Patents

Literature

445results about How to "Avoid impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

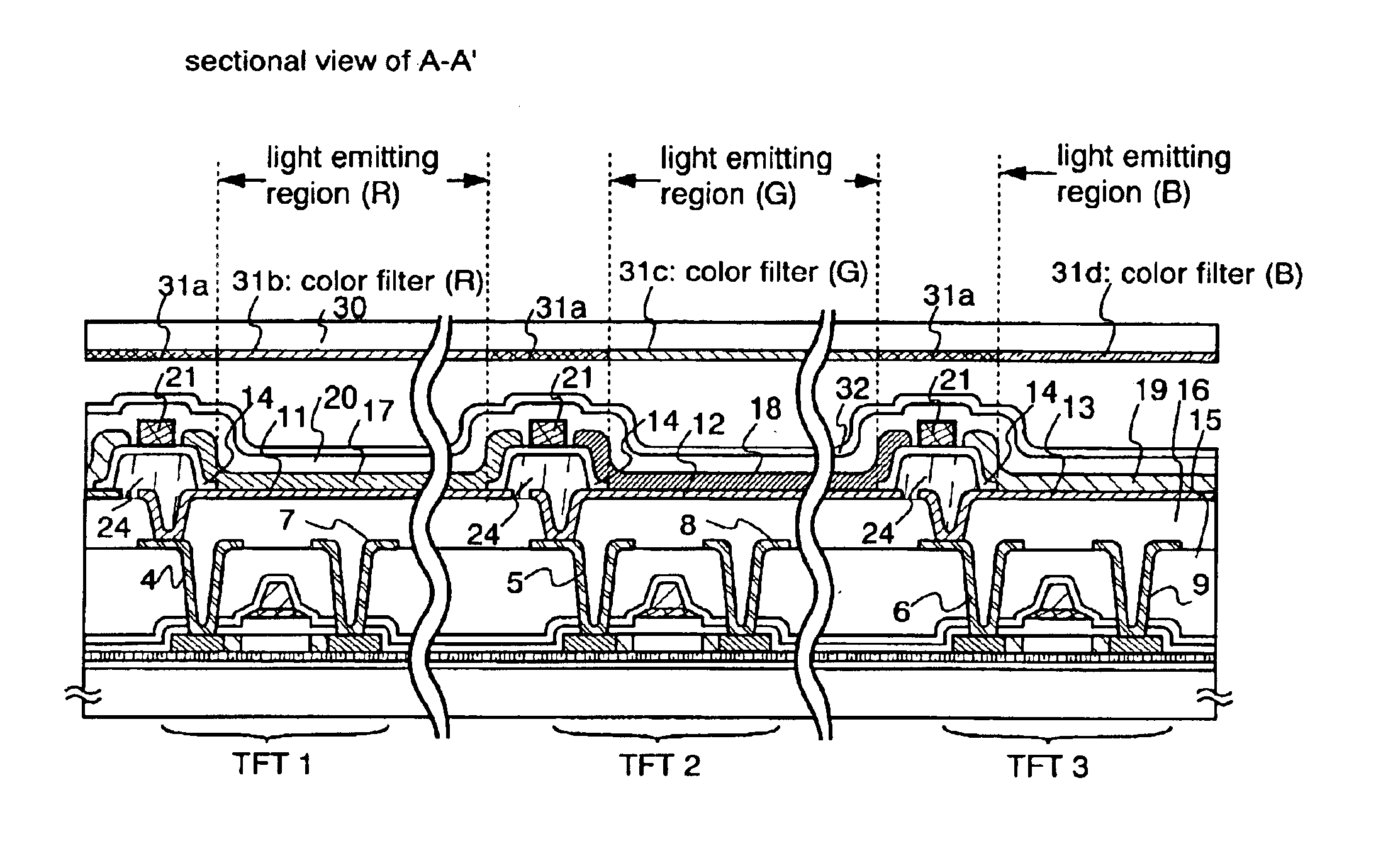

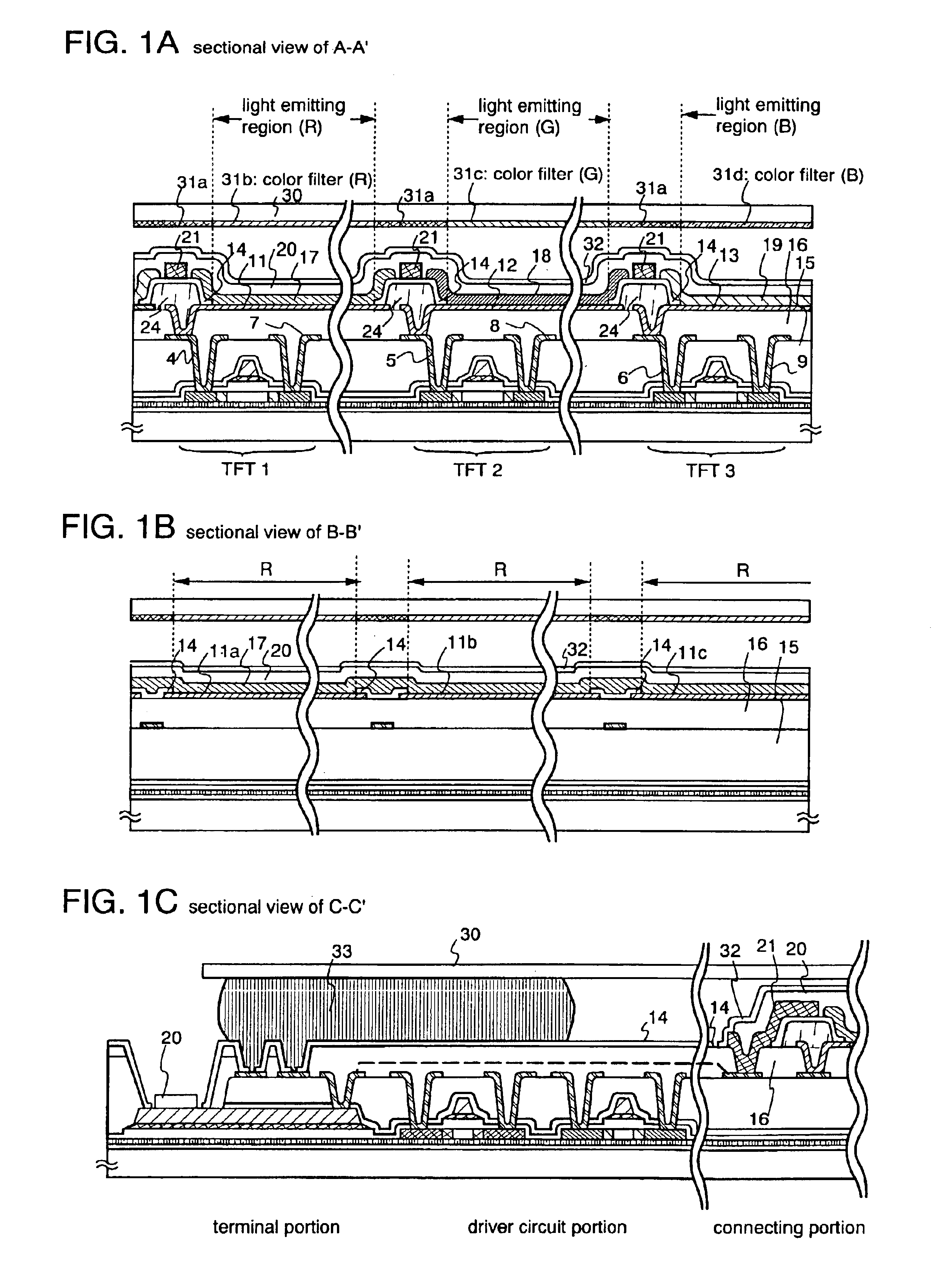

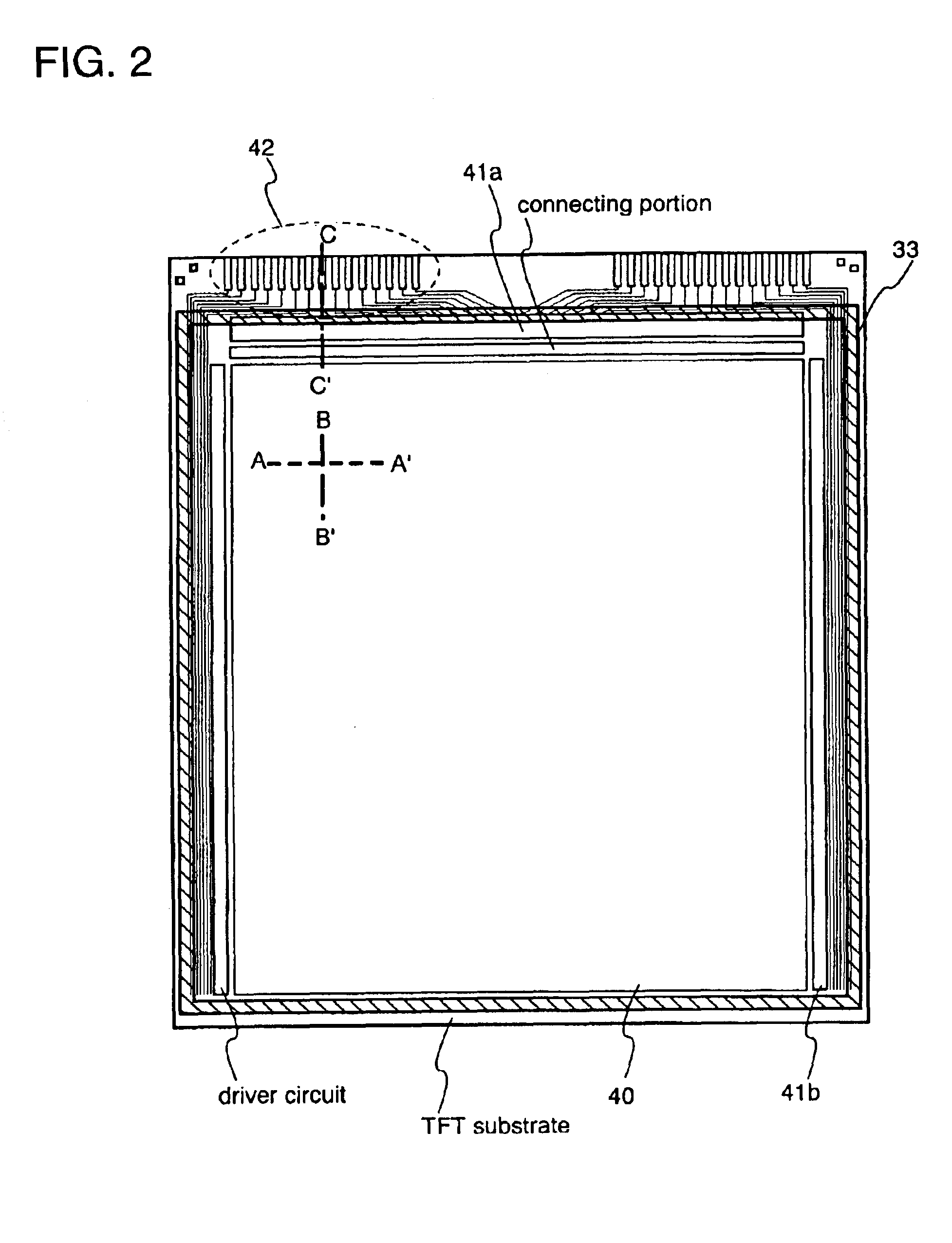

Light emitting device and method of manufacturing the same

InactiveUS6781162B2Effective diffusionImproved light emissionElectroluminescent light sourcesSolid-state devicesHydrogenTransparent conducting film

To provide a light emitting device high in reliability with a pixel portion having high definition with a large screen. According to a light emitting device of the present invention, on an insulator (24) provided between pixel electrodes, an auxiliary electrode (21) made of a metal film is formed, whereby a conductive layer (20) made of a transparent conductive film in contact with the auxiliary electrode can be made low in resistance and thin. Also, the auxiliary electrode (21) is used to achieve connection with an electrode on a lower layer, whereby the electrode can be led out with the transparent conductive film formed on an EL layer. Further, a protective film (32) made of a film containing hydrogen and a silicon nitride film which are laminated is formed, whereby high reliability can be achieved.

Owner:SEMICON ENERGY LAB CO LTD

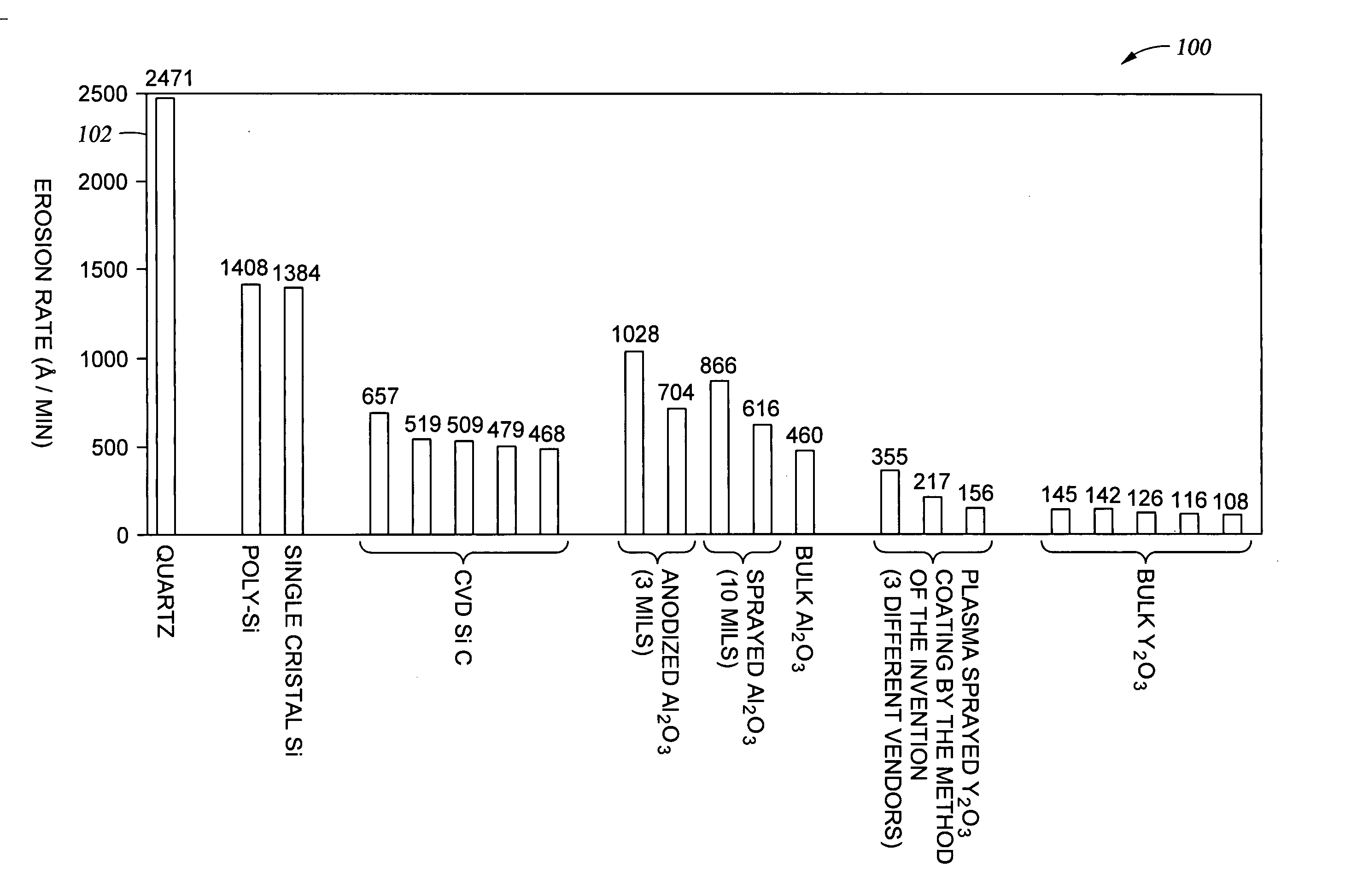

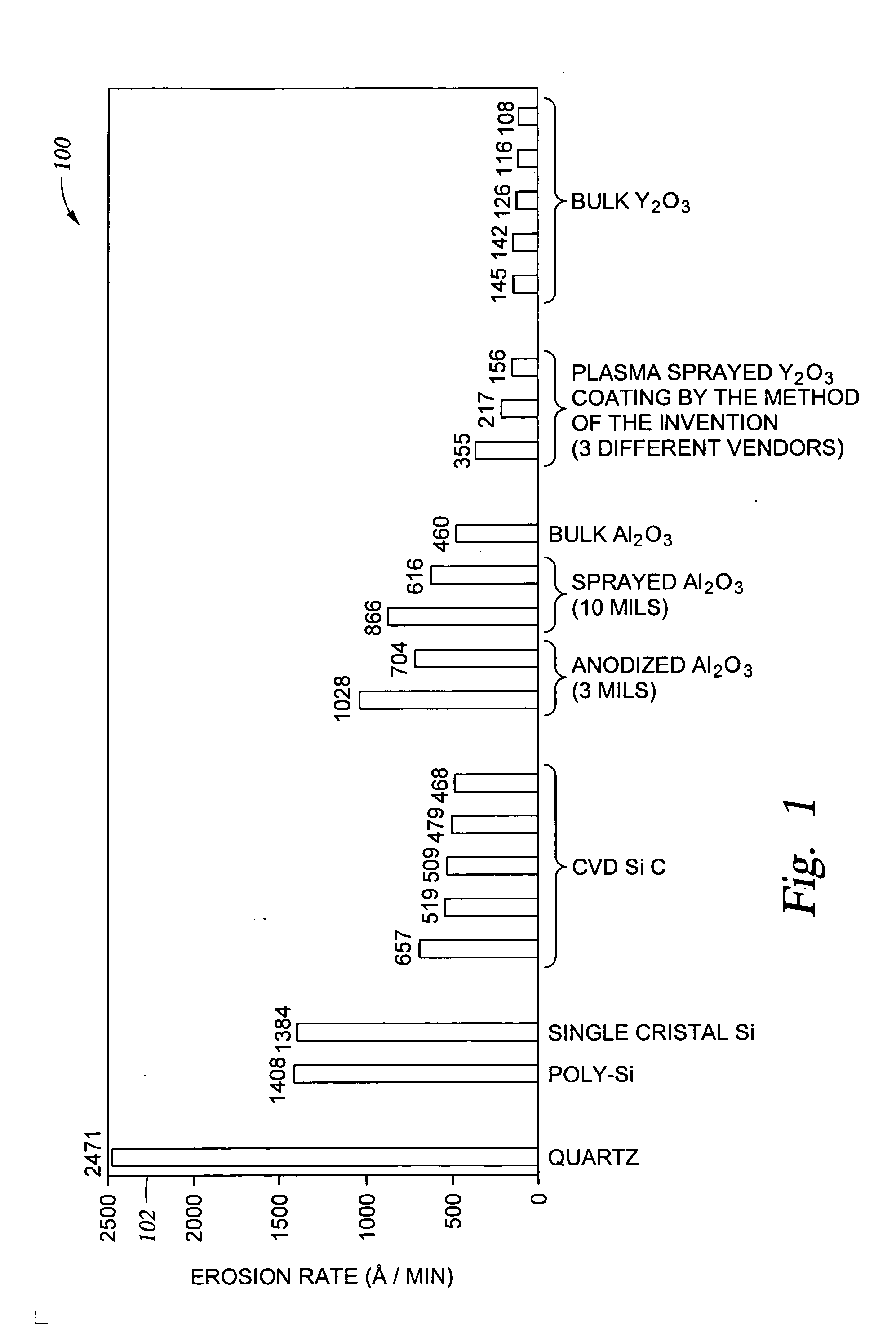

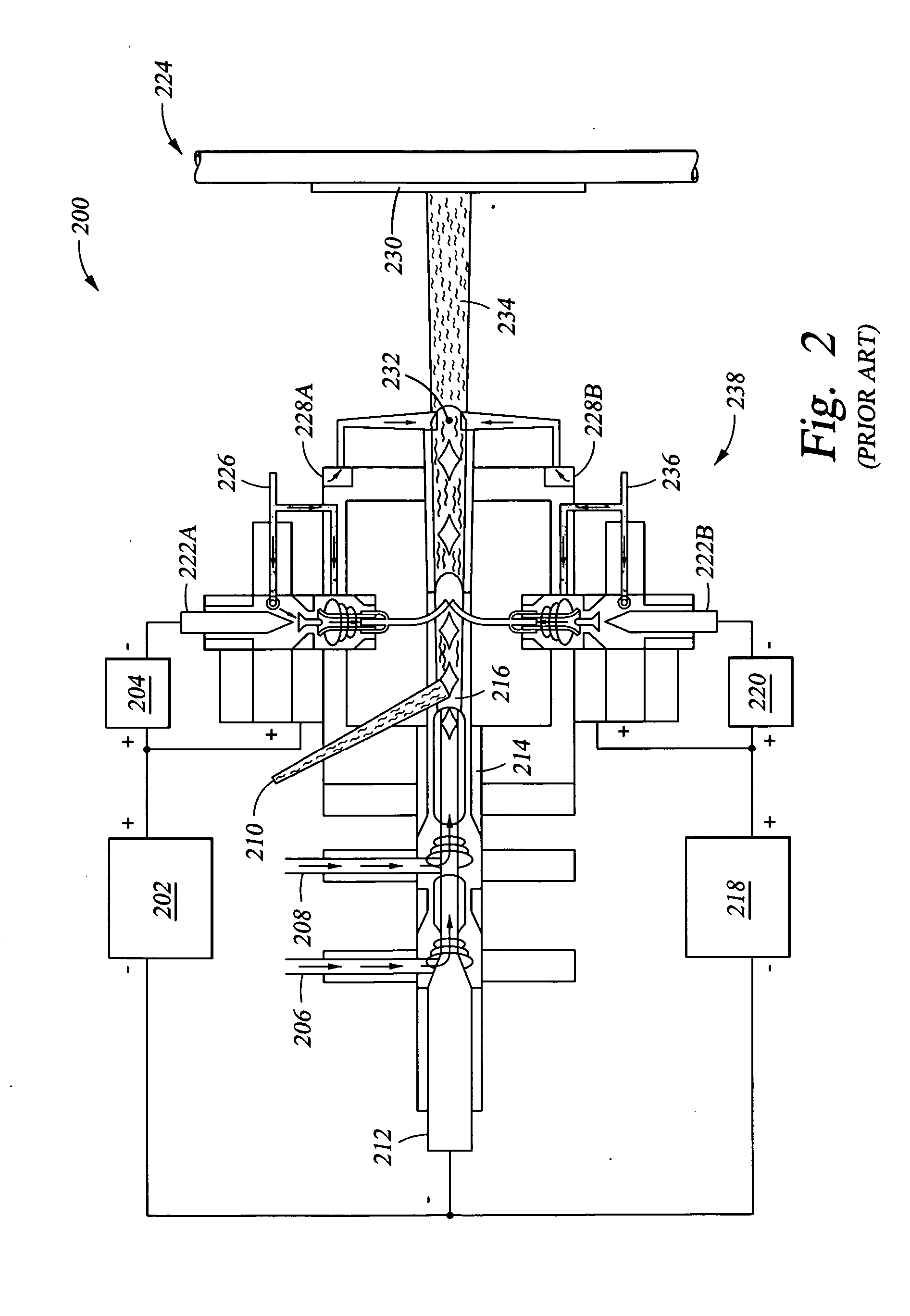

Clean, dense yttrium oxide coating protecting semiconductor processing apparatus

ActiveUS20050037193A1Extended service lifeExcellent plasma corrosion-resistanceLiquid surface applicatorsMolten spray coatingPlasma coatingChemical vapor deposition

Disclosed herein is a method for applying plasma-resistant coatings for use in semiconductor processing apparatus. The coatings are applied over a substrate which typically comprises an aluminum alloy of the 2000 series or the 5000 through 7000 series. The coating typically comprises an oxide or a fluoride of Y, Sc, La, Ce, Eu, Dy, or the like, or yttrium-aluminum-garnet (YAG). The coating may further comprise about 20 volume % or less of Al2O3. The coatings are typically applied to a surface of an aluminum alloy substrate or an anodized aluminum alloy substrate using a technique selected from the group consisting of thermal / flame spraying, plasma spraying, sputtering, and chemical vapor deposition (CVD). To provide the desired corrosion resistance, it is necessary to place the coating in compression. This is accomplished by controlling deposition conditions during application of the coating.

Owner:APPLIED MATERIALS INC

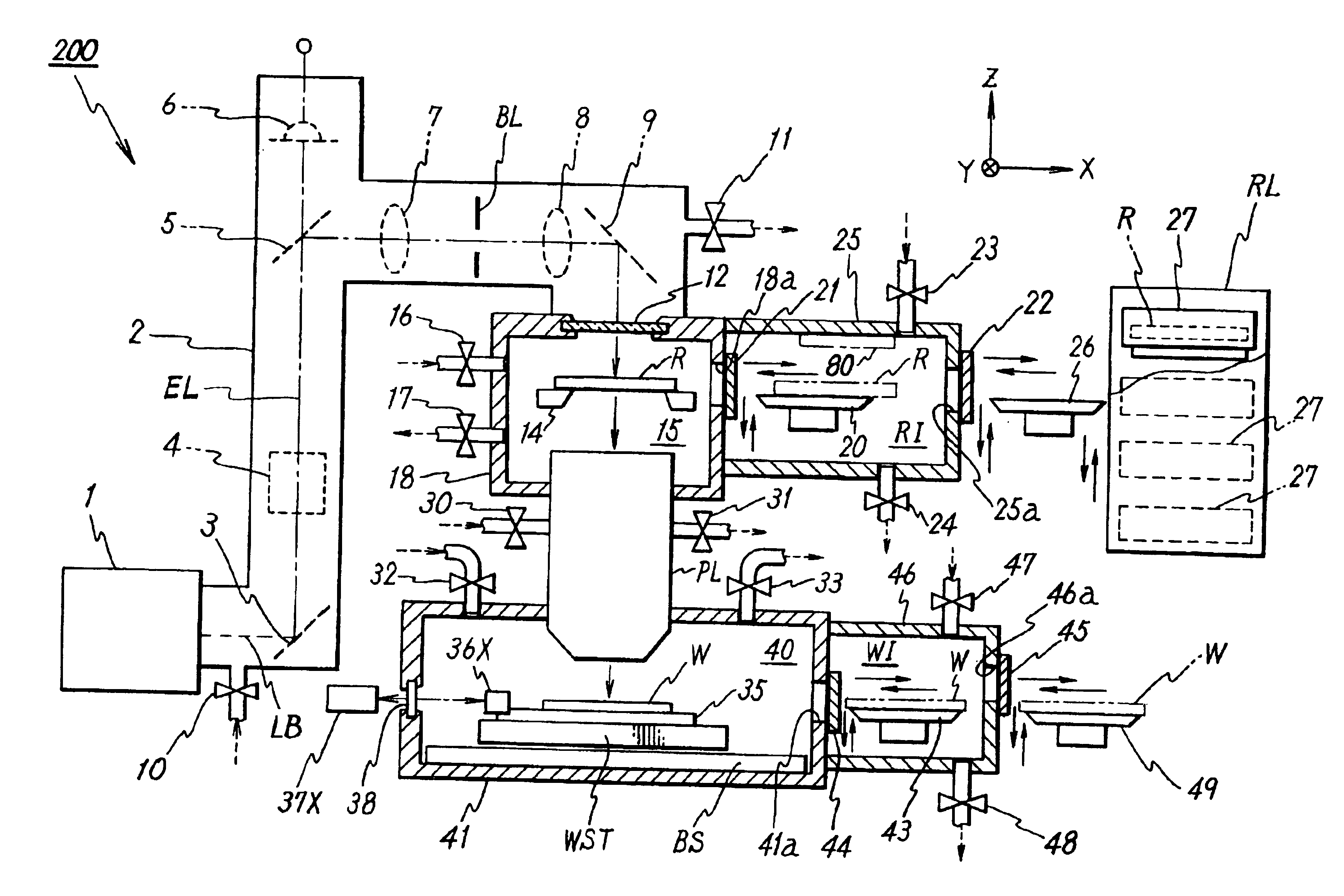

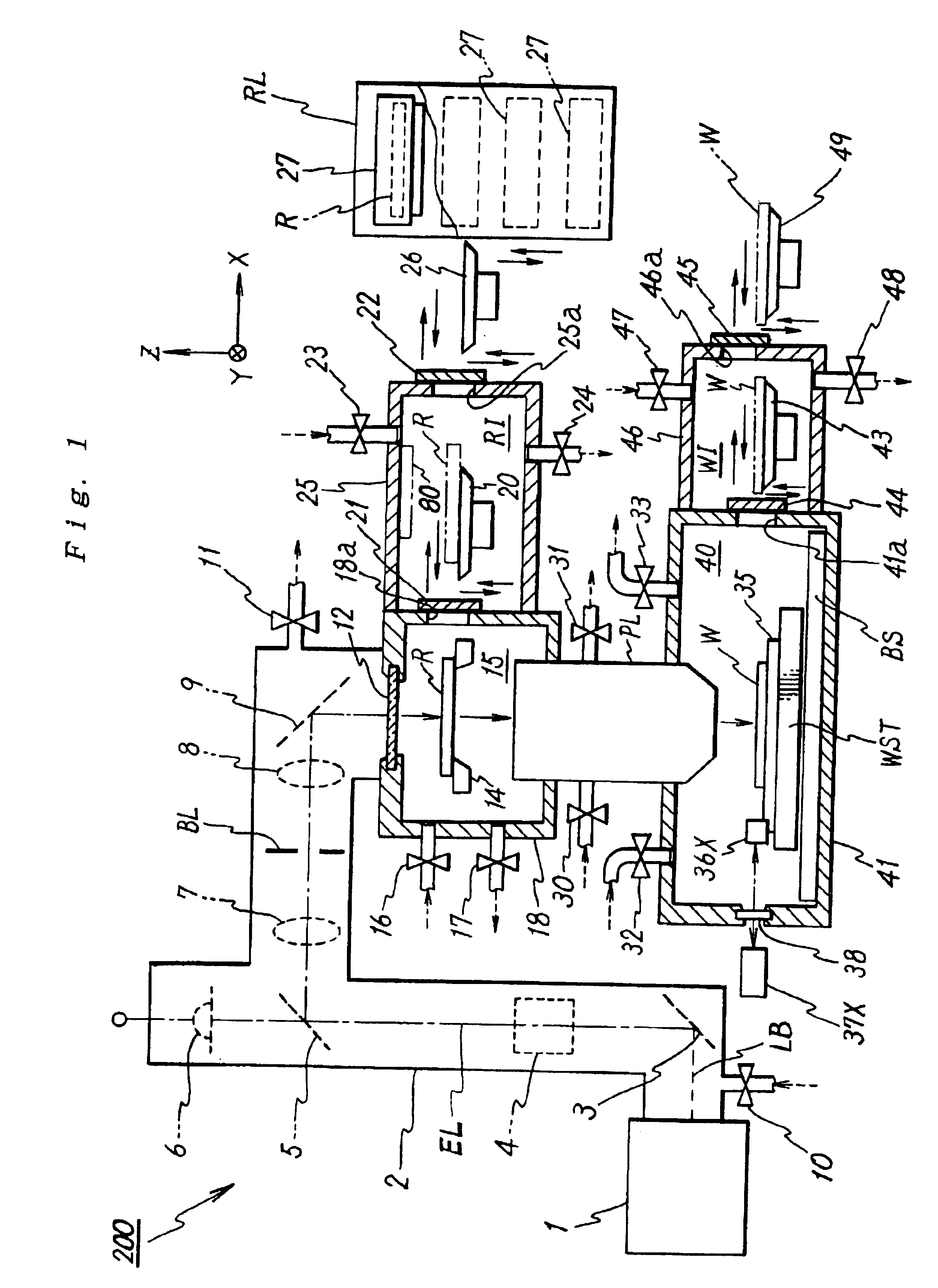

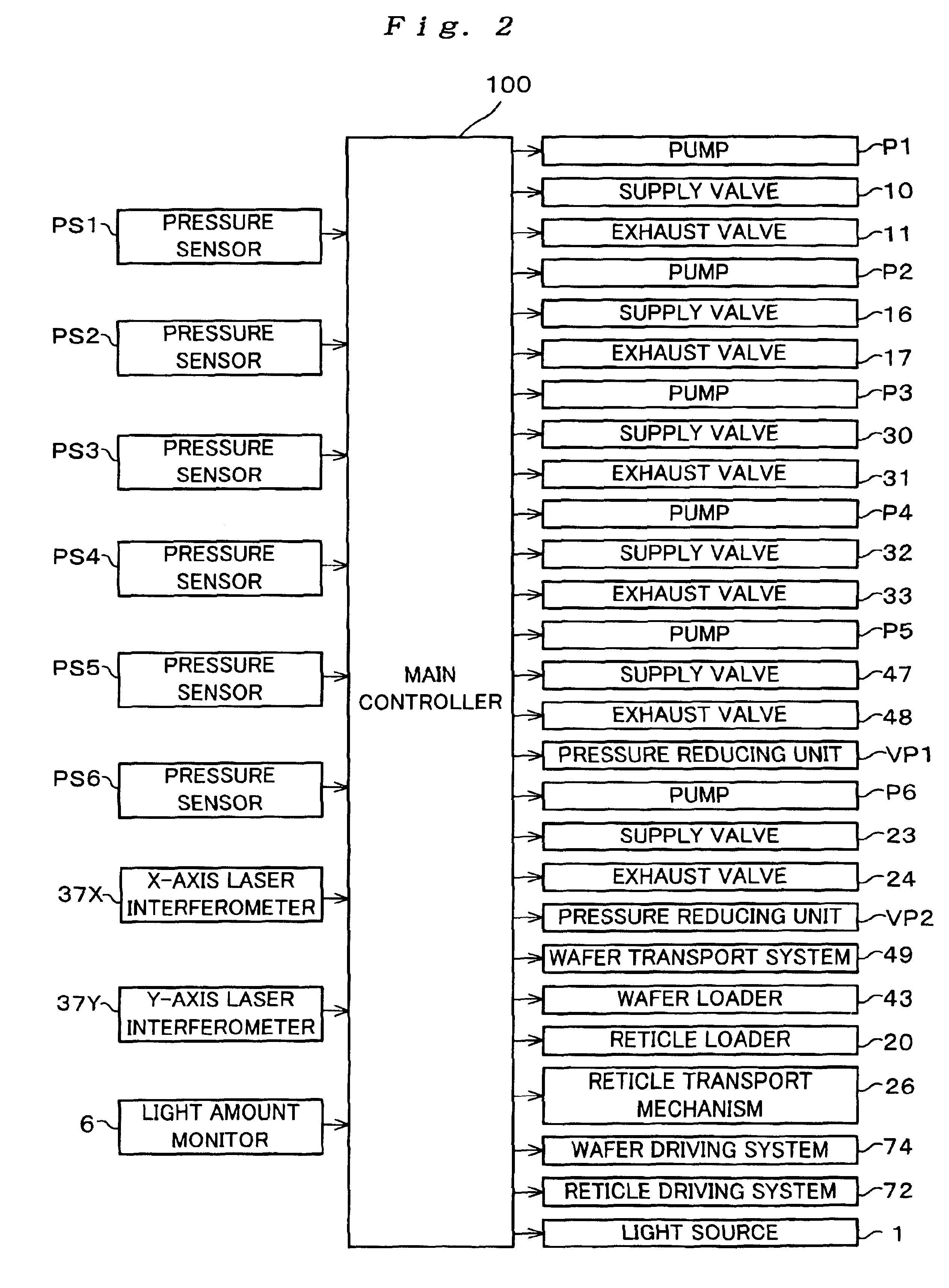

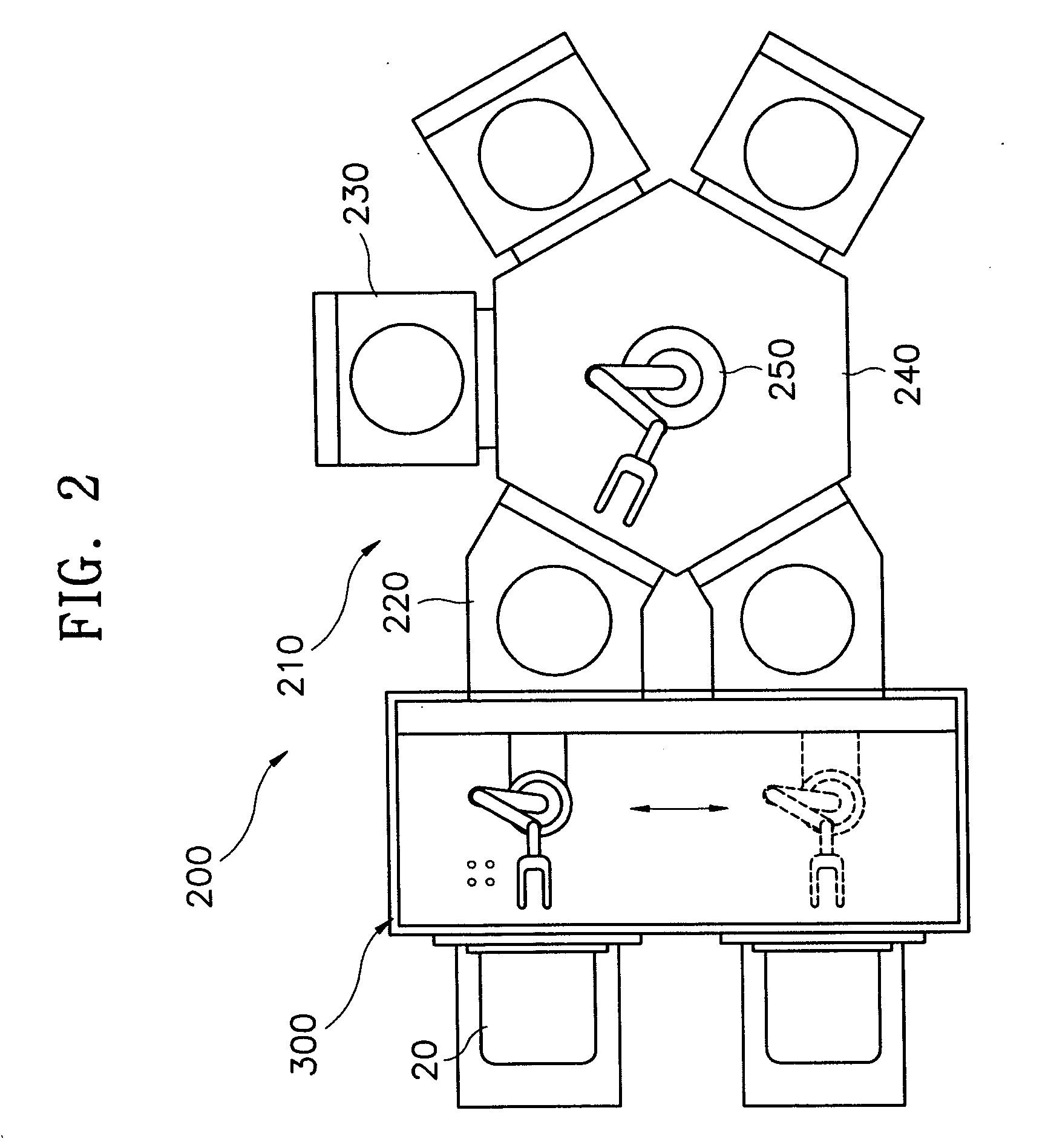

Exposure apparatus and exposure method, and device manufacturing method

InactiveUS6842221B1Stable exposure intensityForming accuratelyPhotomechanical exposure apparatusMicrolithography exposure apparatusMask ROMEngineering

After a mask is carried into a reserve room for temporarily storing before carrying into a mask room filled with specific gas that has an impurity concentration lower than a first concentration (e.g. 1 ppb) and that has a characteristic of absorbing little exposure light, gas-replacement mechanisms replace gas in the reserve room with specific gas having an oxygen concentration not lower than the first concentration. Therefore, when subsequently carrying the mask into the mask room, impurities from the outside (including absorbent gas) can be substantially prevented from getting into the optical path inside the mask room. When replacing a wafer, gas in a reserve room is also replaced in the same way as the above.

Owner:NIKON CORP

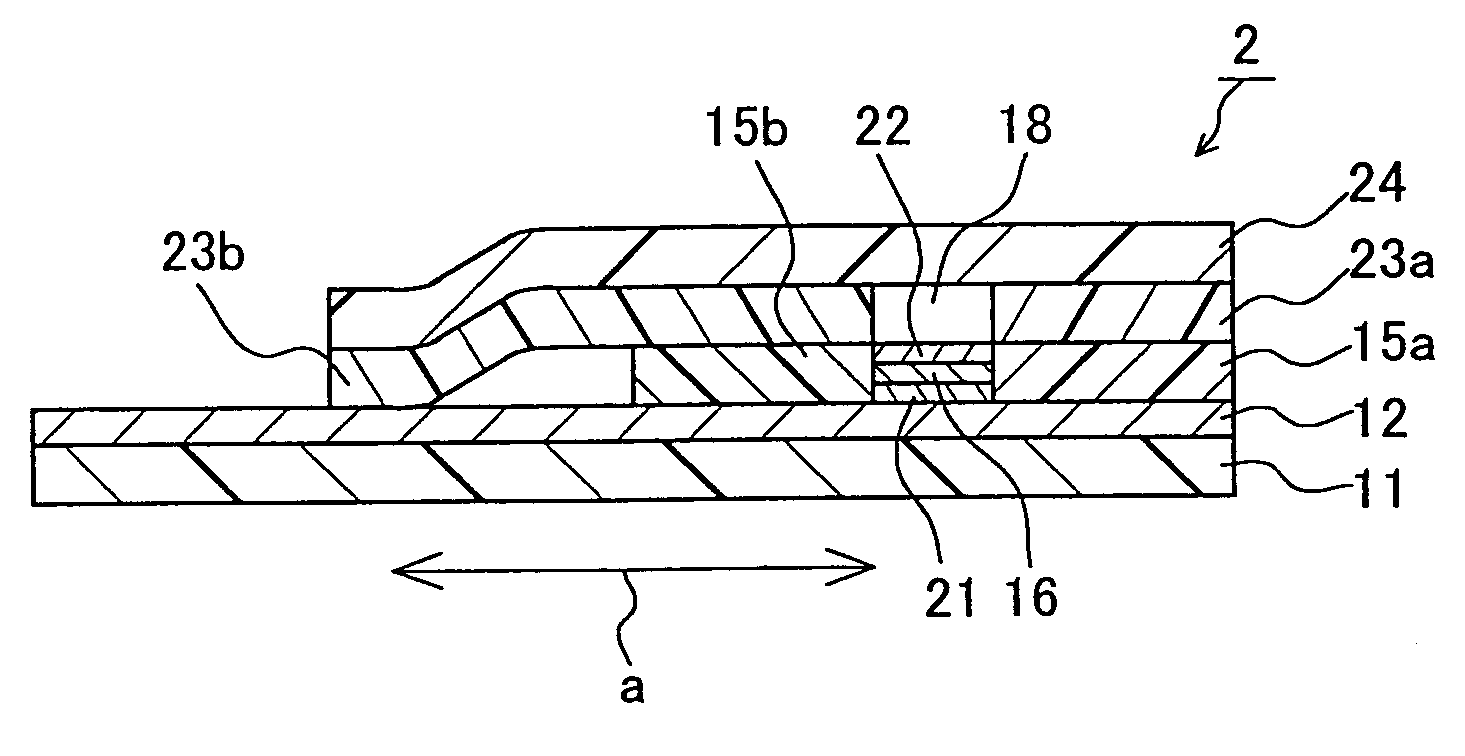

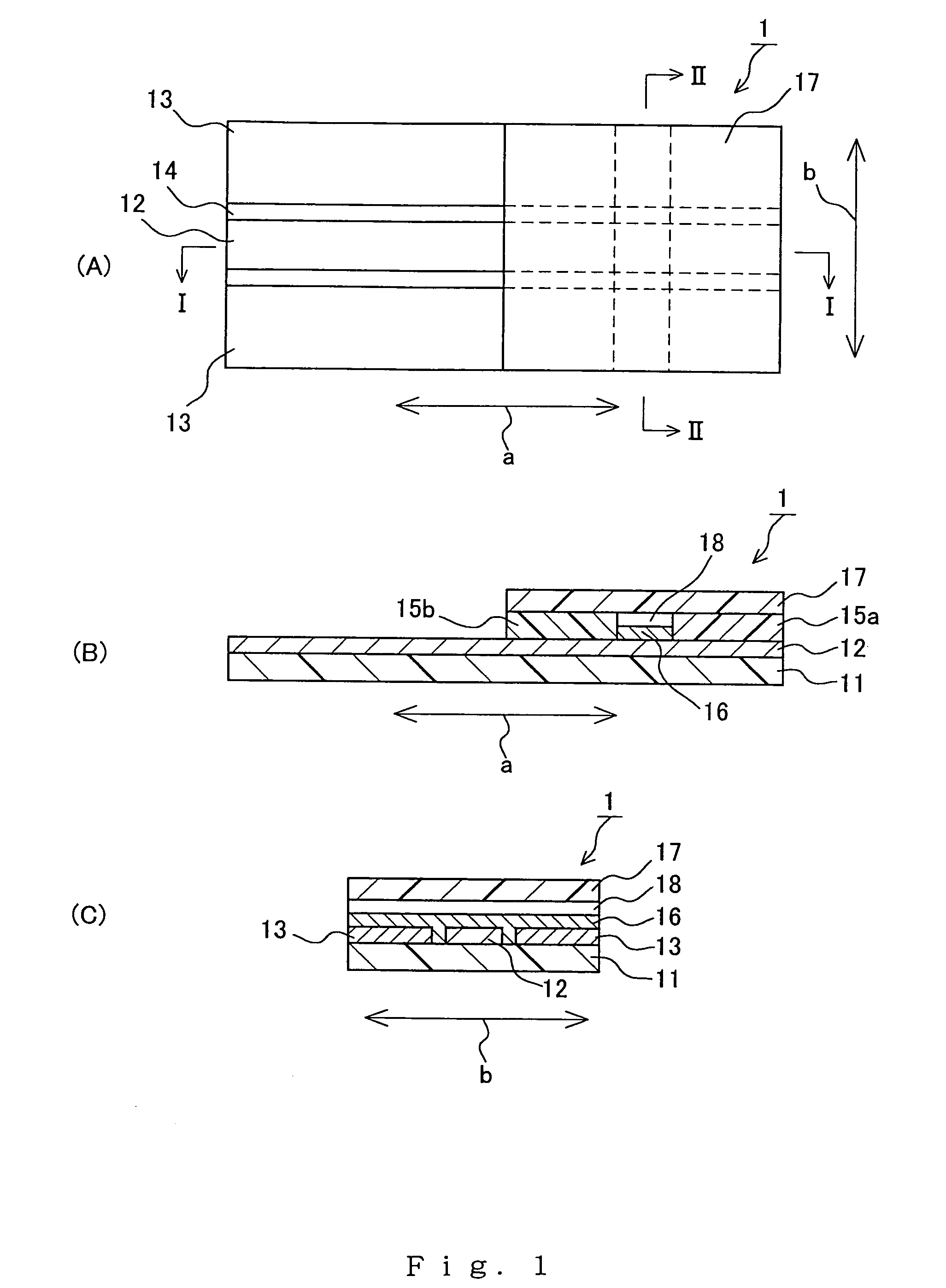

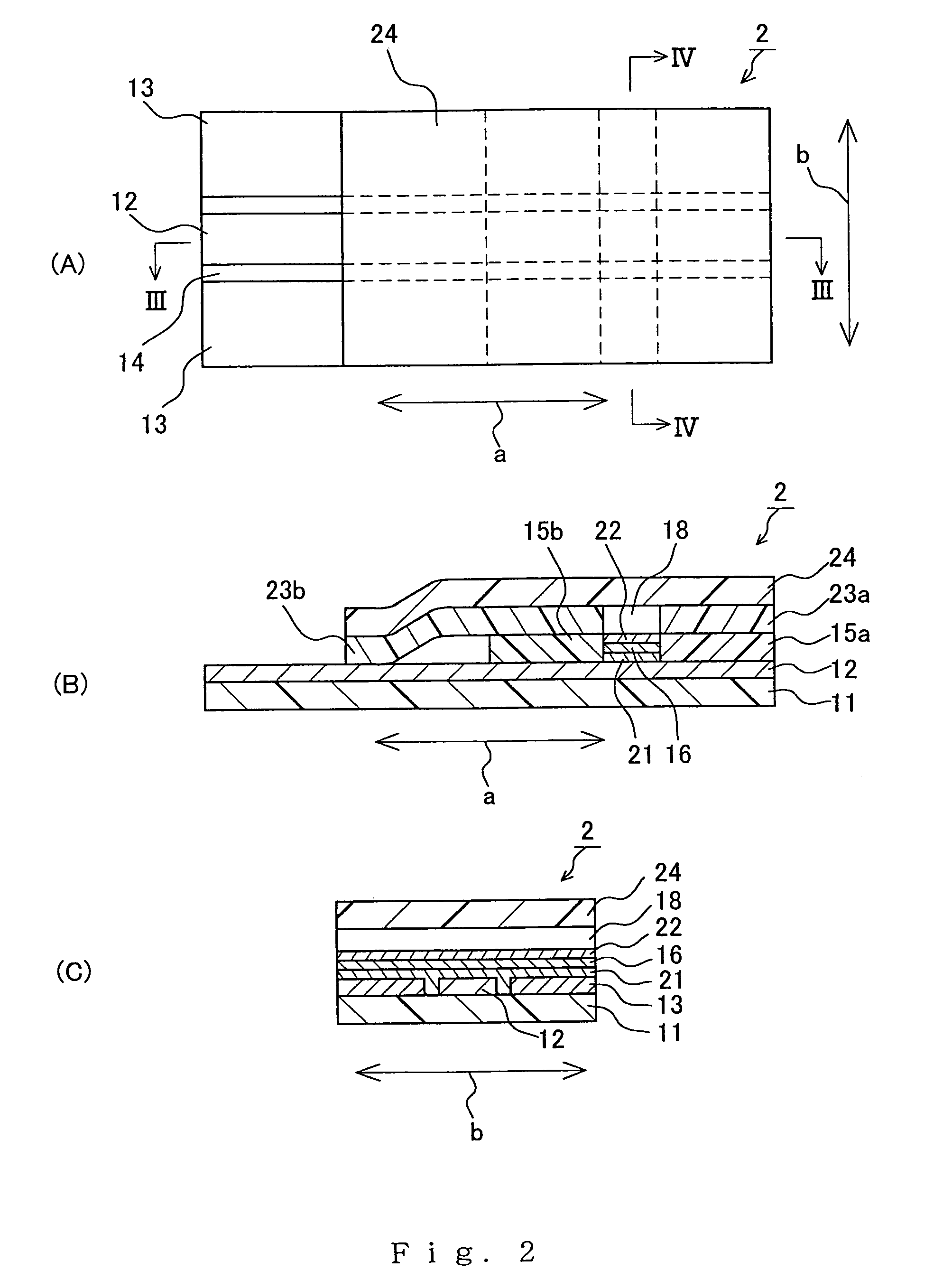

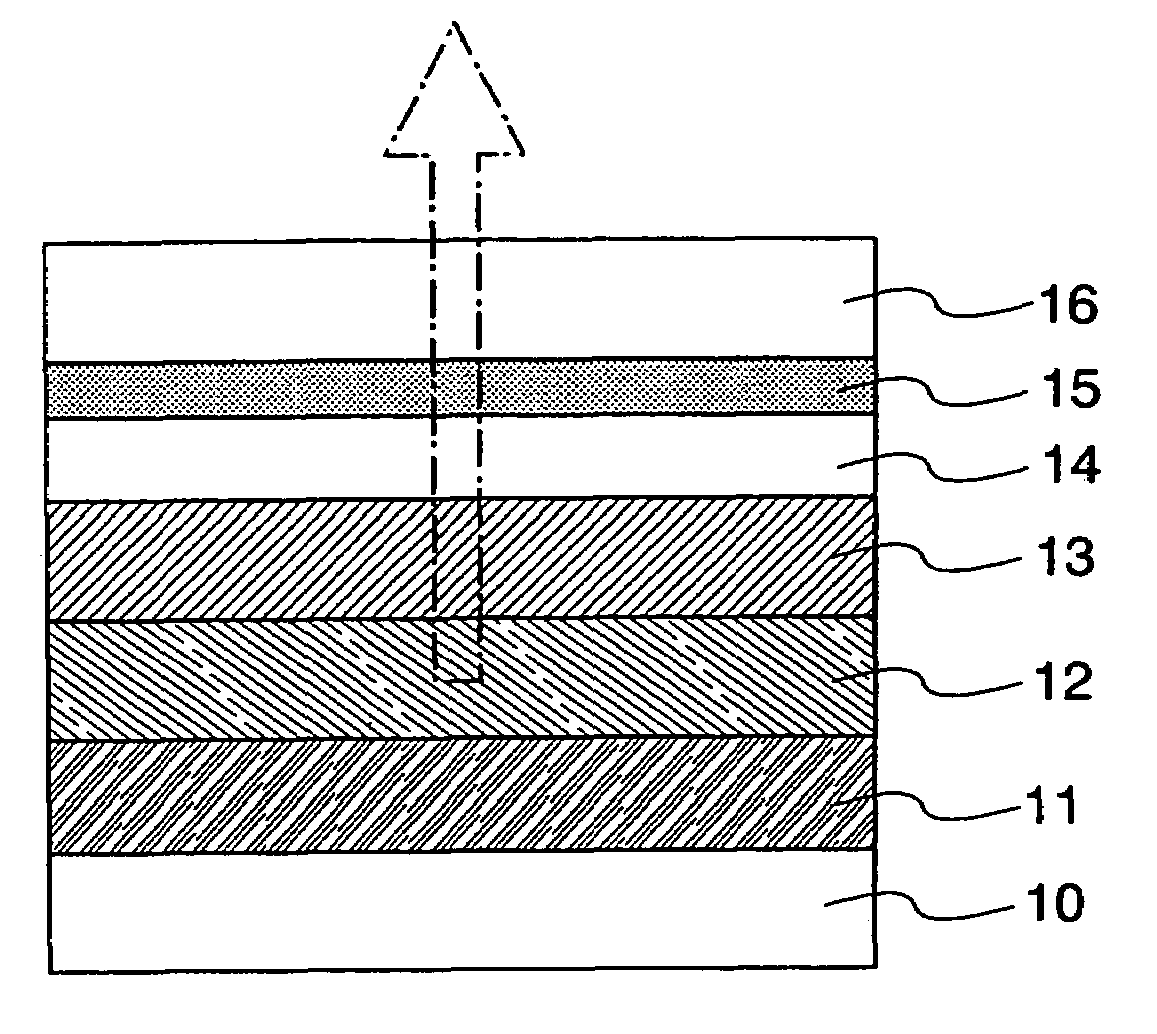

Biosensor

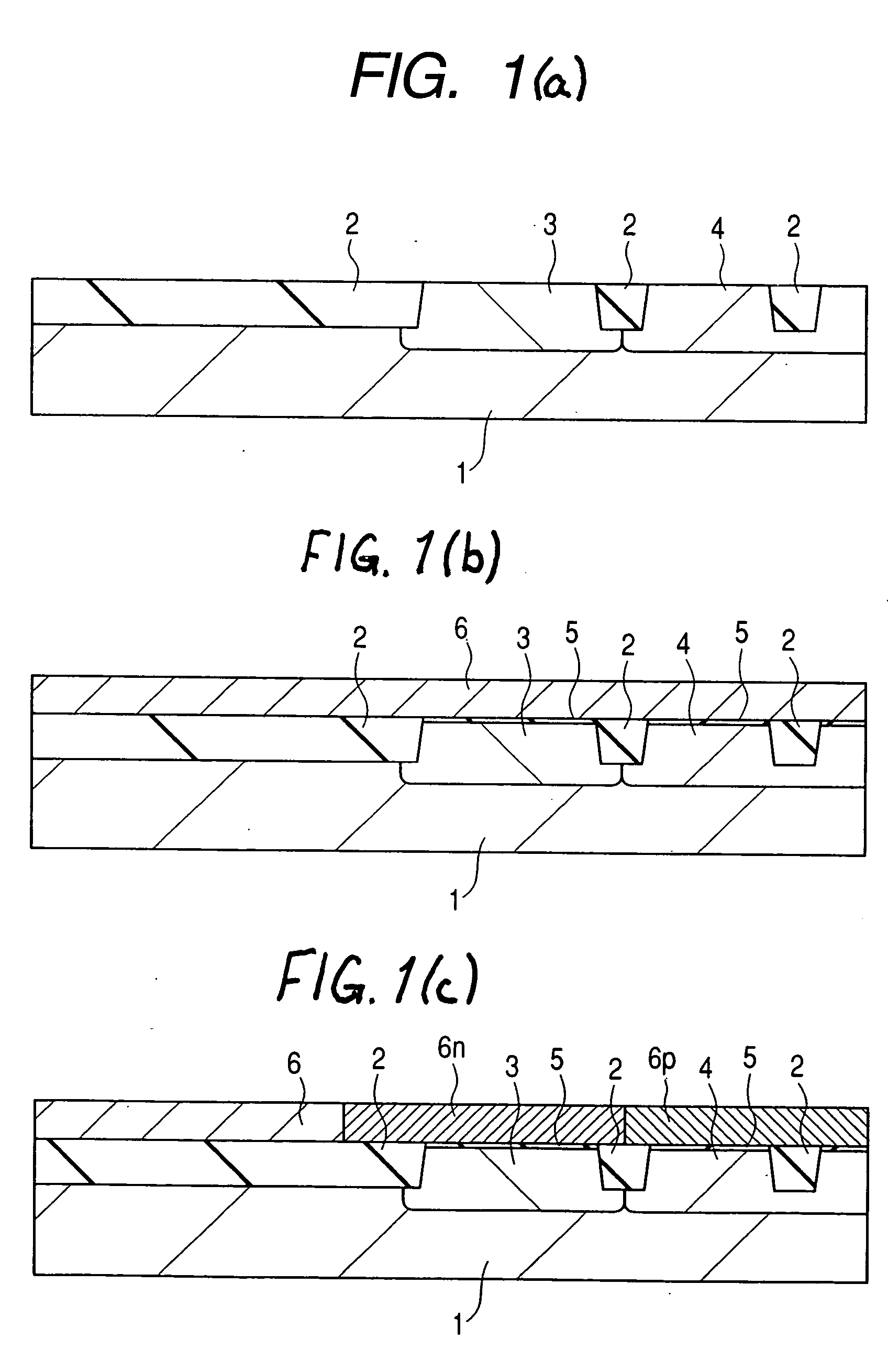

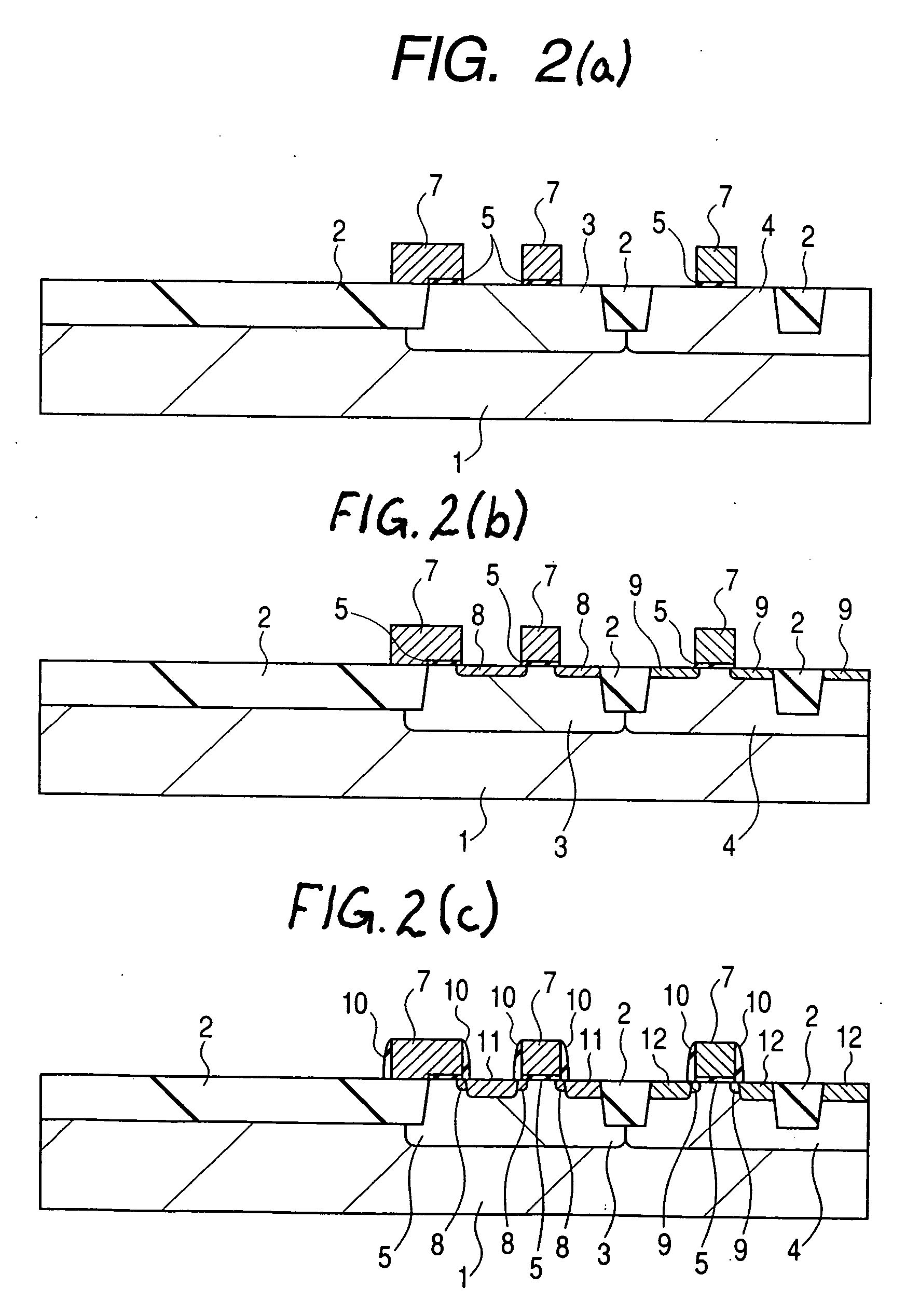

InactiveUS6982027B2Improve accuracyHigh precision measurementImmobilised enzymesBioreactor/fermenter combinationsParticulatesAnalyte

A biosensor is provided, which can measure an analyte in a sample with high precision. The biosensor is produced by disposing a electrode system including a working electrode 12 and a counter electrode 13 on a substrate 11, and then forming a reagent layer 16 containing a reagent and particulates on the electrode system. The influence of the impurities in the sample on the electrode system can be eliminated by the particulates. The average particle diameter of the particulates preferably is in the range from 0.1 to 45 μm.

Owner:ARKRAY INC

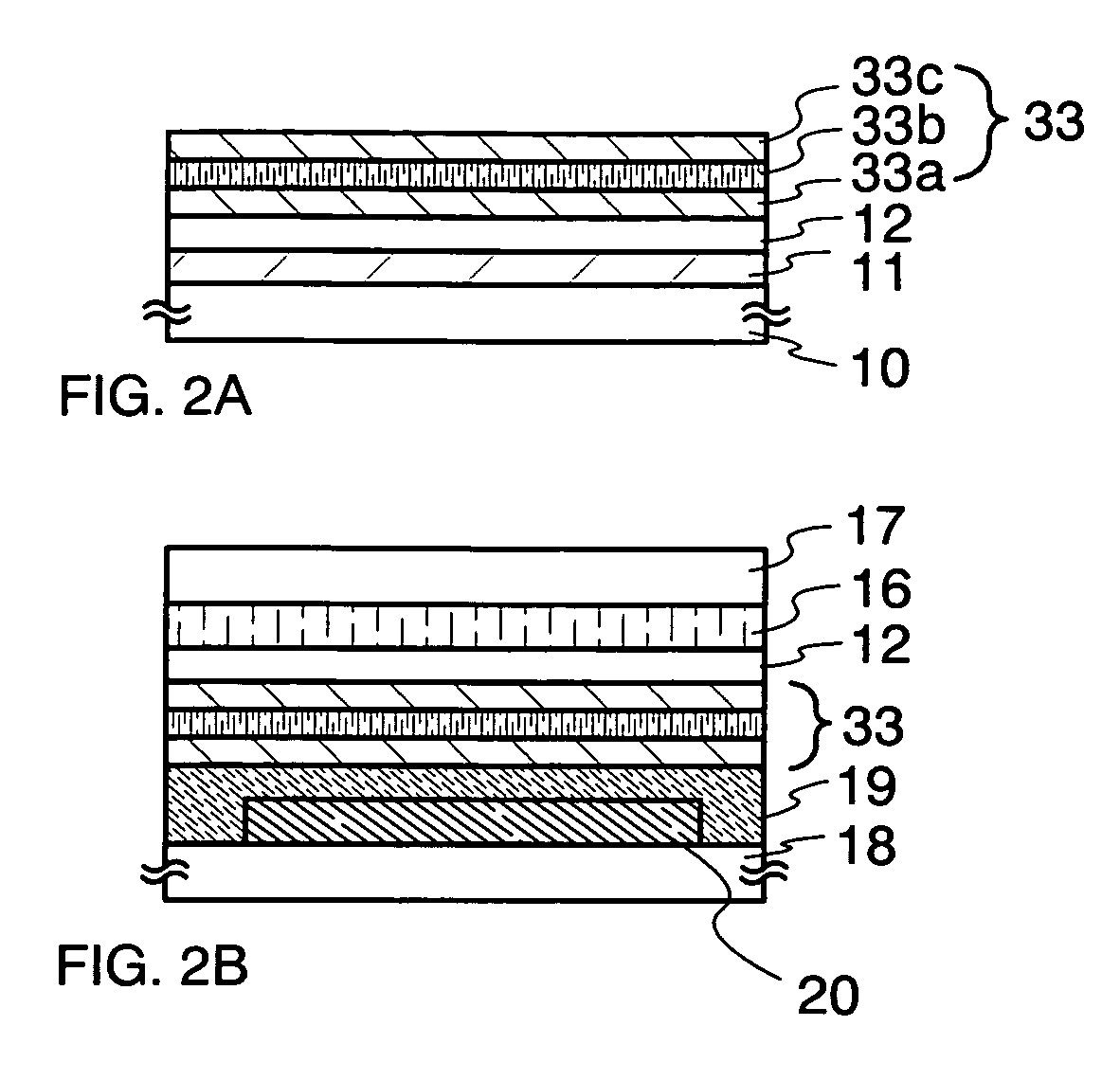

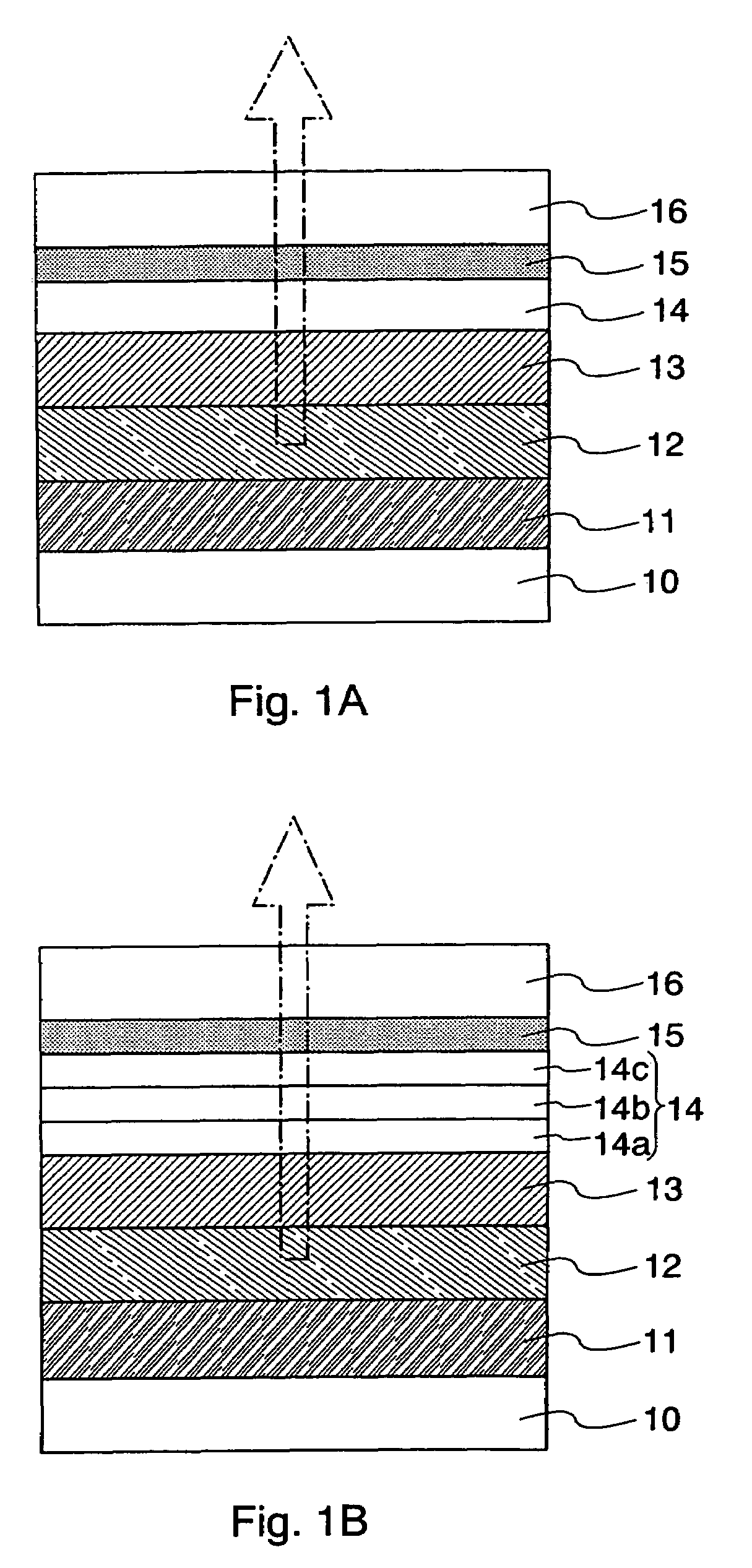

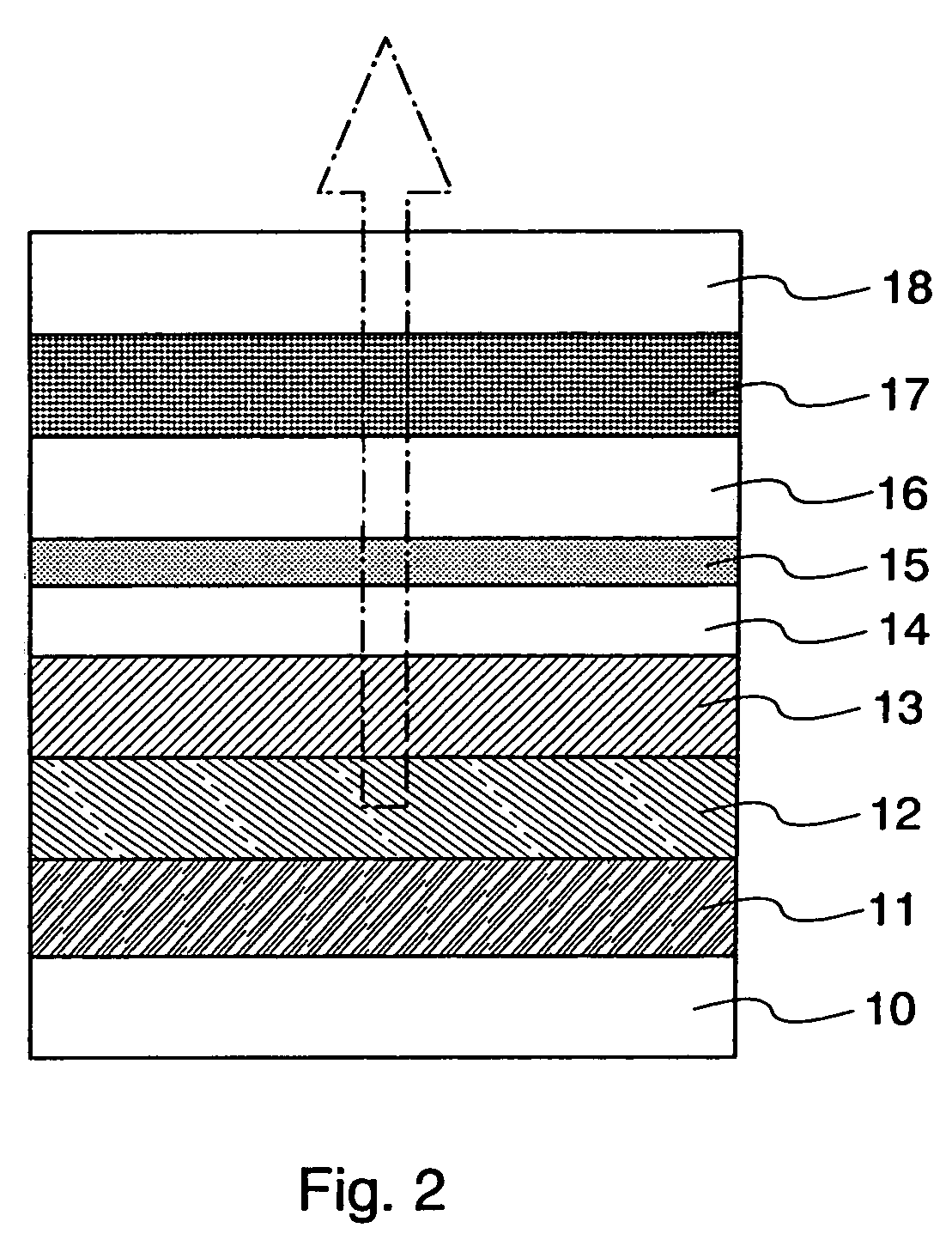

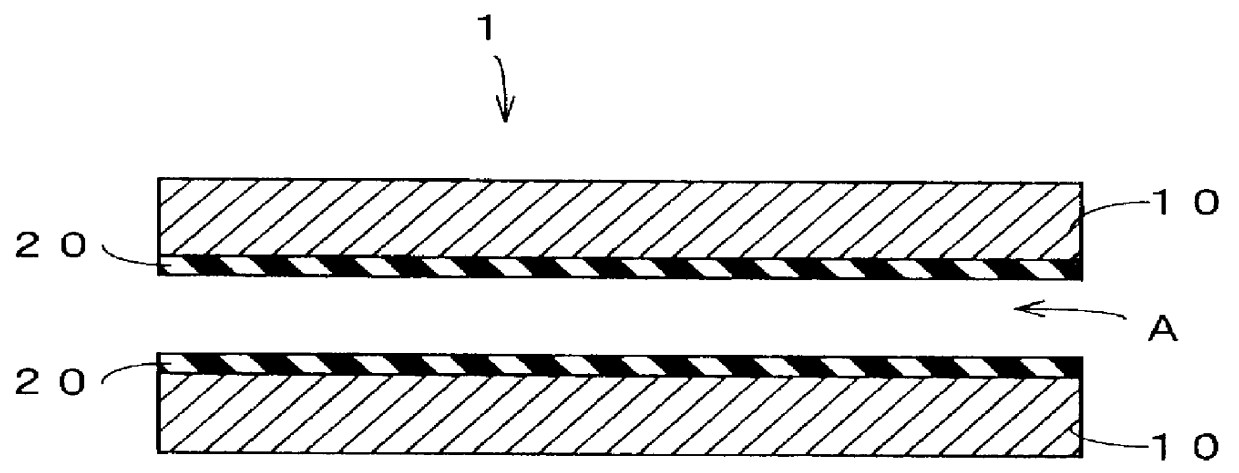

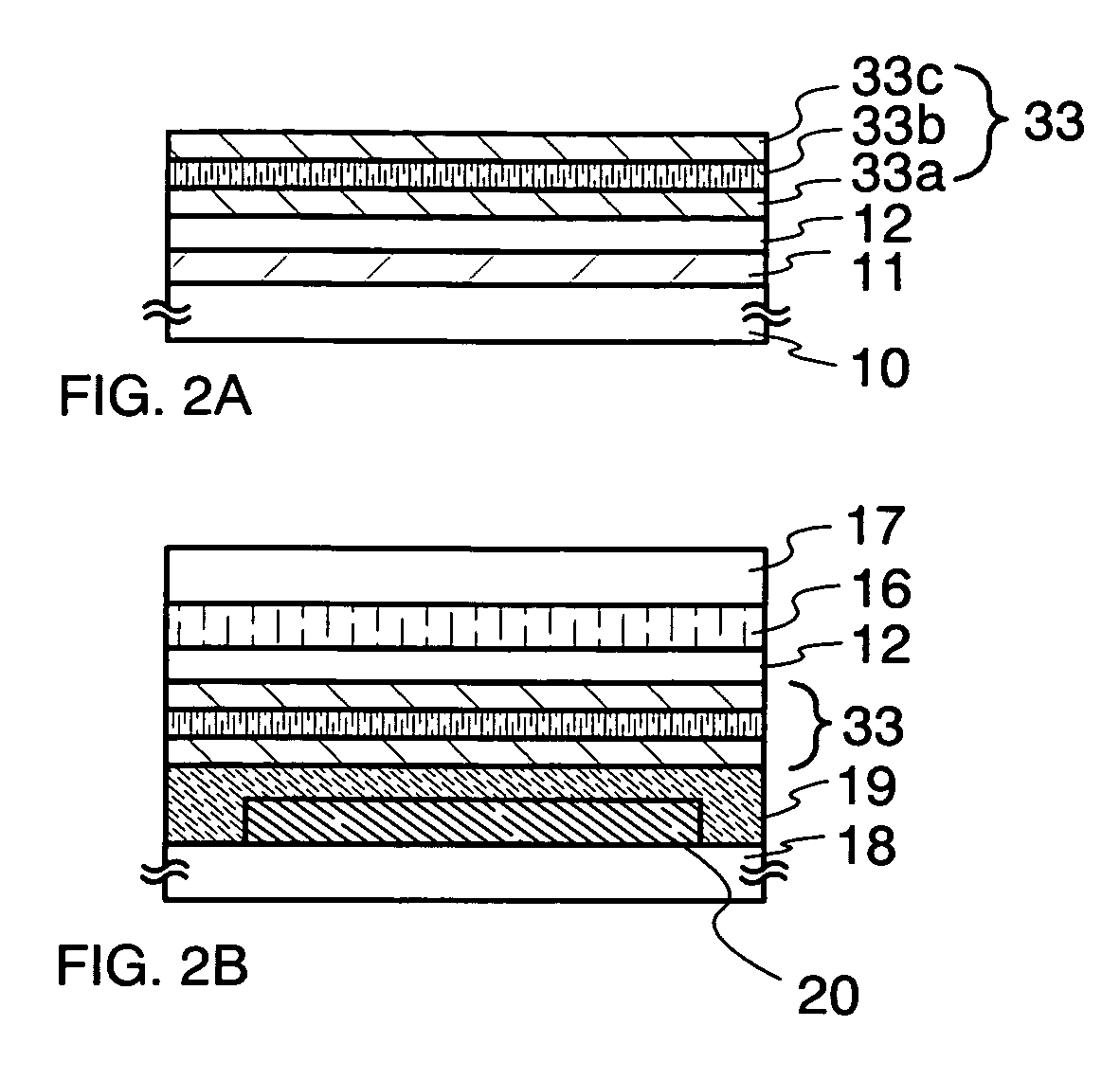

Light-emitting element and display device

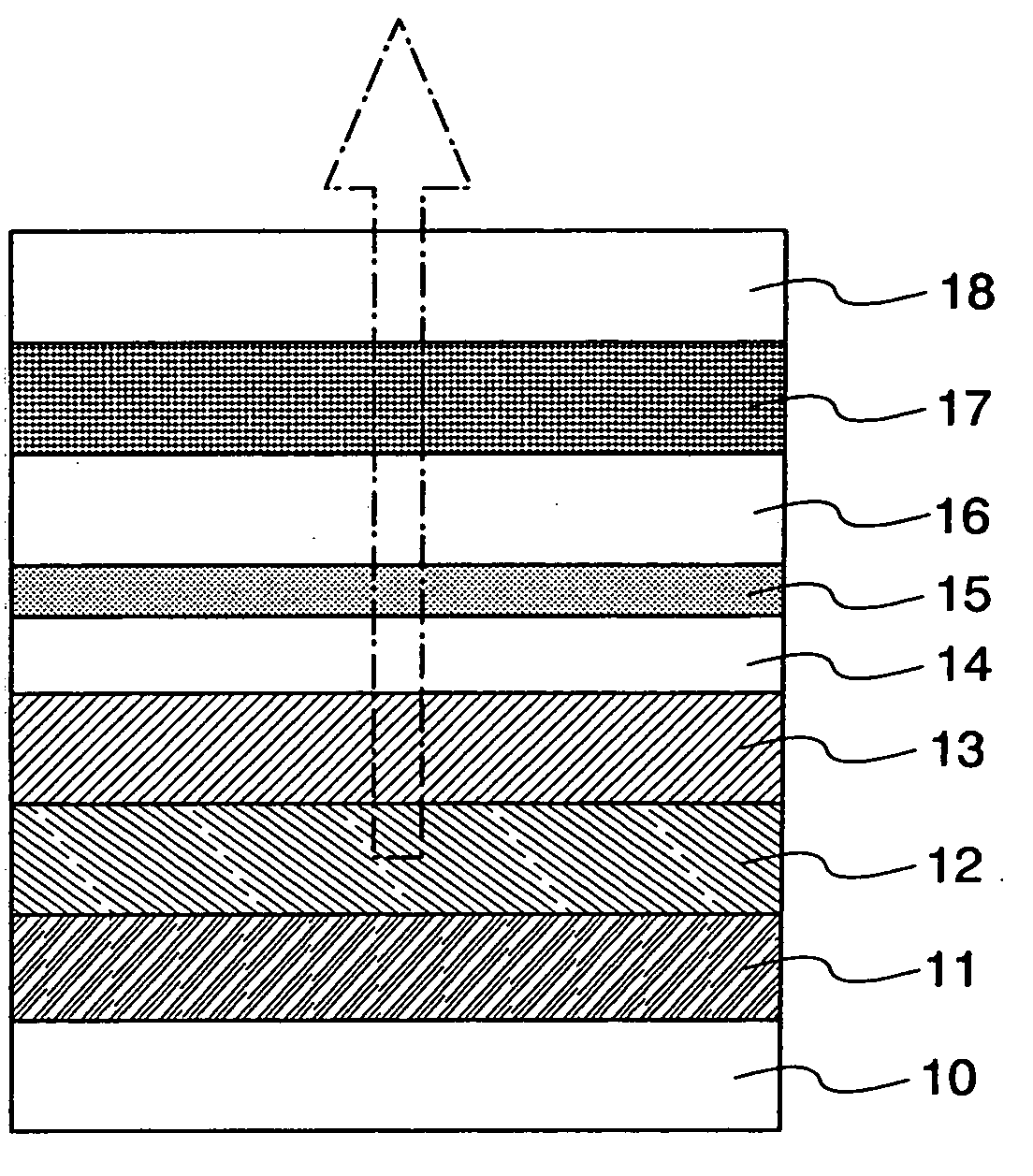

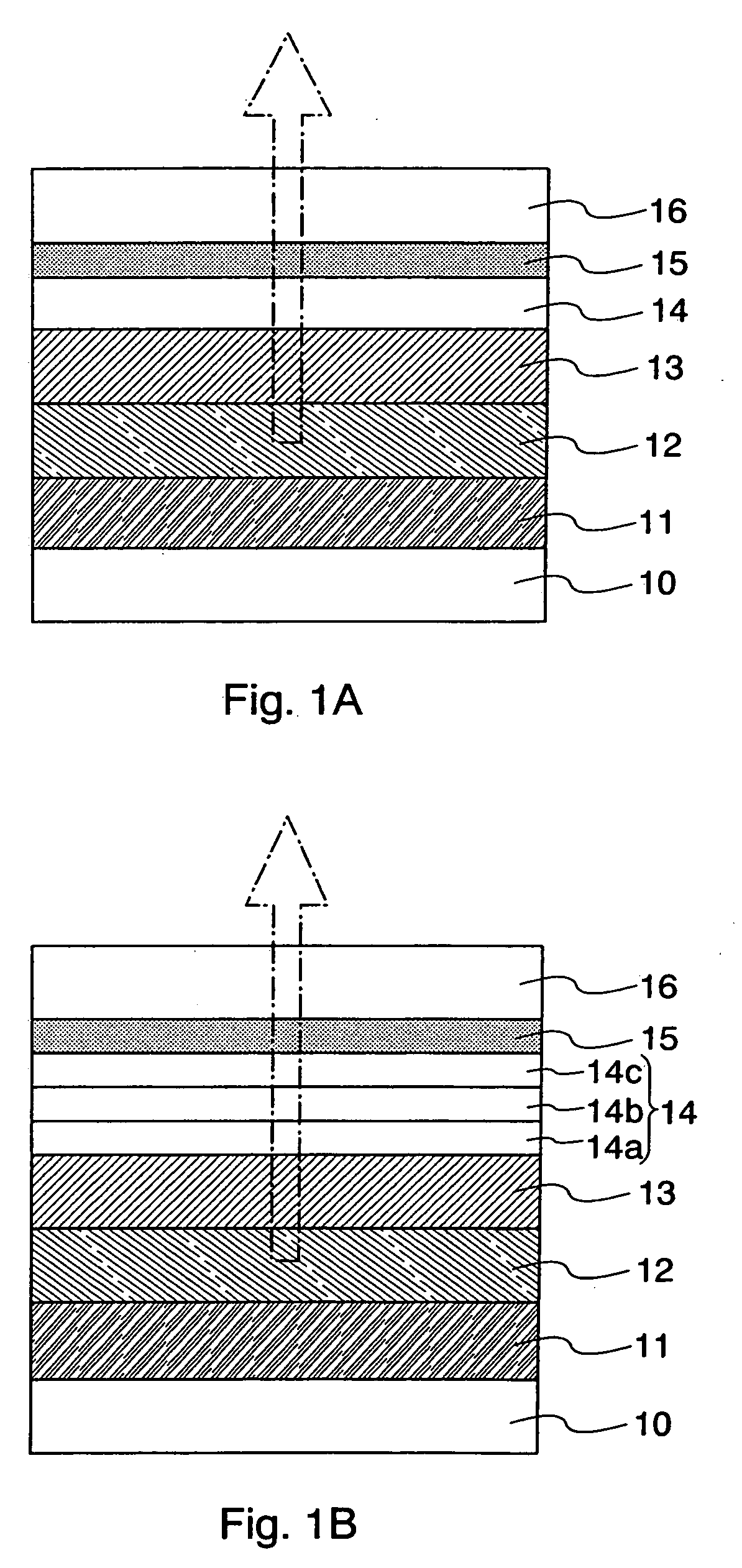

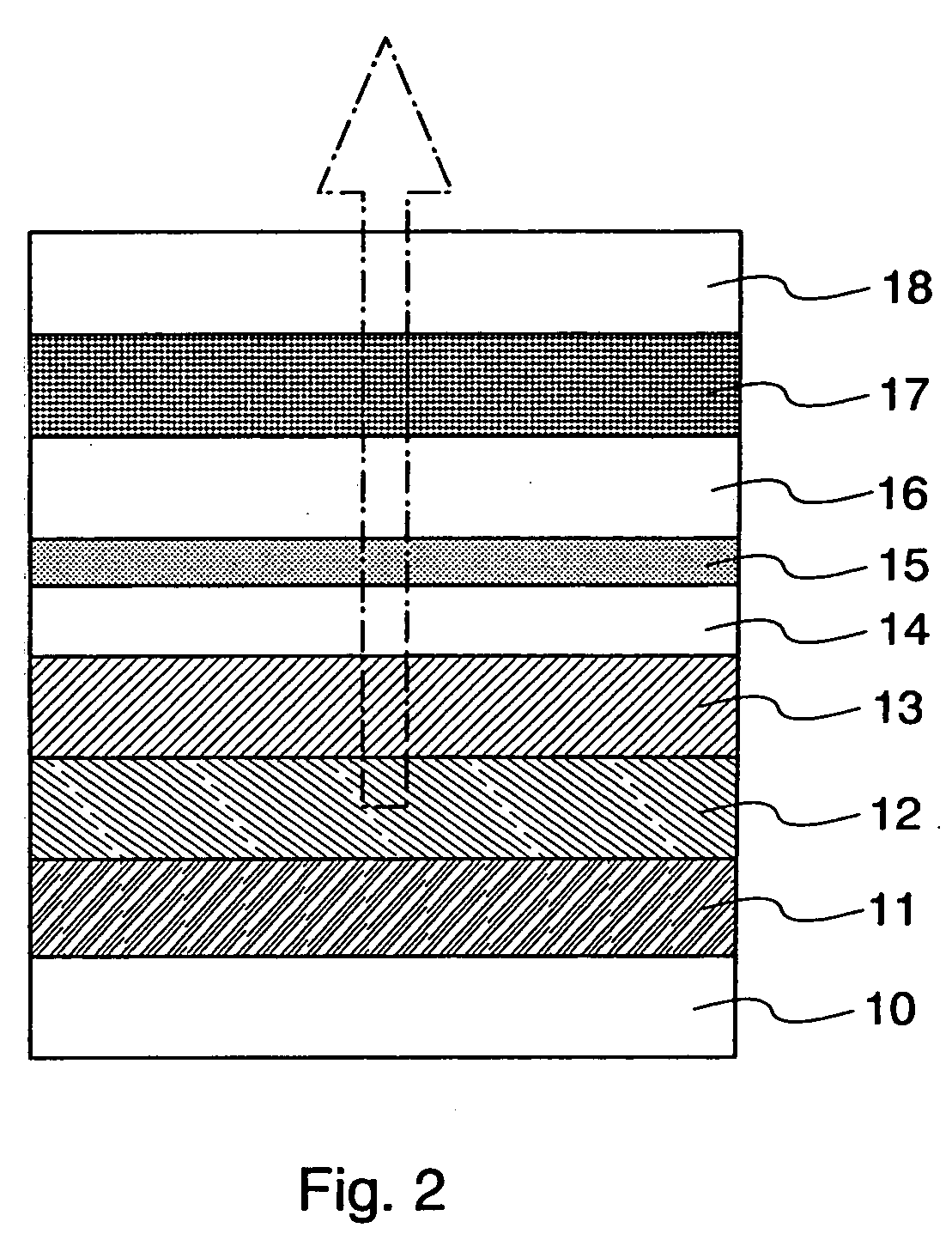

InactiveUS20050263775A1Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingRefractive index

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

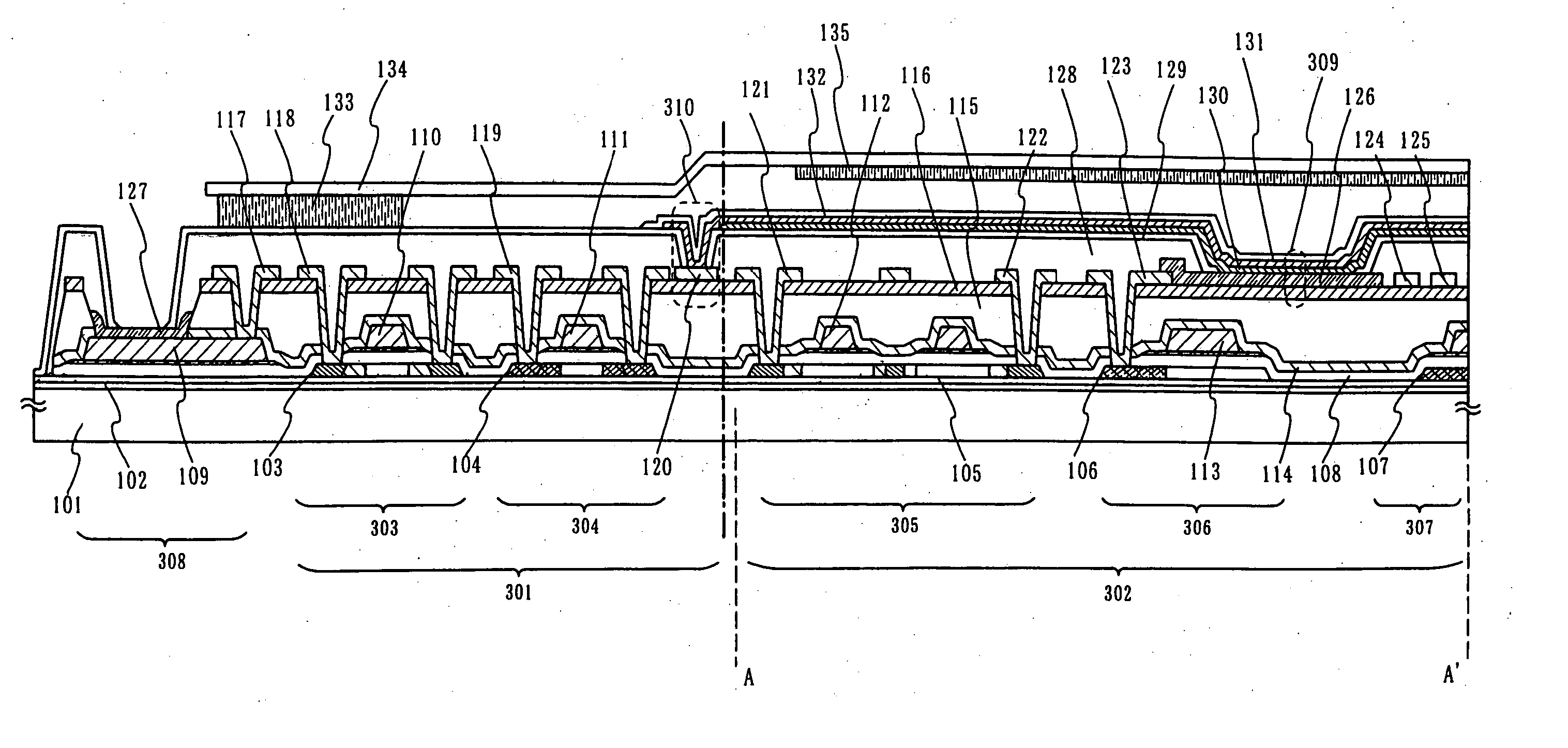

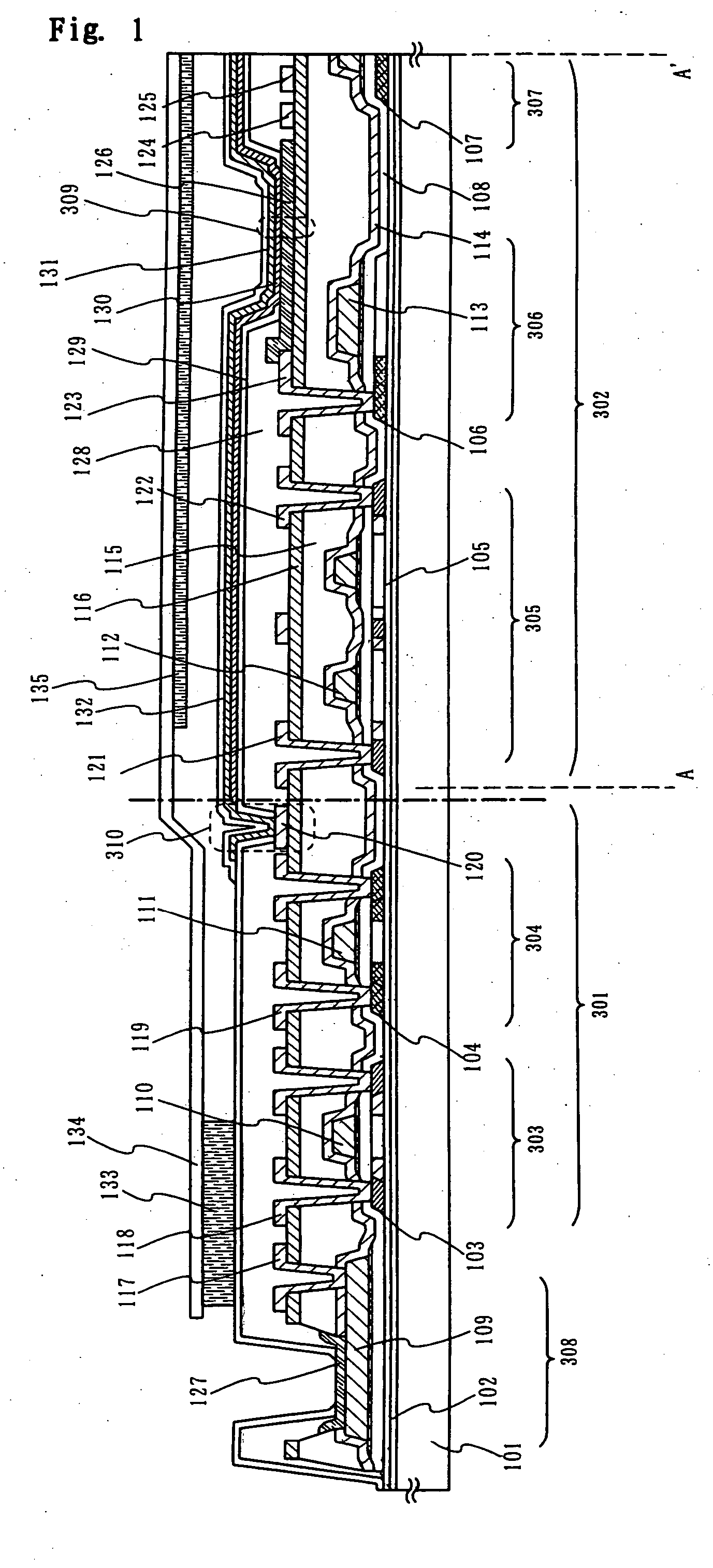

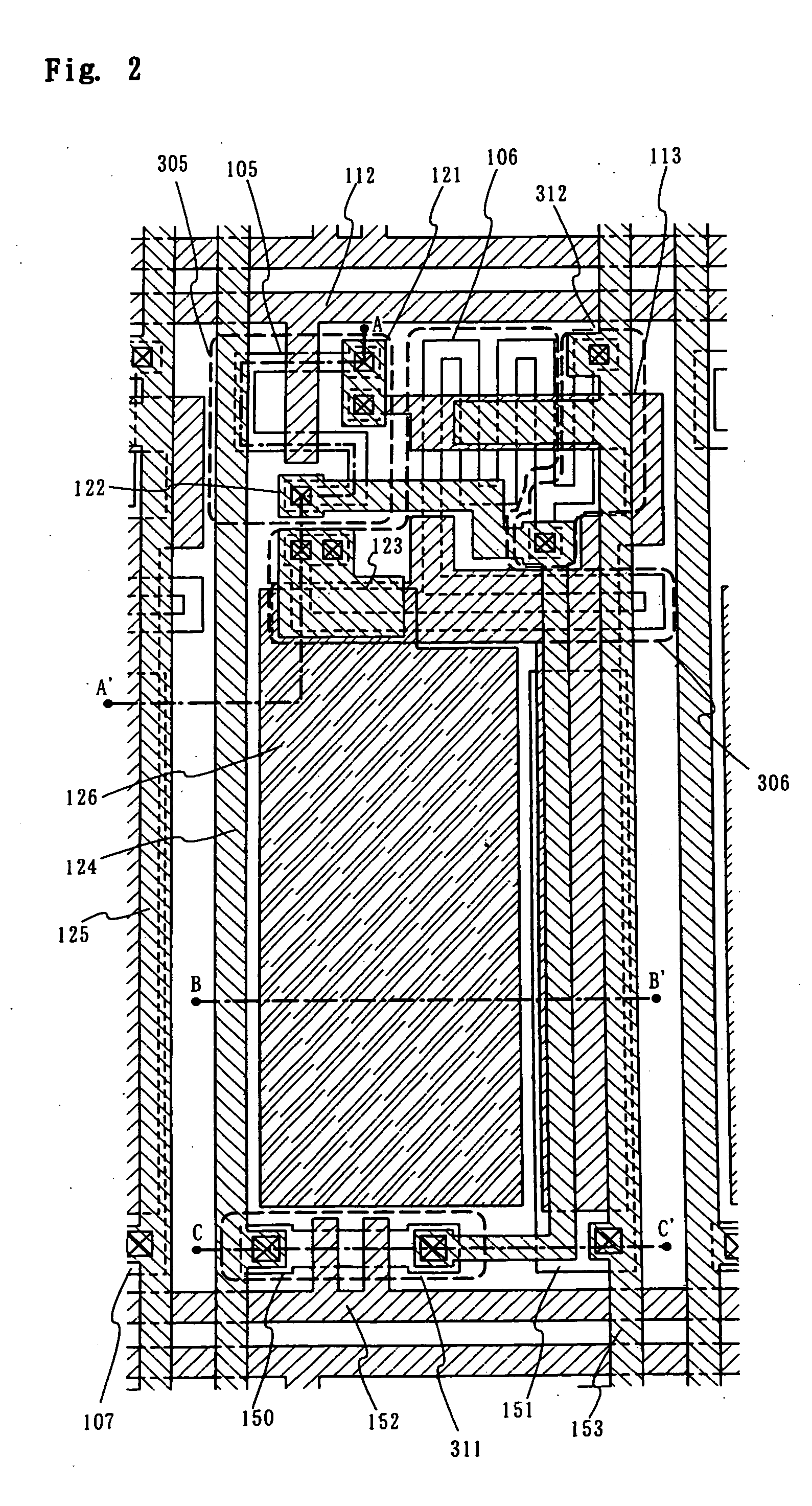

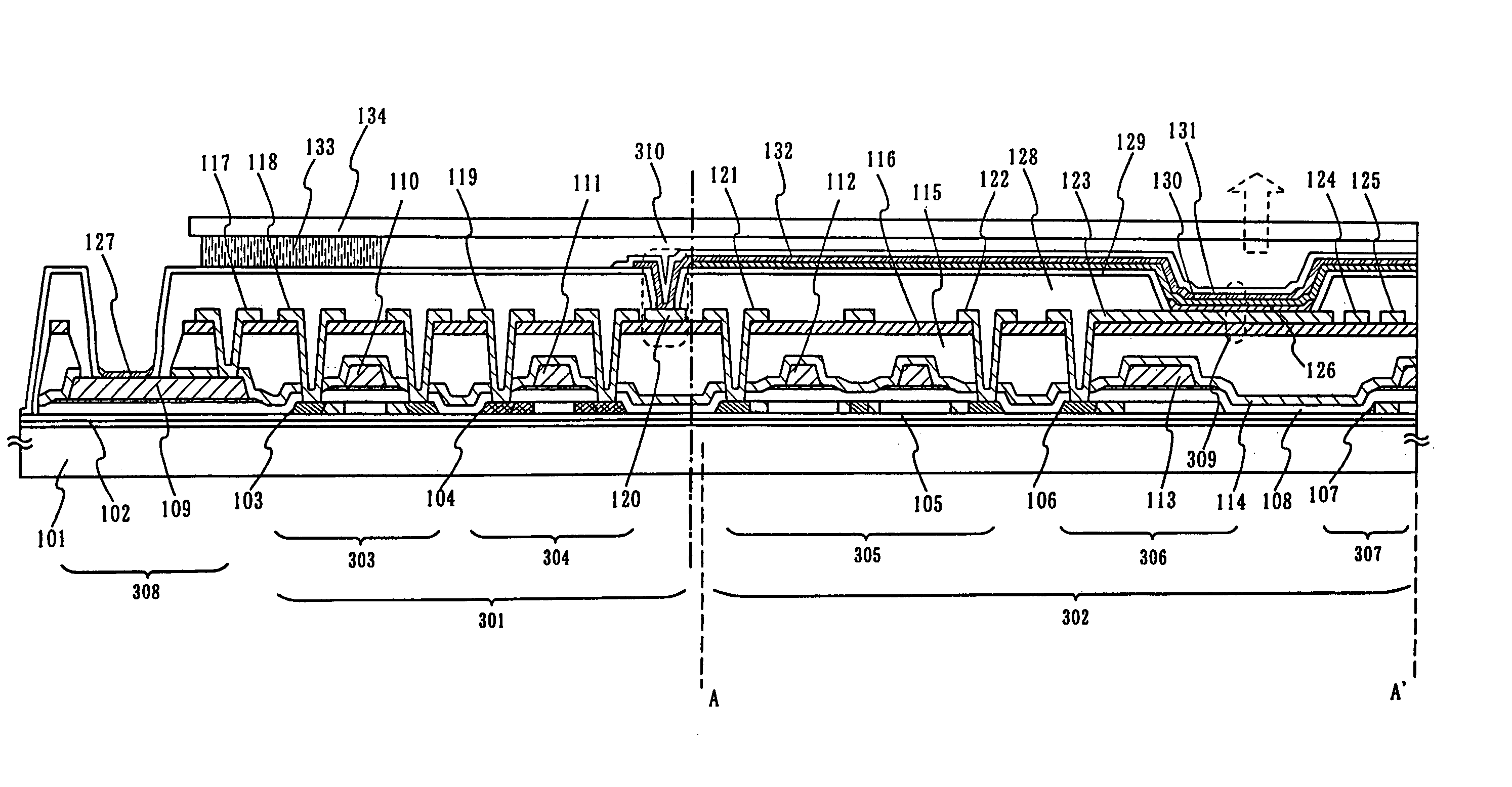

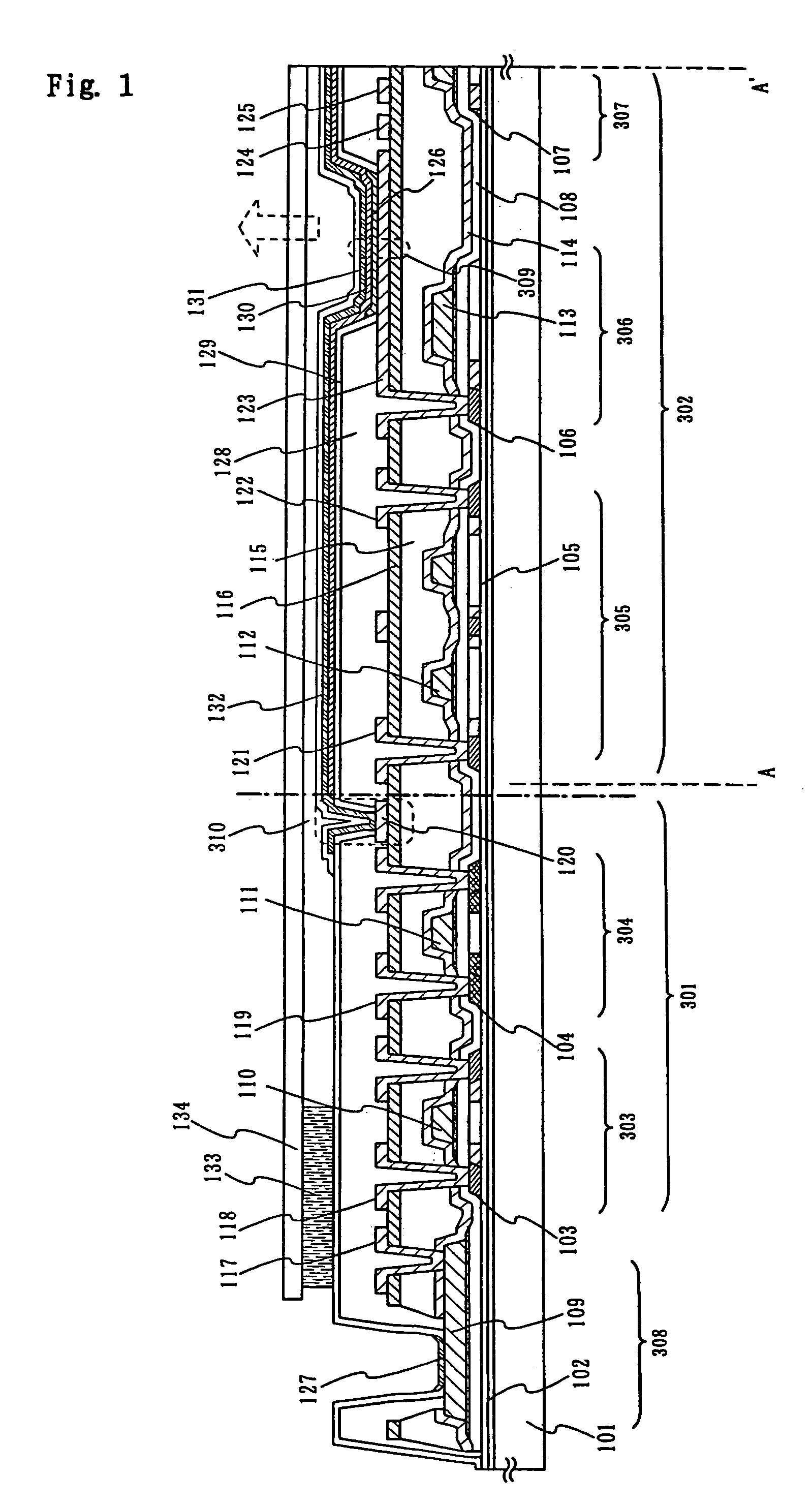

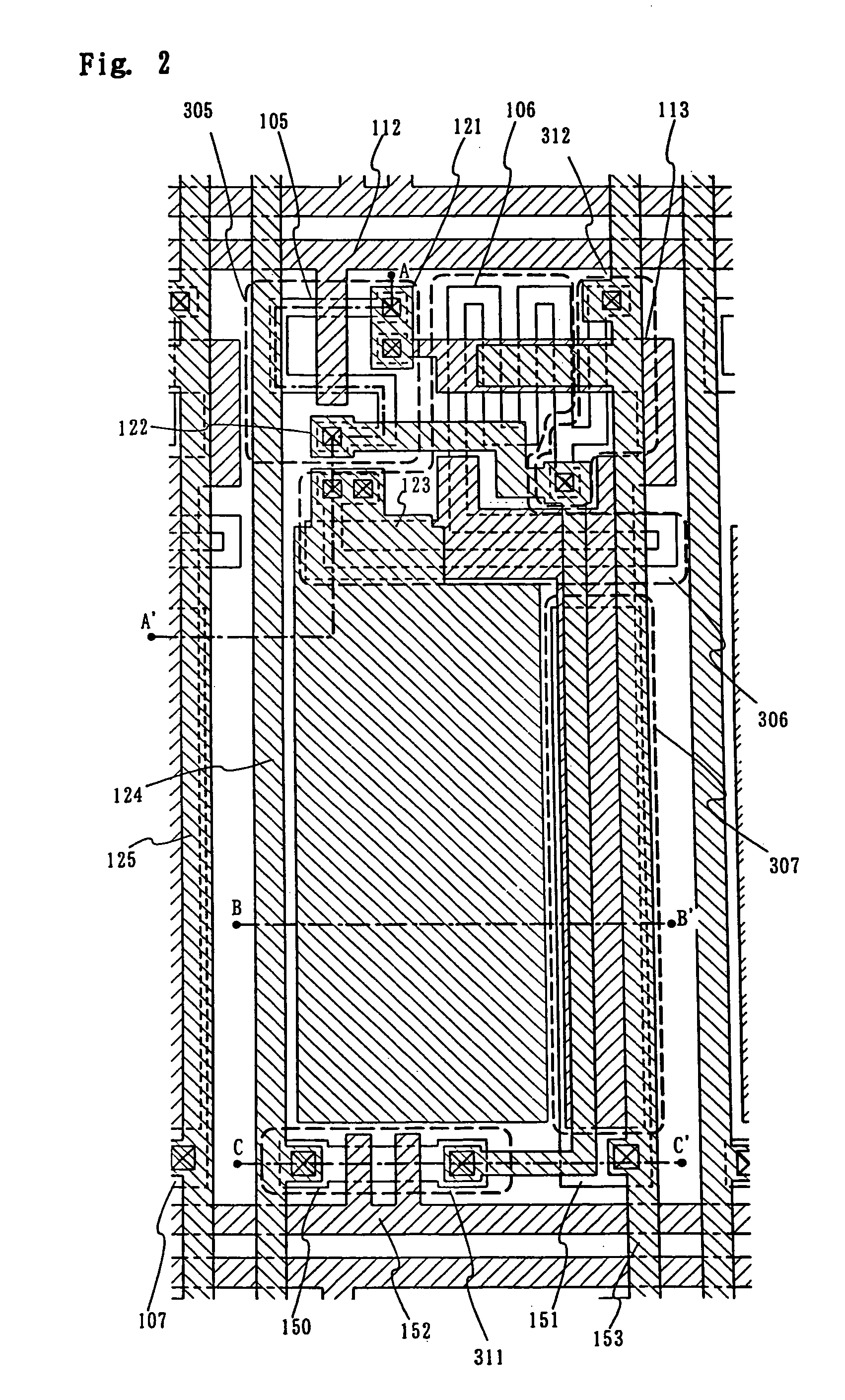

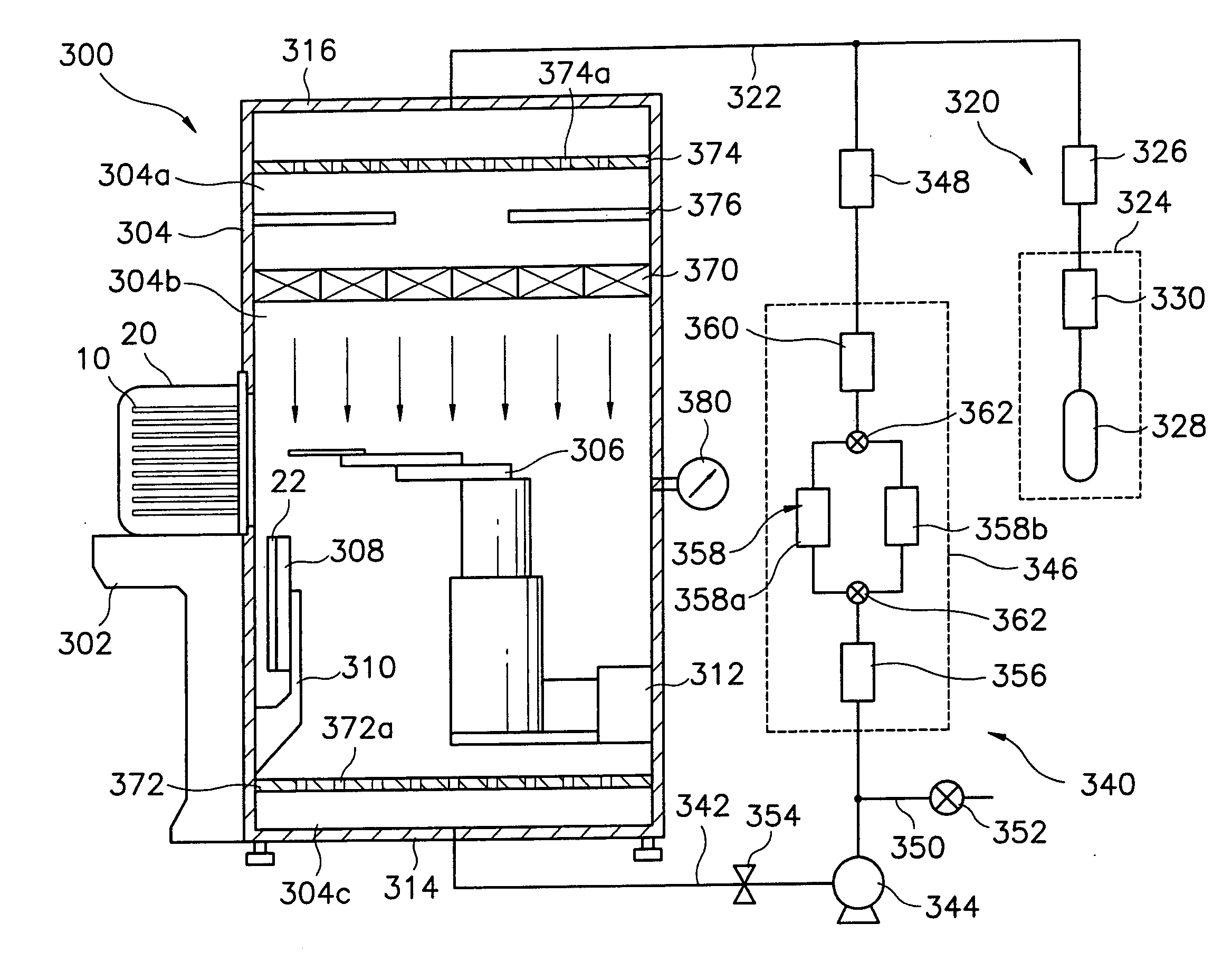

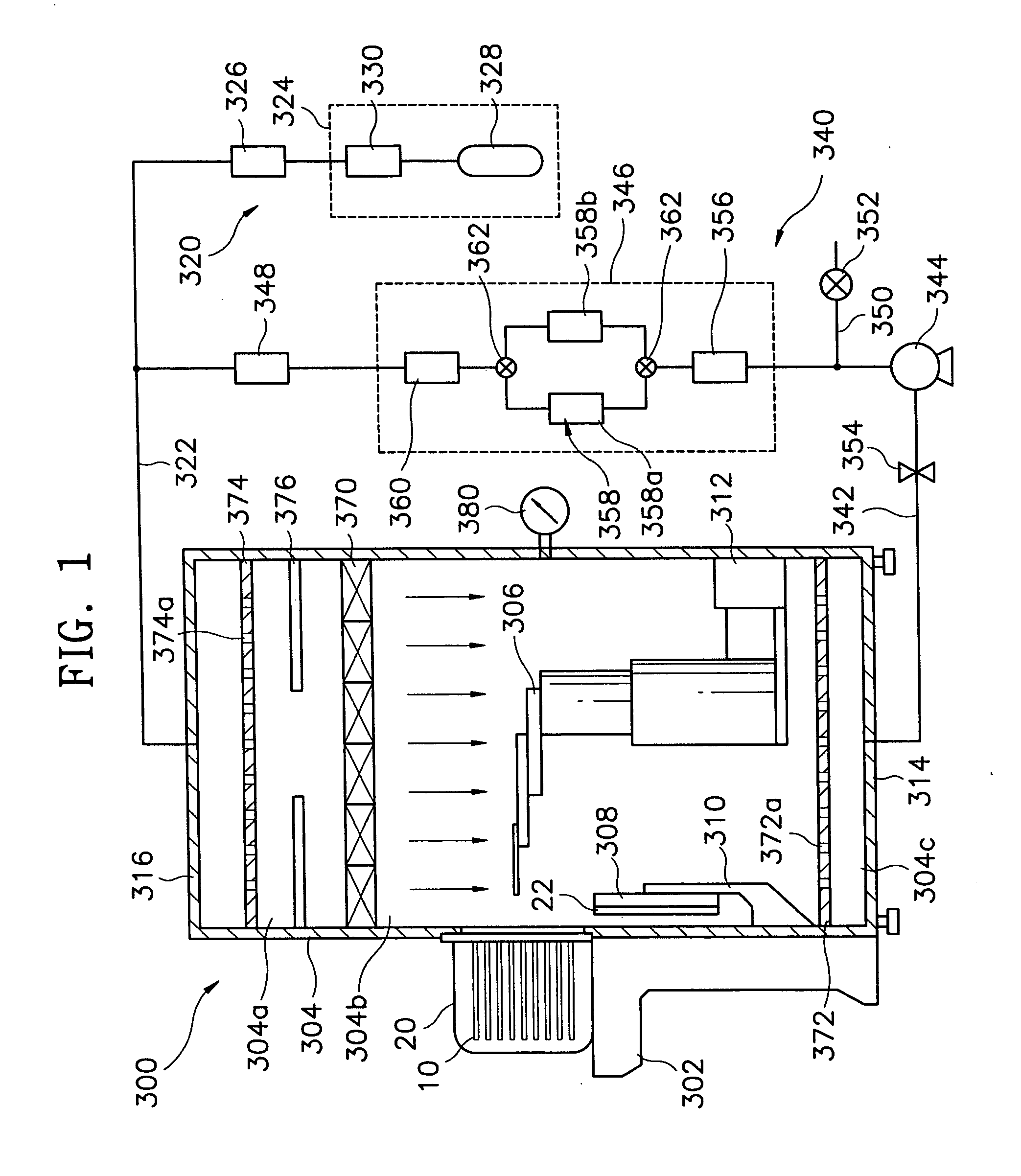

Light emitting device, method of manufacturing the same, and manufacturing apparatus therefor

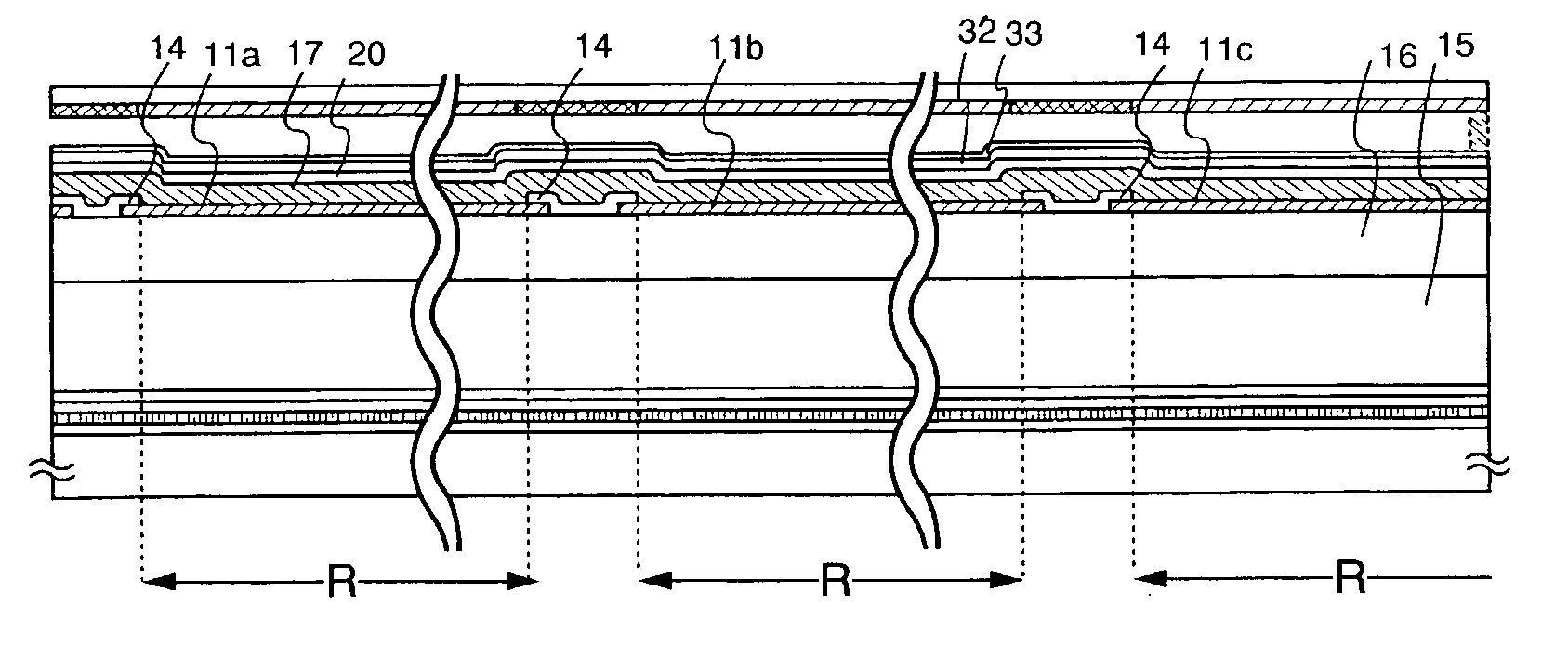

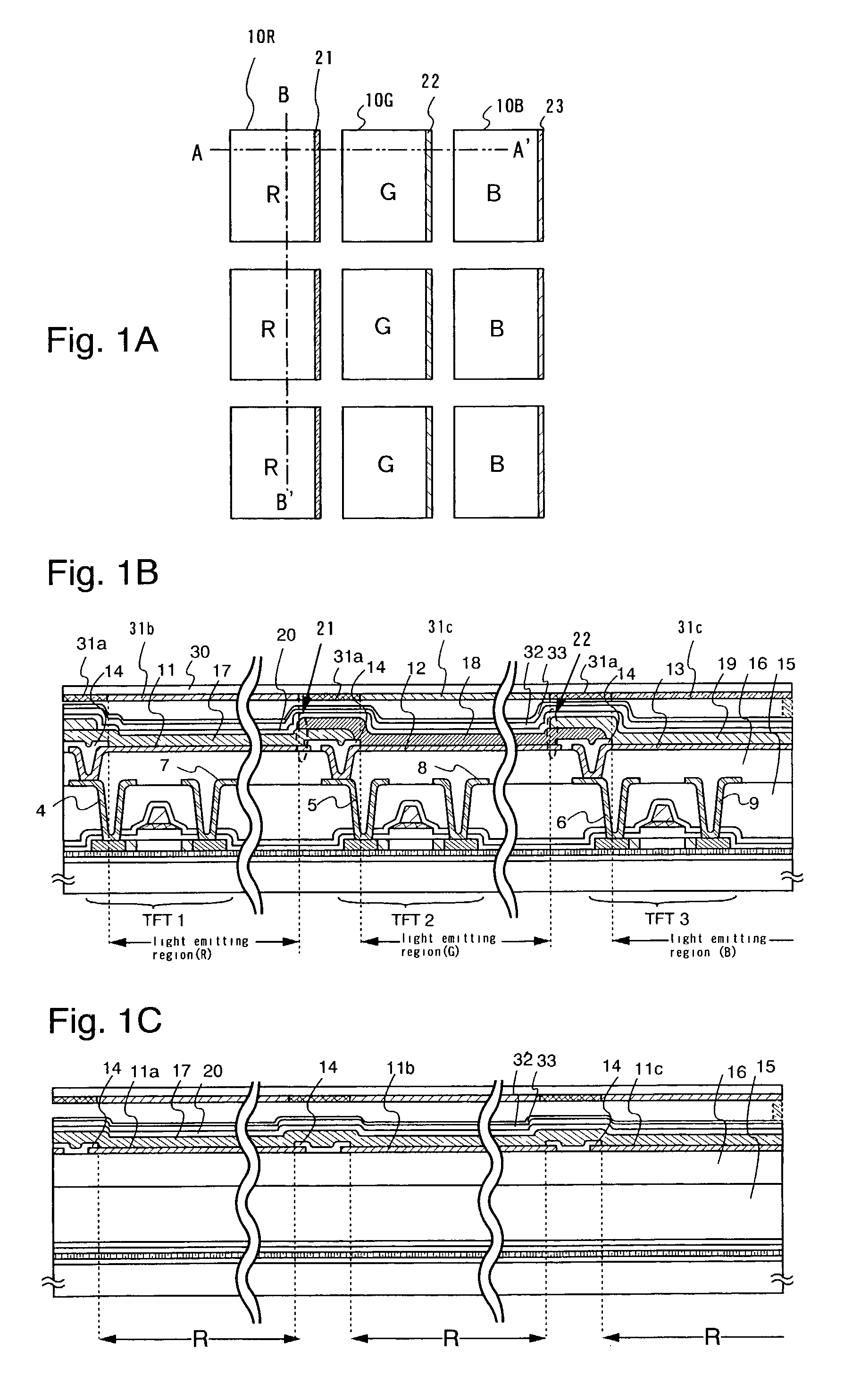

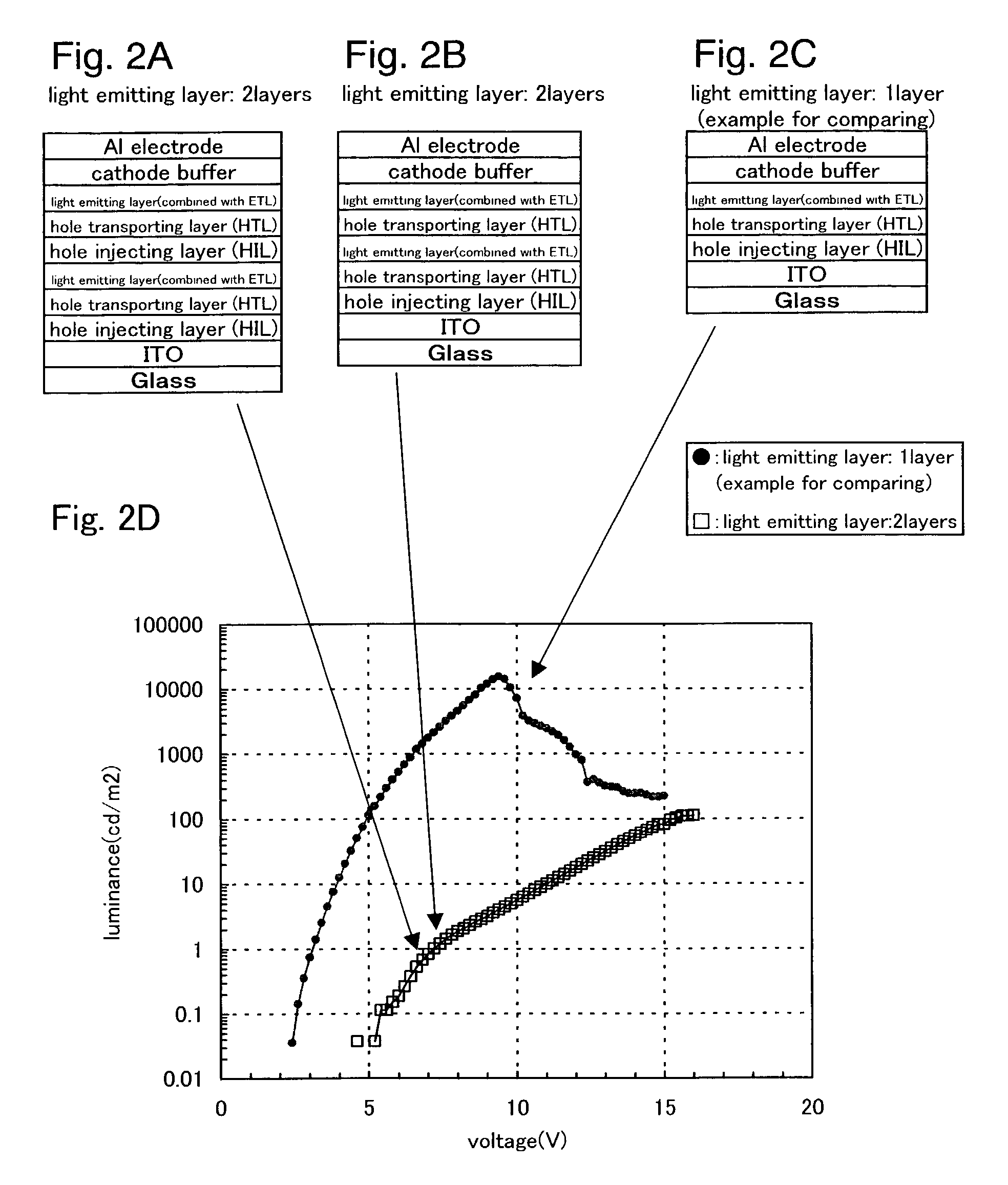

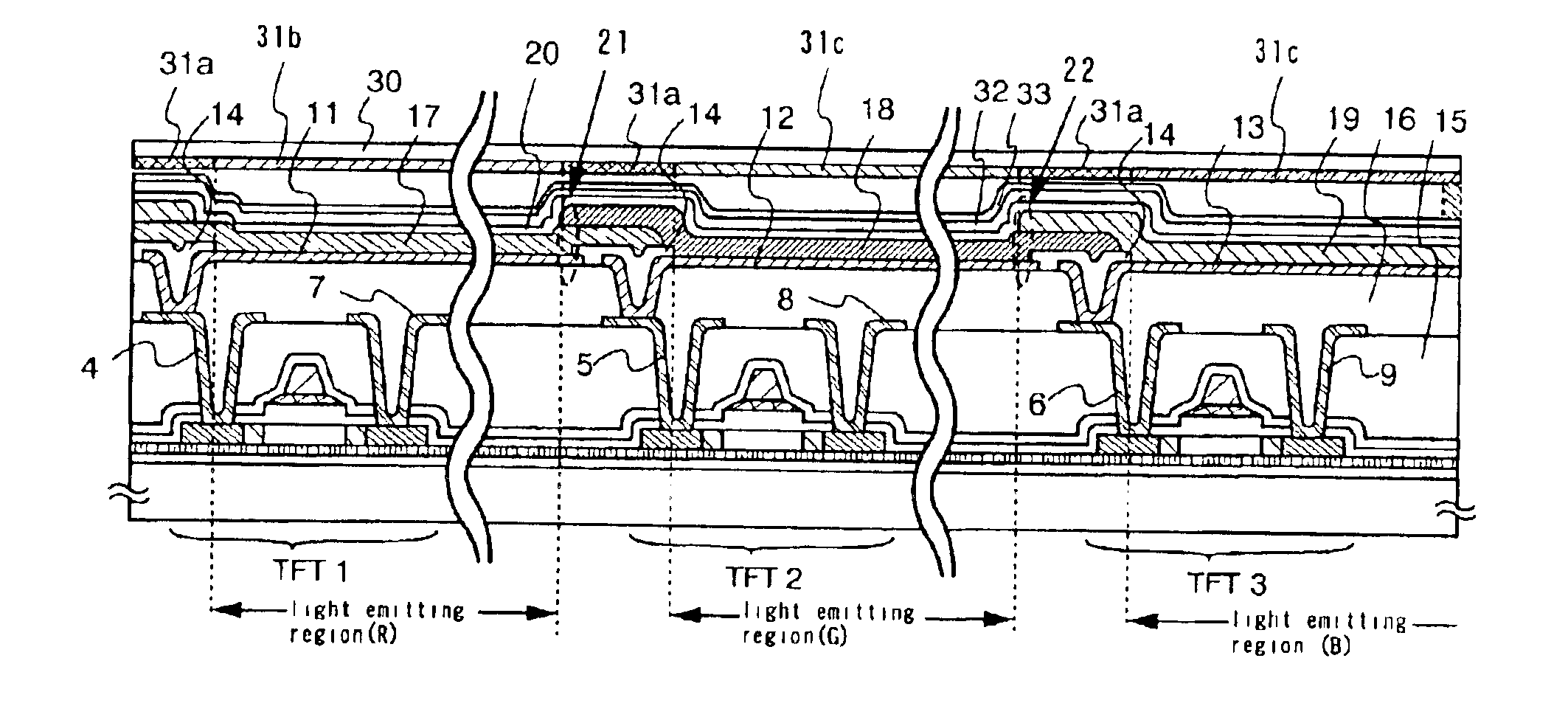

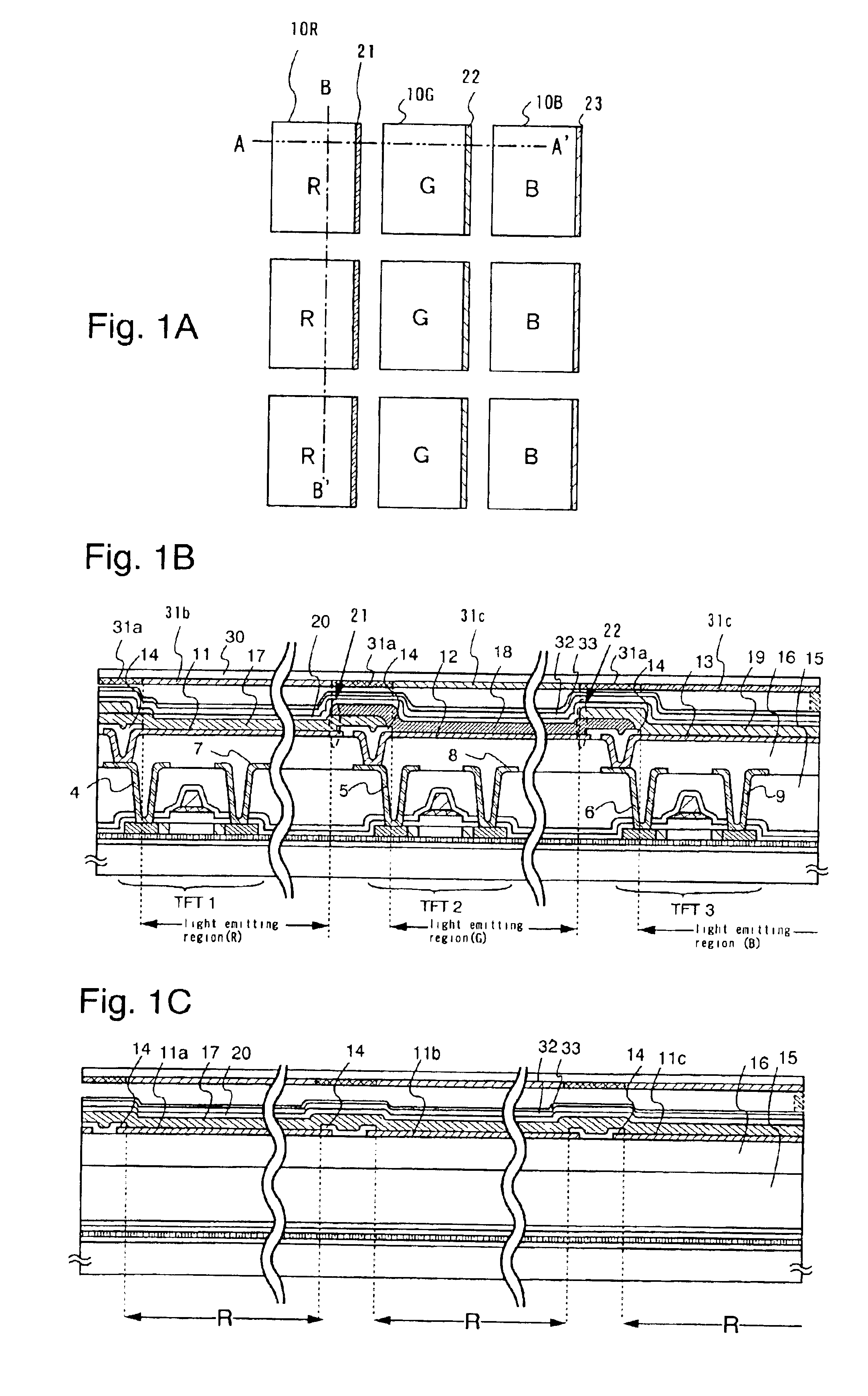

InactiveUS20030122140A1Low costReduce manufacturing costDischarge tube luminescnet screensElectroluminescent light sourcesFlat panel displayHigh definition

A light emitting device having high definition, a high aperture ratio, and high reliability is provided. The present invention achieves high definition and a high aperture ratio with a full color flat panel display using red, green, and blue color emission light by intentionally forming laminate portions, wherein portions of different organic compound layers of adjacent light emitting elements overlap with each other, without depending upon the method of forming the organic compound layers or the film formation precision.

Owner:SEMICON ENERGY LAB CO LTD

Light emitting device, method of manufacturing the same, and manufacturing apparatus therefor

InactiveUS6815723B2Low costReduce manufacturing costDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceFlat panel display

A light emitting device having high definition, a high aperture ratio, and high reliability is provided. The present invention achieves high definition and a high aperture ratio with a full color flat panel display using red, green, and blue color emission light by intentionally forming laminate portions, wherein portions of different organic compound layers of adjacent light emitting elements overlap with each other, without depending upon the method of forming the organic compound layers or the film formation precision.

Owner:SEMICON ENERGY LAB CO LTD

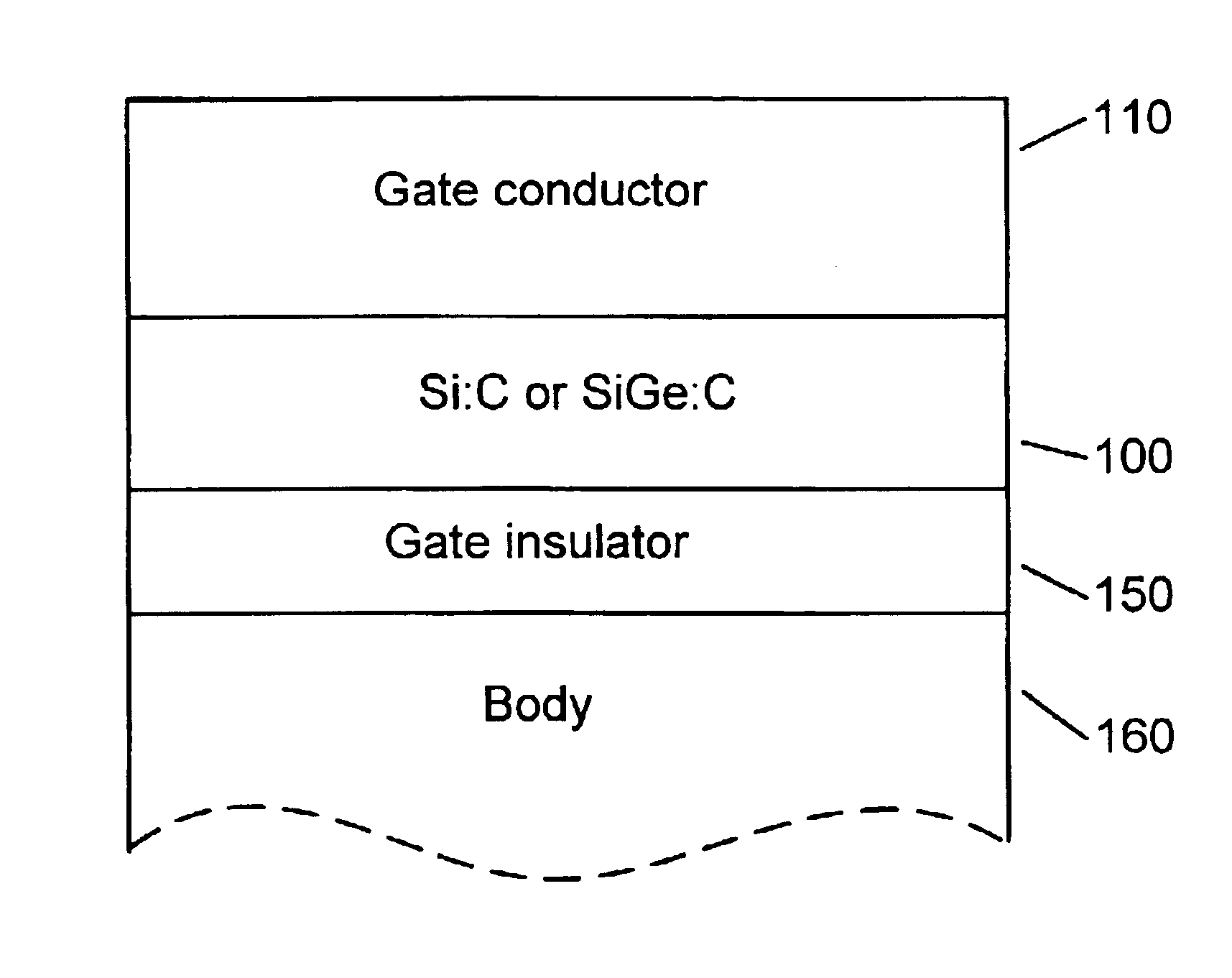

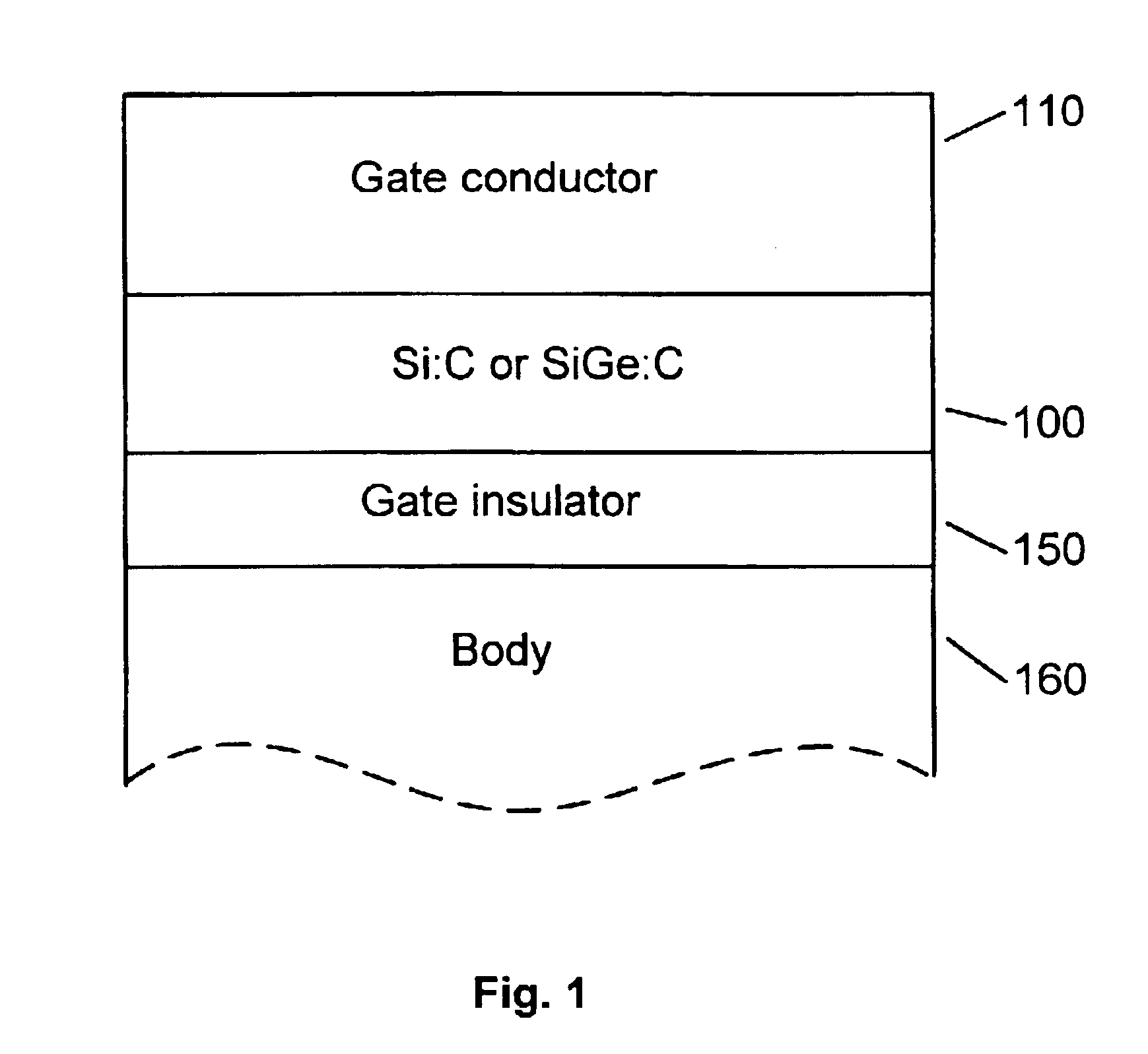

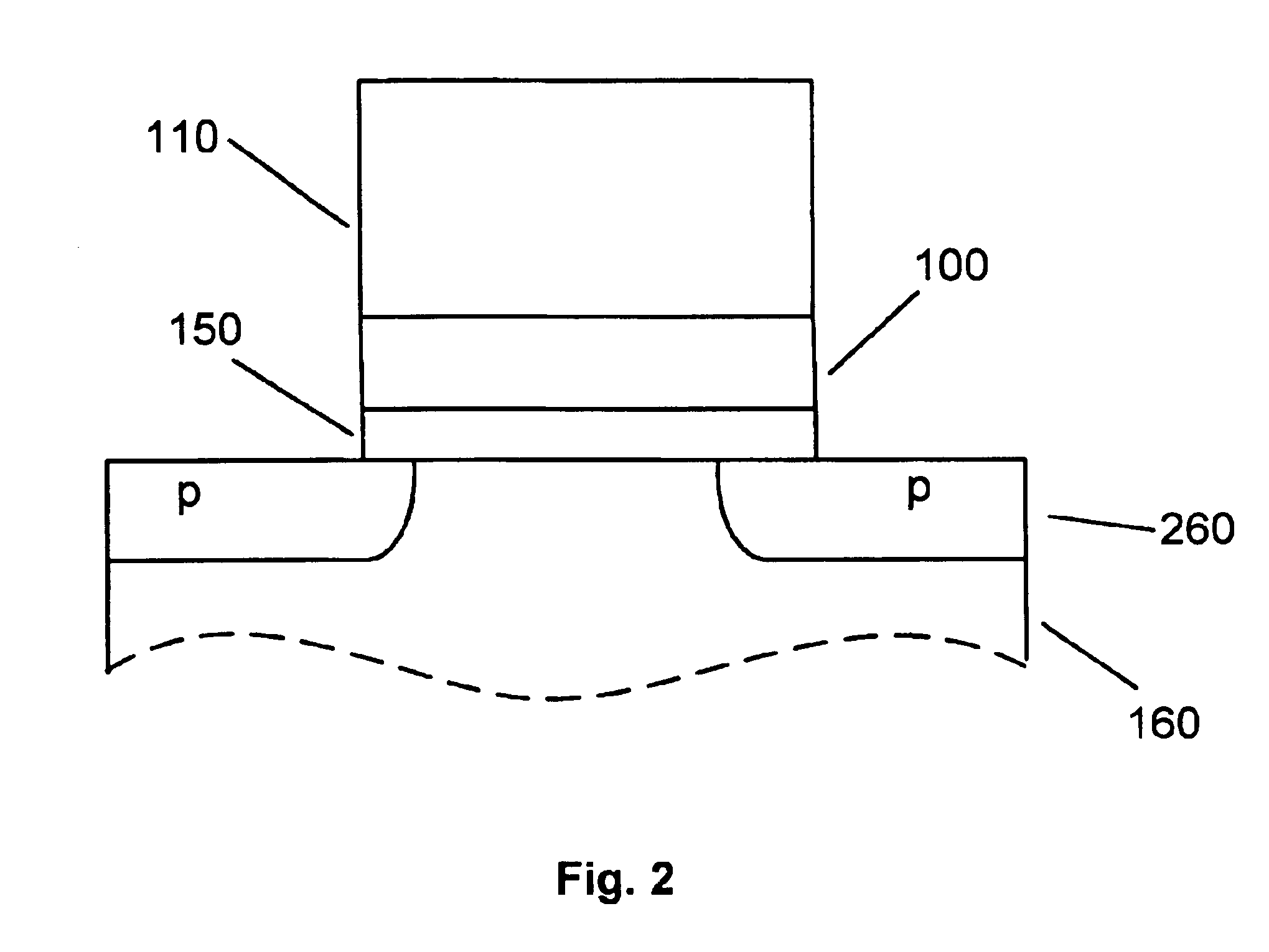

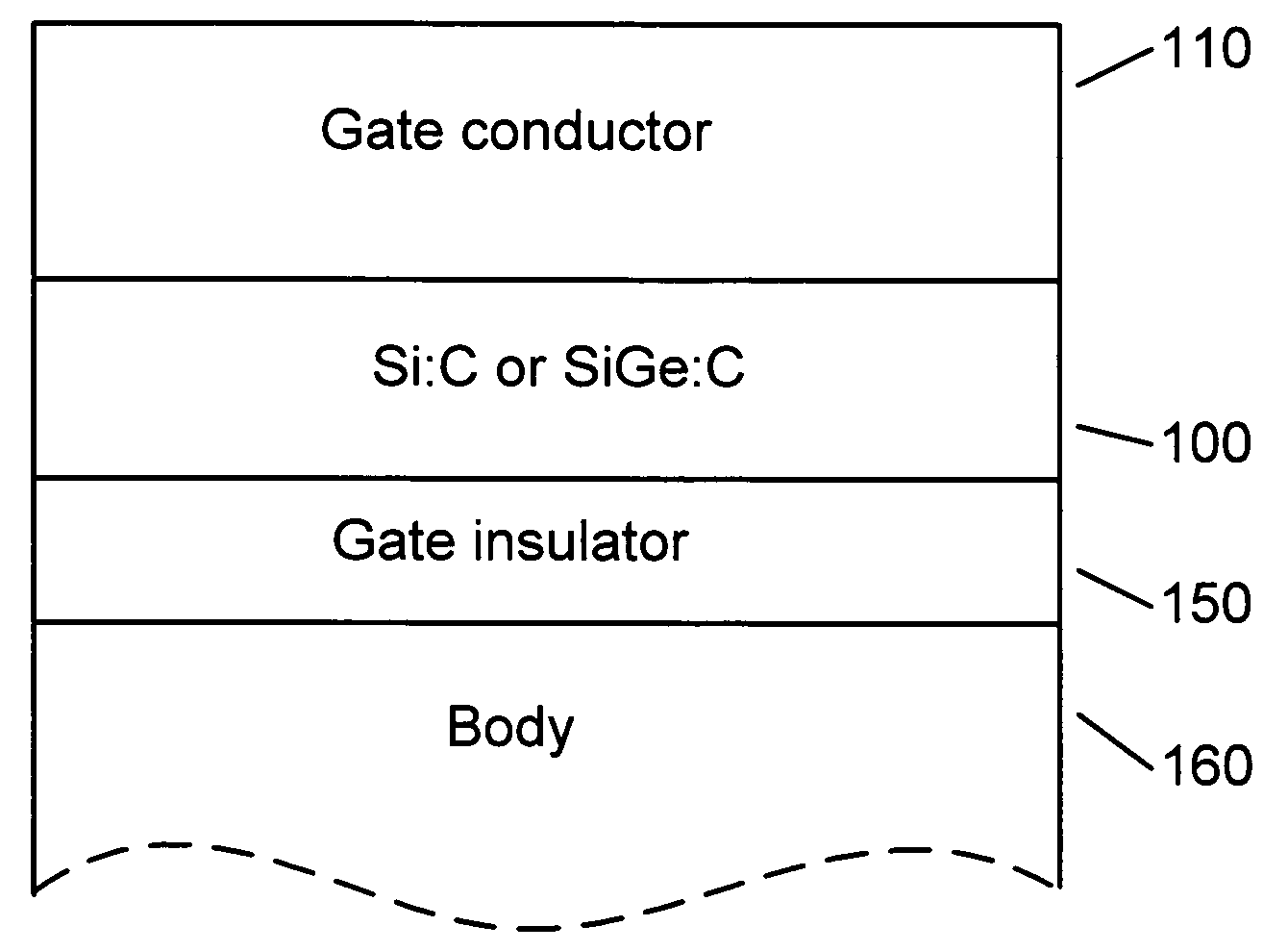

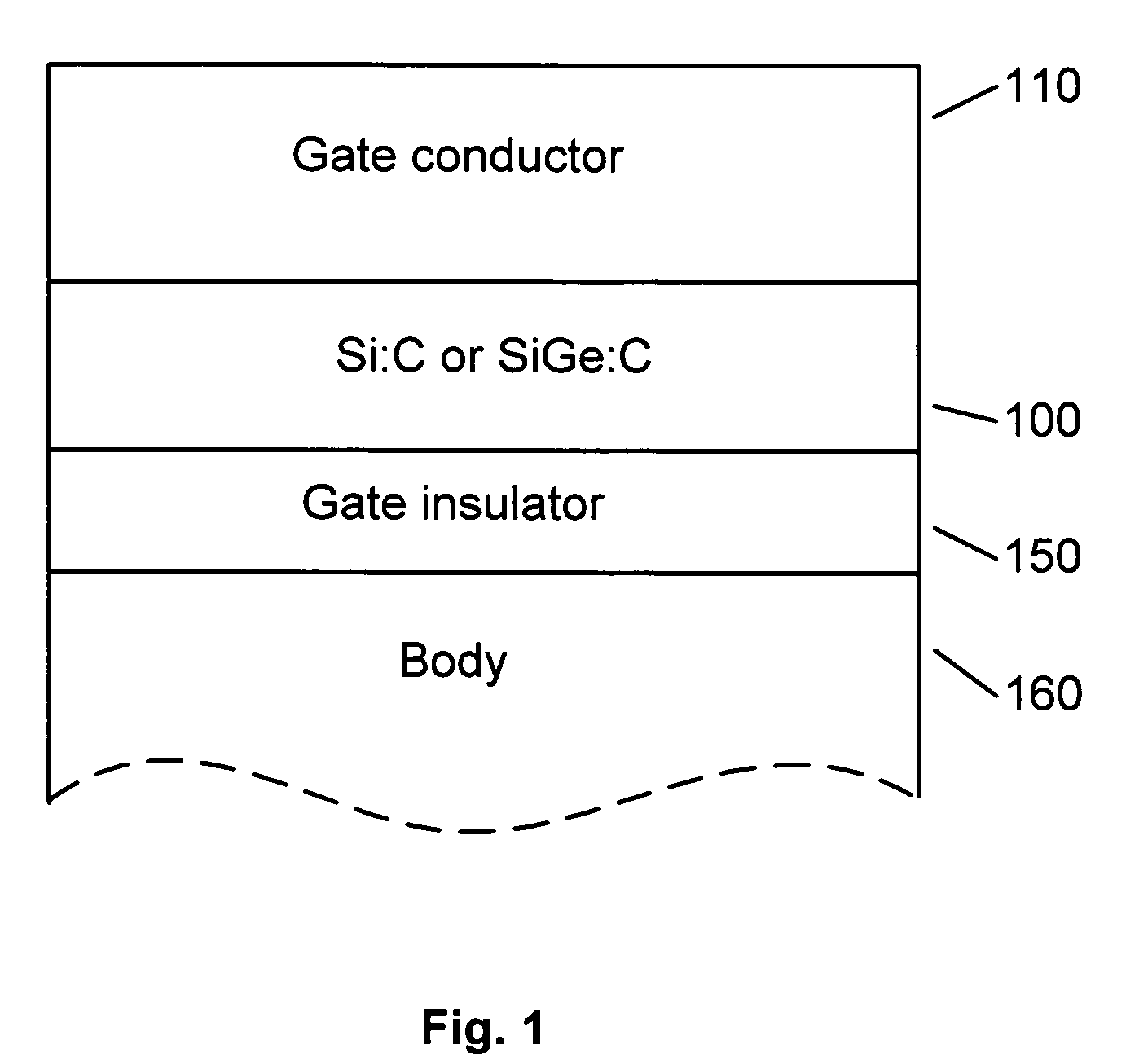

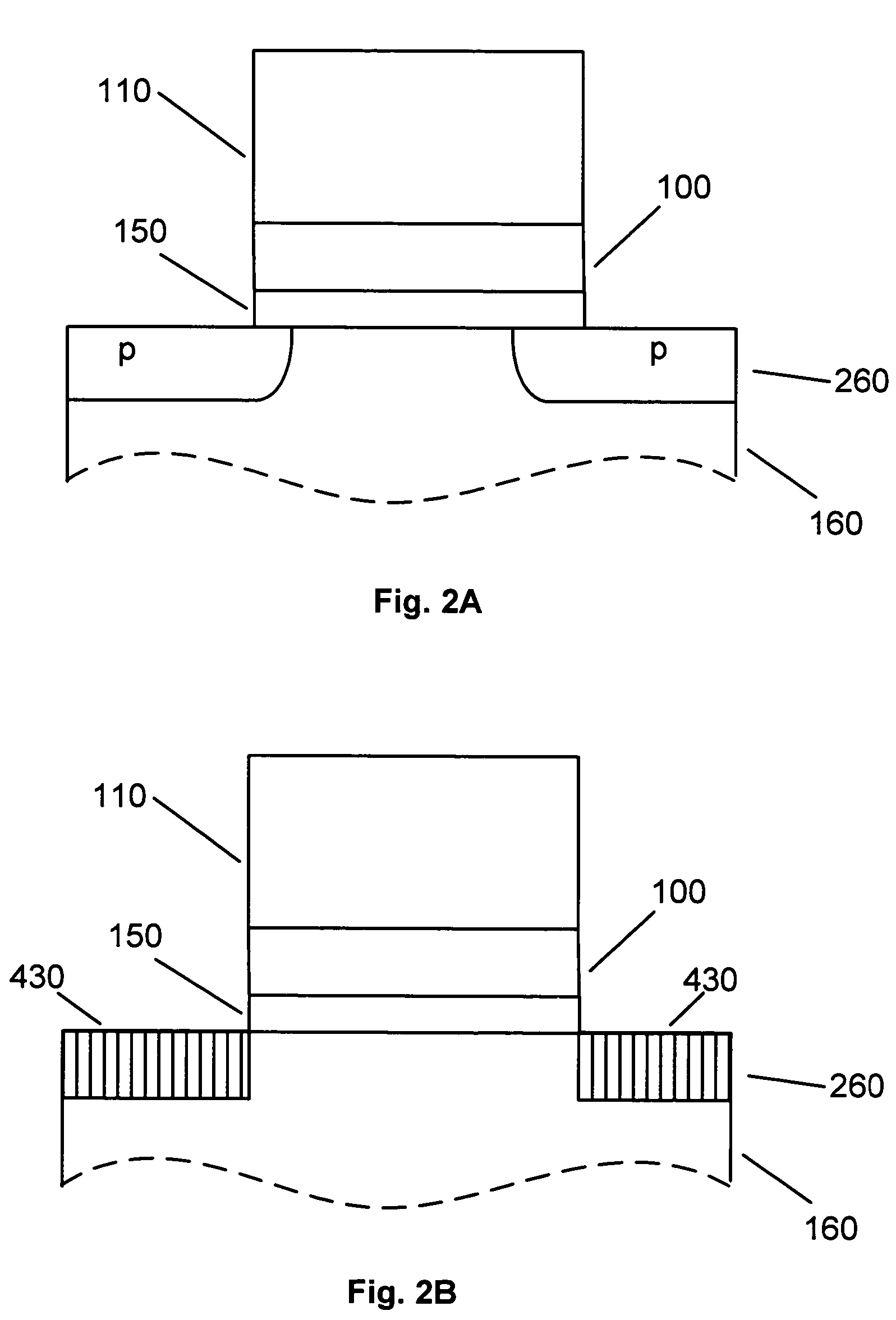

High performance FET devices and methods therefor

InactiveUS6909186B2Suitable for low temperature operationIncrease the areaTransistorSemiconductor/solid-state device detailsDopantGate insulator

Structure and methods of fabrication are disclosed for an enhanced FET devices in which dopant impurities are prevented from diffusing through the gate insulator. The structure comprises a Si:C, or SiGe:C, layer which is sandwiched between the gate insulator and a layer which is doped with impurities in order to provide a preselected workfunction. It is further disclosed how this, and further improvements for FET devices, such as raised source / drain and multifaceted gate on insulator, MODFET on insulator are integrated with strained Si based layer on insulator technology.

Owner:IBM CORP

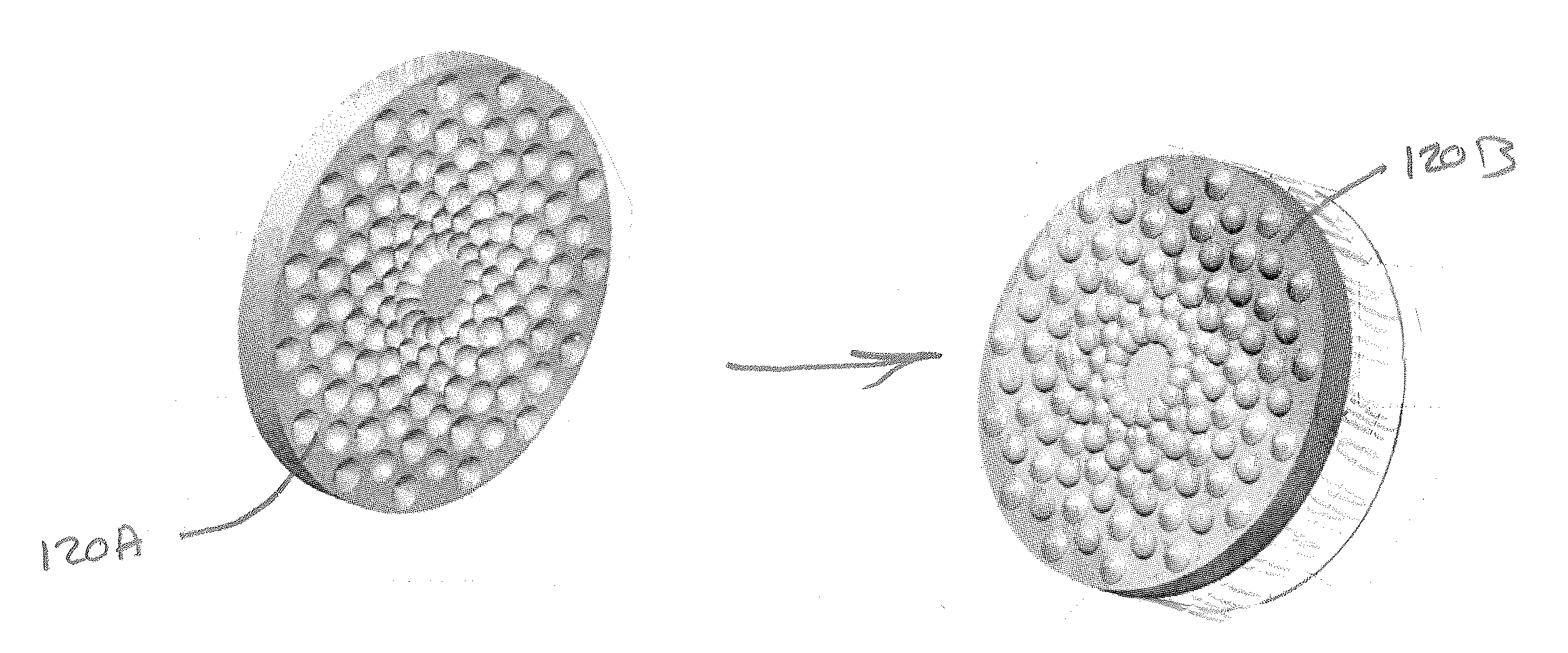

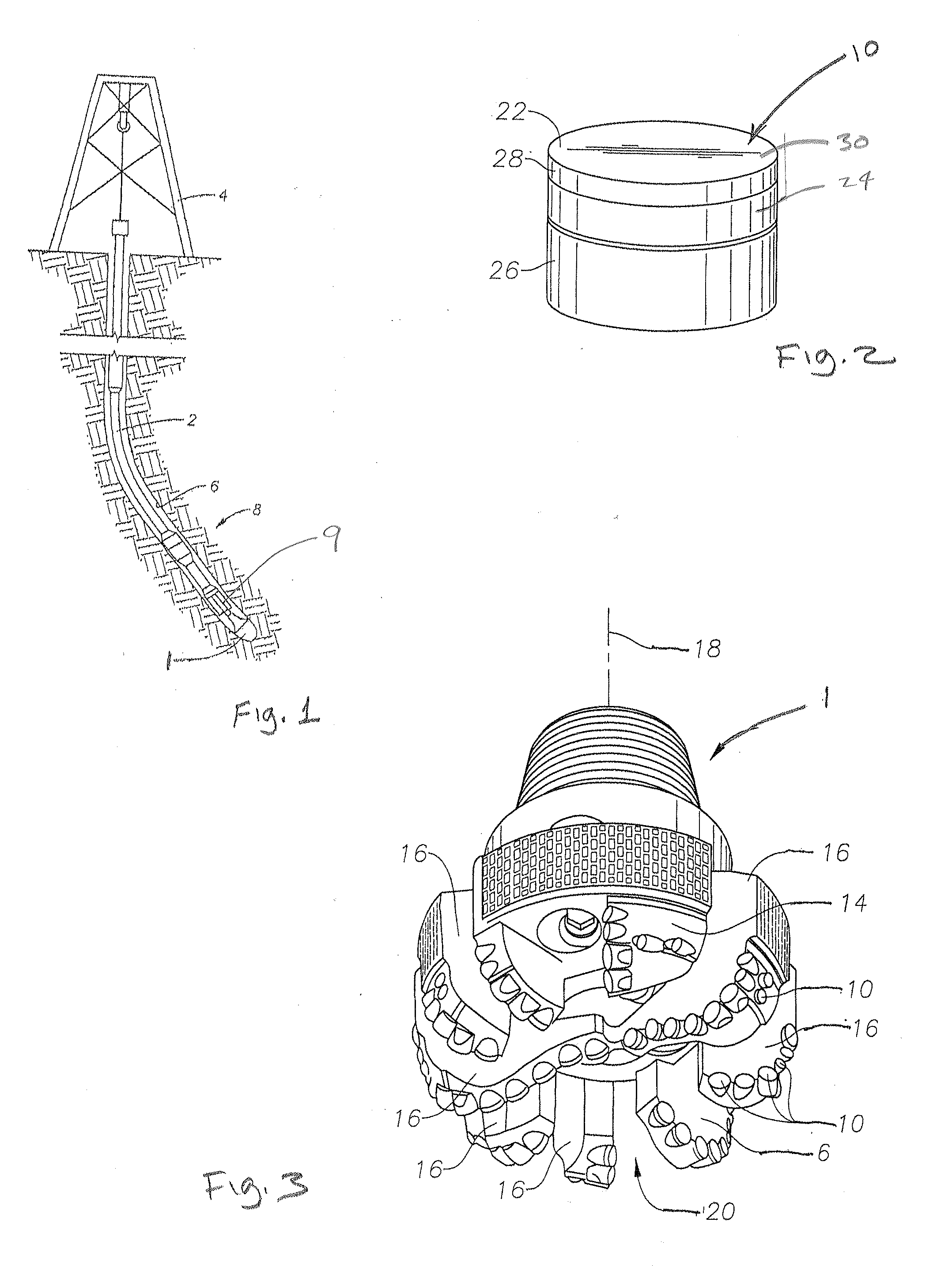

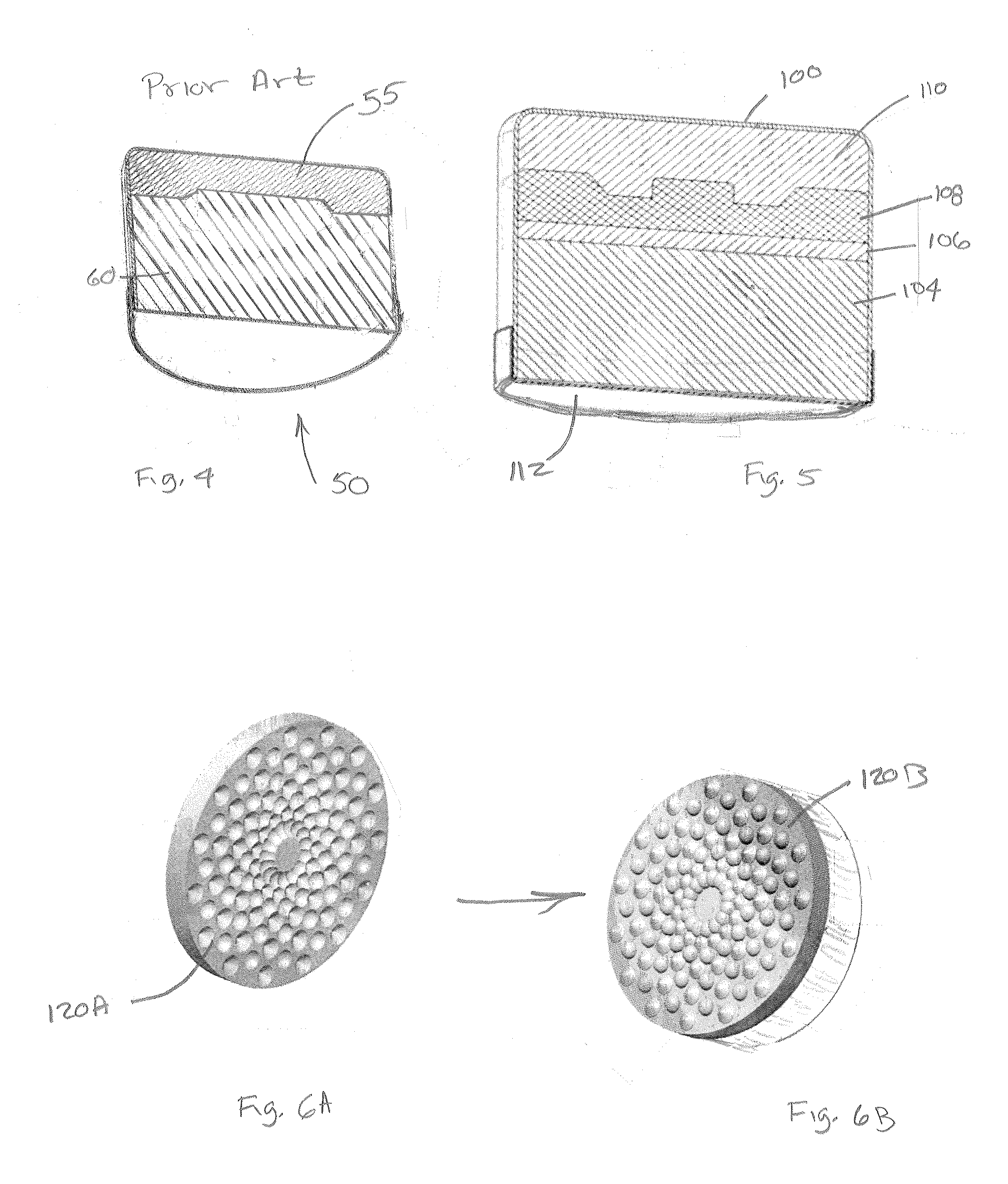

Sacrificial Catalyst Polycrystalline Diamond Element

InactiveUS20110171414A1Reduce formationLow level of contaminationPigmenting treatmentDrill bitsMetallurgyPolycrystalline diamond

A superhard composite material comprising a polycrystalline diamond cutter (PDC) having a cutting surface and cutting edges having a polycrystalline diamond thickness of about 3 mm is integrally formed with a sacrificial catalyst source that is removed later in the processing of the of the cutter.

Owner:NAT OILWELL VARCO LP

High performance FET devices and methods thereof

ActiveUS20050156169A1Facilitated DiffusionAvoid impuritiesTransistorSemiconductor/solid-state device detailsDopantGate insulator

Structure and methods of fabrication are disclosed for an enhanced FET devices in which dopant impurities are prevented from diffusing through the gate insulator. The structure comprises a Si:C, or SiGe:C, layer which is sandwiched between the gate insulator and a layer which is doped with impurities in order to provide a preselected workfunction. It is further disclosed how this, and further improvements for FET devices, such as raised source / drain and multifaceted gate on insulator, MODFET on insulator are integrated with strained Si based layer on insulator technology.

Owner:INT BUSINESS MASCH CORP

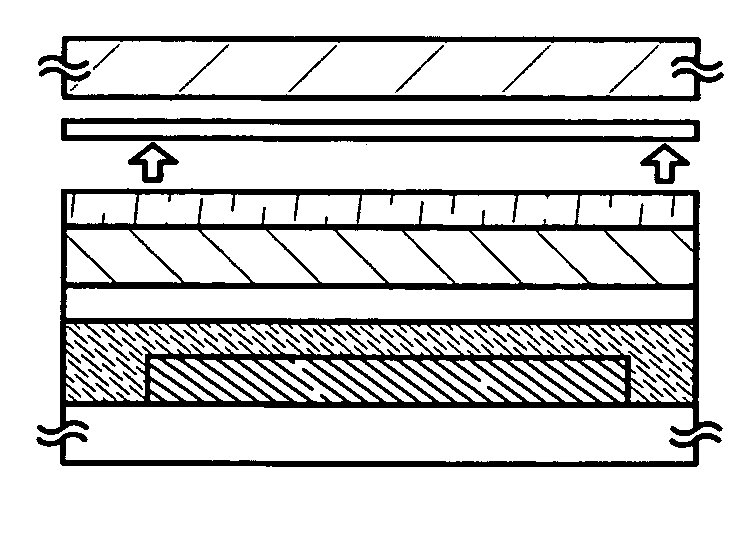

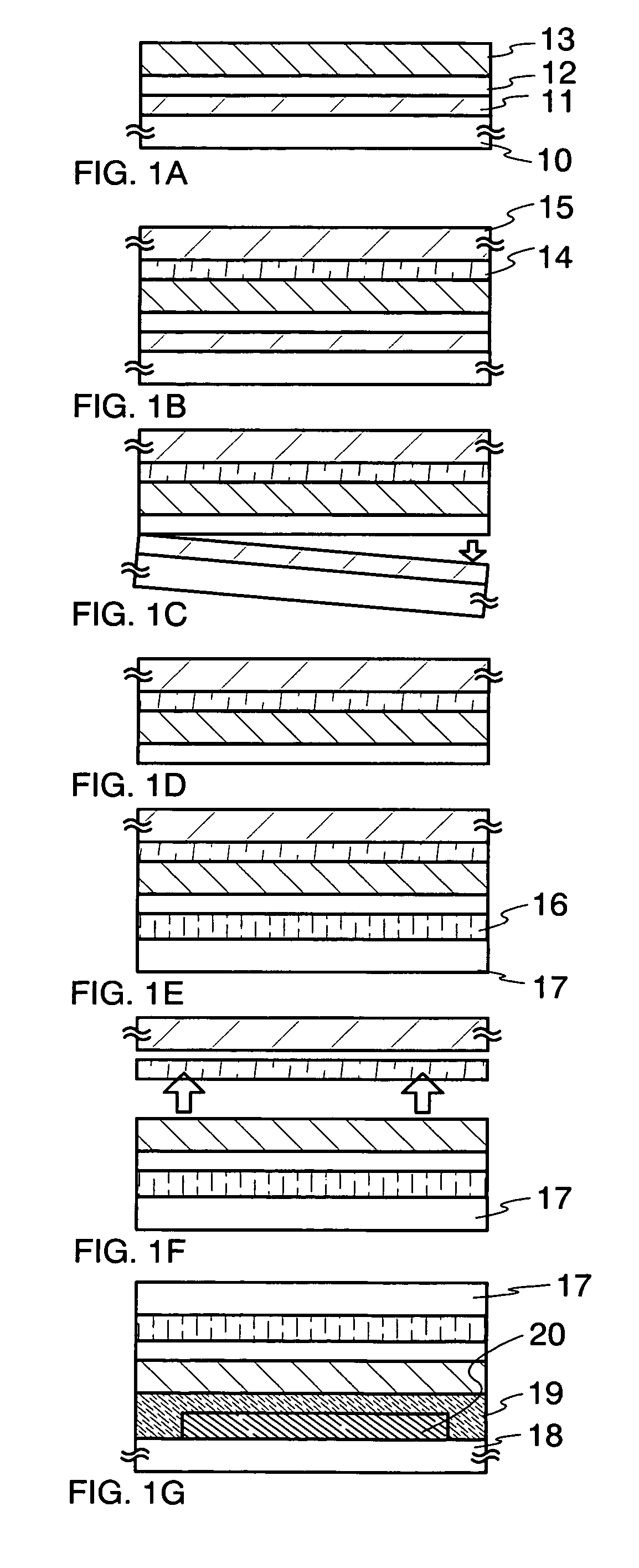

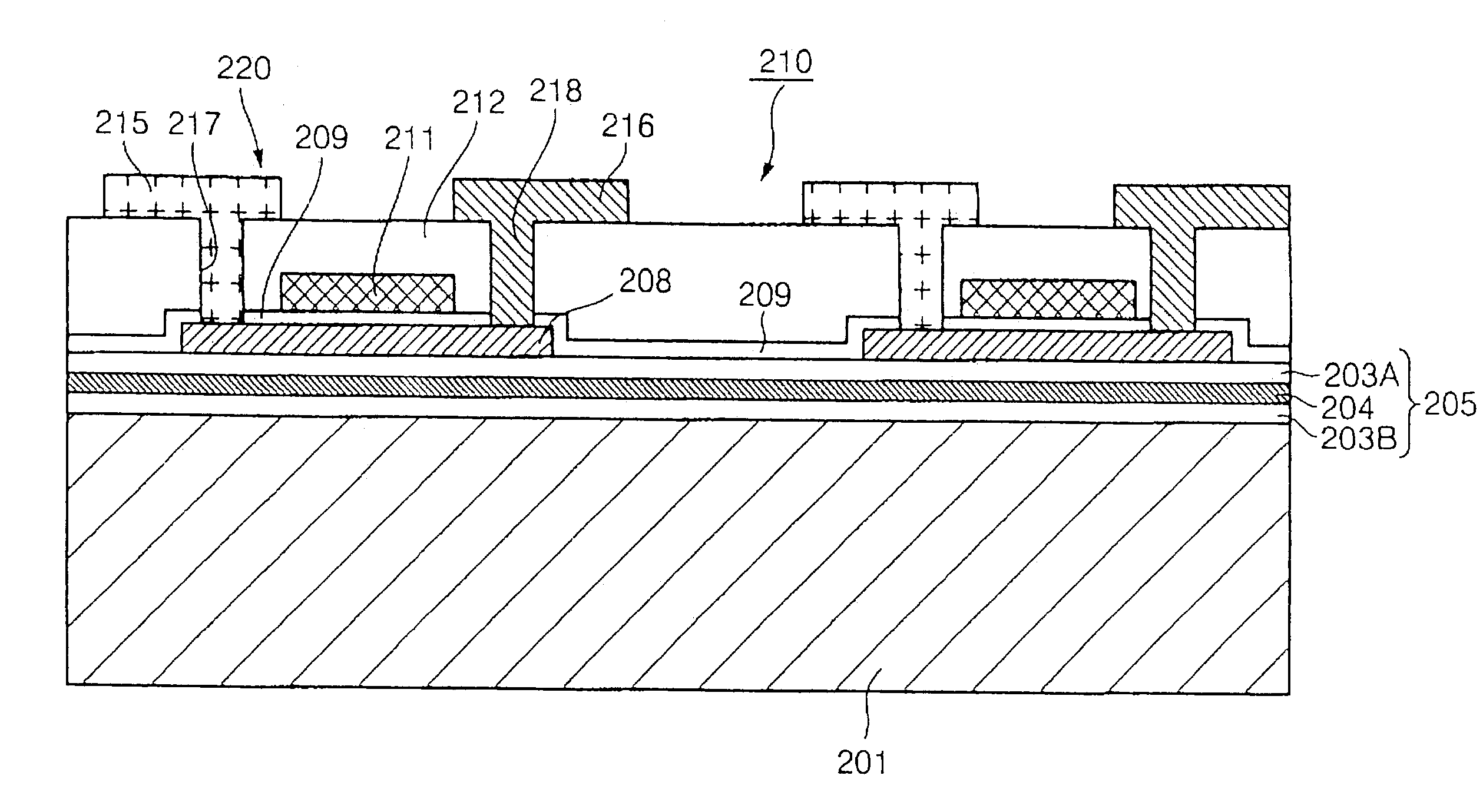

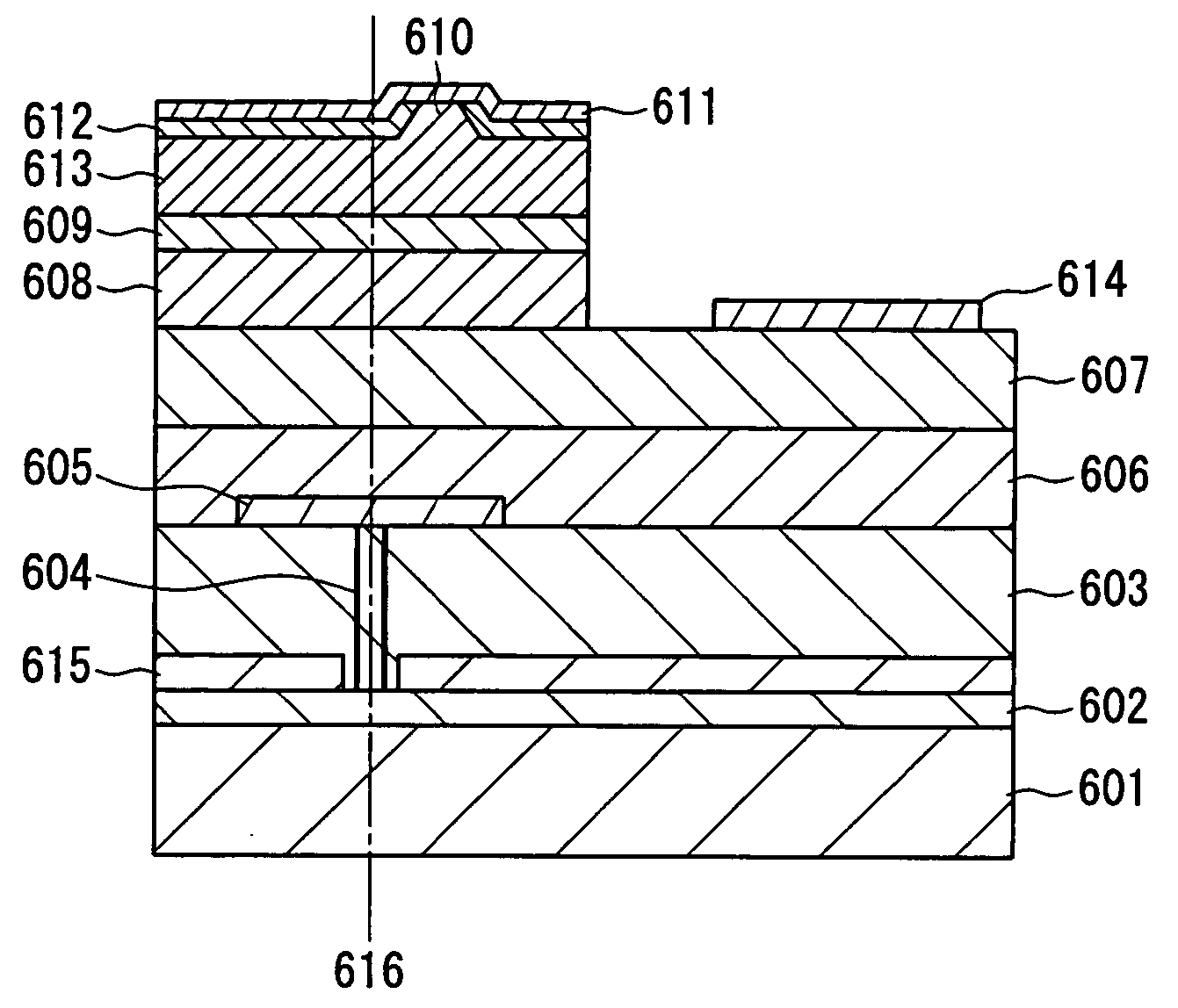

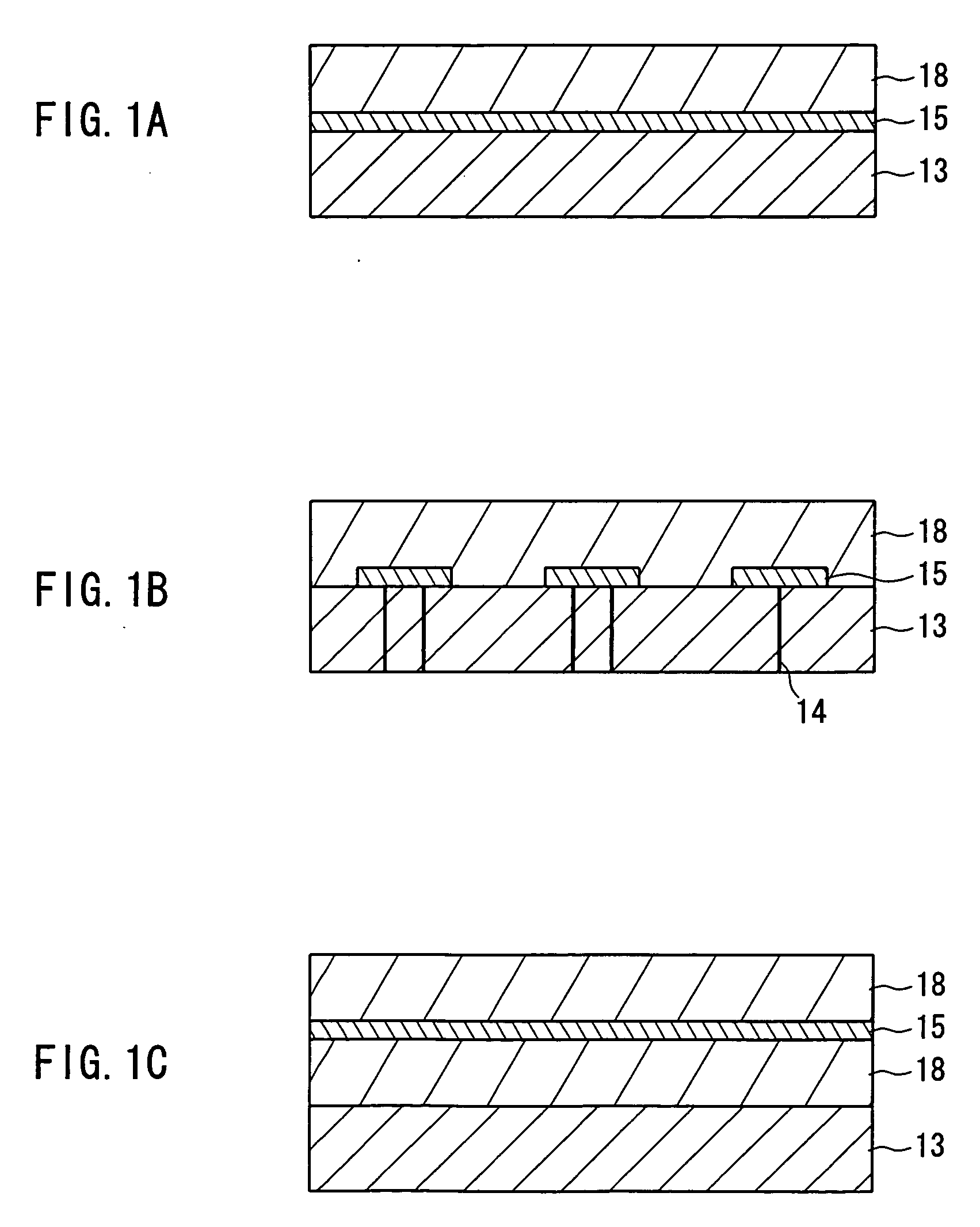

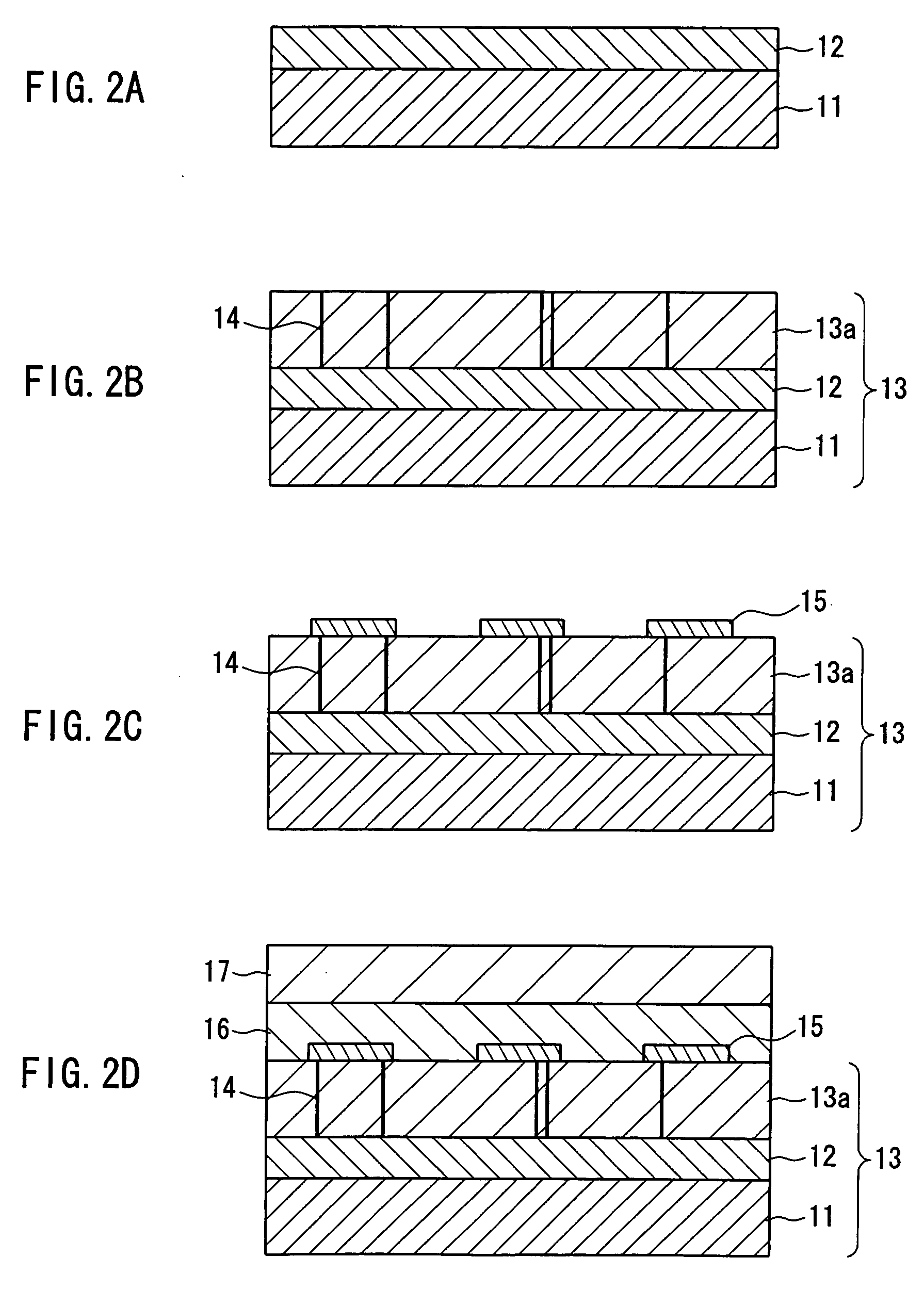

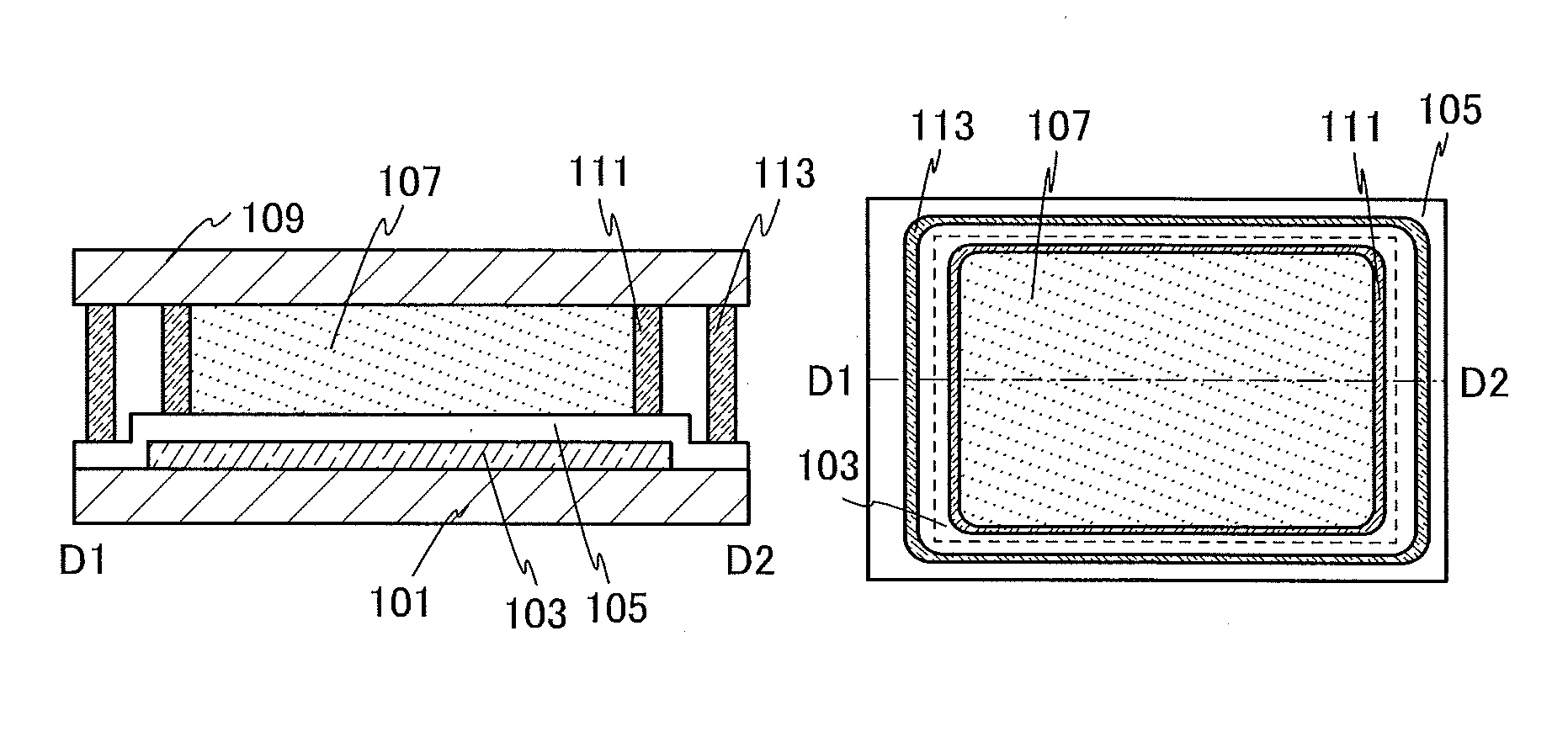

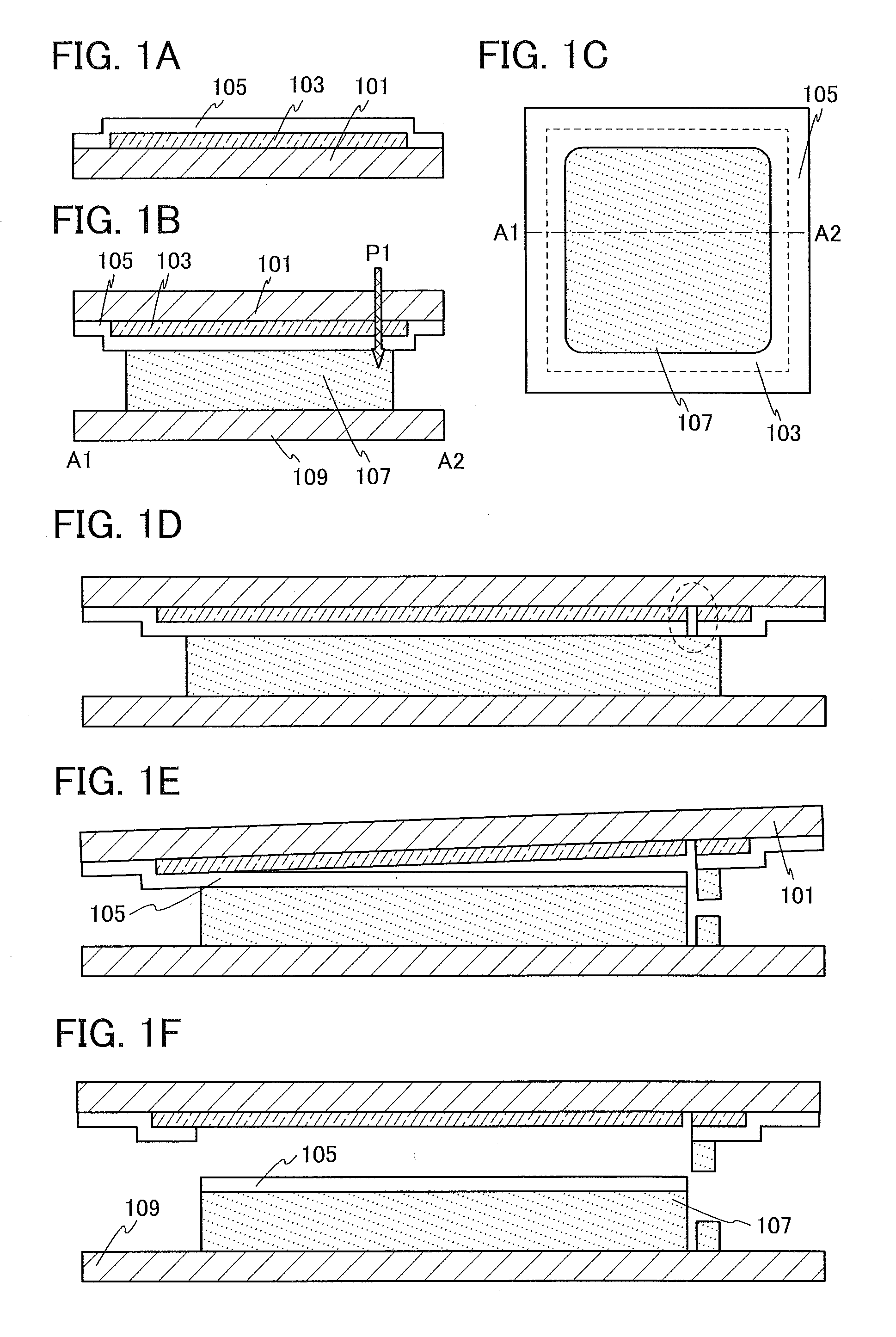

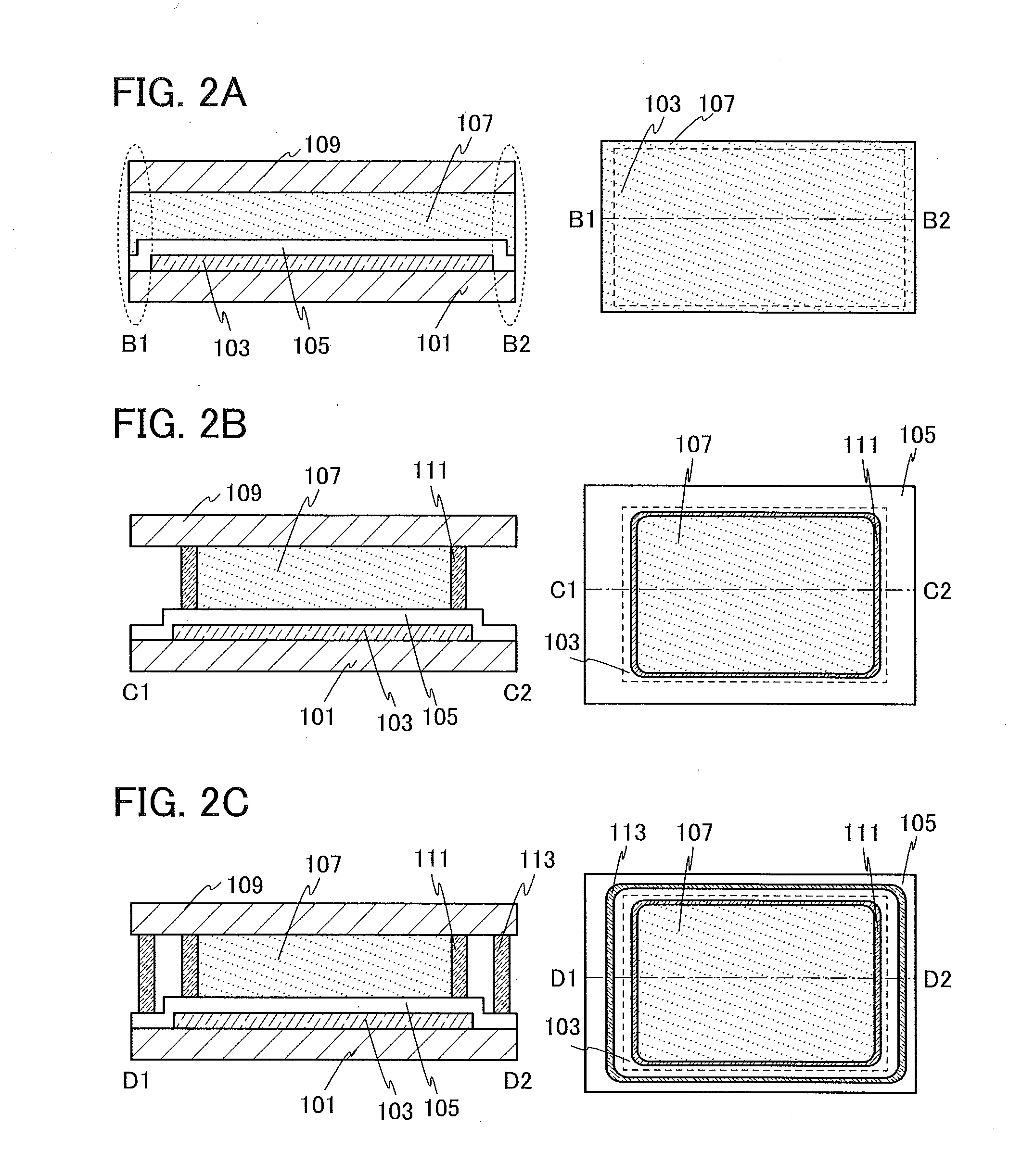

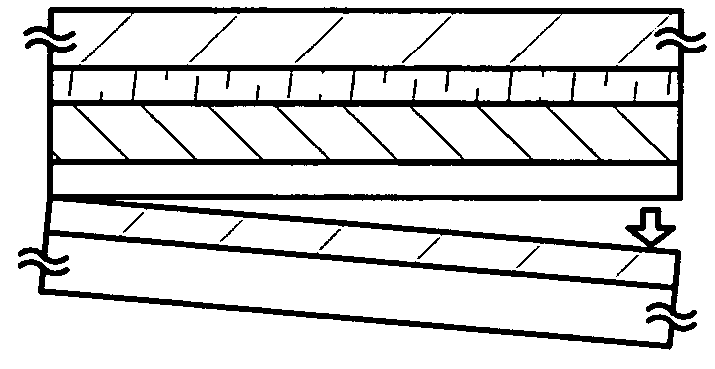

Semiconductor device, method of manufacturing thereof, and method of manufacturing base material

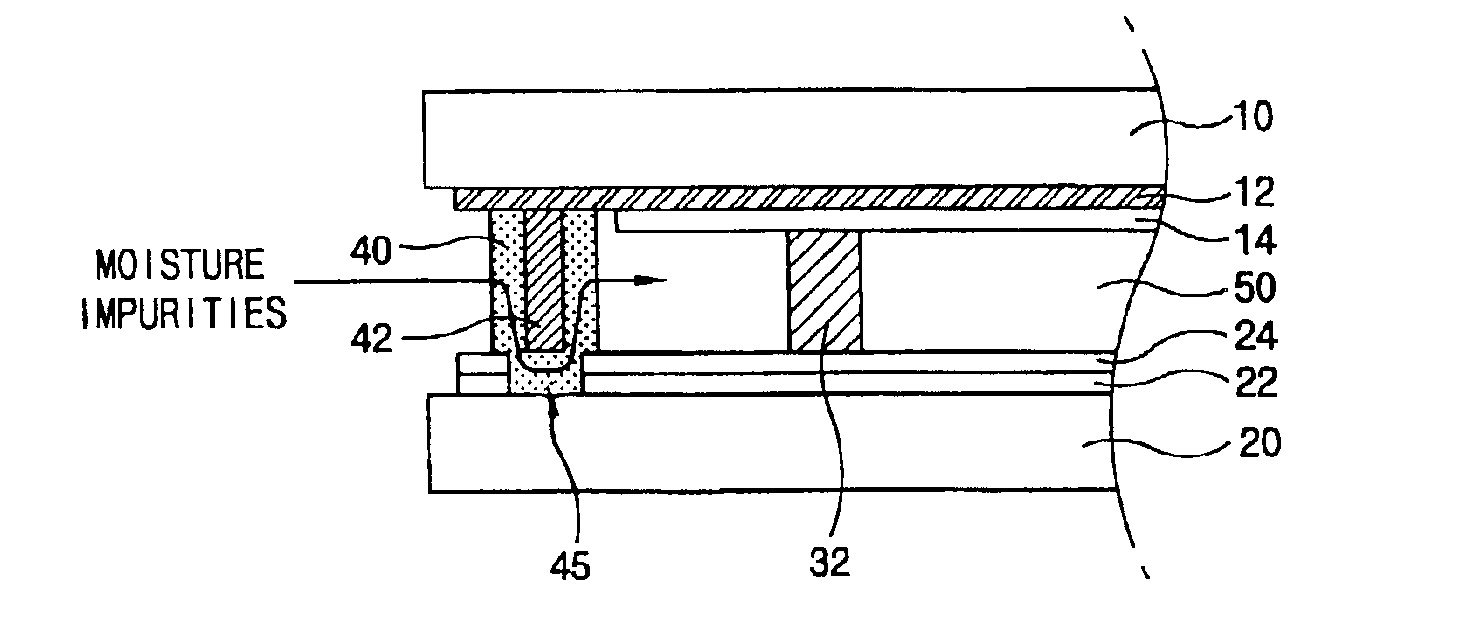

ActiveUS7229900B2Highly reliable sealing structureAvoid impuritiesDischarge tube luminescnet screensDecorative surface effectsMoistureImpurity

It is an object of the invention to provide a lightweight semiconductor device having a highly reliable sealing structure which can prevent ingress of impurities such as moisture that deteriorate element characteristics, and a method of manufacturing thereof. A protective film having superior gas barrier properties (which is a protective film that is likely to damage an element if the protective film is formed on the element directly) is previously formed on a heat-resistant substrate other than a substrate with the element formed thereon. The protective film is peeled off from the heat-resistant substrate, and transferred over the substrate with the element formed thereon so as to seal the element.

Owner:SEMICON ENERGY LAB CO LTD

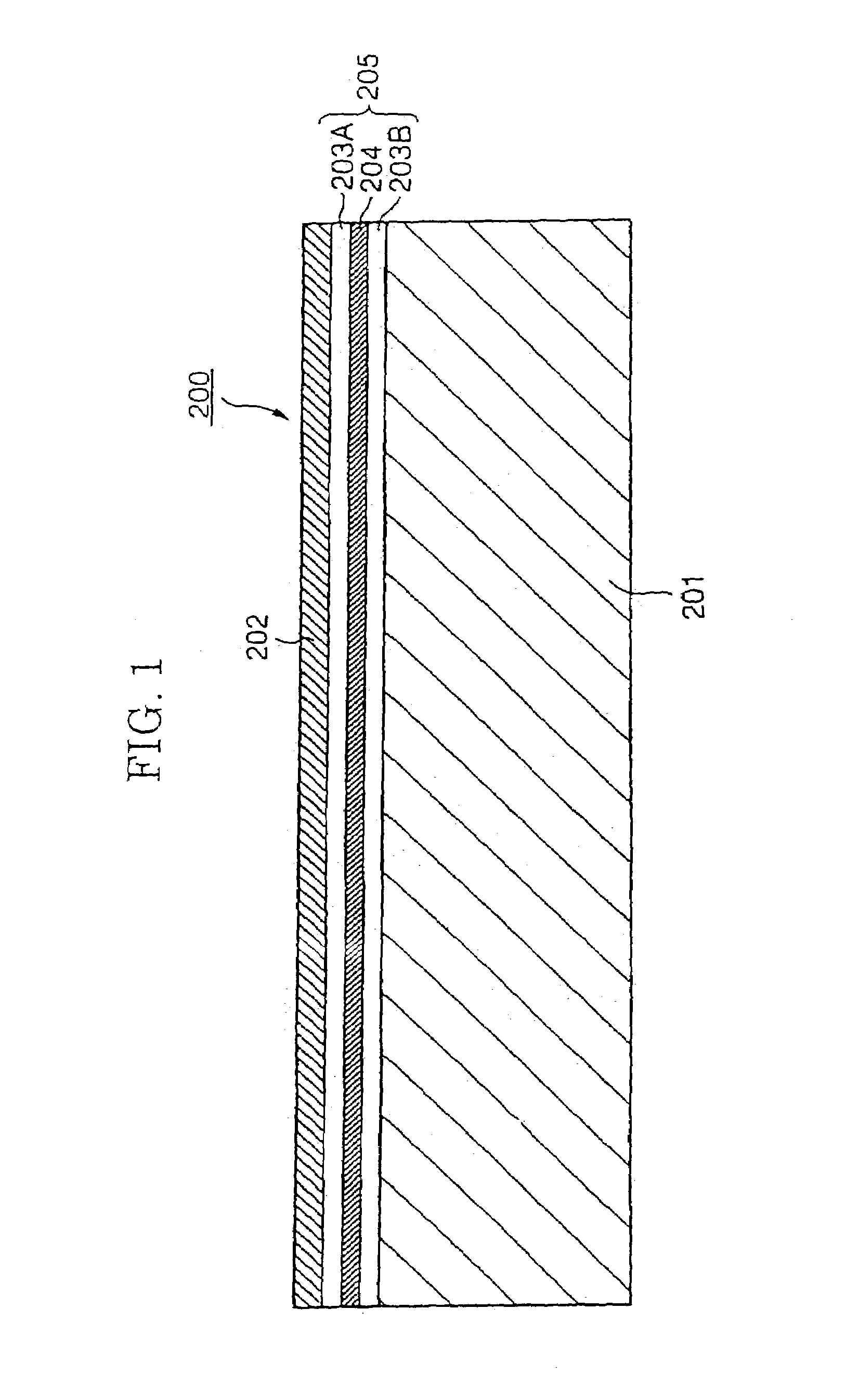

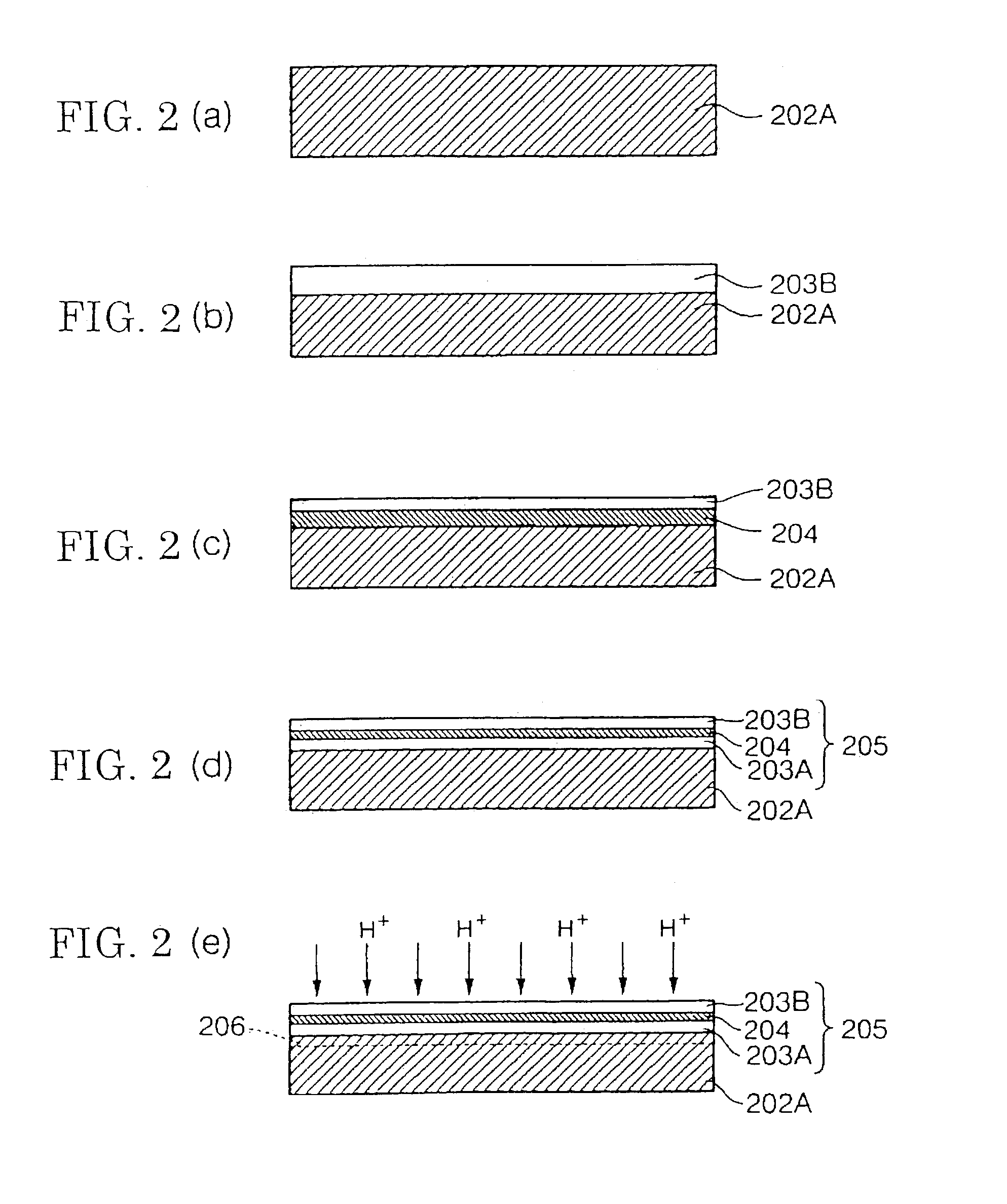

SOI substrate, element substrate, semiconductor device, electro-optical apparatus, electronic equipment, method of manufacturing the SOI substrate, method of manufacturing the element substrate, and method of manufacturing the electro-optical apparatus

InactiveUS7112514B2Avoid impuritiesInhibit deteriorationTransistorSolid-state devicesSoi substrateMono layer

An SOI (Silicon On Insulator) substrate is provided with: a support substrate (201); a single crystal silicon layer (202) disposed above one surface of the support substrate; an insulation portion (205) disposed between the support substrate and the single crystal silicon layer, the insulation portion comprising a single layer of an insulation film or a lamination structure of a plurality of insulation films, and including a silicon nitride film or a silicon nitride oxide film (204).

Owner:SEIKO EPSON CORP

Group-III-element nitride crystal semiconductor device

InactiveUS20050082564A1Prevent the diffusion of impuritiesReduce diffusion coefficientLaser detailsSemiconductor/solid-state device manufacturingAlkaline earth metalNitrogen

In a Group-III-element nitride semiconductor device including a Group-III-element nitride crystal layer stacked on a Group-III-element nitride crystal substrate, the substrate is produced by allowing nitrogen of nitrogen-containing gas and a Group III element to react with each other to crystallize in a melt (a flux) containing at least one of alkali metal and alkaline-earth metal, and a thin film layer is formed on the substrate and the thin film has a lower diffusion coefficient than that of the substrate with respect to impurities contained in the substrate. The present invention provides a semiconductor device in which alkali metal is prevented from diffusing.

Owner:PANASONIC CORP

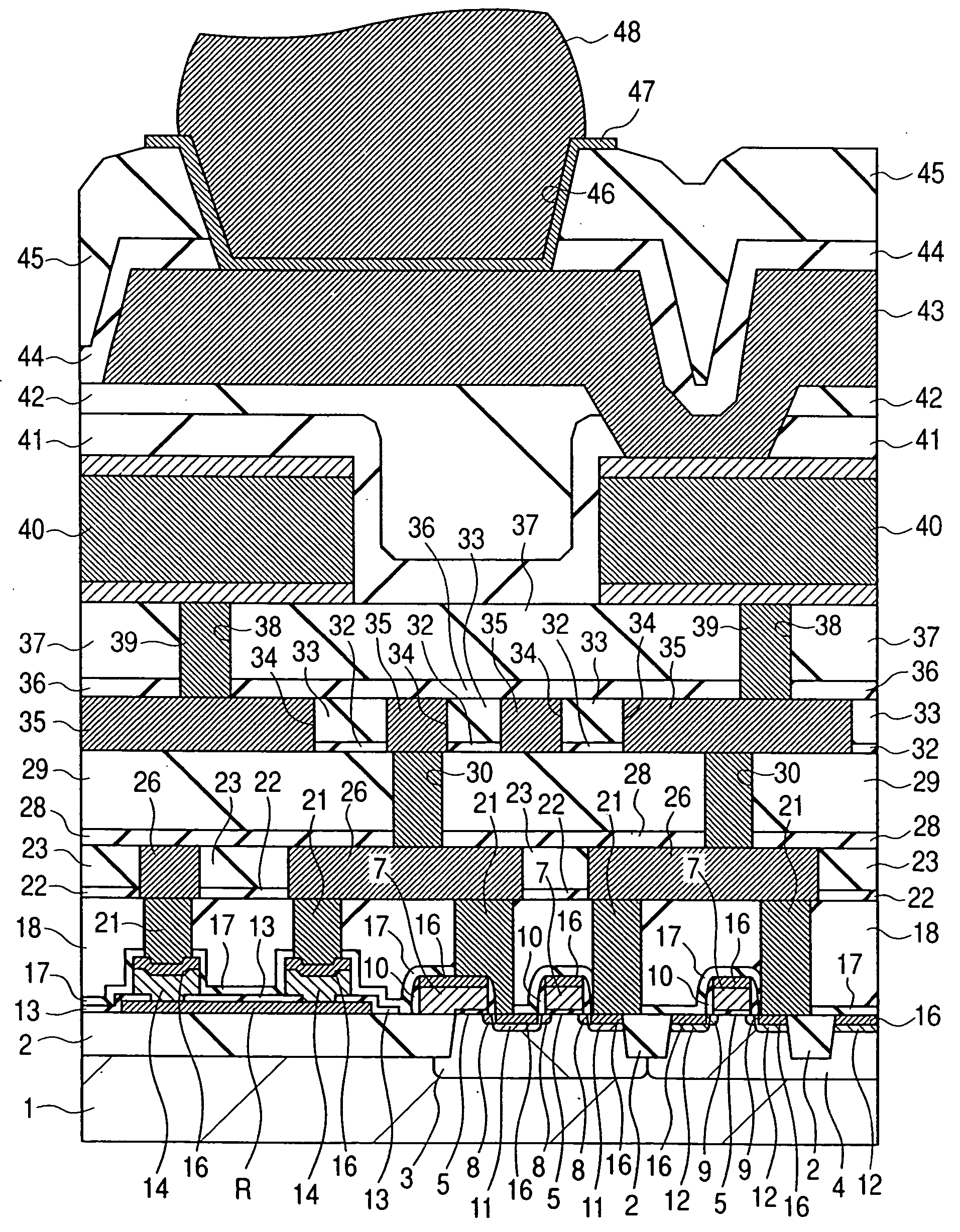

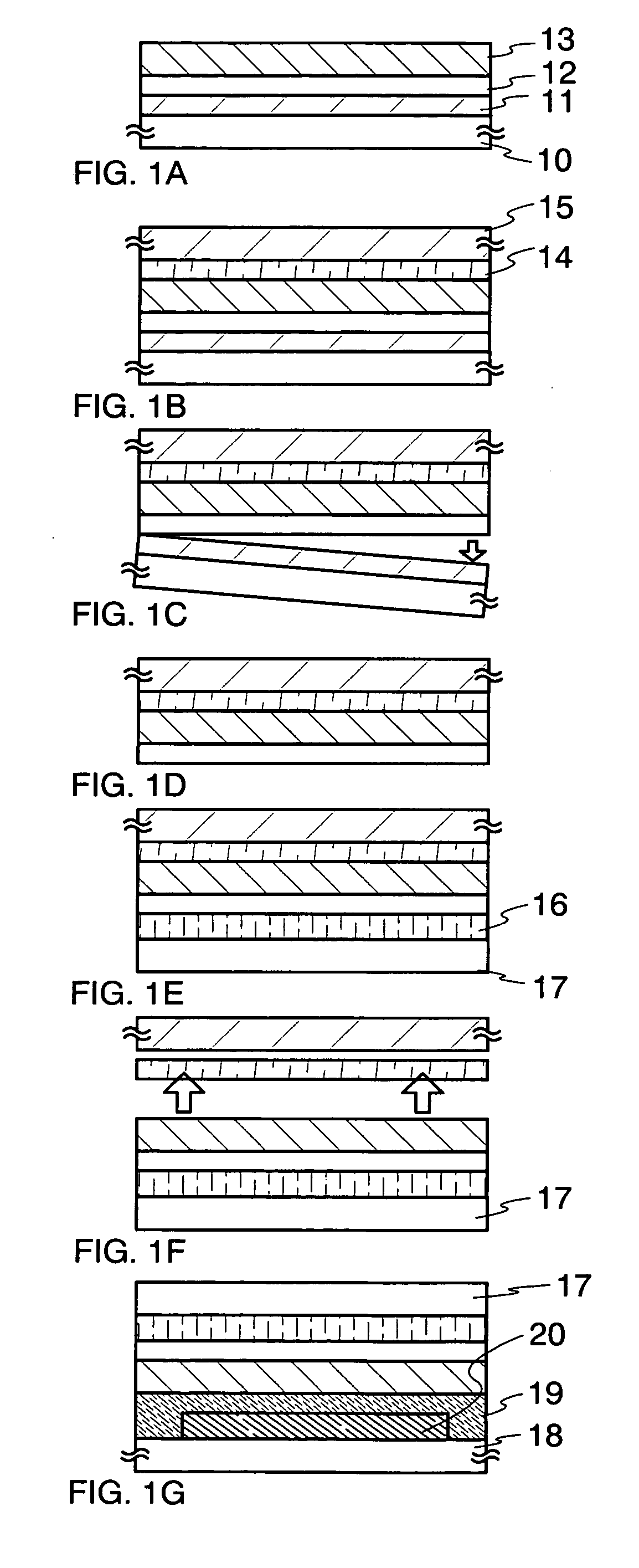

Semiconductor integrated circuit device and process for manufacturing the same

InactiveUS20050020021A1Image degradationLess fluctuationTransistorSolid-state devicesDevice materialHydrogen content

In the manufacture of a semiconductor device having a high-performance and high-reliability, a silicon nitride film 17 for self alignment, which film is formed to cover the gate electrode of a MISFET, is formed at a substrate temperature of 400° C. or greater by plasma CVD using a raw material gas including monosilane and nitrogen. A silicon nitride film 44 constituting a passivation film is formed at a substrate temperature of about 350° C. by plasma CVD using a raw material gas including monosilane, ammonia and nitrogen. The hydrogen content contained in the silicon nitride film 17 is smaller than that contained in the silicon nitride film 44, making it possible to suppress hydrogen release from the silicon nitride film 17.

Owner:RENESAS ELECTRONICS CORP

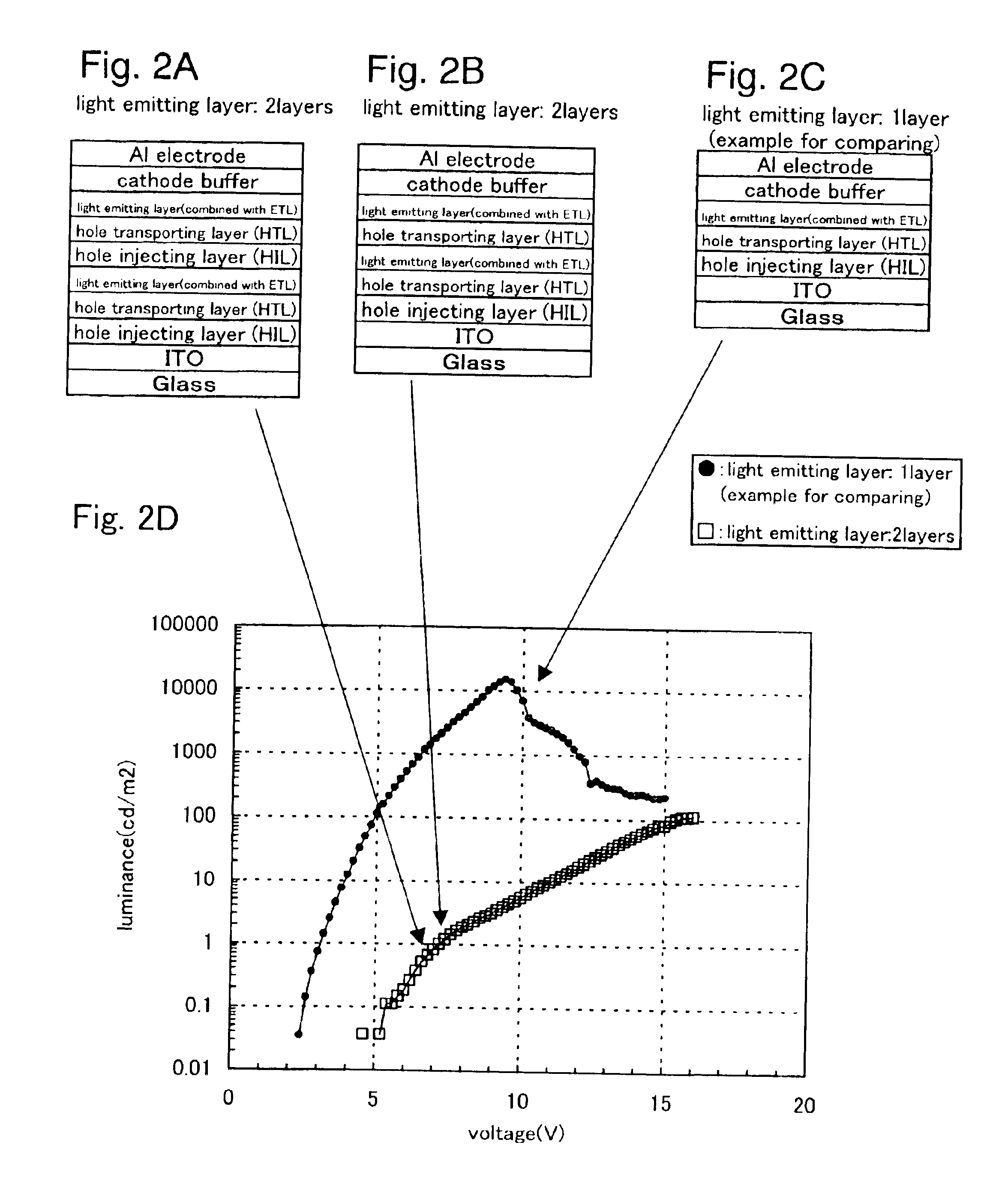

Light emitting apparatus and method for manufacturing the same

InactiveUS20060006424A1Improve reliabilityInhibit deteriorationTransistorSolid-state devicesSimple Organic CompoundsContact formation

Owner:SEMICON ENERGY LAB CO LTD

Light emitting apparatus and method for manufacturing the same

InactiveUS20050224820A1Improve reliabilityInhibit deteriorationSolid-state devicesSemiconductor/solid-state device manufacturingSimple Organic CompoundsInsulation layer

The light emitting apparatus according to the invention having a thin film transistor and a light emitting element, comprises; a first inorganic insulation layer on the lower surface of a semiconductor layer, a second inorganic insulation layer on the upper surface of a gate electrode, a first organic insulation layer on the second inorganic insulation layer, a third inorganic insulation layer on the first organic insulation layer, a wiring layer extending on the third inorganic insulation layer, a second organic insulation layer overlapped with the end of the wiring layer and having an inclination angle of 35 to 45 degrees, a fourth inorganic insulation layer formed on the upper surface and side surface of the second organic insulation layer and having an opening over the wiring layer, a cathode layer formed in contact with the wiring layer and having side end overlapped with the fourth inorganic insulation layer, and an organic compound layer formed in contact with the cathode layer and the fourth inorganic insulation layer and comprising light emitting material, and an anode layer formed in contact with the organic compound layer comprising the light emitting material, wherein the third inorganic insulation layer and the fourth inorganic insulation layer are formed with silicon nitride or aluminum nitride.

Owner:SEMICON ENERGY LAB CO LTD

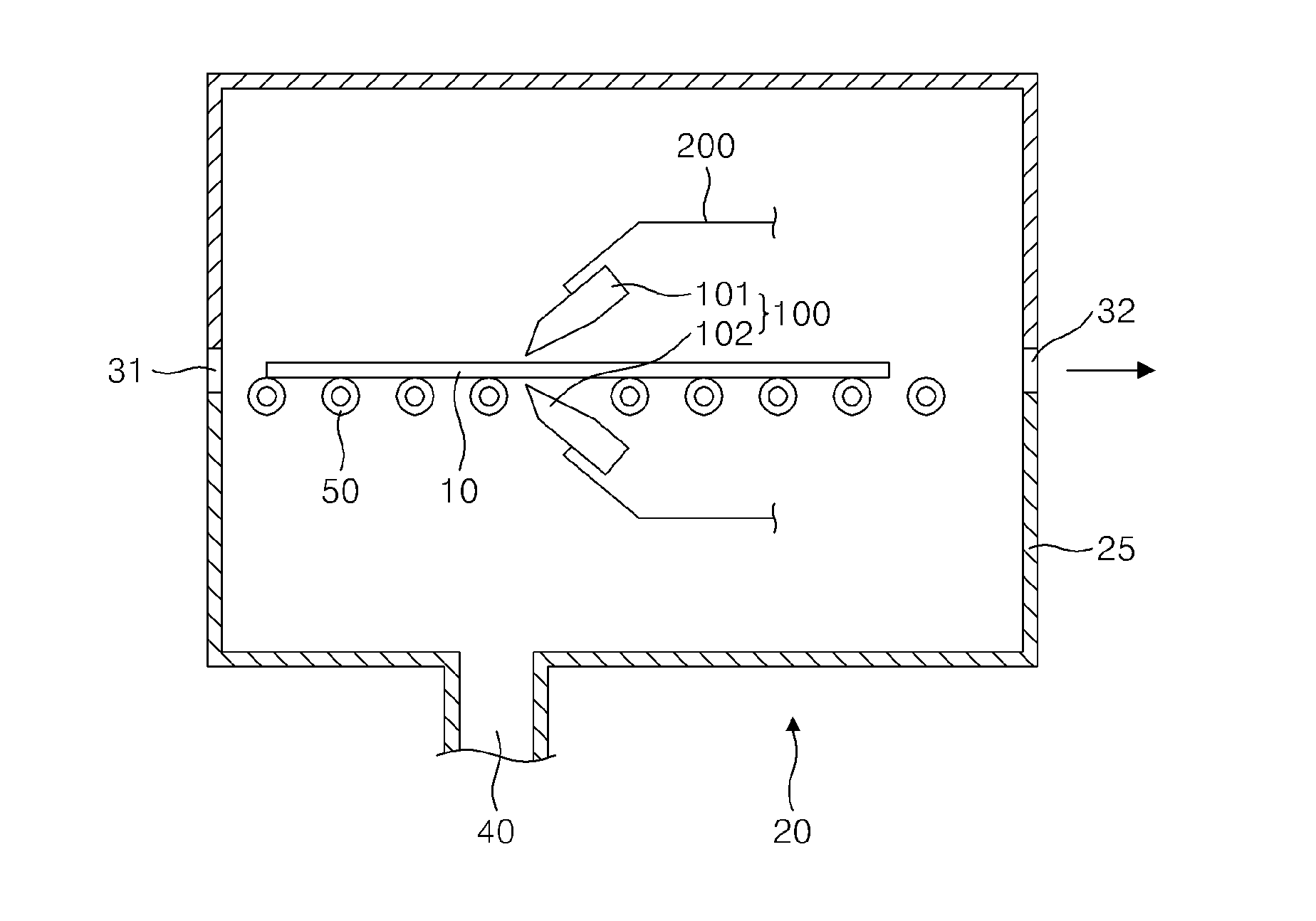

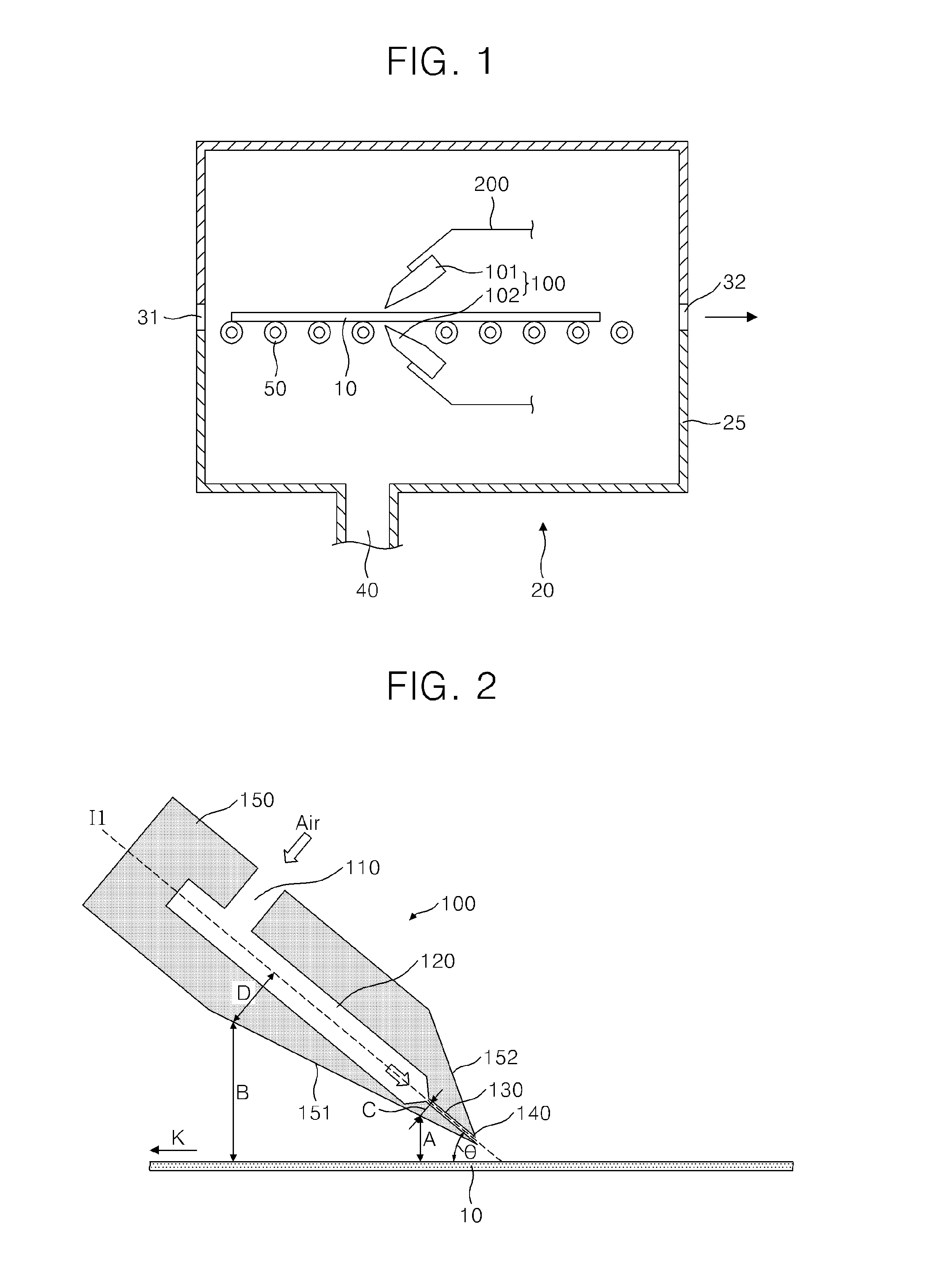

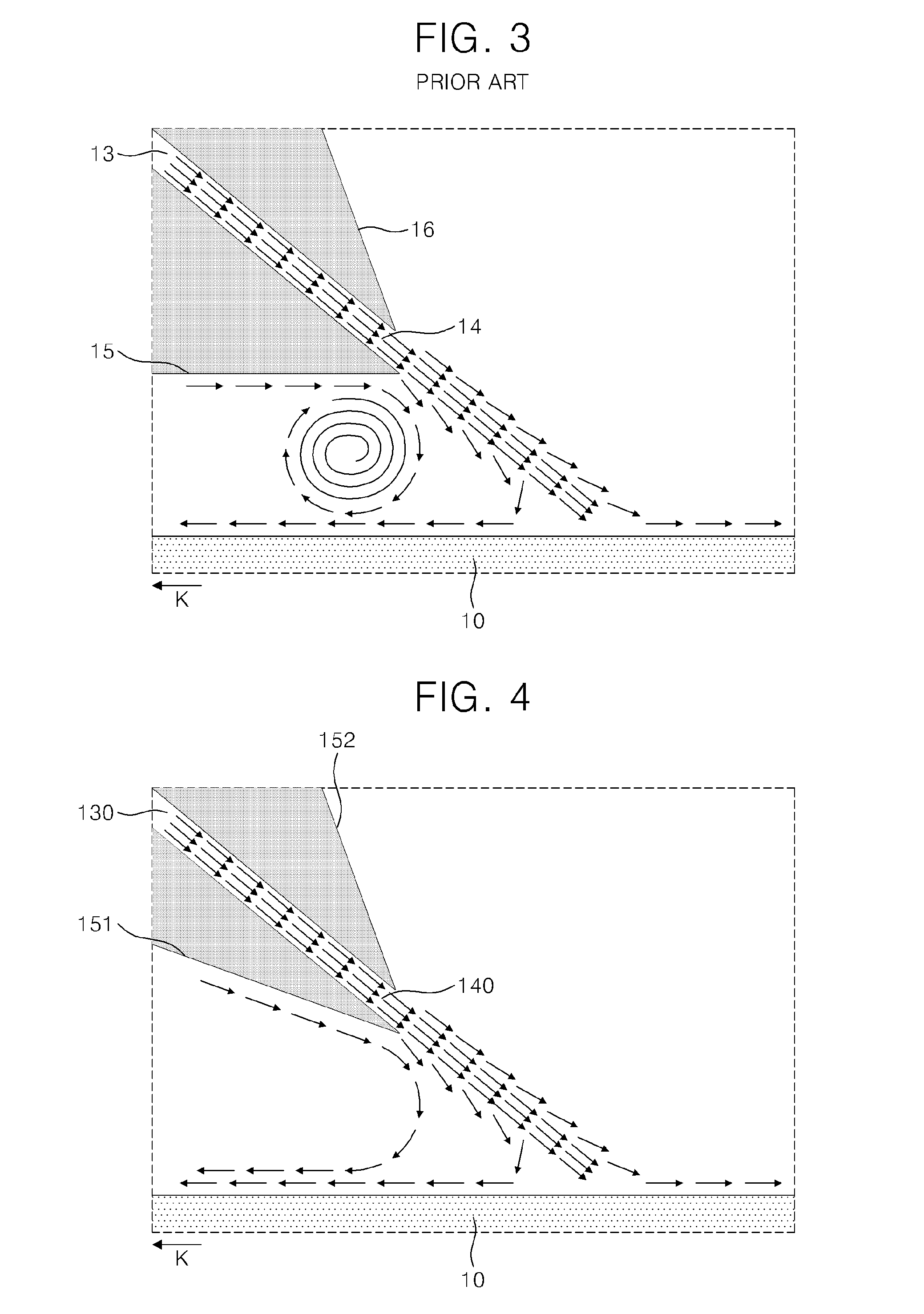

Air knife and substrate drying apparatus having the same

InactiveUS20080244925A1Avoid impuritiesDrying gas arrangementsSemiconductor/solid-state device manufacturingAir knifeReference line

An air knife capable of preventing drying defects during substrate drying processes includes an inlet through which air is supplied from an outside of the air knife, a chamber which stores the air flowing through the inlet, and an outlet which is connected to the chamber and sprays the air stored in the chamber on a substrate, and a main body having a lower end portion extending from the outlet and past at least a portion of the chamber, wherein an angle between the lower end portion of the main body and a body reference line extended from the outlet is less than 40 degrees.

Owner:SAMSUNG ELECTRONICS CO LTD

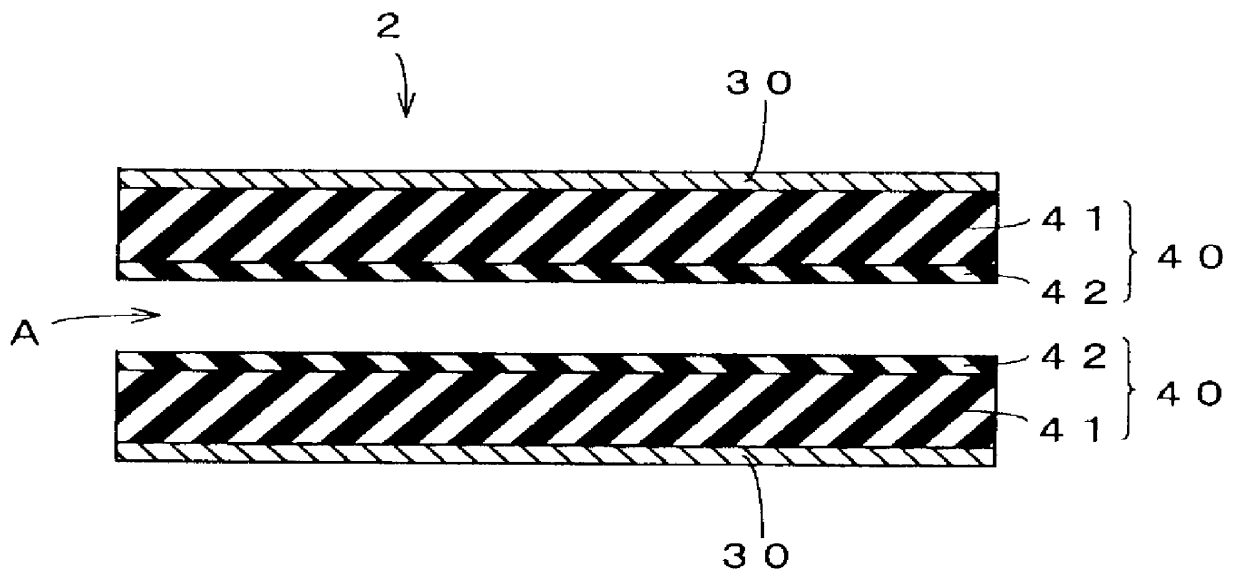

Light-emitting element and display device

InactiveUS7202504B2Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingDisplay device

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

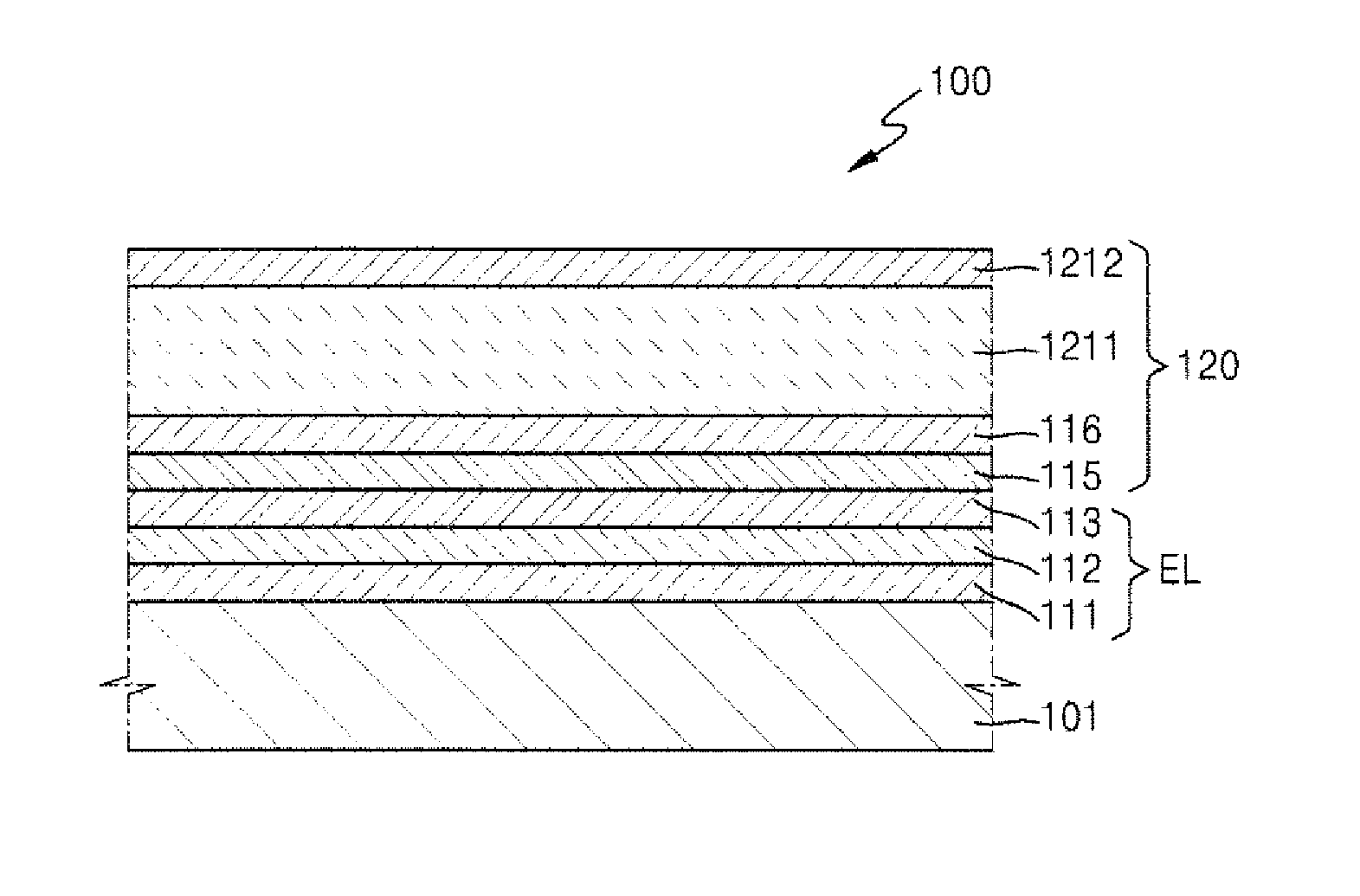

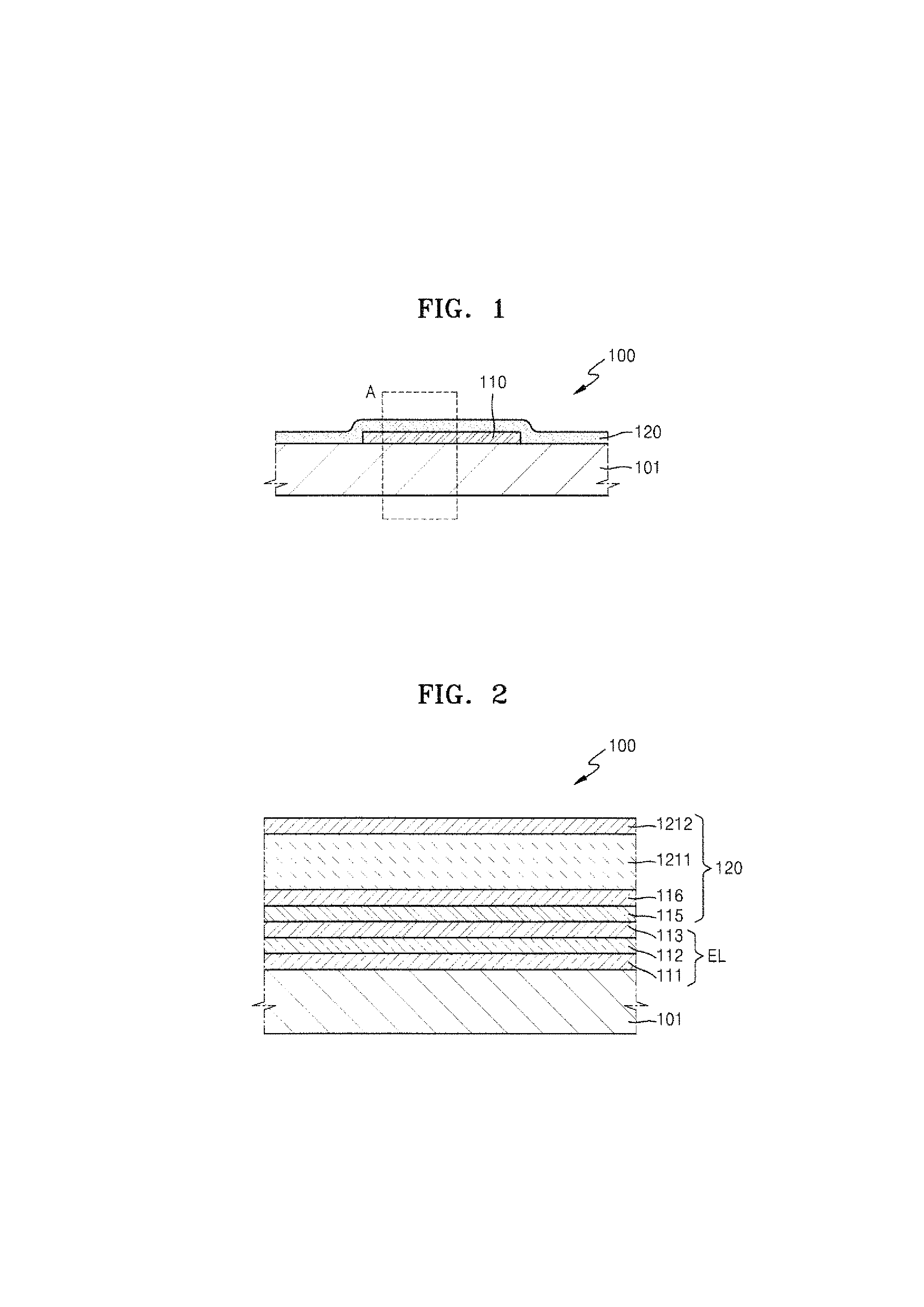

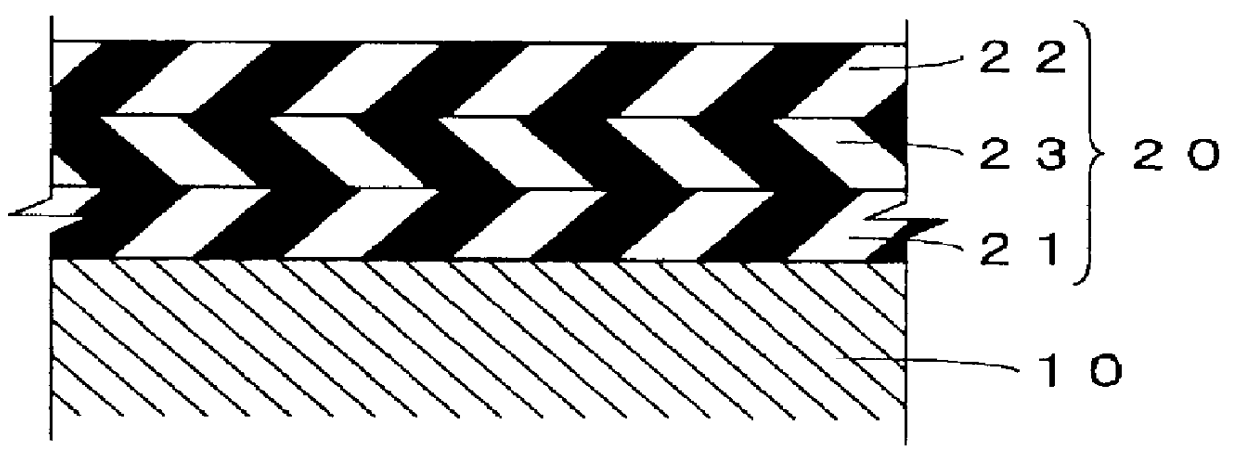

Organic Light Emitting Display Apparatus and Method of Manufacturing Organic Light Emitting Display Apparatus

ActiveUS20130181602A1Prolong lifeDelaying revelation of progressive dark spotsDischarge tube luminescnet screensElectroluminescent light sourcesPorous layerOrganic light emitting device

An organic light emitting display apparatus includes a substrate, an organic light emitting portion comprising a plurality of organic light emitting devices formed on the substrate, and an encapsulation portion for encapsulating the organic light emitting portion. The encapsulation portion includes a porous layer formed on the organic light emitting portion, a planarization layer formed on the porous layer, and a barrier layer formed on the planarization layer. The porous layer prevents impurities from being concentrated at a part of the porous layer.

Owner:SAMSUNG DISPLAY CO LTD

Discharge cell for ozone generator

InactiveUS6046533AEffectively suppress the time-related reduction in the ozone concentrationAvoid impuritiesLamp incadescent bodiesThermionic cathodesOzone generatorElectricity

A discharge cell for use in an ozone generator is provided which can suppress a time-related reduction in ozone concentration without adding a catalytic gas such as nitrogen gas to oxygen gas as a raw material gas. The discharge cell includes a pair of electrodes disposed in an opposed spaced relation with a discharge space therebetween, and a dielectric layer of a three-layer structure consisting of three ceramic dielectric layers successively stacked on at least one of the electrodes, wherein a first dielectric layer of the dielectric layer contacting the one electrode contains no titanium dioxide, wherein a second dielectric layer of the dielectric layer exposed to the discharge space contains titanium dioxide in a metal element ratio of not lower than 10 wt %.

Owner:SUMITOMO PRECISION PROD CO LTD

Peeling Method and Light-Emitting Device

ActiveUS20150123106A1Increase productionFabrication yield can be improvedLamination ancillary operationsLayered product treatmentLight emitting device

Owner:SEMICON ENERGY LAB CO LTD

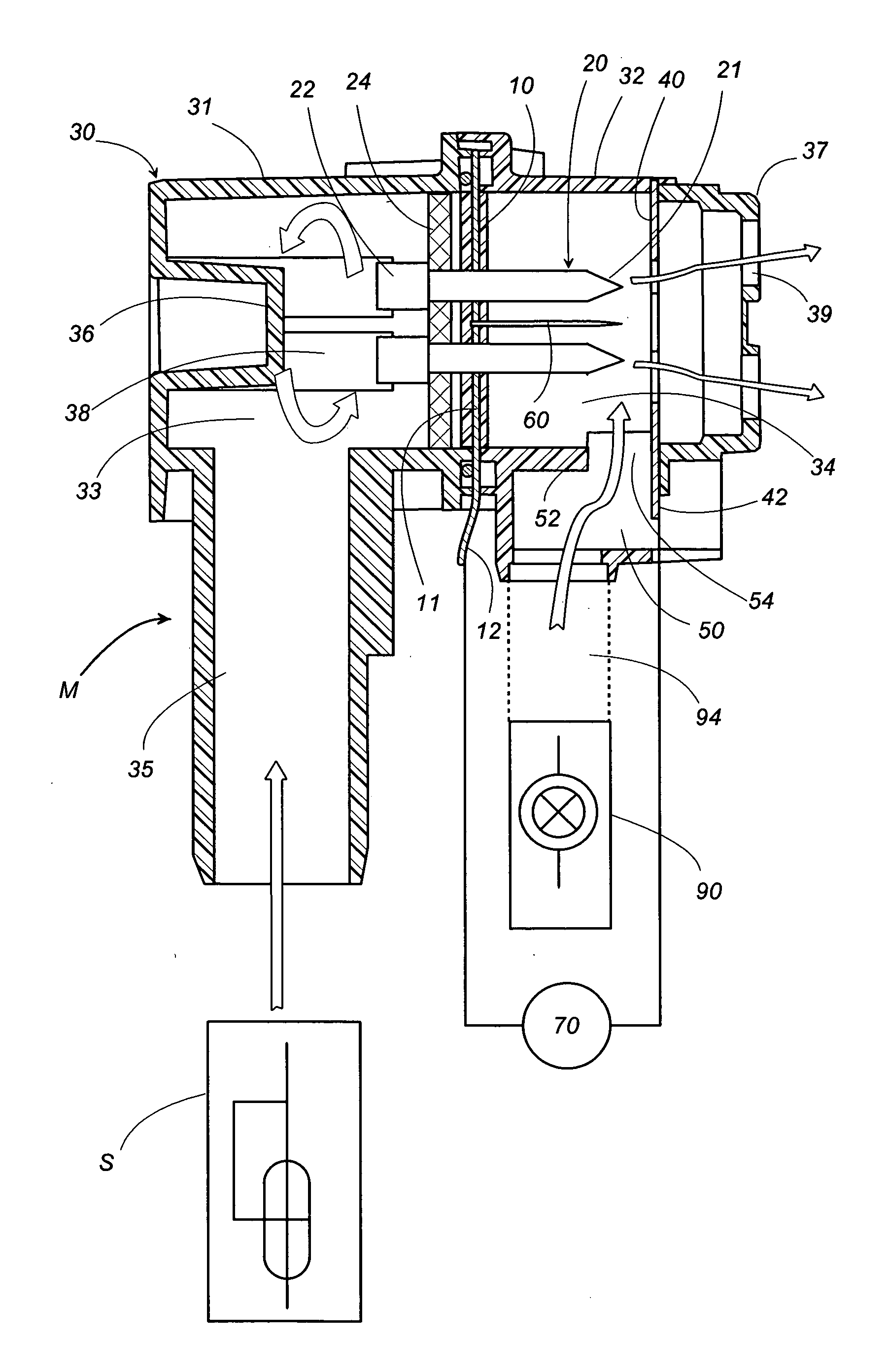

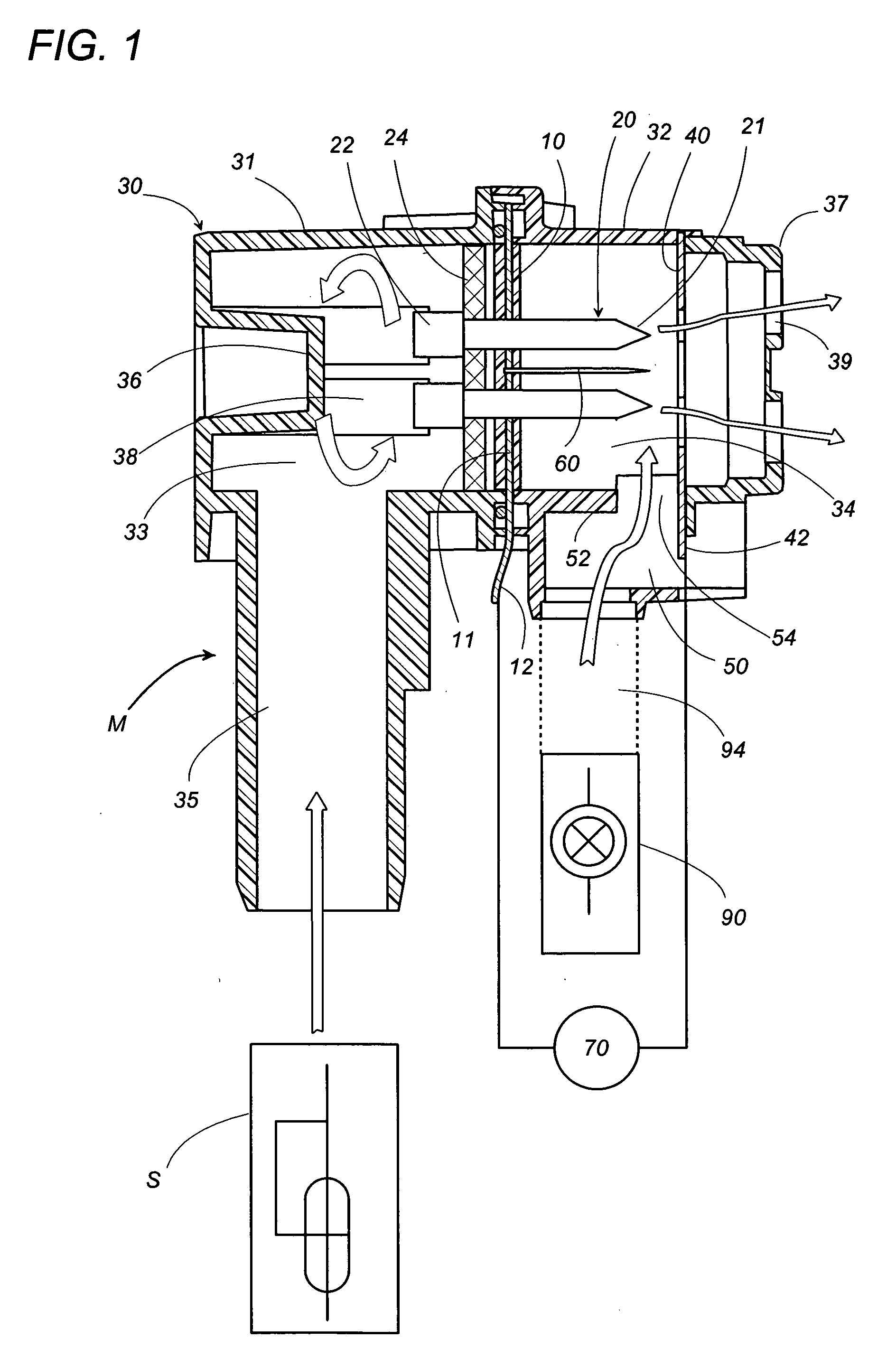

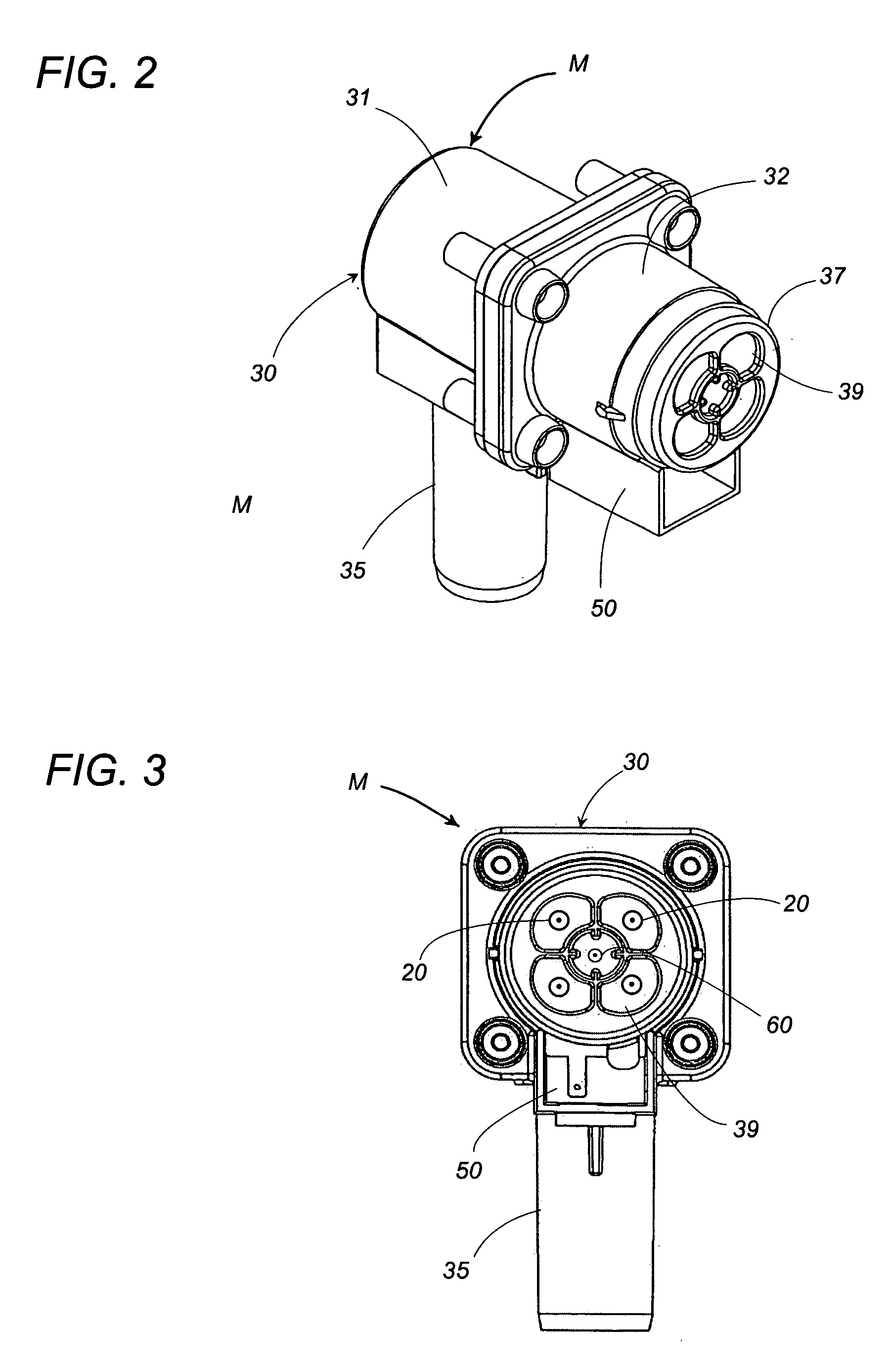

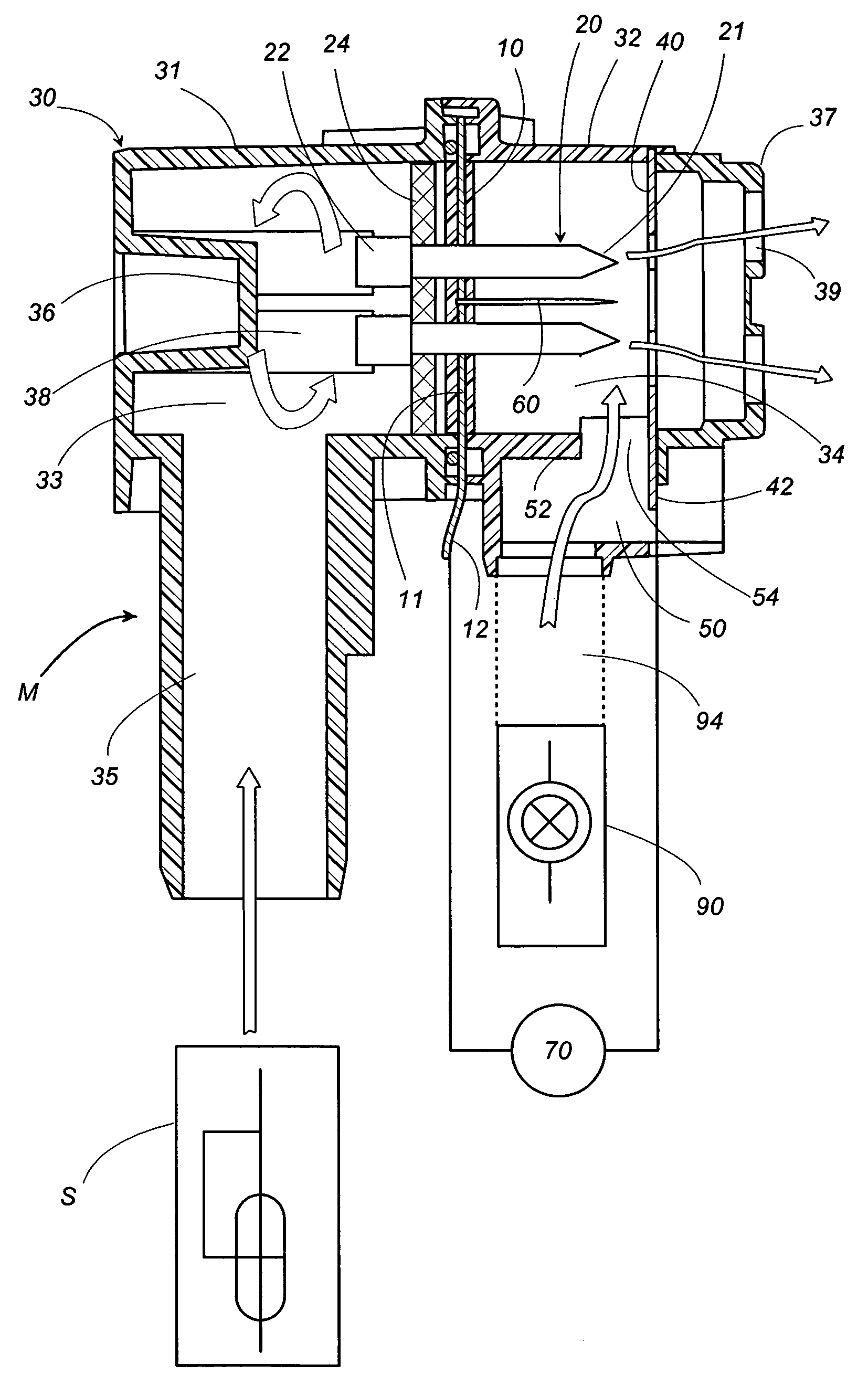

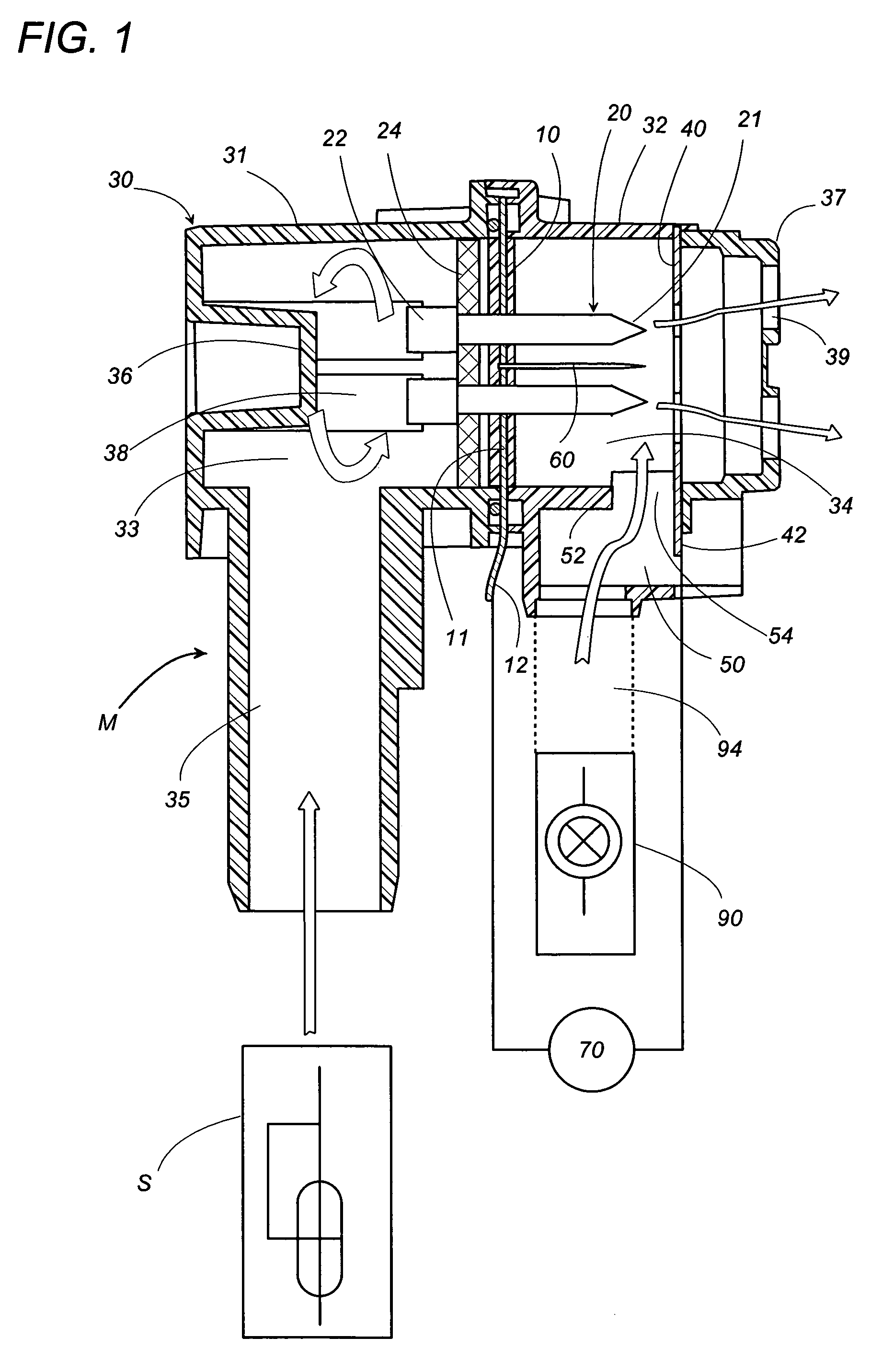

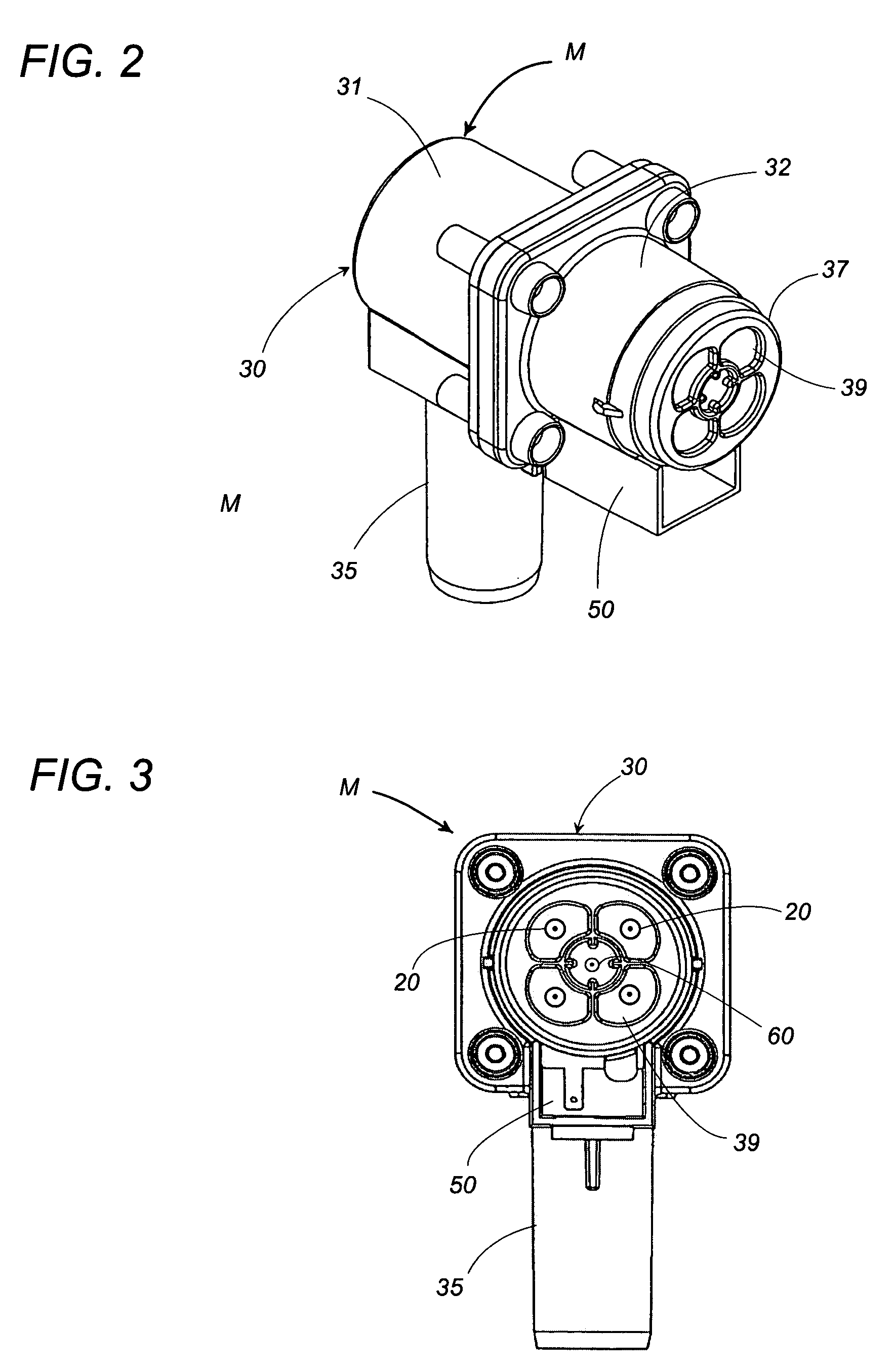

Electrostatic atomizing device and humidifier using this

InactiveUS20060131449A1Stable atomizationPrevent precipitationBurnersLiquid supply arrangementsEngineeringHigh pressure

A carrier is used to carry a liquid, and a high voltage is applied between a discharge end of the carrier and an opposed electrode to emit ionized liquid particles. The carrier has a liquid collecting end opposite to the discharge end to feed the steam of the liquid from a steam generator, condensing the liquid therearound, and feeding the condensed liquid to the discharge end. Accordingly, even when the liquid contains cations such as those of Ca and Mg, the steam of the liquid can extremely reduce the content of these impurities, avoiding the precipitation of the impurities at the discharge end of the carrier to assure stable electrostatic atomization.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Semiconductor device, method of manufacturing thereof, and method of manufacturing base material

ActiveUS20050090075A1Reliable sealing structureHighly reliable sealing structureDischarge tube luminescnet screensDecorative surface effectsMoistureSemiconductor

It is an object of the invention to provide a lightweight semiconductor device having a highly reliable sealing structure which can prevent ingress of impurities such as moisture that deteriorate element characteristics, and a method of manufacturing thereof. A protective film having superior gas barrier properties (which is a protective film that is likely to damage an element if the protective film is formed on the element directly) is previously formed on a heat-resistant substrate other than a substrate with the element formed thereon. The protective film is peeled off from the heat-resistant substrate, and transferred over the substrate with the element formed thereon so as to seal the element.

Owner:SEMICON ENERGY LAB CO LTD

Electrostatic atomizing device and humidifier using the same

InactiveUS7494532B2Stable atomizationPrevent precipitationBurnersLiquid supply arrangementsImpurityPrecipitation

A carrier is used to carry a liquid, and a high voltage is applied between a discharge end of the carrier and an opposed electrode to emit ionized liquid particles. The carrier has a liquid collecting end opposite to the discharge end to feed the steam of the liquid from a steam generator, condensing the liquid therearound, and feeding the condensed liquid to the discharge end. Accordingly, even when the liquid contains cations such as those of Ca and Mg, the steam of the liquid can extremely reduce the content of these impurities, avoiding the precipitation of the impurities at the discharge end of the carrier to assure stable electrostatic atomization.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Method of transferring a substrate

InactiveUS20060225299A1Avoid pollutionAvoid impuritiesDrying gas arrangementsSemiconductor/solid-state device manufacturingPhysical chemistryEnvironmental engineering

Owner:SAMSUNG ELECTRONICS CO LTD

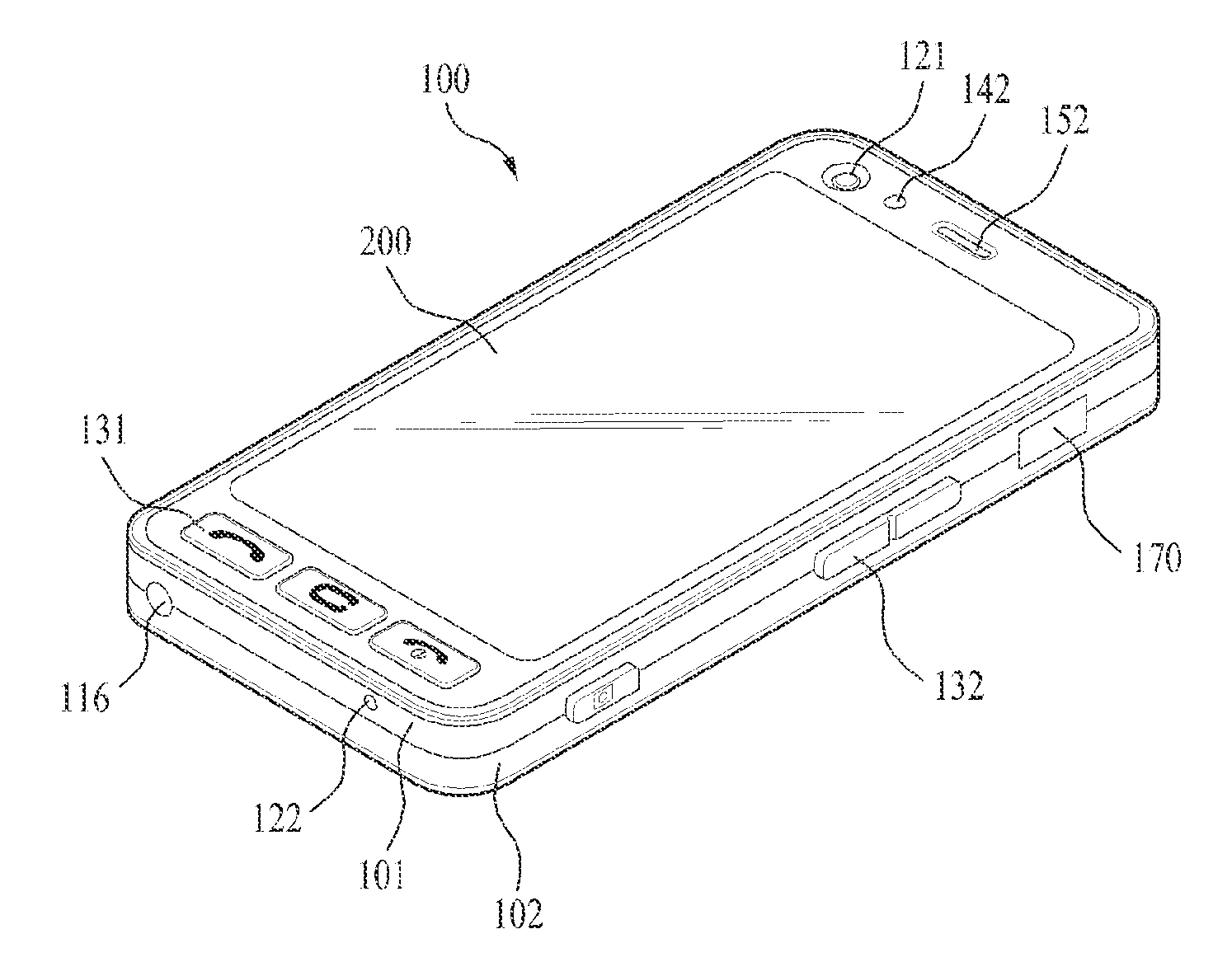

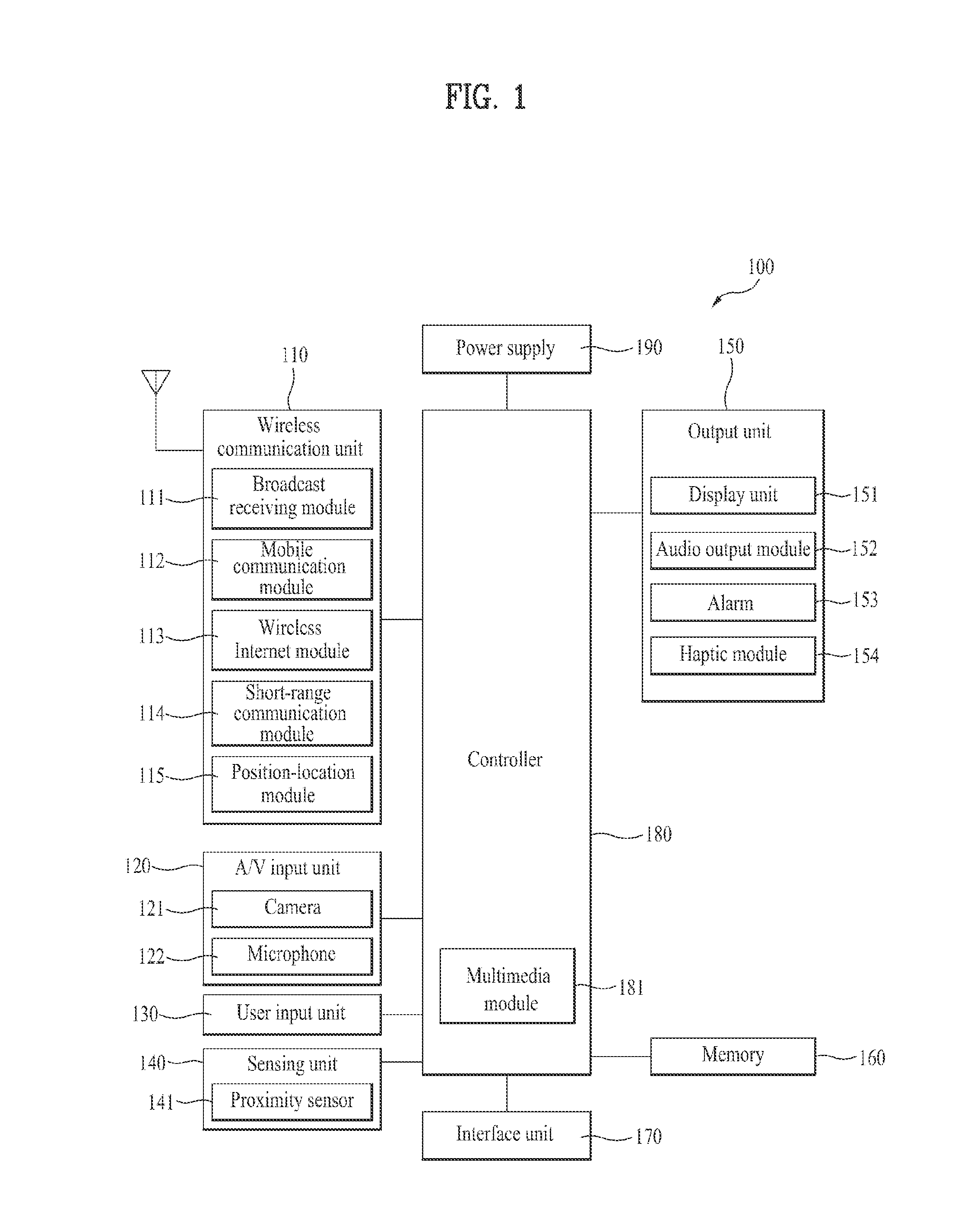

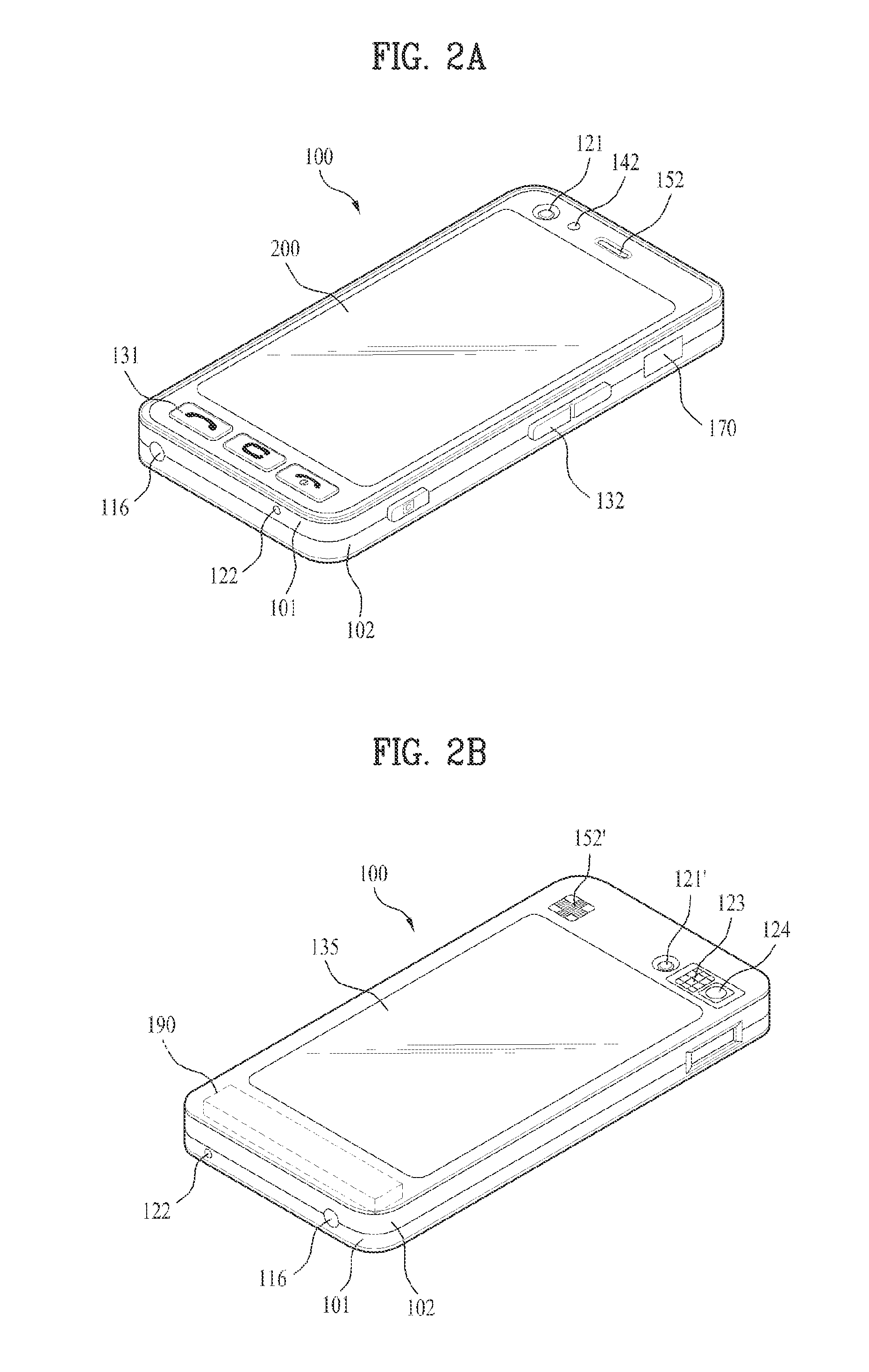

Mobile terminal and manufacturing method thereof

ActiveUS20120236587A1Reduce manufacturing costHigh color reproductionMechanical apparatusGlass reforming apparatusDisplay deviceQuantum dot

A mobile terminal and manufacturing method thereof are disclosed, by which color reproducibility of a display and the expected life span of a display can be enhanced using quantum dots. The present invention may include a display panel, a plurality of light source units spaced apart from each other, and a quantum dot filter unit provided to a light emitting surface of the light source unit to enable a light provided by the light source unit to pass through. And, the quantum dot filter unit may include a light transmissive hollow pipe member having one end opening or both end openings, quantum dots provided within the light transmissive hollow pipe member, and a sealing member configured to seal the one end opening or the both end openings, the sealing member formed of a same material of the light transmissive hollow pipe member.

Owner:LG ELECTRONICS INC

Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

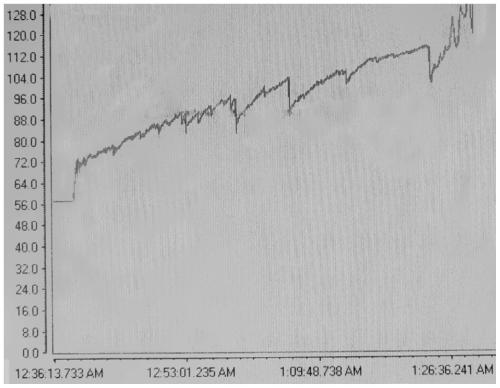

The invention discloses a method for controlling cleanliness of molten steel, and a smelting control method capable of preventing a molten steel gap from nodulation during sulphur and aluminum contained steel pouring, and belongs to the field of smelting. The method for controlling cleanliness of the molten steel comprises the following steps that blast furnace molten iron without desulfuration issubjected to converter smelting, and during converter tapping, deoxygenation, alloying and tapping wash heat are carried out in sequence for carrying out inclusion removal treatment. Through an LF furnace, converter tapping is subjected to refining under the condition that acid soluble aluminum is not adjusted, that is, during tapping, a slagging constituent is added for controlling refining slagcomposition, and after the slag is dissolved, deoxygenation is carried out through a deoxidizing agent. Through the process, the content of sulphur in the molten steel is monitored, ferrous sulfide is used for adjusting the content of sulphur in the molten steel to the first target value, an RH furnace is used for refining LF furnace tapping, in the process, according to the content of the acid soluble aluminum of LF furnace tapping, selective aluminum feeding is carried out to adjust the content of the aluminum to the second target value, and after RH furnace refining is finished, calcium treatment is carried out. According to the process, the cleanliness of the molten steel can be improved, the nodulation problem during molten steel pouring can be avoided, and the stopper bar curve rising can be controlled.

Owner:SGIS SONGSHAN CO LTD

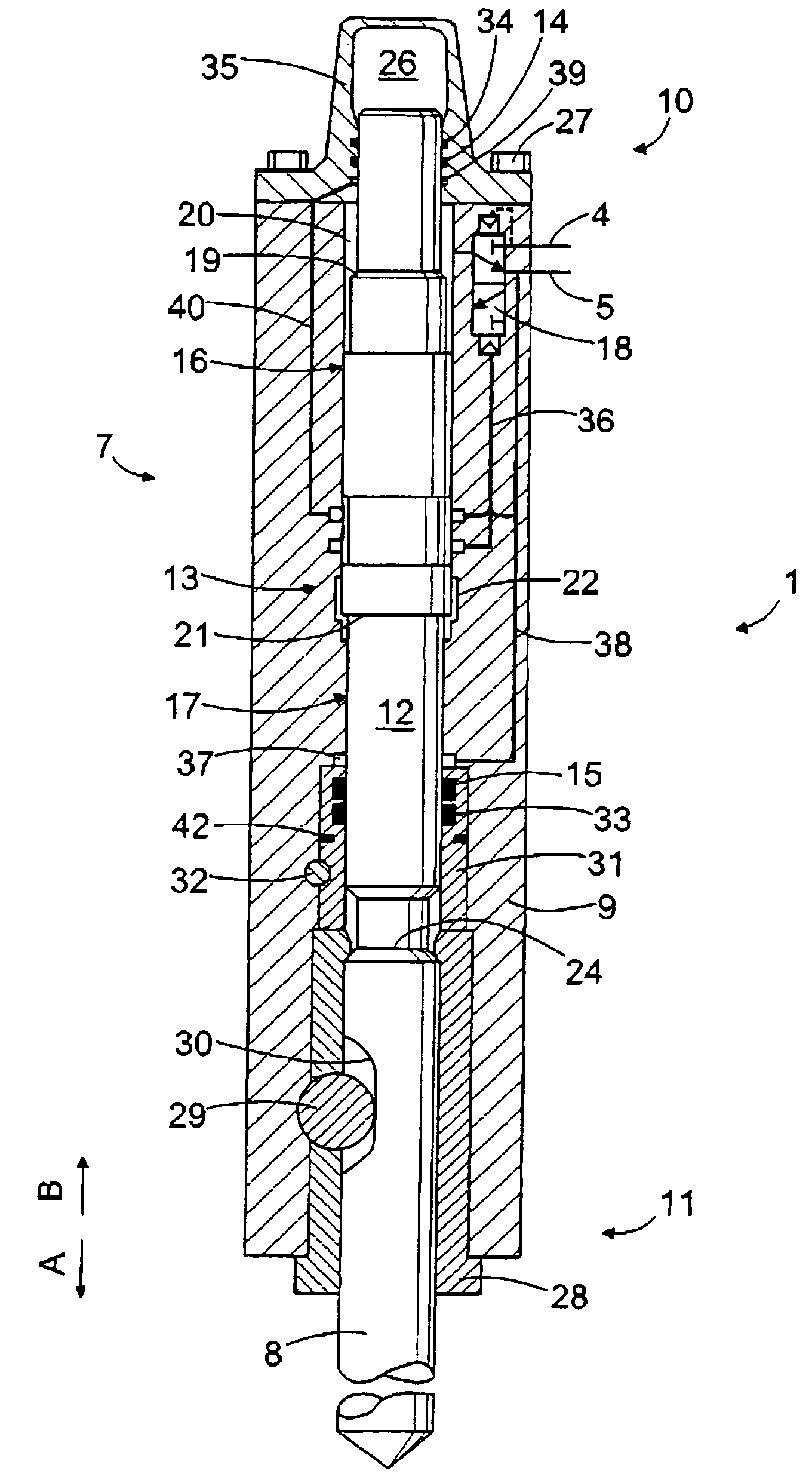

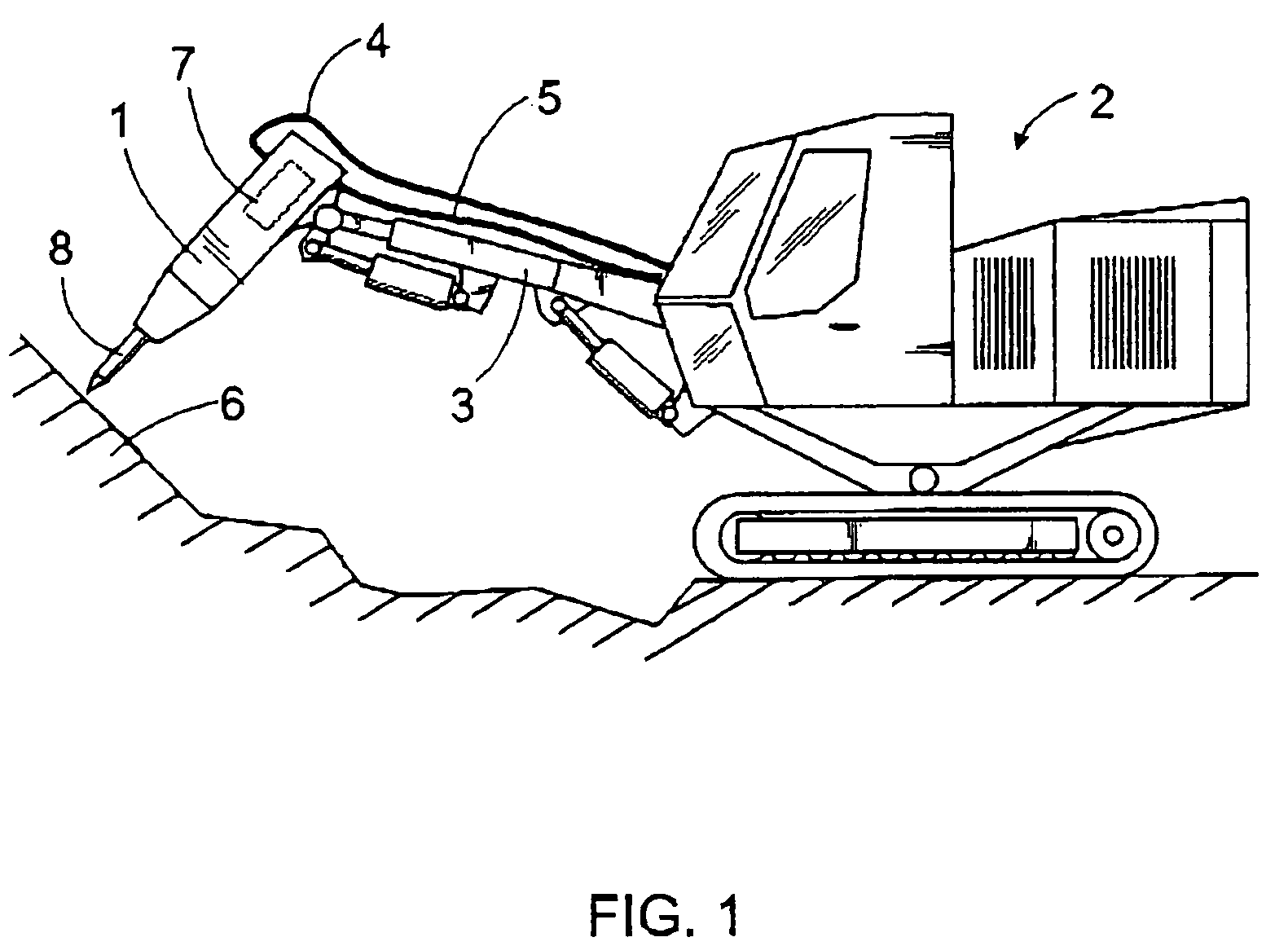

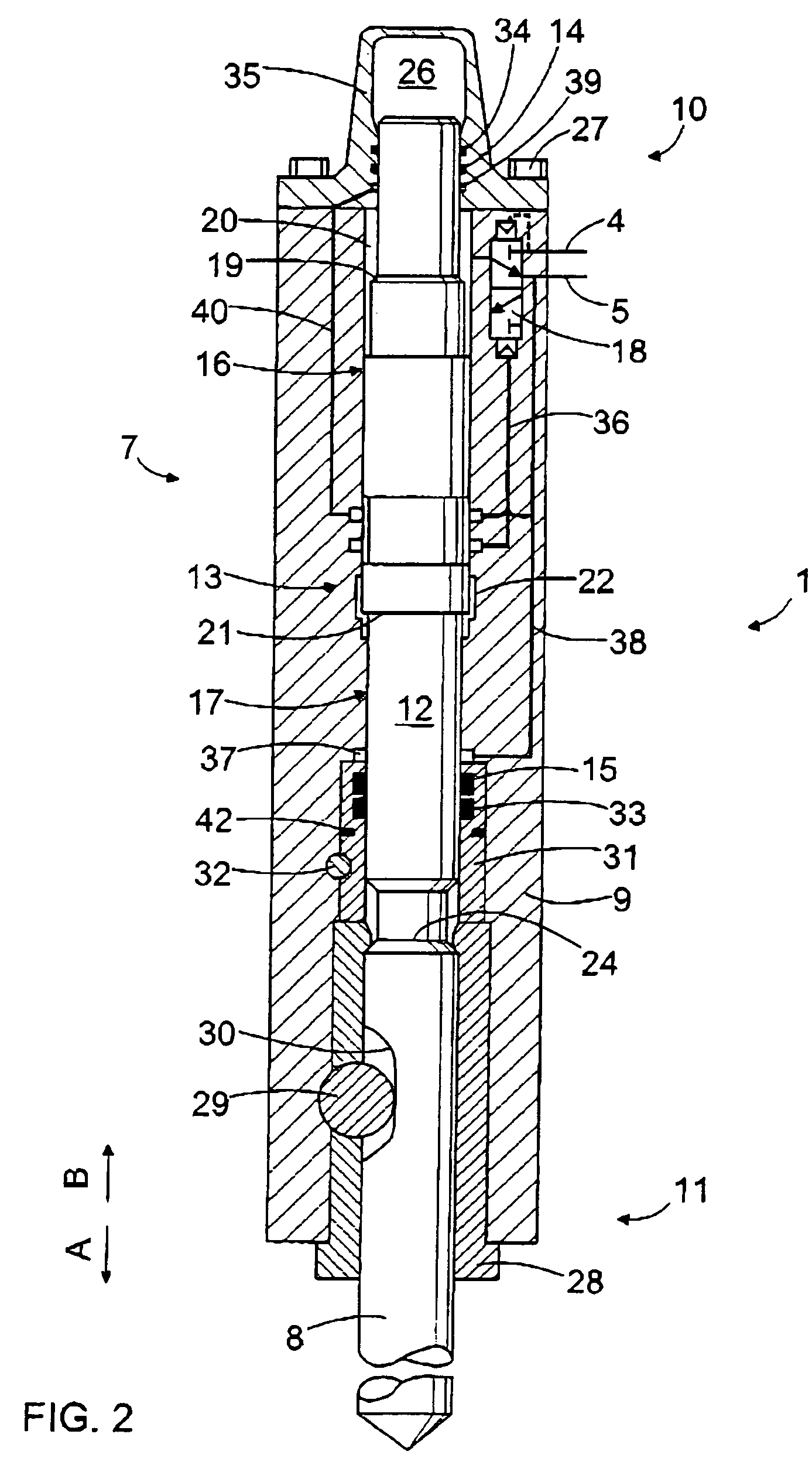

Hydraulic hammer having a sealing bushing

ActiveUS7152692B2Rapid and less maintenanceManufactured with lessReciprocating drilling machinesSoil-shifting machines/dredgersEngineeringMechanical engineering

A hydraulic hammer having a sealing bushing includes a percussion piston that delivers strokes to a tool. A lower part of the percussion piston is sealed with respect to a frame by the sealing bushing, which includes one or more lower seals. The sealing bushing does not contribute to the bearing of the percussion piston and it is arranged in place through the lower end of the hydraulic hammer.

Owner:SANDVIK TAMROCK

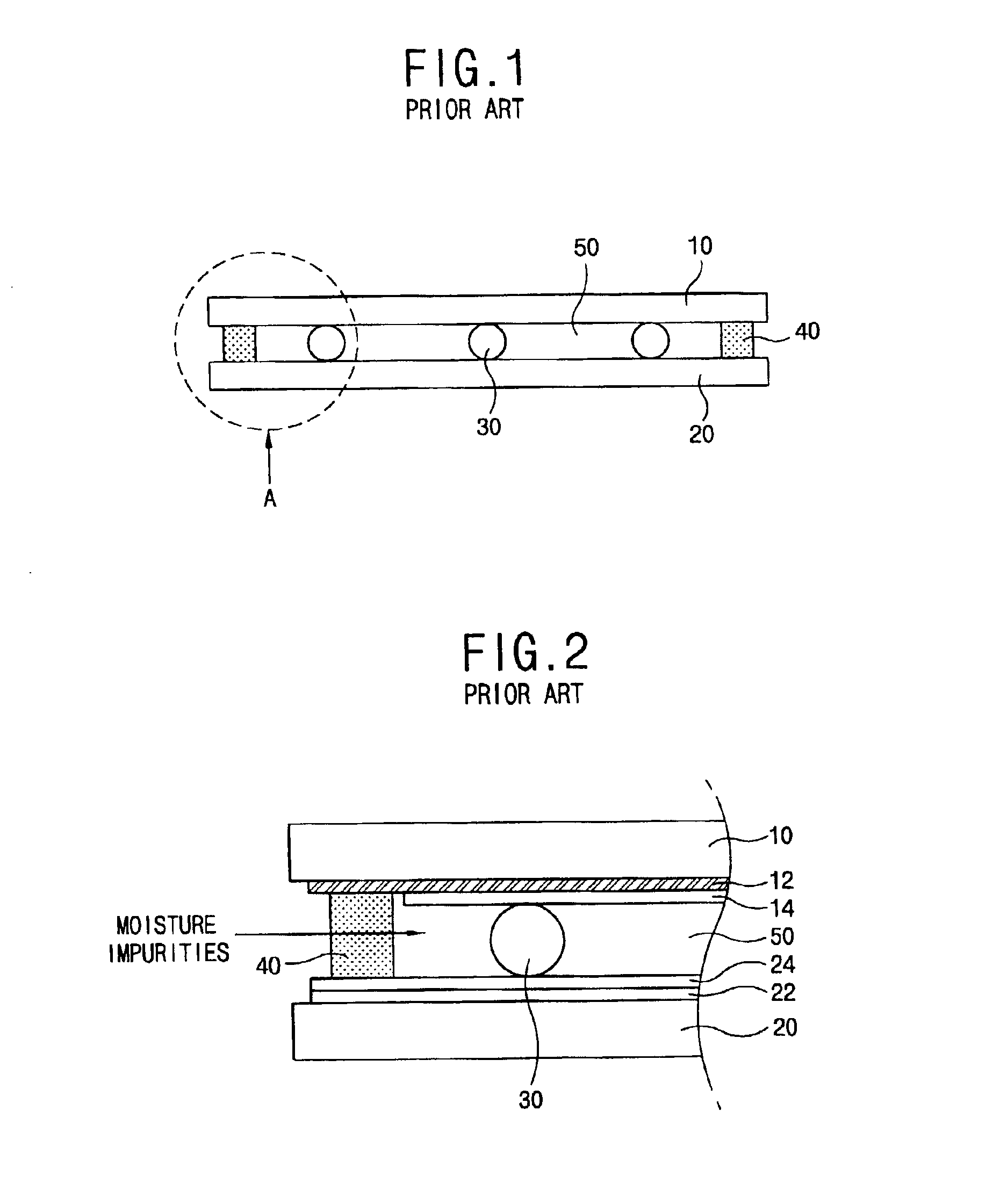

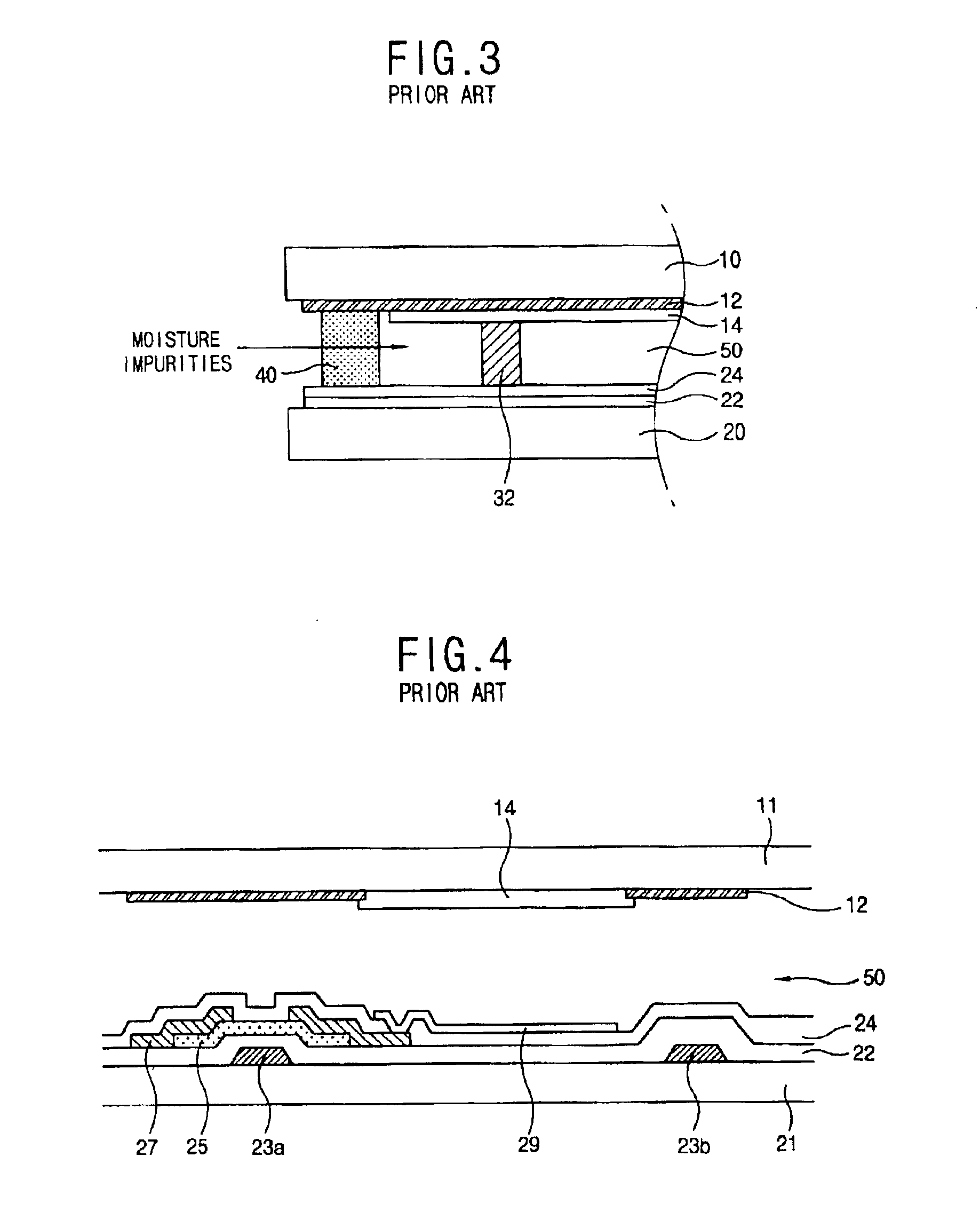

Liquid crystal display device sealing structure and method of fabricating the same

InactiveUS6882399B2Reduce parasitic capacitanceImprove image qualityNon-linear opticsLiquid-crystal displayEngineering

A liquid crystal display device includes a liquid crystal panel having first and second substrates attached to each other and separated by a spacer, a sealing unit for sealing the first and second substrates along a peripheral area of the liquid crystal panel, and a sealing pattern disposed within the sealing unit.

Owner:LG DISPLAY CO LTD

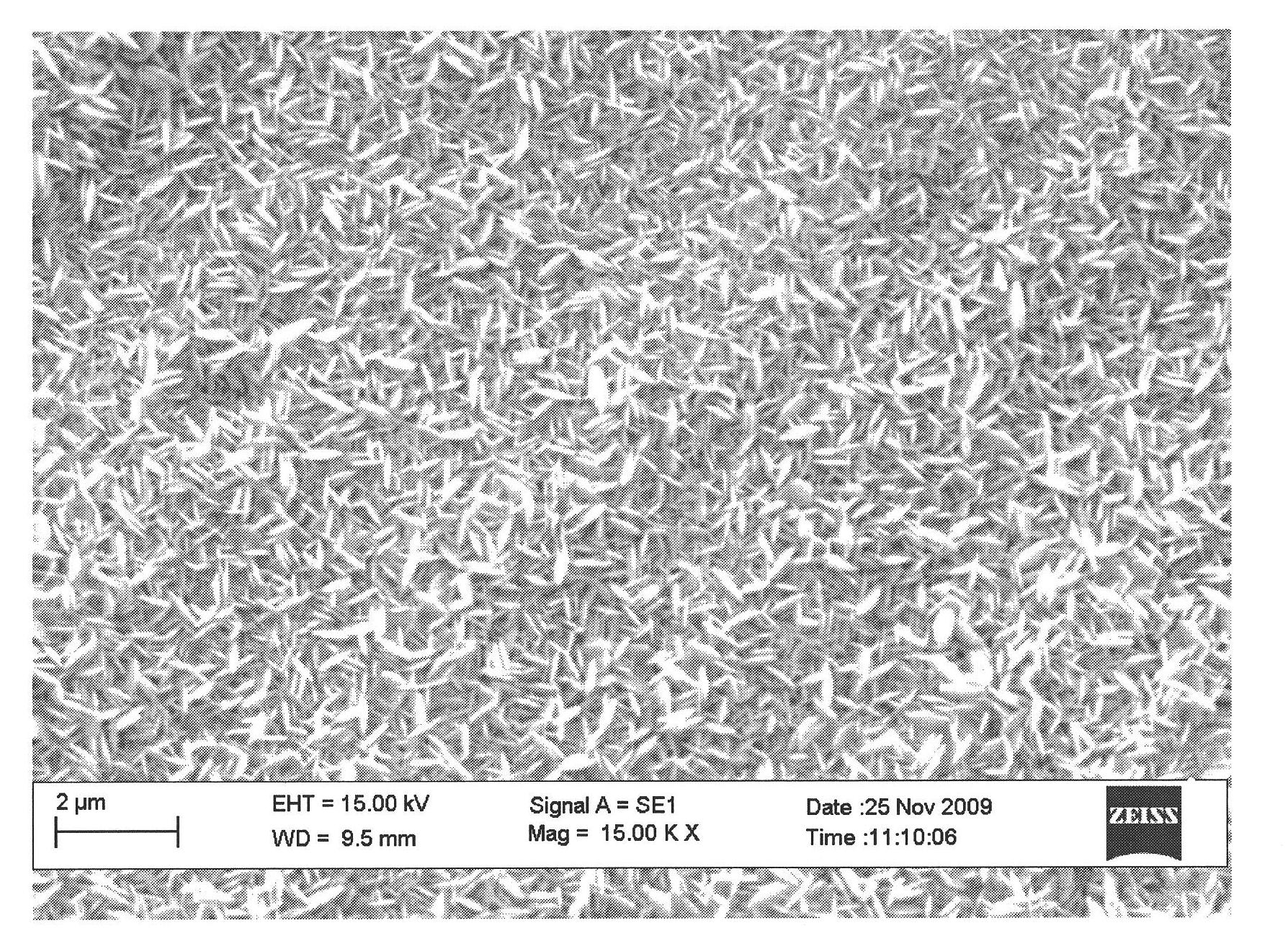

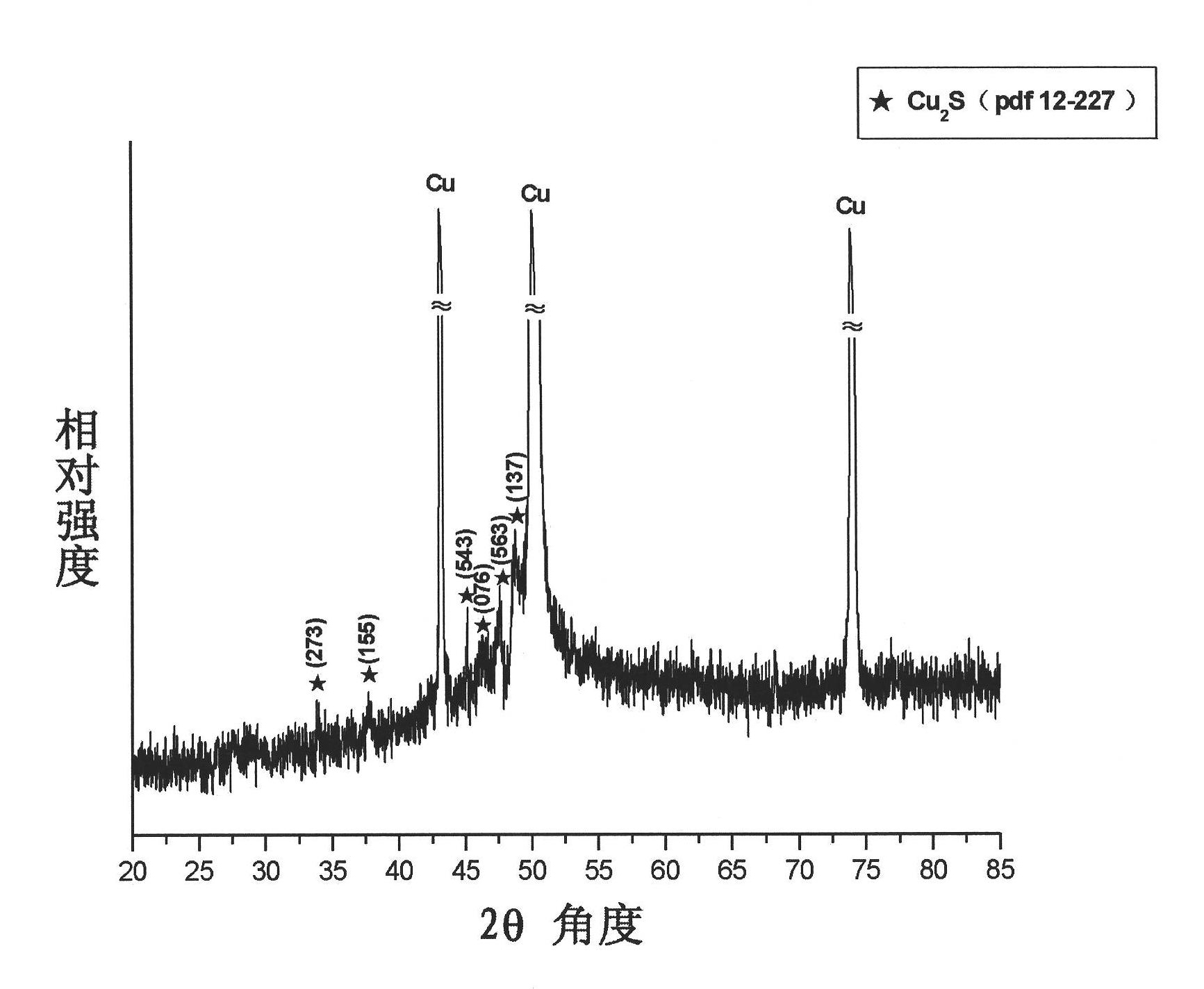

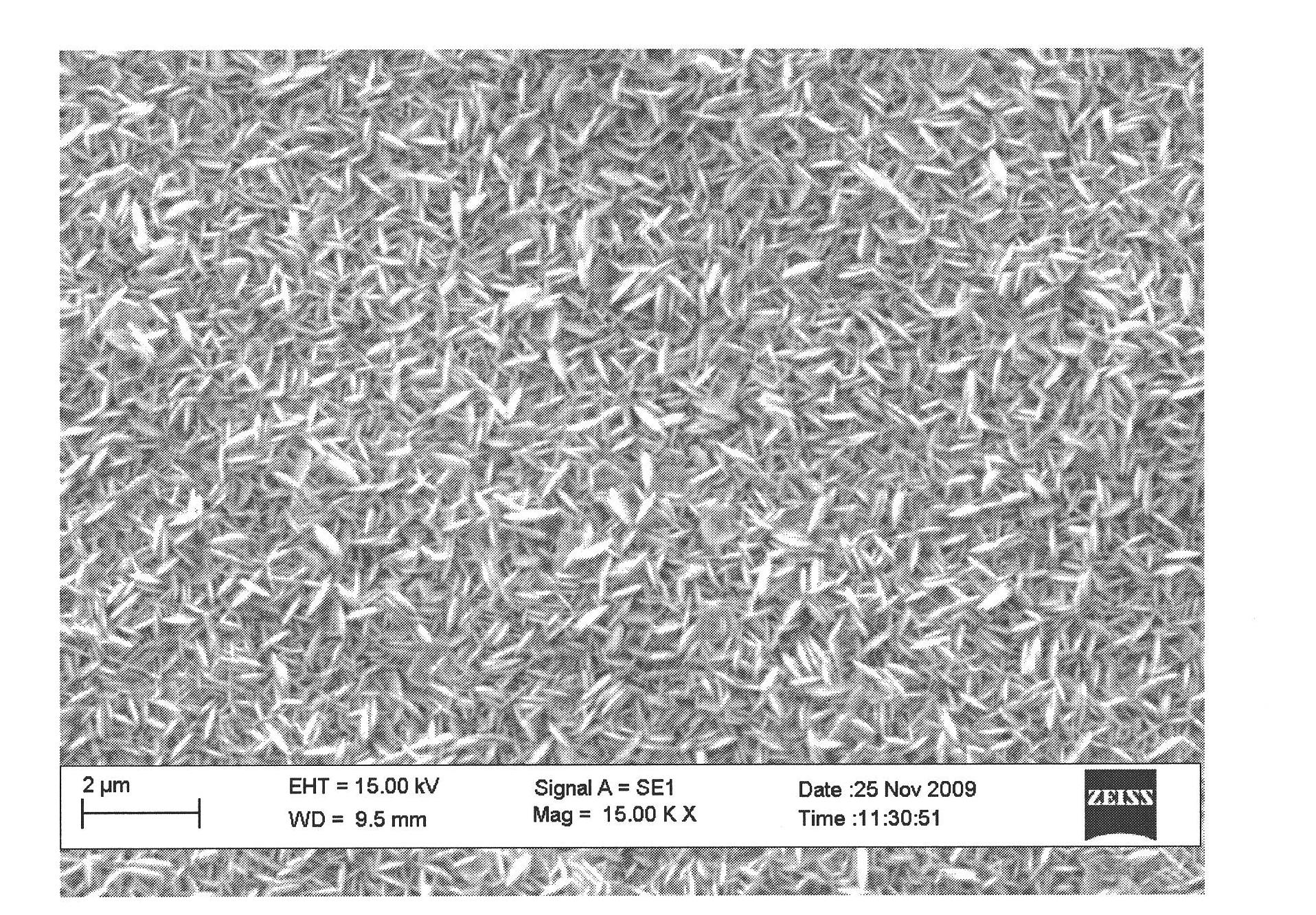

Chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at low temperature

InactiveCN101792173ALow reaction temperatureReduce energy consumptionNanostructure manufactureCopper sulfidesN dimethylformamideFilm material

The invention provides a chemical method for synthesizing flaky CuxSy nanocrystalline optoelectronic film controllably at a low temperature. The method comprises the following steps: firstly adding sulfur powder in a container, secondly adding organic solvent N,N-dimethylformamide or absolute alcohol, wherein the volume of organic solvent is more than a half of the capacity of the container; standing at 0-60 DEG C for 1h to ensure that the sulfur powder dissolved in organic solvent is saturated, horizontally placing substrate material with a new and clean metal copper surface on the bottom of the container to avoid directly contacting with sulfur powder, reacting at 0-60 DEG C for 5-24h, cleaning the product with absolute alcohol, drying at room temperature to in-situ prepare the big area film material composed of flaky CuxSy nanocrystalline on the metal copper surface of the substrate material, wherein x:y=1-2. The method of the invention adopts low temperature, has low energy consumption, is simple, green and environmentally friendly and particularly applicable to large-area industrial production, and does not use any template, add any surfactant and perform complicated post-processing operations such as purification.

Owner:XUCHANG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com