Patents

Literature

37results about How to "Avoid manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

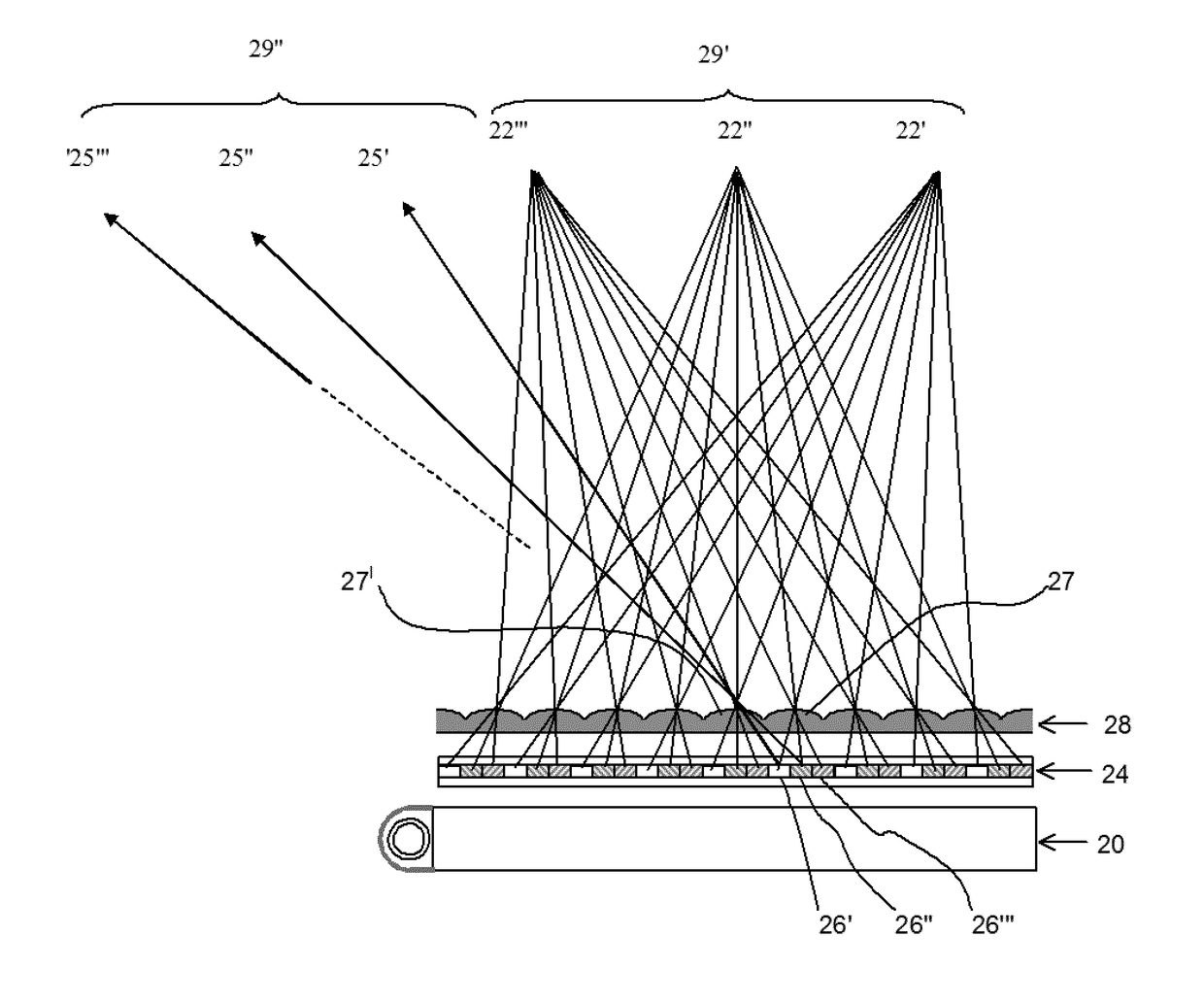

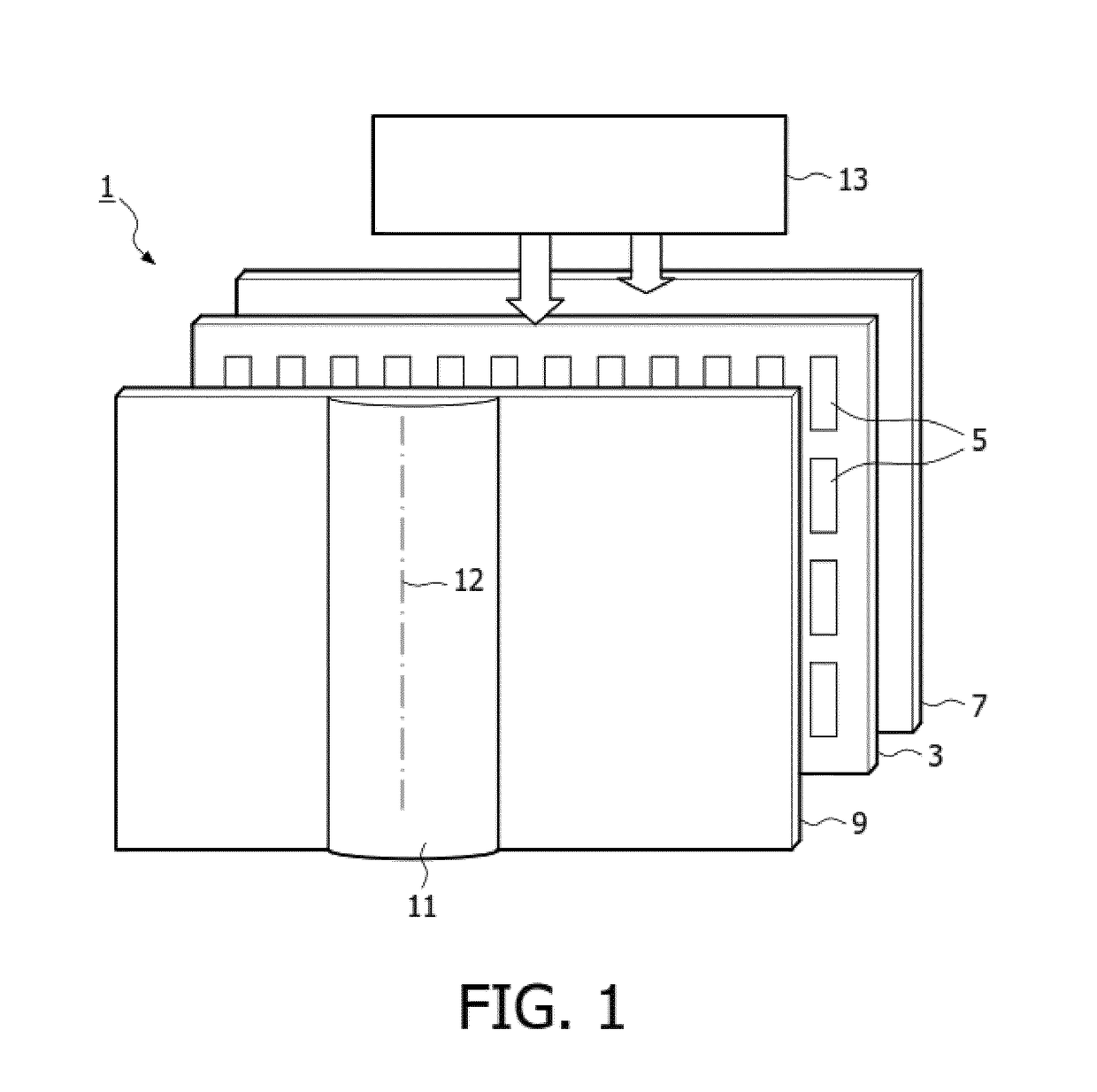

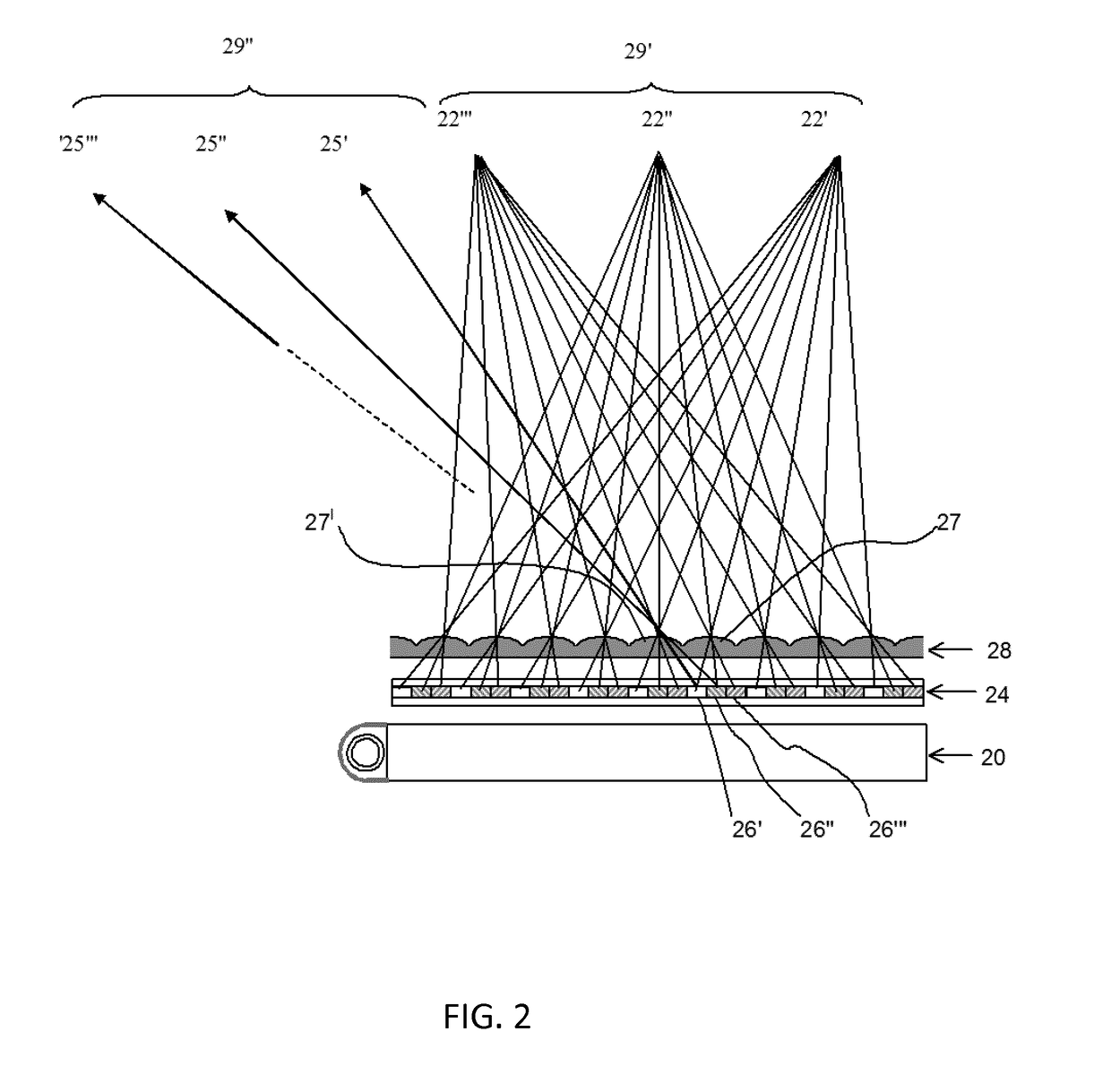

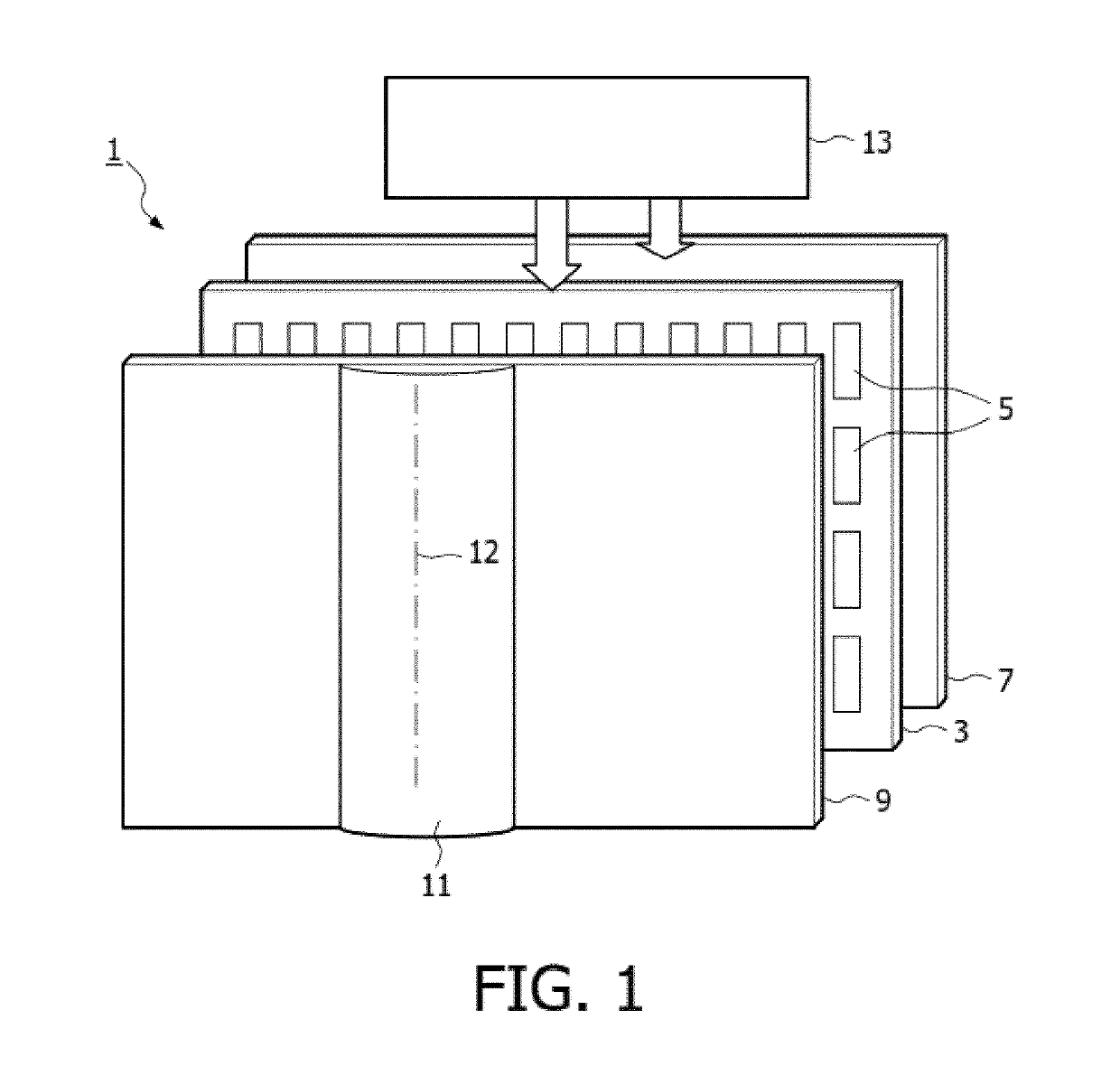

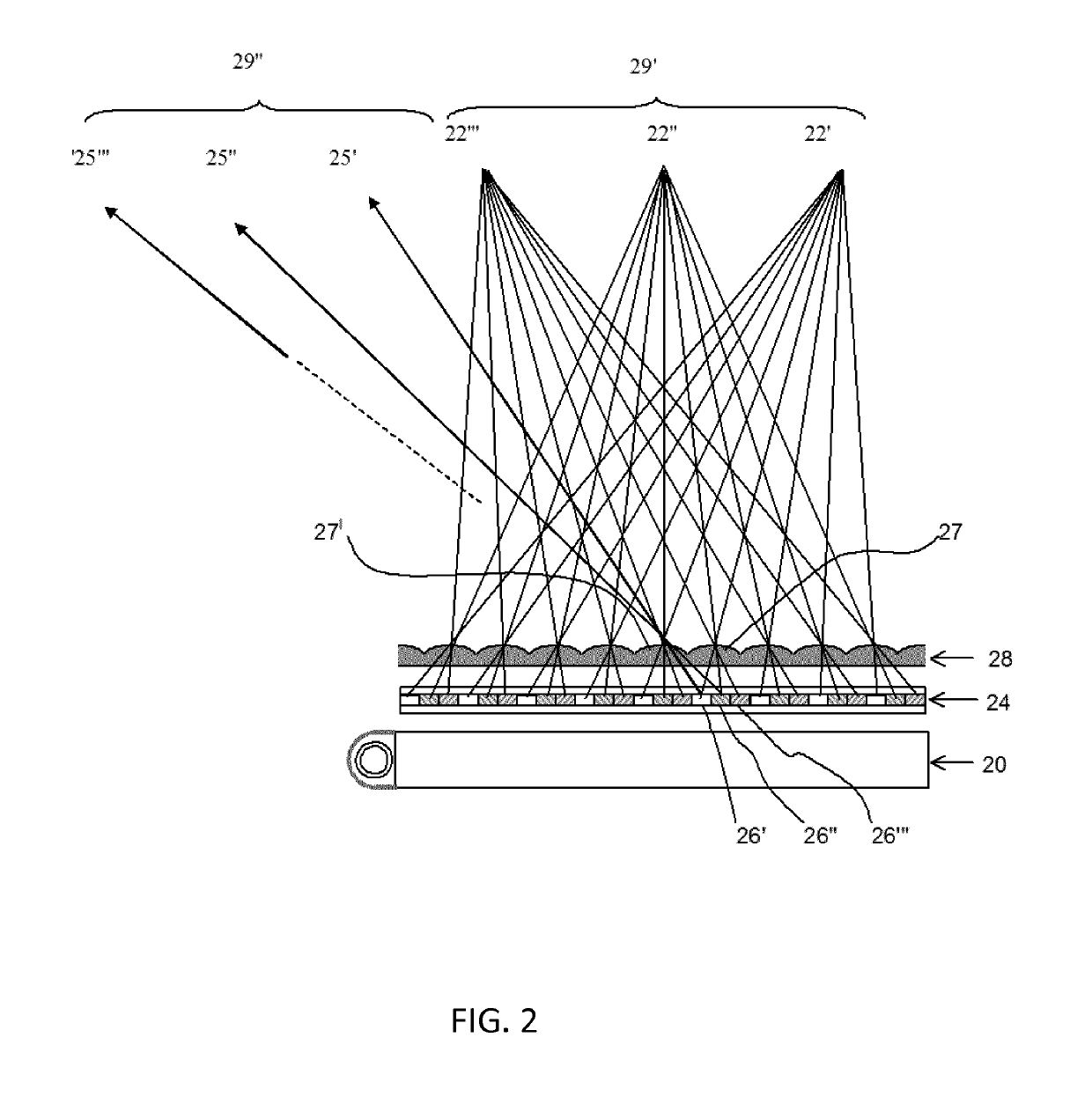

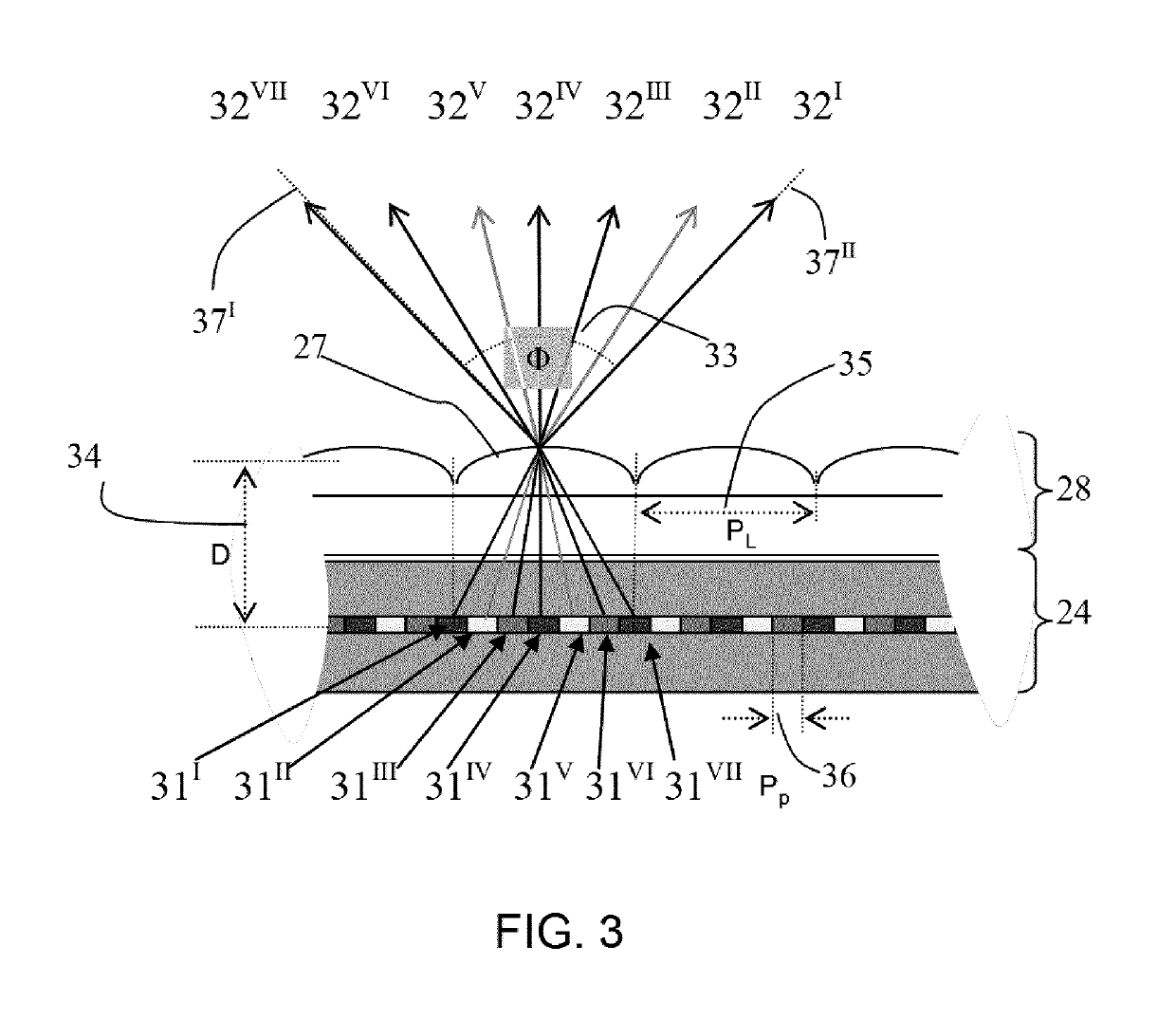

Display device and driving method

ActiveUS20180259799A1Avoid contactImprove response speedMechanical apparatusLight guides for lighting systemsLateral angleDisplay device

A display device has a light blocking arrangement for selectively blocking light which has or would be emitted at large lateral angles. The display can be configured so that light reaching these elements is either allowed to reach the viewer or is blocked from reaching the viewer. This means that a public viewing mode can be chosen or a private viewing mode. The light blocking elements are controlled optically in order to simplify the construction and control.

Owner:KONINKLJIJKE PHILIPS NV

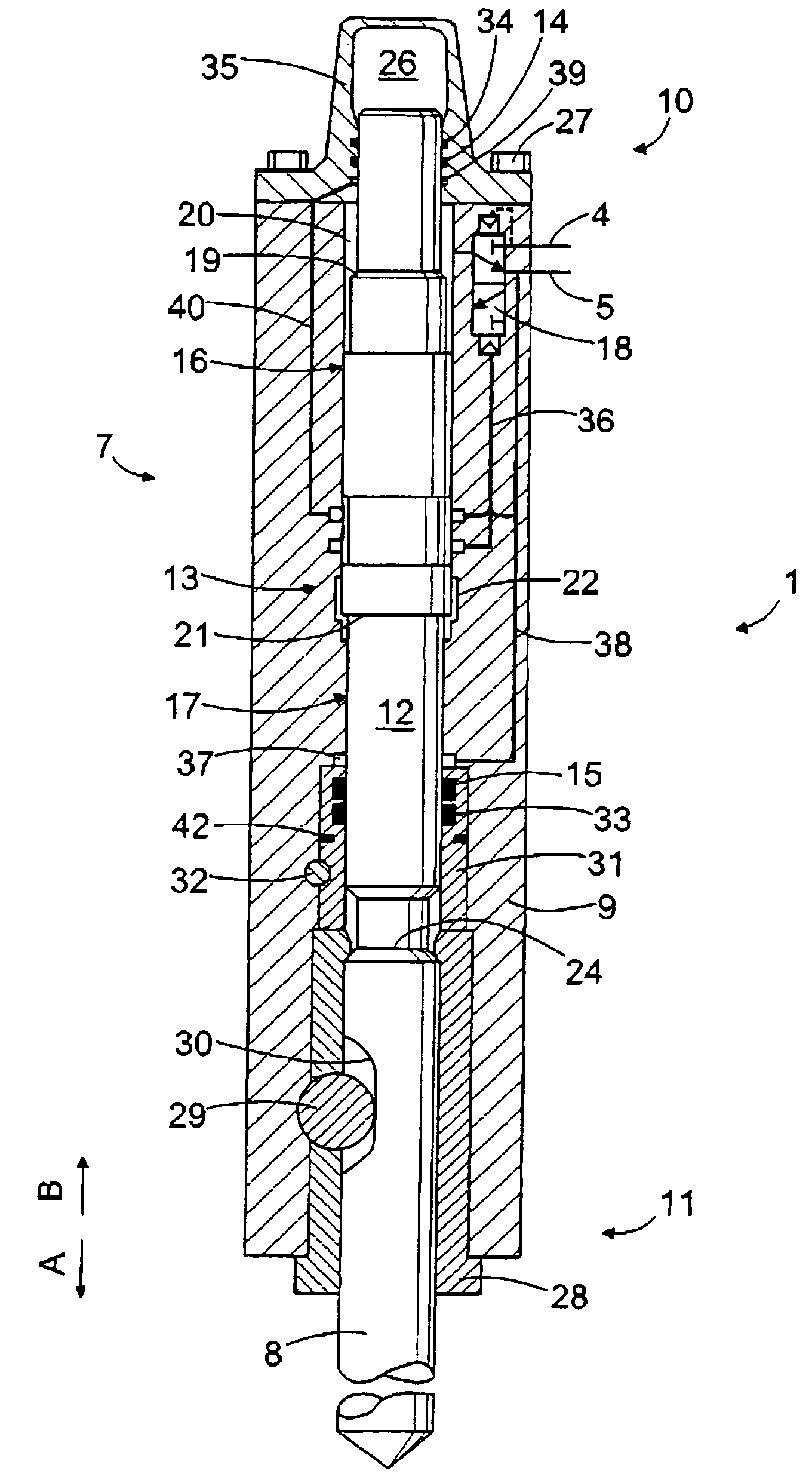

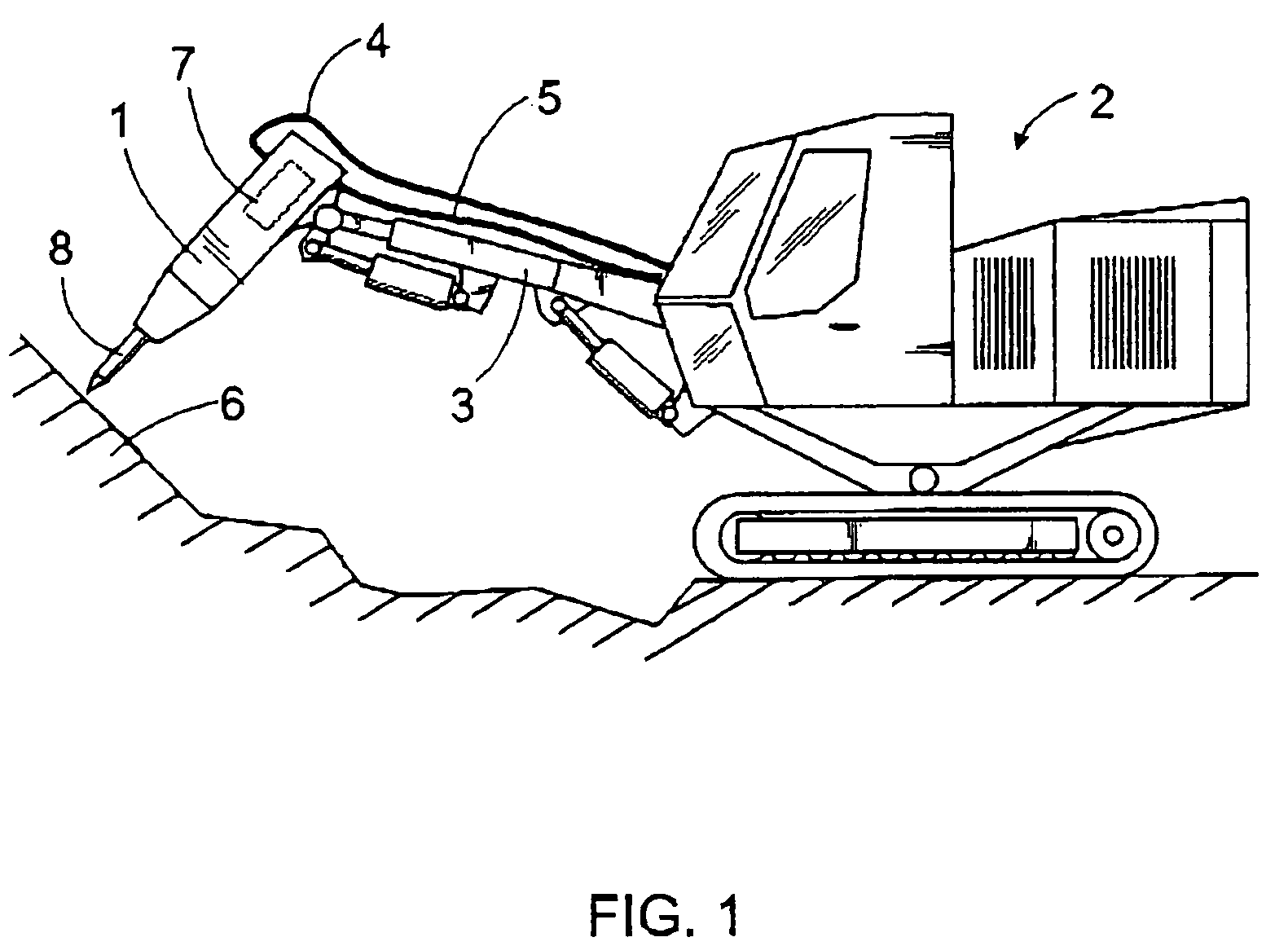

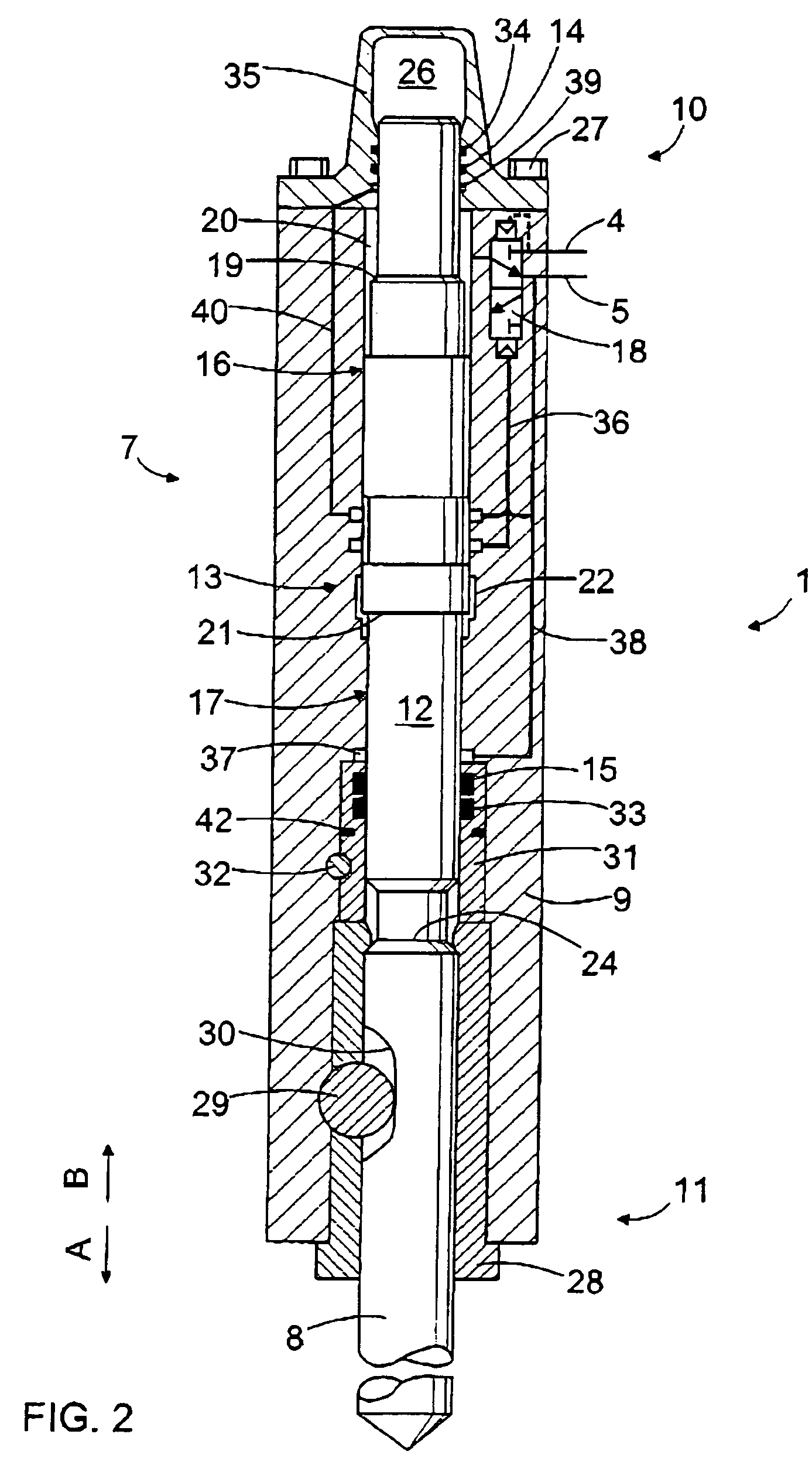

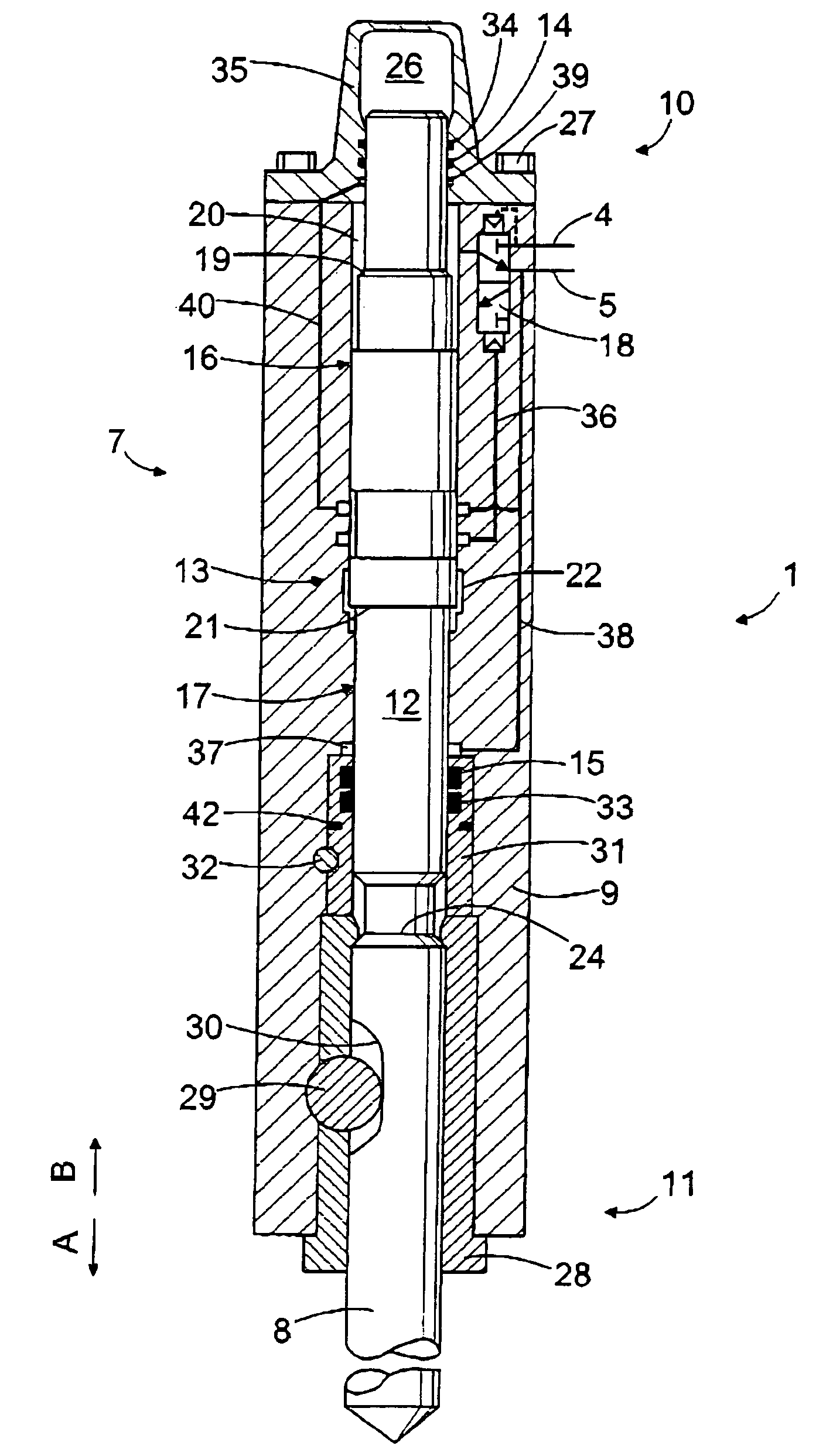

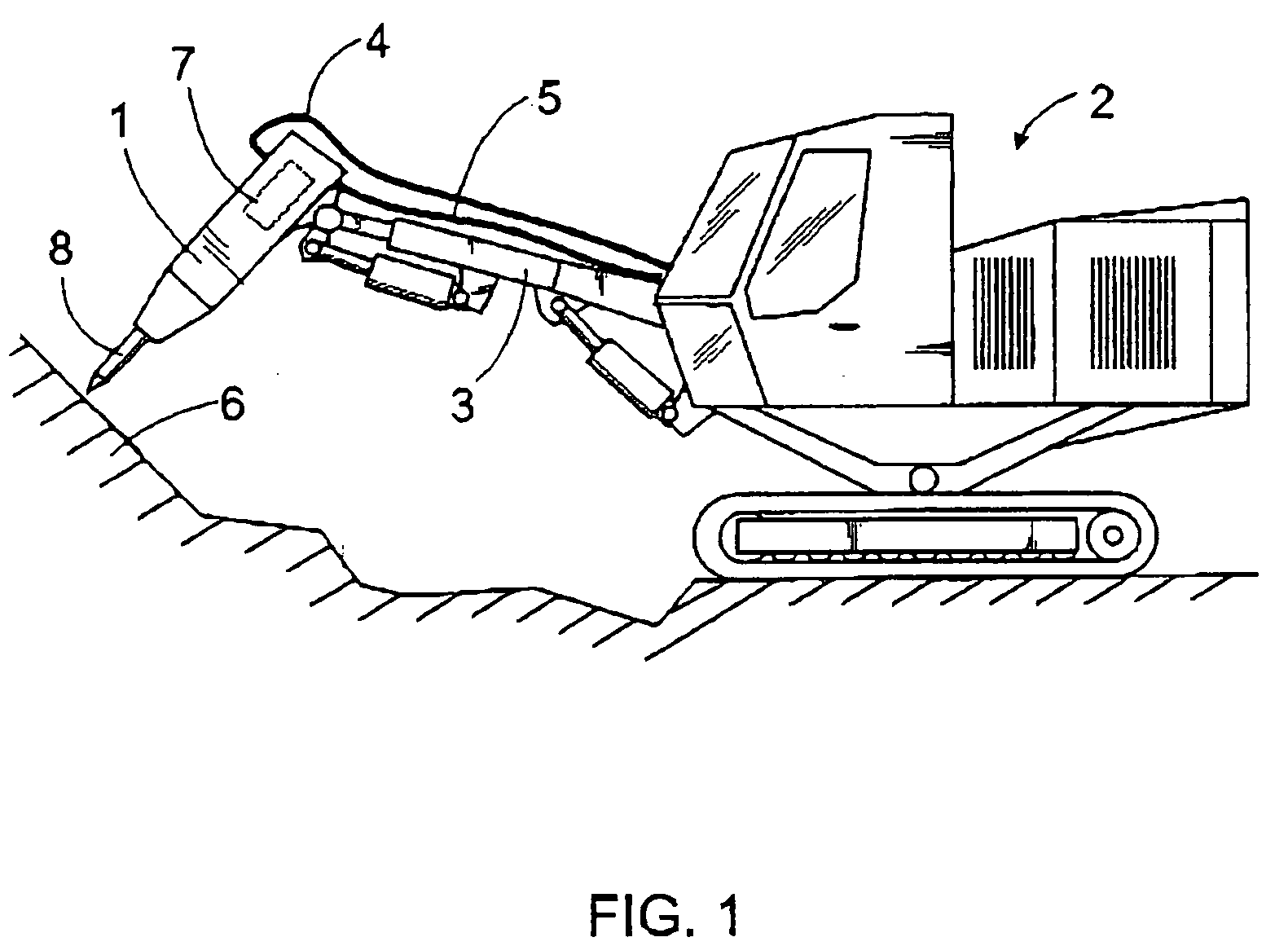

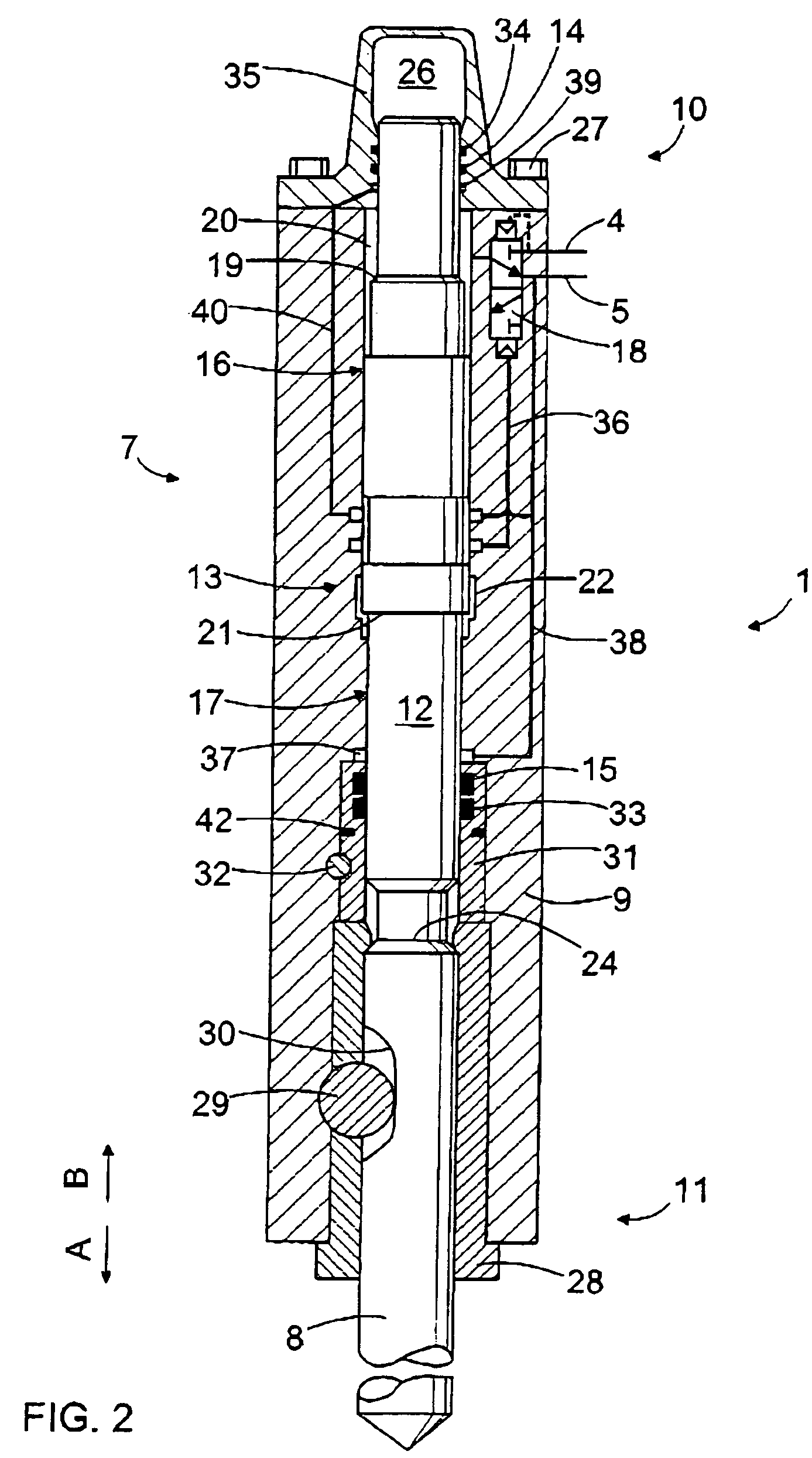

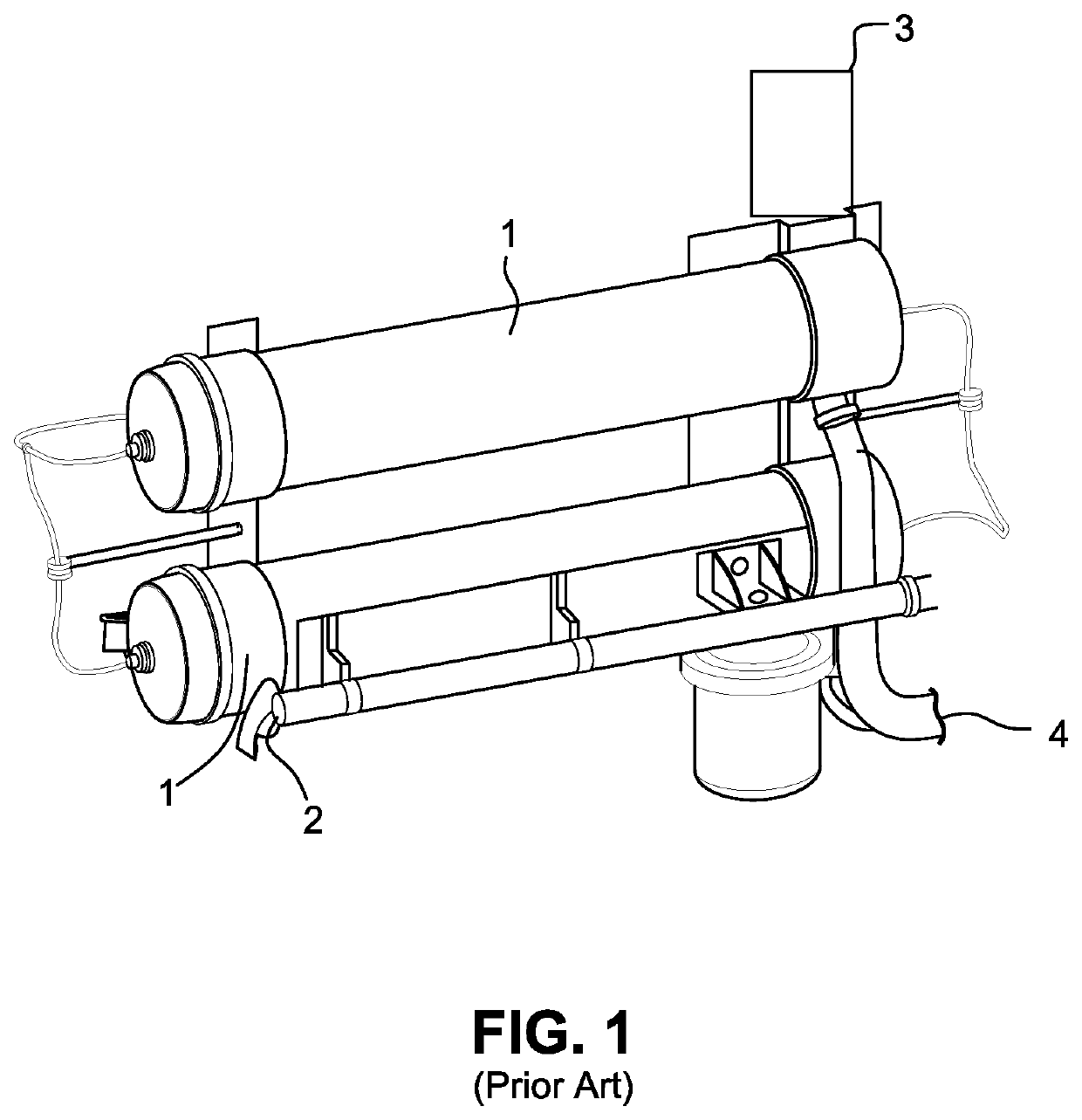

Hydraulic hammer having a sealing bushing

ActiveUS7152692B2Rapid and less maintenanceManufactured with lessReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringMechanical engineering

A hydraulic hammer having a sealing bushing includes a percussion piston that delivers strokes to a tool. A lower part of the percussion piston is sealed with respect to a frame by the sealing bushing, which includes one or more lower seals. The sealing bushing does not contribute to the bearing of the percussion piston and it is arranged in place through the lower end of the hydraulic hammer.

Owner:SANDVIK TAMROCK

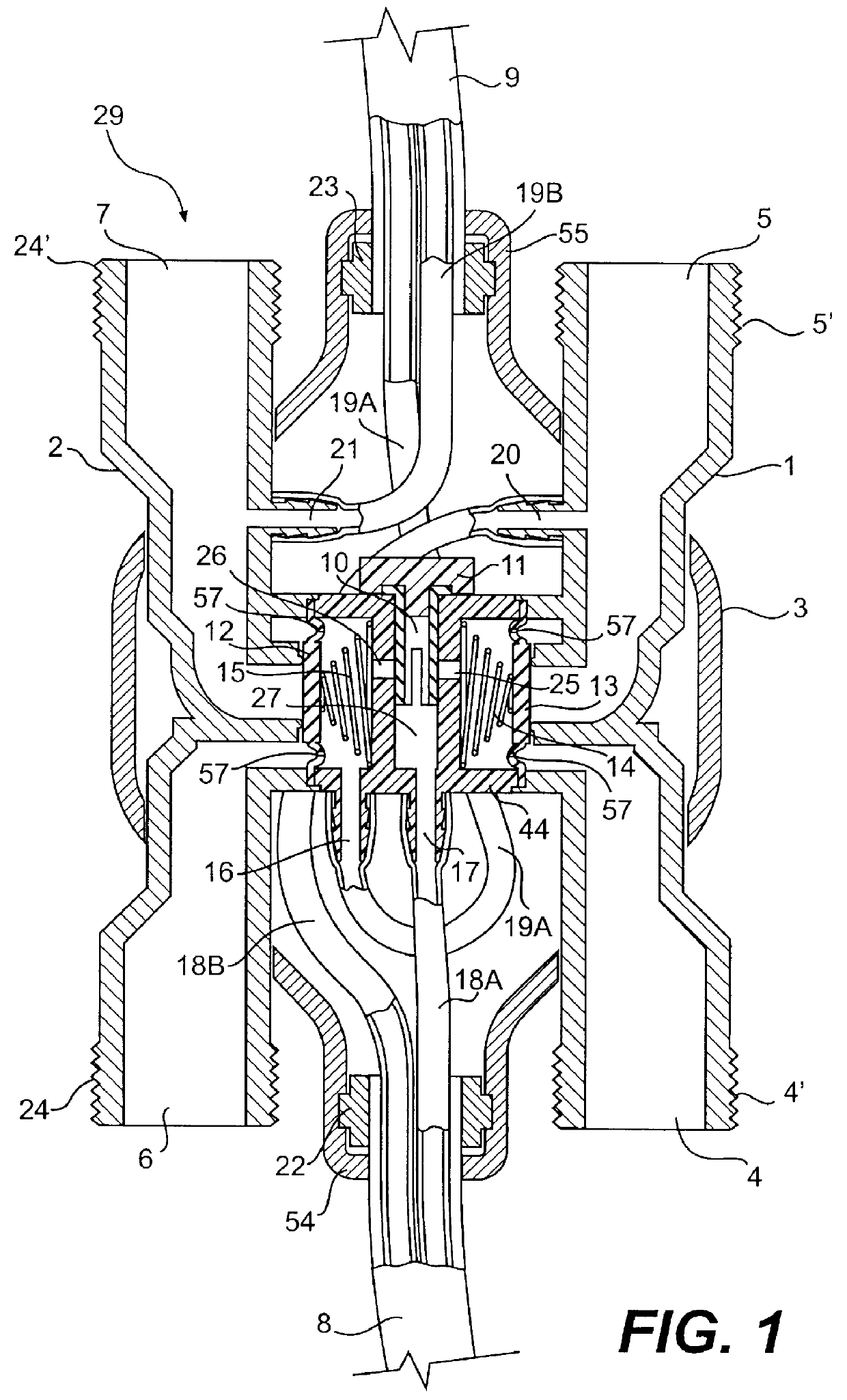

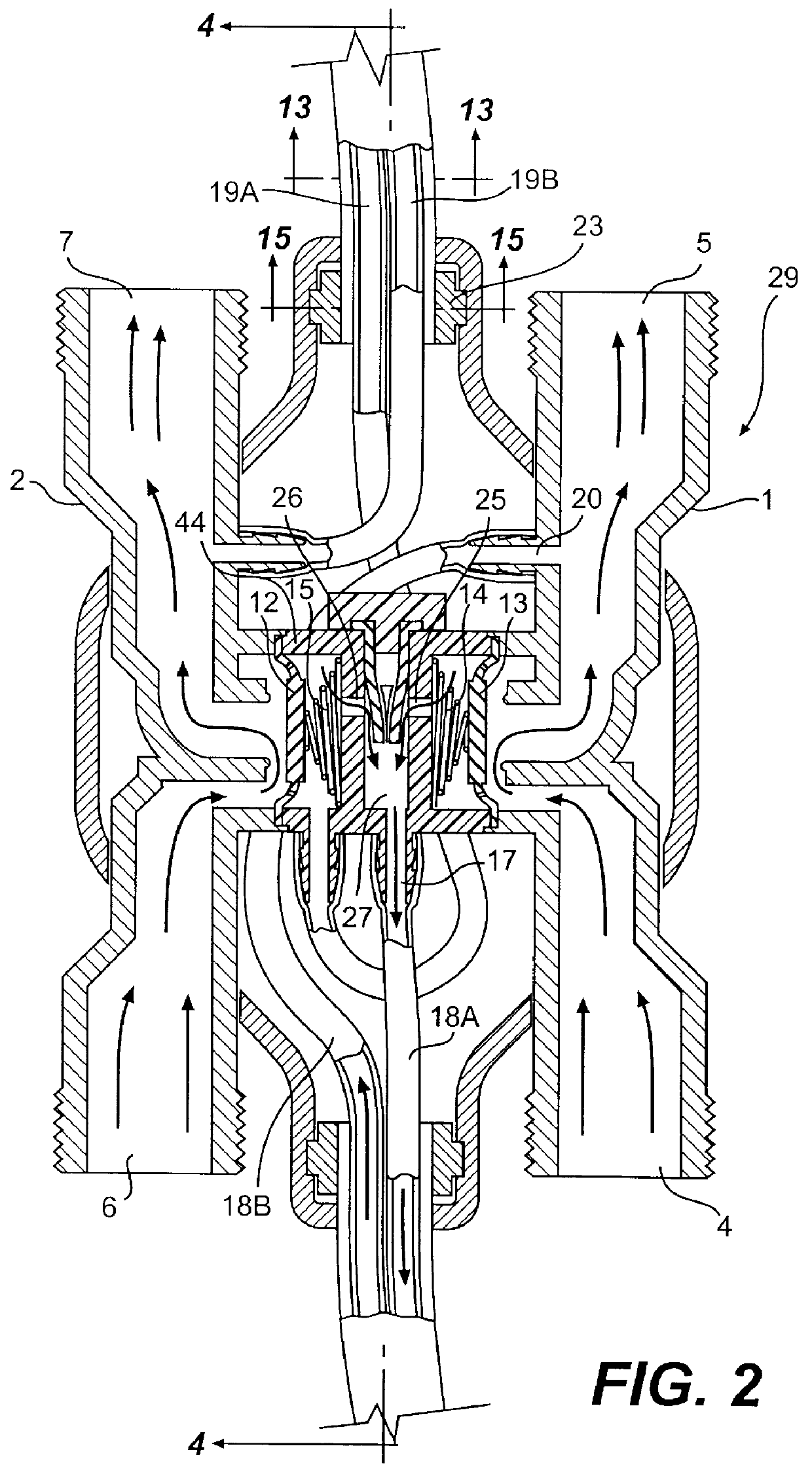

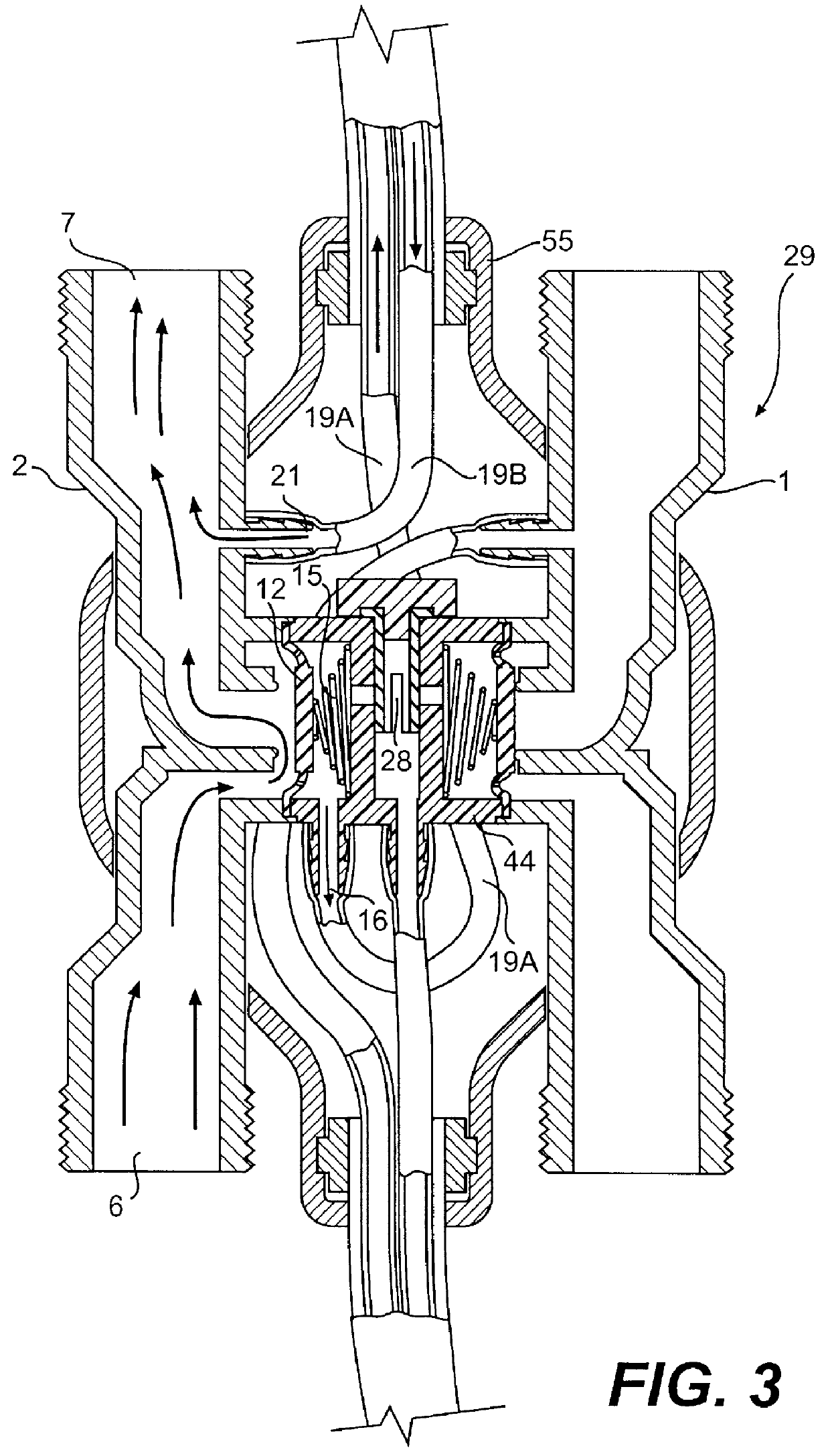

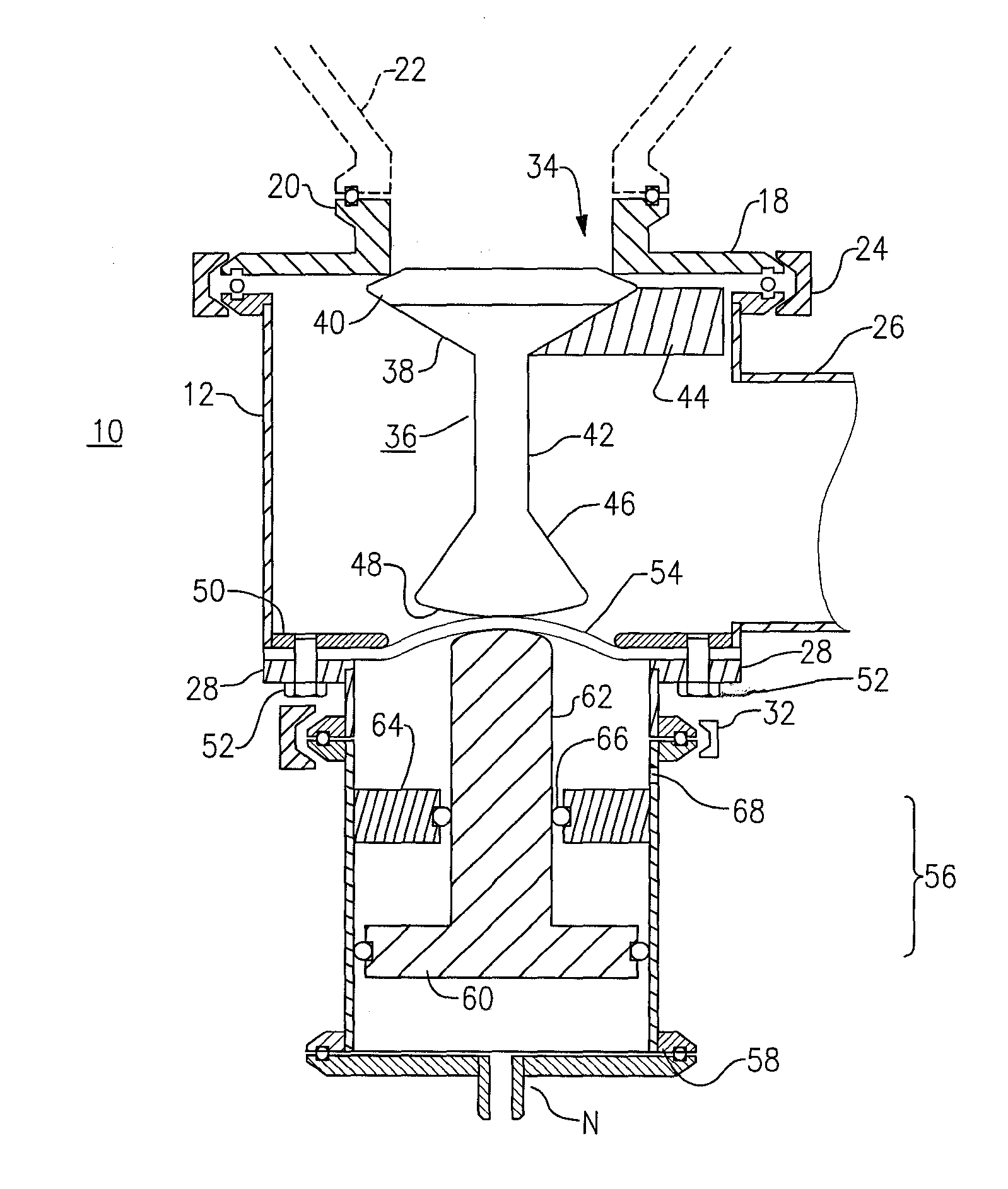

Flow control apparatus

InactiveUS6109288AAvoid manufacturingCompetitive priceTemperature control without auxillary powerEqualizing valvesEngineeringDiaphragm valve

A flow control apparatus for regulating the flow of hot and cold water through a mixing valve and for preventing undiluted hot water from being inadvertently delivered to a common outlet includes a common chamber and a pair of diaphragm valves on opposite sides of the common chamber. It also includes a check valve in the common chamber for opening and closing the diaphragm valves. Conventional piping, preferably flexible piping is used to connect the mixing valve to a source of hot water and to a source of cold water. The diaphragm valves and check valve are connected and arranged to prevent the flow of hot water through the mixing valve in the absence of a flow of cold water. The flow control apparatus may also include a mechanism for overriding the mixing valve in order to deliver an undiluted flow of hot water to the common outlet.

Owner:AL HAMLAN SALEH A

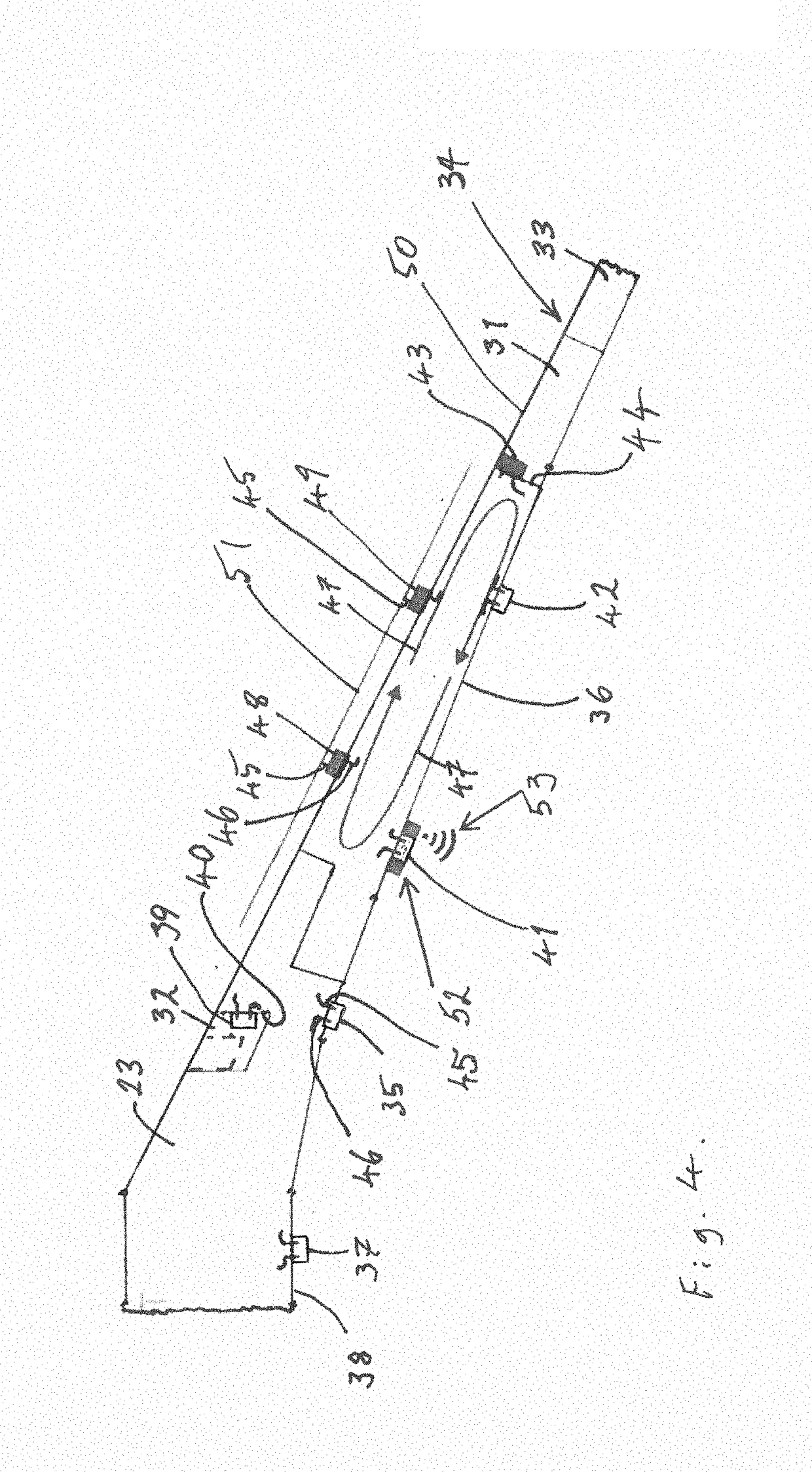

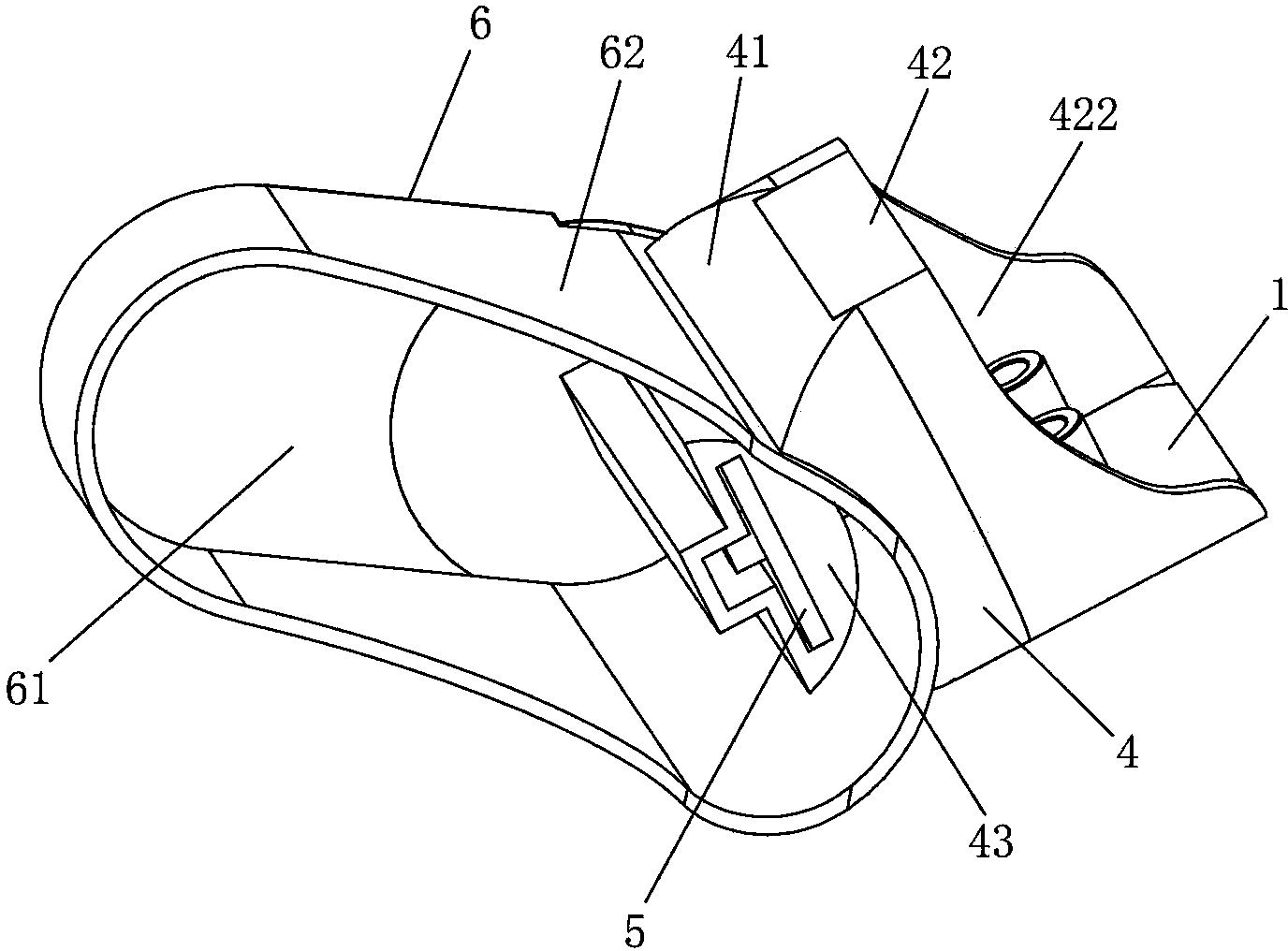

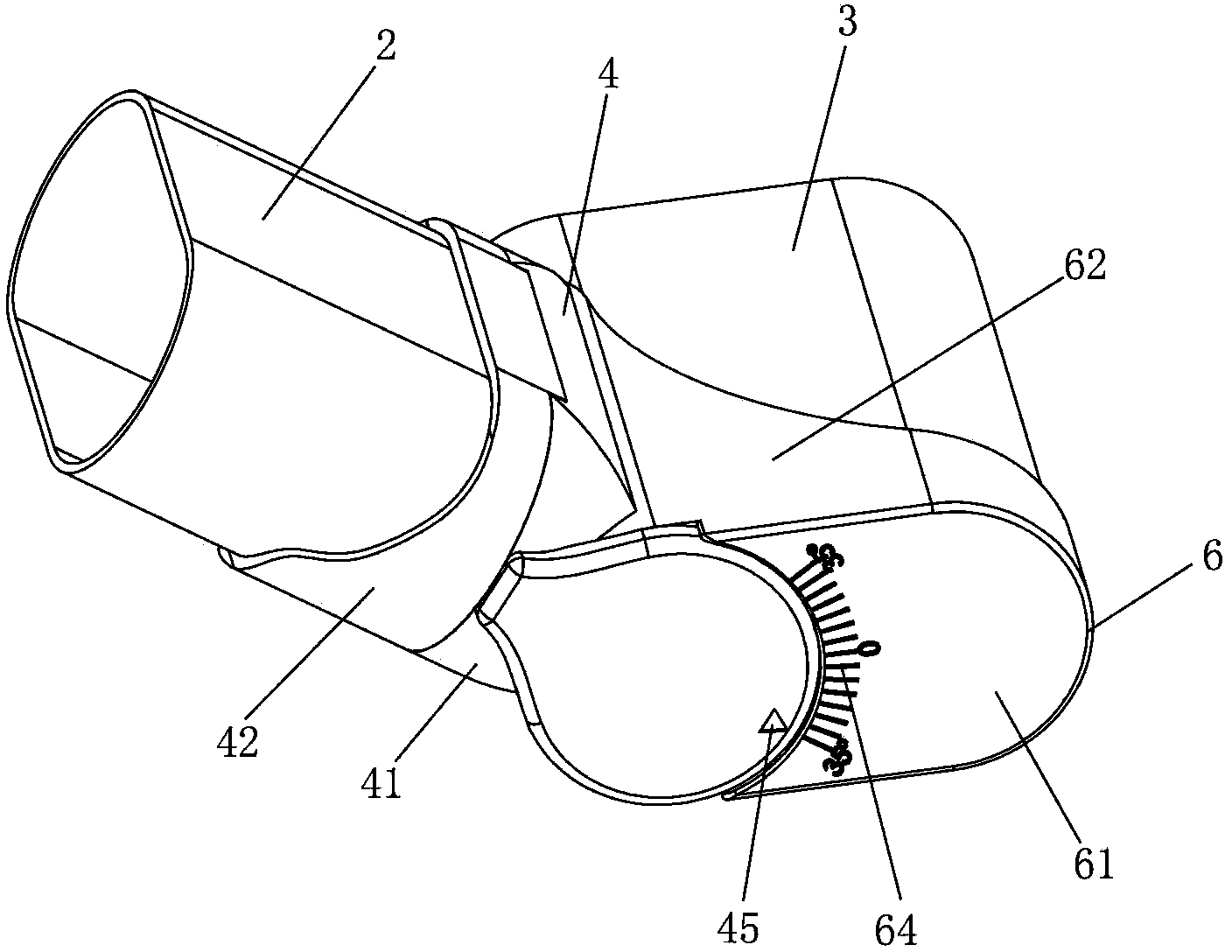

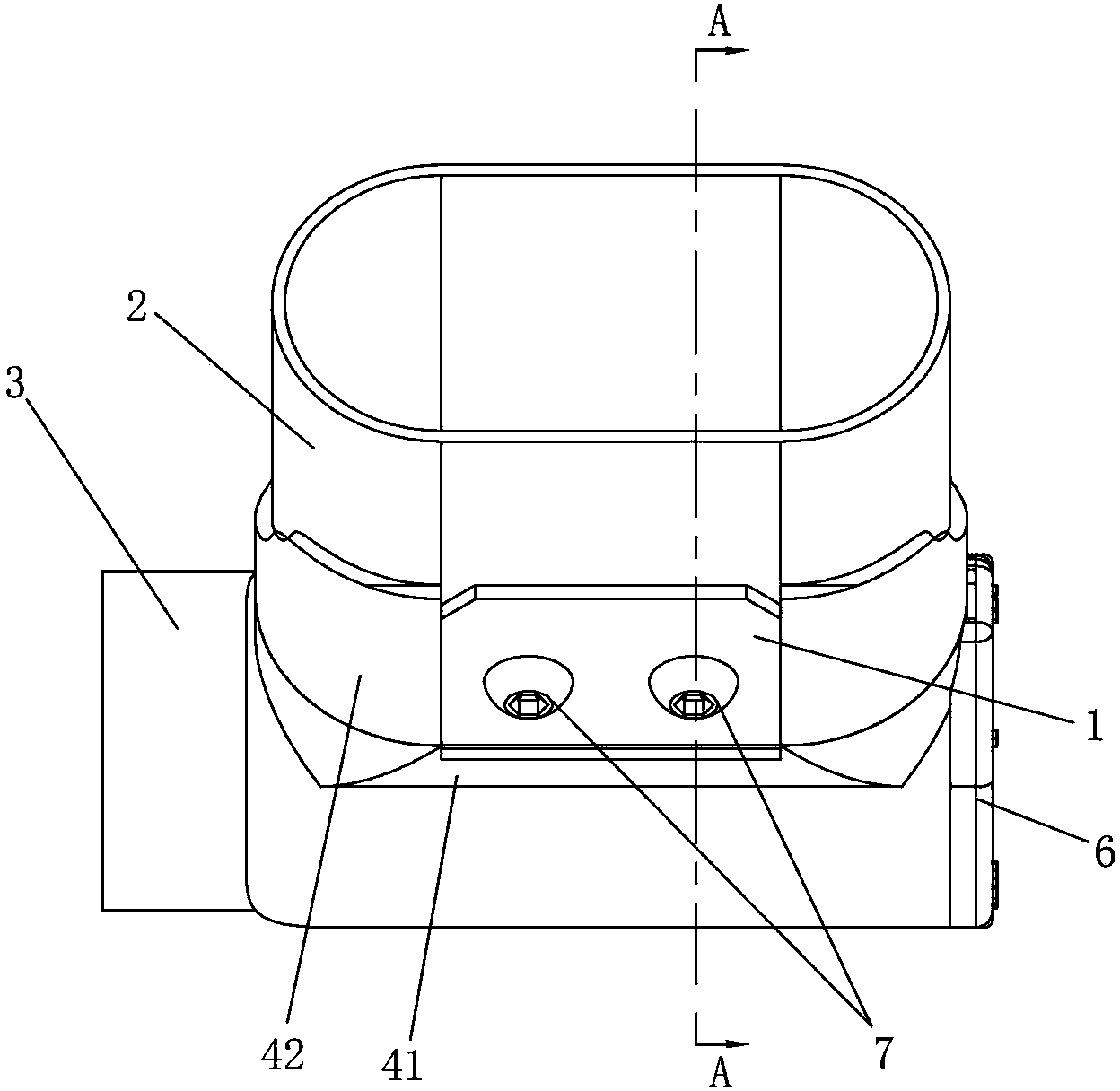

Hydraulic hammer

ActiveUS20050167131A1Rapid and less complex maintenanceMore freedomReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringMechanical engineering

The invention relates to a hydraulic hammer comprising a percussion piston (12) for delivering strokes to a tool (8). The lower part of the percussion piston is sealed to the frame (9) by means of a sealing bushing (31) comprising one or more lower seals (15). The sealing bushing does not contribute to the bearing of the percussion piston and it is arranged in place through the lower end of the hydraulic hammer (1). Further, the invention relates to a tool bushing (28) into which the sealing bushing (31) is integrated.

Owner:SANDVIK TAMROCK

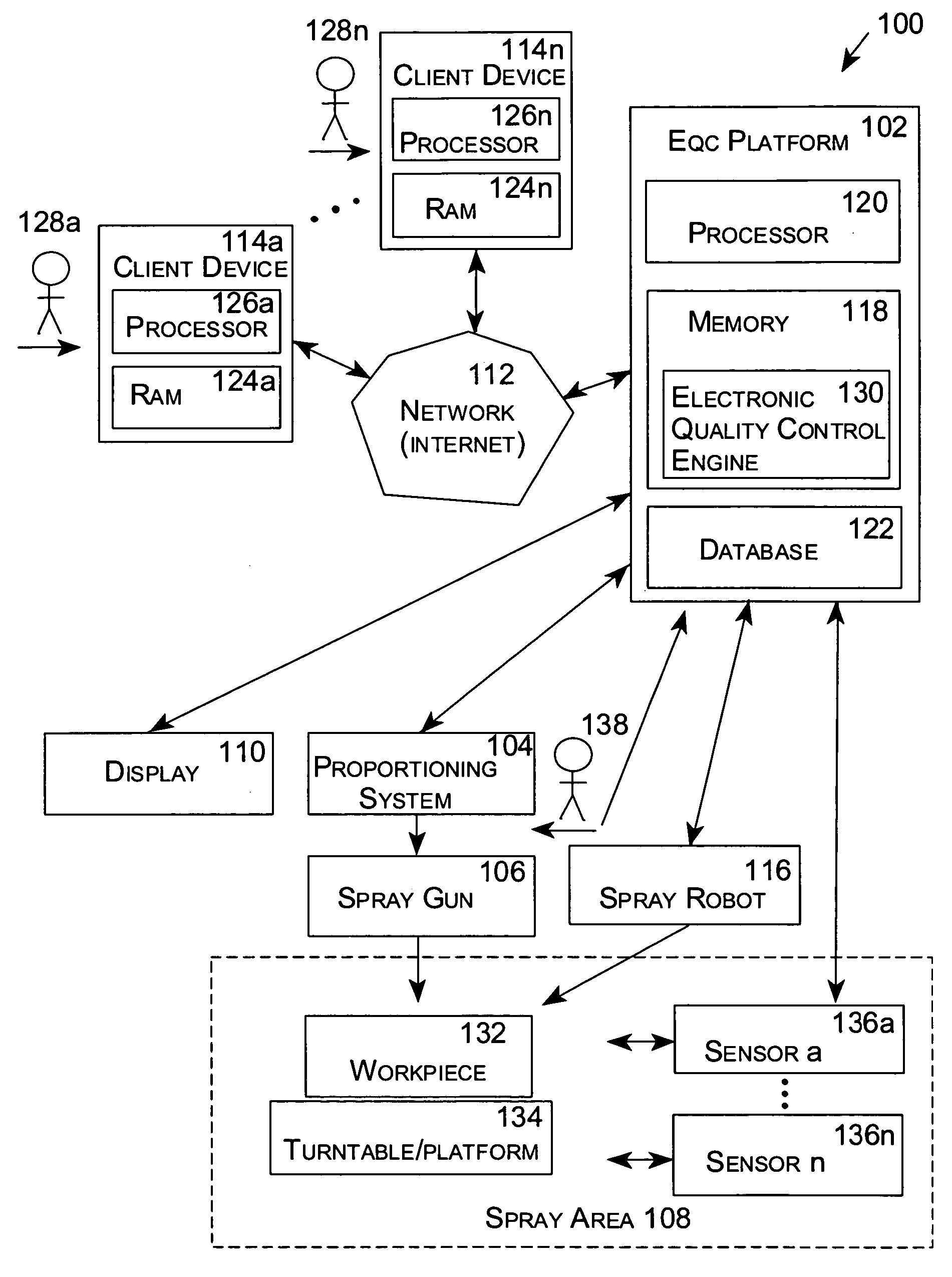

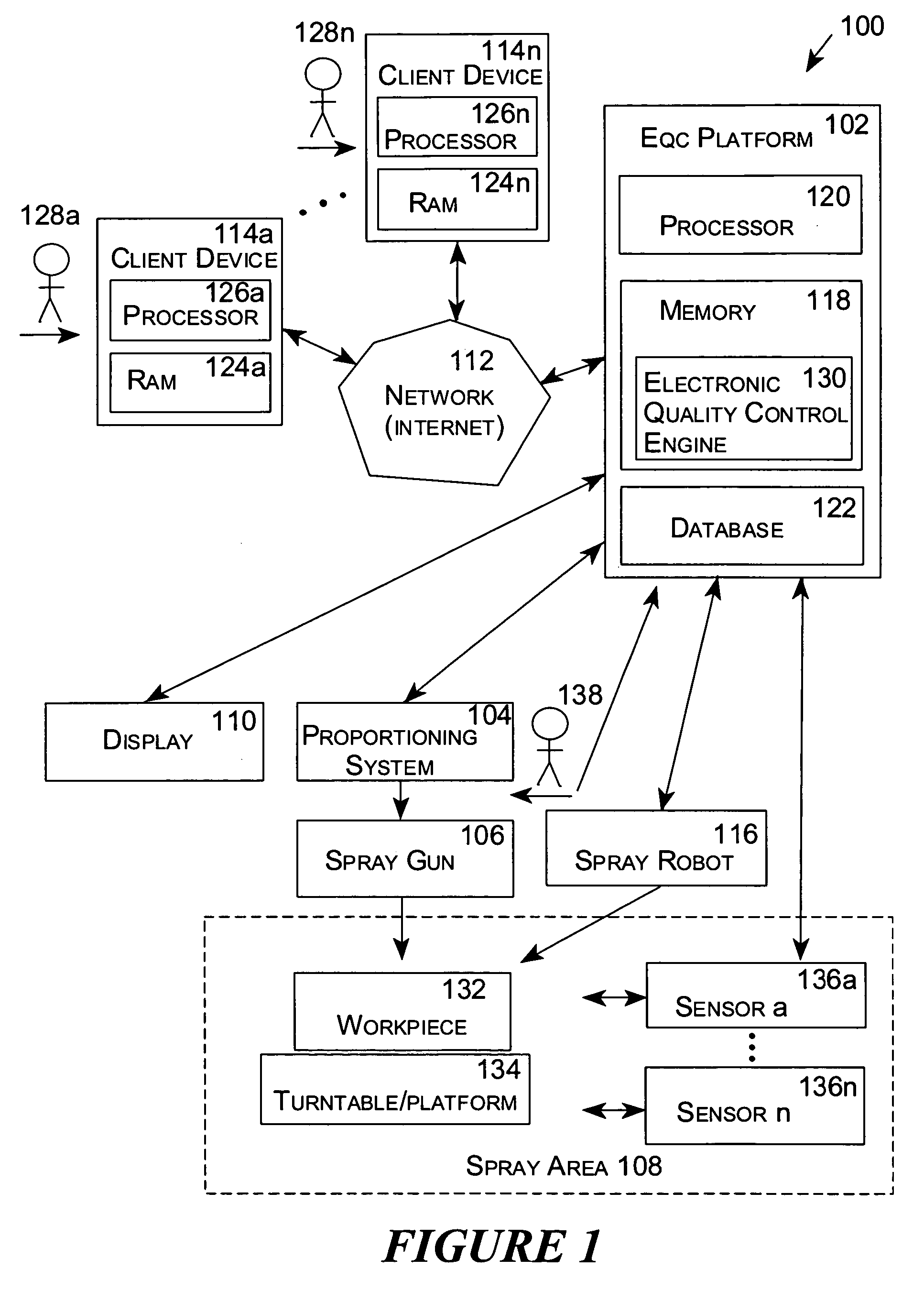

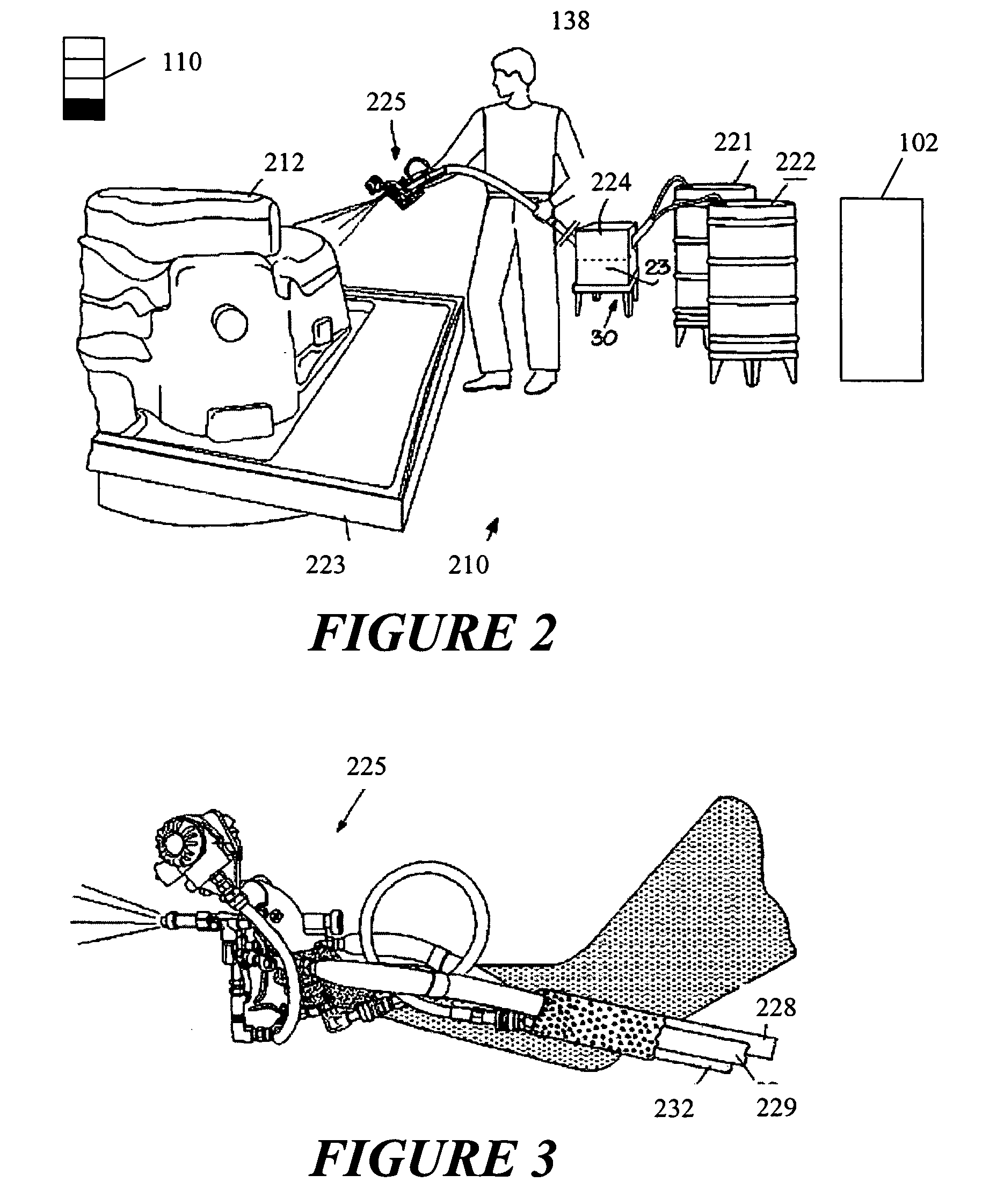

Systems and methods for providing electronic quality control in a process for applying a polyurethane to a substrate

ActiveUS20060200263A1Avoid manufacturingAvoid makingSampled-variable control systemsLiquid surface applicatorsQuality controlEngineering

The present invention comprises systems and methods for providing electronic quality control in a process for applying a polyurethane to a substrate. One aspect of the present invention includes a computer-implemented method for providing electronic quality control during manufacturing of a polyurethane coated article. The method can include providing a user interface for a user to input at least one operating characteristic associated with a process for manufacturing a polyurethane coated article. Furthermore, the method can include receiving a selection of at least one operating characteristic from the user, and receiving at least one condition associated with the operating characteristic. Moreover, the method can include monitoring a process for manufacturing a polyurethane coated article, wherein a change to the operating characteristic can be detected. The method can also include generating a notification if the at least one condition is detected.

Owner:ISOTEC INT

Photoelectricity conversion device and its making method

InactiveCN101017855AImprove conversion efficiencyImprove efficiencyFinal product manufacturePhotovoltaic energy generationBiochemical engineeringTransducer

The provided photoelectricity transducer has simple structure, high transducing efficiency, well stability, and no pollution. The related manufacture method is simple, and frees to the vacuum environment for low cost.

Owner:刘津平

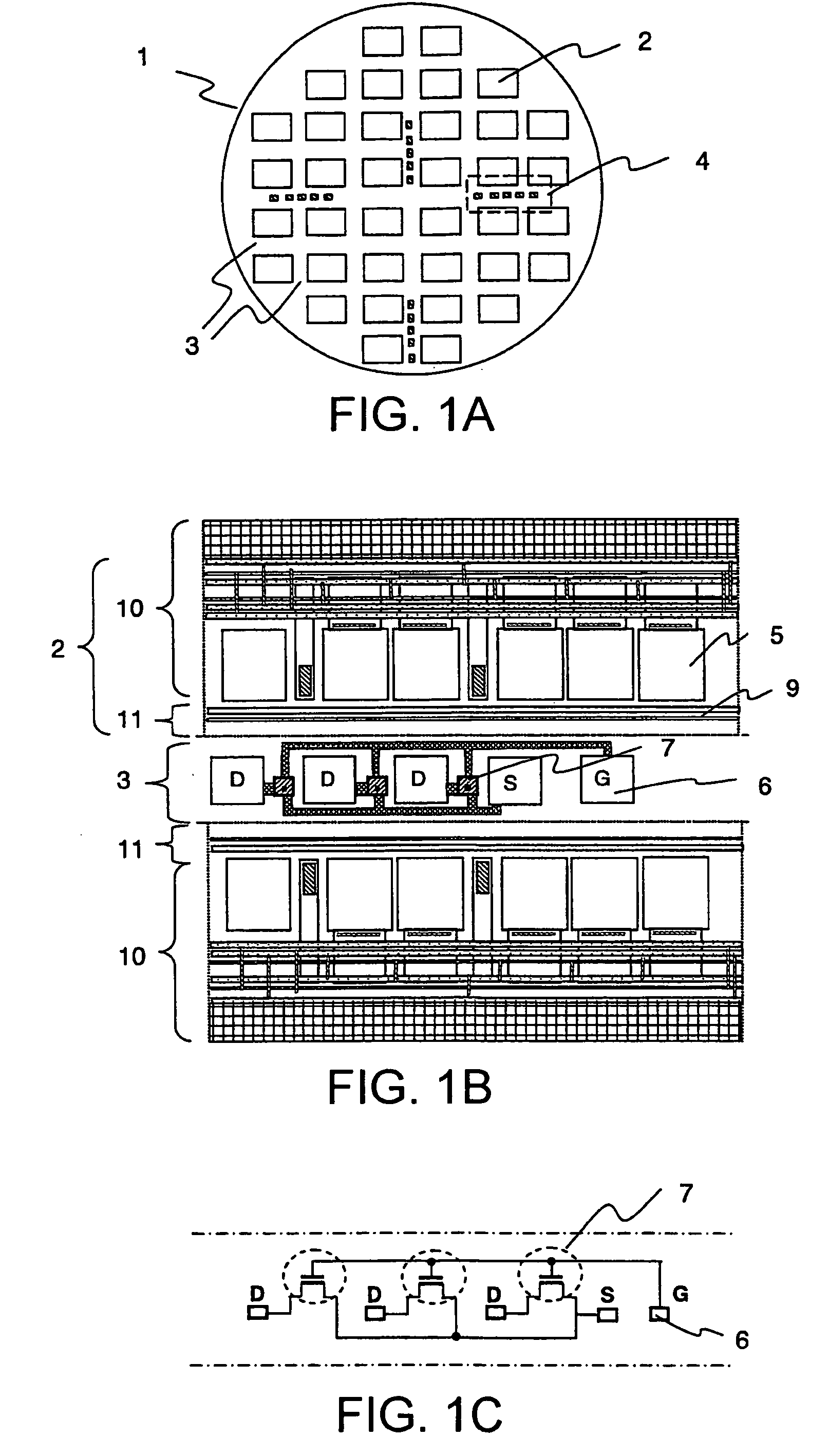

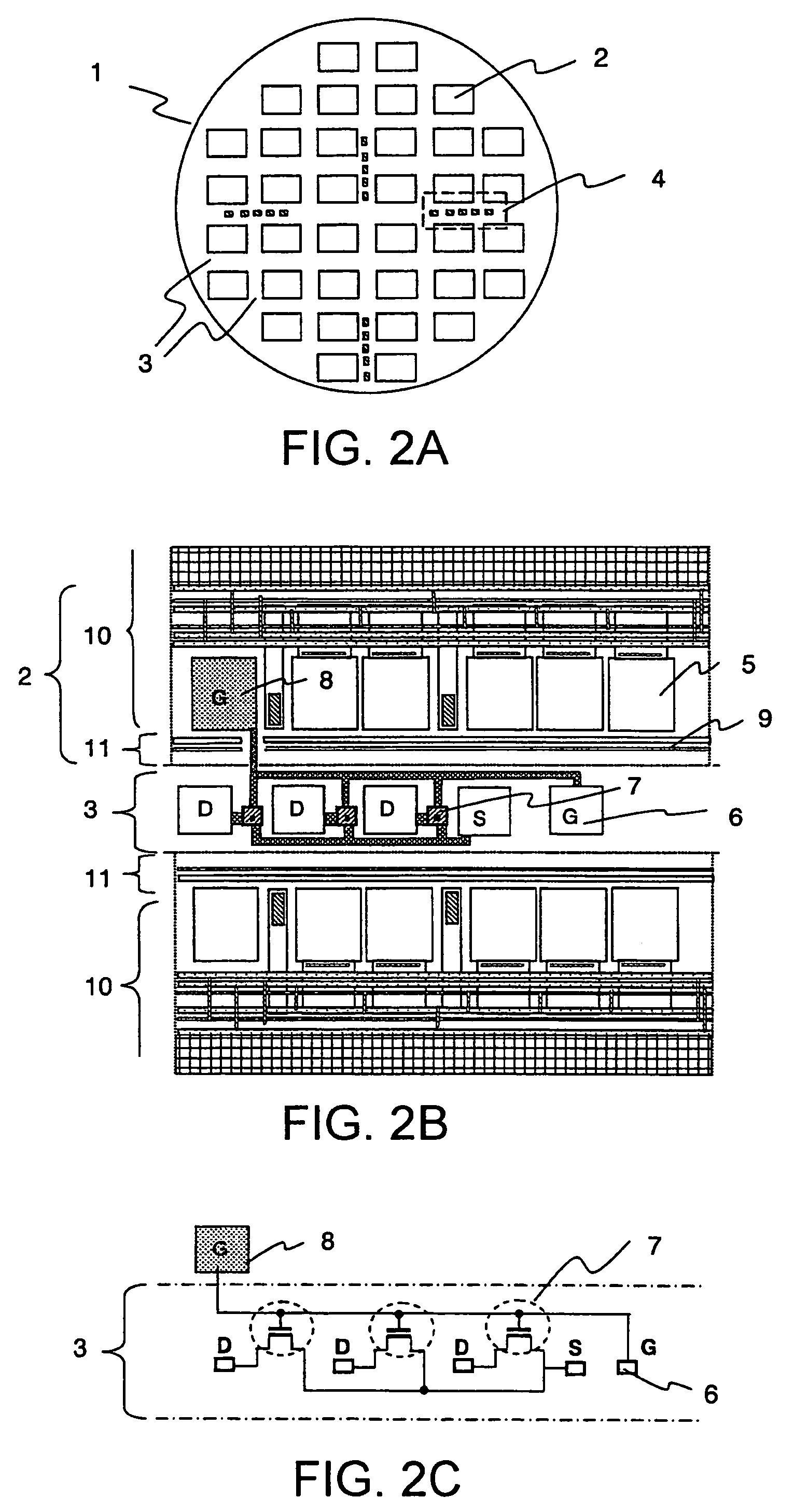

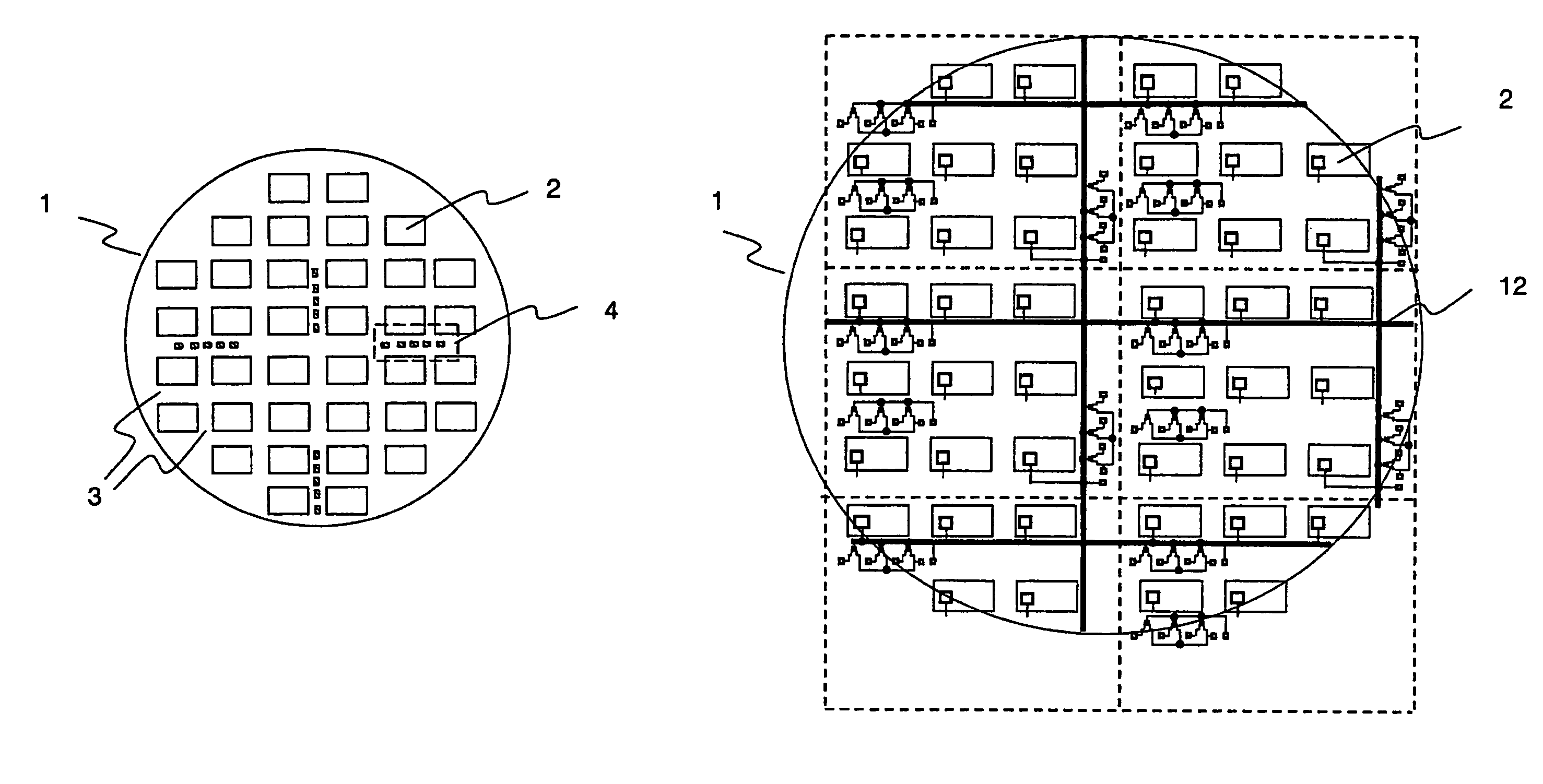

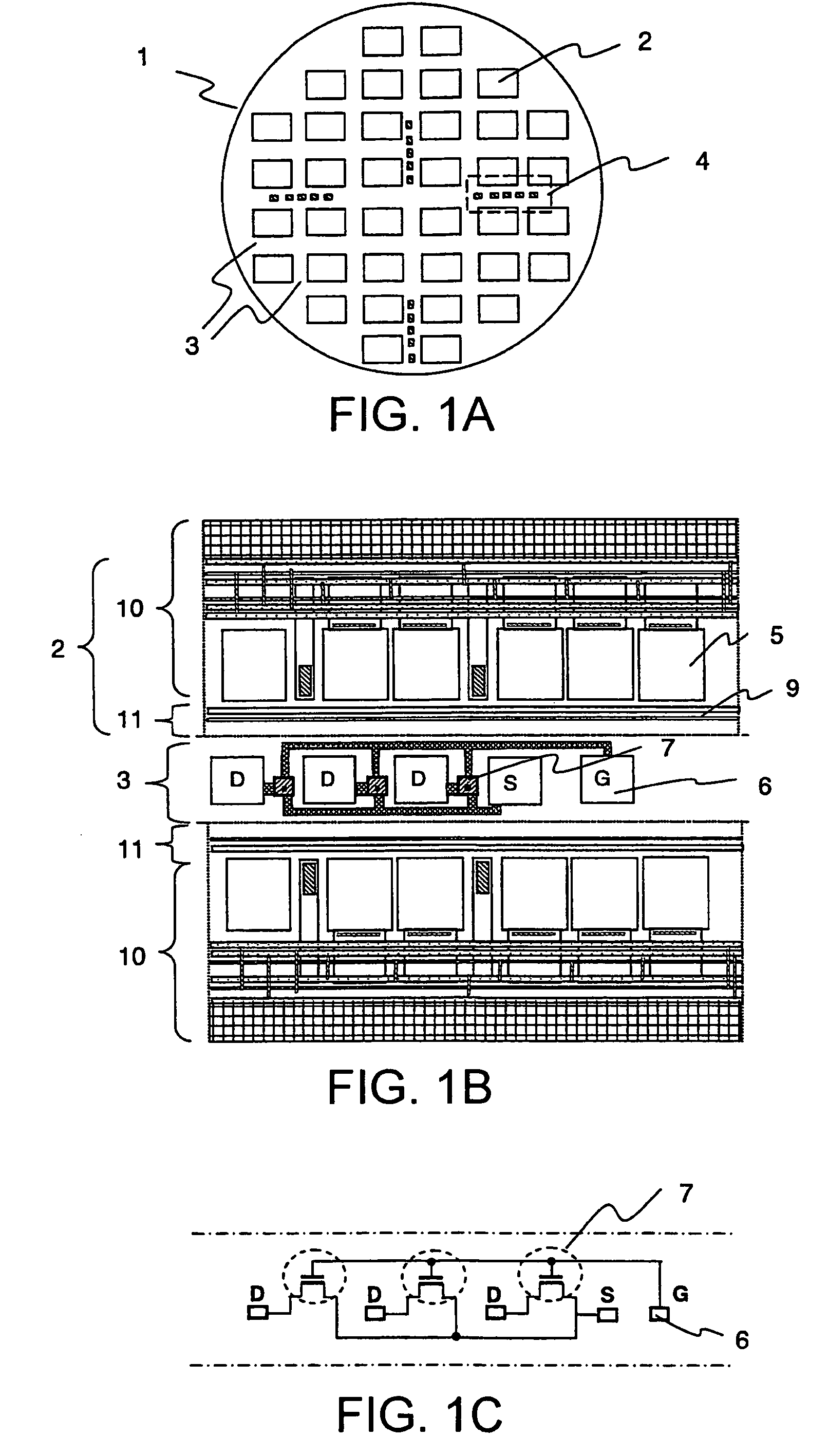

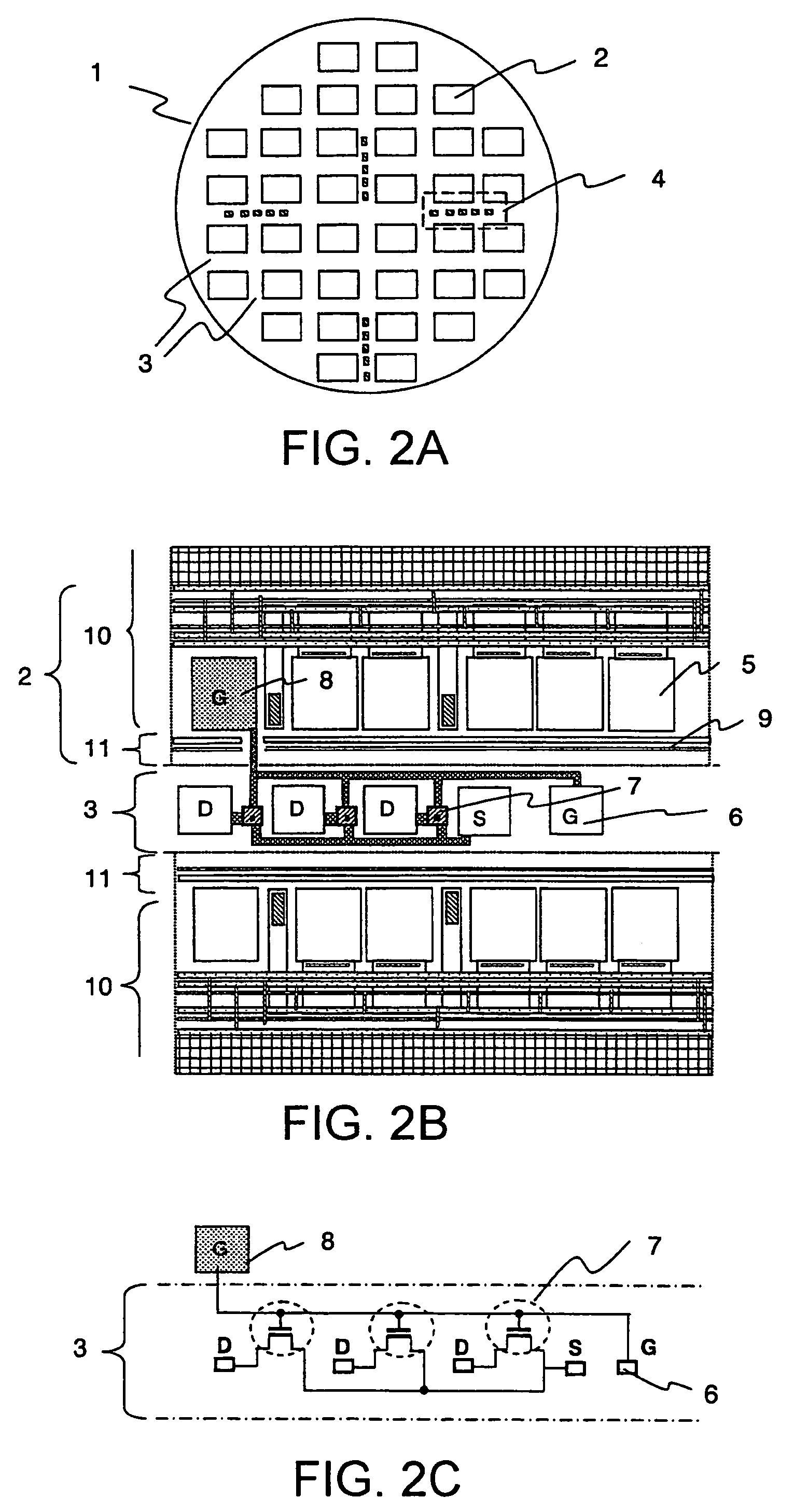

Semiconductor device

InactiveUS20080169467A1Avoid Information LeakagePrevent leakageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsSemiconductorSemiconductor device

A transistor of a characteristic checking element has a gate electrode connected to a measurement pad disposed in a dicing line and to an internal measurement pad disposed inside a semiconductor device. In a P / W process, a gate insulating film of the transistor is broken by an electric voltage applied via the internal measurement pad. Since the gate insulating film of the transistor is broken, a new current path is formed. Thus, measurement of accurate characteristics of the characteristic checking element is inhibited.

Owner:LONGITUDE SEMICON S A R L

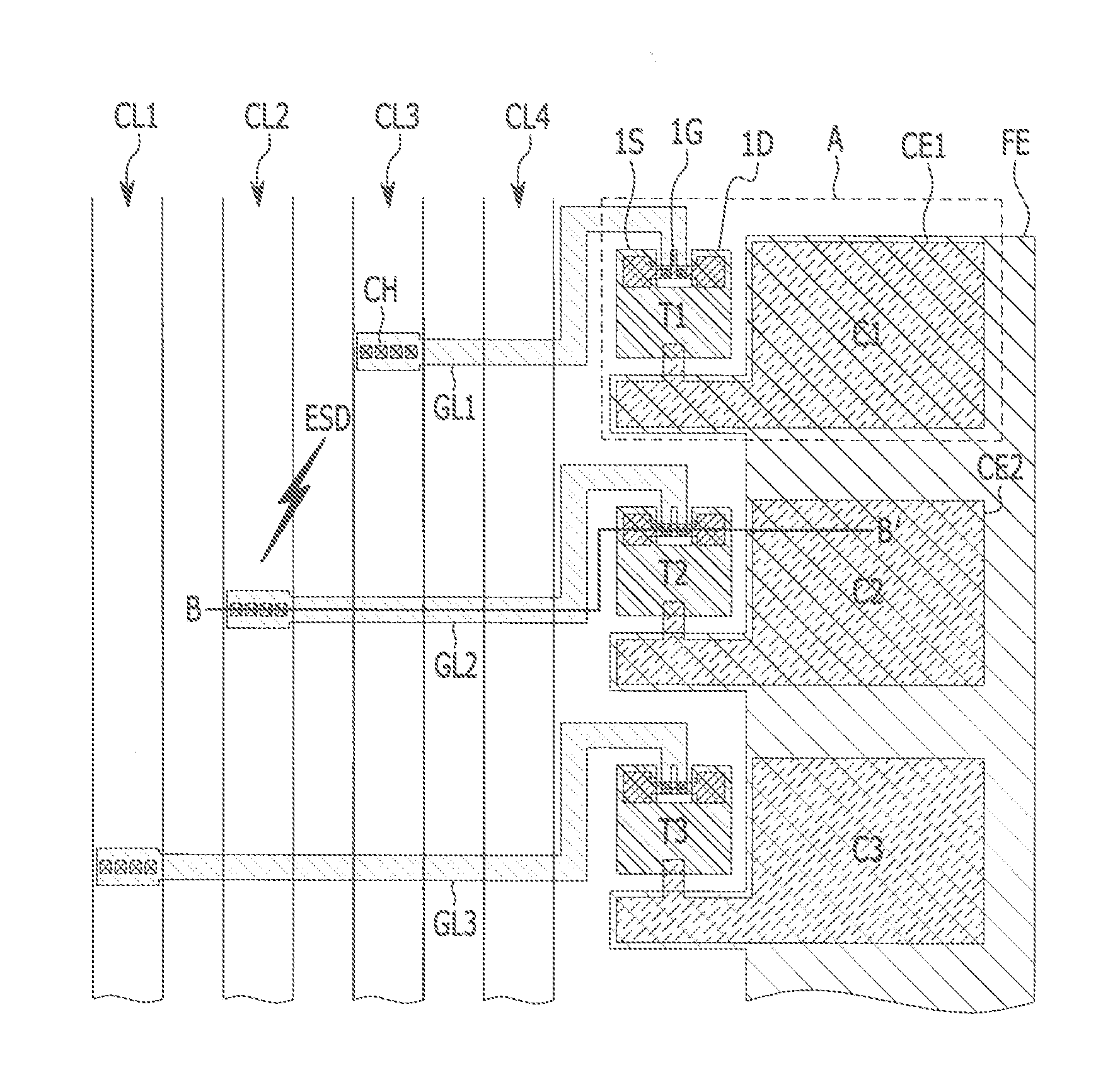

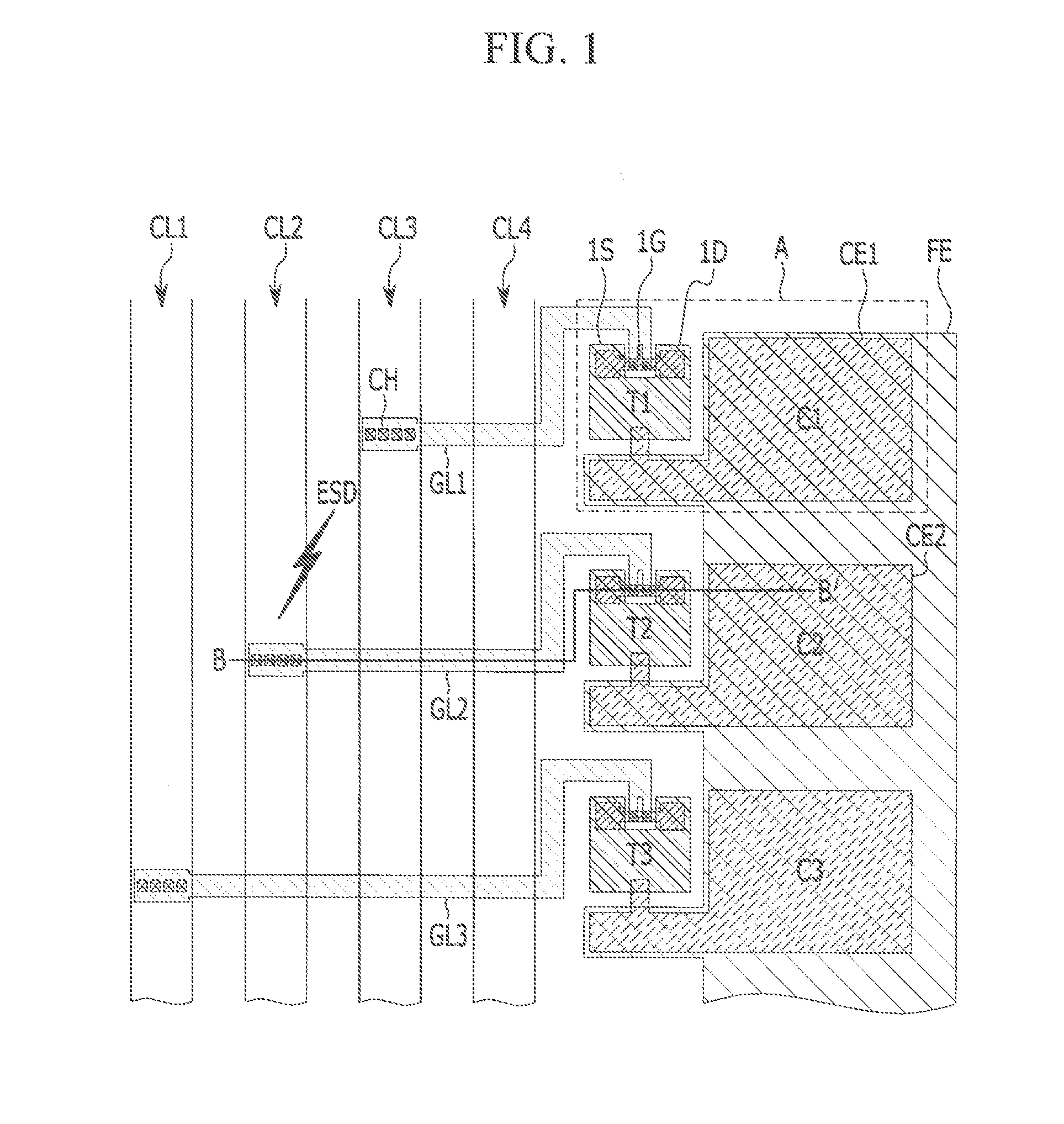

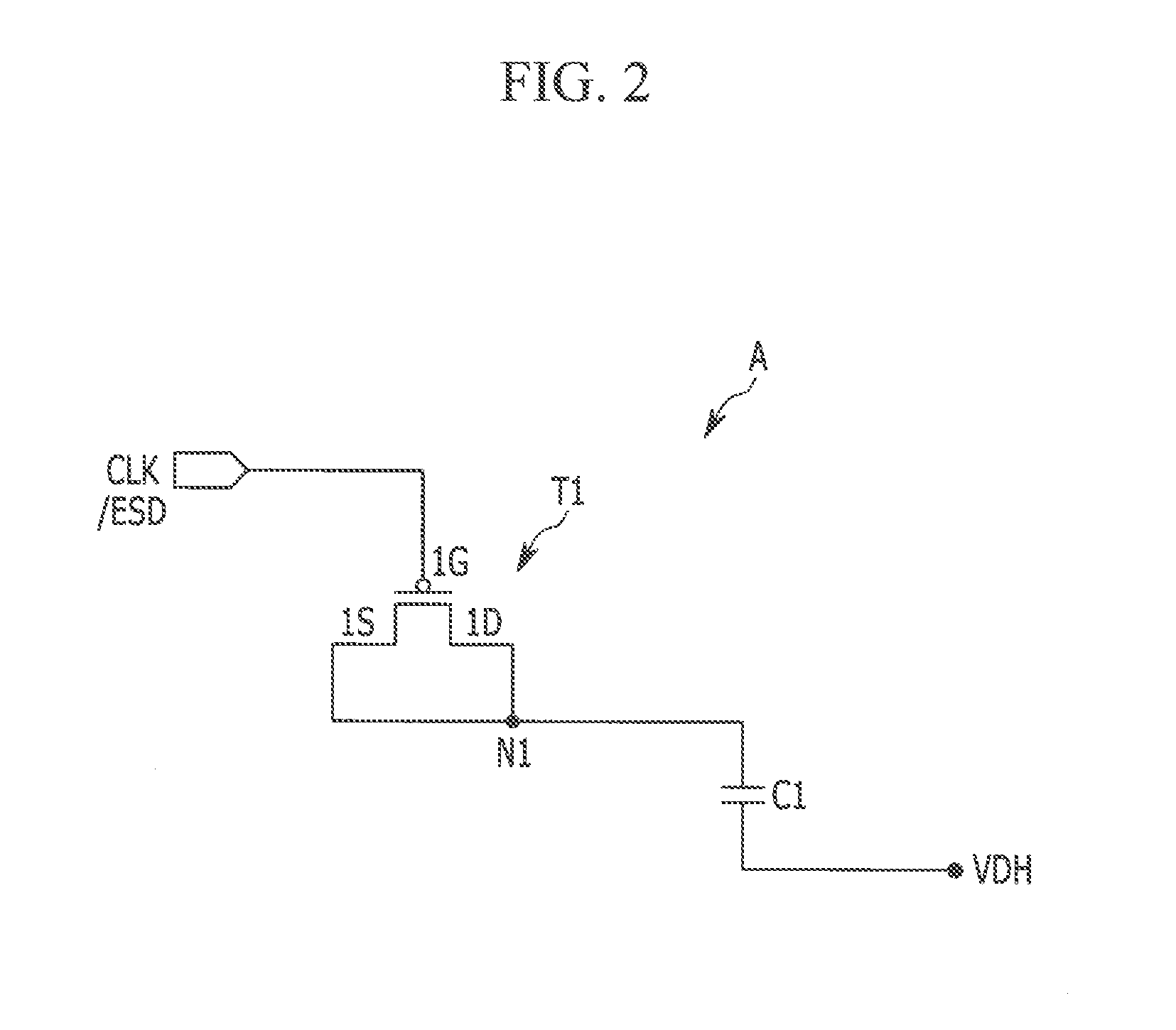

Circuit for preventing static electricity and display device having the same

ActiveUS20140210807A1Avoid malfunction or damageAvoid damageTransistorSemiconductor/solid-state device detailsEngineeringDriver circuit

A static electricity prevention circuit of a display device including: a driving circuit configured to drive a display unit that displays an image, at least one clock signal wire configured to transmit a clock signal to the driving circuit, at least one transistor electrically coupled to the dock signal wire, and at least one capacitor including a first electrode coupled to a source electrode and to a drain electrode of the transistor, and a second electrode configured to be maintained at a voltage,

Owner:SAMSUNG DISPLAY CO LTD

Semiconductor device

InactiveUS8704223B2Avoid Information LeakagePrevent leakageSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringSemiconductor

A transistor of a characteristic checking element has a gate electrode connected to a measurement pad disposed in a dicing line and to an internal measurement pad disposed inside a semiconductor device. In a P / W process, a gate insulating film of the transistor is broken by an electric voltage applied via the internal measurement pad. Since the gate insulating film of the transistor is broken, a new current path is formed. Thus, measurement of accurate characteristics of the characteristic checking element is inhibited.

Owner:LONGITUDE SEMICON S A R L

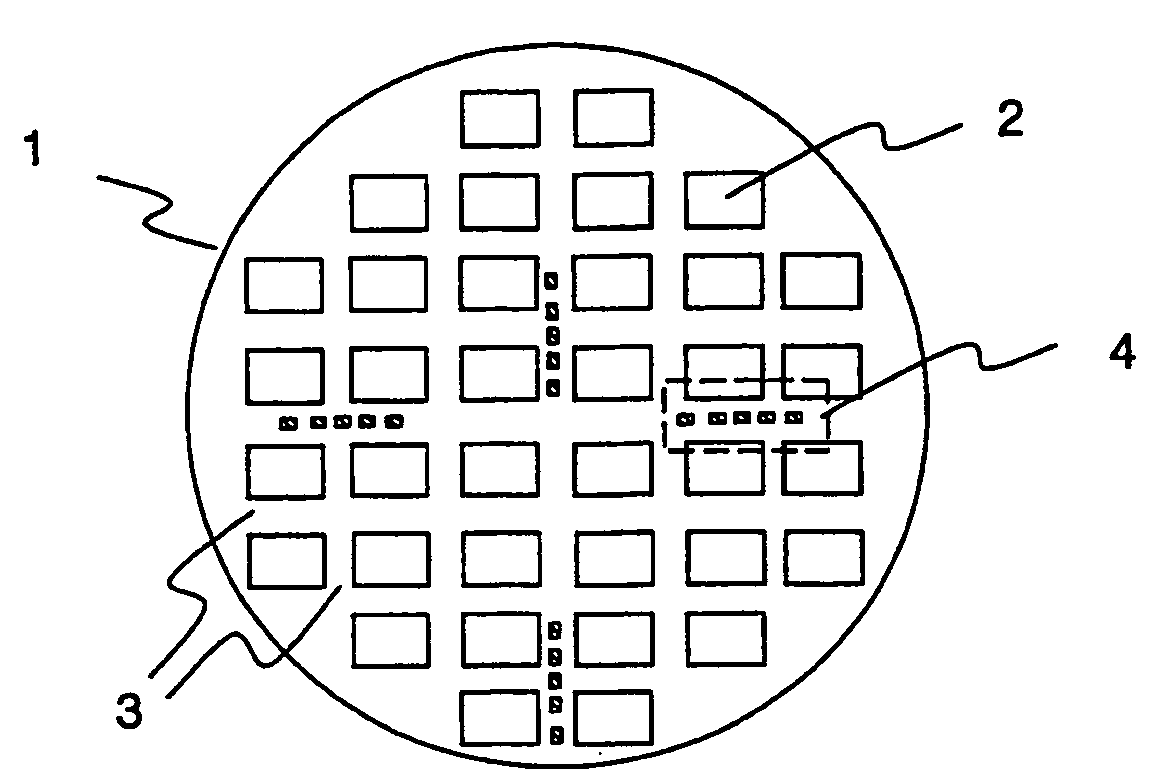

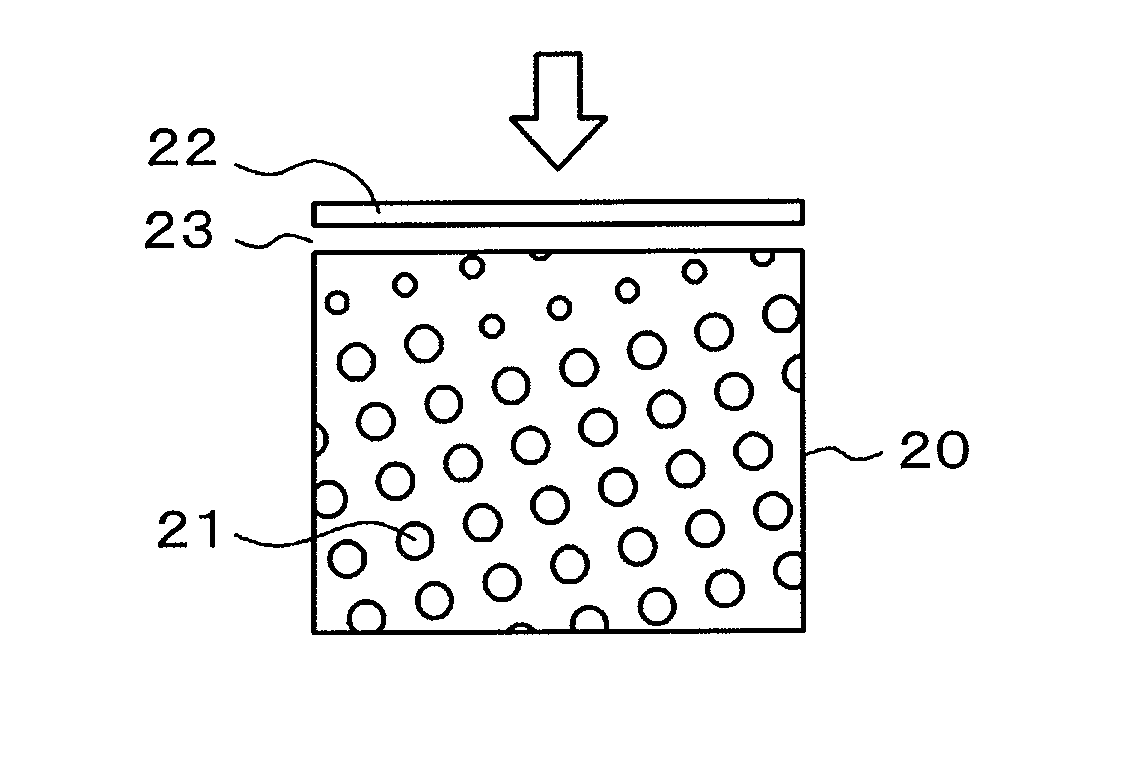

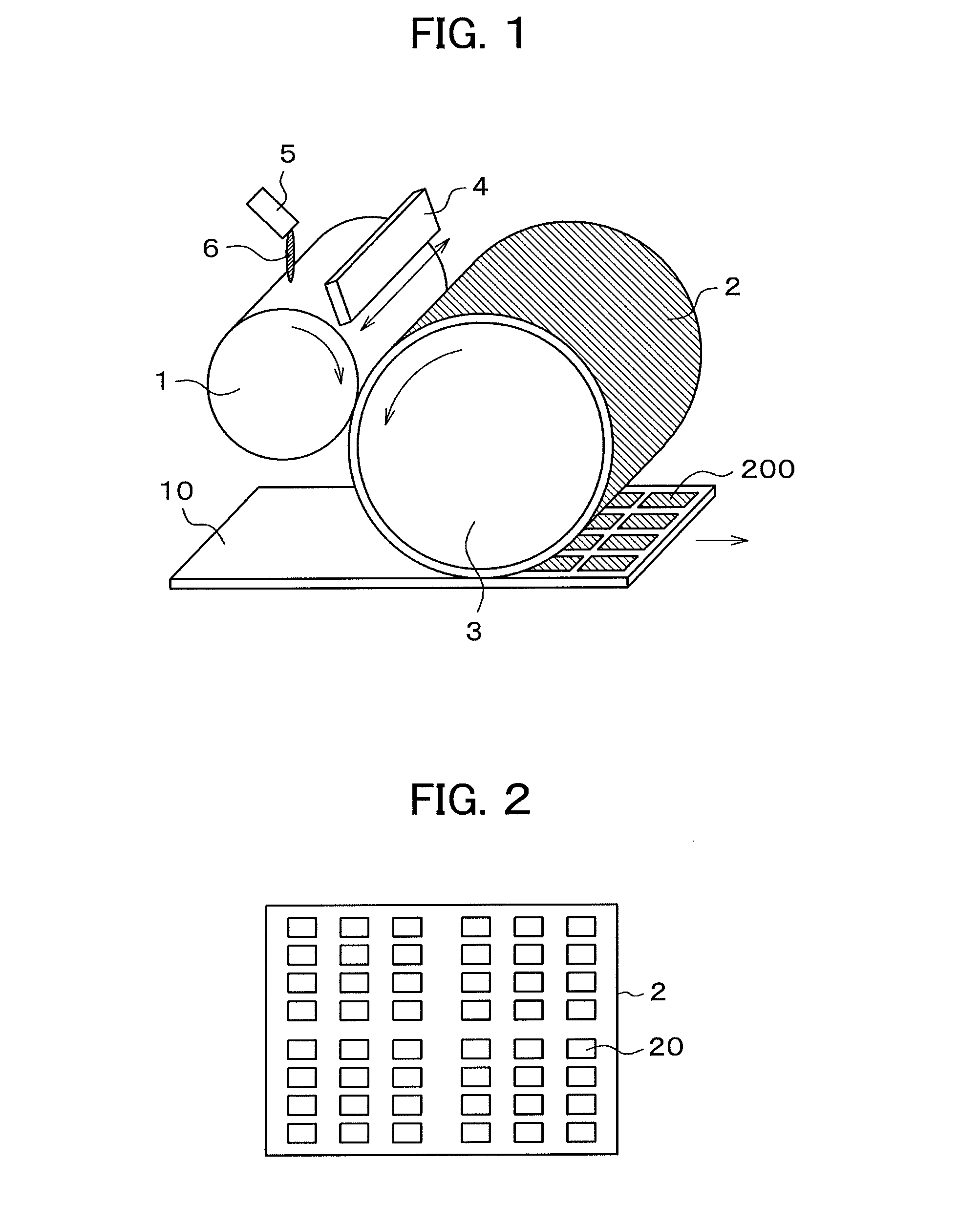

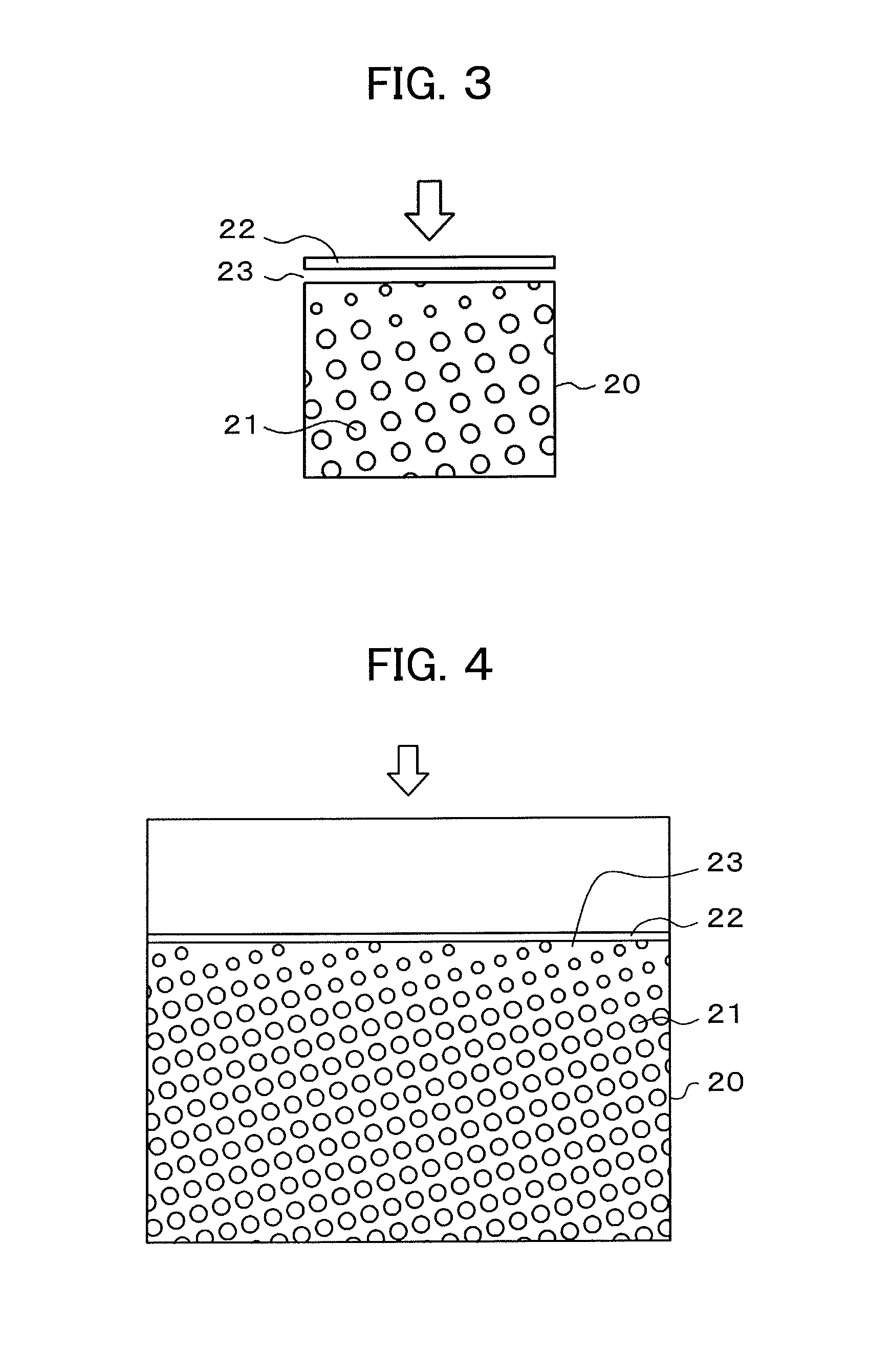

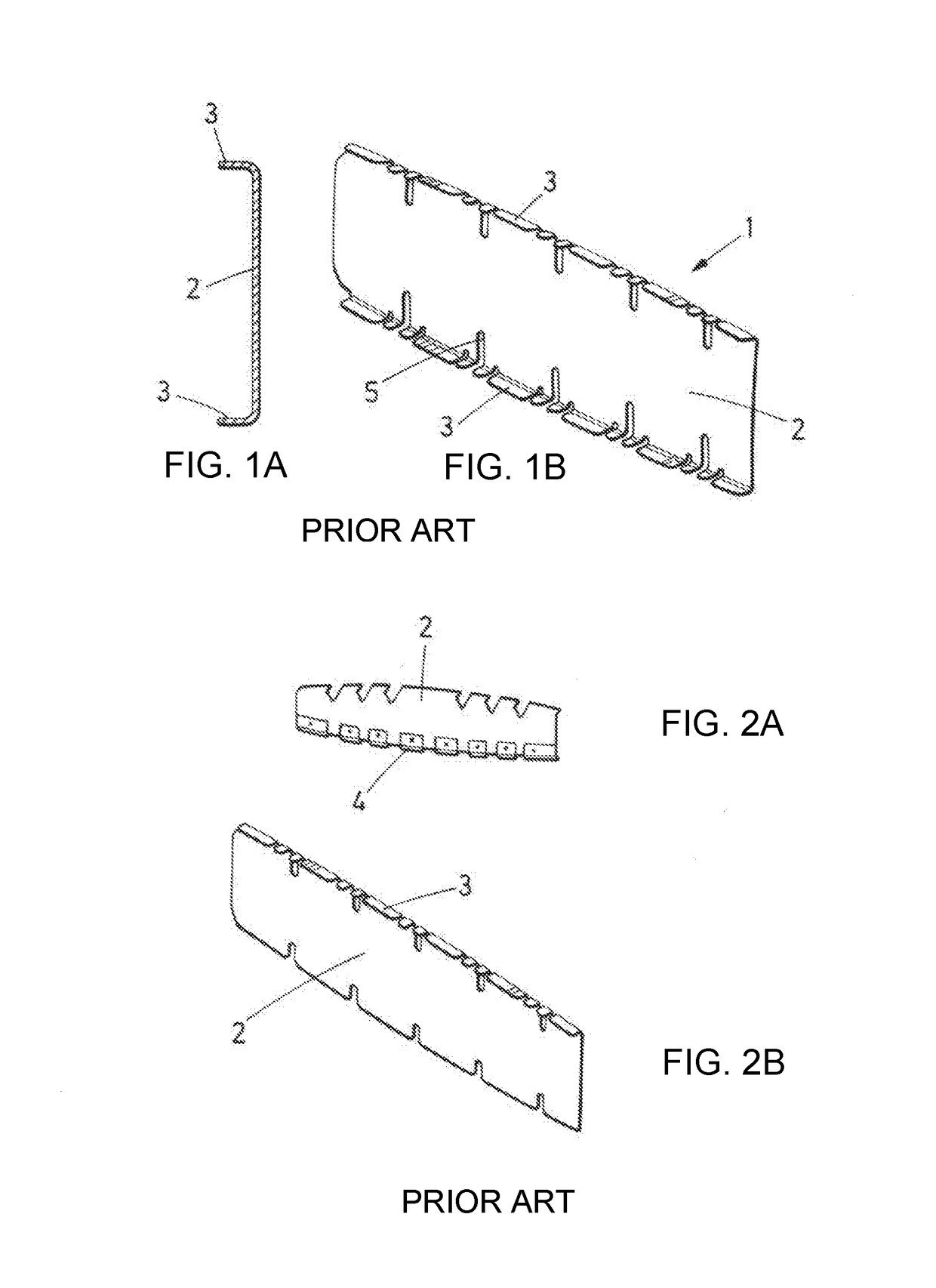

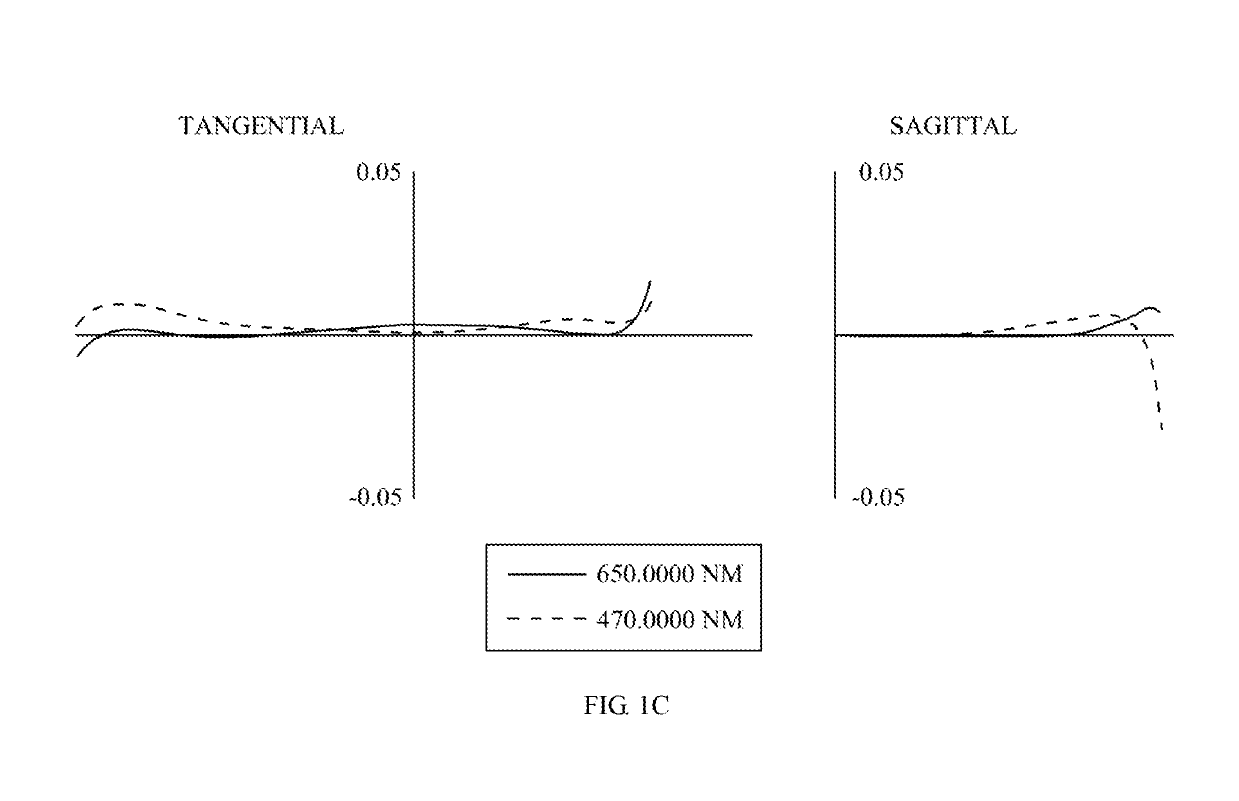

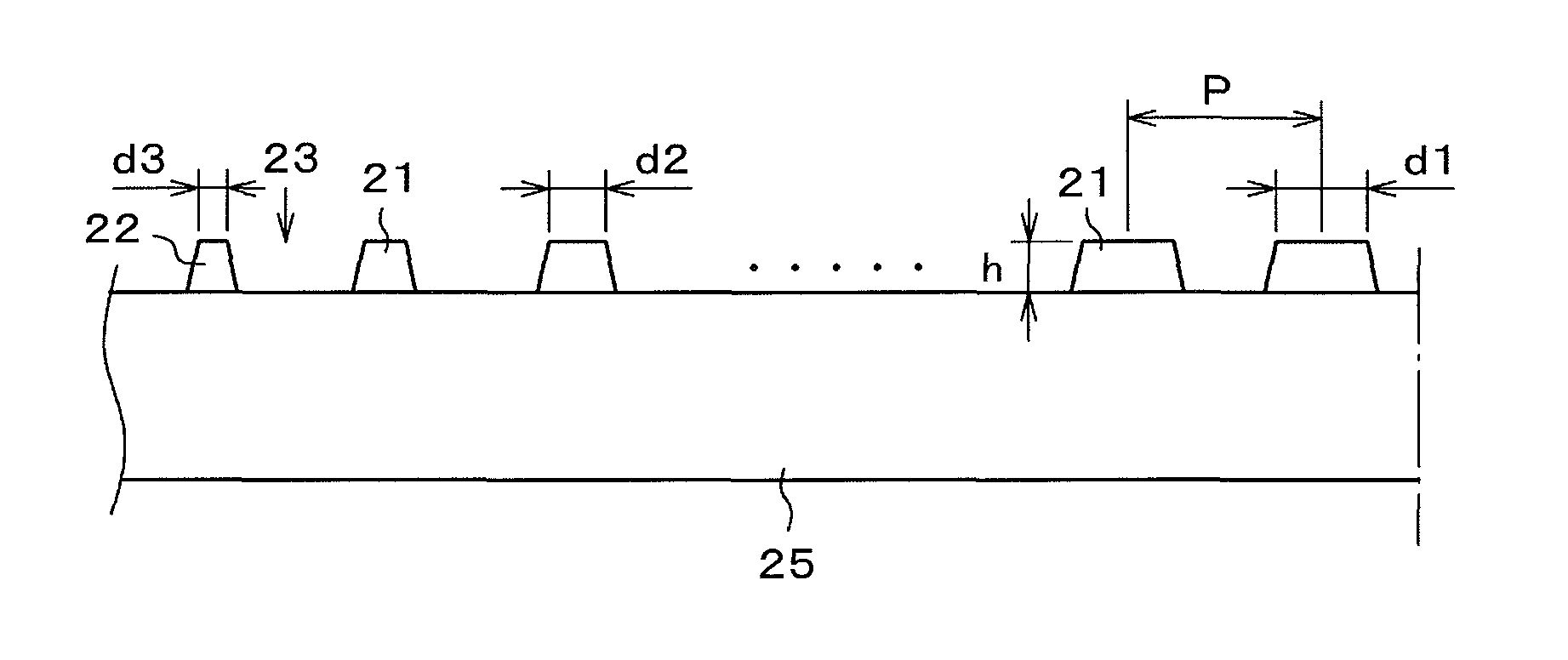

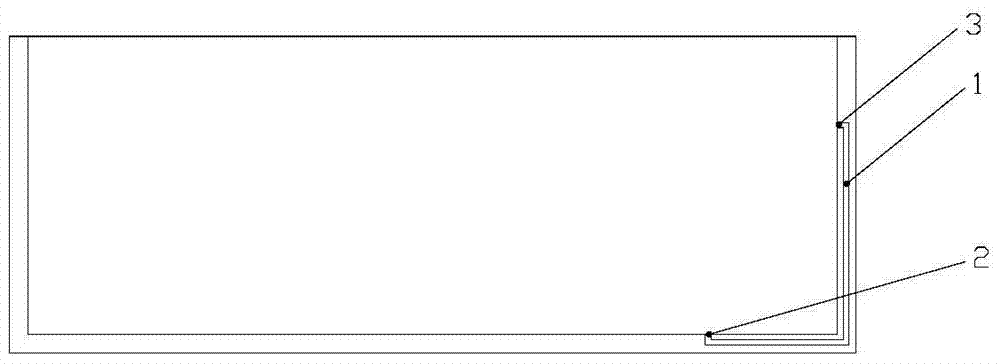

Oriented film printing plate and manufacturing method for liquid crystal display device

ActiveUS20140168596A1Prevent in manufacture yieldSmall diameterPlate printingOther printing apparatusLiquid-crystal displayElectrical and Electronics engineering

In order to prevent protruded parts formed on an oriented film print pattern of a printing plate for flexographic printing from being lost, a linear bank is formed on the periphery of one side of the oriented film print pattern where wiping work is started. The bank prevents the protruded part in the oriented film print pattern from being lost by the wiping work. The protruded parts are formed in a matrix in order to retain an oriented film liquid in the oriented film print pattern. Thickness irregularity of the oriented film due to presence of the bank is reduced by making the diameters of the protruded parts smaller in a peripheral region than in a central region of the oriented film print pattern and forming a space between the peripheral-side protruded parts and the bank.

Owner:JAPAN DISPLAY INC

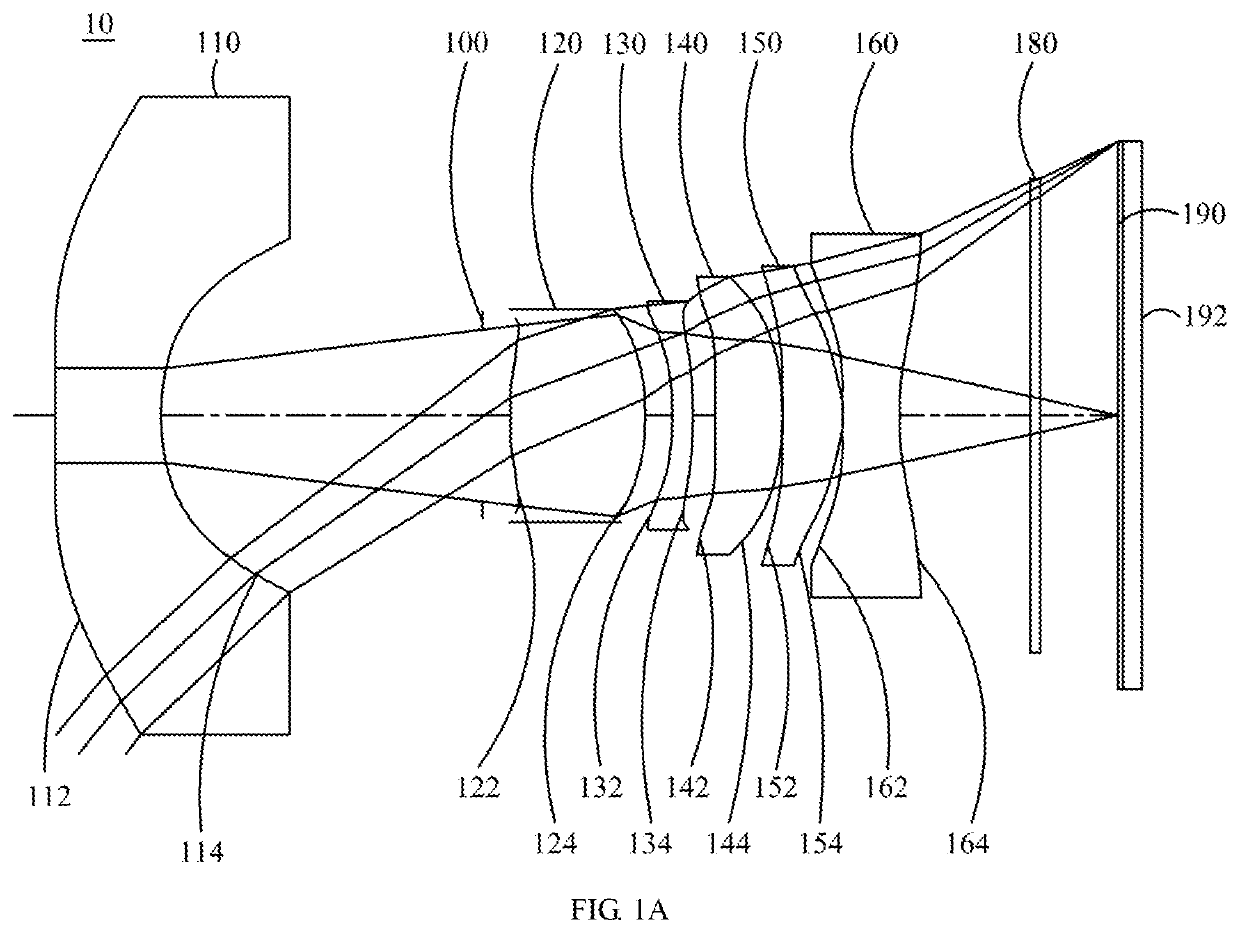

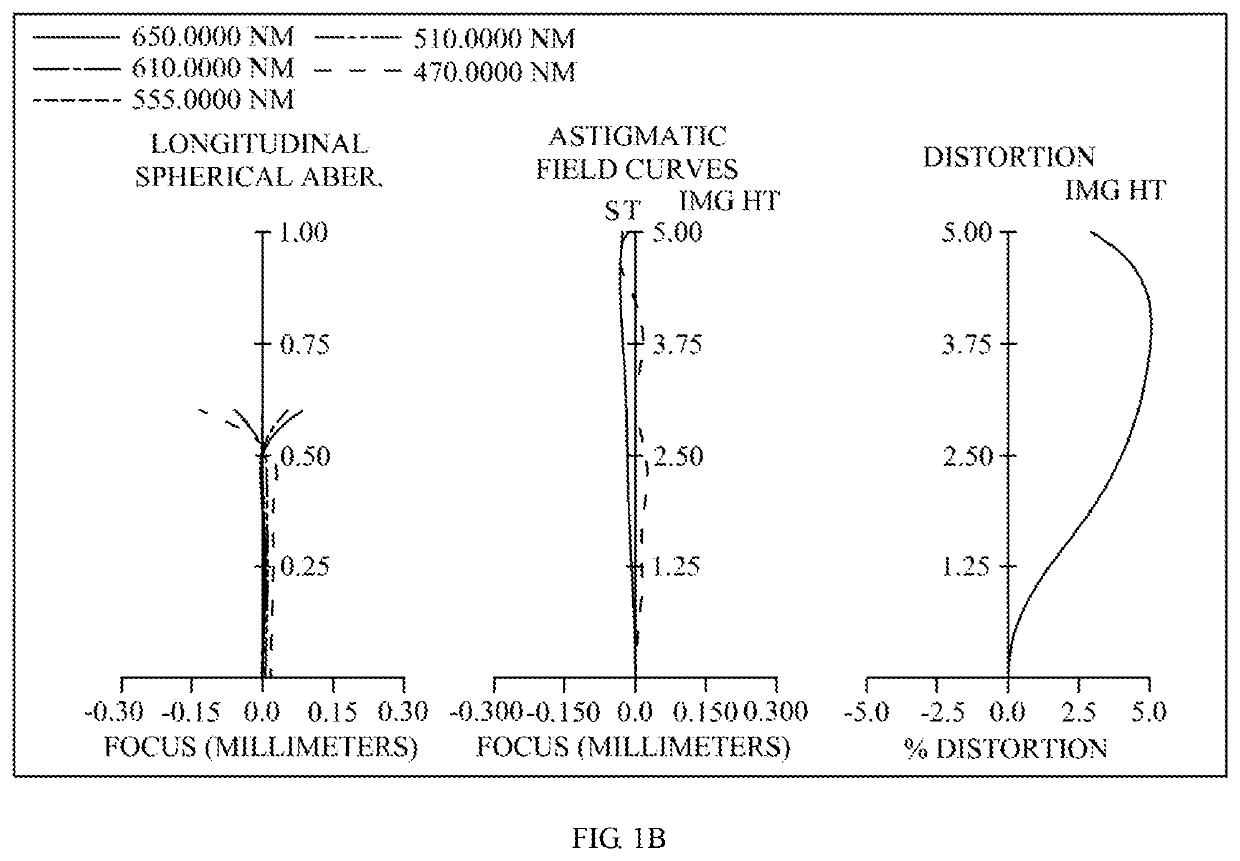

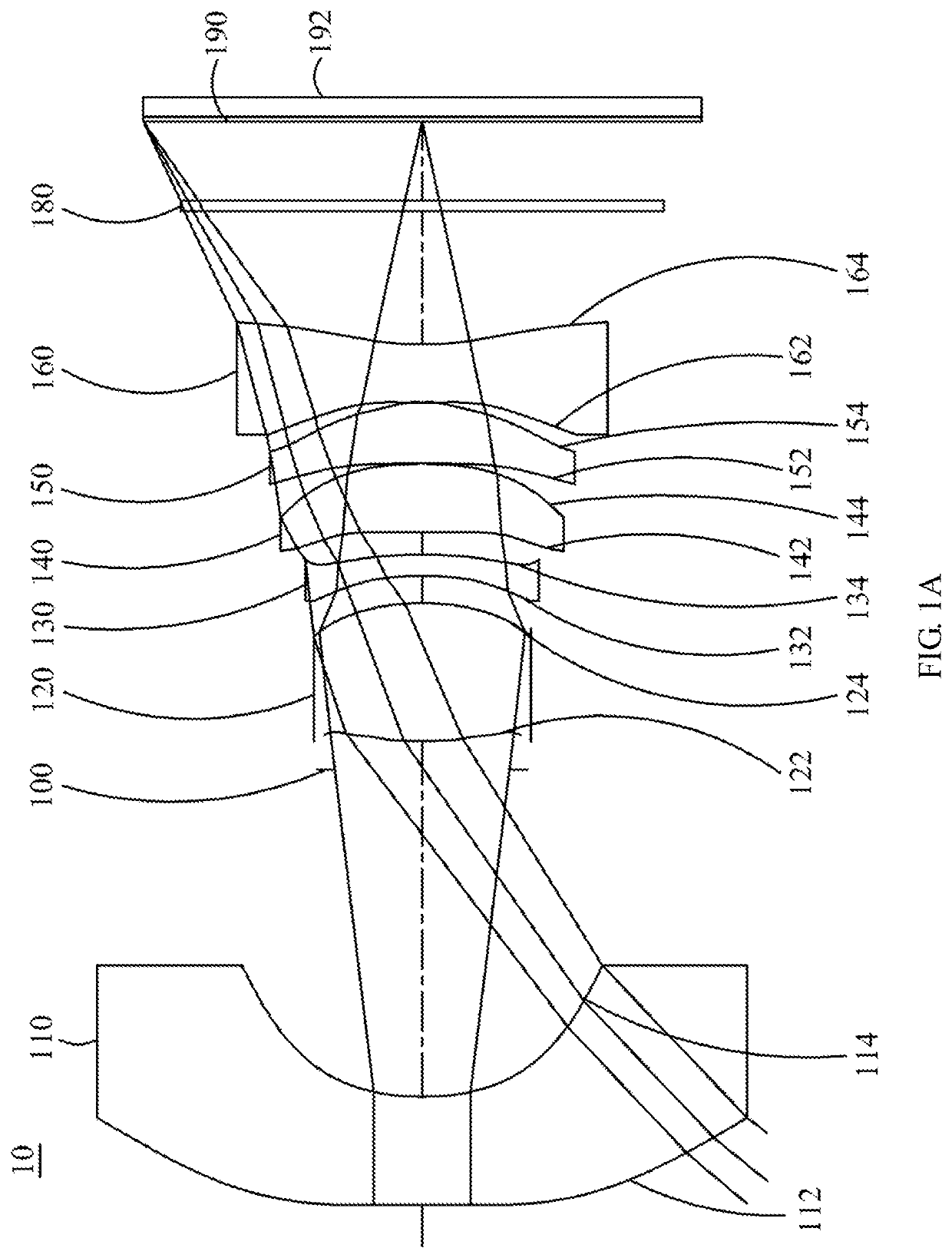

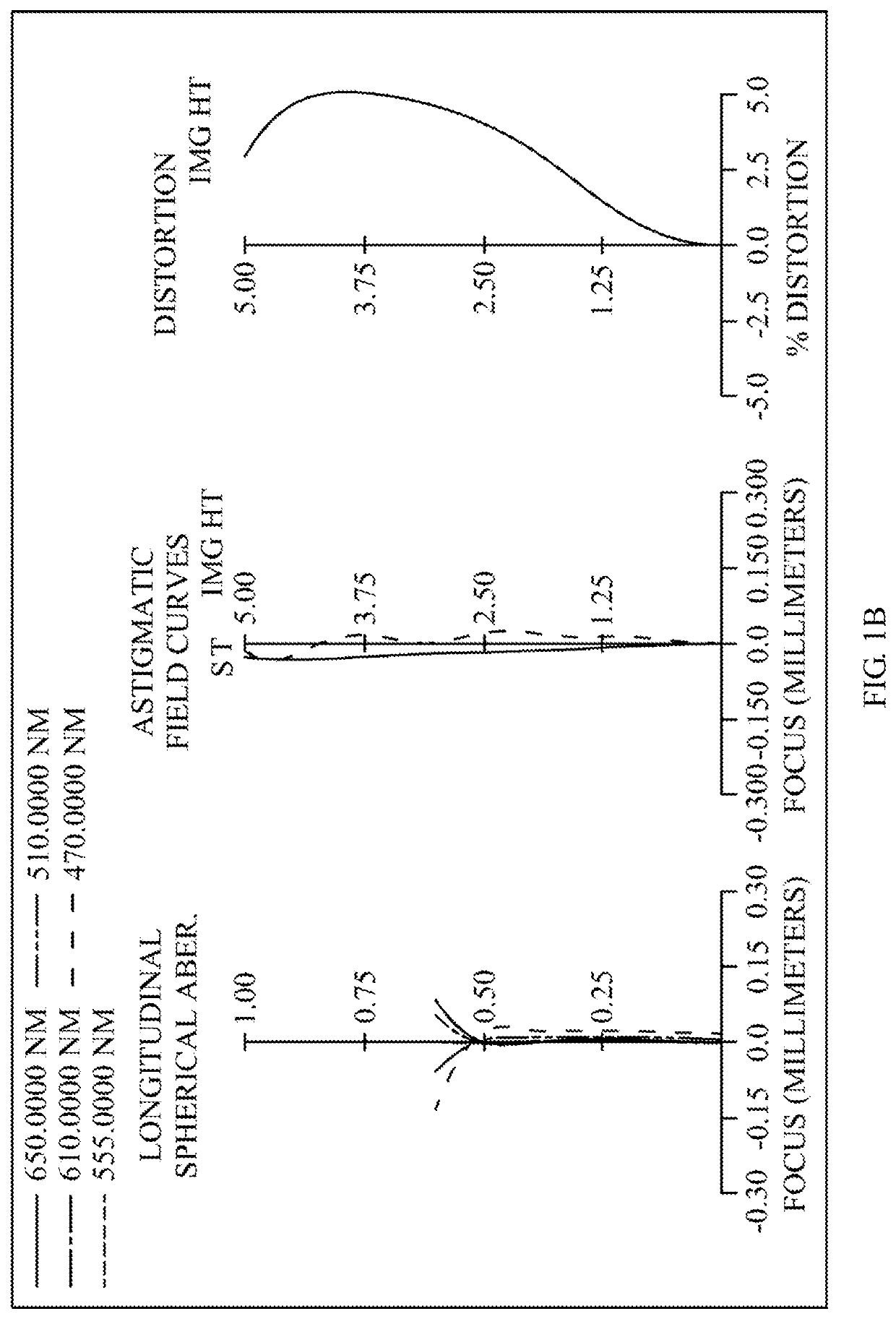

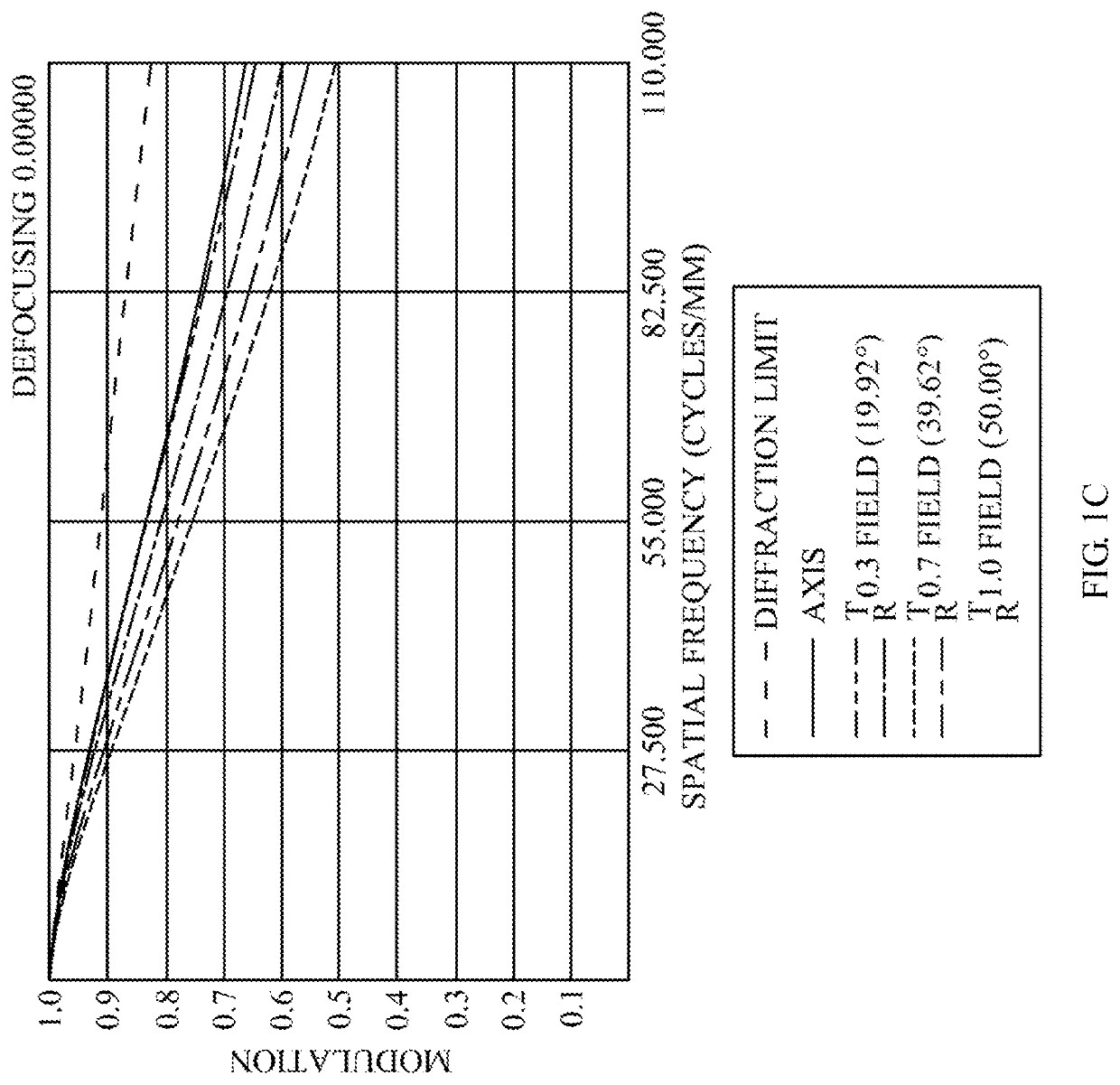

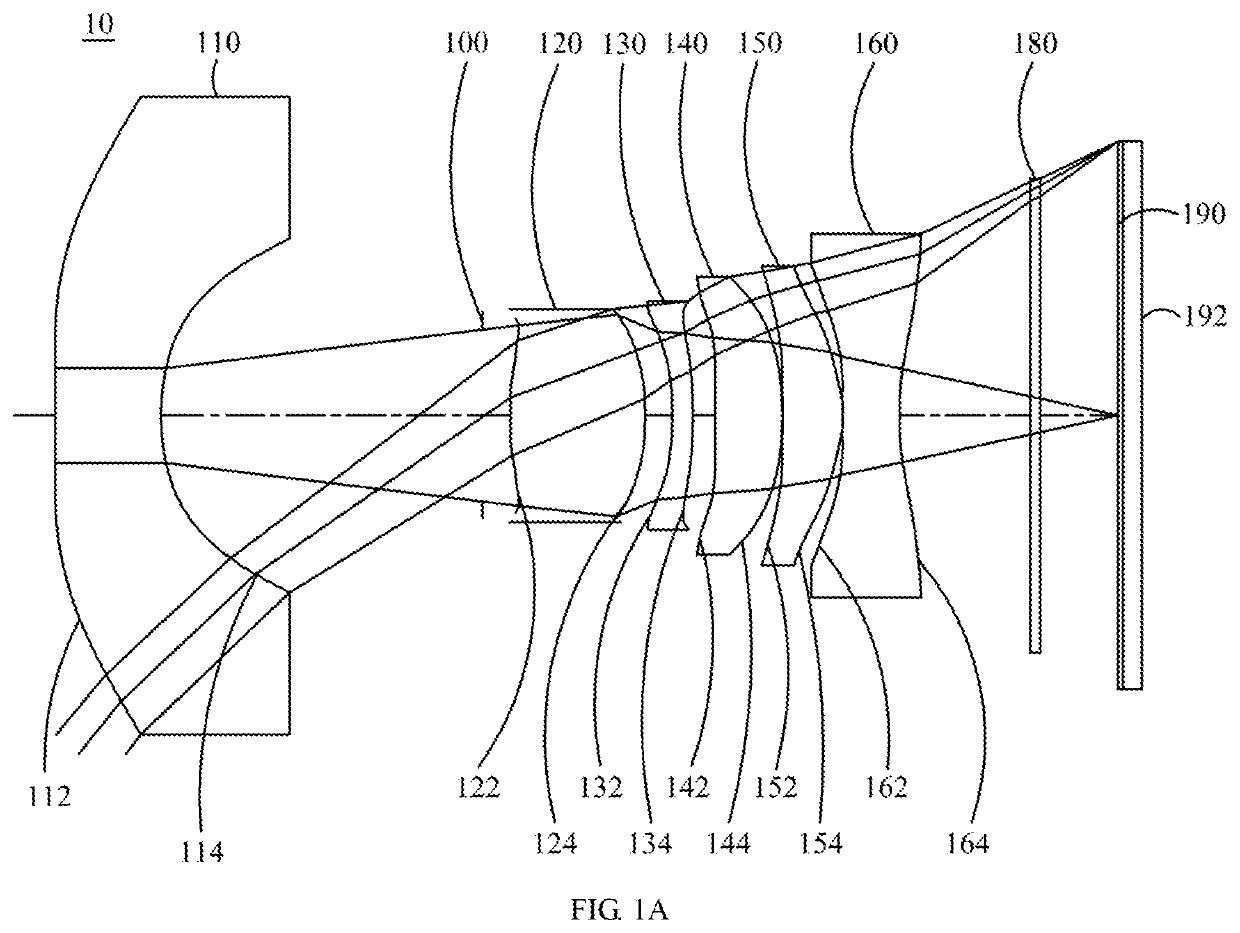

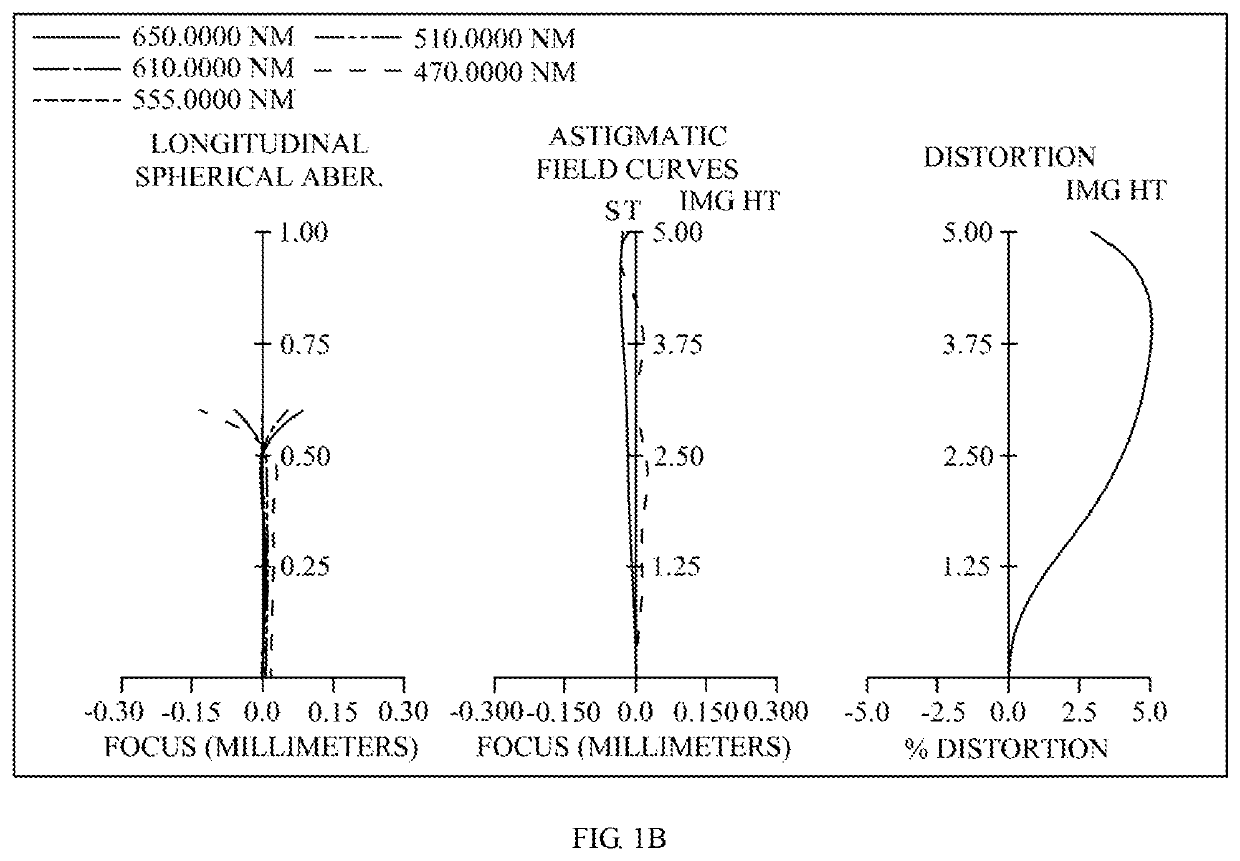

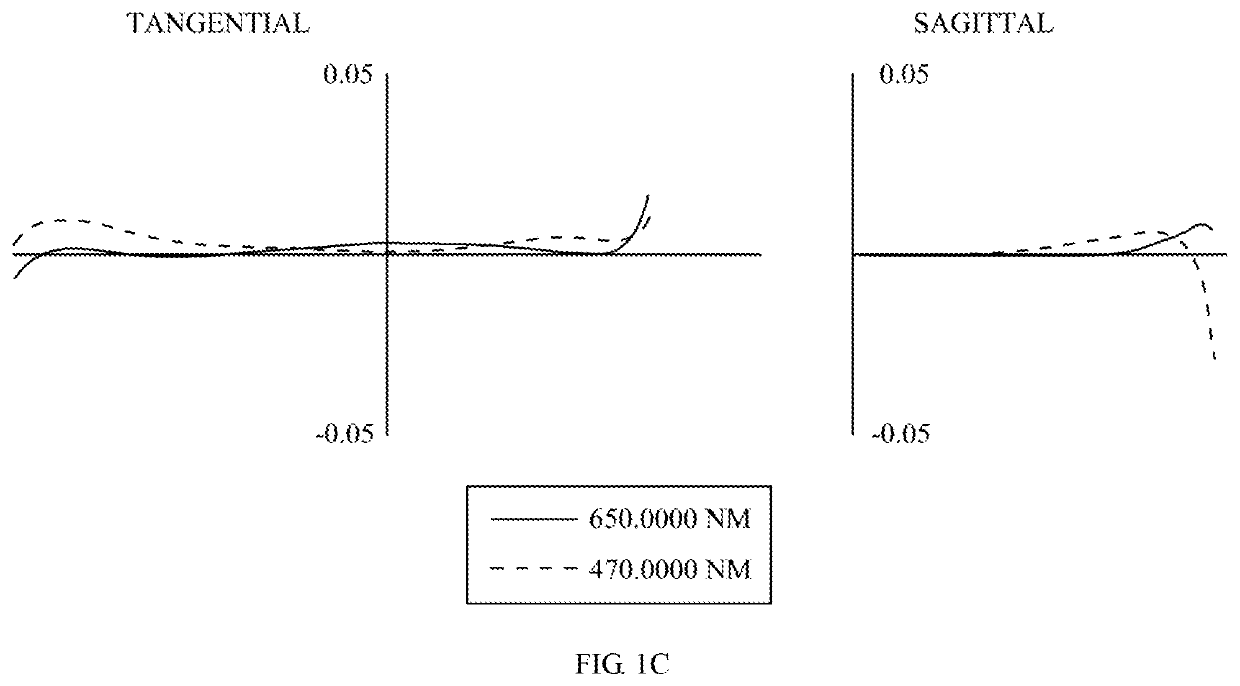

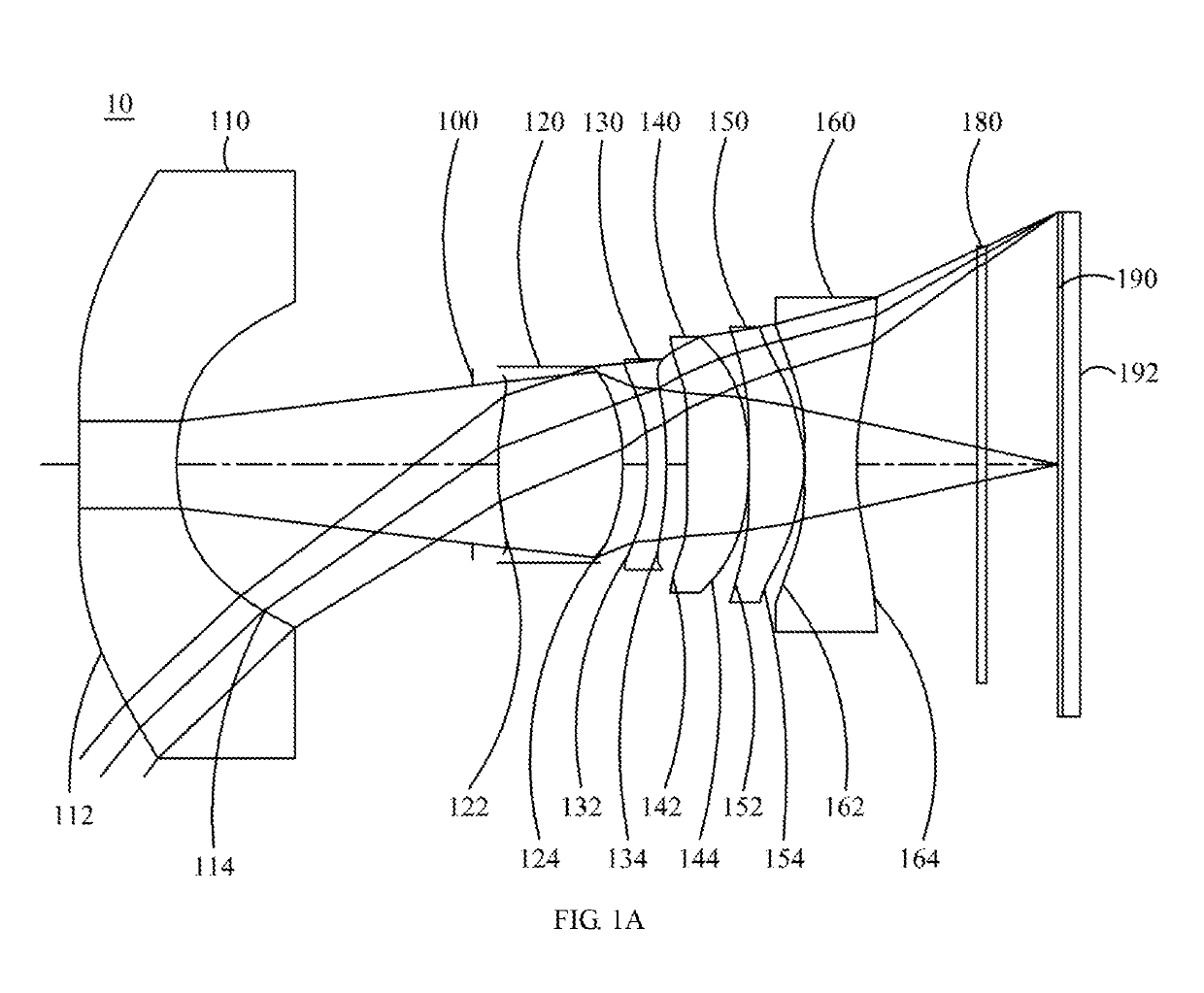

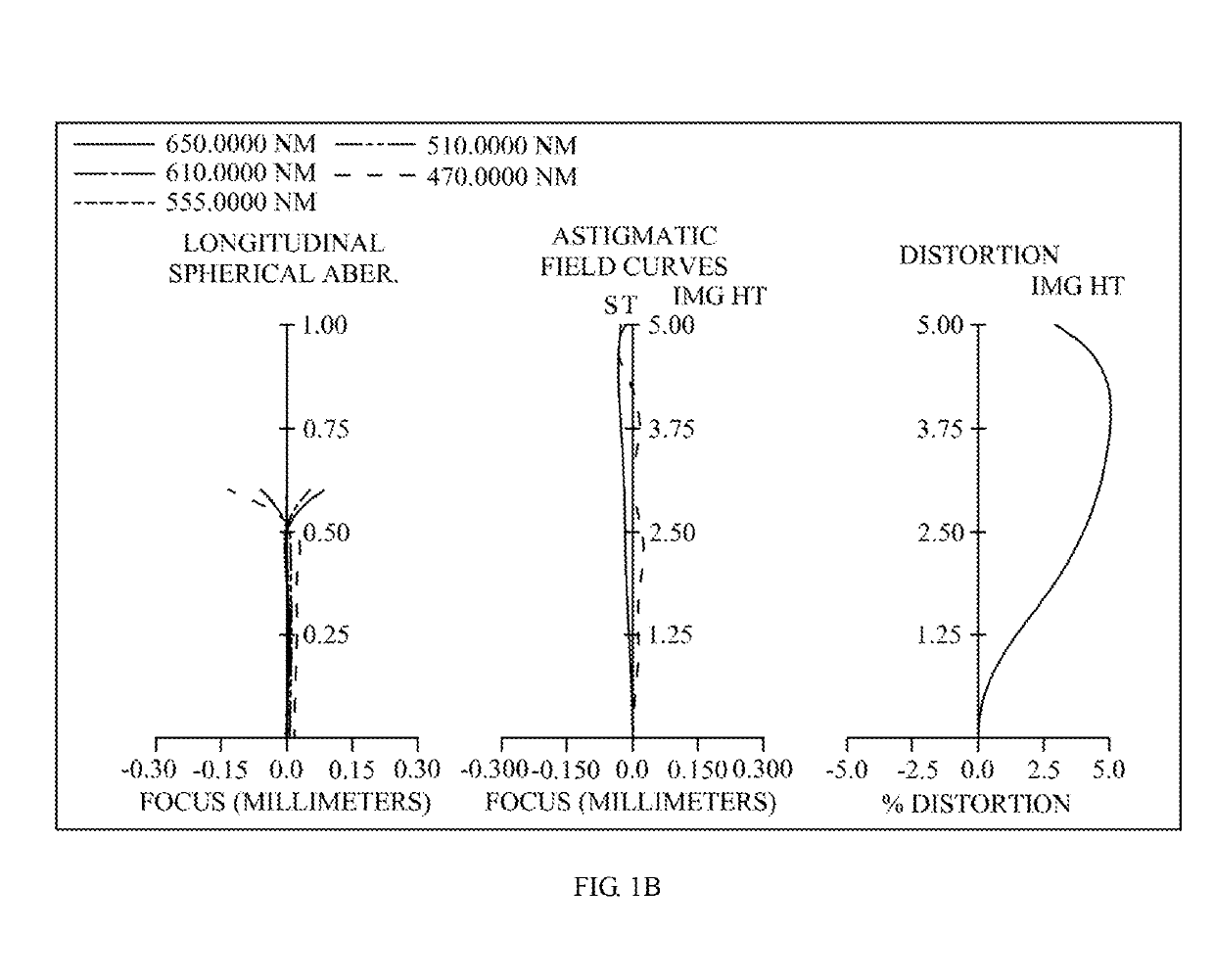

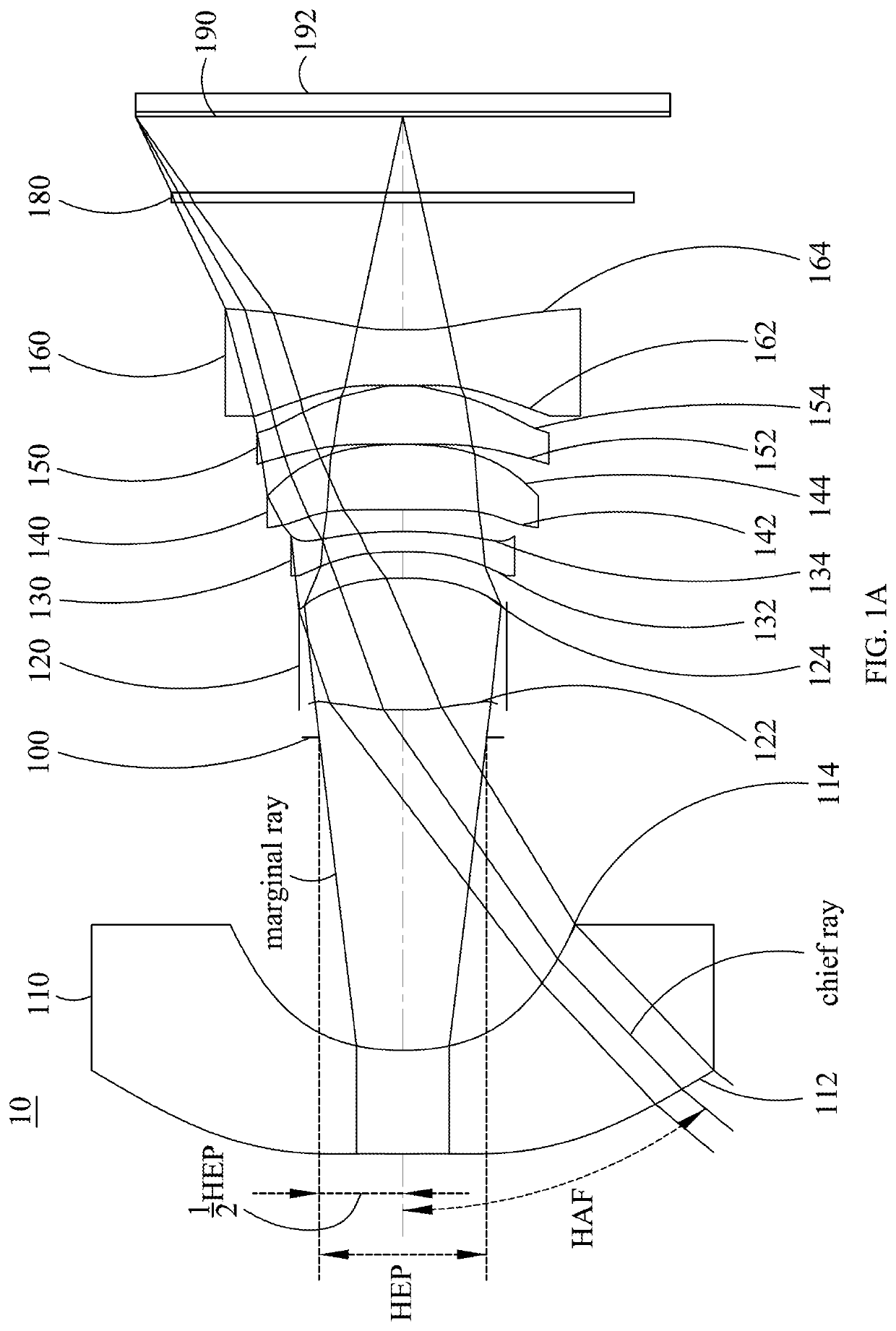

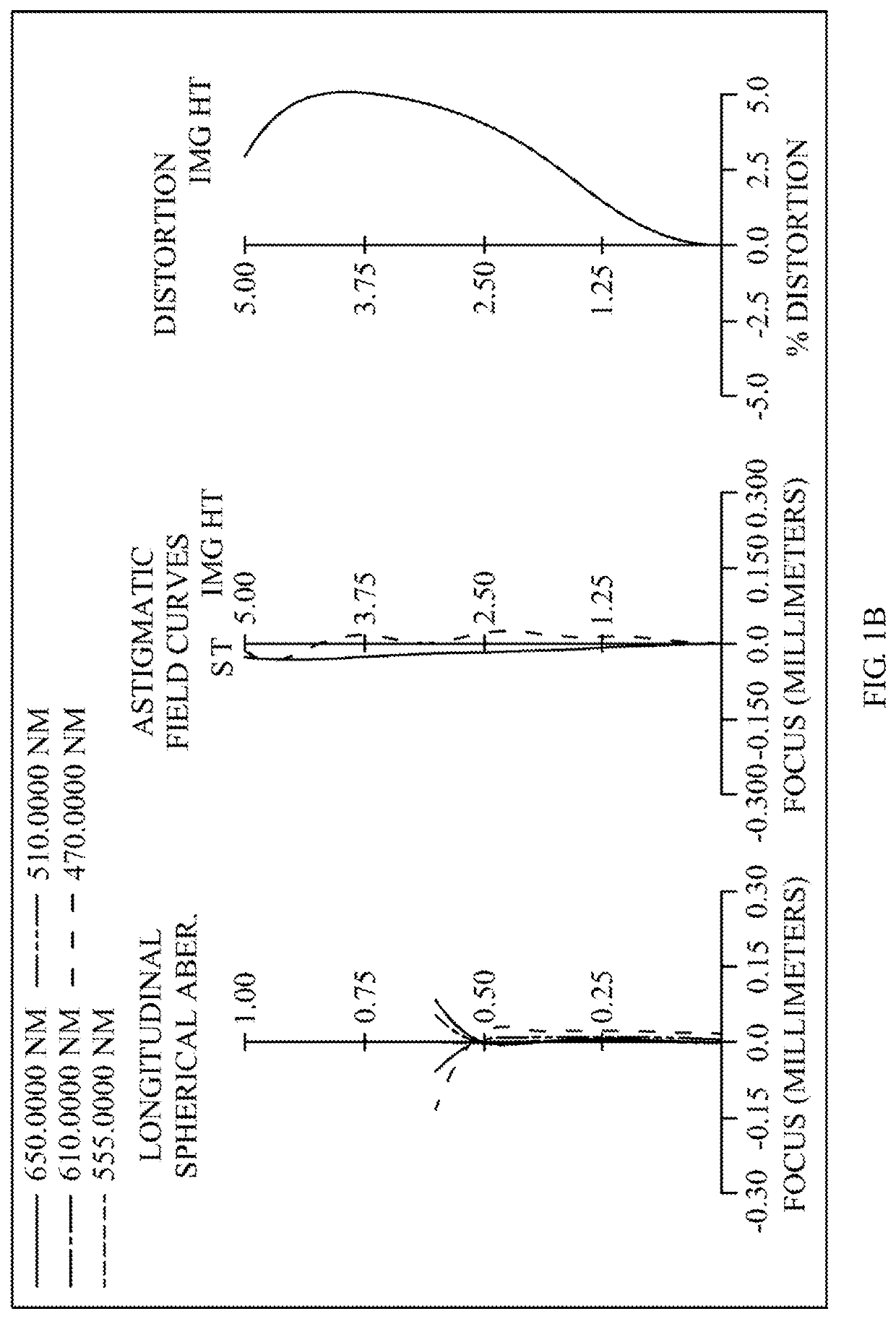

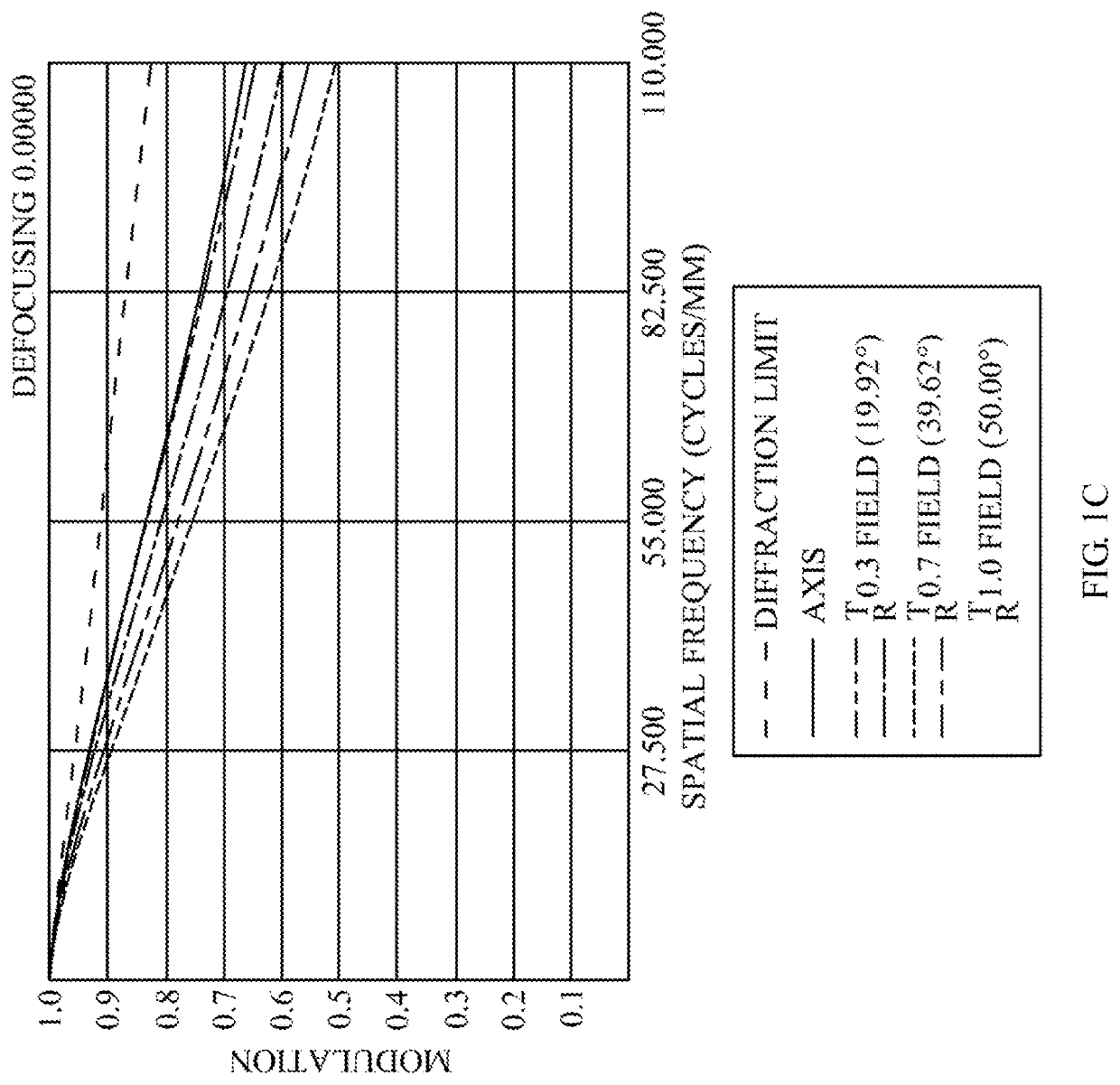

Six lens optical image capturing system having visible and infrared image planes

ActiveUS10816765B2Increase the amount of lightQuality improvementOptical elementsOphthalmologyImaging quality

An optical image capturing system is provided. In order from an object side to an image side, the optical image capturing system includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens. At least one lens among the first lens to the fifth lens has positive refractive power. The sixth lens may have negative refractive power and an object side and an image side thereof are aspherical wherein at least one surface of the sixth lens has an inflection point. The optical image capturing system has six lenses with refractive power. When meeting some certain conditions, the optical image capturing system may have outstanding light-gathering ability and an adjustment ability about the optical path in order to elevate the image quality.

Owner:ABILITY OPTO ELECTRONICS TECH

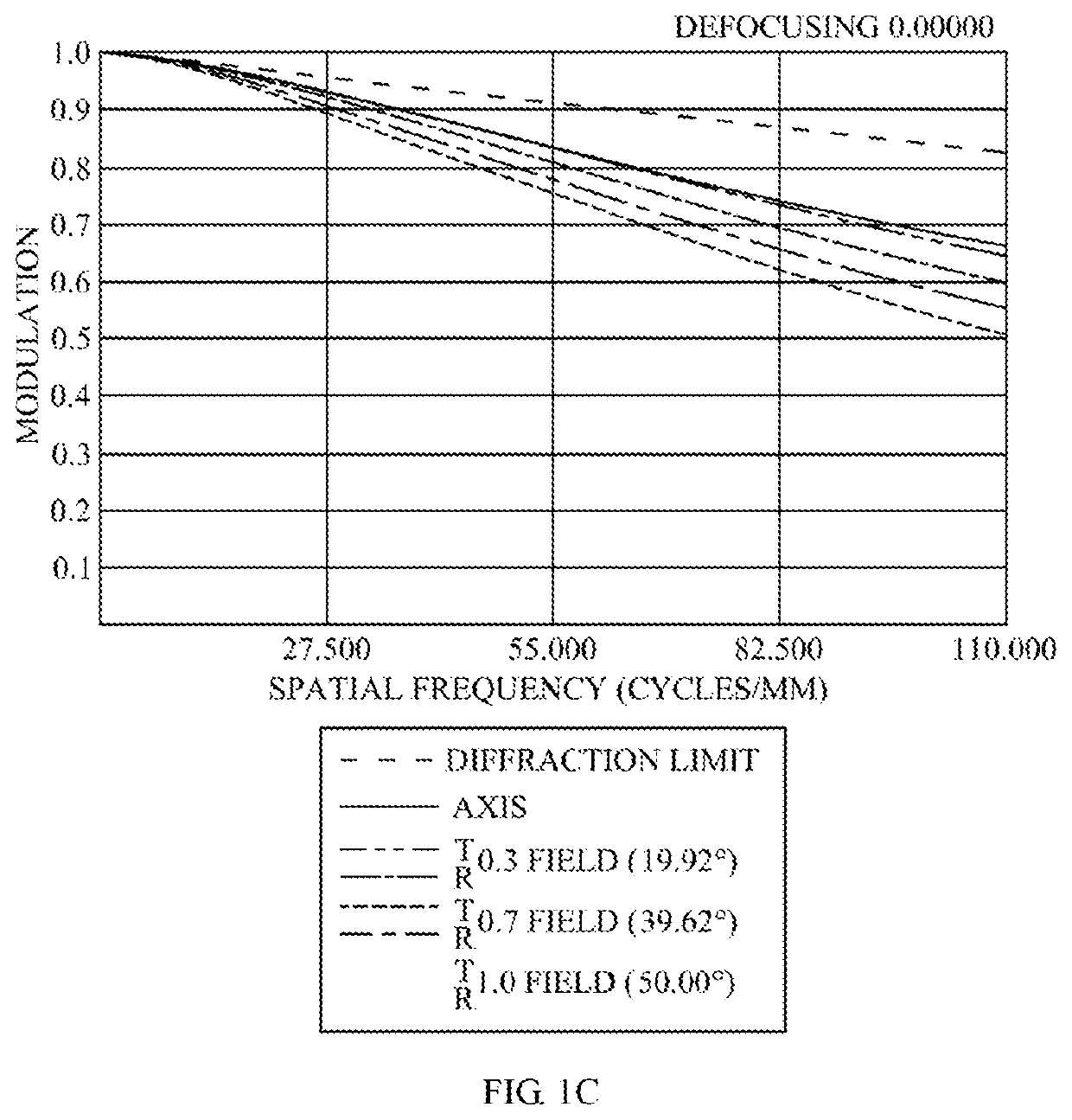

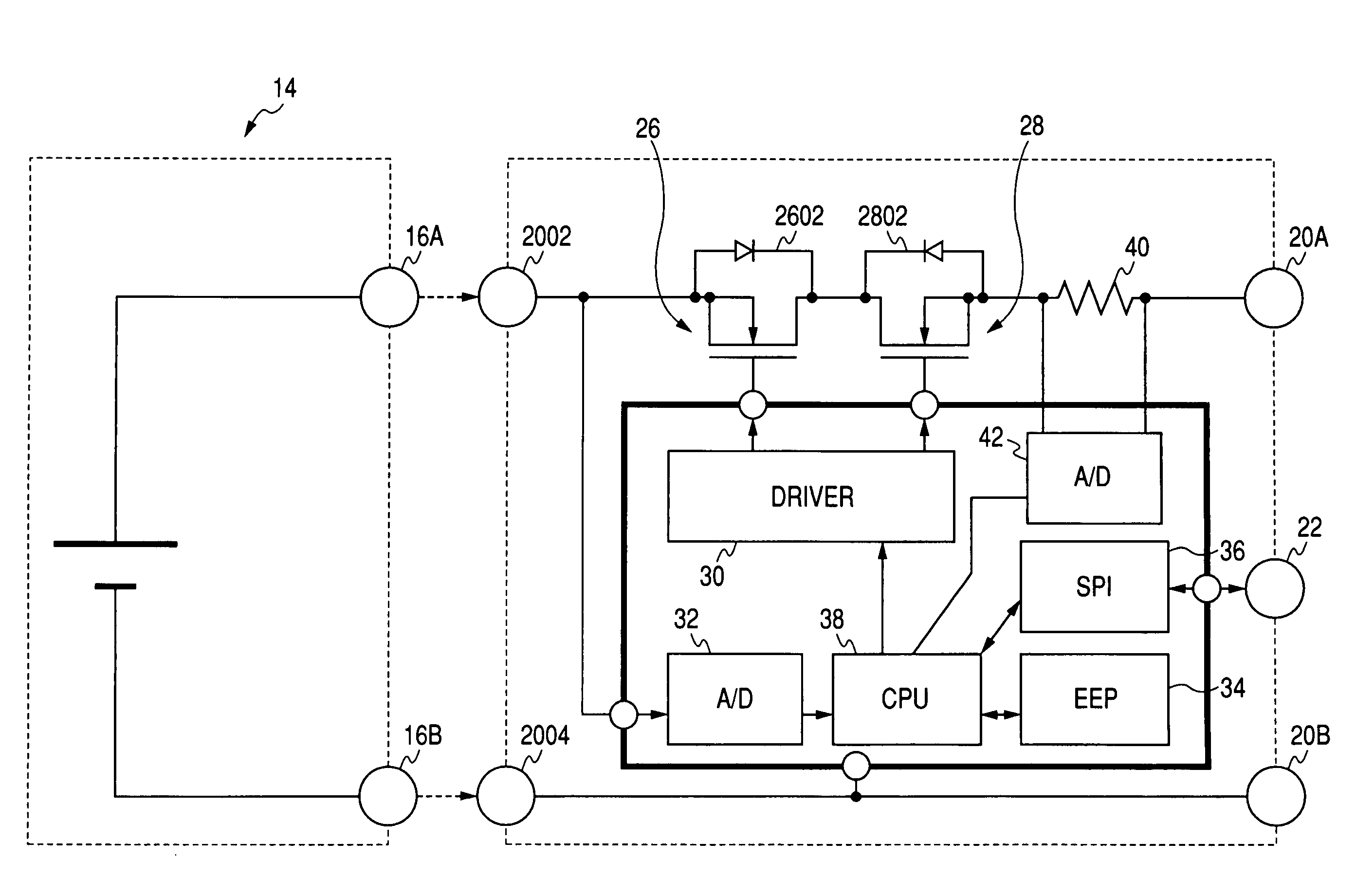

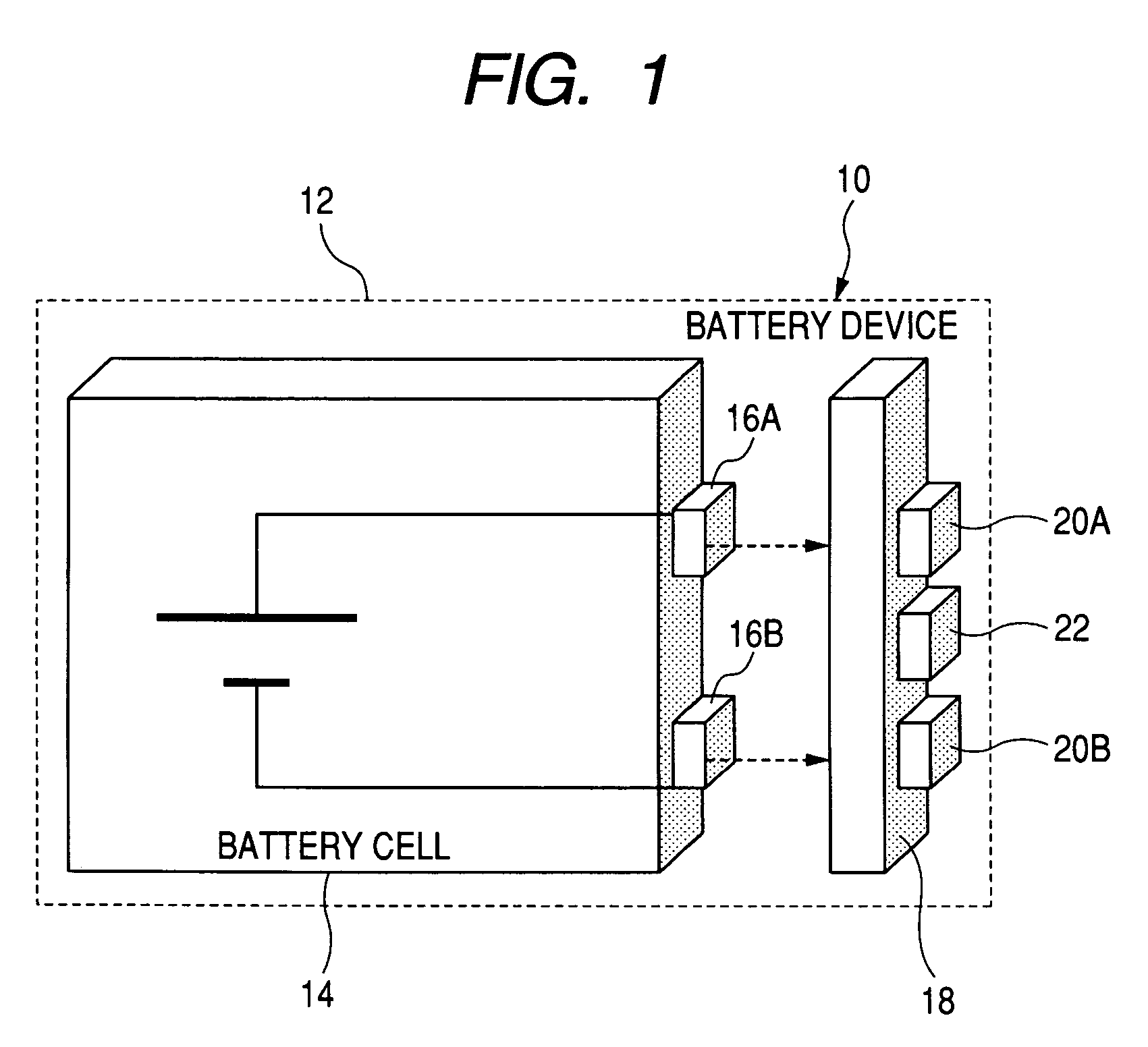

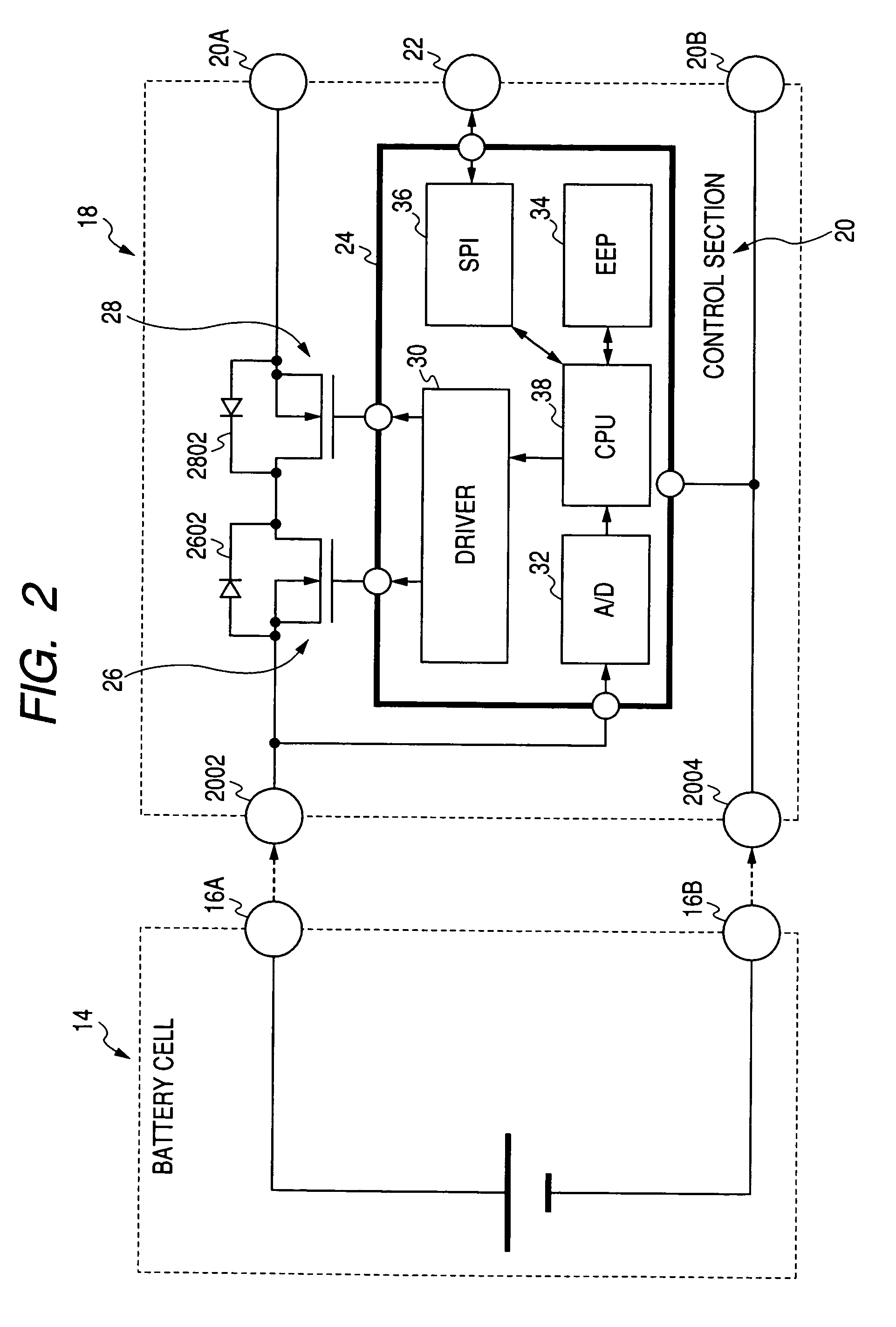

Battery device

InactiveUS7723949B2Avoid manufacturingAvoid distributingCells structural combinationSecondary cells charging/dischargingElectricityElectrical battery

A battery device includes a battery cell including a cell terminal, a case that houses the battery cell, a battery terminal provided to the case and electrically connected to the cell terminal, and a control section that is housed in the case and allows and inhibits charge and discharge of the battery cell, wherein the control section includes a detection section that detects an output voltage value of the cell terminal at an interval, and assuming that the latest output voltage value detected by the detection section is V1, and the output voltage value detected by the detection section immediately before the latest output voltage value V1 is V0, the control section allows charge and discharge of the battery cell if |ΔV| (ΔV=V1−V0) is smaller than a reference value, and to inhibit charge and discharge of the battery cell if |ΔV| is equal to and greater than the reference value.

Owner:SONY CORP

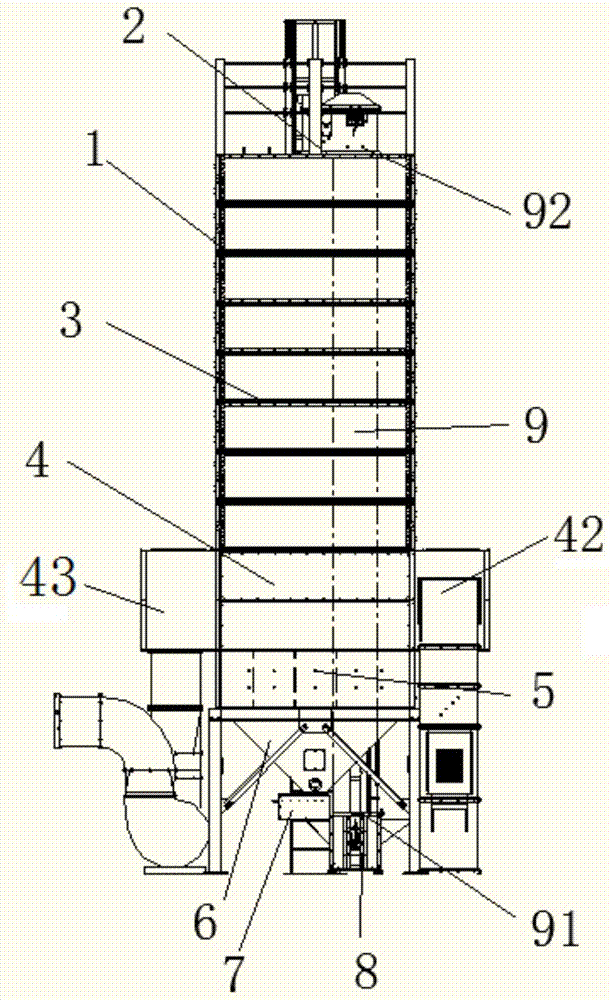

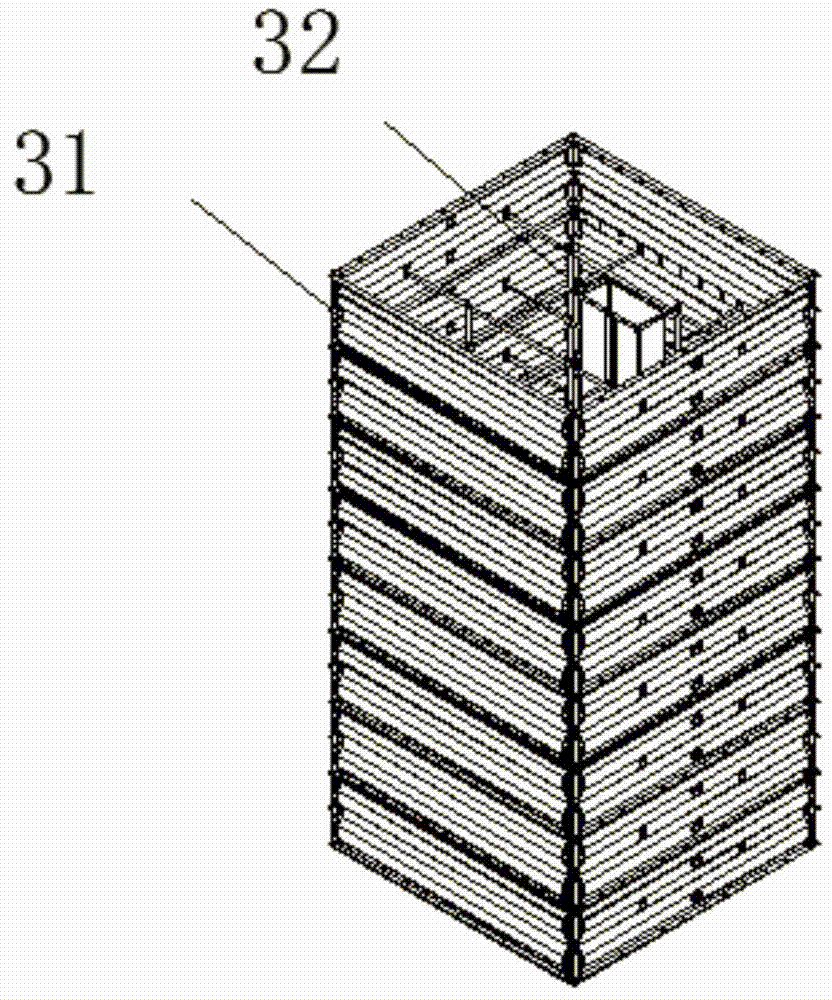

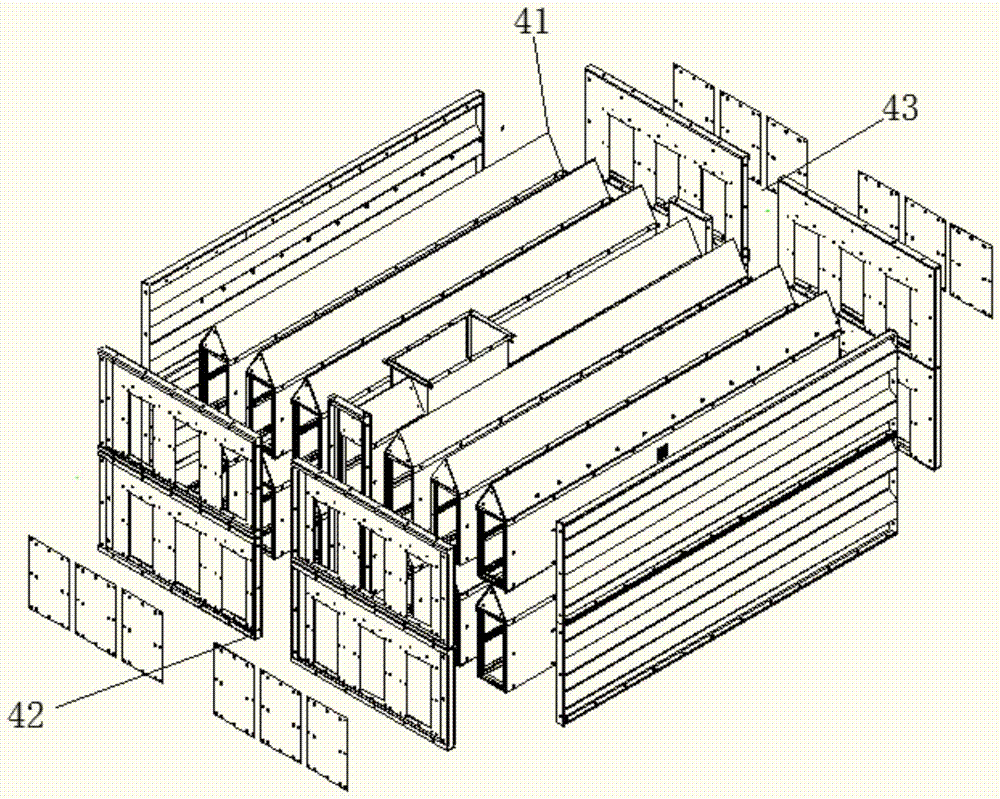

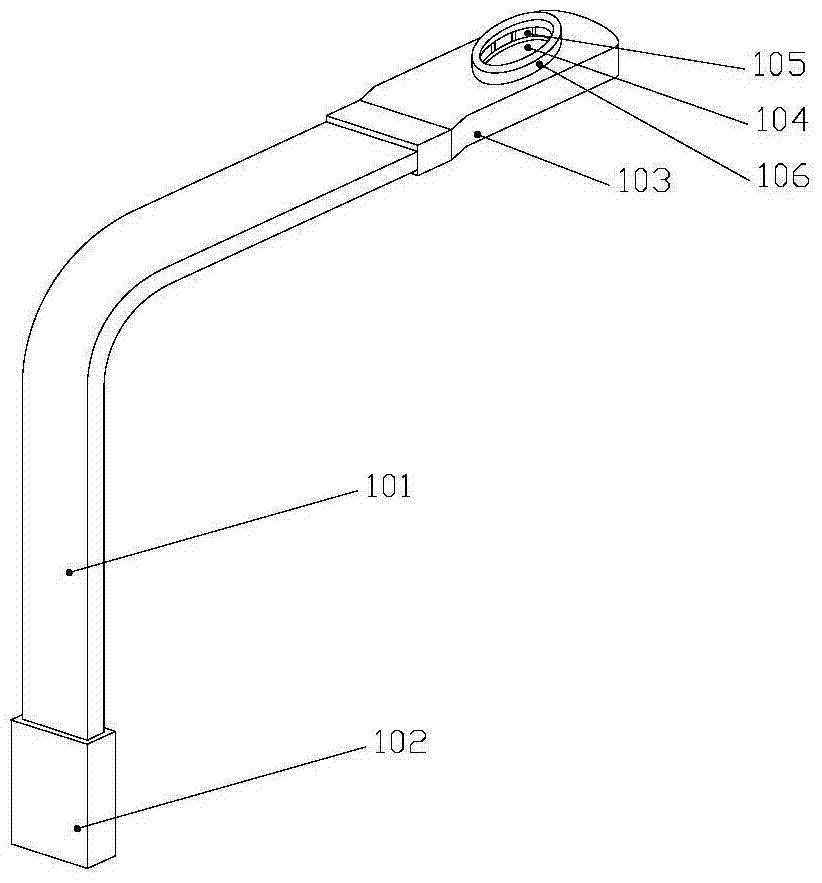

Novel batched type circulated drying machine

InactiveCN107091568AReduce the use effectImprove cycle efficiencyDrying gas arrangementsDrying solid materialsMechanical engineering

The invention discloses a novel batched type circulated drying machine applied to the production field. The novel batched type circulated drying machine structurally comprises a shell, the shell is internally provided with a feeding opening, a storing part, a drying layer and a discharging device from top to bottom, the discharging device comprises a discharging inlet connected with the drying layer and a discharging outlet connected with a discharging hopper, the discharging hopper comprises a discharging opening provided with a three-way gate and a three-way gate circulation outlet, and the three-way gate circulation outlet is connected with a machine tail feeding hopper; and a lifting machine for lifting materials in the machine tail feeding hopper to the position above the storing part is arranged in the shell. According to the novel batched type circulated drying machine, the lifting machine is arranged in the shell, and the materials falling to the bottom are transported to the upper portion of the shell and are then scattered to be circulated for drying operation. The lifting machine is directly arranged, extra application of conveying equipment like material transferring equipment is avoided, the production cost is reduced, the number of equipment maintaining points is decreased, and the working efficiency of the drying machine is greatly improved.

Owner:GSS SYST SUZHOU

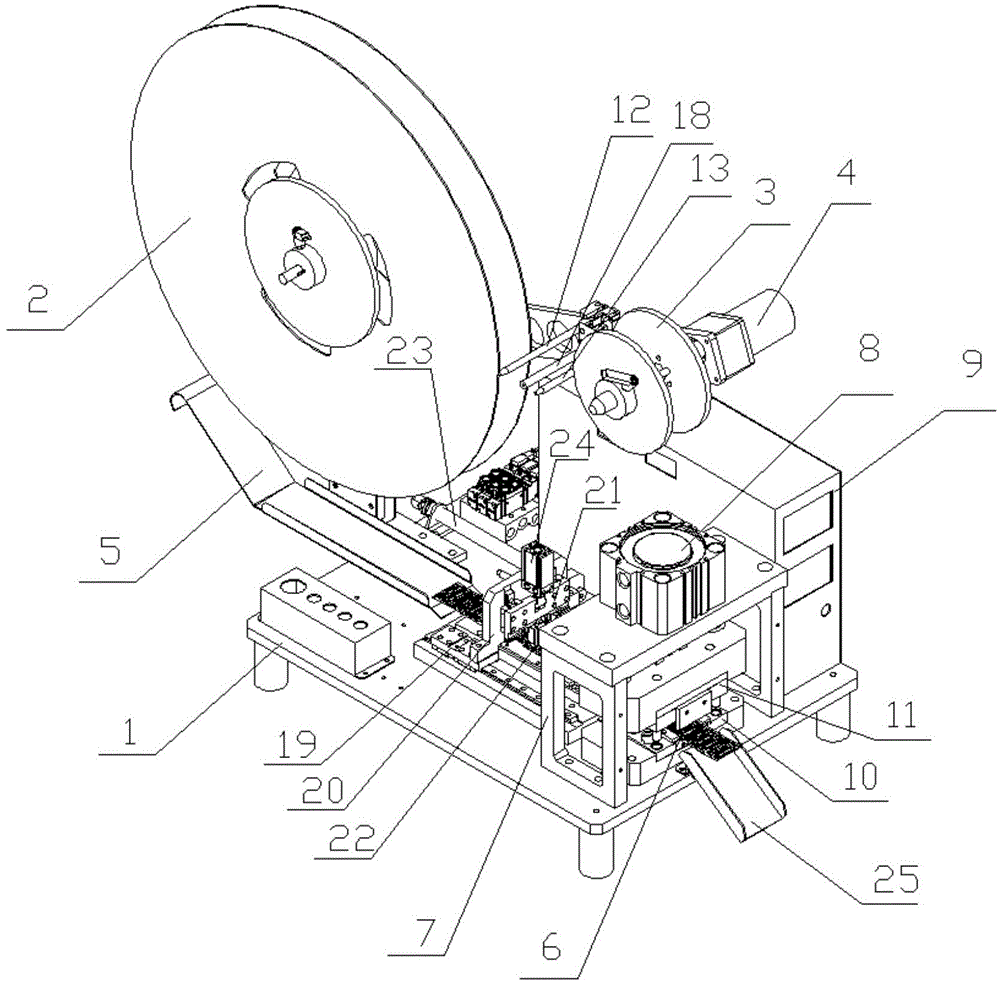

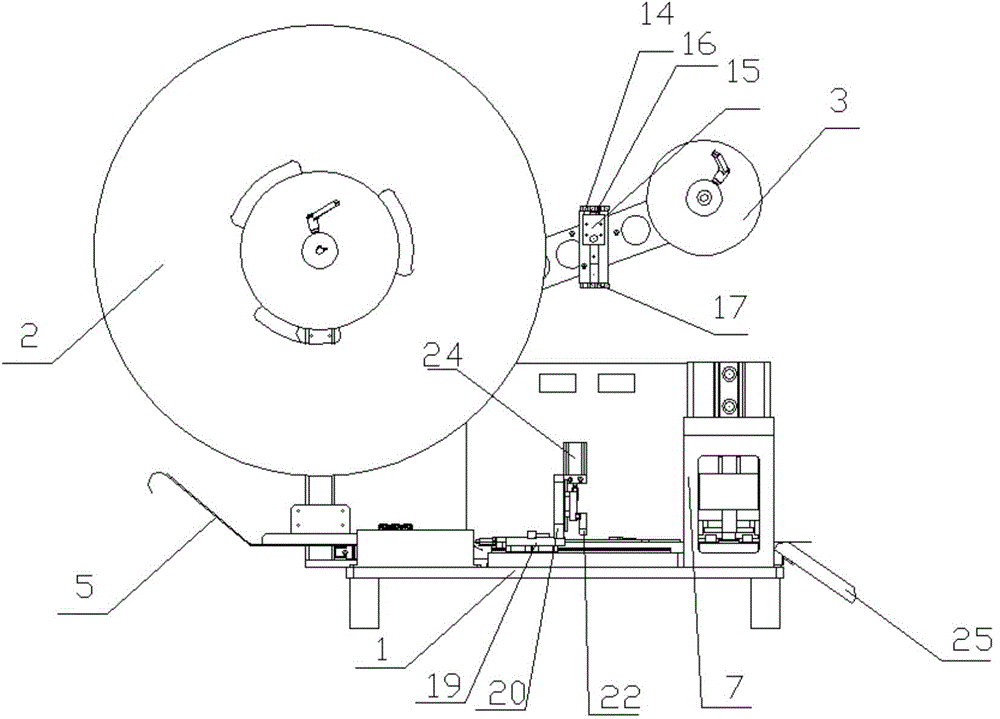

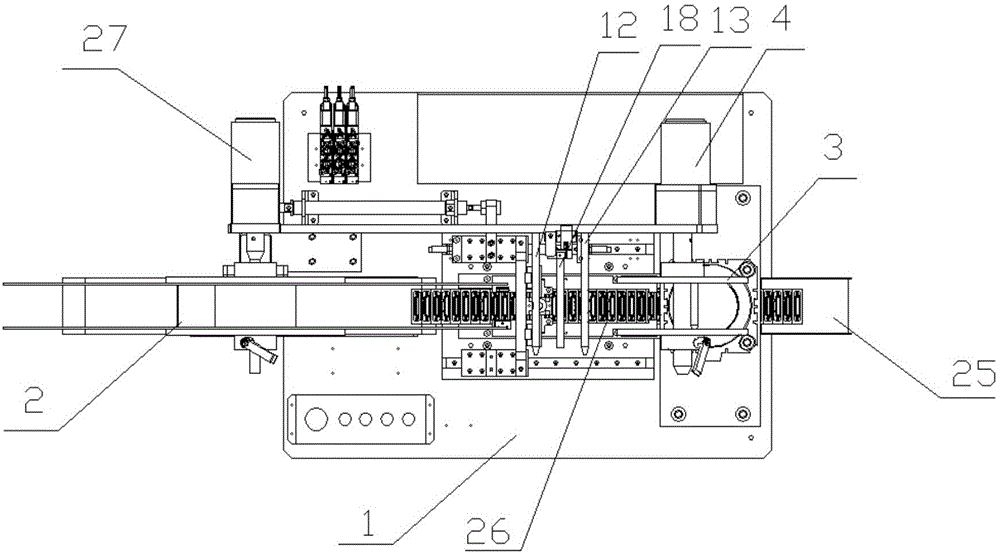

Sheet cropping equipment

InactiveCN105458061AAvoid manufacturingReduce production costsMetal-working feeding devicesStripping-off devicesEngineeringMultiple function

The invention discloses sheet cropping equipment. A material plate is driven by a material plate driving device to rotate. A paper plate is driven by a paper plate driving device to rotate. A paper tape tensioning state inducing device can induce the tension condition of a material strap which is drawn out of the material plate to enter the paper plate and transmit information to a controller. A material strap track is exactly located right below the material plate and connected with a material conveying channel. The material plate, a material plate support, the material strap and the material strap track can form a conduction loop to be electrically connected with the controller. The material plate support is connected with a lower-voltage power source. A material pulling device is fixed over the material conveying channel. A material pulling driving device can drive the material pulling device to pull the material strap to move. A material strap channel exactly passes through a knife edge of a lower die body of a stamping die. A plunger chip is arranged on an upper die body. The upper die body is driven by a stamping driving device to move longitudinally. The controller controls actions of all devices. According to the sheet cropping equipment, multiple functions are achieved through the equipment; the production cost is reduced; the production efficiency is improved; deformation of products is avoided due to the fact that the products are not tensioned by a paper tape, and the defective rate of the products is decreased.

Owner:昆山金群力精密组件有限公司

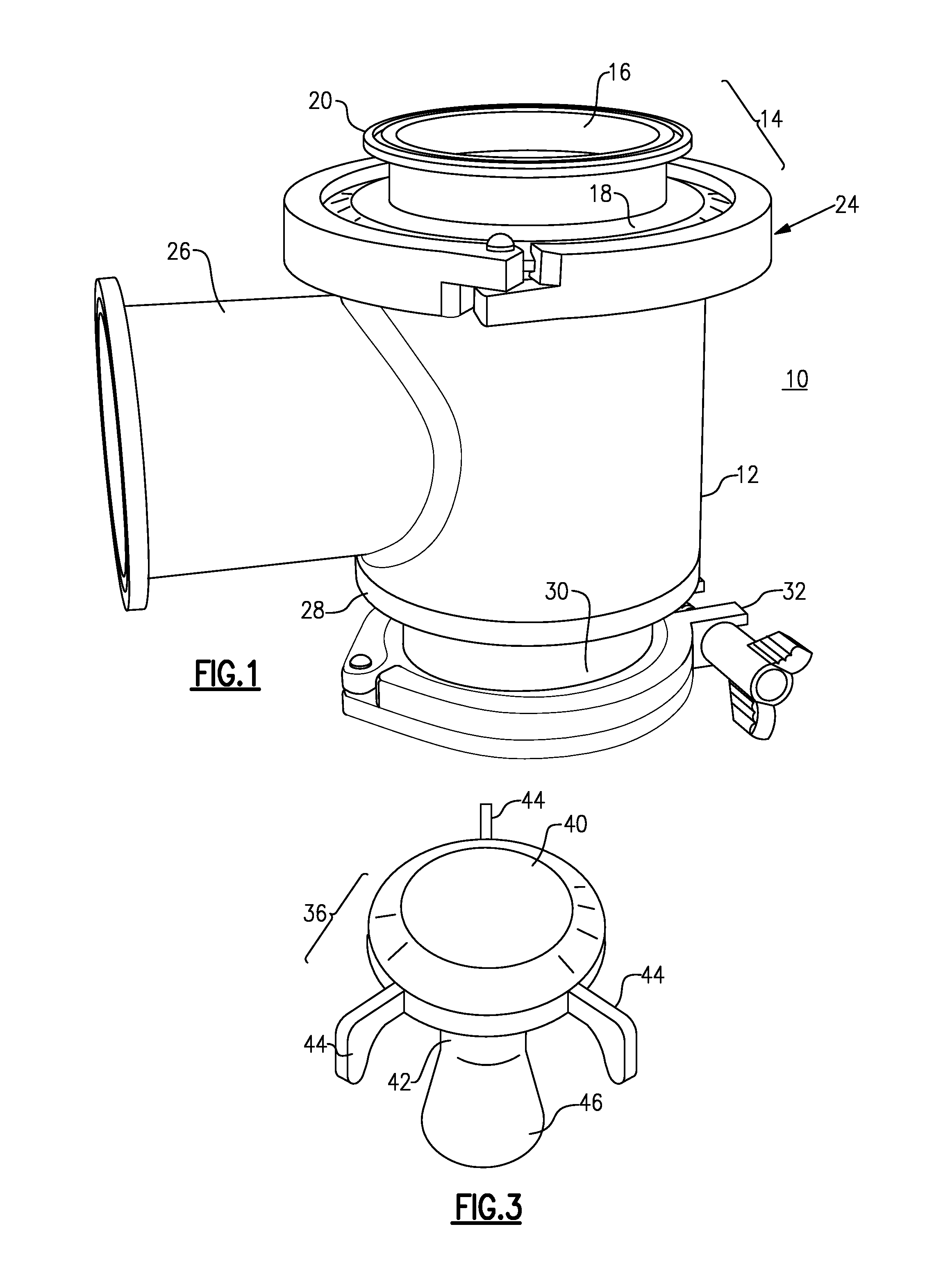

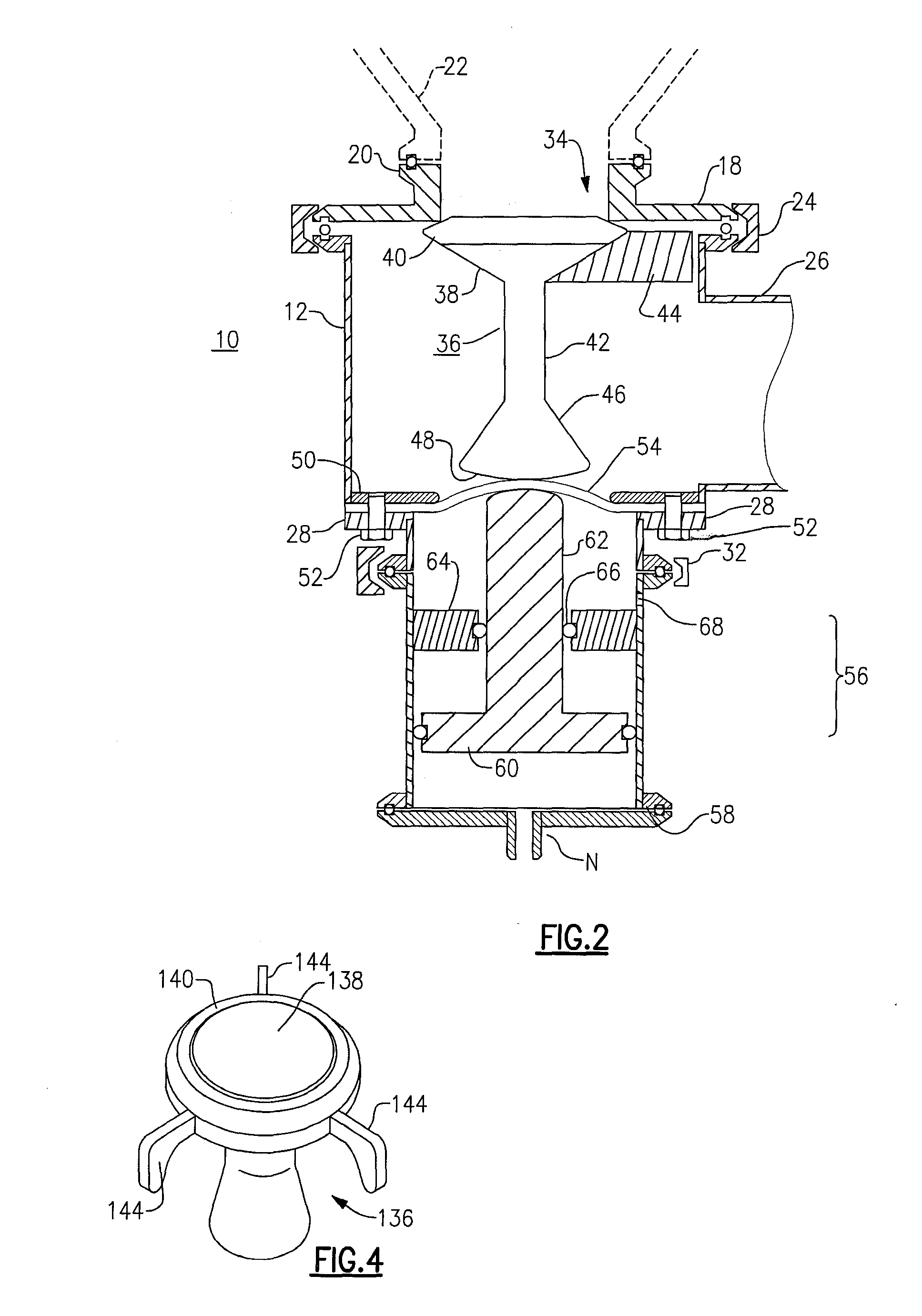

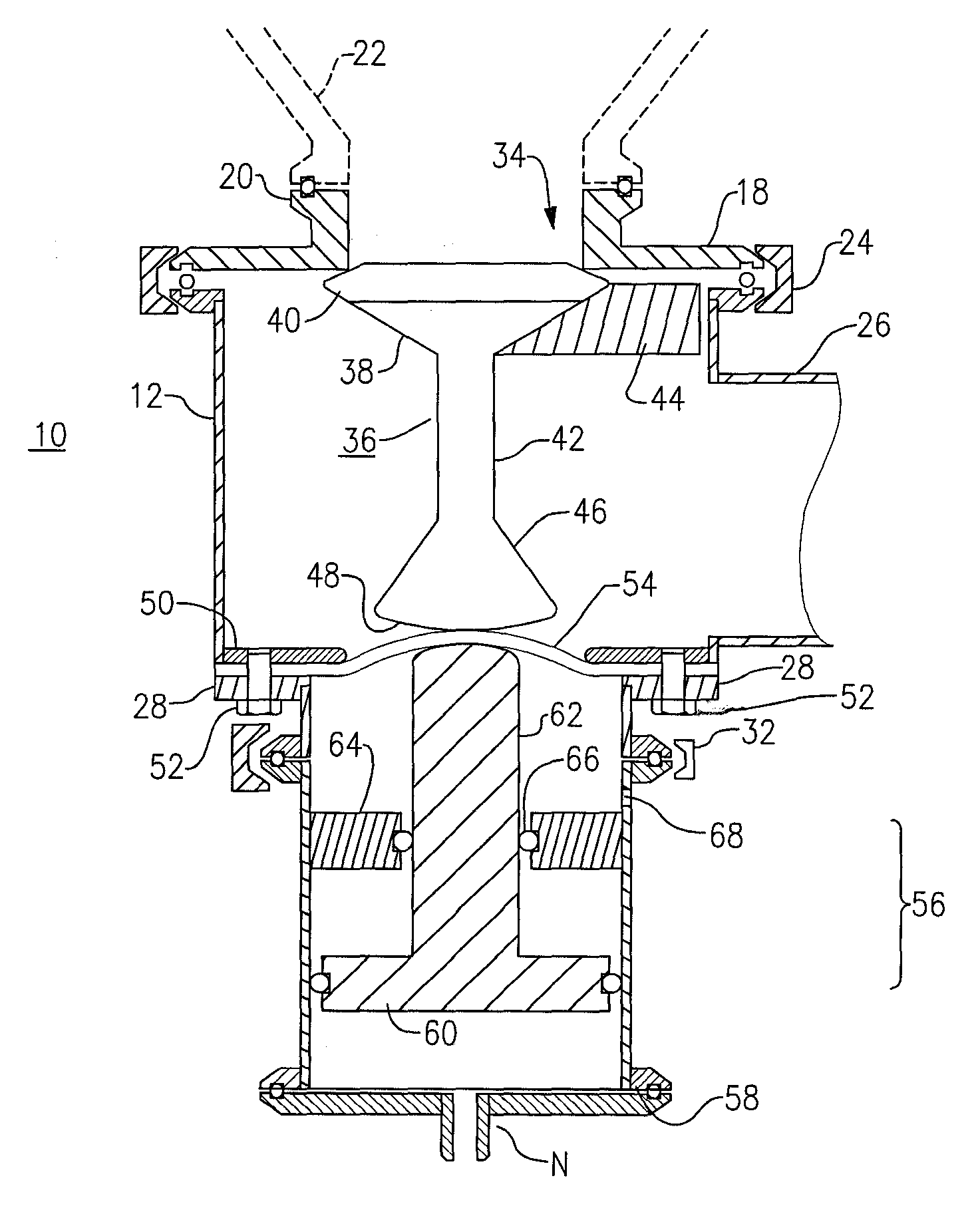

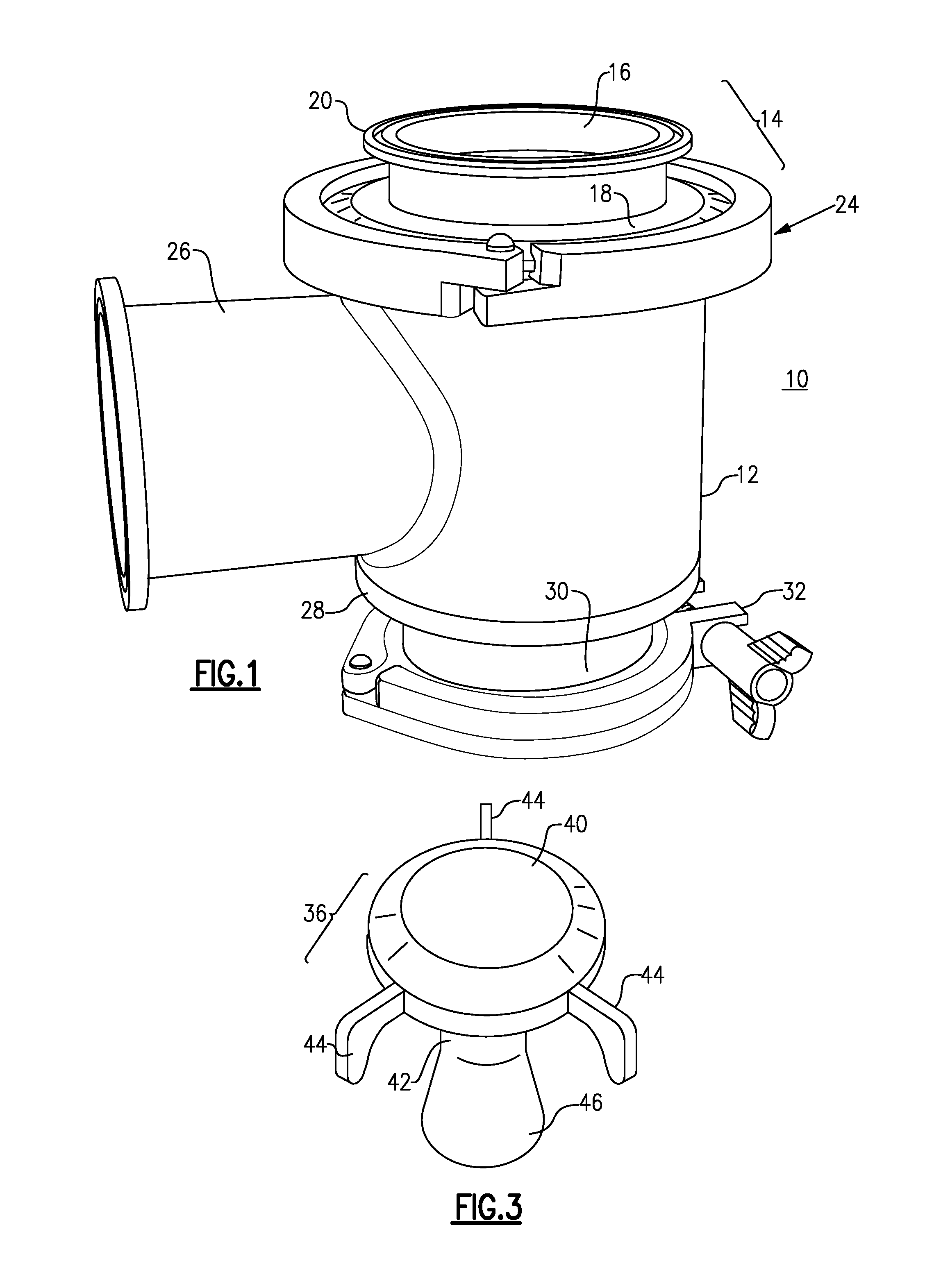

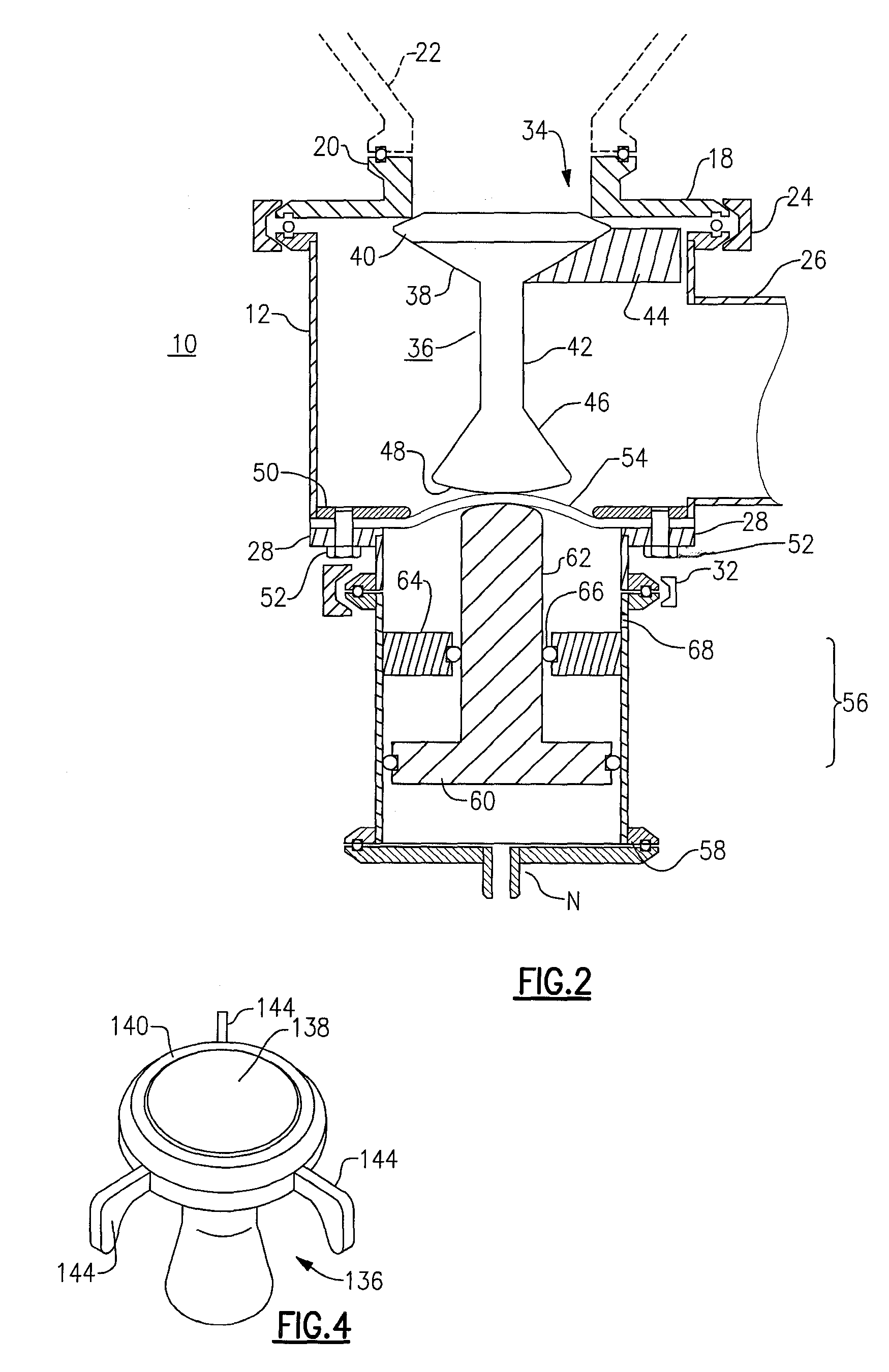

Aseptic or Sanitary Diaphragm Valve

InactiveUS20140027661A1Easy constructionSimple and reliable processSpindle sealingsDiaphragm valvesEngineeringDiaphragm valve

An aseptic valve or sanitary valve employs a floating plug situated within a cylindrical valve housing. The floating valve plug has a head that seats against an inlet opening, and has a stem and a generally conic foot that rests upon a diaphragm formed of a flexible, food-grade membrane. An actuator below the diaphragm urges the plug up to lodge against the inlet opening, and relieves force on the membrane and plug to open the valve. Spacer arms radiate from the stem or head of the plug, to keep the plug centered in the housing.

Owner:FELDMEIER EQUIP

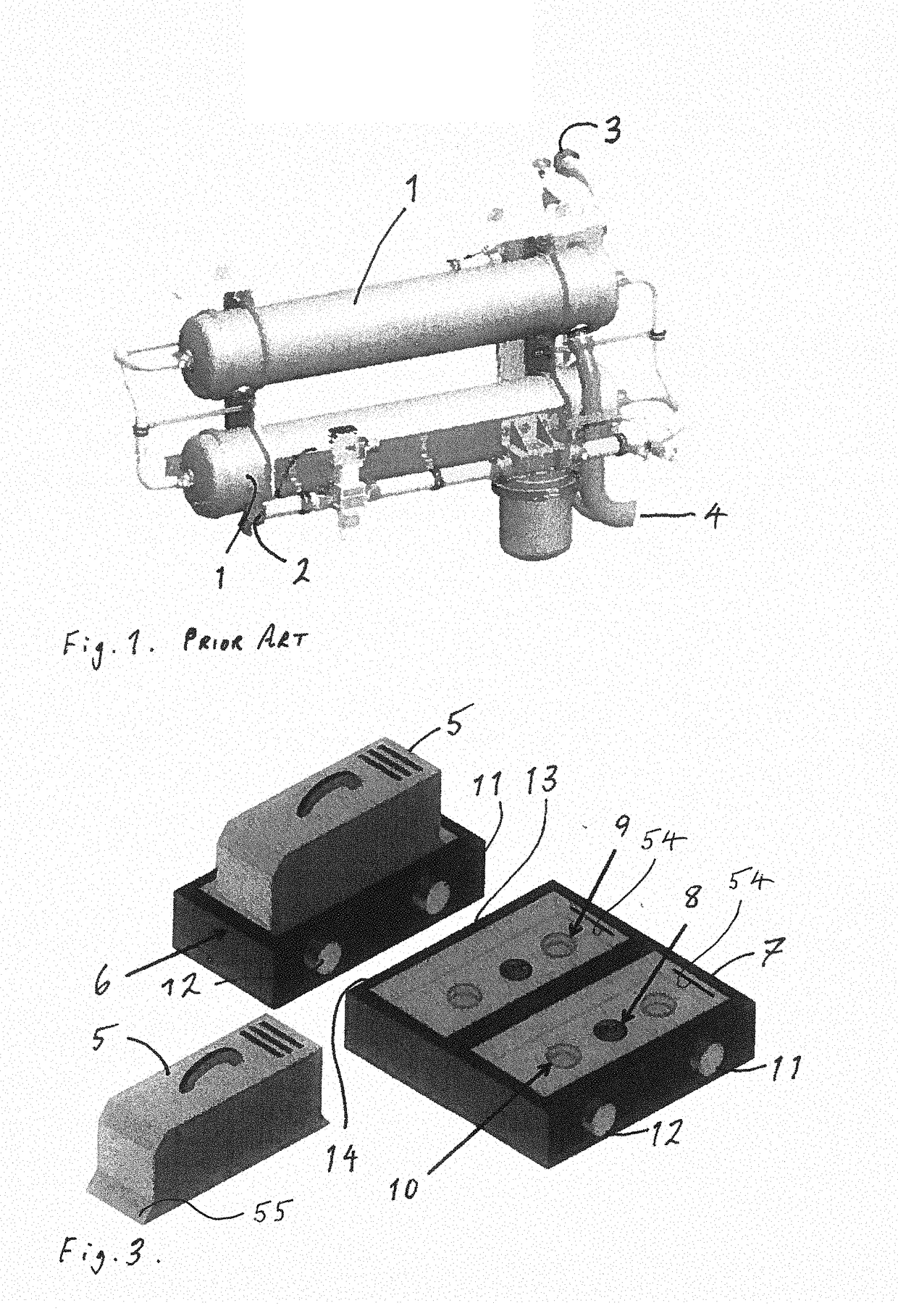

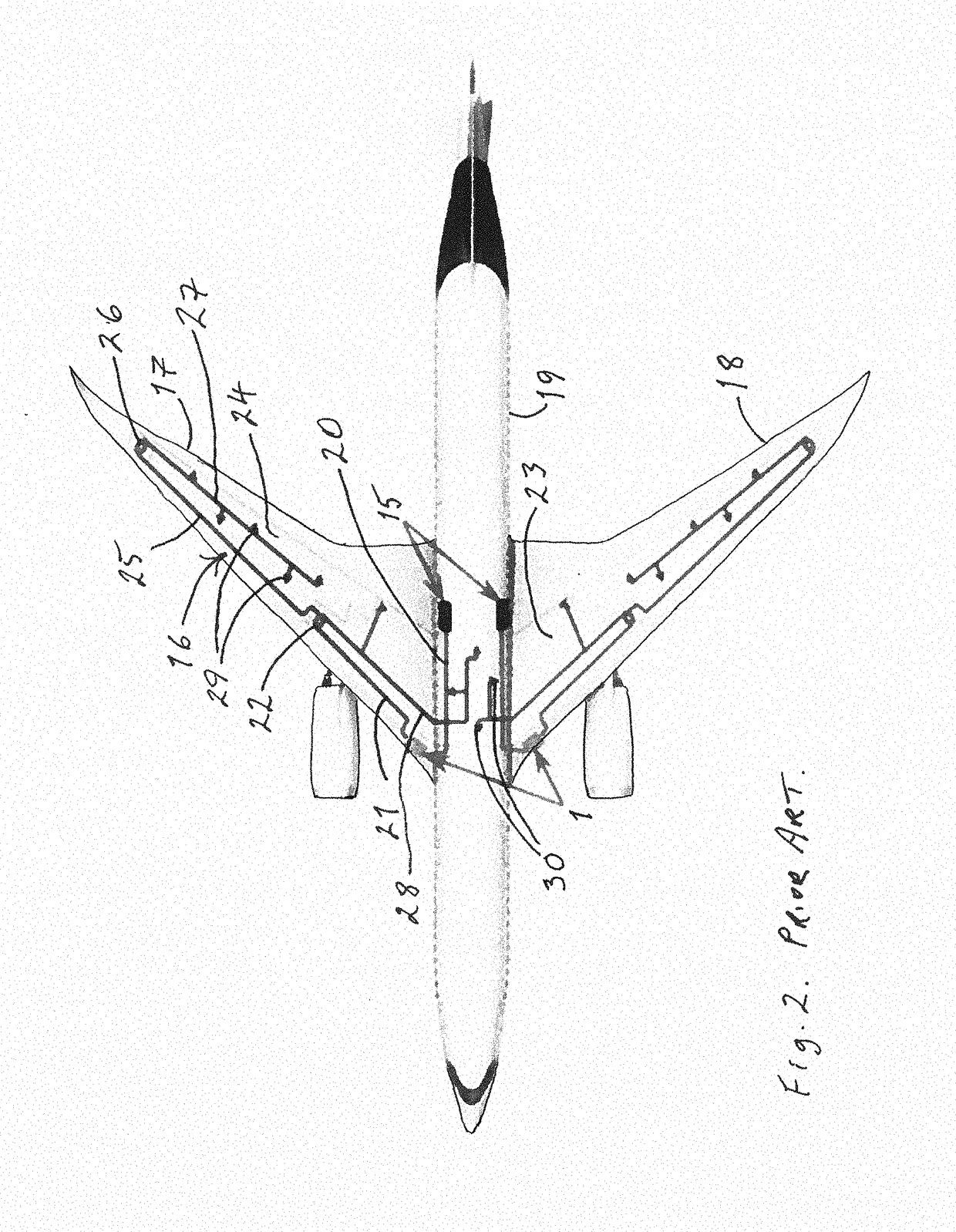

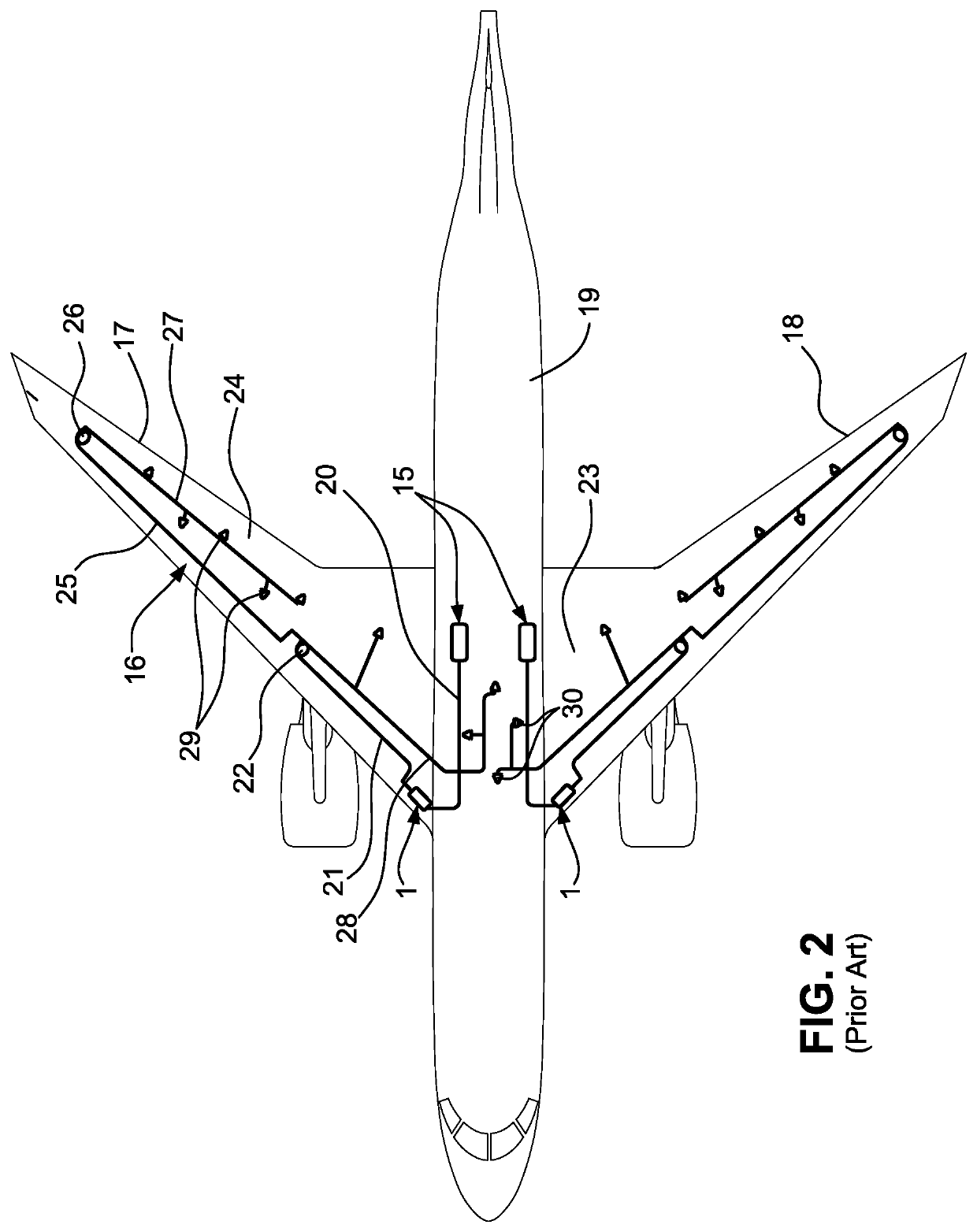

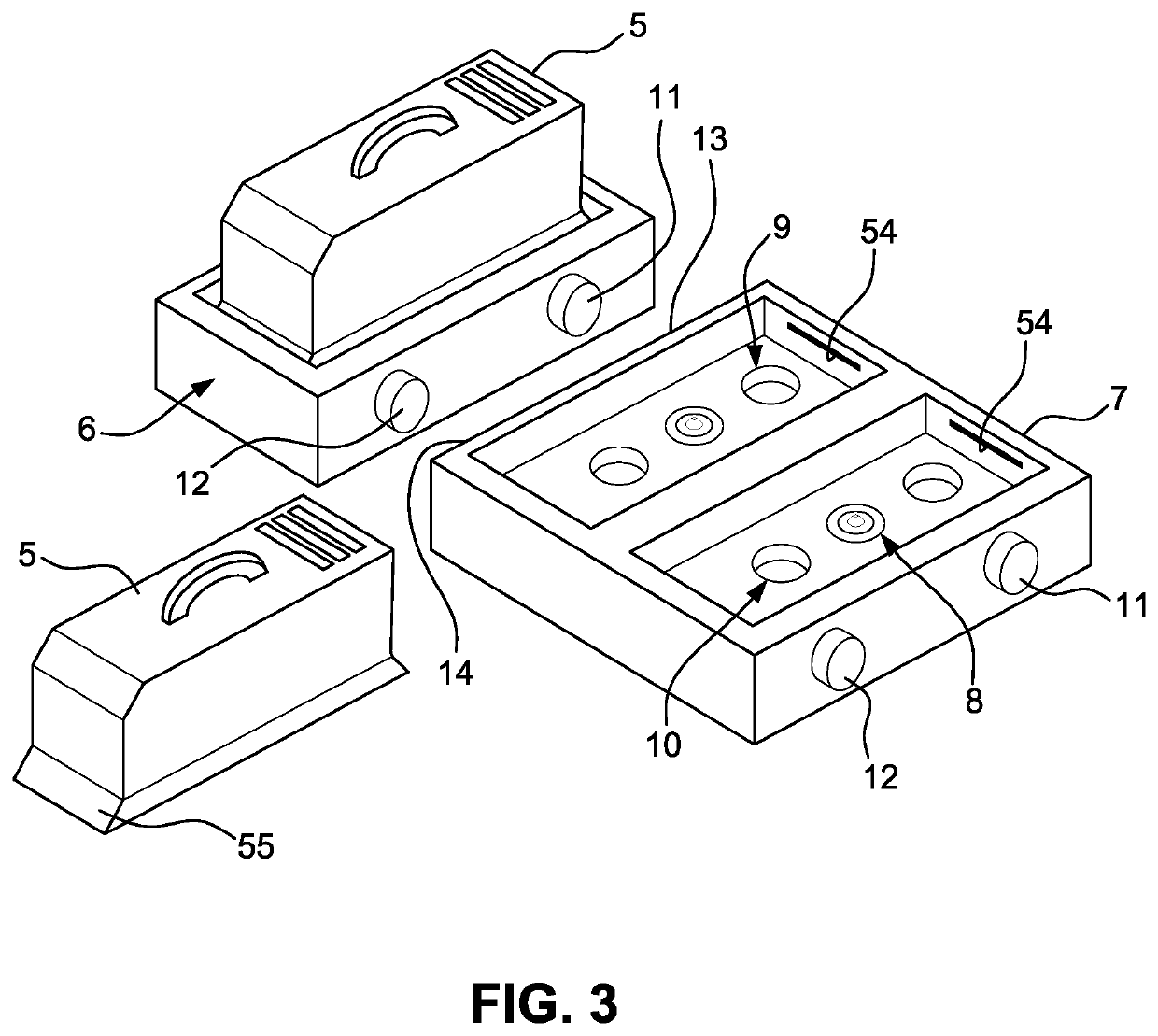

Fuel tank inerting system

ActiveUS20180370650A1Conveniently mountedEasy to removeAir-treatment apparatus arrangementsFuel tank safety measuresInerting systemUllage

A fuel tank inerting module, a fuel tank inerting system for an aircraft, and a method of providing fuel tank inerting systems for aircraft are disclosed. The module includes an inlet for ullage gas from a fuel tank, a catalyst, an outlet for the ODA, sensors, filters and valves. The module is sized and shaped to fit in a range of positions near to fuel tanks in various aircraft. The inerting system includes one or more modules connected to the fuel tanks and a controller to control passage of ullage and ODA between the fuel tanks and the modules. The method includes providing an inert gas generation module compatible with any suitable aircraft, positioning one or more modules in an aircraft at locations near to a fuel tank to be inerted.

Owner:AIRBUS OPERATIONS LTD

Optical image capturing system

ActiveUS20190361229A1Reduce the overall heightBack focal length is reducedOptical elementsImaging qualityImage quality

An optical image capturing system is provided. In order from an object side to an image side, the optical image capturing system includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens. At least one lens among the first lens to the fifth lens has positive refractive power. The sixth lens may have negative refractive power and an object side and an image side thereof are aspherical wherein at least one surface of the sixth lens has an inflection point. The optical image capturing system has six lenses with refractive power. When meeting some certain conditions, the optical image capturing system may have outstanding light-gathering ability and an adjustment ability about the optical path in order to elevate the image quality.

Owner:ABILITY OPTO ELECTRONICS TECH

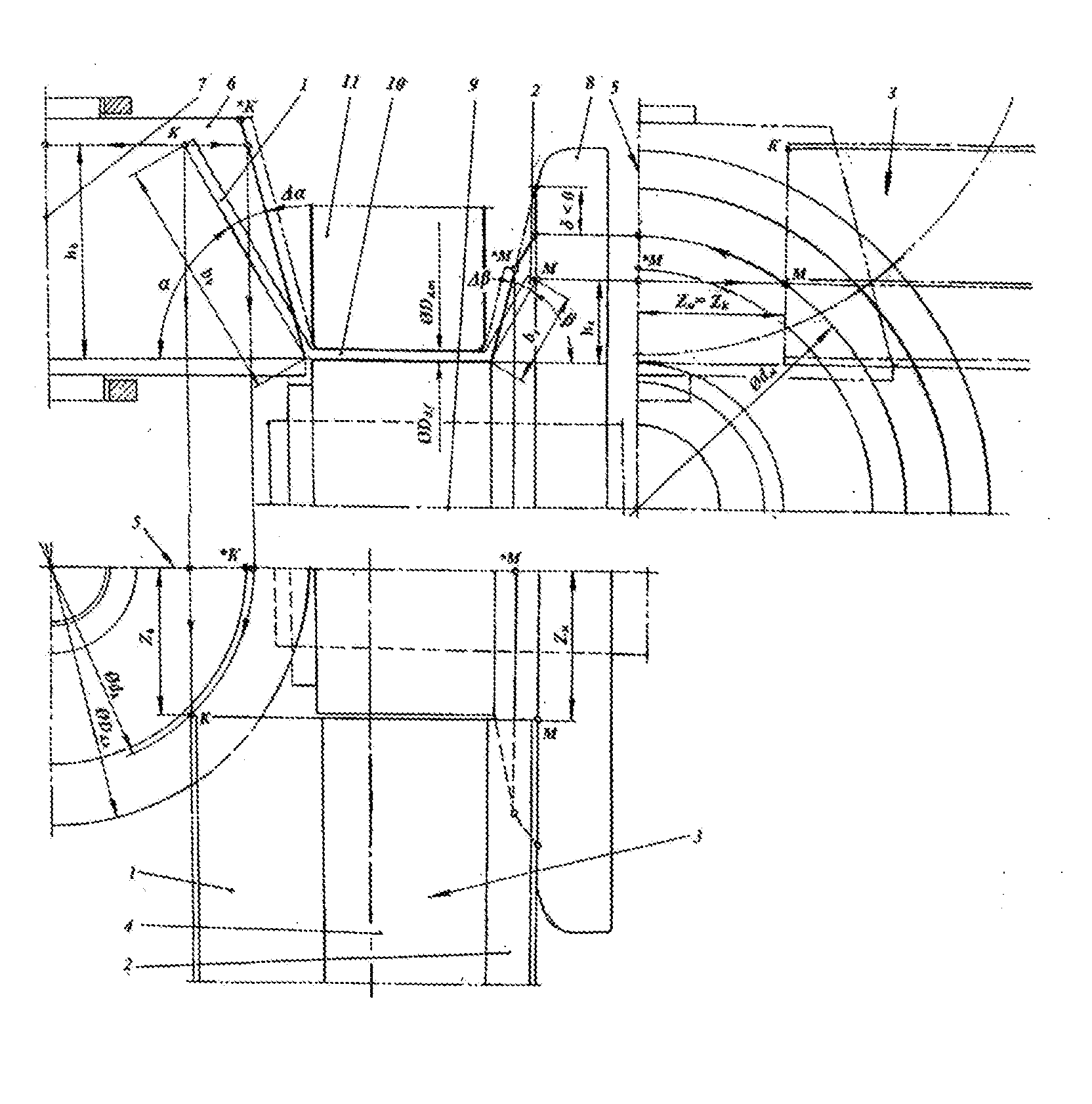

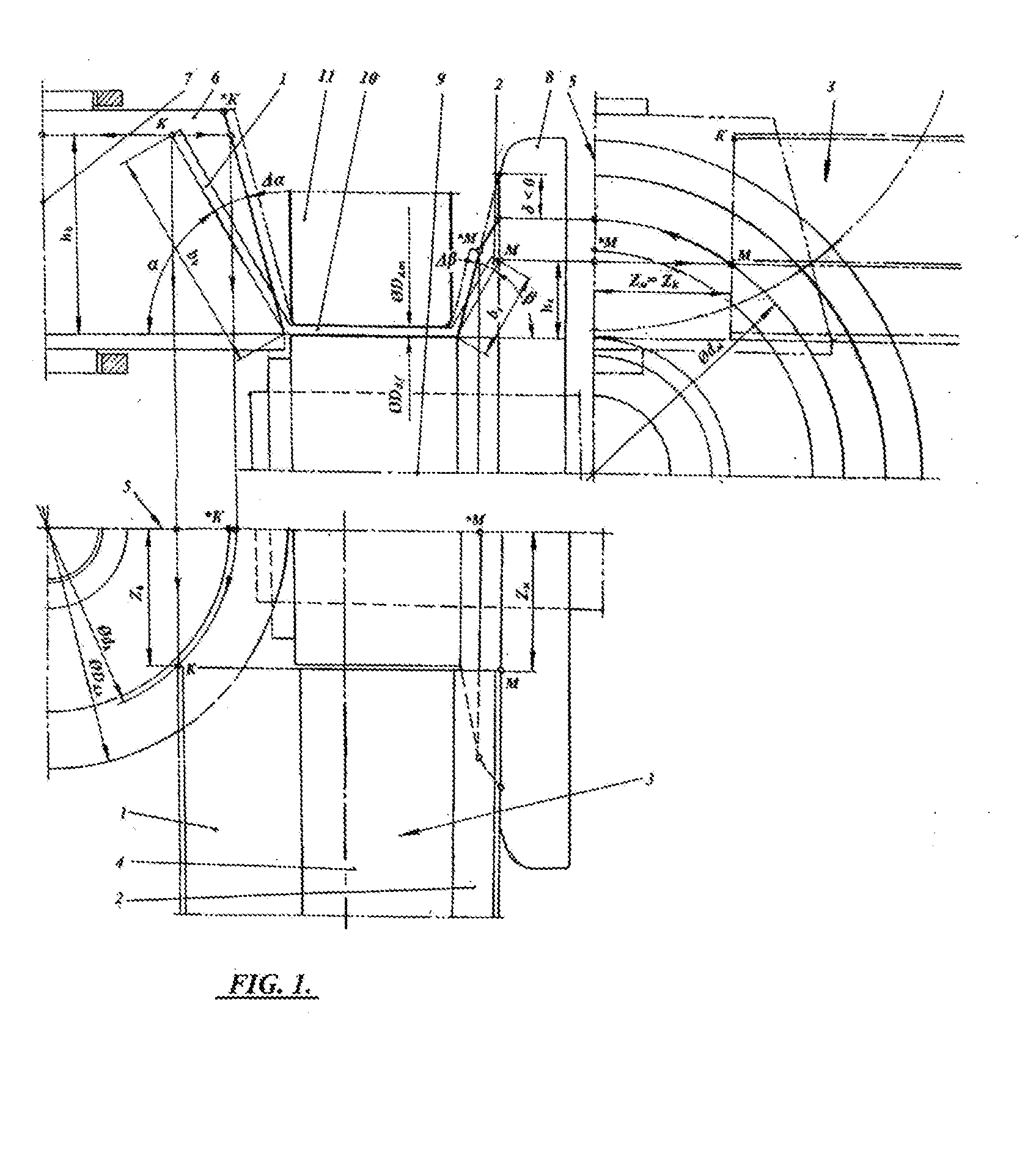

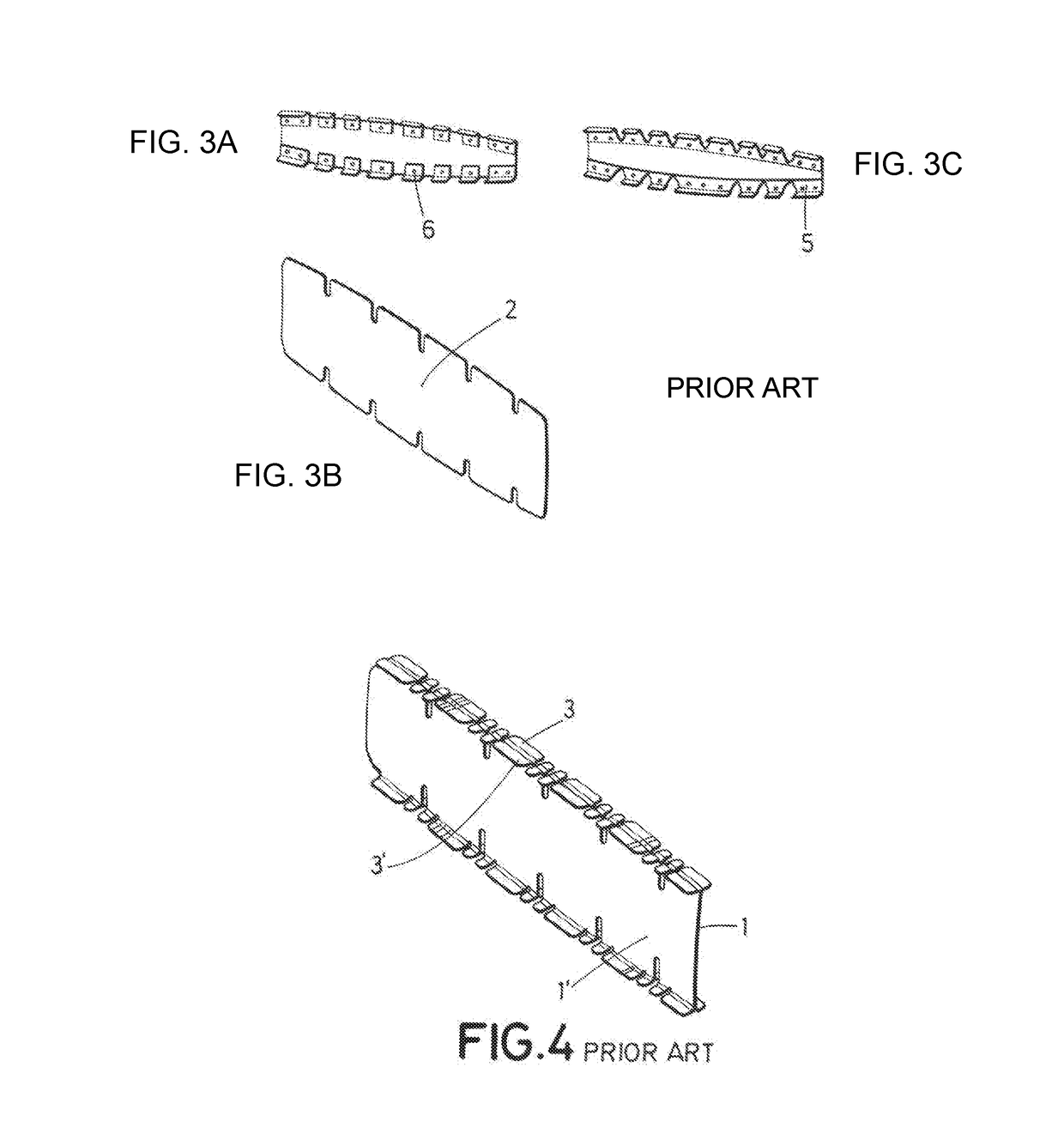

Method and Apparatus for Manufacturing Asymmetrical Roll-Formed Sections

InactiveUS20140150513A1Simple structureAvoid displacementMetal rolling stand detailsMetal rolling arrangementsRoll formingLateral displacement

A roll-forming station for forming asymmetrical sheet metal beams with unequal flanges, where both of the unequal flanges contact the rolls simultaneously and where the diameters of the rolls are such that the bending moments applied to the unequal flanges are identical in magnitude. This prevents lateral displacement of the workpiece during forming.

Owner:DOKTOROV MARK YEFIMOVICH +2

Composite rib for a torsion box and manufacturing method thereof

InactiveUS20170088249A1Avoid assemblyAvoid manufacturingSpars/stringersWeight reductionEngineeringOne shot

The present disclosure refers to the configuration and manufacturing process of a rib for the construction of an aircraft torsion box. In the method, a flat stack of plies of composite material is layered up, which is then cut to form a flat pre-form having an outer contour having flanges, and an internal contour having two or more diagonal trusses with flanges at opposite sides. The flat pre-form is press-formed to fold the flanges of the outer and internal contour to form a rib pre-form, which is finally cured. The present disclosure also refers to a composite rib having a unitary body by forming a single pre-form of stacked plies. The present disclosure allows the manufacture of the rib in one-shot process, integrating all the ribs components such that the assembly time and cost of the rib are minimized.

Owner:AIRBUS OPERATIONS SL

Optical image capturing system

ActiveUS10746964B2Increase the amount of lightQuality improvementTelevision system detailsColor television detailsOphthalmologyImaging quality

An optical image capturing system is provided. In order from an object side to an image side, the optical image capturing system includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens. At least one lens among the first lens to the fifth lens has positive refractive power. The sixth lens may have negative refractive power and an object side and an image side thereof are aspherical wherein at least one surface of the sixth lens has an inflection point. The optical image capturing system has six lenses with refractive power. When meeting some certain conditions, the optical image capturing system may have outstanding light-gathering ability and an adjustment ability about the optical path in order to elevate the image quality.

Owner:ABILITY OPTO ELECTRONICS TECH

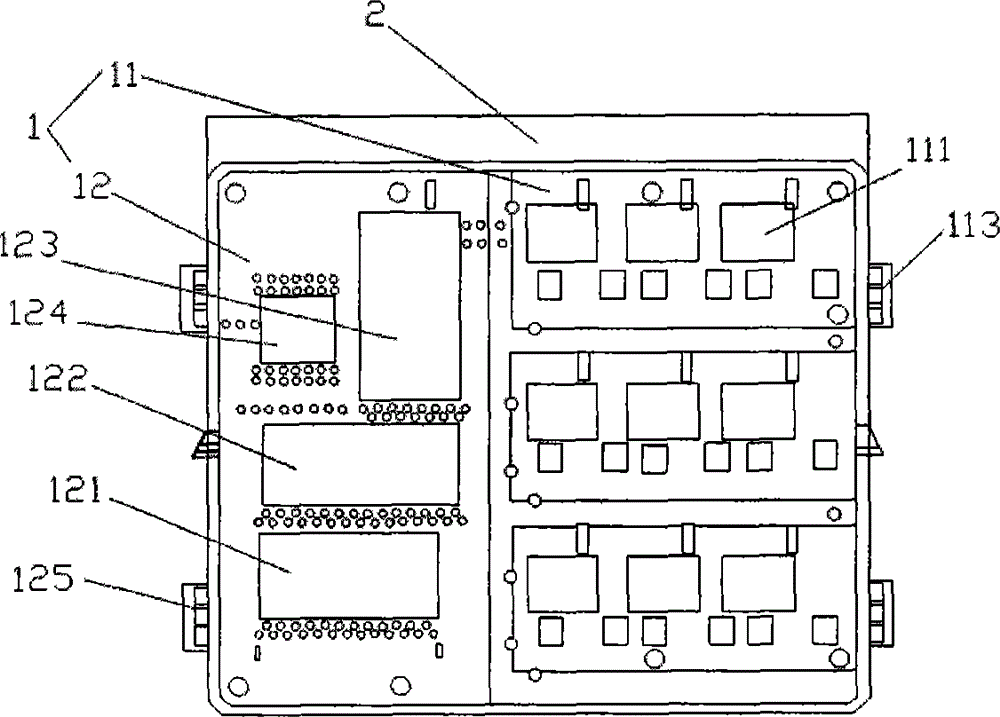

Single-phase nine-station transparent electric meter box

InactiveCN106033094ALarge capacityEasy to installTime integral measurementEngineeringCircuit breaker

The invention discloses a single-phase nine-position transparent electric meter box, which includes a main body of the electric meter box. The box body 1 and the plastic box body 2 are respectively equipped with a fixed plate 1 and a fixed plate 2, and the plastic box body 1 is divided into three rows and three rows of electric meter chambers, and each electric meter chamber is equipped with a transparent waterproof door 1, plastic There are circuit breaker room 1, circuit breaker room 2, incoming line switch room and main switch room inside the box body 2. Four circuit breakers are respectively installed in circuit breaker room 1 and circuit breaker room 2. Circuit breaker room 1, circuit breaker There is a transparent waterproof door 2 outside the room 2 and the main switch, and a detachable arc-shaped rain-shielding panel is installed on the top of the meter box body. The present invention has a plurality of electric meter chambers, so that the capacity is larger, and it is convenient to gather and install a plurality of electric meters, and it is also convenient for people to manage and use, and the use is safer, and the service life is greatly improved.

Owner:长沙聚善电力科技有限公司

Optical image capturing system

ActiveUS20190243103A1Reduce the overall heightCorrect optical aberrationTelevision system detailsColor television detailsImaging qualityImage quality

An optical image capturing system is provided. In order from an object side to an image side, the optical image capturing system includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens. At least one lens among the first lens to the fifth lens has positive refractive power. The sixth lens may have negative refractive power and an object side and an image side thereof are aspherical wherein at least one surface of the sixth lens has an inflection point. The optical image capturing system has six lenses with refractive power. When meeting some certain conditions, the optical image capturing system may have outstanding light-gathering ability and an adjustment ability about the optical path in order to elevate the image quality.

Owner:ABILITY OPTO ELECTRONICS TECH

Oriented film printing plate and manufacturing method for liquid crystal display device

ActiveUS9387715B2Avoid manufacturingPlate printingFoil printingLiquid-crystal displayElectrical and Electronics engineering

In order to prevent protruded parts formed on an oriented film print pattern of a printing plate for flexographic printing from being lost, a linear bank is formed on the periphery of one side of the oriented film print pattern where wiping work is started. The bank prevents the protruded part in the oriented film print pattern from being lost by the wiping work. The protruded parts are formed in a matrix in order to retain an oriented film liquid in the oriented film print pattern. Thickness irregularity of the oriented film due to presence of the bank is reduced by making the diameters of the protruded parts smaller in a peripheral region than in a central region of the oriented film print pattern and forming a space between the peripheral-side protruded parts and the bank.

Owner:JAPAN DISPLAY INC

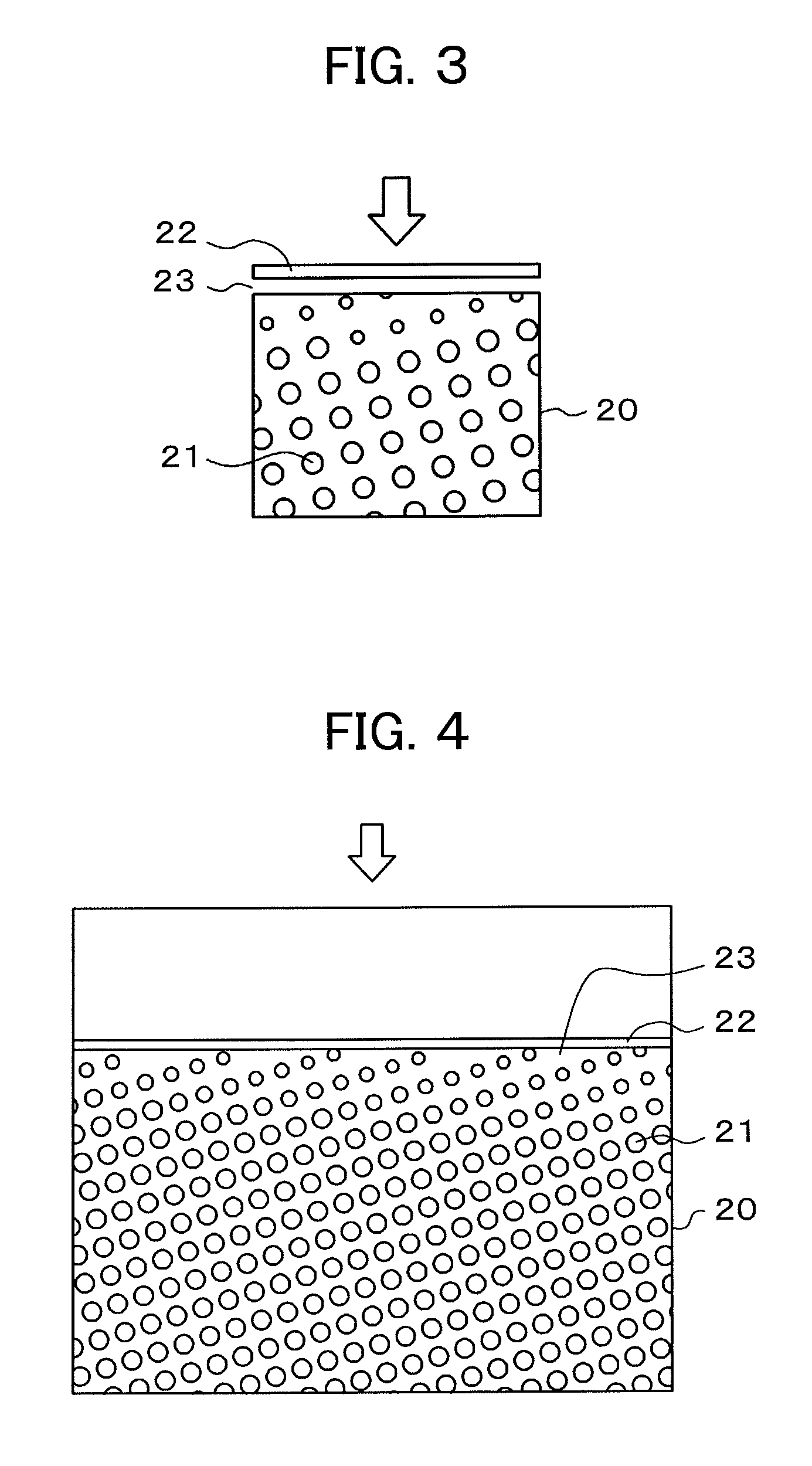

Display device and driving method

ActiveUS10451906B2Improve privacyAvoid manufacturingMechanical apparatusLight guides for lighting systemsTelecommunicationsLateral angle

A display device has a light blocking arrangement for selectively blocking light which has or would be emitted at large lateral angles. The display can be configured so that light reaching these elements is either allowed to reach the viewer or is blocked from reaching the viewer. This means that a public viewing mode can be chosen or a private viewing mode. The light blocking elements are controlled optically in order to simplify the construction and control.

Owner:KONINKLJIJKE PHILIPS NV

Corner connecting component for guardrail surface tube

ActiveCN102787702BLow costEasy to produceBridge structural detailsAuxillary members of forms/shuttering/falseworksUltimate tensile strengthFastener

The invention discloses a corner connecting component for a guardrail surface tube, which comprises a metal connecting piece and a first sealing decorating part, wherein the first sealing decorating part comprises a body and a seal cartridge which is fit with the body and is used for sealing the end of the inclined surface tube of a guardrail, the body is connected with an extension part which extends into a horizontal surface tube from the port of the horizontal surface tube, the metal connecting piece is provided with a second connecting part and a first connecting part which is used for connecting with the inclined surface tube, and the second connecting part penetrates through the fastener of the horizontal surface tube to be connected with the extension part. The corner connecting component has the advantages of simple structure, low cost, high connection strength, convenience and quickness for installation, good attractiveness and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Fuel tank inerting system

ActiveUS11225333B2Easy to removeEasy to disassembleAir-treatment apparatus arrangementsFuel tank safety measuresPtru catalystInerting system

A fuel tank inerting module, a fuel tank inerting system for an aircraft, and a method of providing fuel tank inerting systems for aircraft are disclosed. The module includes an inlet for ullage gas from a fuel tank, a catalyst, an outlet for the ODA, sensors, filters and valves. The module is sized and shaped to fit in a range of positions near to fuel tanks in various aircraft. The inerting system includes one or more modules connected to the fuel tanks and a controller to control passage of ullage and ODA between the fuel tanks and the modules. The method includes providing an inert gas generation module compatible with any suitable aircraft, positioning one or more modules in an aircraft at locations near to a fuel tank to be inerted.

Owner:AIRBUS OPERATIONS LTD

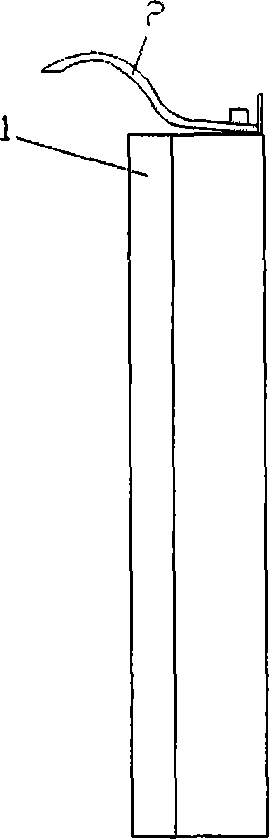

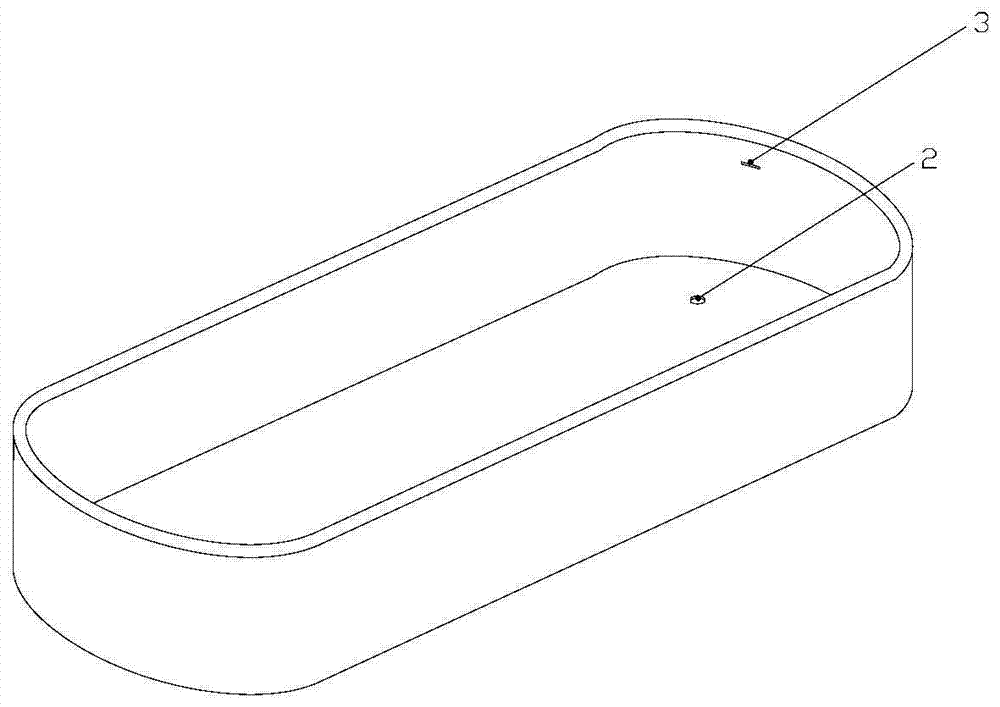

A built-in overflow pipe in a water storage container, a bathtub with the overflow pipe, and a manufacturing method thereof

Owner:YUJIE SANITARYWARE

Aseptic or sanitary diaphragm valve

InactiveUS8807518B2Easy constructionSimple and reliable processSpindle sealingsDiaphragm valvesDiaphragm valveEngineering

An aseptic valve or sanitary valve employs a floating plug situated within a cylindrical valve housing. The floating valve plug has a head that seats against an inlet opening, and has a stem and a generally conic foot that rests upon a diaphragm formed of a flexible, food-grade membrane. An actuator below the diaphragm urges the plug up to lodge against the inlet opening, and relieves force on the membrane and plug to open the valve. Spacer arms radiate from the stem or head of the plug, to keep the plug centered in the housing.

Owner:FELDMEIER EQUIP

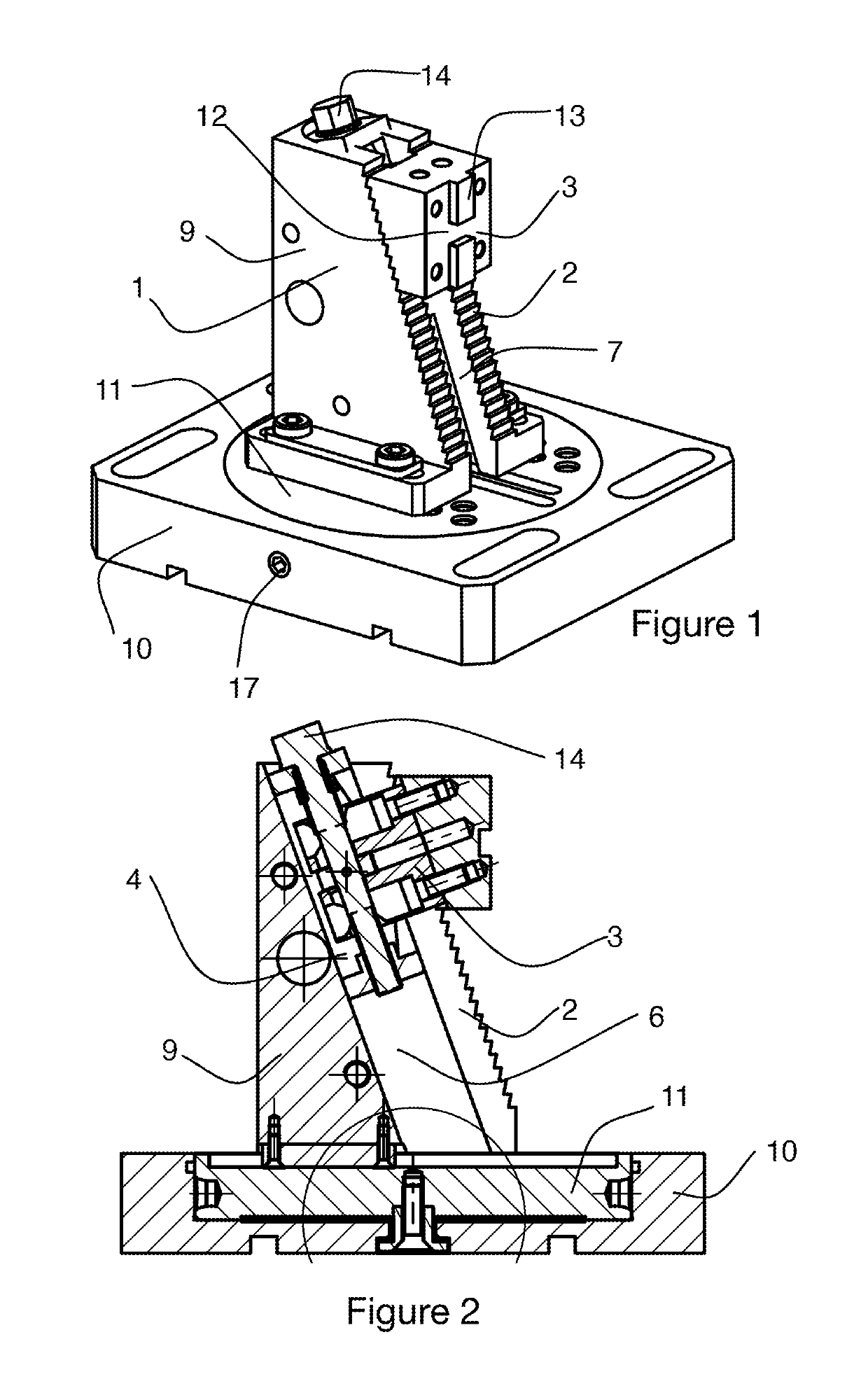

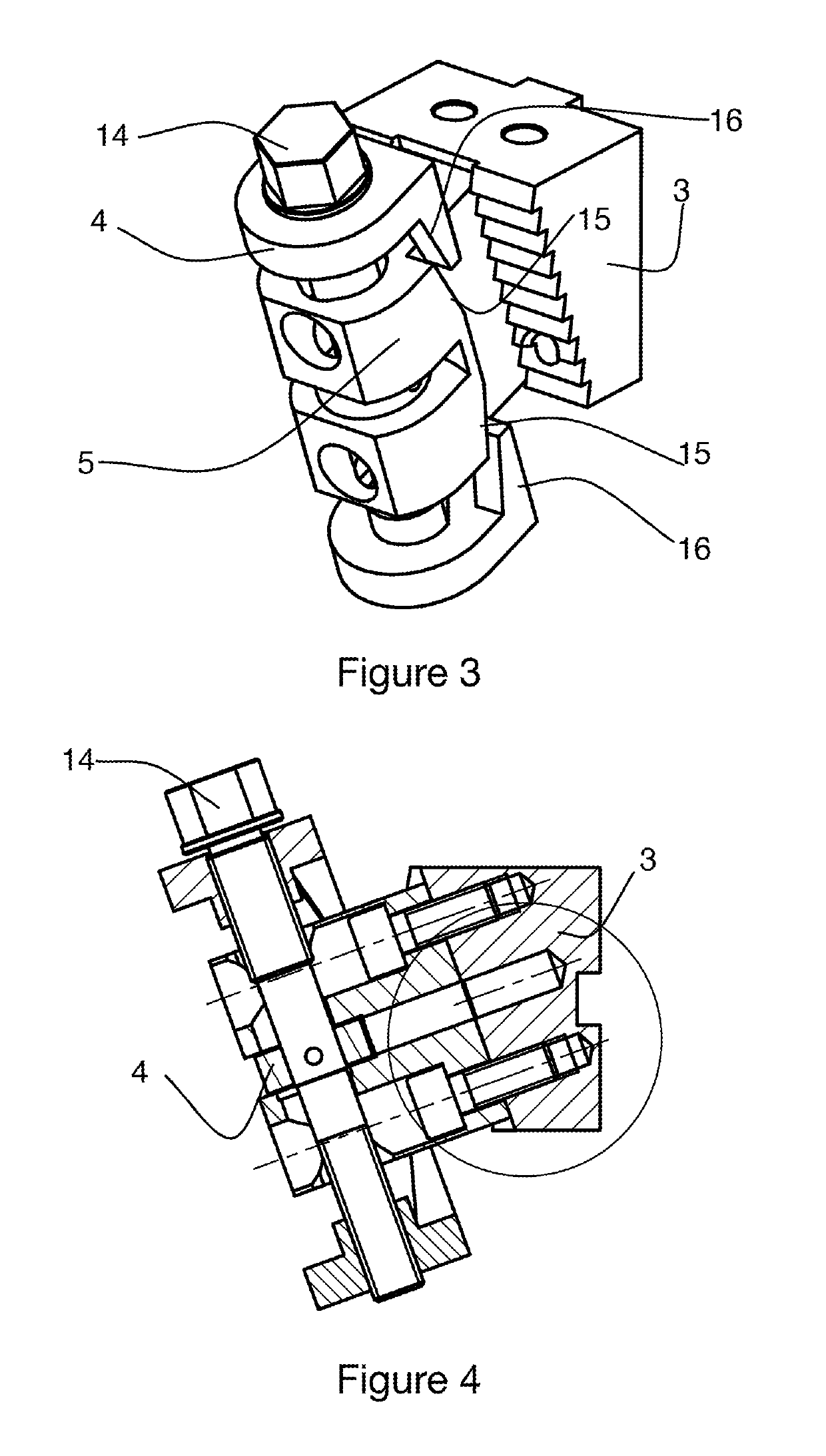

Universal holder for workpiece to be machined

InactiveUS20190134784A1Avoid designAvoid manufacturingWork holdersPositioning apparatusEngineeringMechanical engineering

A universal holder for a workpiece to be machined including a serrated inclined plane and an equally serrated positioning block mounted in a movable manner along the inclined plane in an adjustment position and in a fixed manner along the inclined plane in a clamping position for a machining operation.

Owner:NEWTOOLCONCEPT SARL

Optical image capturing system

An optical image capturing system is provided. In order from an object side to an image side, the optical image capturing system includes a first lens, a second lens, a third lens, a fourth lens, a fifth lens, and a sixth lens. At least one lens among the first lens to the fifth lens has positive refractive power. The sixth lens may have negative refractive power and an object side and an image side thereof are aspherical wherein at least one surface of the sixth lens has an inflection point. The optical image capturing system has six lenses with refractive power. When meeting some certain conditions, the optical image capturing system may have outstanding light-gathering ability and an adjustment ability about the optical path in order to elevate the image quality.

Owner:ABILITY OPTO ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com