Patents

Literature

101results about How to "Reliable sealing structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

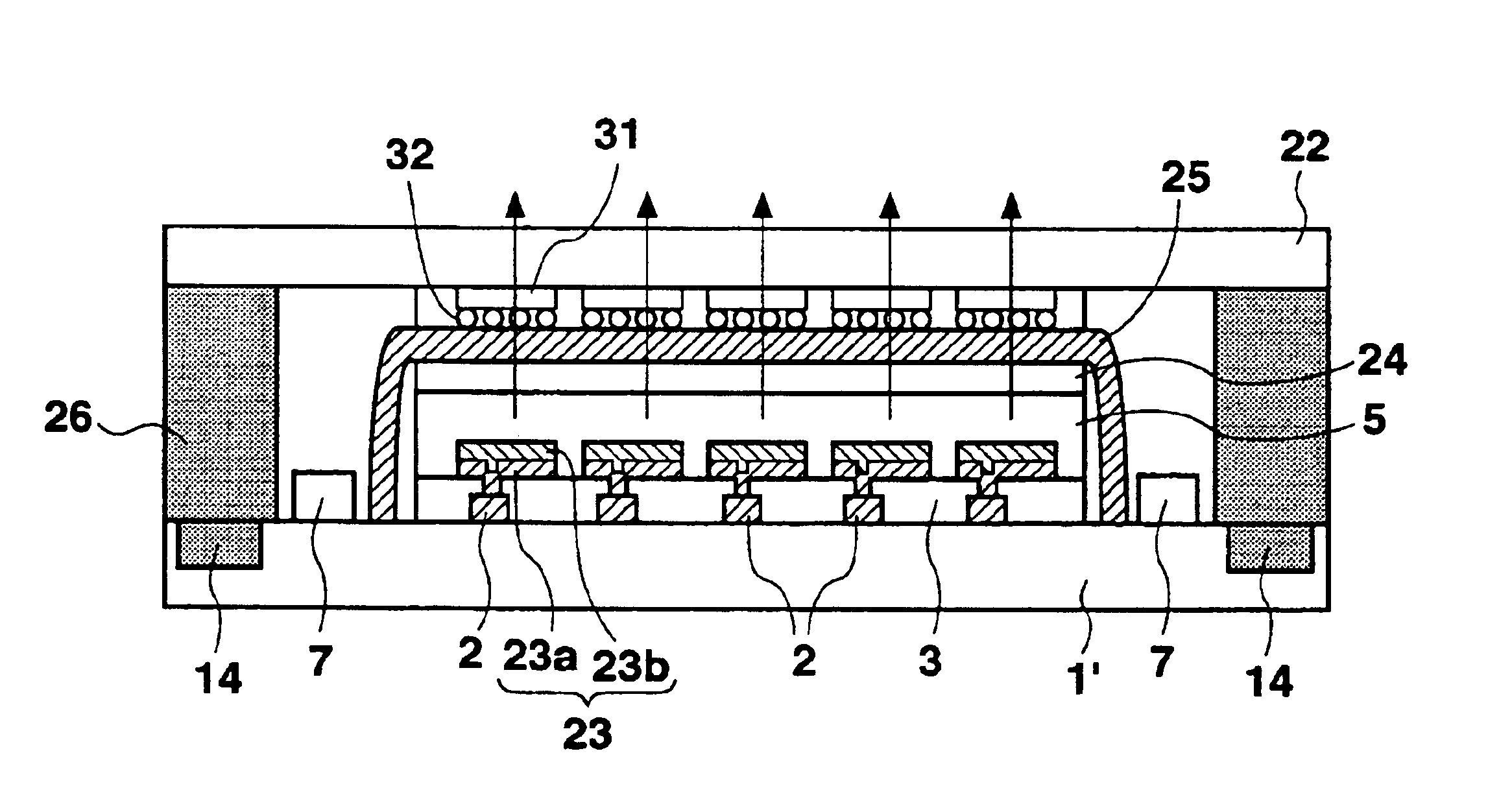

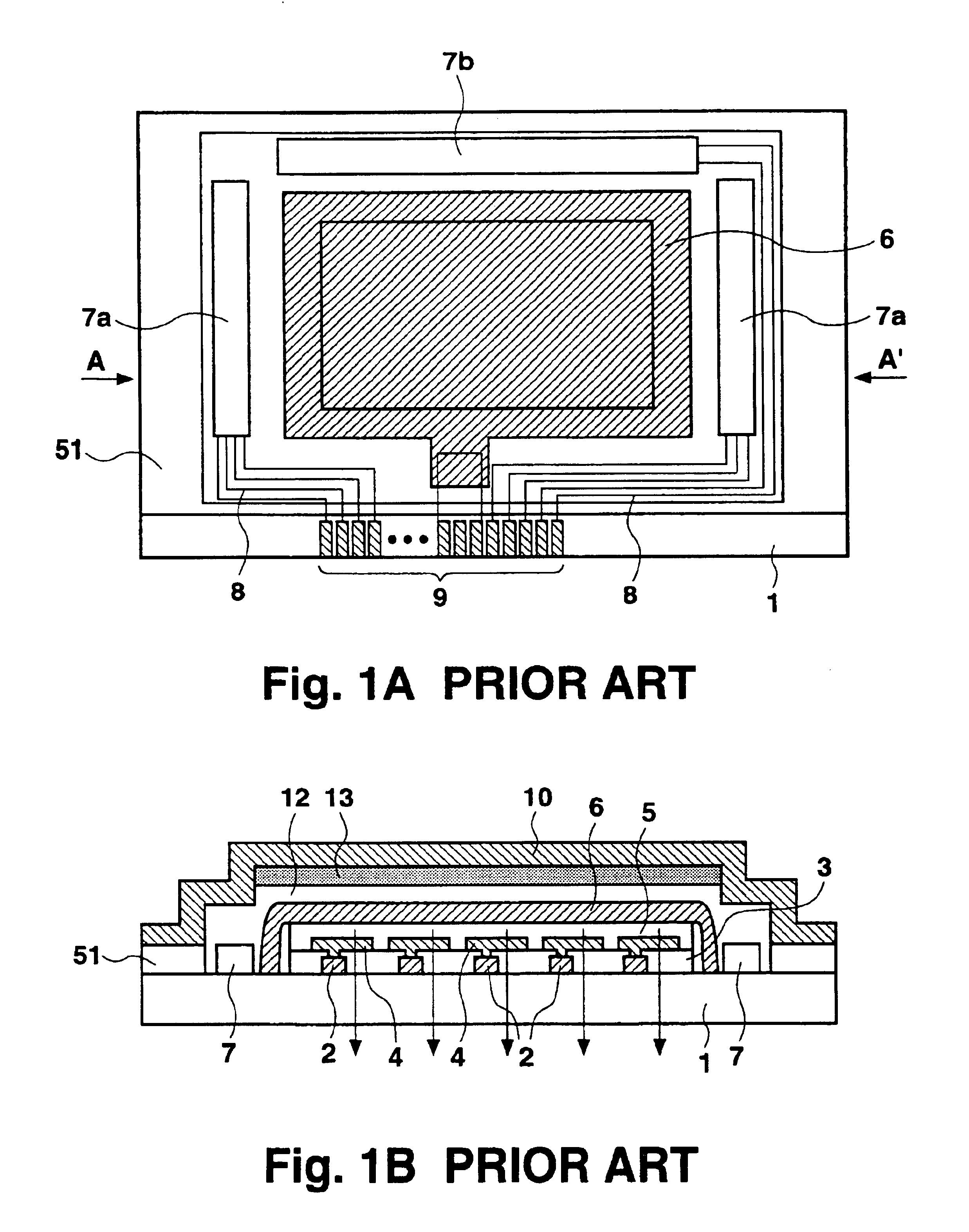

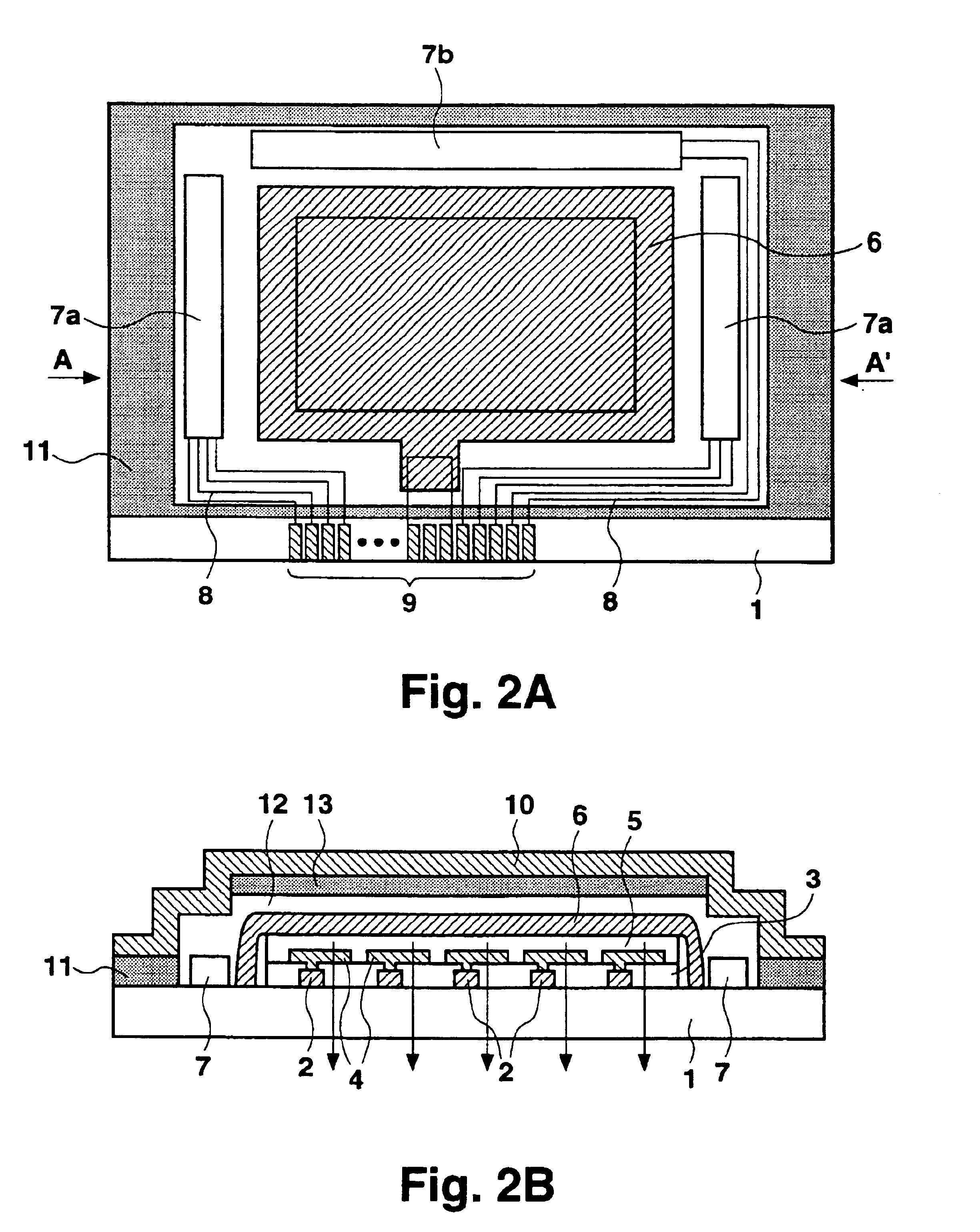

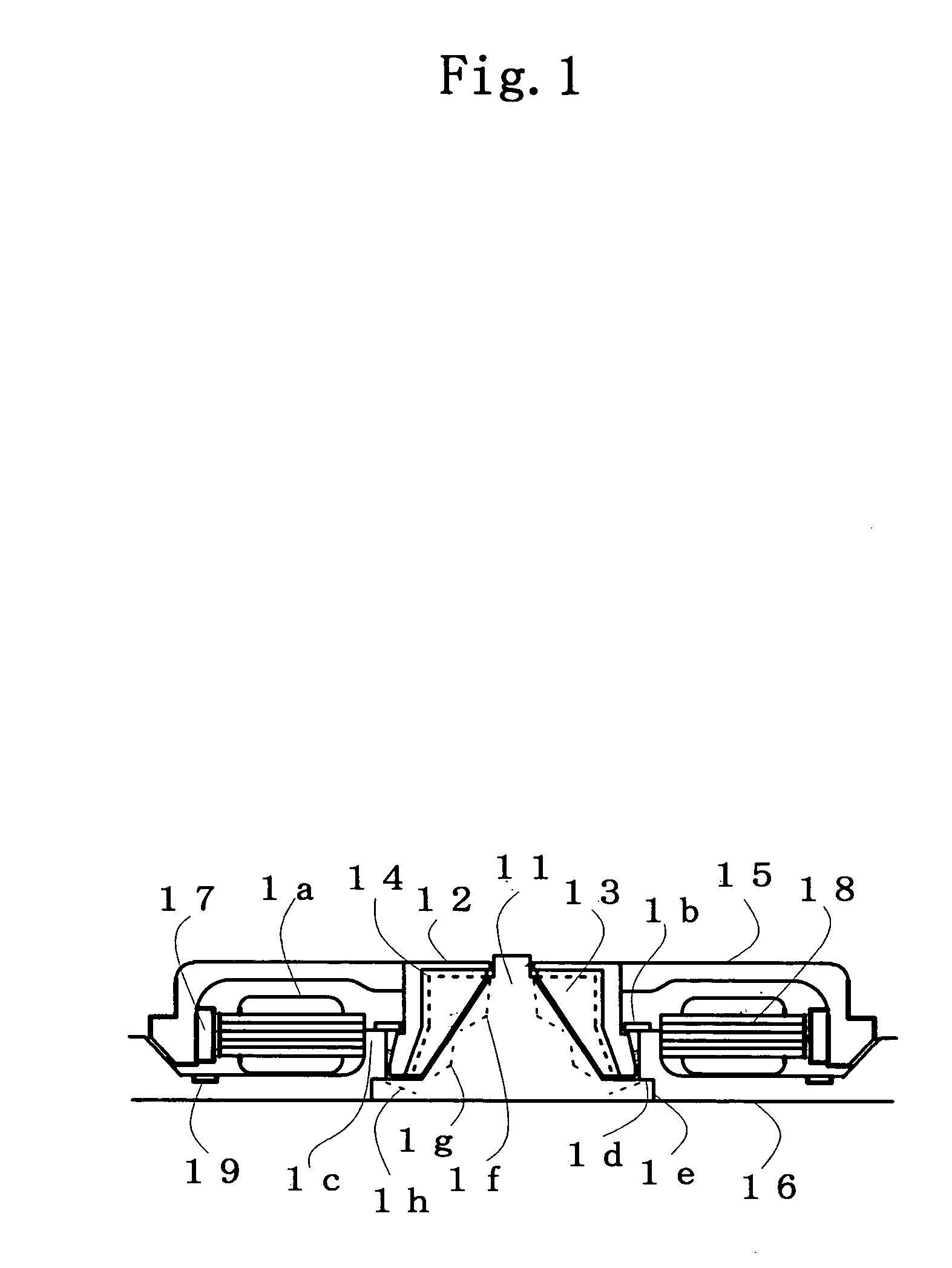

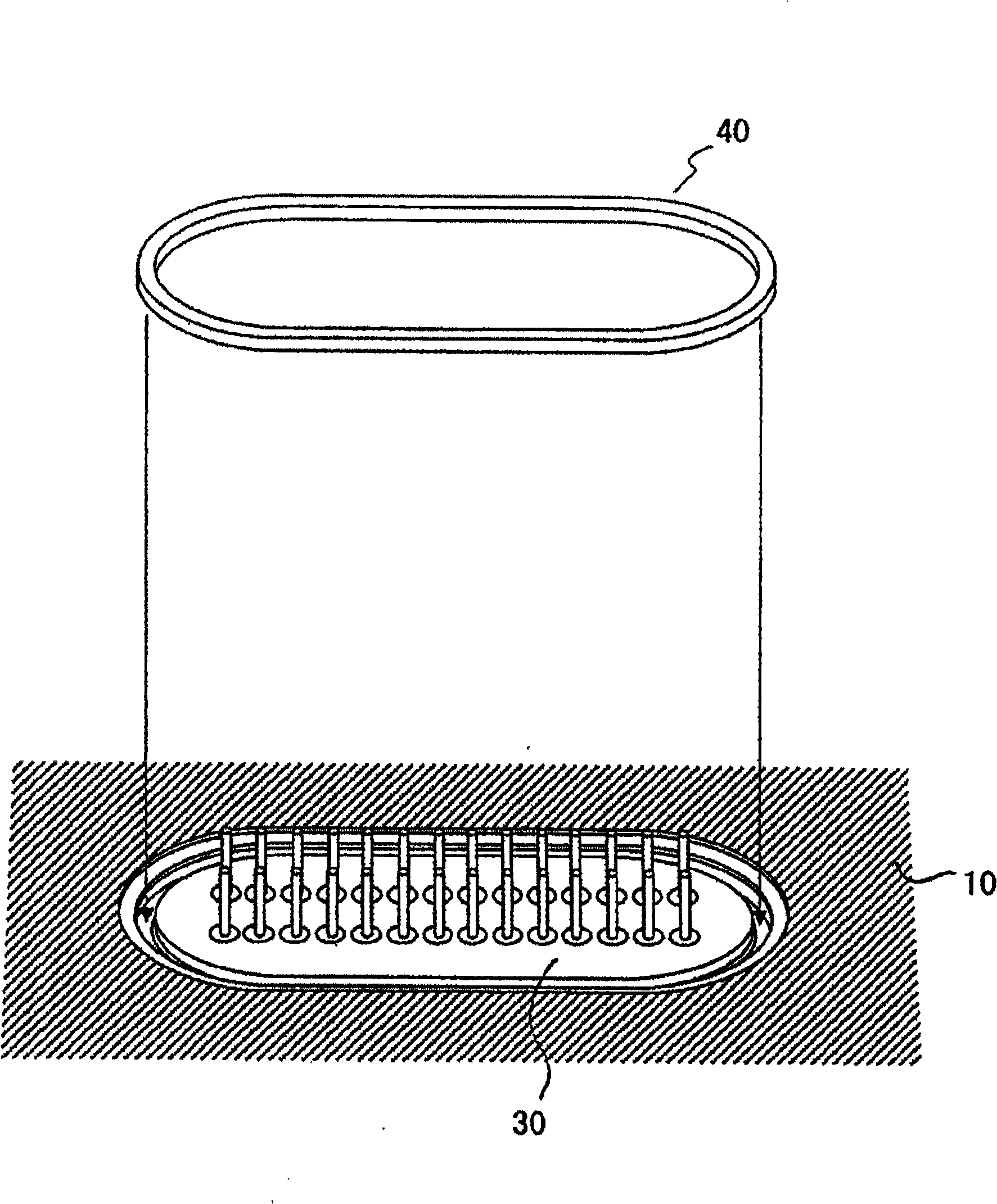

Electroluminescence display device having a desiccant

InactiveUS6833668B1Increase the aperture ratioReliable sealing structureDischarge tube luminescnet screensElectroluminescent light sourcesDesiccantDisplay device

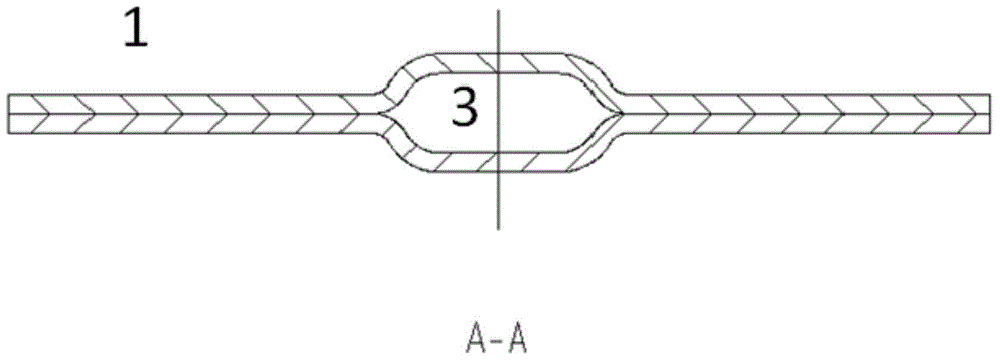

Powder desiccant is mixed into a seal which adheres a first substrate to a second substrate, thereby sealing a display region. Almost no moisture permeates through the outer surfaces of the substrates sandwiching the display region, while moisture permeating through the seal is adsorbed by the desiccant. An emissive layer is thereby prevented from deterioration due to moisture. By covering the display region with a resin sealing layer composed of resin having desiccant mixed therein, the display region can reliably be protected from moisture. By forming a groove in the substrate and placing a desiccant therein, moisture can be further reliably adsorbed.

Owner:SANYO ELECTRIC CO LTD

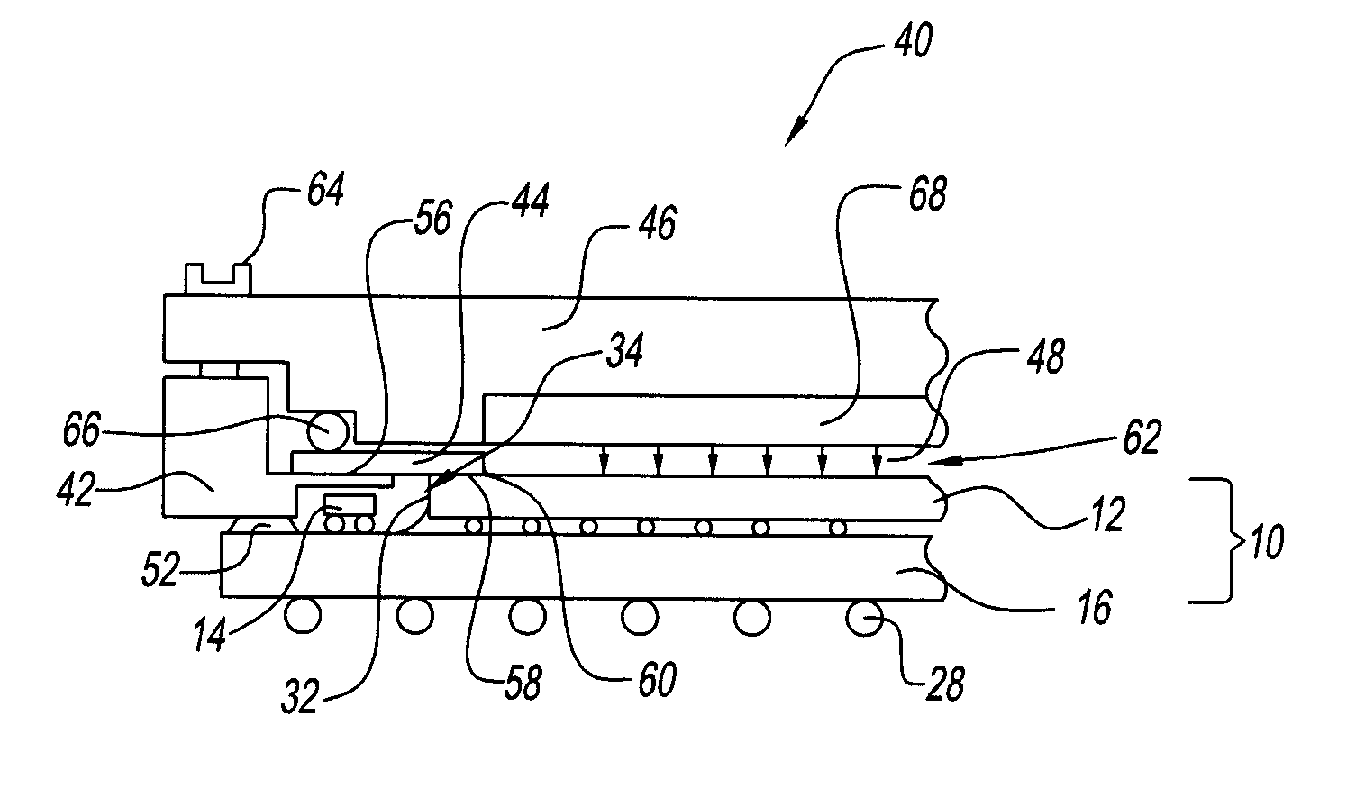

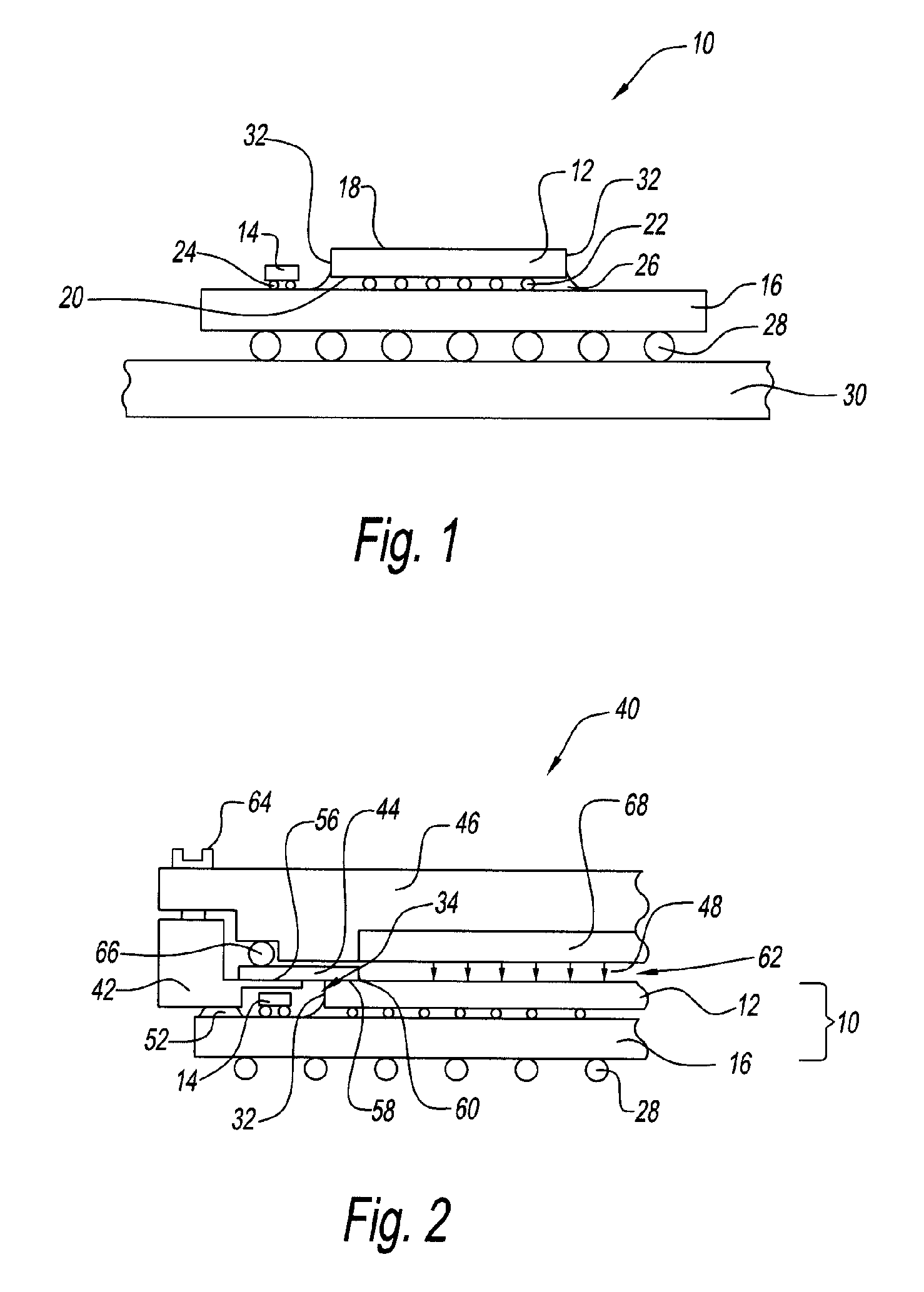

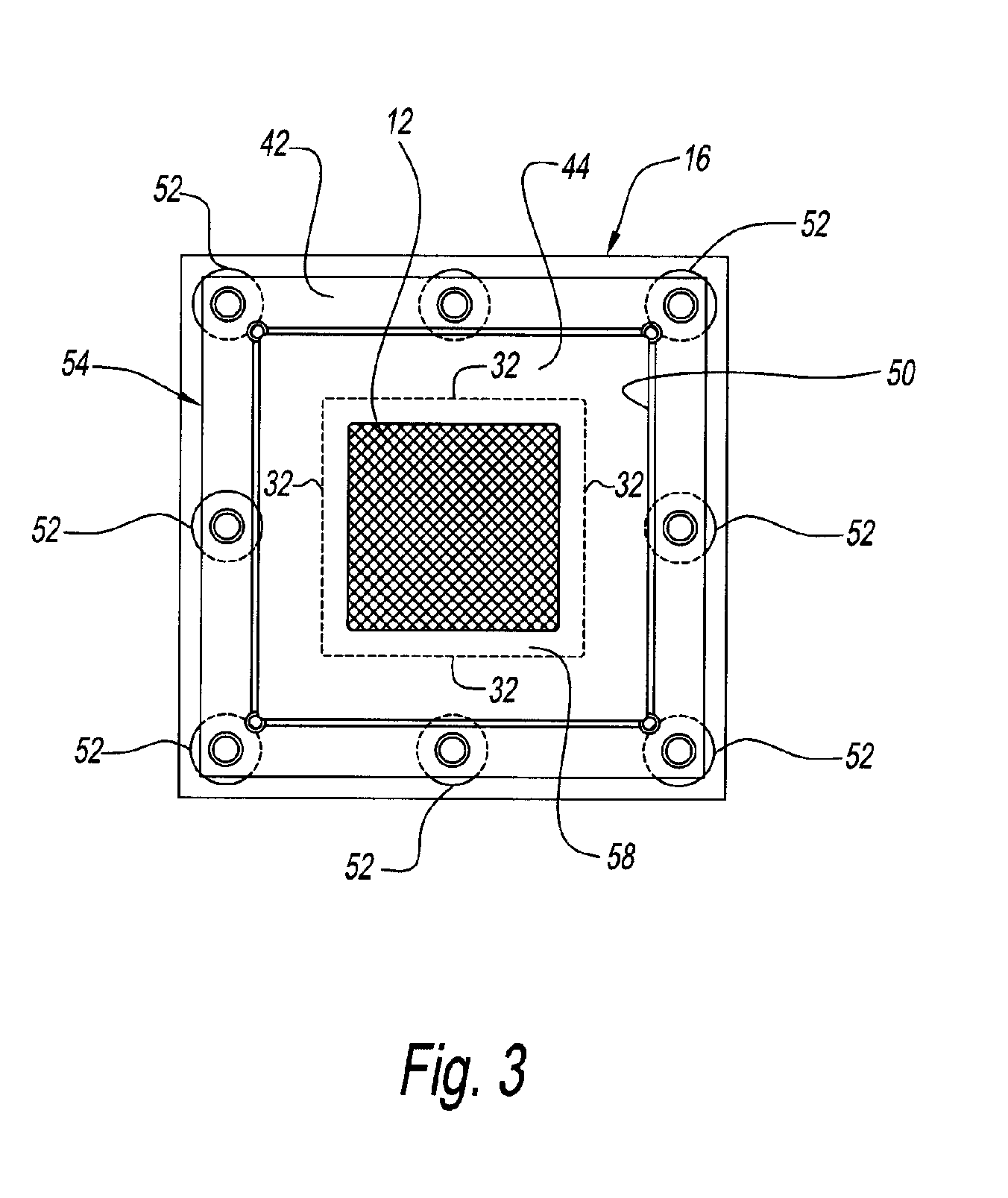

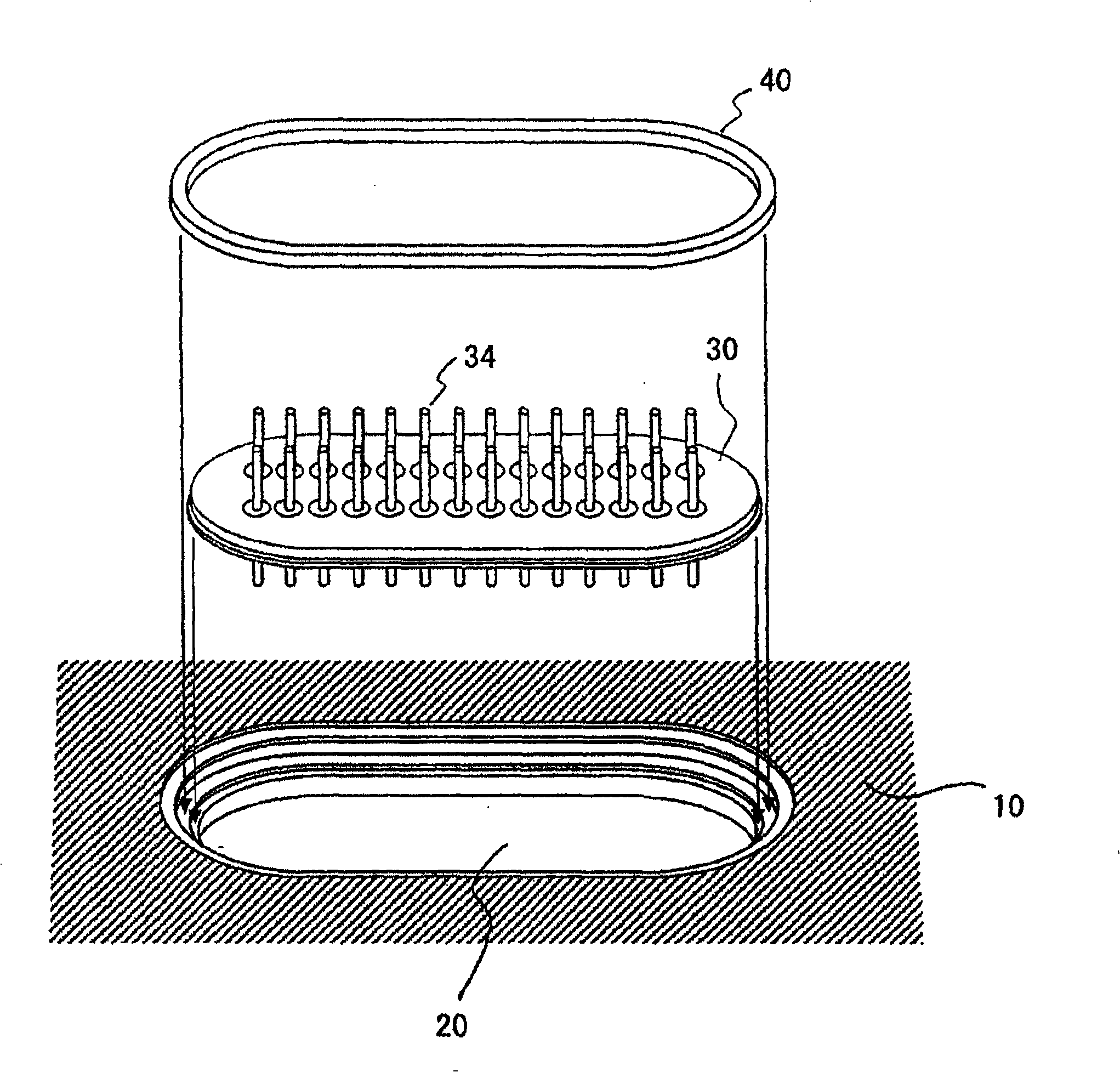

Fluidic cooling systems and methods for electronic components

ActiveUS7079393B2Reliable sealing structureSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectronic component

A cooling system for an electronic component on a component carrier is provided. The system includes a frame, a spray manifold, and a sealing member. The frame has an opening and is connectable to the component carrier so that an annular area is defined between the opening and the electronic component. The spray manifold is sealed over the opening to define a spray area over a back surface of the electronic component. The spray manifold sprays a cooling fluid on the back surface. The sealing member seals the annular region so that input / output connectors on the component carrier are isolated from the cooling fluid.

Owner:GLOBALFOUNDRIES U S INC

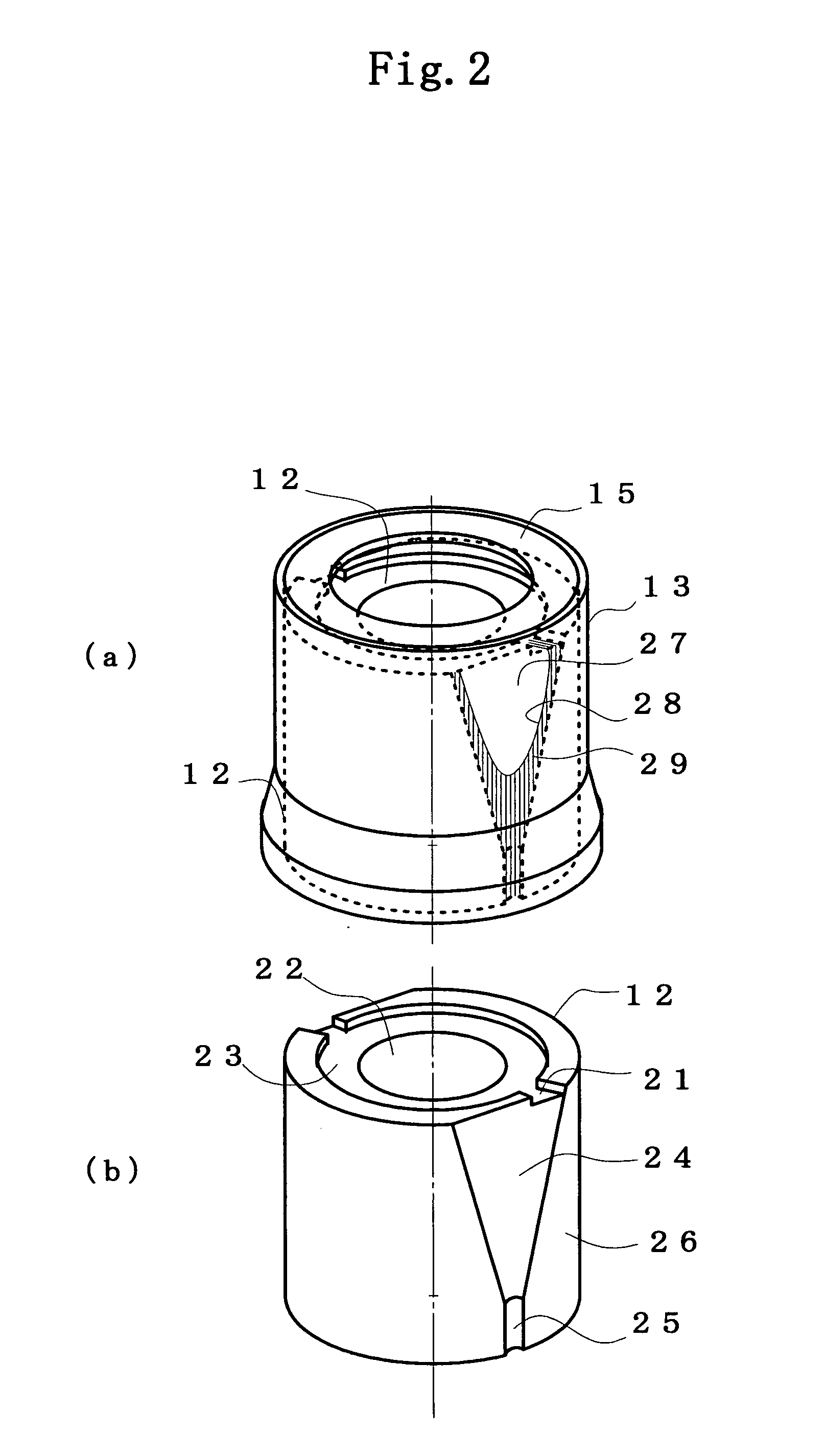

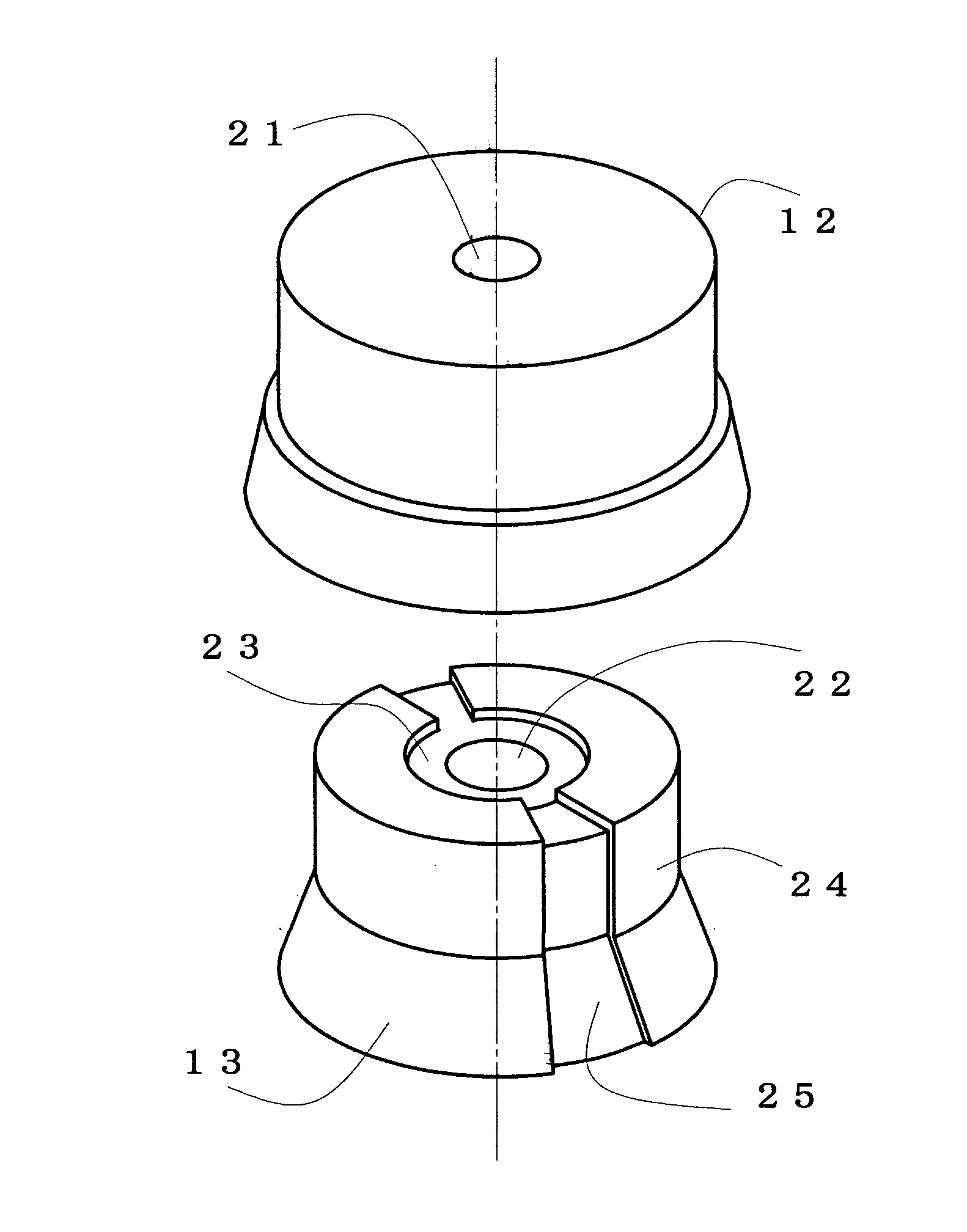

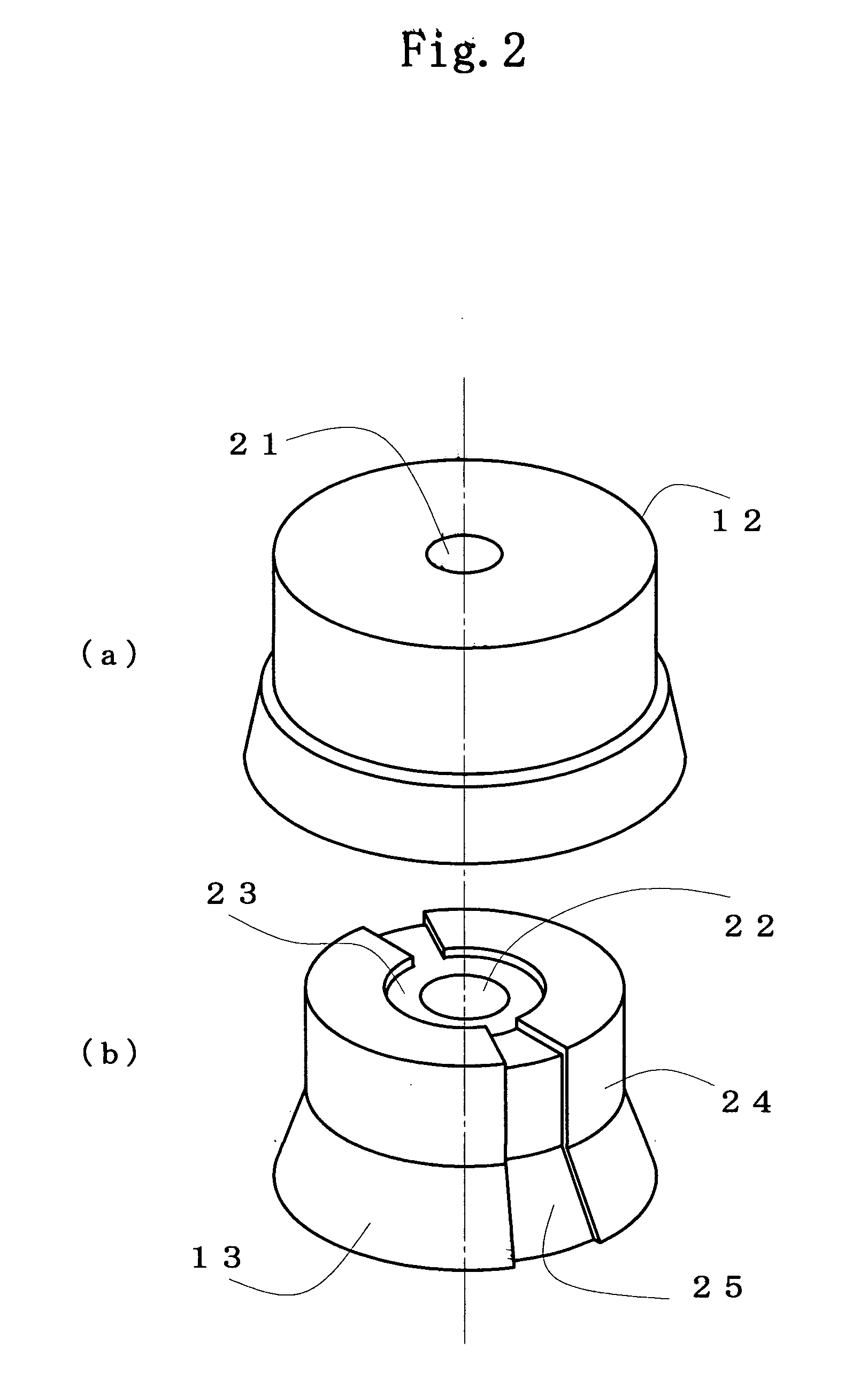

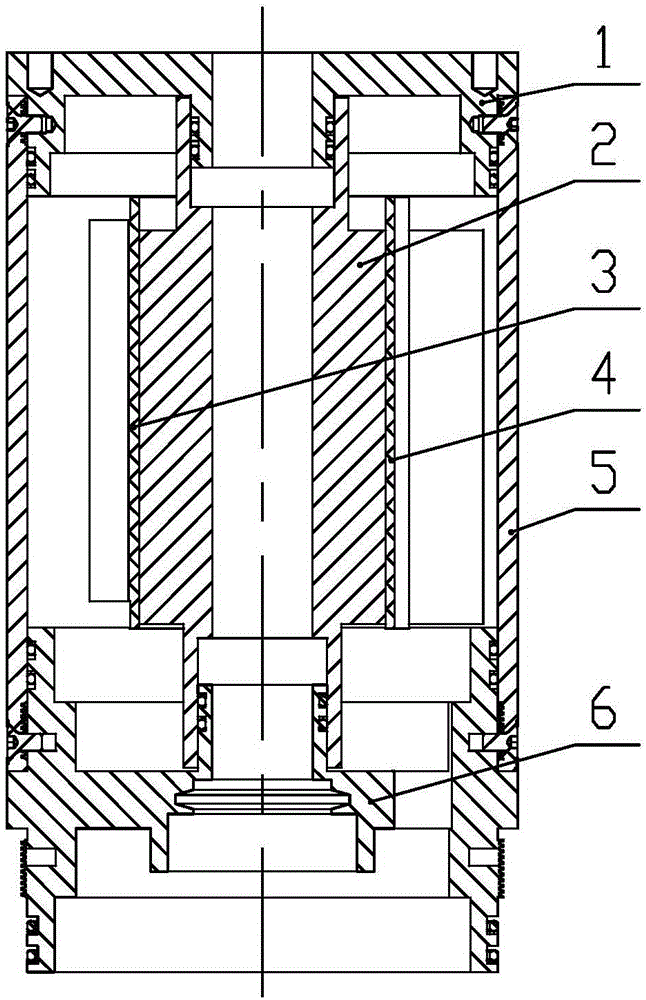

Fluid dynamic bearing motor attached at both shaft ends

InactiveUS20060039634A1Improve accuracyLow profileShaftsBearing componentsEngineeringCentrifugal force

A fixed shaft type fluid dynamic bearing motor having two interfaces of a lubricant at least, in which a channel leading from near the outer region of a rotating sleeve top end to near the periphery of the bottom of the sleeve is formed in the sleeve. The lubricant near the outer region of a rotating sleeve top end is thrown out into the channel by centrifugal force, and further conveyed to near the periphery of the bottom of the sleeve by centrifugal force and / or by slanted channel in circumferential direction. A dynamic-pressure generating groove for pumping the lubricant toward the top end of the sleeve is formed between the fixed shaft and the sleeve. The dynamic-pressure generating groove and the centrifugal force cause the circulation of the lubricant, thereby sealing the lubricant. According to the invention, axial space smaller than that of tapered seals can be utilized to achieve a low-profile recording disk drive.

Owner:KURA LAB

Fixed shaft type fluid dynamic bearing motor

InactiveUS20060002638A1Easy to controlEliminate the effects ofShaftsBearing componentsEngineeringCentrifugal force

A fixed shaft type fluid dynamic bearing motor having two interfaces of a lubricating fluid. A channel leading from near the top end of the inner periphery of a rotating sleeve to near the periphery of the bottom of the sleeve is formed in the sleeve. The lubricating fluid flows into the channel by centrifugal force, and further conveyed to near the periphery of the bottom of the sleeve by centrifugal force and / or by slanted channel in circumferential direction. A dynamic-pressure generating groove for pumping the lubricating fluid toward the top end of the sleeve is formed between the fixed shaft and the sleeve. The dynamic-pressure generating groove and the centrifugal force cause the circulation of the lubricating fluid, thereby sealing the lubricating fluid. A cone bearing or a cylindrical bearing can be used for bearing configuration. Also, the axial space smaller than that of tapered seals can be utilized.

Owner:KURA LABORATRIES CORP

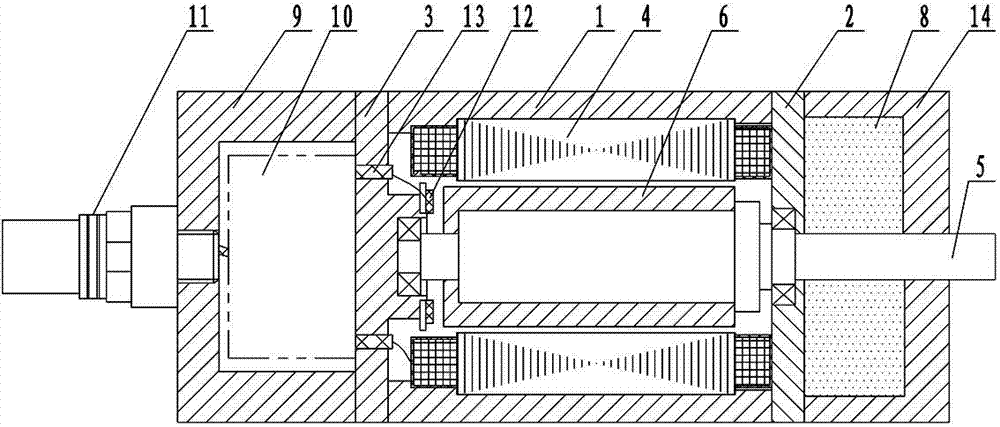

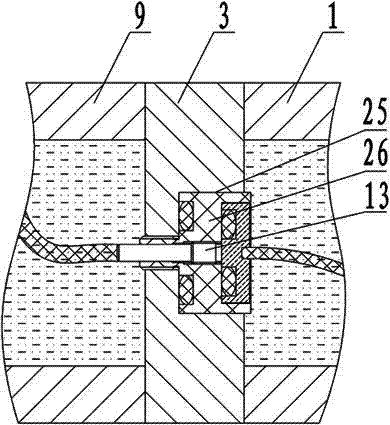

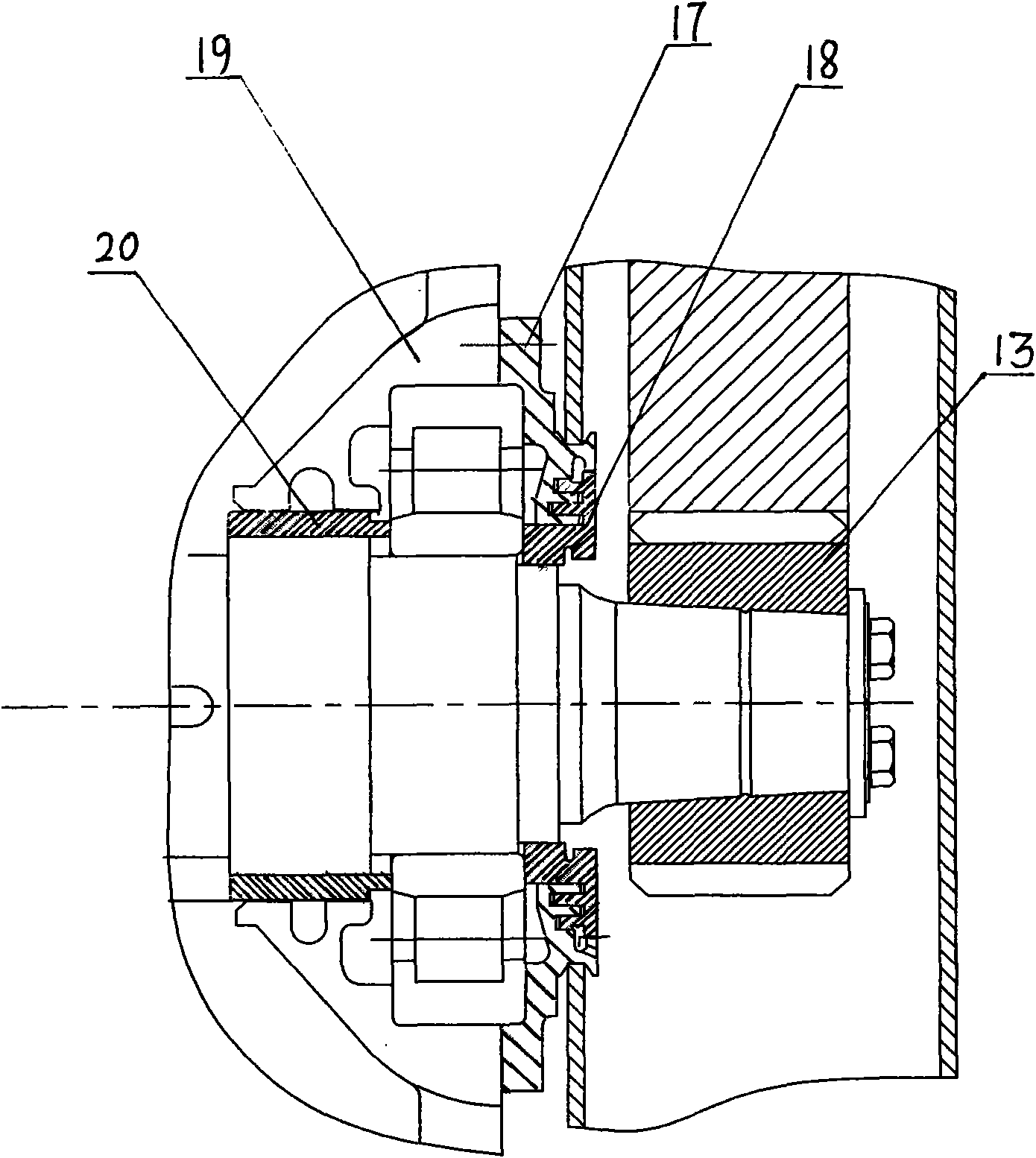

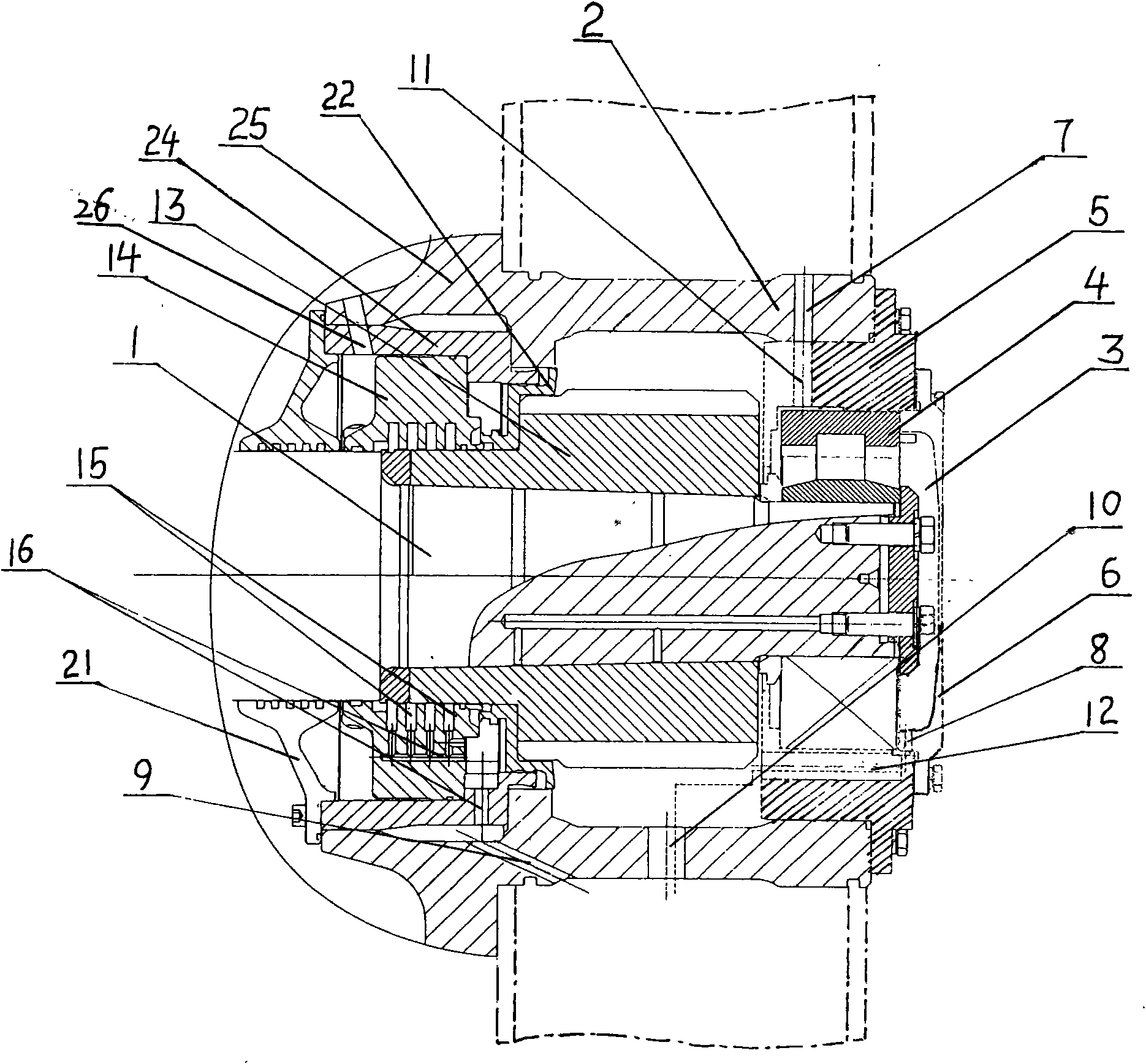

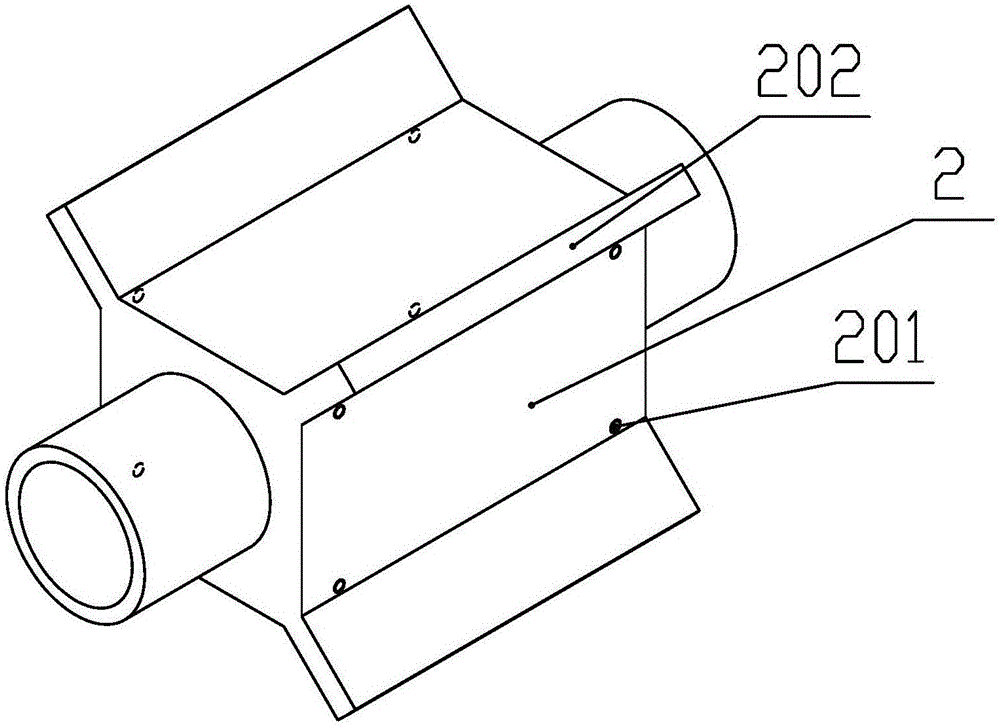

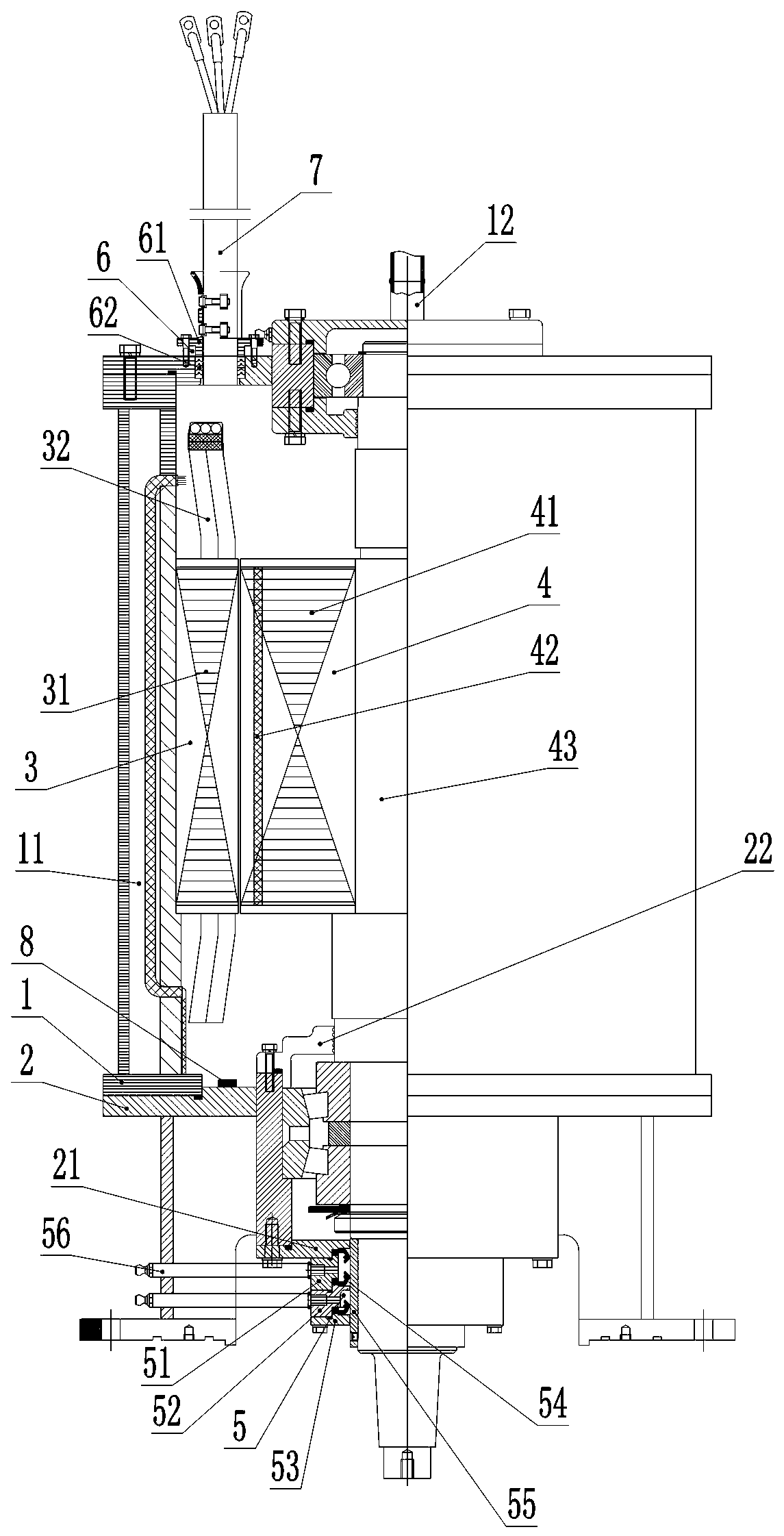

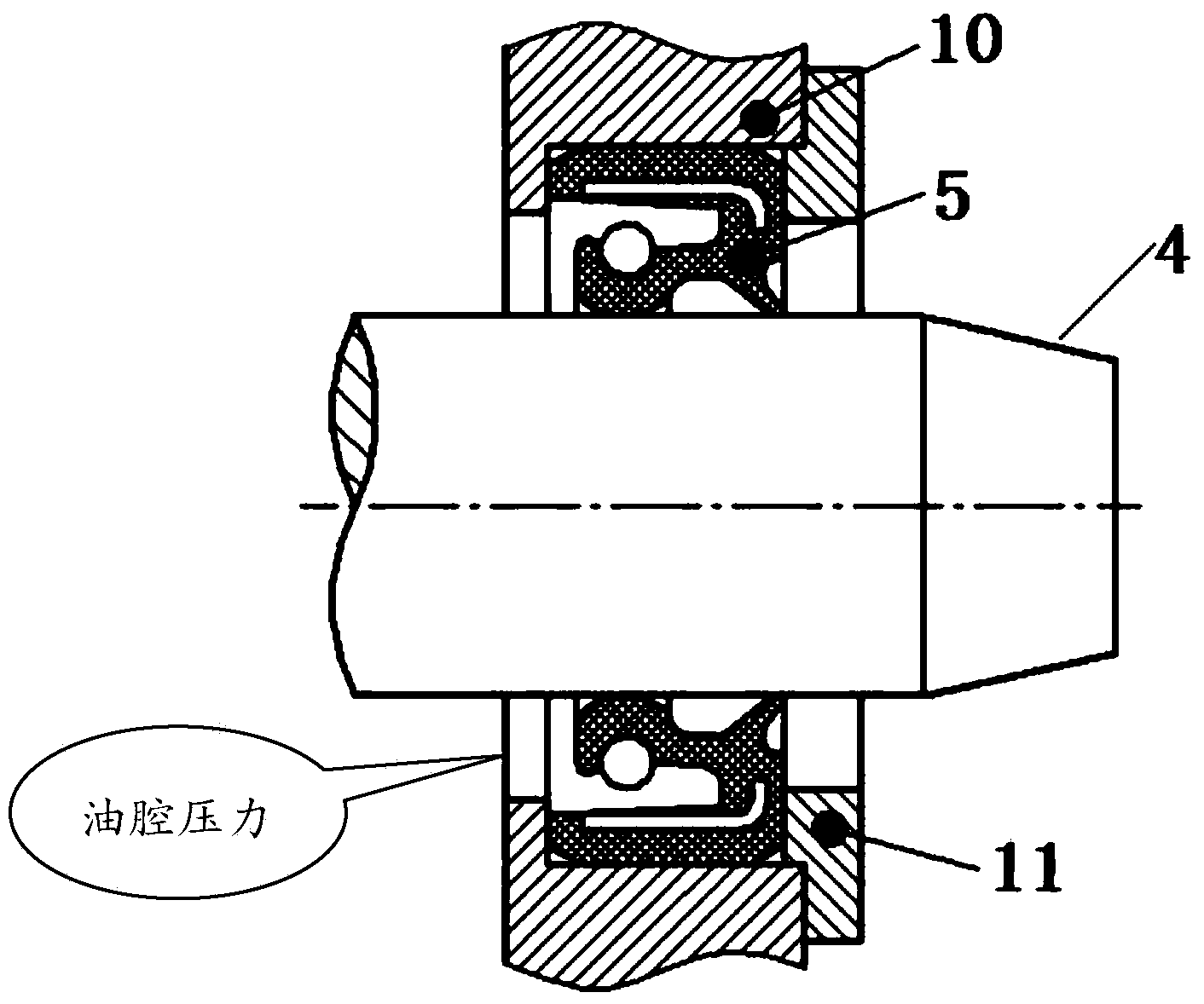

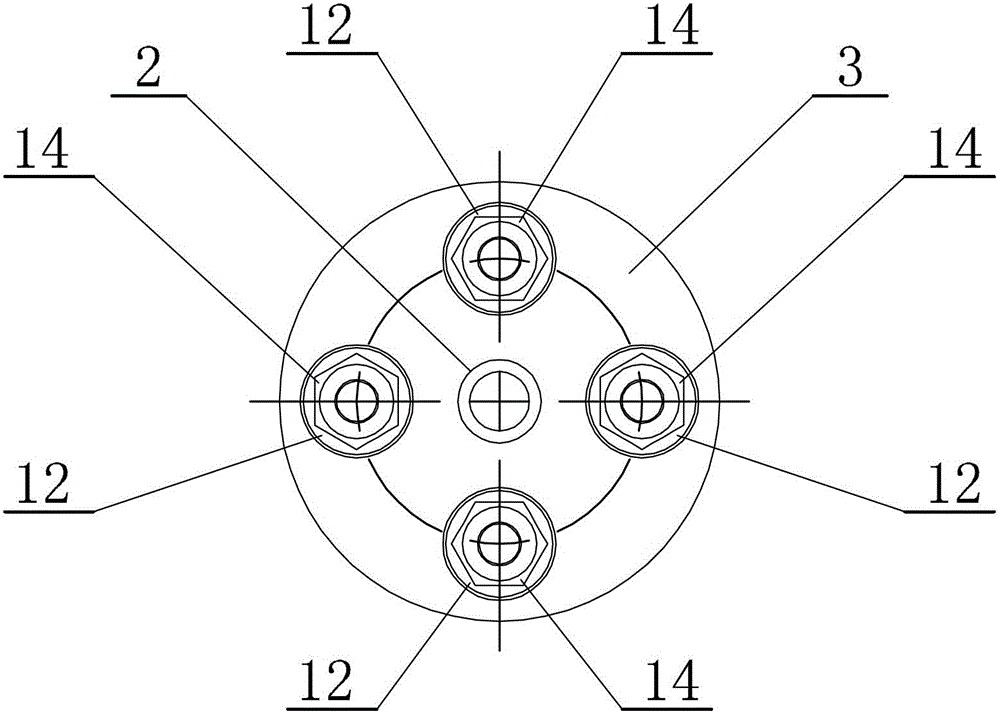

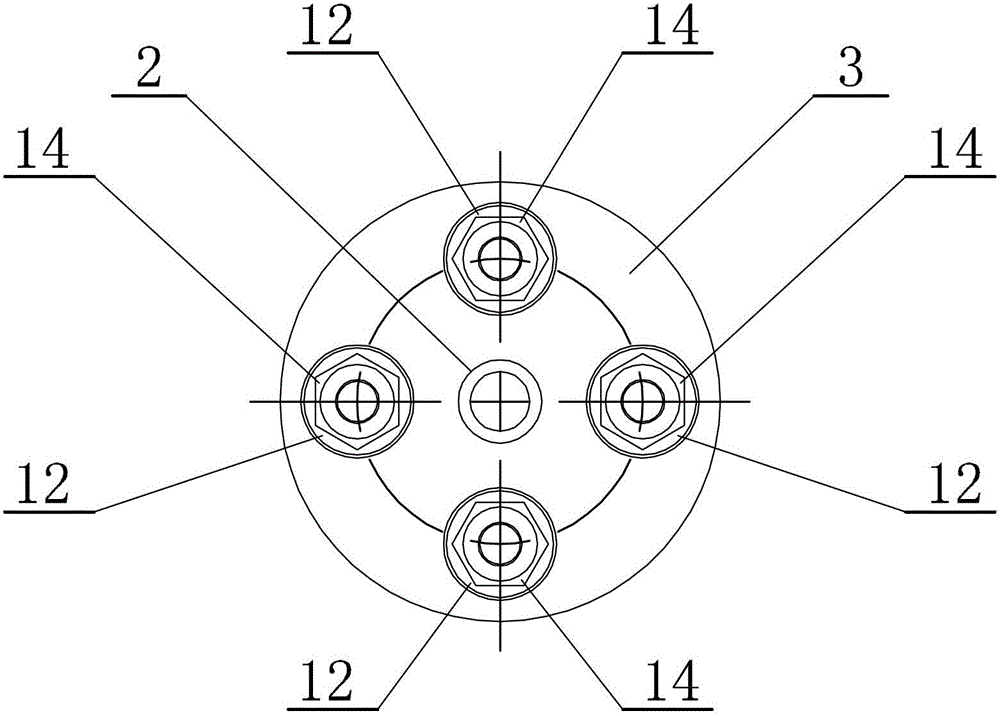

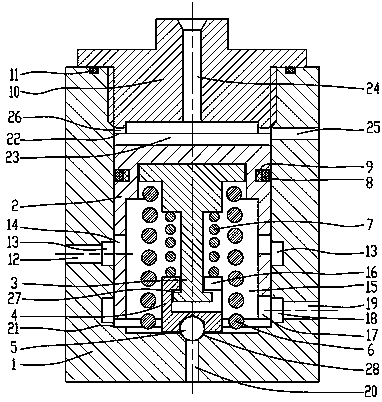

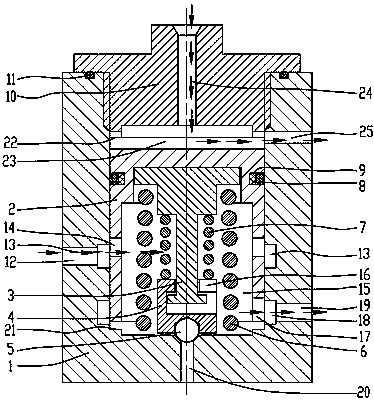

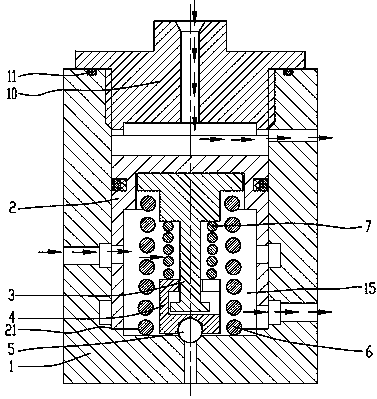

Controller integrated deep sea motor

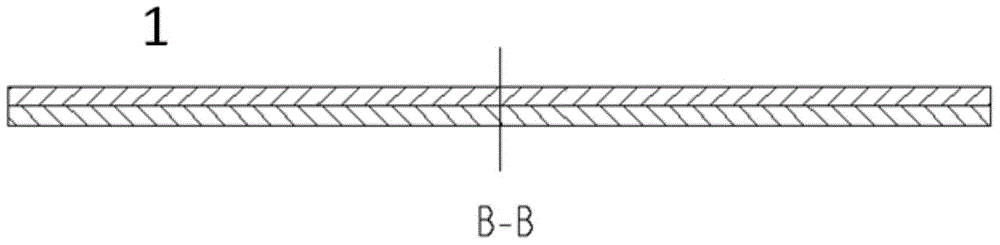

ActiveCN102761204ASimple structureCompact structureAssociation with control/drive circuitsSupports/enclosures/casingsPressure balanceControl theory

The invention discloses a controller integrated deep sea motor. The controller integrated deep sea motor comprises a motor shell (1), a front end cover (2), a rear end cover (3), a stator (4), a motor shaft (5) and a rotor (6), wherein the outer side of the front end cover (2) is provided with a pressure balance and dynamic seal integrated mechanism (8); the outer side of the rear end cover (3) is provided with a controller hatchcover (9), and the controller hatchcover (9) is internally provided with a driving controller (10); the inner side of the rear end cover (3) is provided with a Hall integrated circuit (12); and the driving controller (10) is respectively connected with the Hall integrated circuit (12) and the stator (4) through an electric conduction screw (13) arranged on the rear end cover (3). The controller integrated deep sea motor provided by the invention has the beneficial effects that the balance of inner and outer pressure of the underwater motor is realized, and thus the motor is light enough; a balanced structure and a dynamic seal structure are integrated, and thus the structure of the underwater motor is compact; and the controller and the motor are integrated, so that the size of the motor is further recued, and the reliability of the motor is good.

Owner:CHENGDU OUXUN TECH CO LTD

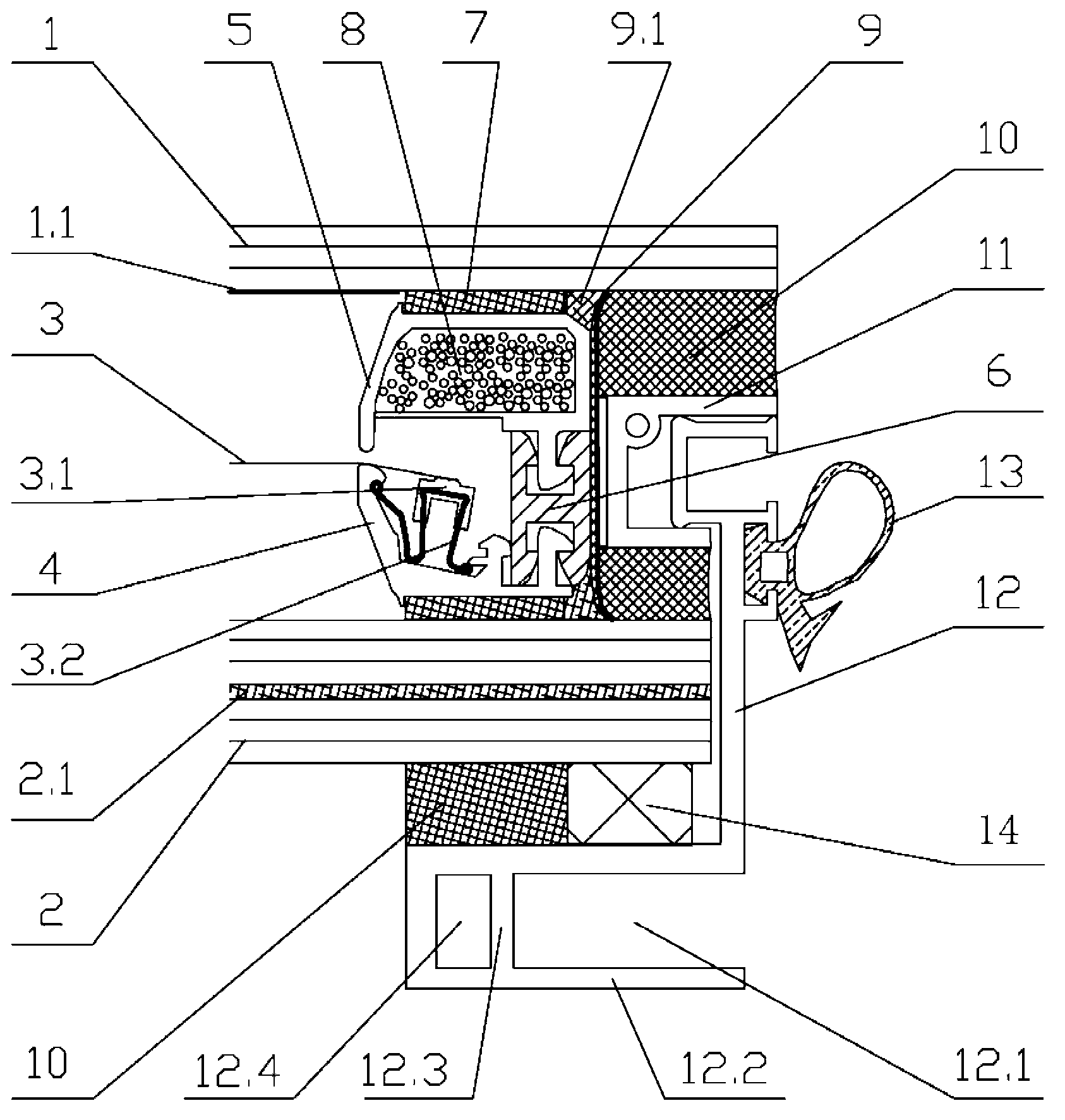

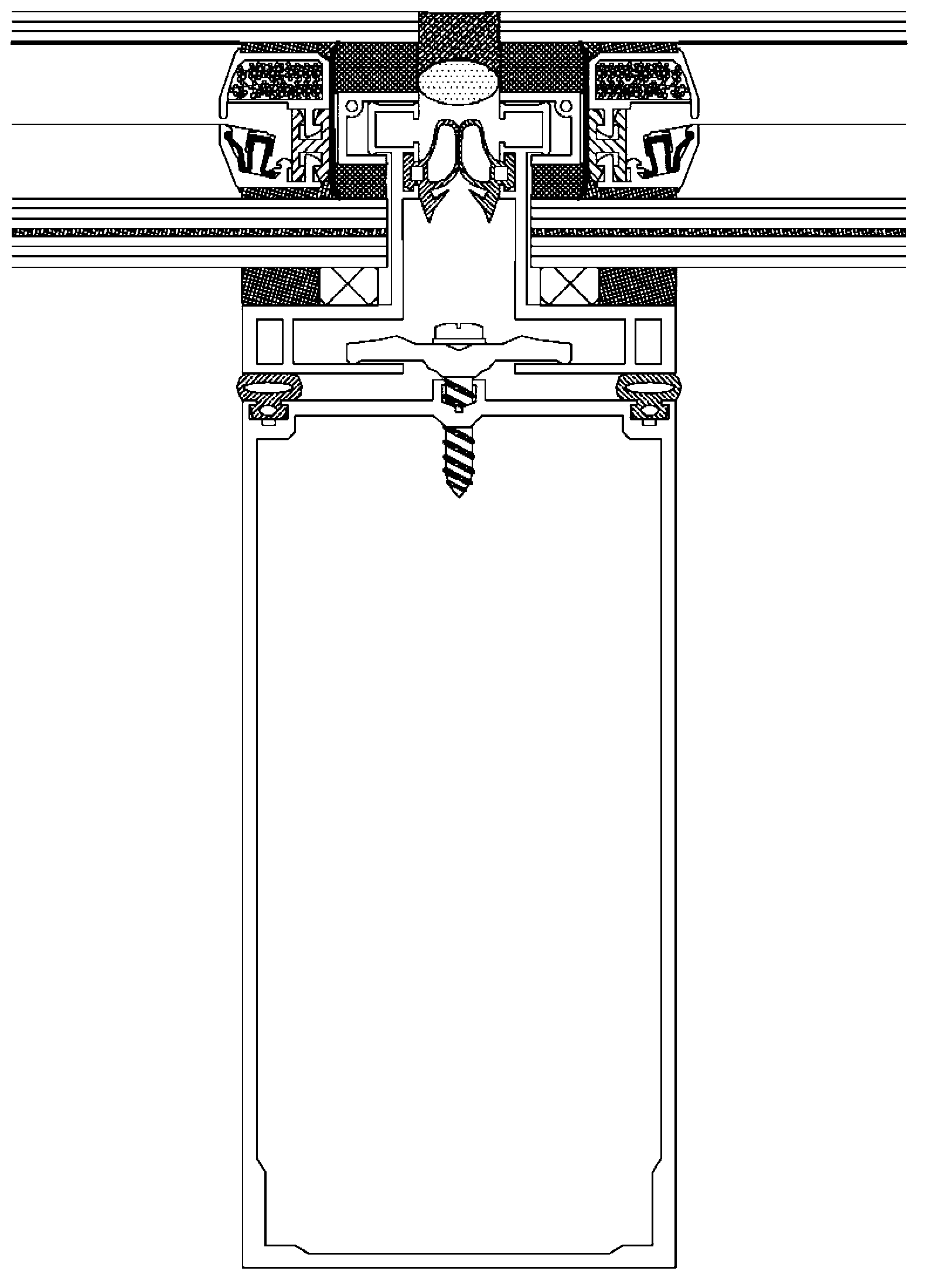

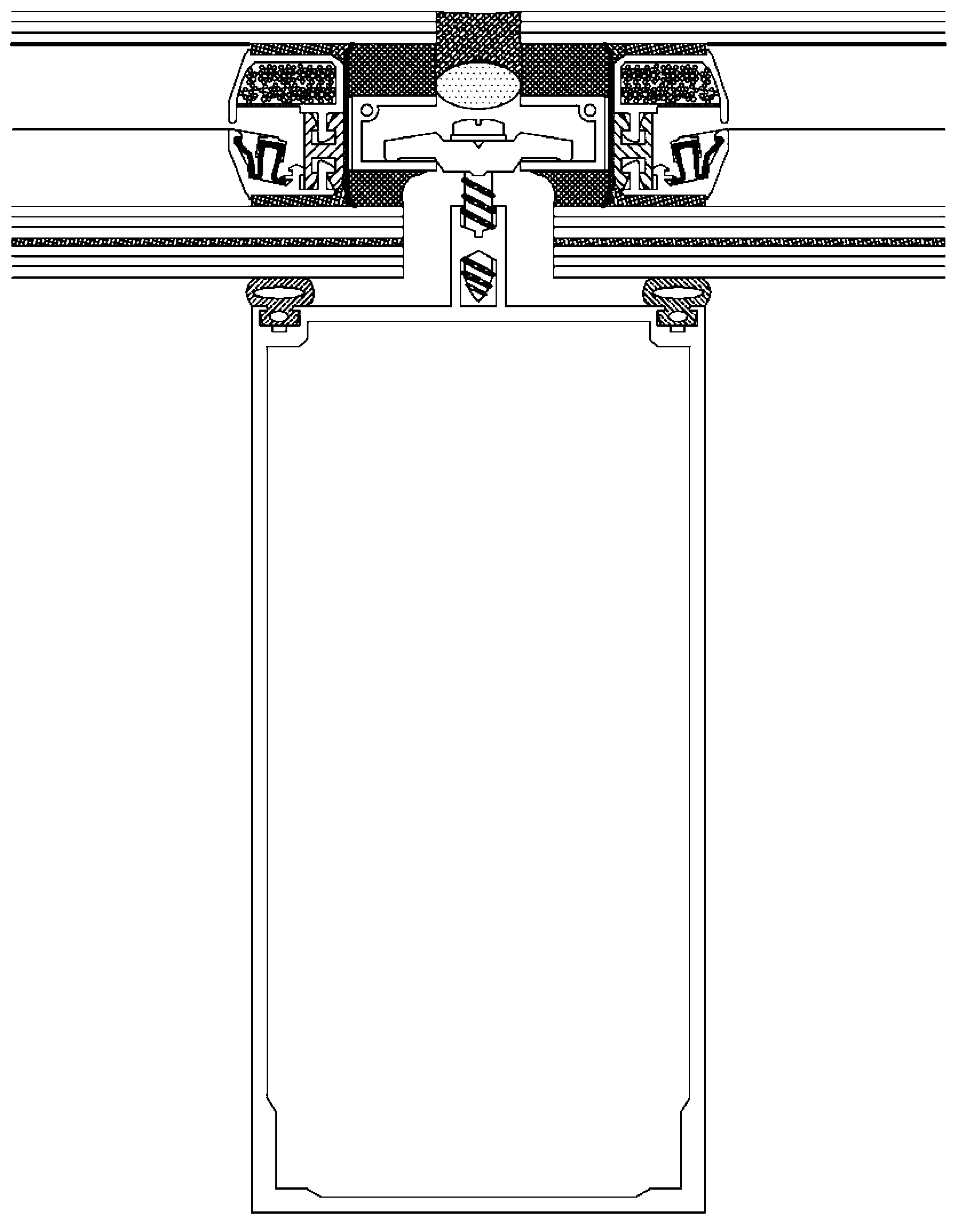

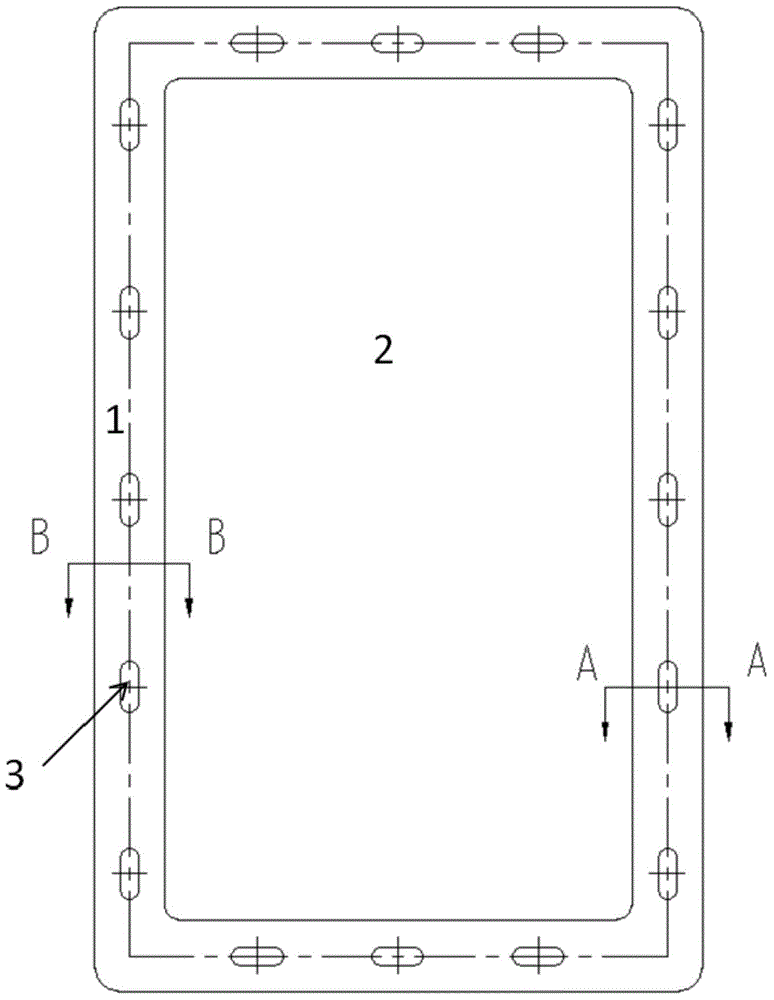

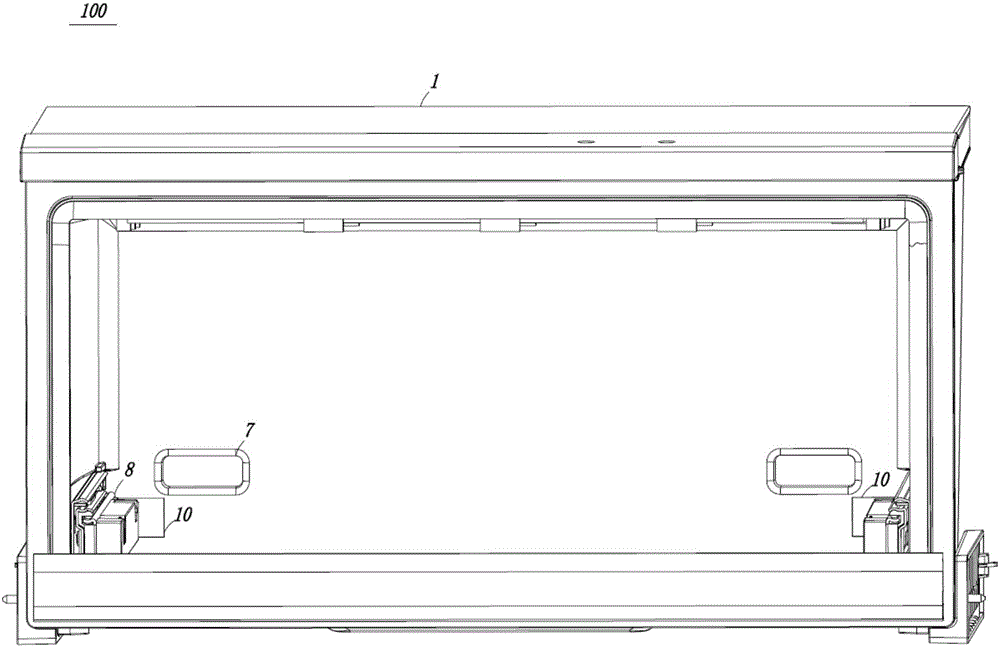

Double-hollow glass ceiling module with film suspended therein

ActiveCN103074966AConvenient lightingImprove heat insulationRoof covering using slabs/sheetsWallsMoisture condensationThermal deformation

The invention discloses a double-hollow glass ceiling module with a film suspended therein. An optical control film serves as a middle layer, and an internally suspended film structure frame, a mounting structure frame, a reinforcing separating strip and glass are sealed into an integral double-hollow glass plate. An inner structure frame and an outer structure frame are made from a novel heat-isolating material with a coefficient of thermal expansion similar to that of the glass. The internally suspended film structure frame is structurally connected through a heat-isolating bridge. A butyl rubber tape on the outer surface of the internally suspended film structure frame serves as a first sealing layer. A second sealing layer consists of the external reinforcing separating strip and a silicone structural sealant, the whole structure is always consistent to the thermal deformation of the glass, so that the sealing capability of the whole system is more reliable, and the heat-isolating property, the moisture condensation-preventing property, the sound-isolating property and the like are greatly improved. Dirt is not easily accumulated on the outer surface of a mounted ceiling, so that the ceiling is convenient to clean and maintain. The double-hollow glass ceiling module has a flexible assembling and mounting way, and can be applied to different vertical surfaces of an outer building rail.

Owner:伟视幕墙(淮安)有限公司

High-rotating-speed pulling motor

InactiveCN101552514AProtection lifeEffectively utilize high-speed operationMechanical energy handlingSupports/enclosures/casingsPinionLubrication

The present invention specifically relates to a high-rotating-speed pulling motor. The invention settles a problem that defects and deficiencies exist in the illogical structure of prior motor. The end cap of high-rotating-speed pulling motor is installed with a cylinder jacket protruding frontwards. A rotor shaft is placed I the cylinder jacket. A bearing is sleeved with a bearing inner cap. The front end surface of bearing is pressed with a bearing outer cover. The back side of bearing is installed with a pinion which is composed of a transmission teeth part and a shaft sleeve part. The cylinder jacket is provided with a transmission opening. The top of cylinder jacket is provided with an oil inlet through hole. The lower part of back end plane of bearing outer cover is provided with a groove. The bearing inner cover is provided with an oil hole which is communicated with the groove and the oil inlet through hole. The shaft sleeve part of pinion is fixed with an oil slinger. The back side of oil singer is provided with a back sealing ring. The back sealing ring is fixed with a protective cover and is provided with a plurality of radial annular sealing grooves. The lower part of annular sealing grooves is provided with an oil leakage channel. The base part of cylinder jacket is provided with a main oil return hole and an auxiliary oil return hole. The high-rotating-speed pulling motor of the invention not only realizes the oil lubrication of bearing, but also overcomes the problem of oil leakage. Simultaneously the service lifetime of bearing is guaranteed.

Owner:CRRC YONGJI ELECTRIC CO LTD

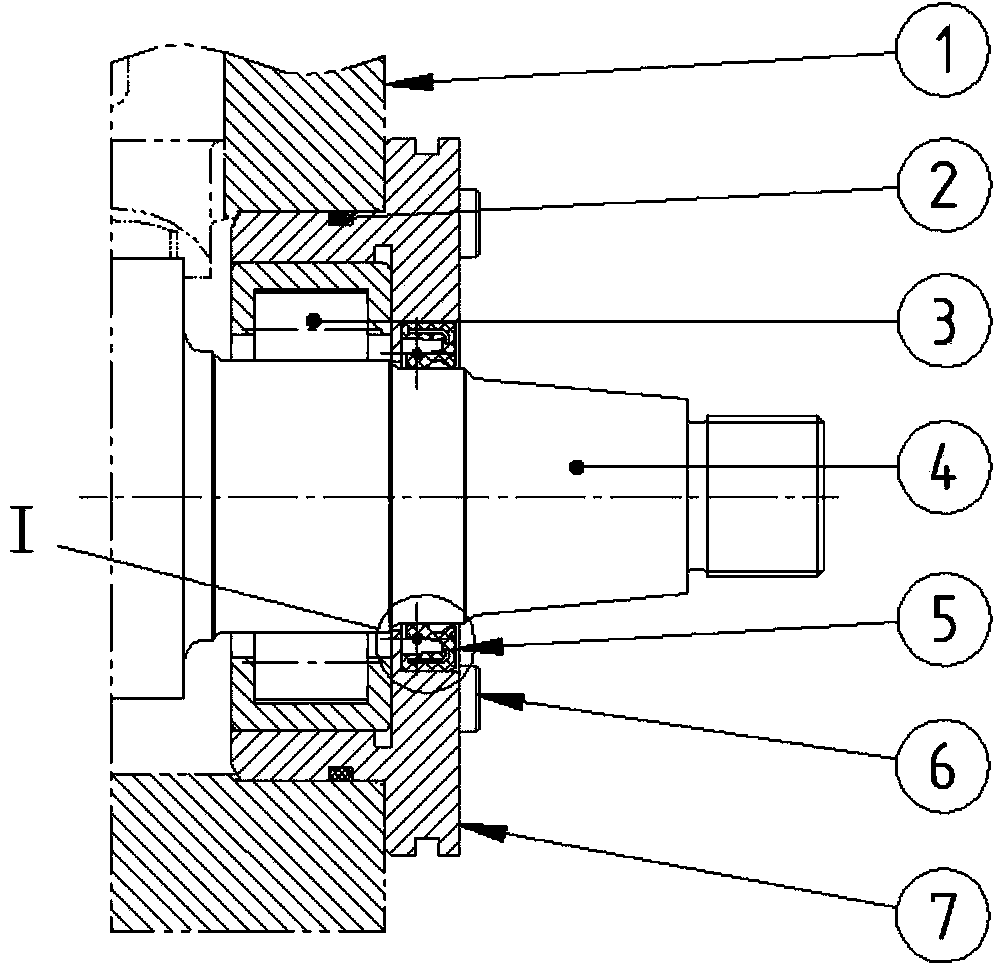

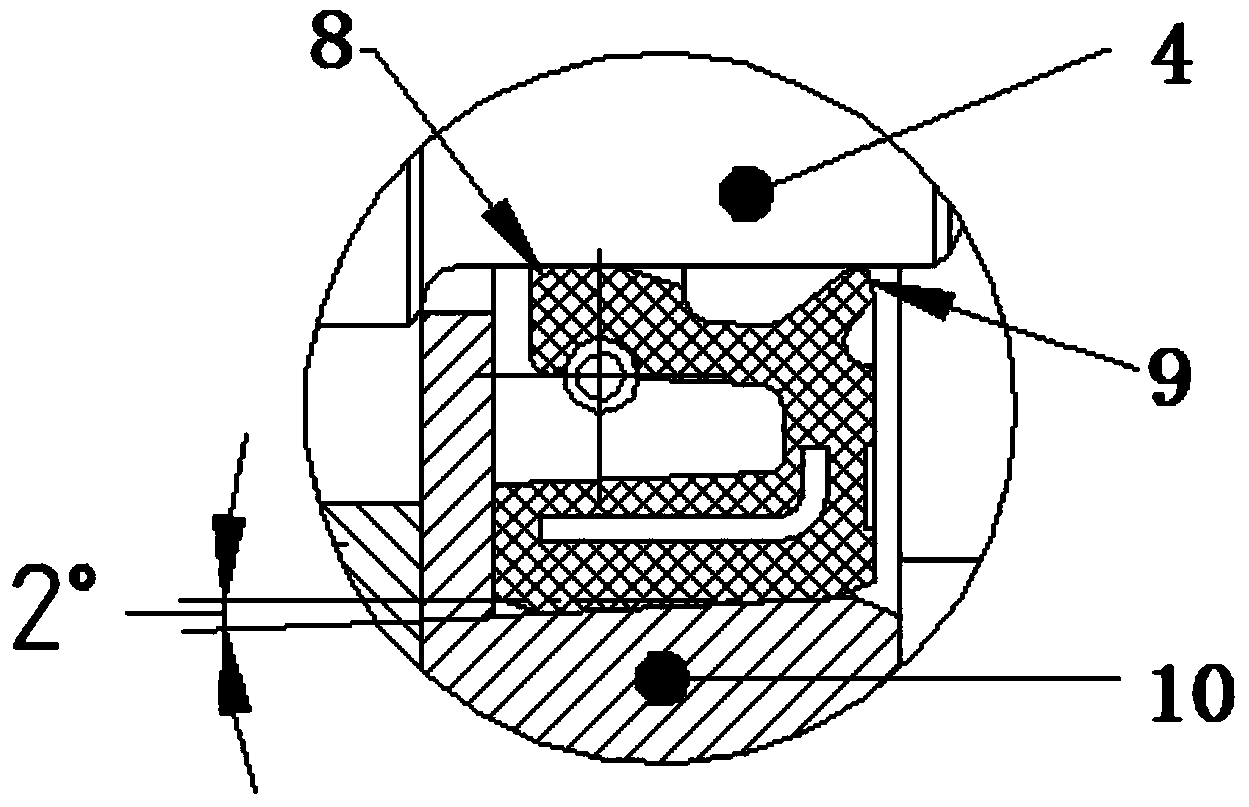

Non-contact seal device for high-speed shaft of gear speed reducer

ActiveCN104061317AStop the spreadSimple mechanical structureEngine sealsGearing detailsReducerEngineering

The invention discloses a non-contact seal device for a high-speed shaft of a gear speed reducer. The non-contact seal device comprises the high-speed shaft, a sealing ring, a transparent cover, a static ring, a dynamic ring, an oil leakage groove, a bearing and a bearing sleeve. The bearing is arranged in the bearing sleeve, the transparent cover is fixedly connected to the outer end of the bearing sleeve and is provided with a lower edge stretching into the bearing sleeve, the static ring is arranged between the lower edge and the bearing in a pressing mode, the dynamic ring is fixedly connected to the high-speed shaft, and an axial labyrinth is formed by the static ring and the dynamic ring. The sealing ring is fixedly connected to the high-speed shaft, a ring groove is formed in the peripheral wall of the sealing ring, a radial labyrinth is formed by the sealing ring and an opening of the transparent cover, a cavity is formed between the radial labyrinth and the axial labyrinth, the axial oil leakage groove is formed in the lower edge and the inner wall of the bearing sleeve, and the oil leakage groove is communicated with the cavity and the inner portion of a box. The non-contact seal device is simple in mechanical structure, easy to machine and assemble, low in cost and capable of achieving the reliable sealing effect.

Owner:JIANGSU JINWO MACHINERY

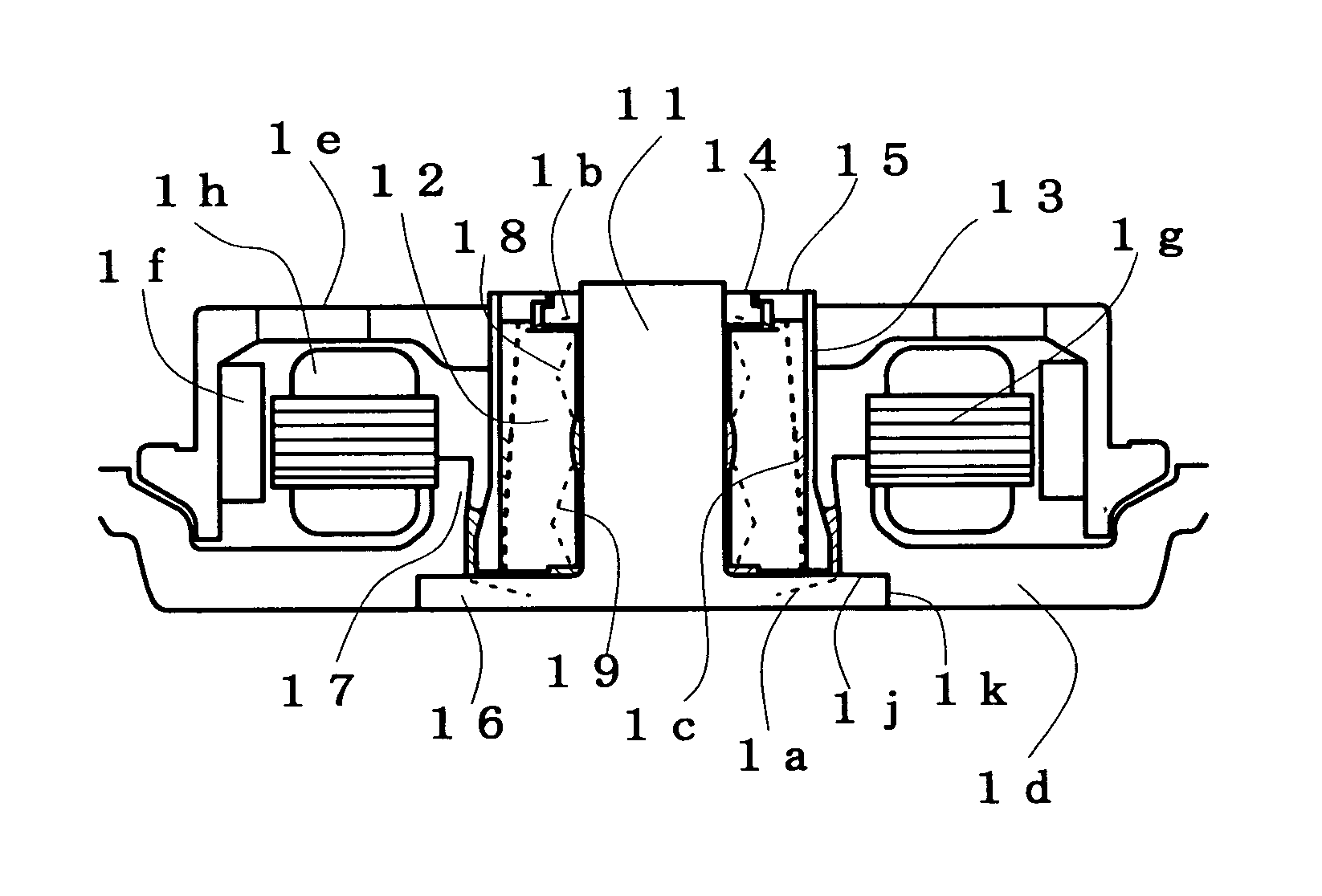

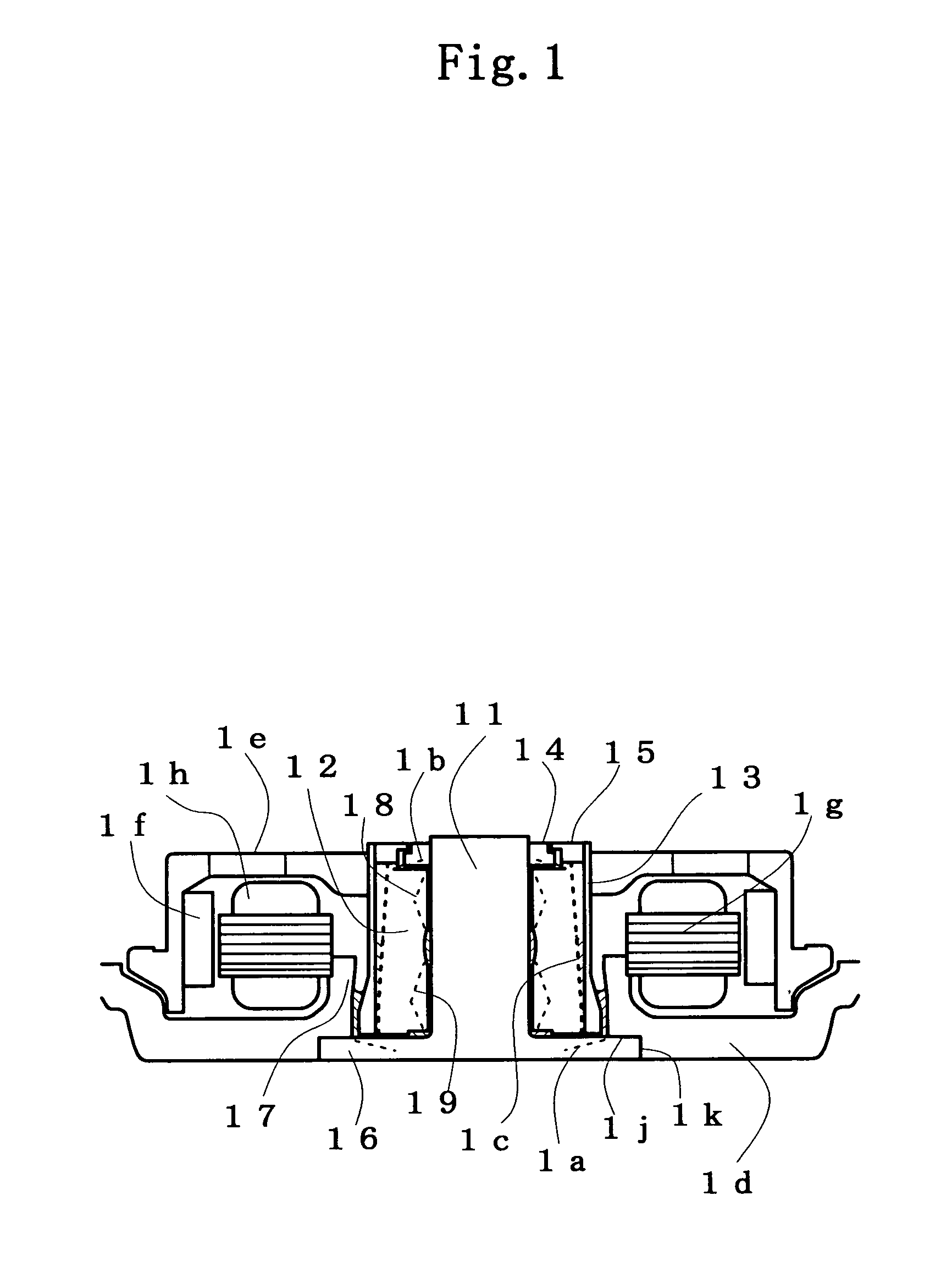

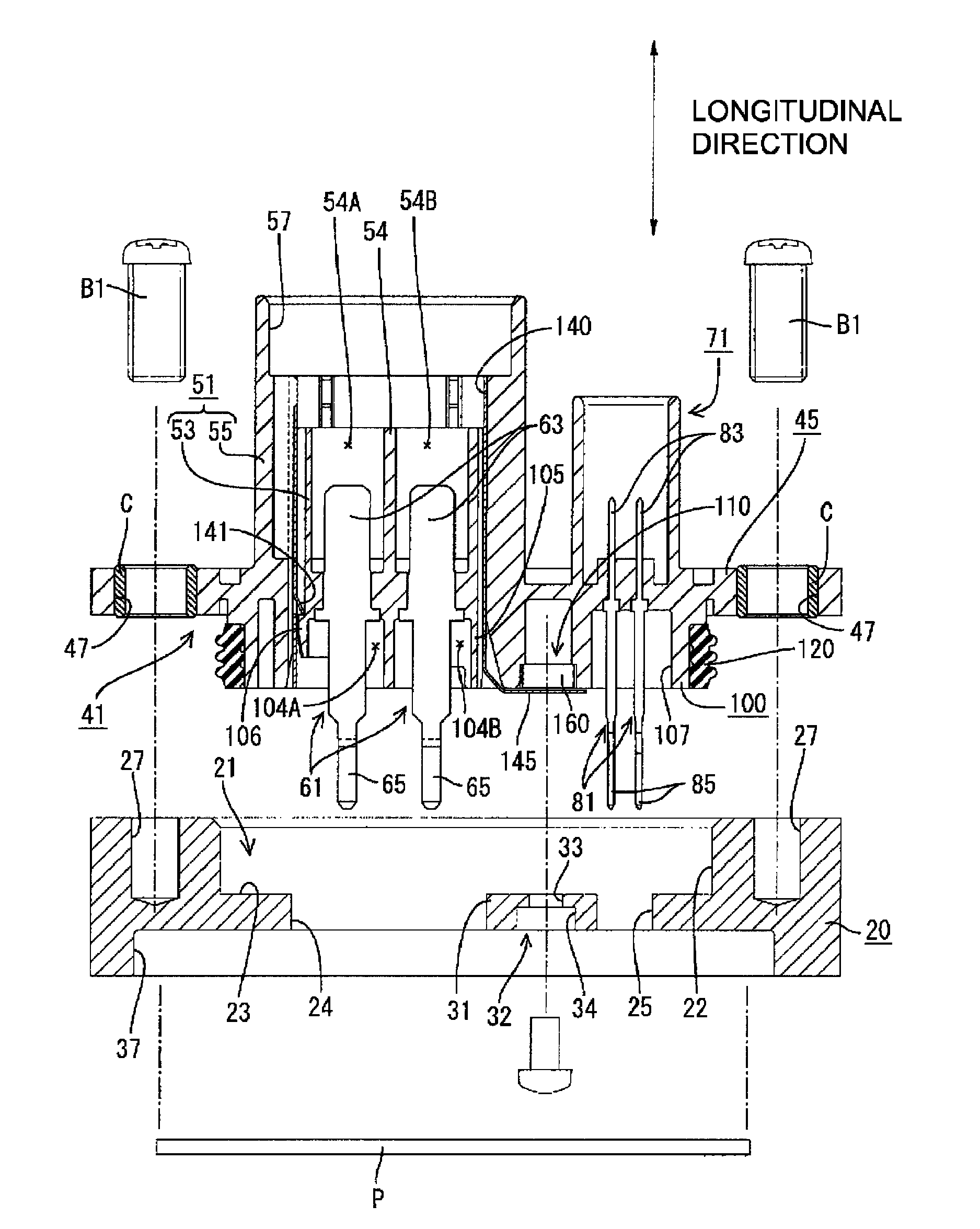

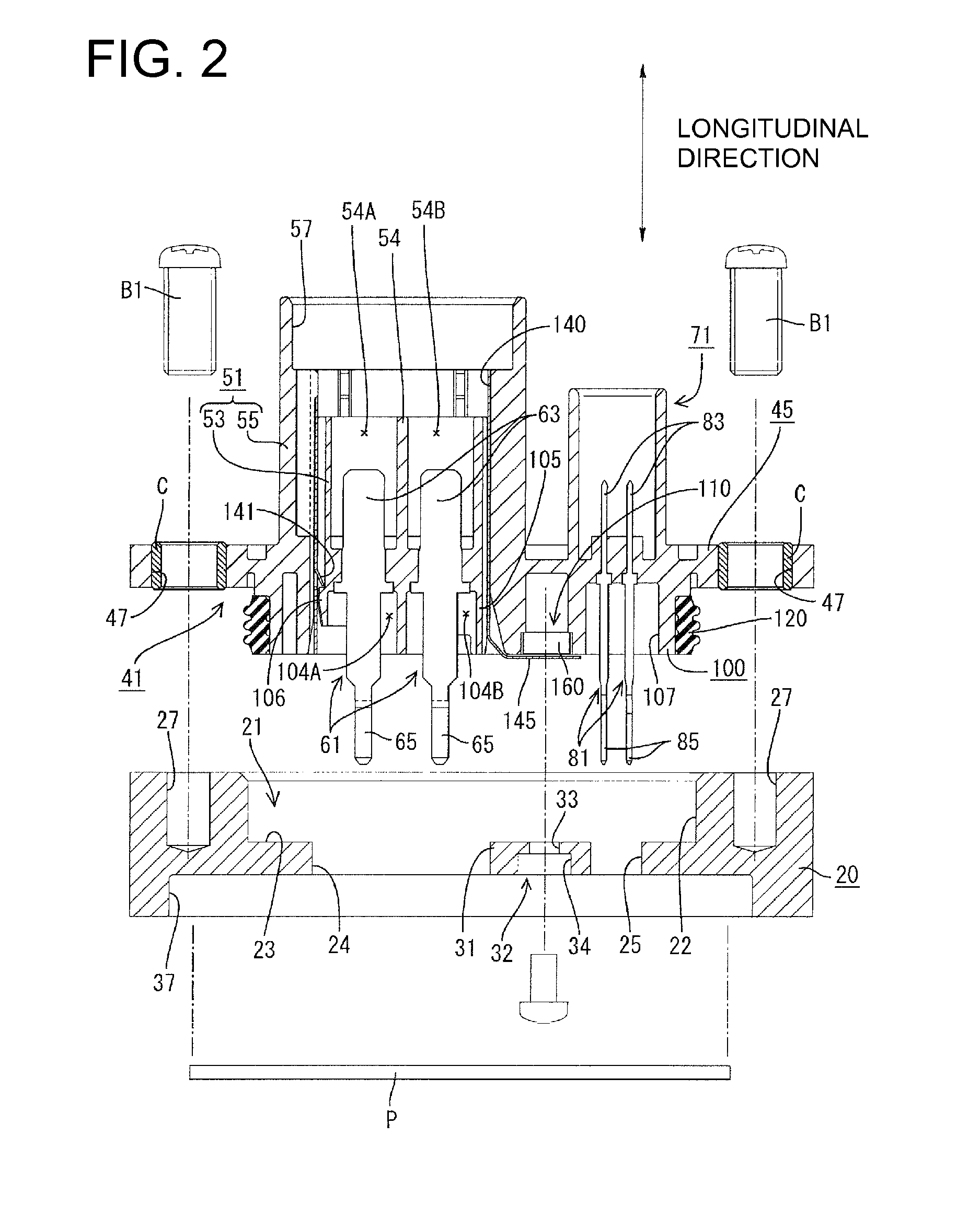

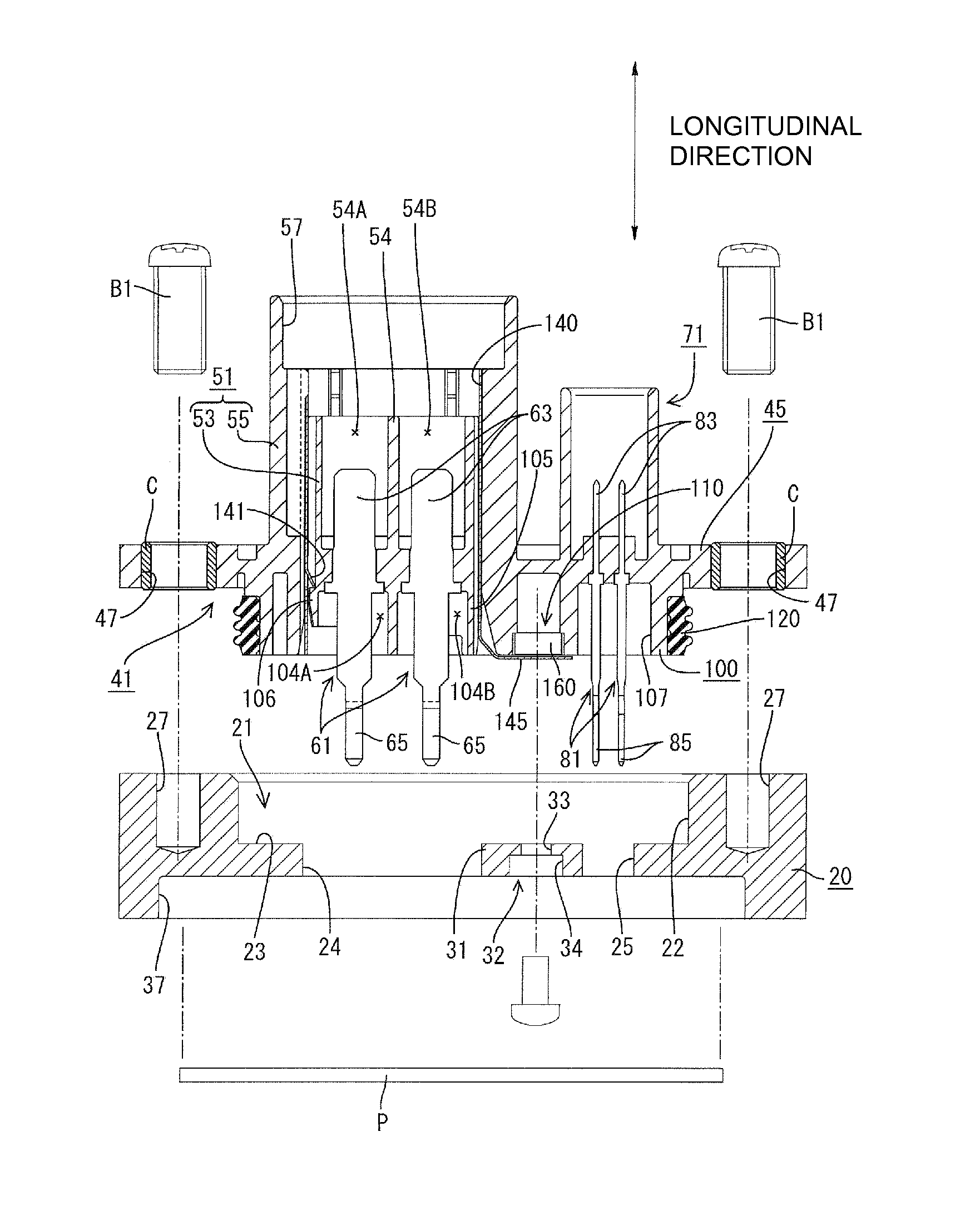

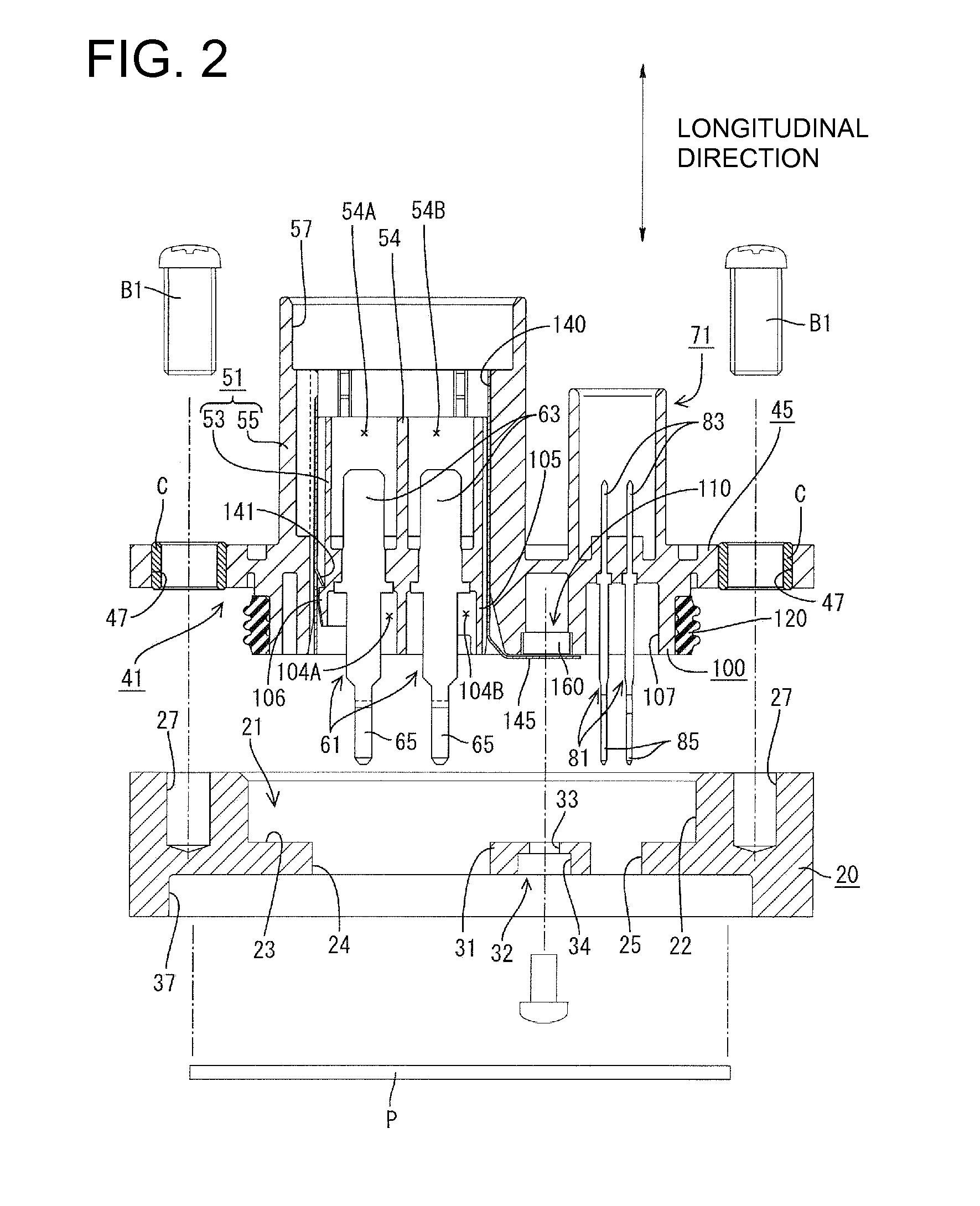

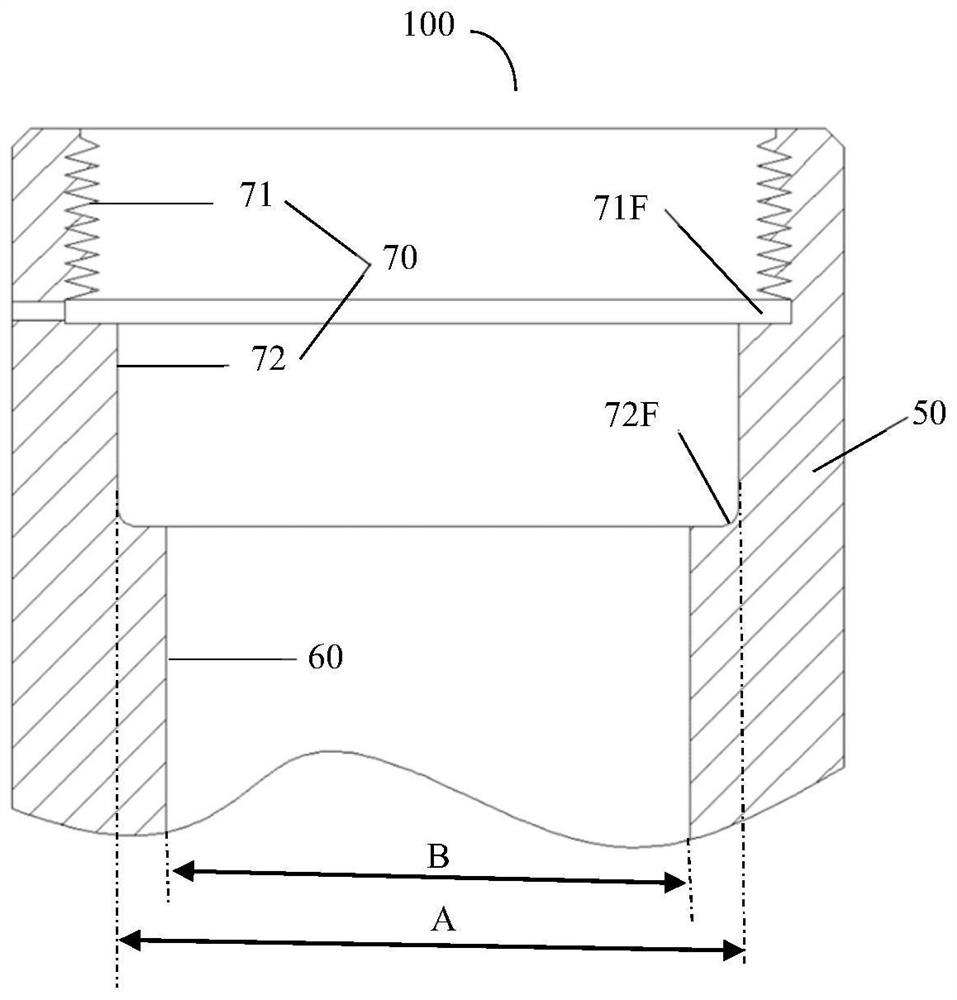

Shield connector mounting structure and shield connector

InactiveUS8052472B2Stable structureIncrease loadCoupling protective earth/shielding arrangementsConnection contact member materialEngineeringMechanical engineering

Owner:SUMITOMO WIRING SYST LTD

Shield connector mounting structure and shield connector

ActiveUS20110045693A1Highly reliable sealing structureStable structureCoupling protective earth/shielding arrangementsConnection contact member materialEngineeringMechanical engineering

A shield connector (40) includes a housing with a base (45) to be mounted into a metallic mating member. A connector fitting (51) is formed on a top side of the base (45) and a mounting projection (100) is formed on an under side of the base (45). A shield shell (140) is mounted between an inner tube (53) and an outer tube (54) of the connector fitting (51). A nut accommodating portion (110) is formed in the mounting projection (100) of the housing (41) and a nut 160 is mounted in the nut accommodating portion (110) to be freely movable in the longitudinal direction. A connecting portion (145) extends to close an opening of the nut accommodating portion (110) while being bent sideways at a rear end of the shield shell (140) in the longitudinal direction.

Owner:SUMITOMO WIRING SYST LTD

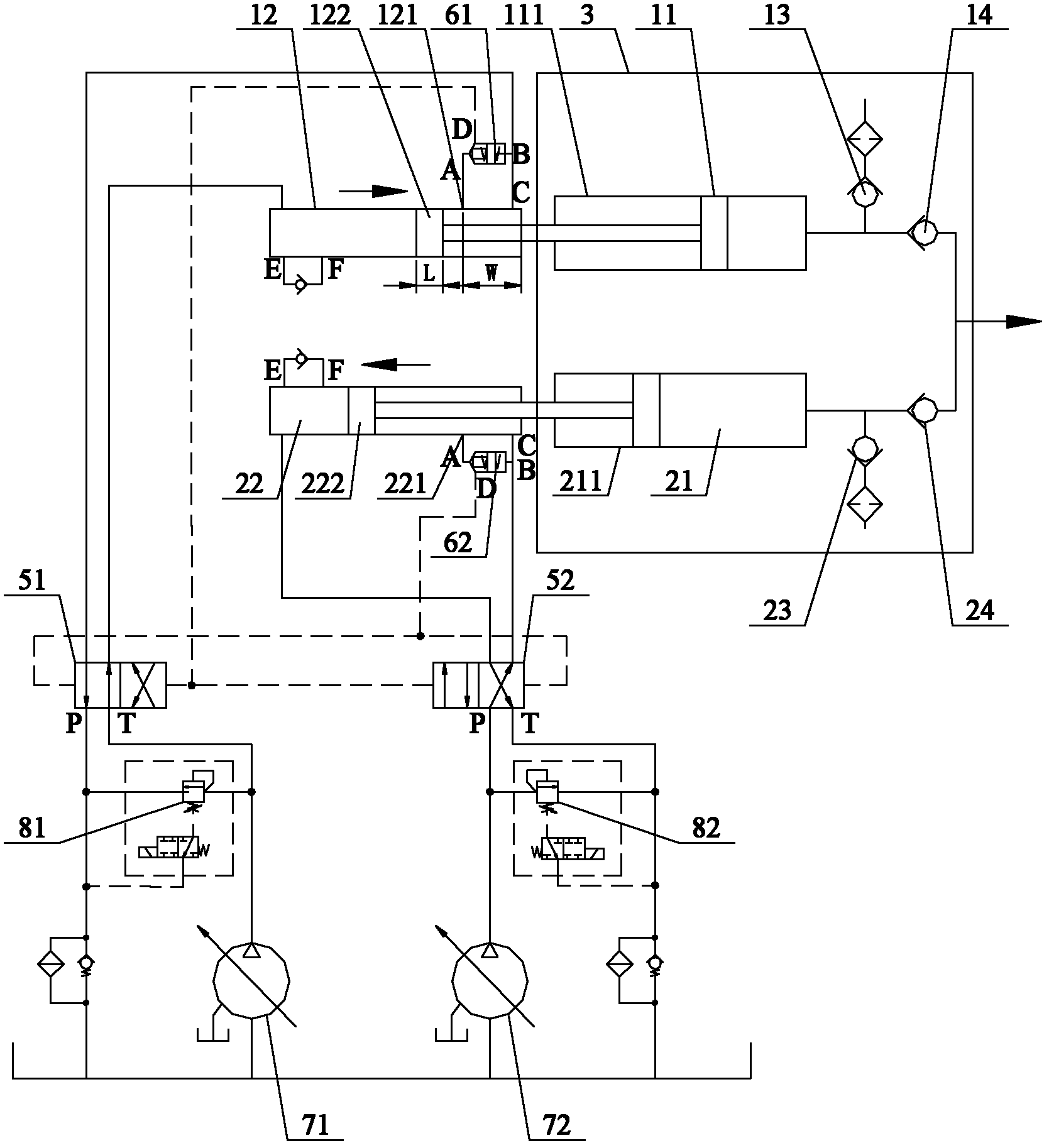

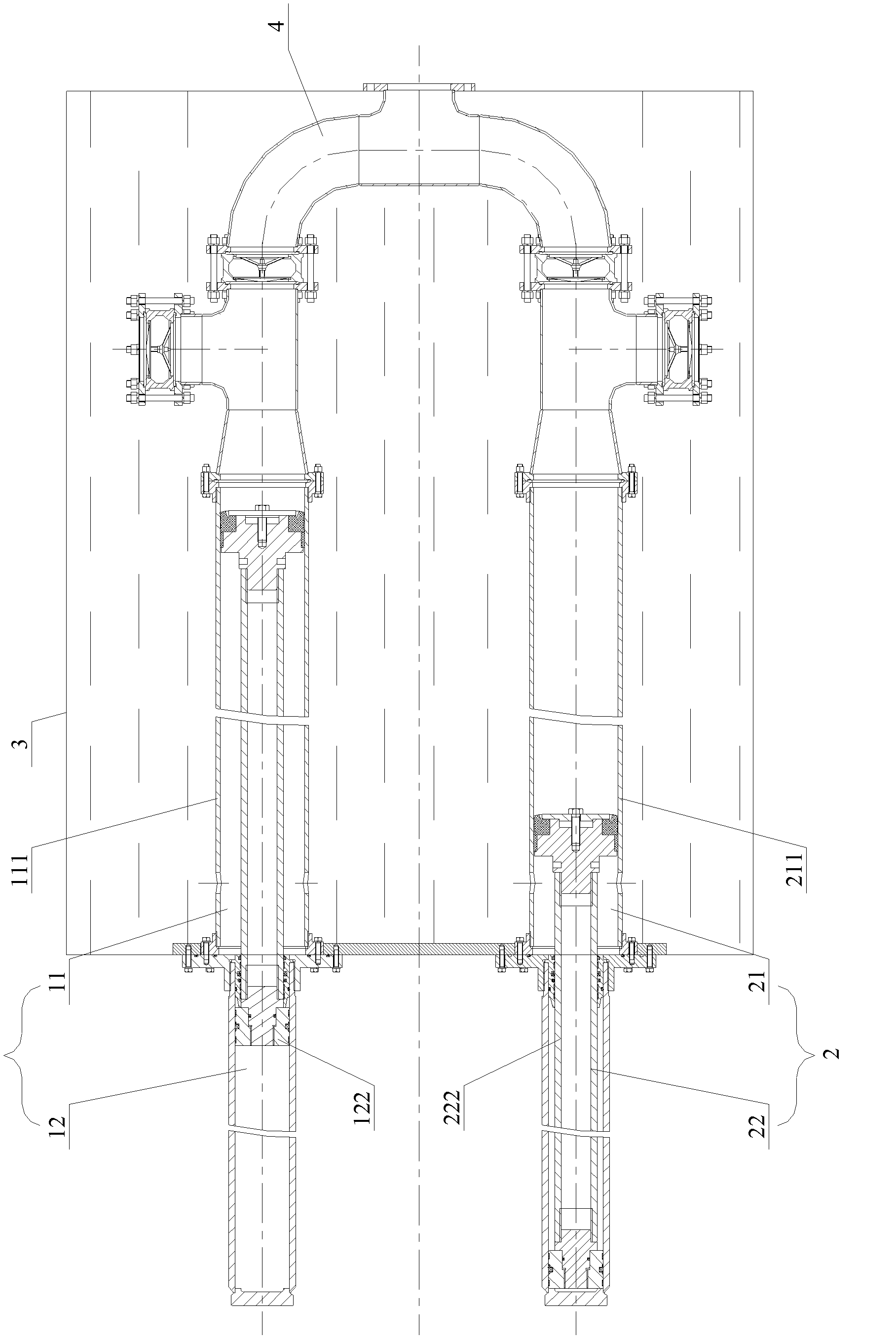

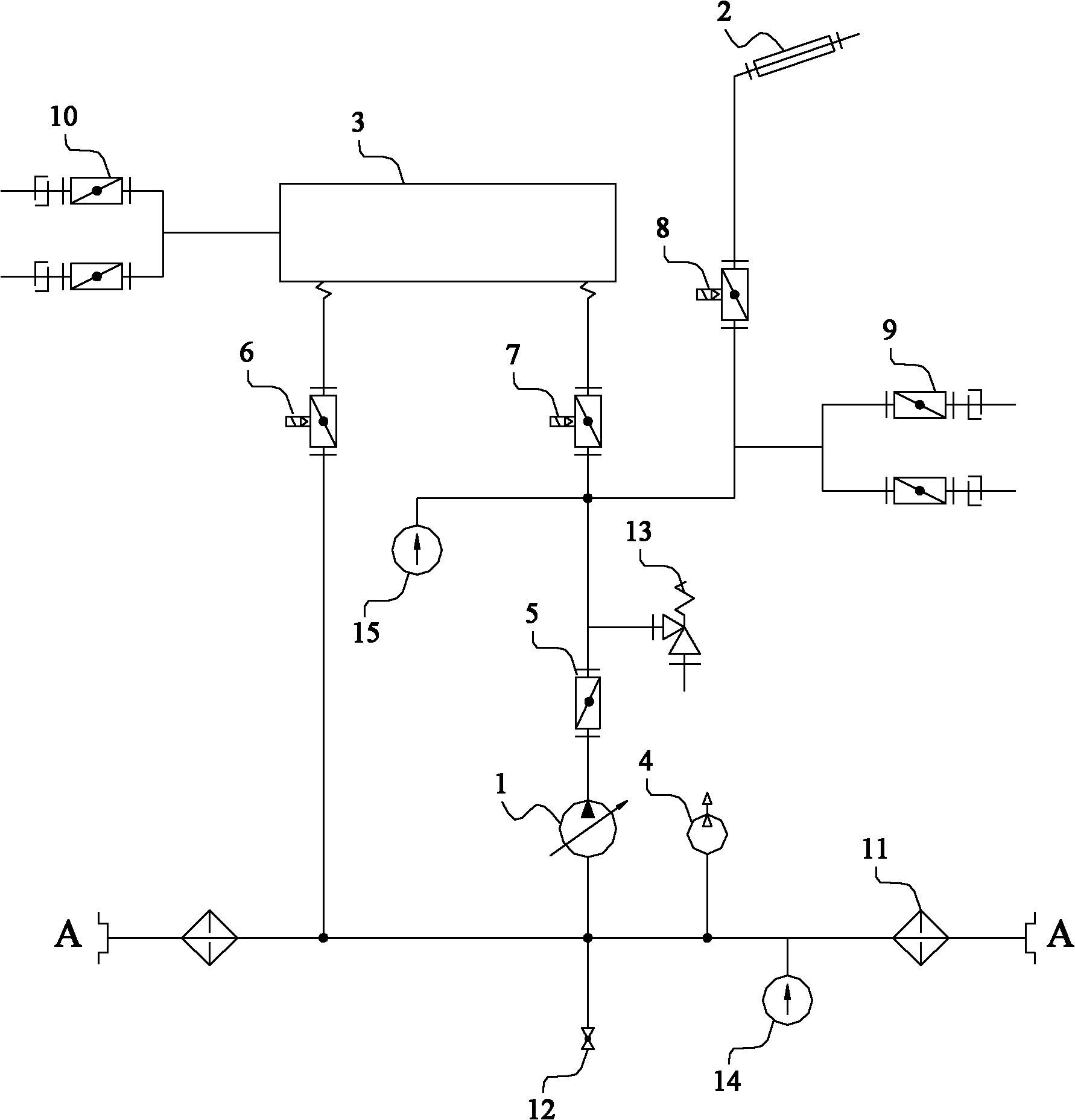

Plunger water pump and liquid control system thereof

InactiveCN102330649APrevent internal leakageIncrease output flow and water pressurePiston pumpsPump installationsPlunger pumpStructural principle

The invention discloses a plunger water pump. The plunger water pump provided by the invention comprises two plunger groups which are composed of water cylinders and oil cylinders, a water cylinder piston and an oil cylinder piston of each plunger group are synchronously displaced, a water gap of each water cylinder barrel is provided with a water inlet one-way valve which is in one-way conduction with a cylinder tube cavity from the outside and a water outlet one-way valve which is in one-way conduction with the cylinder tube cavity from the cylinder tube cavity to the outside; and two oil cylinders are alternately stretched under the control of a control valve. The plunger water pump provided by the invention breaks through a traditional water pump structural principle, two oil cylinders are adopted to alternately move and retreat, thereby driving two water cylinders pistons to alternately move, and further the switch of two working conditions is respectively realized; compared with the prior art, the plunger water pump is capable of effectively improving the output flow and the water utilization pressure on the basis of the continuous no-interval foundation; and the invention also provides a liquid control system of the plunger water pump.

Owner:XUZHOU HEAVY MASCH CO LTD

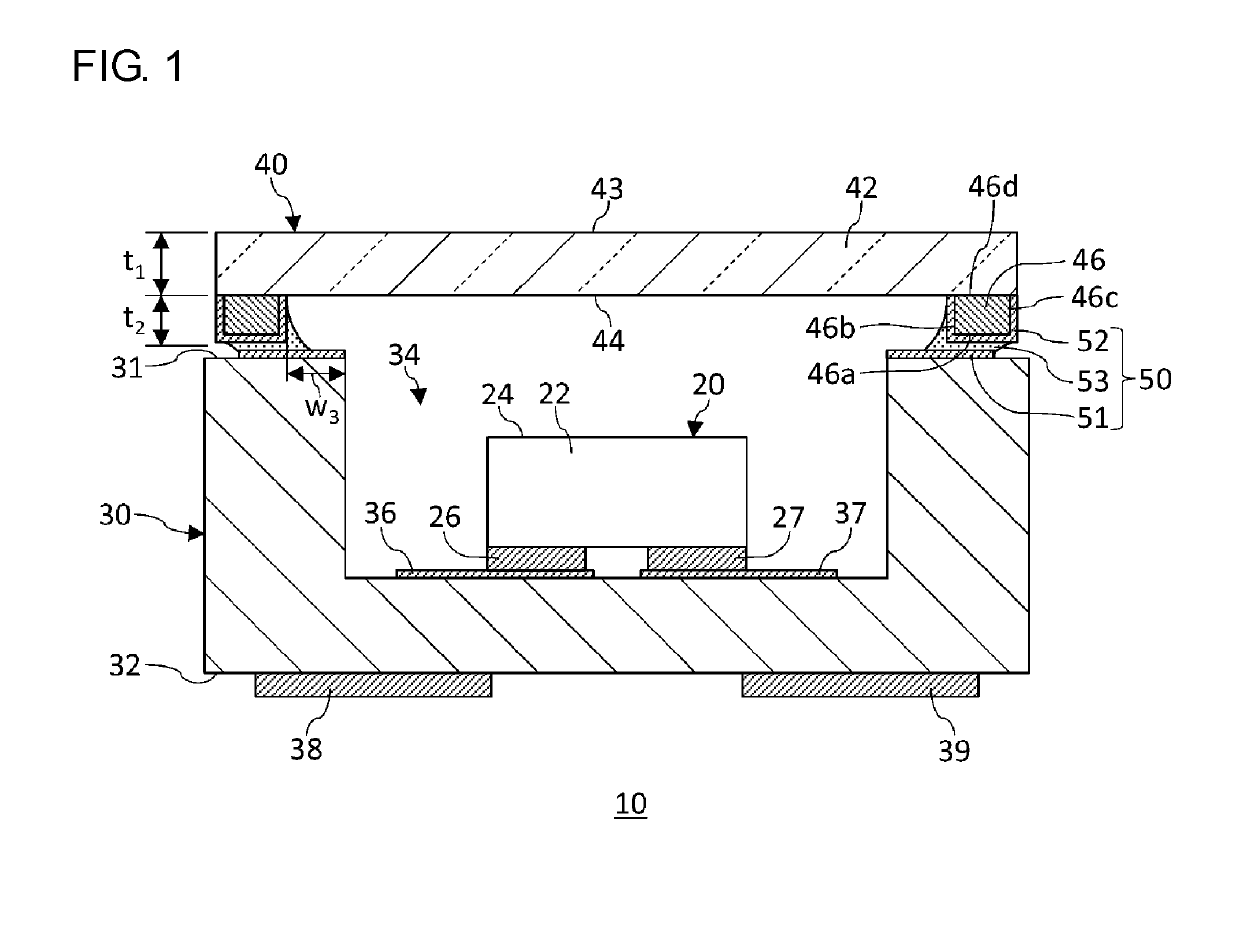

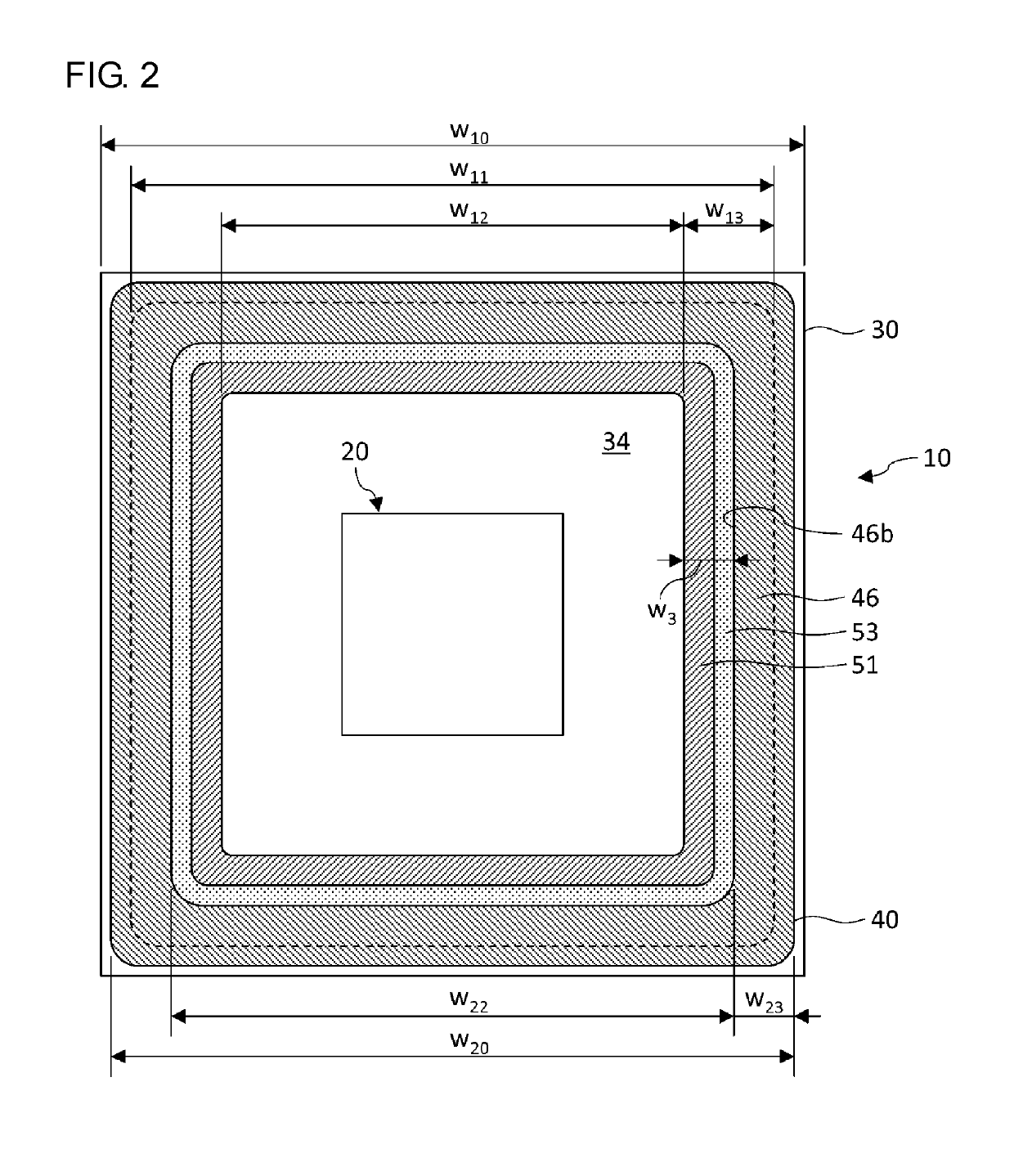

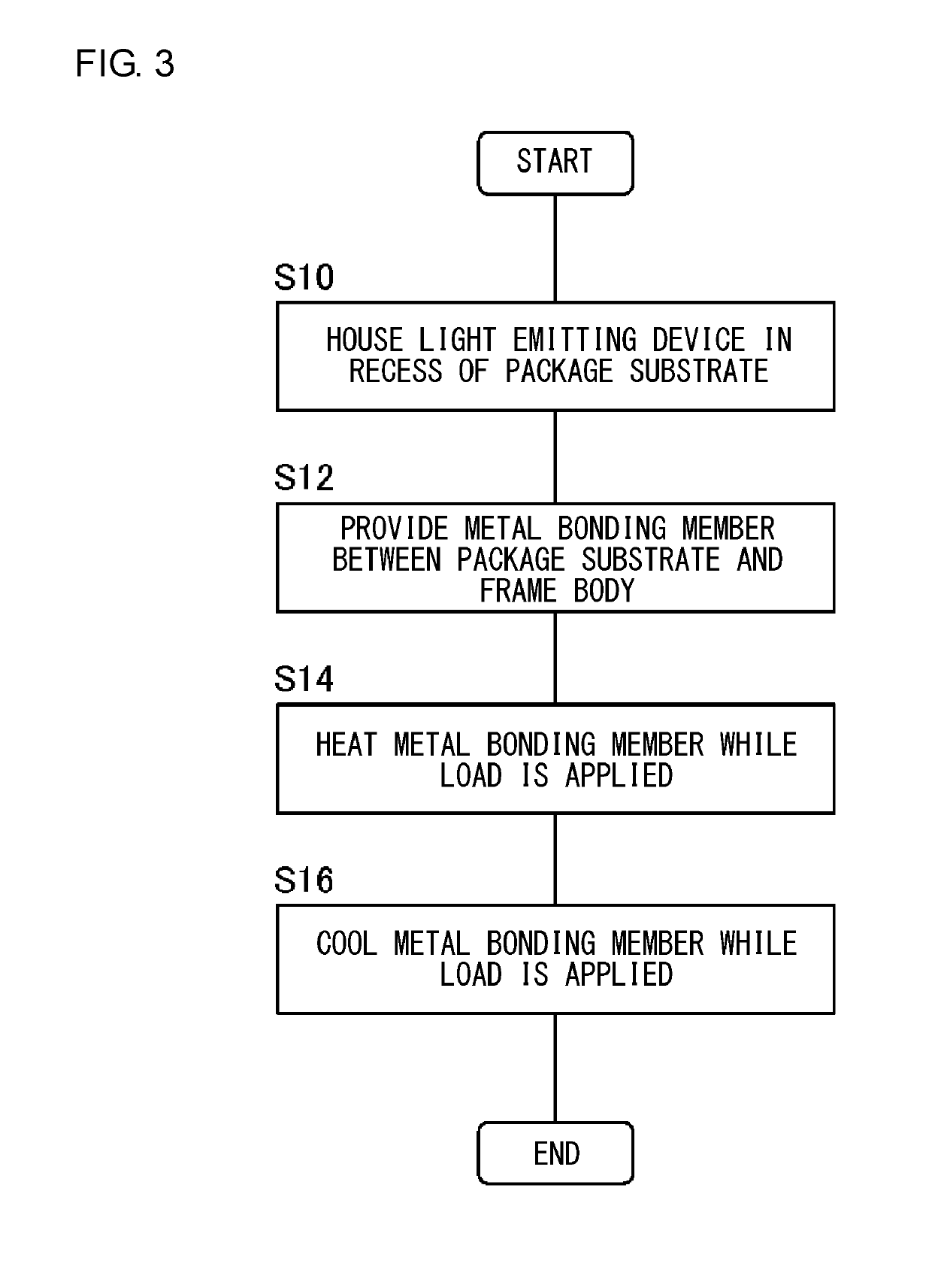

Optical semiconductor apparatus and method of manufacturing optical semiconductor apparatus

ActiveUS20190189861A1Improve reliability and manufacture yieldImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal binding

A light emitting apparatus includes: a package substrate; a light emitting device housed in a recess of the package substrate; a window member provided to cover an opening of the recess; and a sealing structure that seals a space between the package substrate and the window member. The window member includes a glass plate having an inner surface that faces the optical semiconductor device and a frame body provided on the inner surface of the glass plate. The sealing structure includes a first metal layer provided on a top surface of the package substrate, a second metal layer provided on a bottom surface and an inner circumferential surface of the frame body, and a metal bonding part provided between the first and second metal layers, at least a portion of the metal bonding part being provided on the inner circumferential surface.

Owner:NIKKISO COMPANY

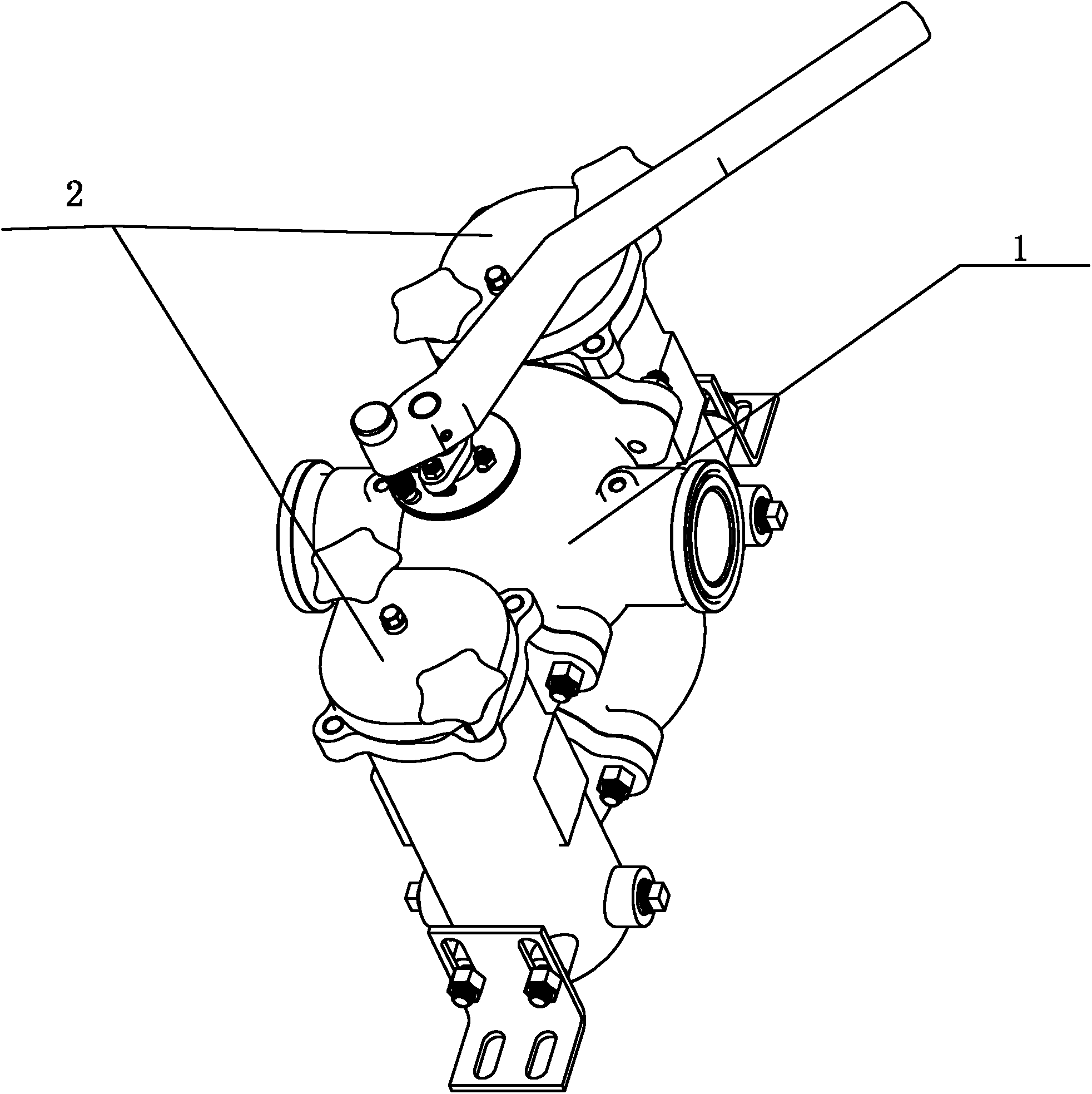

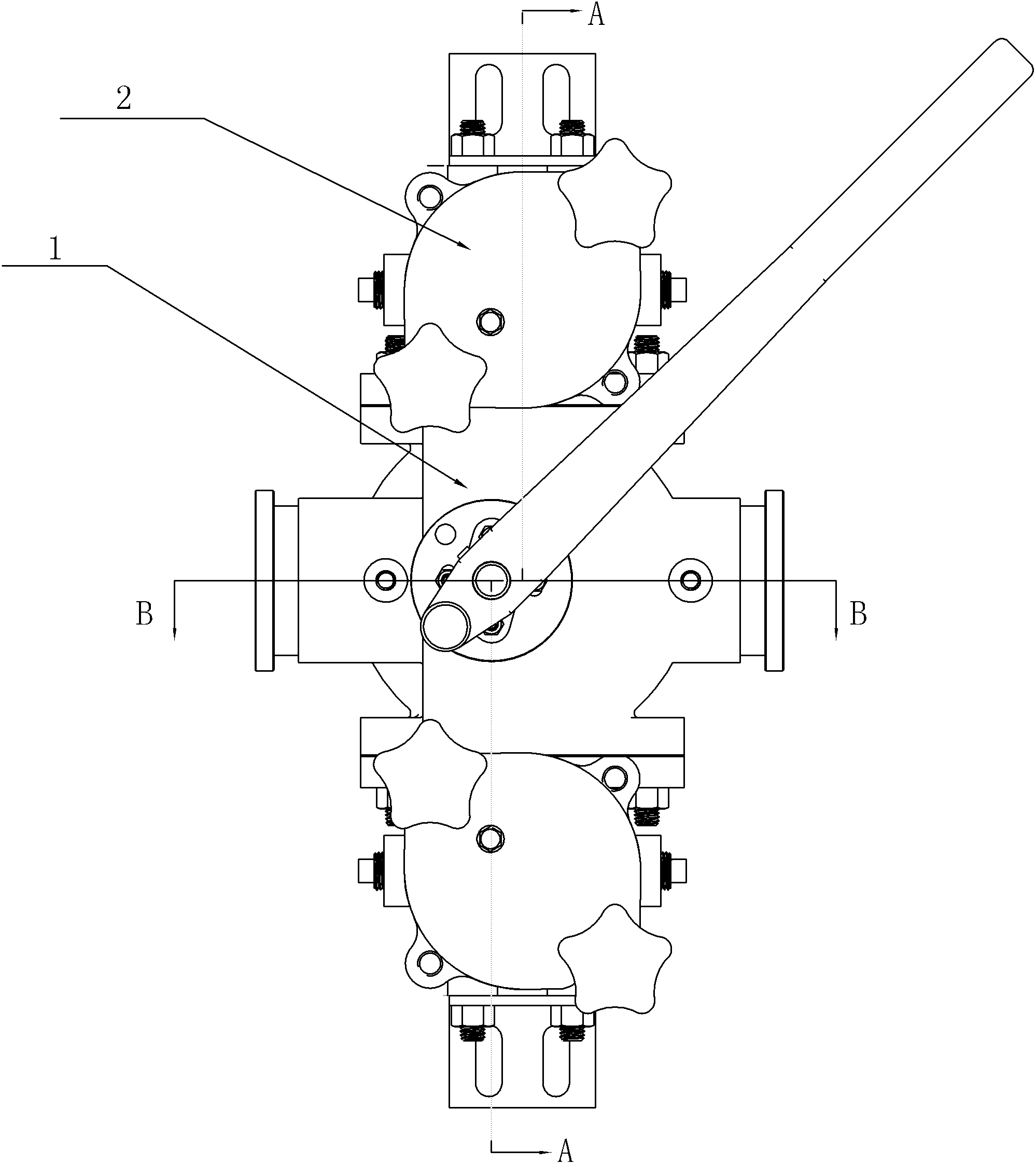

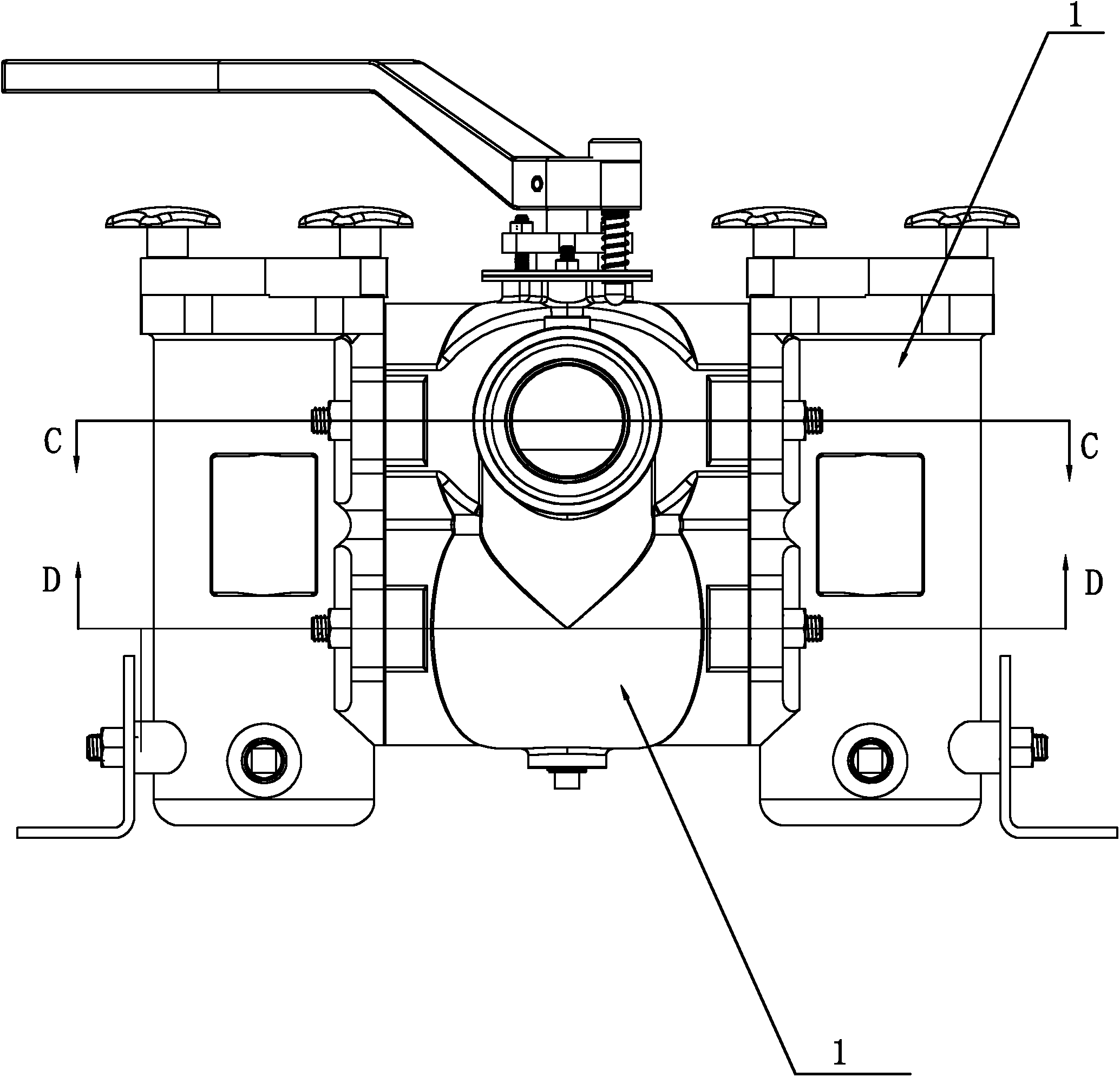

Multifunctional double-drum filter valve

ActiveCN102359658AEffective blockageStrong pressing forceValve arrangementsFiltration separationEngineeringAngle alpha

The invention relates to a double-drum filter valve, wherein an included angle Alpha which is matched with the rotation angle of an upper plunger valve is formed between the central axis of the seal end of a valve seat a and the central axis of the seal end of a valve seat b in an upper valve cavity; an included angle Beta which is matched with the rotation angle of a lower plunger valve is formed between the central axis of the valve port seal end of a valve seat c and the central axis of the valve port seal port of a valve seat d in a lower valve cavity; and the included angle Alpha and theincluded angle Beta are both 90 DEG. Due to the setting of the included angles, the clamping force between the valve and the valve seats is increased, and the sealing performance is improved; in addition, a seal ring is arranged on the seal end of each valve seat, two axial ends of the upper plunger valve and the lower plunger valve are respectively provided with a ceramic cup-cover-shaped seal structure which forms plug seal to the seal ends of the valve seats, and a positioning flange on each seal structure is in a shape of a cone which is narrowed along the free end. With the structure design, when the plunger valve and the valve seats are sealed, double seal surface seal of end surface and lateral surface is formed, and the plug seal is more reliable; and when a single filtering drum works, a filtering drum which does not work cannot generate liquid leakage.

Owner:正球阀门集团有限公司

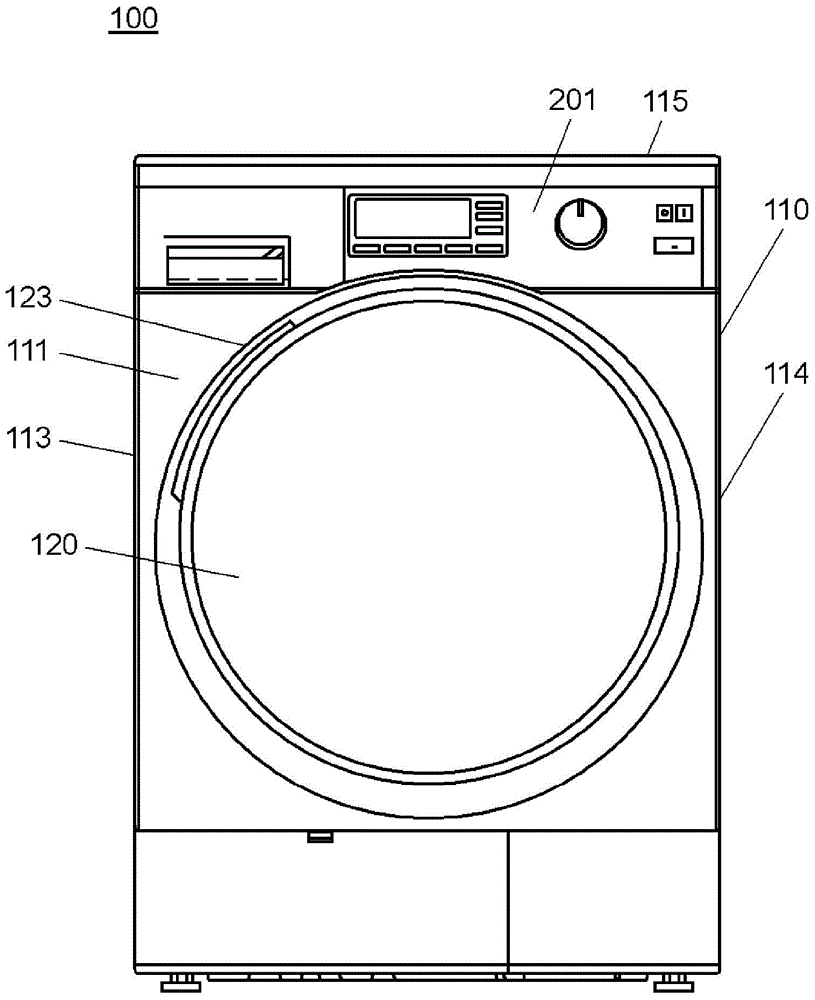

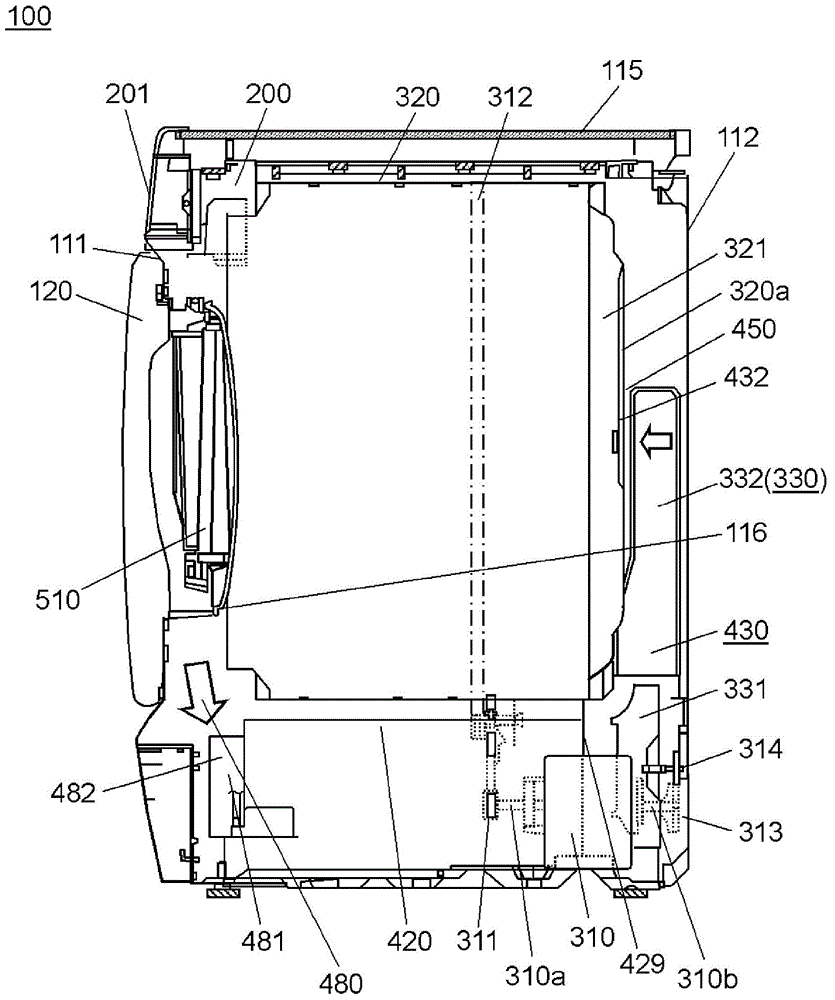

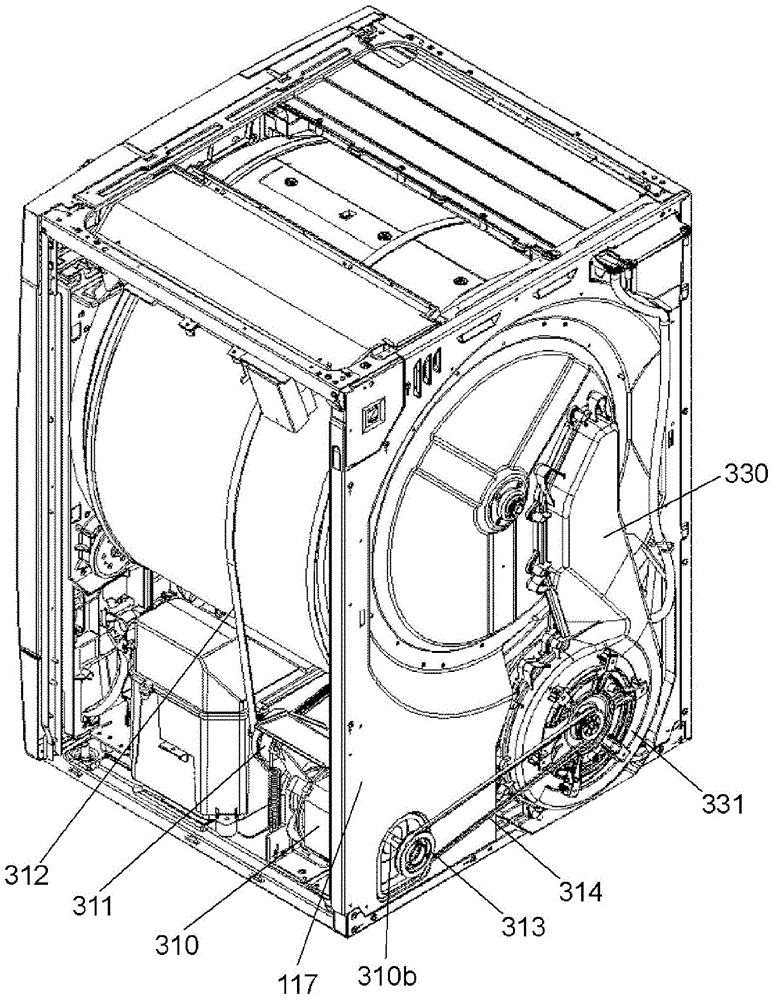

Clothes drier

ActiveCN104411876AEasy loading and unloadingPrevent leakageTextiles and paperLaundry driersEngineeringMechanical engineering

This clothes drier (100) comprises: a drying chamber (320) that houses clothes; an insertion port (116) through which clothes are inserted into and removed from the drying chamber (320); a door (120) that closes the insertion port (116); and a lint filter (510) detachably provided in the door (120). The door (120) faces the insertion port and has a housing unit (121) housing the lint filter (510). The lint filter (510) and the housing unit (121) are connected via a sealing unit (513) and the sealing unit (513) is configured so as to be inclined relative to the vertical direction. As a result, a clothes drier (100) that prevents reduction in drying performance caused by leakage of drying air from the lint filter (510) can be achieved.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

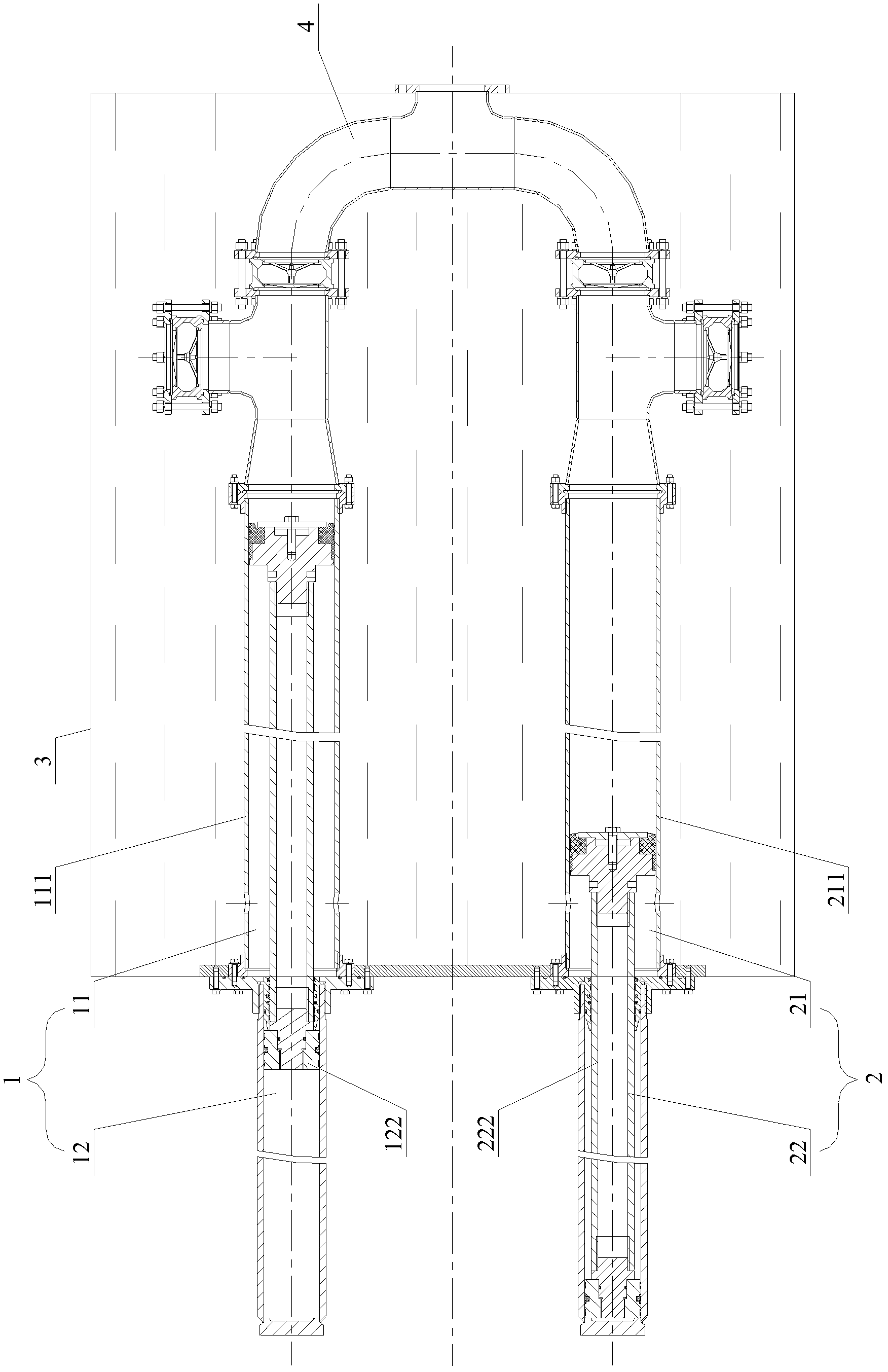

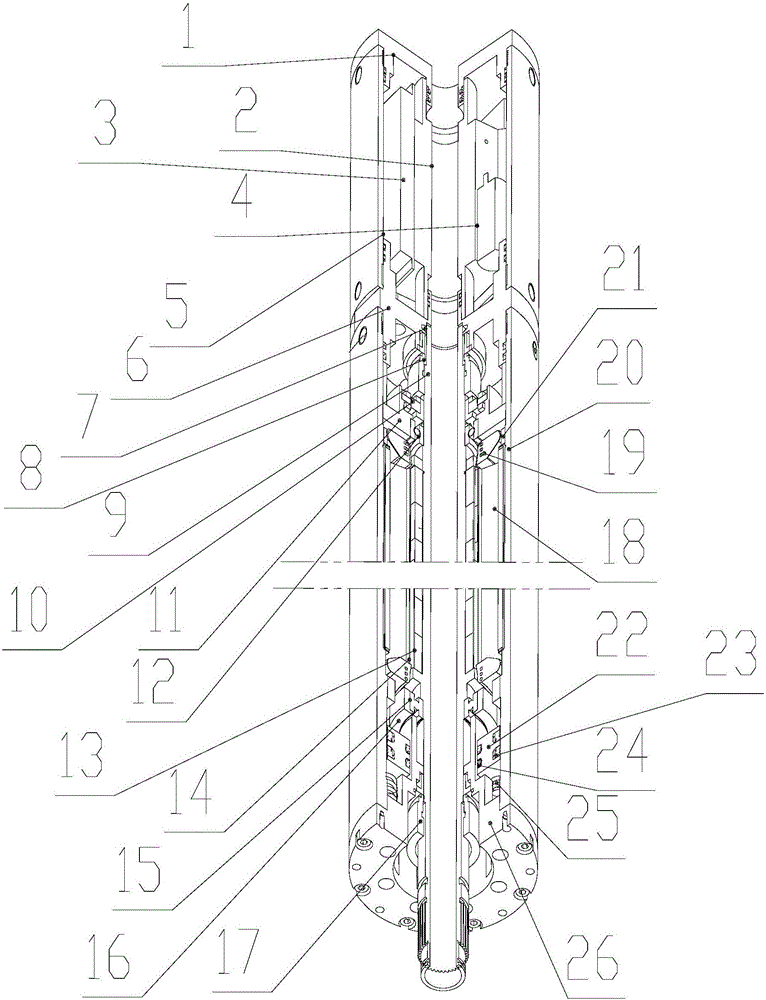

Drive motor of underground electric drilling tool

ActiveCN105162289AEfficient driveGuaranteed to workStructural associationSupports/enclosures/casingsDrive motorHigh pressure

Provided in the invention is a drive motor of an underground electric drilling tool. The drive motor comprises a housing in a cylindrical shape, a rotor shaft, a rotor, a stator, and a piston. The rotor shaft having a central hole penetrates the inside of the housing along the axial direction; an enclosed cavity for filling oil fluid is formed between the rotor shaft and the housing; and the rotor shaft extends out of the cavity and is connected with a load. The rotor is arranged in the cavity and is fixed on the rotor shaft. The stator arranged in the cavity is sleeved between the housing and the rotor. The piston in an annular shape can be sleeved between the rotor shaft and the housing in a sealing and sliding mode at an axial direction; and the piston located at the bottom of the cavity can slide to balance pressures inside and outside the cavity. The provided drive motor has a high efficiency and can adapt to an underground high-temperature high-pressure complex external environment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

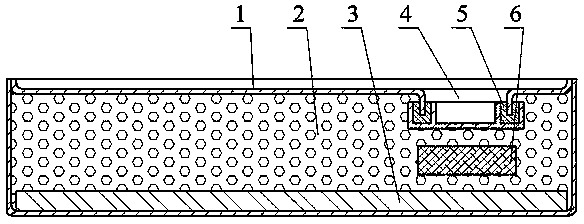

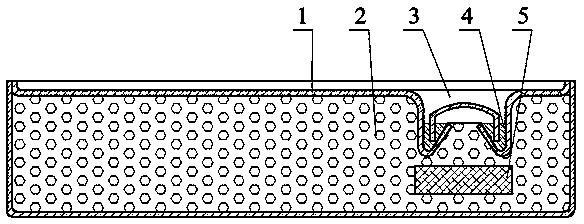

Metal vacuum composite insulation plate with getter and preparation method thereof

InactiveCN104295017ASimple sealing structureReliable sealingCovering/liningsThermal insulationVacuum furnaceGetter

The invention discloses a metal vacuum composite insulation plate with a getter. The metal vacuum composite insulation plate comprises a shell, a core material, a core plate and a vacuum cavity, and is characterized in that the shell is a metal plate or a metal composite plate, wherein the core material is positioned in the vacuum cavity for providing additional strength to the shell and guaranteeing the flatness of the shell under atmospheric pressure; the vacuum cavity is a closed cavity formed by performing the welding edge sealing under normal pressure and the high-temperature opening sealing under vacuum for the shell; the opening sealing is a step that an extraction opening prefabricated in the shell is automatically sealed in a vacuum furnace by using a low-temperature solder according to a liquid sealing principle; and the getter is arranged in the vacuum cavity. A preparation method of the metal vacuum composite insulation plate is simple in process; and the prepared metal vacuum composite insulation plate with the getter can overcome the defects of a traditional insulation plate and a traditional vacuum insulation plate, and can be improved in strength, and heat insulation, sound insulation, fire prevention and decoration functions.

Owner:戴长虹

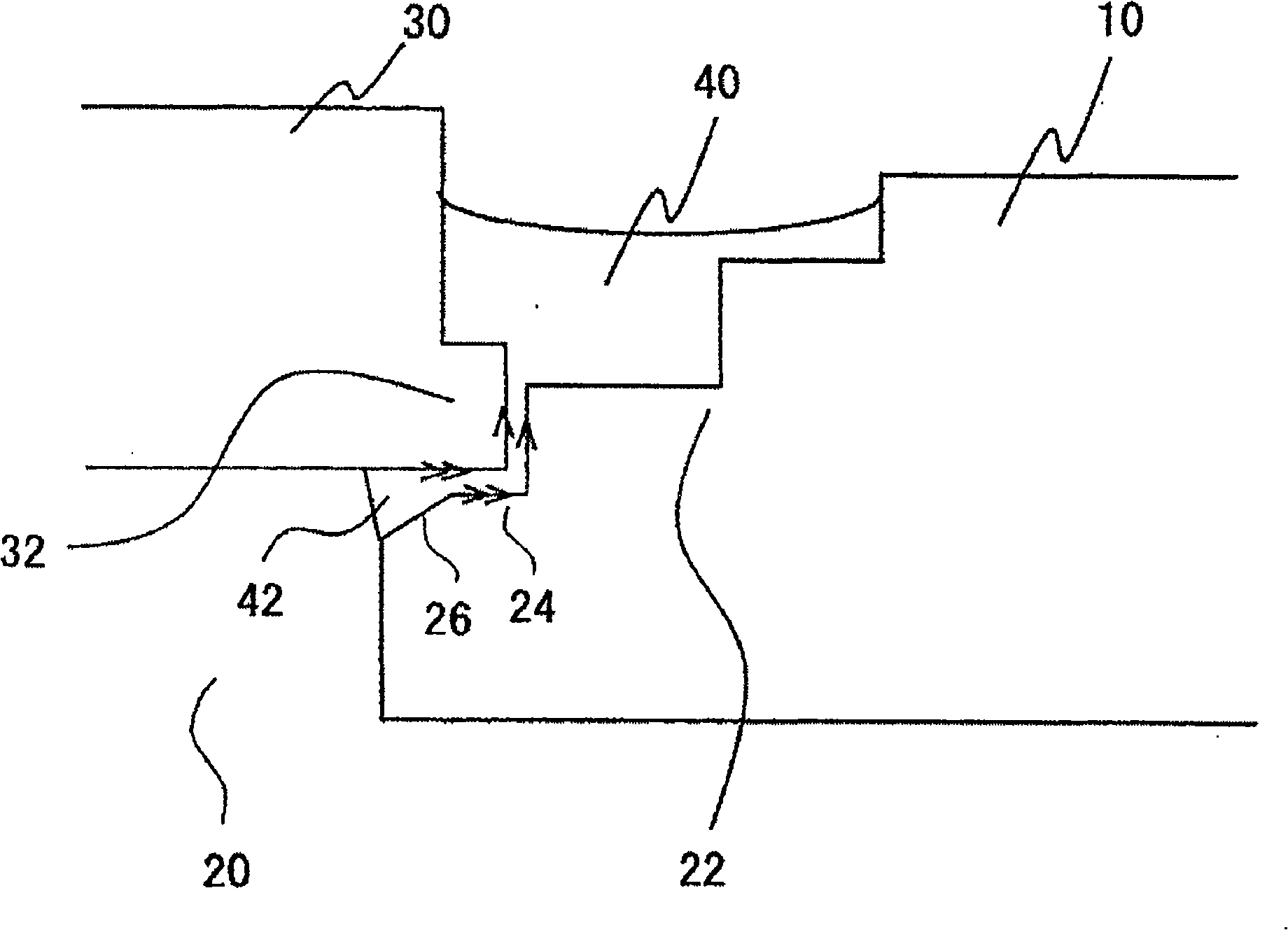

Magnetic disk drive and soldering method of feed-through

InactiveCN101290791ALeak won'tReliable sealing structureUndesired vibrations/sounds insulation/absorptionRecord information storageLow densitySoldering

The invention provides a solder connecting structure with high reliability, characterized in that, even if the flange of lead wire of sealed disk driver is made of kovar that is an iron-based material, the low density gas may almost not leak out; and a base of the driver is made of aluminium-based alloy. The base 10 has a step-shaped portion 22 located inside the periphery of an opening 20; a bevel 26 extending out of the base 10 is formed at the edge of a surface 24 of the step-shaped portion; a flange 32 of the lead wire 30 is placed on the bevel 26; therefore, a round corner of the solder 42 is not only formed inside of the base 10, but also formed outside of the same, when the step-shaped portion 22 of base is connected with the flange 32 of lead wire by welding.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Metal vacuum insulation plate with getter and preparation method thereof

InactiveCN104295015AStable and reliable productionEasy to produceCovering/liningsThermal insulationFire preventionGetter

The invention discloses a metal vacuum insulation plate with a getter. The metal vacuum insulation plate comprises a shell, a core material and a vacuum cavity, and is characterized in that the shell is a metal plate or a metal composite plate, wherein the core material is positioned in the vacuum cavity for providing additional strength to the shell and guaranteeing the flatness of the shell under atmospheric pressure; the vacuum cavity is a closed cavity formed by performing the welding edge sealing under normal pressure and the high-temperature opening sealing under vacuum for the shell; the opening sealing is a step that a prefabricated extraction opening in the shell is automatically sealed in a vacuum furnace by using a low-temperature solder according to a liquid sealing principle; and the getter is arranged in the vacuum cavity. A preparation method of the metal vacuum insulation plate is simple; and the prepared metal vacuum insulation plate with the getter can overcome the defects of a traditional insulation plate and a traditional vacuum insulation plate, and can improve the strength, and the heat insulation, sound insulation, fire prevention and decoration functions.

Owner:戴长虹

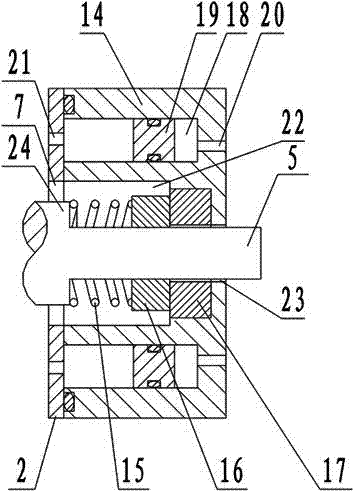

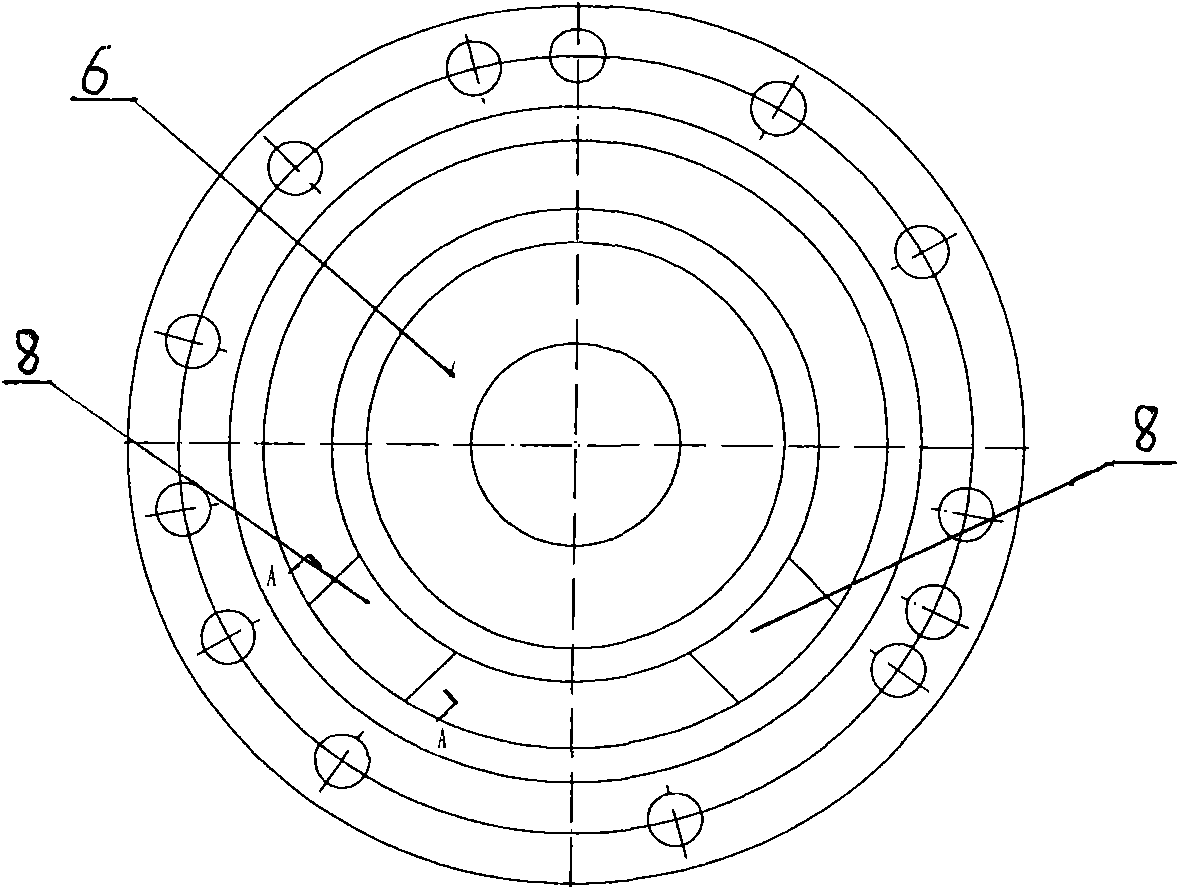

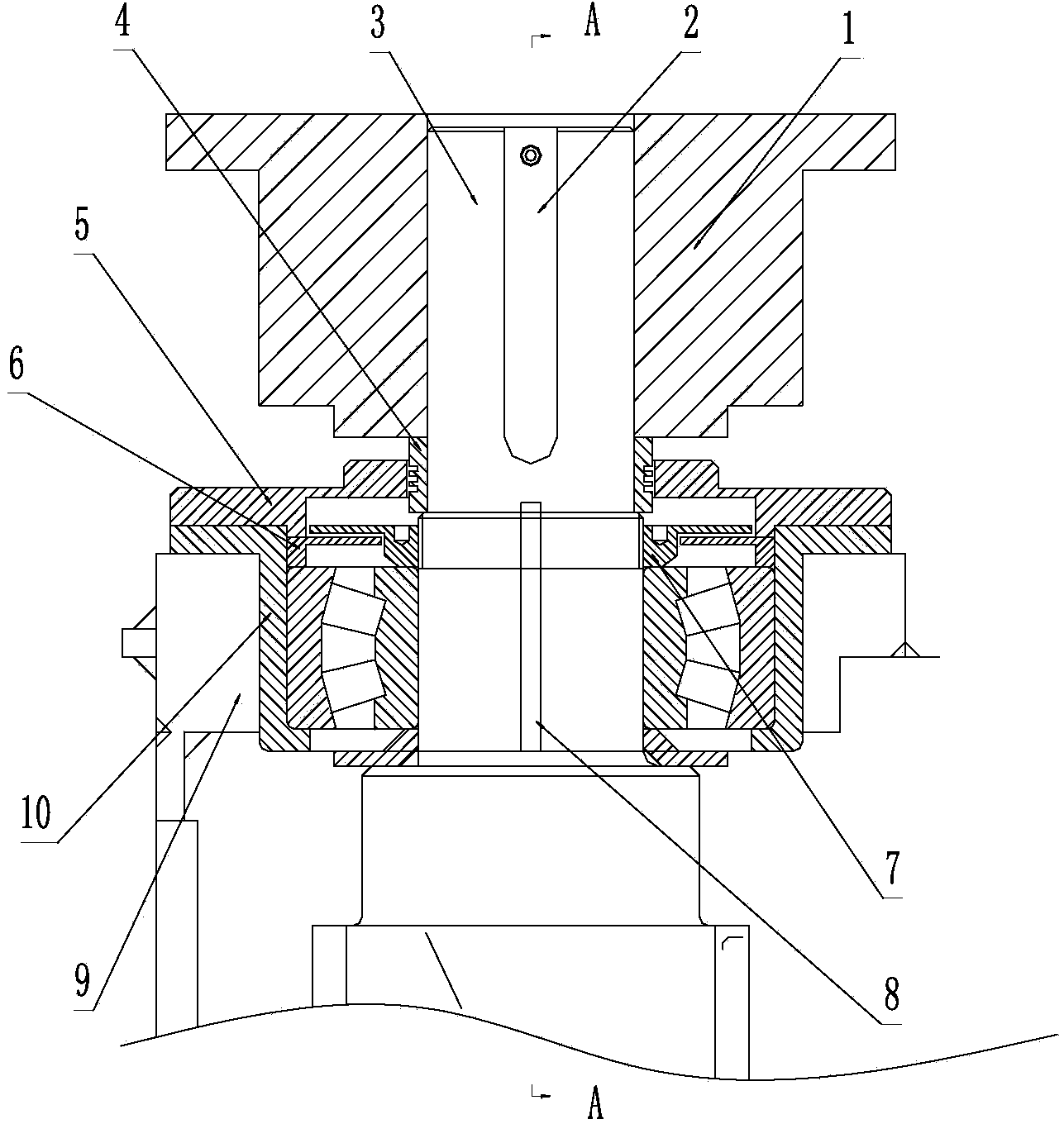

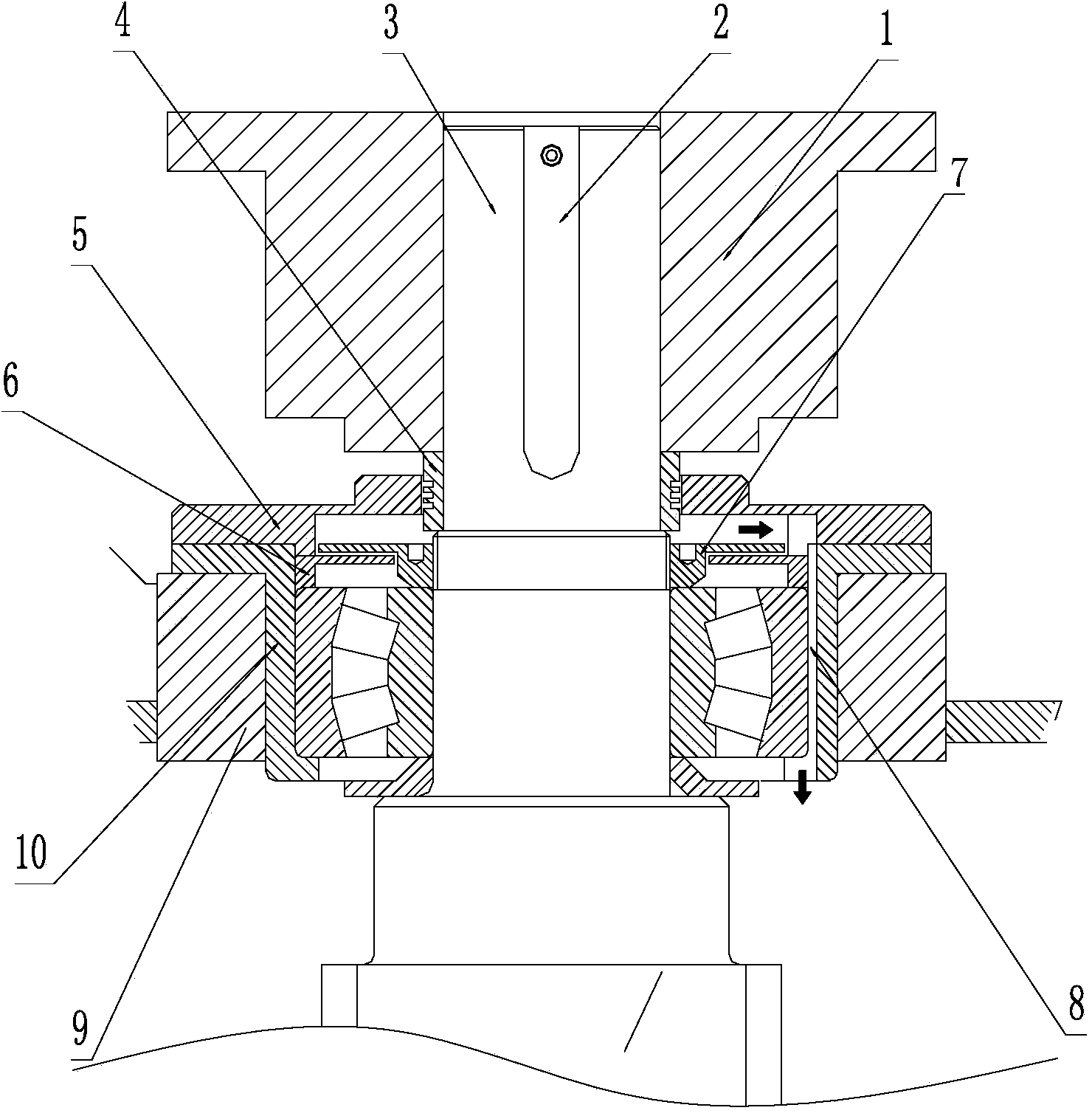

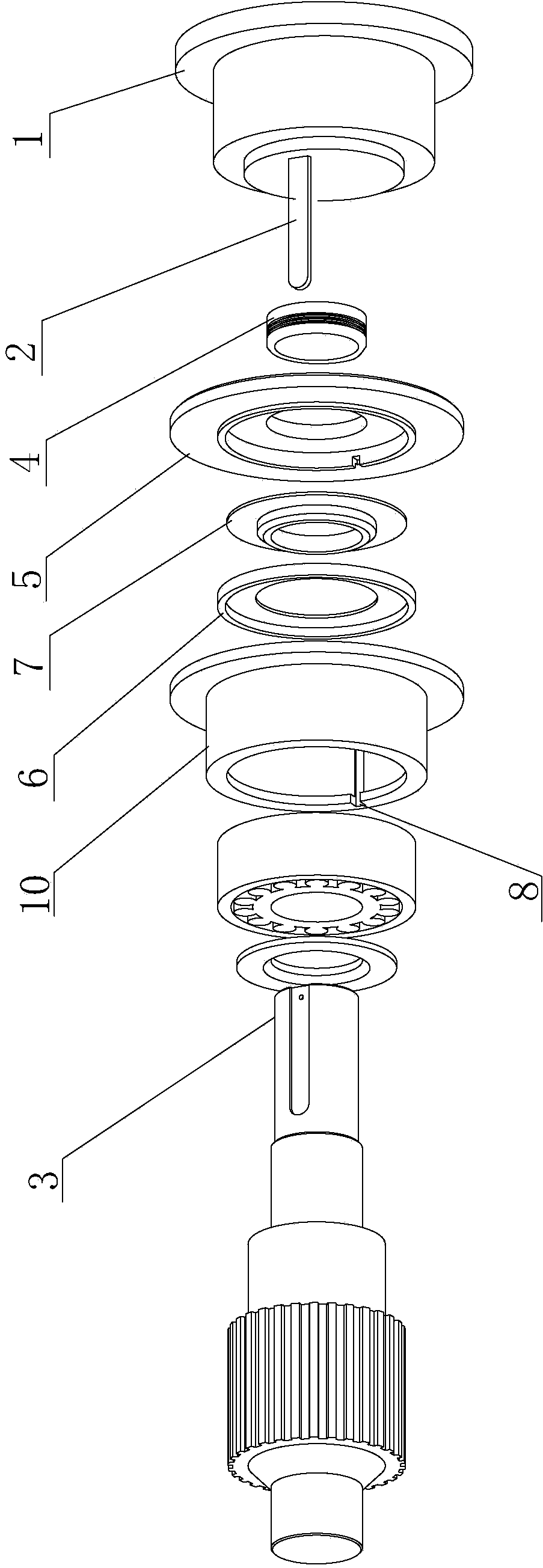

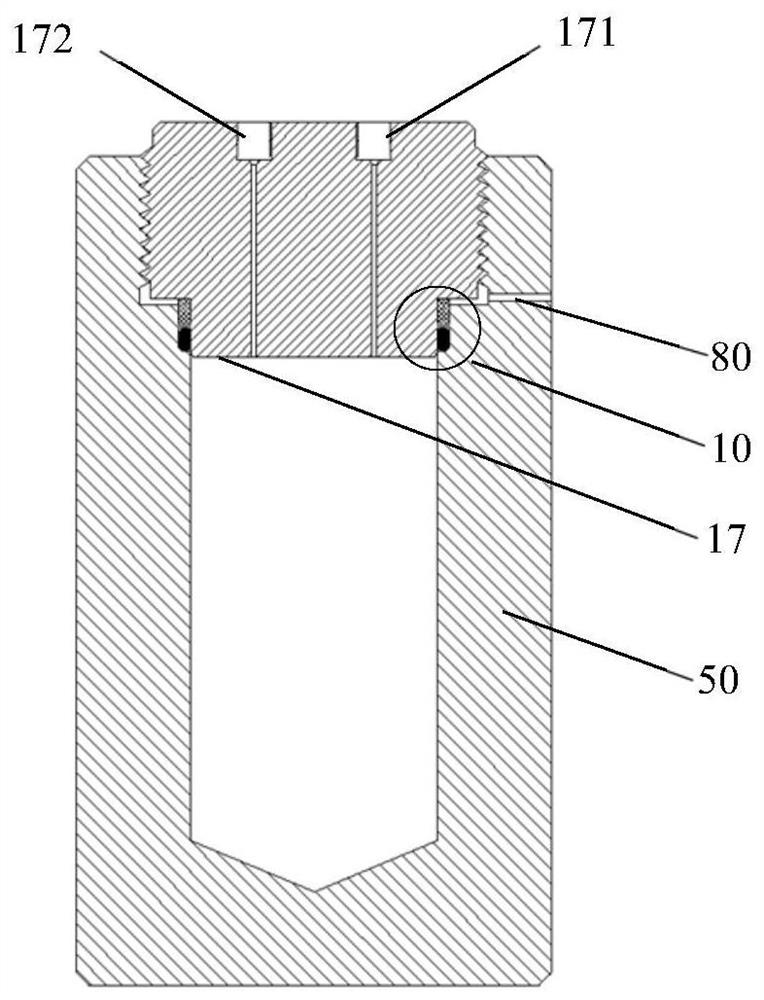

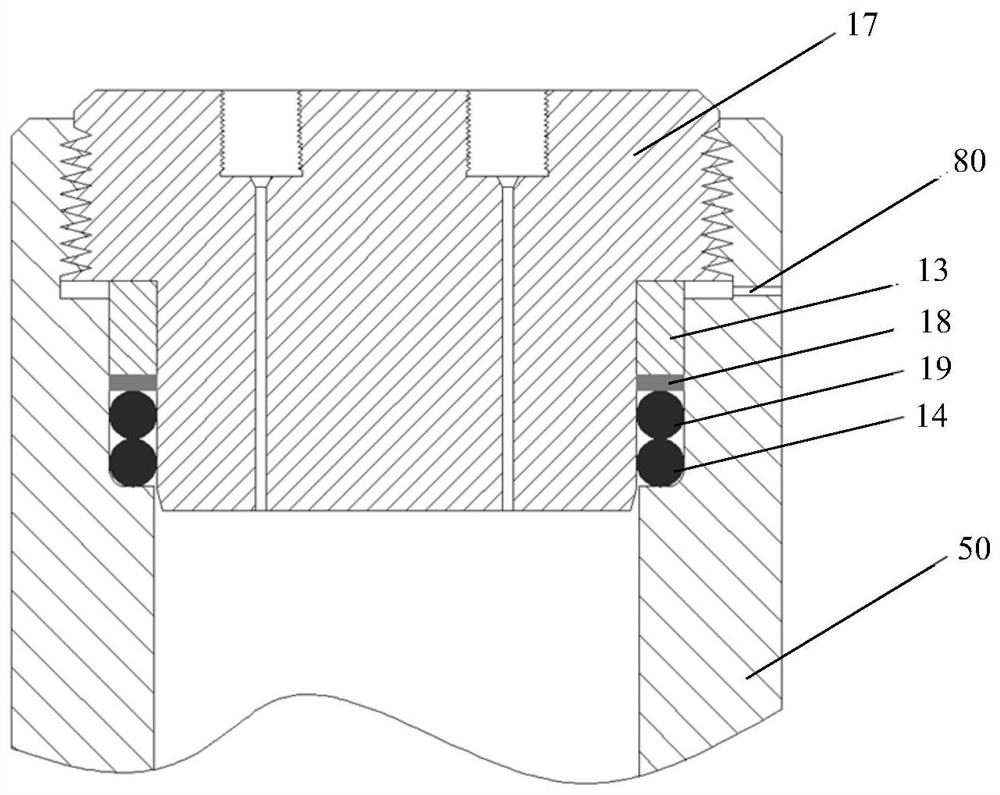

Amphibian permanent magnet submersible motor with protection level IP68

PendingCN109327099AGuaranteed tightnessReliable sealing structureStructural associationSupports/enclosures/casingsWear resistantMagnet

The invention discloses an amphibian permanent magnet submersible motor with a protection level IP68. The amphibian permanent magnet submersible motor comprises a machine seat, a shaft extension end cap, a shaft extension end bearing outer cover, a shaft extension end bearing inner cover, a stator, a rotor, a shaft run-through sealing device, a cable sealing device, a water leakage alarm device and an outgoing cable, wherein the shaft run-through sealing device comprises two annular sealing cavities coaxial with a rotor shaft, and the two annular sealing cavities are formed by encircling firstsealing sleeves, second sealing sleeves, sealing covers and shaft sleeves; the shaft sleeves are made of a wear-resistant material and are thermally sleeved on the rotor shaft; the shaft sleeves andthe rotor shaft are fixed by fastening screws; framework oil seals are arranged in the two annular sealing cavities; and the annular seal cavities are filled with lubricating grease during working. The sealing structure of the motor is reliable, so as to prevent dust and water at a certain pressure from entering the motor; and the motor can meet the sealing requirements of IP68 more easily duringassembling.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD +1

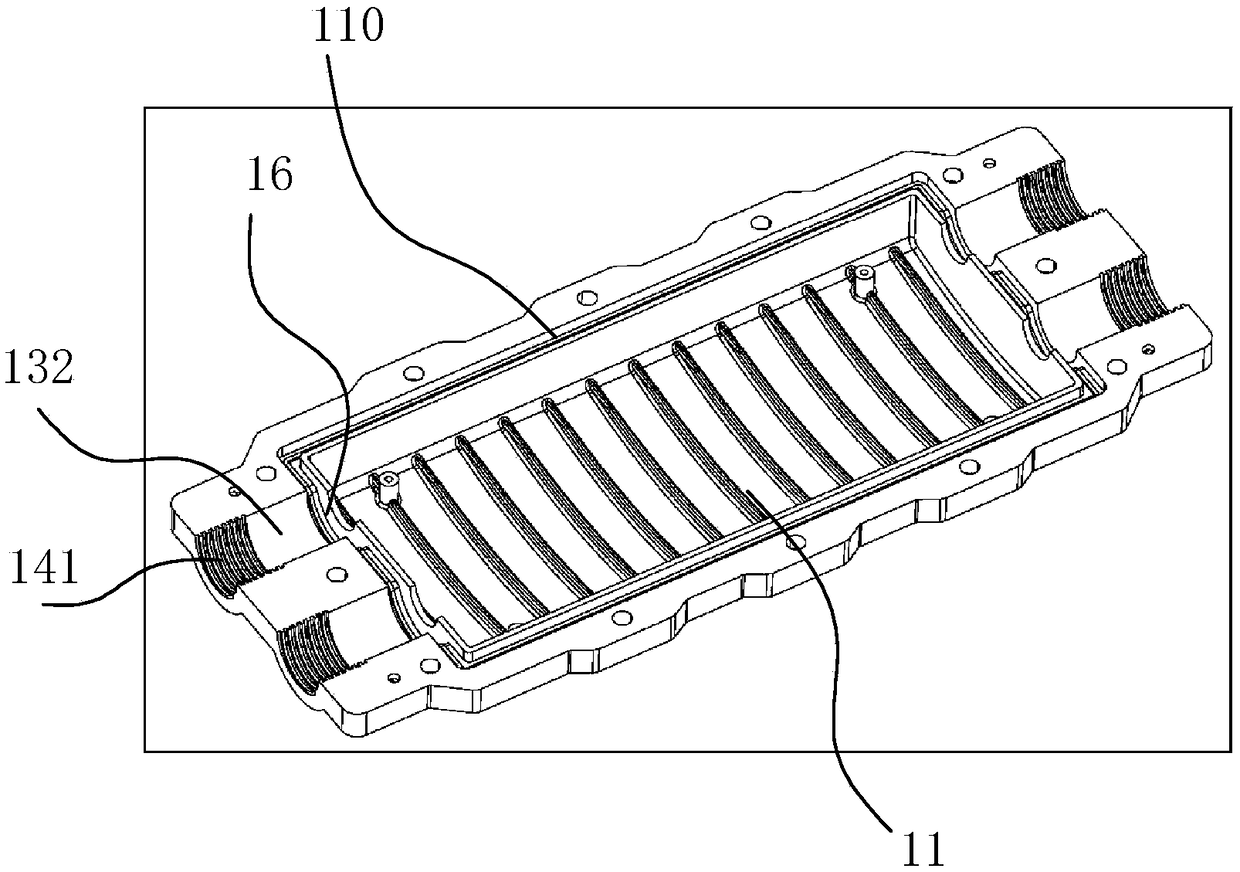

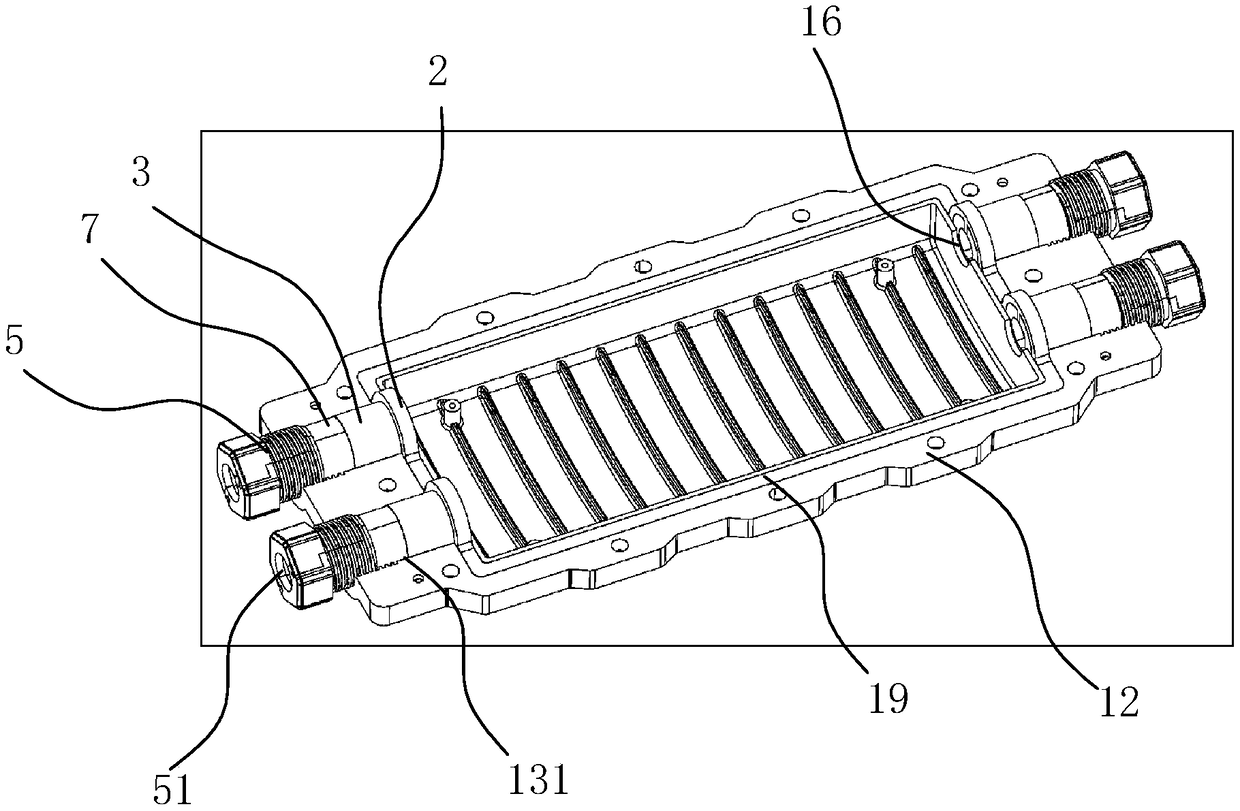

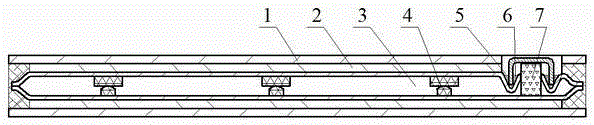

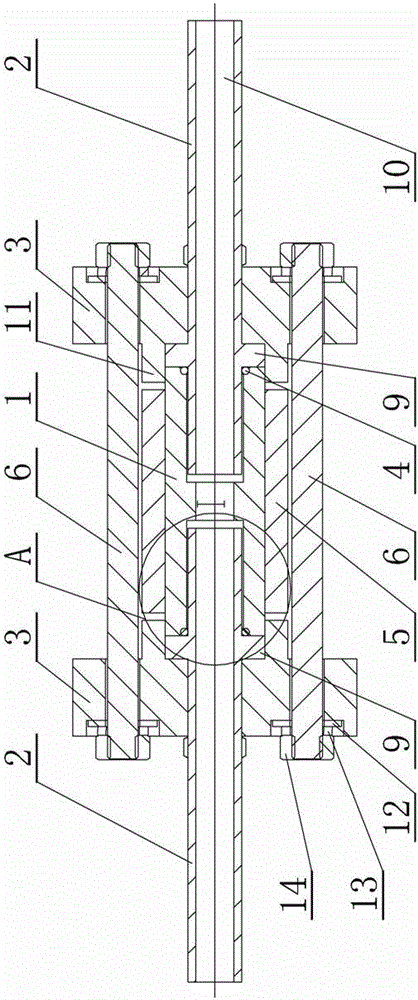

High-reliability thin bipolar plate sealing structure

InactiveCN104538655AReliable sealing structurePrevent overpressureFuel cell auxillariesFuel cell detailsThin metalEngineering

The invention relates to a high-reliability thin bipolar plate sealing structure. Bulges are uniformly distributed on the sealing areas of a thin bipolar plates; sealing sheets are pressed and positioned by the bulges; the outer edges of two sides of the sealing sheets are large than the outer edges of two sides of the thin bipolar plates; the two sealing sheets are respectively provided with sealing sheet bulges and sealing sheet grooves in the positions which correspond to the outer edges of two sides of the thin bipolar plates; the sealing sheet bulges are arranged in the sealing sheet grooves; and the two sealing sheets are combined together through the sealing sheet bulges and the sealing sheet grooves. The high-reliability thin bipolar plate sealing structure provided by the invention is reliable and effective; effective limiting grooves are formed between each section of the thin bipolar plates, single battery can be prevented from being over-pressed, and electric piles can be kept consistent; the frame of a membrane electrode can be protected against deformation, and the physical structure of the membrane electrode can be prevented from being damaged; the sealing sheets can be positioned and arranged conveniently and can be operated efficiently; the sealing sheets can be manufactured from a variety of materials; the outer edges of the sealing sheets protrude out of the outer sides of the electric piles, thus the sealing sheets can prevent the short circuit of the thin metal bipolar plates and guarantee the insulativity of the electric piles; and the sealing sheets have buffering and damping functions and can improve the reliability of the thin bipolar plates applied to the engineering.

Owner:SUNRISE POWER CO LTD

Cam shaft oil pressure seal end cover

The invention discloses a cam shaft oil pressure seal end cover which can prevent separating of a lip-shaped maze sealing ring and can seal a cam shaft end with high reliability. The cam shaft oil pressure seal end cover comprises an end cover body (7) and a framework lip-shaped maze sealing ring (5) hooping a cam shaft to prevent engine oil leakage. The end cover body (7) is assembled at the power input end of the cam shaft and fixed connected to the end face of an oil storage cavity opening of a pump box (1). A roller and outer ring assembly (3) passing through the cam shaft is arranged in a step hole in the inner side of the end cover body (7), and a main lip opening and an auxiliary lip opening of the lip-shaped maze sealing ring (5) hoop the neck of the cam shaft (4) to form a sealing strap which is also arranged in the step hole in the inner side of the end cover body (7). A reverse conical anti-separating structure preventing the sealing ring from separating in the axial direction is arranged on an installing seat hole, provided with the lip-shaped maze sealing ring (5), of the end cover body (7), and the reverse conical anti-separating structure is an inverse-conical-angle conical hole with the big end inside. The cam shaft oil pressure seal end cover effectively eliminates the failure, occurring frequently at the prototype sample stage, of separating of the framework lip-shaped maze sealing ring, and a sealing structure is reliable.

Owner:成都威特电喷有限责任公司

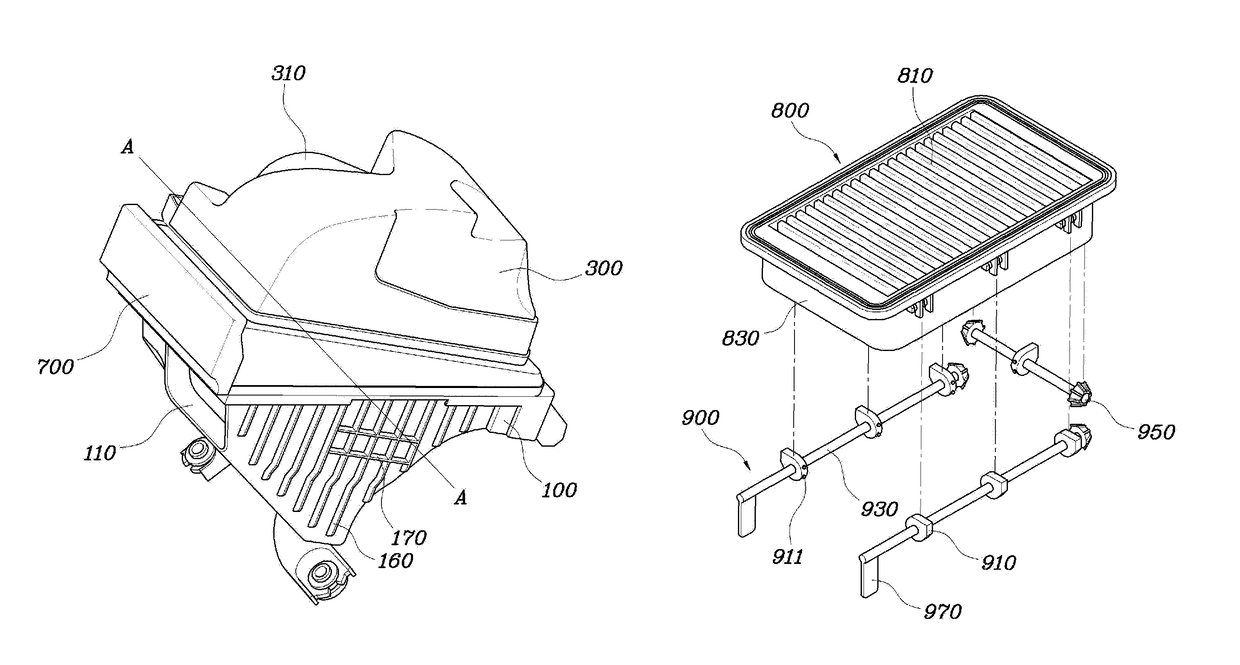

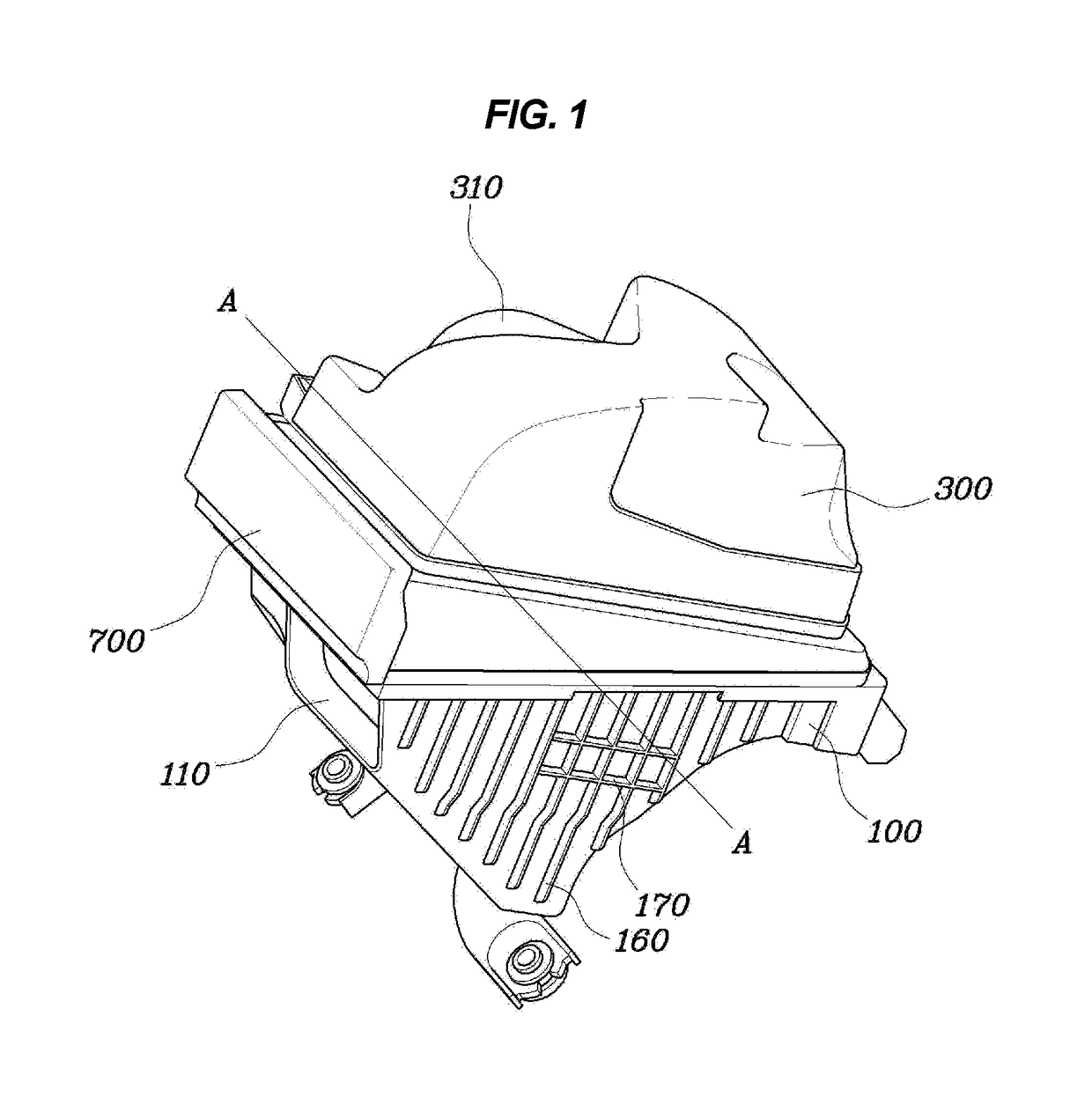

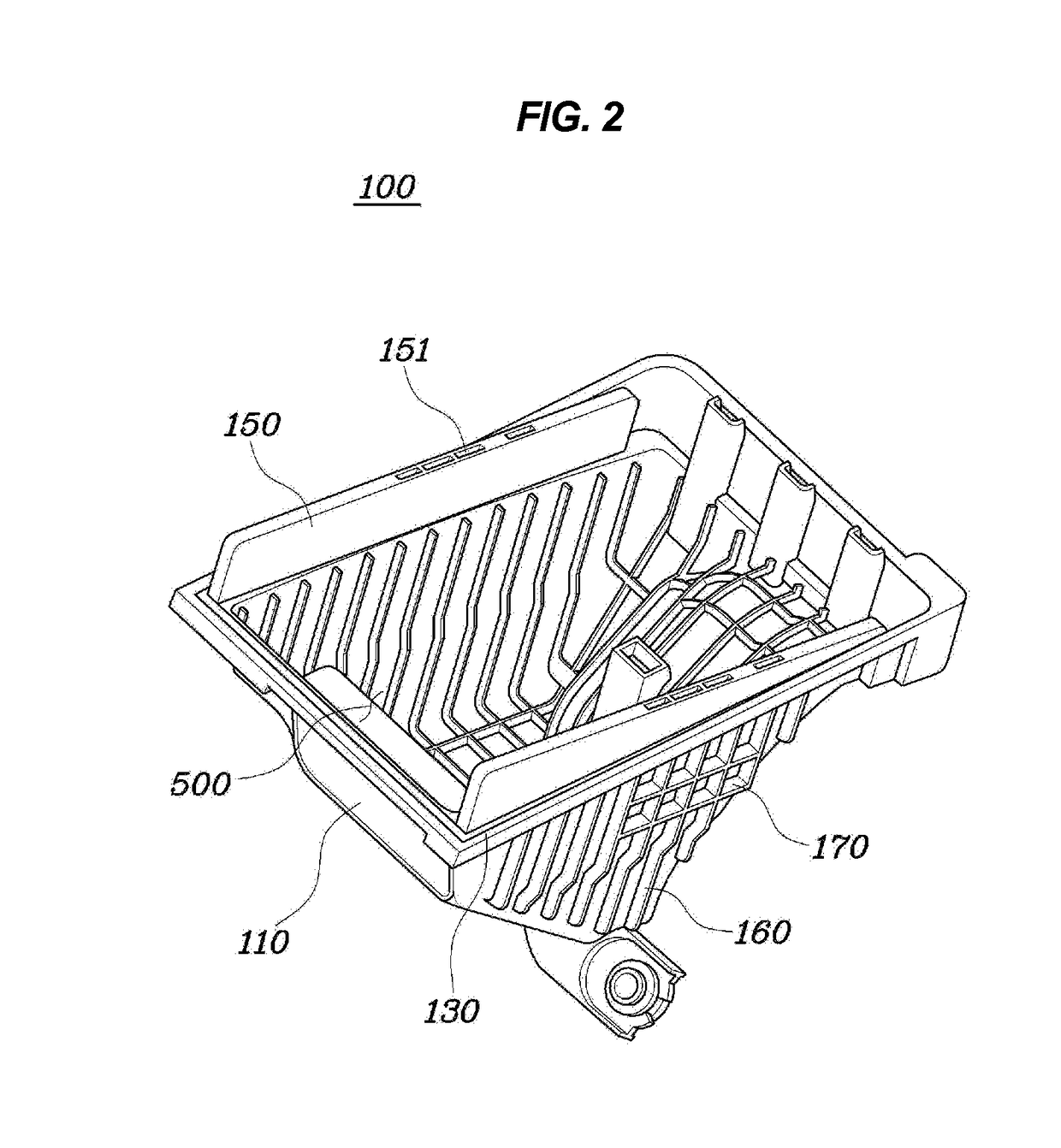

Air cleaner apparatus for vehicle and mold unit for fabricating the same

ActiveUS9599074B2High strengthImprove body strengthDispersed particle filtrationMachines/enginesCouplingAir cleaners

An air cleaner apparatus for a vehicle includes a body defining therein a storage space. The body has an intake port through which air is to be taken in, a laterally-bent support section disposed at an upper portion, and plate-shaped reinforcement members disposed above the storage space and having a predetermined thickness, wherein a cover is coupled to the upper portion of the body, defines therein a storage space, and has a discharge port at one side through which air is to be discharged and a laterally-bent coupling section disposed at a lower side, wherein an opening is provided at front sides of the body and cover, and serves as an entrance through which a filter member is stored or taken out, and wherein a plate-shaped cover is coupled to a front portion of the storage part in order to open or close the storage part.

Owner:HYUNDAI MOTOR CO LTD +1

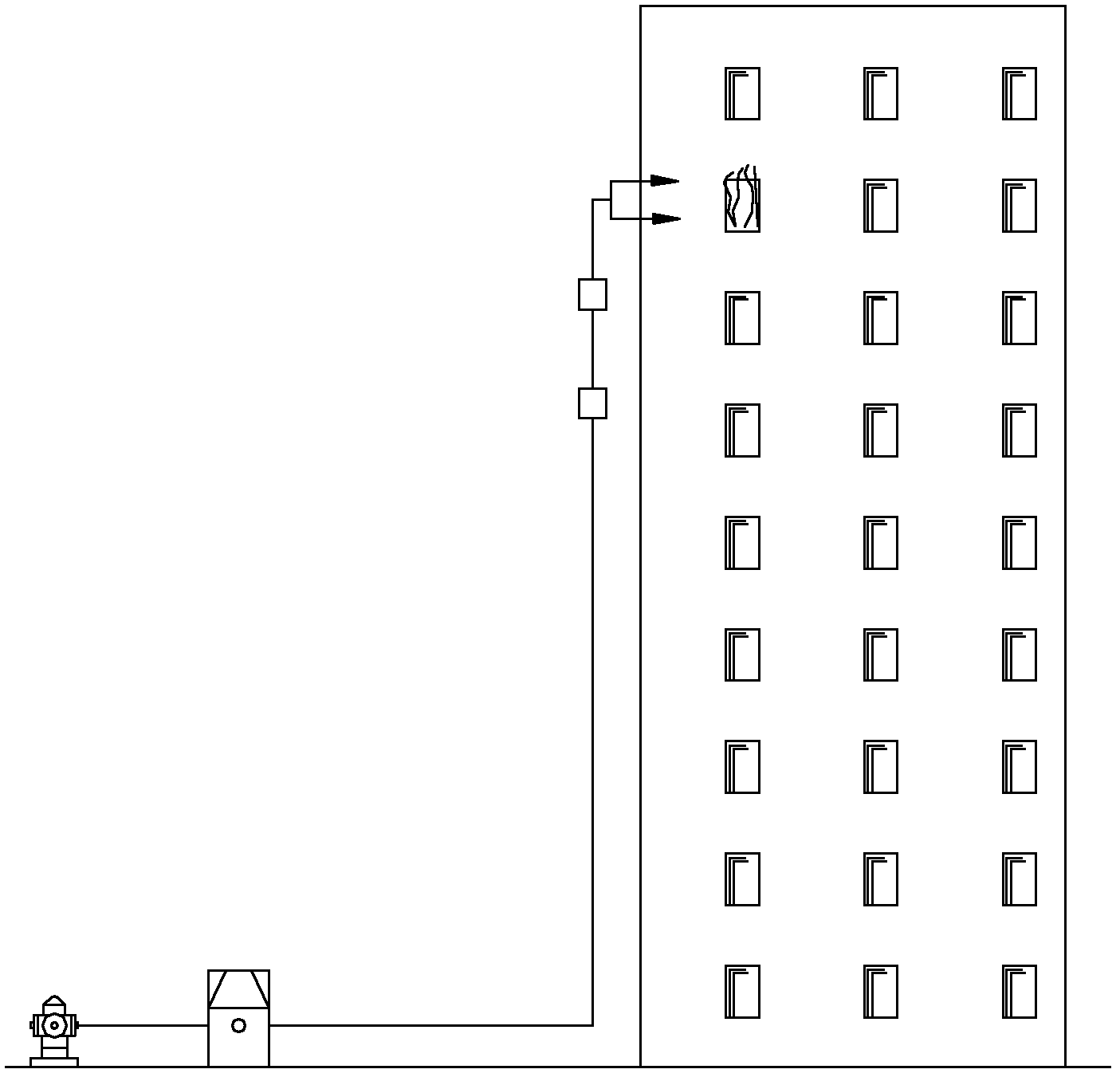

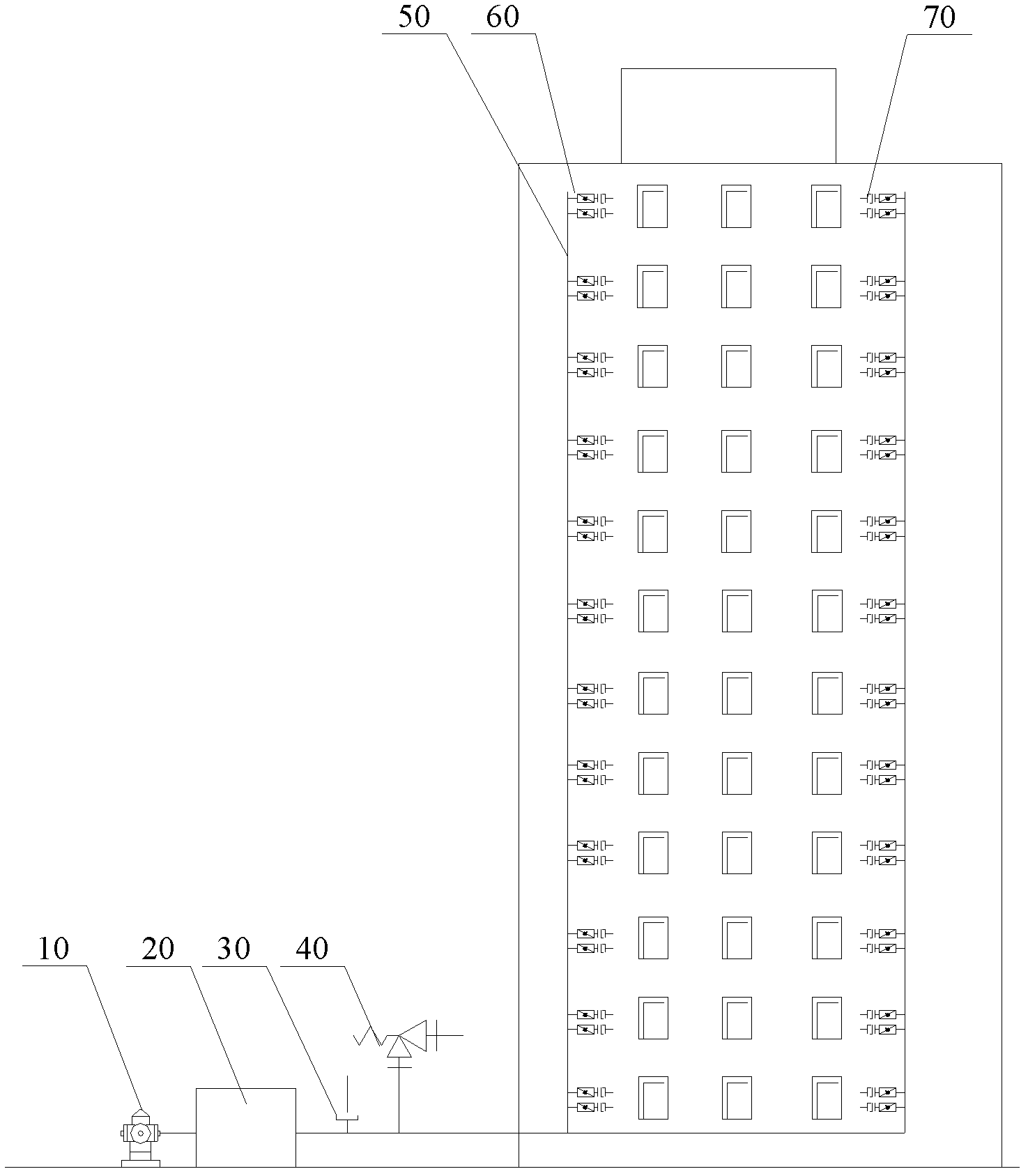

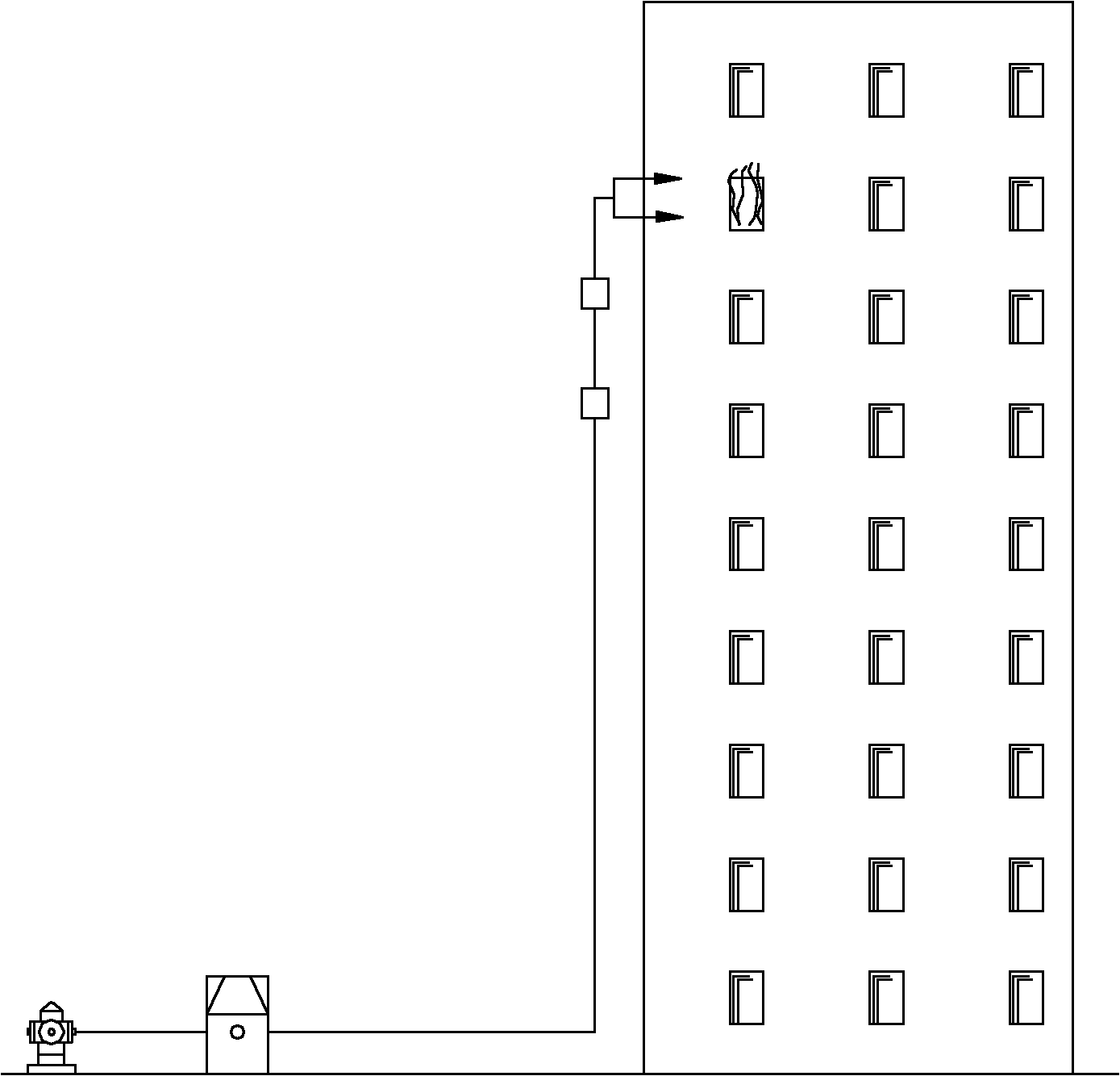

High rise building and fixed fire fighting system thereof

ActiveCN102423526AReliable sealing structurePrevent internal leakageFire rescueControl valvesHydraulic fluid

The invention discloses a high rise building. A plunger pump of the high rise building has two oil cylinders provided with getting hydraulic fluid ports communicated with an inner cavity of cylinder barrel. The getting hydraulic fluid ports are arranged on a cylinder barrel side wall which has a distance from an end of a rodless cavity larger than that from the piston length position of the oil cylinder. The getting hydraulic fluid port of the first oil cylinder is communicated with control oil ports of a first hydraulic control direction valve and a second hydraulic control direction valve so as to drive the first hydraulic control direction valve and the second hydraulic control direction valve to respectively be in a first operation position and a second operation position. The getting hydraulic fluid port of the second oil cylinder is communicated with the control oil ports of the first hydraulic control direction valve and the second hydraulic control direction valve so as to drive the first hydraulic control direction valve and the second hydraulic control direction valve to respectively be in the second operation position and the first operation position. The system of the invention can effectively improve the output flow and the water pressure on the basis of continuous water supply.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

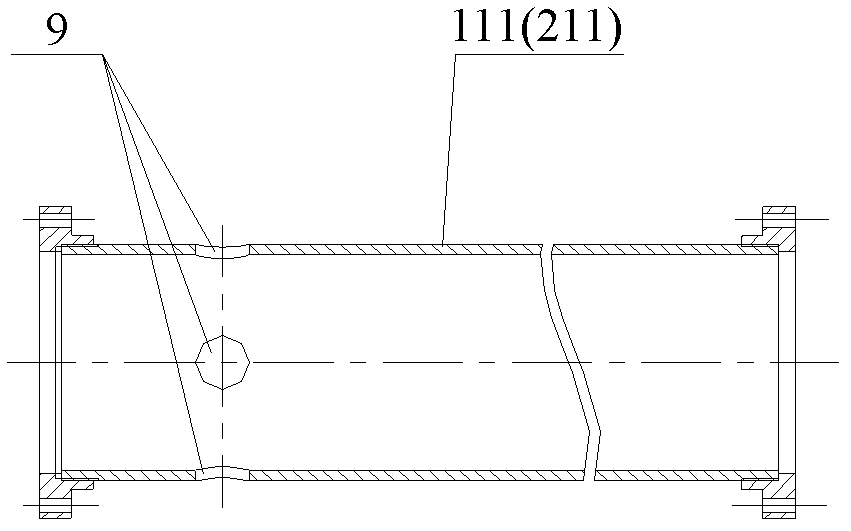

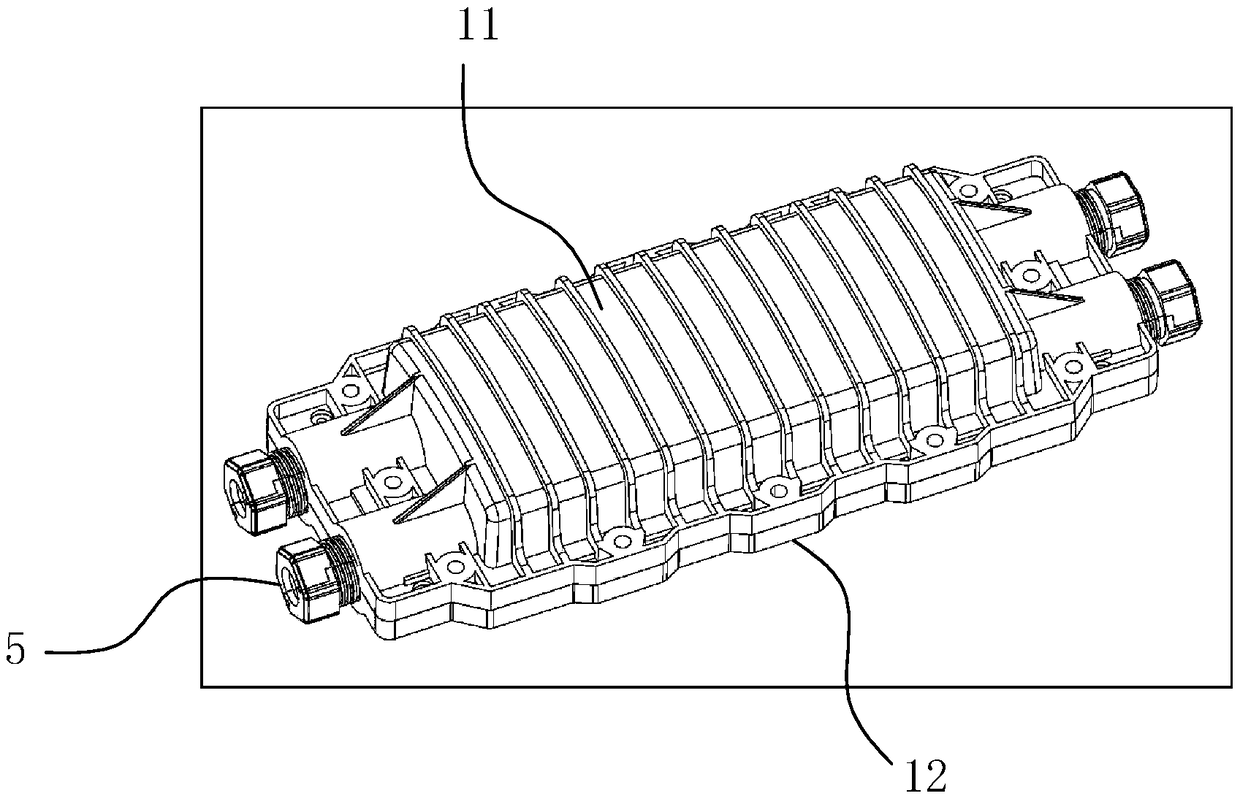

Stepped sealing structure of optical cable connector box

InactiveCN108983380AIncrease the amount of extrusionReduce volumeFibre mechanical structuresEngineeringRetaining ring

The invention discloses a stepped sealing structure of an optical cable connector box. The stepped sealing structure is characterized in that the stepped sealing structure comprises an upper box bodyand a lower box body, the optical cable connector box is provided with an optical cable embedding hole used for allowing an optical cable to penetrate through, the optical cable embedding hole is provided with a retaining ring, an elastic sealing ring and an extrusion member arranged in sequence from the inside to the outside, the retaining ring, the elastic sealing ring and the extrusion member each comprise a penetrating hole used for allowing the optical cable to penetrate through, the retaining ring is fixed in the inner end of the optical cable embedding hole, an end portion of the elastic sealing ring is abutted against the retaining ring, and the retaining ring is formed by a hard inner core and an elastic sealing peripheral member arranged at the periphery of the hard inner core. According to the stepped sealing structure, an area of the optical cable embedding hole of the optical cable connector box adopts stepped sealing, the sealing of the optical cable embedding hole is realized through the elastic sealing ring, the sealing between the upper box body and the lower box body is realized through the elastic sealing peripheral member of the retaining ring, and the sealing structure is more reliable.

Owner:胡肖平

Metal composite vacuum panel with getter and preparation method thereof

ActiveCN103422634BGuaranteed suction capacitySimple sealing structureCovering/liningsThermal insulationComposite plateAir tightness

A metal composite vacuum plate with getters comprises face plates, connecting layers and a vacuum chamber and is characterized in that the face plates are made of metal plates or metal composite plates; the face plates and / or the connecting layers provide additional strength for the vacuum chamber, so that smoothness of the vacuum chamber under atmosphere is guaranteed; the vacuum chamber is a sealed cavity which is formed in the mode that the edges of metal plates are sealed in a welding mode under normal pressure and the openings of the metal plates are sealed by high temperature under vacuum; the opening sealing operation is conducted as follows: an extraction opening preformed in the vacuum chamber is automatically sealed in a vacuum furnace by low-temperature welding fluxes on the basis of the liquid sealing principle; upholders and the getters are arranged in the vacuum chamber. A method for manufacturing the metal composite vacuum plate with the getters is simple in process, the prepared metal composite vacuum plate with the getters can overcome the defects of an existing heat preservation plate and an existing vacuum heat insulation plate, the air tightness of the vacuum chamber of the metal composite vacuum plate with the getters can be effectively guaranteed, the service life of the metal composite vacuum plate with the getters is prolonged, and strength, heat and sound insulation performance and fireproof performance of the metal composite vacuum plate with the getters can be improved.

Owner:江苏富盈汇林达建筑科技有限公司

Low-temperature insulator and manufacturing method thereof

InactiveCN102723150AGuaranteed indicators of vacuumImprove long-term operational reliabilitySuperconductors/hyperconductorsSuperconductor devicesIndiumBiochemical engineering

The invention relates to a sealing device and a manufacturing method thereof, and particularly relates to a low-temperature insulator and a manufacturing method thereof. The invention aims to solve the problems that the low-temperature sealing performance of the low-temperature insulator is likely to be affected by tensile stress, bending stress and torsional stress in all warm areas, and the reliability of the insulator after repeated cooling and heat cycle is low. A sleeve is sleeved on the outer surface of a main insulating tube; an insulating pressure plate and an adapter tube are arranged at each end of the main insulating tube; each insulating pressure plate is provided with an axial through hole and four pull rod through holes; each adapter tube is provided with a ledge, passes through the axial through hole on the corresponding insulating pressure plate and is fixedly connected inside the main insulating tube; the ledge on each adapter tube is attached to the main insulating tube; the insides of the two adapter tubes and the main insulating tube are communicated to form an airflow passage; four tensioning screws are arranged between the two insulating pressure plates; and an indium ring is arranged between the main insulating tube and the ledge of the adapter tube. The low-temperature insulator is used for low-temperature pipelines.

Owner:HARBIN INST OF TECH

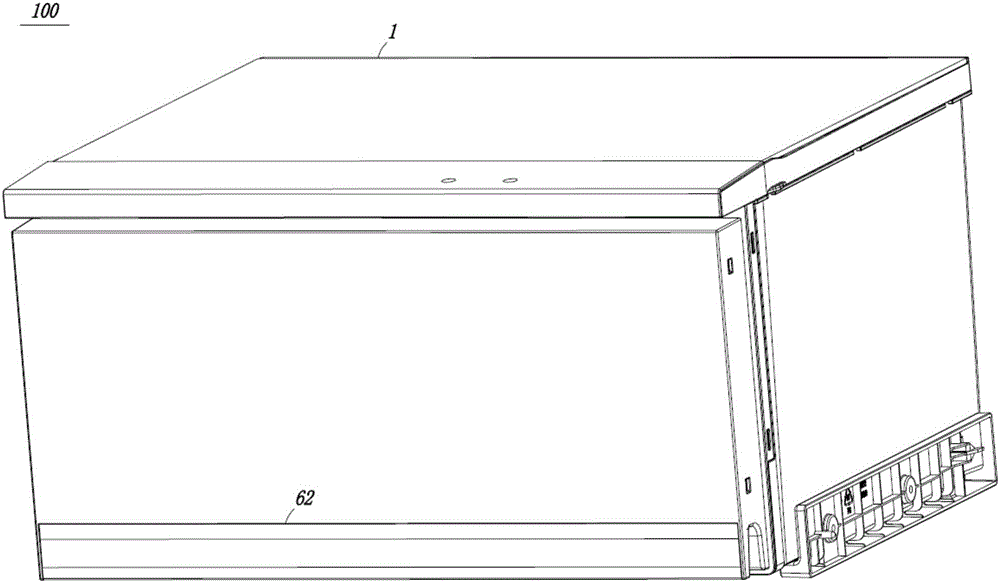

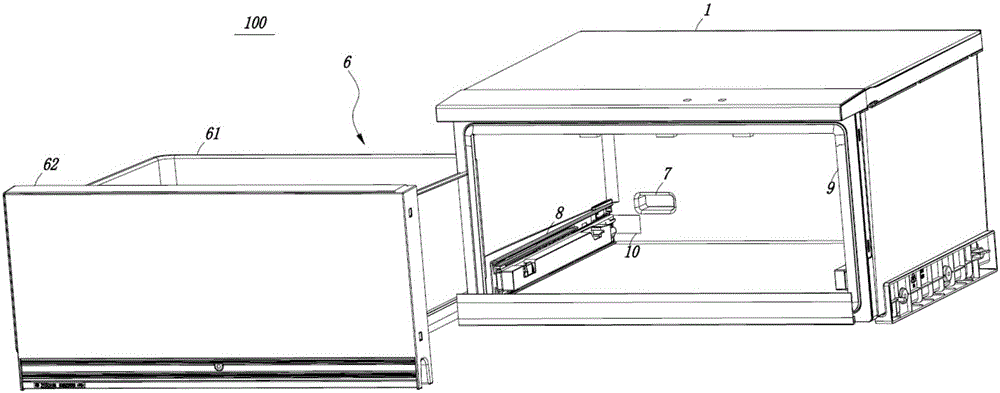

Constant-temperature compartment of refrigerator

InactiveCN106052256AReliable sealing structurePrevent overflowLighting and heating apparatusDomestic refrigeratorsCold airRefrigerated temperature

The invention discloses a constant-temperature compartment of a refrigerator. The constant-temperature compartment comprises a compartment body, wherein a storage space with an opening in one side is defined in the compartment body; the constant-temperature compartment further comprises a drawer; the drawer is connected with the compartment body through sliding rail mechanisms, and can move between a first position where an opening of the compartment body is closed and a second position where the opening of the compartment body is opened; first magnets are arranged on one side of the back part of the compartment body; second magnets are arranged on one side of the back part of the drawer; and the polarity of the first magnets is opposite to that of the second magnets, so that acting force that drives the drawer to move from the second position to the first position is supplied to the drawer. According to the constant-temperature compartment of the refrigerator, due to the attracting force of the first and second magnets, a sealing structure between the drawer and the compartment body is more reliable, so that the phenomenon that the efficiency of the refrigerator is reduced because cold air escapes from a fit clearance between the drawer and the compartment body is prevented.

Owner:HAIER SMART HOME CO LTD

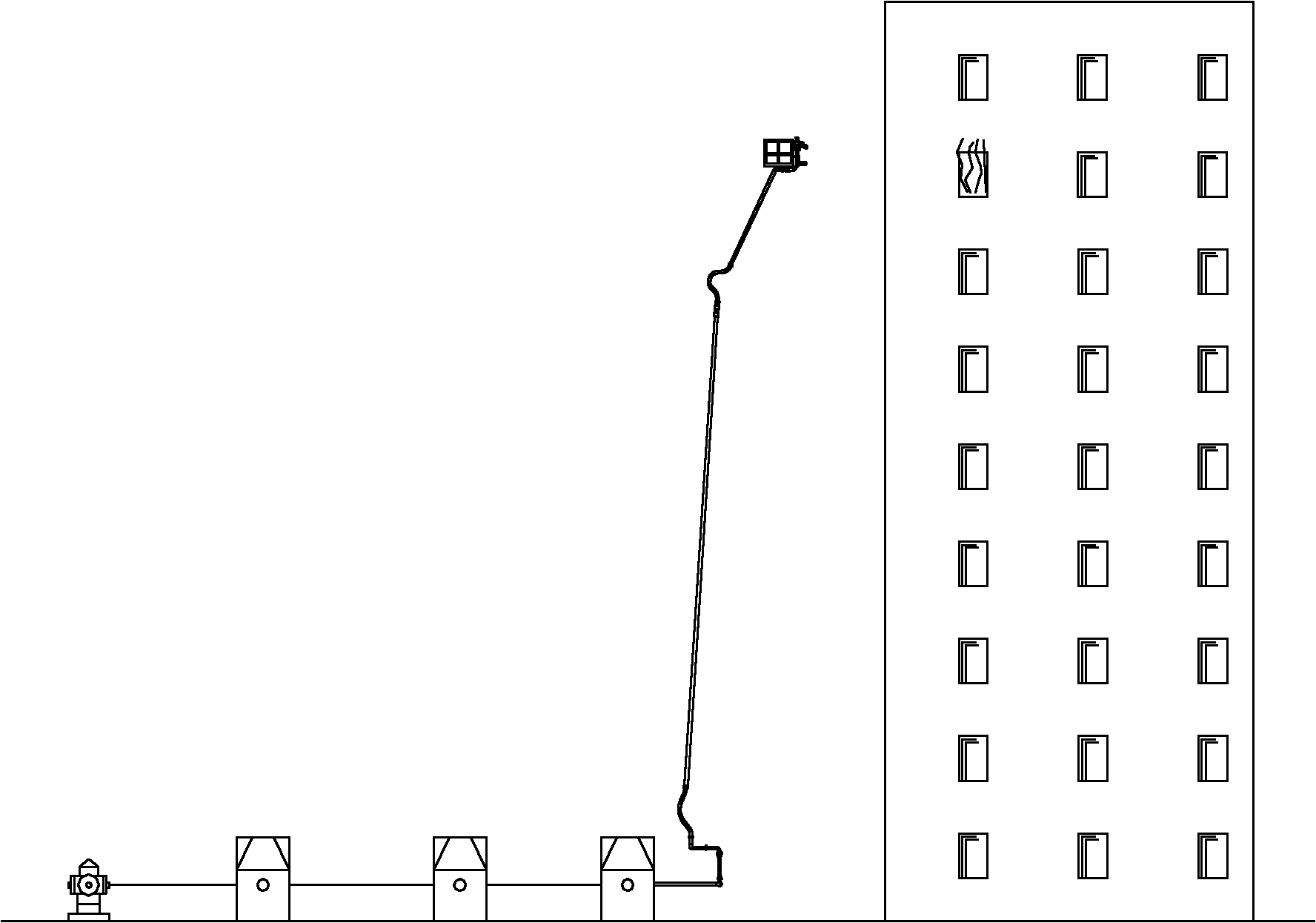

Fire extinguishing system and fire engine containing the same

InactiveCN102423521AReliable sealing structurePrevent internal leakageFire rescueEngineeringControl valves

The invention discloses a fire extinguishing system, comprising a fire extinguishing medium pot and a plunger pump for pumping the fire extinguishing medium. The plunger pump comprises two plunger groups consisting of a medium cylinder and an oil cylinder; a medium cylinder piston and an oil cylinder piston of each plunger group conduct synchronous displacement; and a flow passage port of a cylinder barrel of each medium cylinder is communicatively provided with an unidirectional conductive inflow non return valve from outside to a cavity of the cylinder barrel and an unidirectional conductive outflow non return valve from the cavity of the cylinder barrel to an external outlet; the inflow non return valve communicates with the fire extinguishing medium pot; the two oil cylinders are configured in a way of alternative telescoping by controlling of a control valve. The plunger pump of the present invention employs two oil cylinders for alternative advancing and recession to drive alternative movements of the two medium cylinder pistons, so as to realize switching between two working states respectively. Compared with a prior art, the fire extinguishing system of the invention can effectively increase an output flow and water usage pressure on the premise of continuous non-intermittent water supply. Based on the fire extinguishing system, the invention also provides a fire engine containing the fire extinguishing system.

Owner:XUZHOU HEAVY MASCH CO LTD

Novel pressure regulating valve structure

PendingCN109519589ASimple structureImprove leakageOperating means/releasing devices for valvesEqualizing valvesSpring forceEngineering

The invention belongs to the technical field of diesel oil and natural gas dual fuel injection systems, and particularly relates to a novel pressure regulating valve structure. The novel pressure regulating valve structure comprises a regulating valve body, a piston, a valve joint and a valve seat. The piston is arranged in the regulating valve body. A piston gas cavity is formed by the piston andthe regulating valve body. A pressure relief gas channel is arranged at the bottom of the regulating valve body. The valve seat is arranged at the position, corresponding to the pressure relief gas channel, in the regulating valve body. A valve rod is arranged in the piston. The valve seat presses a steel ball onto a regulating valve body sealing conic face of the regulating valve body through spring force of a valve rod spring. The valve joint is arranged on the regulating valve body and is provided with an oil inlet hole. An oil cavity is formed between the valve joint and the piston. The novel pressure regulating valve structure has the beneficial effects that the structure is simple; the sealing structure is effective and reliable; the problem of serious leaking of current pressure regulating valve products is solved; the machining difficulty is reduced; and arrangement complexity of an oil channel and the gas channel is reduced.

Owner:英嘉动力科技无锡有限公司

Static sealing structure and pressure vessel with static sealing structure

PendingCN111927951AThe molding process is safe and reliableReliable sealing structureEngine sealsPressure vesselsHead (vessel)Physics

The invention provides a static sealing structure and a pressure vessel with the static sealing structure. The pressure vessel comprises a vessel shell, a vessel cavity formed by a cavity inside the vessel shell and a groove structure opened at the top of the vessel shell and in communication with the vessel cavity; and the diameter of the groove structure in the horizontal direction is larger than that of the vessel cavity in the horizontal direction. The static sealing structure is assembled in the groove structure and comprises a sealing end and a sealing assembly, the sealing end comprisesa head and a sealing shaft rod connected with the head, the sealing assembly comprises a sealing ring and a sealing check ring which sleeve the sealing shaft rod part in an up-and-down contact manner, so that functional partitioning is achieved, and if a workpiece in a functional area goes wrong, a new workpiece can be used for replacement; the whole pressure vessel does not need to be scrapped,and the use cost is reduced.

Owner:INST OF GEOLOGY CHINA EARTHQUAKE ADMINISTRATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com