Ultrahigh-performance concrete waterproof composite liquid and preparation method thereof

A technology of ultra-high-performance composite fluid, which is applied in the preparation of the concrete waterproof composite fluid, and in the field of ultra-high-performance concrete waterproof composite fluid, can solve the problems of remote location, inconvenient transportation, and difficult design ideas to reduce erosion damage , Reduce slump loss, improve water retention and segregation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention further provides a preparation method of the ultra-high performance concrete waterproof composite liquid, comprising the following steps:

[0032] (1) dissolving the soluble aluminum salt in water to obtain an intermediate product;

[0033] (2) adding a silane coupling agent to the intermediate product, heating, then adding an antioxidant and a stabilizer, and stirring at a constant temperature to obtain a concrete waterproof composite liquid.

[0034] In one embodiment of the present invention, in step (2), the heating temperature is 60-80° C., and the heating time is 20-30 minutes.

[0035] In one embodiment of the present invention, in step (2), the constant temperature stirring time is 60-120 min.

[0036] In a specific embodiment of the present invention, dissolve soluble aluminum salt in water, then add silane coupling agent, stir and heat up to 60-80°C, continue stirring for 20-30min, then add antioxidant and stabilizer, stir at constant te...

Embodiment 1

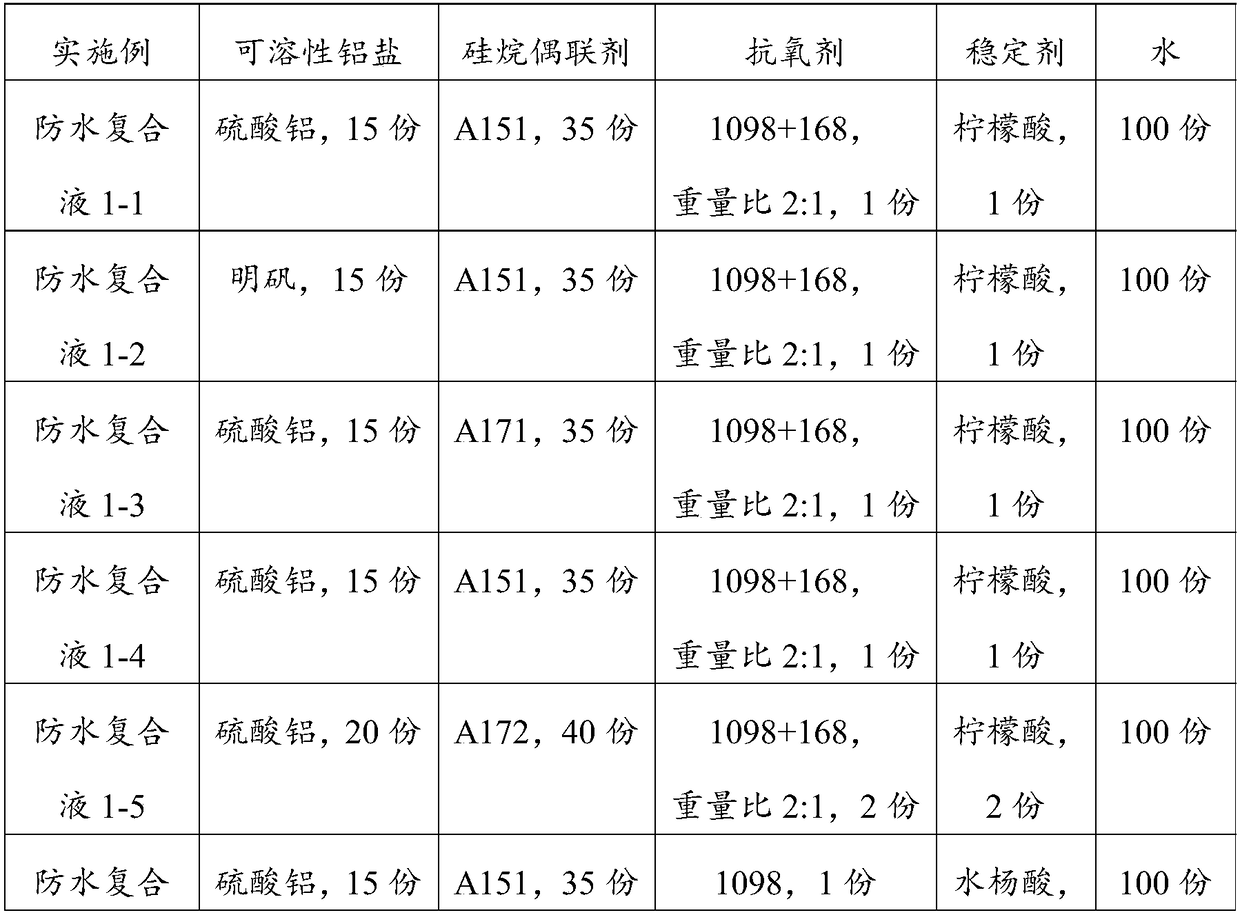

[0050] Dissolve soluble aluminum salt in water, then add silane coupling agent, stir and heat up to 70°C, continue stirring for 20 minutes, add antioxidant and stabilizer, and stir at constant temperature for 60 minutes to obtain concrete waterproof composite liquid. The composition and parts by weight of each material are shown in Table 1.

[0051] Table 1

[0052]

[0053]

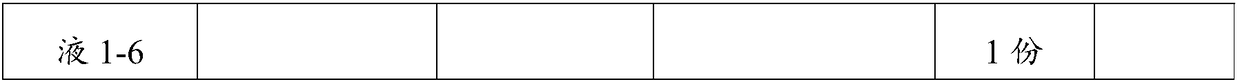

[0054] The waterproof compound liquid is used in concrete, and the composition of the concrete is: relative to 1000 kg of stones, the amount of Portland cement is 600 kg, the amount of sand is 400 kg, the amount of water is 200 kg, and the amount of waterproof compound liquid is 10 kg , the consumption of phenolic fiber is 20kg.

[0055] The waterproof composite liquid 1-1 to the waterproof composite liquid 1-6 are used in concrete to obtain concrete 1-1 to concrete 1-6. The mixing method is as follows: mix the above-mentioned stones, portland cement, sand, water, and waterproof compound liquid a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com