Patents

Literature

153results about How to "Improve sand control effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

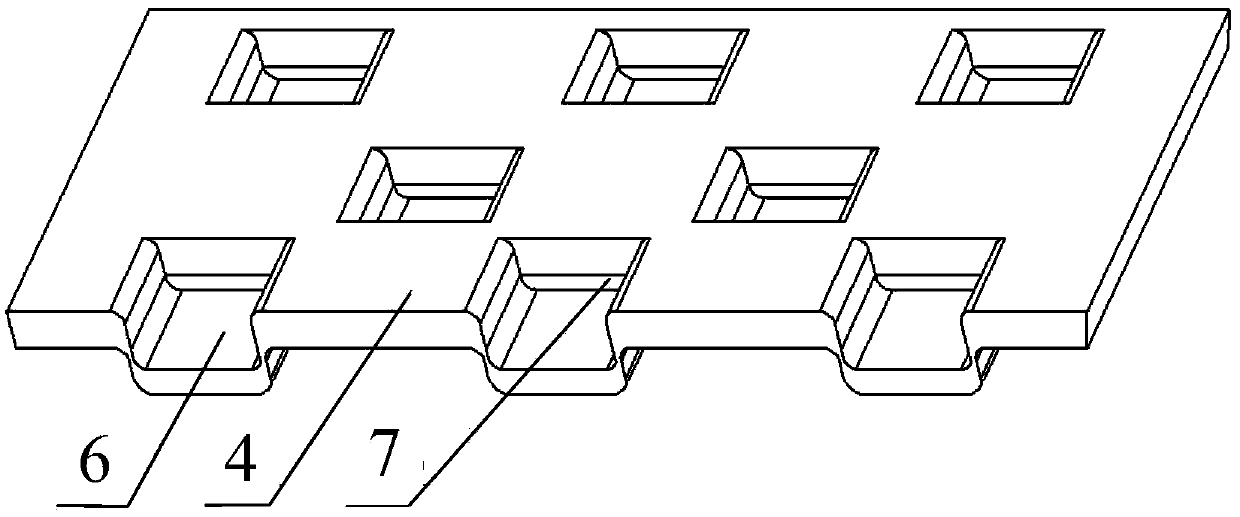

Wind prevention and sand fixation greening planting technology

InactiveCN103141278APrevent movementAvoid burialClimate change adaptationForestrySandhillNormal growth

The invention discloses a wind prevention and sand fixation greening planting technology with good sand control effect. The wind prevention and sand fixation greening planting technology mainly comprises the following steps of: firstly arranging a plurality of strip sand-protecting barriers in a traveling dune zone; then mix-seeding herbaceous plant seeds in open grounds among the strip sand-protecting barriers, and planting shrub seedlings at the positions where the strip sand-protecting barriers are located; and finally fertilizing among the strip sand-protecting barriers and inside the strip sand-protecting barriers. According to the wind prevention and sand fixation greening planting technology, normal germination growth of most herbaceous plant seeds and shrub seedlings can be ensured without planting by multiple times; moreover, the growth period of herbaceous plants is relatively short, so that grass capable of sand fixation can be formed in a short time to further ensure normal growth of shrub seedlings; a grass and shrub forest can be formed in a relatively short time, two to three years in general, through the combination of the sand fixation of sand-protecting barriers with grass and shrub plants so as to achieve the effects of wind prevention and sand fixation; and the desertification of land can be effectively prevented. The technology is suitable for popularization and application in the technical field of sand control.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

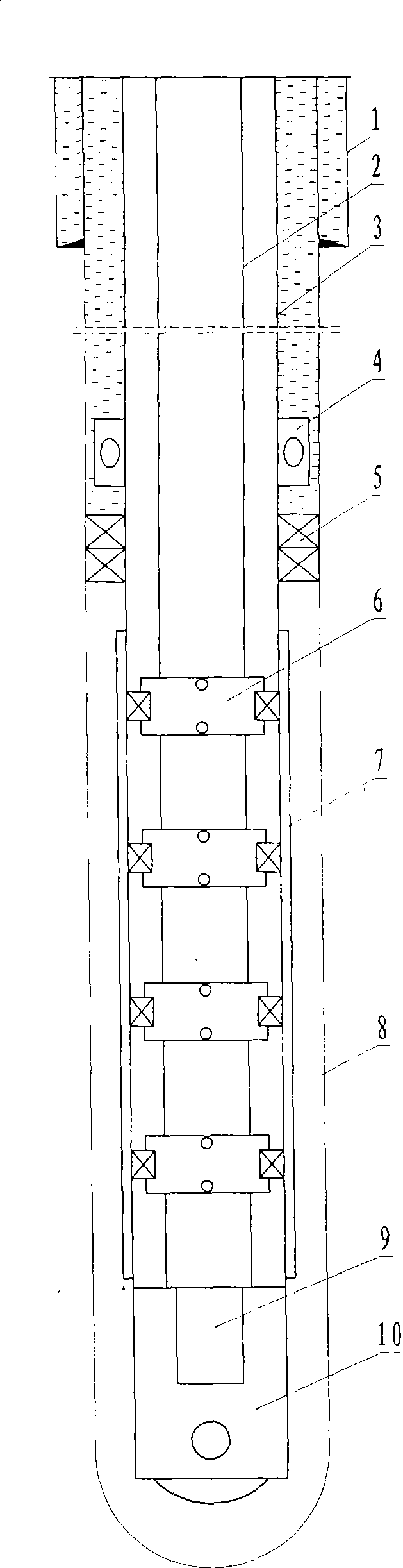

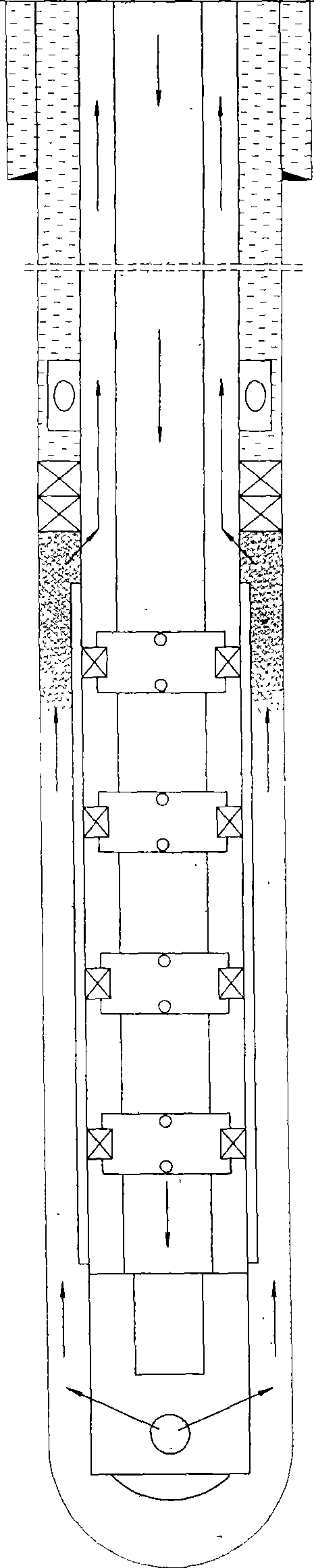

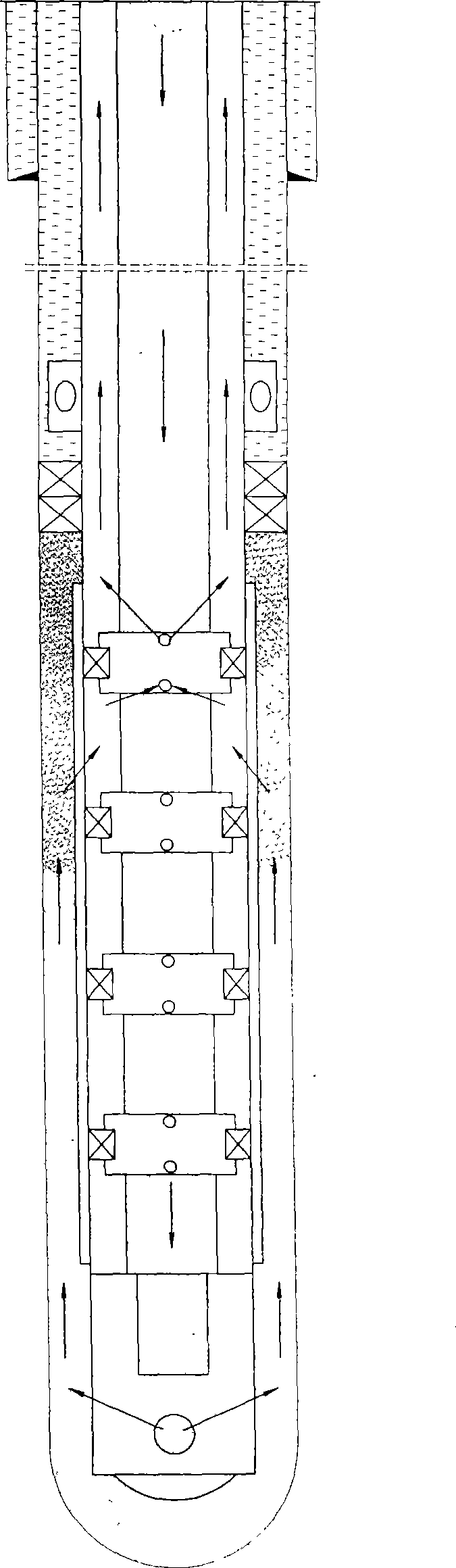

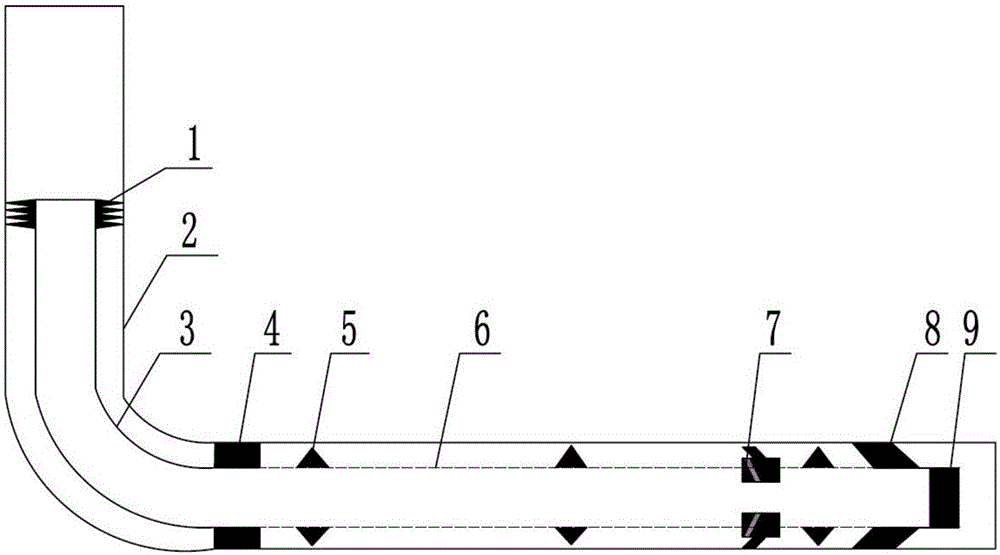

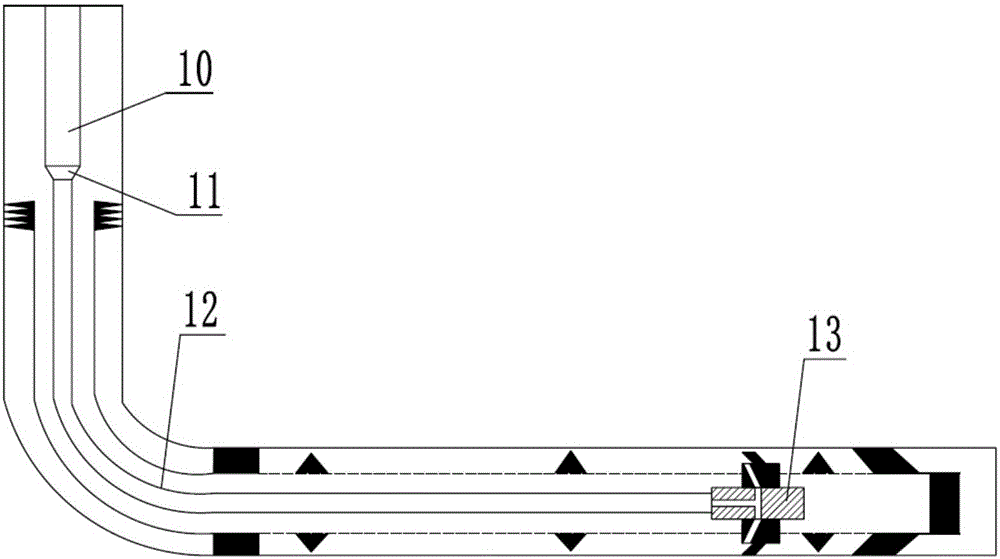

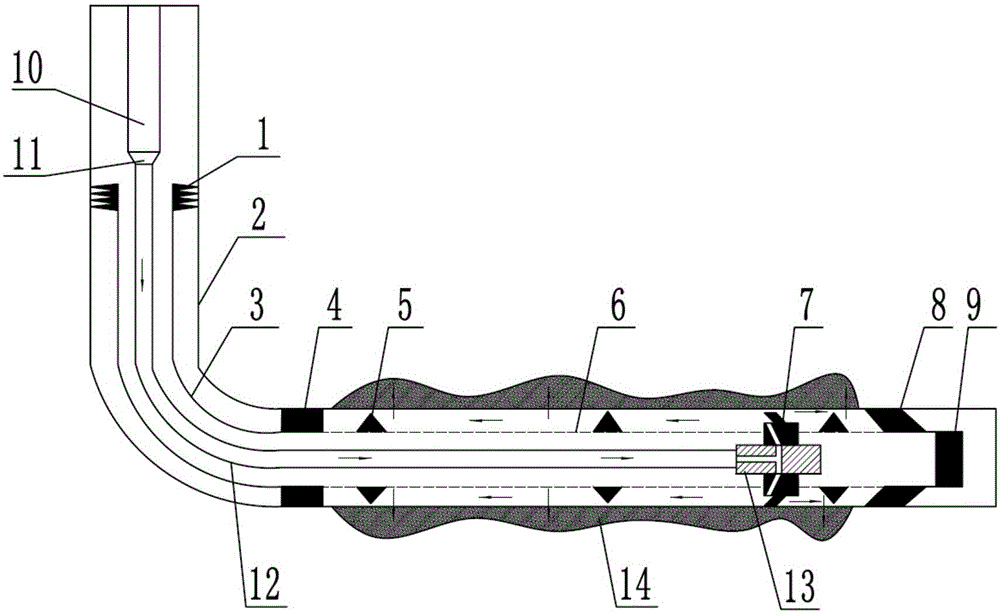

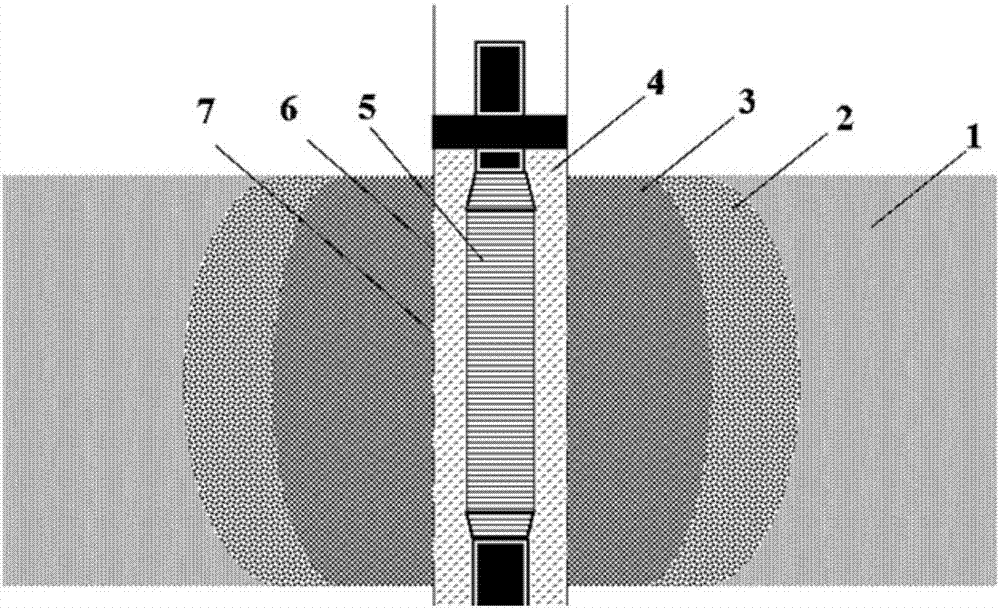

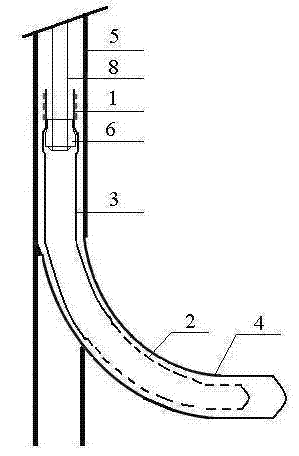

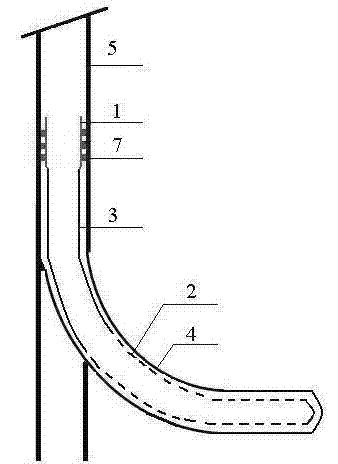

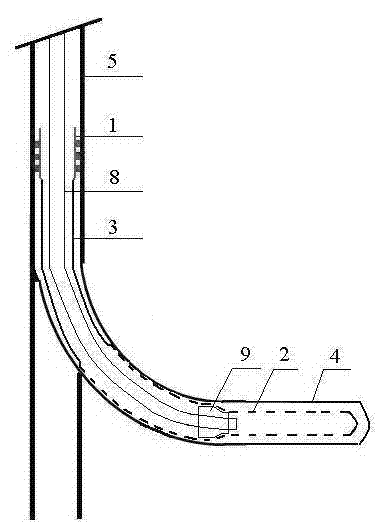

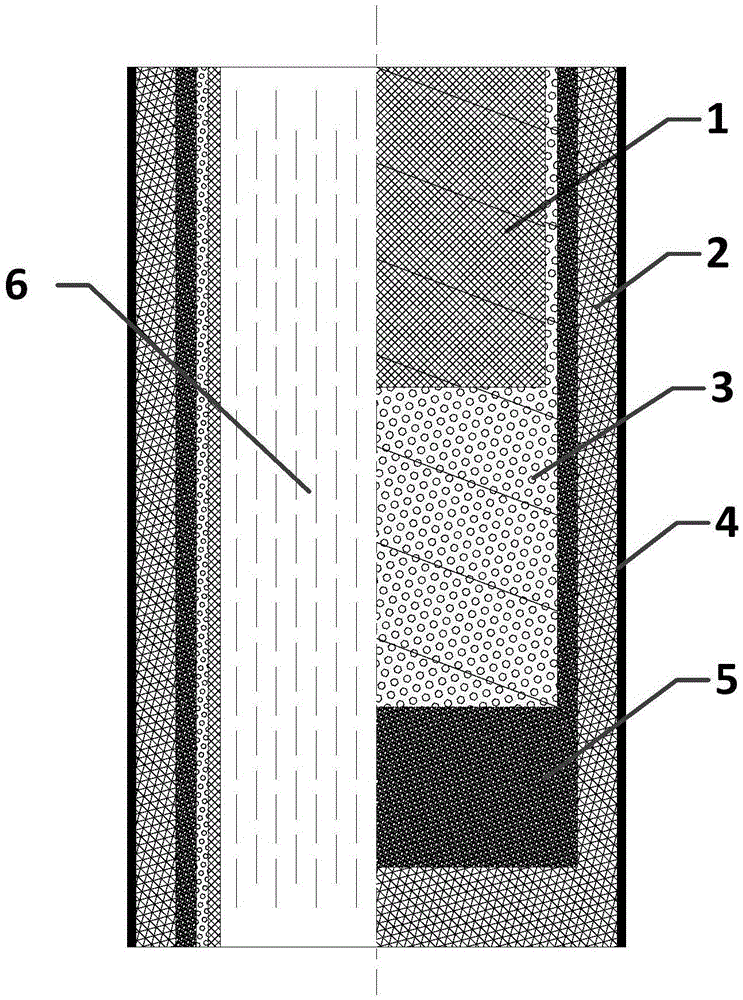

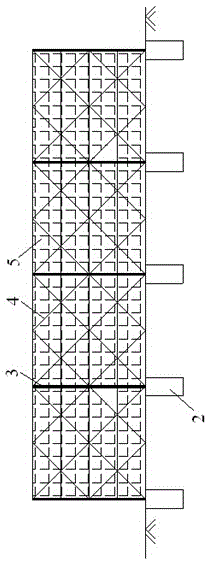

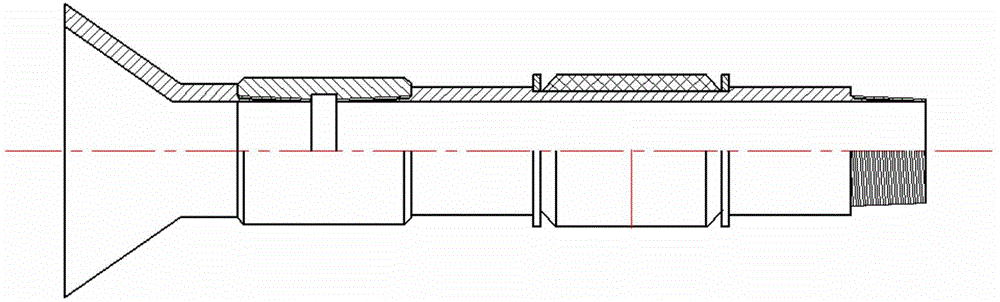

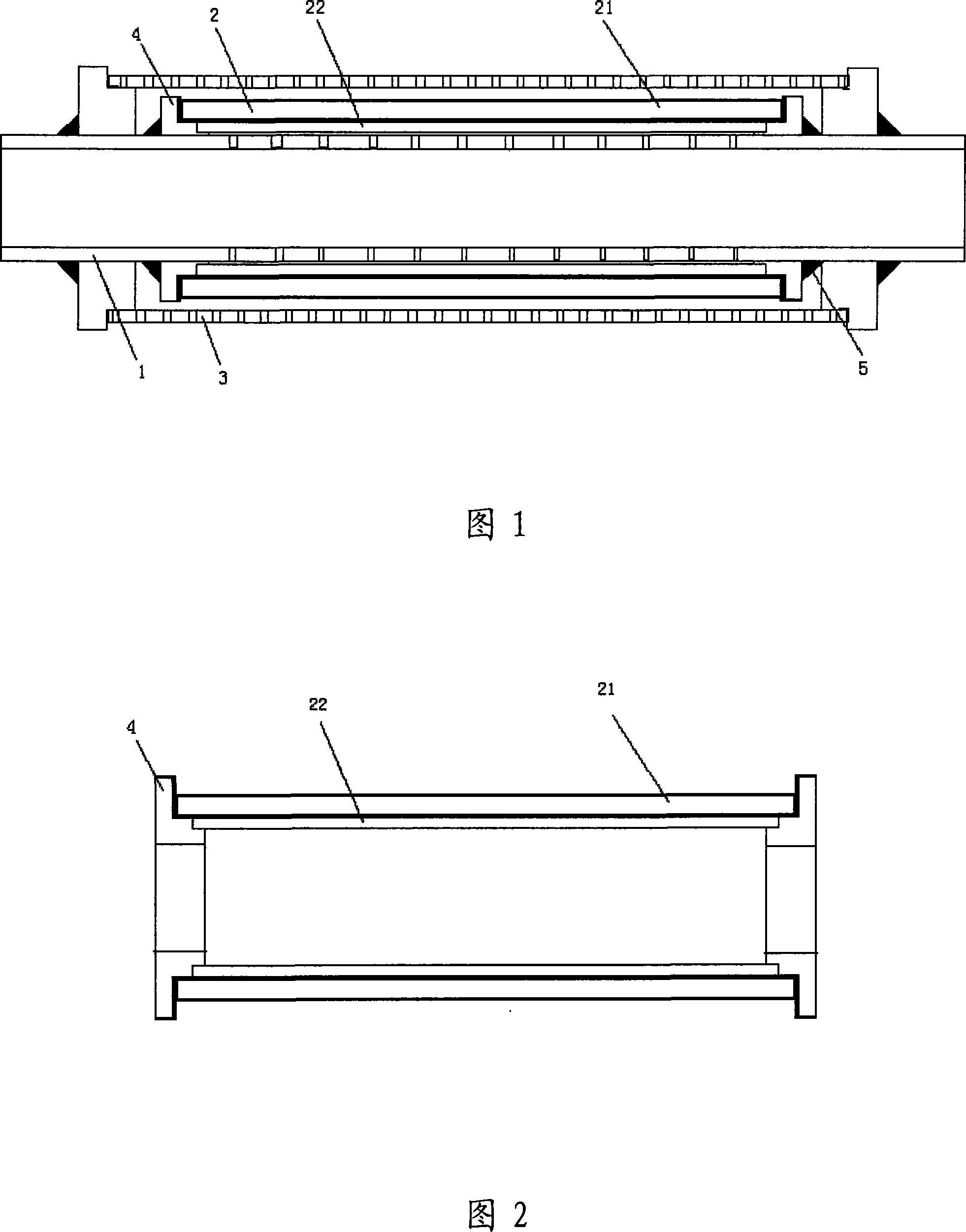

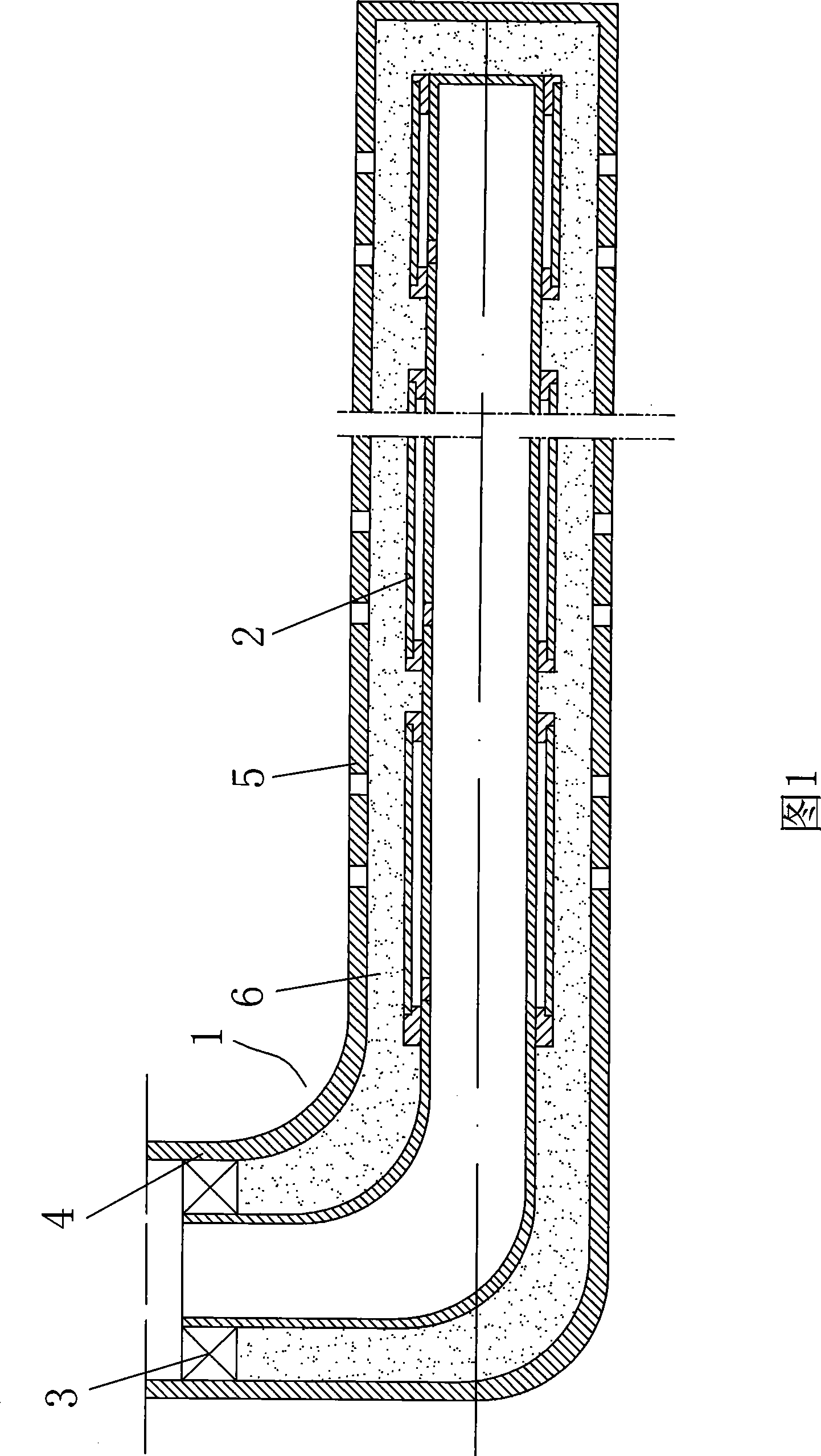

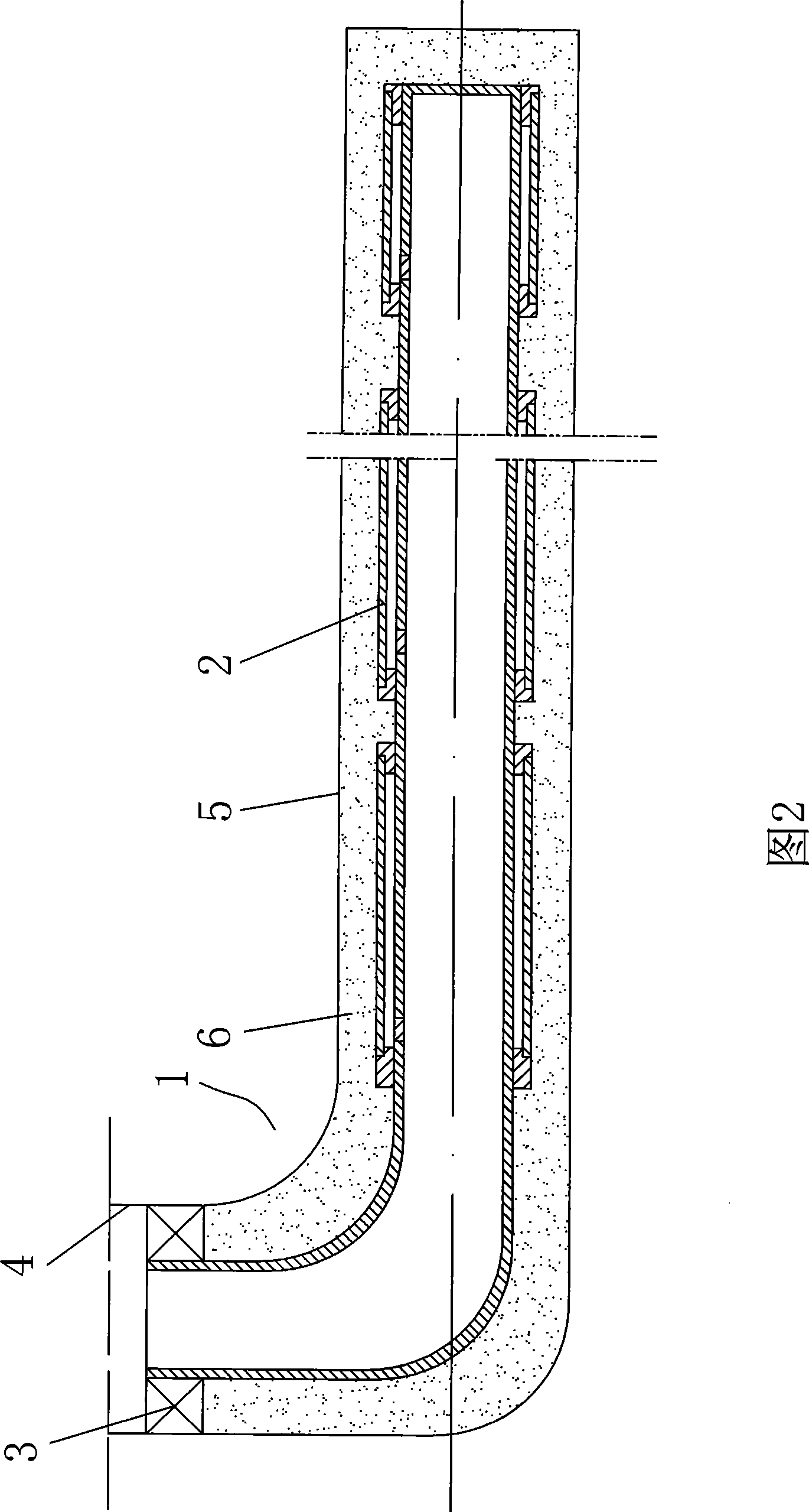

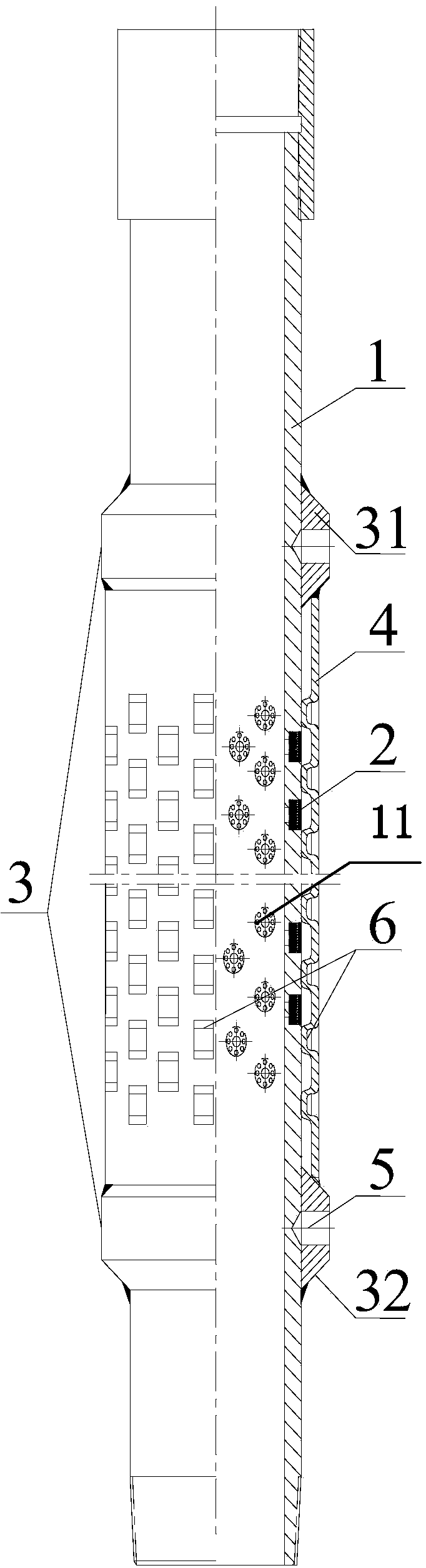

Horizontal well tube exterior subsection gravel filling sand prevention process and pipe column

The invention relates to a segmented gravel packing sand prevention technique outside a tube of a horizontal well. A segmented packing packer is adopted to pack an annular space between a sand prevention sieve tube and a tubing into a plurality of well sections which are not communicated with each other, a sand prevention technique tube column is packed by segmented gravel, and the packing of segmented gravel is carried out according to the following technique steps: (A) the gravel is deposited outside the sand prevention sieve tube at the front end of a first stage packing packer after passing through the segmented packing packer, a packing assembly and a packing server from the tubing, and when the packed gravel is deposited and extended below the first stage packing packer, a packing channel of a next well section is automatically opened under the effect of differential pressure; and (B) the step (A) is continuously carried out, and the gravel is deposited and packed section by section progressively. A device comprises an open hole packer, a sand prevention sieve tube outside an oil-string casing in an open hole section, and the segmented packing packer, the packing assembly and the packing server which are sequentially connected on the tubing column in the oil-string casing in the open hole section. The technique has the characteristics of full packing, strongness, high efficiency and the like, and is widely used in the horizontal well sand prevention technique of oil extraction.

Owner:RES INST OF PETROLEUM ENG SHENGLI OIL FIELD SINOPEC

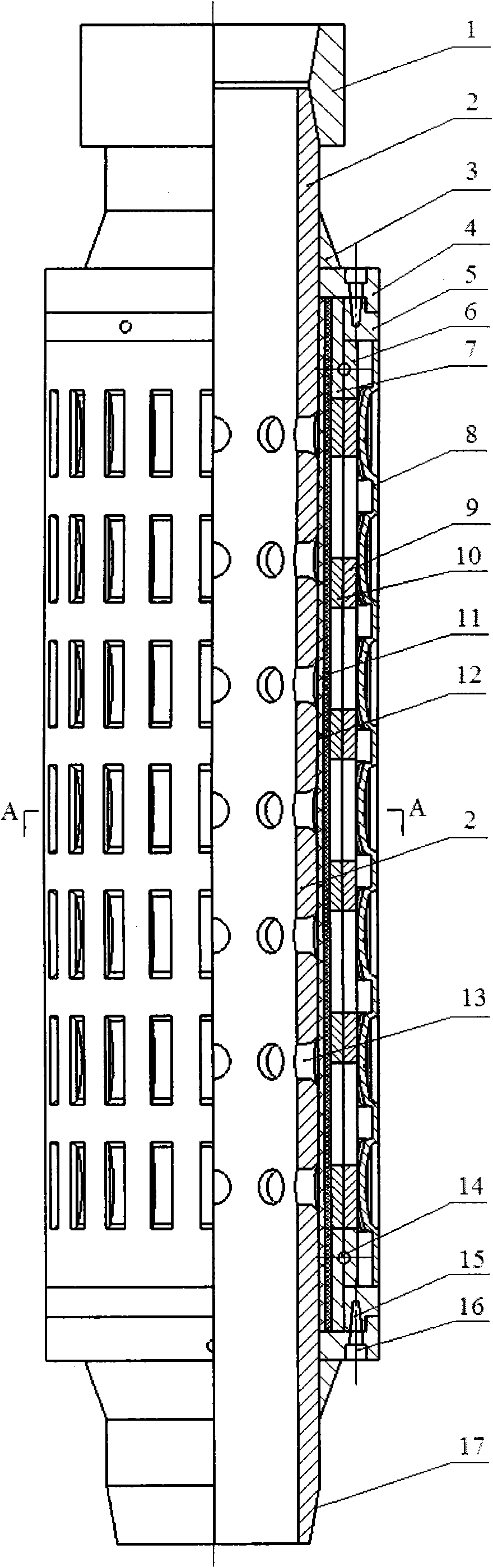

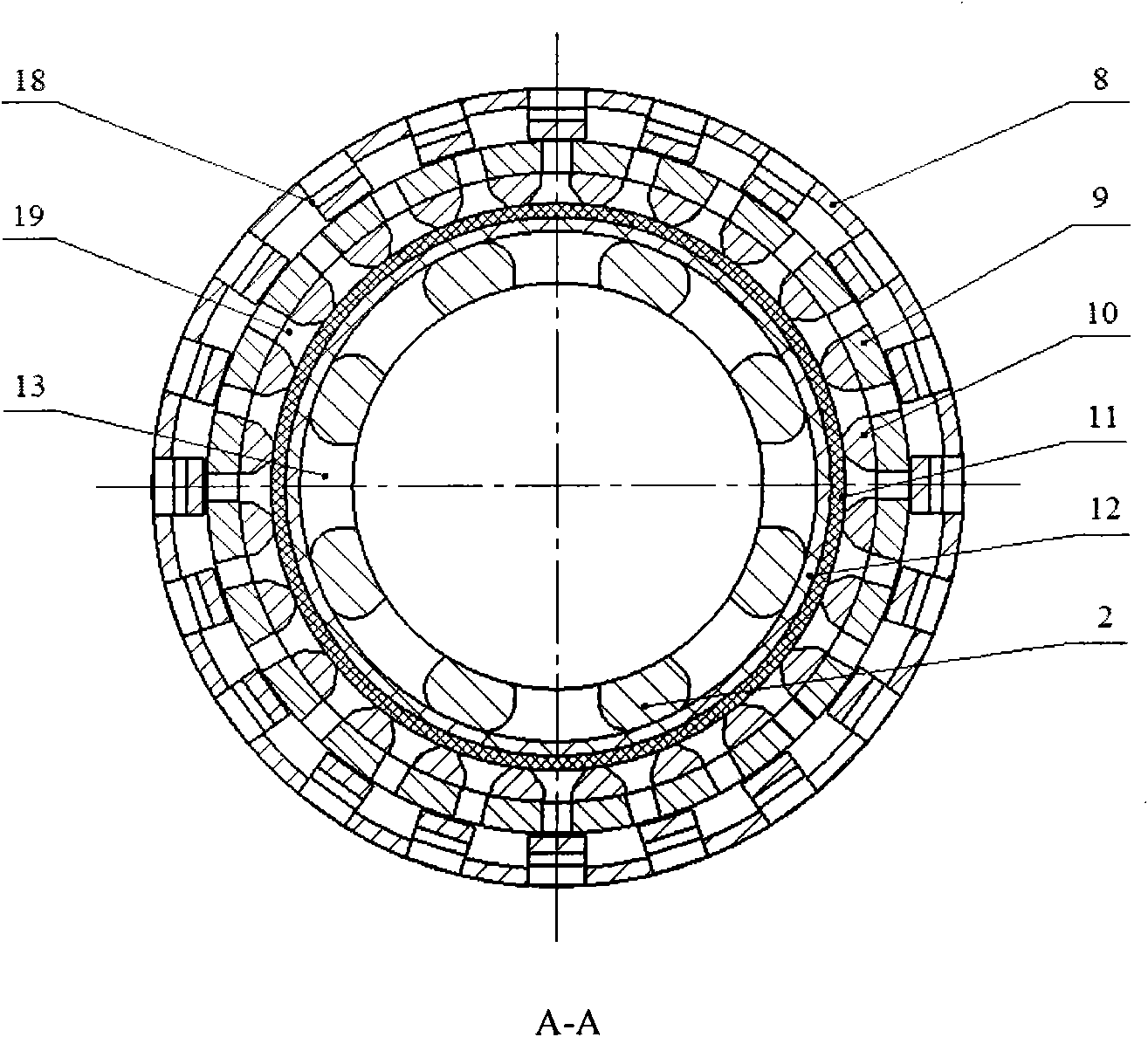

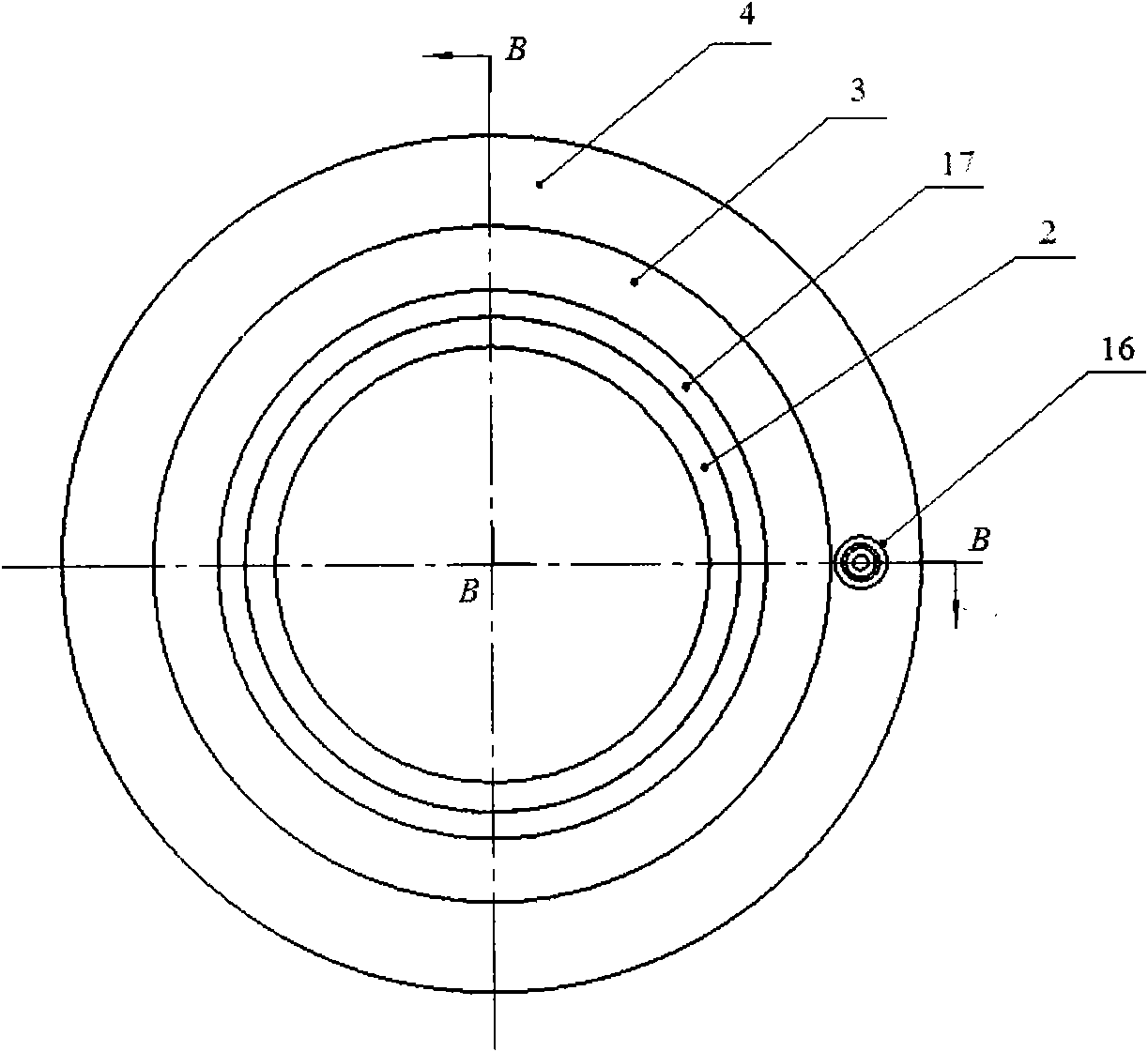

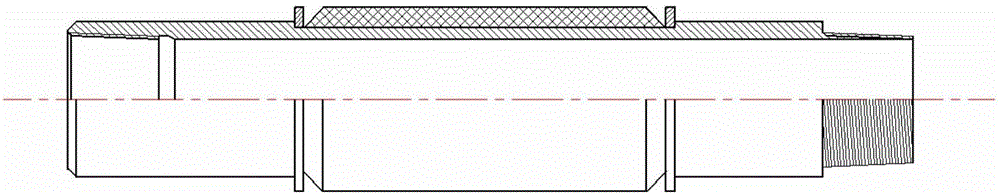

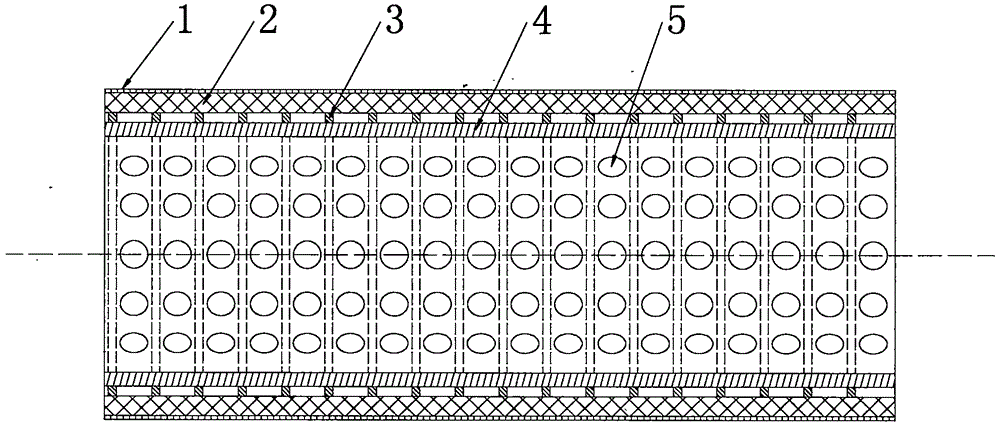

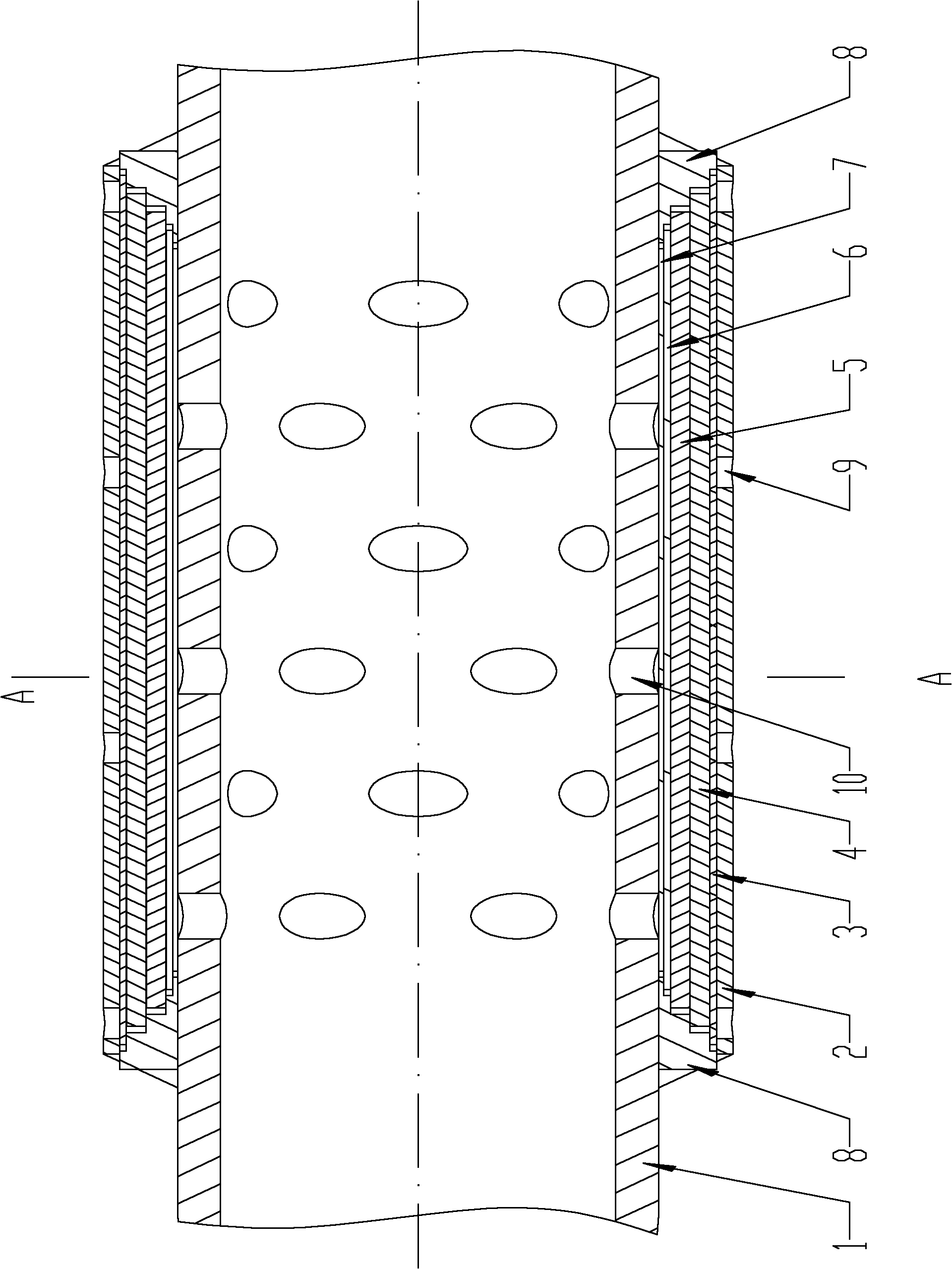

Novel sand control screen pipe with adjustable on-site sand stop precision

ActiveCN102071914AFunction increaseGood sand blocking effectFluid removalHigh volume manufacturingReal time design

The invention discloses a novel sand control screen pipe with adjustable on-site sand stop precision, and belongs to the field of oil well completion sand control. The novel sand control screen pipe mainly comprises five parts, namely a central pipe, a fixed-precision sand stop layer, an adjustable-precision sand stop layer, an outer protective sleeve and a sand stop precision precise adjusting mechanism, wherein the central pipe is provided with spirally distributed through holes and is mainly used for supporting the entire screen pipe and allowing oil to pass through; the fixed-precision sand stop layer is mainly used for controlling sand; the adjustable-precision sand stop layer can change the sand stop precision under the adjustment of the precise adjusting mechanism to play a major role in sand control; the outer protective sleeve is mainly used for protecting the internal structure of the screen pipe and reducing erosion effect of internal fluid and sand; and the sand stop precision precise adjusting mechanism is mainly used for adjusting sand stop precision of the adjustable-precision sand stop layer. Compared with the conventional sand control screen pipe with fixed sand stop precision, the adjustable-precision sand control screen pipe can realize on-site real-time design and sand stop precision adjustment aiming at the characteristics of a single well to improve the sand control effect; the novel sand control screen pipe is convenient for mass production of the screen pipe manufacturers and can precisely control the sand control precision; and the novel sand control screen pipe is convenient for screen pipe development, is convenient for suppliers to provide a sand control design, integrated service of the sand control screen pipe, and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-strength high-permeability chemical sand prevention agent, and preparation method and application thereof

InactiveCN104650840AObvious advantageObvious effectFluid removalDrilling compositionHigh humidityOil water

The invention provides a high-strength high-permeability chemical sand prevention agent, and a preparation method and an application thereof. The high-strength high-permeability chemical sand prevention agent is composed of a proppant, a cementing agent, an accelerator, a curing agent and a coupling agent according to a certain ratio. The preparation method comprises the following steps: above raw materials are mixed at a specific temperature, and are stirred, and the obtained mixture is cured for a certain period of time to obtain the high curing strength sand prevention agent. The sand prevention agent has good tolerance to acid, water, salt and oil, has high stability in high temperature and high humidity environment, and is mainly used in chemical sand prevention well extract production, serious casing deformation well sand prevention, and sand prevention of wells without mechanical sand prevention and oil water wells with low reservoir temperature in order to increase liquid production of the oil well, prolong the period of validity of well sand prevention, increase the amount of oil and reduce the production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process pipe column

The invention discloses a process pipe column. The process pipe column comprises a sand prevention pipe column and a filling service pipe column. A reverse packer is installed at the bottom of the sand prevention pipe column and corresponds to a packer at the upper portion of the sand prevention pipe column, pressure balance is achieved in the high-pressure extrusion process, the sand prevention pipe column is prevented from displacing under the effect of high-pressure sand-carrying fluid, cooperation of a bottom filling tool and a filling server is guaranteed, gravel in a horizontal well pipe is effectively extruded for filling sand prevention work, sand prevention well completion is smoothly achieved, and an oil-gas field is efficiently developed. According to the process pipe column, a reservoir can be fractured, wide and short cracks can be formed in a near well-bore zone, the seepage capacity of the reservoir is greatly improved, the yield increase effect is achieved, the sand blocking radius is expanded to the reservoir, the sand prevention effect is better, and the sand prevention efficiency period is longer.

Owner:PETROCHINA CO LTD

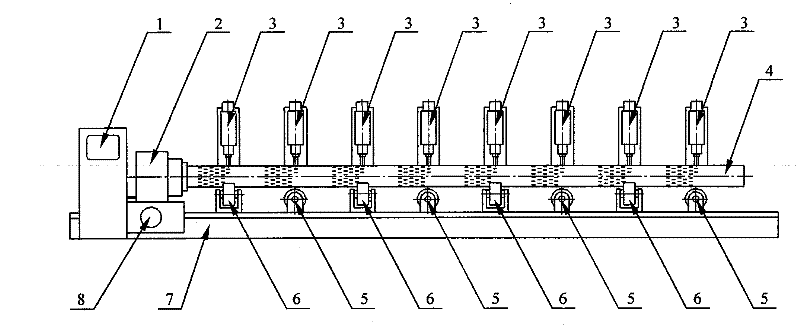

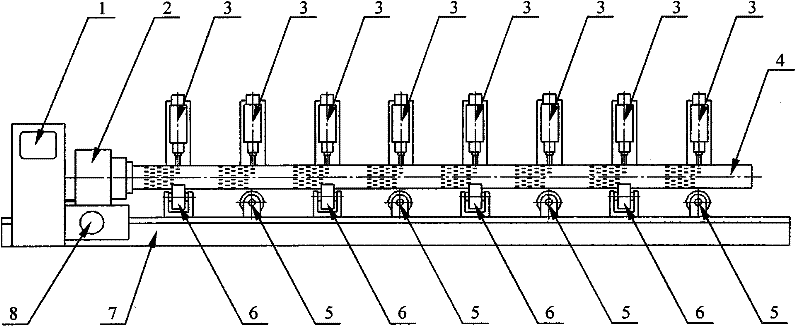

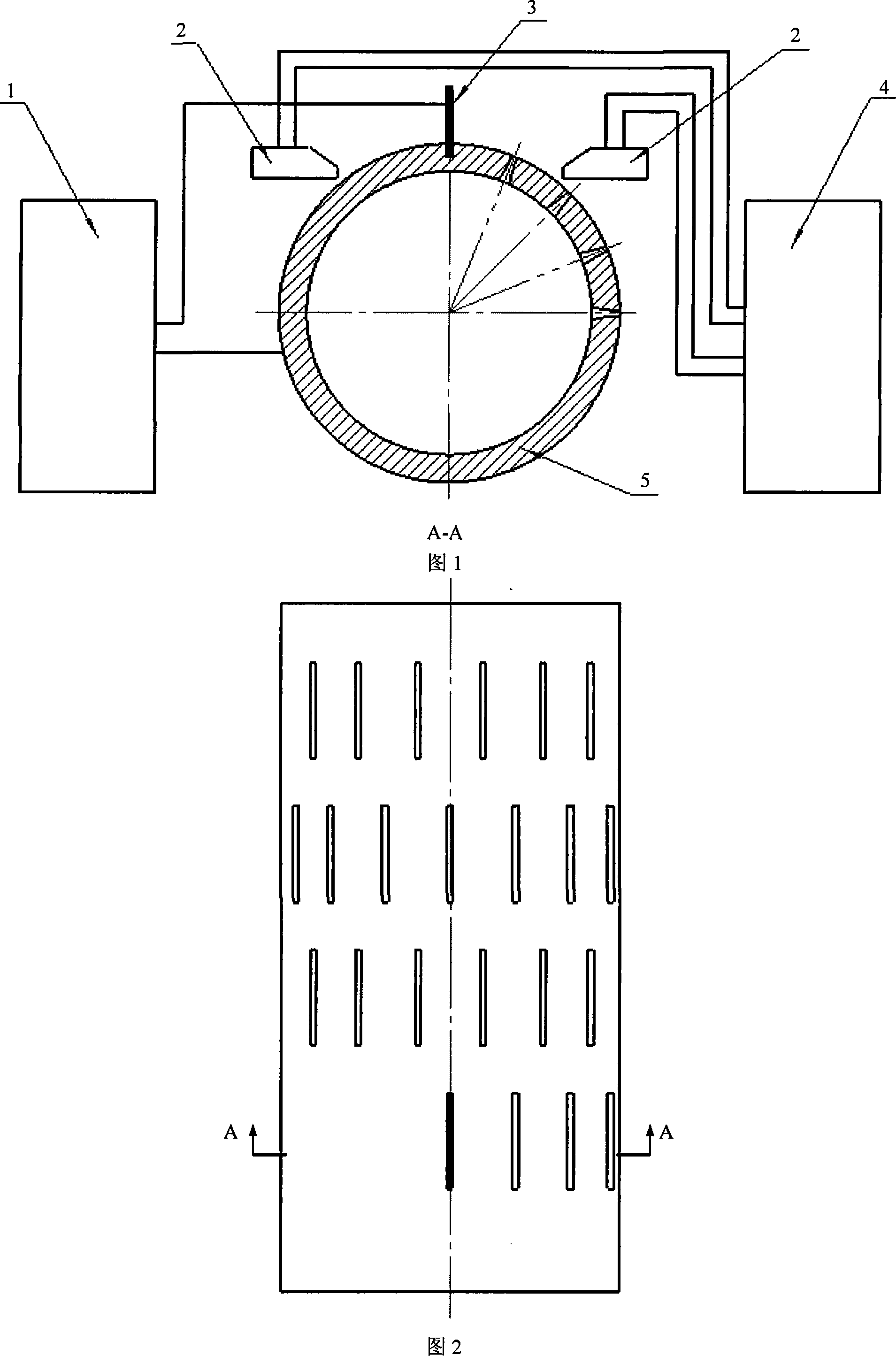

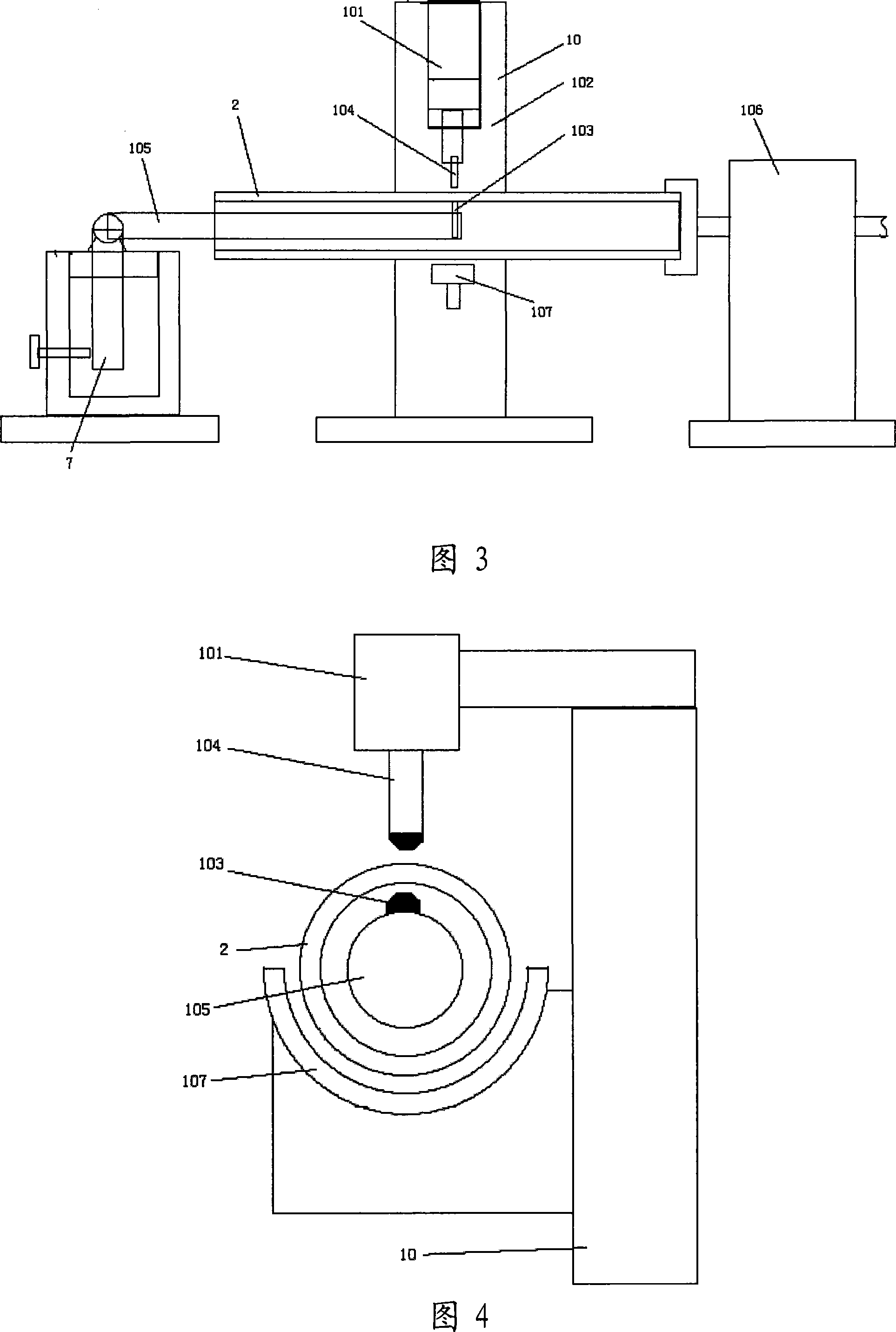

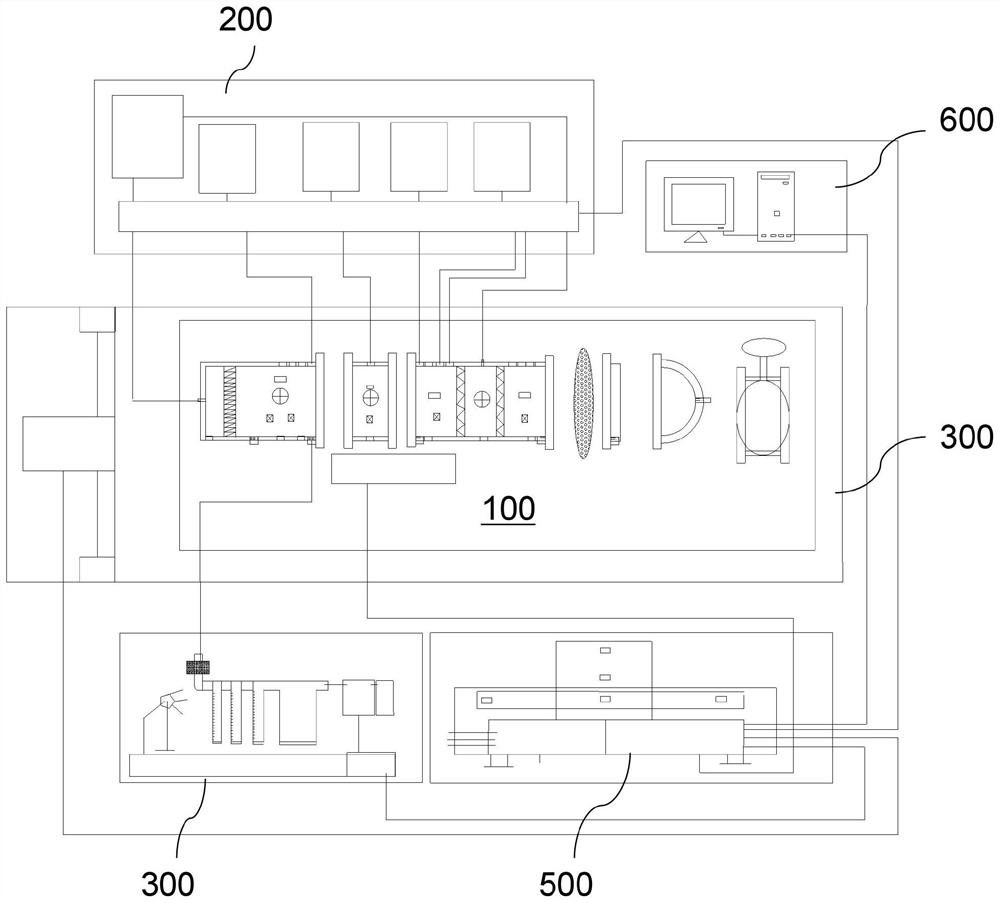

Plasma machining production line of dual-trapezoid slotted sieve tube

The invention relates to a plasma machining production line of a dual-trapezoid slotted sieve tube, belonging to the field of machining. The production line comprises a main control table, a digital control rotary work table, a plasma machining machine tool, an axial feed driving device, a radial rotary supporting device, an axial guiding and transmission device and a tool body. When processing is performed, the main control table is used for controlling the machining and moving states of the plasma machine tool, the digital control rotary work table, the axial feed driving device, the axial guiding and transmission device and the radial rotary supporting device, the plasma machining machine tool is used for machining slots of the dual-trapezoid slotted sieve tube, the digital control rotary work table drives the slotted sieve tube to perform a rotary indexing movement; when a circle of slots are completely machined, the axial feed driving device drives the slotted sieve tube to move to a designated position axially, the next circle of slots are machined, and the steps are repeated to machine a whole slotted sieve tube. In the invention, modification of a slotted surface material can be realized in the machining process, and the phenomenon of 'match head' does not exist at two ends of the machined slot.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

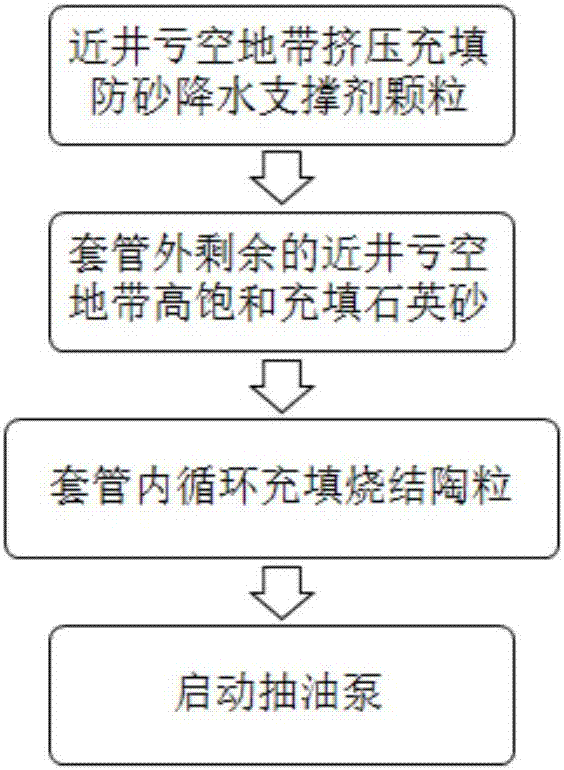

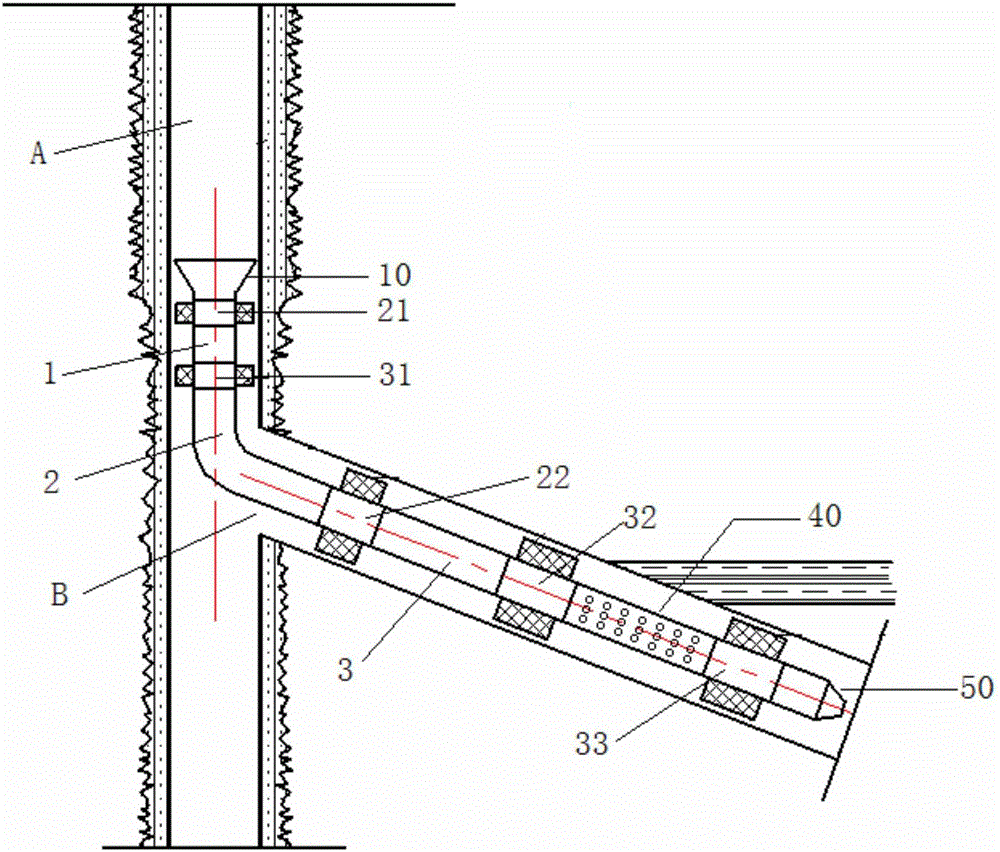

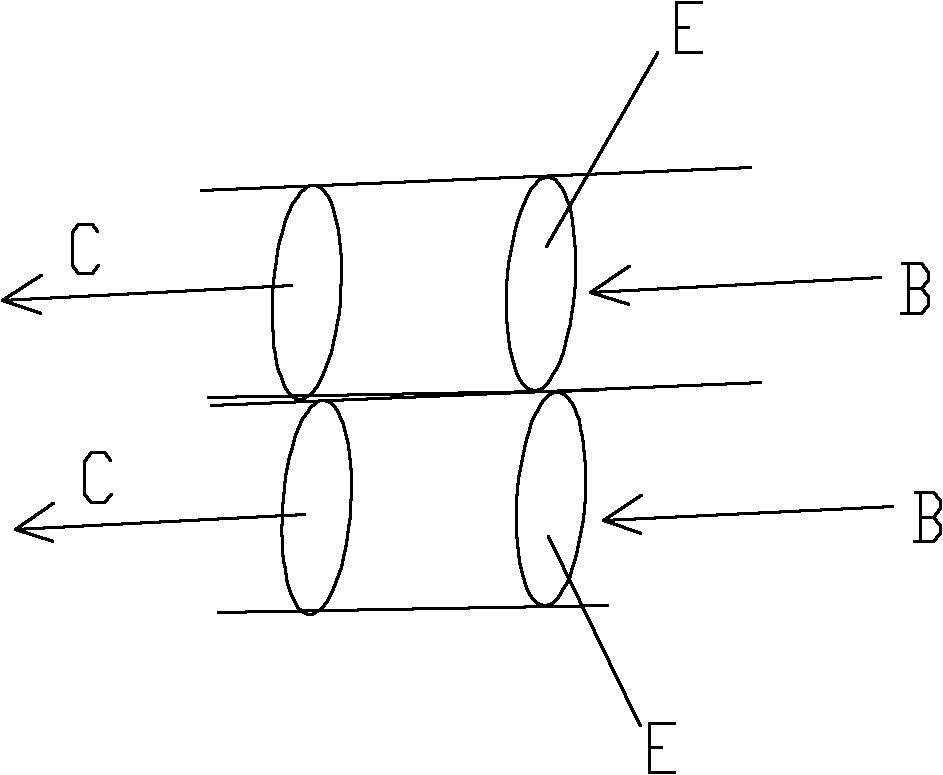

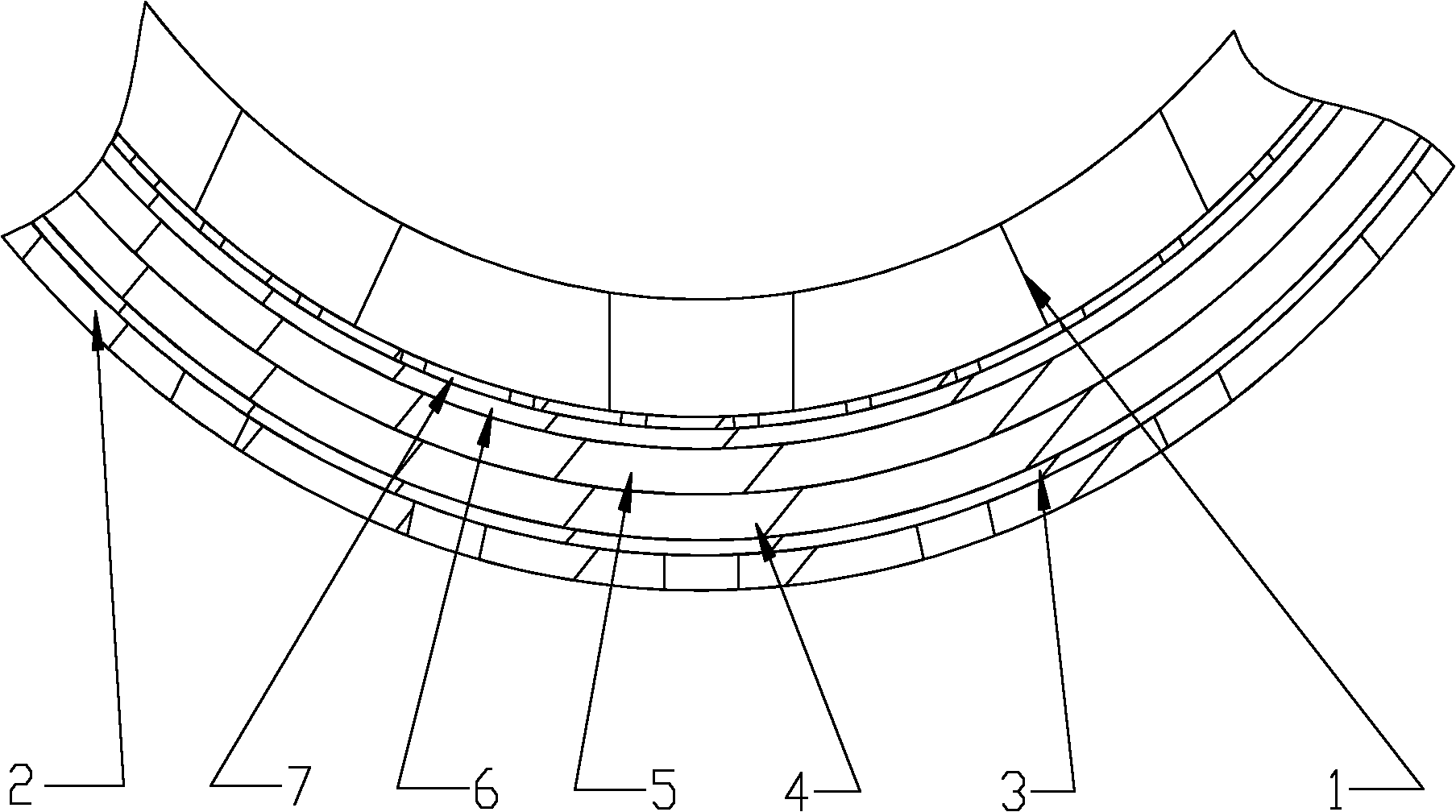

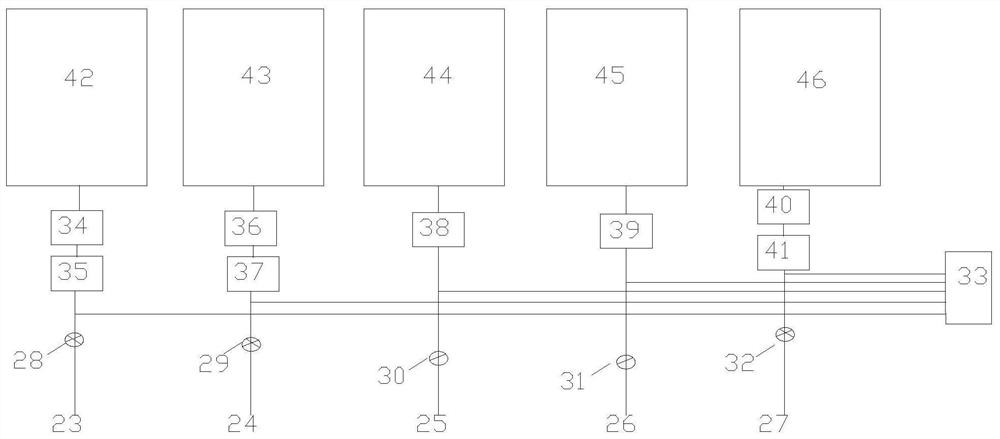

Multi-section-plug high-saturation filling water and sand controlling method for silty fine sand reservoir

InactiveCN107575187AStrong precipitation abilityHigh Sand Control StrengthFluid removalEngineeringOil water

The invention relates to a multi-slug high-saturation filling method for controlling water and sand in silt and fine sand reservoirs, belonging to the technical field of filling and sand prevention for oil and natural gas exploitation industries. The multi-stage sand retaining barriers are arranged in between, and the multi-stage sand retaining barriers include: the fourth-stage sand retaining barriers, the third-stage sand retaining barriers, and the second-stage sand retaining barriers arranged radially outwardly along the mechanical sand control screens and the first-stage sand retaining barrier; the first to third-stage sand retaining barriers respectively contain particles of corresponding particle sizes, and the present invention uses a four-stage sand retaining barrier formed by three-stage slugs, which solves the problem of single particle diameter in unconsolidated sandstone reservoirs. The sand control of gravel filling cannot meet the sand control requirements of oil wells with high water content in the late stage of silty sand reservoir exploitation. This method reduces the water content of oil wells and maximizes the silt and fine sand Production of wells with high water cut in reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Casing sidetracked well completion method using expansion screen tube

InactiveCN103089180AIncrease inner diameterReduce voidsFluid removalRubber ringStructural engineering

The invention relates to a casing sidetracked well completion method using an expansion screen tube. The casing sidetracked well completion method includes laying down a tail tubular pile with an expansion screen tube into a preset position in a well, and pressing and hanging an expansion hanger to enable a rubber ring on the expansion hanger to attach into an original well casing for suspending and sealing a completion tubular pile; subjecting the expansion screen tube to adaptive expansion through a reducing expansion tool, enabling the expansion screen tube to cling to the well wall after expansion, and eliminating an annular space of the screen tube and the well wall. The casing sidetracked well completion method has the advantages that the hanger can have larger inner diameter after being expanded, late oil exploration and operation are facilitated, runout of the tail tube head is prevented, the expansion screen tube clings to the well wall after being expanded, drift diameter is large, oil flow area and sand filter area are enlarged, sand prevention effect of the screen tube is improved, and exploration effect that capacity and exploration and recovery rate are increased are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

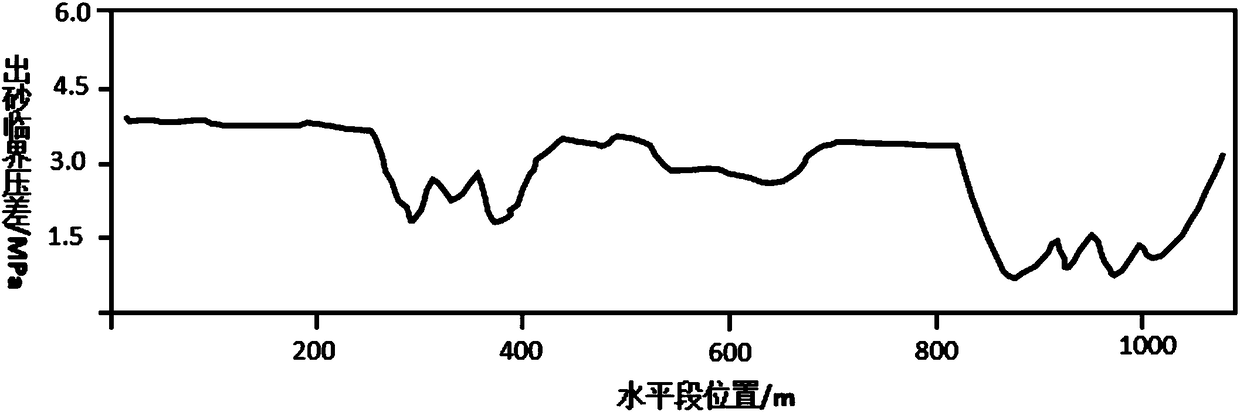

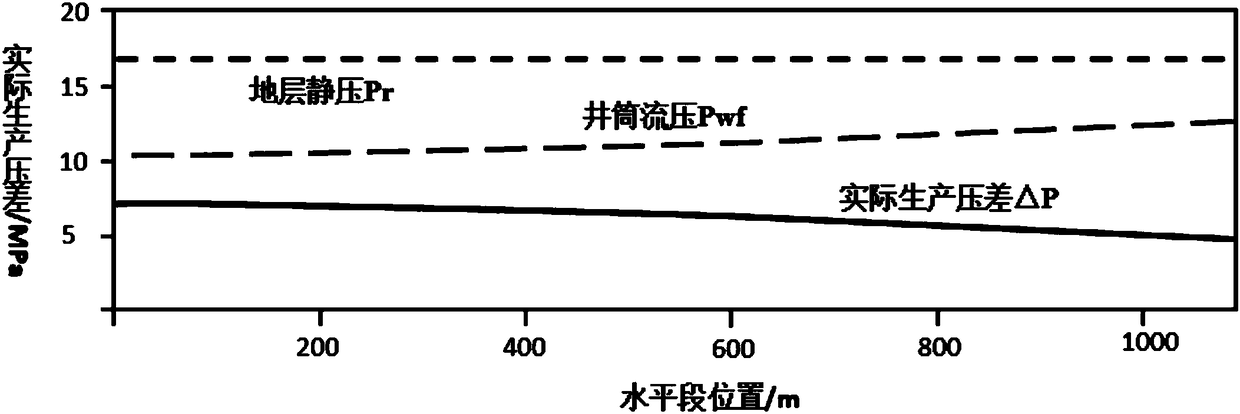

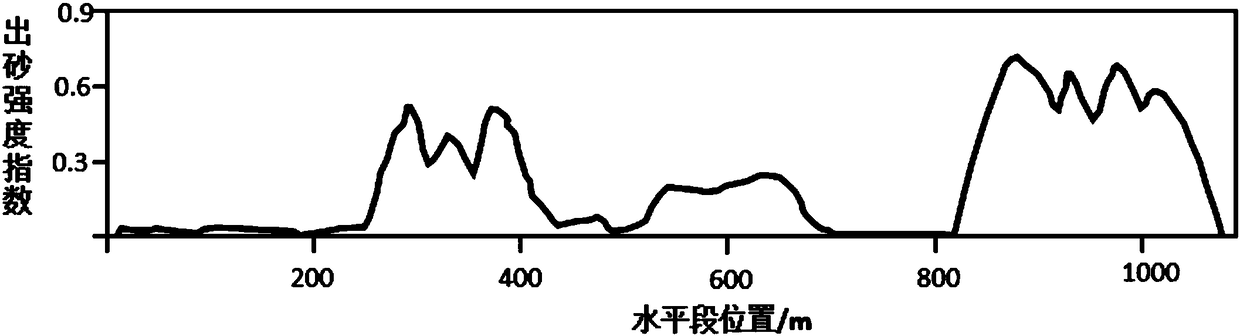

Horizontal well horizontal section relative sand outlet deficit profile prediction and sand prevention section grading method

ActiveCN108331574AIncrease productionOptimize the sand control schemeSurveySoil scienceEconomic benefits

The invention relates to a horizontal well horizontal section relative sand outlet deficit profile prediction and sand prevention section grading method which comprises the steps that S1, distributionof reservoir rock mechanical parameter along the horizontal well horizontal section is calculated; S2, sand outlet critical production pressure difference distribution of the horizontal well horizontal section is predicted; S3, the actual bottomhole flowing pressure and the actual production pressure difference of all points of the horizontal section are calculated, and the bottomhole flowing pressure, namely, the bottomhole flowing pressure at the root end of the horizontal section is calibrated; S4, sand outlet net pressure difference is calculated, and dimensionless calculation is conducted to obtain a sand outlet strength index; S5, a relative sand outlet profile map of a horizontal well is drawn, the sand outlet deficit degree grade is divided, and he sand outlet degree is sectioned;and S6, the section grading scheme for section grading sand prevention is determined. Section grading sand prevention is guided by relative sand outlet profile prediction, the problem that general sand prevention of the horizontal well is high in blindness and poor in sand prevention effect is solved, the cost of sand prevention operation is reduced, long-term stable production of the horizontalwell is guaranteed, and economic benefits are increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Novel self-expansion screen pipe

The invention provides a novel self-expansion screen pipe, comprising a shape memory alloy slotted base pipe, a metal screen pipe, a water-soluble filler layer, a shape memory polymer layer and a water-soluble protective layer sequentially from inside to outside. The shape memory alloy slotted base pipe is made of shape memory alloy, contracts to a pre-expansion shape at high temperature and self-expands under temperature effect after being tripped in to a specified position; the shape memory polymer layer contracts to a pre-expansion state at high temperature and never changes in shape at normal temperature. Compared with the prior art, the novel self-expansion screen pipe has the advantages that the diameter is increased through the expansion pipe technology; multiple producing layers can be subjected to sand prevention treatment at a time; gravel filling is not required so that the influence of insufficient filling on sand prevention effect is avoided; fewer string trips-in are required so that operation cost is reduced; double filtration with the screen pipe and the shape memory polymer layer is achieved, improving the sand prevention effect; a well wall can be effectively supported so that wall collapse due to sand discharge is prevented.

Owner:CNPC BOHAI DRILLING ENG

Alkali-resistant film-coating propping agent suitable for ASP compound flooding

The invention relates to the technical field of oil field oil production engineering, and particularly belongs to an alkali-resistant film-coating propping agent suitable for ASP compound flooding. The propping agent mainly solves the problems that an existing coating film propping agent is not resistant to alkali, the propping agent is transferred in the ASP compound flooding process, accordinglyfracturing cracks are closed, and fracturing measures fail. The propping agent comprises, by weight, 90-93% of quartz sand, 2.5-5% of alkali-resistant resin, 1.3-3.6% of a curing agent, 0.07% of a silane coupling agent, 1.5% of a diluent and 0.5% of a lubricant. The alkali resistance of the film-coating propping agent is improved, so that the film-coating propping agent still has relatively highcompressive strength under a strong alkali system of ASP compound flooding, and requirements of the ASP compound flooding oil-water well fracturing measures are met.

Owner:PETROCHINA CO LTD +1

Method for processing sieve tube composite seam

ActiveCN101085485AEasy to processHigh strengthElectric circuitsPlasma welding apparatusElectromagnetic fieldPlasma energy

The invention relates to oil sand control screen complex sealing. The sheet tool electrode and the oil pipe connect with the positive and negative side of the controllable plasma, using discharged micro fine plasma high temperature etching for machining. Through the controlling of plasma energy and strength and frequency of the oscillating electromagnetic field, allowing the energy changing based on the preset rules, two sides of the plasma post generating regular reciprocating oscillation to realize the sealing machining. It can cut complex seal with outside narrow and inside wide one, featuring in high machining precision and low in cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Loose sand oil accumulation replacement sand prevention method

The invention provides a sand control technology for loose sandstone. Before sand control, by foam huff and negative-pressure mixed arrangement, the foam is used to discharge reservoir sand and clay particle fully, which are distributed unevenly near borehole zone; than high-pressure gravel is filled to sand control, even gravels are filled in the deficit stratum near borehole to improve the seepage behavior near borehole zone. The invention changes the seepage behavior of uneven stratum near borehole zone in basic, improves the well production rate, reduces the plugging near borehole zone by solid particles such as fine-silt sand, clay particle and so on in effect, and prolongs the valid period of sand control.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

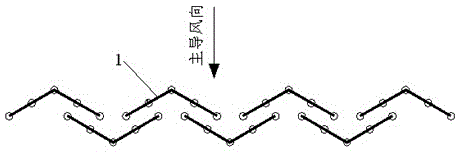

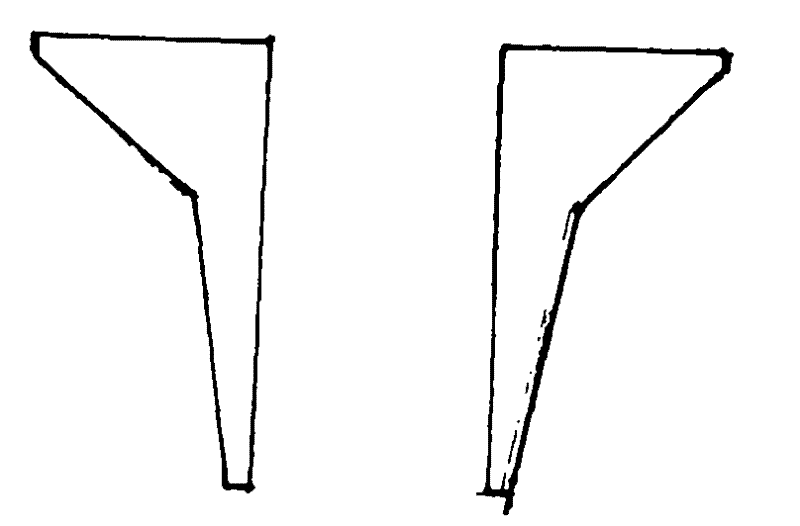

Gas-solid separation type sand barrier

The invention provides a gas-solid separation type sand barrier. The gas-solid separation type sand barrier is composed of two rows of combined sand barrier bodies arranged side by side. The gap is formed between the two rows of combined sand barrier bodies. Each row of combined sand barrier body is composed of multiple V-shaped single sand barrier bodies arranged side by side. The gap is formed between every two adjacent single sand barrier bodies in the same row of combined sand barrier bodies. The gap between every two adjacent single sand barrier bodies in one row of combined sand barrier bodies and the gap between every two adjacent single sand barrier bodies in the other row of combined sand barrier bodies are alternately spaced. The opening direction of the single sand barrier bodies in one row of combined sand barrier bodies is opposite to the opening direction of the single sand barrier bodies in the other row of combined sand barrier bodies. The separation sand barrier serves as a novel sand barrier, and sand grains and airflow in wind-sand flow are easily separated; the sand prevention efficiency is high, and the installation speed is high; and construction is easy and convenient, price is low, and the cost performance is high.

Owner:NORTHWEST RES INST CO LTD OF C R E C

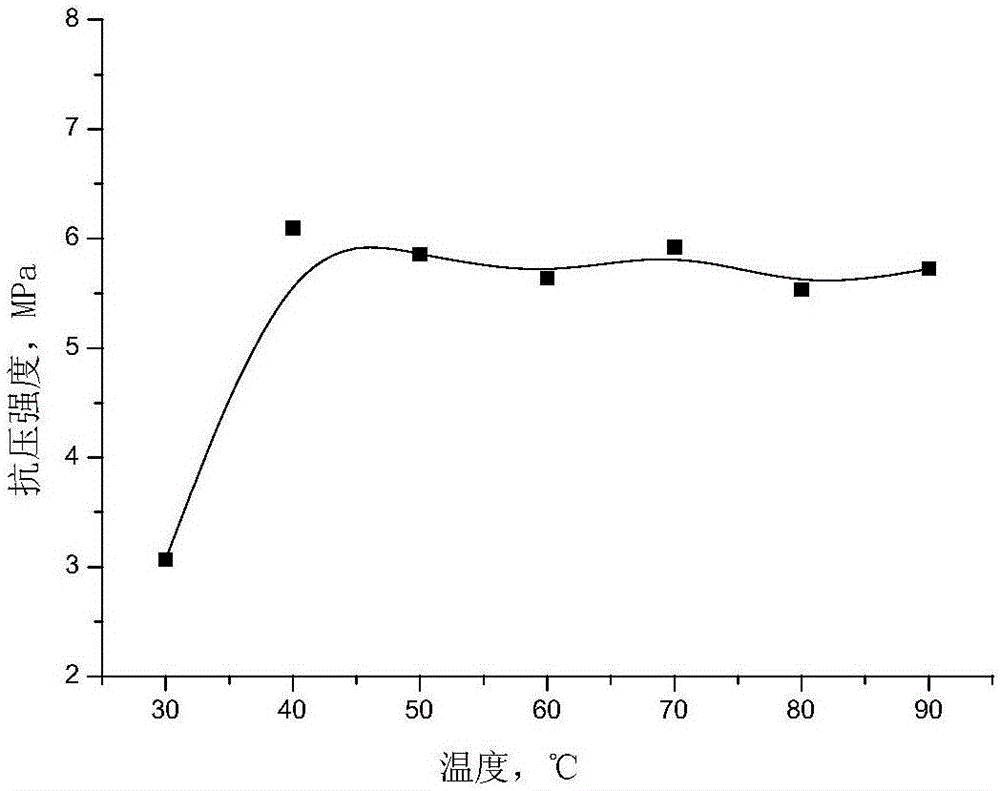

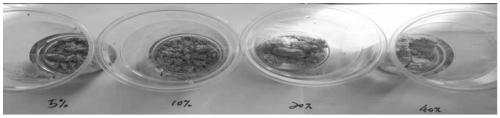

Low-density foam resin sand preventing agent suitable for sand production horizontal well of unconsolidated sandstone reservoir and preparation method of low-density foam resin sand preventing agent

ActiveCN106634920ALow costSimple preparation processFluid removalDrilling compositionApparent densityFoaming agent

The invention relates to a low-density foam resin sand preventing agent suitable for a sand production horizontal well of an unconsolidated sandstone reservoir and a preparation method of the low-density foam resin sand preventing agent. The low-density foam resin sand preventing agent is prepared from the following raw material components in percentage by weight: 97.1 to 98.85 percent of cementing agent, 0.3 to 0.8 percent of foaming agent, 0.7 to 1.3 percent of foam stabilizer, 0.05 to 0.5 percent of curing agent and 0.1 to 0.3 percent of coupling agent. The apparent density of the low-density foam resin sand preventing agent disclosed by the invention is 0.558 to 0.634g / cm<3>, and the low-density foam resin sand preventing agent can be uniformly injected into a heterogeneity stratum; the compressive strength of a system solidified rock core is 5.2 to 7.7MPa, and the permeability of the system solidified rock core is 1.1 to 3.5mu m<2>, so the low-density foam resin sand preventing agent can be applied to sand prevention of an ordinary vertical well, chemical sand control of a horizontal well, a highly-deviated well and irregular boreholes as well as secondary sand prevention after mechanical sand control is failed; besides, the low-density foam resin sand preventing agent is simple in preparation and construction process and wide in industrial raw material source, and can be well and widely applied to the field of chemical sand control of an oil-water well.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Uprighting and sand preventing integrated pipe column and operating method thereof

ActiveCN106121548AImprove permeabilityPrevent collapseDrilling rodsFluid removalEngineeringOil water

The invention discloses an uprighting and sand preventing integrated pipe column which comprises a suspension head, automatic expansion uprighting nipples, automatic expansion sealed uprighting nipples, a screen pipe, a guide cone and sleeves. The suspension head adopts a structure of an inverted cone cylinder. An internal thread is formed in the inner wall of a conic cylinder extension pipe, and is used for being connected with a rod body of a drill rod. The root of the conic cylinder extension pipe is in threaded connection with the automatic expansion uprighting nipples. The automatic expansion sealed uprighting nipples are connected with the automatic expansion uprighting nipples in sequence through the sleeves. The automatic expansion sealed uprighting nipples are in threaded connection with the screen pipe, the automatic expansion sealed uprighting nipples and the guide cone in sequence. A vulcanized automatic expansion rubber cylinder is arranged at the peripheries of the automatic expansion uprighting nipples / the automatic expansion sealed uprighting nipples. The uprighting and sand preventing integrated pipe column has the beneficial effects that the problem that a conventional sand preventing pipe column is not centered and sealed, so that the sand preventing failure problem or the sand preventing invalidation problem is caused is solved, the stratum can be stabilized, hole collapse or sand flow is prevented, the sand preventing effect is good, the period of validity is long, and oil-water well abandonment is avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

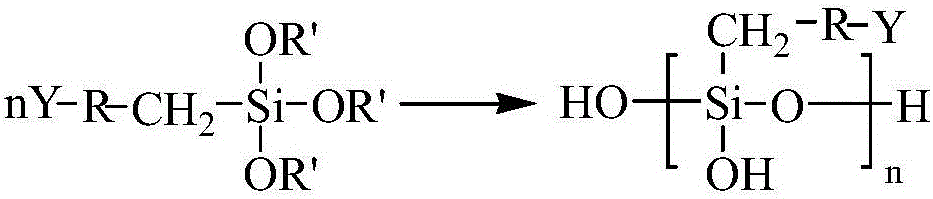

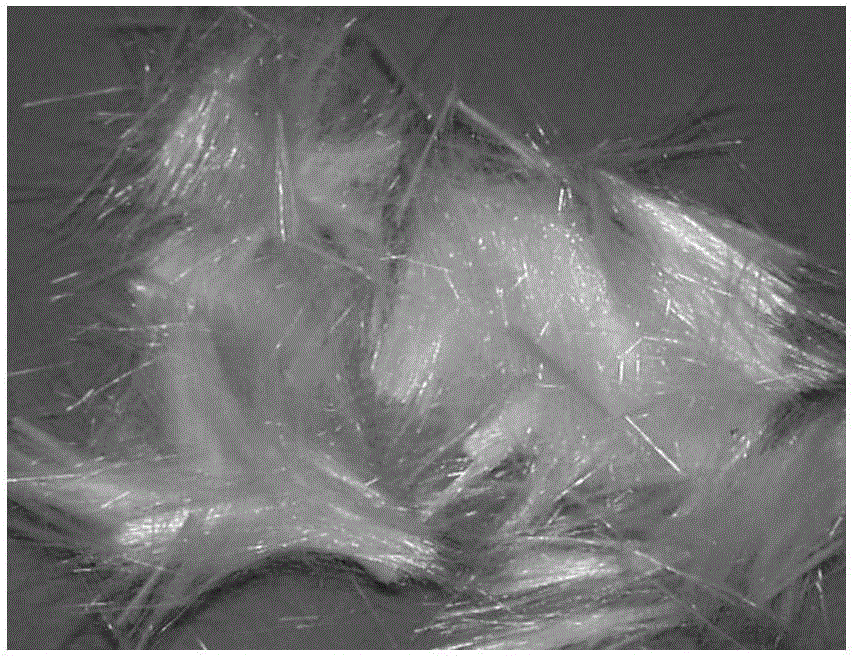

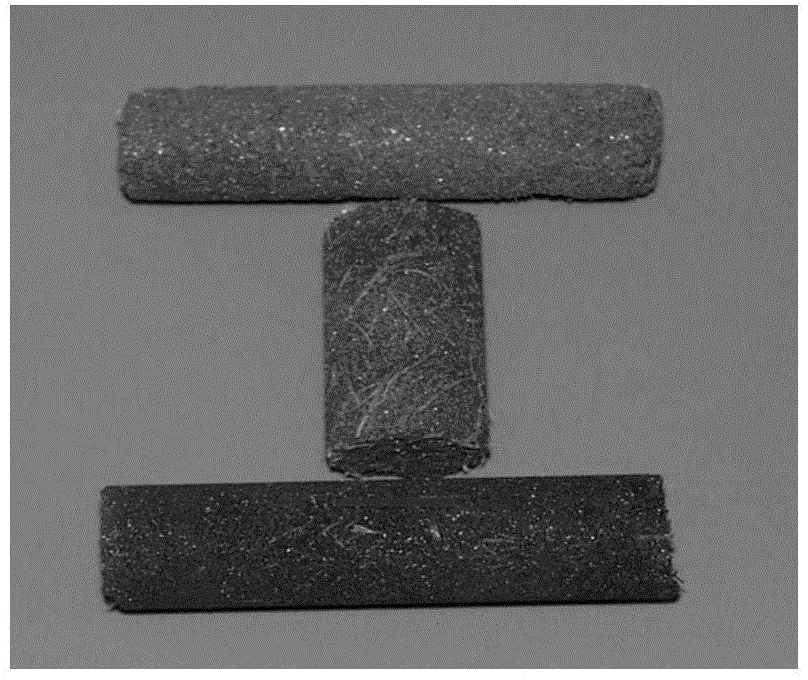

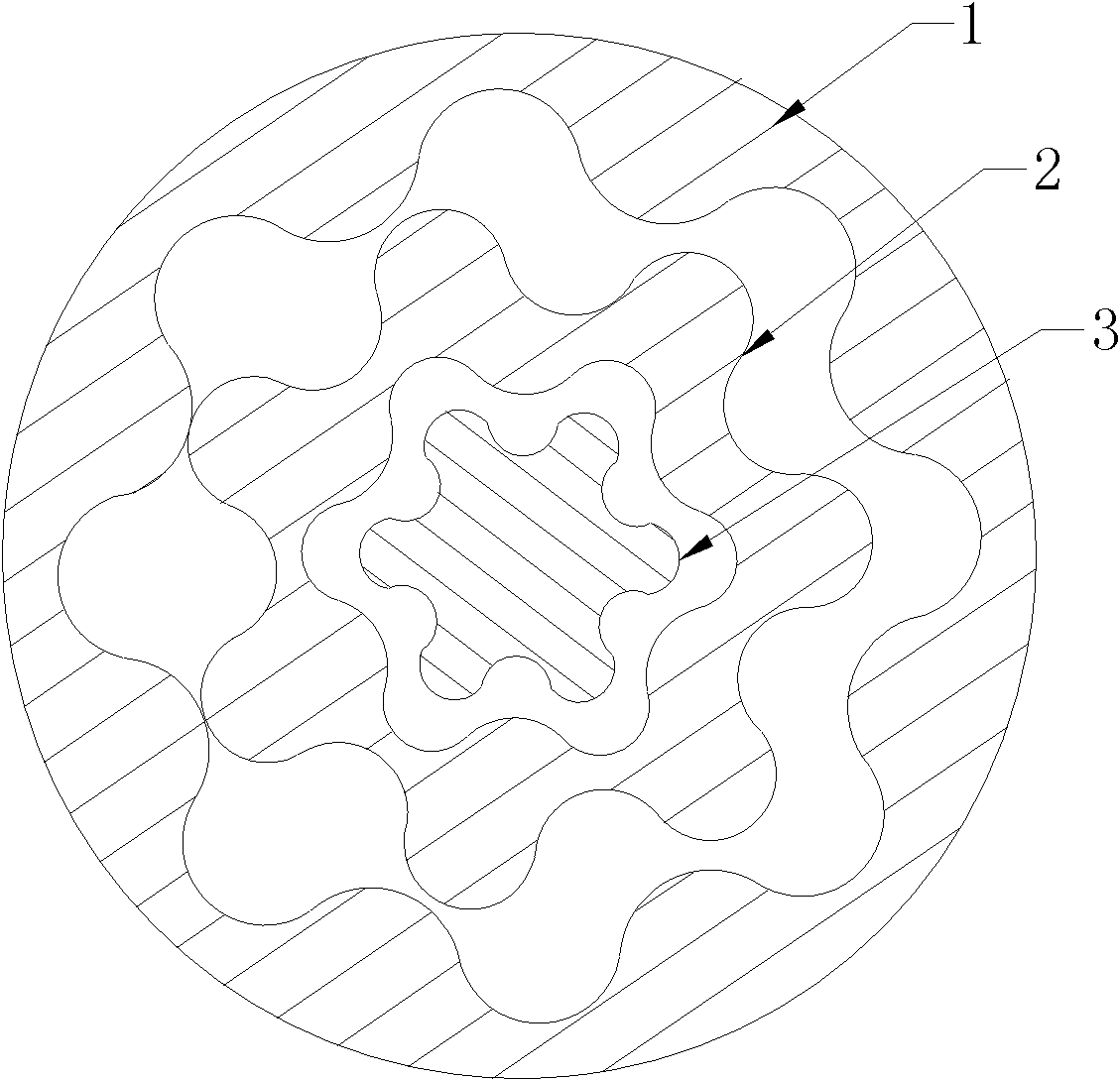

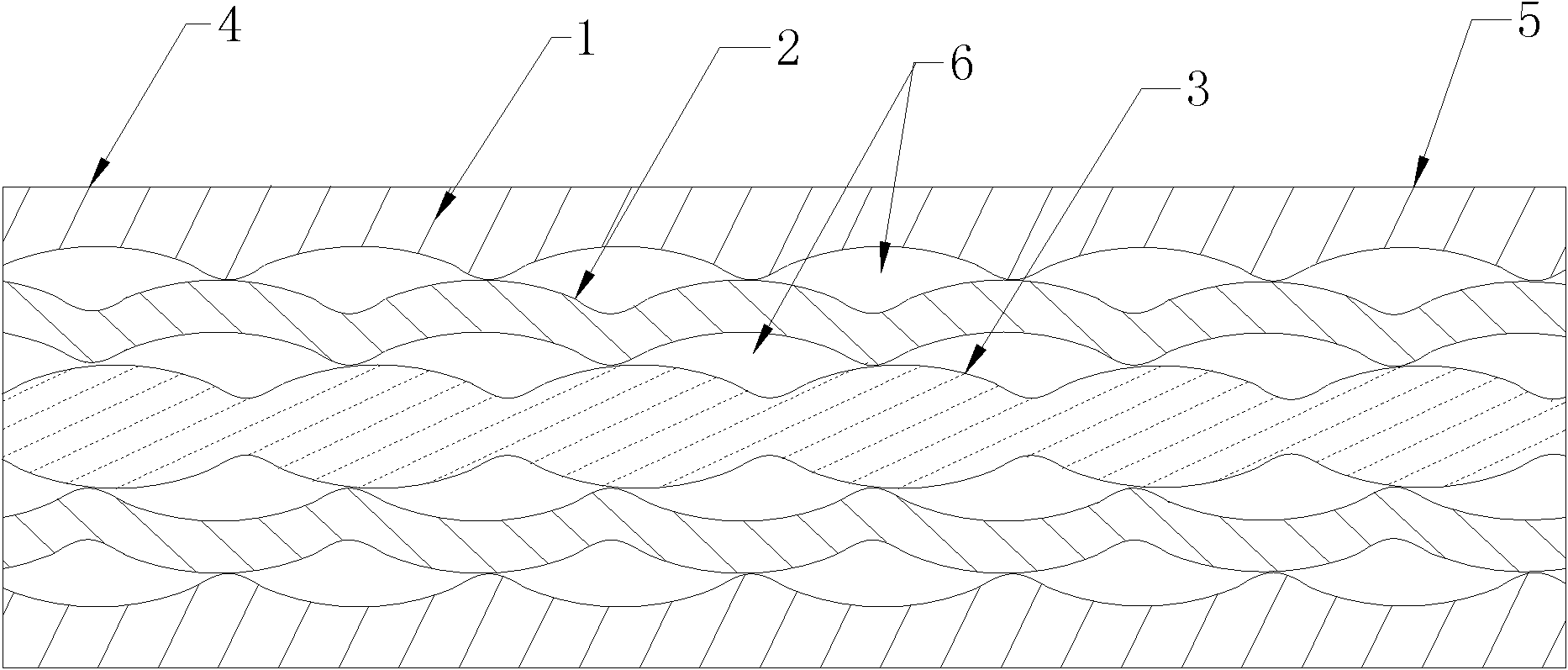

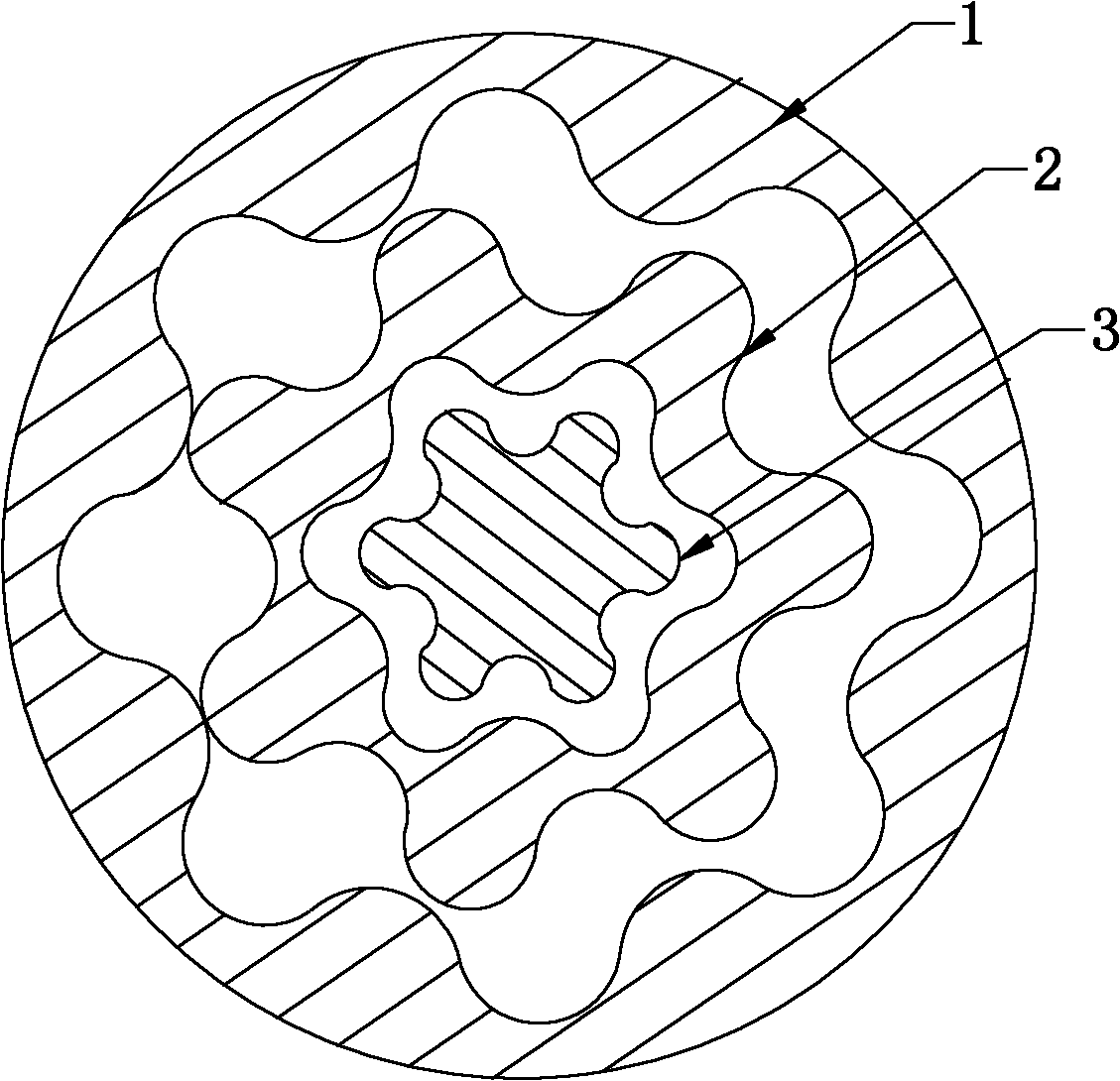

Sand-proof fiber composite filter body, sand-proof sand-filtering tube and preparation method

The invention provides a sand-proof fiber composite filter body, a sand-proof sand-filtering tube and a preparation method. The sand-proof fiber composite filter body is prepared from a propping agent coated with a coating and a fiber which is surface-processed by a silane coupling agent through die-filling thermal moulding. The sand-proof sand-filtering tube is composed of a central tube provided with an overflow hole and the fiber composite filter body sleeving the central tube. The fiber composite filter body is fixed on an overflow hole part on the central tube. The invention also provides the preparation method of the fiber composite filter body and an assembling method of the sand-proof sand-filtering tube. The fiber composite filter body is high in strength, is good in flexibility, is good in medium resistance, is uniform in pore distribution, is good in permeability and is good in sand-proof effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

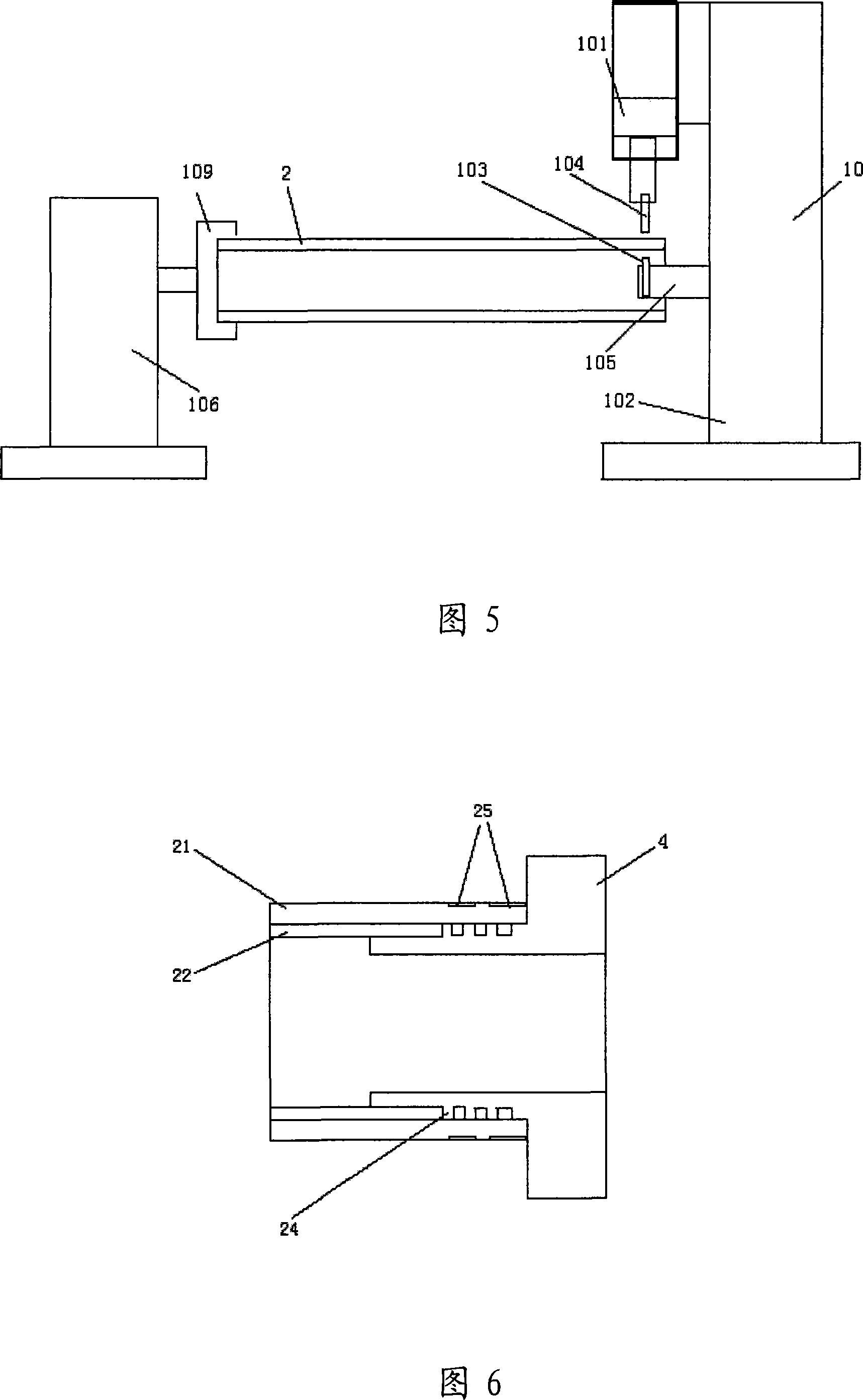

Welding equipment of the sand prevention tube

ActiveCN101116927AImprove sand control effectExtended service lifeResistance electrode holdersWelding/cutting auxillary devicesEngineeringSpot welding

The invention discloses a welding device for sand prevention pipe, which adopts the double-face single spot welding or sew welding art to fix a metal weave net outside a support sheath, therefore, the divulging hole phenomenon of the metal net is eliminated. Because the sand prevention pipe with multilayer metal weave nets is made up, the sand prevention capability and the life-span of the sand prevention pipe are improved. Furthermore, the welding device of the sand prevention pipe achieves penetrating type welding for slender filtering sheath, thereby improving the welding quality of the metal weave net and reducing the making cost of the sand prevention pipe.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

Sand prevention agent for achieving auto-aggregation of sand grains

ActiveCN110317594AHigh strengthImprove heat resistanceDrilling compositionInorganic saltsPolysaccharide

The invention belongs to the technical field of petroleum development, and particularly relates to a sand prevention agent for achieving auto-aggregation of sand grains. The sand prevention agent comprises three parts including an auto-aggregation liquid, an auto-aggregation auxiliary agent and a sand consolidation agent. Main ingredients of the auto-aggregation liquid are natural polysaccharide compounds, and main ingredients of the auto-aggregation auxiliary agent are inorganic salt. The sand prevention agent achieves auto-aggregation of the sand grains through the synergistic effect among chemical agents of the sand prevention agent, the stratum sand grains can be packaged and clustered to be fixed to corresponding positions of the stratum, the consolidation effect is obviously improved, the actuating range is expanded, and a good sand consolidation effect can be achieved on fine-powder sand.

Owner:青岛大地新能源技术研究院

Sand-preventing method of artificial borehole wall, and material for sand prevention

ActiveCN107163926AImprove salt toleranceCalcium resistantFluid removalDrilling compositionAlkylphenolSURFACTANT BLEND

The invention discloses a sand-preventing method of an artificial borehole wall, and a material for sand prevention. The material for sand prevention comprises guide liquid, sand carrying liquid and promoting liquid which are prepared separately, wherein the guide liquid comprises the following components in percentage by weight: 0.5 to 20 percent of sodium chloride, 0.2 to 2 percent of calcium chloride, 0.1 to 1 percent of magnesium chloride, 0.2 to 4 percent of alkylphenol polyoxyethylene, 0.3 to 8 percent of an anionic surfactant capable of resisting calcium and magnesium ions and 0.01 to 6 percent of a dimethyl diallyl ammonium chloride-acrylamide-acrylic acid copolymer; the sand carrying liquid comprises the following components in percentage by weight: 0.01 to 5 percent of a dimethyl diallyl ammonium chloride-acrylamide copolymer and 0.5 to 20 percent of ammonium chloride; and the promoting liquid comprises the following components in percentage by weight: 8 to 22 percent of a penetrating agent and 18 to 35 percent of a dehydroxylation catalyst. The material for sand prevention performs sand prevention, can protect the stratum, has high sand carrying capability, reduces friction and enhances the consolidation strength, and the penetration ratio of the artificial borehole wall formed after sand prevention is more than 12 <mu>m<2>.

Owner:东营市科诺石油技术有限责任公司

Haloxylon aammodendron seedling safety storage overyear method

InactiveCN101213926AGuarantee smooth constructionImprove sand control effectForestryHaloxylon ammodendronHaloxylon

The present invention relates to a method for the safe storage of the saxoul seedling to pass the winter. The method comprises the steps such as the selection of the saxoul seedling, the selection of the soil for the storage of the seedling, the binding of the seedling, the embedding of the seedling, the provisonal planting time of the seedling, etc. The present invention is adopted to plant the 50000 saxoul seedlings and 300000 saxoul seedlings for provisional planting to pass winter along the channel line at Gurbantunggut Desert of North-to-South Water Engineering in Xinjiang Uygur Autonomous Region; the survival rate of the plantation reaches 90 percent and 85 percent respectively, thereby achieving favorable sand-prevention and sand-governing effect, and guaranteeing the successful construction of the engineering at the desert section.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

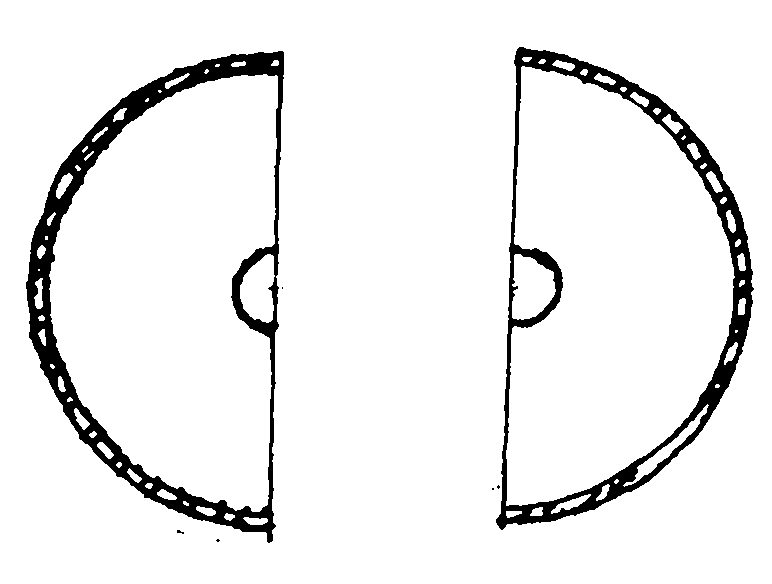

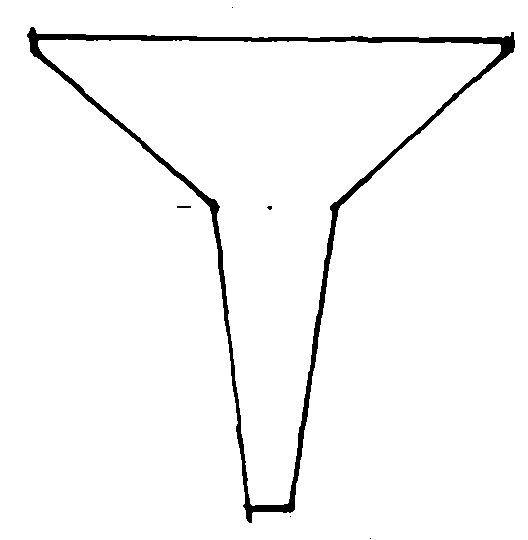

Desert plot sand blocking and water holding planting guarantee apparatus

InactiveCN102187793AImprove sand control effectGeneral water supply conservationCultivating equipmentsSoil scienceWater holding

The invention discloses a desert plot sand blocking and water holding planting guarantee apparatus. The guarantee apparatus is a combined device of a nutrient bag made of a degradable plastic film and a sand blocking and rain collecting funnel cast by hard plastic. A mixture of grass clippings with water content of 60 percent and sandy soil is filled into the nutrient bag, the nutrient bag is embedded into a sandy soil layer after plants are planted on the nutrient bag, and the sand blocking and rain collecting funnel divided into two half parts is closed around the planted plants. The water stored in the nutrient bag can meet the water required by the survival stage of the planted plants, and the sand blocking and rain collecting funnel can continually supply a part of rainwater to the nutrient bag and can also resist the coverage of quicksand on the plants, so that the sand control effect can be greatly improved.

Owner:朱明龙

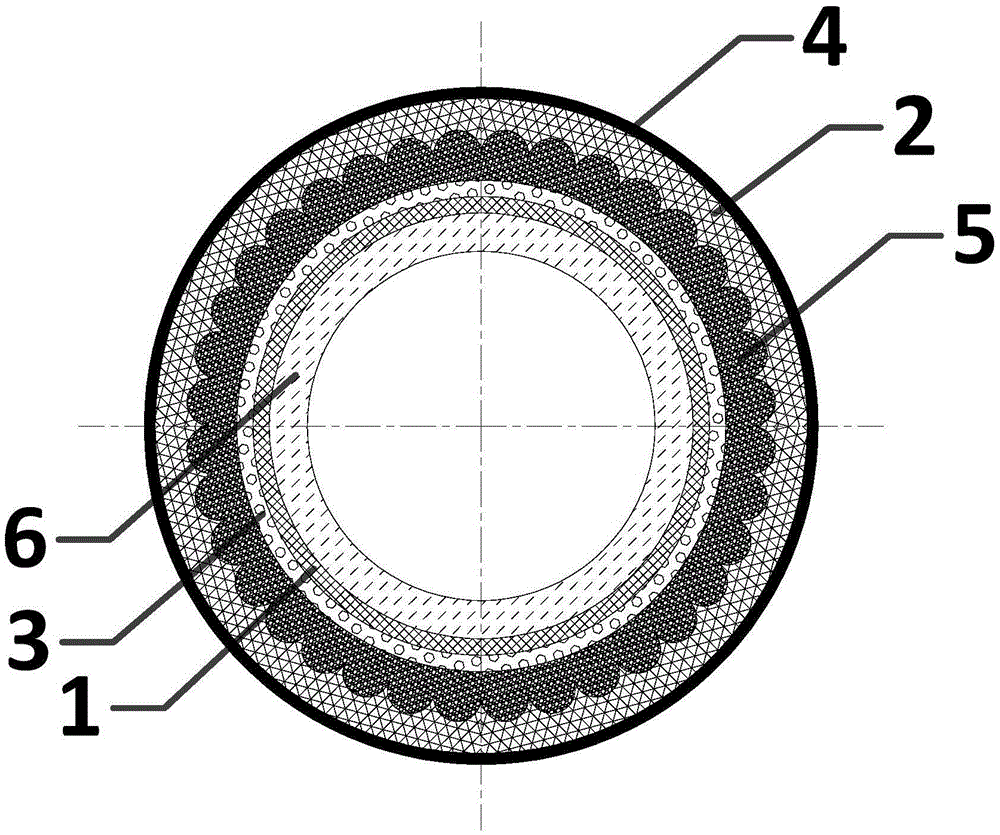

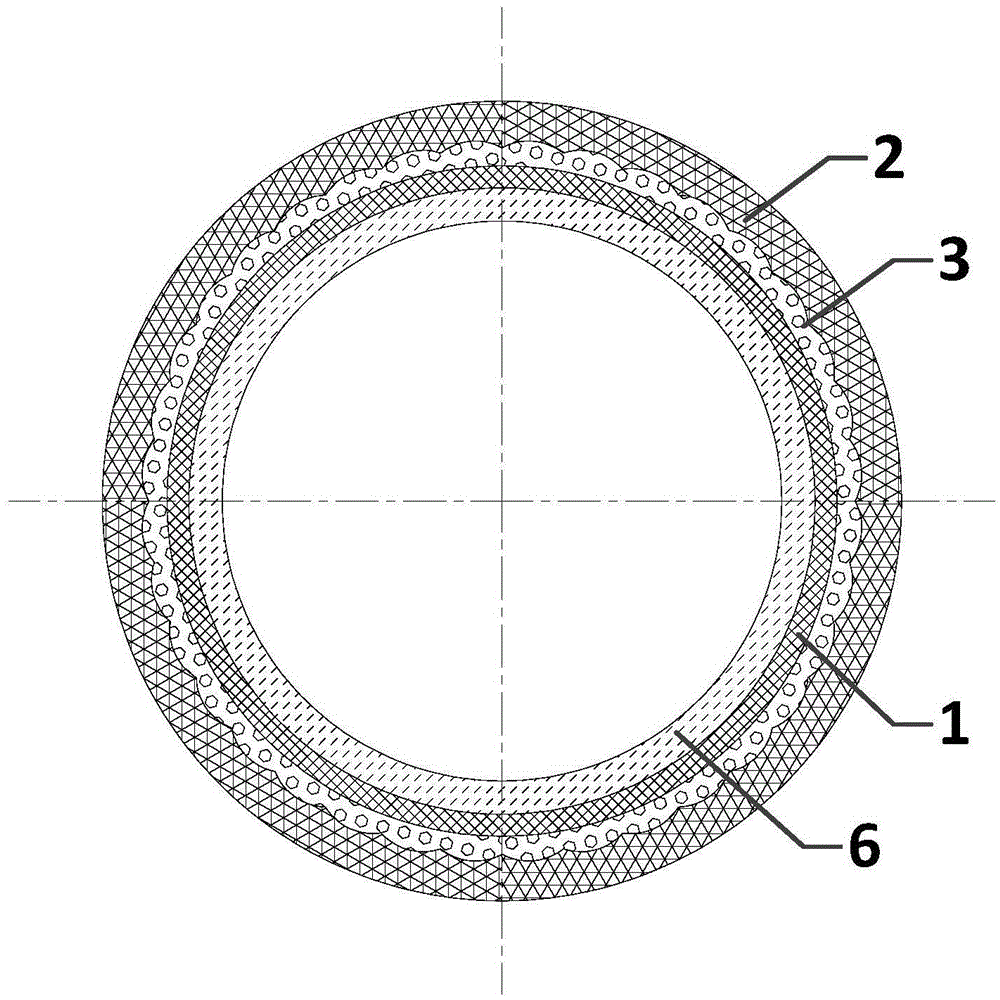

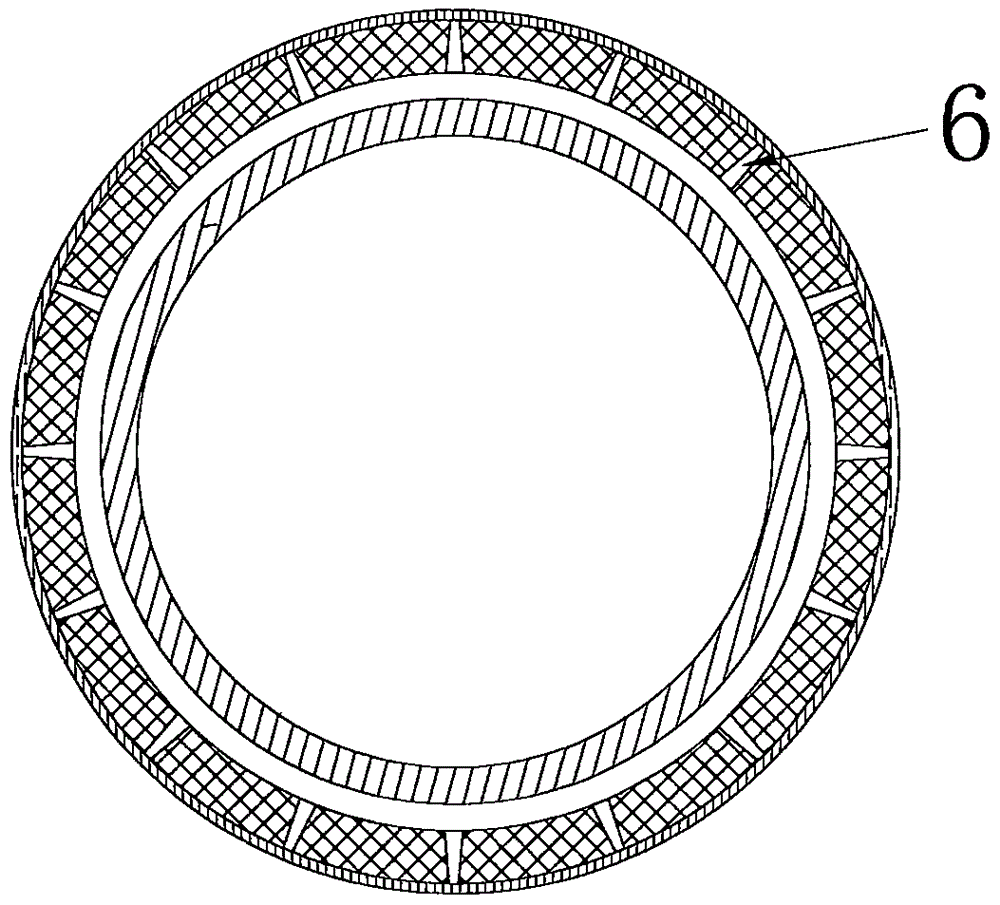

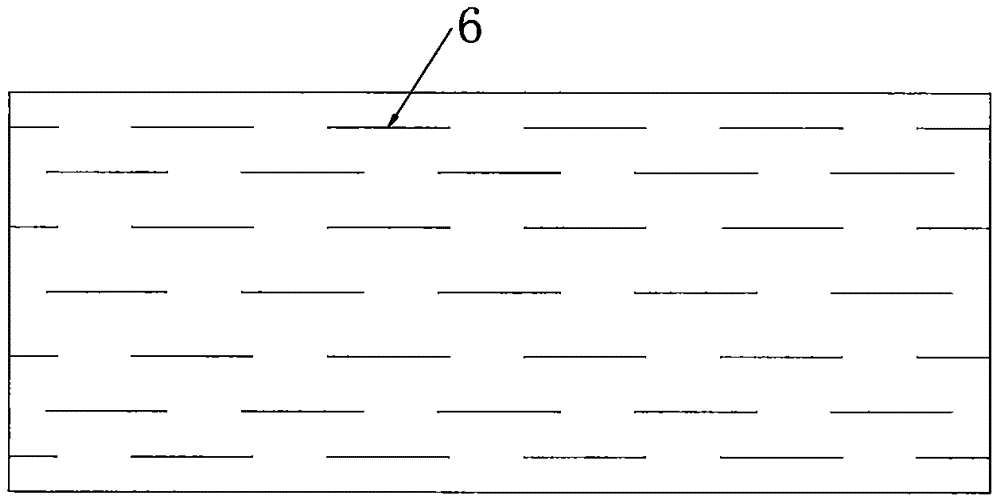

Novel foam metal sand-prevention pipe

InactiveCN105221118AStrong drainage abilityHigh sand control precisionFluid removalFiltrationEngineering

The invention relates to a novel foam metal sand-prevention pipe. The sand-prevention pipe is used for underground sand prevention for an oil and gas field and structurally comprises an outer pipe protective casing, a foam metal sand-prevention layer, wire-winding support strips and a base pipe in sequence from outside to inside, the foam metal sand-prevention layer is provided with flow guide gaps which are distributed in a staggered mode, each flow guide gap is in a trapezoidal shape with the outside narrow and the inside wide, the wire-winding support strips are welded to the outside of the base pipe, the base pipe contains parallel flow guide through holes, each flow guide through hole is located between the corresponding two wire-winding support strips, the minimum filtration diameter of the foam metal sand-prevention layer reaches 0.05 mm, the thickness of the foam metal sand-prevention layer is 0.5-1 cm, and the gap width, at the narrowest position, of each flow guide gap is greater than or equal to 01mm. The novel foam metal sand-prevention pipe is good in permeability and high in strength, each flow guide gap with the outside narrow and the inside wide has the self-cleaning function, by means of the sand-prevention pipe, sand-prevention precision is greatly improved, the service life of the sand-prevention pipe is greatly prolonged, good flow guide capability is achieved, and the liquid flow is effectively increased.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Novel horizontal well sand preventing well completion structure

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Double-stator single-rotor screw motor consubstantial pump

InactiveCN101975159ATo achieve the purpose of decontaminationReduce development costsRotary piston pumpsRotary piston liquid enginesWaxEngineering

Owner:KALAMAYI HONGJI ENG CONSTR

Foam metal composite sand prevention structure and liquid extracting pipe

InactiveCN102220857AImprove sand control effectStrong sand capacityFluid removalMaterials scienceMetal mesh

The invention provides a foam metal composite sand prevention structure and a liquid extracting pipe. The foam metal composite sand prevention structure is sleeved outside a basic pipe and at least comprises a foam metal sand prevention layer made of foam metal. The liquid extracting pipe comprises the basic pipe and the foam metal composite sand prevention structure which is sleeved outside the basic pipe. The sand prevention structure has the sand prevention effect of a gravel filling process, the structural strength of a wire-wound metal mesh, high sand tolerance capacity, low overflow resistance, and a good prevention effect on sand grains with the grain size of more than 60mu m; and when the sand prevention structure is matched with a well cleaning process, a pipe column is not required to be moved for well cleaning, so that the sand prevention effect is further enhanced.

Owner:PETROCHINA CO LTD

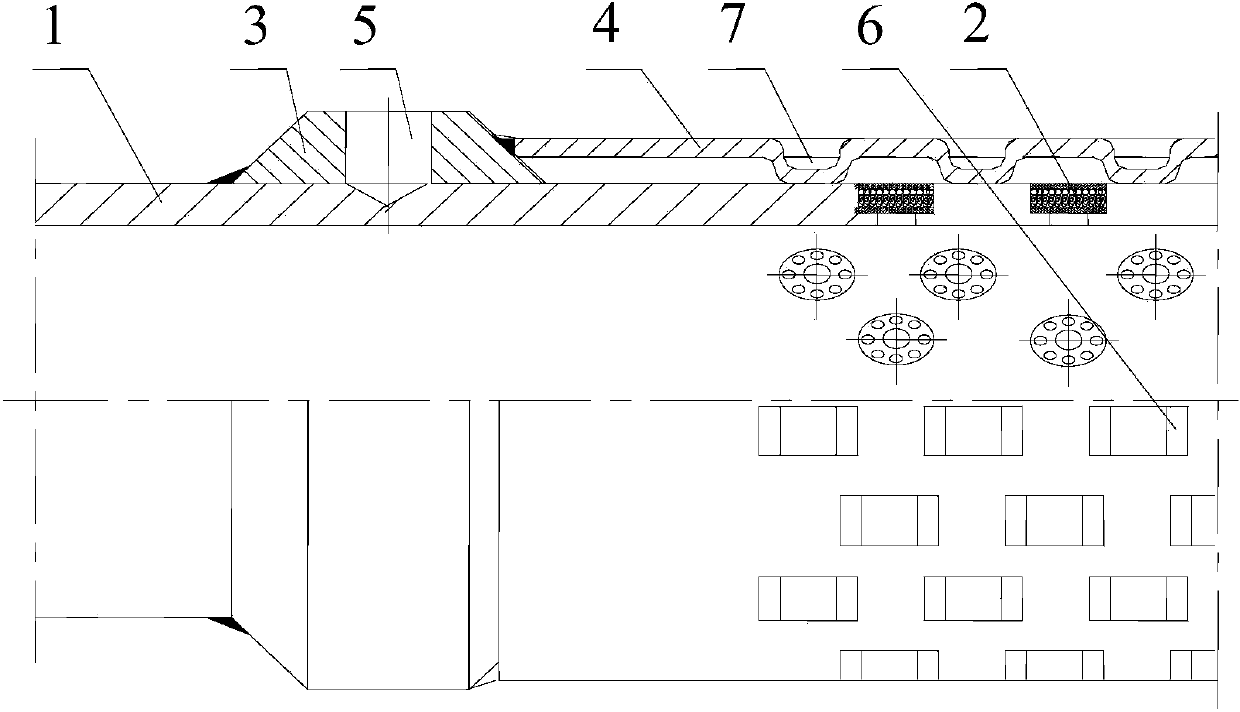

Novel stereo sand control screen

The invention relates to a novel stereo sand control screen which comprises a central base tube, filters, a supporting tray and an overflowing protection sleeve, wherein a plurality of overflowing holes are formed in the wall of the central base tube and filled with the filters, the supporting tray is composed of a first tray body and a second tray body, and the first tray body and the second tray body are fixedly arranged at the two ends of the central base tube respectively; the overflowing protection sleeve is arranged outside the central base tube in a coaxial and sleeved mode, and the two ends of the overflowing protection sleeve are fixed on the central base tube through the first tray body and the second tray body respectively; a plurality of arched structures are arranged on the overflowing protection sleeve, and two screening grooves are formed by each arched structure and the overflowing protection sleeve. The novel stereo sand control screen is good in erosion resistance and filtering effect due to the fact that the overflowing protection sleeve is arranged on the outer layer and the filters are arranged on the inner layer, and especially has good sand prevention and protection functions for gravel packing, removal of burrs left from windowing of a sidetracking well, and removal of burrs left from float collar and float shoe drilling of an operating well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

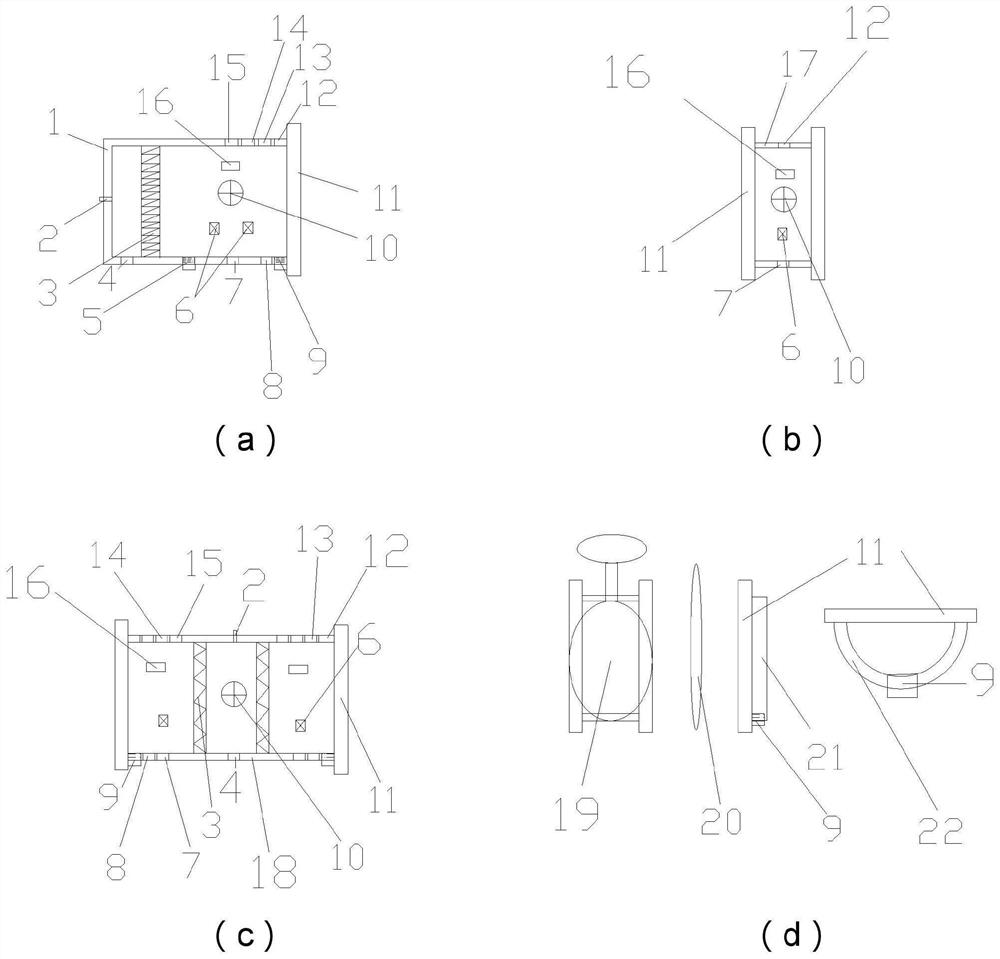

Detachable natural gas hydrate simulation sand production and sand prevention test reaction device and method

ActiveCN112067785AImprove sand control effectEarth material testingChemical/physical/physico-chemical processesWater bathsMining engineering

The invention discloses a detachable natural gas hydrate simulation sand production and sand prevention test reaction device and method. A simulation natural gas hydrate exploitation sand production and sand prevention test is divided into a reaction kettle system, a gas injection water sand system, a gas-water-sand separation metering system, a low-temperature water bath jacket system and a supporting and safety system. Reaction kettles in the reaction kettle system can be combined into different reaction kettles according to different experiment conditions and purposes. The reaction kettlesmainly comprise left and right reaction kettles, secondary left and right reaction kettles, a central reaction kettle and a sealing cover. The reaction kettle system disclosed by the invention has thecharacteristic of a flexible assembly design, and the reaction kettle without a sieve tube for realizing hydrate generation and decomposition is formed by combining the left and right reaction kettles and the sealing cover; and a series of sand production and sand prevention tests of a single well and double wells without an observation area, a single well and double wells of a single observationarea, a single well and double wells of double observation areas and the like can be simulated by combining the left reaction kettle, the right reaction kettle, reaction kettle accessories, the secondary left reaction kettle, the secondary right reaction kettle and the central reaction kettle.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

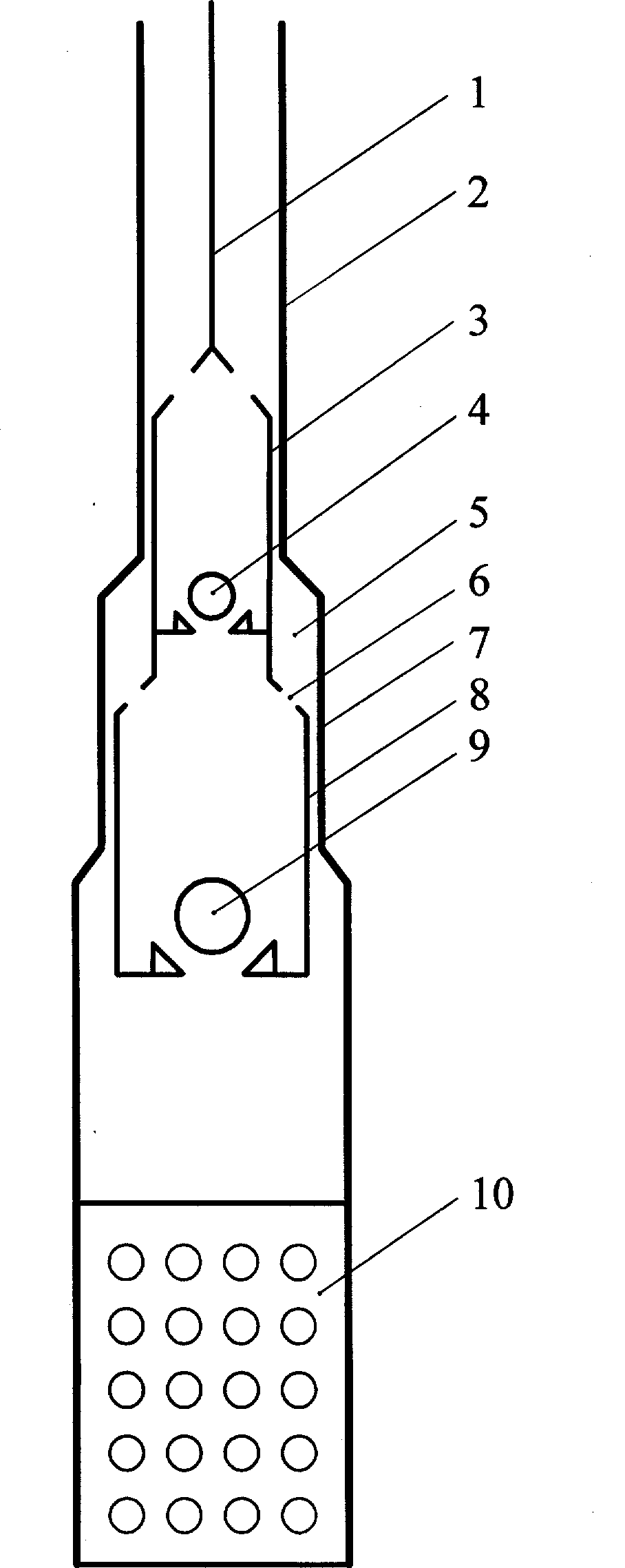

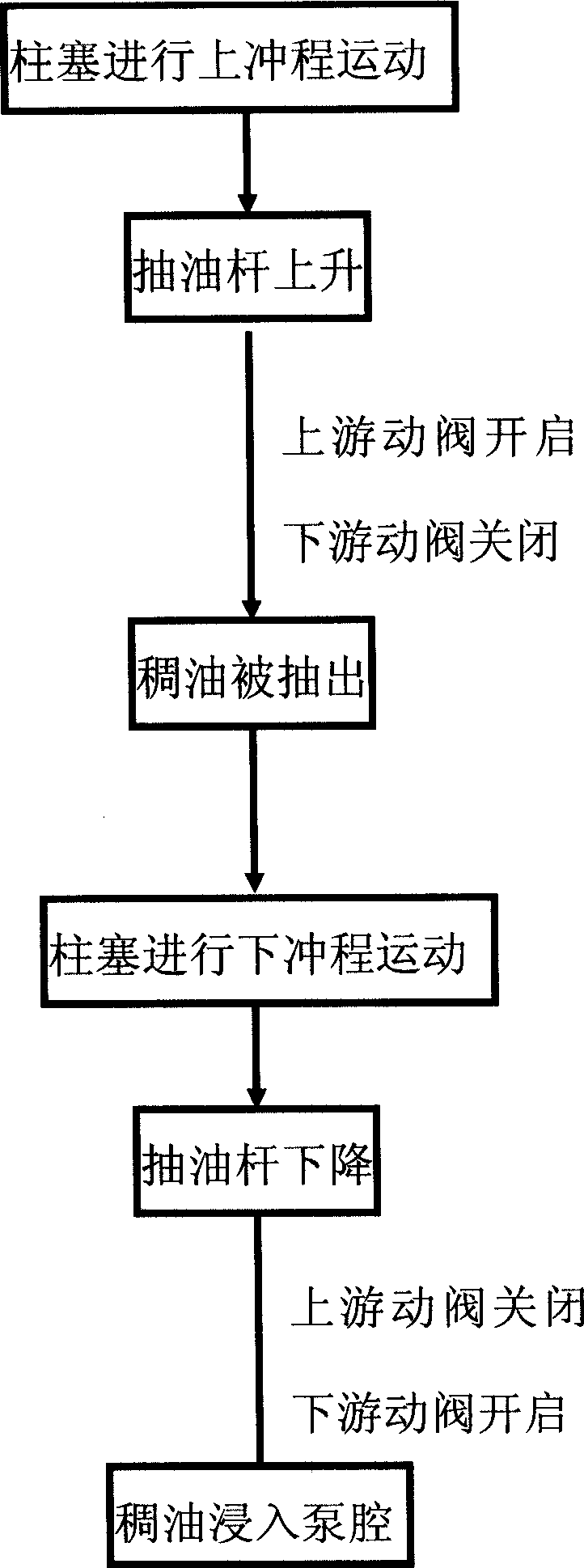

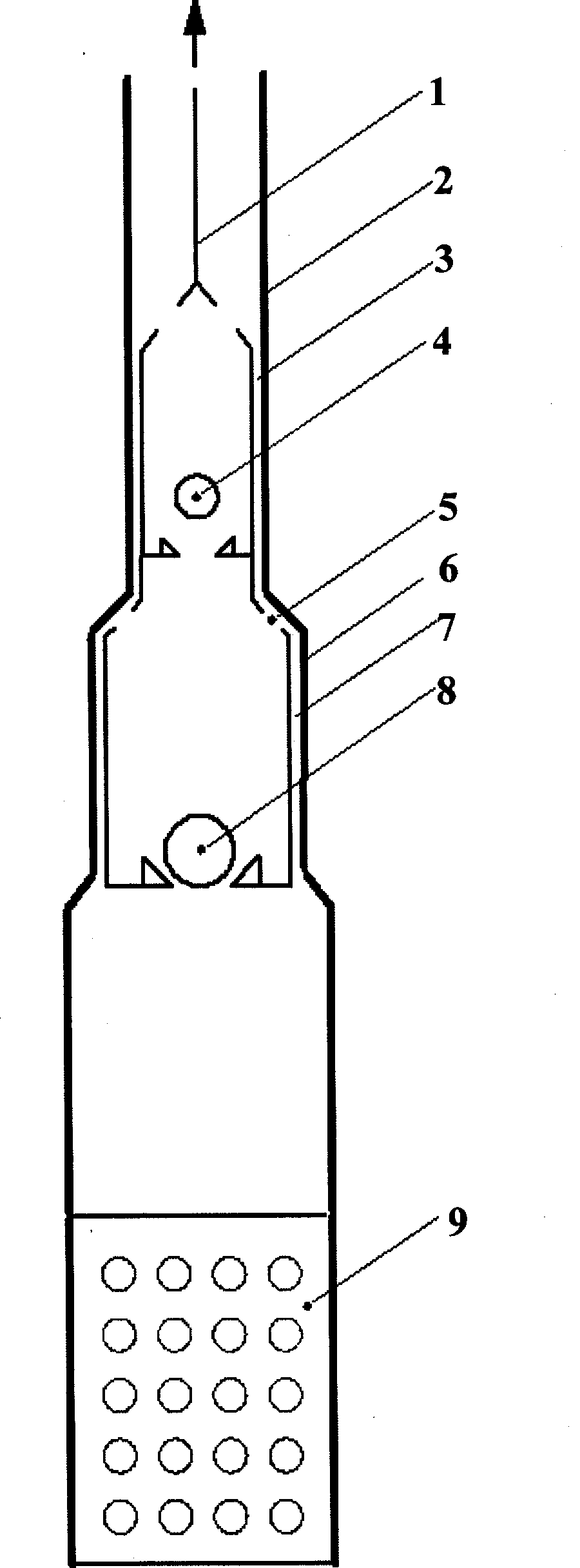

Process for backwashing permeable downhole filter by high pressure fluid column in oil conduit

The invention provides a method and a technology using a high-pressure liquid column in an oil pipe for reversely flushing a sand filtering pipe, and expounds the selection of the type of the oil extracting pump and the basic calculation and the selection of the oil extractor related to the technology. According to the concrete implementing process of the technology using the high-pressure liquid column for reversely flushing a sand filtering pipe and aiming at the thick oil well of high sand concentration, the method and the technology have excellent effects on improving the sand resistance and the oil extracting efficiency of the oil extracting pump, in particular on prolonging the service life of the oil extracting pump. The technology does not need additional working equipment to realize the function and the effect of high oil extracting efficiency and long service life through using the normal production equipment for work by improving the structure of the pump body of the oil extracting pump of a plunger piston type. The realization of the technology and the process enables the oil extracting pump used for the production of a sand-outlet oil well to solve the sand clamping phenomenon caused by the sand entering between the plunger piston and the pump cylinder and the blockage of the sand filtering pipe caused by sand by one-time work, thus, the scuffing and the abrasion of the cylinder of the pump are reduced, the blockage substance in the sand filtering pipe is completely removed, and the production period of the oil well and the service life of the pump are prolonged. The production well realizing the method of the technology and using the technology has high oil extracting efficiency and long production period.

Owner:王霞

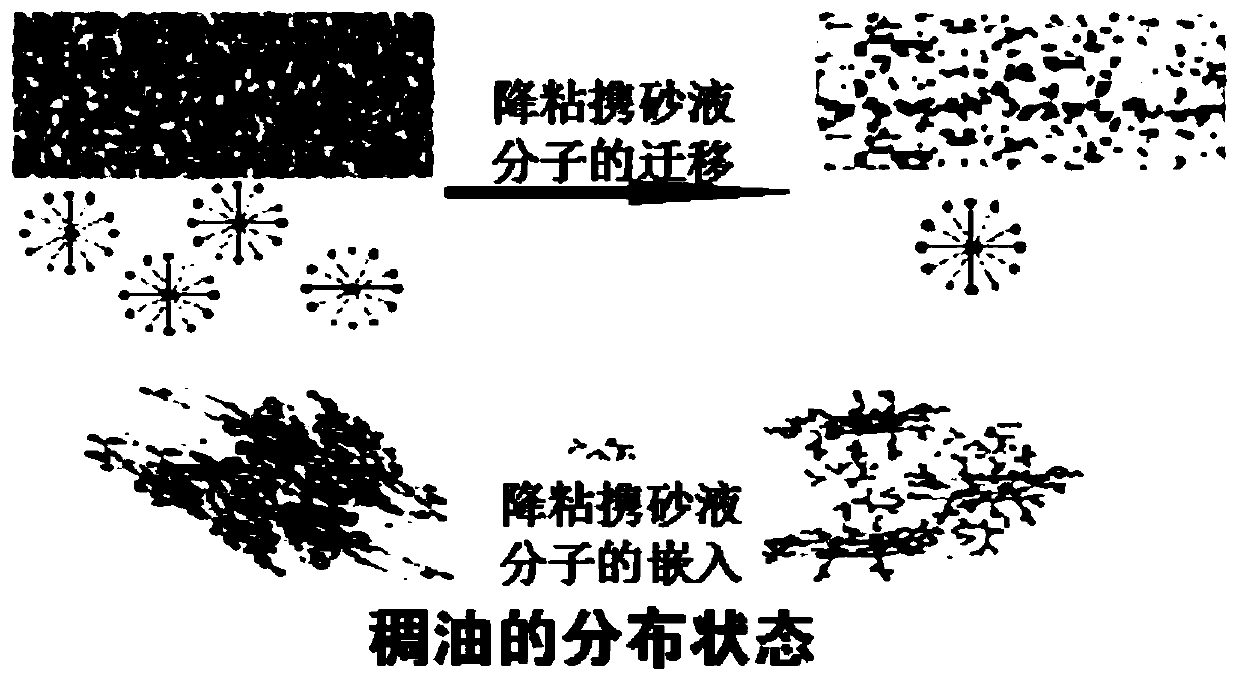

Viscosity-reducing sand-carrying fluid and preparation method thereof

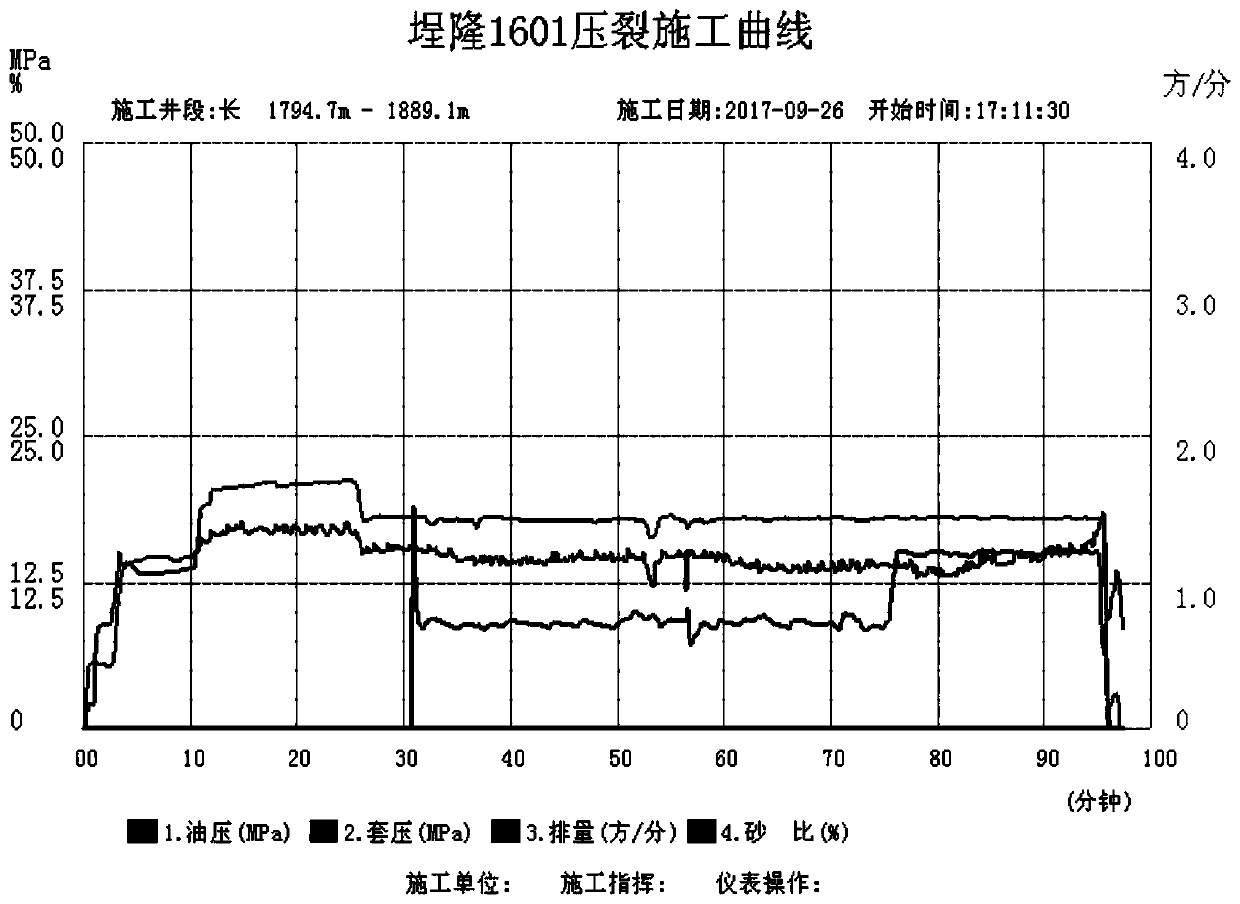

InactiveCN110791271APrevent hydration migrationLow viscosityFluid removalDrilling compositionDemulsifierOil water emulsion

The invention belongs to the technical field of oil extraction, and particularly relates to a viscosity-reducing sand-carrying fluid and a preparation method thereof. The viscosity-reducing sand-carrying fluid comprises the following components in parts by mass: 0.25-0.30 part of a thickening agent; 0.5 to 1.0 part of an anti-swelling agent; 0.20 to 0.30 part of a cleanup additive; 1.5 to 2.5 parts of a demulsifying agent; 3.0 to 5.0 parts of a viscosity reducer; 90-100 parts of water. The viscosity-reducing sand-carrying fluid is capable of smoothly bringing a propping agent into stratum to fill channels and pores; the added anti-swelling agent can prevent clay from hydration migration, the added demulsifying agent can realize oil water separation, and realize demulsifying of oil-water emulsion in a short time, the viscosity reducer plays a role to reduce the viscosity of crude oil, and after construction is finished, the viscosity-reducing sand-carrying fluid is subjected to gel breaking and flowing back under the action of formation temperature, pressure and the cleanup additive.

Owner:DAGANG OIL FIELD GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com