Clean water pump

A technology for a clean water pump and a pump base, applied in the field of clean water pumps, can solve the problems of reducing the service life of the water pump, limiting the use range of the water pump, easy to bite, etc., and achieves the effects of reducing consumption, reducing weight and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

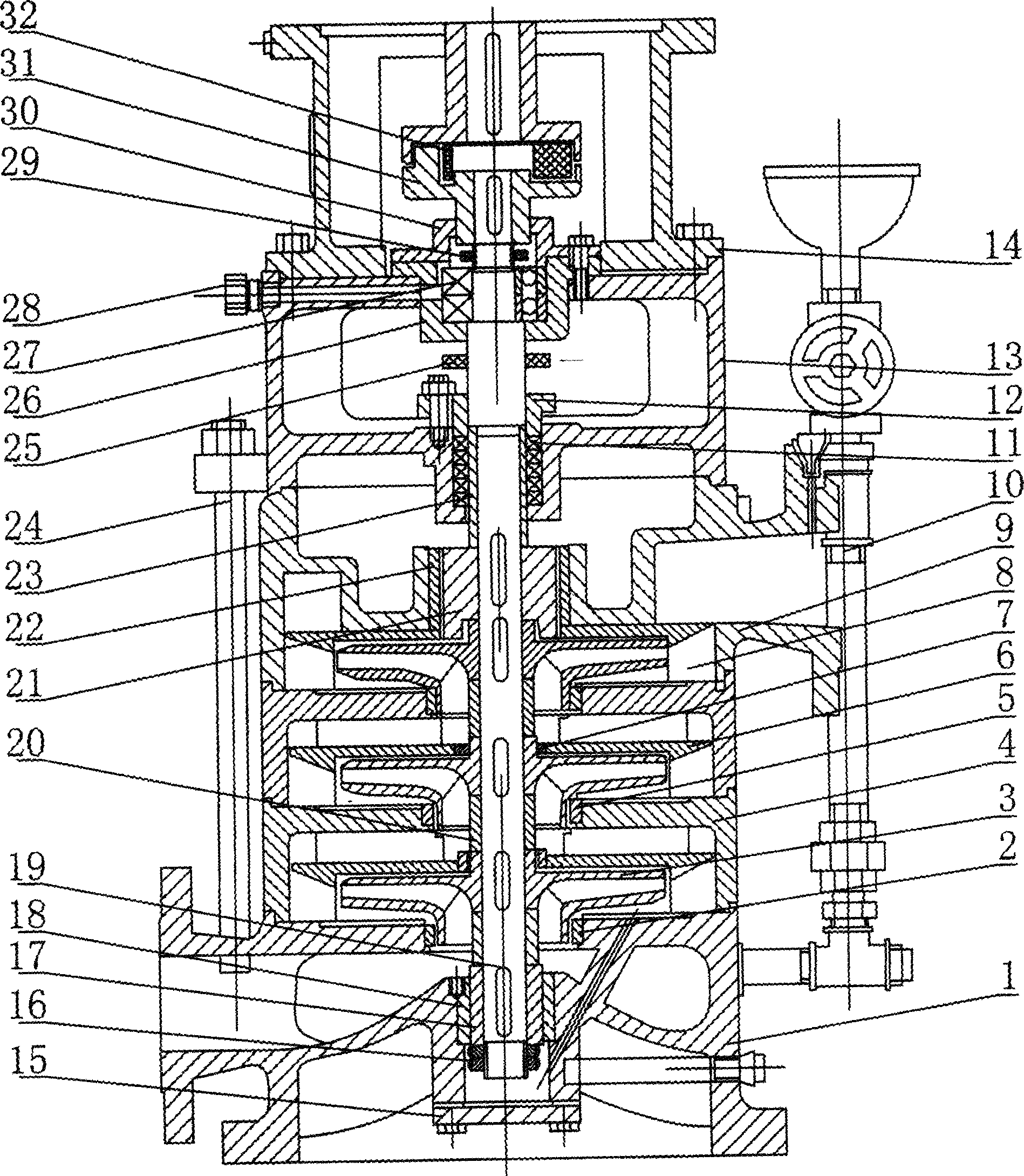

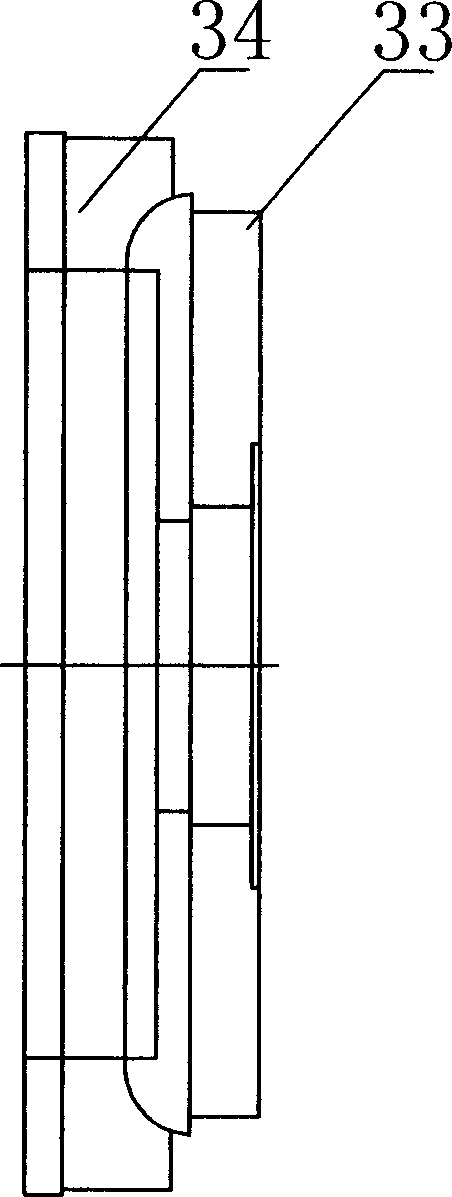

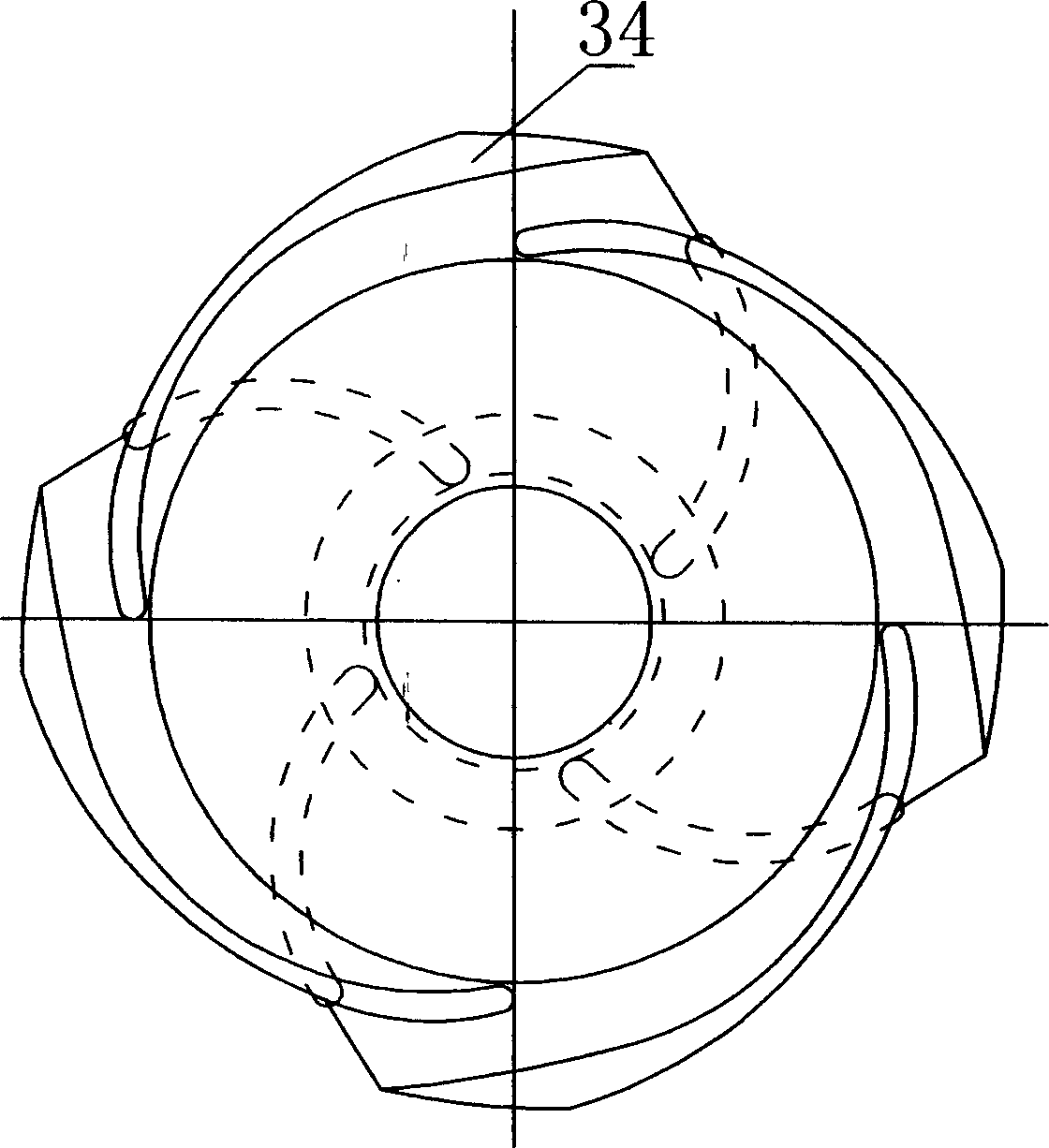

[0011] As shown in the figure, the clean water pump has a pump base 1. A bearing bush 18 is arranged at the center of the pump base 1. The center hole of the pump base 1 is at the bottom and sealed by a cover plate 15. The upper end surface of the pump base 1 is fitted with a clearance. The middle section 4 is connected, and the upper end surface of the middle section 4 is connected with a back section 9 through a clearance fit, and a support 13 is connected with a clearance fit on the back section 9, and the pump seat 1, the middle section 4, the back section 9 and the support 13 are pulled Tight bolts 24 are fixedly connected, and a drive shaft 19 is provided at the central position of the pump base 1, the middle section 4, the rear section 9 and the support 13; the support 13 is connected with a motor base 14 through clearance fit, and a Coupling 31, the coupling 31 is connected with the drive shaft 19, the elastic block 32 is installed in the coupling 31, and the sleeve arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com