Welding equipment of the sand prevention tube

A technology for welding equipment and sand control pipes, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of shrinkage, welding difficulties, low welding strength, etc., to reduce manufacturing costs, improve sand control ability and service life, The effect of improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

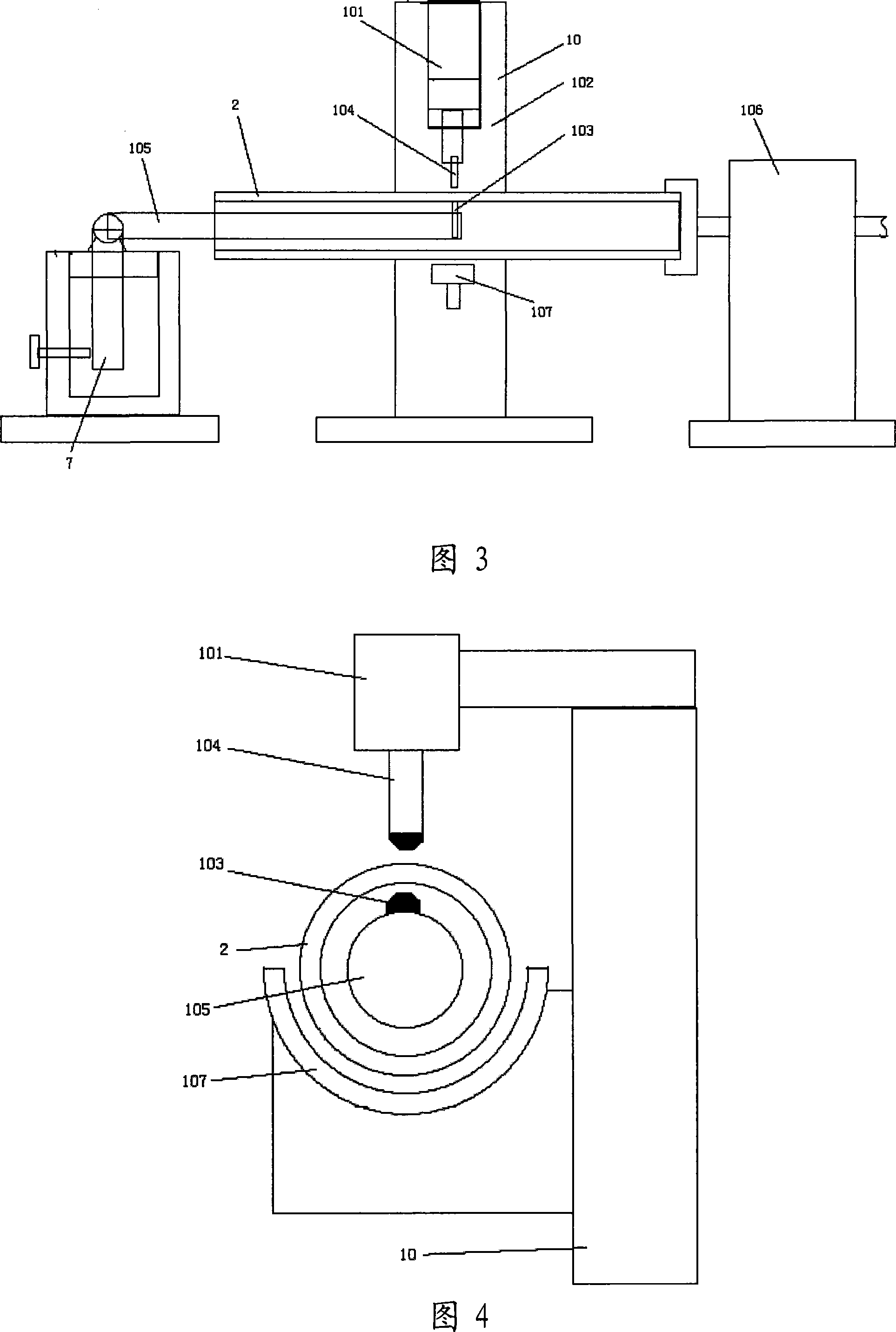

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

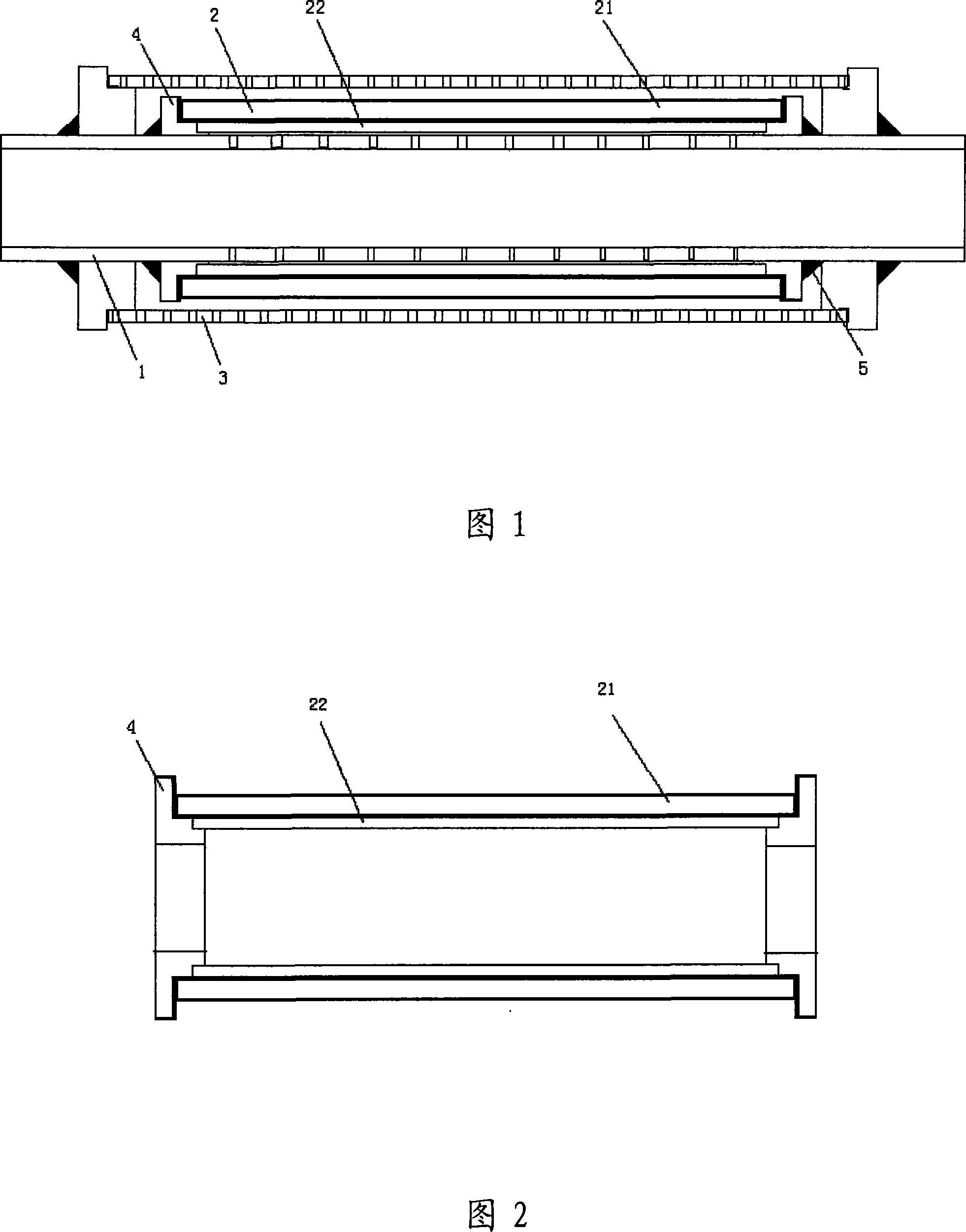

[0021] Referring to Fig. 1, the sand control pipe manufactured by the present invention is composed of a base pipe 1 with a plurality of through holes on the pipe wall, a filter sleeve 2 and an outer protective sleeve 3 with a plurality of leakage holes on the pipe wall; wherein, the filter sleeve 2 covers Set on the outside of the base pipe 1, and the outer protective cover 3 covers the outside of the filter sleeve 2; the specific manufacturing method is:

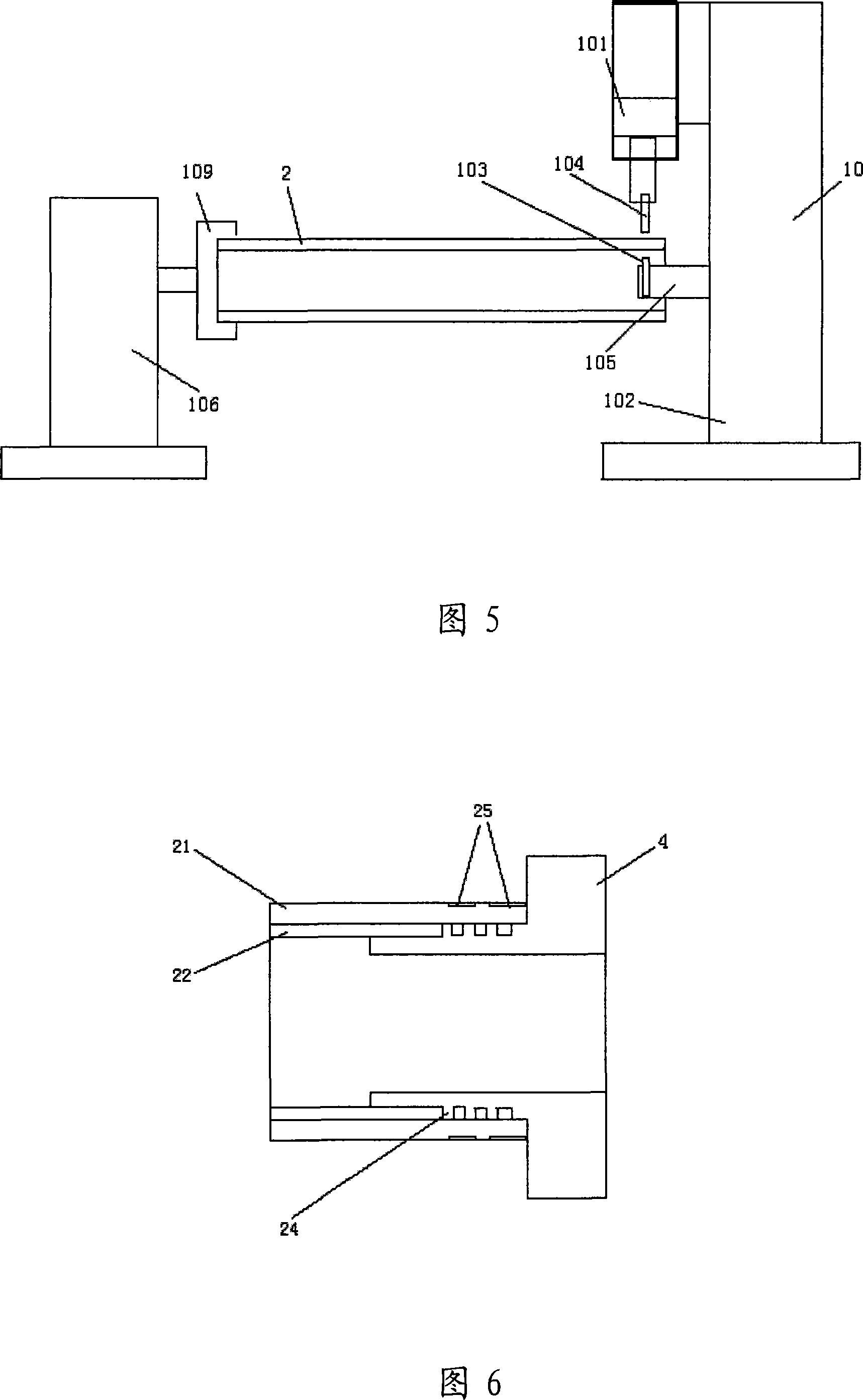

[0022] Step 1: Wrap the metal filter 21 on the outside of the support sleeve 22, and fix the metal filter 21 on the outer wall of the support sleeve 22 by welding, the metal filter 21 completely covers all the filter holes on the support sleeve 22, Form filter sleeve 2;

[0023] Step 2: Fix the filter sleeve 2 on the outer wall of the base pipe 1, and the filter sleeve 2 completely covers a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com