Patents

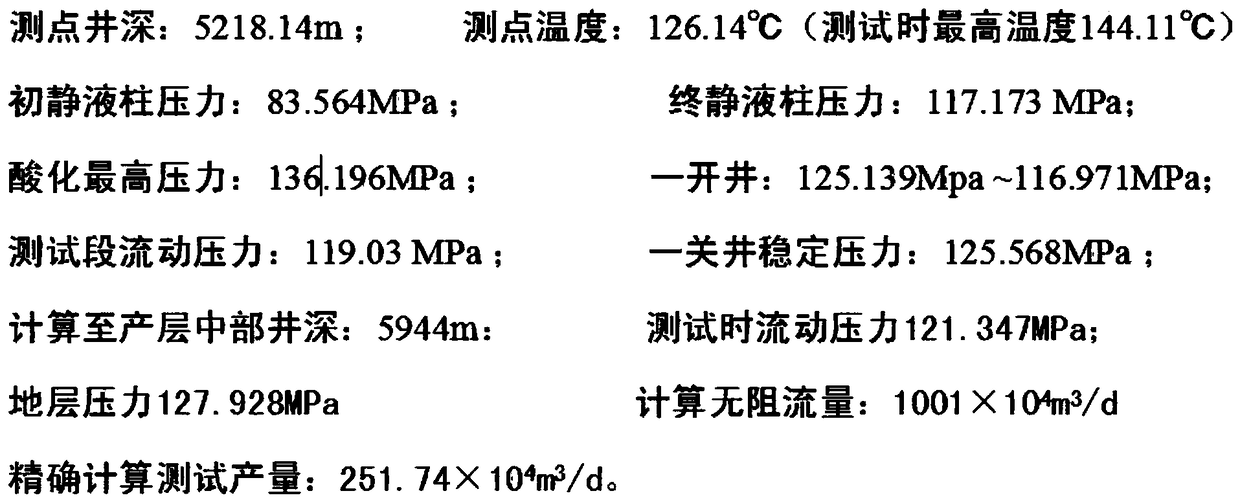

Literature

68results about How to "Reduce erosion damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

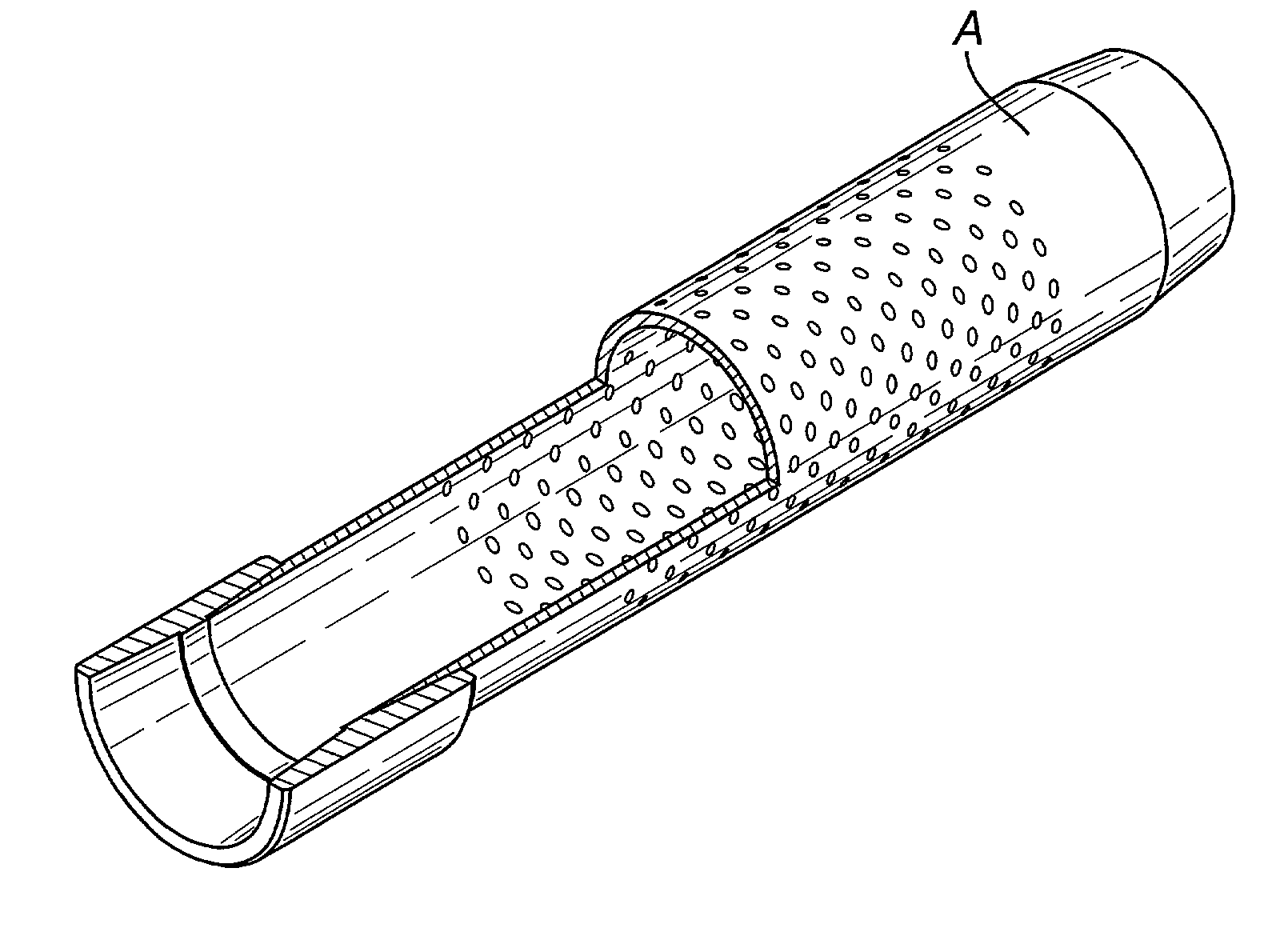

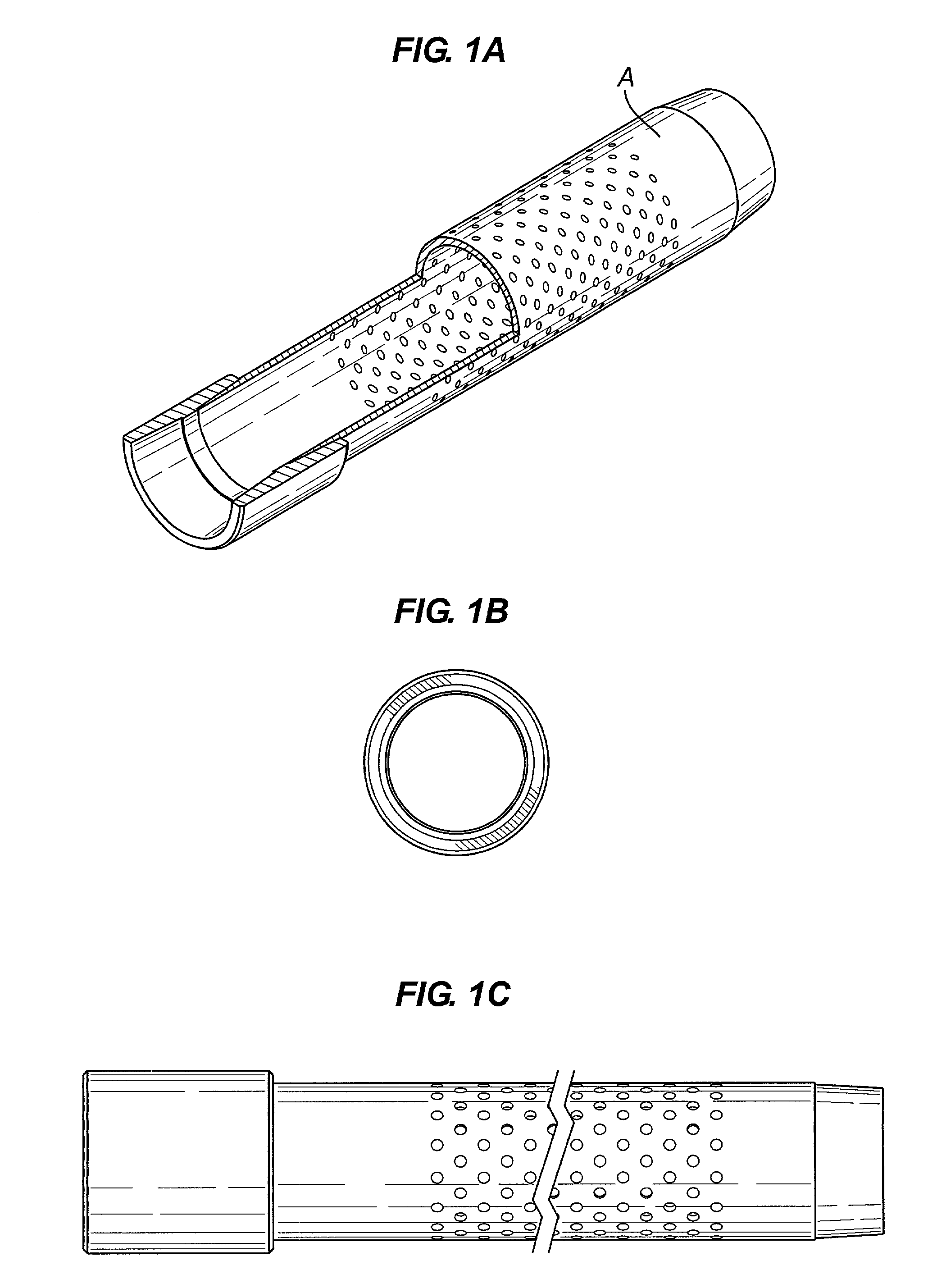

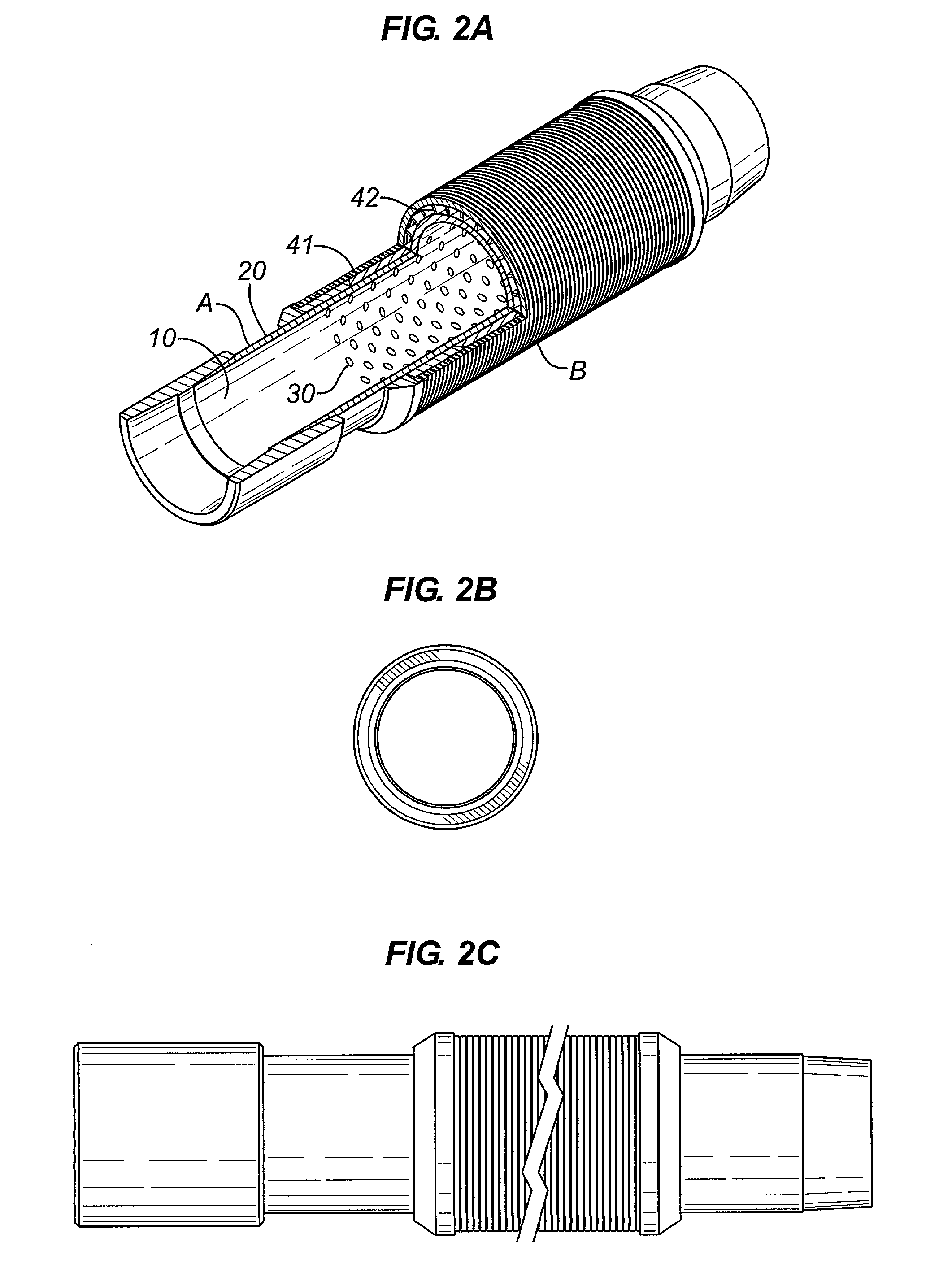

Knitted wire fines discriminator

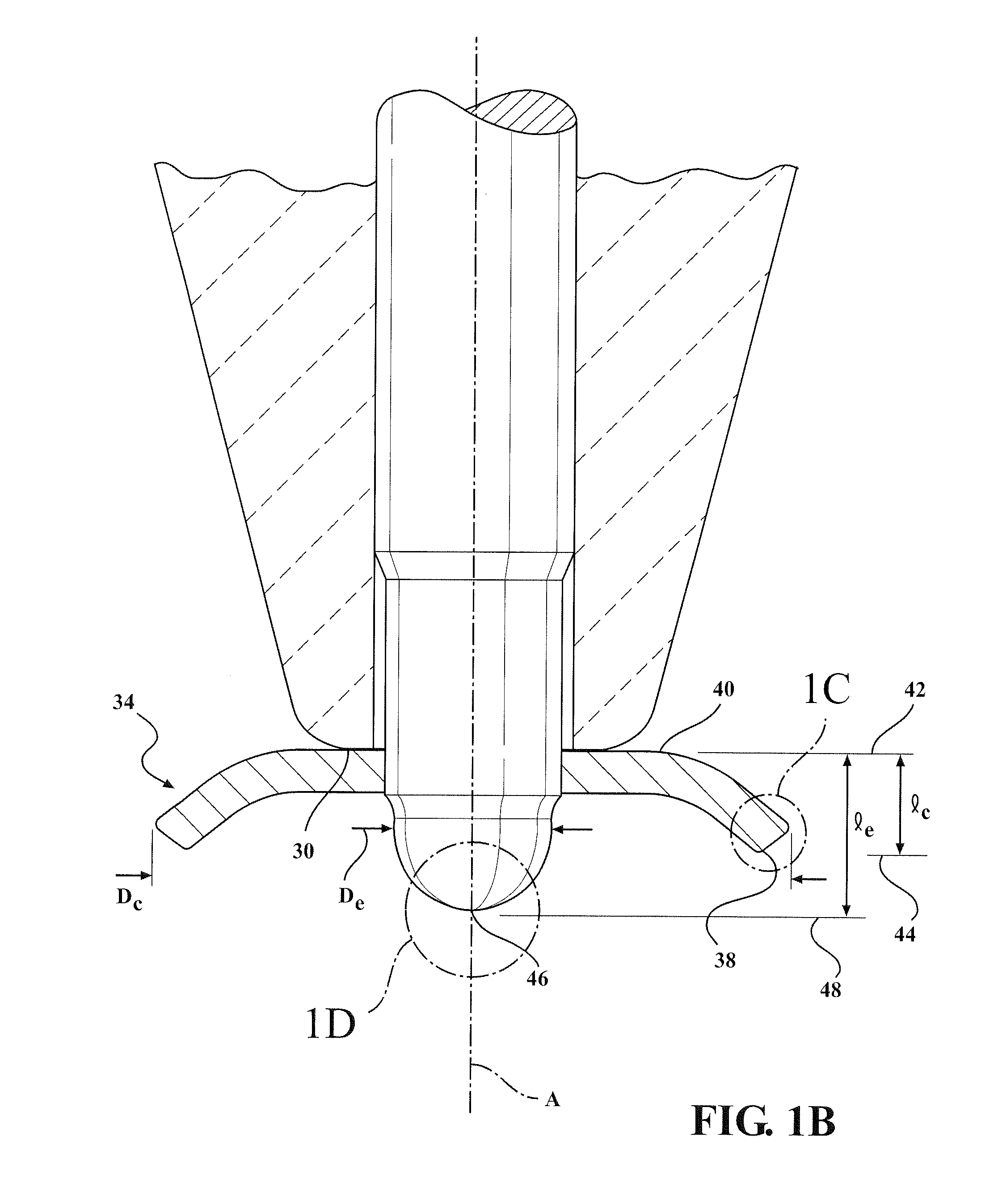

InactiveUS20030173075A1Reduce riskReduce erosion damageFluid removalDrinking water installationDiscriminatorTerrain

Particularly, the knitted wire fluid / gas energy absorber and fines discriminator is designed to provide significantly, enhanced erosion resistance and durability through absorbing energy from fluid moving at elevated and erosive velocities through an energy absorbing and flexible structure, providing also a tortuous path for the fluid / gas, thereby, reducing the risk of sand production and sub terrain erosion damage to tubulars. The wire used for the knitted wire fluid / gas energy absorber and fines discriminator may be made from a range of different materials which possess the desired combination of properties required for this process, and lend themselves to knitting, may be compressed, exhibit desired mechanical strength and flex. Such materials may be: Stainless steel of various grades, metallic alloys of various kinds, (zinc, copper etc), wire made of various fibers such as Kevlar, Aramid and a range of other suitable materials.

Owner:MORVANT DAVE +1

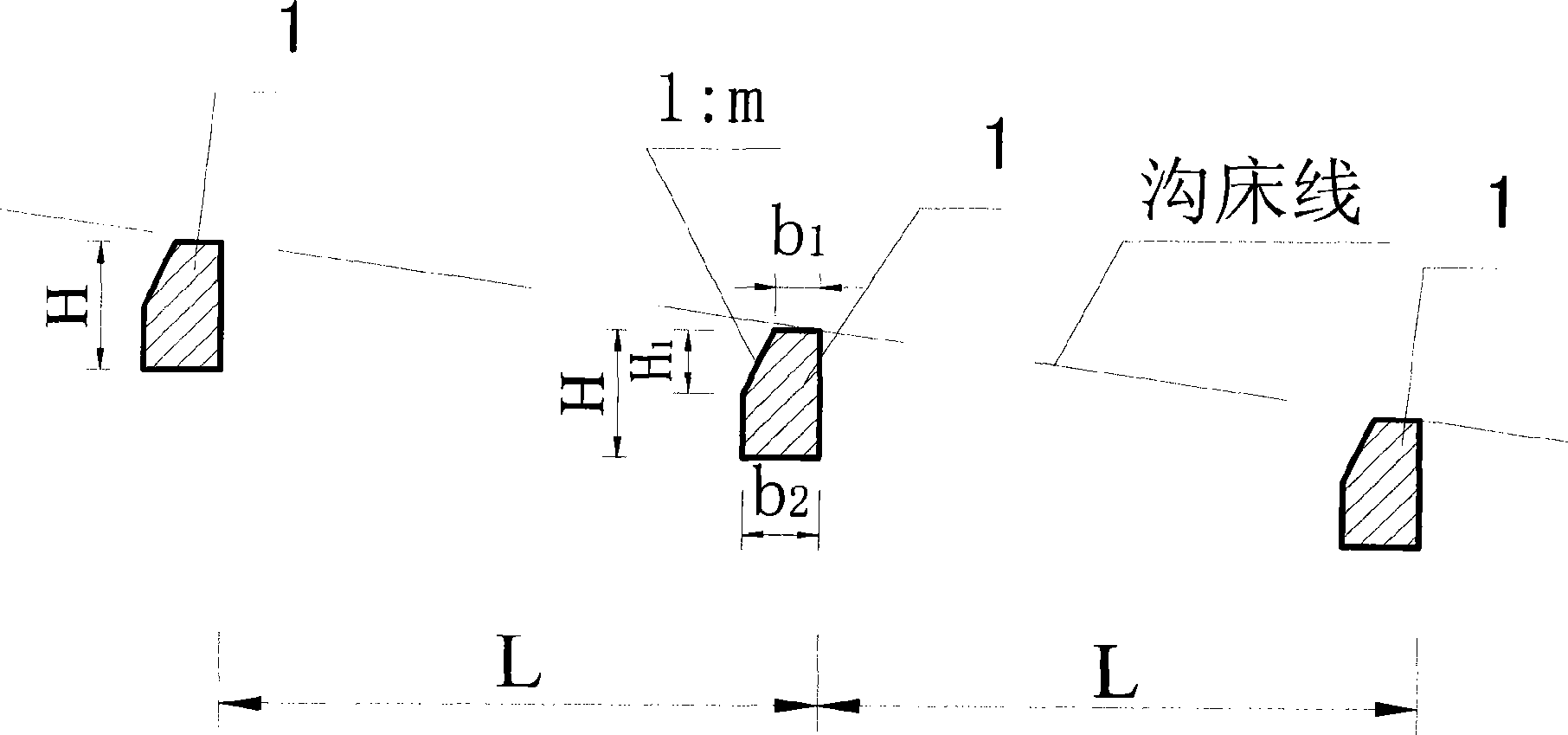

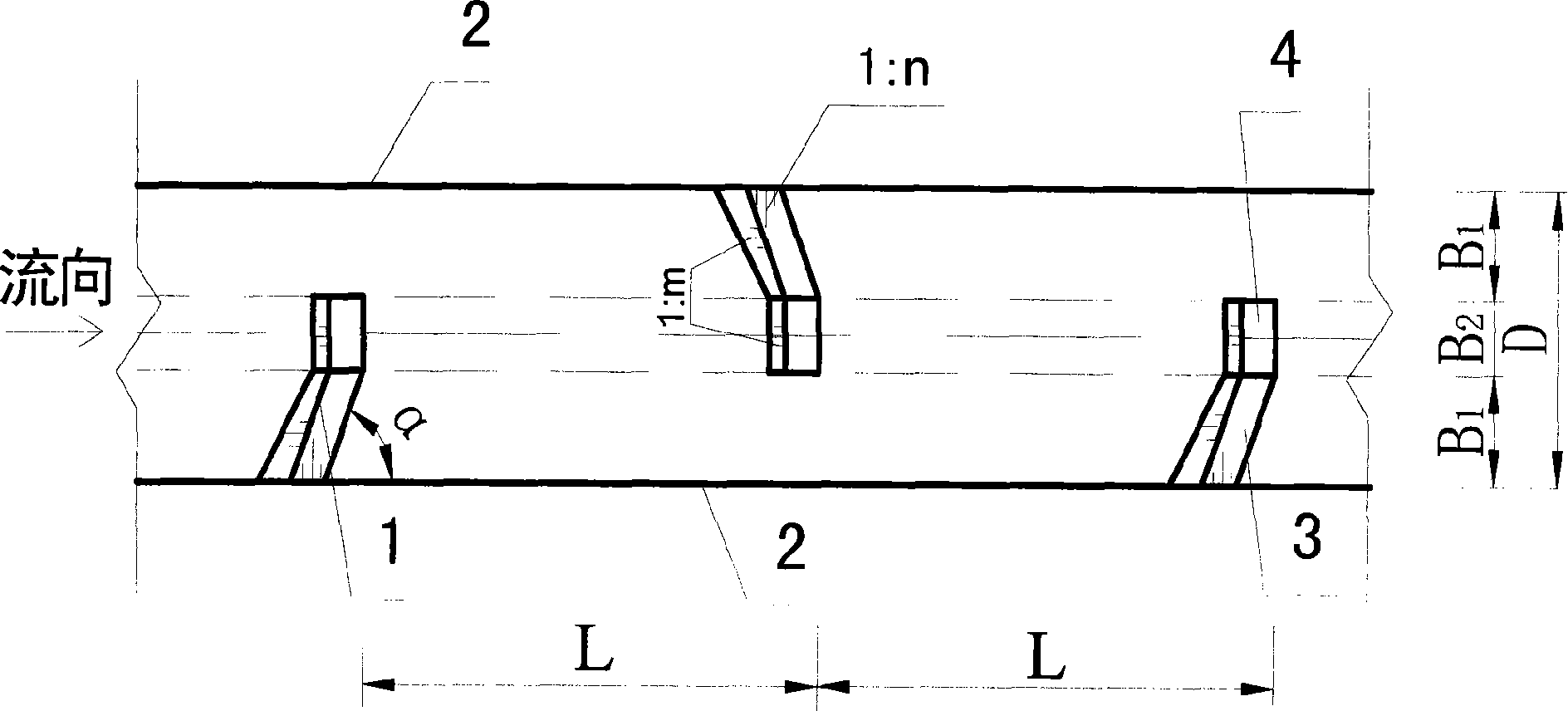

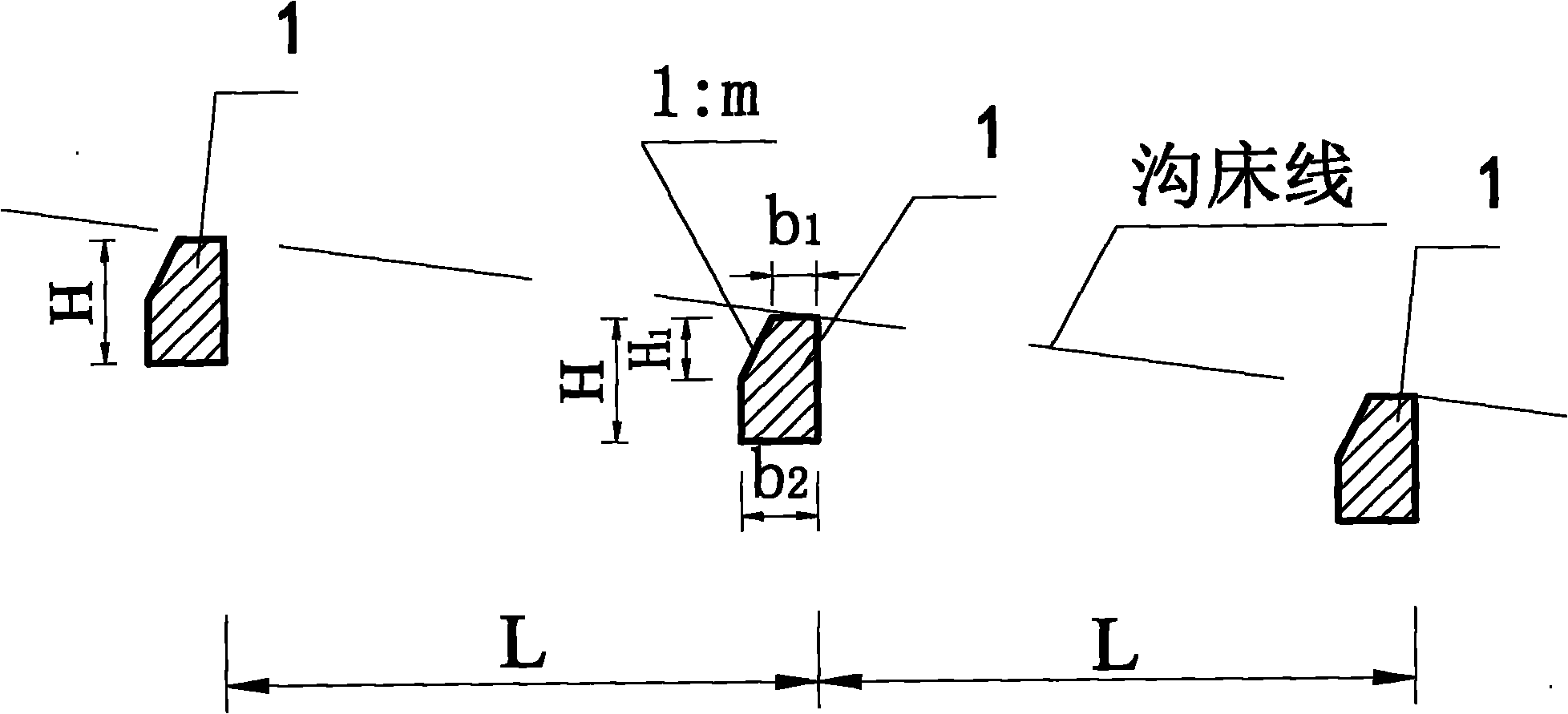

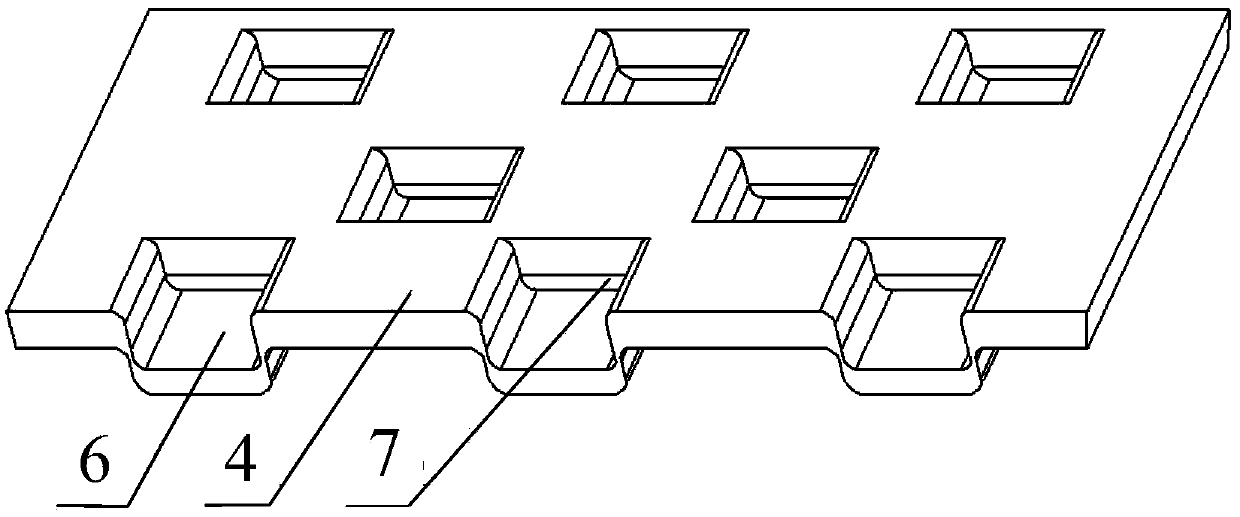

Mud-stone flow discharge guiding groove based on step anti-flushing notched sill group and use thereof

InactiveCN101476305AFlush smoothlyReduce erosion damageMarine site engineeringEngineeringCurrent technology

The invention discloses a debris flow draining and guiding groove based on step type erosion protection dentated sill group and application thereof. the debris flow draining and guiding groove comprises flow limiting walls, and a step type erosion protection dentated sill group disposed therein connected and cooperated therewith; the step type erosion protection dentated sill group consists of a plurality of erosion protection dentated sills imbedded in a certain depth with a certain distance therebetween; the transverse length B of the erosion protection dentated sill in the direction perpendicular to the flow limiting wall is less than the width D of the debris flow draining and guiding groove; and the erosion protection dentated sills are staggered between the two flow limiting walls. Compared with the current technologies, the invention can fully drain the debris flow safely and smoothly with low cost, can meet the requirement from structrual type mud flow to mountain torrents burst in the drainage area; and can maintain the contacting of the aquatic organisms in the groove bed to benefit the groove ecology restoration.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

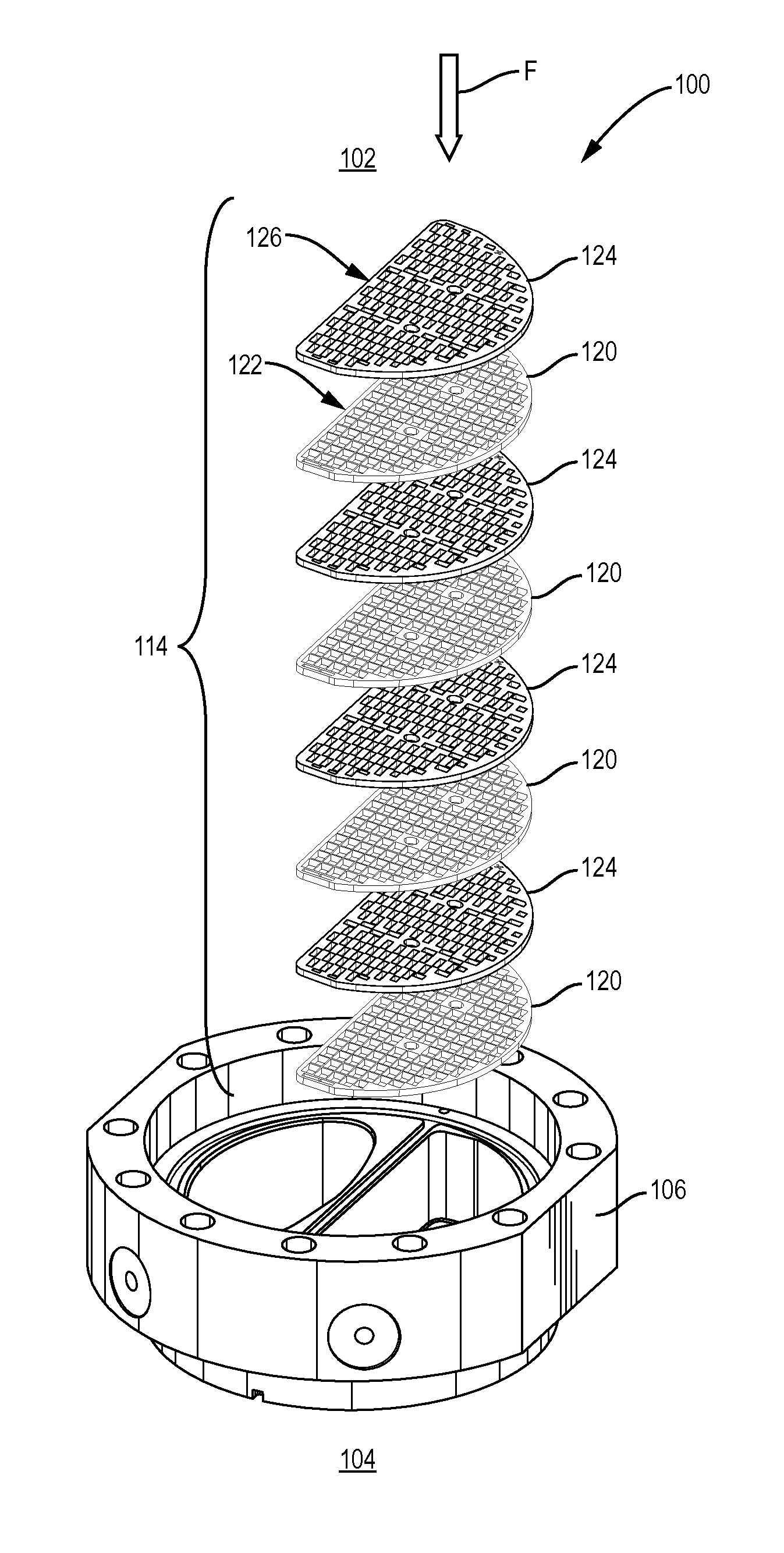

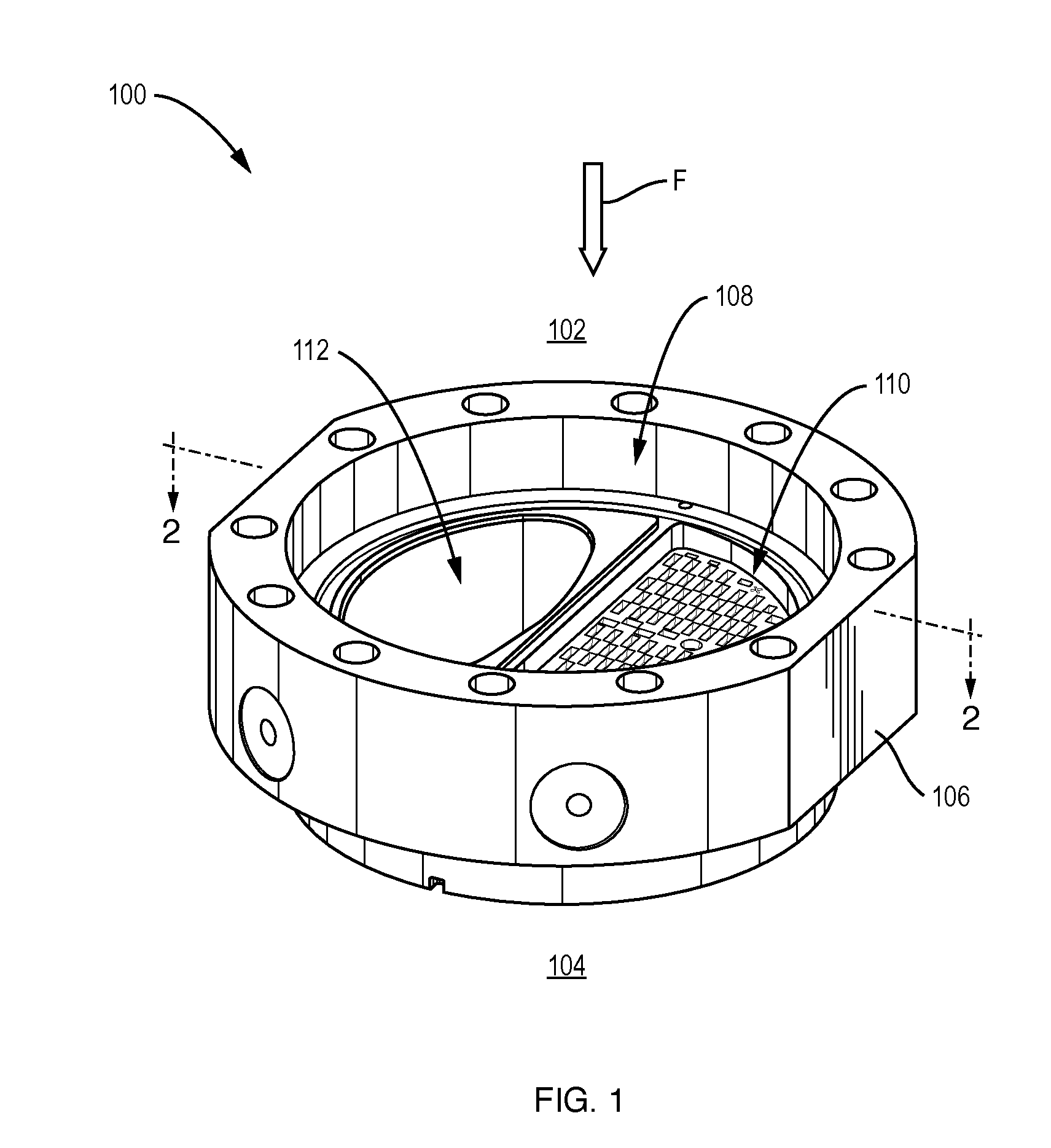

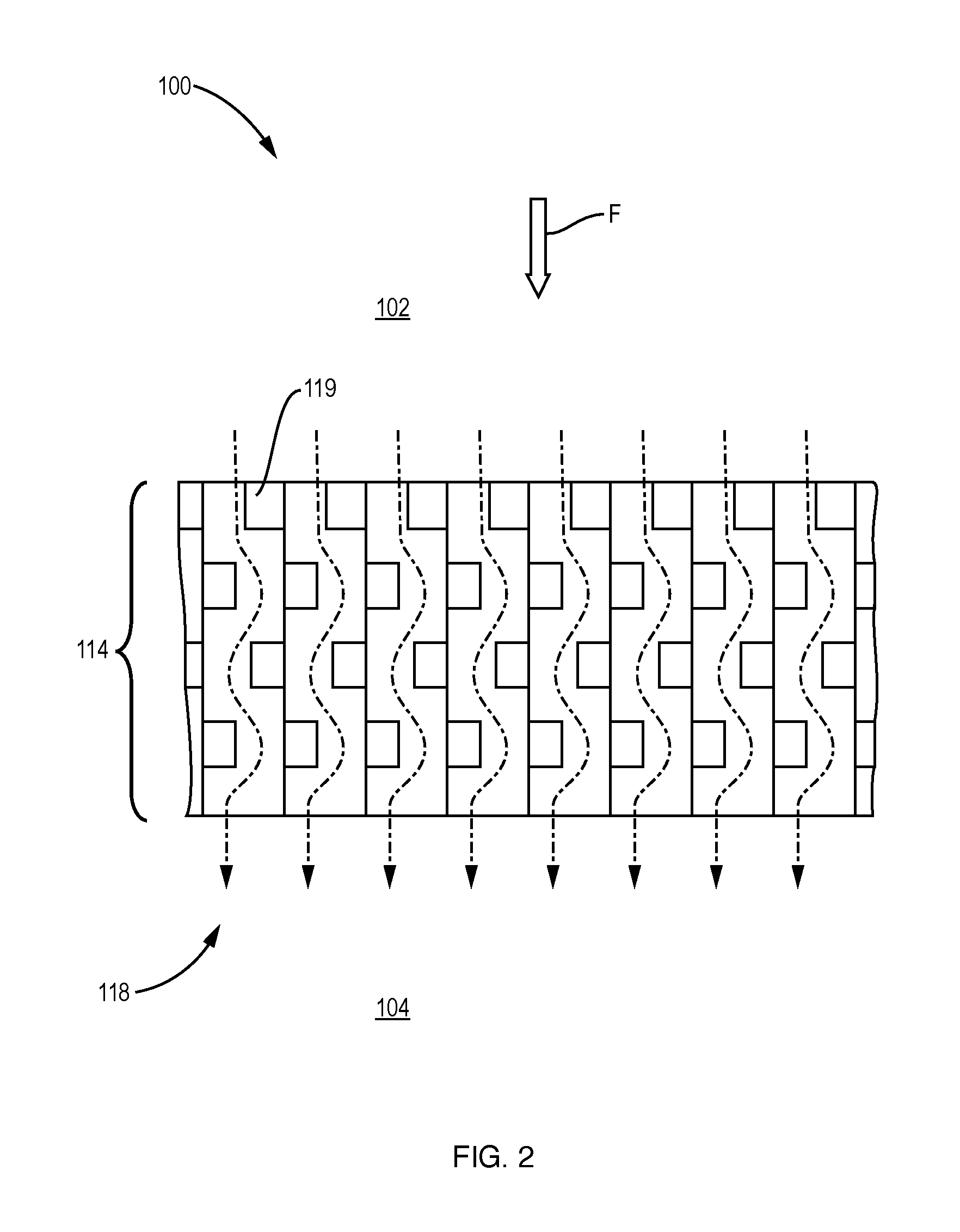

Noise attenuation device and fluid coupling comprised thereof

InactiveUS20140069737A1Improved noise attenuationReduce erosion damageValve members for absorbing fluid energySilencing apparatusWorking fluidFluid coupling

Embodiments of a noise attenuation device comprise a plurality of stacked plates that form channels to reduce energy in a flow of working fluid that transits the noise attenuation device. In one embodiment, the stacked plates include plates having openings in different patterns. Orientation of the plates align the patterns in a housing to form the channels. In one example, the plates are disposed in a fluid coupling (e.g., a valve and / or flow regulator) that includes a throttling element. The plates are spaced apart from the throttling element, thereby permitting the working fluid to flow through all of the channels whether the throttling element is fully or partially open.

Owner:DRESSER IND INC

Glass fibre reinforced plastic and anti-fouling corrosion resistant protecting agent for surface of high molecular products thereof

InactiveCN101338039AExcellent water repellencyExcellent weather resistance and durabilityCoatingsIonCorrosion resistant

The invention relates to a surface antifouling corrosion-resistant protectant for glass fiber reinforced plastic and other polymer products. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, is composed of fluoro-alkyl silane, long-chain alkyl silane, nanometer SiO2, alkyl silicate, alcohol, inorganic acid catalysts and de-ionized water or distilled water. The surface antifouling corrosion resistant protectant for glass fiber reinforced plastic and other polymer products, which is provided by the invention, can form a layer of low surface water-repellent, oil-proof, antifouling, anti-sticking, anti-ultraviolet and corrosion-resistant coat film on the surfaces of the glass fiber reinforced plastic and the other polymer products, the water contact angle can reach as high as 149 DEG, the purposes of effective reduction of rain accumulation as well as the attachment of atmospheric dust, guano, etc. on the surfaces of the glass fiber reinforced plastic and the other polymer products, acid rain corrosion damage resistance, salt mist corrosion damage resistance, ultraviolet corrosion damage resistance and reduction of use and maintenance cost are achieved.

Owner:SHANGHAI NALE MATERIAL TECH

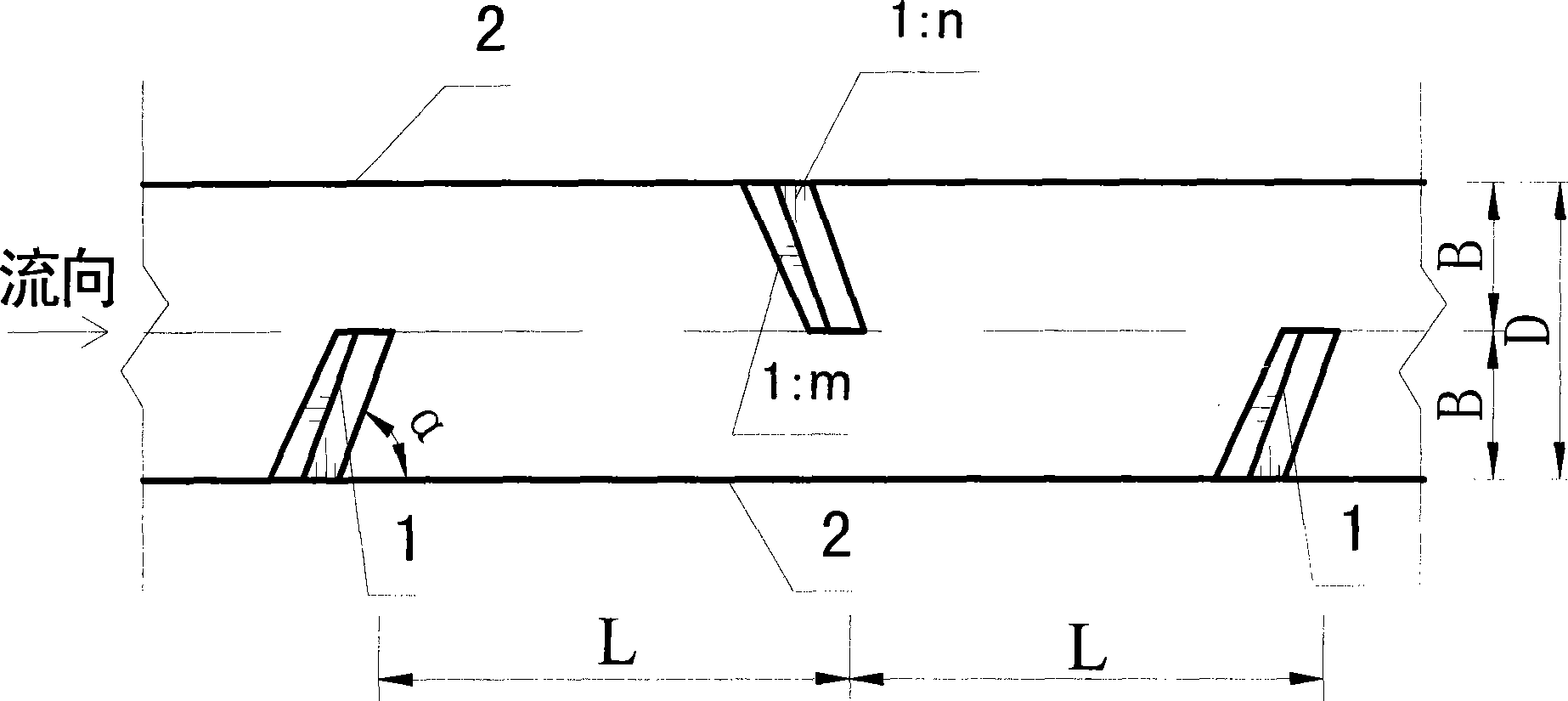

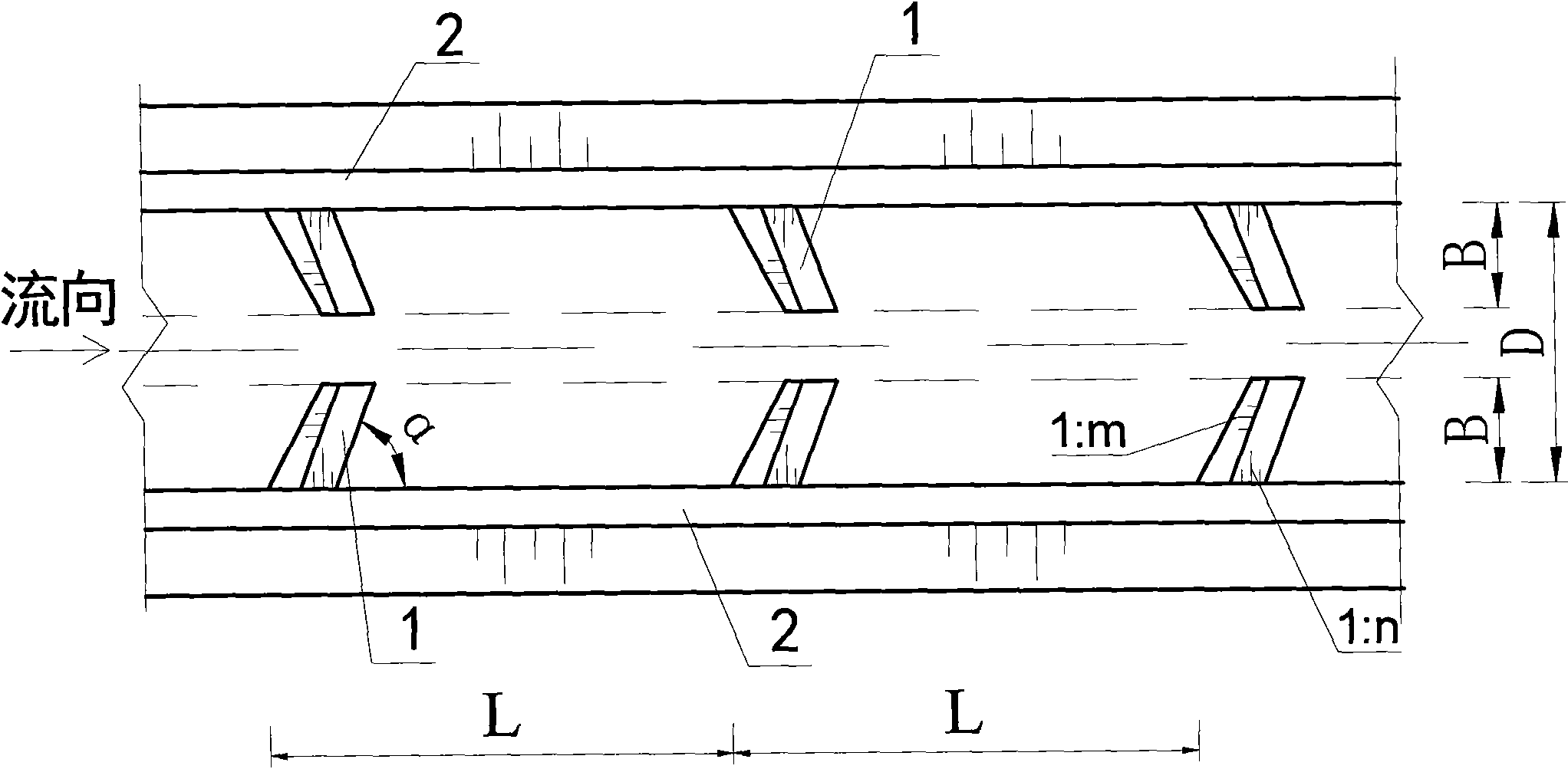

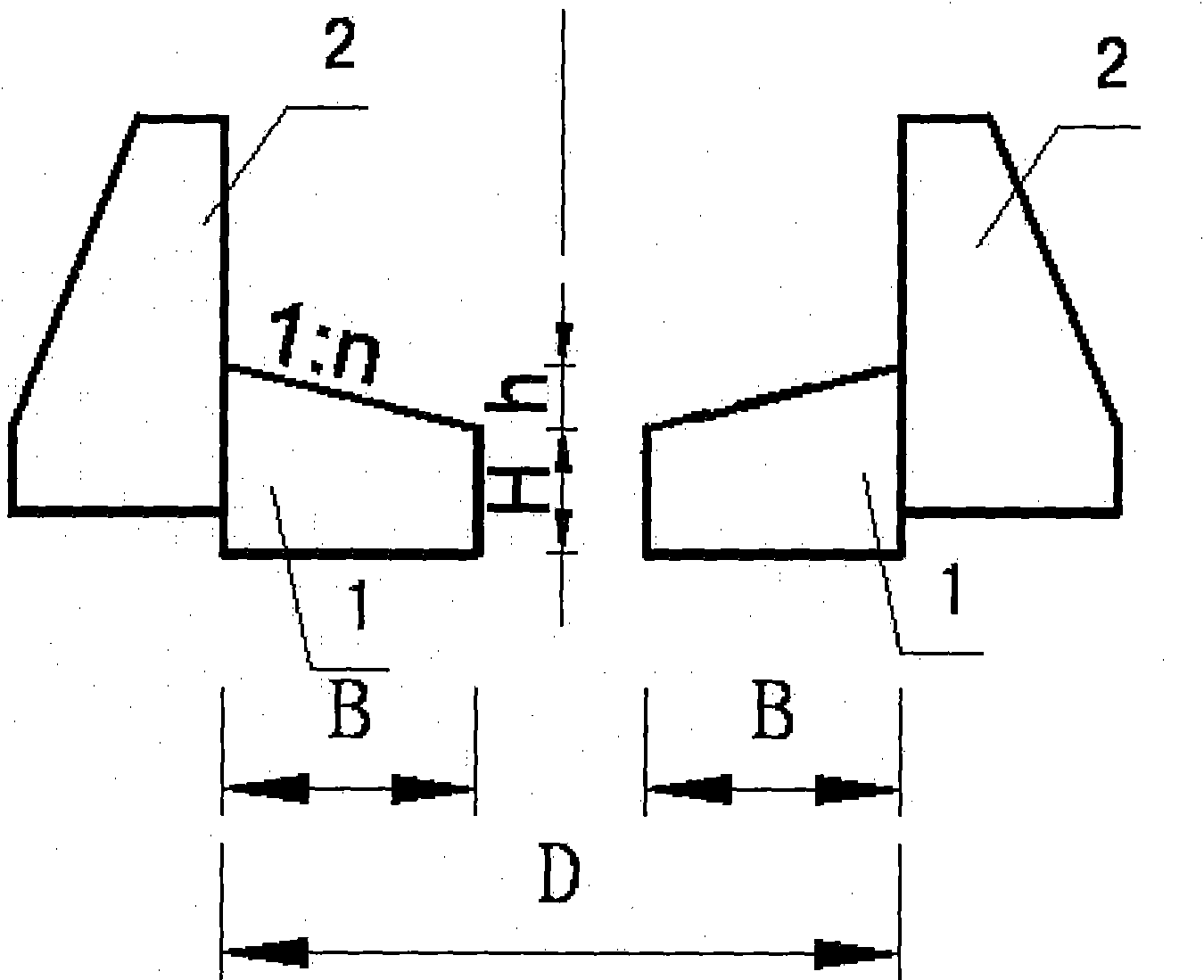

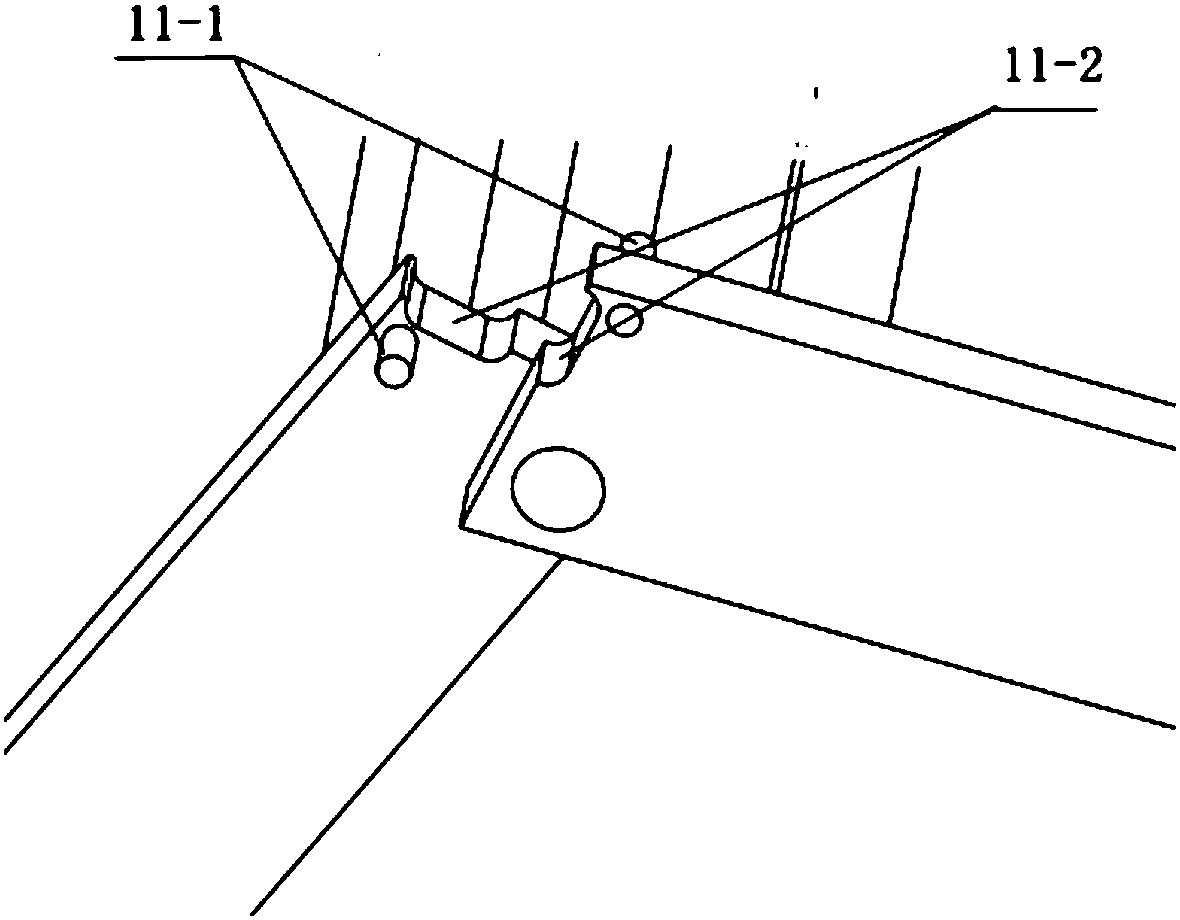

Debris flow guiding slot based on step anti-erosion toothed sill group and application thereof

InactiveCN101851906ASmall amount of workFlush smoothlyArtificial water canalsMarine site engineeringEngineeringDebris flow

The invention discloses a debris flow guiding slot based on a step anti-erosion toothed sill group and the application thereof. The slot structurally comprises beam side walls and a step anti-erosion toothed sill group which is arranged between the walls, connected and matched with the same; the step anti-erosion toothed sill group comprises a plurality of anti-erosion toothed sills with a certain depth, and every two steps are distributed by a certain spacing; the two anti-erosion toothed sills are symmetrically distributed on the left side and the right side relative to the centerline of the guiding slot between the beam side walls to commonly form one step of the step anti-erosion toothed sill group; and the width D of the debris flow guiding slot is more than two times of horizontal length B of the anti-erosion toothed sills in the vertical direction of the beam side walls. Compared with the prior art, the invention can meet the requirements on the excretion of fluid with quite great changes from thin debris flow to mountain flood, can fully keep the up and down relationship of aquatic organisms in a gully, is beneficial to the ecological restoration a channel, can fully guarantee the stability of the beam side walls, is not easy to have debris flow deposition under the circumstance that the gradient of the gully is quite small, and is beneficial to long-termed operation.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

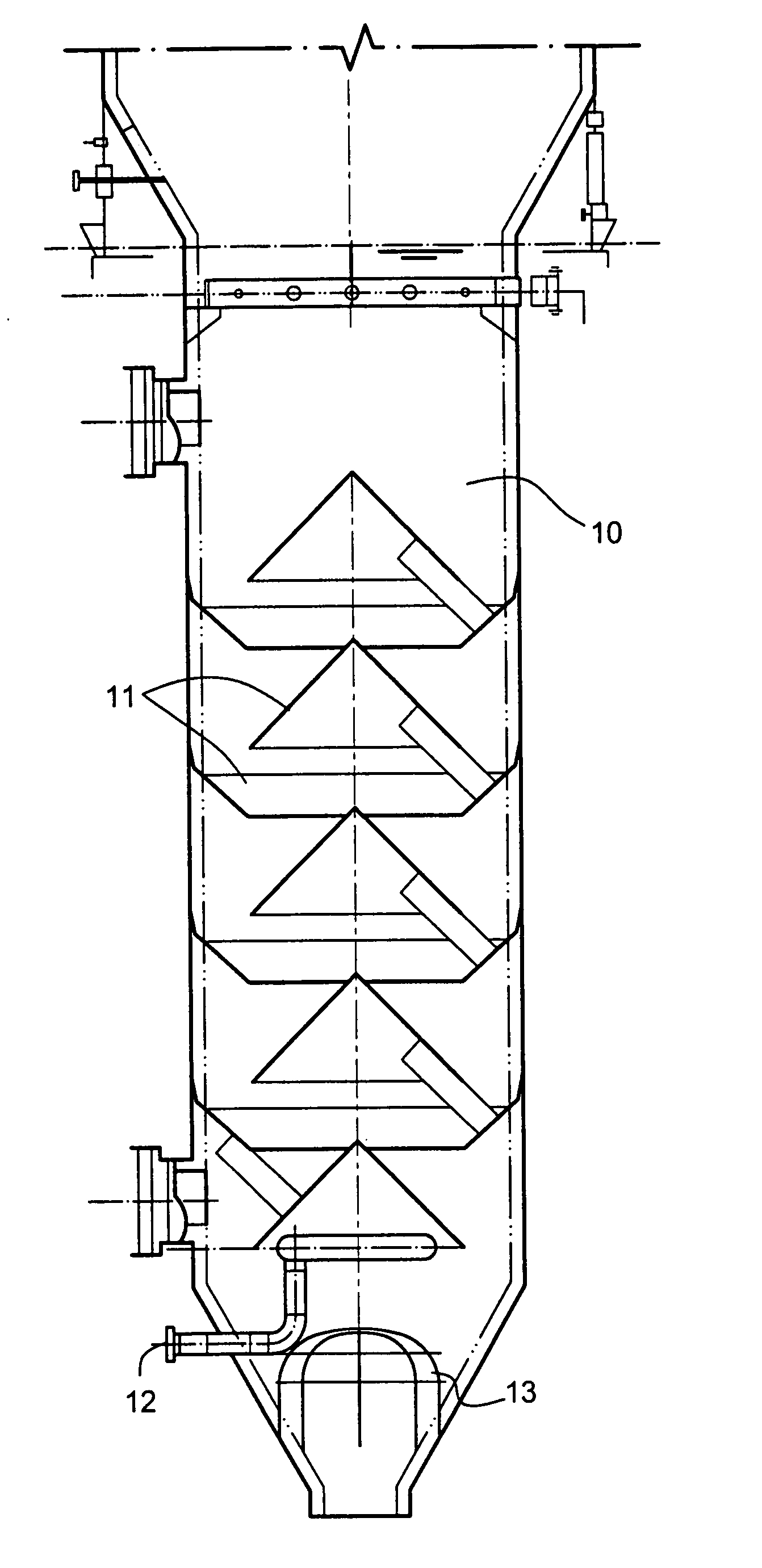

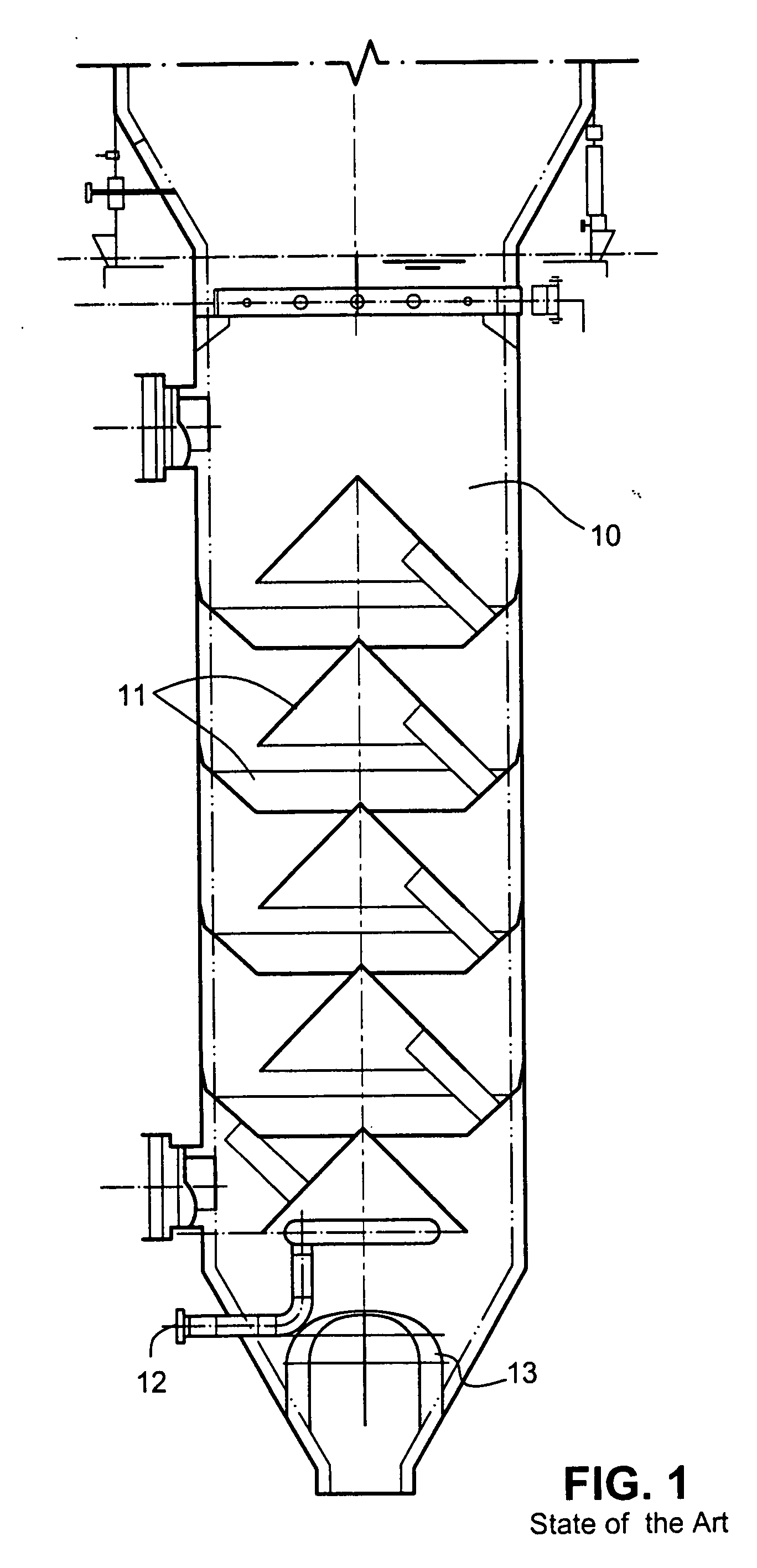

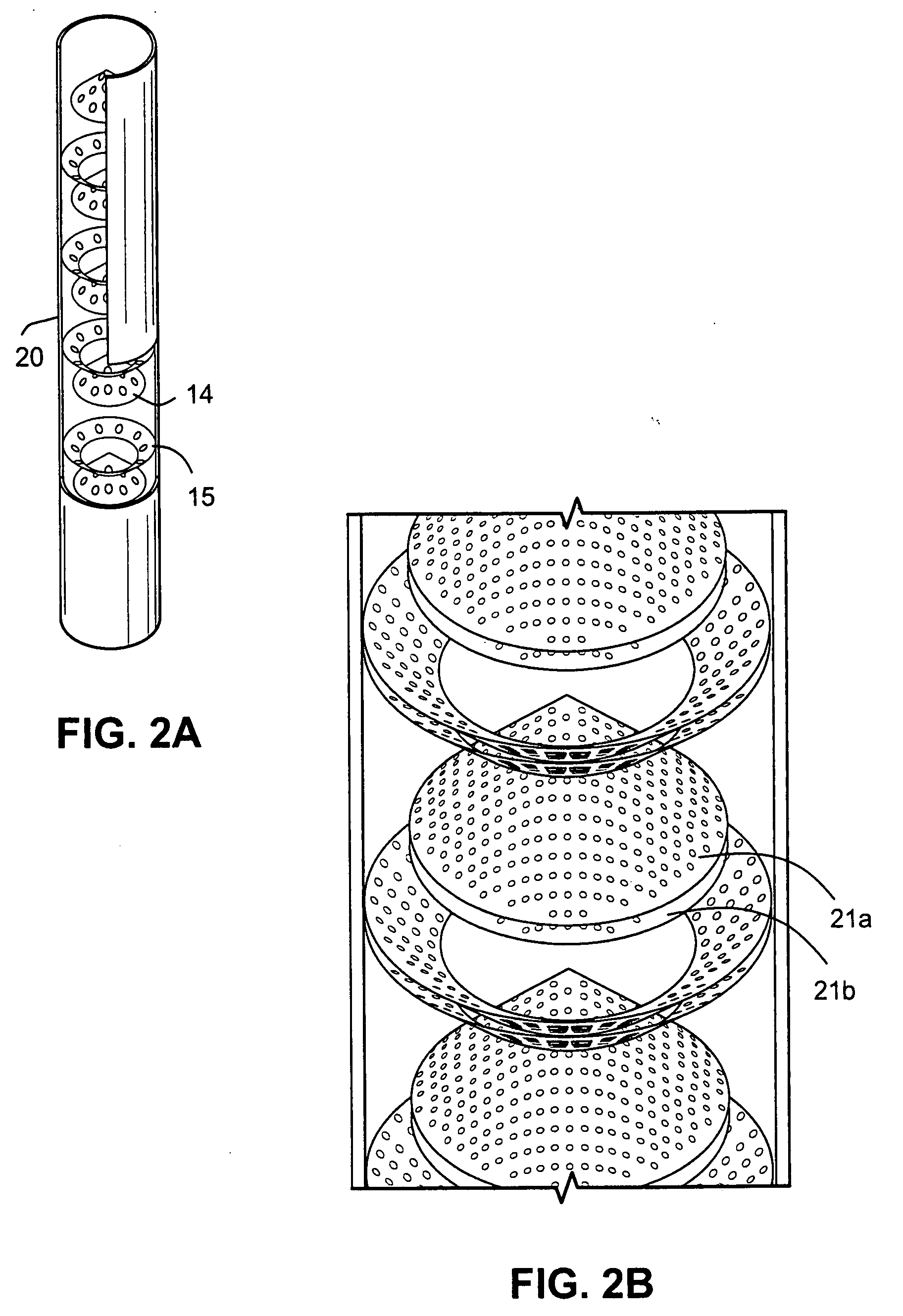

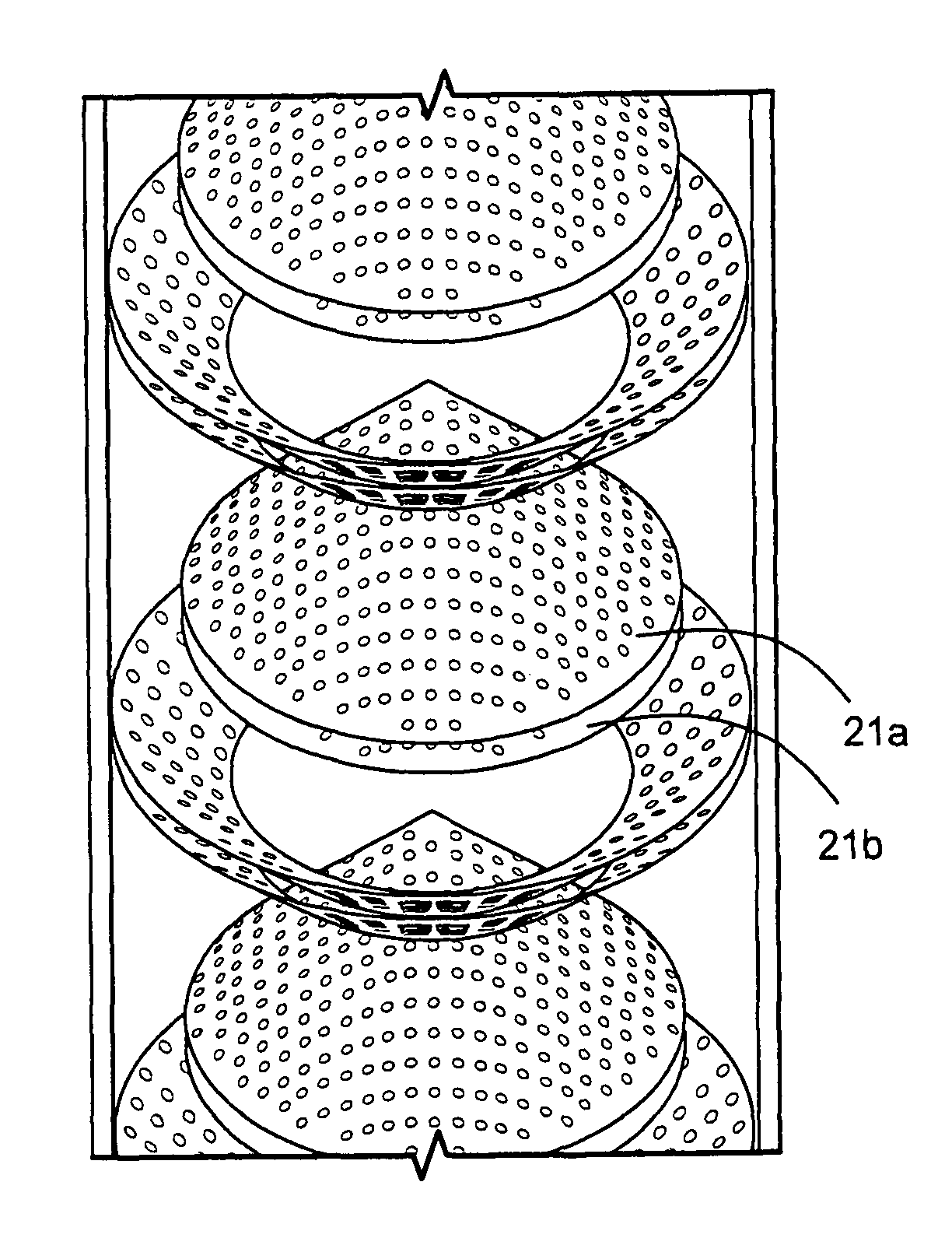

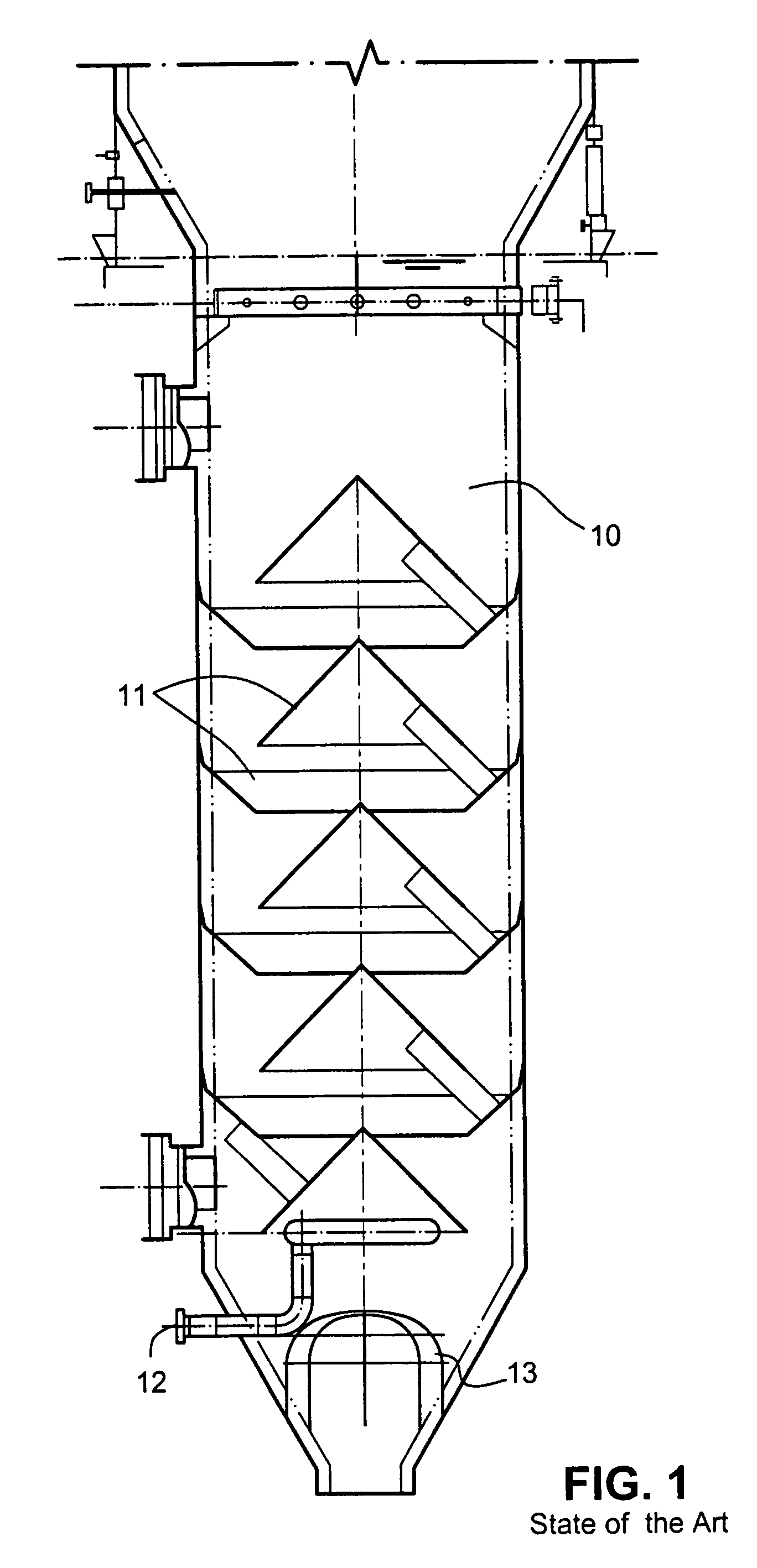

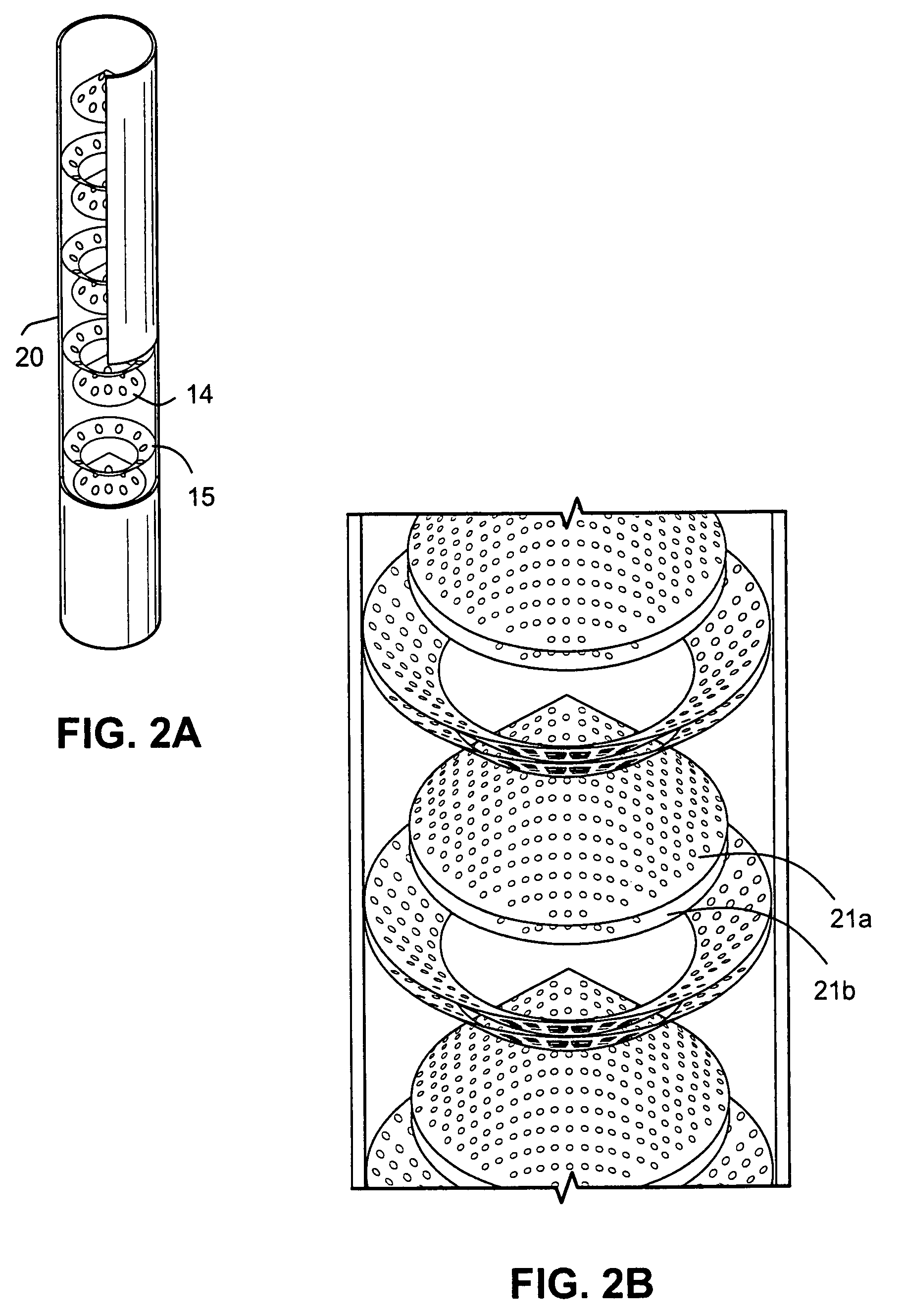

Stripping apparatus for the gas-solid separation process in a fluidized bed

InactiveUS20080253937A1Volume maximizationMaximizes stripping volumeDispersed particle separationFuel re-atomisation/homogenisationGas solidFluidized bed

A stripping apparatus is described for the gas-solid separation process in a fluidized bed in a counter-current flow of a stripping fluid. The apparatus includes sets of perforated baffle-plates with holes, fixed in series, alternating central and lateral plates inside a stripping chamber. The holes in the baffle-plates, in number, size and in circular or elliptical lay-out, are oriented in offset position in relation to the holes in the parallel and subsequent baffle-plates, reducing the damage of erosion on the perforated baffle-plates and optimizing stripping of the fluidized solid particles.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Stripping apparatus for the gas-solid separation in a fluidized bed

InactiveUS7799285B2Volume maximizationMaximizes stripping volumeDispersed particle separationFuel re-atomisation/homogenisationGas solidFluidized bed

A stripping apparatus is described for the gas-solid separation process in a fluidized bed in a counter-current flow of a stripping fluid. The apparatus includes sets of perforated baffle-plates with holes, fixed in series, alternating central and lateral plates inside a stripping chamber. The holes in the baffle-plates, in number, size and in circular or elliptical lay-out, are oriented in offset position in relation to the holes in the parallel and subsequent baffle-plates, reducing the damage of erosion on the perforated baffle-plates and optimizing stripping of the fluidized solid particles.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

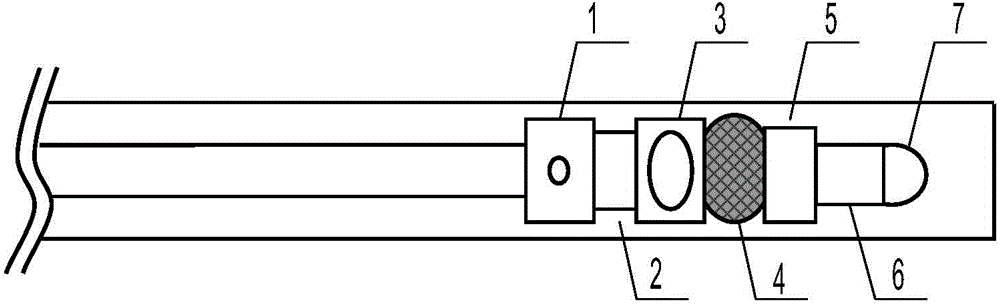

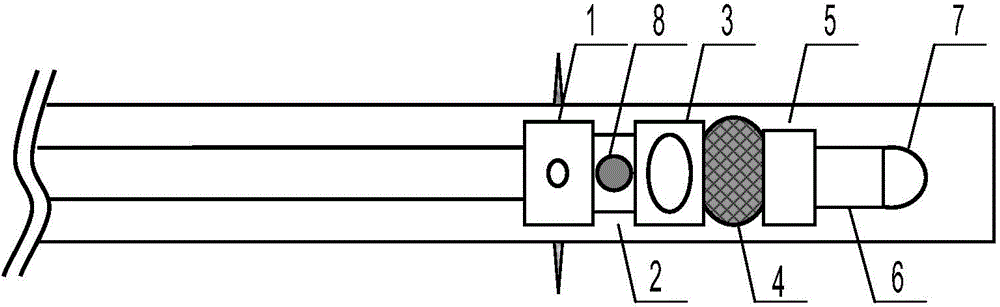

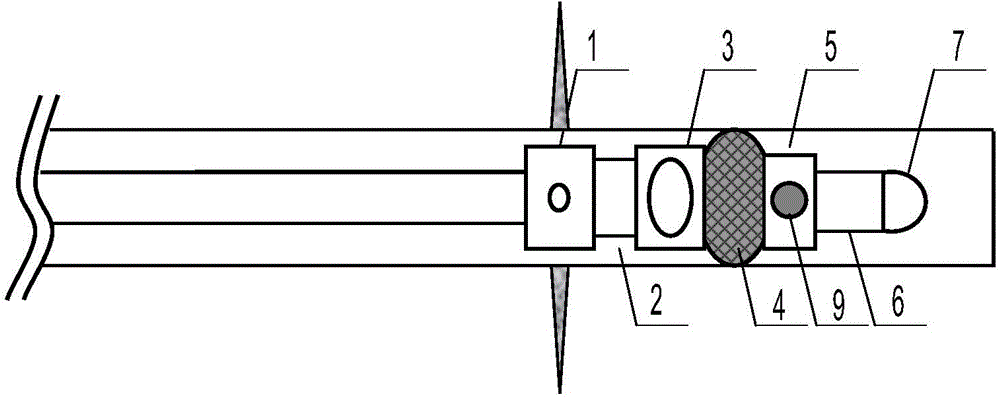

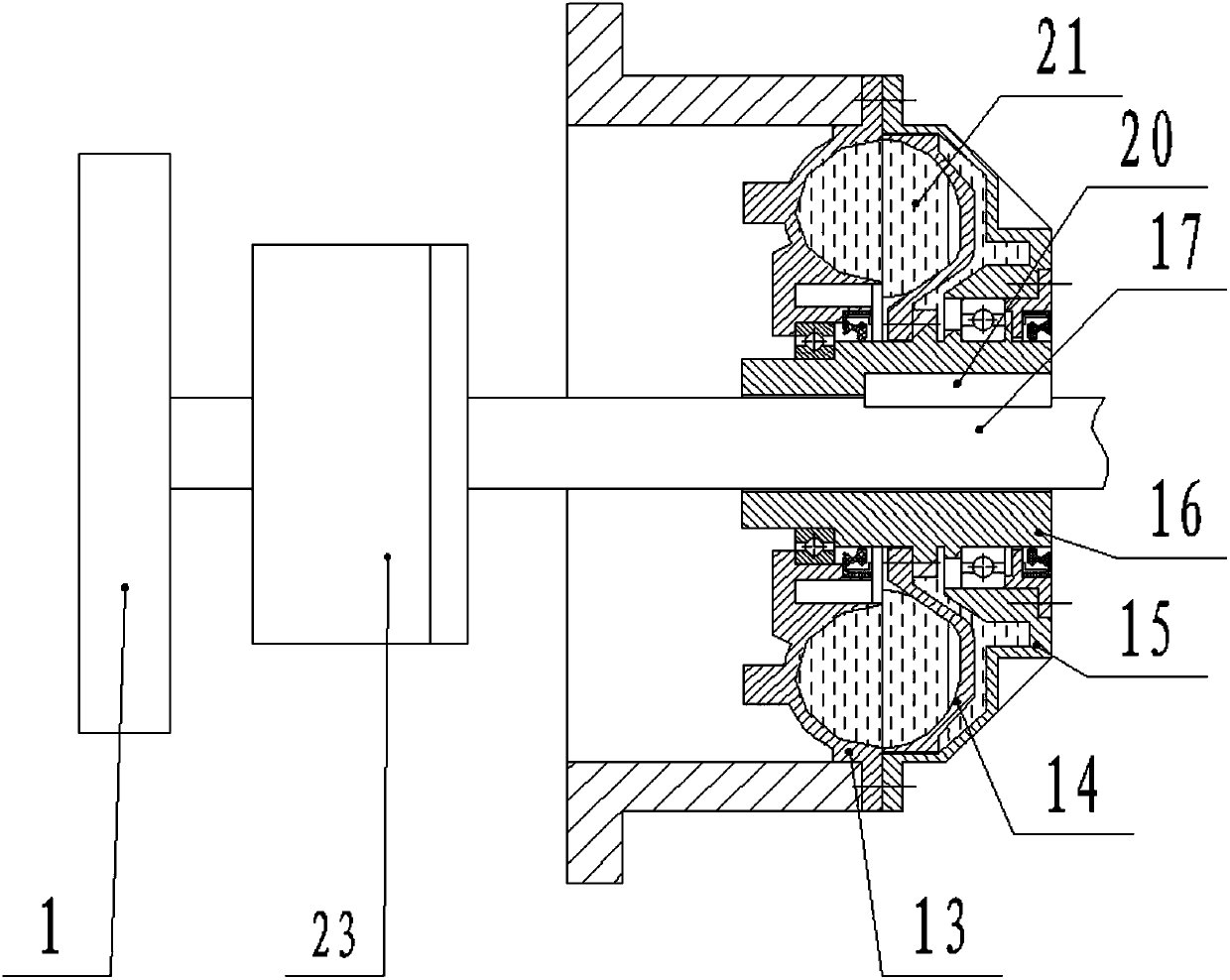

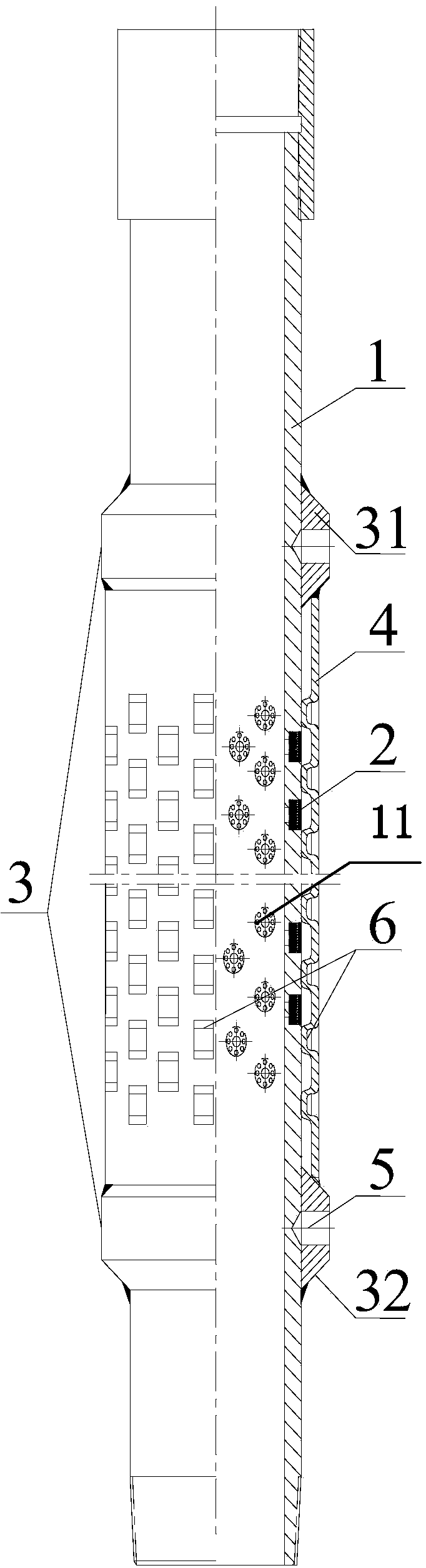

Hydraulic sand blasting perforation large-displacement fracturing technological tubing string and method

The invention discloses a hydraulic sand blasting perforation large-displacement fracturing technological tubing string and method and belongs to the technical field of oil and gas field exploration and development. A hydraulic sand blower is connected with a first ball seat, the other end of the first ball seat is connected with a throttle sand blower, the other end of the throttle sand blower is connected with a K344 packer, the other end of the K344 packer is connected with a second ball seat, the other end of the second ball seat is connected with a sieve tube, the other end of the sieve tube is connected with a plug, the first ball seat is provided with a sealing ball corresponding to a ball seat at the lower end of the sand blower, and the second ball seat is provided with a sealing ball corresponding to a ball seat at the lower end of the K344 packer. The sand blasting perforation fracturing integrated tubing string is adopted, a liquid outlet channel is changed by throwing the sealing balls of different sizes, and different liquid outlet channels are adopted at the different construction stages; the construction requirement for multi-section fracturing by the one-trip tool is met.

Owner:PETROCHINA CO LTD

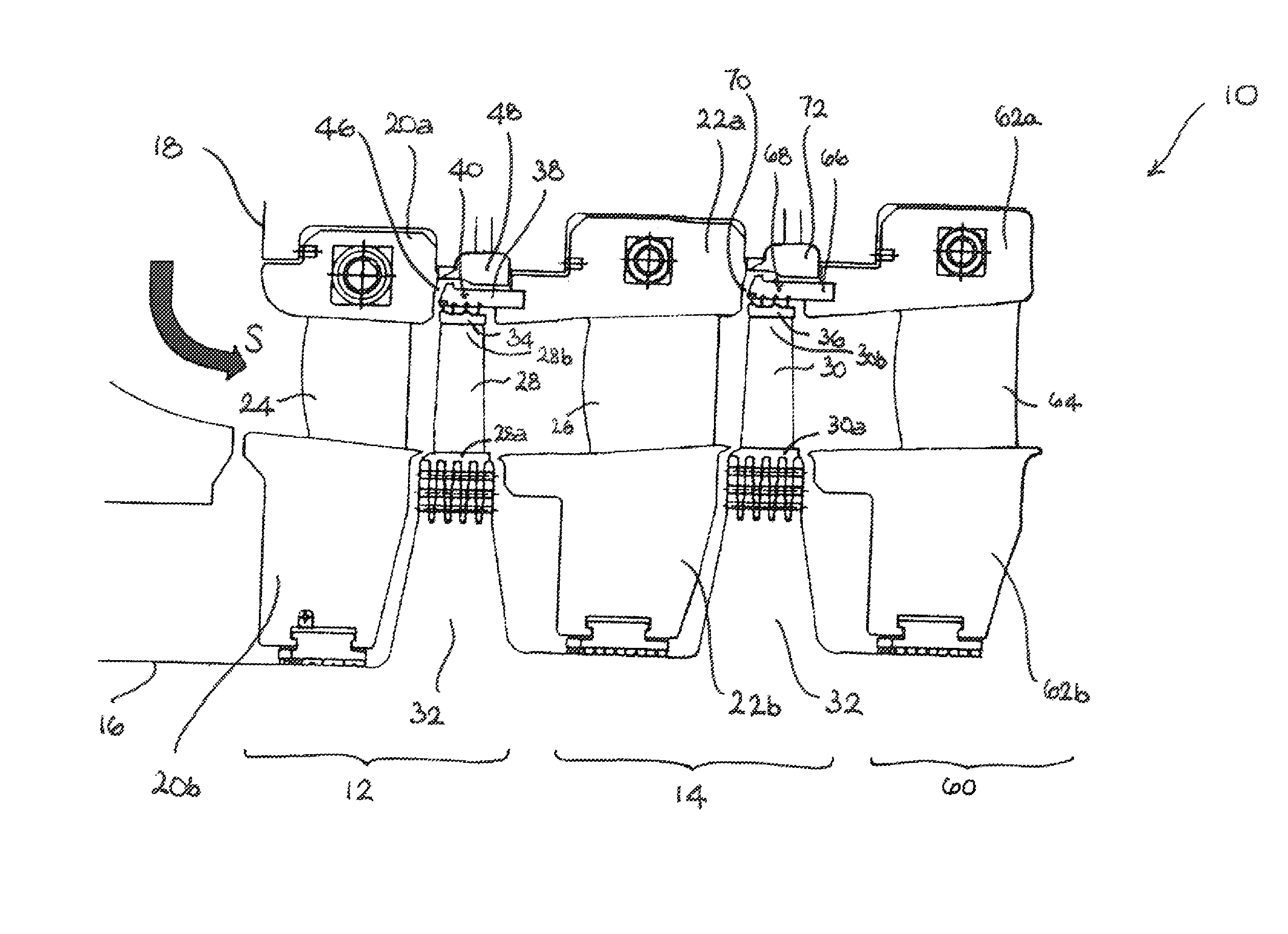

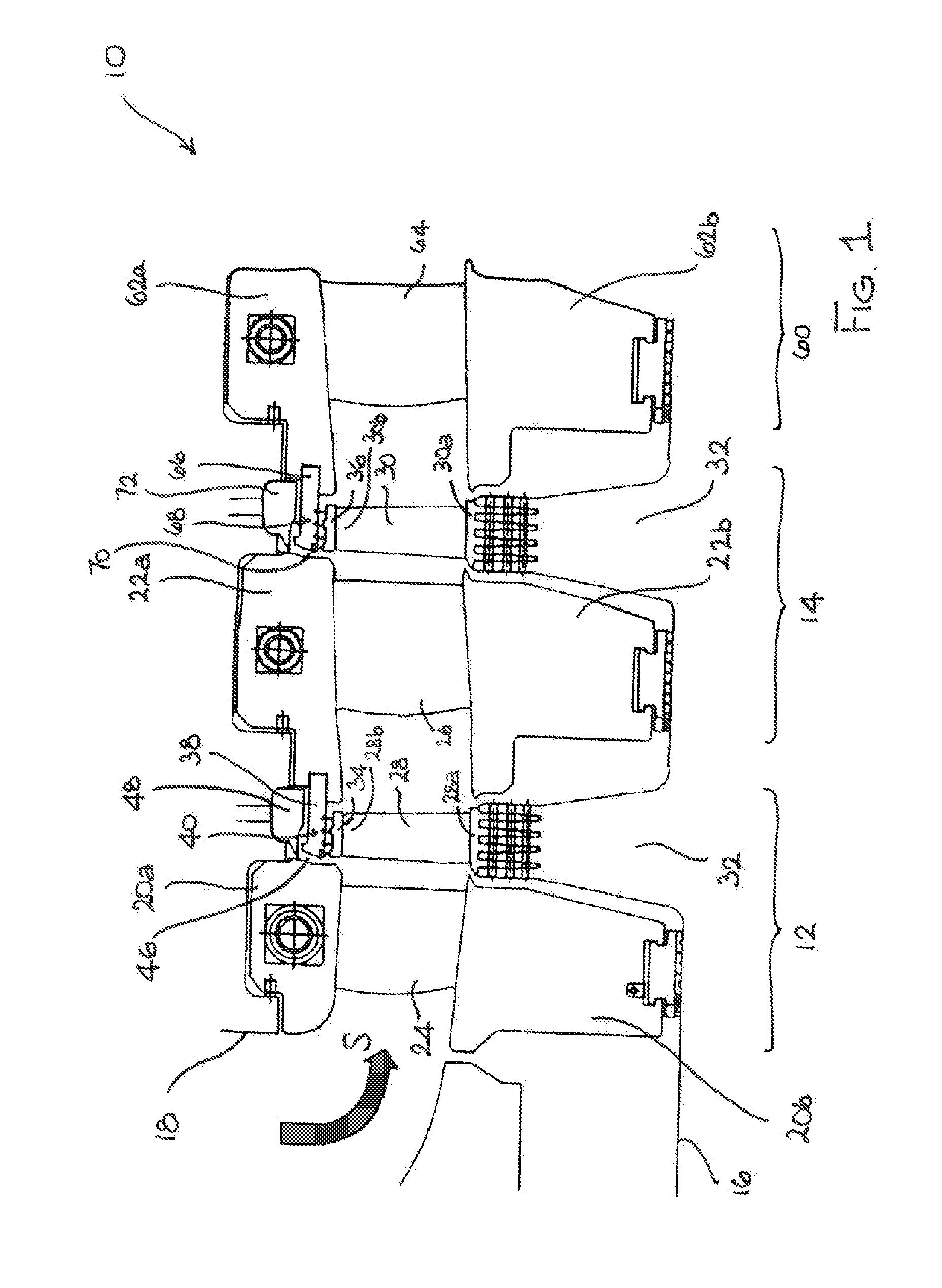

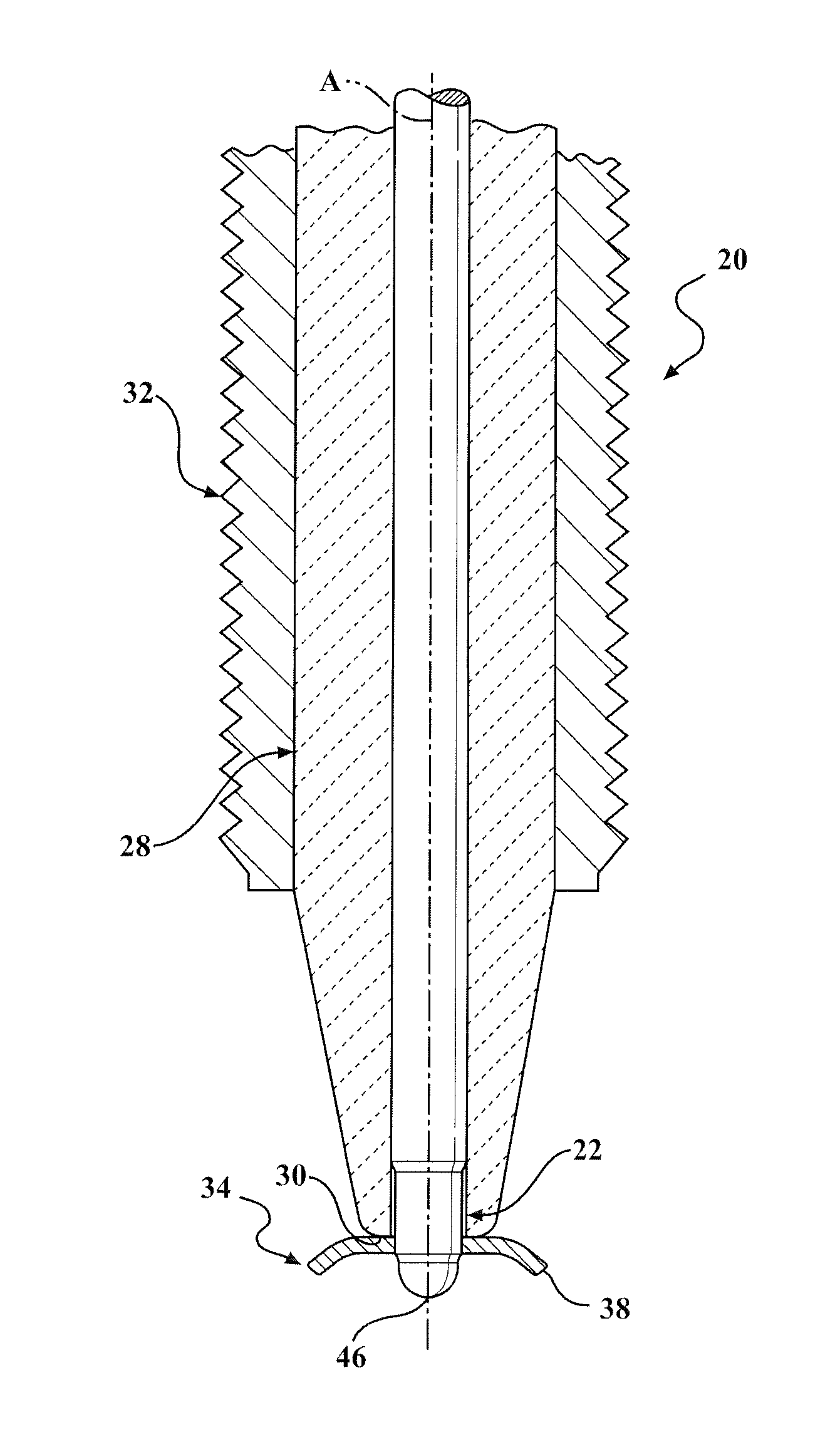

Solid particle diversion in an axial flow steam turbine

ActiveUS8714915B2Reduce erosion damageSignificant proportionPump componentsEngine fuctionsSolid particleTurbine

An exemplary axial flow steam turbine is disclosed which includes a motor, a turbine casing and at least first and second turbine stages, with the second turbine stage being located adjacent to and downstream from the first turbine stage. A radially outer static diaphragm ring of the second turbine stage includes an annular axial extension extending in an upstream axial direction and carrying a circumferential tip sealing device which cooperates with shrouds of a circumferential row of moving blades of the first turbine stage. An upstream end of the annular axial extension is axially spaced from a radially outer static diaphragm ring of the first turbine stage such that a circumferential passage is defined between the upstream end of the annular axial extension and the radially outer static diaphragm ring of the first turbine stage. Solid particles are diverted from steam flow by a circumferential passage during operation.

Owner:GENERAL ELECTRIC TECH GMBH

Vibration fatigue life prediction method for gas storage gas injection string

InactiveCN108915669AConvenient helicity analysisPerfect regularConstructionsTechnical supportVibration fatigue

The invention discloses a vibration fatigue life prediction method for a gas storage gas injection string. The vibration fatigue life prediction method comprises the steps of analysis on string actingforce generated by flowing of a fluid in the string, analysis on the additional load generated when the fluid passes through a bent area of the string, analysis on stiffness and strength of the oil string of a natural gas well, analysis on vibrating damage to the string, and analysis on erosion damage to the buckling string. Technical support is provided for safe operation of a gas storage, and decision making of maintaining and repairing for the string of the gas well.

Owner:南智(重庆)能源技术有限公司

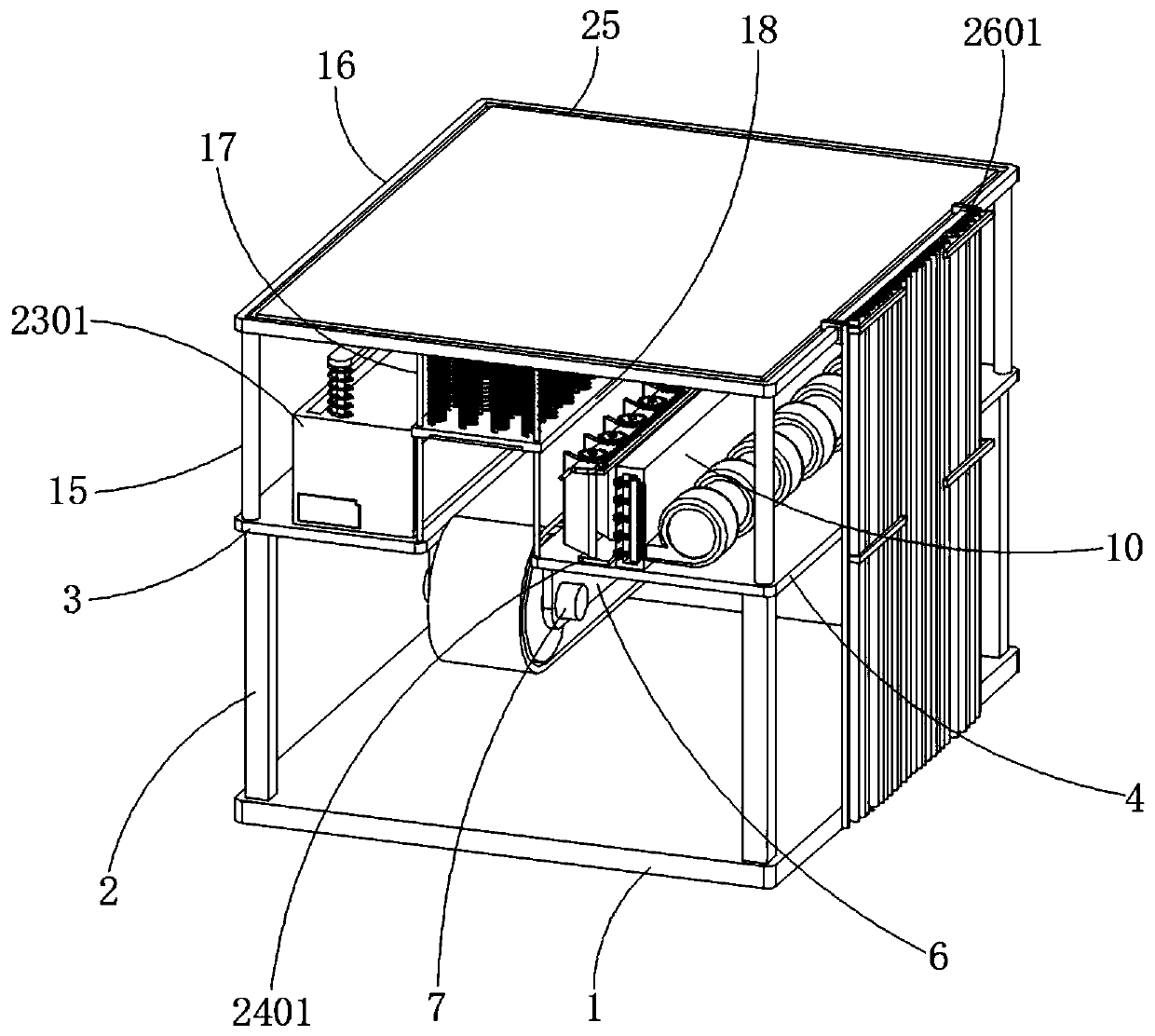

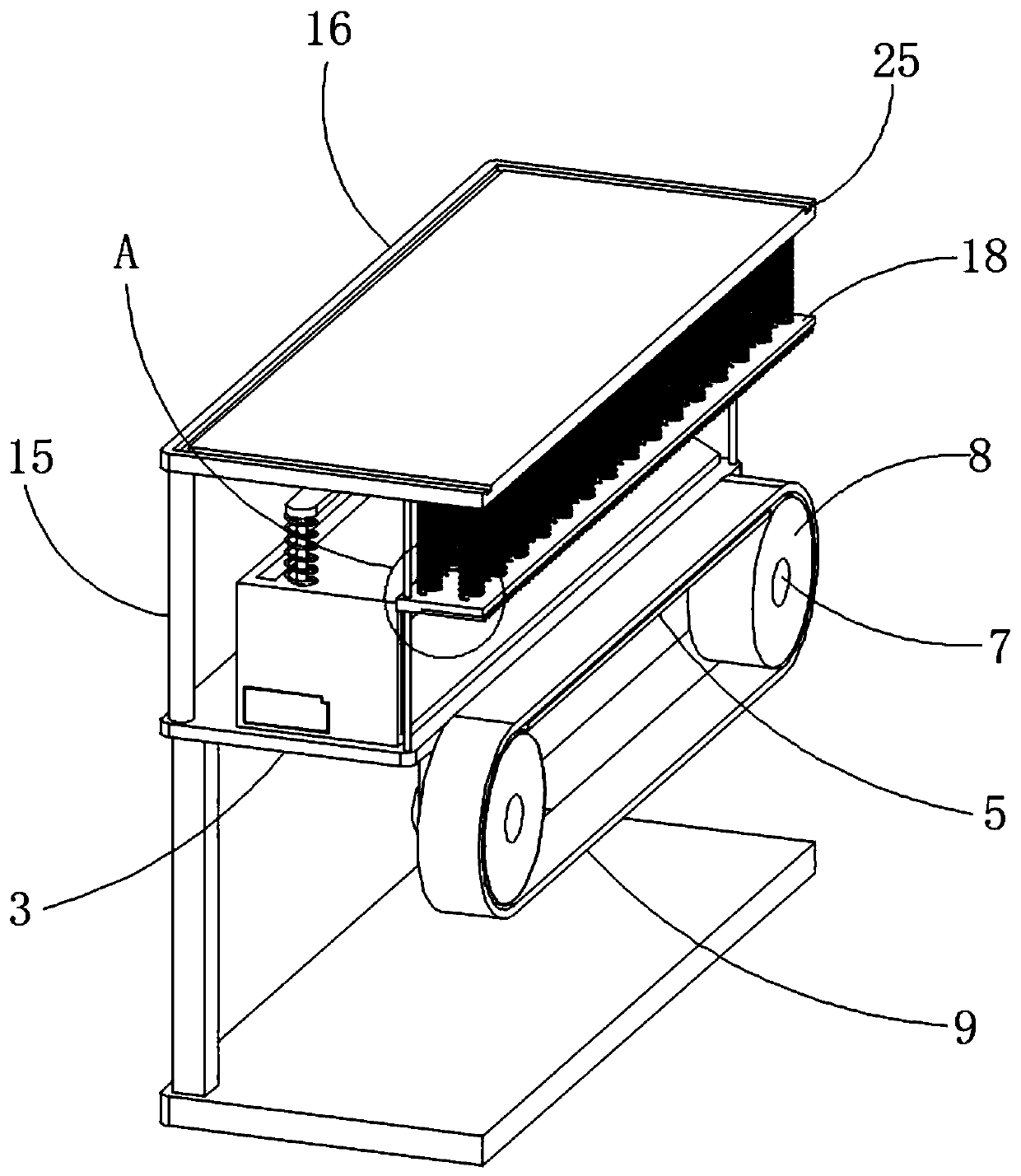

Through hole ash blowing device used in mechanical part machining

InactiveCN110560426AWon't shake and fallShorten the timeFouling preventionDispersed particle filtrationMachine partsEngineering

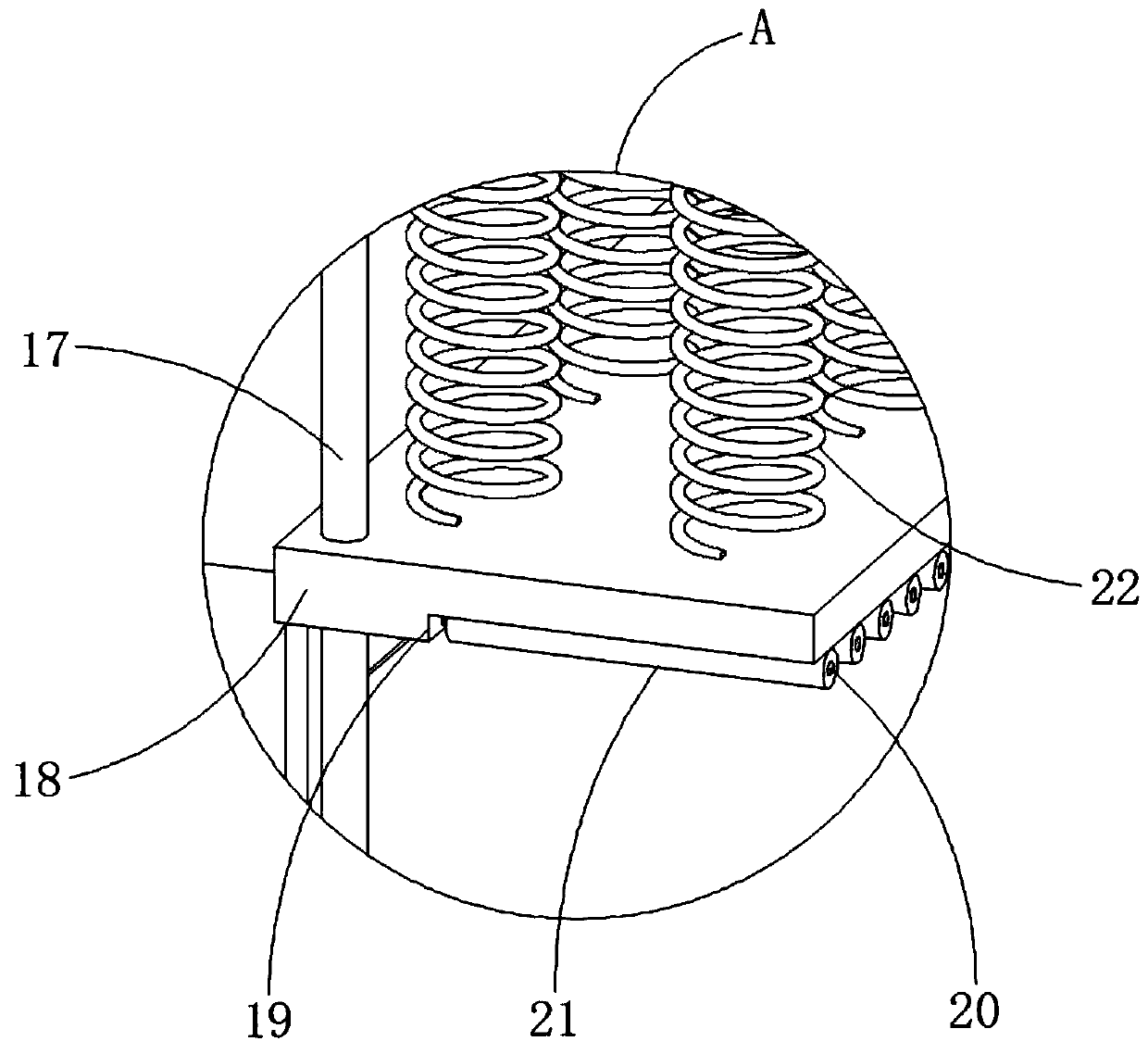

The invention discloses a through hole ash blowing device used in mechanical part machining. First supporting frames are welded to the positions of all corners of the top end of a supporting bottom plate, a first middle plate is welded to the top ends of the two first supporting frames located on one edge portion of the top end of the supporting bottom plate, and the outer sides of two sleeve rollers are sleeved and connected with a conveying belt. An air blower is installed at the bottom of the surface of the other side of a cavity in a communication manner, and clamping springs are installedat the top end of a clamping plate at equal intervals. The through hole ash blowing device is scientific, reasonable and safe and convenient to use; a clamping plate is used for clamping a part to the top end of the conveying belt, the part is pushed to move along with the conveying belt so that through hole ash blowing operation can still be conducted in the part moving process, and the part canbe rapidly placed and move; ash blowing and transportation are combined, the time consumed in the ash blowing process is greatly shortened, and the work efficiency is improved; and meanwhile, a rubber sleeve and a supporting plate are arranged, and therefore the part can be more stable in the moving process and cannot wobble and fall.

Owner:HUZHOU TEACHERS COLLEGE

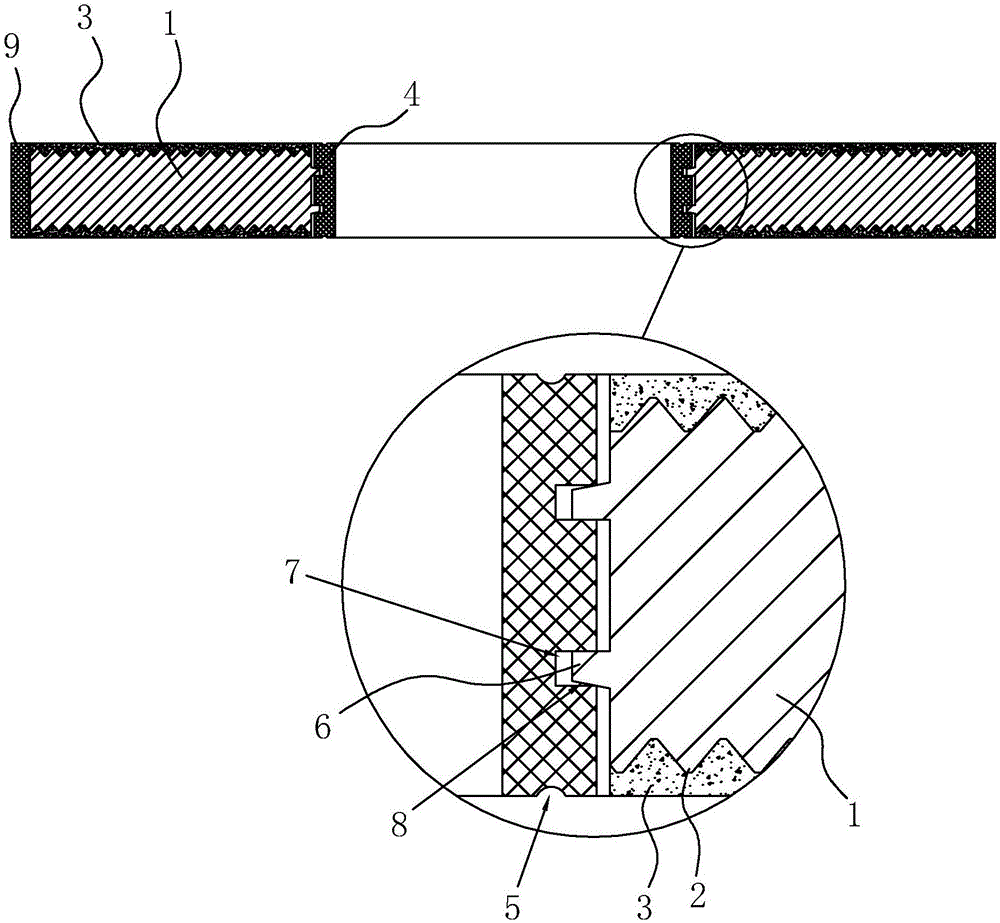

Wave tooth composite gasket

The invention discloses a wave tooth composite gasket. According to the technical scheme, the wave tooth composite gasket is characterized by comprising an annular metal framework, wave teeth concentric with the annular metal framework are arranged on the upper side and the lower side of the annular metal framework, and the wave teeth on the two sides are arranged in a staggered manner; flexible nonmetal layers are further compounded to the upper side and the lower side of the annular metal framework; a first annular rubber ring made of fluorous rubber materials is arranged on the inner ring face of the annular metal framework, and the thickness of the first annular rubber ring is larger than the thickness of the annular metal framework and smaller than or equal to the sum of the thickness of the annular metal framework and the thicknesses of the flexible nonmetal layers on the upper side and the lower side. The wave tooth composite gasket has good resilience performance and sealing performance, repeated impacts and erosion of fluid to the annular metal framework and the flexible nonmetal layers can be reduced through the first annular rubber ring, the sealing performance of the gasket is improved, and the service life of the gasket is prolonged.

Owner:CIXI HIGH NEW COXIN SEALING MATERIAL

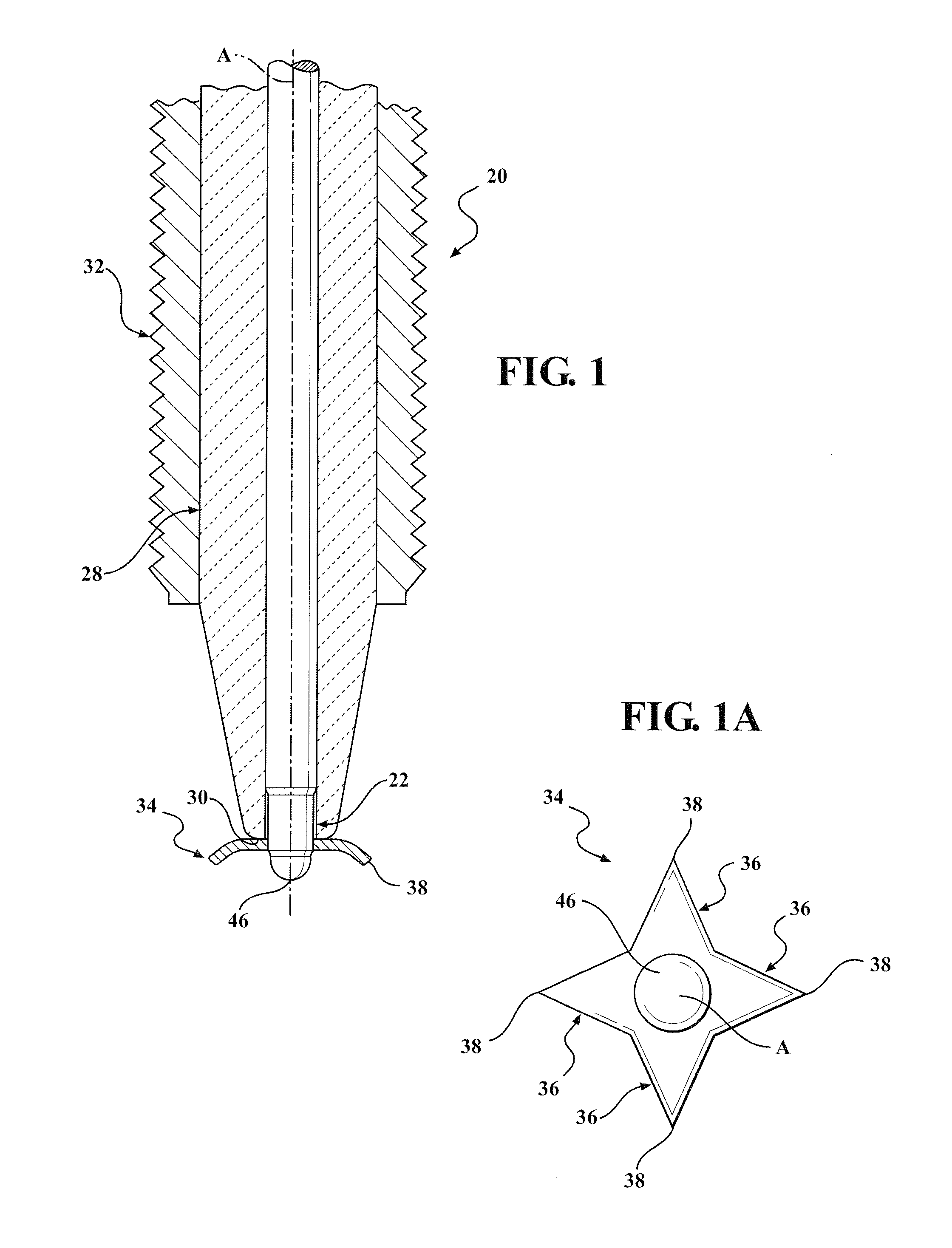

Wear protection features for corona igniter

ActiveUS20140261270A1Increase field strengthReduce erosion damageSpark gapsWave amplification devicesCorona dischargeEngineering

A corona igniter comprises an electrode with a central extended member extending along a central axis and a crown extending radially outwardly from the central extended member. The central extended member has an extended length and the crown has a crown length. The extended length is greater than the crown length such that the extended member approaches a piston more closely than the crown. In addition, the firing tips of the crown each present a first spherical radius which is less than a second spherical radius of the central extended member. Thus, if arcing occurs, it forms from the central extended member, rather than from the crown. Accordingly, the firing tips of the crown experience less wear and remain sharp. In addition, due to the sizes of the spherical radii, corona discharge is more likely to form from the firing tips than from the central extended member.

Owner:FEDERAL MOGUL IGNITION

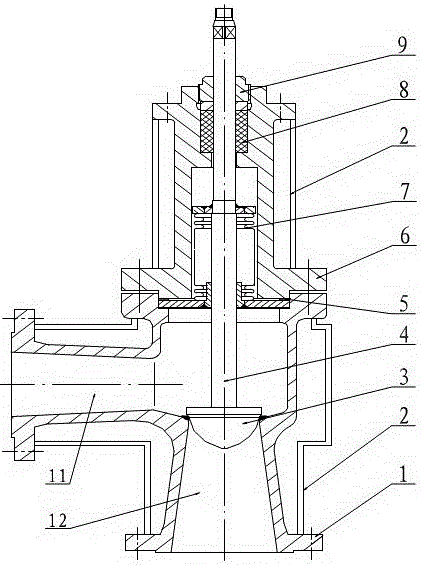

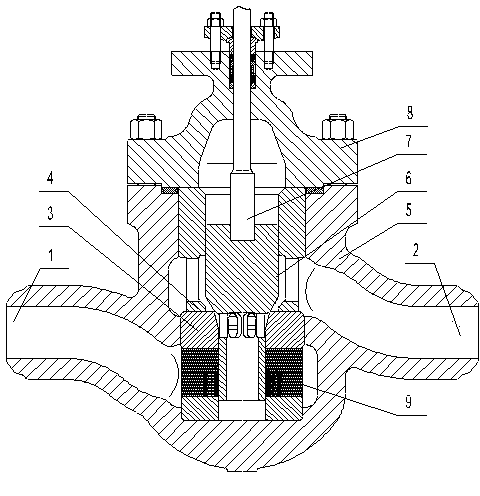

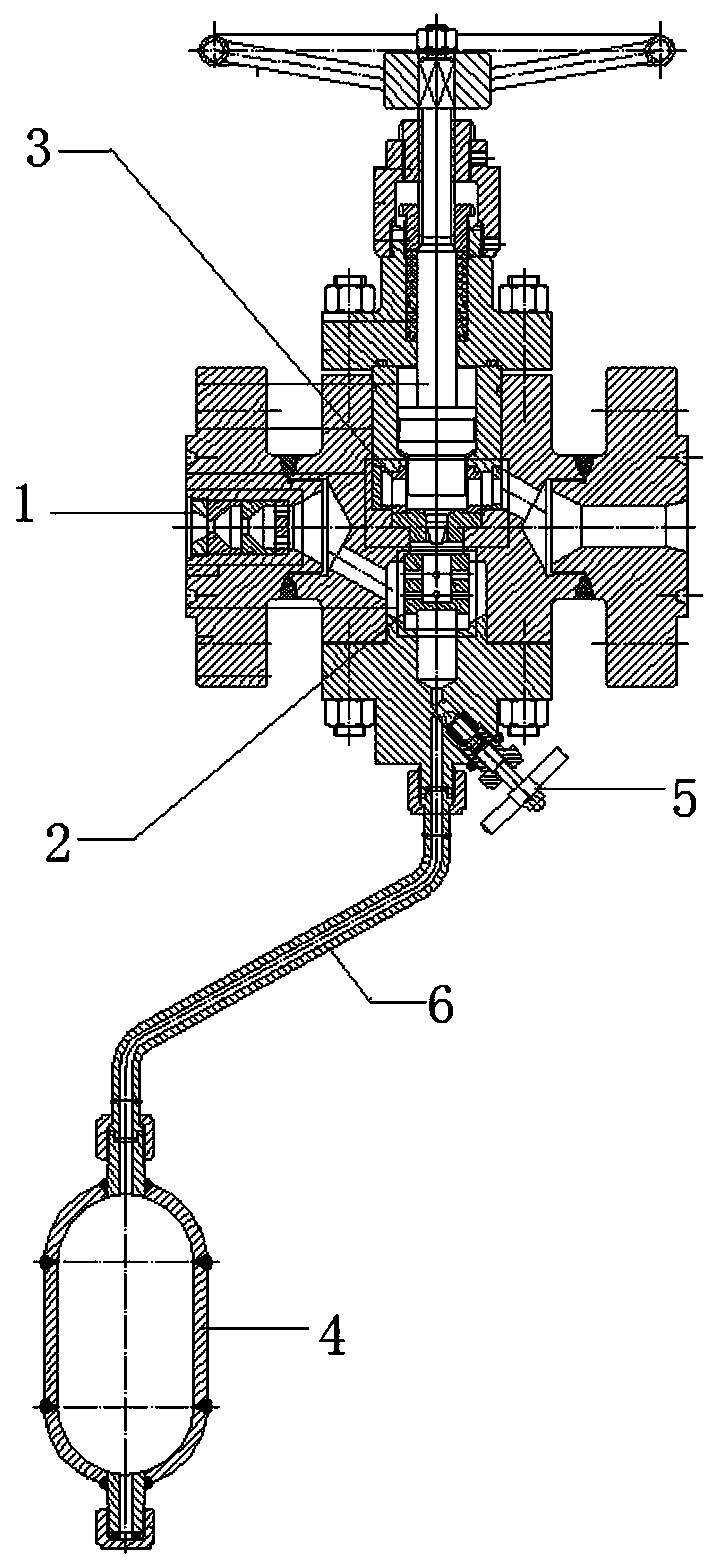

Blockage-proof and leakage-proof angular fused salt regulating valve

InactiveCN106015589AExtended service lifeAvoid depositionSpindle sealingsThermal insulationMolten saltEngineering

The invention discloses an anti-blocking and anti-leakage molten salt angular regulating valve, which comprises a valve body, a valve core, a valve stem, a valve cover, a sealing gasket, a bellows assembly, a sealing packing, a packing gland, a thermal insulation jacket and a fastening The valve body is an integral angular valve body, and its inlet and outlet channels are in the shape of a Venturi tube. The upper part of the outlet channel of the valve body is directly processed with a sealing cone that is suitable for sealing with the valve core. The valve cover is fixed A bellows assembly is installed in the upper end of the valve body and the inner cavity of the bonnet. The upper end of the bellows assembly is welded to a proper position in the middle of the valve stem. The sealing gasket is a 316L toothed gasket. Insulation jackets are added. The beneficial effect is that the flow path of the valve cavity is smooth, the inner cavity has no dead angle, good self-cleaning performance, excellent corrosion resistance, and the easy-to-solidify crystalline medium is not easy to deposit and block, especially suitable for industrial molten salt and other easy-to-solidify, crystalline medium working conditions. , The product has a long service life.

Owner:ZHEJIANG KEHAI INSTR

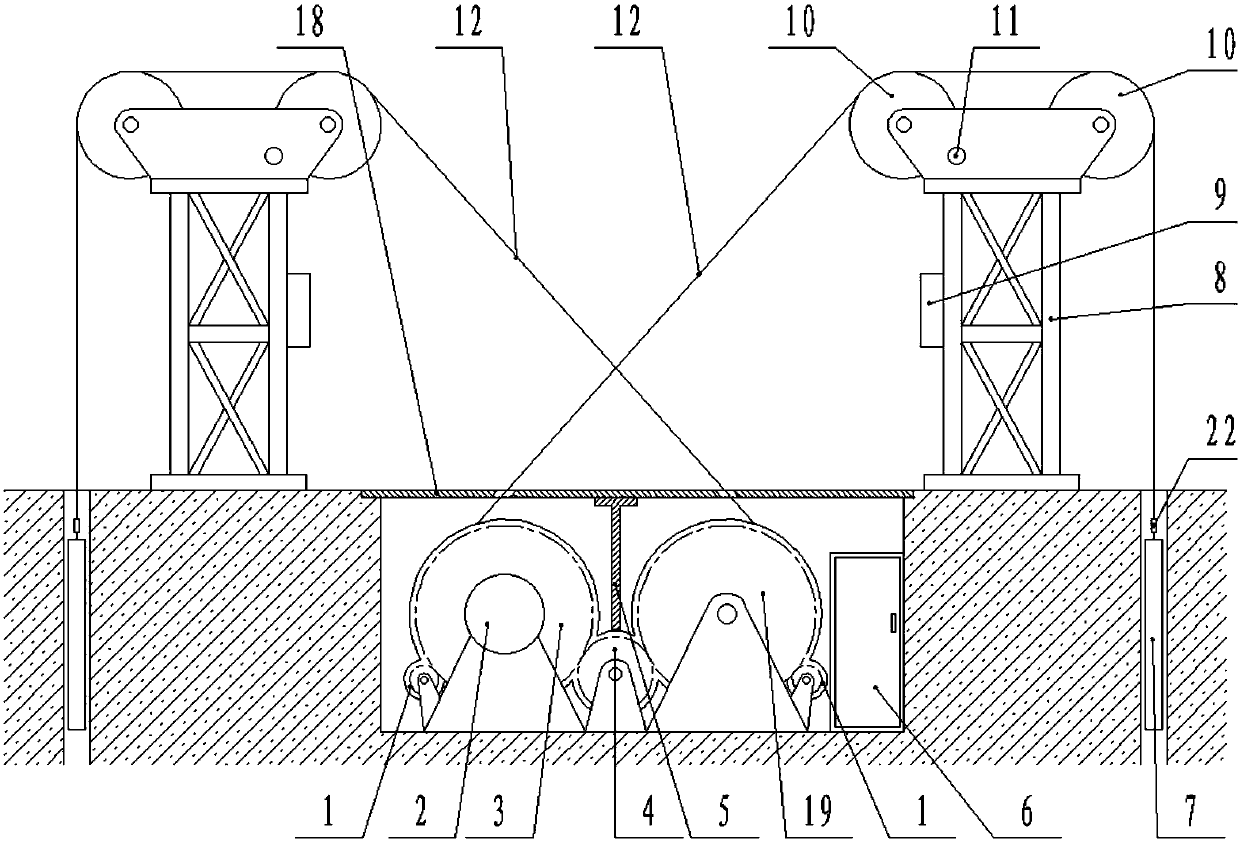

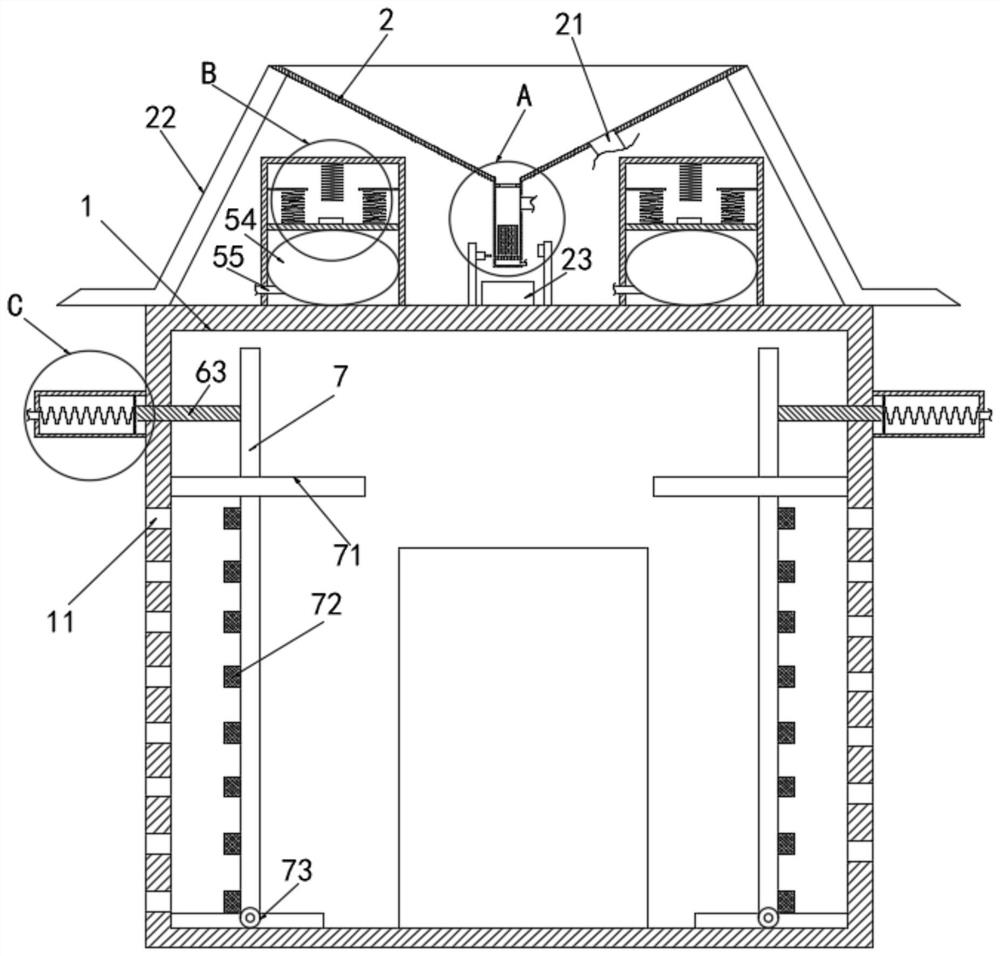

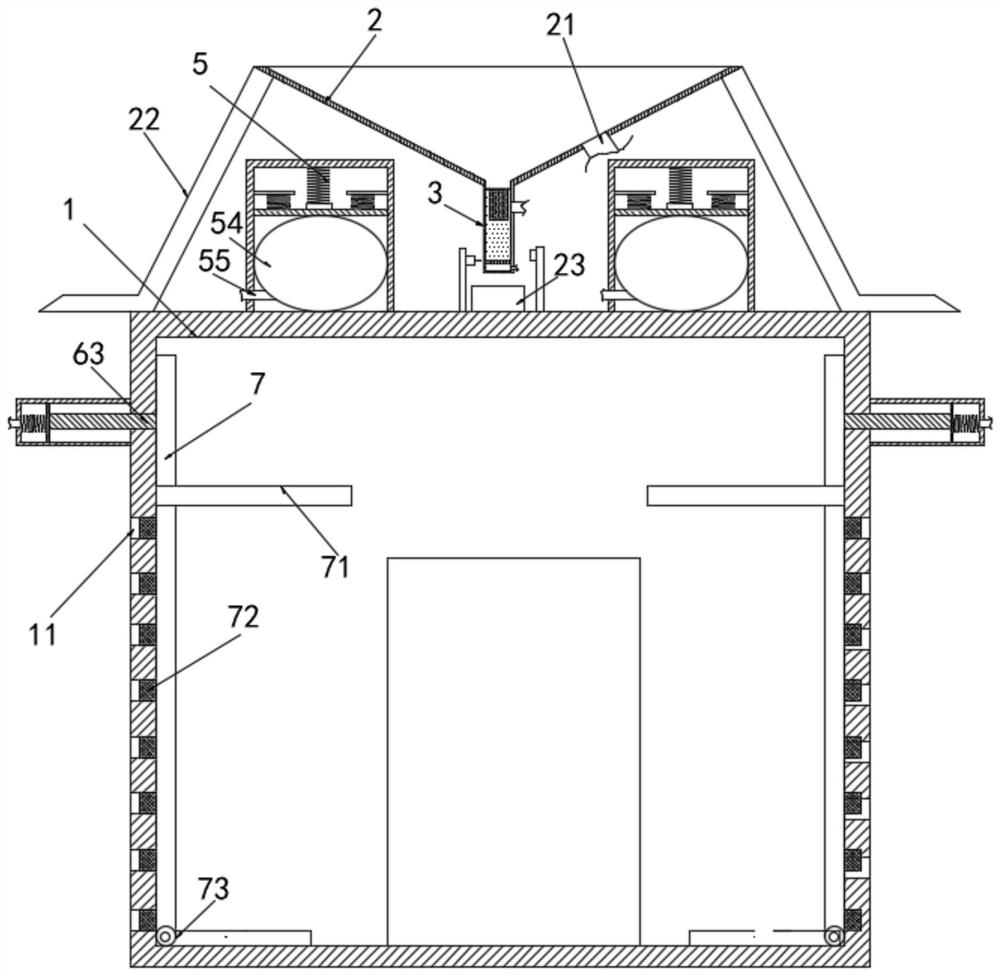

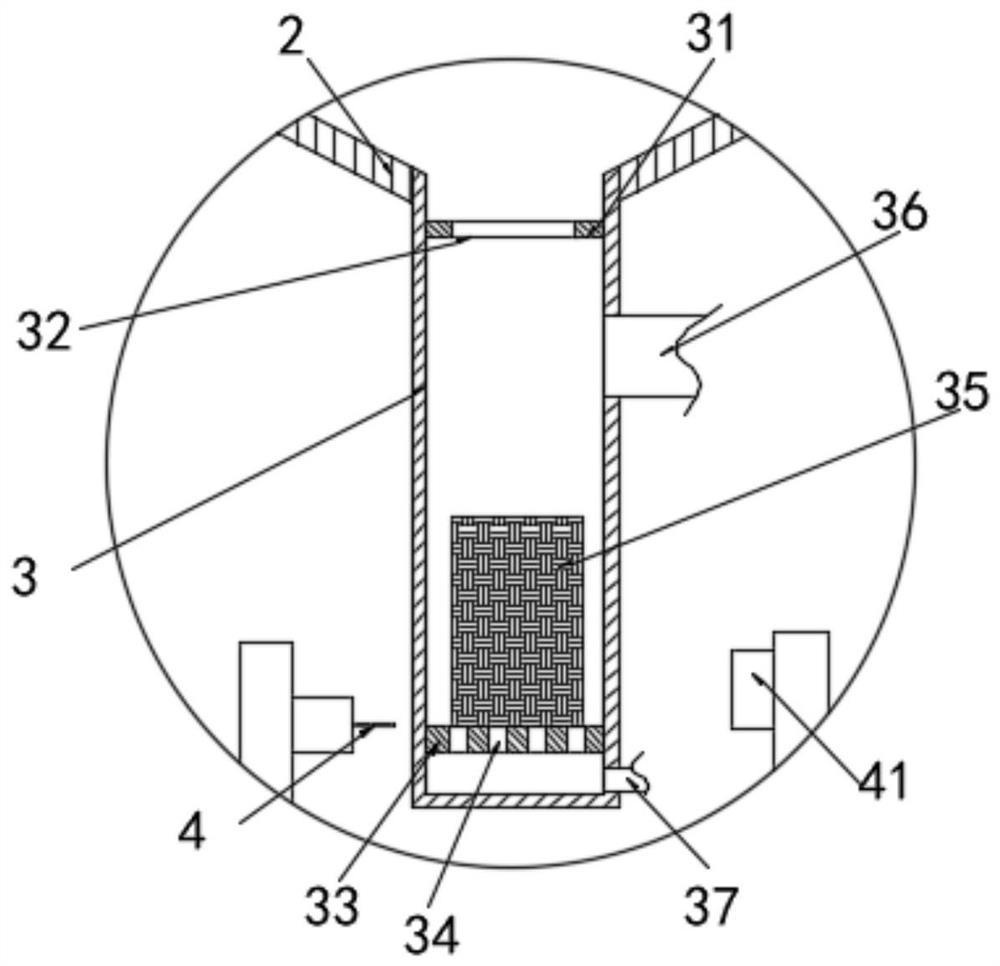

Multi-well coordinating frequency-conversion control oil pumping unit system

The invention belongs to the field of oil production equipment in oil fields, and in particular relates to a multi-well coordinated frequency conversion control pumping unit system, which includes a driving device, an oil extraction rope, an oil pump, a derrick and a frequency conversion control cabinet. The driving device includes a motor, a speed reduction mechanism and a reel. The motor drives the reel to rotate through the reduction mechanism. One end of the oil extraction rope is wound on the reel, and the other end goes around the fixed pulley on the top of the derrick and connects with the plunger of the downhole oil well pump. Correspondingly, both the derrick and the oil well pump are Each has two sets, and there is no protrusion on the ground between the two derricks, and the driving device is arranged in a square pit under the ground. The driving device is arranged below the ground, which can make full use of the space between two oil wells, reduce the area of the well site, and thereby reduce the damage to the surface vegetation. At the same time, encapsulating the driving device can effectively reduce the erosion damage to bearings and rubber parts caused by dust and sunlight, thereby extending the maintenance cycle and reducing maintenance costs.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Alternating-current power distribution equipment capable of preventing rainwater from permeating

InactiveCN111987600APrevent infiltrationAvoid damageSewerage structuresSubstation/switching arrangement cooling/ventilationPhoto irradiationEngineering

The invention relates to the technical field of AC distribution box waterproofingm, and further discloses alternating-current power distribution equipment capable of preventing rainwater from permeating. The equipment comprises an alternating current distribution device main body, the wall of the AC power distribution device main body is provided with ventilation holes. A water collecting hopper is arranged on the alternating-current power distribution device body, a test tube is arranged at the bottom end of the water collecting hopper and comprises a suspension block, an illuminating lamp isarranged on the left side of the test tube, a photoresistor is arranged on the right side of the test tube, a solenoid is arranged below the water collecting hopper, an iron block is arranged under the solenoid, and a first spring is arranged at the right end of the solenoid. When the suspension block floats upwards, the light of the illuminating lamp irradiates the photoresistor, so that the resistance value of the photoresistor is instantly reduced. When rainwater enters the power distribution device, the current connected to the external coil of the solenoid is increased, the baffle blockon the baffle plate enters the vent hole to block the vent hole, and the rainwater cannot enter the device through the vent hole, so that the effect of preventing the rainwater from entering the powerdistribution device is achieved, and the device is prevented from being damaged by the rainwater.

Owner:兰世亮

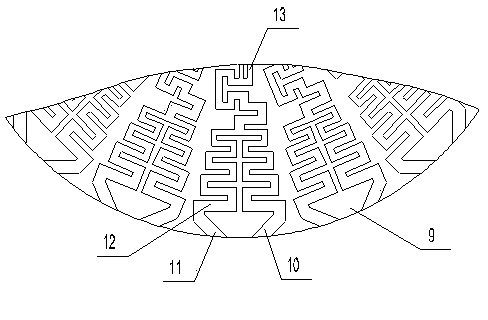

Labyrinth type minimum flow valve

InactiveCN103867729AEasy to useImprove sealingValve members for absorbing fluid energyLift valveCavitationEngineering

The invention discloses a labyrinth type minimum flow valve which comprises a valve body, a valve cover and a valve rod. The valve cover is installed above the valve body. A water inlet passageway is arranged on one side of the position below the valve body. A water outlet passageway is arranged on the other side of the position below the valve body. The passageway intersection of the water inlet passageway and the water outlet passageway is provided with a valve base. A plurality of labyrinth discs are evenly welded to the periphery of the valve base and arranged at the downstream portion of the water inlet passageway. One end of the valve rod is fixed into the valve cover. The other end of the valve rod is provided with a valve element which is movably arranged into the inner wall of the valve base. Through the method, the labyrinth type minimum flow valve can be effectively sealed and can effectively prevent cavitation.

Owner:SUZHOU DOUSON VALVE CO LTD

Novel stereo sand control screen

The invention relates to a novel stereo sand control screen which comprises a central base tube, filters, a supporting tray and an overflowing protection sleeve, wherein a plurality of overflowing holes are formed in the wall of the central base tube and filled with the filters, the supporting tray is composed of a first tray body and a second tray body, and the first tray body and the second tray body are fixedly arranged at the two ends of the central base tube respectively; the overflowing protection sleeve is arranged outside the central base tube in a coaxial and sleeved mode, and the two ends of the overflowing protection sleeve are fixed on the central base tube through the first tray body and the second tray body respectively; a plurality of arched structures are arranged on the overflowing protection sleeve, and two screening grooves are formed by each arched structure and the overflowing protection sleeve. The novel stereo sand control screen is good in erosion resistance and filtering effect due to the fact that the overflowing protection sleeve is arranged on the outer layer and the filters are arranged on the inner layer, and especially has good sand prevention and protection functions for gravel packing, removal of burrs left from windowing of a sidetracking well, and removal of burrs left from float collar and float shoe drilling of an operating well.

Owner:CHINA NAT OFFSHORE OIL CORP +2

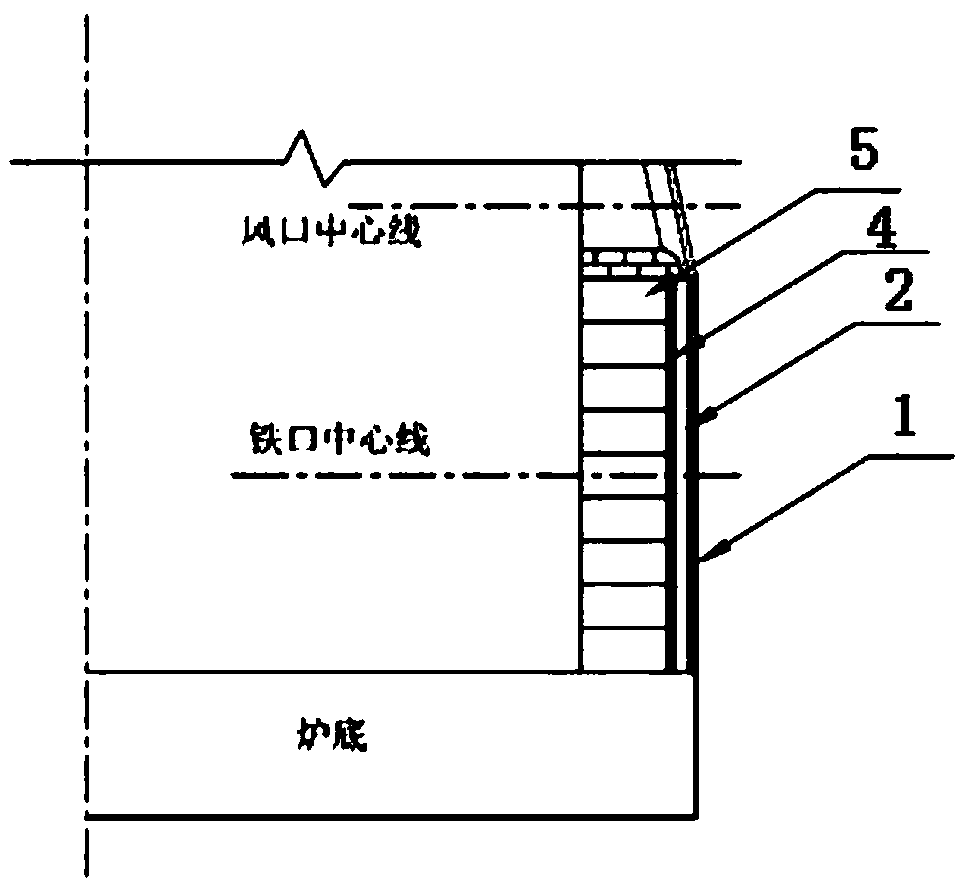

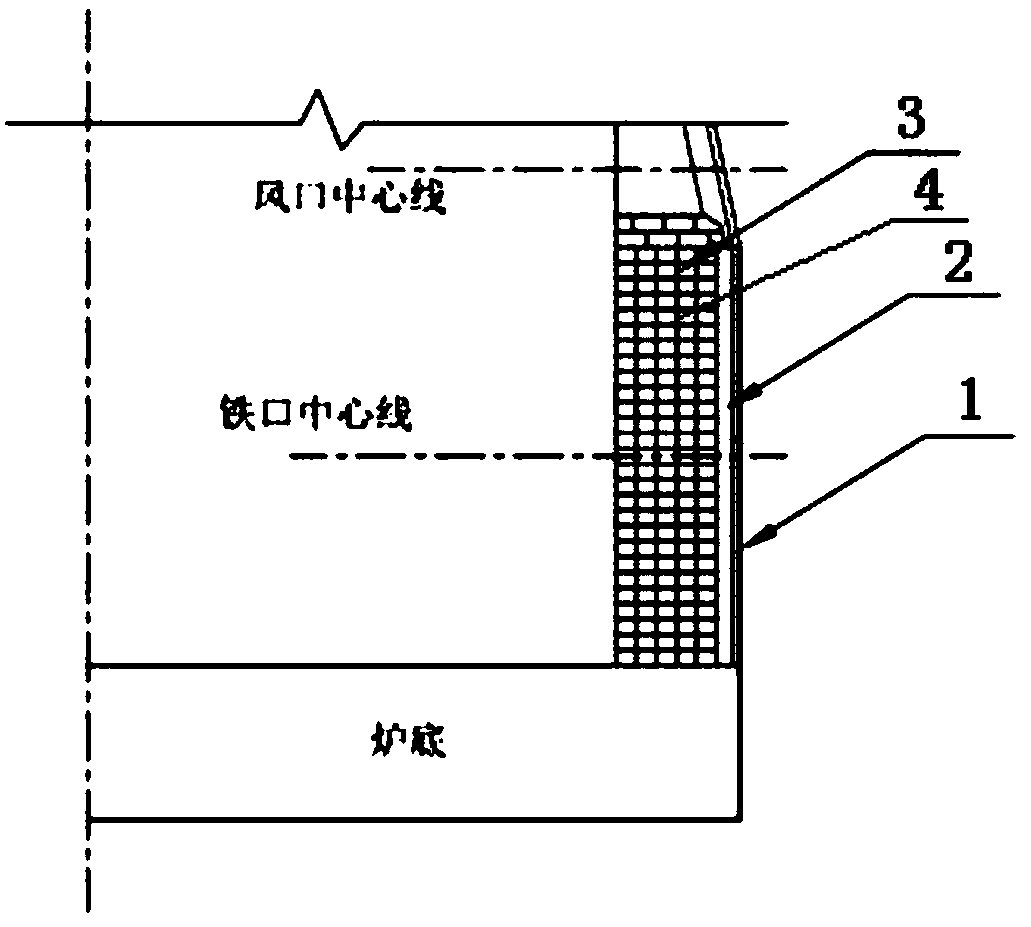

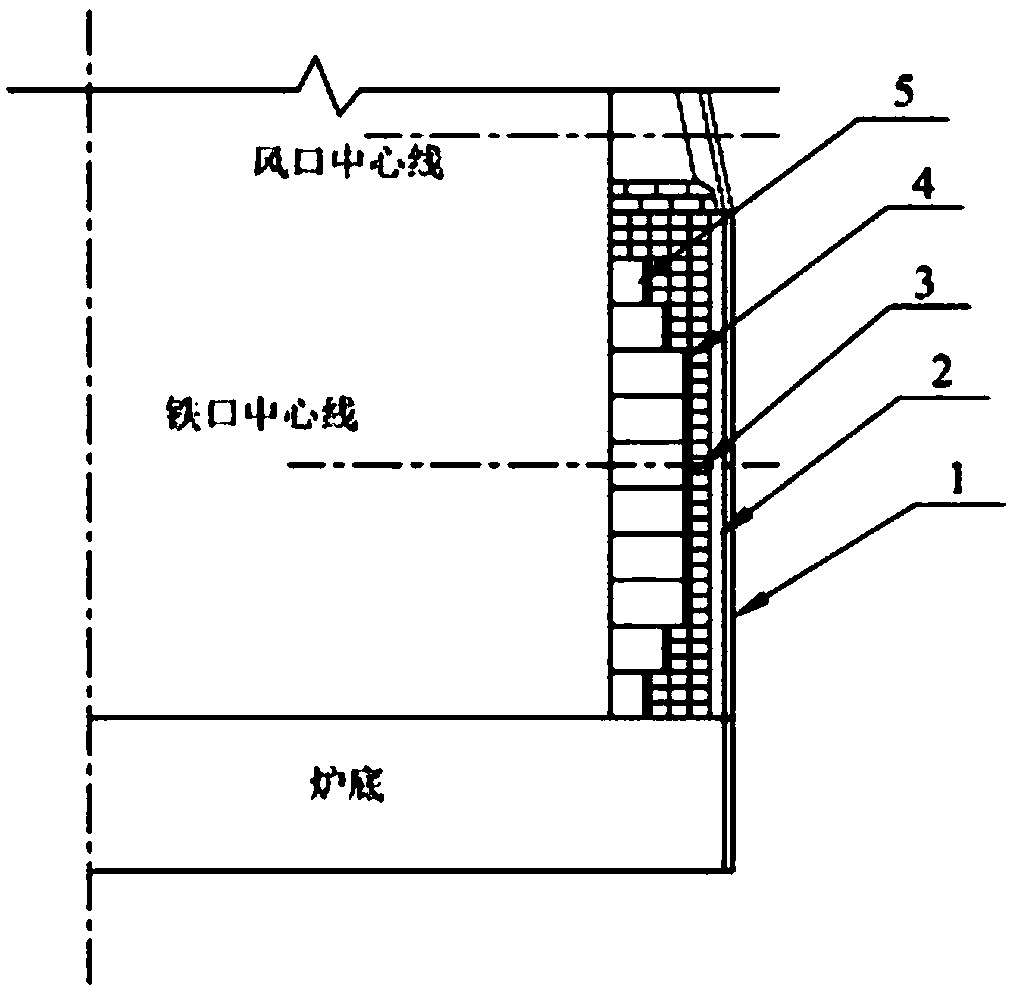

High-heat-conductivity long-life blast furnace hearth and brick lining building method

ActiveCN109055639AAlleviate brick lining crackingAchieving Overall LongevityBlast furnace detailsInternal formsHearthErosion

The invention discloses a high-heat-conductivity long-life blast furnace hearth and further provides a brick lining building method of the high-heat-conductivity long-life blast furnace hearth. The high-heat-conductivity long-life blast furnace hearth comprises a furnace shell, a cooling wall and brick linings which are arranged sequentially from outside to inside. On the lower portion of the hearth, the lower-middle portion of the hearth, the middle of the hearth, the upper-middle portion of the hearth and the upper portion of the hearth, the brick linings comprise small-block carbon bricks,carbon ramming material layers and large-block carbon bricks which are arranged sequentially; and at the top of the hearth, the brick linings are formed by building a plurality of small-block carbon bricks. According to the high-heat-conductivity long-life blast furnace hearth, cracking of the hearth brick linings due to thermal stress and erosion damage caused by harmful elements through cracks can be avoided, circulation erosion of molten iron can be further resisted effectively, thus the erosion damage to the hearth is relieved, and the service life of a blast furnace is prolonged.

Owner:武汉钢铁有限公司

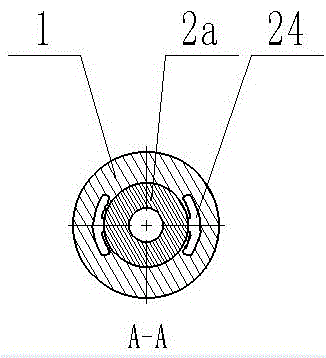

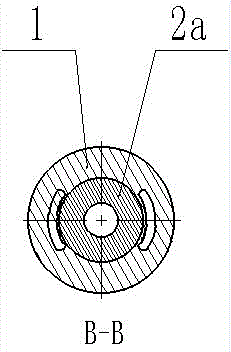

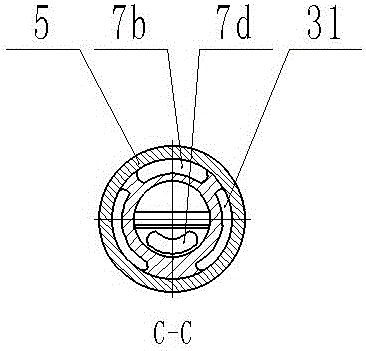

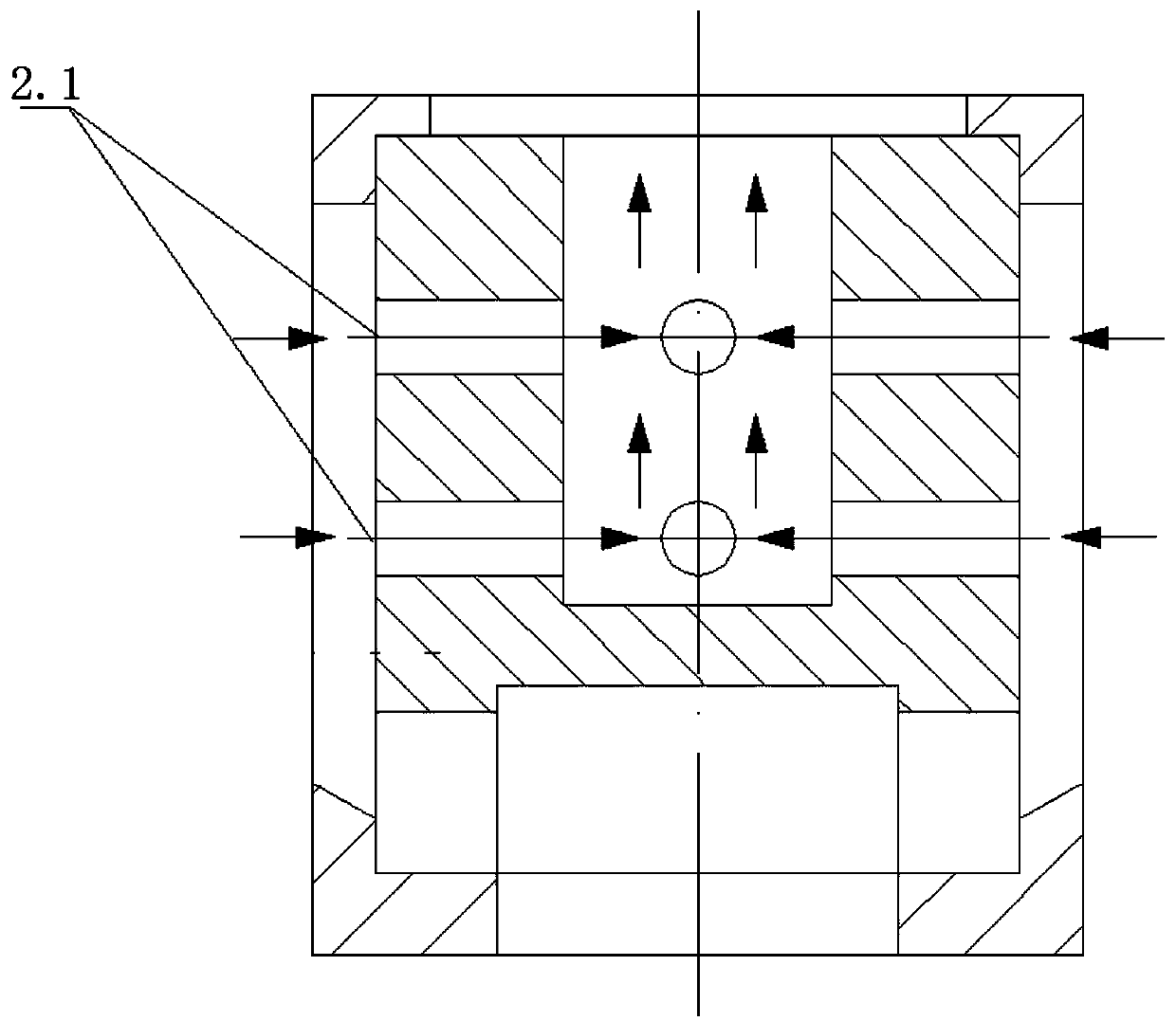

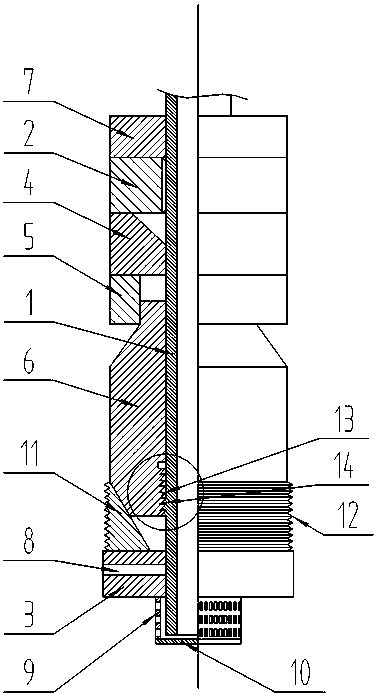

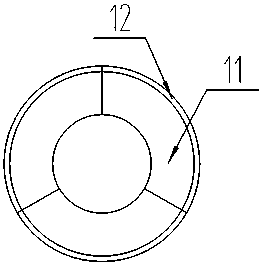

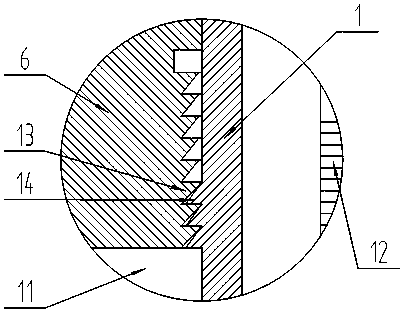

Rolling type constant flow fluidic efflux hammer

The invention relates to a rolling type constant flow fluidic efflux hammer, and belongs to the field of petroleum and gas drilling techniques. According to the technical scheme, a flow divider assembly is installed in an upper connector, a first middle connector is connected with the lower end of the upper connector, an internal cylinder body is connected with the lower end of a bistable fluidic element, the internal cylinder body is connected with a cylinder cover, and the bistable fluidic element, the internal cylinder body and the cylinder cover are limited in the first middle connector; an energy storage leaf spring is arranged inside the internal cylinder body and limited through a limit groove and a limit boss, and a punch hammer is connected with an integral type piston and installed inside the internal cylinder body; four roll ball assemblies are arranged uniformly along the circumference of the punch hammer, a third middle connector is connected with the lower end of the second middle connector, and a hammering block is arranged in the third middle connector in a sleeved mode; splines are arranged on the hammering block, a roll ball assembly is arranged on the parts of the splines, and a lower connector is connected with the lower end of the hammering block. The rolling type constant flow fluidic efflux hammer can increase impacting energy of an impacter, reduce erosion destruction of the bistable fluidic element, improve stability and reliability of the impacter and prolong the service life of the impacter.

Owner:SOUTHWEST PETROLEUM UNIV

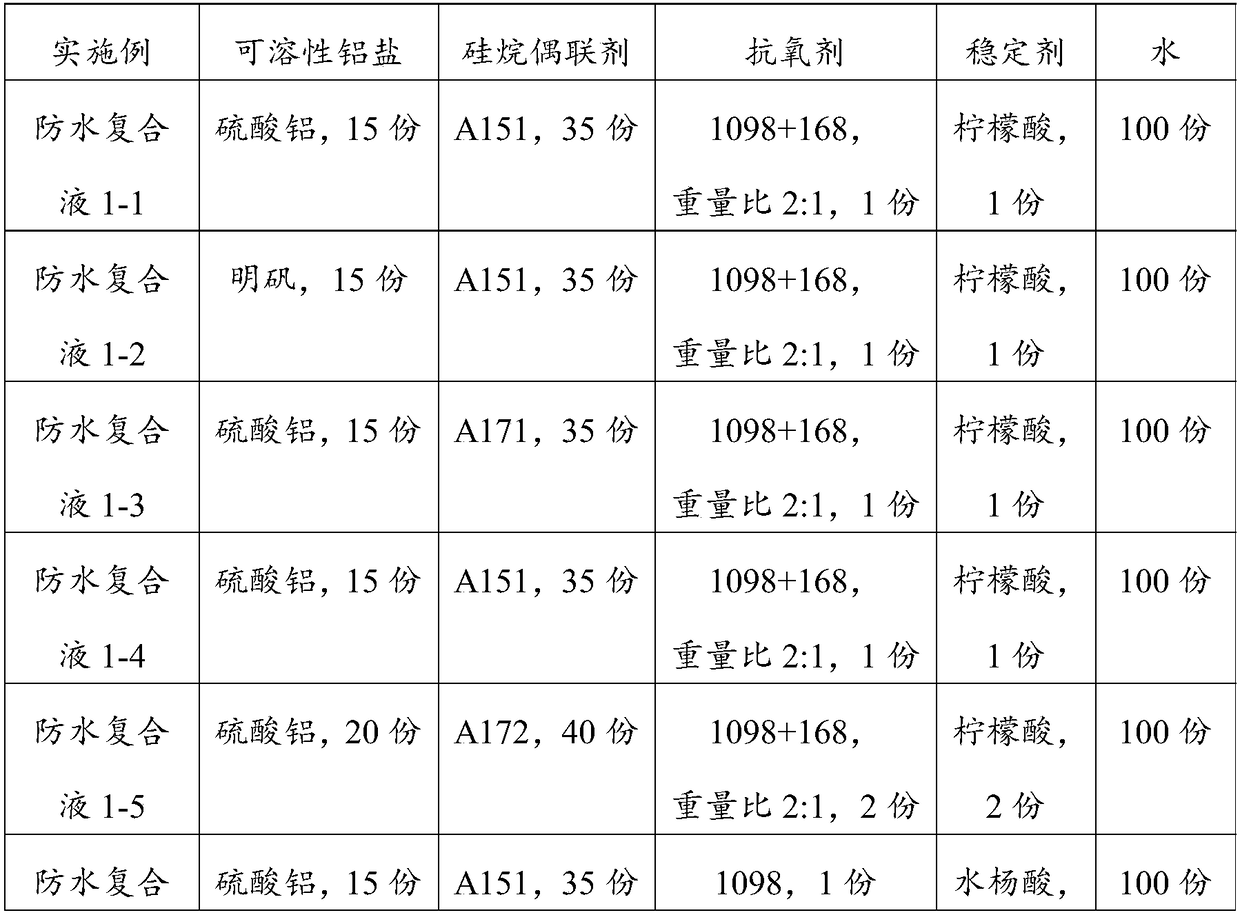

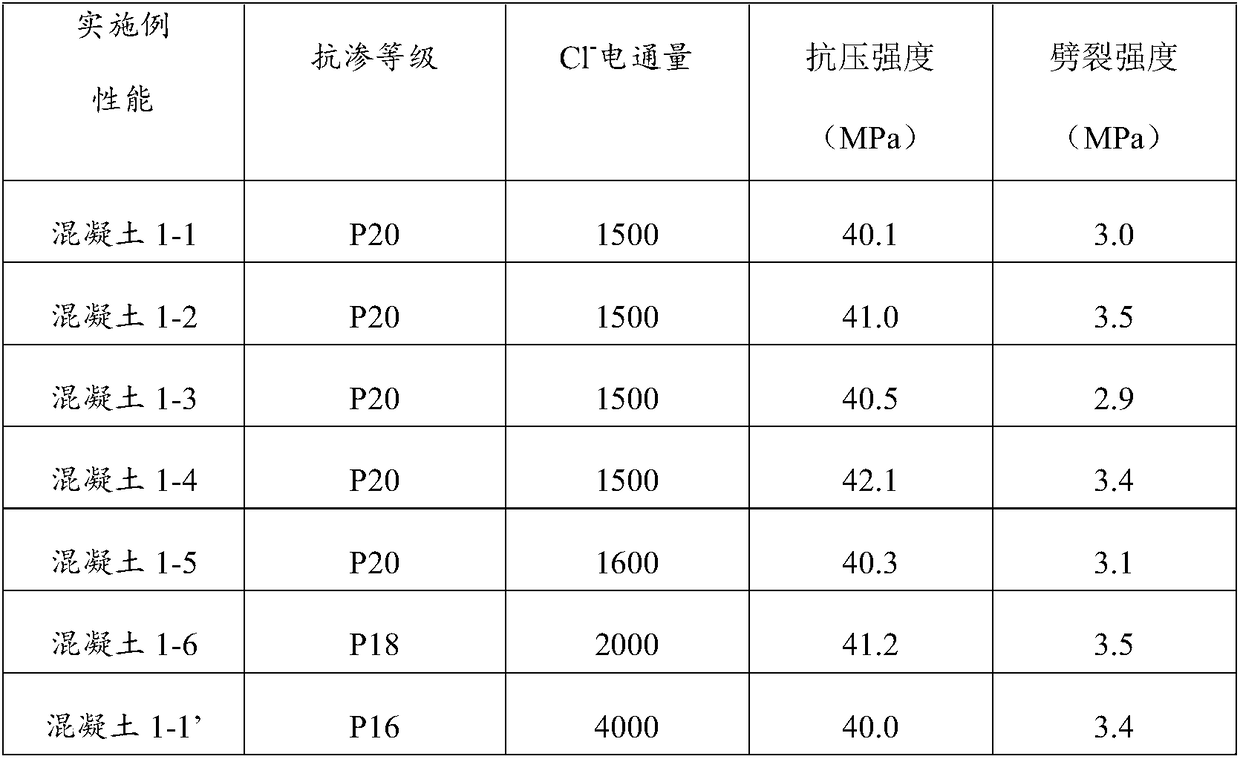

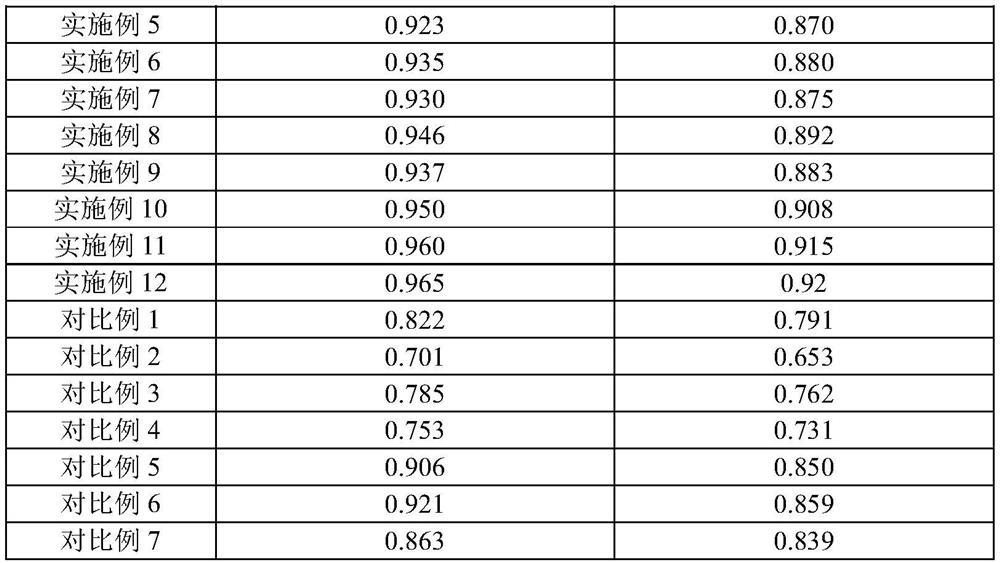

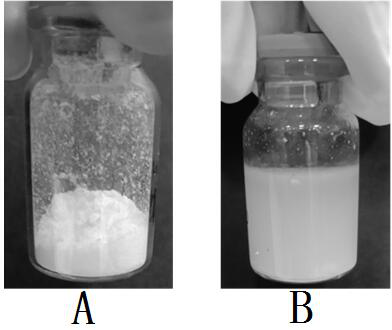

Ultrahigh-performance concrete waterproof composite liquid and preparation method thereof

ActiveCN108516727AImproves water retention and segregation resistanceReduce erosion damageRebarSilane coupling

The invention relates to ultrahigh-performance concrete waterproof composite liquid being prepared from, by weight, 10-30 parts of soluble aluminum salt, 20-50 parts of a silane coupling agent, 0.5-5parts of an antioxidant, 0.5-5 parts of a stabilizer, and 100-200 parts of water. The concrete waterproof composite liquid has anti-seepage and anti-seawater-corrosion effect; as a concrete additive,the composite liquid can greatly improve the water-retaining property and anti-separation effect of concrete, reduces erosive damage on a protective layer surface of steel bars due to sea wave and seasand, and reduces and fines capillaries on the surface of concrete, thereby reducing capillary inhalation of the concrete to salts, alkalis and the like and reducing slump loss of concrete.

Owner:山东好运新材料有限公司

High-strength elastic waterproof building coating

InactiveCN107880658AImprove waterproof performanceImprove permeabilityAntifouling/underwater paintsPaints with biocidesBasementWater vapor

The invention relates to the technical field of research and development of building coatings and discloses a high-strength elastic waterproof building coating. The building coating is excellent in waterproof property, has ultra-strong infiltration capacity, excellent impervious performance and high harmful chemical erosion resistance, is capable of automatically and rapidly repairing micro-cracks, non-toxic, excellent in flexibility, safe and environmentally friendly, capable of resisting displacement of the building due to expansion or contraction, excellent in gas permeability, favorable for vapor volatilization inside the building, excellent in cohesiveness with most of base materials, convenient in construction, seamless, high in curing speed and applicable to roof, balconies, bathrooms, kitchens, swimming pools, basements, reservoirs, interior walls and the like, can greatly reduce erosion and damage effects of external moisture and corrosive media on concrete construction, and has significances for improving the durability and service life of concrete buildings.

Owner:安徽力峰建材科技有限公司

Anti-corrosion saline-alkaline-tolerant concrete and preparation method thereof

The invention relates to the technical field of anti-corrosion concrete, and particularly discloses anti-corrosion and saline-alkaline-tolerant concrete and a preparation method thereof. The anti-corrosion and saline-alkaline-tolerant concrete is mainly prepared from the following raw materials in parts by weight: 1500-1800 parts of aggregate, 600-800 parts of sand, 150-200 parts of cement, 50-80 parts of fly ash, 20-35 parts of silica fume, 5-10 parts of fibers, 100-130 parts of water, 6-8 parts of a water reducing agent, 2-5 parts of an expanding agent and 12-25 parts of a preservative, wherein the preservative is prepared from the sum of the mass of ethylenediamine oleate and bisphenol A diallyl ether and a beta-diketone compound according to the mass ratio of (20 to 32) to (5 to 7). The anti-corrosion and salt-tolerant concrete can be used for building construction in a saline-alkali environment, and has the advantage of good corrosion resistance.

Owner:深圳市恒星建材有限公司

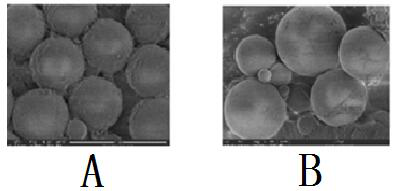

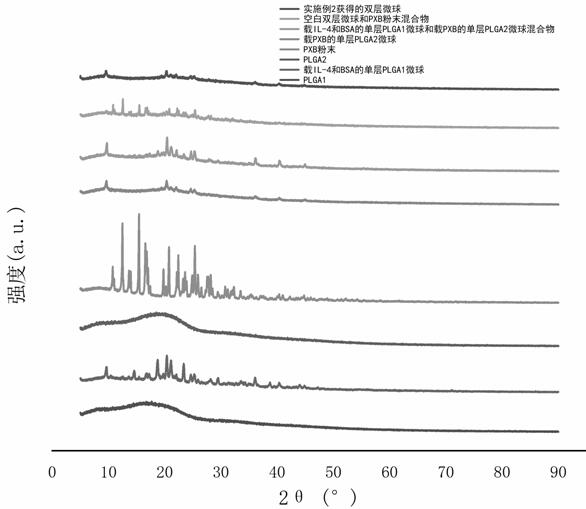

Double-layer microspheres loaded with parecoxib, interleukin-4 and bovine serum albumin and used for treating osteoarthritis and preparation method of double-layer microspheres

ActiveCN113876724AUniform sizeRound appearancePowder deliveryPeptide/protein ingredientsMicrosphereNon steroid anti inflammatory drug

The invention relates to double-layer microspheres loaded with parecoxib, interleukin-4 and bovine serum albumin and used for treating osteoarthritis and a preparation method of the double-layer microspheres, and belongs to the technical field of drug carrier research. Drugs carrying different physical and chemical properties are prepared by two-time multiple emulsion solvent volatilization method, the purpose of the invention is to solve the bottleneck problems of clinically restricting osteoarthritis drug treatment at present or meet urgent requirements of people for handling of pain and mobility inconvenience problems caused by inflammatory reaction during osteoarthritis attack, infection problem caused by repeated injection in articular cavity injection, and the problem of poor patient medication dependency caused by cardiotoxicity and gastrointestinal reaction caused by oral administration of non-steroidal anti-inflammatory drugs, and long-term chronic properties of osteoarthritis.

Owner:SHANDONG UNIV

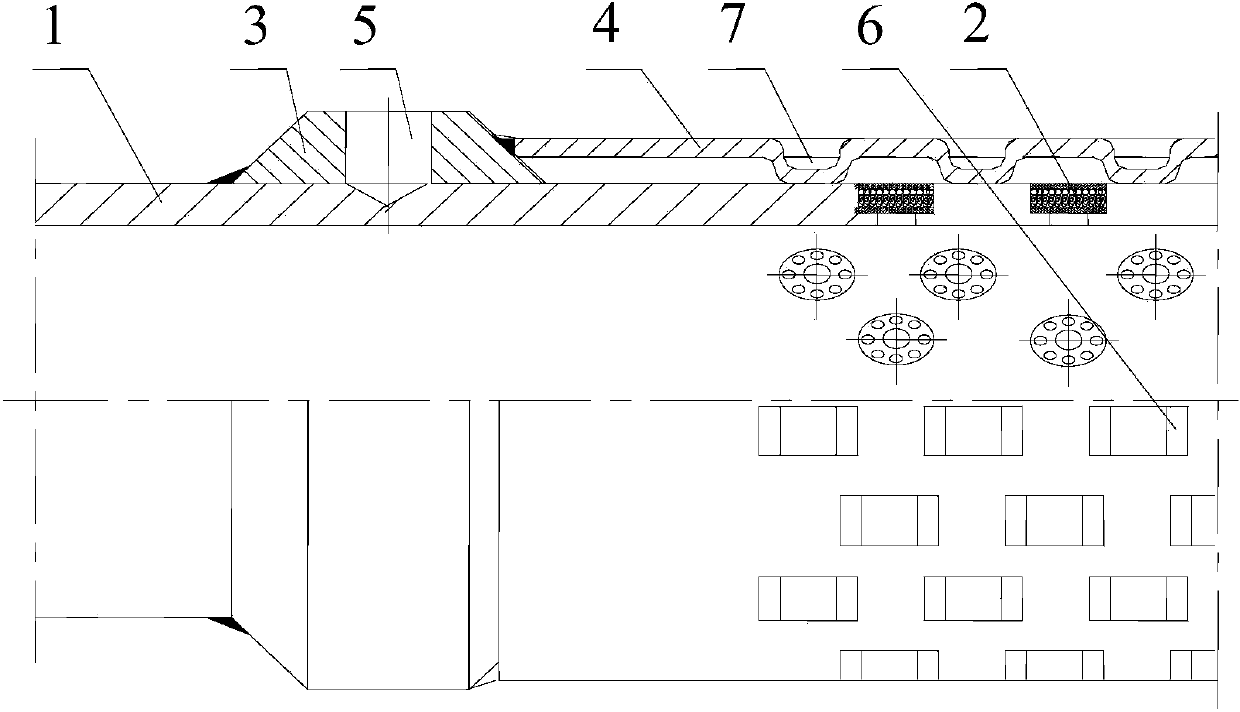

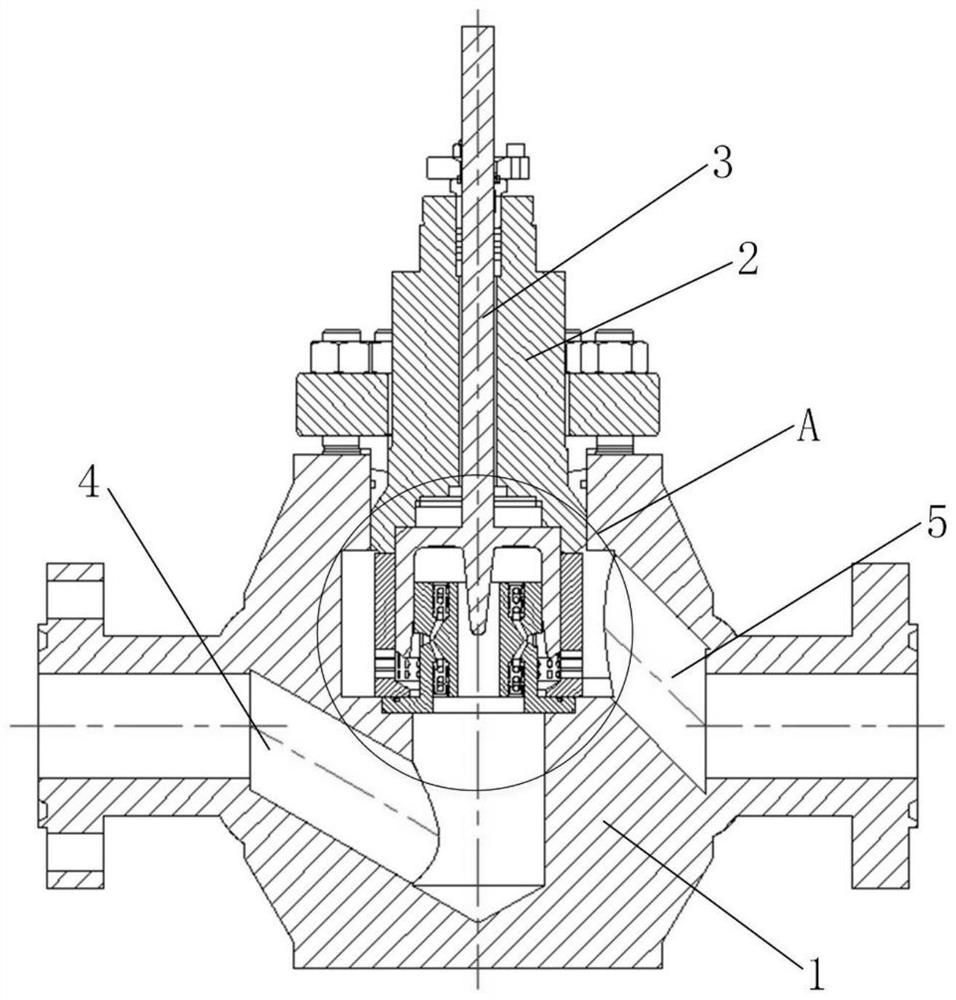

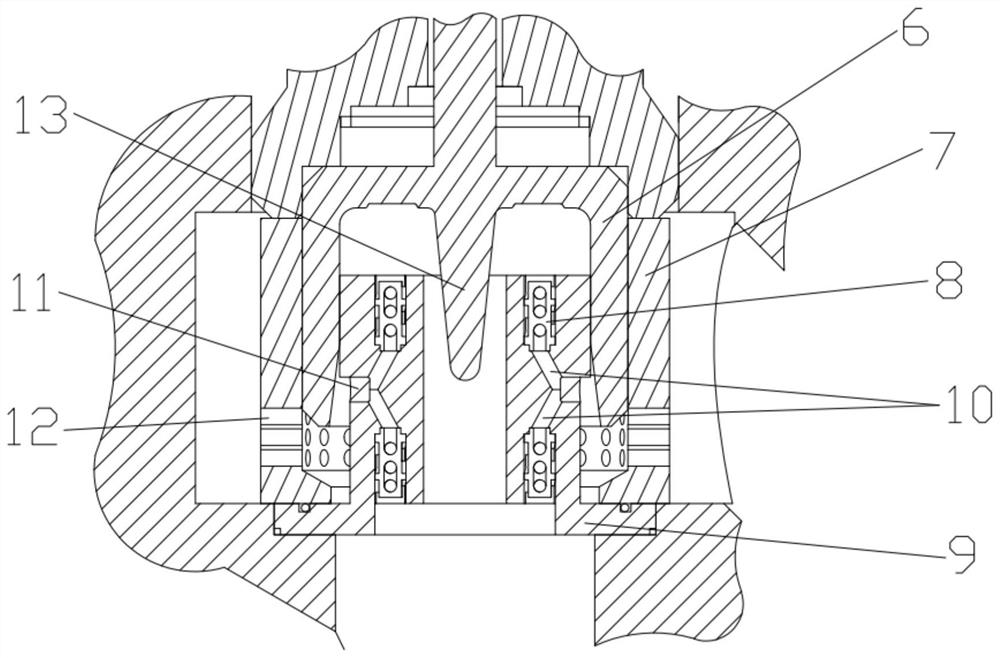

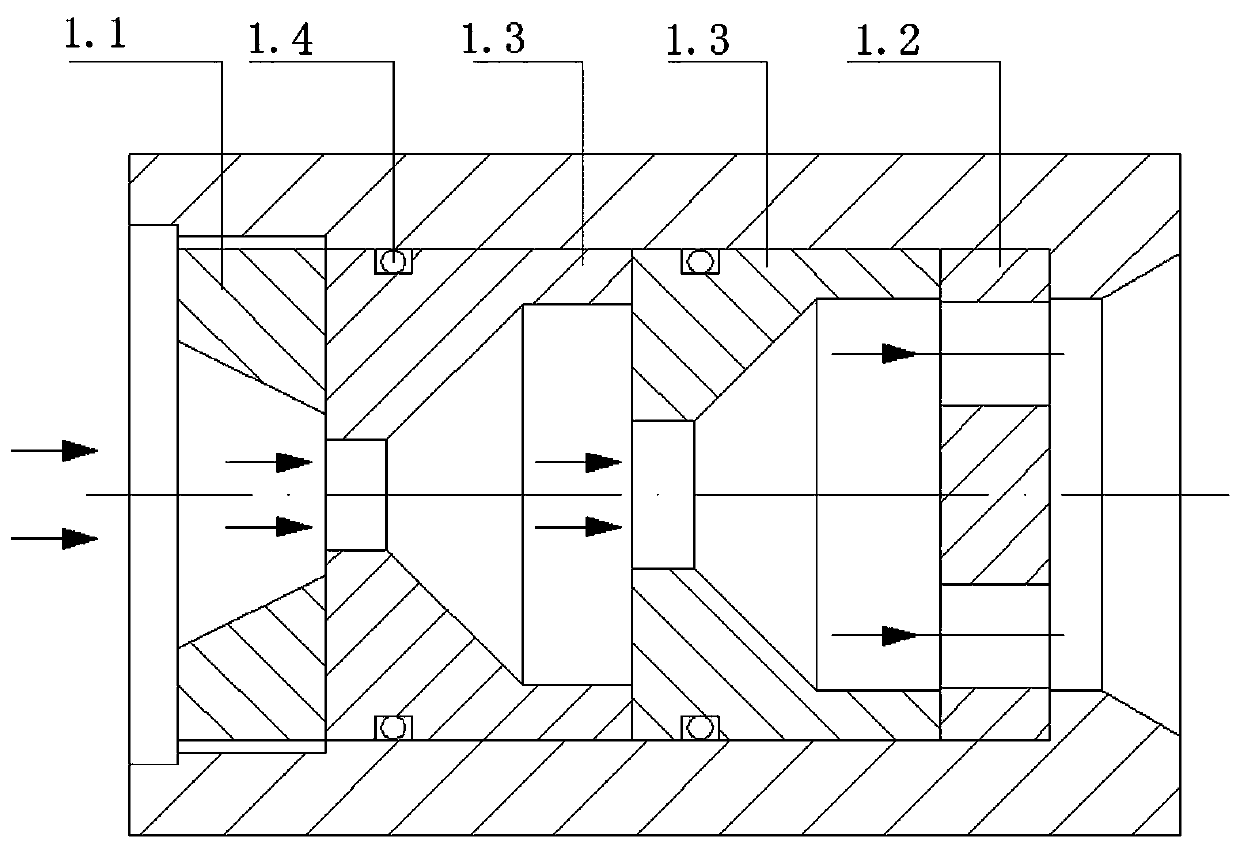

Novel throttling reverse type pressure-reducing and speed-controlling regulating valve

ActiveCN112096960AImprove step-down capabilityExtended service lifeValve members for absorbing fluid energyLift valveSleeve valveControl engineering

The invention belongs to the related technical field of pressure regulating valves, and discloses a novel throttling reverse type pressure-reducing and speed-controlling regulating valve which comprises a valve body, a valve deck, a valve rod, a throttling assembly, a novel sleeve type valve element and a flow guide sleeve, wherein the valve deck is connected to the valve body, one end of the valve rod penetrates through the valve deck and then stretches into the valve body, and the valve rod is used for driving the novel sleeve type valve element to move; the novel sleeve type valve element is connected to the end, located in the valve body, of the valve rod and located between the throttling assembly and the flow guide sleeve; the flow guide sleeve is contained in the valve body, and thethrottling assembly is partially contained in the flow guide sleeve; and the throttling assembly comprises a plurality of space corner throttling elements, multiple throttling flow channels are formed in the space corner throttling elements, and the multiple throttling flow channels communicate with one another in the axial direction of the space corner throttling elements. The regulating valve improves pressure reduction and energy consumption effects and consumes the kinetic energy of a medium to effectively control the flow velocity of the medium in a pressure reduction element.

Owner:HUAZHONG UNIV OF SCI & TECH

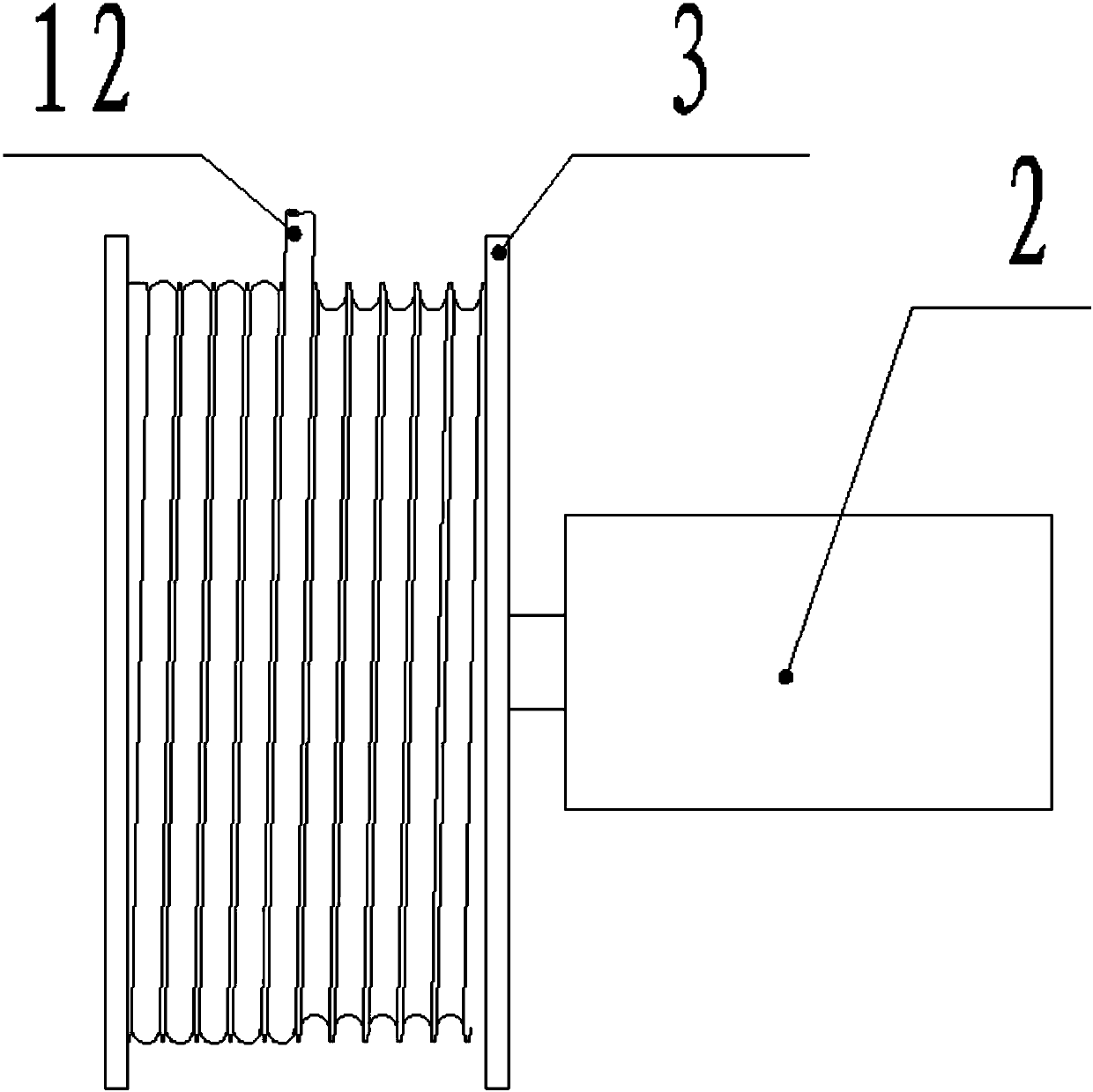

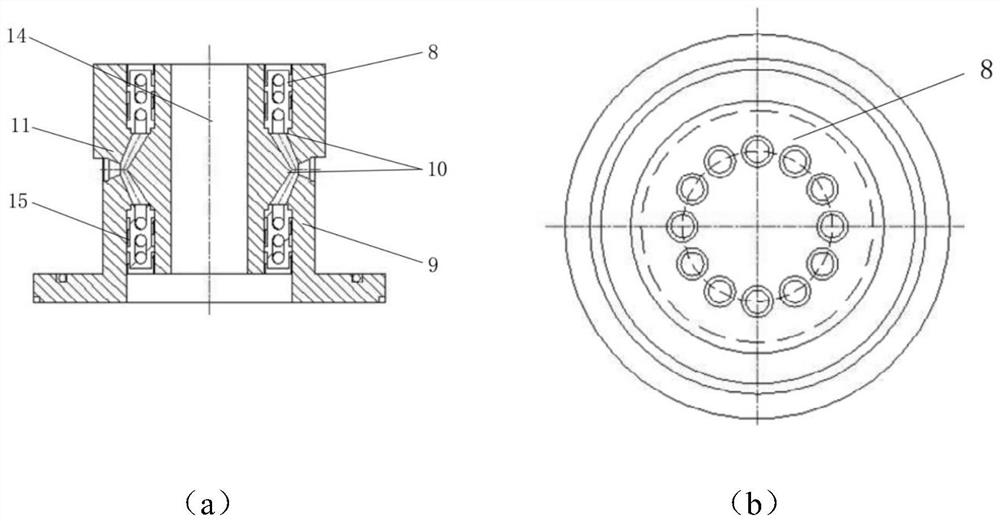

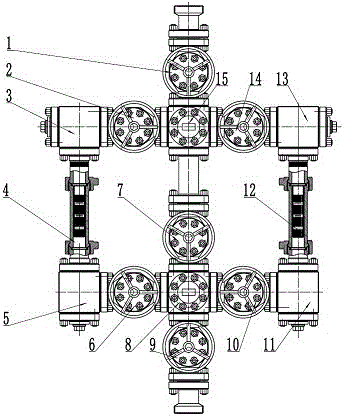

High-pressure fine filtering manifold and filtering method thereof

InactiveCN106437575AImprove filtering effectContinuous circulation filter effect is goodFlushingWell drillingFiltration

The invention relates to a high-pressure fine filtering manifold and a filtering method thereof which are mainly suitable for being applied to an oil and gas well drilling and grinding cyclic operation ground process. The manifold mainly comprises two high-pressure filtering short sections, seven manual flat gate valves, two pipeline five-way joints, four pipeline three-way joints and a manifold pipeline; the filtering manifold is of a one-in one-out structure, the two sides are controlled by adopting the manual flat gate valves and the high-pressure filtering short sections, and the middle is directly arranged. The high-pressure fine filtering manifold has the benefits that under the filtering action of the two high-pressure filtering short sections, the convenient replacement of the short sections is ensured, the uninterrupted and continuous drilling and grinding fluid cyclic filtration treatment and control are realized, the filtering capacity, the filtering efficiency and the filtering quality of mechanical impurities in drilling and grinding fluid are greatly improved, the purposes of drilling and grinding fluid cyclic fine filtration and utilization are achieved, and the erosion damage caused by the large-sized mechanical impurities in the drilling and grinding fluid to the downstream choke manifold is avoided; the high-pressure fine filtering manifold is good in continuous cyclic filtration effect, strong in practicability and suitable for being applied to the oil and gas well drilling and grinding cycle operation ground process.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD CHANGQING DOWNHOLE TECH CO

Three-stage throttling valve

ActiveCN110159772AExtended service lifeReduce the gas flow rateLift valveValve housingsThree stageEngineering

The invention belongs to the technical field of stop valve structures, and discloses a three-stage throttling valve. The three-stage throttling valve comprises a valve body with a pressure inlet and apressure outlet, a passage opening controlled by a valve core to be opened or closed is arranged in the valve body to communicate the pressure inlet and the pressure outlet, produced gas enters the valve body from the pressure inlet and exits from the pressure outlet through the passage opening, the produced gas enters the pressure inlet with low pressure and exits from the pressure outlet with high pressure, the pressure inlet is provided with a throttling part I for throttling and depressurizing, a throttling part II for removing impurities of the produced gas through opposite flow is arranged at the passage opening, and the valve core is provided with a throttling part III which protects the valve core through staged depressurization.

Owner:四川长仪油气集输设备股份有限公司

Bridge plug with sand production prevention function for fracturing and using method thereof

ActiveCN111577199AReduce erosion damageSolve the problem of borehole sand pluggingFluid removalSealing/packingLine tubingExplosive material

The invention relates to the field of downhole pressure dividing tools for fracturing oil and gas fields, and particularly relates to a bridge plug with a sand production prevention function for fracturing and a using method thereof. The bridge plug comprises a center pipe, a seat sealing push cylinder, a base, a ball seat, a sealing rubber cylinder, a seat sealing cylinder, a locking part and anexplosive, wherein the outside of the center pipe is sequentially sleeved with the base, the locking part, the seat sealing push cylinder, the sealing rubber cylinder, the ball seat, the seat sealingcylinder and the explosive from bottom to top, the explosive, the seat sealing cylinder, the ball seat and the sealing rubber cylinder are in contact with each other, the lower end of the seat sealingpush cylinder is in contact with the locking part and is located in the locking part, the top end of the seat sealing push cylinder is located in the sealing rubber cylinder, and the inner circumferential surfaces of the explosive, the seat sealing cylinder, the ball seat, the sealing rubber cylinder and the seat sealing push cylinder are in clearance fit with the center pipe. According to the bridge plug, the problems of high-speed erosion damage of returned solid substance to a wellhead, an oil extraction pipeline and a gas pipeline and blockage of the inner diameter of a bridge plug by thereturned solid substance and the like are effectively solved, and the bridge plug capable of preventing blockage is achieved.

Owner:PETROCHINA CO LTD

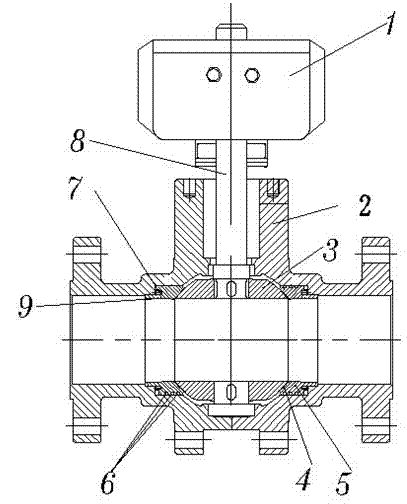

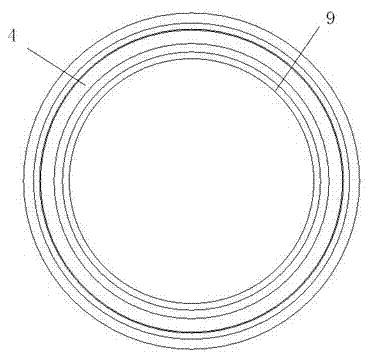

Ball valve with circular arc transition-type anti-erosion seal valve seat

InactiveCN103032599AReduce erosion damageExtended service lifePlug valvesValve members for absorbing fluid energyMaterial ErosionHeight difference

The invention discloses a ball valve with a circular arc transition-type anti-erosion seal valve seat. The ball valve comprises a drive mechanism, a valve body, a ball body and two valve seats with the same structure, wherein the ball body in the valve body is driven to rotate by the drive mechanism through a valve rod; the valve seats are arranged at a fluid inlet and a fluid outlet; each valve seat is provided with circular arc transition-type anti-erosion seal; an outer cylinder of the valve seat is in a step ring-shaped structure; the contact part of a big end and the ball body is in an arc surface; the middle part of the arc surface is provided with a layer of ring-shaped seal surface; the inner surface of the valve seat is provided with a circular arc transitional surface of the valve seat, wherein the diameter of one end of the circular arc transitional surface, close to the ball body, is small, and the diameter of one end of the circular arc transitional surface, far away from the ball body, is big; a ring-shaped groove is arranged on a connecting part of the circular arc surface at the contact part of the valve seat and the ball body as well as a small end of the inner surface of the valve seat; the outer ring of a big end of the valve seat is provided with a seal ring clamp groove; and a pretightening force spring is arranged in the spring clamp groove on a shoulder side of the valve seat. With the adoption of the ball valve with the circular arc transition-type anti-erosion seal valve seat, erosion corrosion of a medium to the ball body is prevented; the pretightening force between the valve seat and the ball body is increased because of the height difference generated by a circular arc inclination angle, and the ball valve seal performance is improved.

Owner:ZHEJIANG SCI-TECH UNIV

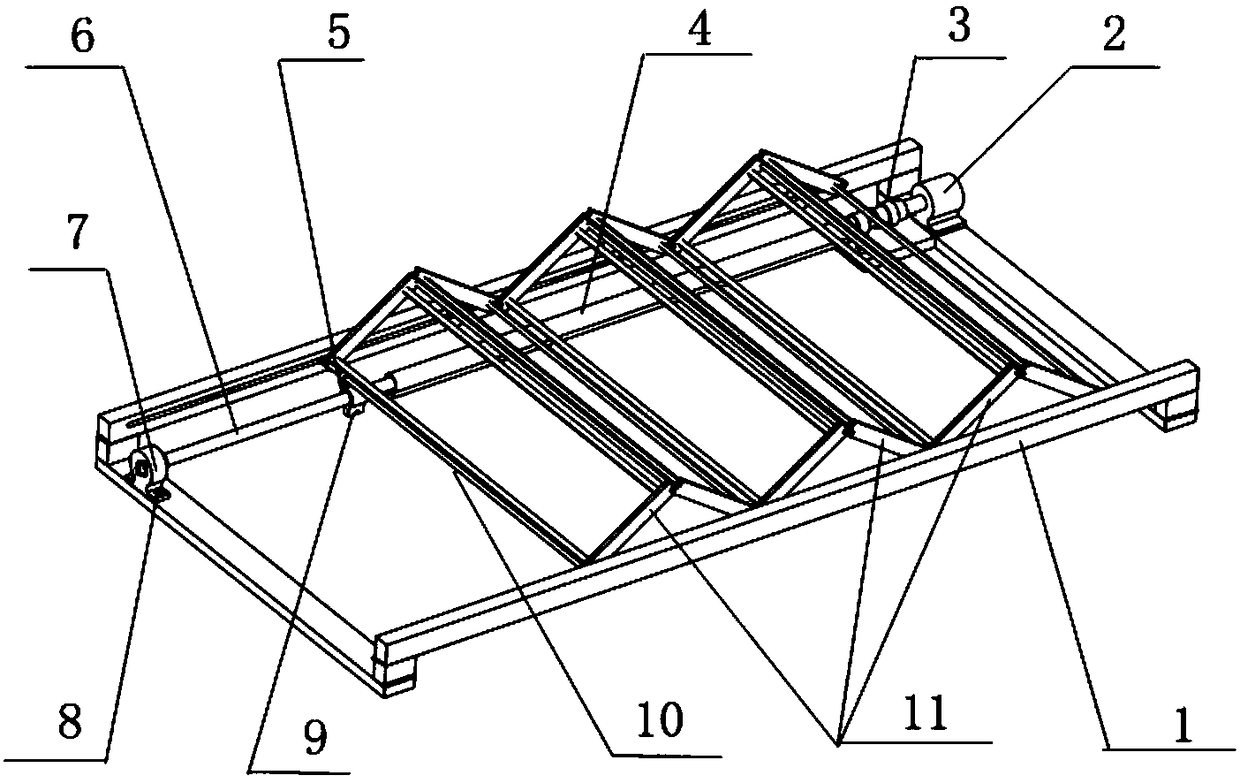

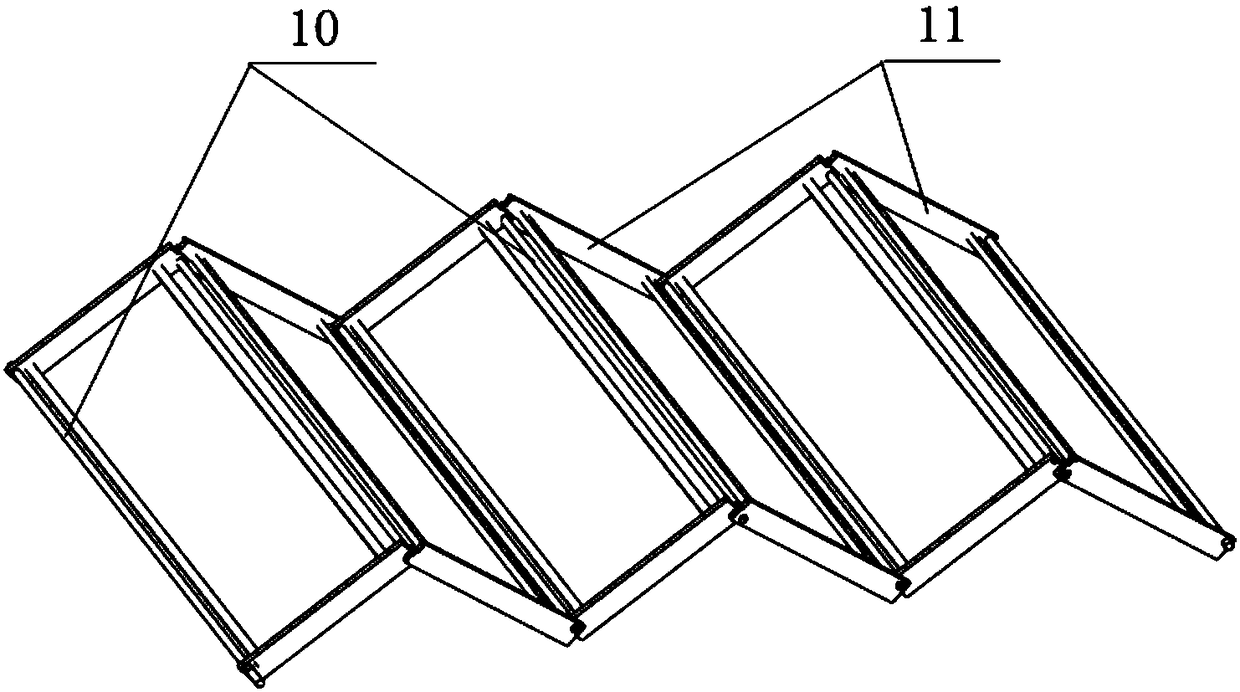

A non-full open foldable solar device

InactiveCN106369850BAvoid damageReduce erosion damagePhotovoltaic supportsSolar heating energyEngineeringScrew thread

The invention relates to a non-fully open foldable solar device, which is composed of a track chassis, a motor, a connecting piece, a lead screw, a slider and a foldable truss; the lead screw is arranged inside the track chassis, and one end thereof is supported by One end of the foldable truss is hinged to the track underframe, the other end is connected to the connector, and the connector is connected to the slider. The slider fits on the lead screw and fits with the lead screw thread; the foldable truss is formed by hinged joints of multiple single girders in turn, and any hinge of the single girders is equipped with an angle limit mechanism, and the angle limit mechanism The included angle between any two adjacent single girders can be limited, and the single girders are provided with solar photovoltaic panels. According to the external environment, the single girder plate of the present invention can be unfolded or folded at any angle, satisfying energy conversion under different conditions, and reducing damage to the device by the external environment.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com