Non-contact seal device for high-speed shaft of gear speed reducer

A gear reduction, non-contact technology, applied in the direction of engine seals, transmission parts, belts/chains/gears, etc., can solve the problems of heavy replacement workload, long maintenance time, and shutdown losses, etc., to achieve low cost, The effect of avoiding downtime loss and reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

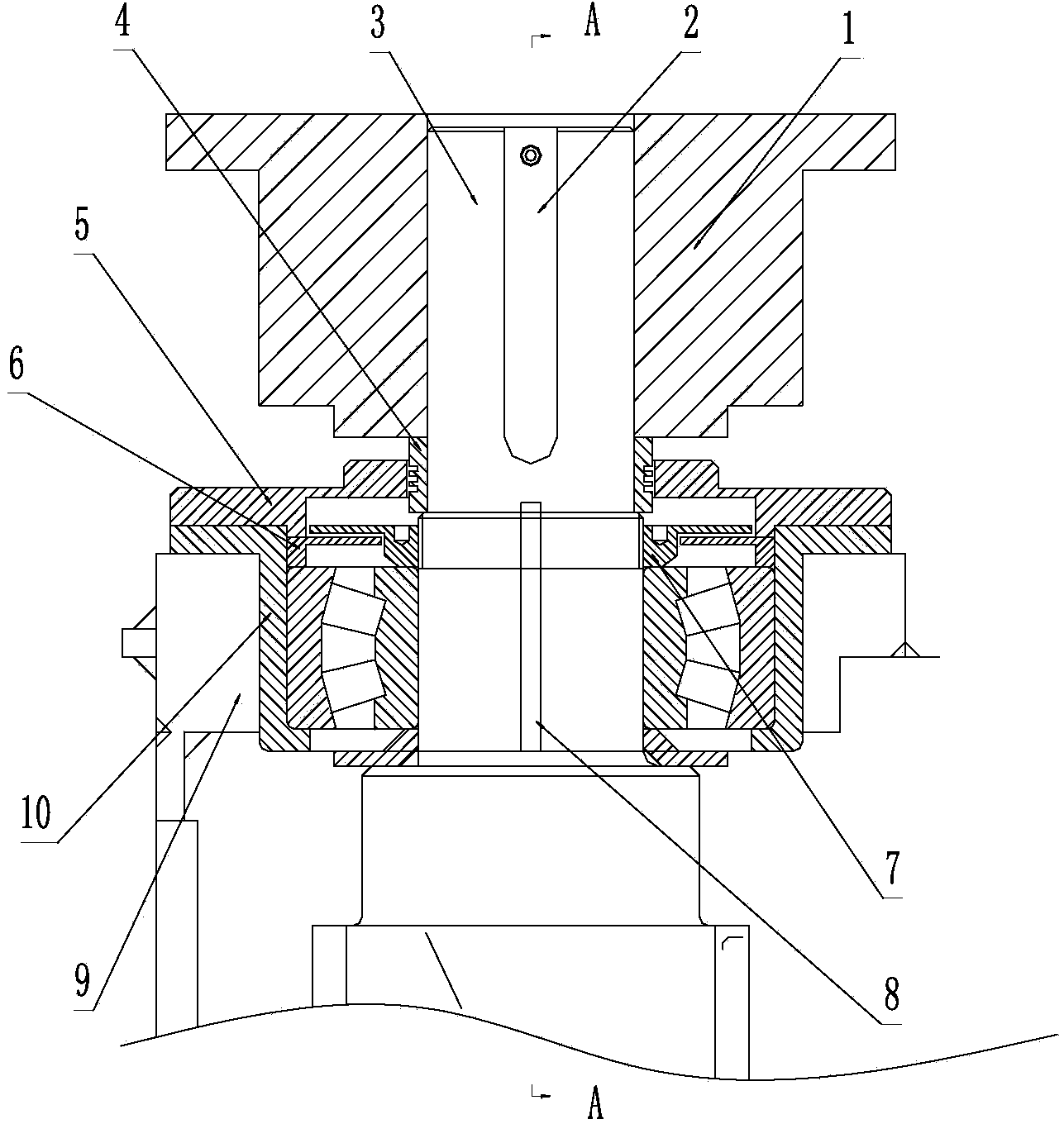

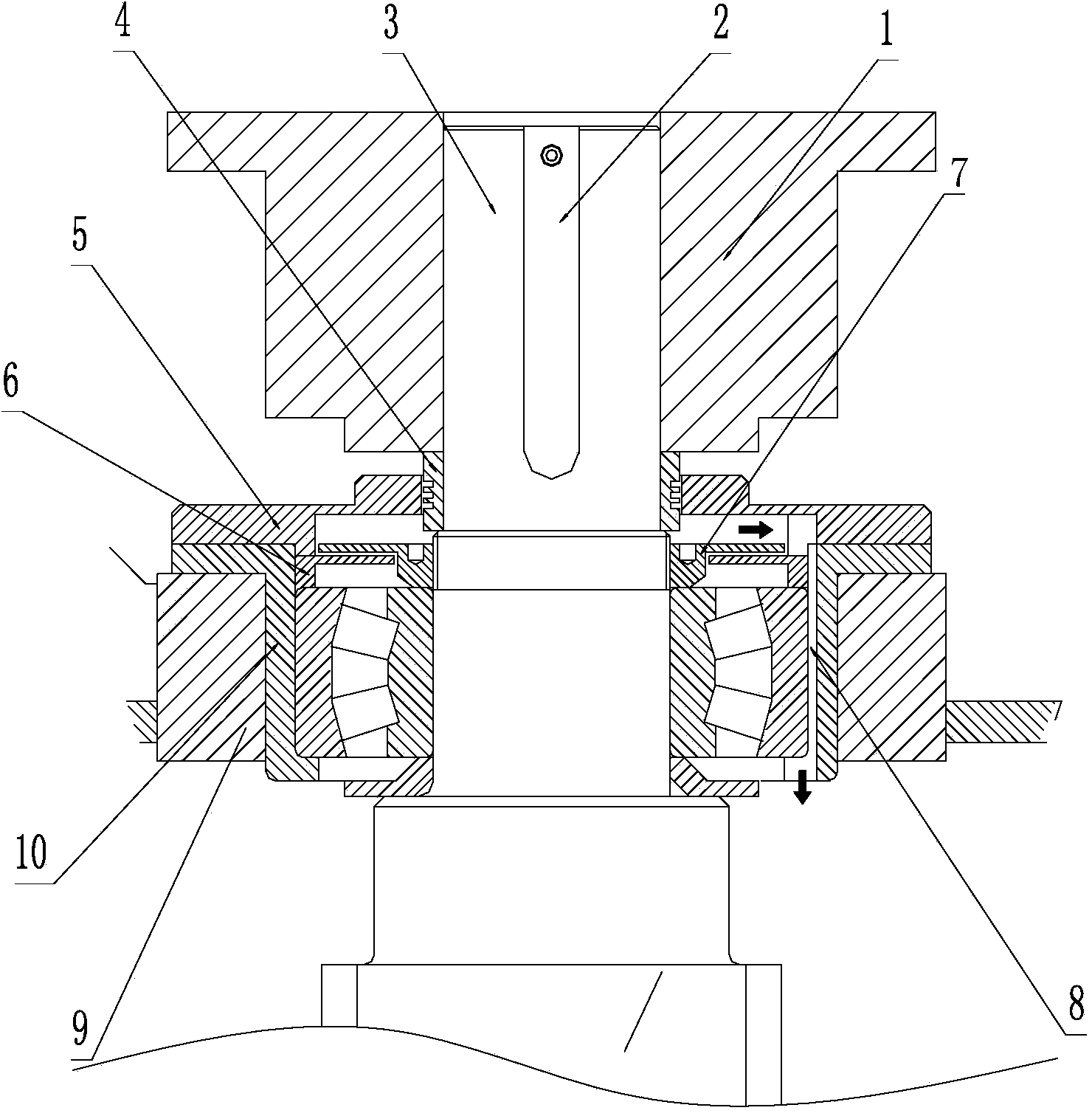

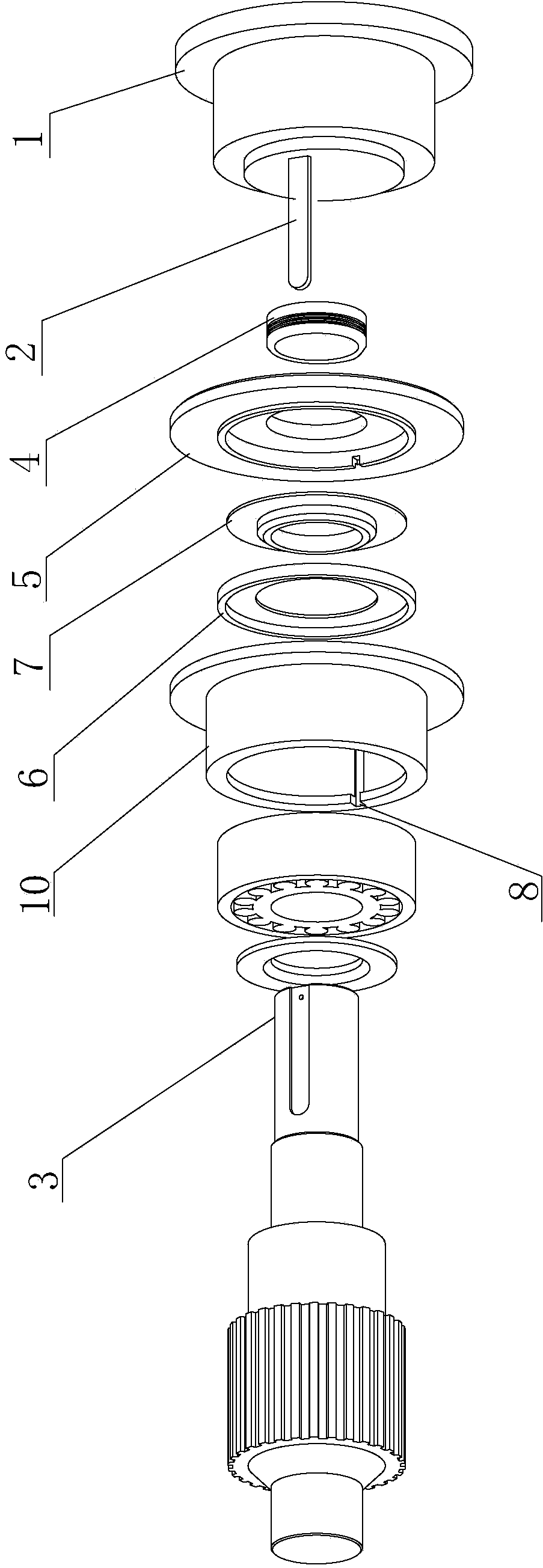

[0017] Embodiment: The non-contact sealing device for the high-speed shaft of the gear reducer in this embodiment is as follows figure 1 and figure 2 As shown, it includes half coupling 1, key 2, high-speed shaft 3, sealing ring 4, transparent cover 5, static ring 6, moving ring 7, oil drain groove 8, gear reducer casing 9 and bearing sleeve 10. The coupling half 1 is fixedly connected to the input end of the high-speed shaft 3 through the key 2, and the bearing sleeve 10 is fixed on the gear reducer casing 9. The high-speed shaft 3 passes through the opening on the transparent cover 3, and the outer cylindrical surface of the sealing ring 4 has multiple annular grooves, and is mounted on the high-speed shaft 3 by interference fit or transition fit. The through cover 5 is fastened to the outer end surface of the bearing sleeve 10 by bolts, and the openings on the sealing ring 4 and the through cover 5 have a small radial fit gap, forming a radial labyrinth seal structure. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com