Glass panel cleaning device for flat panel display

A flat-panel display and cleaning device technology, applied in the directions of cleaning flexible objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of flat-panel display panel damage, lowering the production efficiency of the flat-panel display panel, increasing maintenance costs, etc., to prevent Poor cleaning, best results, reduced dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

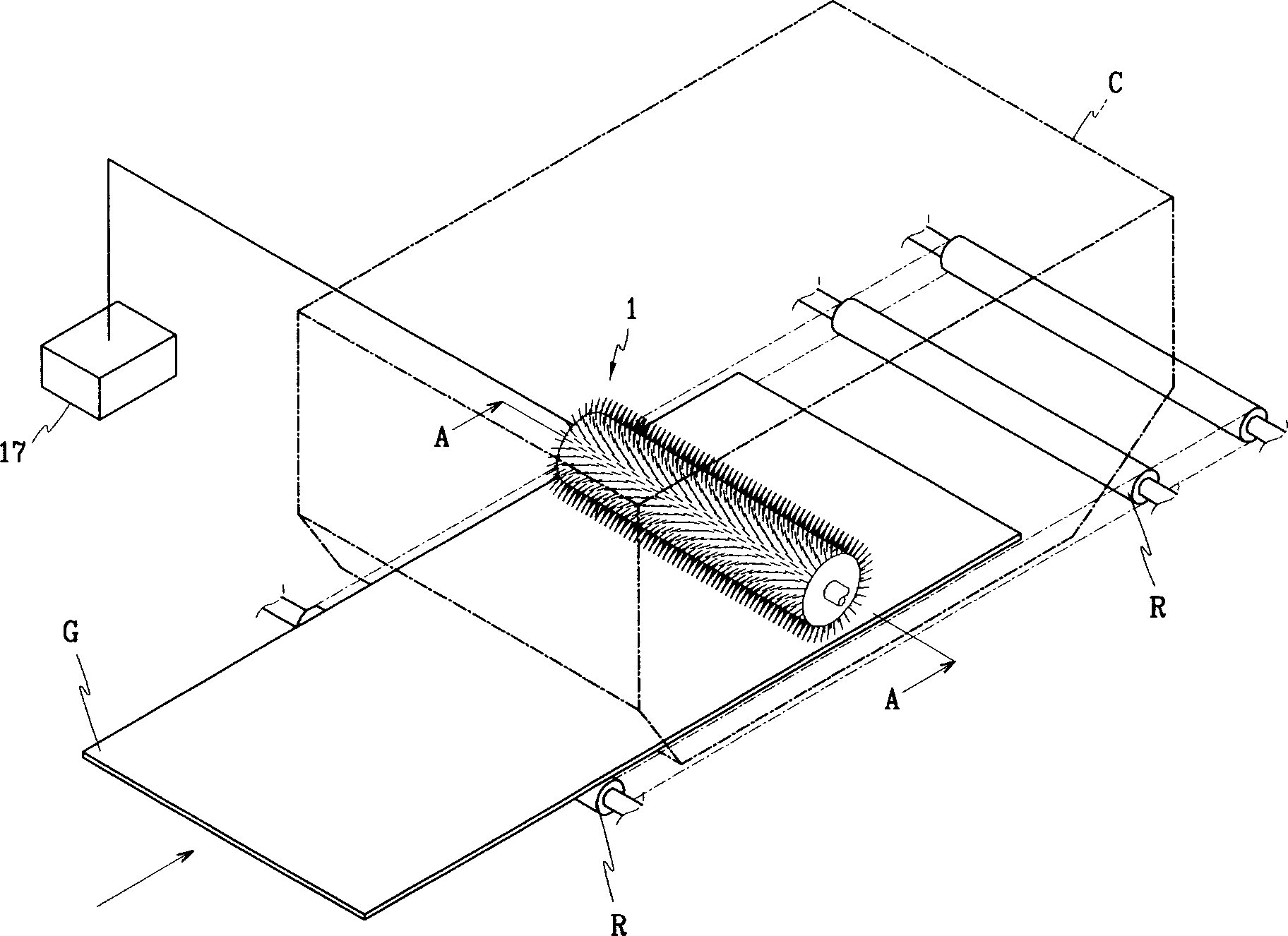

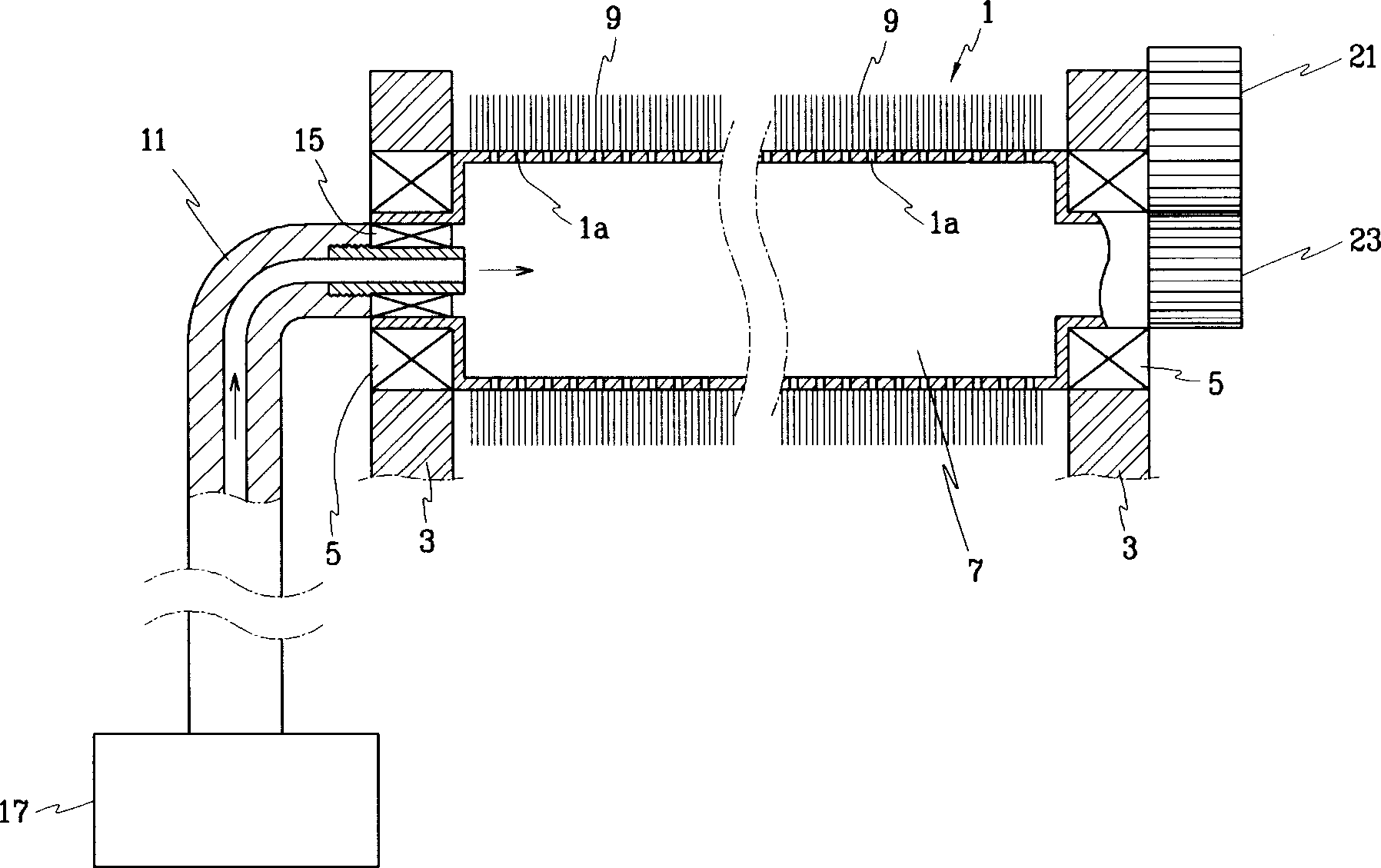

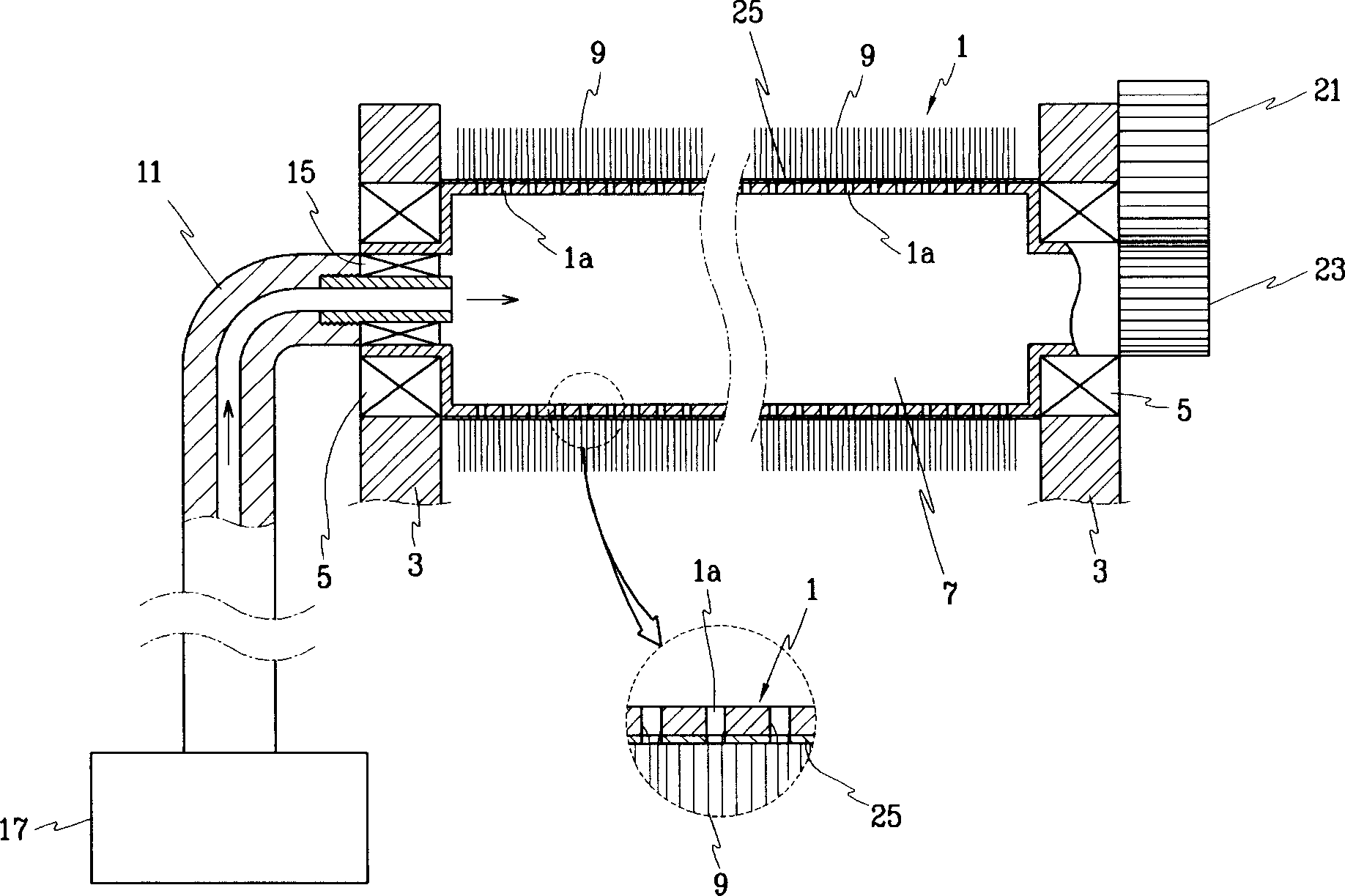

[0014] figure 1 is a structural diagram for explaining an embodiment of the present invention, and shows a glass cleaning device for a flat panel display. Such a glass plate cleaning apparatus includes: a cleaning chamber C; a glass plate conveyance device R for conveying a glass plate G to be cleaned to the cleaning chamber C; Such as figure 2 As shown, the rotating part 1 is rotatably installed on the support part 3 installed in the cleaning chamber C. That is, on both sides of the cleaning chamber C, support parts 3 capable of supporting the rotating parts 1 are installed, and bearings 5 are installed on these supporting parts 3, and the bearing inner rings of the bearings 5 are engaged with the rotating parts 1 . One side of the rotating member 1 is connected to a power transmission member constituted by a gear or the like for tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com