Online detecting device and method for turbocharger

A turbocharger and testing device technology, which is applied to measuring devices, testing of machine/structural components, instruments, etc., can solve the problem of time-consuming, unsaleable turbocharger cleanliness, and inability to guarantee turbocharger qualification, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

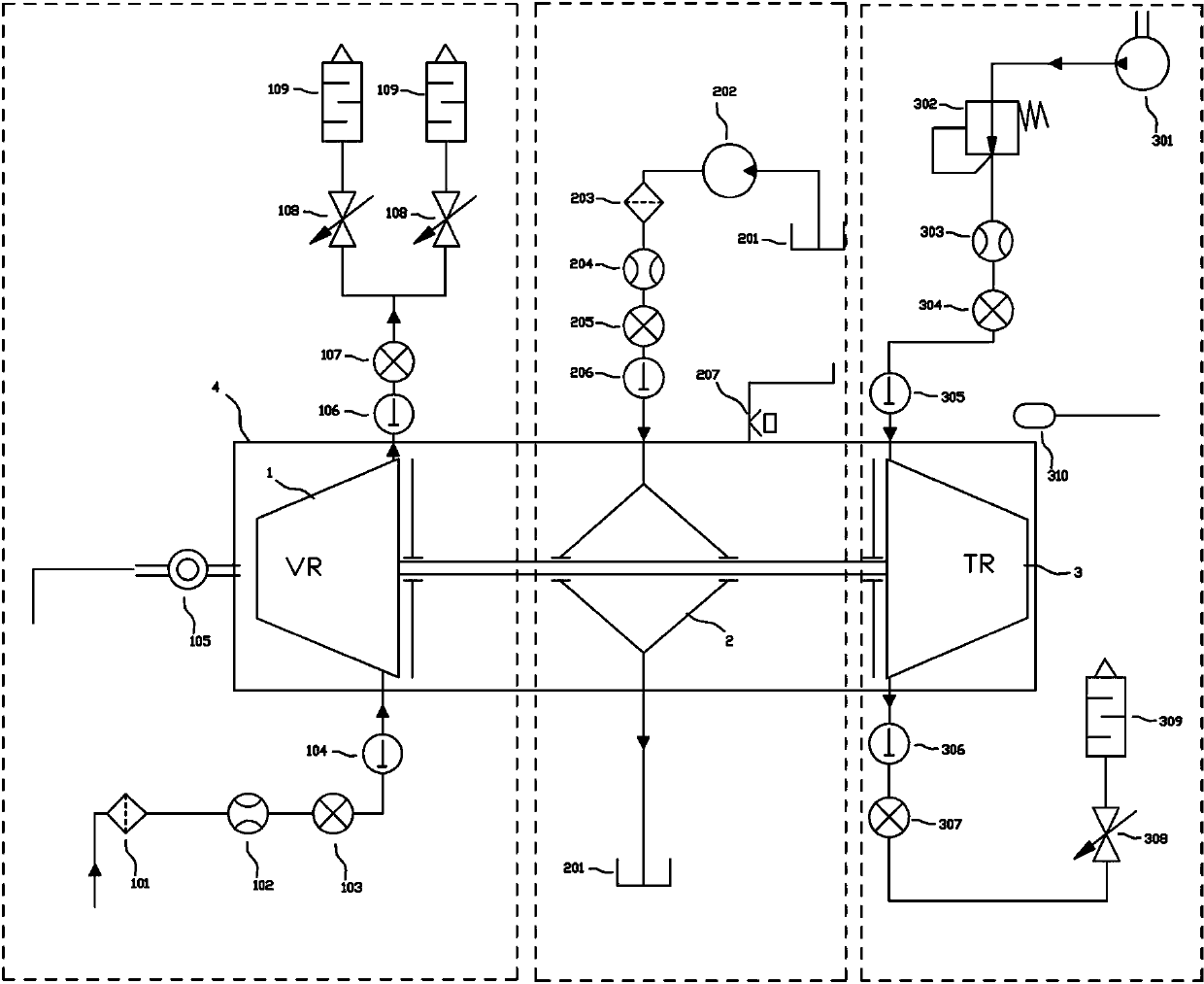

[0033] Depend on figure 1As shown, the turbocharger online detection device of the present invention includes a bearing lubrication system, which includes a bearing lubrication system, a compressor end test system, a turbine end test system, a vibration sensor, a noise sensor and a speed sensor.

[0034] The bearing lubrication system includes a lubricating oil tank 201, an oil inlet pipe connected at one end to the outlet of the lubricating oil tank 201 and the other end to the lubricating oil inlet of the turbocharger, one end connected to the lubricating oil outlet of the turbocharger and the other end to the lubricating oil The oil return pipe connected to the inlet of the oil tank 201 is provided with a lubricating oil pump 202 , a lubricating oil flow measuring instrument 204 , a third pressure sensor 205 and a third temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com