Series-parallel hybrid-driven piezoelectric pump

A hybrid drive and series pump technology, applied to pumps with flexible working elements, pumps, machines/engines, etc., can solve the damage of wafer-type piezoelectric vibrators, low energy efficiency and reliability, and reduce the overall effective power output of the driver. problems, to achieve the effect of small pulsation, stable fluid output, and increase output flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

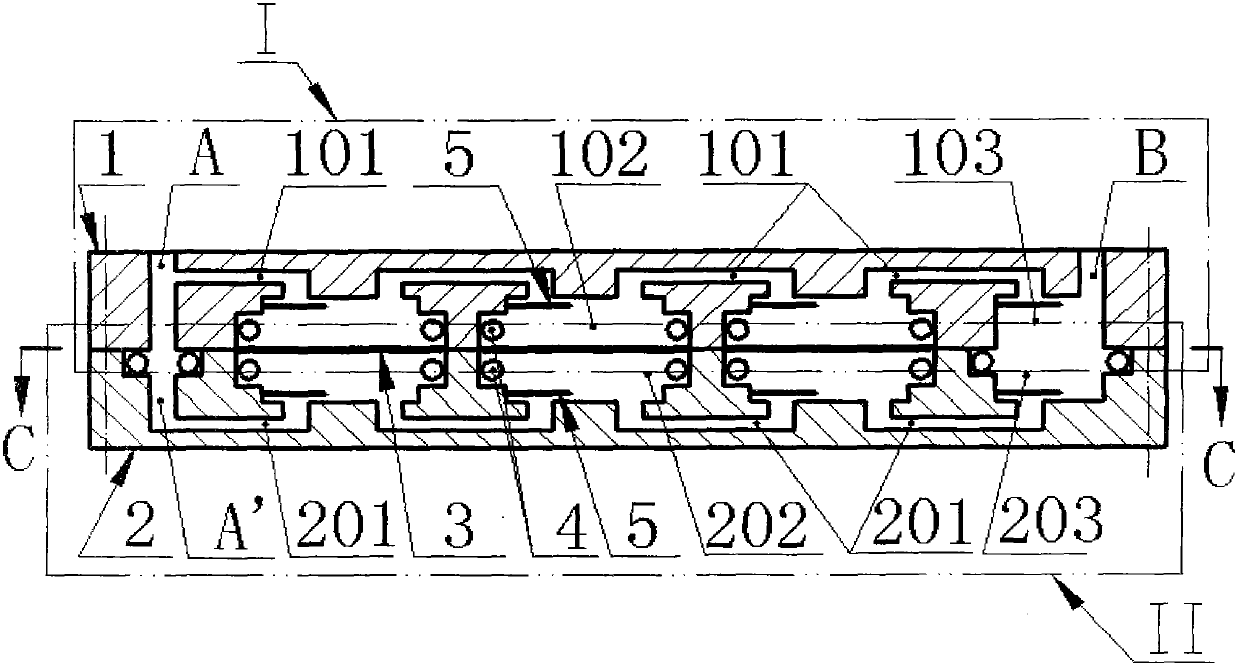

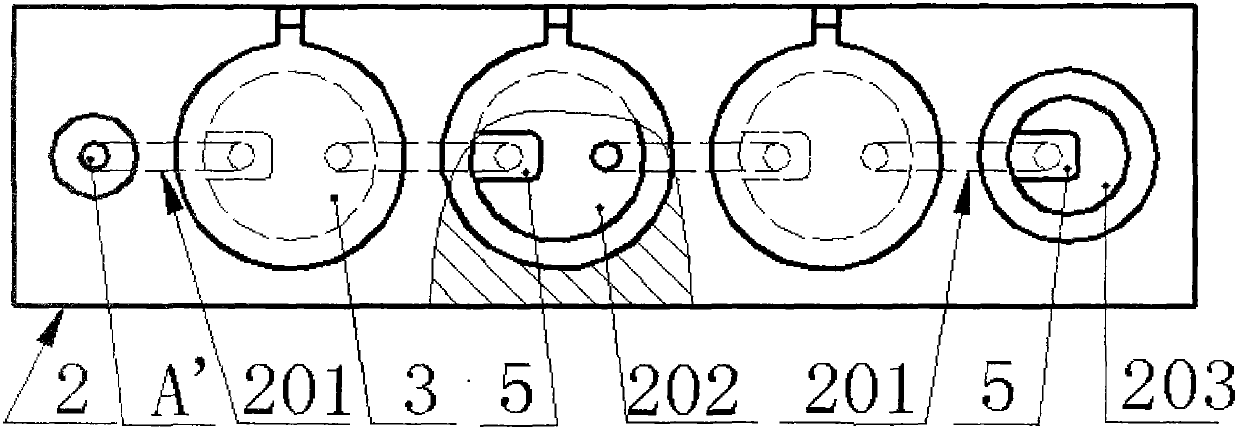

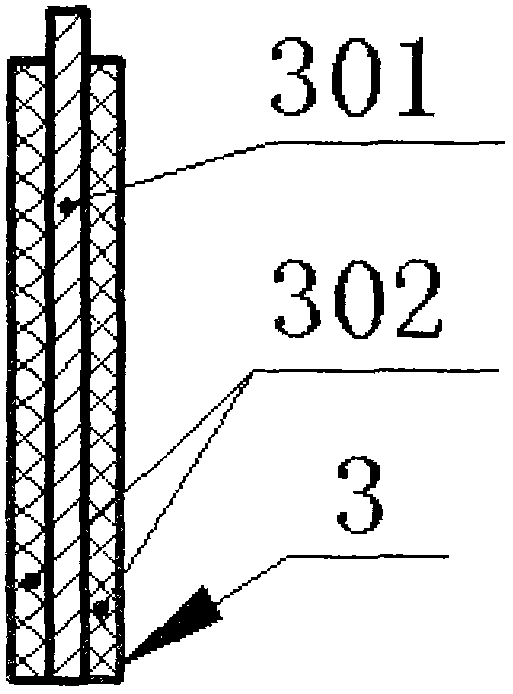

[0016] Such as figure 1 , figure 2 , as shown in Figure 3, the upper pump body 1 and the lower pump body 2 are connected by screws; 2-20 piezoelectric vibrators 3 are crimped on the pump cavity 102 on the upper pump body 1 and the lower pump body 2 through the sealing ring 4 Between the upper pump chamber 202, the piezoelectric vibrator 3 is formed by bonding a metal substrate 301 and a piezoelectric wafer 302; at the inlet of the pump chamber 102 and the outlet valve chamber 103 on the upper pump body 1, and at the lower pump body 1 The pump chamber 202 on the body 2 and the inlet of the outlet valve chamber 203 are bonded with a valve plate 5; on the upper pump body 1, between the inlet A and its adjacent pump chamber 102, two adjacent pump chambers 102, and between the outlet valve chamber 103 and the adjacent pump chamber 102 through the inter-chamber flow channel 101, the outlet valve chamber 103 is also communicated with the outlet B, the series pump chamber 102 locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com