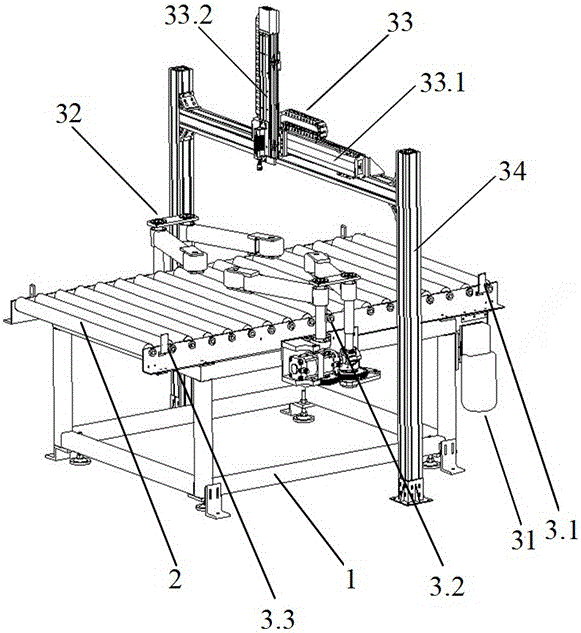

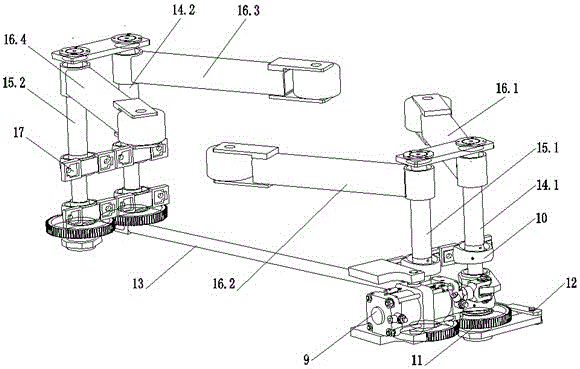

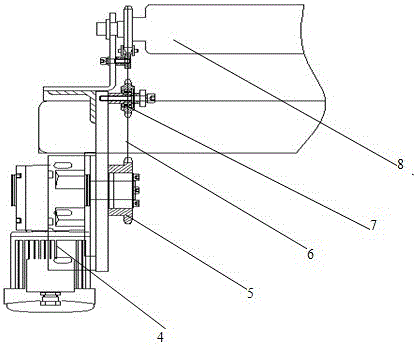

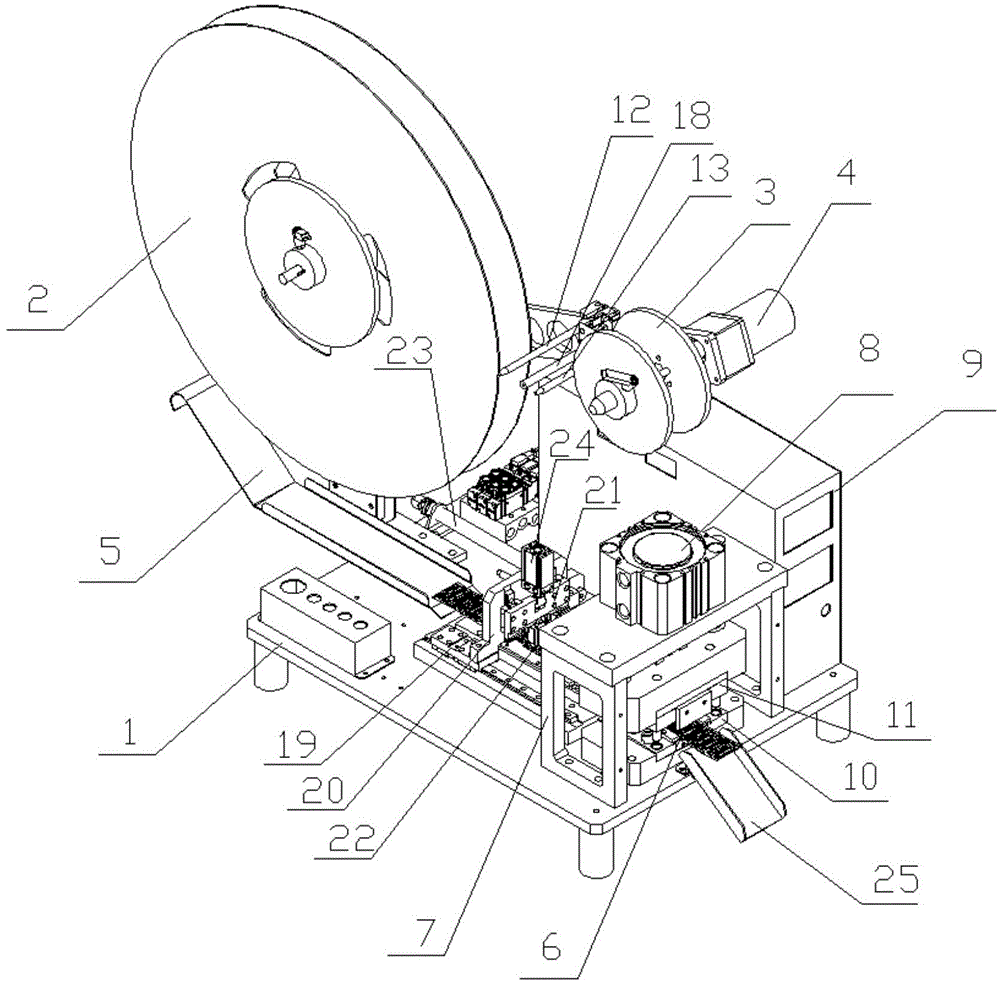

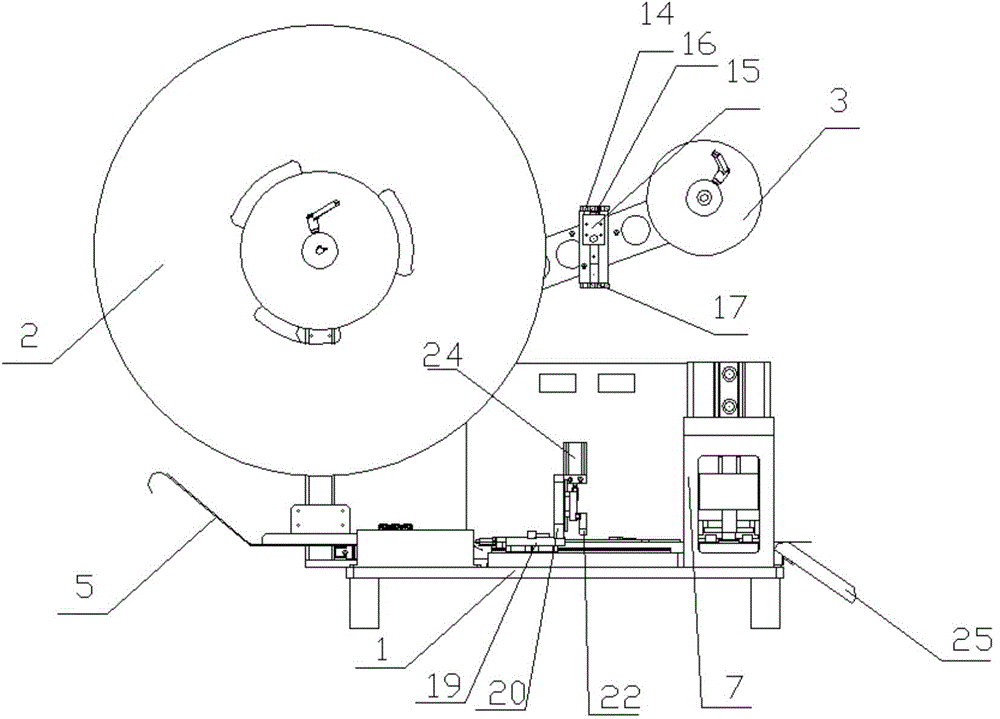

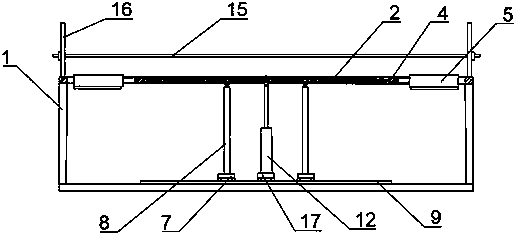

All-steel tire side automatic positioning code printer

InactiveCN106042665AImprove coding automationReduce production costsTypewritersManipulatorEngineering

The invention relates to an all-steel tire side automatic positioning code printer. The all-steel tire side automatic positioning code printer comprises a base framework, a centering mechanism, a delivery mechanism, optoelectronic switches, a portal frame, a two-axis moving manipulator and a code printing mechanism, wherein the centering mechanism is mounted on the base framework and used for clamping tires delivered by the delivery mechanism; the delivery mechanism is mounted on the base framework and used for delivering the tires; the optoelectronic switches are mounted on the base framework and used for detecting the positions of the tires; the portal frame is disposed above the base framework; the two-axis moving manipulator is disposed on the portal frame; and the code printing mechanism is disposed on the two-axis moving manipulator and used for performing code printing on the tires. The all-steel tire side automatic positioning code printer has the beneficial effects that by configuring the automatic code printer, code printing work for the tires with different specifications can be achieved, the tire side code printing automation degree is improved, and the production cost of enterprises is reduced.

Owner:SHANDONG LINGLONG ELECTROMECHANICAL

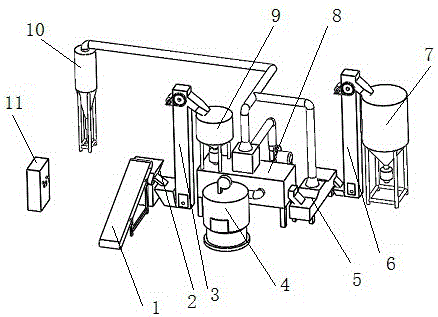

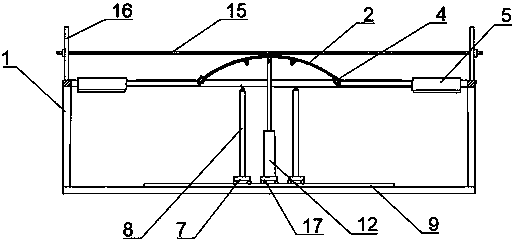

Precoated sand regenerating production line

InactiveCN106077447AReduce environmental pollutionReduce production costsMould handling/dressing devicesHot blastPulverizer

The invention discloses a precoated sand regenerating production line and belongs to the field of steel casting. The precoated sand regenerating production line comprises a pulverizer, a raw material sieving machine, a raw material conveyor, a raw material elevator, a hot blast heater, a finished product sieving machine, a finished product elevator, a finished product stock bin, a regenerating furnace, a regenerating furnace feeder, a dust removal system and a control system, wherein the pulverizer is mounted at the front end of the raw material sieving machine; the raw material sieving machine is mounted between the pulverizer and the raw material conveyor; the raw material conveyor is mounted between th raw material sieving machine and the raw material elevator; the raw material elevator is mounted at the front end of the regenerating furnace; the hot blast heater is mounted on the side edge of the regenerating furnace; and the control system is mounted on a console and is connected with all functional parts. The precoated sand regenerating production line has the characteristics of realizing reutilization of precoated sand, reducing environmental pollution and lowering production cost.

Owner:YUZHOU KUNLUN MOLD CO LTD

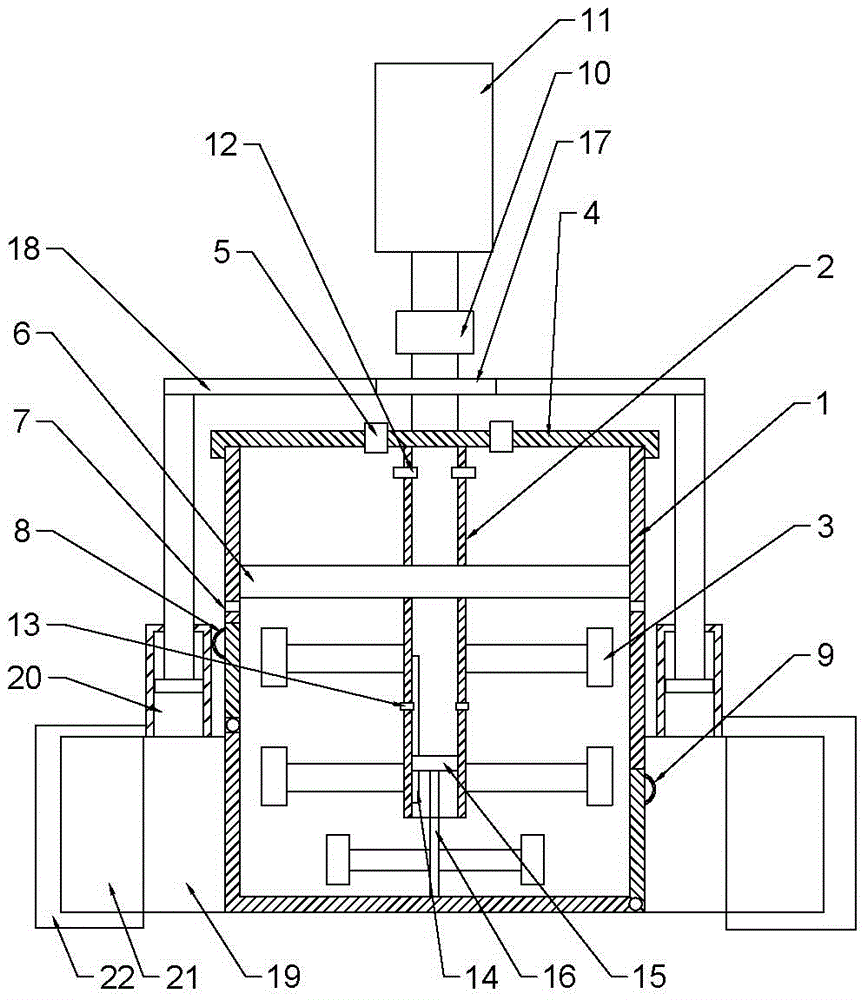

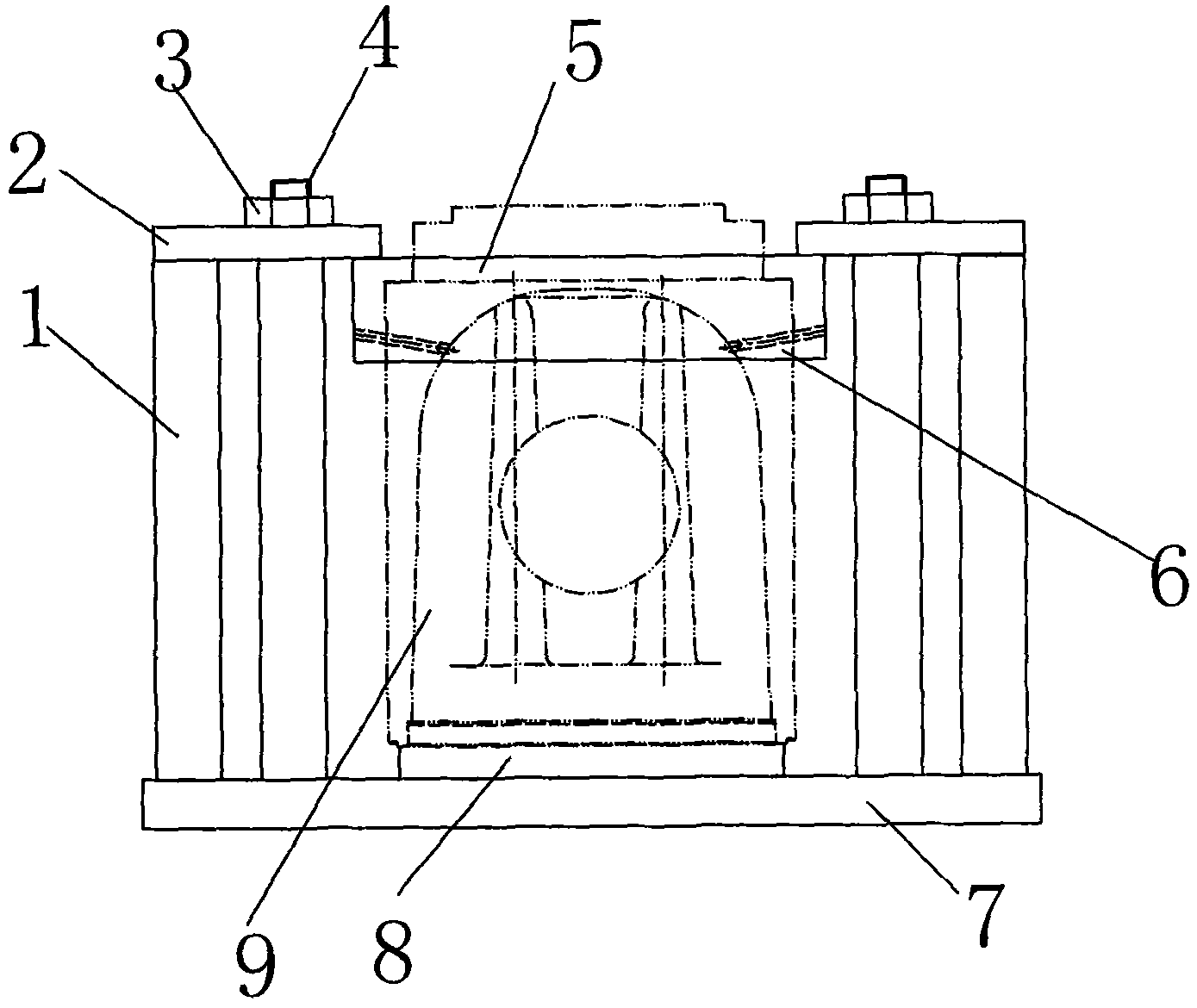

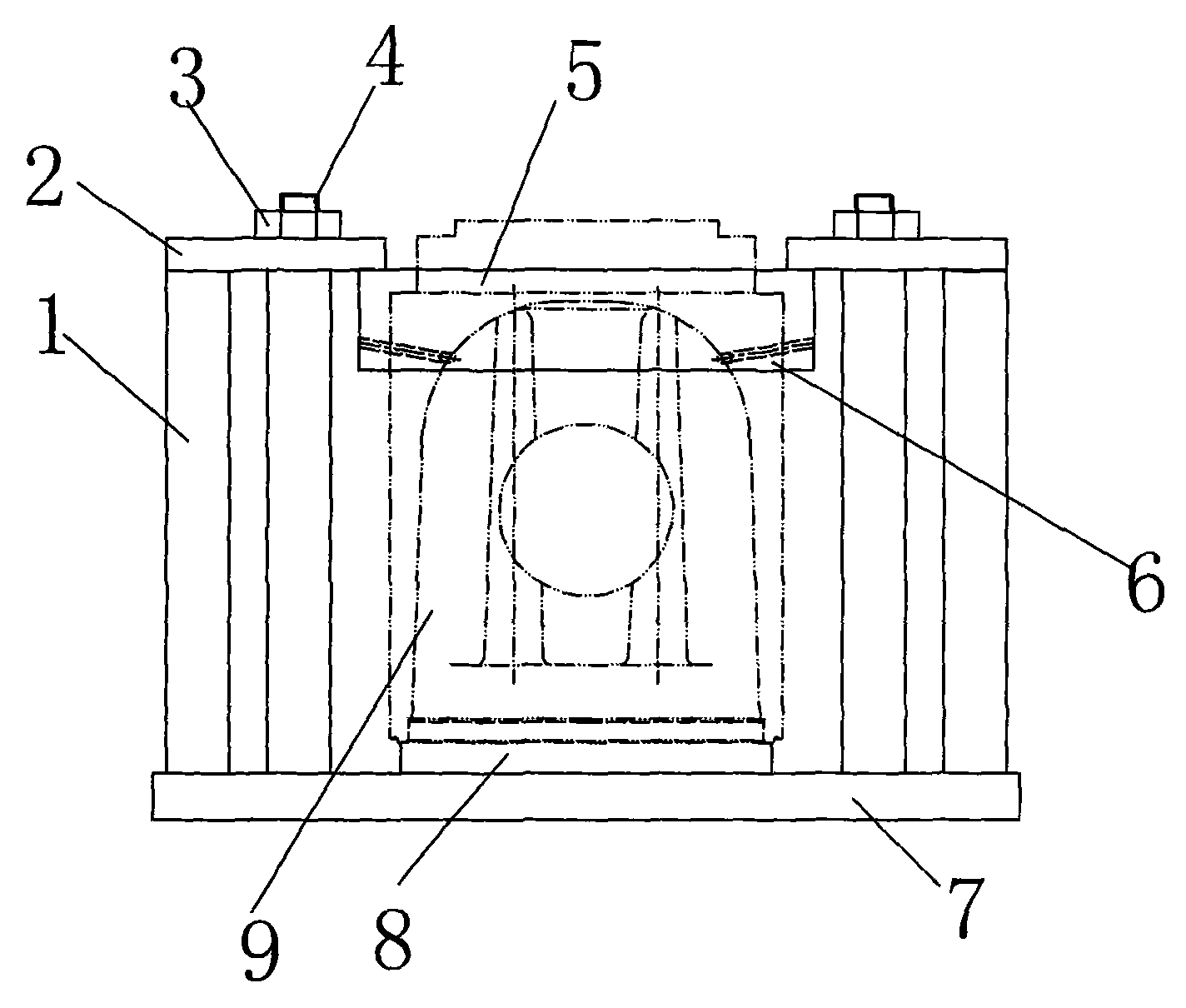

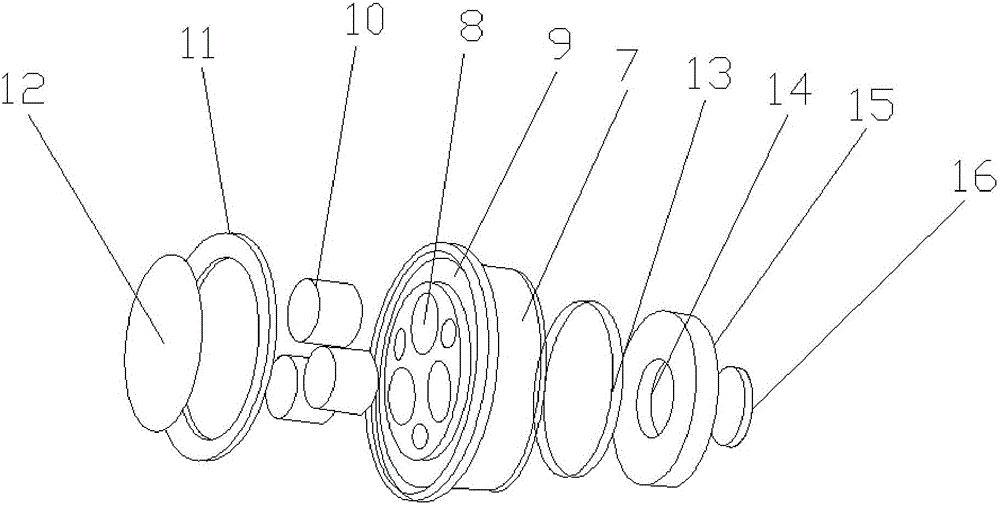

Piston aluminum skirt universal arbitrary indexing inclined hole rotary drill jig

InactiveCN101927366AImprove processing efficiencyReduce production costsDrill jigsBoring/drilling machinesPistonDrill hole

The invention discloses a piston aluminum skirt universal arbitrary indexing inclined hole rotary drill jig which comprises a rotary table [7], wherein the table surface of the rotary table [7] is provided with two supporting rods [1], the table surface is fixed with a positioning disk [8] which is provided with a step surface, through holes are arranged in the two supporting rods [1] and internally provided with screws [4] with bottoms limited in the rotary table, the upper ends of the screws [4] are provided with nuts [3], the screws in the nuts [3] are sleeved with a pressure plate [2], a drill jig [5] used for fixing an aluminum skirt [9] is arranged between the two supporting rods [1], the center of the drill jig [5] is provided with a step hole matched with the upper part of the aluminum skirt, and the side surface of the drill jig [5] is provided with a drill hole [6] matched with the dip angle of the aluminum skirt. The invention has the advantages of high processing efficiency and low production cost.

Owner:TONGLING JINGHENG MACHINERY

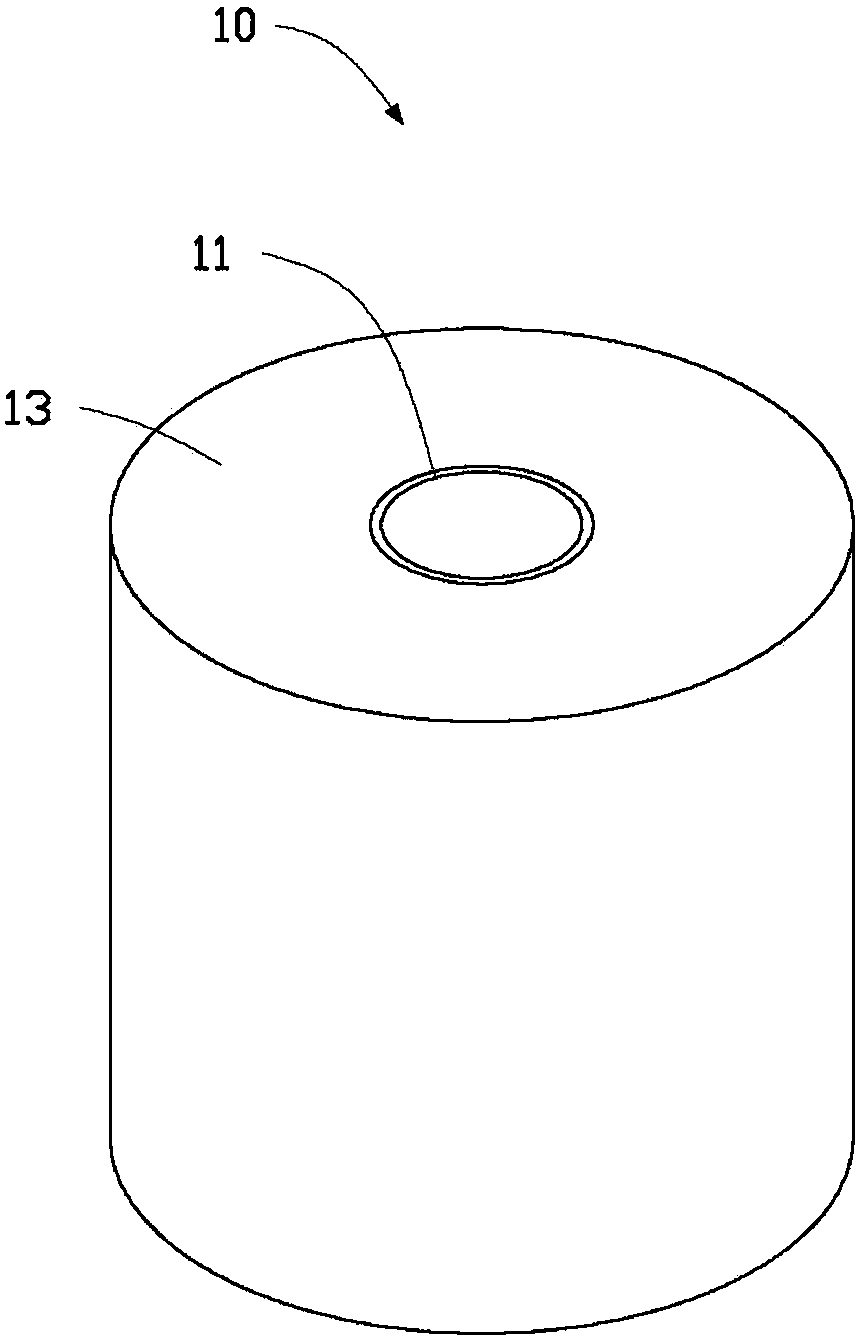

Deodorant paper for daily use

InactiveCN103610417AAdd lessReduce production costsNon-fibrous pulp additionDomestic applicationsDeodorantToilet

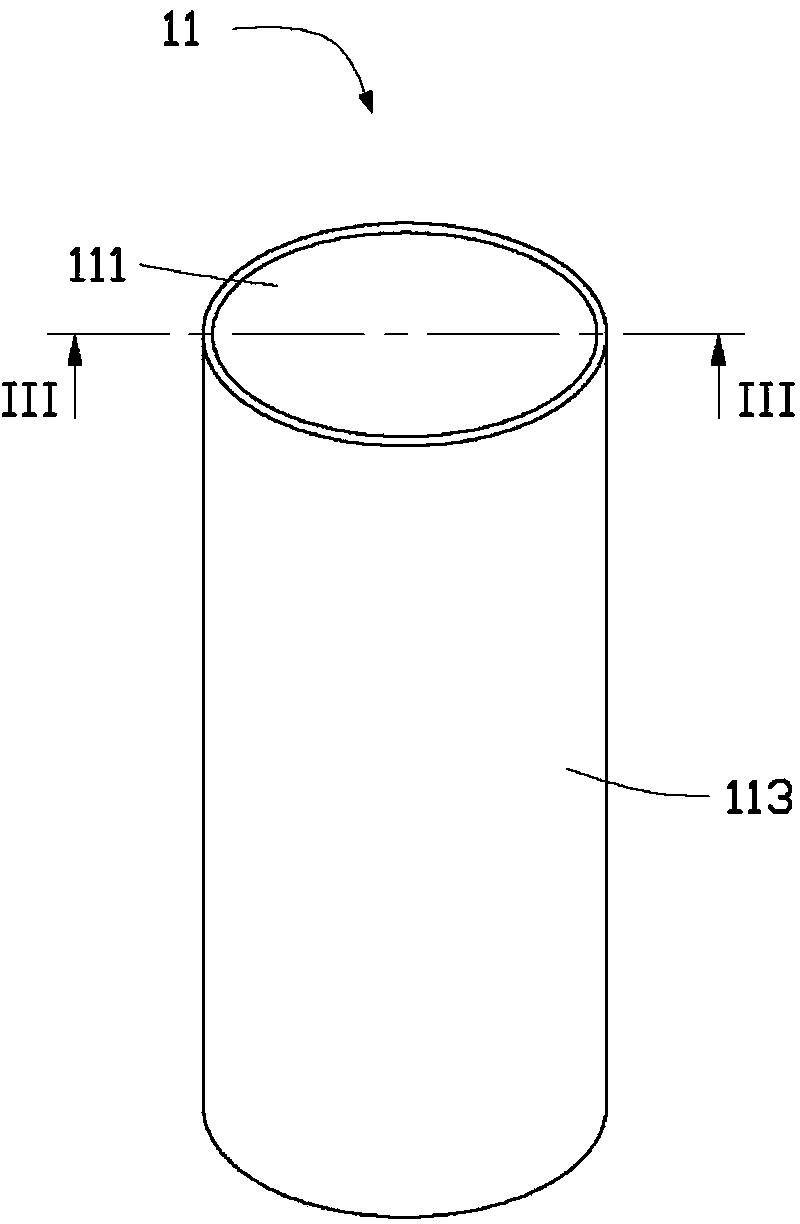

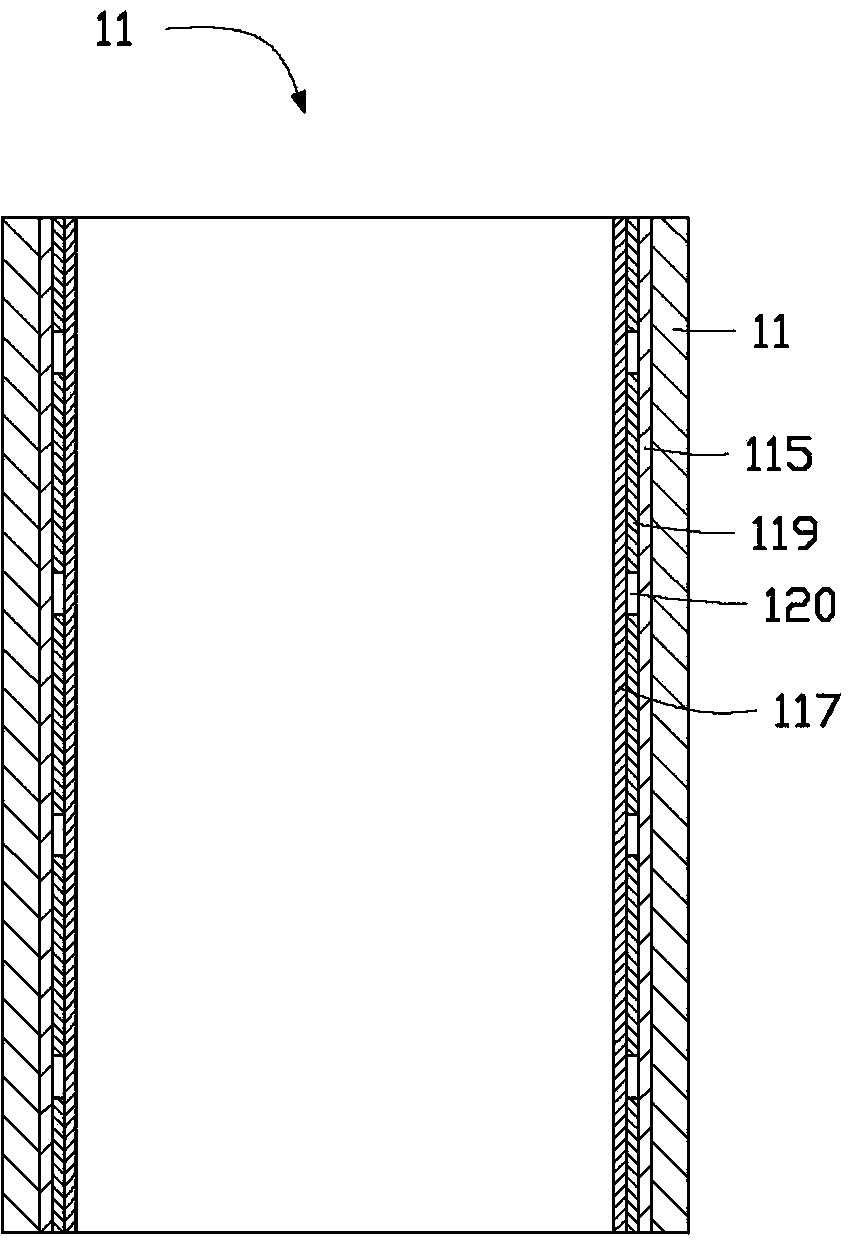

Deodorant paper for daily use comprises a paper core tube and roll paper wound on the paper core tube. The paper core tube comprises an outer side in contact with the roll paper and an inner side not in contact with the roller paper. The inner side is provided with a deodorant layer. The deodorant paper for daily use is applicable to places such as toilets and kitchens, functions in wiping basically and also functions in deodorization. Compared to the existing deodorant plate for daily use, the deodorant paper for daily use has the advantages that addition of deodorant is reduced effectively, and production cost of the deodorant paper for daily use is further reduced. In addition, the deodorant is added to the inner wall of the paper core tube, and the problem that direct addition of the deodorant to the paper for daily use causes harm to the skin of users is avoided.

Owner:GOLD HONG YE PAPER

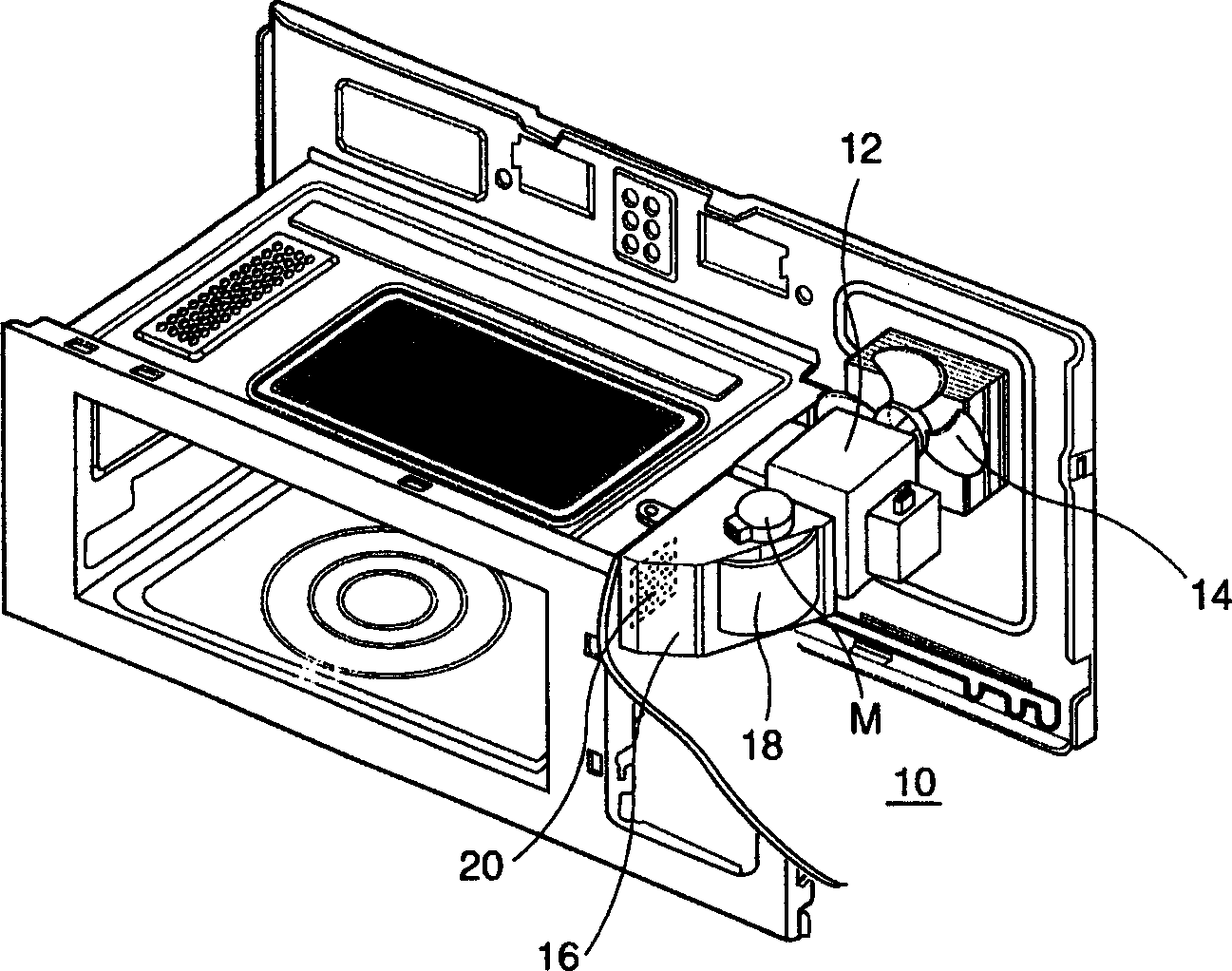

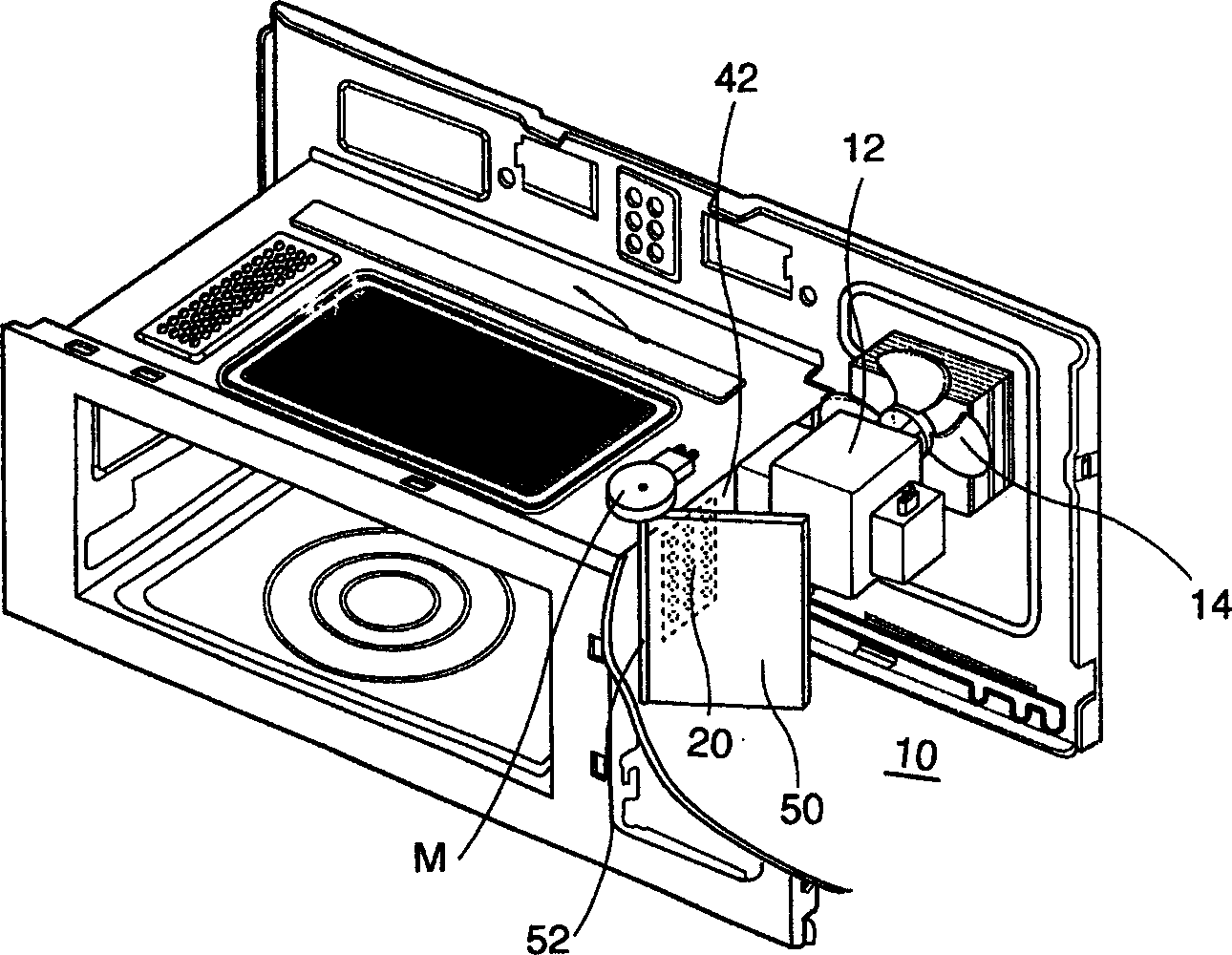

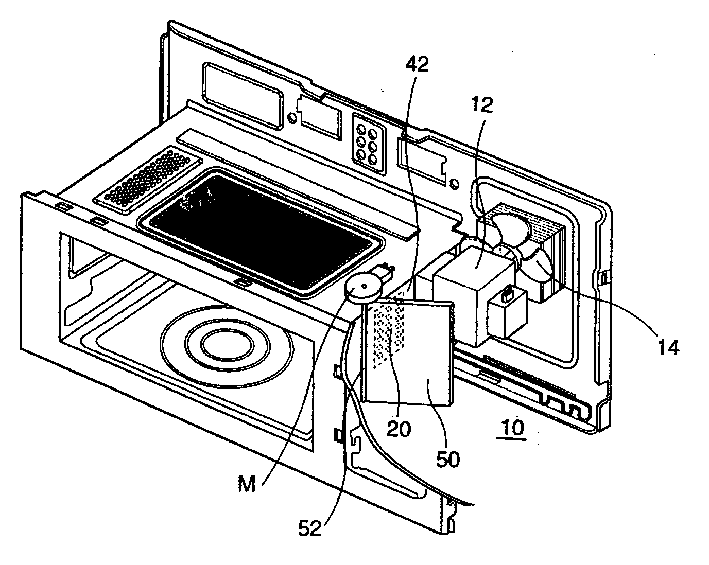

Air flow guide apparatus for microwave oven

InactiveCN1455169ASimple structureReduce production costsDomestic stoves or rangesLighting and heating apparatusMicrowave ovenAirflow

The device for leading airflows comprises the magnetron, the transformer, the blowing fan, the entrance of the heating room in the electric control chamber as well as the plate type switching board and the actuating motor for rotating the switching board. The switching board opens or closes the heating room caused by rotating the one end setup at round the sidewall of the electric control chamber. The rotating center of the switching board positioned at the entrance of the heating room is at the end of the board far away from the blowing fan M. the rotating center is setup along the top and bottom direction. The switching board controls air passing through the entrance entering into inside the heating room. Comparing with prior art, the invented leading device is simpler. Thus, it reduces the production cost and the production efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Formed coke for closed calcium carbide production mainly prepared from semi-coke powder

The invention discloses a formed coke for closed calcium carbide production mainly prepared from semi-coke powder, which is produced by using a main material semi-coke powder with the fixed carbon content of not less than 80%, an auxiliary material gas fat coal or coke and an adhesive for reinforcing and bonding the semi-coke powder. The production method comprises the following steps: uniformly mixing the main material and auxiliary material in a stirrer, adding the adhesive liquid into the stirred raw and auxiliary materials according to the proportion of the semi-coke powder and adhesive, continuing stirring until the mixture can not be sticky to the hand when being grasped by the hand, and forming the mixture in a forming machine, wherein the mechanical strength of the wet formed coal is 40-60N, and the formed coal can not become flat or scattered after freely falling to an iron plate from a 2m height; sending the formed coal with the degree of perfection of 98% above into a pyrolyzing furnace; and pyrolyzing under closed oxygen conditions, thereby obtaining the formed coke for closed calcium carbide production mainly prepared from semi-coke powder. The formed coke for closed calcium carbide production mainly prepared from semi-coke powder greatly optimizes the use of the semi-coke powder, enhances the market benefit value of the semi-coke powder, saves the coke resources, greatly lowers the cost of the calcium carbide production industry, and has obvious economic benefit and social benefit.

Owner:三门峡中兴节能环保科技有限公司

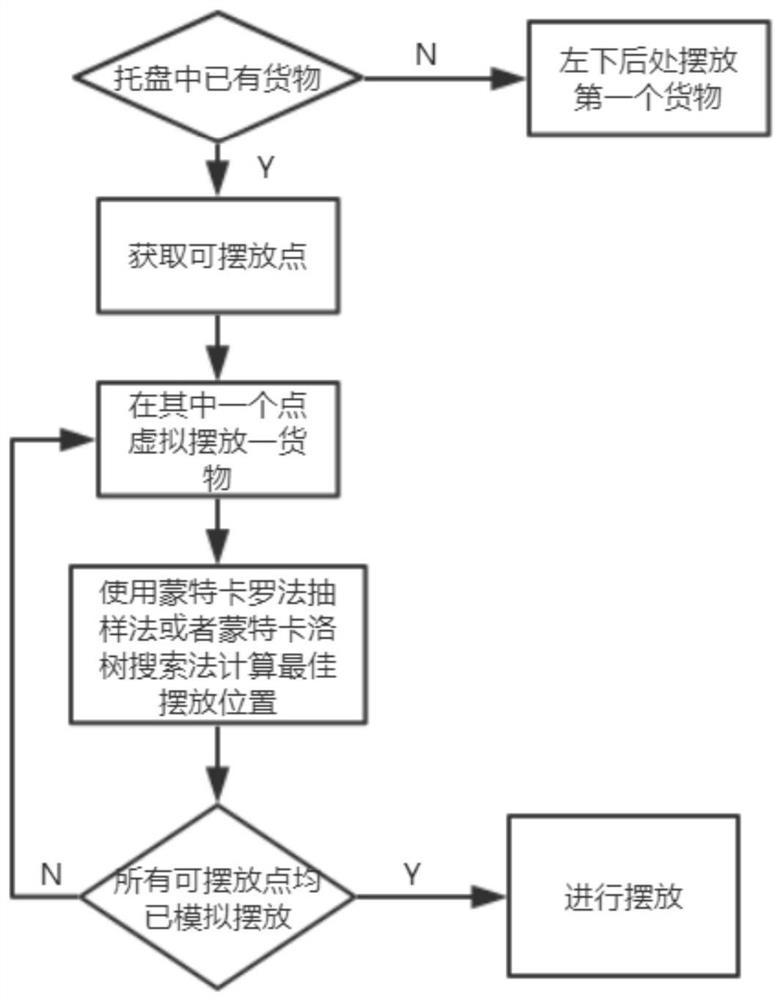

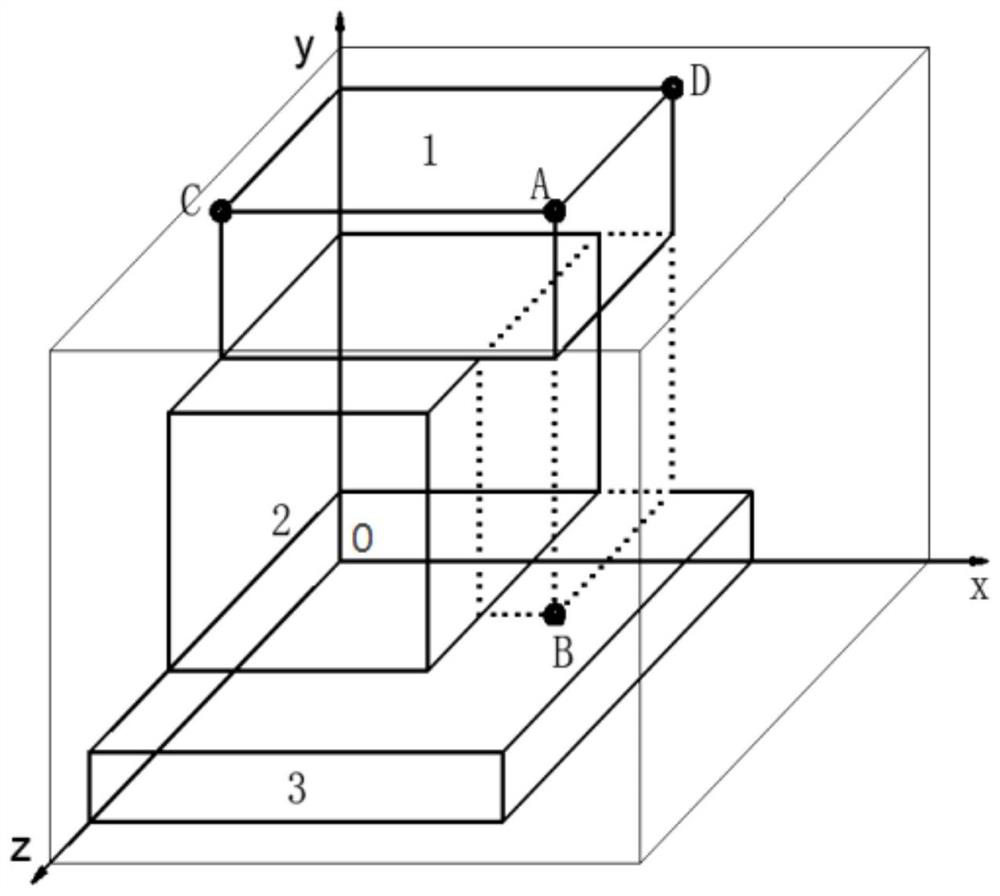

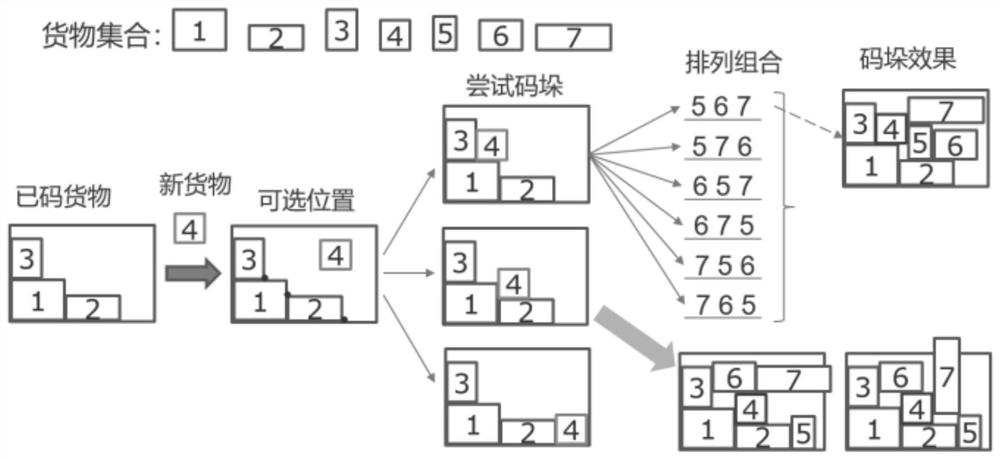

On-line cargo stacking method based on under-complete information

ActiveCN111891758AImprove pallet space utilizationReduce production costsStacking articlesSortingStructural engineeringMechanical engineering

The invention relates to an on-line cargo stacking method based on under-complete information. The on-line cargo stacking method based on the under-complete information is characterized by comprisingthe following steps that 1, all positions l capable of accommodating cargoes are recorded into a position set L; 2, screening is carried out according to whether the contact area between each position l and the bottom of the corresponding cargo a<1> meets a safe placement requirement or not when the corresponding cargo a<1> to be placed is placed and whether obstacles exist in the vertical direction or not; 3, corresponding placement positions of all the cargoes are found, an average value m<1> of the number of trays required by all schemes is recorded, a Monte Carlo sampling method is used for calculating a corresponding average number m of trays needed when the corresponding cargo a<1> is placed at each position l, and the minimum value in m is selected; and 4, the step 1to the step 3 are repeated till stacking of all the cargoes is completed. The method can effectively improve a space utilization rate of the trays.

Owner:GUANGDONG UNIV OF TECH

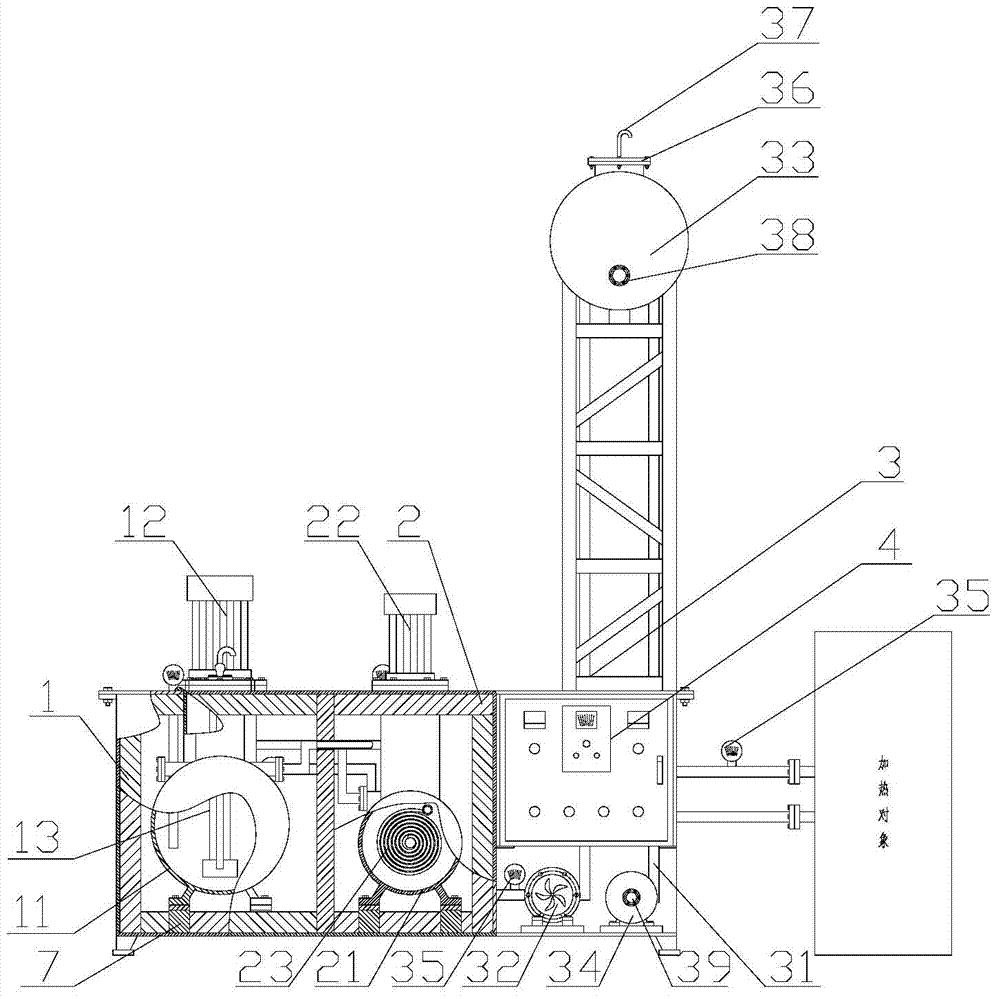

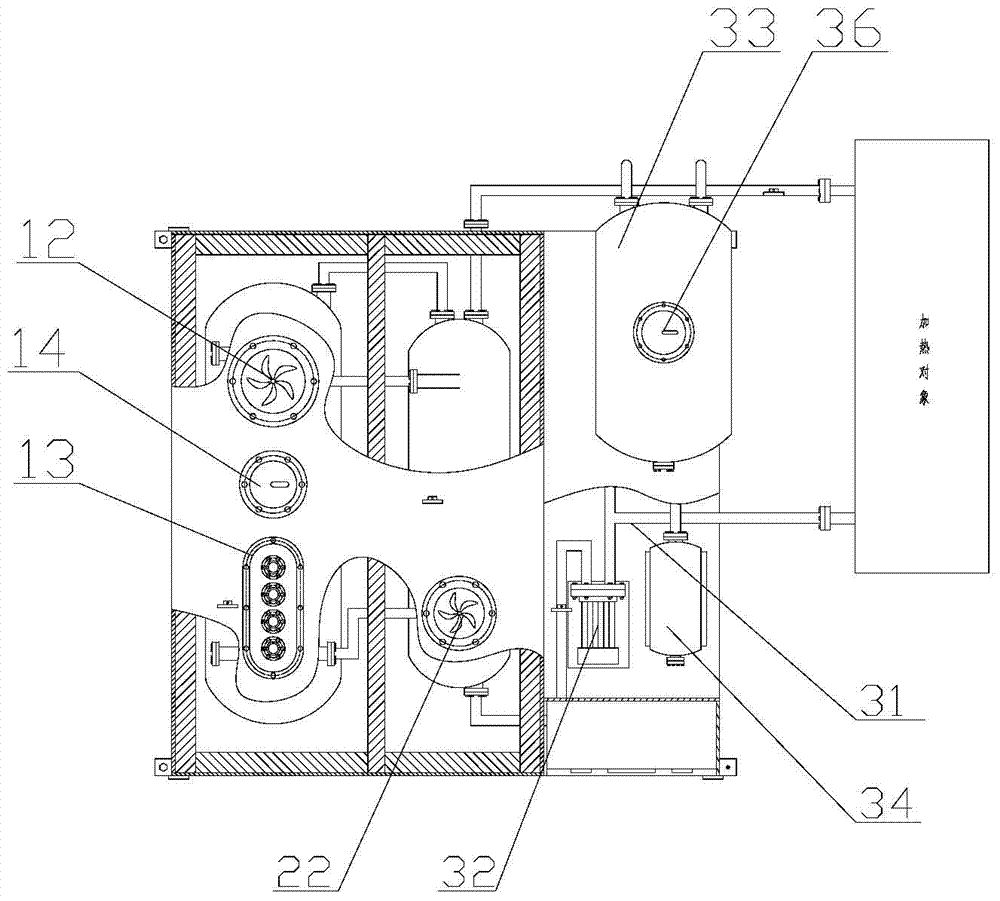

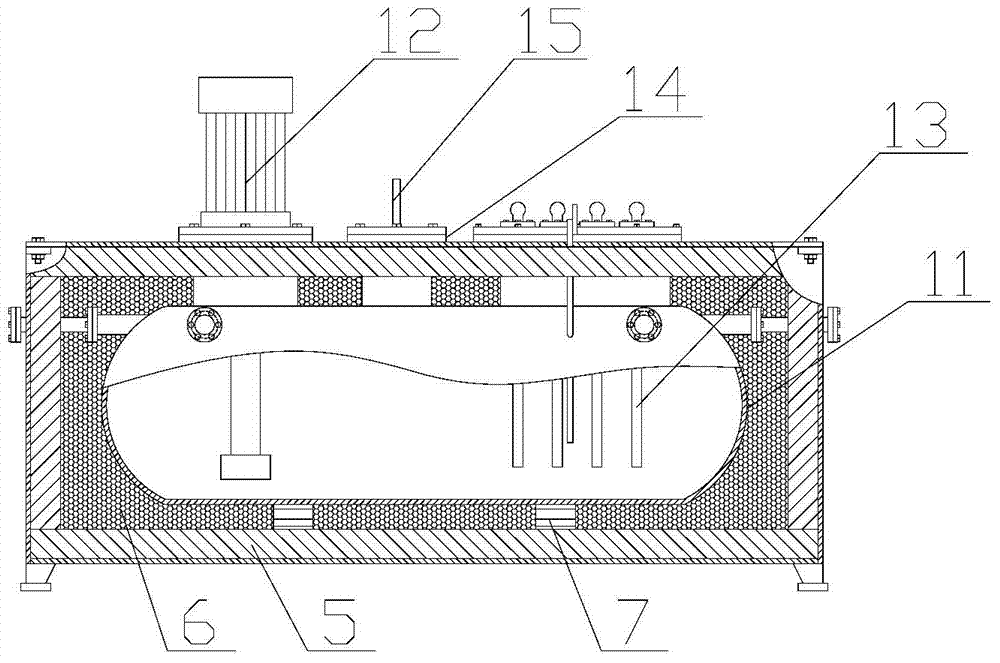

Electric heating energy-saving storage unit

InactiveCN103591688AReduce production costsReduce electricity pressureStorage heatersExpansion tankElectric heating

The invention discloses an electric heating energy-saving storage unit which is simple in structure, environmentally friendly and energy saving. The electric heating energy-saving storage unit comprises an electric heat storage device, a constant temperature heat exchanger, and a heat transfer oil heating device. The electric heat storage device comprises a heat storage tank, an ultrahigh temperature pump arranged on the heat storage tank, and an electric heating wire. The heat storage tank is filled with organic liquid. The organic liquid can be heated to the high temperature lower than 550 DEG C under the normal pressure. The constant temperature heat exchanger comprises a constant temperature tank, a temperature control pump disposed on the constant temperature tank, and a heat transfer soil heated coil disposed inside the constant temperature tank. The constant temperature tank is communicated with the heat storage tank. The heat transfer oil heating device is connected with a hot oil circulating pump providing cyclic power, an expansion tank and an oil storage tank storing heat transfer oil and heated through a heat transfer oil circulating pipeline. The electric heating energy-saving storage unit stores heat energy by electric heating in off-peak periods, the heat energy is used for production and processing in peak periods, production cost is reduced, and pressure of using electricity in peak periods is reduced.

Owner:泉州恒灼热力机械科技有限公司

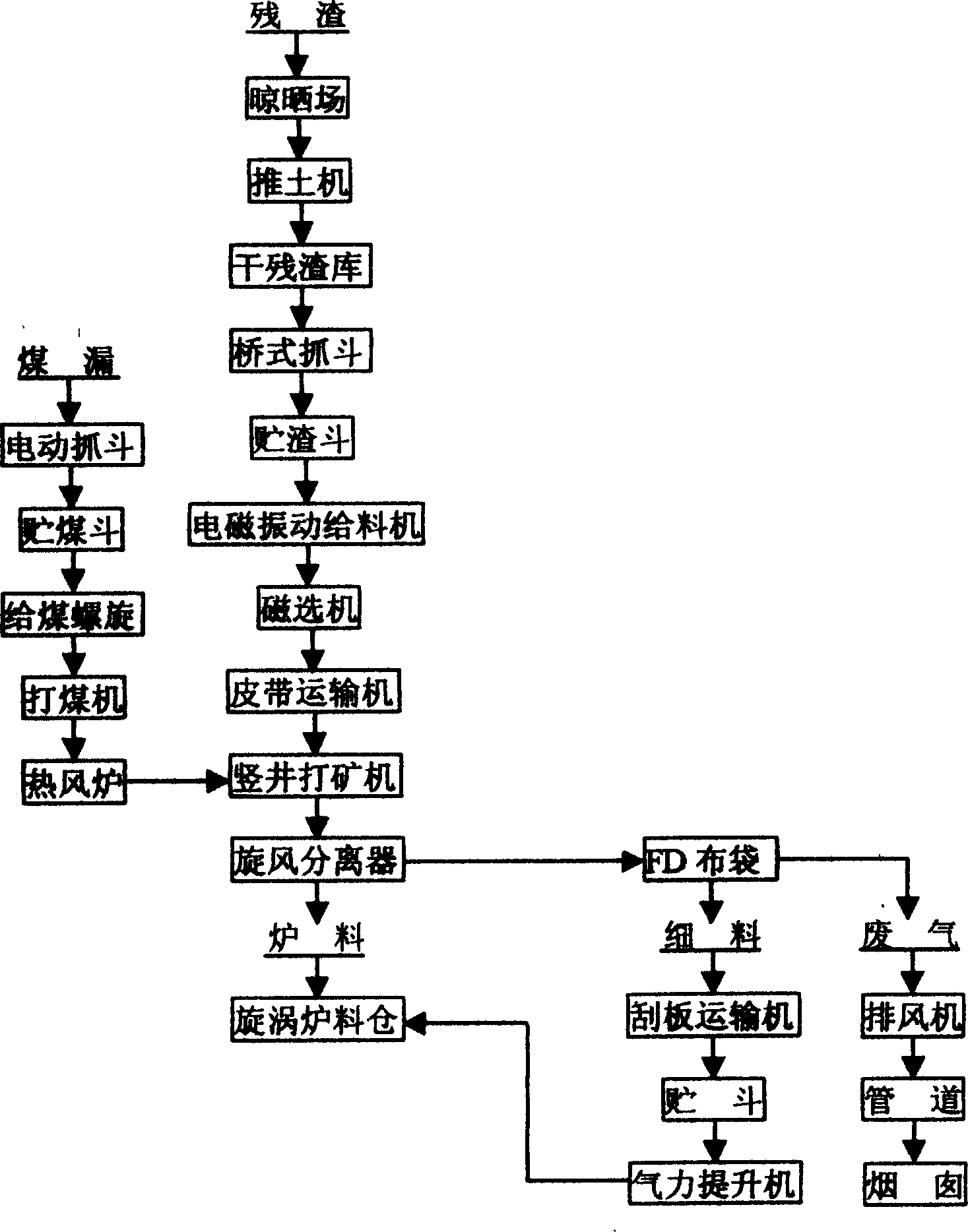

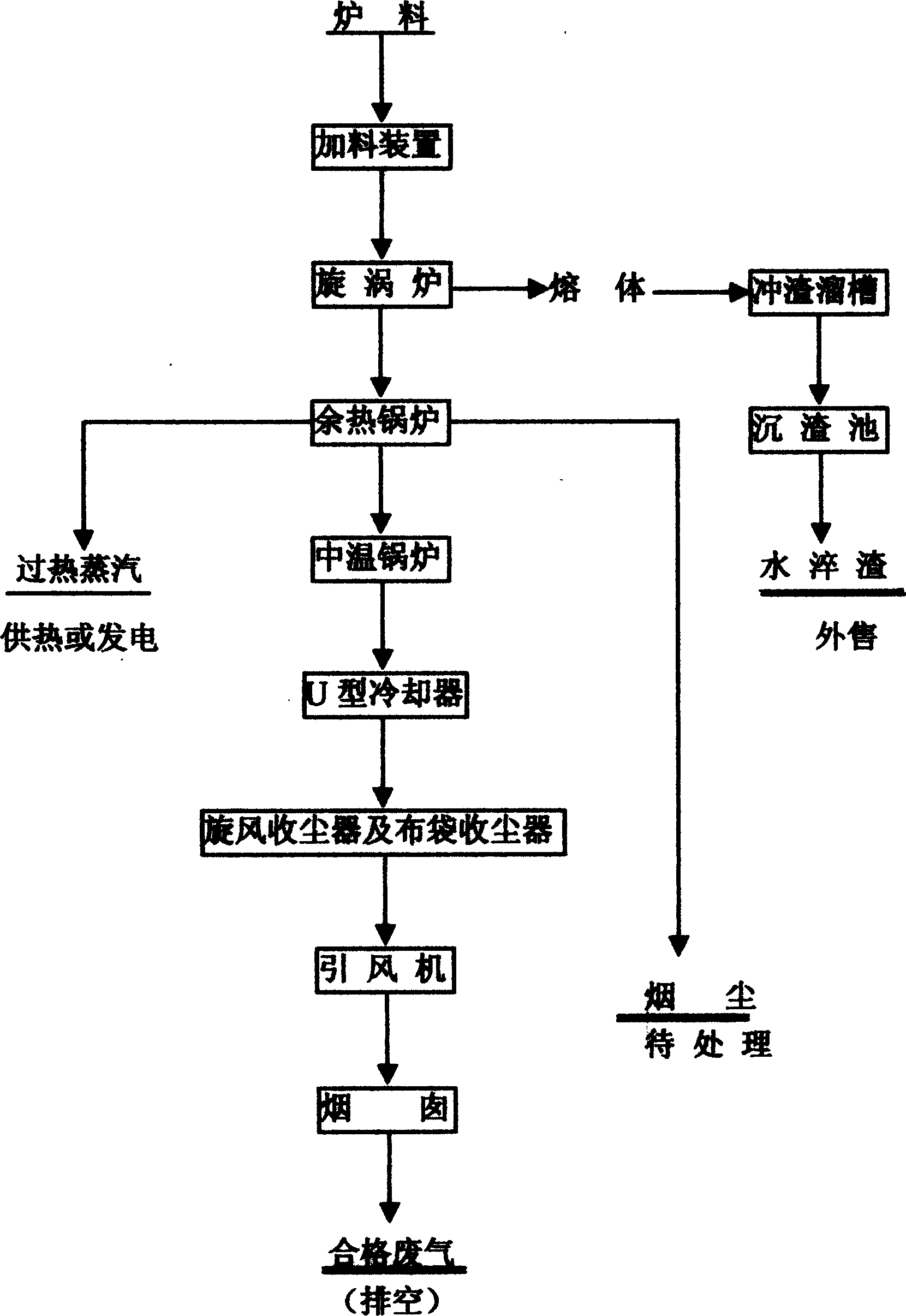

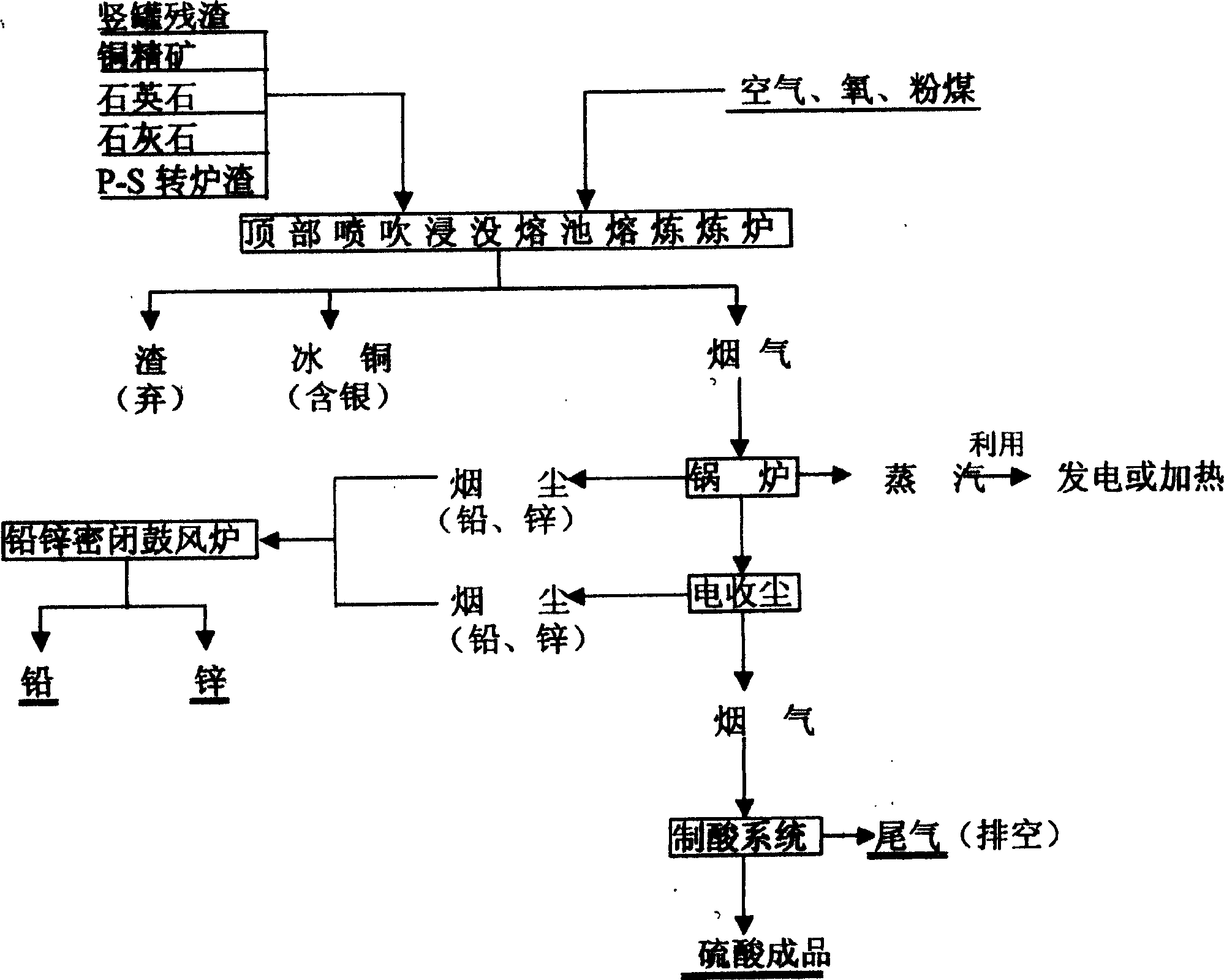

Comprehensive recovery technique of zinc vertical retorting residue

The vertical tank zinc-smelting bottom, copper concentrate and slag-making agent of quartzite, lime stone and vessel slag are mixed, and added from top and sprayed to immerse meltnig bath of smelting-furnace, at the same time the oxygen gas and air are injected by means of spray gun, and then reacted at 1150-1250 deg.C so as to produce matte and discarded slag. The reaction heat required for smelting copper can be provided by carbon contained in the vertical tank zinc-smelting bottom, the other heat can be recovered in the boiler for power generation, the contained silver is enriched in the matte, and the contained lead and zinc are enriched in the smoke and dust of smelting furnace, the silver can be recovered in the copper-smelting next procedure.

Owner:中冶葫芦岛有色金属集团有限公司

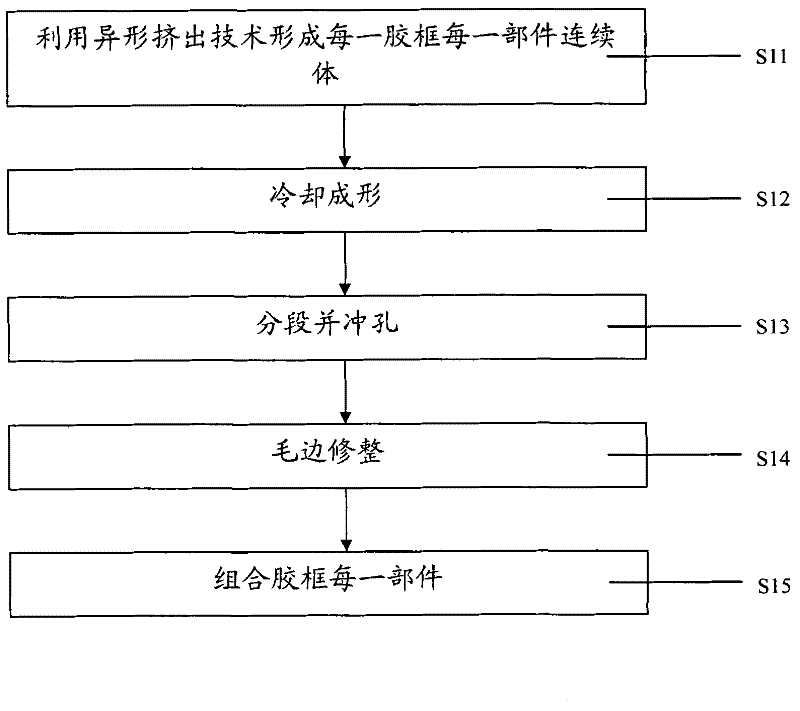

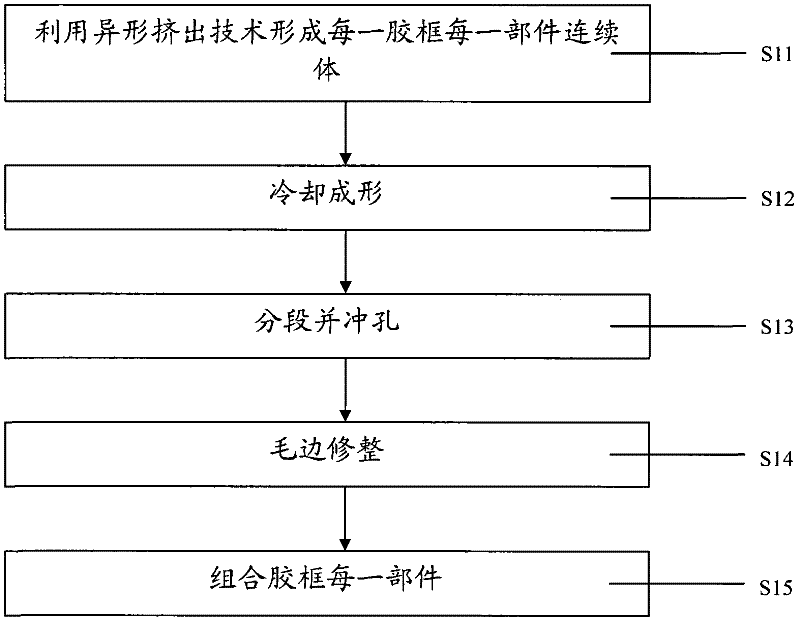

Adhesive frame making method

InactiveCN102243391AReduce production costsReduce forming costNon-linear opticsAbnormal shapedLiquid-crystal display

The invention provides an adhesive frame making method which is applied to adhesive frames of LCD (Liquid Crystal Display) backlight sources and comprises the steps of: forming a continuum of each part of each adhesive frame by using an irregular extrusion technology; cooling each continuum; segmenting each continuum and punching system locking and attaching holes to form each part of each adhesive frame; and assembling all the parts into the corresponding adhesive frame. By adopting the adhesive frame making method provided by the invention, the mould production cost can be reduced greatly so as to reduce forming cost, a long and thin member can be formed, and a fastener type design is beneficial to reduction of the using amount of screws, so that the cost can be reduced by 20%.

Owner:AU OPTRONICS CORP

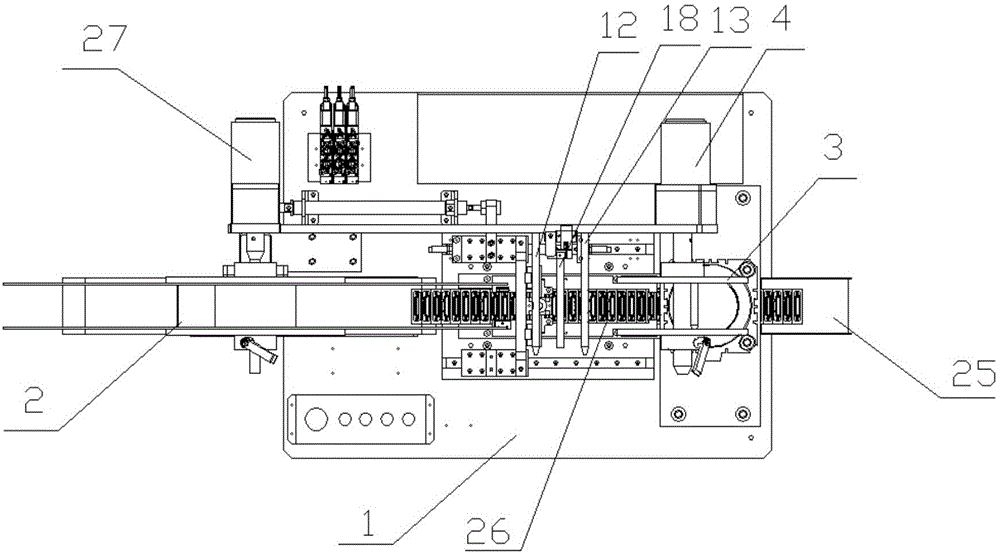

Sheet cropping equipment

InactiveCN105458061AAvoid manufacturingReduce production costsMetal-working feeding devicesStripping-off devicesEngineeringMultiple function

The invention discloses sheet cropping equipment. A material plate is driven by a material plate driving device to rotate. A paper plate is driven by a paper plate driving device to rotate. A paper tape tensioning state inducing device can induce the tension condition of a material strap which is drawn out of the material plate to enter the paper plate and transmit information to a controller. A material strap track is exactly located right below the material plate and connected with a material conveying channel. The material plate, a material plate support, the material strap and the material strap track can form a conduction loop to be electrically connected with the controller. The material plate support is connected with a lower-voltage power source. A material pulling device is fixed over the material conveying channel. A material pulling driving device can drive the material pulling device to pull the material strap to move. A material strap channel exactly passes through a knife edge of a lower die body of a stamping die. A plunger chip is arranged on an upper die body. The upper die body is driven by a stamping driving device to move longitudinally. The controller controls actions of all devices. According to the sheet cropping equipment, multiple functions are achieved through the equipment; the production cost is reduced; the production efficiency is improved; deformation of products is avoided due to the fact that the products are not tensioned by a paper tape, and the defective rate of the products is decreased.

Owner:昆山金群力精密组件有限公司

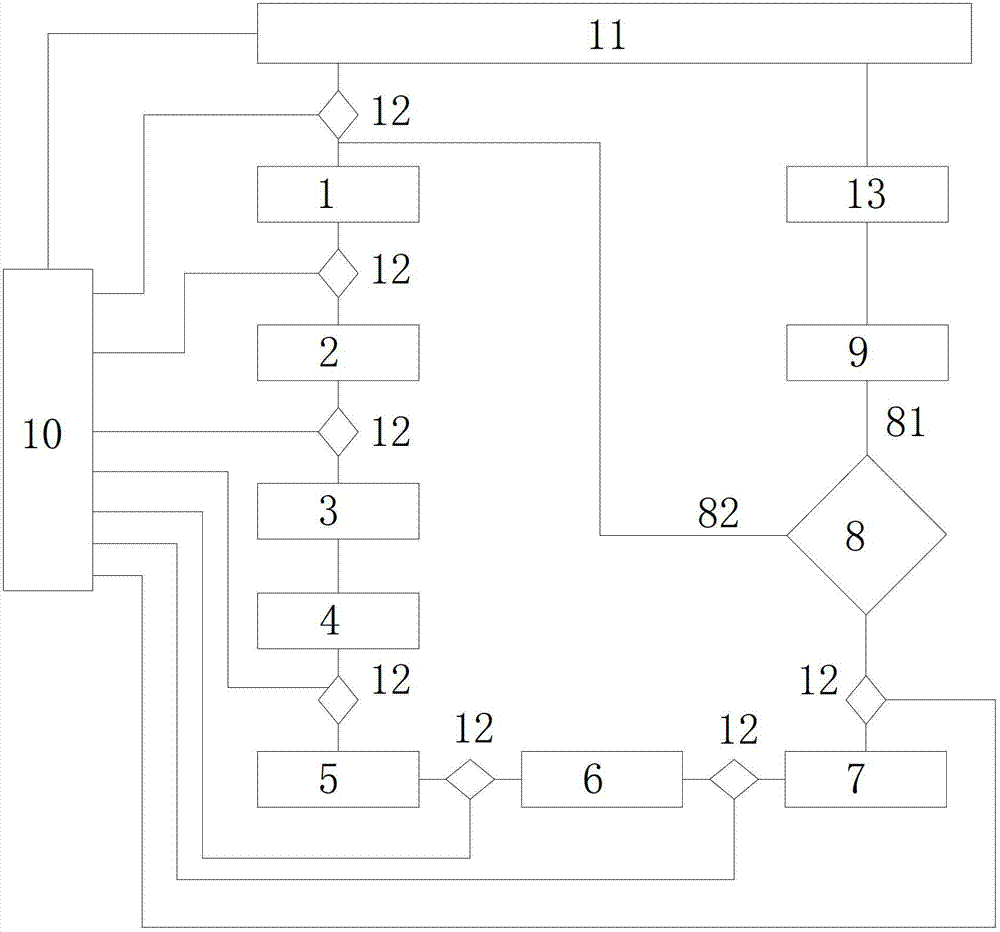

Device and method for recovery, purification and reusing of high-purity HE(helium) in crystal growth

ActiveCN103204483AReduce production costsAutomate recyclingNoble gas compoundsMolecular sieveProgrammable logic controller

The invention discloses a device and a method for recovery, purification and reusing of high-purity HE(helium) in crystal growth. The device comprises a gas booster pump, a first gas storage tank, an oil gas filter, a molecular sieve, a second gas storage tank, an ultralow temperature adsorbing cooling pump, a heat regenerator, a gas detector, a third gas storage tank and a PLC (programmable logic controller) controller. The method includes pressurizing, purifying, edulcorating and the like. The device and the method for recovery, purification and reusing of high-purity HE in crystal growth have the advantages that the molecular sieve and the cooling pump are taken as an adsorbing source to perform physical adsorption, an automatic detecting and control system is built up to perform circular purification and to reach the 5N high-purity level, HE filled in a cavity is recovered, purified and reused in the crystal growth to realize automatic HE recovery, purification and reuse, and more than 80 % HE production cost is saved.

Owner:贵阳嘉瑜光电科技咨询中心

Preparation method for environment-friendly denitrification catalyst

ActiveCN107744819AReduce production costsSimple preparation processDispersed particle separationCatalyst activation/preparationChemical industryCinder

The invention belongs to the technical field of environmental protection of chemical industry, and discloses a preparation method for a denitrification catalyst of pyrite cinder. The denitrification catalyst is obtained through steps of pyrite cinder pretreatment, pyrite cinder modification and active component loading. The preparation method comprises the following steps: placing pretreated pyrite cinder into a cane sugar solution, then successively carrying out hydrothermal treatment, filtering, drying and calcining so as to obtain modified pyrite cinder coated with a carbon microsphere coating, and loading active components of vanadium pentoxide, yttrium nitrate and cerium sulfate into the modified pyrite cinder so as to finally obtain the denitrification catalyst based on the pyrite cinder. According to the invention, the pyrite cinder is used as a raw material and is transformed into the novel denitration catalyst by modification. The catalyst provided by the invention has high reaction activity in a range of 200 to 400 DEG C.

Owner:安徽金森源环保工程有限公司

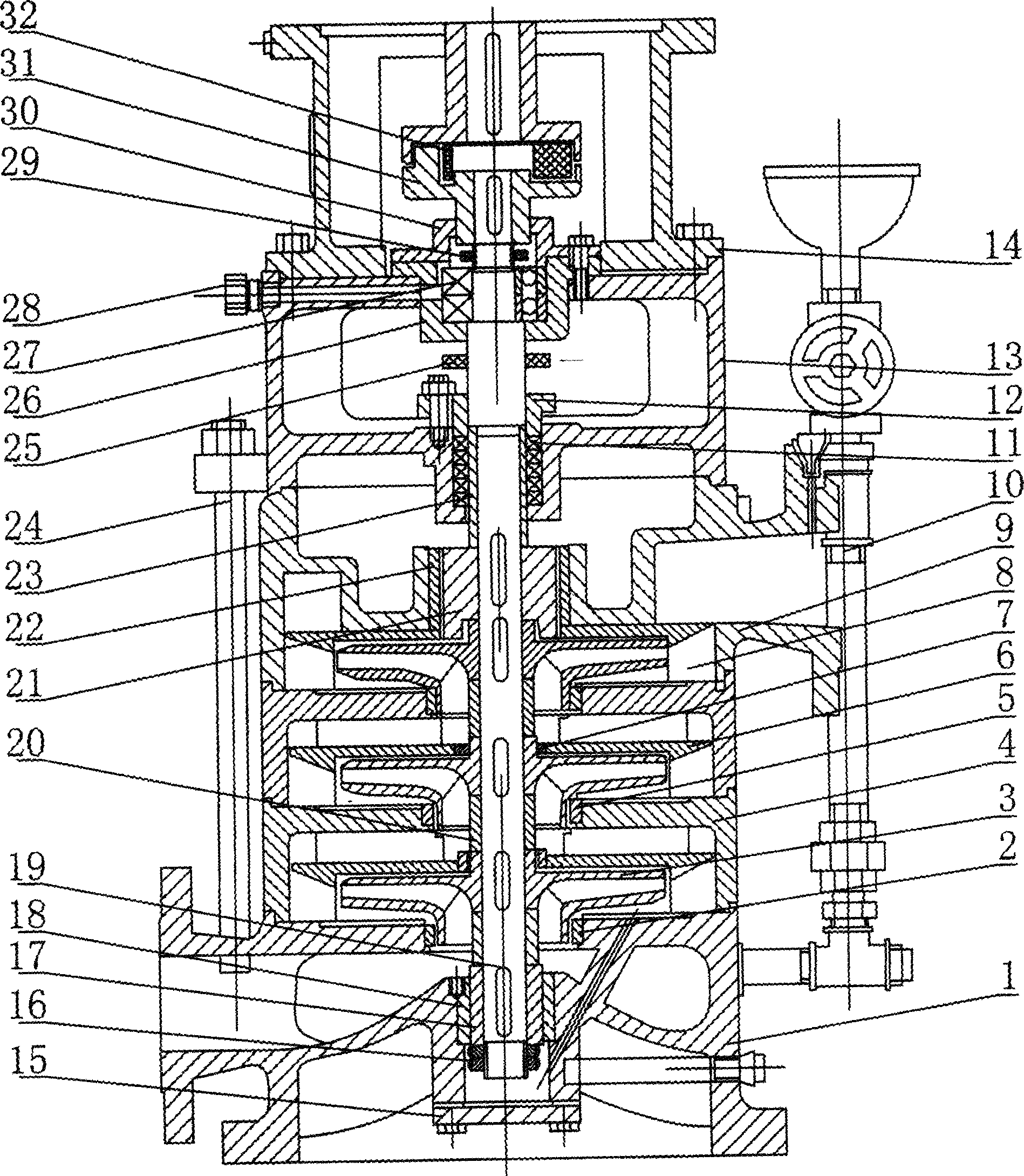

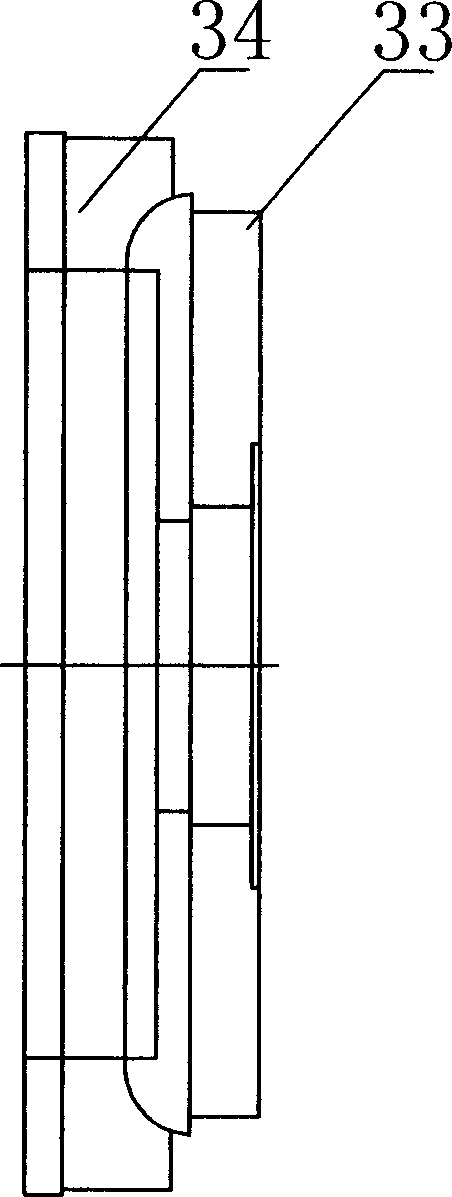

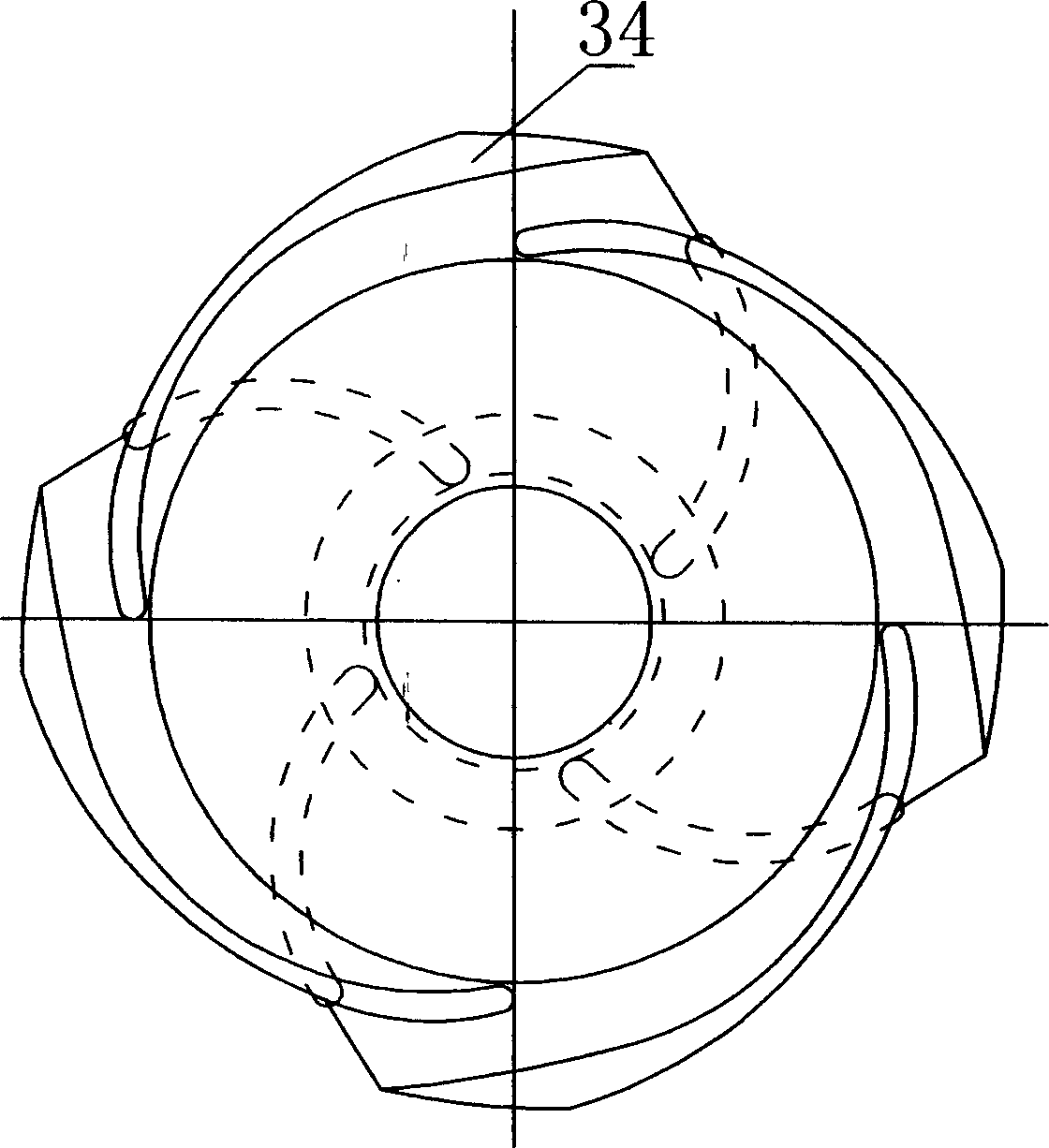

Clean water pump

InactiveCN1664375AReduce production costsImprove the finishPump componentsPump installationsFeed pressureImpeller

The invention relates to a clean water pump that includes cover board, pump base, middle section, mouth circle, guide vane, guide vane cover, back section, back guide vane, supporting, tighten bolt, motor base, shaft connector, drive shaft, shaft cover A, shaft cover B, impeller, sealed circle, balance drum, balance drum cover, shaft cover C, feeding pressure cover, water proof circle, bearing box, bush, oil cup, and bearing water filling returning pipe. The material of pump base, middle section, mouth circle, guide vane, guide vane cover, back section, back guide vane, supporting, motor base, shaft connector, drive shaft, shaft cover A, shaft cover B, impeller, balance drum, balance drum cover, shaft cover C, feeding pressure cover, water proof circle, bearing box, bush, oil cup, and bearing water filling returning pipe is ABS engineering plastic. The advantage is that: it needs not to be machined, and it has high temperature endurable, high intensity, high steadily and high reliability, etc.

Owner:王双成

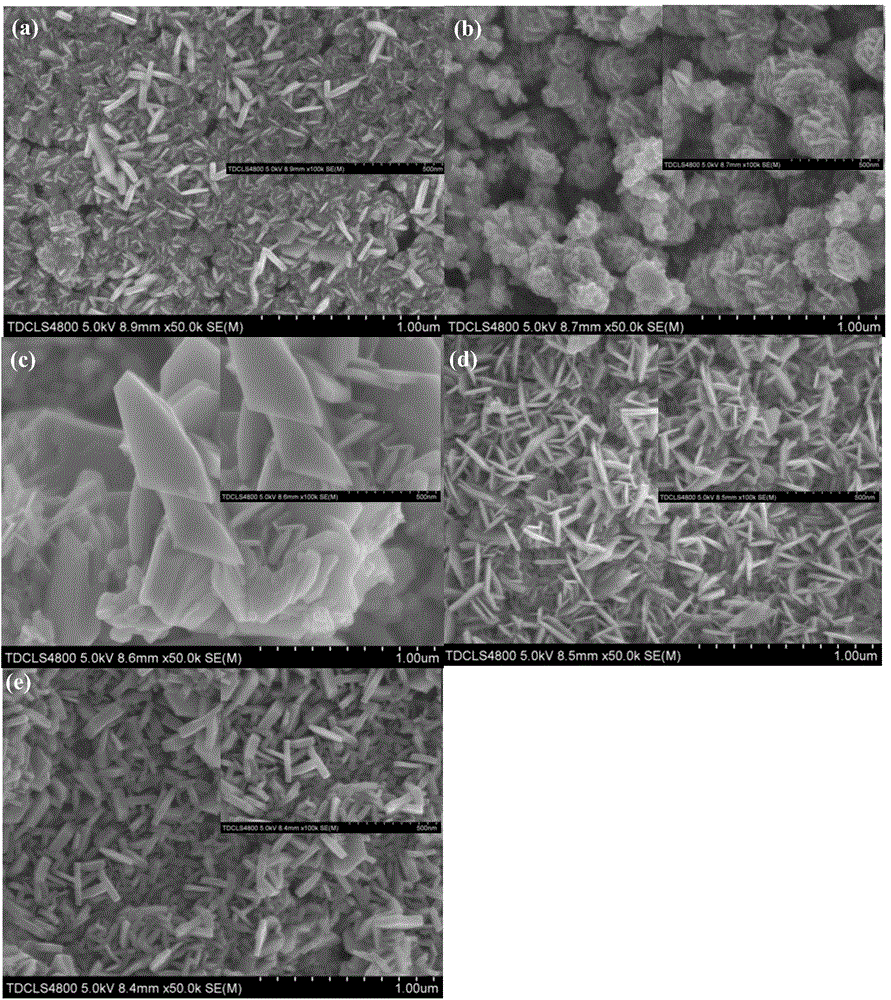

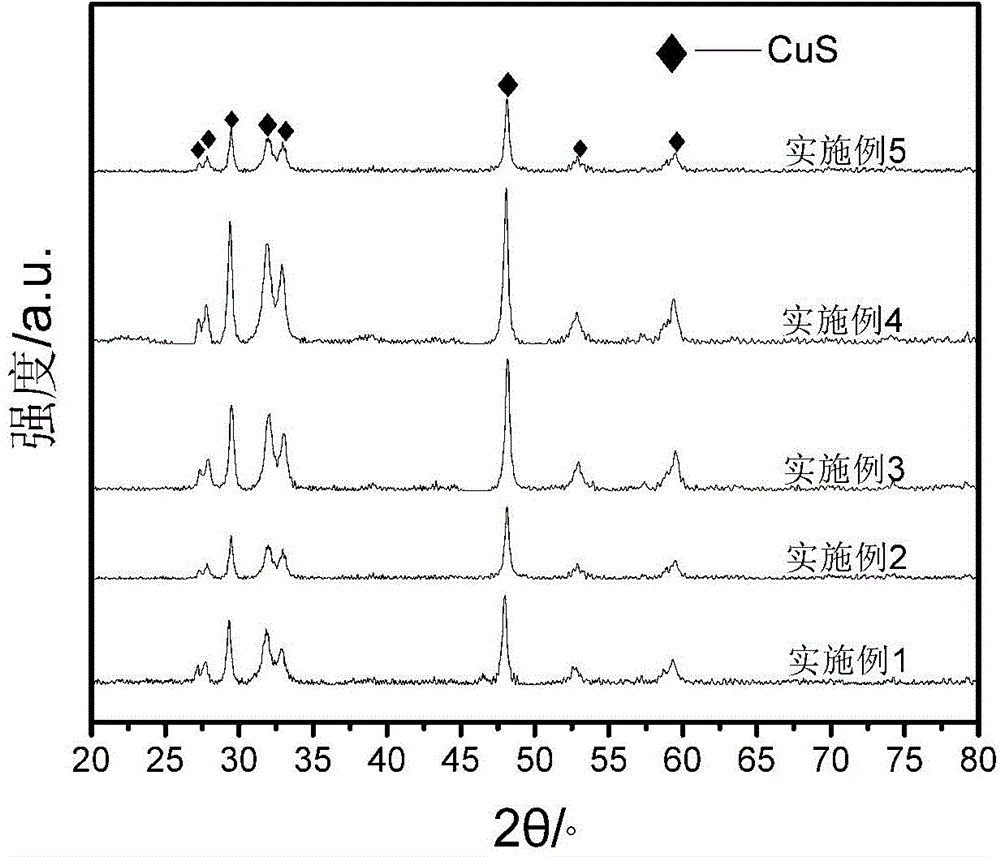

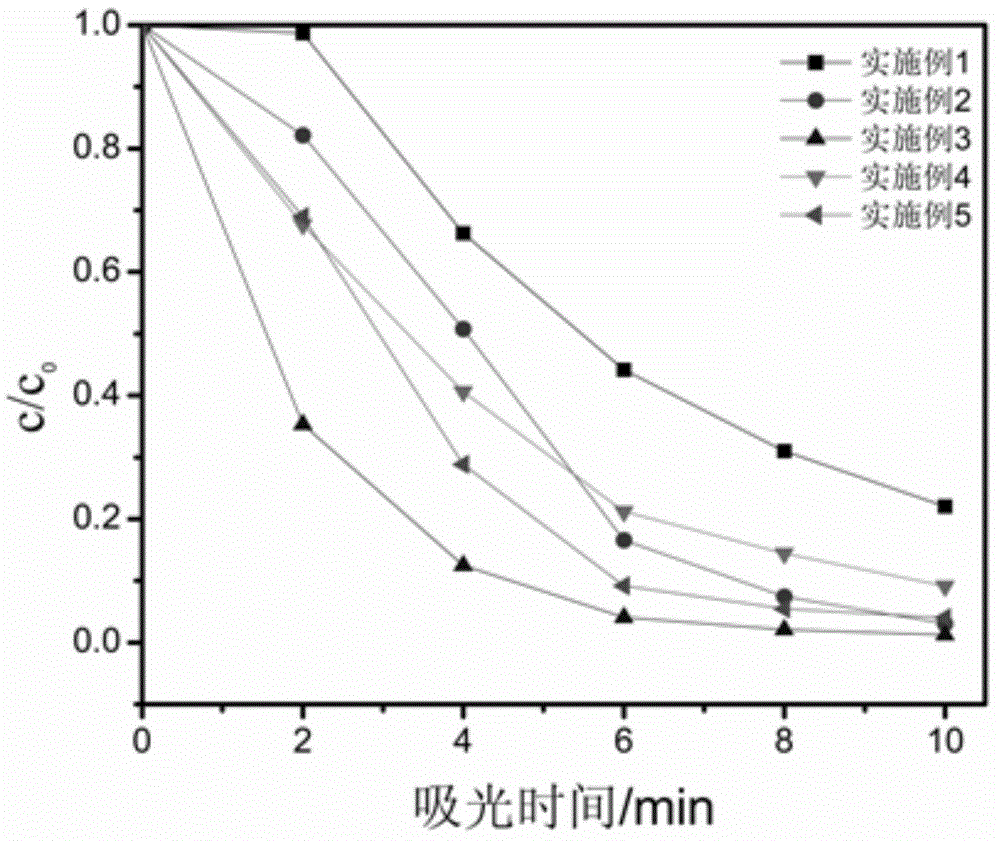

Method for preparing nanosheet cluster-structure cupric sulfide from titanium-copper amorphous alloy and application thereof

InactiveCN104628028AReduce production costsEasy to prepareMaterial nanotechnologyPhysical/chemical process catalystsIonTitanium

The invention discloses a method for preparing nanosheet cluster-structure cupric sulfide from a titanium-copper amorphous alloy. The cupric sulfide powder prepared by the method has the advantages of large specific area and high photocatalytic activity. The method comprises the following steps: putting a titanium-copper amorphous alloy strip (comprising 30-70 atm% of Ti and 30-70 atm% of Cu) and a sulfuric acid water solution with the molar concentration of 10-15M into a closed vessel to react at 60-120 DEG C for 24-96 hours, flushing the sample prepared by reaction with deionized water, and drying in a 50-DEG C drying box to obtain the nanosheet cluster cupric sulfide powder. The synthesis method has the advantages of simple manufacturing process and low raw material cost, and is simple, feasible and economical.

Owner:TIANJIN UNIV

Binder for preparing formed coke by taking semi coke powder as main raw material

The invention discloses a binder for preparing formed coke by taking semi coke powder as a main raw material. The binder comprises the following raw materials in percentage by weight: 65-75% of corn starch, 25-15% of dextrin, 4-6% of borax, 3-1% of 502 rubber powder, 2-1% of polystyrene amide and 1-2% of thiourea, totally 100%. The raw materials are ground to obtain dried powder of the binder. According to the dried powder of the binder used, 20kg of sodium hydroxide and 910kg of water are added into every 70kg of special dried powder binder to synthesize the liquid binder. The invention provides a binder for producing formed coke for airtight calcium carbide production by taking semi coke powder as the main raw material. The binder is used for binding semi coke powder, so that the semi coke powder is greatly optimized in use, thereby improving the market benefit and value, saving the coke resource, and meanwhile, greatly lowering the calcium carbide production cost. Therefore, the binder is very remarkable in economic and social benefits.

Owner:三门峡中兴节能环保科技有限公司

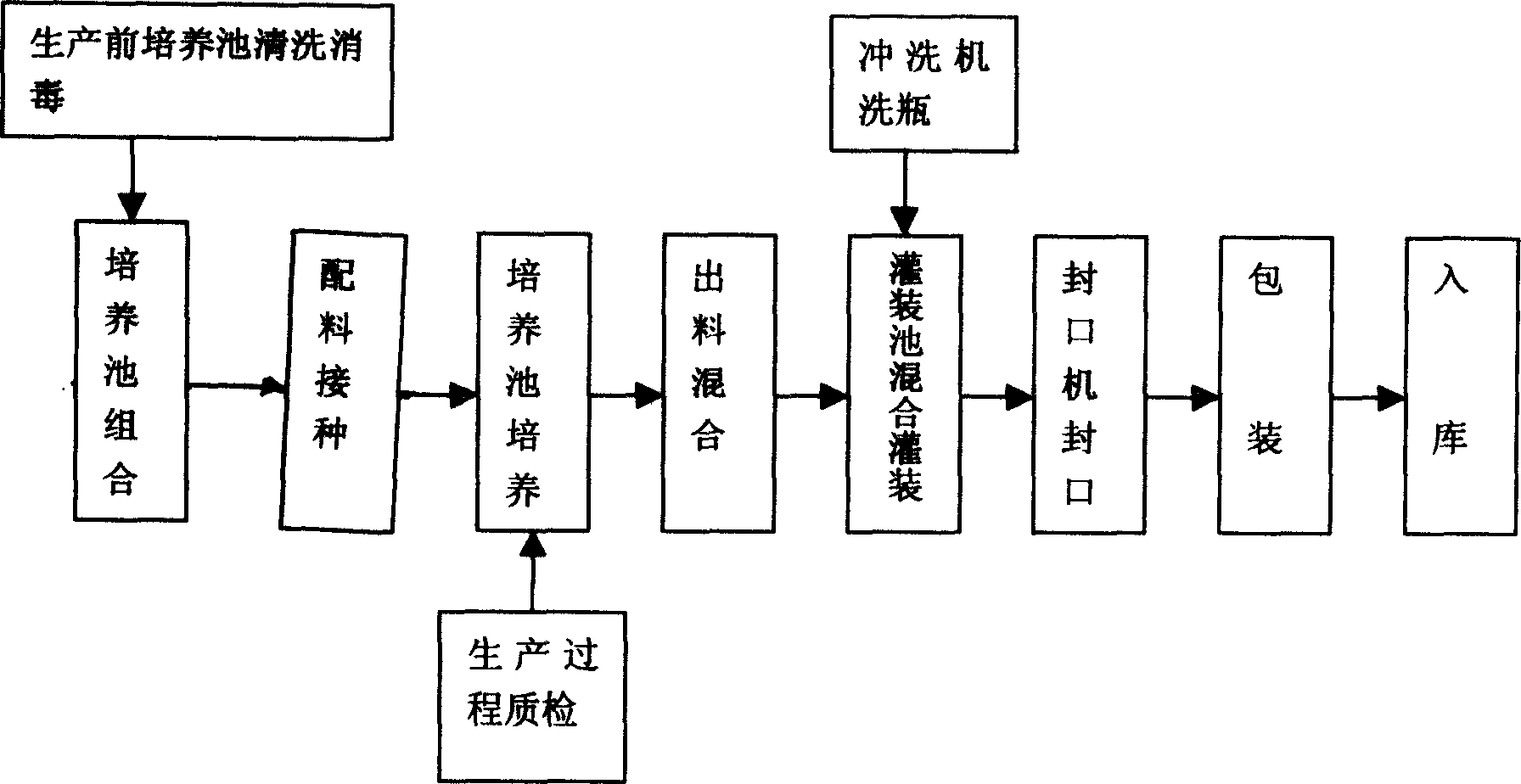

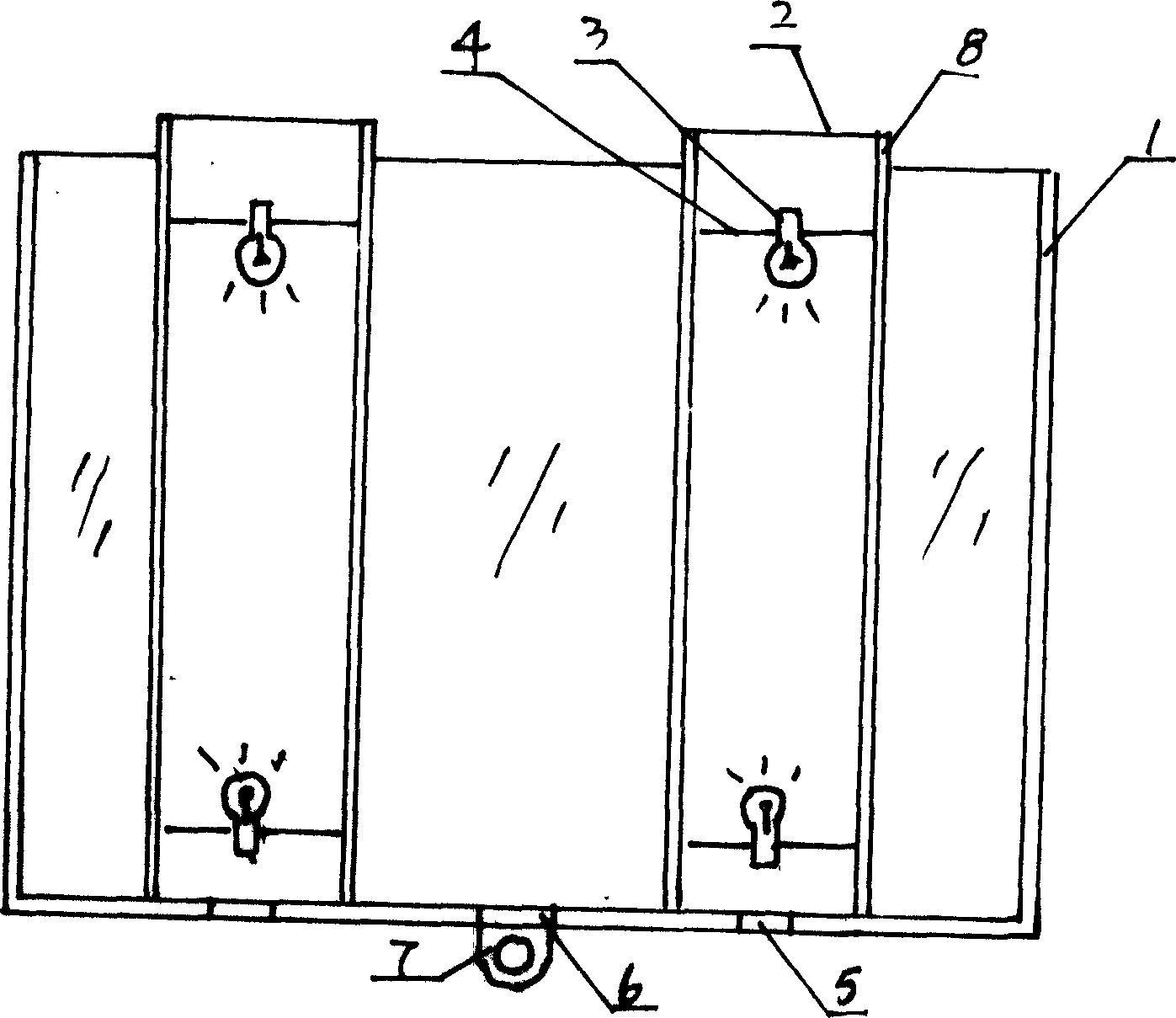

Culture pond process of producing photosynthetic bacteria for animal and plant

InactiveCN1441054ASave money on electricity billsReduce production costsBacteriaApparatus sterilizationCulture mediumsPhotosynthetic bacteria

The culture pond process of producing photosynthetic bacteria for animal and plant includes culture pond assembling, clenaing of culture pond and production site, disinfection, compounding culture meidum, inoculating, illumination, regulating temperature of culture medium, random sampling, packing and sealing. The present invention has the advantages of low power consumption, less covered area, reduced loss of photosynthetic bacteria, arbitrary combination and being suitable for production in plant of different scales.

Owner:赵平初

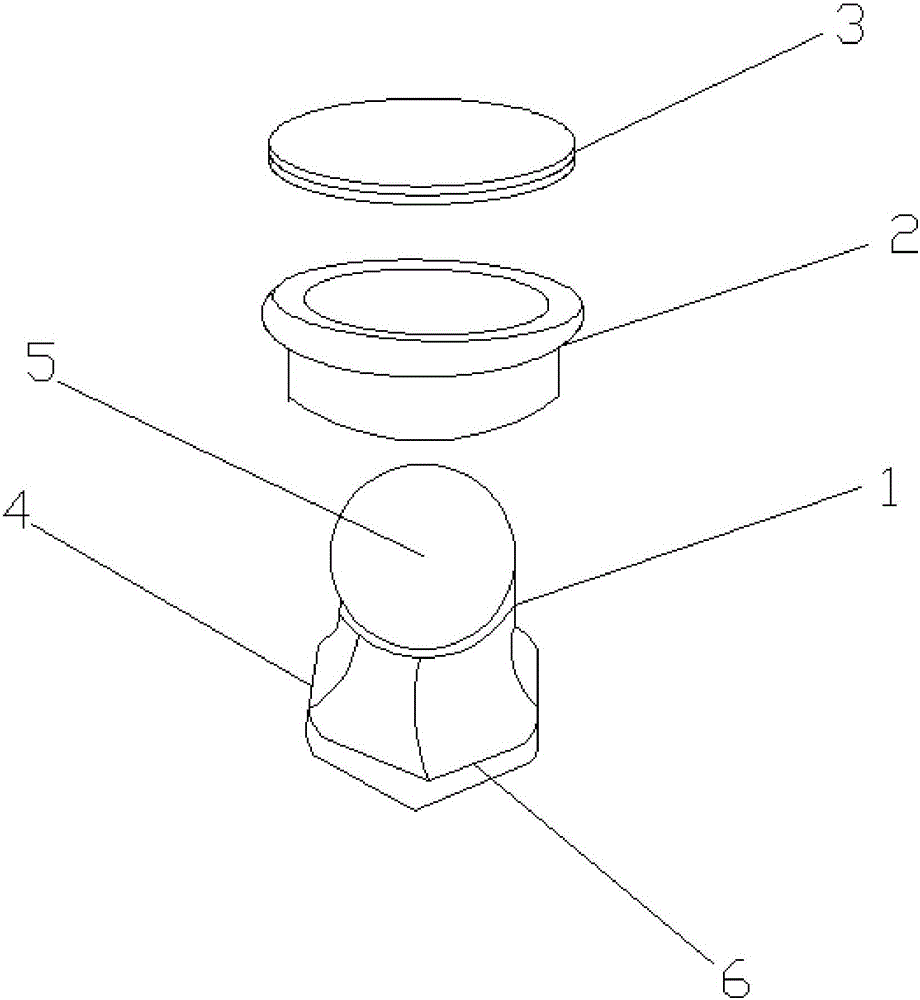

Magnetic suction type cell phone support

InactiveCN105979049ASave materialReduce production costsTelephone set constructionsMagnetEngineering

The invention discloses a magnetic suction mobile phone bracket, which includes a bracket, a suction cup and a magnetic attraction piece. The bracket includes a base and steel balls. The bottom surface of the base is provided with an adhesive layer 1. The main disk body is provided with a strong magnetic installation groove and a circular groove, a strong magnet is installed in the strong magnetic installation groove, a non-slip silicone pad is arranged in the circular groove, and a decorative sheet is arranged on the upper end of the main disk body. The lower end of the main disk body is provided with a groove, and a magnetic reinforcing sheet and a ring magnet are installed in the groove, and the ring magnet is provided with a central hole, and an anti-slip sheet is arranged in the center hole, and the magnetic attraction sheet and the The main discs attract each other, and the magnetic attraction sheet is provided with an adhesive layer 2. This magnetic mobile phone holder has good adsorption effect, takes up little space, and can rotate 360°; meanwhile, it has the advantages of simple structure, easy operation, and strong practicability. .

Owner:张日龙

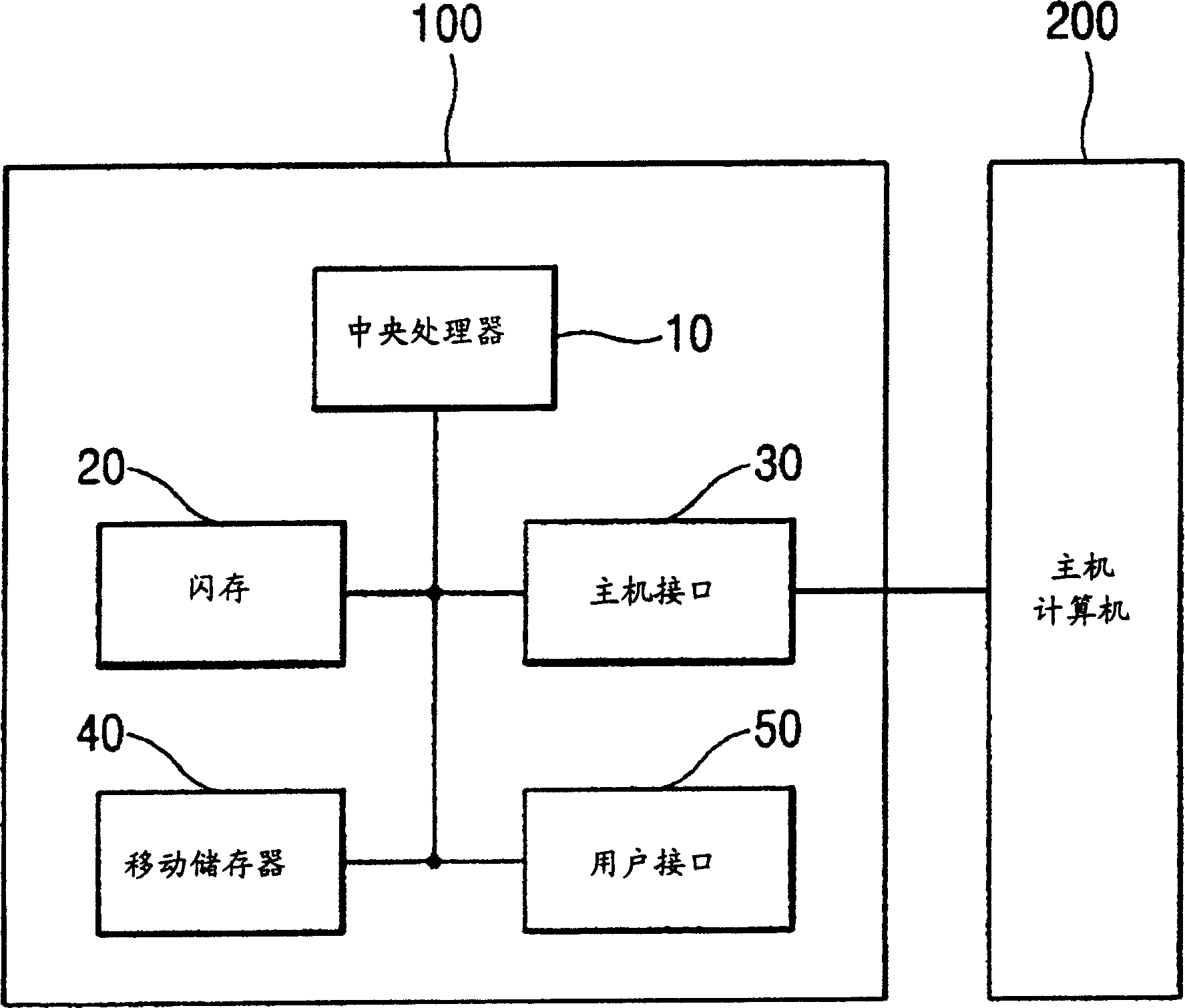

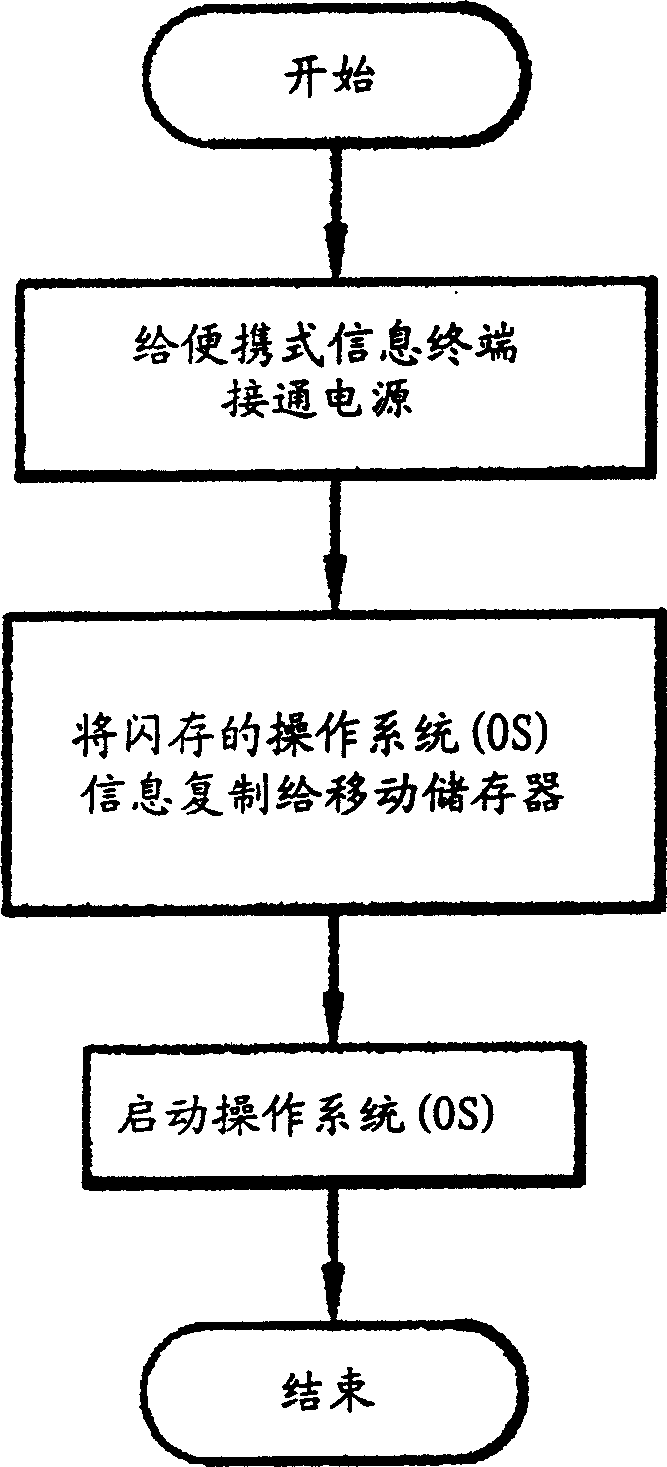

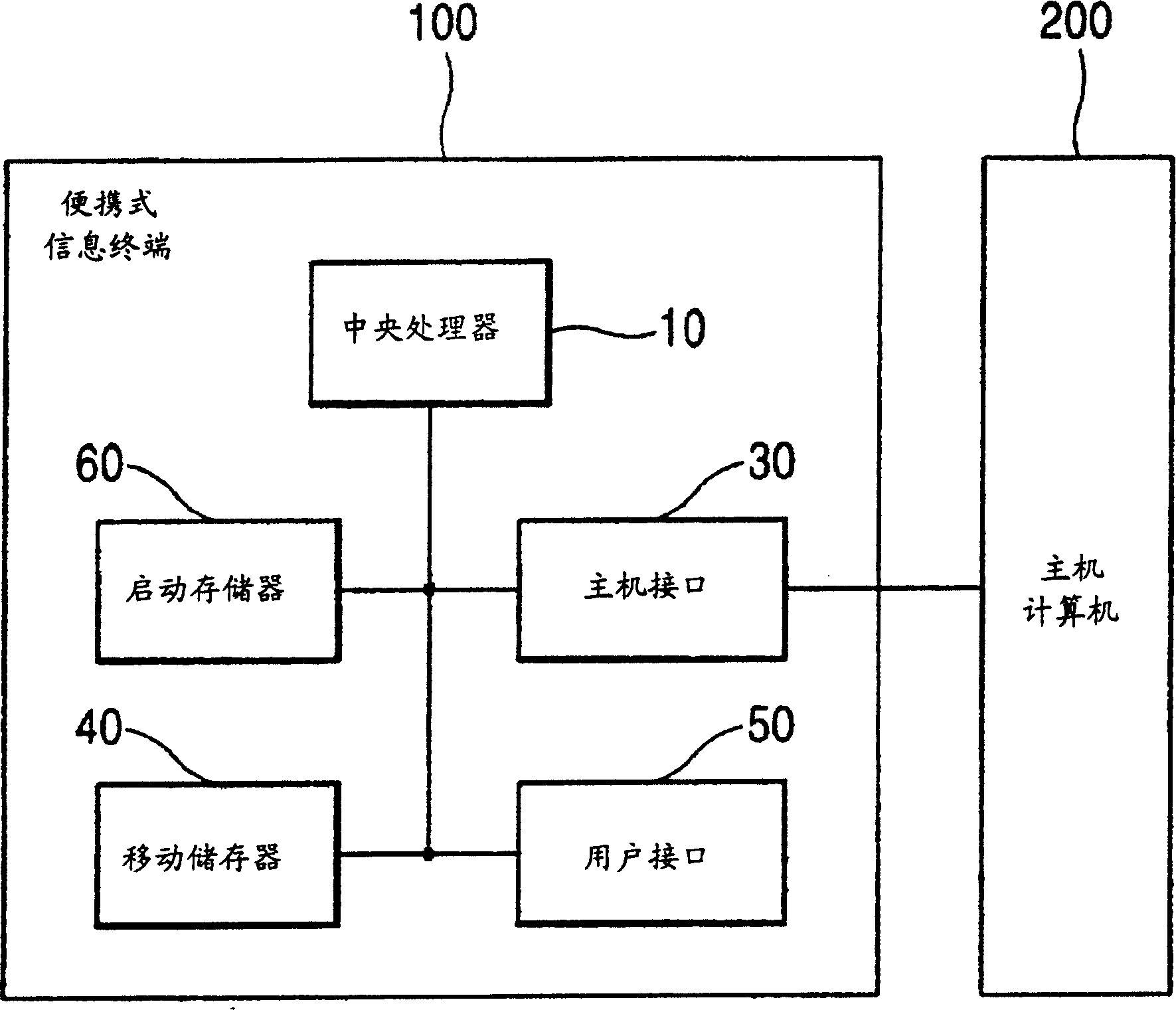

Portable information terminal and method for starting its operation system

InactiveCN1755625AReduce production costsLow production costProgram loading/initiatingSystem informationElectricity

The invention relates to an opening method of a portable information end and its operating system which can open the operating system by outer computer down operating system. The portable information end comprises: a storage which ascertains the connection of the host machine and sets the code of channel when giving the electricity to the portable information end, a host machine interface which provides the communicating channel between the host computer and the portable information end, a mobile storage which stores the operating system information from the host computer, a CPU which executes the code stored on the opening storage, sets the communicating channel between the host computer and the portable information end, stores the operating system information on the mobile storage and controls each part of the portable information end.

Owner:LEJIN ELECTRONICS KUNSHAN COMPUTER CO LTD

Forming method for instantly-molded decorating concrete component

ActiveCN109176831AShorten production timeReduce production costsCeramic shaping apparatusMaterials scienceCasting

The invention belongs to the technical field of concrete component manufacturing and particularly relates to a forming method and device for an instantly-molded decorating concrete component. The method includes the following steps that firstly, a base mold is manufactured; secondly, a silica gel soft film is made; thirdly, concrete casting is performed; and fourthly, concrete is deformed so thatthe concrete component is obtained. The device comprises a support and a deforming soft plate; two guiding grooves are formed in the top of the support, and the deforming soft plate is arranged between the two guiding grooves; a connection steel strip is fixed to each of the side edges of the deforming soft plate; a propelling cylinder is arranged at the top end of the support, and an ejecting rodof the propelling cylinder is connected to the middle portions of the connection steel strips; and the bottom face of the deforming soft plate is provided with a horizontal moving structure and a vertical moving structure. The forming method and device for the instantly-molded decorating concrete component can make the concrete bent in the concrete component manufacturing process, the manufacturing time is saved, and cost is reduced.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

Steam drying room

InactiveCN107234042AEnergy savingReduce production costsFeed water supplyPretreated surfacesExhaust gasWater storage

The invention discloses a steam drying room. The steam drying room comprises a drying room body, a supporting frame, hooks, steam boxes, cooling pipes, a water storage pool, a water pump, steam inlet pipes, a boiler, an exhaust fan and a suction hood, and is characterized in that the supporting frame is fixed in the drying room body; the multiple steam boxes are fixedly mounted on the lower plane of the supporting frame evenly; each hook is fixedly mounted in the position, between every two adjacent steam boxes, on the supporting frame; the lower ends of the steam boxes communicate with the cooling pipes; the cooling pipes are connected with the water storage pool; the water pump is fixedly mounted in the water storage pool and connected with the boiler; the upper ends of the steam boxes are connected with the steam inlet pipes; the exhaust fan is fixedly mounted on the inner wall of the right end of the drying room body; an air inlet of the exhaust fan is connected with the suction hood; and the suction hood is obliquely fixed to the ground of the drying room body. The steam drying room has the advantages of being capable of saving energy, reducing the production cost and the like.

Owner:安徽枫帆轨道装备有限公司

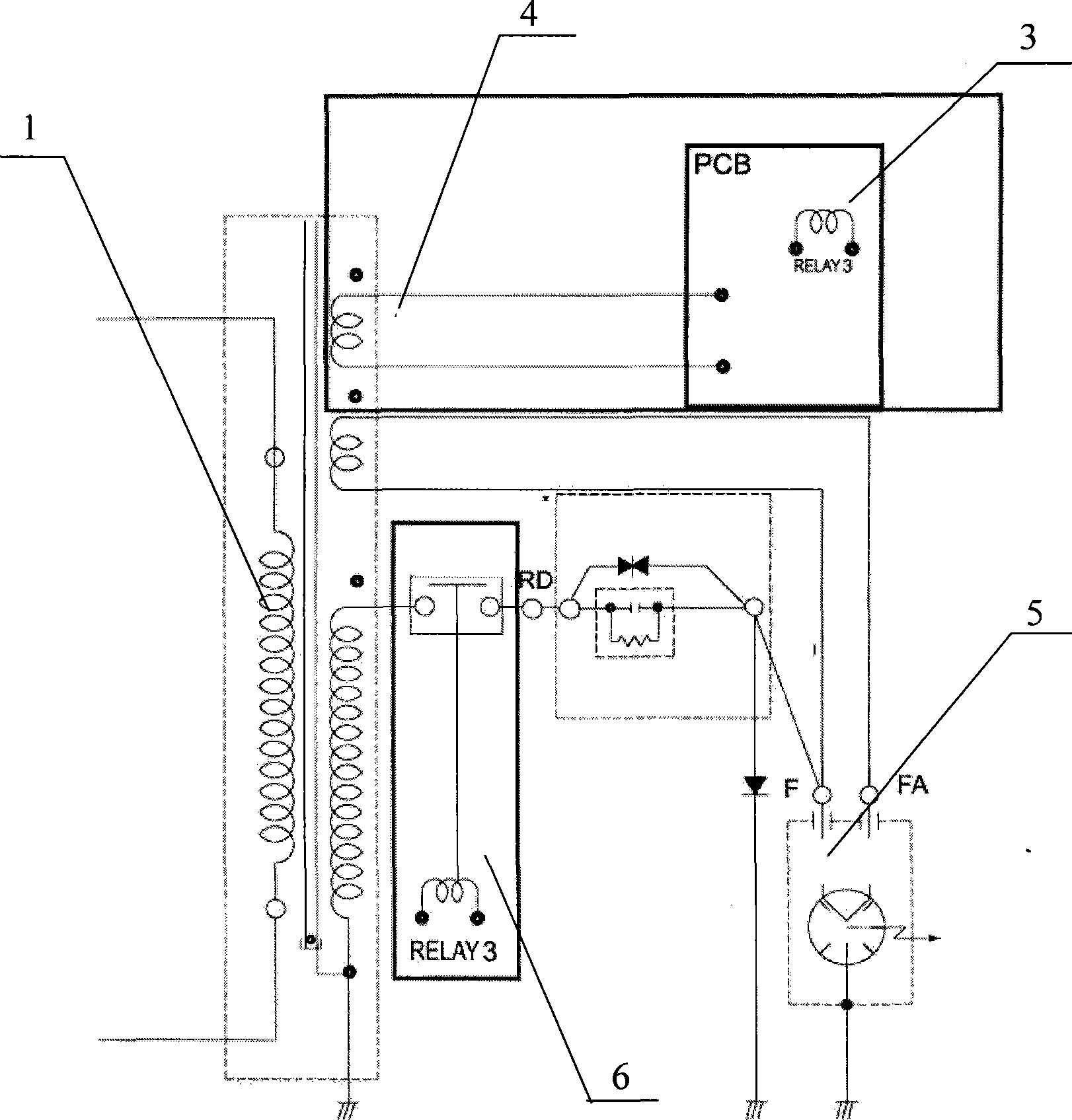

High and low-voltage transformer for micro-wave oven

InactiveCN101399113ASimple structureReduce production costsDomestic stoves or rangesLighting and heating apparatusLow voltage circuitsMicrowave

The invention discloses a high and low voltage common transformer of a microwave that comprises a high voltage main coil which is connected with a power source and a high voltage secondary coil which is used for forming the secondary pole of the high voltage main coil and is used for the power supply of a magnetron of the microwave. A relay is arranged between an output end of the high voltage secondary coil and the magnetron of the microwave. The secondary pole of the high voltage main coil is also provided with a low voltage secondary coil which is connected with a PCB plate of a control circuit of the microwave and is used for the power supply of the control circuit of the microwave. The relay is arranged on the PCB plate of the control circuit of the microwave. A normally open contact of the relay is connected between the high voltage secondary coil and the magnetron of the microwave. The relay coil is connected on a control chip of the PCB plate 3 of the control circuit of the microwave. As the high and low voltage common transformer of the microwave is added with a group of independent secondary coils on the secondary pole of the high voltage transformer, a low voltage transformer is composed to supplie power to the low voltage circuit, thus the whole circuit has simple structure; the production cost is lowered and the production efficiency is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

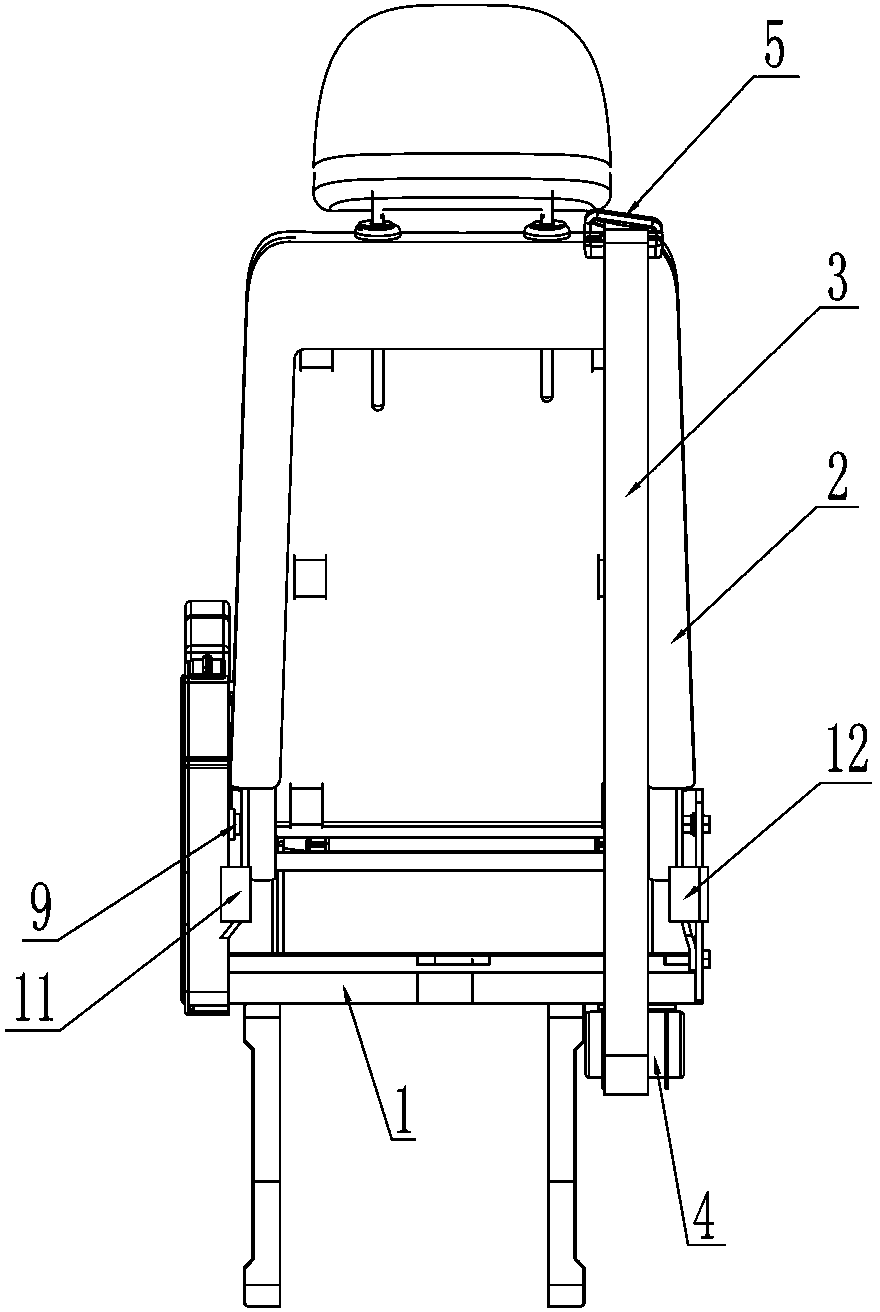

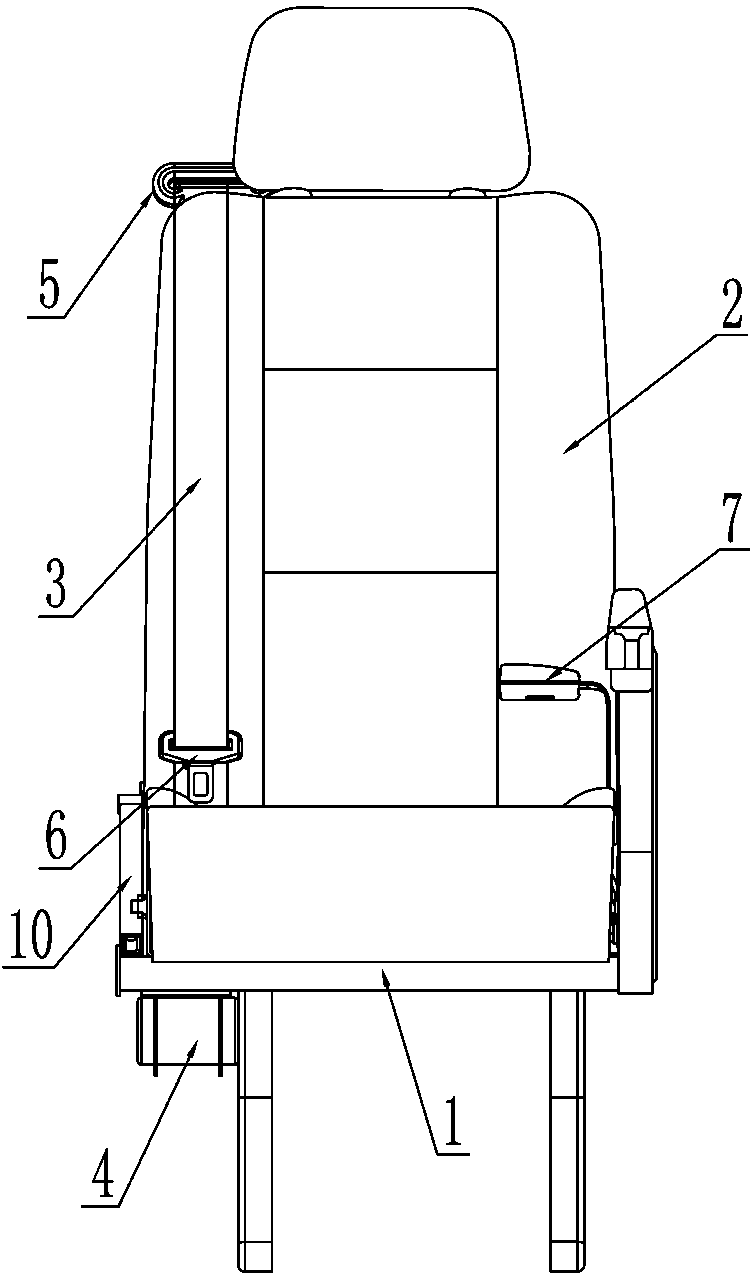

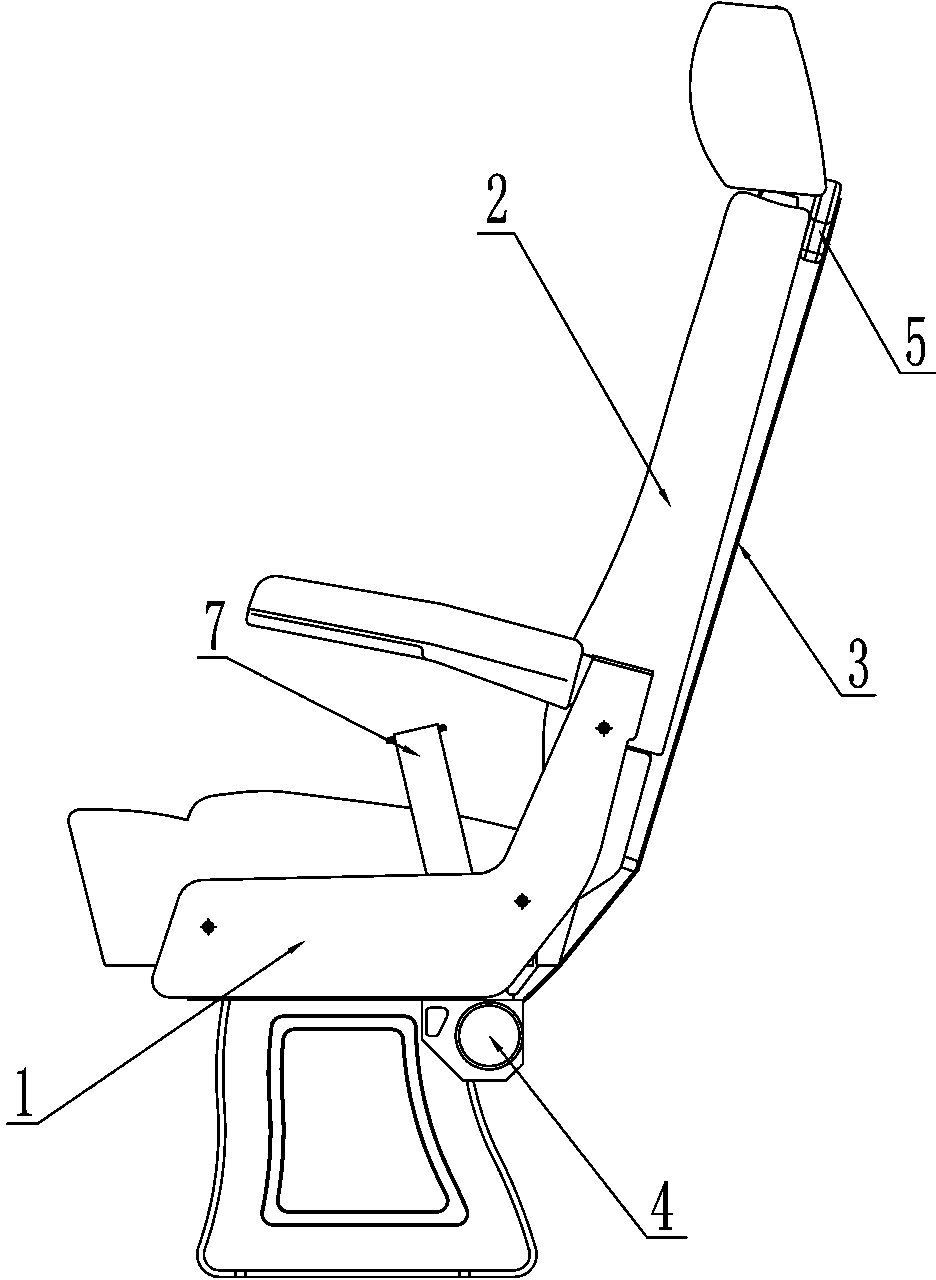

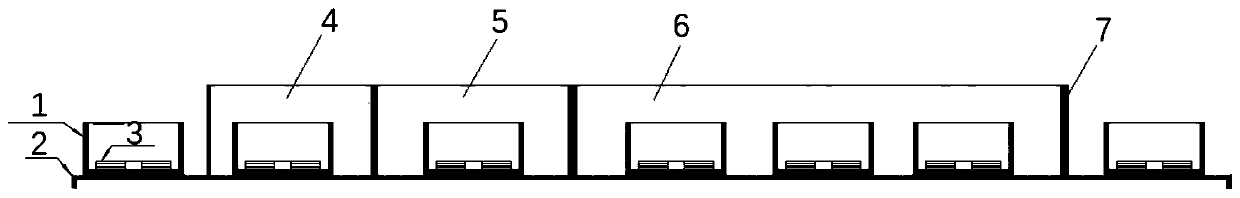

Passenger seat of passenger car

InactiveCN103625414AImprove the safety of useReduce production costsVehicle seatsBelt anchoring devicesCushionWrench

The invention discloses a passenger seat of a passenger car. The passenger seat of the passenger car comprises a seat cushion framework and a backrest framework, wherein the backrest framework is hinged to the rear side of the seat cushion framework through connecting shafts, a safety belt retractor provided with a safety belt is fixed to the lower portion of one side of the seat cushion framework, a safety belt fixing ring is arranged on the upper side of the backrest framework, one end of the safety belt is fixed to the safety belt retractor, the other end of the safety belt penetrates through the safety belt fixing ring along the front side face of the backrest framework from bottom to top, and then is fixed to the seat cushion framework, the safety belt is sleeved with a safety belt spring bolt, a safety belt lock catch is arranged on the side, opposite to the safety belt retractor, of the seat cushion framework, and can be used in cooperation with the safety belt spring bolt to carry out locking, a gas spring is arranged between the front end of the backrest framework and the seat cushion framework, the barrel end of the gas spring is hinged to the portion, below the connecting shafts, of the backrest framework, the locking end of a piston rod of the gas spring is hinged to the seat cushion framework, and an unlocking wrench which can control the gas spring to lock is further arranged at the locking end of the piston rod of the gas spring. The passenger seat of the passenger car has the advantages that safety performance is high, and the enterprise production cost is low.

Owner:ZHANGJIAGANG LONGJING AUTOMOBILE PARTS

Brake disc continuous siliconizing furnace and working method thereof

ActiveCN110906734AReduce production costsLow production costCharge composition/stateFurnace typesPressure regulatorAssembly line

The invention relates to a brake disc continuous siliconizing furnace and a working method thereof, which belong to the technical field of carbon-ceramic brake disc production. The brake disc continuous siliconizing furnace comprises an outer furnace shell, a vacuum chamber, a high-temperature reaction chamber and a low-temperature buffer chamber which are each provided with a protective gas inflation device, wherein vacuum sealing doors are arranged on the two sides of the vacuum chamber; heating pipes are arranged all around the high-temperature reaction chamber and connected with an intelligent temperature controller by means of a pressure regulator; the low-temperature buffer chamber is provided with a heat preservation layer, and the high-temperature reaction chamber communicates withthe low-temperature buffer chamber; a track and a crucible sleeve are arranged at the bottom part of the outer furnace shell, and the crucible sleeve sequentially enters the vacuum chamber, the high-temperature reaction chamber and the low-temperature buffer chamber through the track; the carbon-ceramic brake disc is pushed into the vacuum chamber after being arranged in the crucible sleeve; oxygen in a product is pumped away, an argon gas is introduced to micro-positive pressure, then the product is fed into the high-temperature reaction chamber for dissolved silicon permeation, the productis fed into the low-temperature buffer chamber from the high-temperature reaction chamber for pre-cooling after permeation, and then the product is pushed out of the low-temperature chamber for discharging, thereby achieving the purpose of assembly line siliconizing production, and reducing the production cost of the carbon-ceramic brake disc.

Owner:山东道普安制动材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com