Method for controlling cleanliness of molten steel, and smelting control method capable of preventing molten steel gap from nodulation during sulphur and aluminum contained steel pouring

A cleanliness and molten steel technology, applied in the field of smelting, can solve the problems of low cleanliness of molten steel and easy nodules at the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

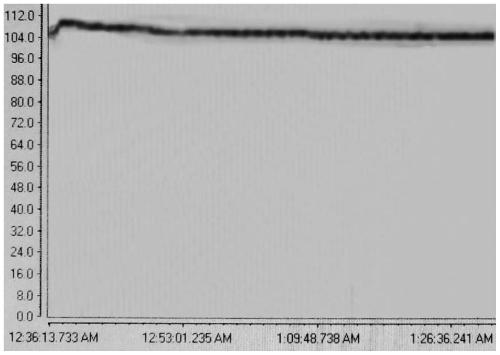

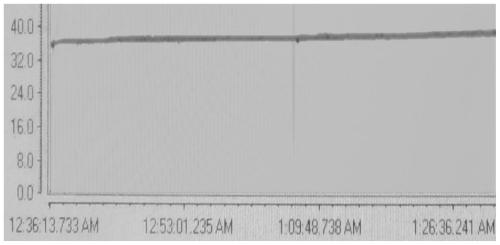

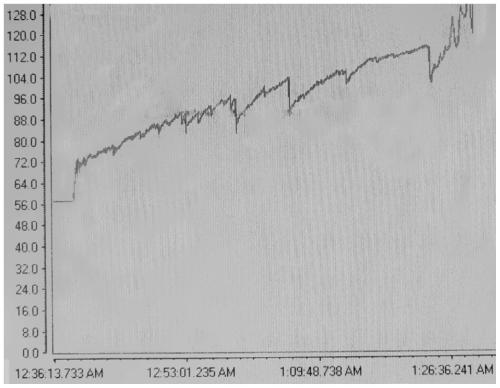

Image

Examples

Embodiment 1

[0098] For the production of a certain steel containing sulfur and aluminum, the composition control requirements of the finished product are: C: 0.19-0.21%, Si: 0.20-0.30%, Mn: 0.70-0.80%, Cr: 0.80-0.90%, Als; 0.010-0.030 %, target 0.015%, P: ≤0.025%, S: 0.020-030%.

[0099] Its smelting process is as follows:

[0100] The blast furnace molten iron is transferred to the converter for smelting without pretreatment and desulfurization, and the carbon at the end of the converter is controlled at 0.08-0.15%.

[0101]Add 2.3kg / t of aluminum and iron to 1 / 3 of the tapping, add C, Si, Mn, Cr alloy elements to adjust the composition of molten steel to the lower limit of the range, add 3.0kg / t of slag lime to the 3 / 4 of tapping, and synthesize Slag 2.5kg / t. The slag material is added during the tapping process to remove impurities through slag washing, and to keep warm during transportation to the LF refining furnace.

[0102] 2.0kg / t of lime and 4.5kg / t of low-alkalinity slag are ...

Embodiment 2

[0106] For the production of a certain steel containing sulfur and aluminum, the composition control requirements of the finished product are: C: 0.34-0.38%, Si: 0.60-0.75%, Mn: 0.95-1.05%, Cr: 0.10-0.0.25%, V: 0.25 ~0.35%, Als: ≤0.030%, P: ≤0.025%, S: ≤0.040~0050%.

[0107] Concrete process steps are:

[0108] The blast furnace molten iron is smelted in the converter, and the carbon at the end of the converter is controlled at 0.08-0.25%. Specifically, 1 / 3 of the tapping is added with 1.5kg / t of aluminum and iron, 2 / 3 of the tapping is added with C, Si, Mn, Cr, V and other alloying elements to adjust the composition of molten steel to the lower limit of the range, and 3 / 4 of the tapping is added with slag Lime 3.0kg / t, synthetic slag 2.5kg / t.

[0109] The steel from the converter is transferred to the LF refining furnace, and the refining furnace is added to the station to add 2.0kg / t of lime, 4.5kg / t of low-alkalinity slag, and add 0.8kg / t of slag surface composite deoxidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com