Method for preparing nanosheet cluster-structure cupric sulfide from titanium-copper amorphous alloy and application thereof

A technology of amorphous alloys and amorphous alloys, applied in the direction of copper sulfide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of reaction temperature, reaction pressure, long reaction time, etc., and achieve low implementation cost , low cost, uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: prepare the copper sulfide of nanosheet cluster structure with titanium-copper amorphous alloy, the steps are as follows:

[0018] Step 1. Prepare Ti with a thickness of 10 μm-30 μm according to the atomic percentage content of Ti and Cu are both 50% 50 Cu 50 Amorphous alloy strip;

[0019] Step two, the Ti obtained in step one 50 Cu 50 The amorphous alloy strip is cut into a sample with a width of 20 mm and a length of 3 cm. After the sample is ultrasonicated in absolute ethanol for 10 minutes, it is cleaned with deionized water and then dried in the air for use;

[0020] Step 3: Take 0.1g of the sample obtained in step 2 and put it in a closed container together with 46ml of sulfuric acid aqueous solution with a molar concentration of 15M for reaction, and put it in a 90°C drying oven for 48 hours. After the reaction, use the sample obtained Rinse with deionized water, and dry in a drying oven at 50°C. The powder obtained after drying is copper sulfi...

Embodiment 2

[0027] Embodiment 2: prepare the copper sulfide of nanosheet cluster structure with titanium-copper amorphous alloy, identical with step one and two of embodiment 1, only be that the concentration of the sulfuric acid aqueous solution that uses in step three is different, namely:

[0028] Step 3: Take 0.1g of the sample obtained in step 2 and place it in a closed container together with 46ml of sulfuric acid aqueous solution with a molar concentration of 14M for reaction, and put it in a 90°C drying oven for 48 hours. After the reaction, use the sample obtained Rinse with deionized water, and dry in a drying oven at 50°C. The powder obtained after drying is copper sulfide powder with nanosheet cluster structure.

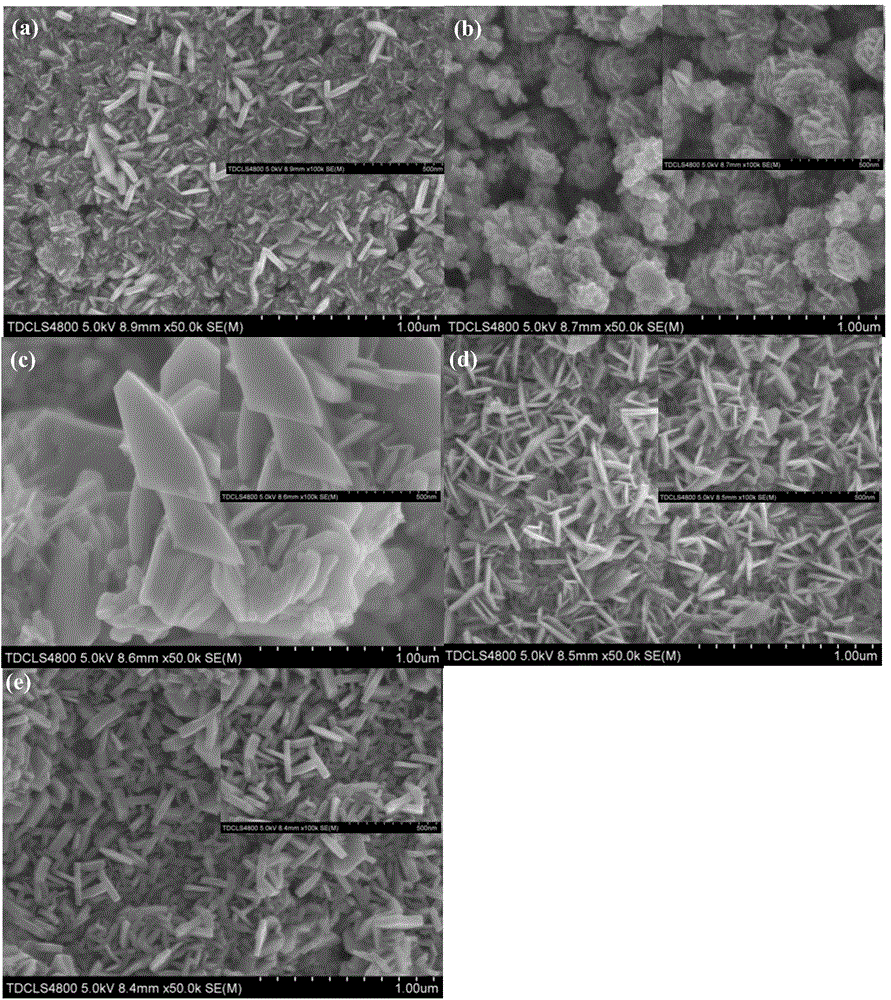

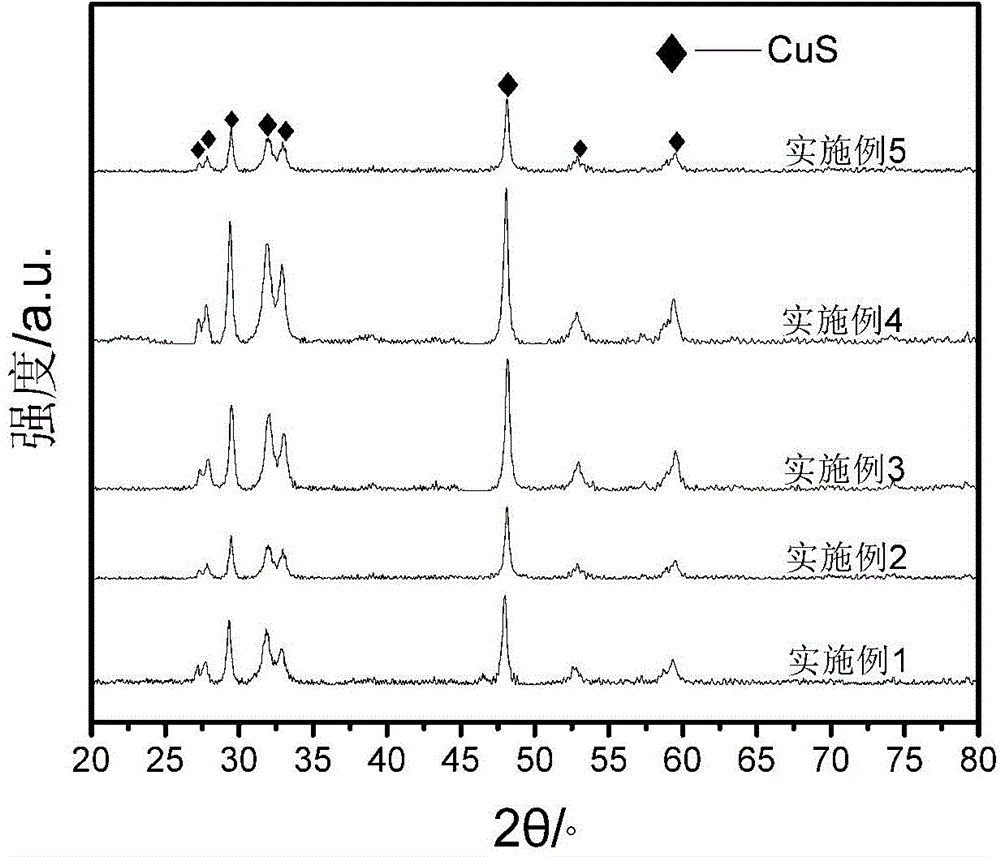

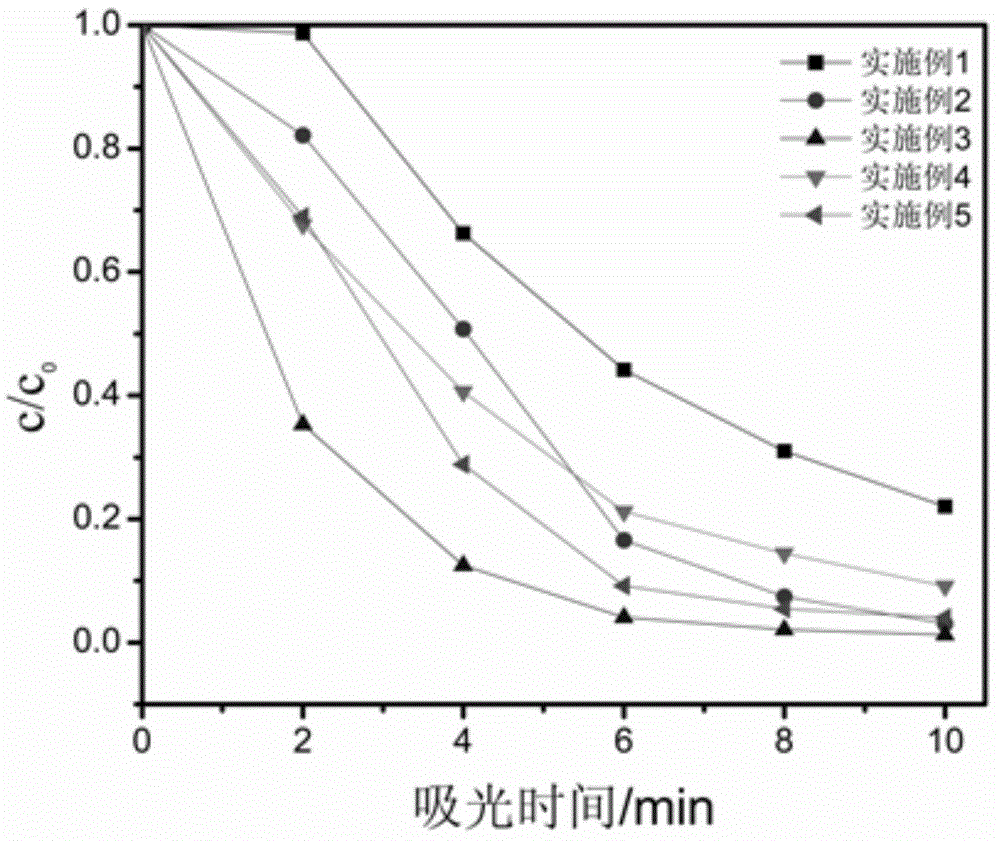

[0029] figure 1 (b) among shows the microtopography photograph of the copper sulfide that embodiment 2 prepares, figure 2 The XRD figure of the copper sulfide prepared by embodiment 2 is shown in the example; The copper sulfide of the nanosheet cluster structure pr...

Embodiment 3

[0030] Embodiment 3: prepare the copper sulfide of nanosheet cluster structure with titanium-copper amorphous alloy, identical with step one and two of embodiment 1, only be that the temperature of reaction in step three is different, namely:

[0031] Step 3: Take 0.1g of the sample obtained in step 2 and place it in a closed container together with 46ml of sulfuric acid aqueous solution with a molar concentration of 15M for reaction, and put it in a drying oven at 110°C for 48 hours. After the reaction, use the sample obtained Rinse with deionized water, and dry in a drying oven at 50°C. The powder obtained after drying is copper sulfide powder with nanosheet cluster structure.

[0032] figure 1 (c) shows the microscopic topography photo of the copper sulfide prepared in embodiment 3, figure 2 The XRD pattern of the copper sulfide prepared by embodiment 3 is shown in the example; the copper sulfide of the nanosheet cluster structure prepared by the embodiment is applied in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length dimension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com