High rise building and fixed fire fighting system thereof

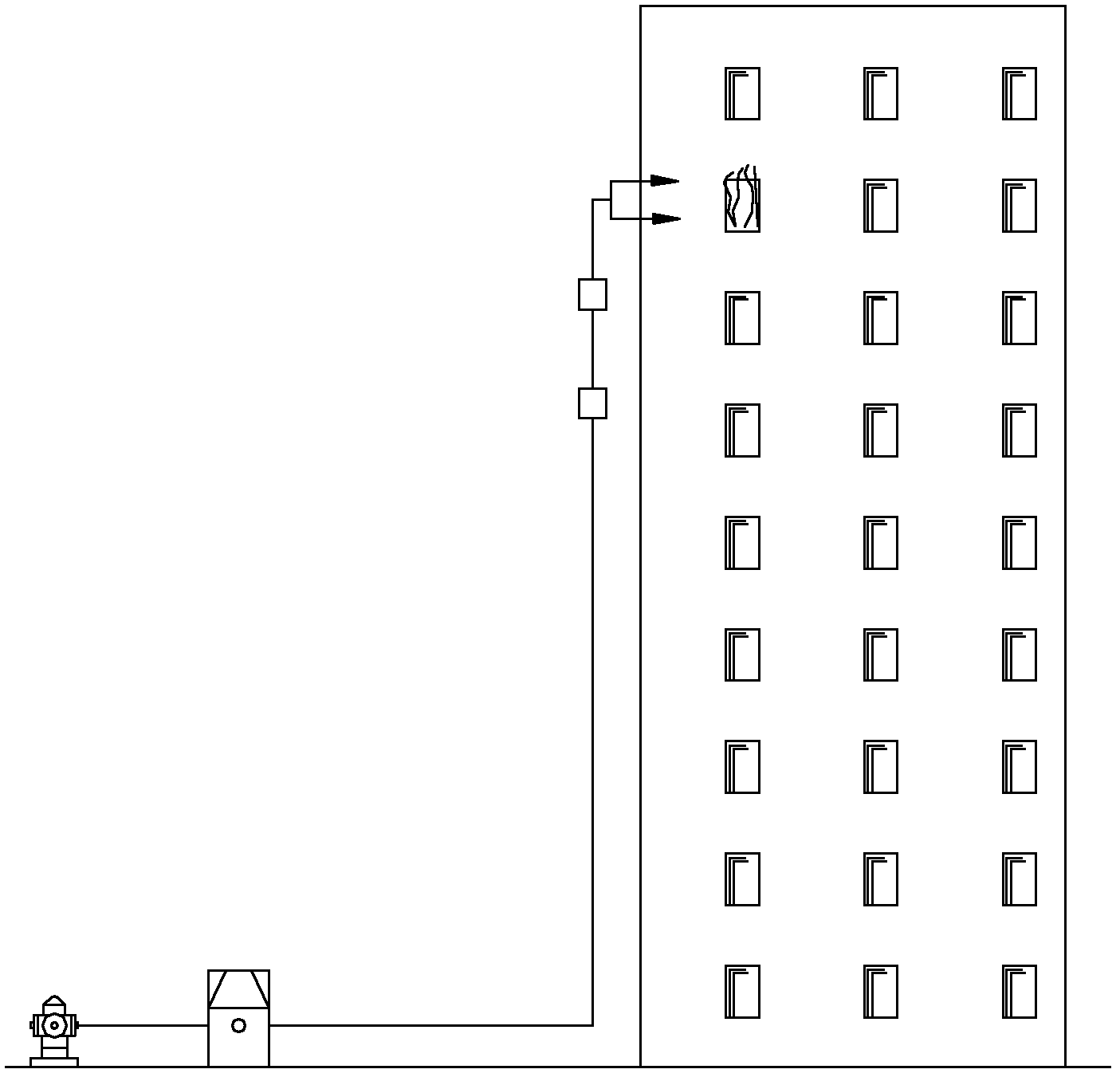

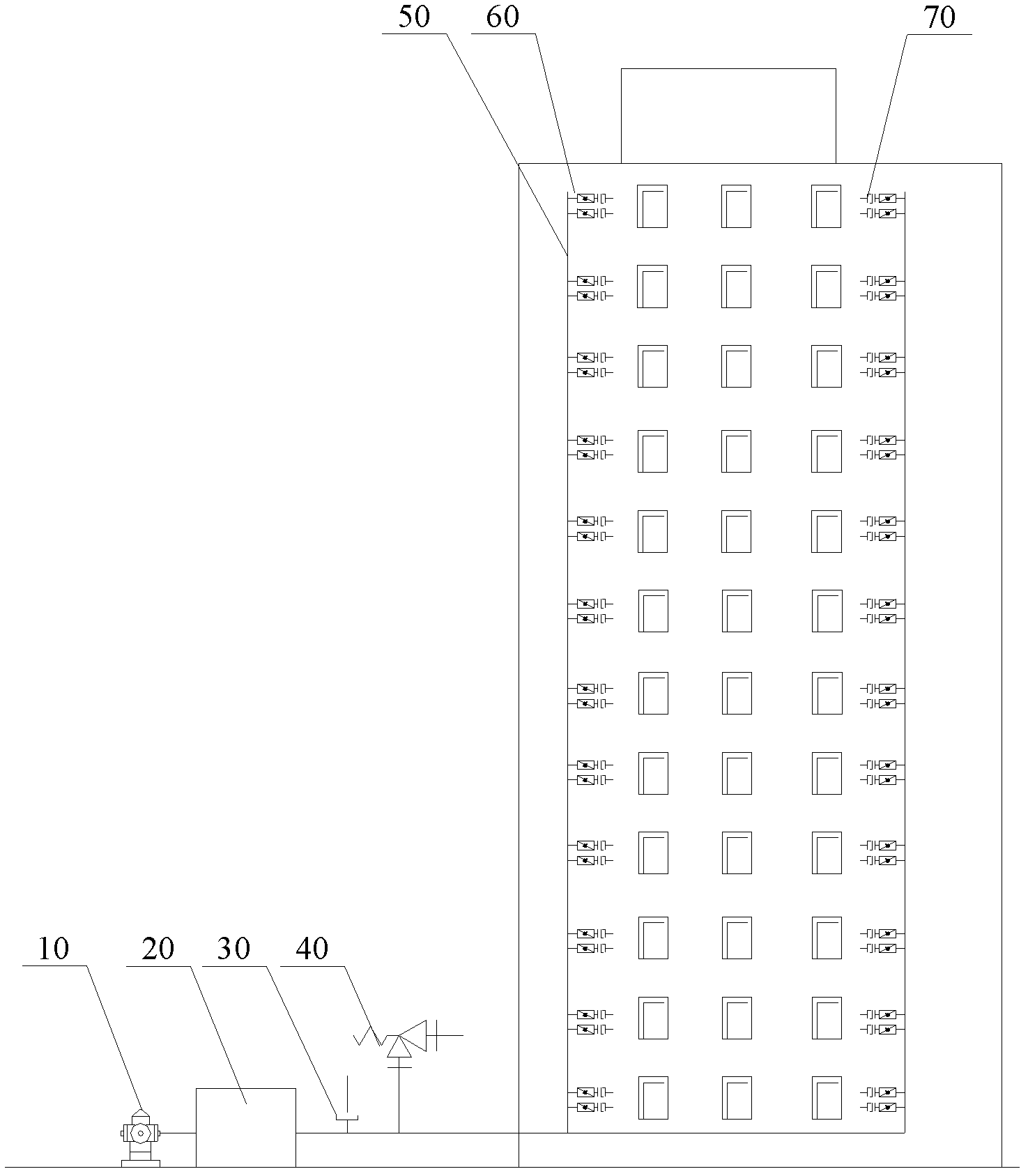

A technology for high-rise buildings and firefighting systems, applied in fire rescue and other directions, can solve problems such as insufficient water supply pressure, inability to effectively extinguish fires, and inability of fixed firefighting facilities to effectively meet the water consumption for firefighting, and achieve the effect of preventing internal leakage and optimizing design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

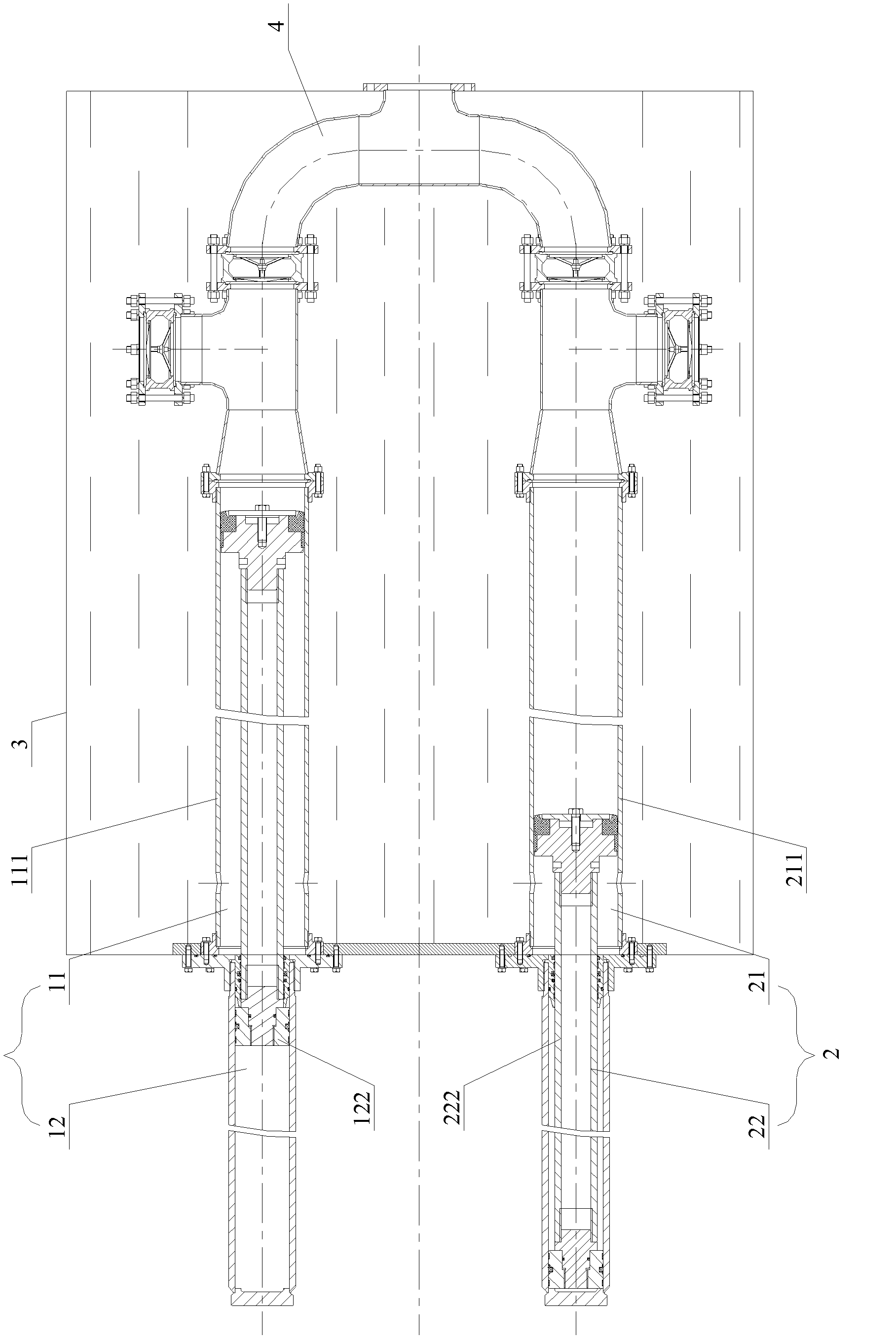

[0032] The core of the present invention is to provide a hydraulically controlled double plunger pump with optimized structure, which includes two plunger groups composed of a medium cylinder and an oil cylinder. The medium cylinder piston and the oil cylinder piston of each plunger group move synchronously with each other. The flow ports of the medium cylinder barrel are connected with an inflow check valve unidirectionally communicated from the outside to the inner cavity of the cylinder barrel, and an outflow check valve unidirectionally communicated from the inner cavity of the cylinder barrel to the outer outflow port; two The cylinder is configured to expand and contract alternately under the control of the control valve. Compared with the prior art, the present invention can reliably increase the output pressure and flow rate of the pump, thereby meeting the requirements for fire fighting and extinguishing of super high-rise buildings.

[0033] Hereinafter, this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com