Patents

Literature

71results about How to "Increase output flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

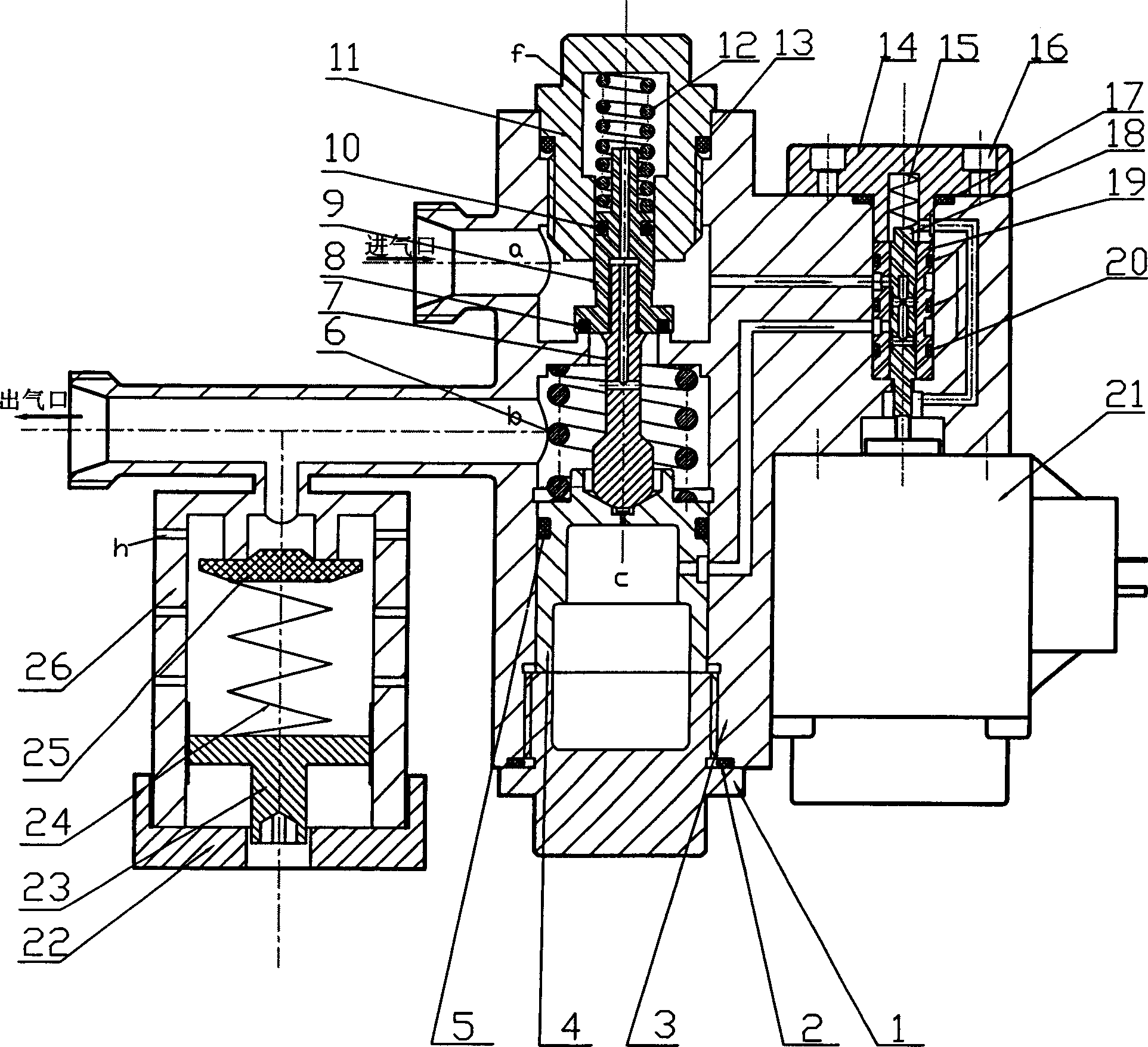

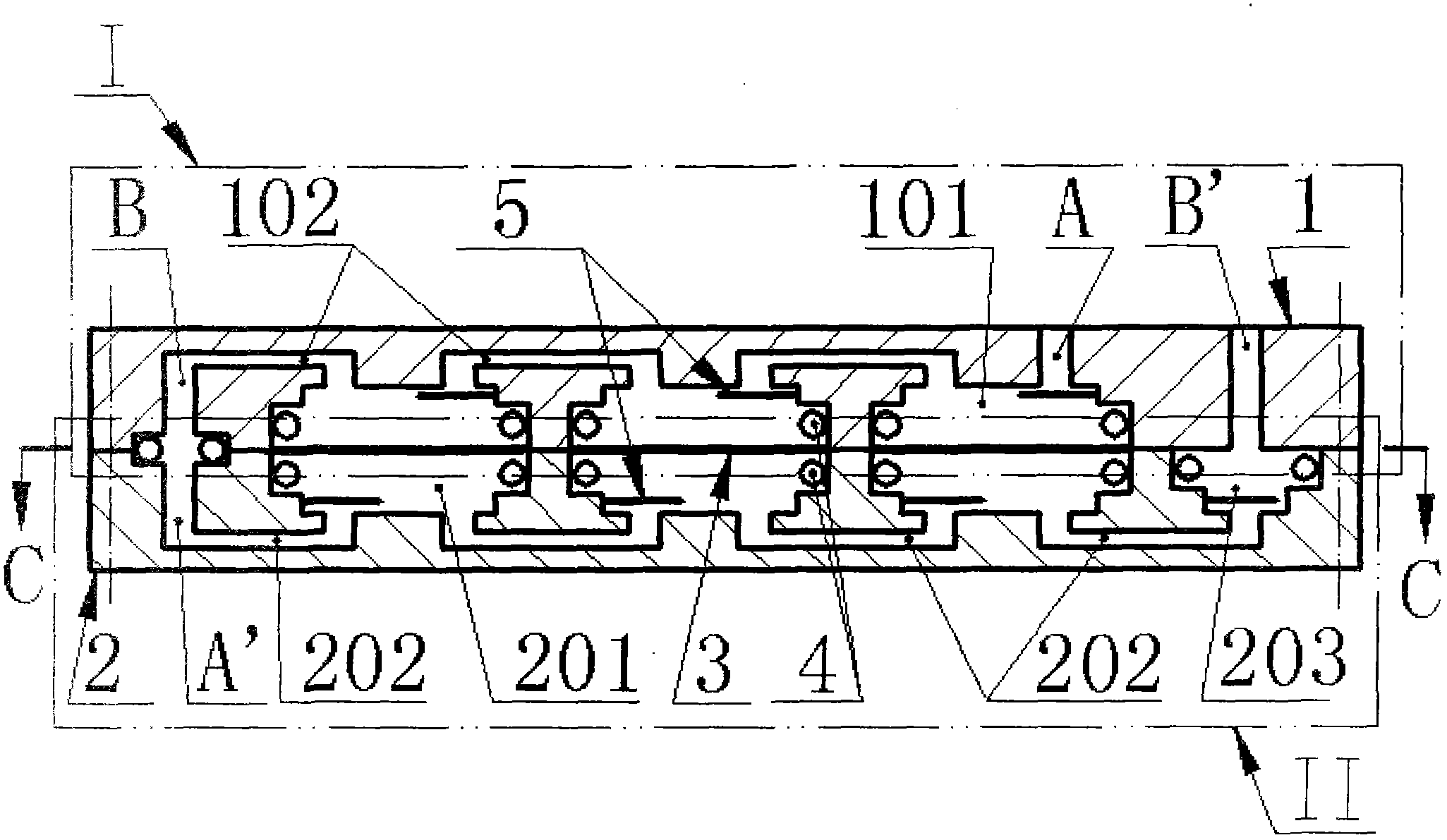

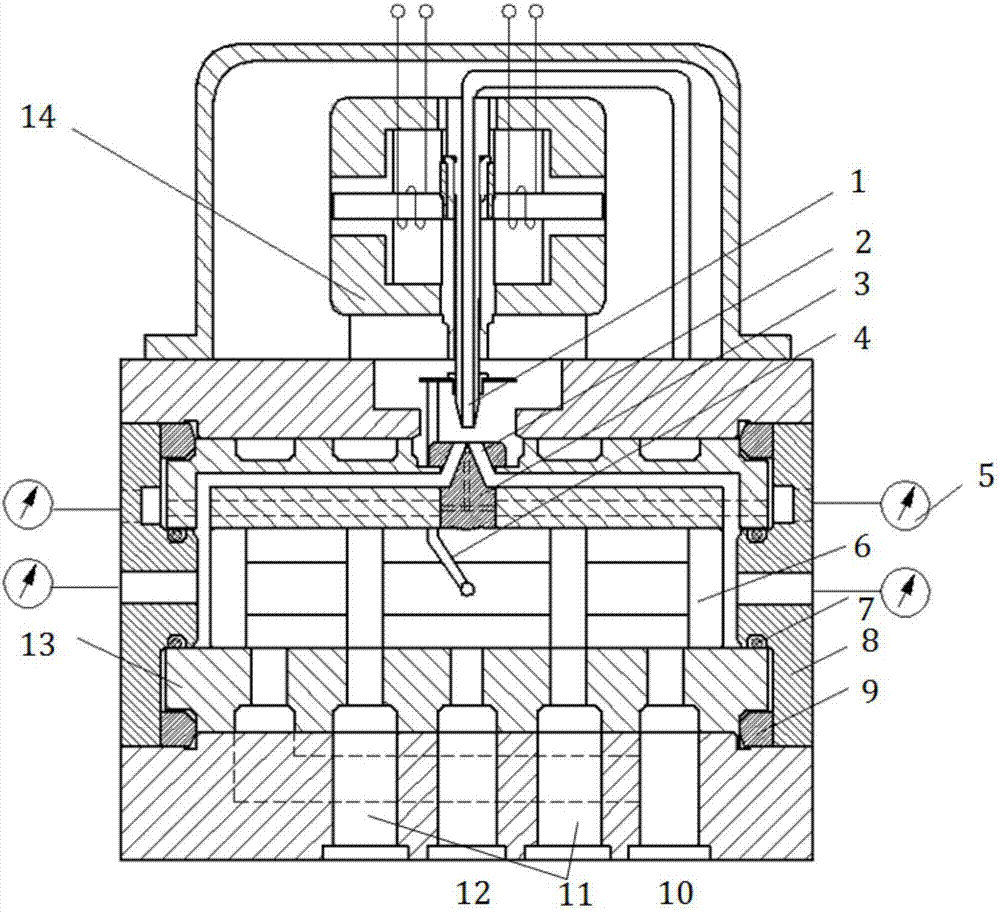

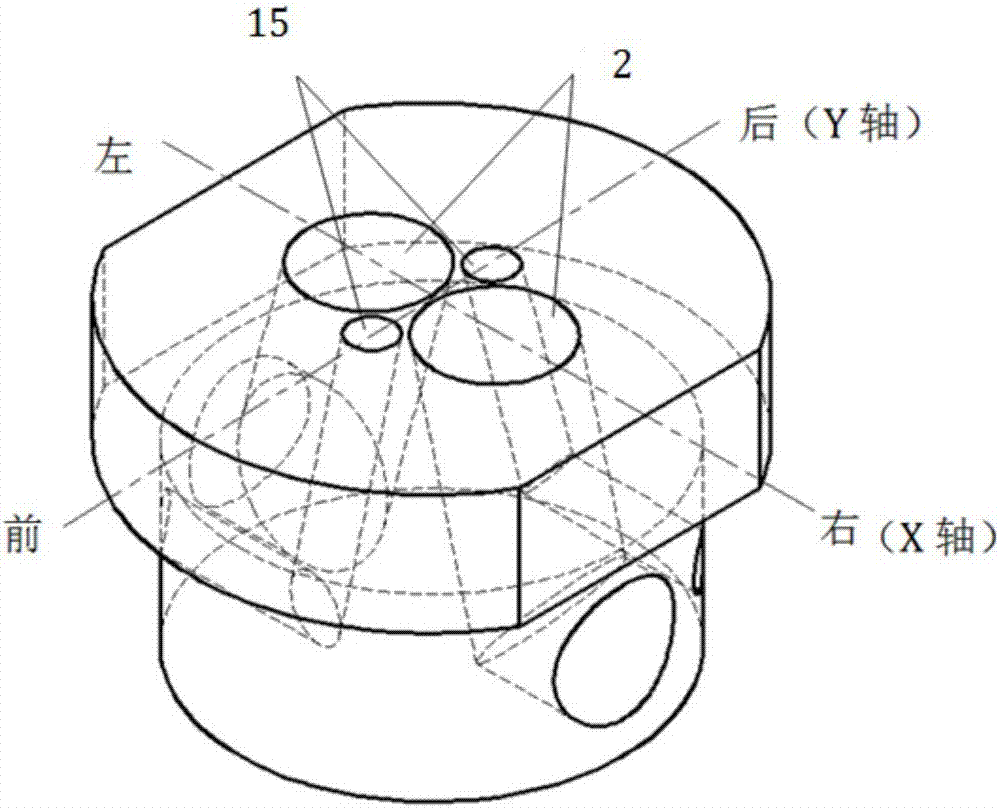

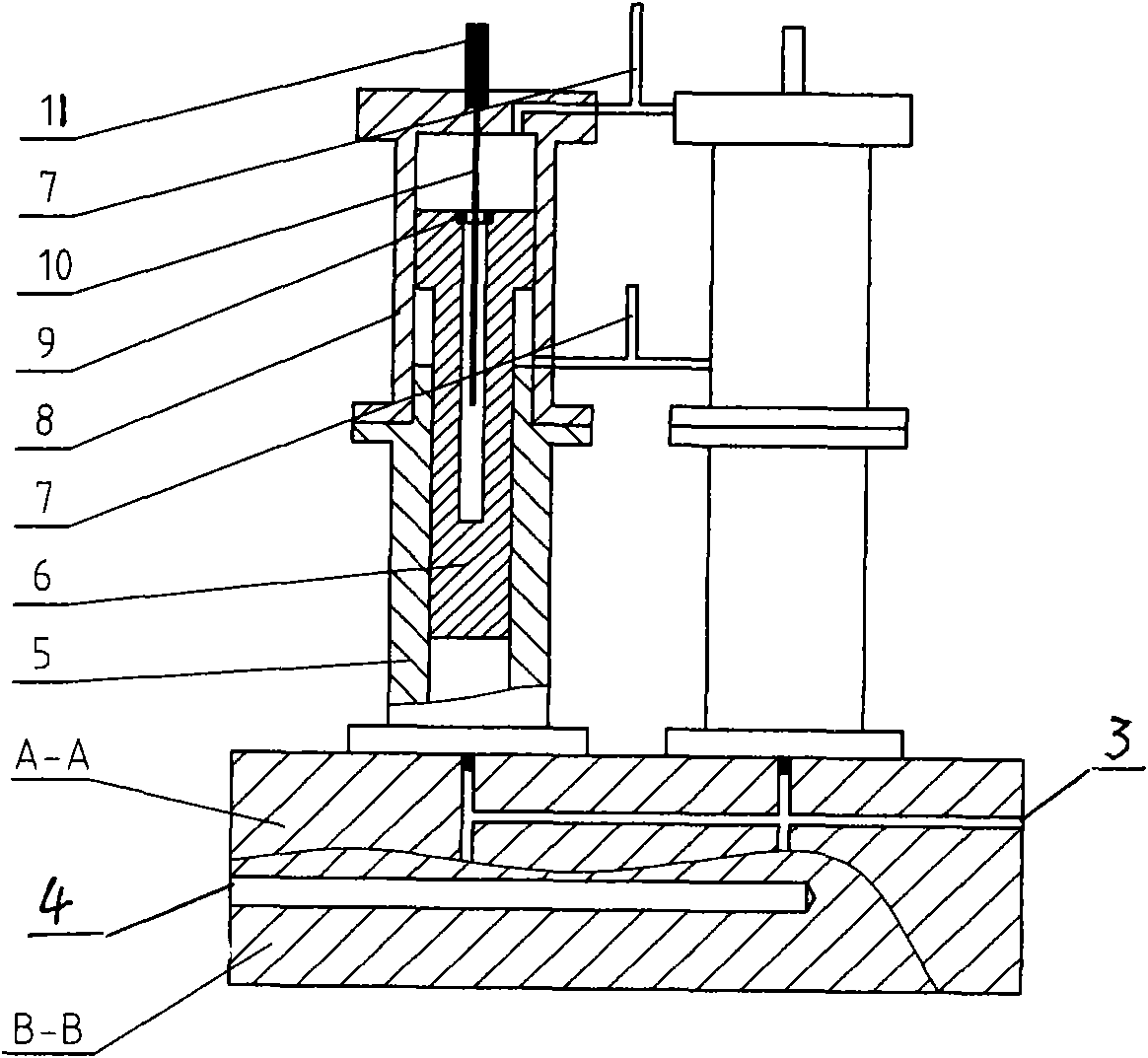

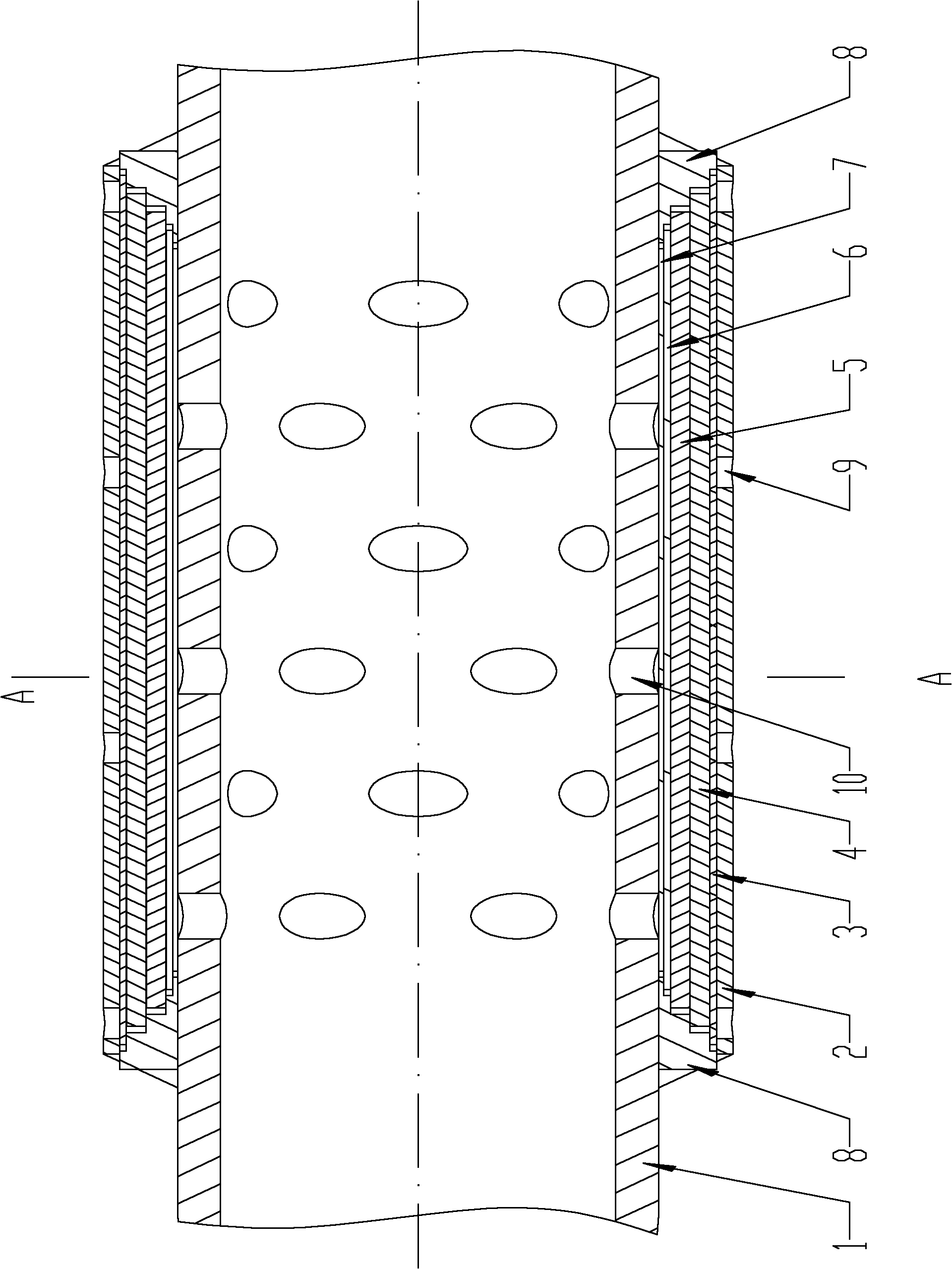

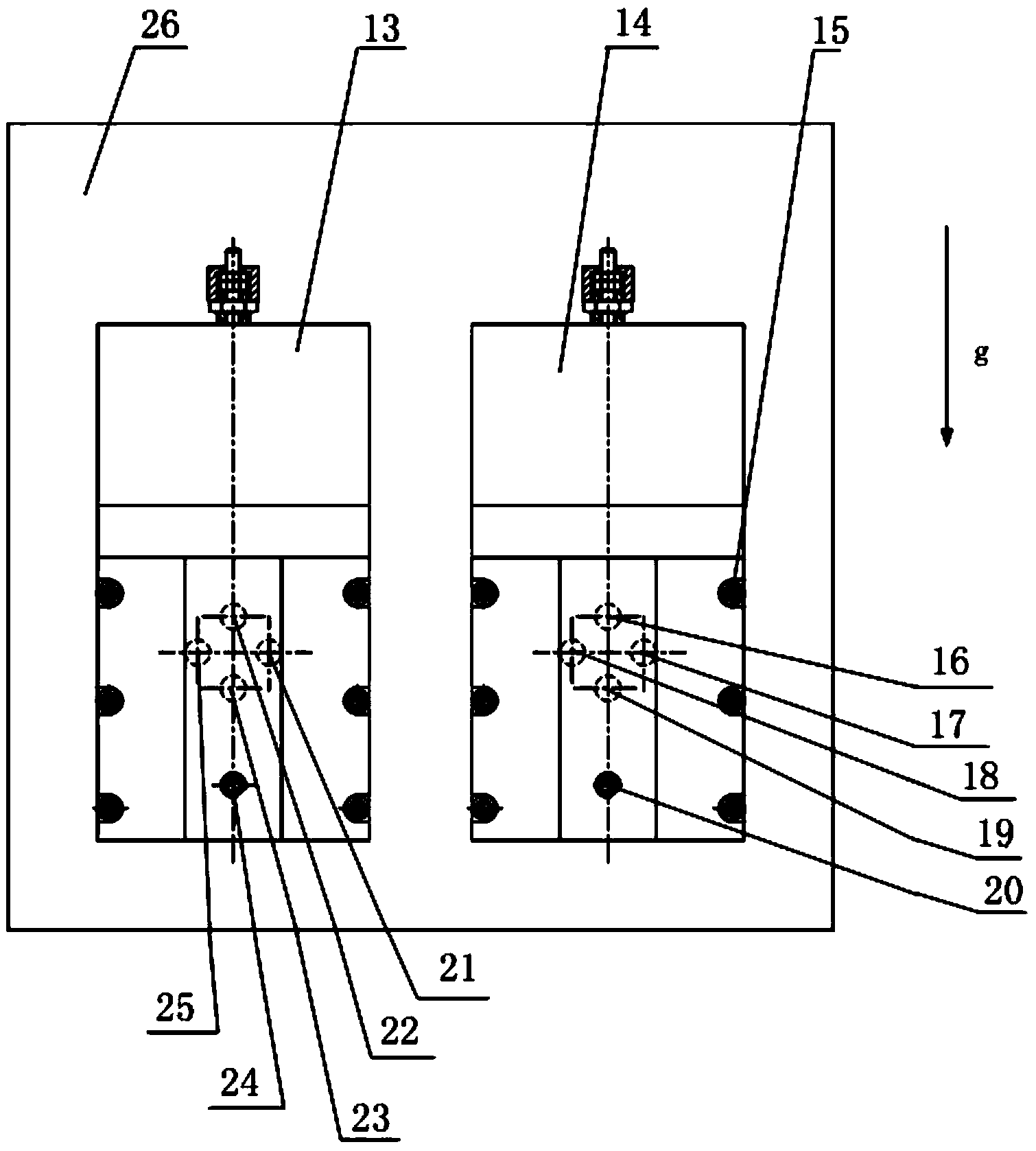

Series-parallel hybrid-driven piezoelectric pump

InactiveCN102678528AIncrease output flowStable outputFlexible member pumpsPositive-displacement liquid enginesPiezoelectric pumpHybrid drive

The invention relates to a series-parallel hybrid-driven piezoelectric pump, and belongs to the fields of fluid transmission and control. Upper and lower pump bodies are connected through screws; 2 to 20 piezoelectric vibrators are connected between pump cavities of the two pump bodies in a pressed mode; valve sheets are adhered to the pump cavities of the upper and lower pump bodies and the inlets of valve cavities; the inlet of the upper pump body and the adjacent pump cavity, two adjacent pump cavities, and the valve cavities and the adjacent pump cavities are communicated through inter-cavity flow channels; the valve cavities are communicated with outlets; a series pump I is formed by the pump cavities and the piezoelectric vibrators; the inlet of the lower pump body and the adjacent pump cavity, two adjacent pump cavities, and the valve cavities and the adjacent pump cavities are communicated through inter-cavity flow channels; a series pump II is formed by the pump cavities and the piezoelectric vibrators; the inlets of the series pumps I and II are communicated; and the valve cavities of the series pumps I and II are communicated and communicated with the outlet on the upper valve body. The pump has the advantages that a series-parallel pump is formed by a plurality of piezoelectric vibrators of which the two sides drive fluid simultaneously, so that the pump is high in flow, pressure and energy efficiency, low in pulsation and suitable for constructing a piezoelectric hydraulic driver with high system back pressure.

Owner:ZHEJIANG NORMAL UNIVERSITY

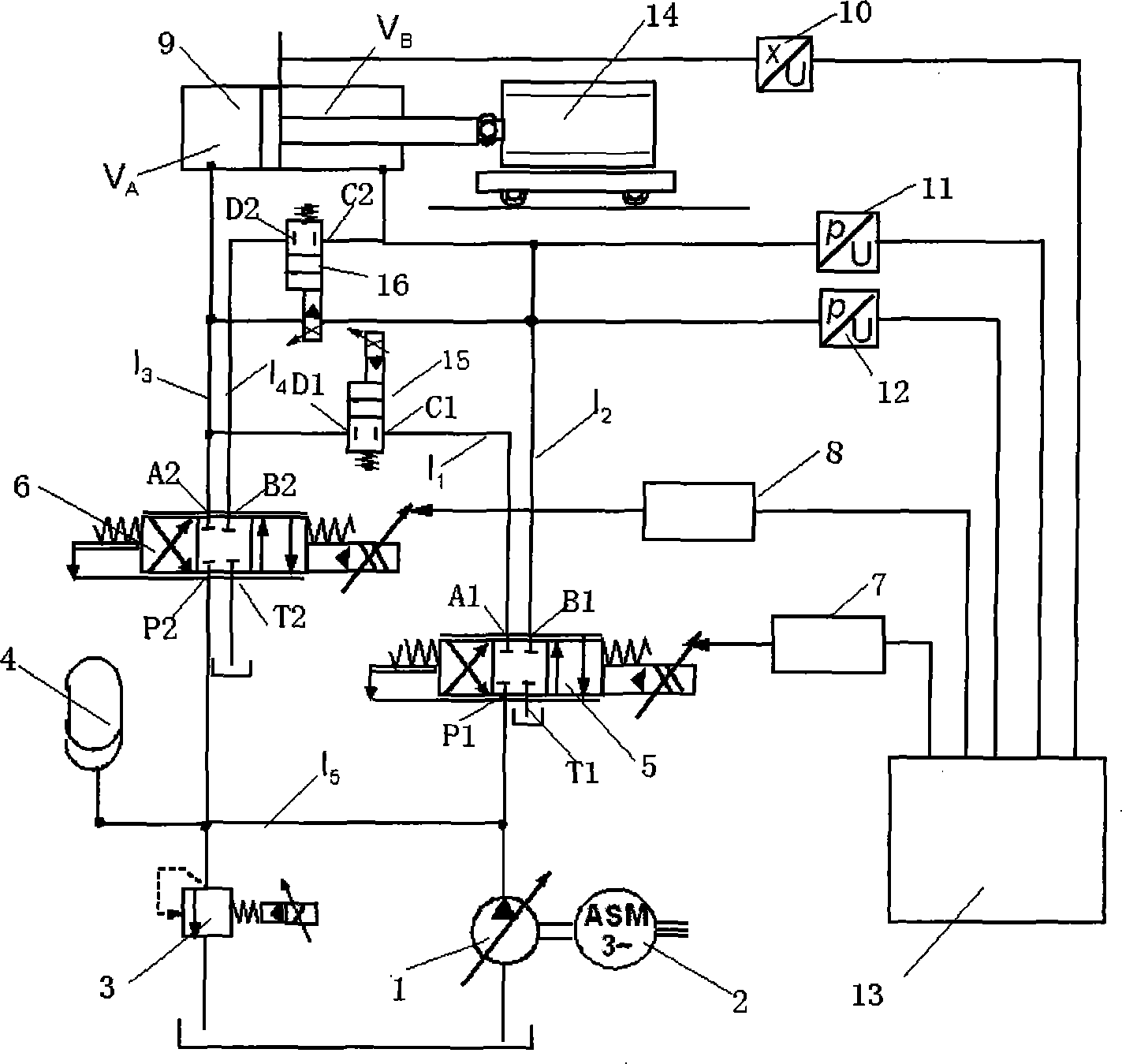

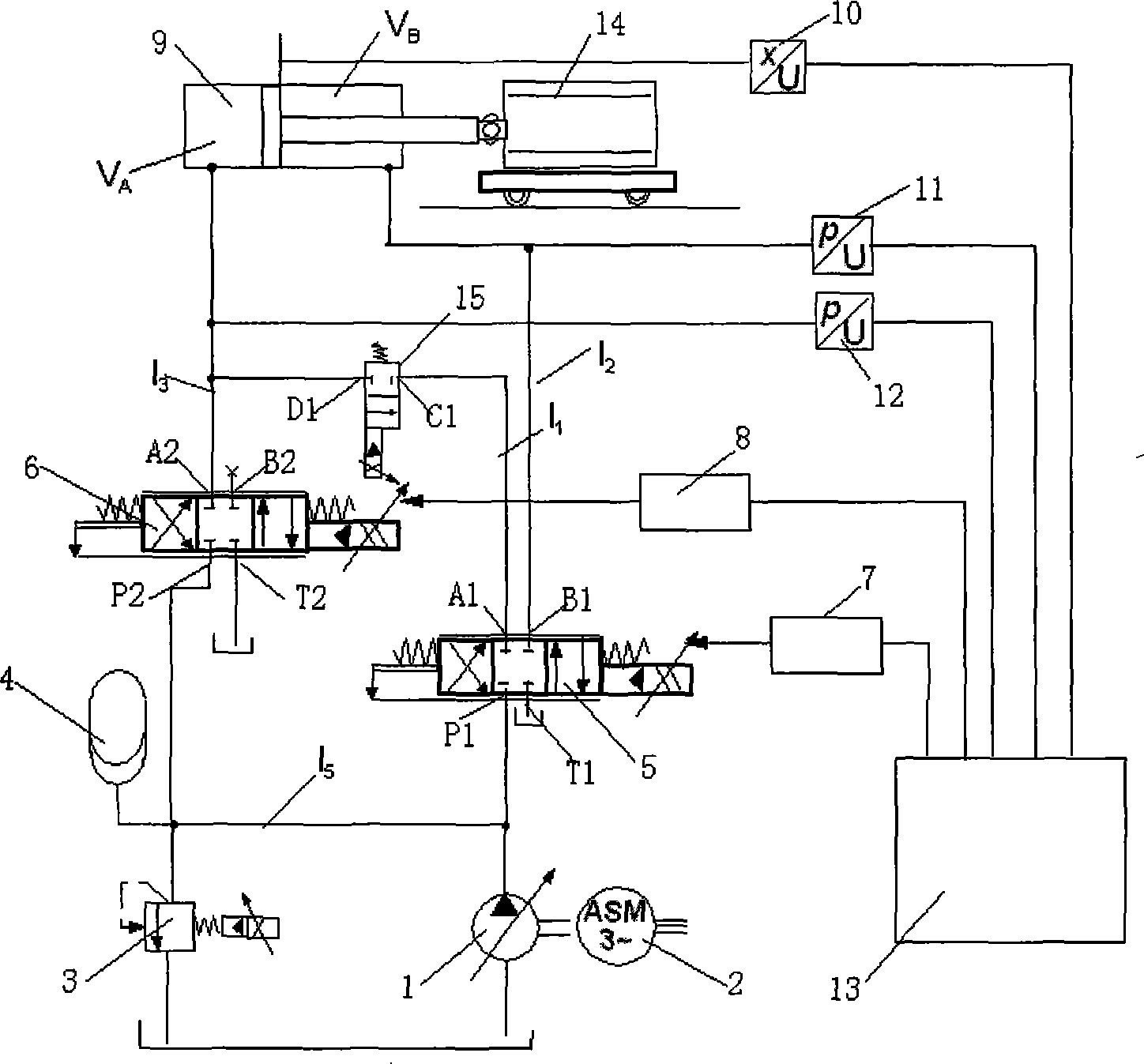

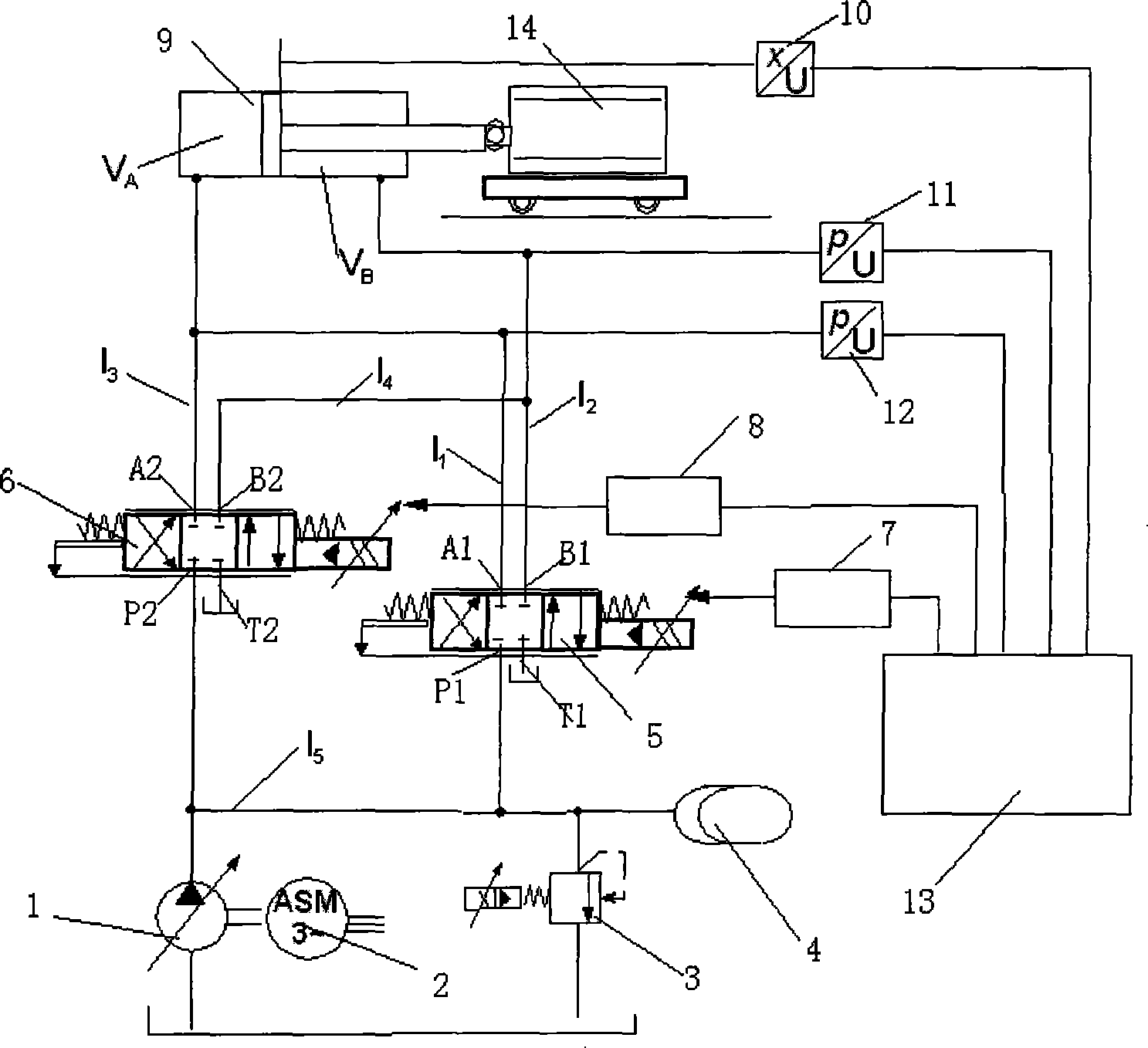

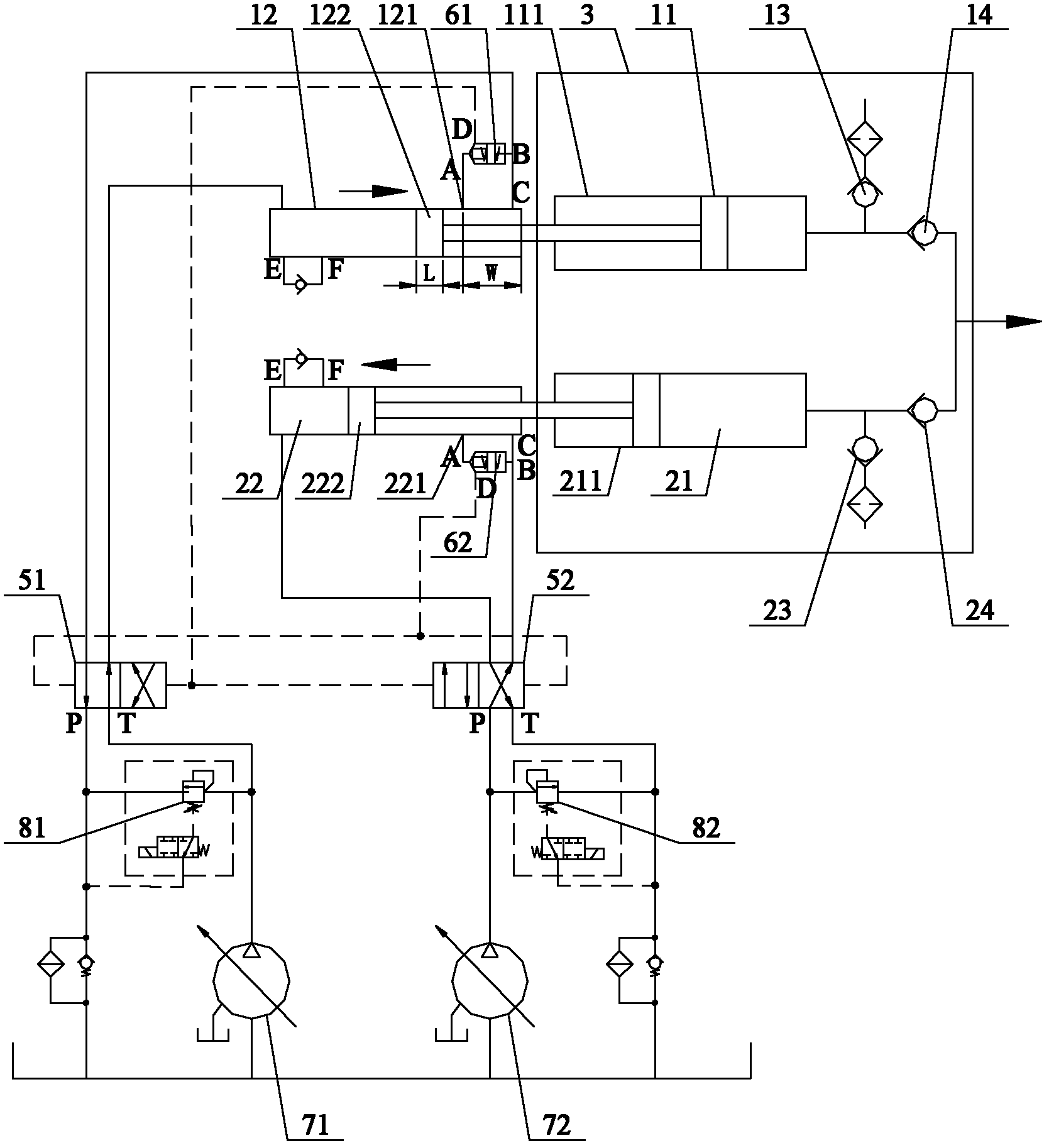

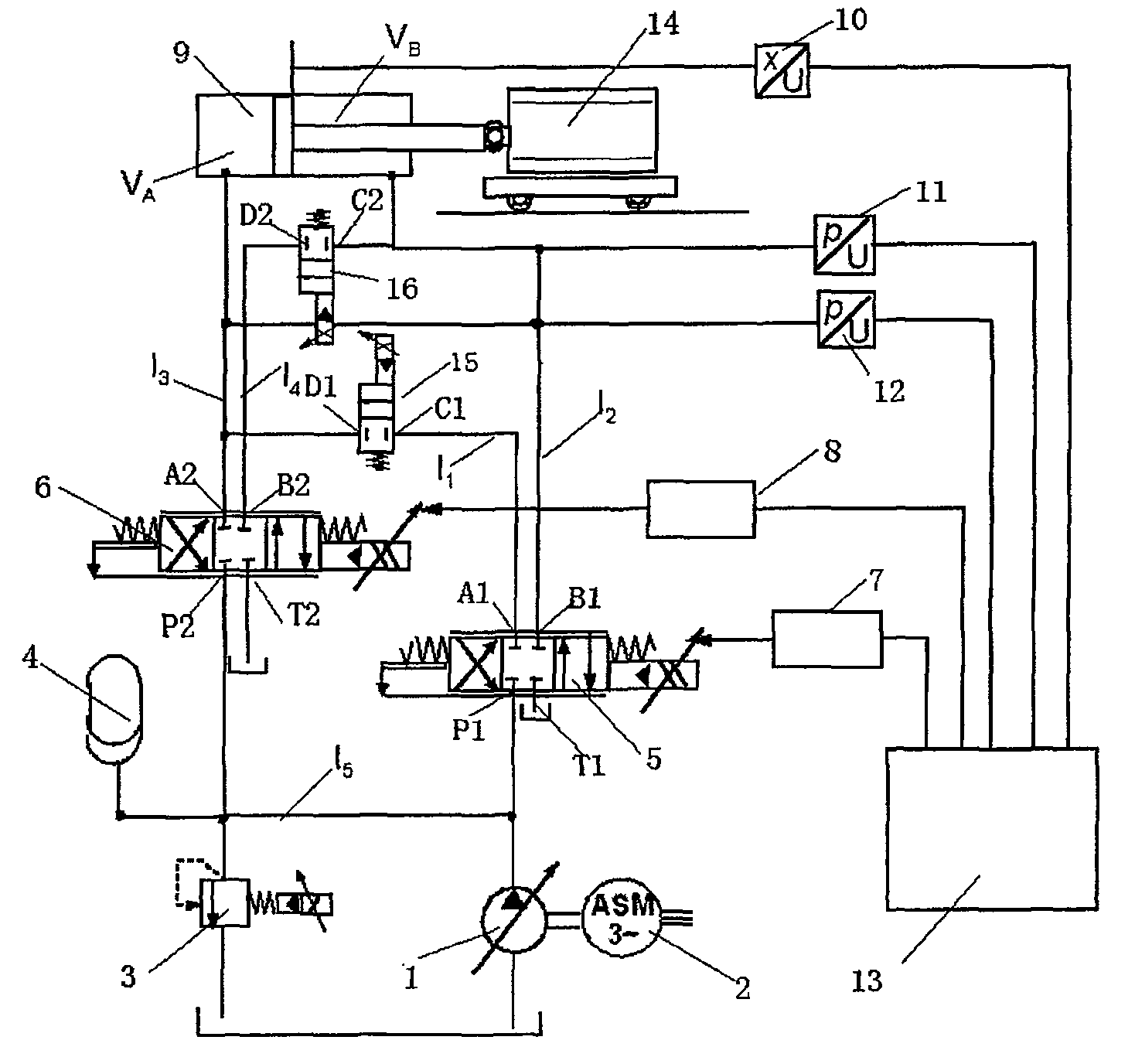

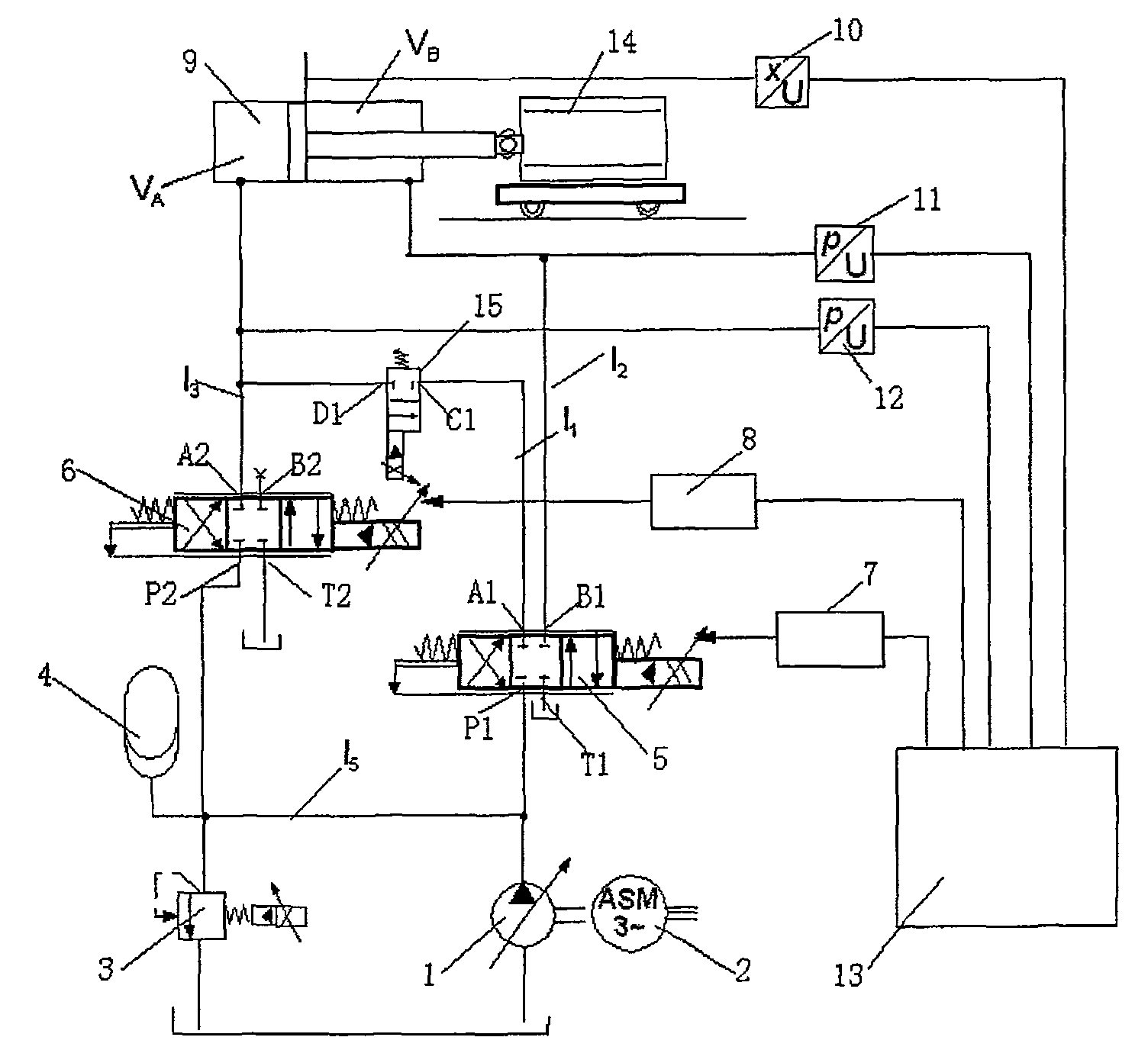

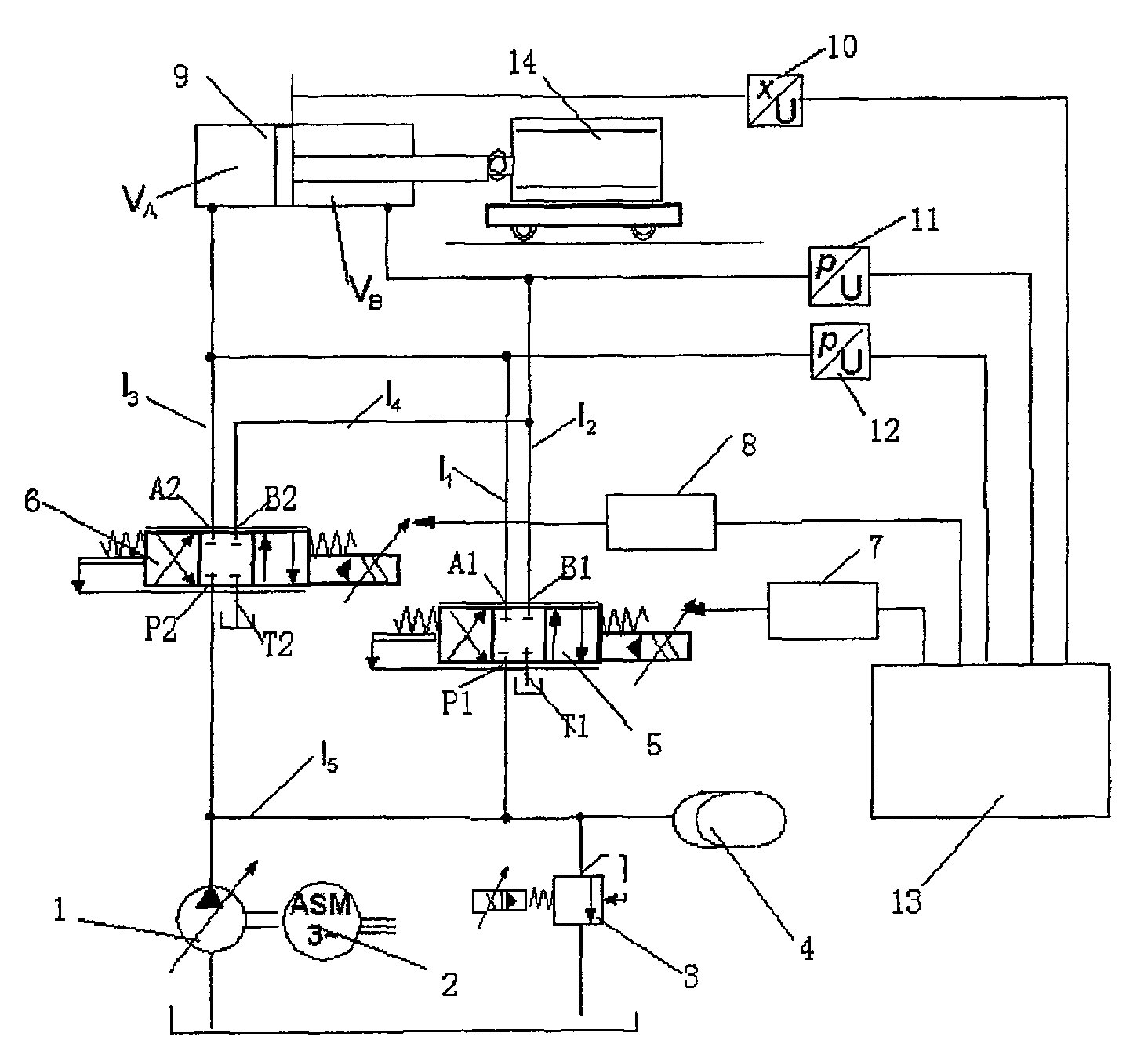

Redundant electrohydraulic servo-controlling system

InactiveCN101245794AImprove responsivenessGuaranteed reliable operationServomotor componentsTraffic volumeProportioning valve

The invention provides a redundancy electro hydraulic servo system, which is an electro hydraulic servo system controlled by a dual-flux servo valve or a dual-servo proportion valve. By a two-position two-way electromagnetic valve, a controllable parallel connection between the two valves is realized, the dynamic adjustment of the control scheme is realized, and the realization of the load motion speed and index is achieved, thus achieving the objects of high efficiency and energy-saving control and simultaneously improving the reliability of the system.

Owner:TAIYUAN UNIV OF TECH

Linear motor-driven plunger pump

InactiveCN102305203AReduce in quantityImprove anti-pollution performancePumpsPositive-displacement liquid enginesPermanent magnet rotorReciprocating motion

The invention relates to a linear motor-driven plunger pump. The mechanical part of the plunger pump comprises a cylinder body I, a cylinder body II, flow distribution valves, an in-sucking communication pipe, out-pressing communication pipes, compacting flanges, plunger rods, linear motor stators, linear motor rotors and guide rails; and the electric part mainly consists of linear motors, a controller, drivers and a position feedback device. The linear motor-driven plunger pump is characterized in that a group of coil-type stators drive a permanent magnet rotor in a combinational way, thus realizing high thrust output of the linear motors. Each flat-type linear motor drives two plungers at the two ends of one plunger rod, and while the double-action plunger rod reciprocates, one end of the double-action plunger rod sucks water and at the same time the other end of the double-action plunger rod presses water. The two cylinders realizes the effective communication between the water sucking loop and water pressing loop of the plunger pump by means of the in-sucking communication pipe and the two out-pressing communication pipes. Each plunger hole is communicated with a flow distribution valve consisting of an in-sucking valve and an out-pressing valve. The electric part controls the out-of-phase movement of the linear motors, thus ensuring the stable combinational flow output of the pump. The linear motor-driven plunger pump disclosed by the invention has the advantages of less mechanical transmission links and high system efficiency and reliability.

Owner:BEIJING UNIV OF TECH

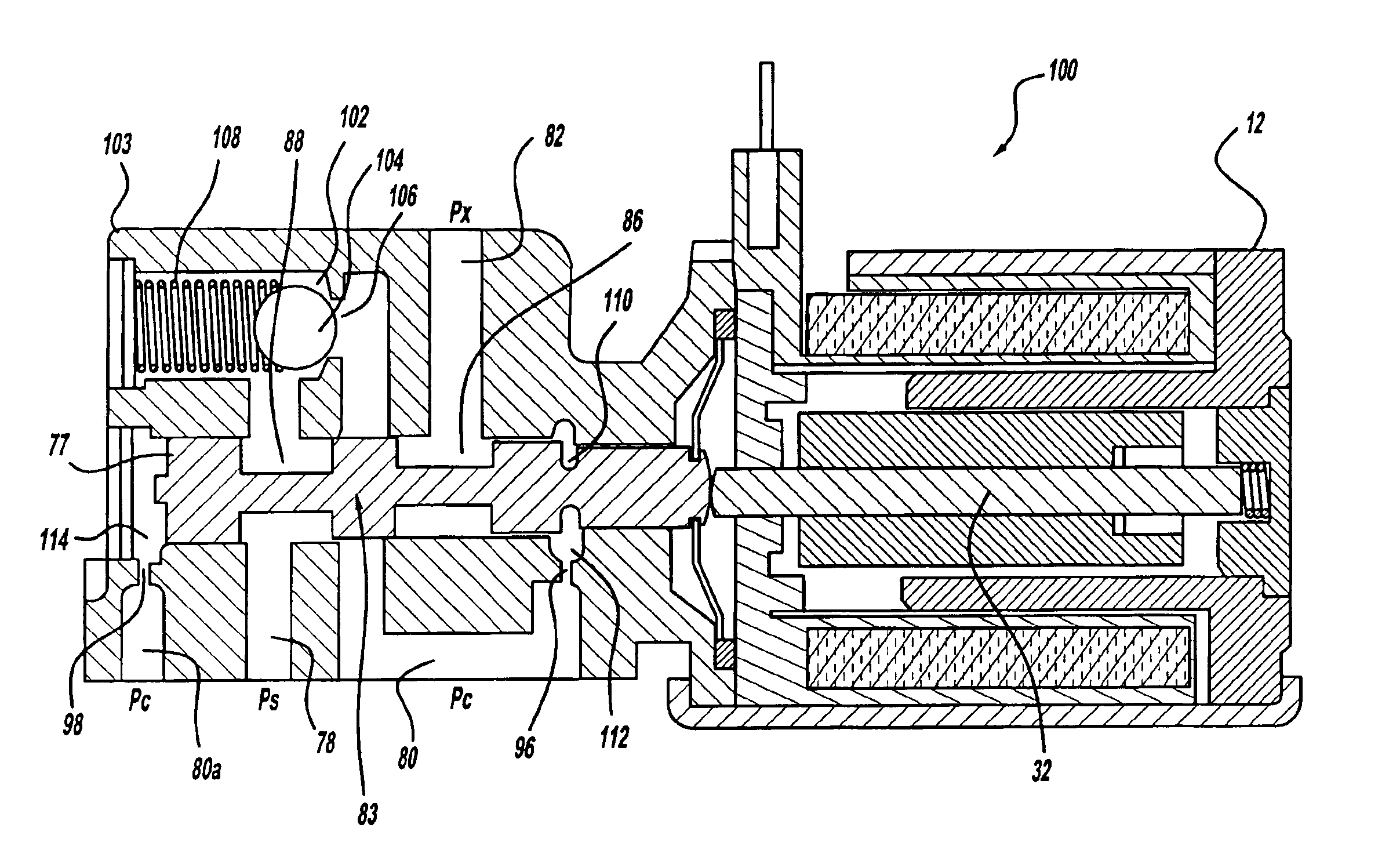

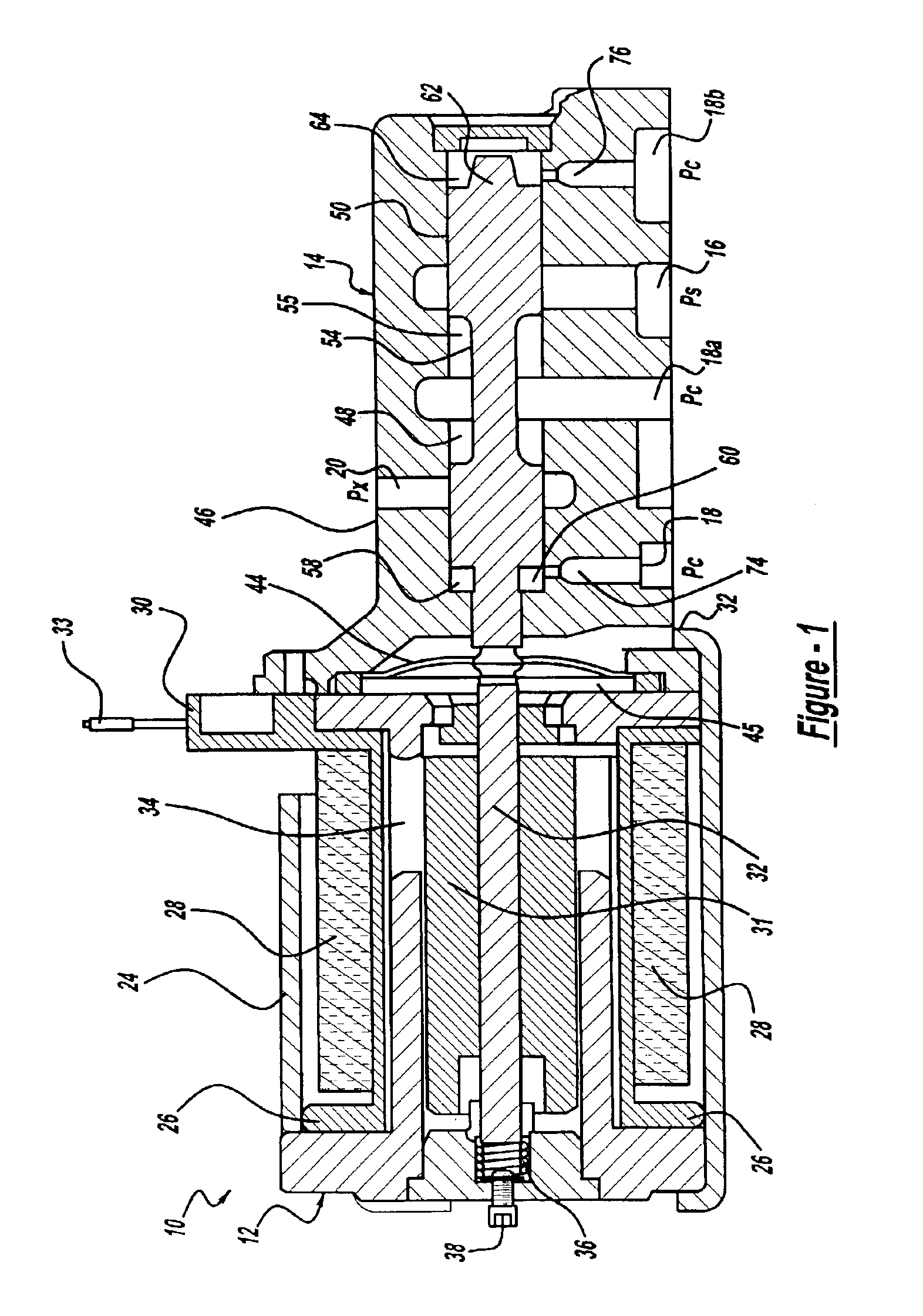

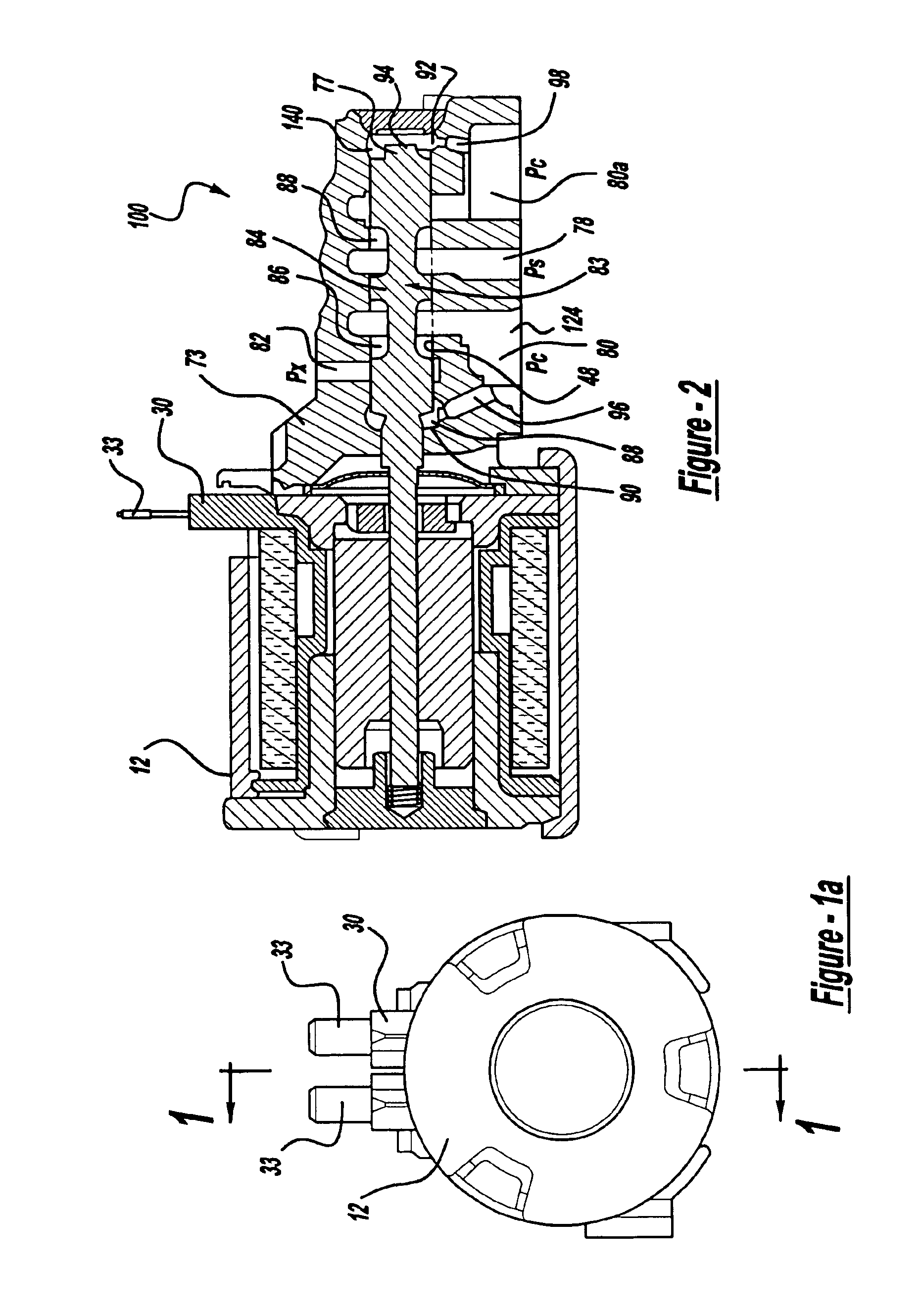

Solenoid control valve

InactiveUS6907901B2Fast and repeatable and stable output pressure responseLow pollution sensitivityOperating means/releasing devices for valvesServomotor componentsSpool valveControl system

A solenoid control valve for use in actuation of a manual hydraulic clutch in a vehicle. The solenoid control valve has an electronically operated solenoid with armature and actuator rod displaced through a channel in the solenoid. A spool valve has a valve body that is coupled at one end to the solenoid. A spool is slidably disposed in the control channel. A first and second dampener chambers are located at the two ends of the spool. The dampeners function to improve the stability in the control system and balance the transient flow forces of the hydraulic fluid as it moves through the valve member. The spool also has a control portion is located between the first end and the second end of the spool. The control portion allows the control portion to communicate with a supply, control and exhaust passages in the valve body.

Owner:BORGWARNER INC

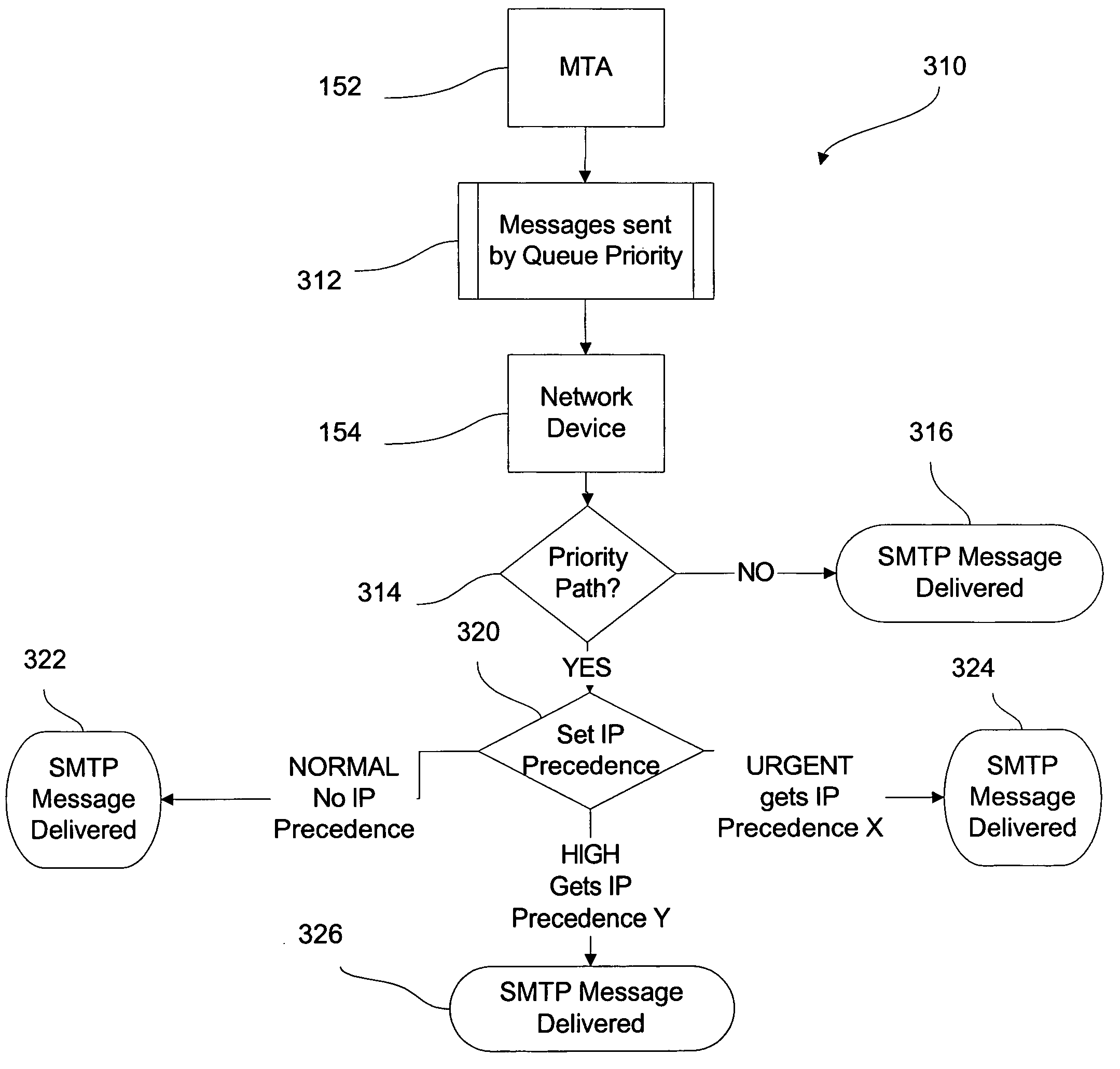

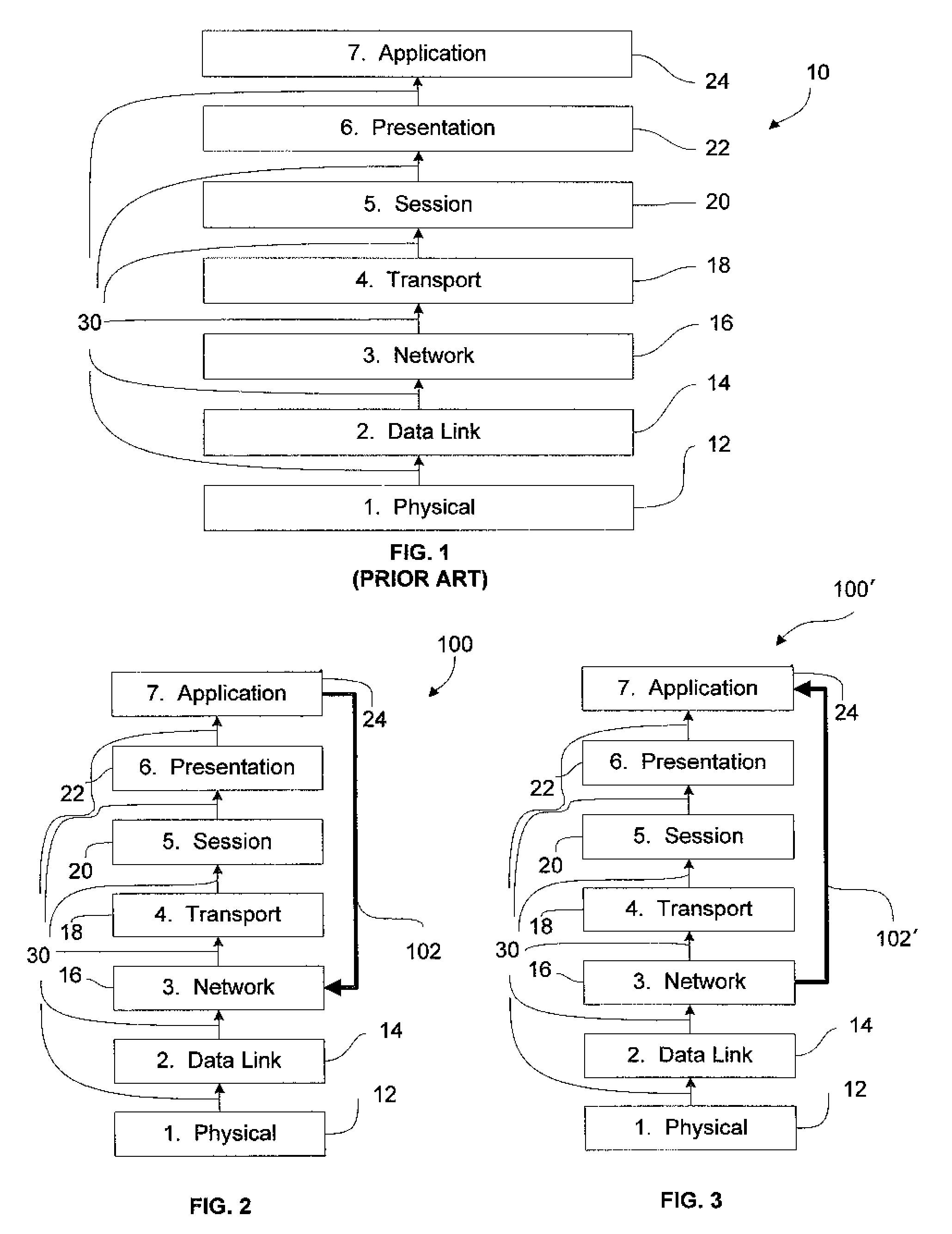

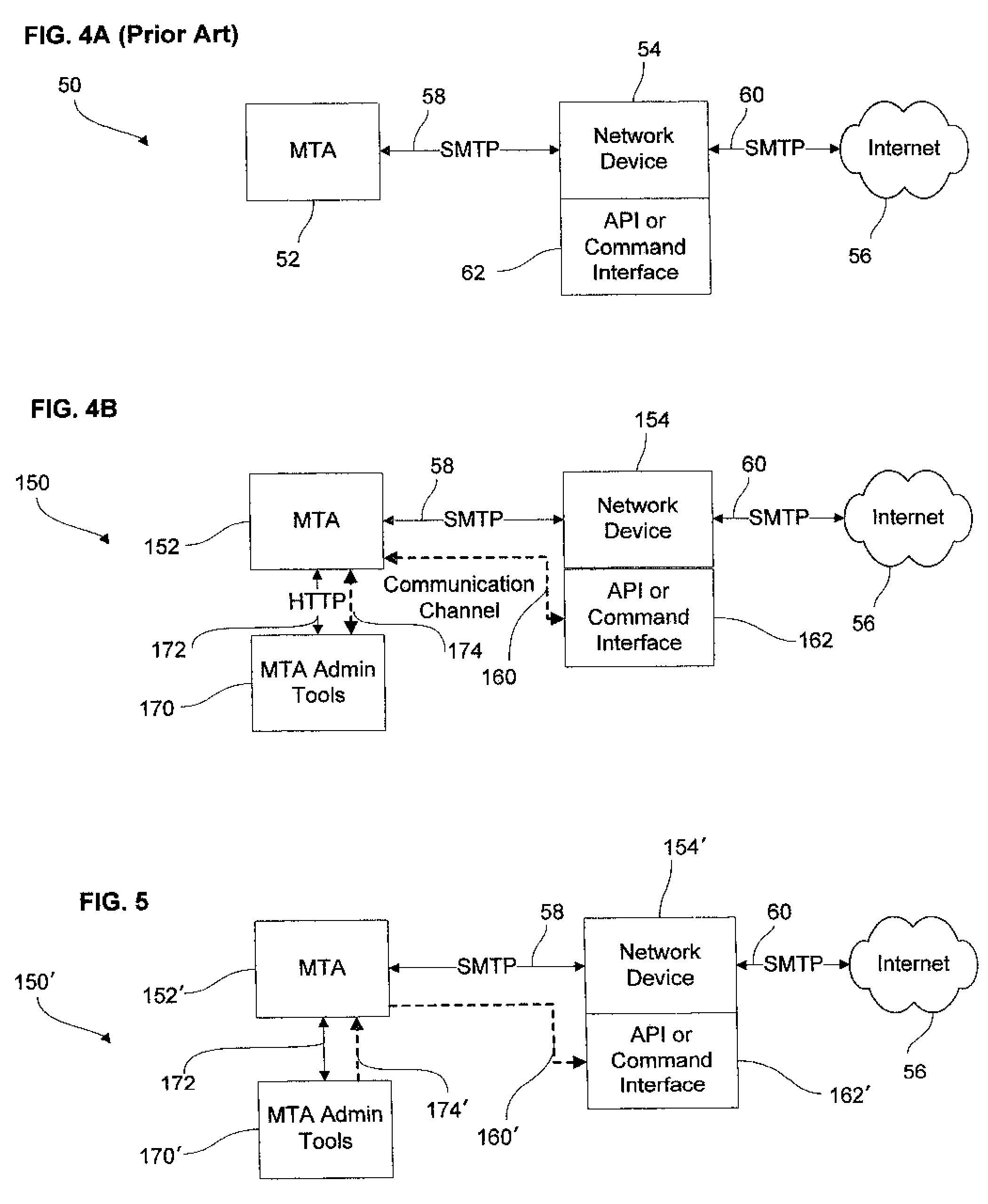

Electronic message delivery system including a network device

ActiveUS7760640B2Increase output flowError preventionTransmission systemsTraffic capacityMessage delivery

In a computer network system based on an open system interconnection model, where the computer network system includes at least a network layer (Layer 3) and an application layer (Layer 7), a system and a method for managing electronic message traffic into and out of the computer network system including defining a communication channel between Layer 3 and Layer 7 for exchanging data directly therebetween for use in enhancing flow of the electronic message traffic.

Owner:QUEST SOFTWARE INC

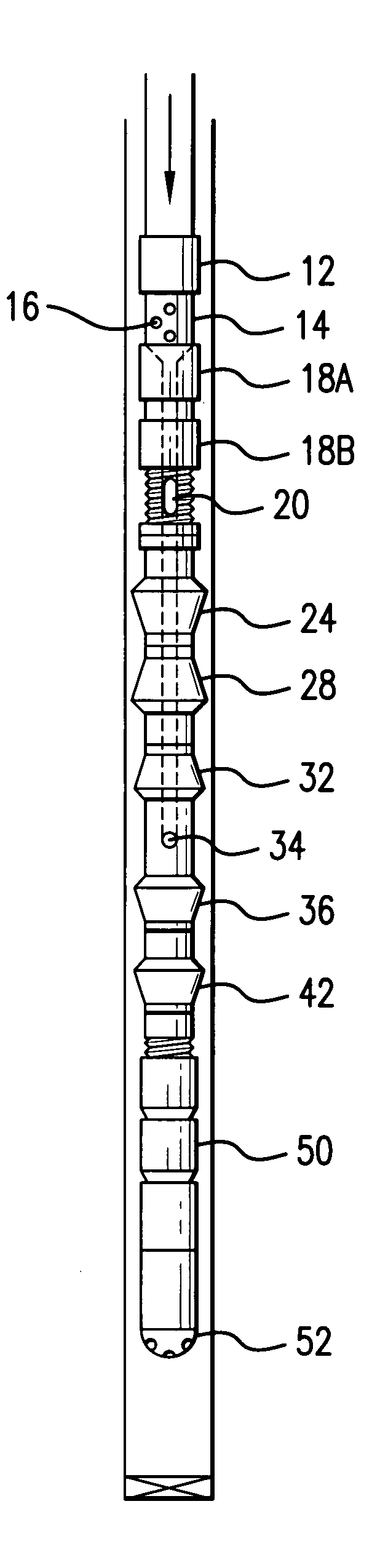

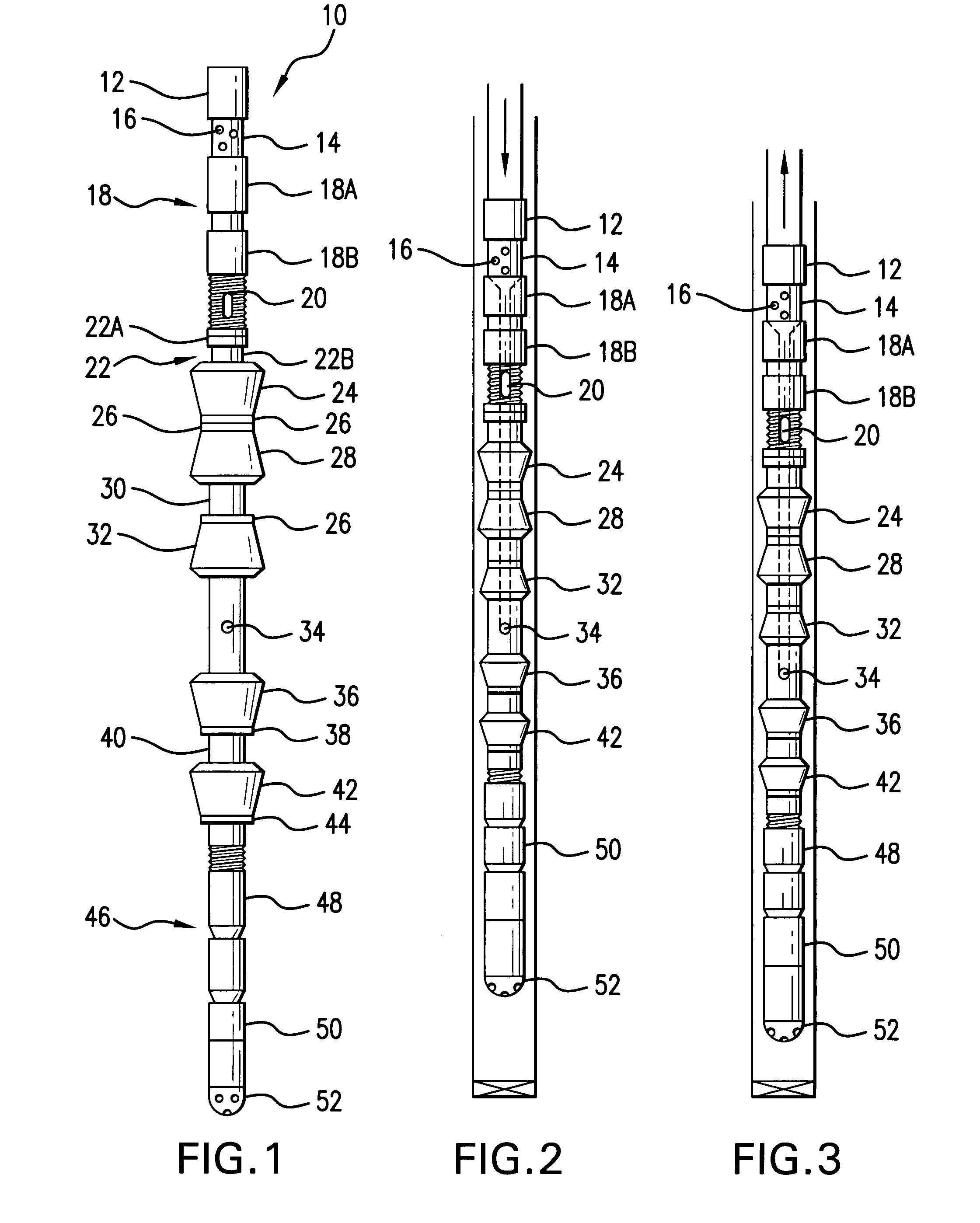

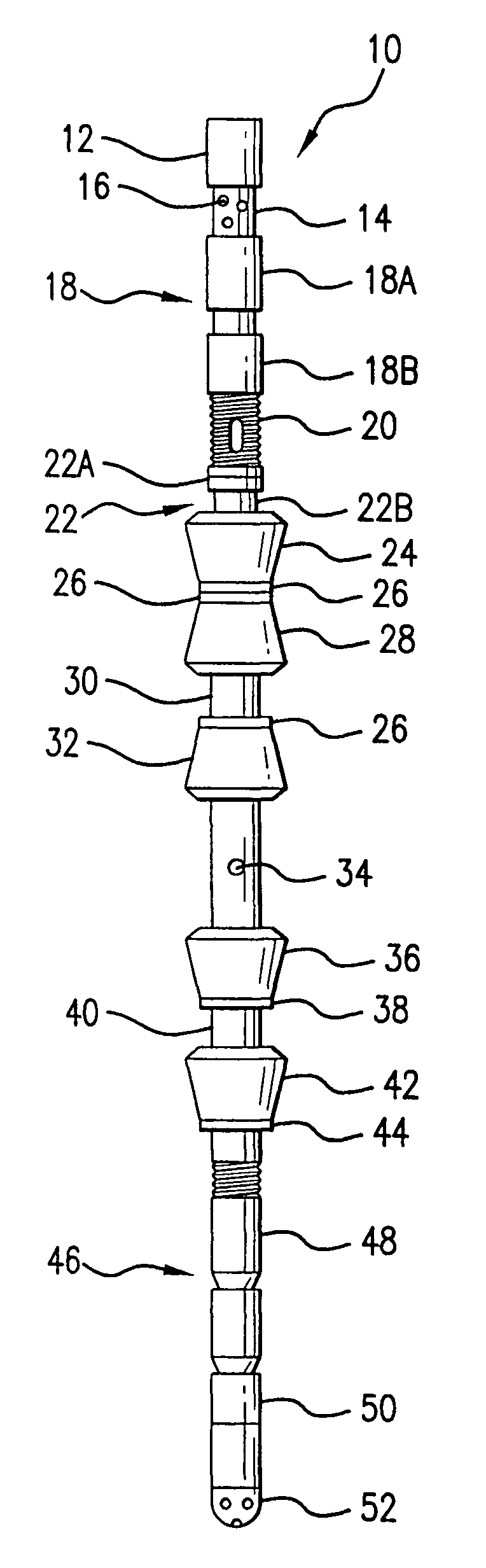

Method for simultaneous removal of asphaltene, and/or paraffin and scale from producing oil wells

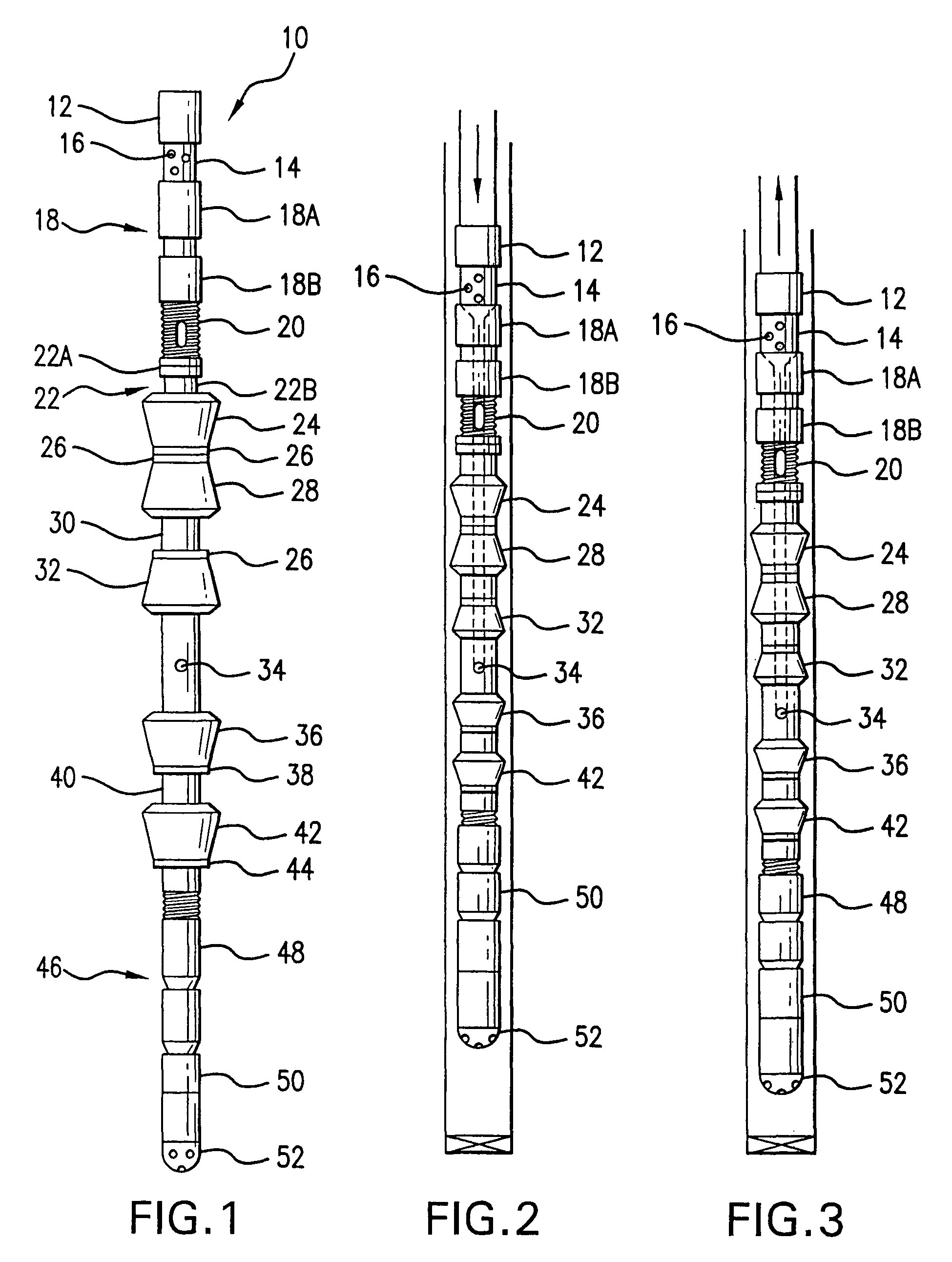

ActiveUS7296627B2Increase output flowLess-expensive and easy to useTransportation and packagingCleaning apparatusParaffin waxHydrocarbon solvents

A method for cleaning oil wells to increase the flow of oil thereof by use of a unique aqueous cleaning emulsion comprising of water, hydrocarbon solvent, detergent and mineral acid. This one step method provides for the simultaneously cleaning / removal of asphaltine and / or paraffin and scale. This method can be used alone or with the assistance of a wash tool which is a combination pressure and surge wash tool having a nipple assembly. A by-pass port is coupled to the nipple assembly and a diverter cup is coupled to the by-pass port. A plurality of pressure wash cups are positioned on the tool. A pressure wash port is located between the plurality of pressure wash cups and a pump shoe assembly is coupled to a bottom pressure wash cup.

Owner:DYER RICHARD J

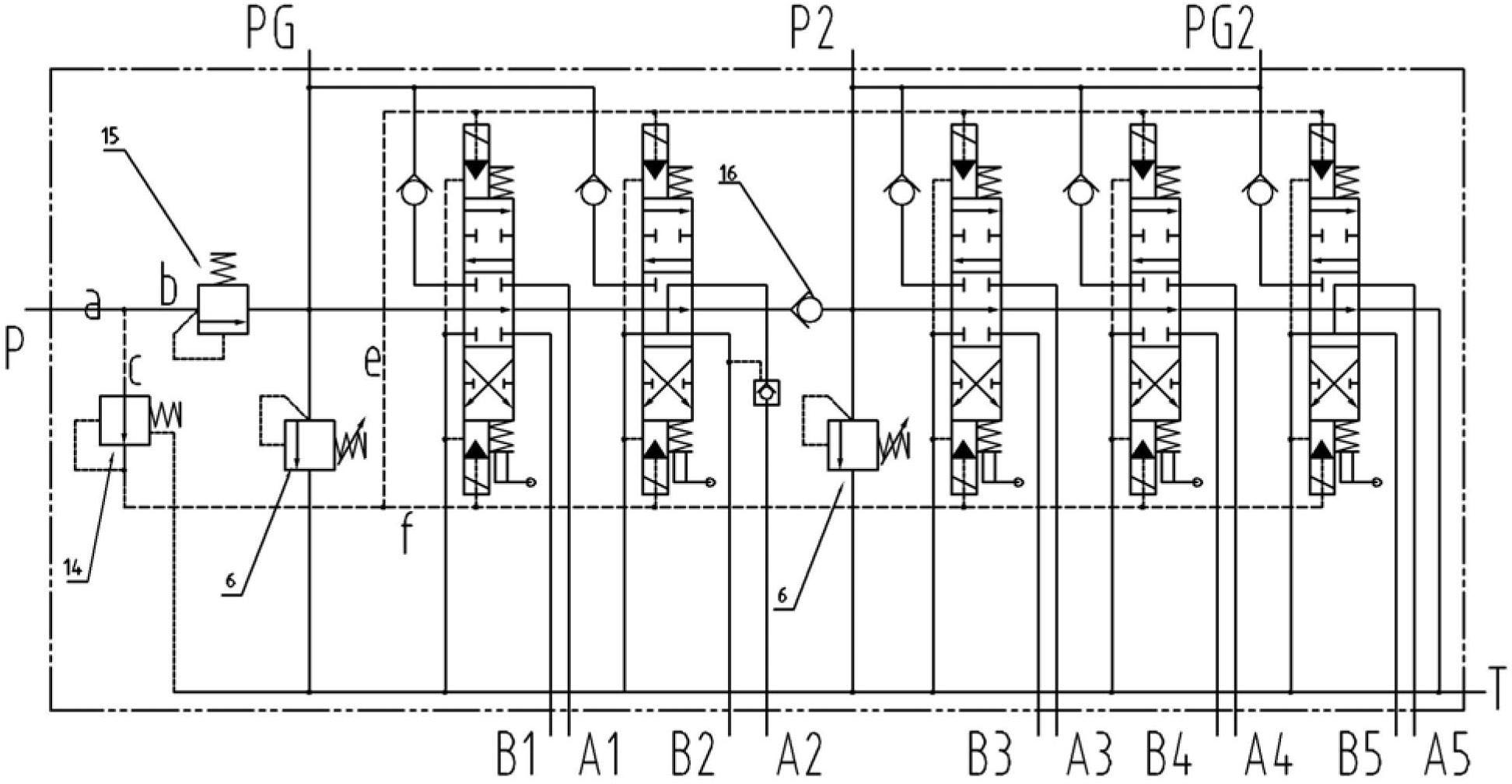

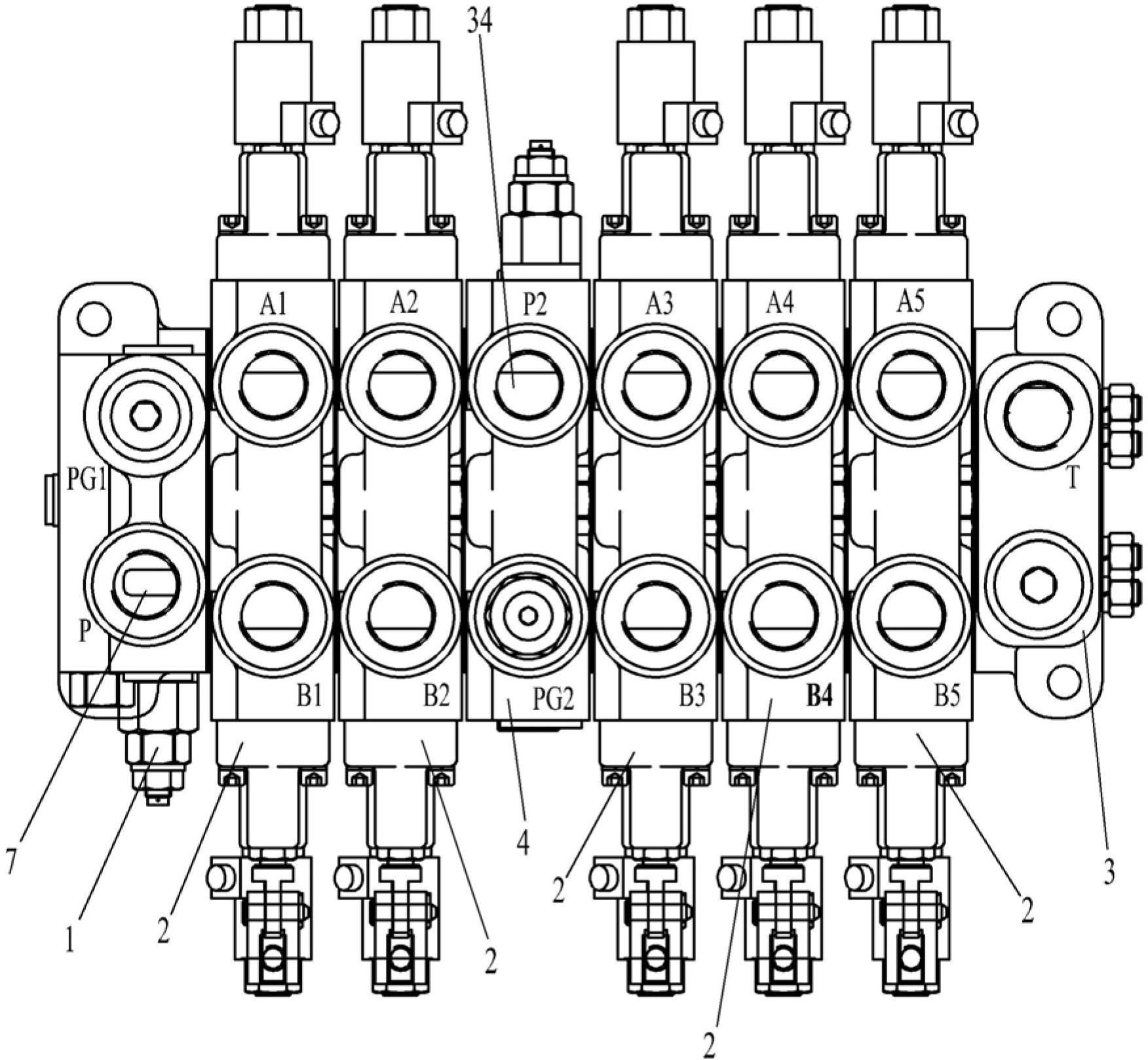

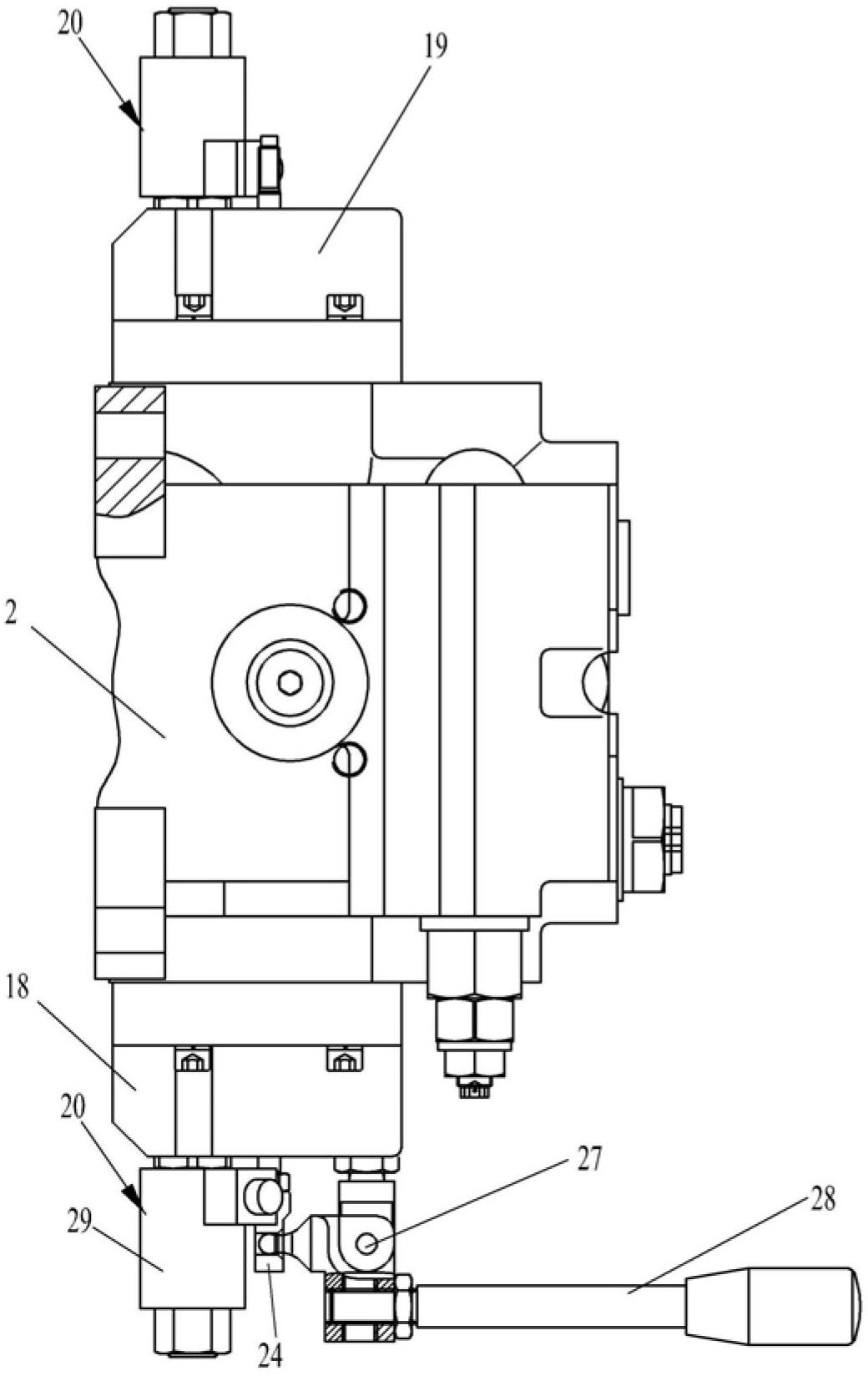

Electro-hydraulic multiple-way directional valve

The invention discloses an electro-hydraulic multiple-way directional valve, wherein an oil inlet valve plate comprises an oil inlet valve body and a safety valve; an oil inlet P is arranged on the oil inlet valve body, a main oil channel, a working oil channel and a first oil channel are arranged in the oil inlet valve body, the main oil channel is communicated with the oil inlet P, and both of the working oil channel and the first oil channel are communicated with the main oil channel; the first oil channel is connected with a pilot oil channel, the pilot oil channel comprises a main pilot oil channel, a first pilot oil channel and a second pilot oil channel, and a pressure reducing valve is arranged at the junction of the main pilot oil channel and the first pilot oil channel; and a slide valve is arranged in the working oil channel, and the working oil channel is connected with an oil return channel via a safety valve. Additionally, directional valve plates are further provided with manual pull rods, flow collecting valves are arranged among the directional valve plates, and a throttling screw plug is arranged in the oil return channel of a pilot control oil channel. The electro-hydraulic multiple-way directional valve disclosed by the invention has the advantages of being capable of omitting a pilot pump and an oil tube, integrated in manual function and hydraulic control function, capable of changing the output flow of a working oil port via flow collection, slow in directional action, etc.

Owner:HEFEI CHANGYUAN HYDRAULICS

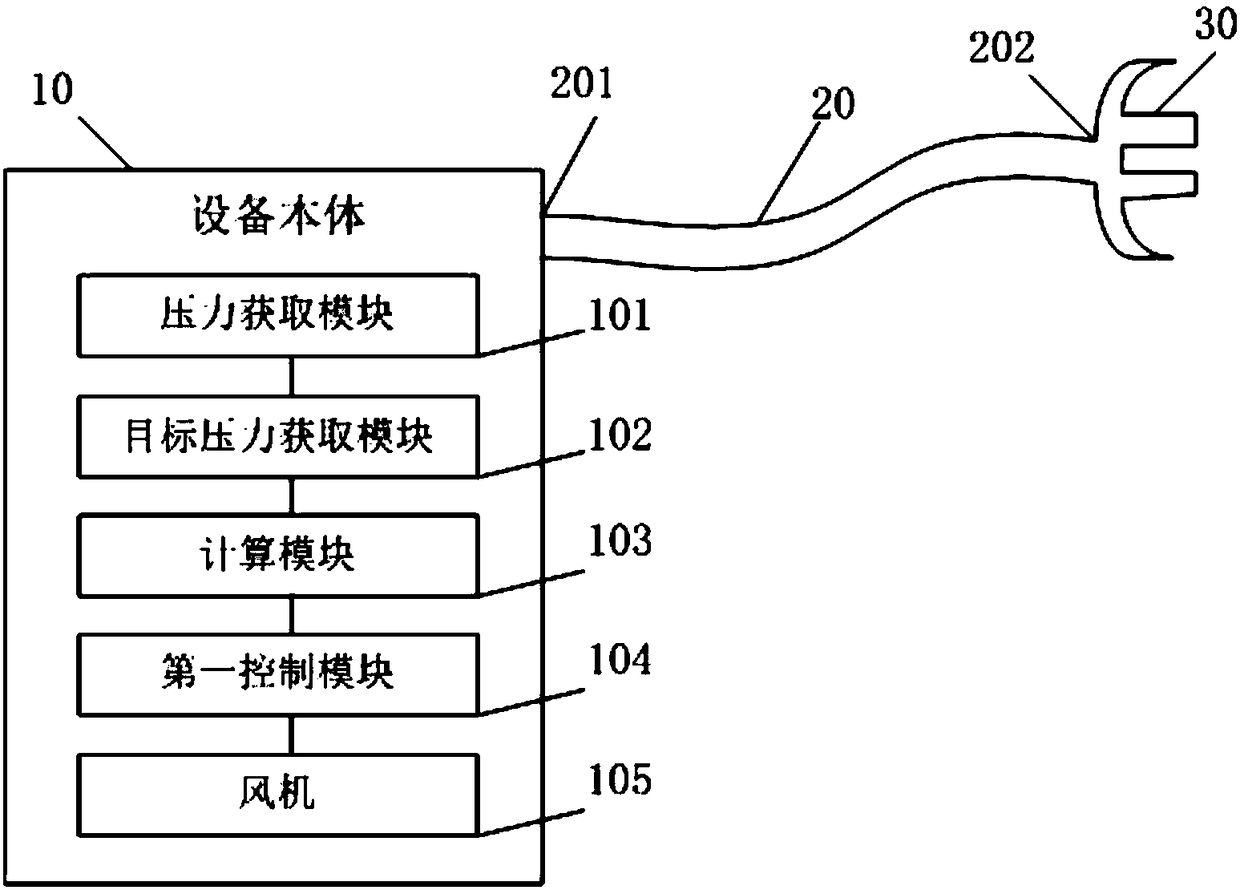

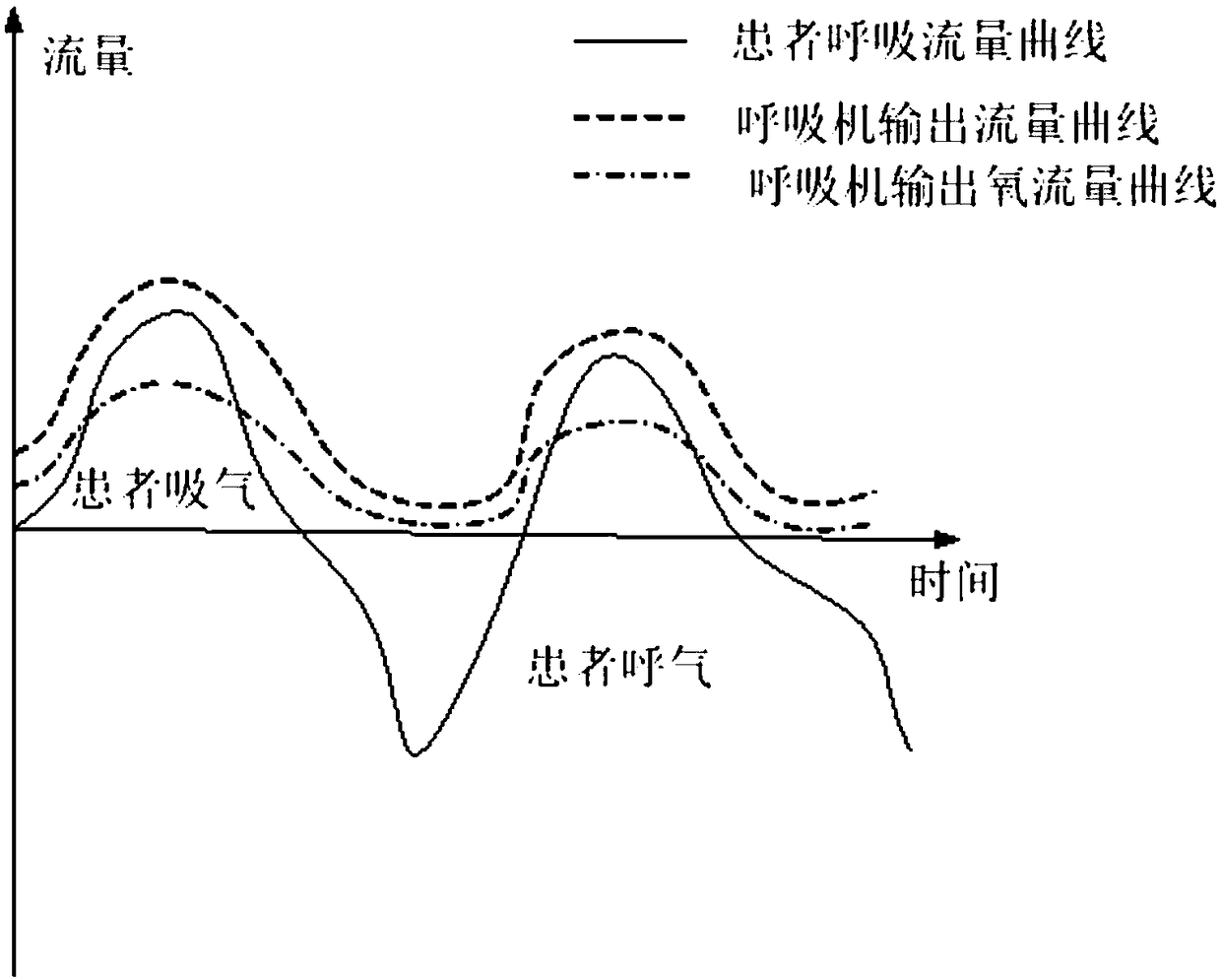

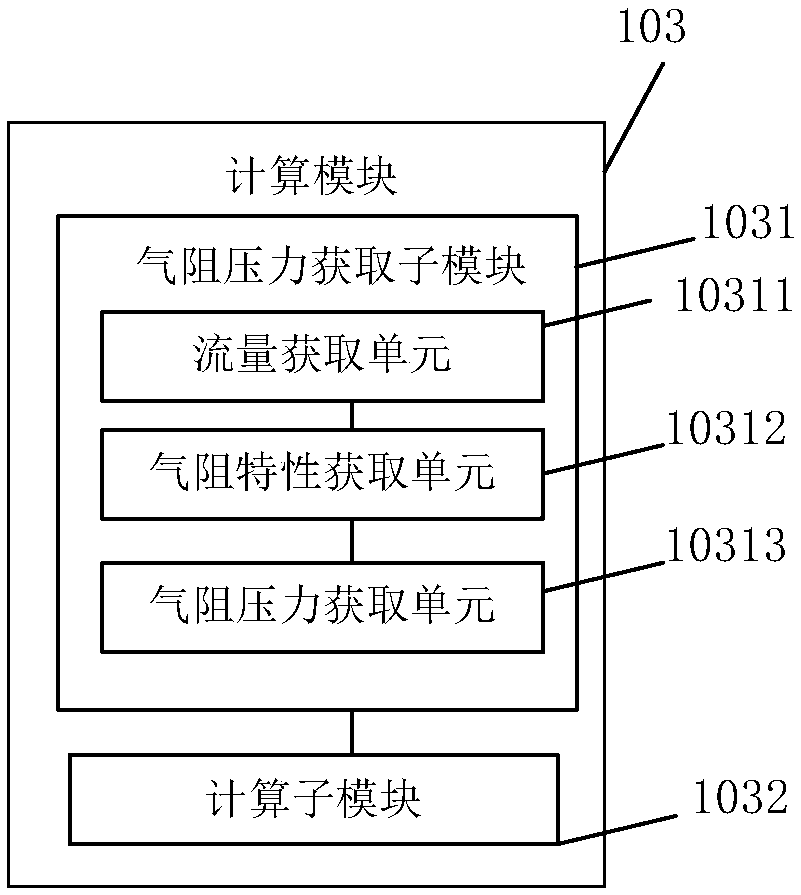

Ventilation treatment device and control method

ActiveCN109303960AThe output pressure value is reducedReduced output flowRespiratorsMedical devicesMedicineTarget signal

The invention provides a ventilation treatment device and a control method. The device comprises a device body, a breathing tube and a patient interface, and the device body further comprises a signalacquisition module configured to acquire an output pressure value of a signal collection point of the device body, a target signal obtaining module for obtaining a target pressure value for a patientinterface end, a calculating module for calculating an actual pressure value of the patient interface end according to the pressure value and the flow value of the signal collection point and a firstcontrol module for adjusting output flow of the device body according to the actual pressure value and a target pressure value. The method determines the actual pressure value of the patient interface by feedback of the output parameter of the signal collection point in the device body, determines the breathing state of the patient according to the comparison between the actual pressure value andthe target pressure value, and outputs the airflow corresponding to a threshold value, so that the air pressure of the received airflow by the patient reaches an expected target pressure value rangeto achieve the therapeutic effect.

Owner:BMC MEDICAL

Slide valve type pilot ultra-high pressure pneumatic proportional pressure-reducing valve

InactiveCN1699808ARealize fully automatic pressure controlImprove reaction speedEqualizing valvesSafety valvesElectricityUltra high pressure

The invention discloses a slide valve pilot super high-pressure air power proportional reduction valve. It comprises a pilot valve and a main valve installed on the same valve body under the control of the proportional electromagnet. The air pressure of the lead valve can control the output pressure of the main valve. The lead valve applying C-type semi-bridge structure, the air of the semi-bridge is drawn from the high air pressure inlet of the main valve, the pilot valve under the control of the proportional electromagnet forms the inlet dynamic air damp; the outlet of the semi-bridge is connected with the outlet of the reduction valve, and a fixing air damp is arranged between them forming the fixing air damp of the outlet. The pressure-regulating chamber is on the dynamic balance status under the control of the pilot valve. The valve just uses a proportional electromagnet. When the system is out of power, the pilot valve and main valve will close automatically with the function of resetting spring and air pressure. When the system pressure is higher than expected, air can release pressure via the dismountable security valve.

Owner:ZHEJIANG UNIV

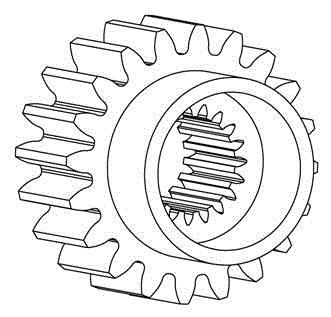

Novel plunger pump

InactiveCN107327382AMovement speed is stableExtended service lifeGearingPump controlReciprocating motionEngineering

The present invention relates to a new type of plunger pump, which includes a driving device, a pump body, a power actuator assembly, and a power transmission assembly; the power actuator assembly includes a guide rod, a chute, and a swing plate that reciprocate in the pump body; The chute is fixedly mounted on one end of the guide rod protruding from the pump body, and the inner side of the chute has two parallel and opposite working planes, the working planes are perpendicular to the guide rod; The power transmission assembly includes an active non-circular gear and a passive non-circular gear meshing with each other, the passive non-circular gear is in transmission connection with the oscillating plate, the active non-circular gear is connected with the driving device, and is driven by the driving device its spinning. The plunger pump can realize the transmission of the sinusoidal mechanism, the pressure angle can be realized by the rotation of the chute and the oscillating disk, and the non-circular gear can realize the smooth movement speed of the guide rod. The equipment is driven by non-circular gears, which can greatly overcome many shortcomings of the cam mechanism, and has a long service life and is not easy to wear.

Owner:殷图源

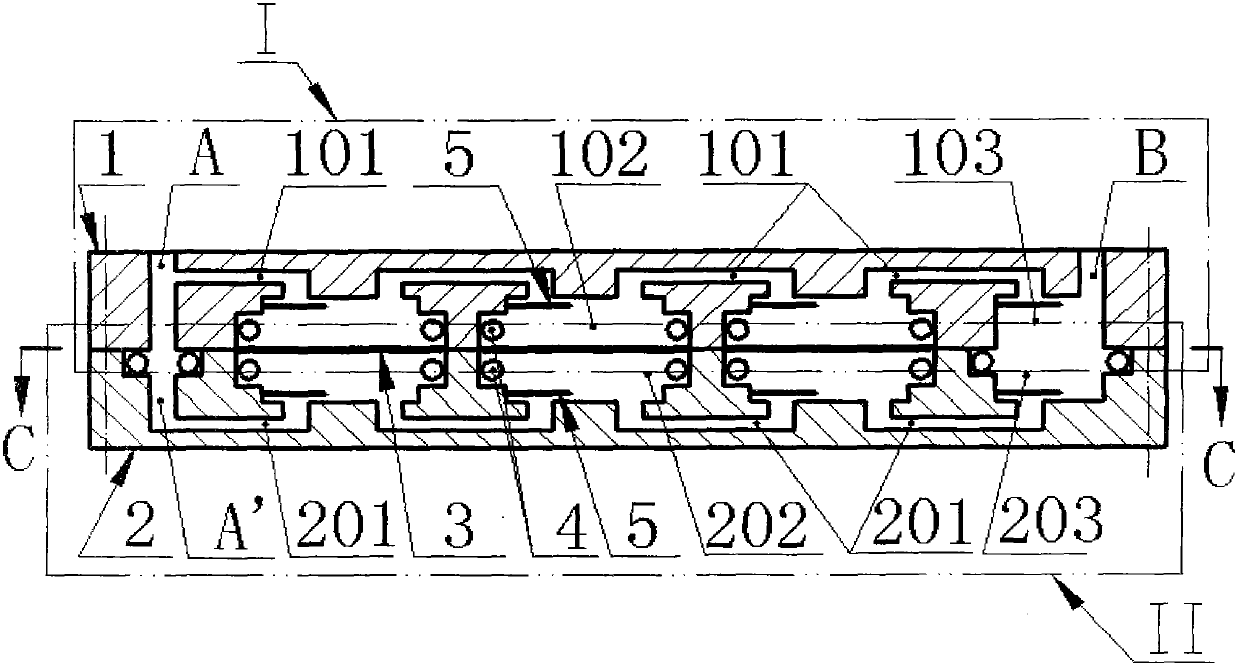

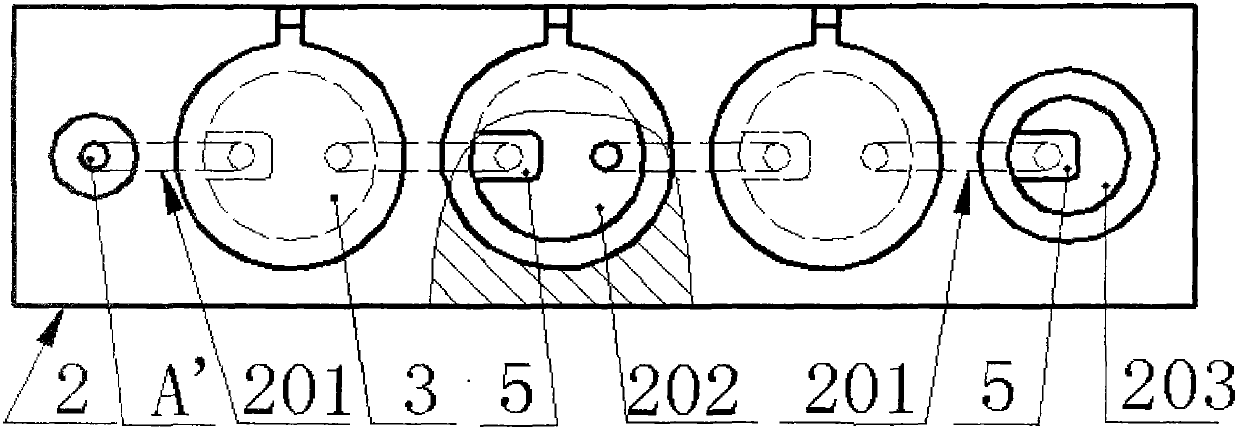

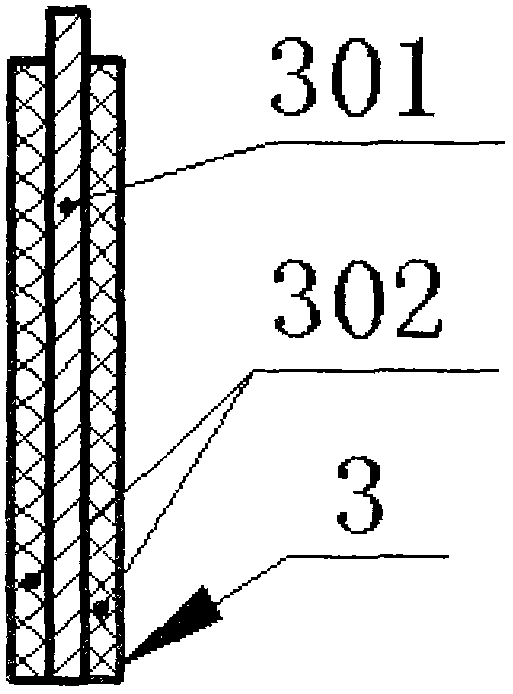

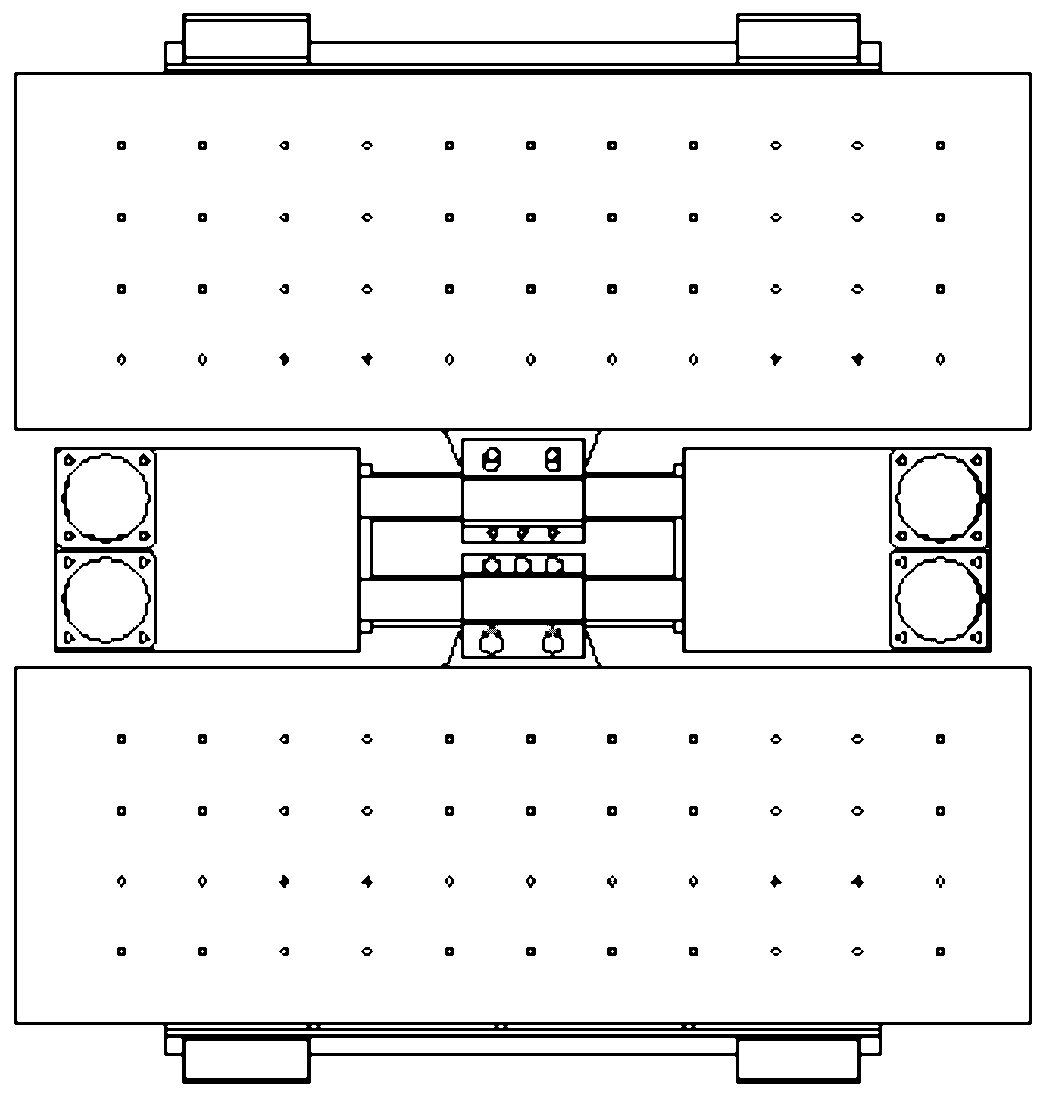

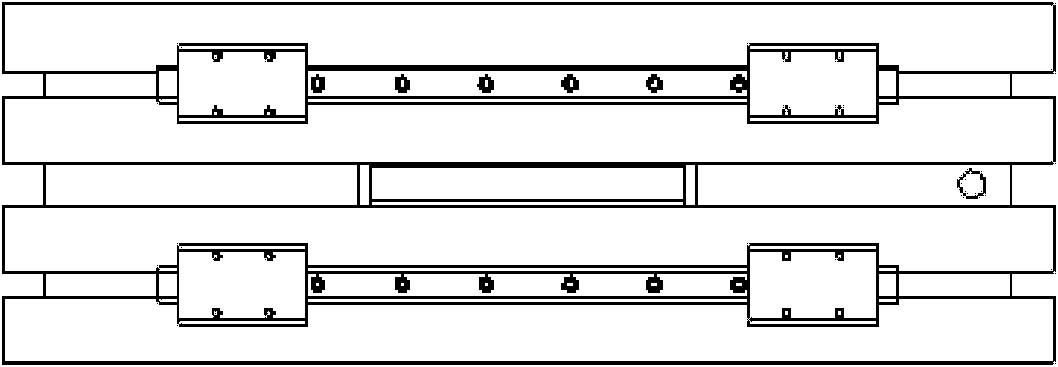

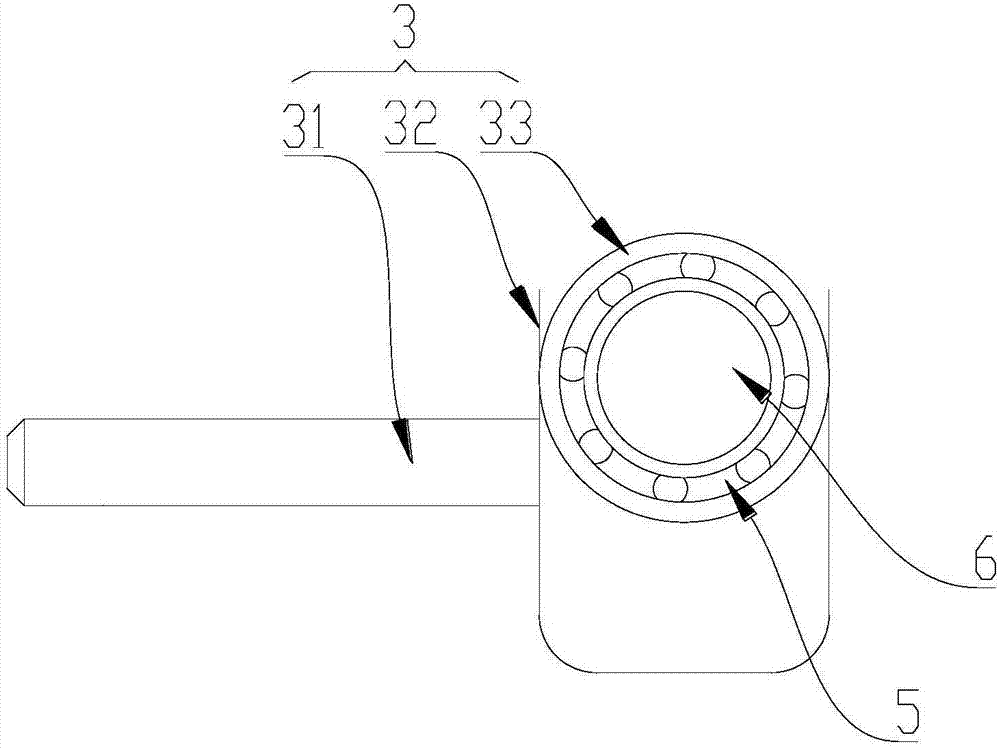

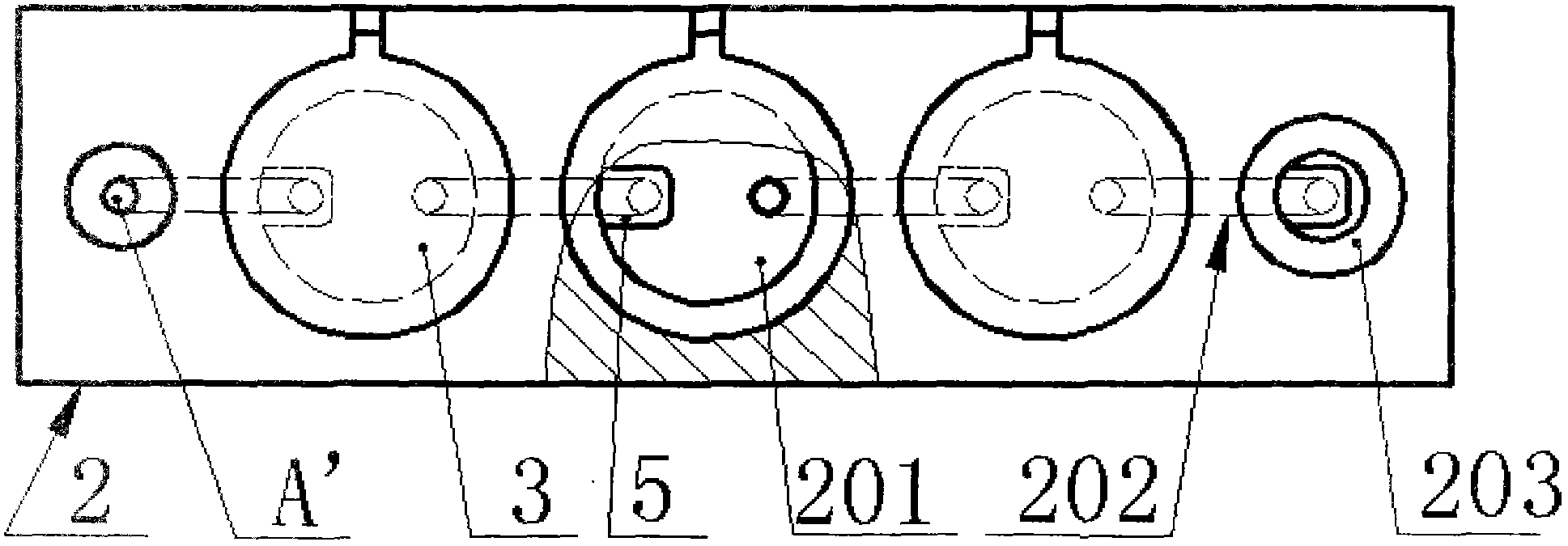

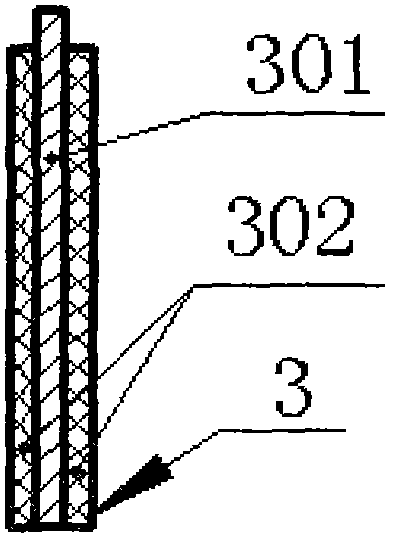

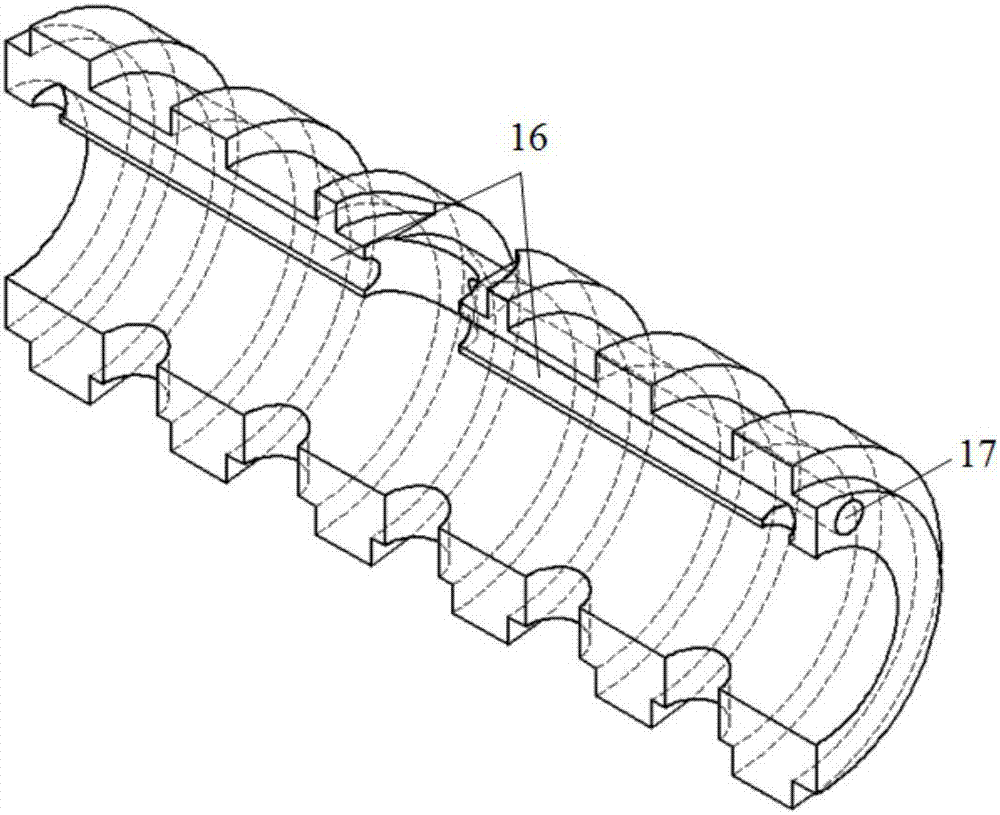

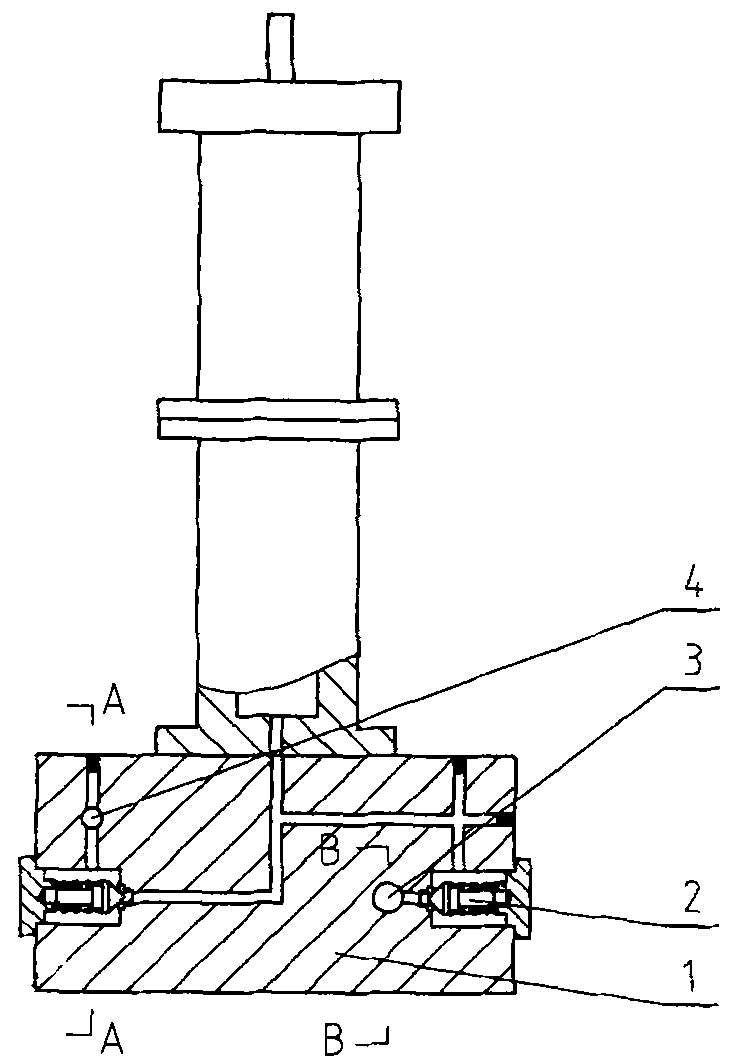

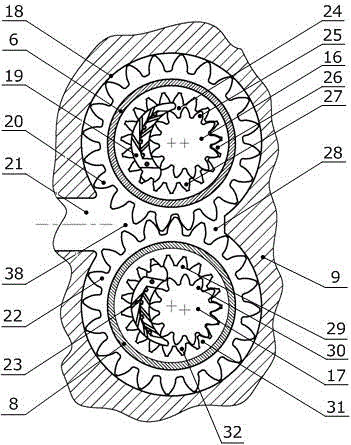

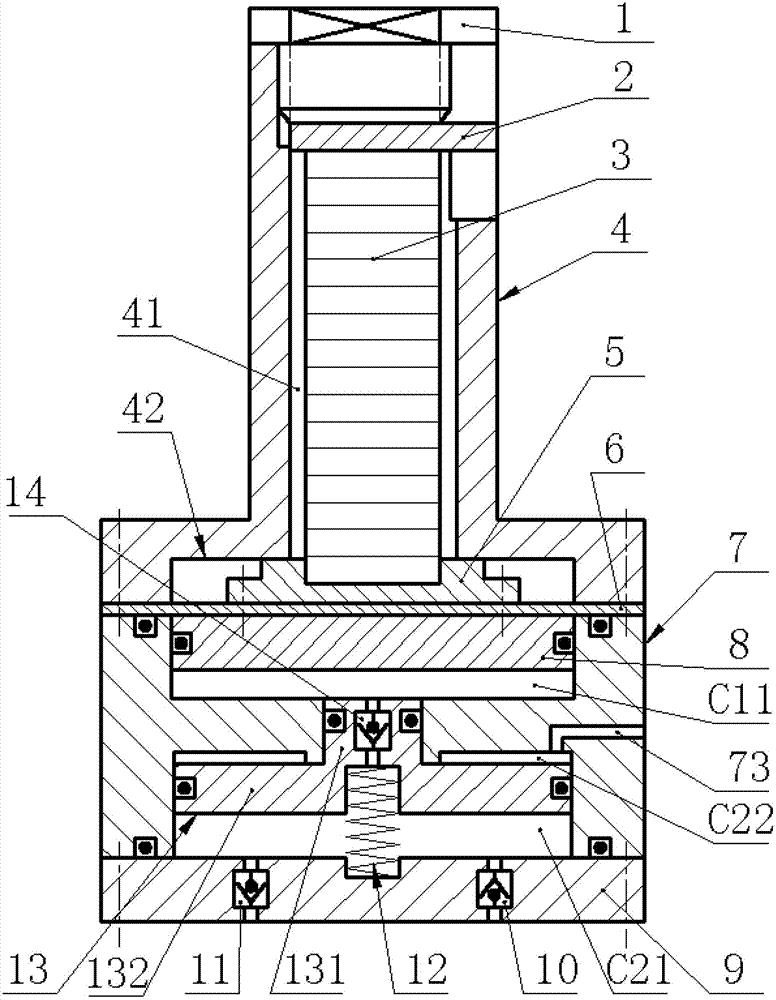

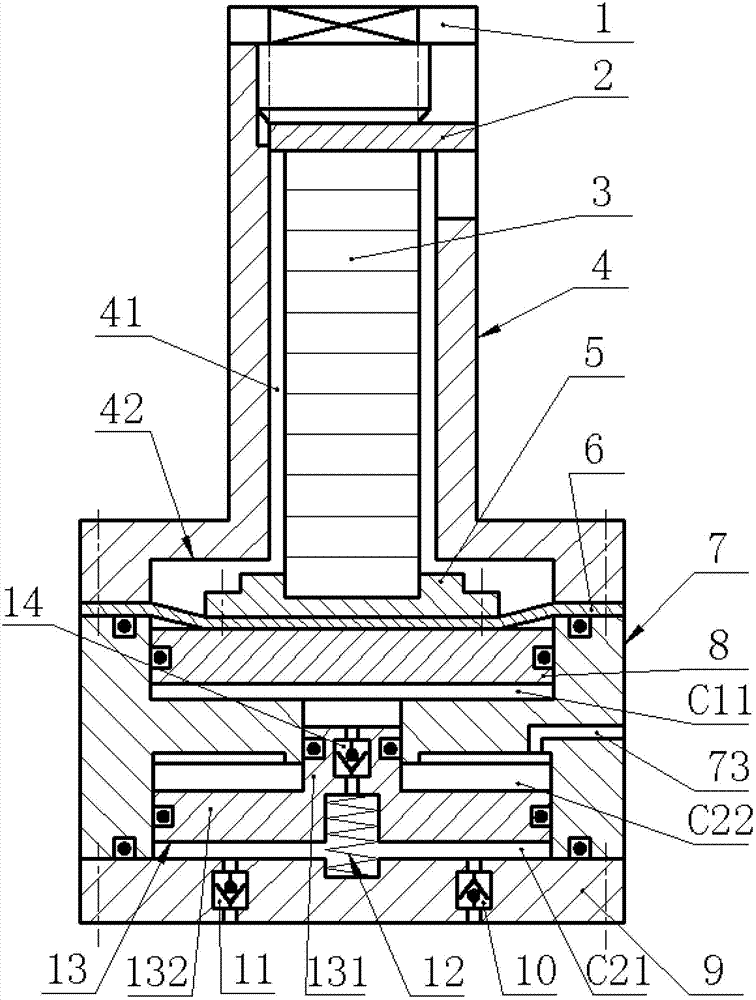

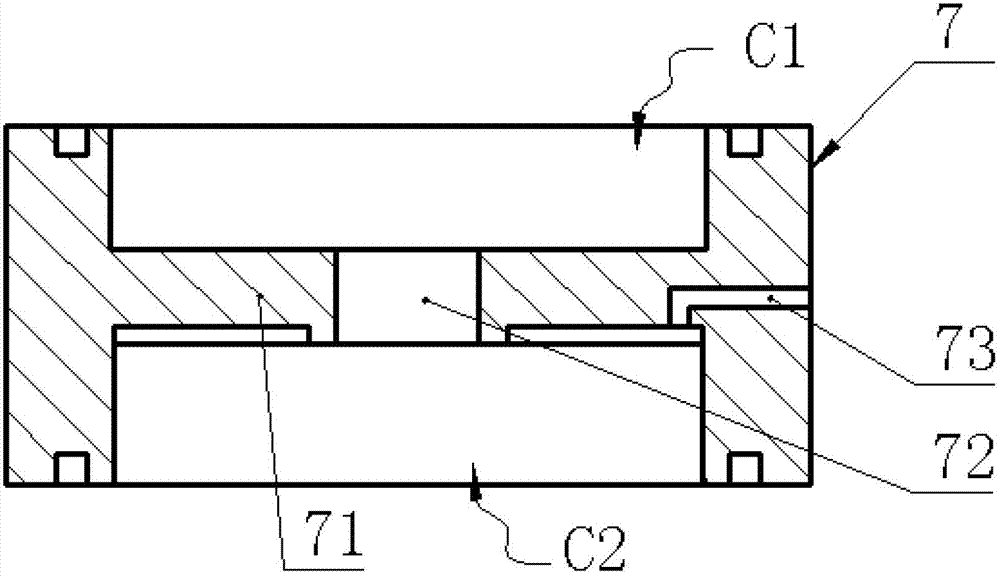

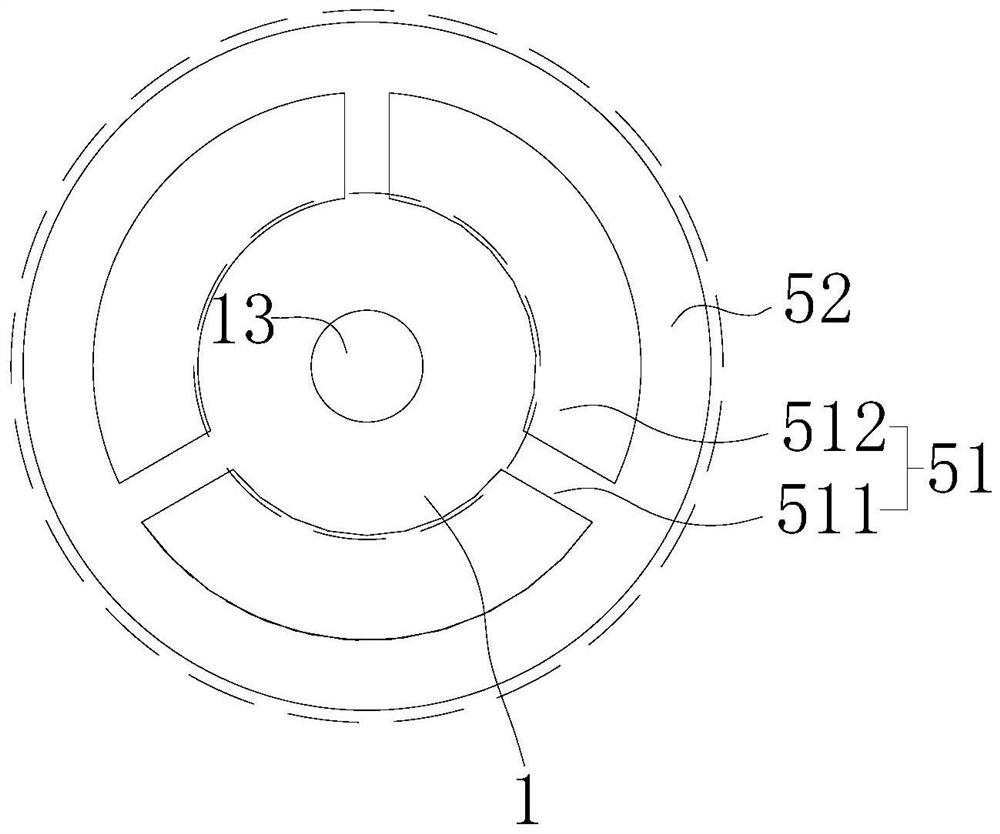

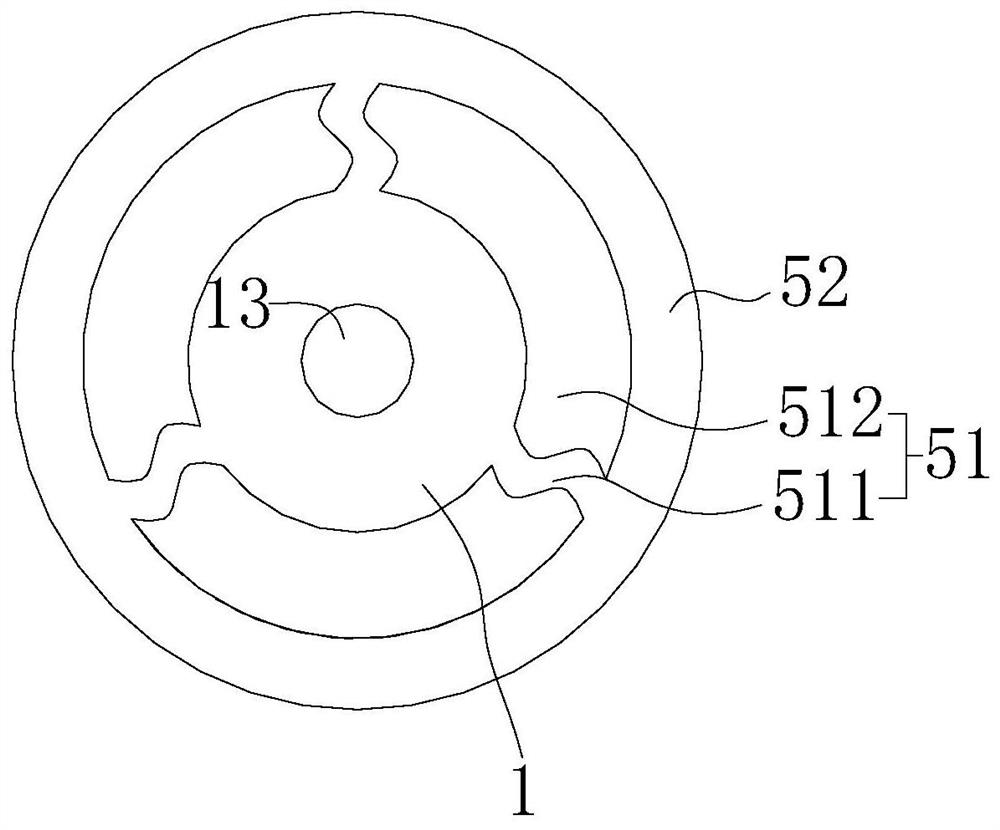

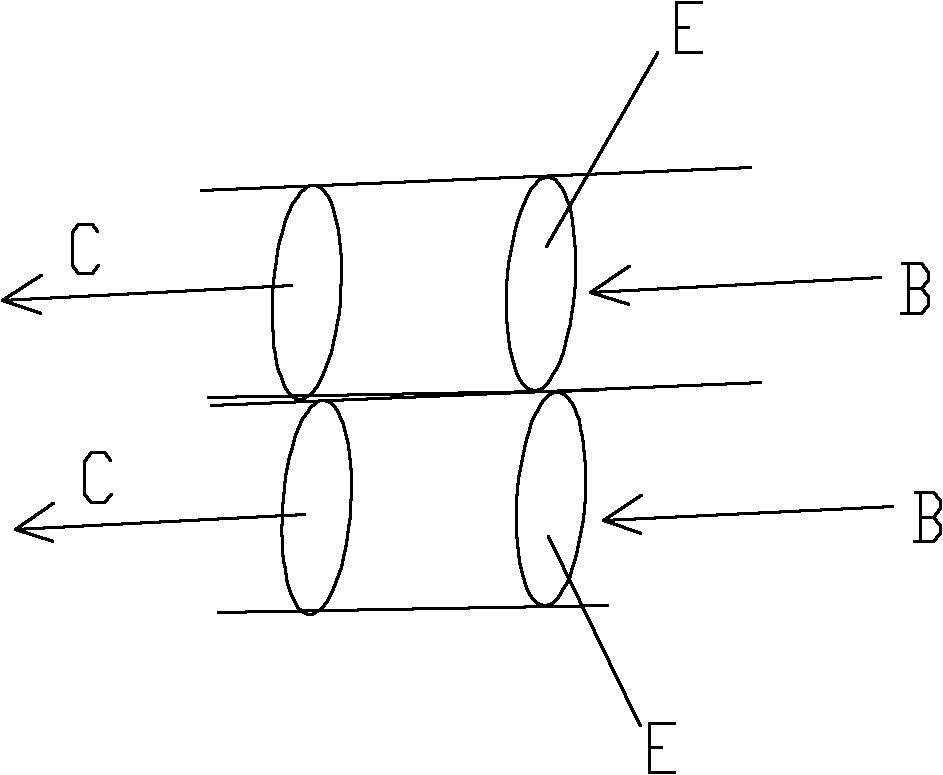

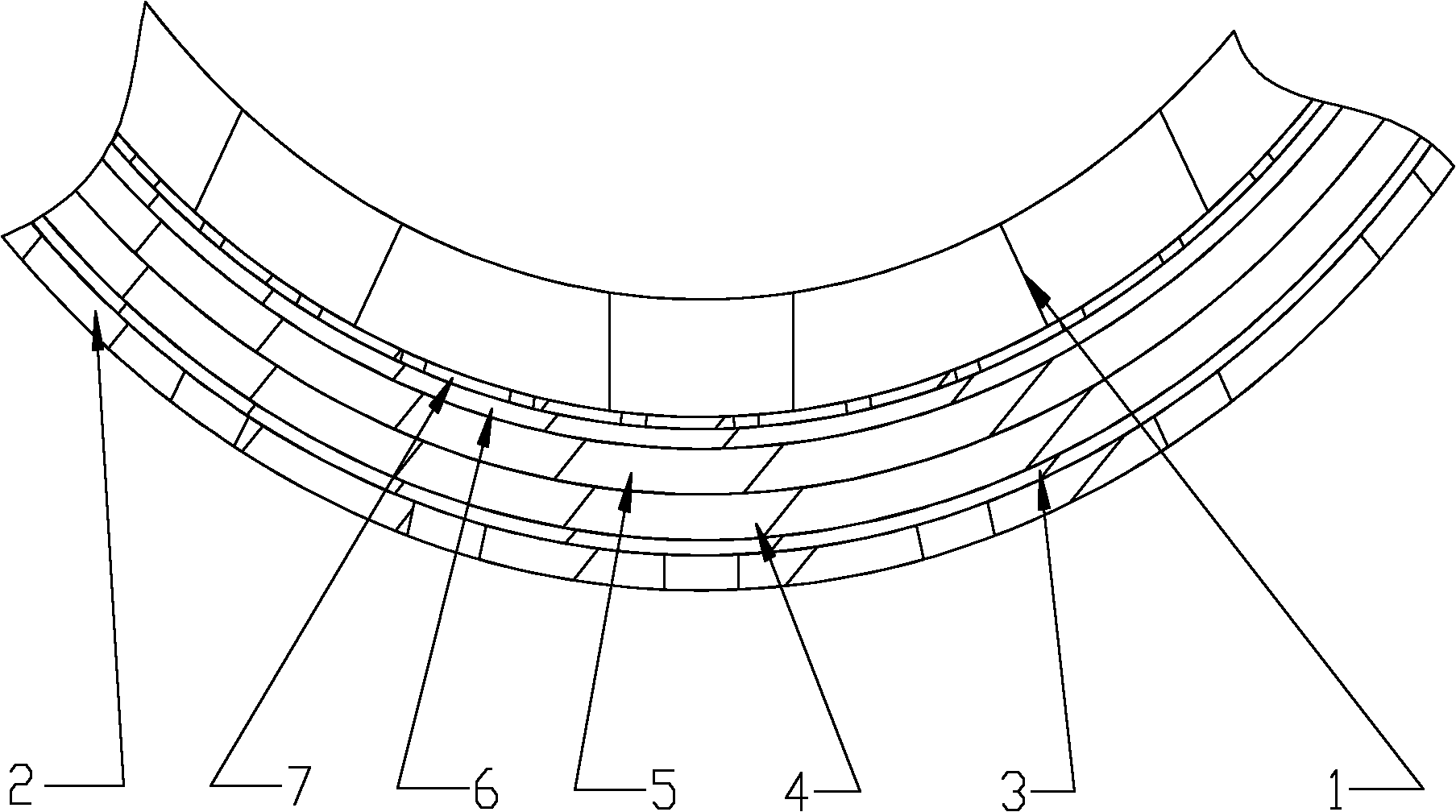

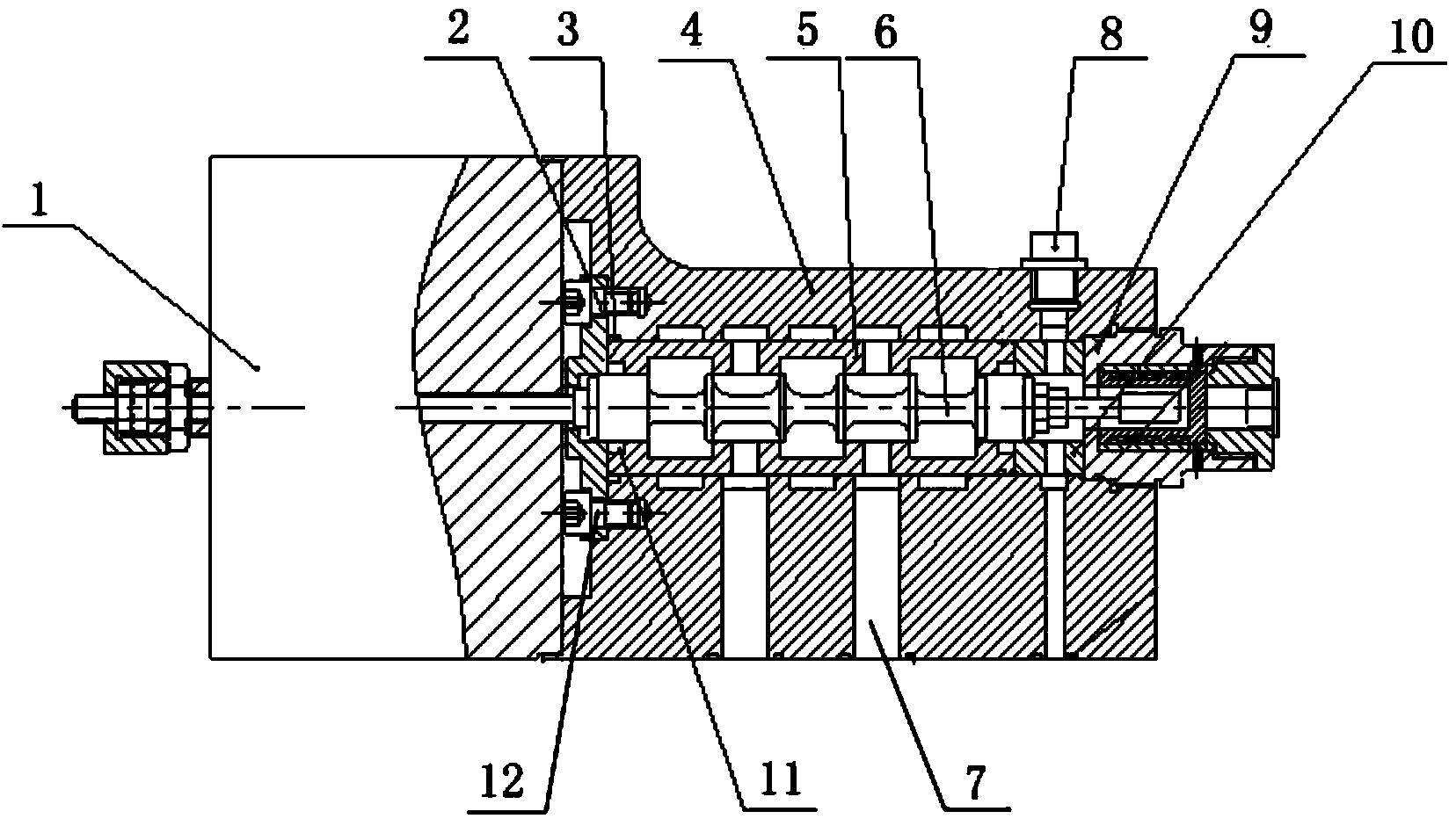

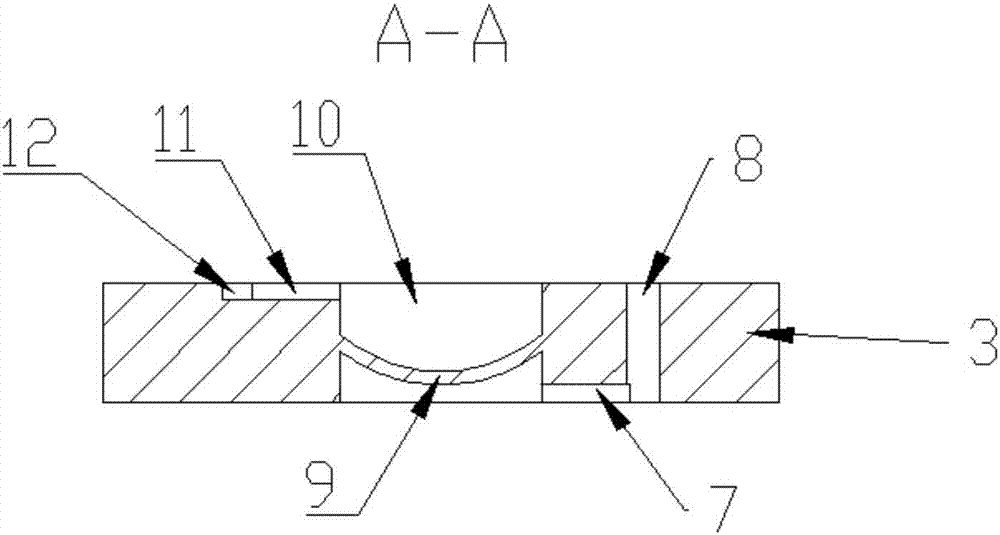

Piezoelectric vibrator bilateral fluid driven series connection pump

InactiveCN102678527AHigh electromechanical energy conversion efficiencyIncrease output flowFlexible member pumpsPositive-displacement liquid enginesElectricityEngineering

The invention relates to a piezoelectric vibrator bilateral fluid driven series connection pump and belongs to the fields of fluid transmission and control. An upper pump body and a lower pump body are connected through a screw, 2-20 piezoelectric vibrators are connected between pump cavities of the two pump bodies in a pressed mode, and valve blocks are pasted at the position of inlets of the pump cavities and an inlet of a valve cavity of the lower pump body. An external inlet of the upper pump body is communicated with adjacent pump cavities, two adjacent pump cavities are communicated through an inter-cavity runner to be connected with the are communicated through an inter-cavity runner to be connected with the piezoelectric vibrators to form a series connection pump I, and an internal outlet and the adjacent pump cavities are communicated through an inter-cavity runner to be connected with the piezoelectric vibrators to form the series connection pump I. an internal inlet of the lower pump body and the adjacent pump cavities are communicated through an inter-cavity runner to be connected with the piezoelectric vibrators to form a series connection pump II, the two the adjacent pump cavities are communicated through an inter-cavity runner to be connected with the piezoelectric vibrators to form the series connection pump II, and a valve cavity and the adjacent pump cavities are communicated through an inter-cavity runner to be connected with the piezoelectric vibrators to form the series connection pump II. An internal outlet of the series connection pump I and the internal inlet of the series connection pump II are communicated, the valve cavity of the series connection pump II is communicated with the external outlet on the upper pump body. The piezoelectric vibrator bilateral fluid driven series connection pump has the advantages that the plurality of the piezoelectric vibrators with two sides driving the fluid simultaneously form series connection piezoelectric pumps, flow quantity is big, pressure and energy efficiency are high, and the piezoelectric vibrator bilateral fluid driven series connection pump is applicable to construction of piezoelectric hydraulic driving with high system backpressure.

Owner:ZHEJIANG NORMAL UNIVERSITY

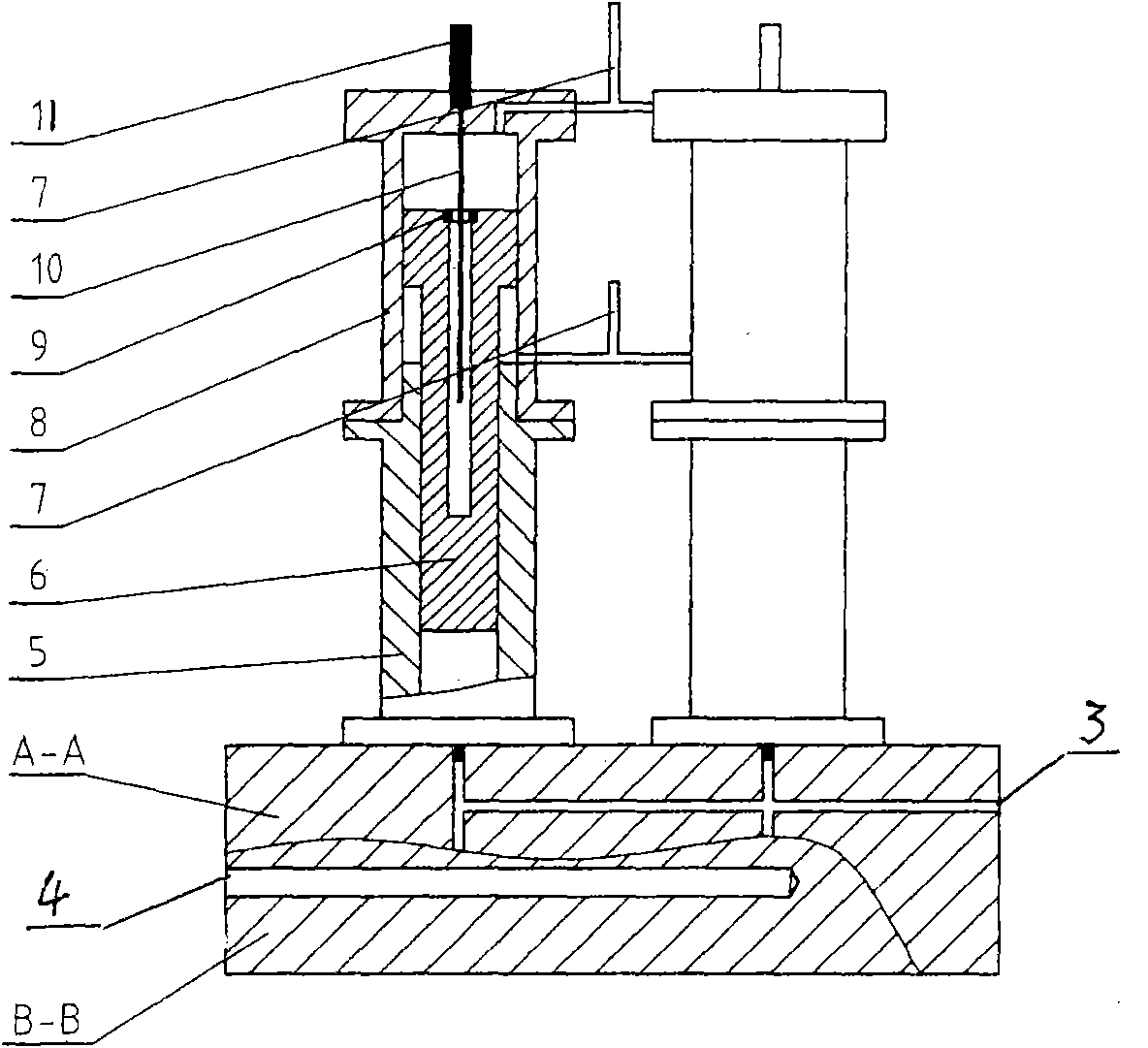

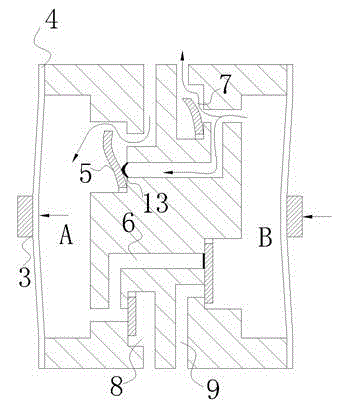

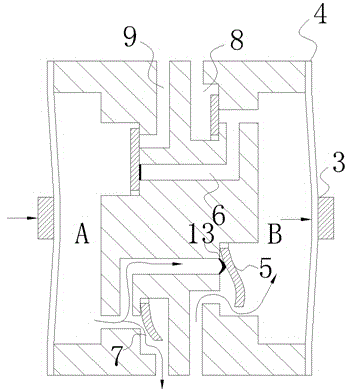

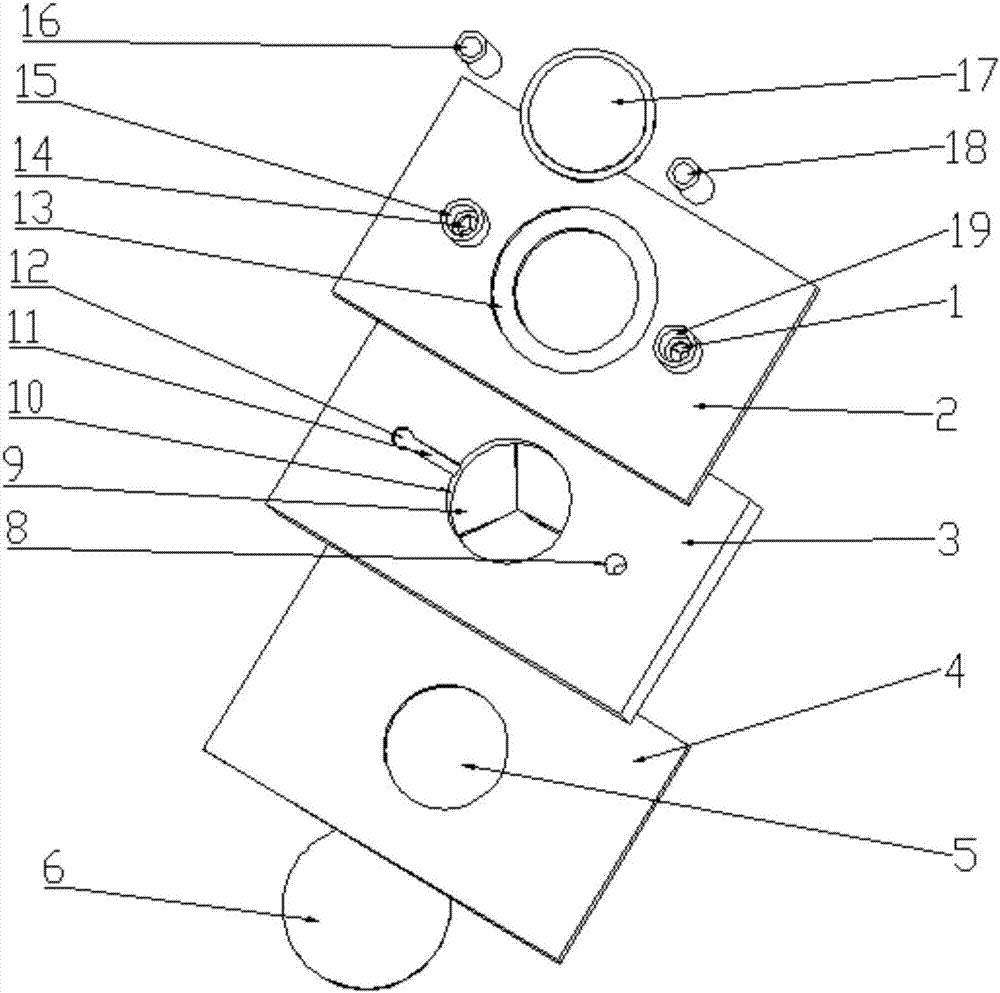

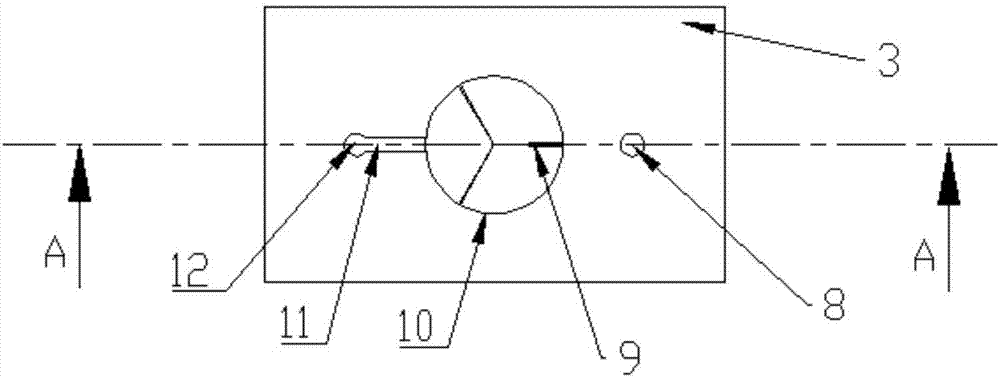

Jet pipe servo valve capable of adjusting axis position of nozzle and adjustment method

InactiveCN107131167AIncrease output flowIncrease jet receiving areaFluid-pressure actuator testingServomotor componentsJet flowTorque motor

The invention discloses a jet pipe servo valve capable of adjusting axis position of a nozzle. The jet pipe servo valve comprises a valve body, a jet nozzle which is arranged on the upper part of the valve body is controlled through a torque motor, adjustment end covers which are arranged on two ends of the valve body, a pressure detection device, a valve bush arranged in the valve body, a valve core arranged in the valve bush and a receiving base which is embedded in the valve core and is used for receiving a flow beam of nozzle jet flow, wherein two jet flow receiving holes are formed in the jet flow receiving base; the two jet flow receiving holes separately communicate with cavities at two ends of the valve core in the valve bush through receiving slot holes formed in the wall of the valve bush; the pressure detection device comprises two pressure detection holes formed in the jet flow receiving base and first pressure sensors arranged on the end covers; and the two pressure detection holes are separately connected with the pressure sensors through detection slot holes formed in the wall of the valve bush. Compared with the prior art, the jet pipe servo valve has the advantages that the axis position of the nozzle can be adjusted; the nozzle is arranged with the axis being centered front and back, so that a leakage rate in the jet pipe servo valve is lowered; and the like.

Owner:TONGJI UNIV

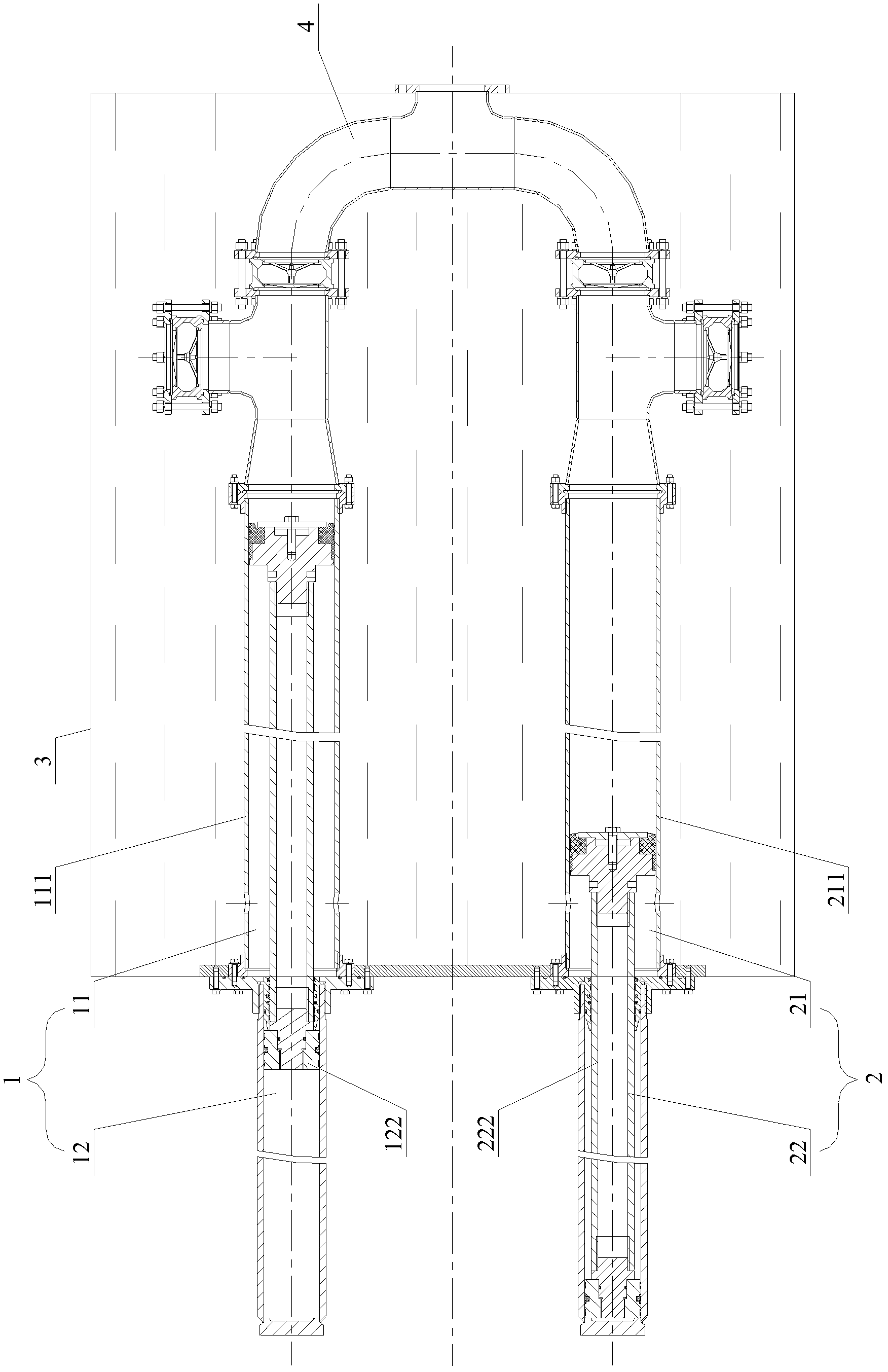

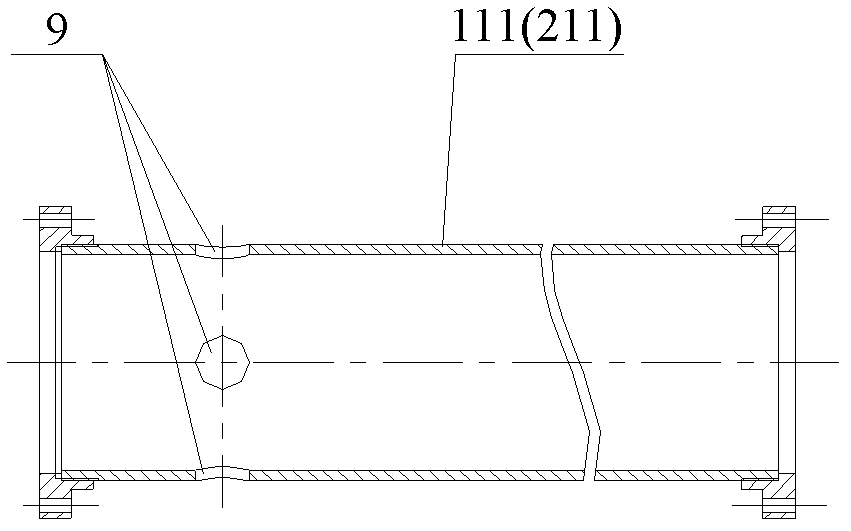

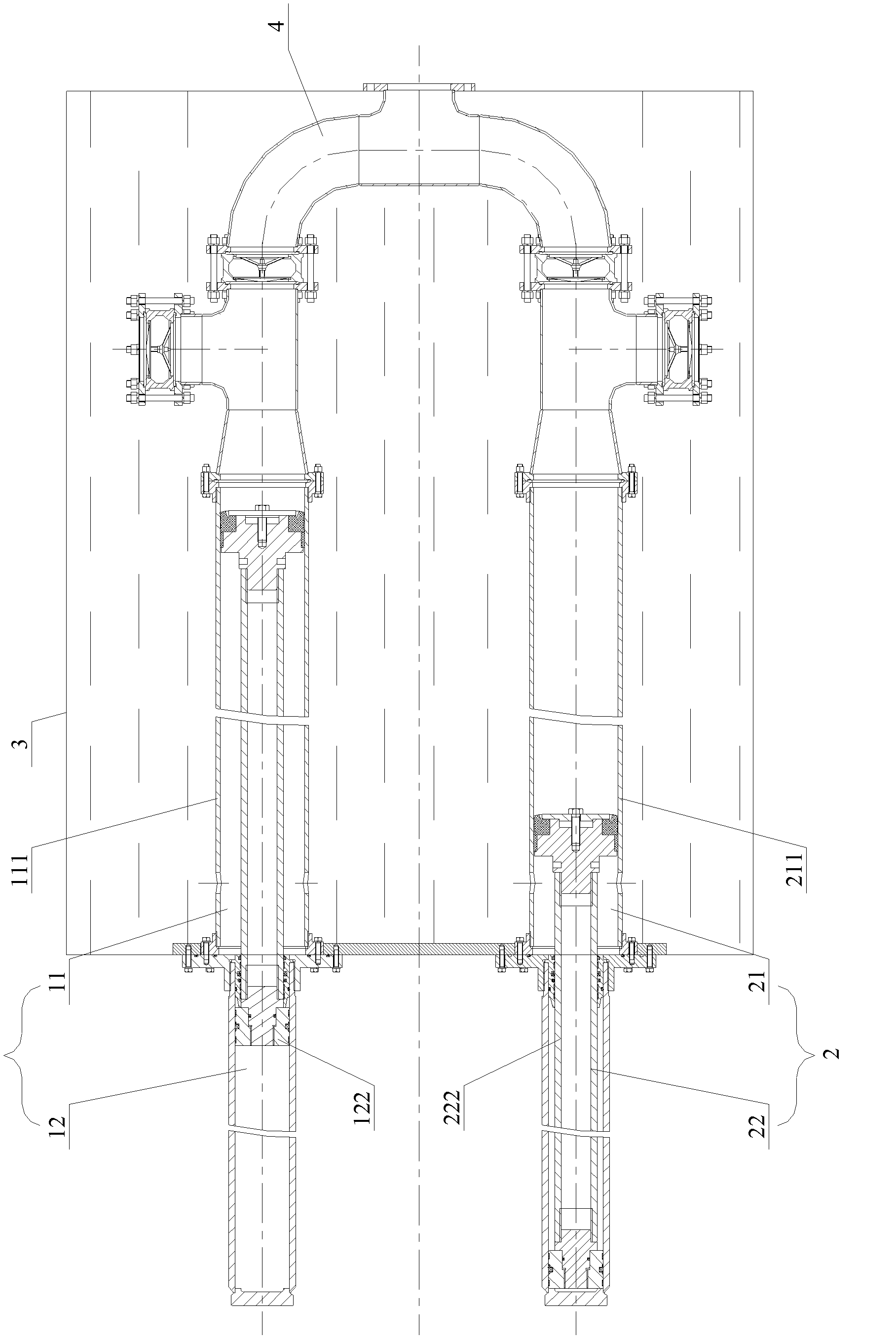

Plunger water pump and liquid control system thereof

InactiveCN102330649APrevent internal leakageIncrease output flow and water pressurePiston pumpsPump installationsPlunger pumpStructural principle

The invention discloses a plunger water pump. The plunger water pump provided by the invention comprises two plunger groups which are composed of water cylinders and oil cylinders, a water cylinder piston and an oil cylinder piston of each plunger group are synchronously displaced, a water gap of each water cylinder barrel is provided with a water inlet one-way valve which is in one-way conduction with a cylinder tube cavity from the outside and a water outlet one-way valve which is in one-way conduction with the cylinder tube cavity from the cylinder tube cavity to the outside; and two oil cylinders are alternately stretched under the control of a control valve. The plunger water pump provided by the invention breaks through a traditional water pump structural principle, two oil cylinders are adopted to alternately move and retreat, thereby driving two water cylinders pistons to alternately move, and further the switch of two working conditions is respectively realized; compared with the prior art, the plunger water pump is capable of effectively improving the output flow and the water utilization pressure on the basis of the continuous no-interval foundation; and the invention also provides a liquid control system of the plunger water pump.

Owner:XUZHOU HEAVY MASCH CO LTD

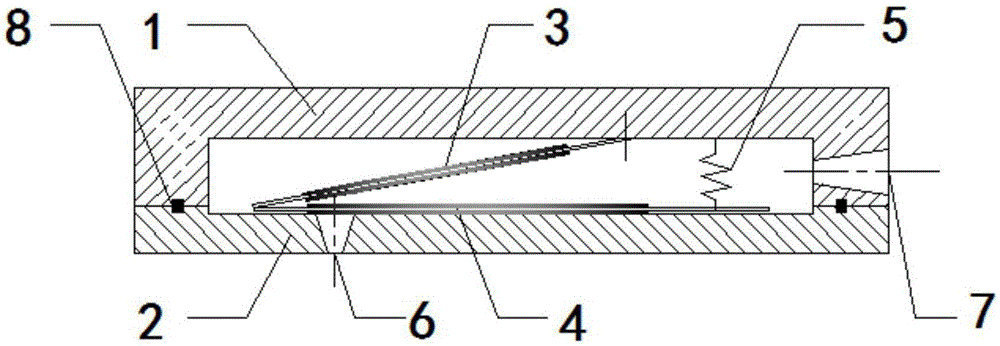

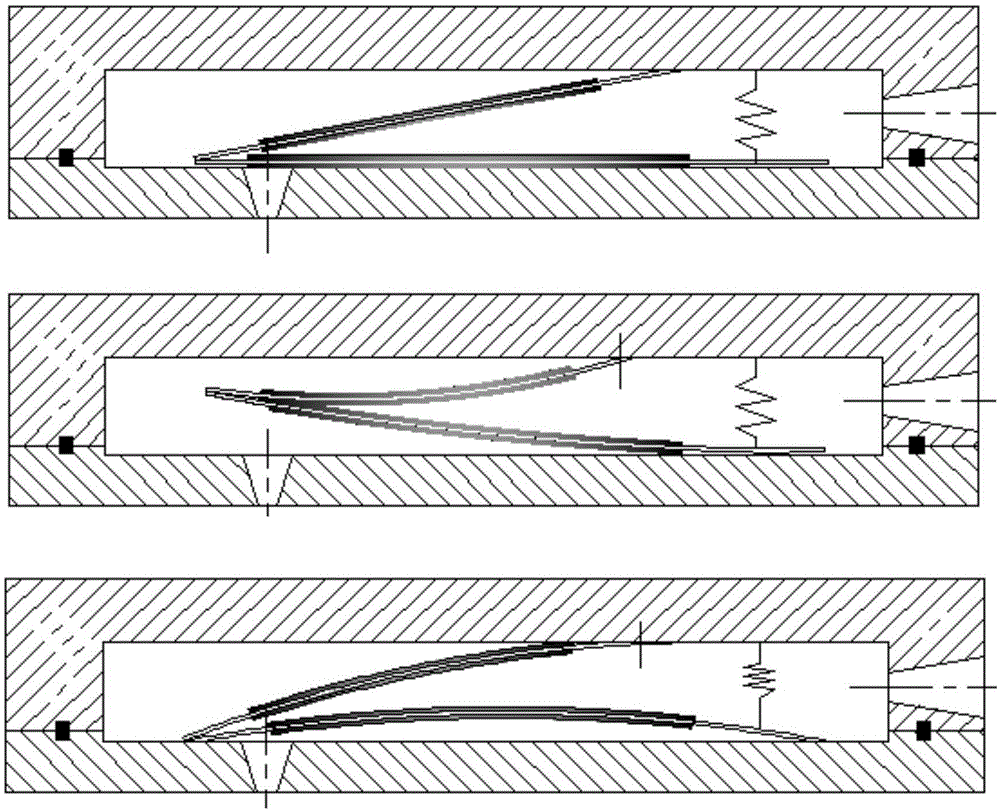

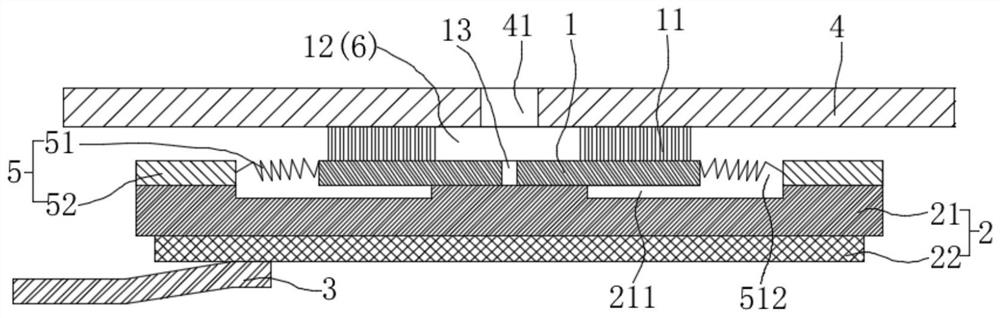

Valveless piezoelectric pump for double-cantilever oscillator

InactiveCN105089994ARealize wet and dry separationIncrease the effective displacementFlexible member pumpsPositive-displacement liquid enginesEngineeringCantilever

A valveless piezoelectric pump for a double-cantilever oscillator comprises an upper pump body, a lower pump body, an upper piezoelectric oscillator body, a lower piezoelectric oscillator body, a pressing spring, a conical inlet, a conical outlet and a sealing ring. The valveless piezoelectric pump is characterized in that the left end of the upper piezoelectric oscillator body is integrally connected with the left end of the lower piezoelectric oscillator body to be in a v shape, the right end of the upper piezoelectric oscillator body is fixed to the upper pump body, and the right end of the lower piezoelectric oscillator body is pressed by the pressing spring. When the piezoelectric pump is in a non-work state, the lower piezoelectric oscillator body is completely in contact with the bearing plane of the lower pump body.

Owner:JILIN UNIV

Supercharger with controllable hydraulic pressure and flow output

InactiveCN101994724AIncrease the diameterIncrease the itineraryFluid-pressure convertersEngineeringHigh pressure

The invention relates to a supercharger with controllable hydraulic pressure and flow output, wherein a twin-charger high-pressure fluid output structure is adopted, and the diameter and the stroke of a piston and a plunger of each charger are increased so as to meet a work pressure output requirement and simultaneously improve output flow, which is 10 times that of the traditional supercharger. A phase different between the operation cycles of the pistons of the two chargers is 180 degrees, the output high-pressure fluid enters a valve seat (1), and a waterway channel in the valve seat (1) is designed in a bridge type loop structure which ensures that the output high-pressure fluid is stable and balanced in flow. A displacement transducer control technology is introduced to meet an automation requirement of a water pressure test-tube engine test, and the work efficiency and the safety performance of a detection test on an oil transferring pipeline are greatly improved.

Owner:云南兴长江实业有限公司

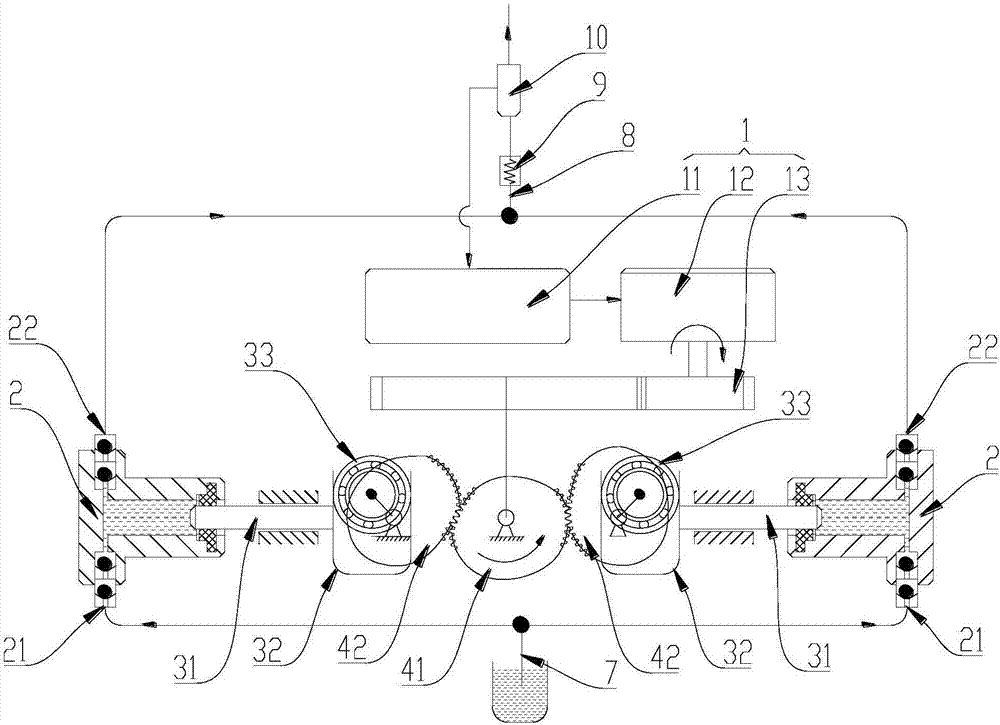

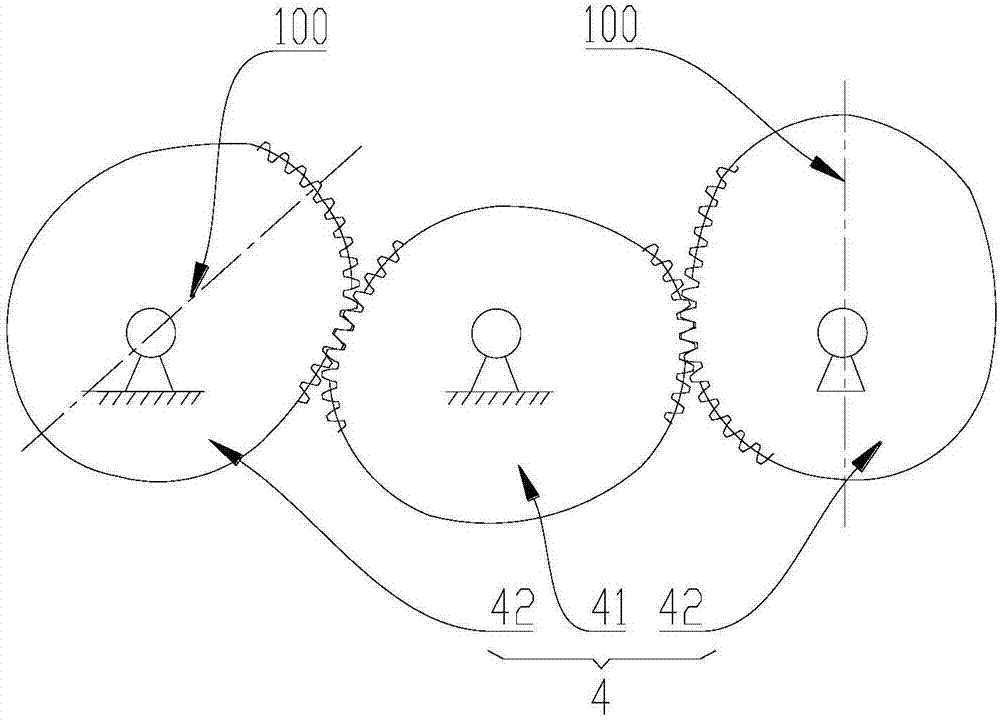

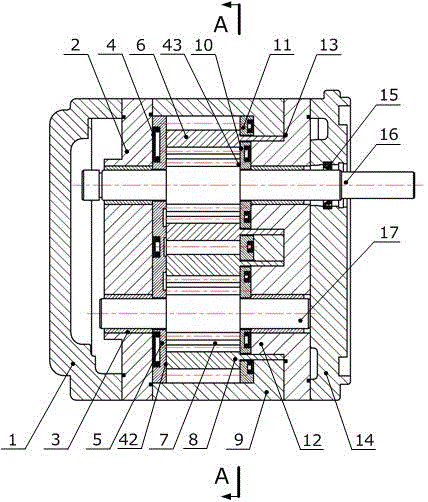

Internally-engaged gear pump applicable to high pressure and large flow

ActiveCN104454511AReasonable forceReduce distortionRotary piston pumpsRotary piston liquid enginesDouble teethEngineering

The invention discloses an internally-engaged gear pump applicable to high pressure and large flow. The internally-engaged gear pump is composed of a pump shell, a first double-tooth ring, a second double-tooth ring, a first gear shaft, a second gear shaft, a radial compensation device, a sliding bearing, a side plate and the like, wherein the first double-tooth ring and the second double-tooth ring are symmetrically arranged in the pump body, and outer teeth of the first double-tooth ring and the second double-tooth ring are engaged to form a first gear pair; the first gear shaft and the first double-tooth ring are engaged to form a second gear pair; and the second gear shaft and the second double-tooth ring are engaged to form a third gear pair. A single input shaft is used for driving the gear pairs to rotate by grades and the distribution of moment on the shaft is reasonable; and the radial unbalance force on each grade of gear pair is small and the anti-pressure ability of the pump under a high pressure working condition is improved. Oil in the pump is pressurized by the plurality of grades of gear pairs so that the output pressure and the flow of the oil are effectively improved; and meanwhile, the two paths of oil on the outlet of the pump are overlapped so that the flow and the pressure pulse of the pump are remarkably reduced and the requirements of a high-precision hydraulic system can be met.

Owner:FUZHOU UNIV

Piezoelectric pump with novel semi-active valve

ActiveCN104564622AAvoid the problem of insufficient opening pressureAvoid Control DifficultiesPositive displacement pump componentsFlexible member pumpsSemi activeHigh pressure

The invention discloses a piezoelectric pump with a novel semi-active valve. An auxiliary oil circuit is added into the traditional oil circuit to guide the discharged high pressure oil into the auxiliary oil circuit and jack an elastic film so as to achieve the auxiliary opening of an oil inlet one-way valve. According to the piezoelectric pump with the novel semi-active valve, the auxiliary opening of the one-way valve is achieved and the high pressure oil can be isolated from the low pressure oil so as to prevent the high pressure oil from entering a low pressure oil chamber due to the elastic film and the symmetrical double-pump structure design is adopted and accordingly the structure is simplified, the work is consistent, the working frequency is increased, and the flow of the hydraulic oil is increased.

Owner:ZHEJIANG UNIV

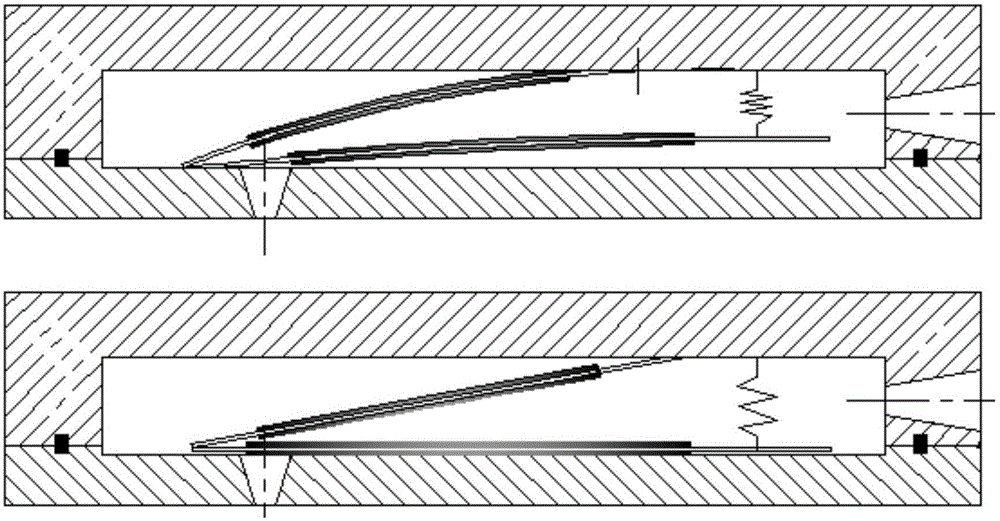

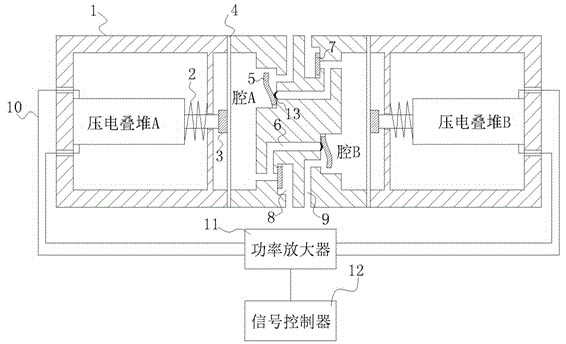

Piezo-stack pump capable of driving double-piston in tandem connection

InactiveCN102966521AIncrease output flowImprove conversion efficiencyFlexible member pumpsPositive-displacement liquid enginesElectricityEngineering

The invention relates to a piezo-stack pump capable of driving double-piston in tandem connection, and belongs to the field of microfluid transmission and control. A pump body is fixed with an upper shell and a lower end cap; an elastic diaphragm is connected between the pump body and the upper shell in a pressing way; a compression cavity piston is connected with the elastic diaphragm and a top block through a screw; the screw is adjusted to squeeze the piezoelectric stack placed in an inner cavity of the upper shell onto the top block through a torsion-proof gasket; a small end of a pump-cavity piston, a check valve placed on the pump-cavity piston, the compression cavity piston and the pump body form the compression cavity; the lower end cap squeezes a large end of the pump-cavity piston onto a separation plate through a balance spring; and the compression cavity and the pump cavity are communicated through the check valve. The piezo-stack pump has the advantages that one piezoelectric stack can drive the two pistons tandemly connected by the fluid compression cavities filled automatically to output fluid, and is not subjected to fluid action when not working, so that the flow of the pump is large, the volume is small, the cost is low, and the electromechanical energy conversion efficiency is high.

Owner:ZHEJIANG NORMAL UNIVERSITY

Staggered-layer supporting structure of piezoelectric micropump and gas control device

PendingCN111980887AMiniaturizationThe structure is reduced or even eliminatedPositive displacement pump componentsFlexible member pumpsEngineeringMicropump

The invention belongs to the technical field of fluid conveying equipment, and particularly relates to a staggered-layer supporting structure of a piezoelectric micropump and a gas control device. Thestaggered-layer supporting structure of the piezoelectric micropump comprises the piezoelectric micropump and a supporting plate, wherein the piezoelectric micropump comprises a resonance plate, a piezoelectric vibrator and an electrode assembly, the resonance plate and the piezoelectric vibrator are sequentially arranged in a stacked mode, and the electrode assembly is connected to the side, away from the resonance plate, of the piezoelectric vibrator; and the side, away from the piezoelectric vibrator, of the resonance plate is supported by the supporting plate, a gap is formed between theresonance plate and the supporting plate so as to form a gas inlet cavity, and the supporting plate is used for supporting and restraining the piezoelectric micropump. The gas control device comprisesthe staggered-layer supporting structure of the piezoelectric micropump and a shell. The technical problems that in the prior art, a piezoelectric micropump needs to be connected to a peripheral supporting part through a connecting part extending in the circumferential direction, the supporting part is laminated and fixed, and the size of the piezoelectric pump is greatly increased are solved.

Owner:常州威图流体科技有限公司

Foam metal composite sand prevention structure and liquid extracting pipe

InactiveCN102220857AImprove sand control effectStrong sand capacityFluid removalMaterials scienceMetal mesh

The invention provides a foam metal composite sand prevention structure and a liquid extracting pipe. The foam metal composite sand prevention structure is sleeved outside a basic pipe and at least comprises a foam metal sand prevention layer made of foam metal. The liquid extracting pipe comprises the basic pipe and the foam metal composite sand prevention structure which is sleeved outside the basic pipe. The sand prevention structure has the sand prevention effect of a gravel filling process, the structural strength of a wire-wound metal mesh, high sand tolerance capacity, low overflow resistance, and a good prevention effect on sand grains with the grain size of more than 60mu m; and when the sand prevention structure is matched with a well cleaning process, a pipe column is not required to be moved for well cleaning, so that the sand prevention effect is further enhanced.

Owner:PETROCHINA CO LTD

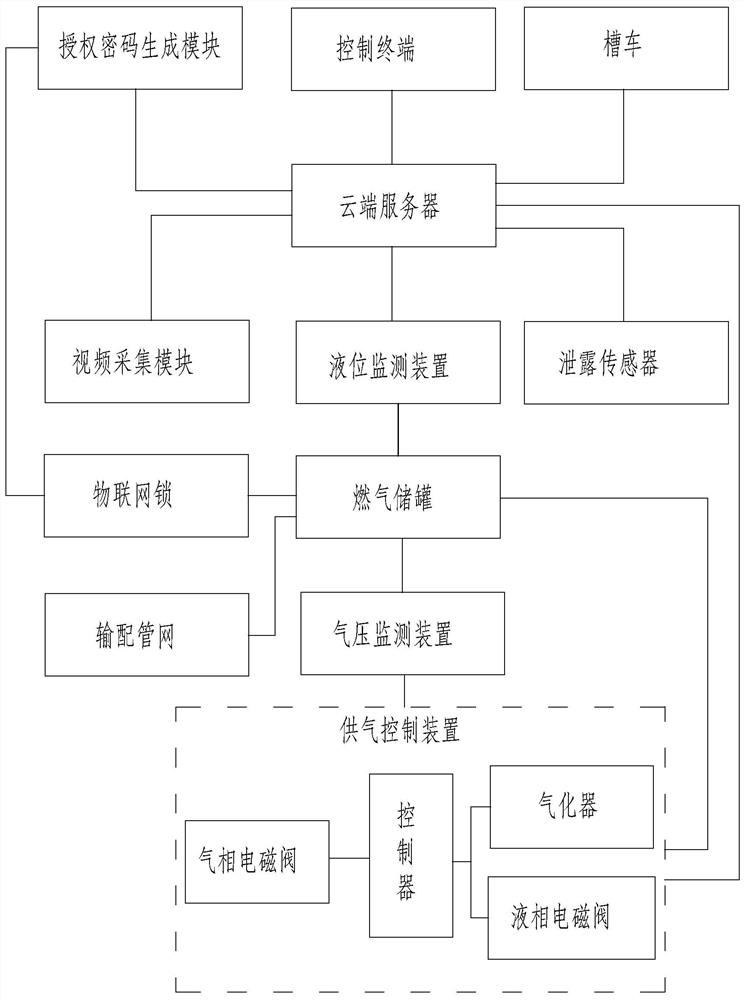

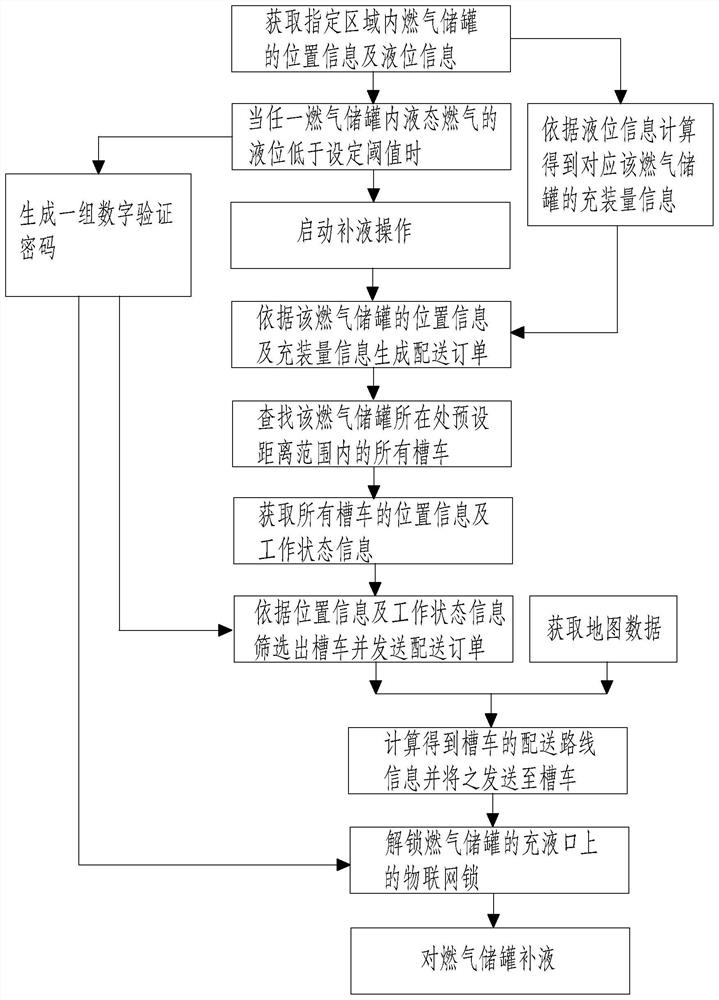

Safety monitoring system and method for small fuel gas storage tank and intelligent terminal

InactiveCN112253995AImprove securityConvenient rehydration operationKey distribution for secure communicationFluid transferredLiquid stateControl engineering

The invention relates to a safety monitoring system and method for a small fuel gas storage tank and an intelligent terminal. The safety monitoring system comprises a liquid level monitoring device arranged on the fuel gas storage tank, a cloud server and a control terminal. The liquid level monitoring device is used for monitoring the liquid level of liquid fuel gas in the fuel gas storage tank and generating liquid level information; the cloud server is connected with the liquid level monitoring device and used for sending the liquid level information to the control terminal; and the controlterminal is connected with a tank car in the designated area and used for generating a scheduling instruction according to the liquid level information and sending the scheduling instruction to the designated tank car. The safety monitoring system has the effect of reducing the workload of workers so as to improve the maintenance efficiency.

Owner:深圳市中燃科技有限公司

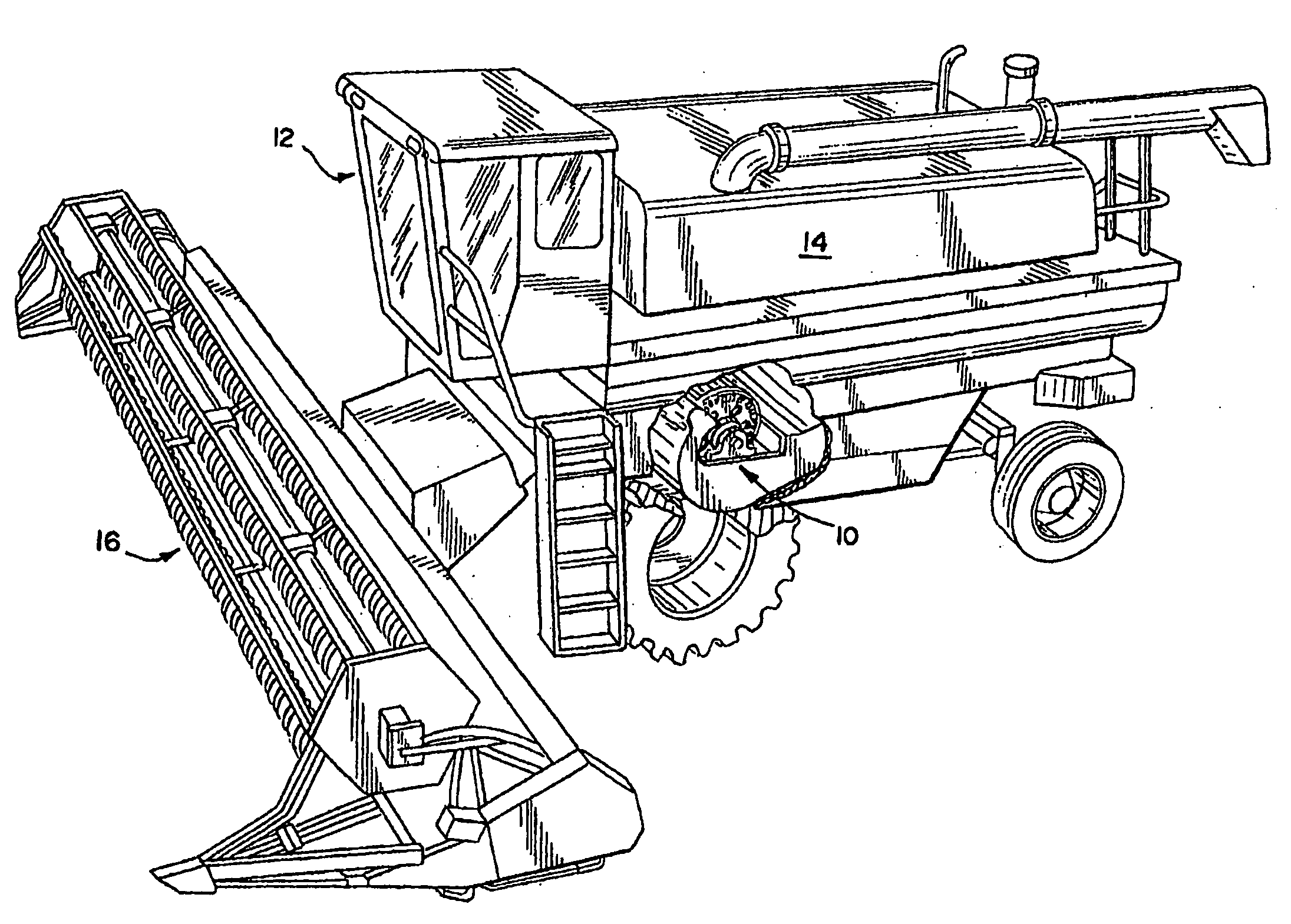

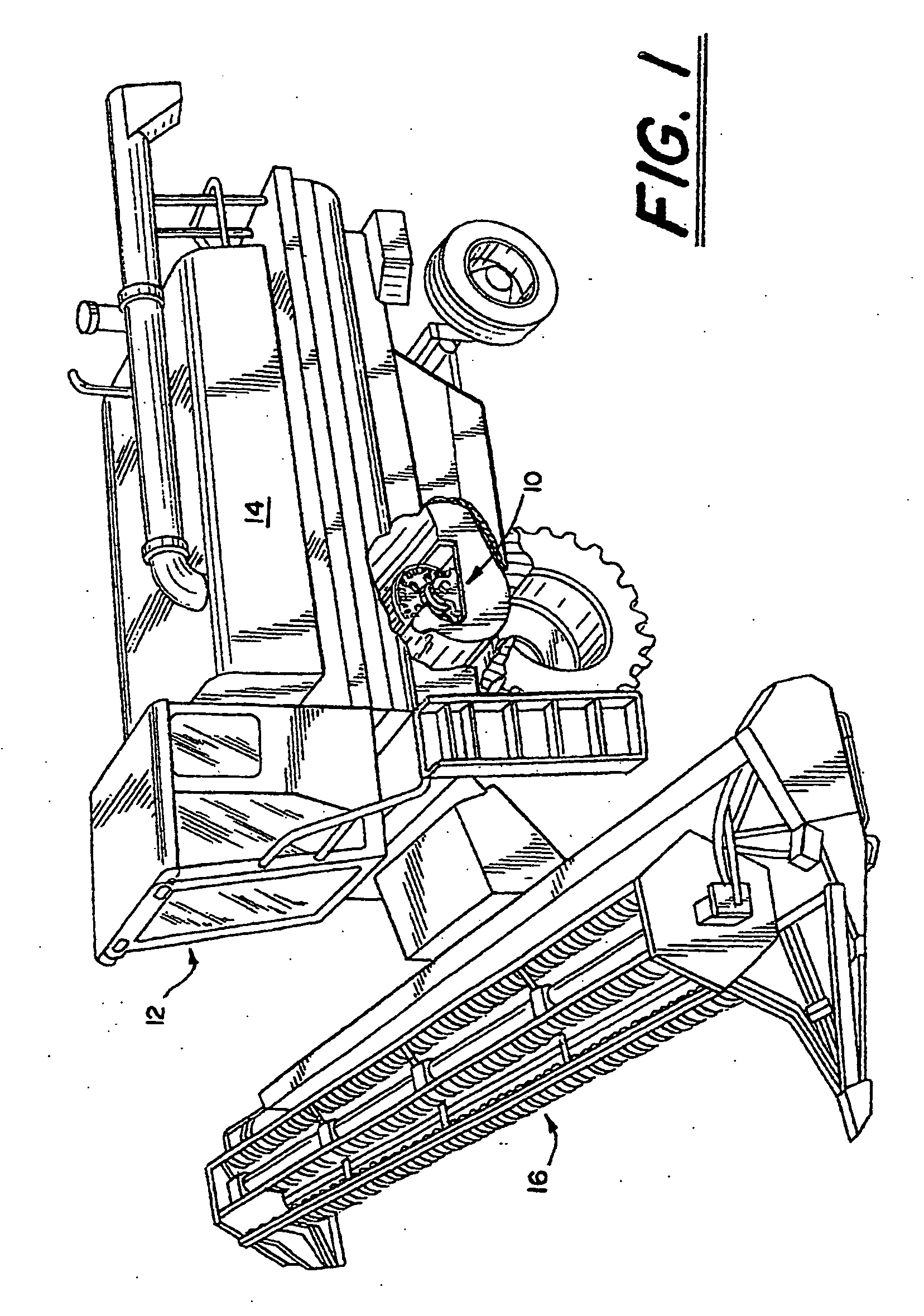

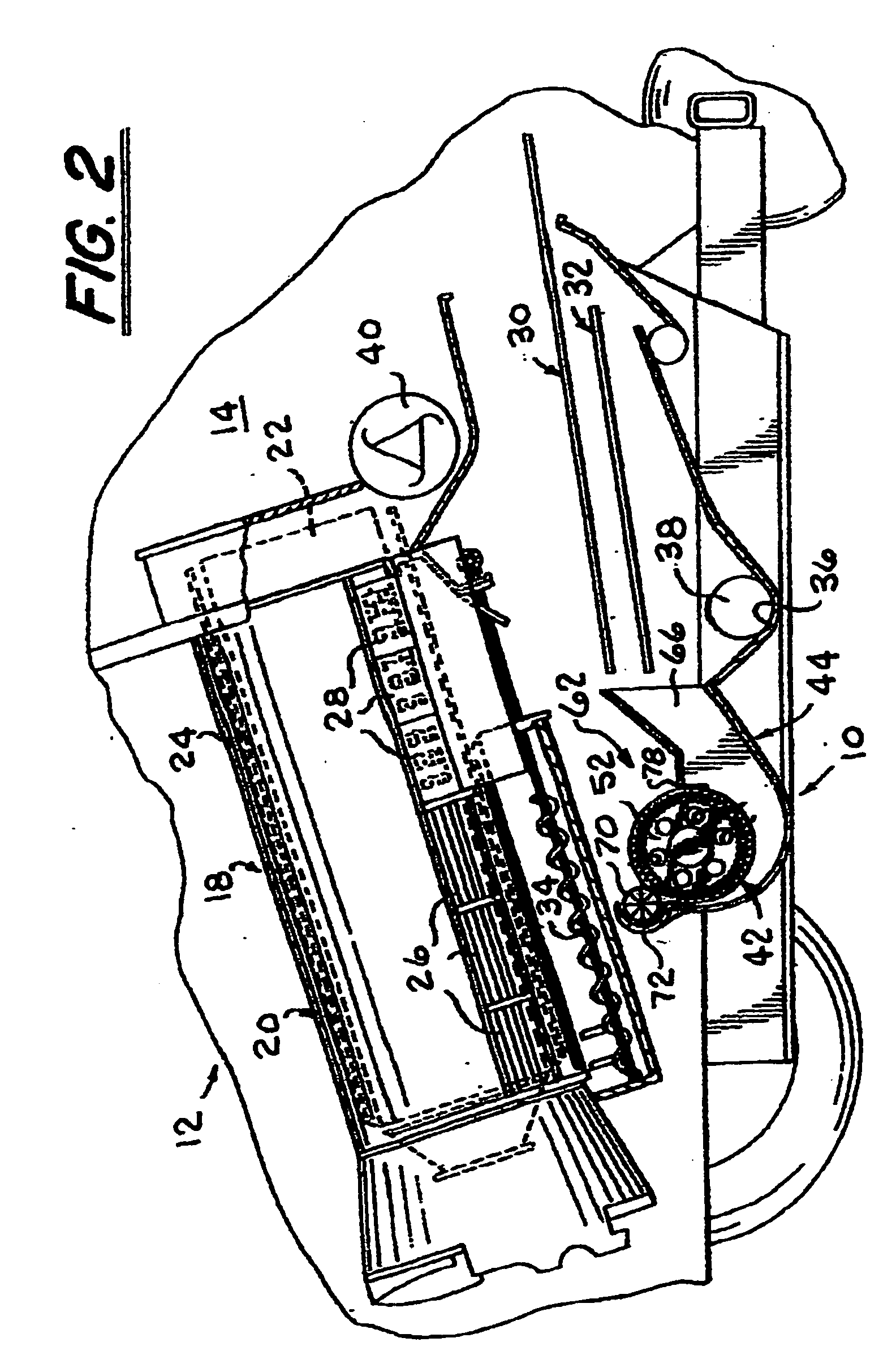

Rotating inlet for cross flow fan

ActiveUS20080004090A1Reduce noiseIncrease airflowSievingCircumferential flow pumpsRotational axisForced-air

A transverse fan assembly that includes a fan rotatably disposed in an air plenum for drawing air through an inlet opening and drivingly forcing air from an outlet opening defined by the air plenum, the inlet opening having an elongate, bladed, inlet rotor oriented on a rotational axis parallel to the fan, extending the length of the fan, and positioned proximate to the fan periphery to increase air flow and improve air flow distribution from the outlet of the air plenum along the length of the fan while generating less noise.

Owner:BLUE LEAF I P

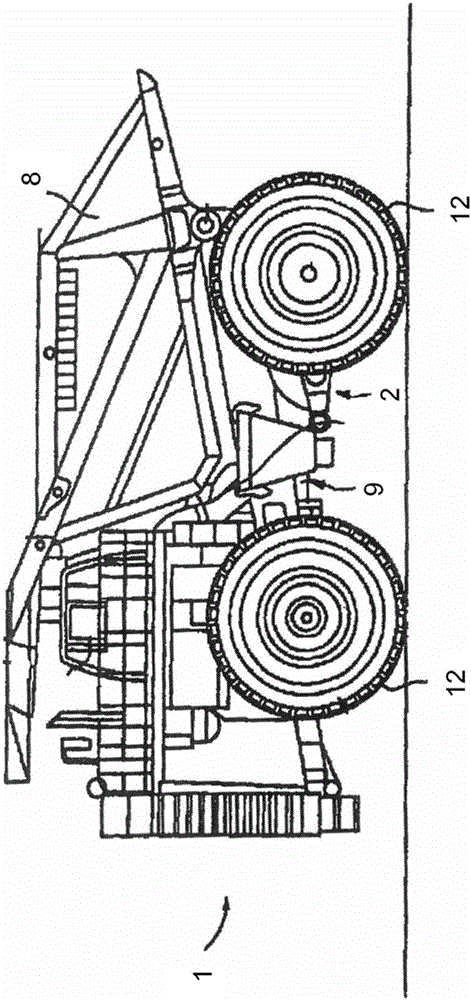

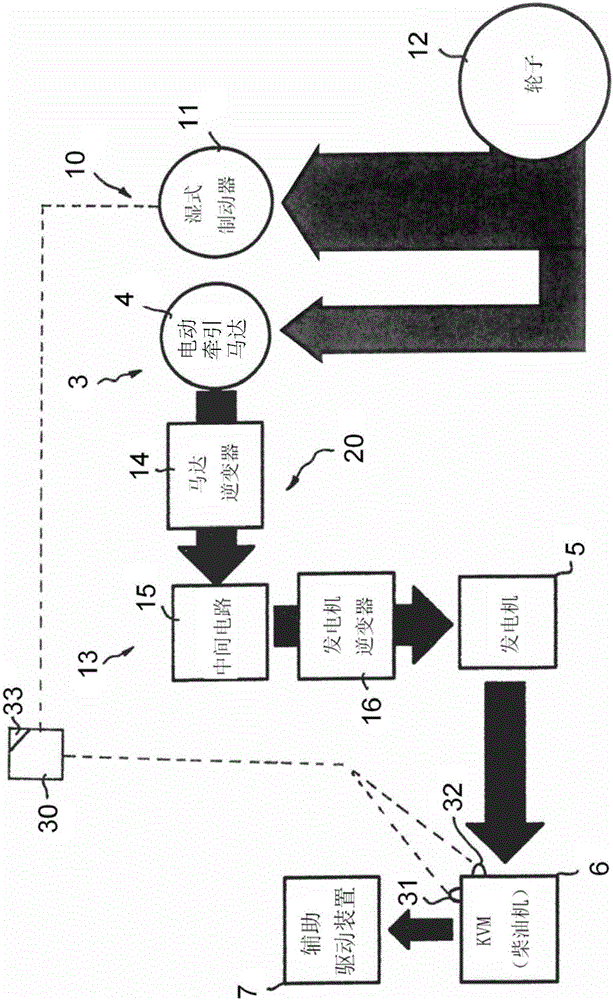

Self-propelled working machine and method for braking working machine of this type

InactiveCN105764731AIncrease braking powerIncrease speedHybrid vehiclesAuxillary drivesEngineeringEngine braking

The invention relates to a self-propelled working machine, preferably in the form of a dumper truck or truck, having an electric drive comprising at least one electric motor (4), a generator (5) driven by a combustion engine (6) for supplying power to the electric drive, and a braking device (4, 11) for braking the working machine. Said braking device provides power-generating braking via the electric drive (4) and a feed-back of electrical engine braking power of the electric motor (4) to the generator (5), in order to support the engine braking power provided by the combustion engine (6). The invention also relates to a method for braking a working machine of this type. According to the invention, a braking control device is provided to automatically engage a mechanical brake (11) in accordance with the engine braking power fed back to the combustion engine and / or in accordance with the operating state of the combustion engine supplied with fed-back engine braking power.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

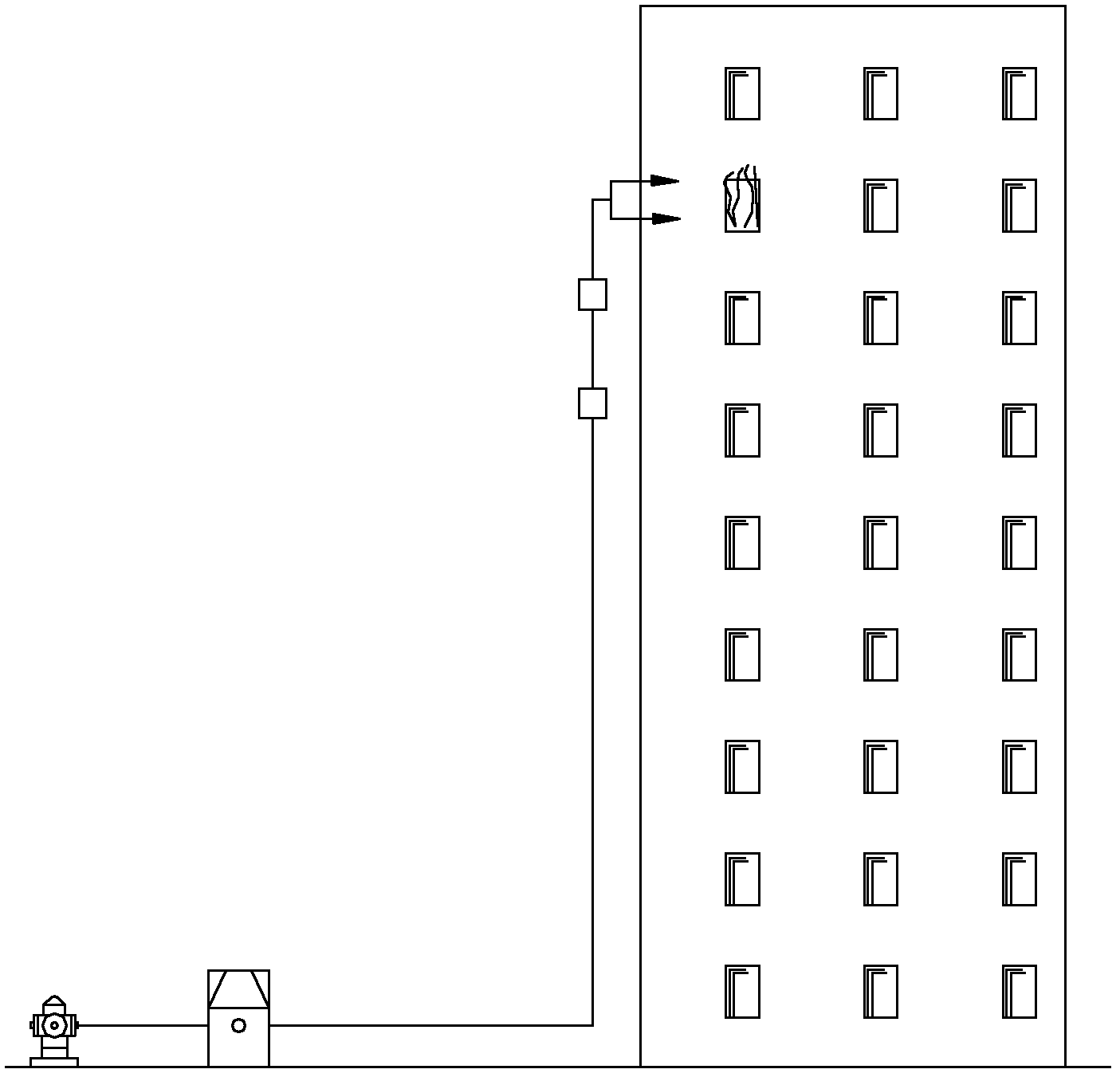

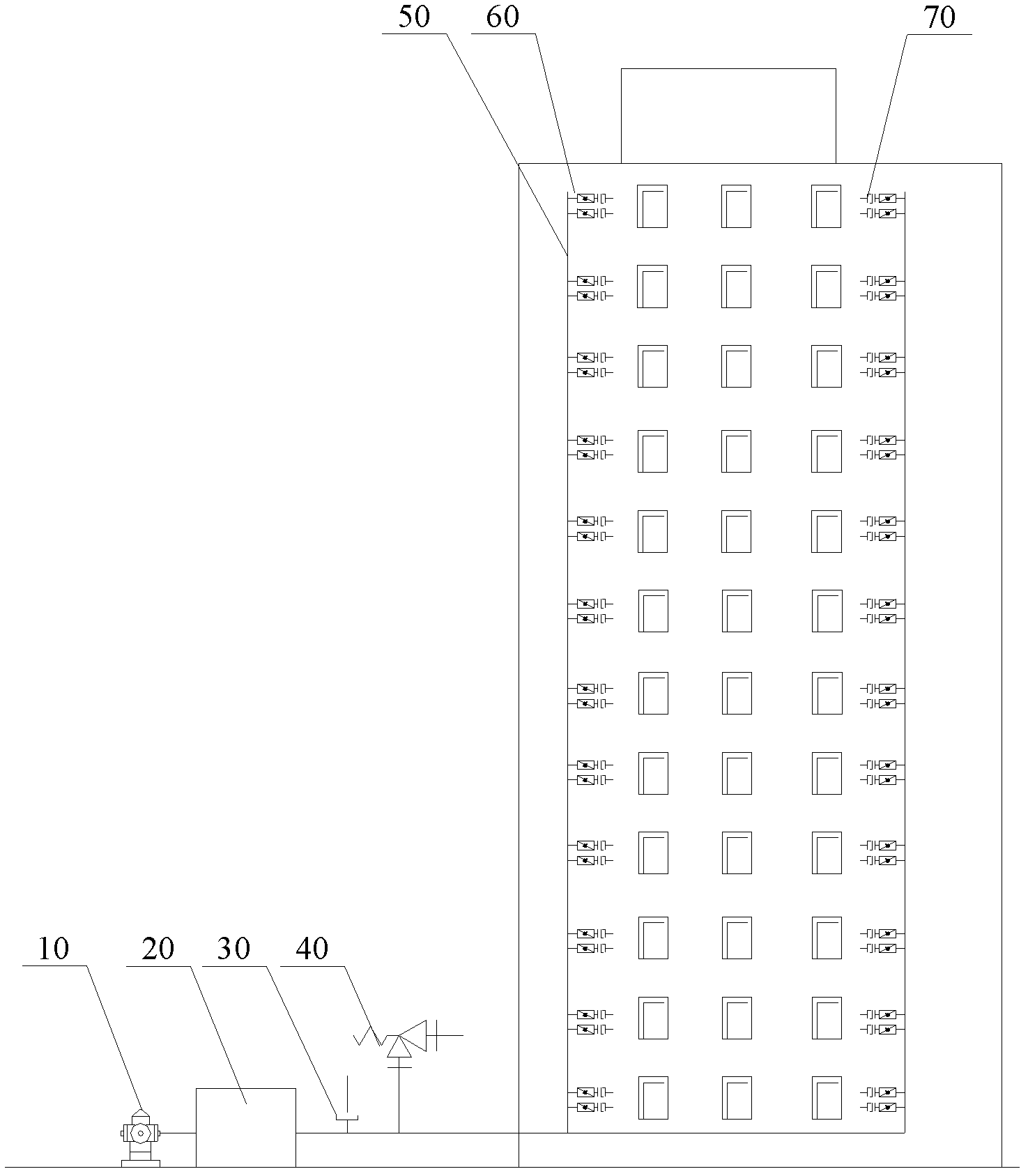

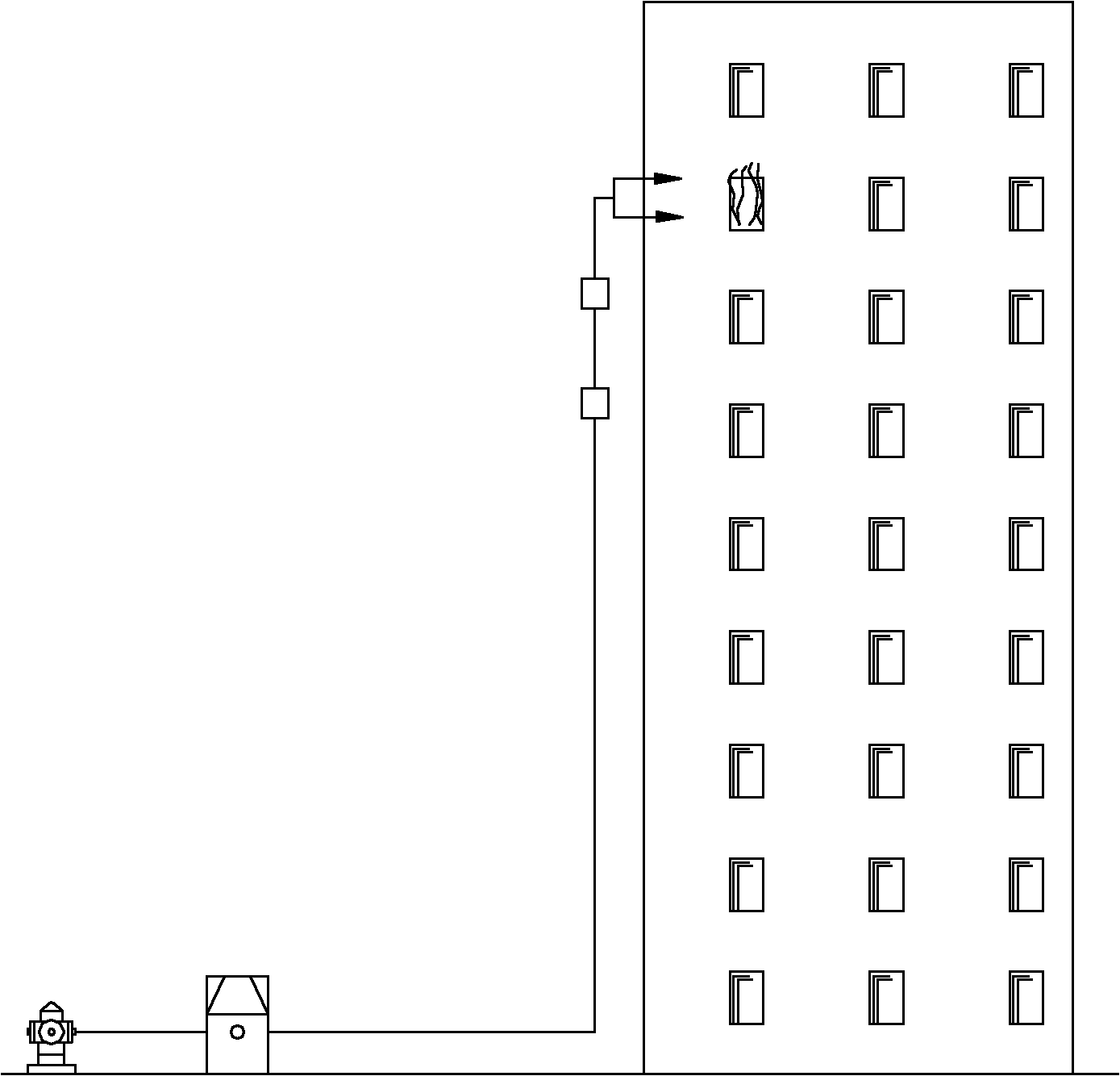

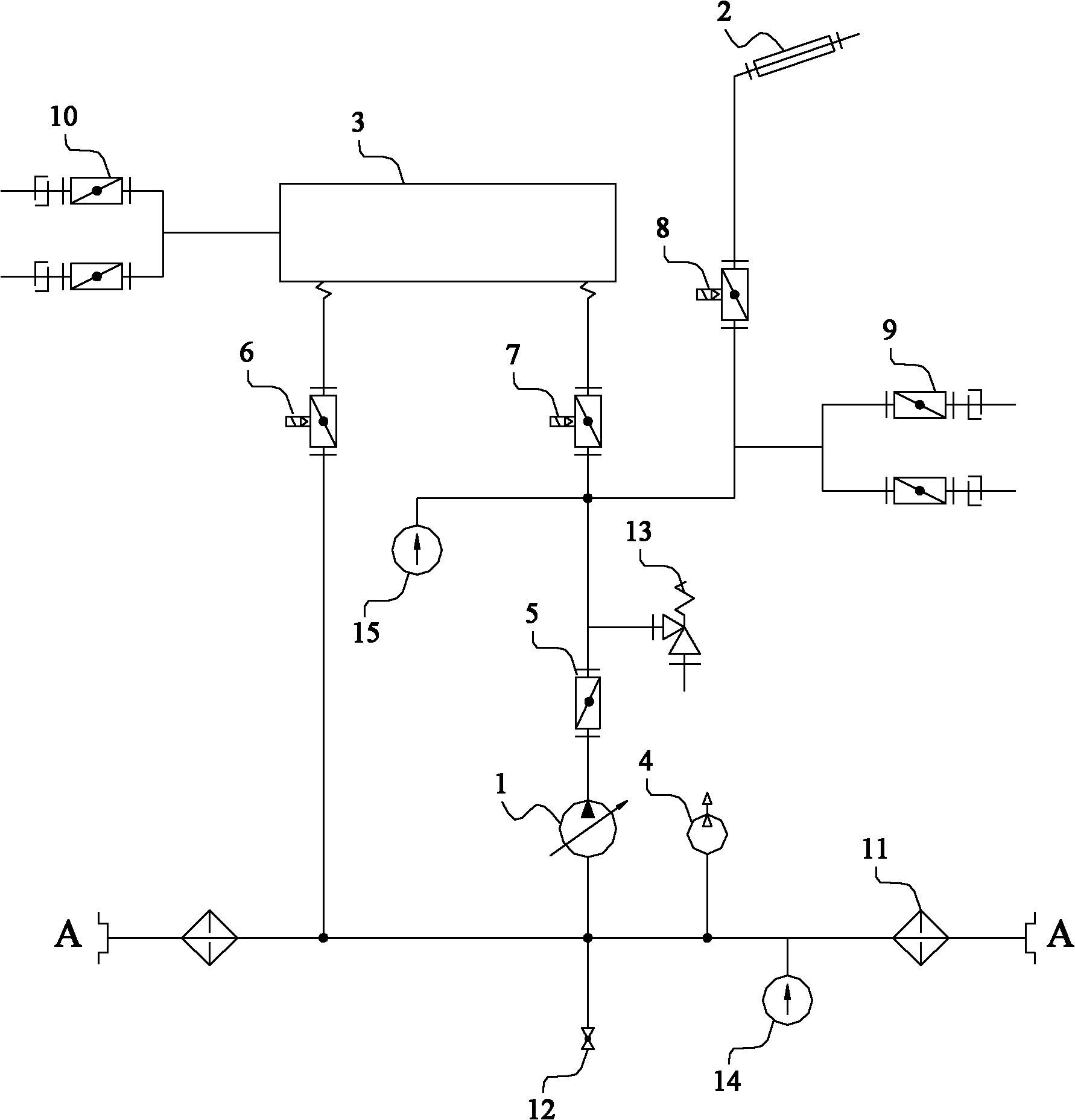

High rise building and fixed fire fighting system thereof

ActiveCN102423526AReliable sealing structurePrevent internal leakageFire rescueControl valvesHydraulic fluid

The invention discloses a high rise building. A plunger pump of the high rise building has two oil cylinders provided with getting hydraulic fluid ports communicated with an inner cavity of cylinder barrel. The getting hydraulic fluid ports are arranged on a cylinder barrel side wall which has a distance from an end of a rodless cavity larger than that from the piston length position of the oil cylinder. The getting hydraulic fluid port of the first oil cylinder is communicated with control oil ports of a first hydraulic control direction valve and a second hydraulic control direction valve so as to drive the first hydraulic control direction valve and the second hydraulic control direction valve to respectively be in a first operation position and a second operation position. The getting hydraulic fluid port of the second oil cylinder is communicated with the control oil ports of the first hydraulic control direction valve and the second hydraulic control direction valve so as to drive the first hydraulic control direction valve and the second hydraulic control direction valve to respectively be in the second operation position and the first operation position. The system of the invention can effectively improve the output flow and the water pressure on the basis of continuous water supply.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

Oil well cleaning compositions

InactiveUS9074121B2Increase output flowLess expensiveCleaning apparatusFluid removalDemulsifierParaffin wax

A method for cleaning oil wells to increase the flow of oil thereof by use of a unique cleaning emulsion comprising of water, hydrocarbon solvent, terpene hydrocarbon material, demulsifier, detergent, and optionally an acid. This one step method provides for the simultaneously cleaning / removal of asphaltene and / or paraffin and scale at a wide range of temperatures. This method can be used alone or with the assistance of a wash tool which is a combination pressure and surge wash tool having a nipple assembly, or a hydro self-rotating nozzle wash tool.

Owner:DYER RICHARD J

Redundant electrohydraulic servo-controlling system

InactiveCN100575716CImprove responsivenessImprove handlingServomotor componentsControl systemElectro hydraulic

Owner:TAIYUAN UNIV OF TECH

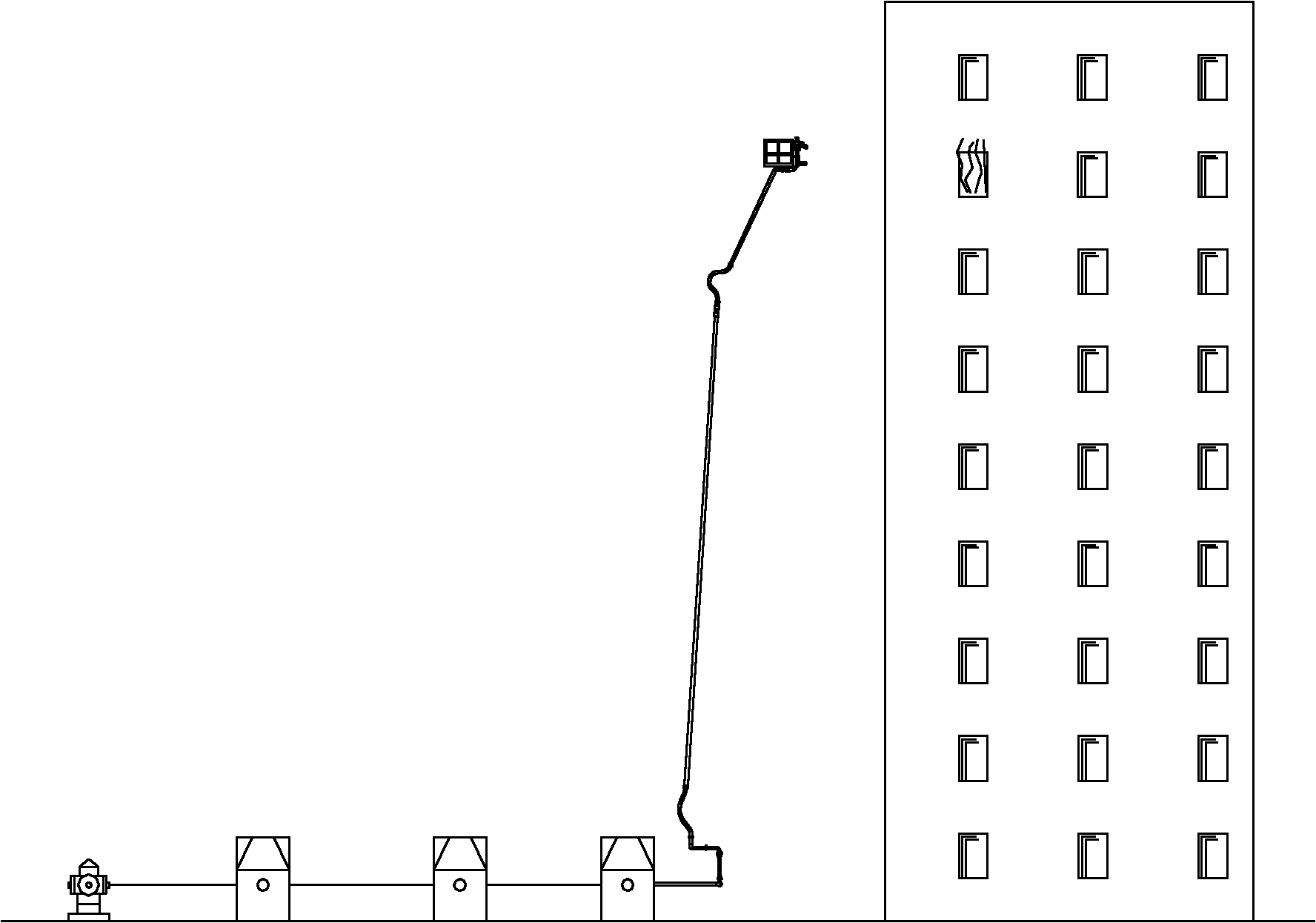

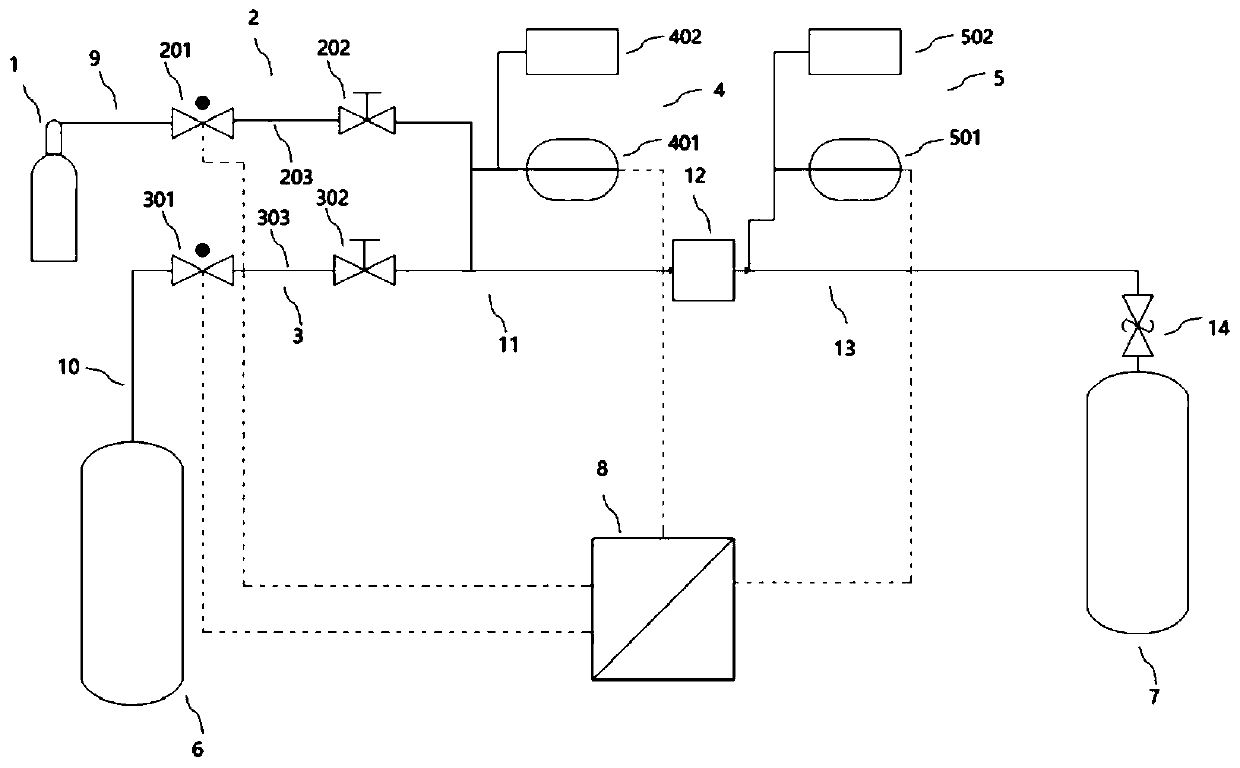

Fire extinguishing system and fire engine containing the same

InactiveCN102423521AReliable sealing structurePrevent internal leakageFire rescueEngineeringControl valves

The invention discloses a fire extinguishing system, comprising a fire extinguishing medium pot and a plunger pump for pumping the fire extinguishing medium. The plunger pump comprises two plunger groups consisting of a medium cylinder and an oil cylinder; a medium cylinder piston and an oil cylinder piston of each plunger group conduct synchronous displacement; and a flow passage port of a cylinder barrel of each medium cylinder is communicatively provided with an unidirectional conductive inflow non return valve from outside to a cavity of the cylinder barrel and an unidirectional conductive outflow non return valve from the cavity of the cylinder barrel to an external outlet; the inflow non return valve communicates with the fire extinguishing medium pot; the two oil cylinders are configured in a way of alternative telescoping by controlling of a control valve. The plunger pump of the present invention employs two oil cylinders for alternative advancing and recession to drive alternative movements of the two medium cylinder pistons, so as to realize switching between two working states respectively. Compared with a prior art, the fire extinguishing system of the invention can effectively increase an output flow and water usage pressure on the premise of continuous non-intermittent water supply. Based on the fire extinguishing system, the invention also provides a fire engine containing the fire extinguishing system.

Owner:XUZHOU HEAVY MASCH CO LTD

Automatic gas-tight testing system

PendingCN109738136AIncrease output flowAchieve recyclingMeasurement of fluid loss/gain rateElectricityGas cylinder

The invention provides an automatic gas-tight testing system. The testing system comprises a gas source, a first valve module, a second valve module, a first detection module, a second detection module, a first gas cylinder, a second gas cylinder, a control unit, a first pipeline, a second pipeline, and a tee pipeline; the gas source communicates with the first valve module through a first pipeline, the first gas cylinder communicates with the second valve module through a second pipeline; a first end of the tee pipeline communicates with the first valve module, a second end of the tee pipeline communicates with the second valve module, and a third end of the tee pipeline communicates with the second gas cylinder; the first detection module is arranged on any end of the tee pipeline, the second detection module is arranged at an opening of the second gas cylinder, and the control unit is electrically connected with the first valve module, the second valve module, the first detection module and the second detection module. The testing system provided by the invention has the advantages that the testing gas is recycled, the automation degree is high, and the gas charging speed is fast.

Owner:BEIJING SINOHYTEC

Electro-hydraulic servo valve suitable for large g value acceleration environment

InactiveCN103591074AHigh frequency responseWaveform distortion is smallServomotor componentsNeutral positionDriving mode

The invention discloses an electro-hydraulic servo valve suitable for a large g value acceleration environment. The electro-hydraulic servo valve comprises a servo valve body and a valve block. The servo valve body comprises a first servo valve body and a second servo valve body. The first servo valve body and the second servo valve body are of the same structure and installed on the valve block side by side. The axial direction of valve cores is the same as the centrifugal acceleration direction of a centrifugal machine. The S port of the first servo valve body is communicated with the S port of the second servo valve body through a channel in the valve block. Through the direct drive mode and the connection mode of the first servo valve body and the second servo valve body, it is guaranteed that the valve core of the first servo valve body and the valve core of the second servo valve body are still located in the neutral position under a centrifugal field, centrifugal force is compensated, high-frequency-response servo control can be provided under the large g value centrifugal field, and the defect that a common servo valve is easily affected by centrifugal acceleration or can not work under the centrifugal environment is overcome; a direct drive large-flow slide valve is adopted, links are few, frequency characteristics are high, and wave form distortion is small.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

Bionic type piezoelectric pump

ActiveCN107202003AEasy to transportHigh trafficFlexible member pumpsPositive-displacement liquid enginesElectricityEngineering

The invention provides a bionic type piezoelectric pump. The bionic type piezoelectric pump comprises an upper sealing piece, a lower sealing piece, a cavity, a water inlet hose, a water outlet hose, a flexible piezoelectric driving piece B and a flexible piezoelectric driving piece A. A counter bore A, a water inlet and a water outlet are formed in the upper sealing piece. The water inlet is provided with a valvula valve A, and the water outlet is provided with a valvula valve C. The cavity is provided with a pump cavity, a water inlet connecting pipe, a water outlet connecting pipe, a water inlet water-collection hole and a water outlet water-collection hole. A one-way flowing valvula valve B is arranged in the pump cavity. The counter bore A corresponds to the pump cavity in position and is used for storing the flexible piezoelectric driving piece A. The lower sealing piece is provided with a counter bore B. The counter bore B is used for mounting and bonding the flexible piezoelectric driving piece B therein. According to the bionic type piezoelectric pump, a double-cavity double-vibrator structure is adopted; the pump cavity, the inlet and the outlet are provided with the valvula valves; the heart of a human body is simulated; and the bionic type piezoelectric pump is provided with the multiple pump cavities and the multiple valvula valves, and the capacity and pressure of the pump can be effectively increased. New reference is provided for research of an artificial heart.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com