Patents

Literature

263 results about "Erosion corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Erosion corrosion is a degradation of material surface due to mechanical action, often by impinging liquid, abrasion by a slurry, particles suspended in fast flowing liquid or gas, bubbles or droplets, cavitation, etc. The mechanism can be described as follows...

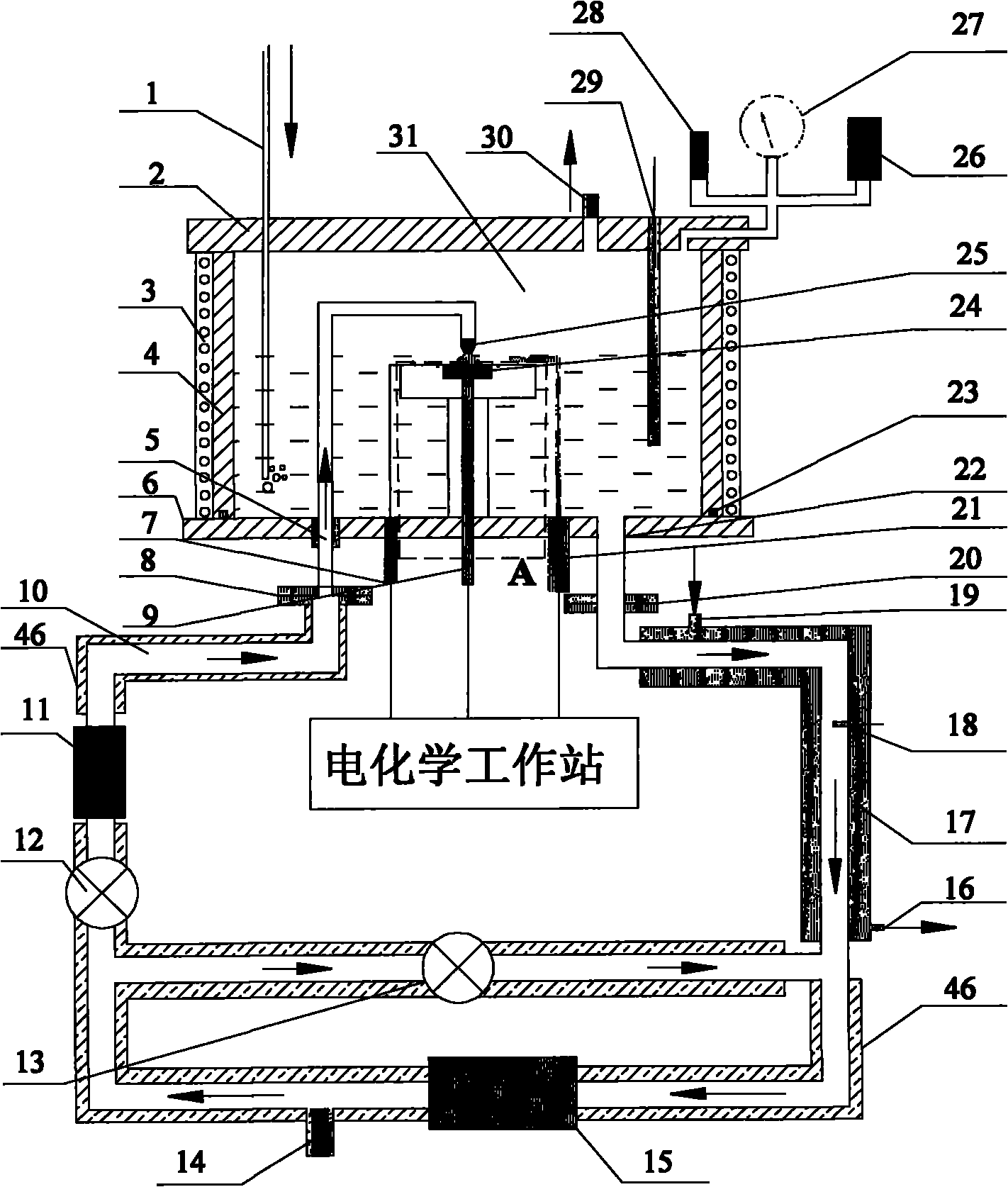

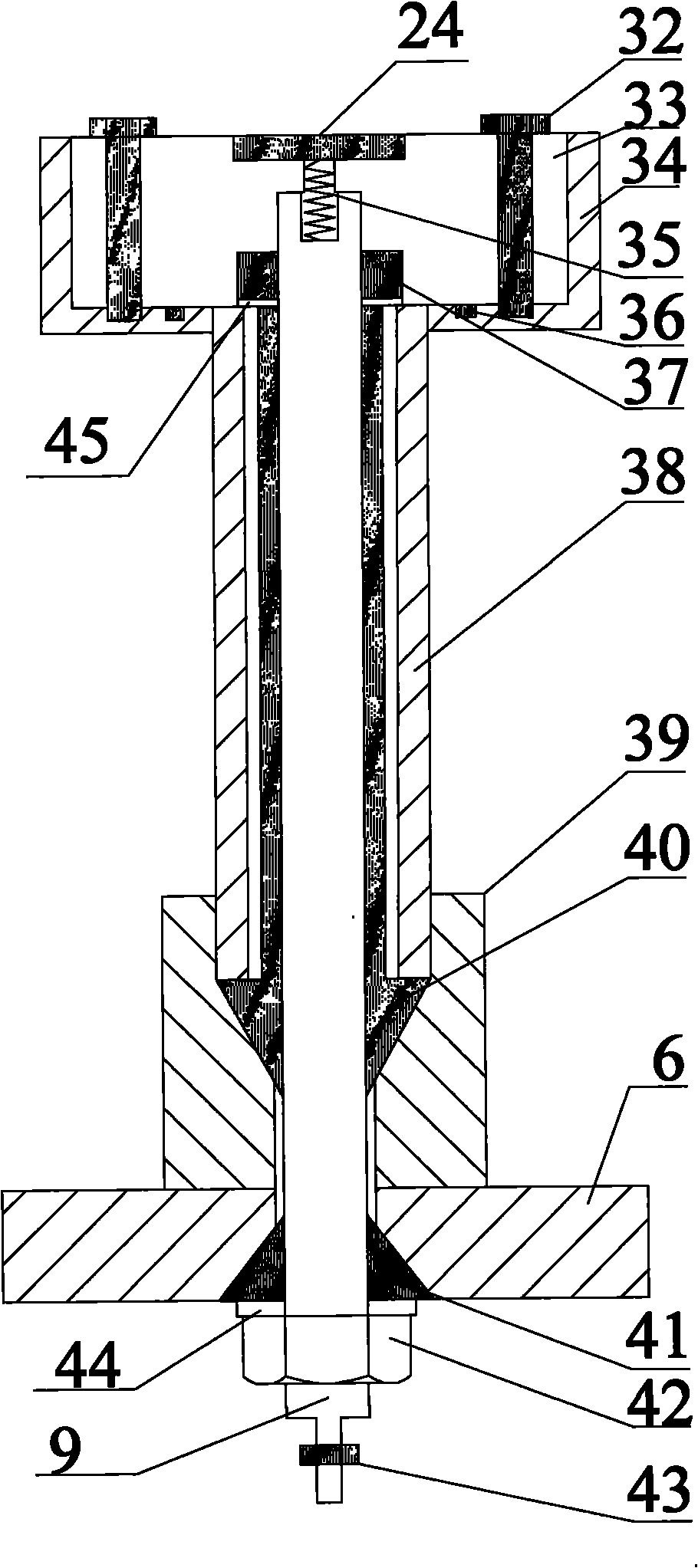

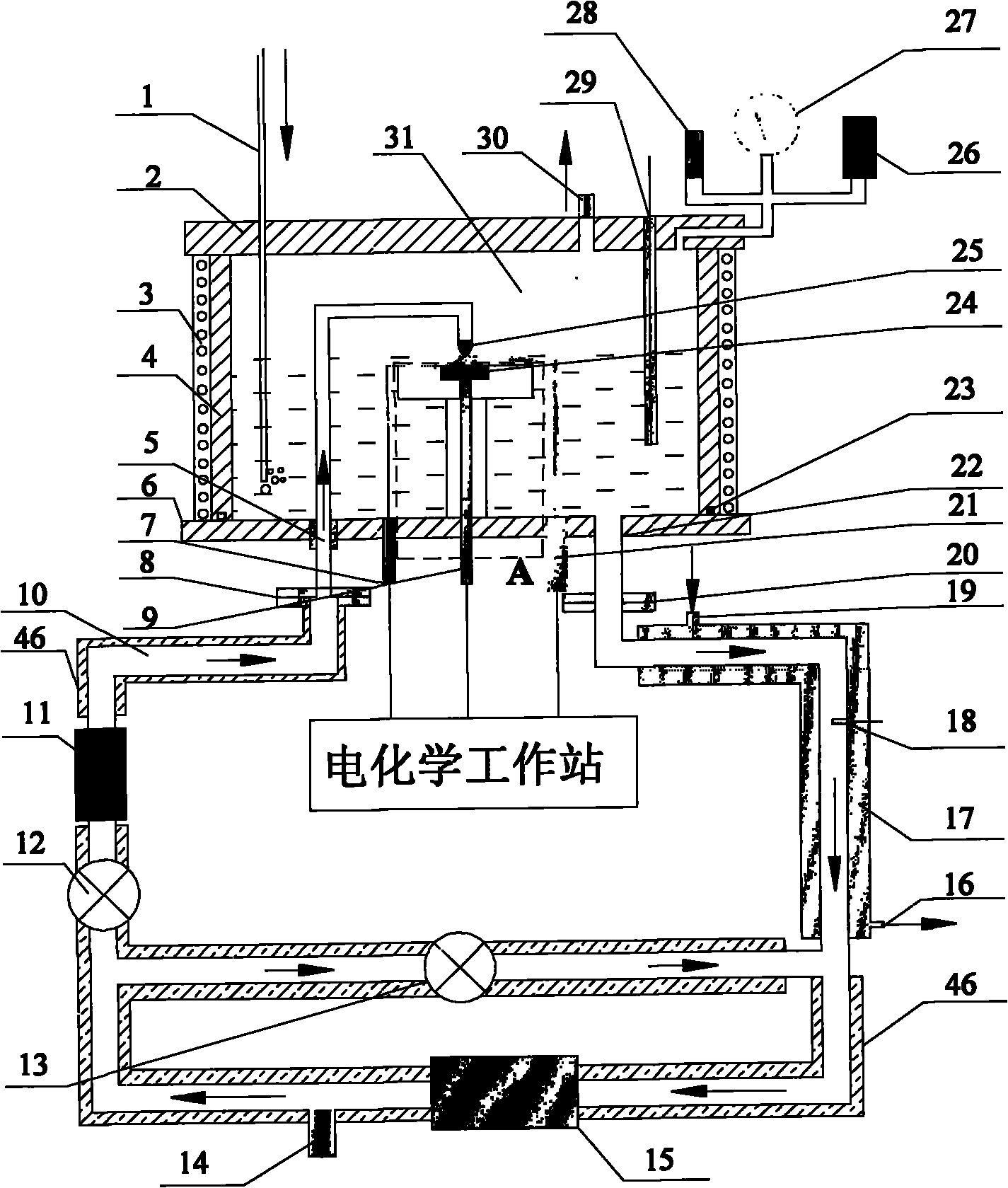

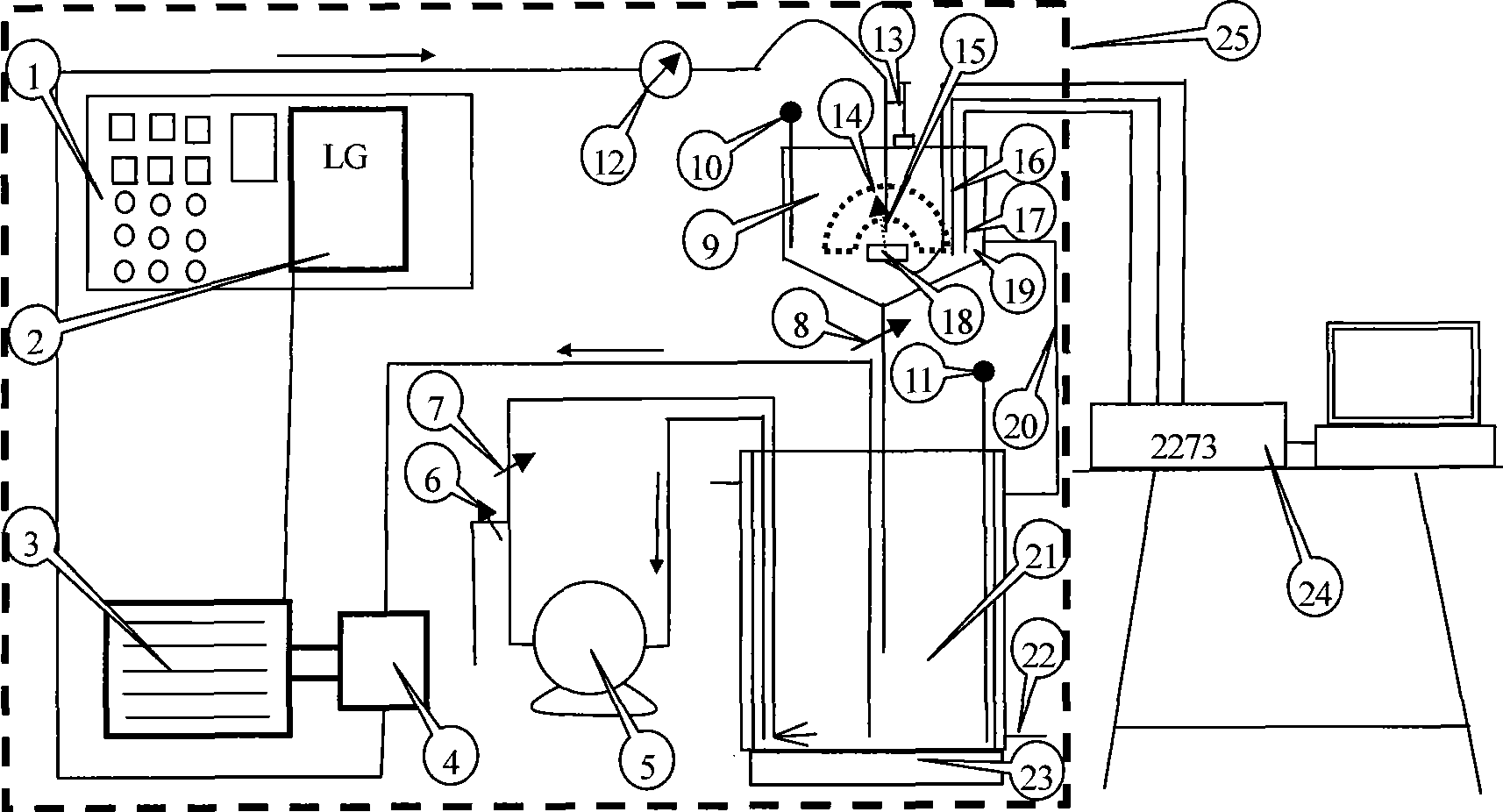

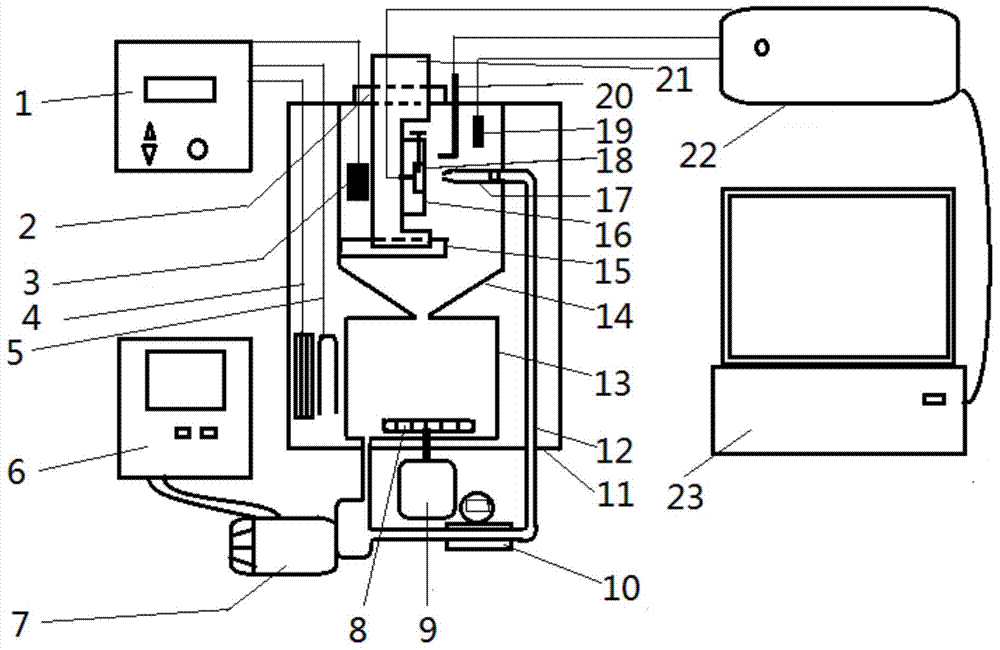

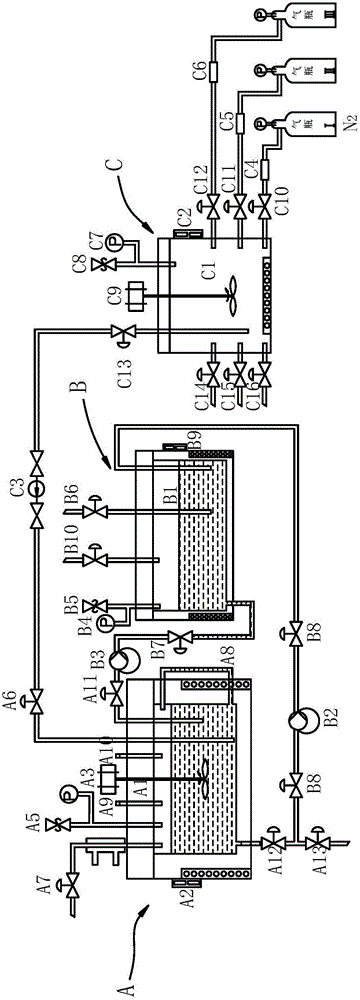

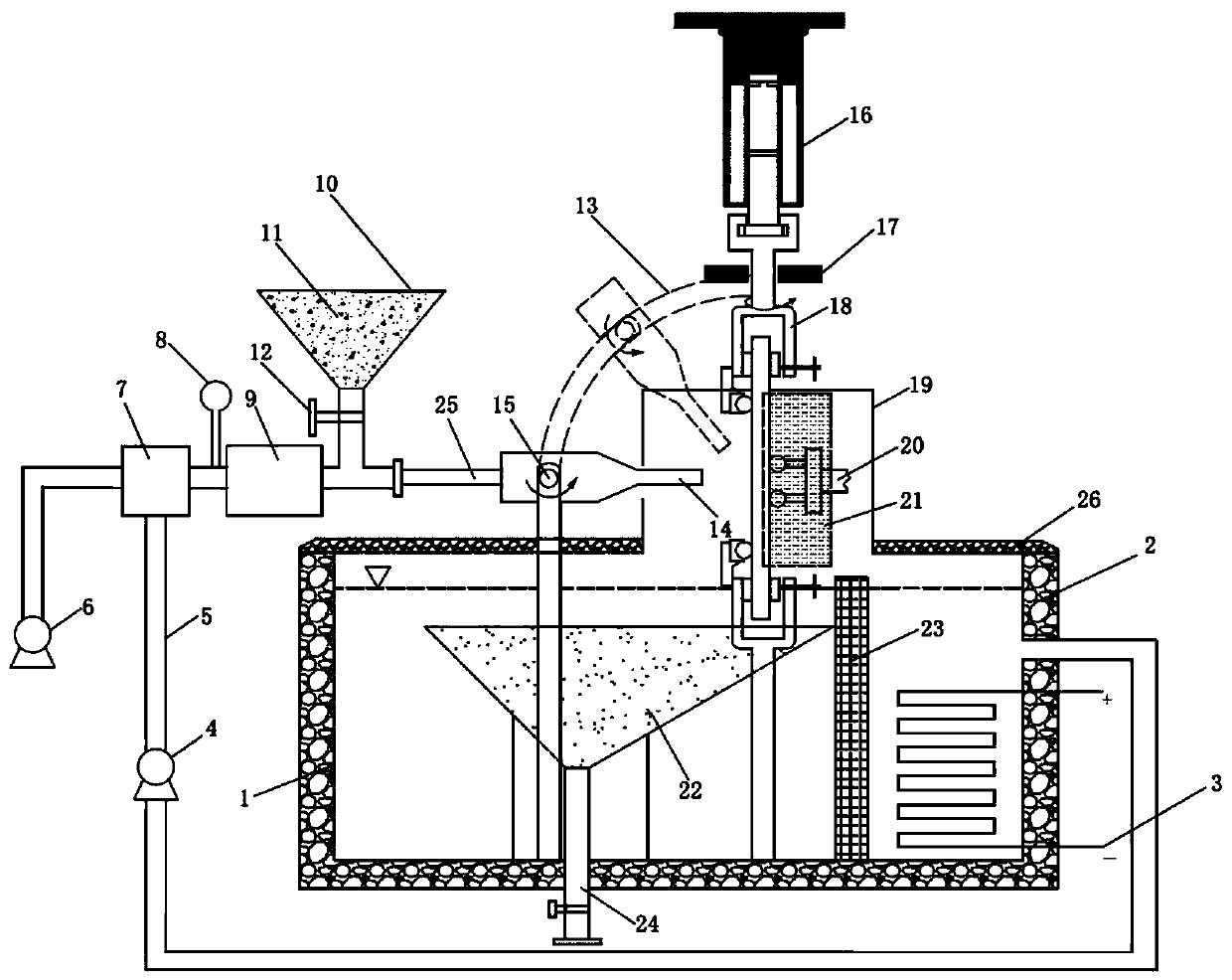

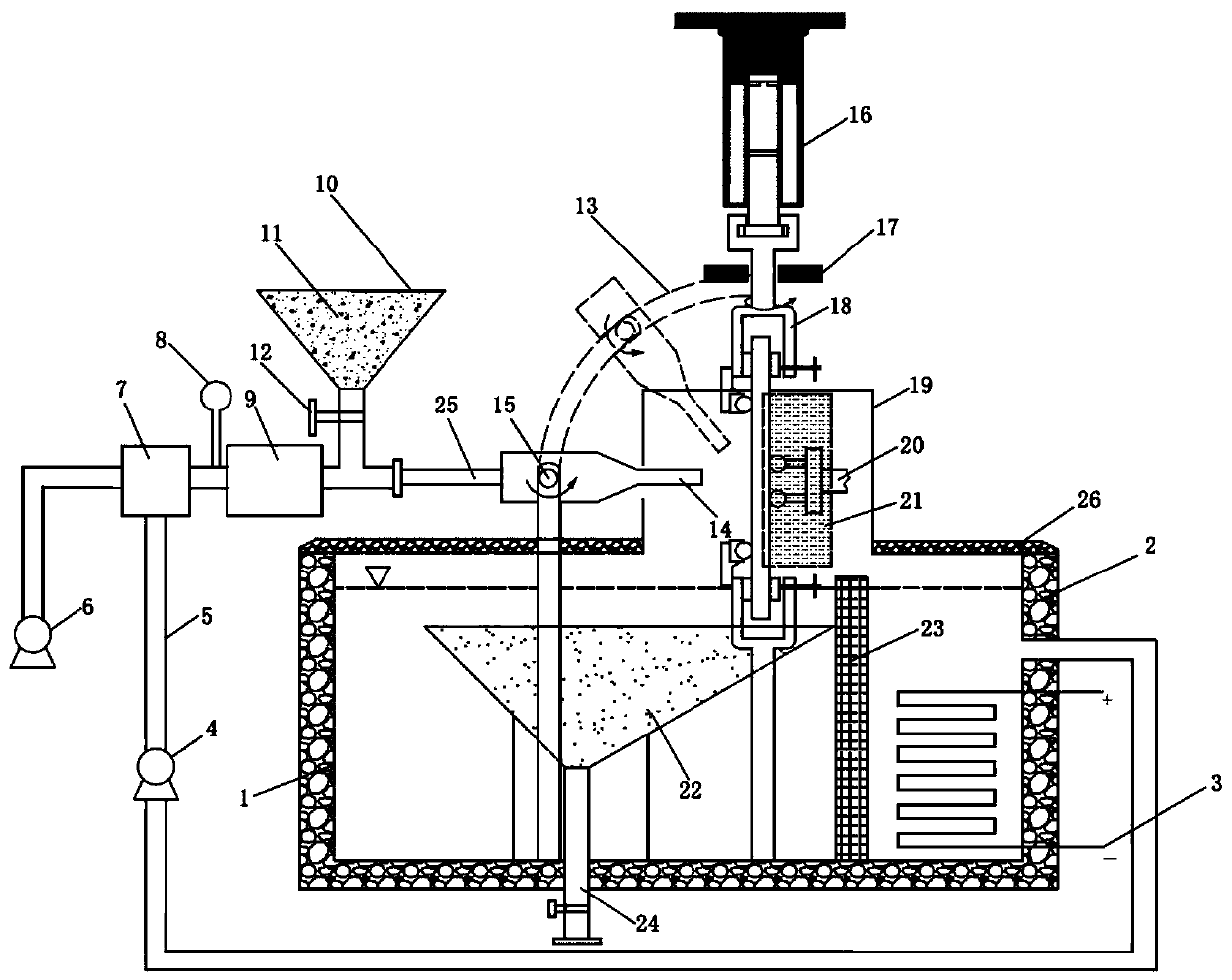

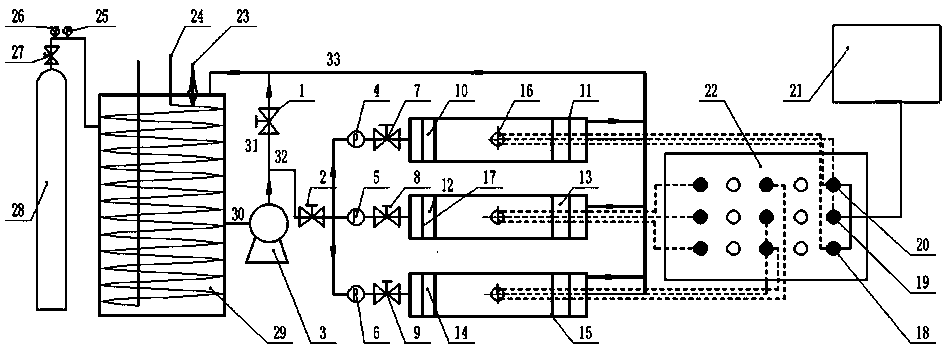

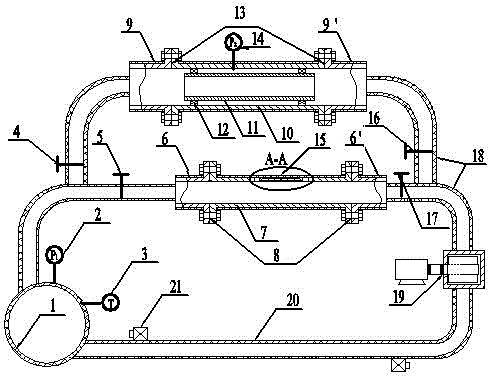

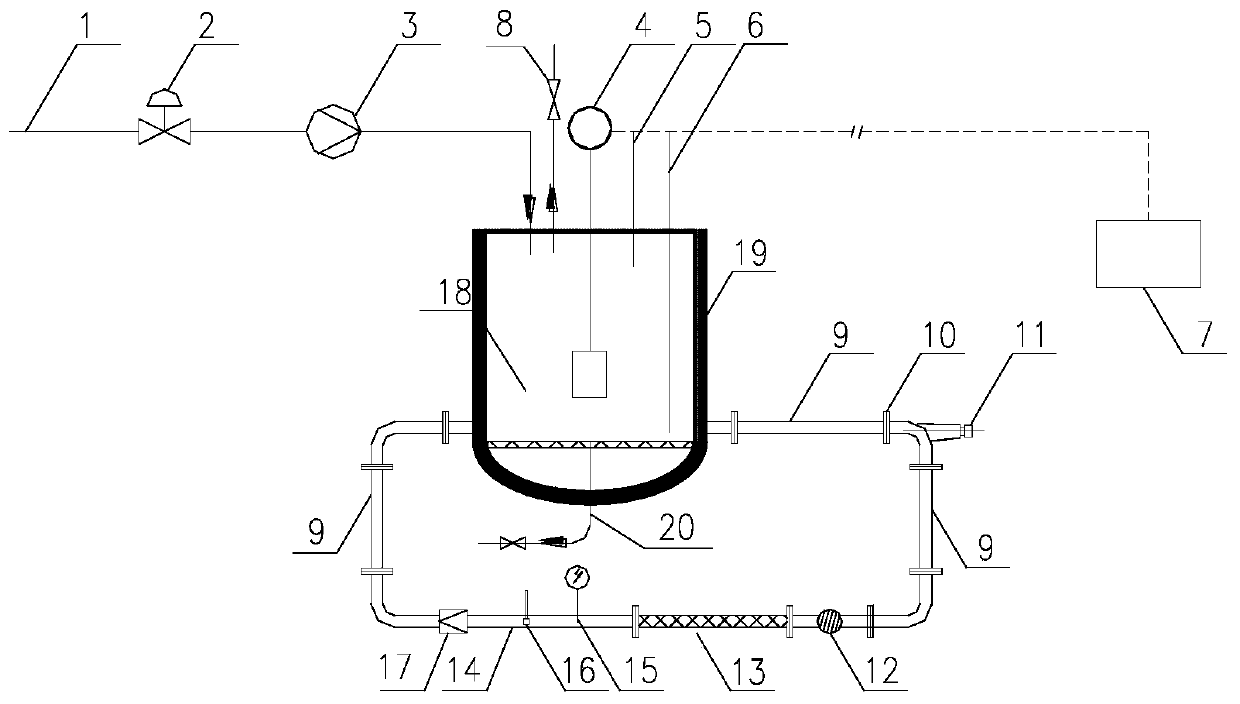

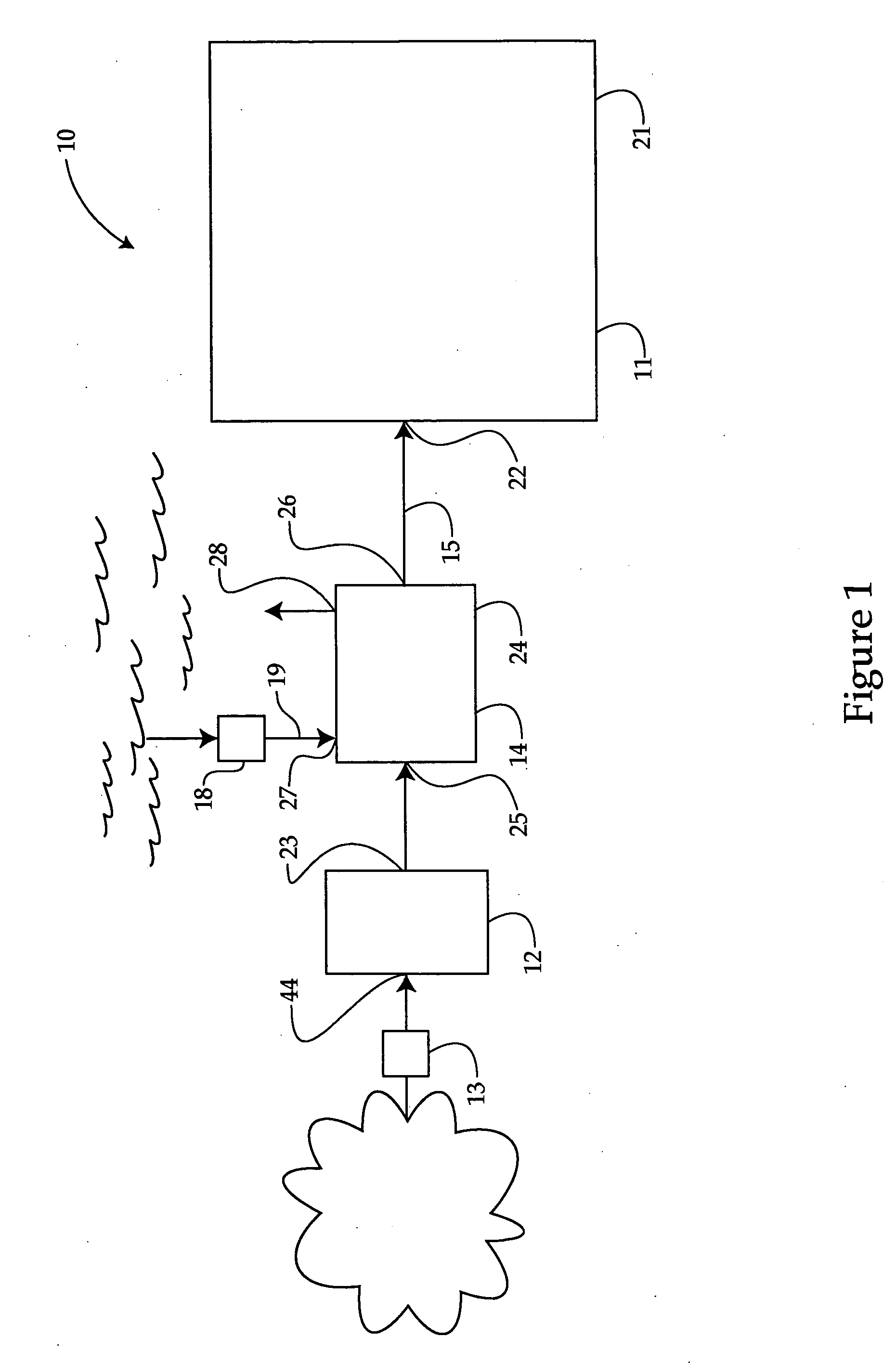

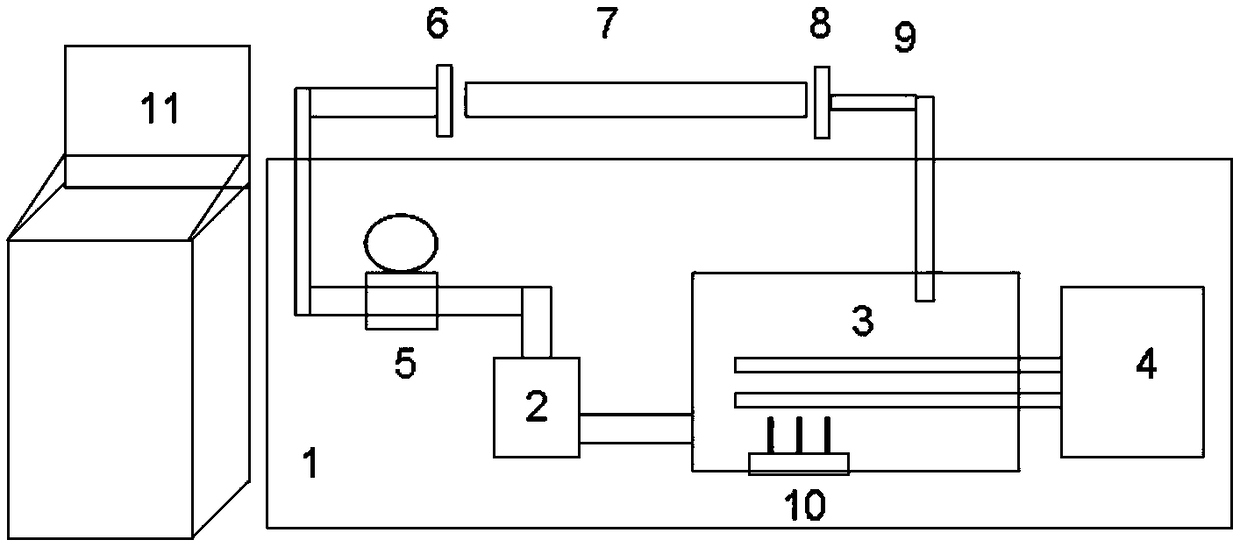

Experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing

The invention discloses an experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing, belongs to the electrochemical field, and is particularly suitable for simulation experiment of erosion corrosion caused by simulating the complex components such as elbow, tee and the like in petroleum and gas collection pipes, petroleum and gas conveying pipes and the like so as to convey the high-temperature high-pressure multi-phase fluid pipe components and in-situ electrochemical signal testing of the erosion corrosion of high-temperature high-pressure fluid under erosion conditions. The apparatus comprises a high pressure kettle, a circulating loop, a high-temperature high-pressure flow gauge, a vortex pump, a control box, a circulating condensation system, a three-electrode system, a signal conduction path, an external electrochemical work station and a high pressure gas bottle. The apparatus has the advantages of simulating the erosion corrosion condition of the fluid medium in the oil and gas pipeline well, testing the electrochemical signal of the working electrode under high-speed spray condition such as polar curve, AC impedance and the like and having important significance to the research of the erosion corrosion action, rule and mechanism of the high-temperature high-pressure fluid.

Owner:UNIV OF SCI & TECH BEIJING

Antiseptic wearable coat and coating method thereof

ActiveCN101191225ATo achieve the purpose of corrosion resistance and wear resistanceEasy to operateMetallic material coating processesRheniumThermal spraying

The invention discloses a corrosion and abrasion resistant coating and a coating method thereof, comprising: firstly, weight percentage of compositions of coating materials adopted is that: carbon: less than or equal to 0.5 percent; chromium: 16 to 26 percent; nickel: 3.5 to 9.5 percent; molybdenum: 1.0 to 4.0 percent; boron: 0.5 to 4.5 percent; silicon: 0.5 to 4.5 percent; copper: 1.0 to 4.0 percent; manganese: 0 to 2.0 percent; rare earth - rhenium: 0.01 to 1.5 percent; the residual is ferrum and inevitable impurities; secondly, pretreatment of the surface of a metallic matrix reaches technological demand; thirdly, thermal spraying is adopted on the matrix surface; a plurality of air cooling nozzles surrounding a spray gun which are in parallel with spraying flame velocity are arranged on the spray gun; travel rate of the spray gun is 150 to 400 millimeters per second; surface temperature of workpieces is controlled to be less than 150 DEG C; an amorphous stainless steel protective coating is formed on the matrix surface finally; fourthly, sundries on the coating surface are cleaned, and the coating is performed sealing treatment. The invention solves the protective problem of erosion-corrosion under the condition of acid humid environment and that Cl<-> ions and dust particles exist.

Owner:BAOSHAN IRON & STEEL CO LTD

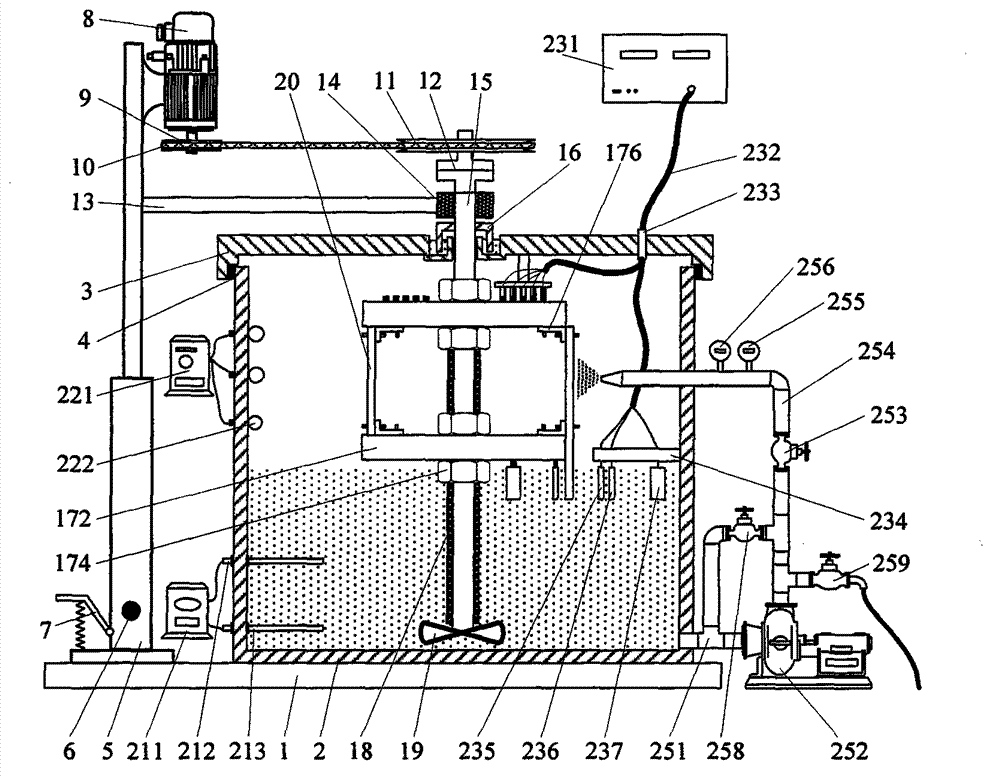

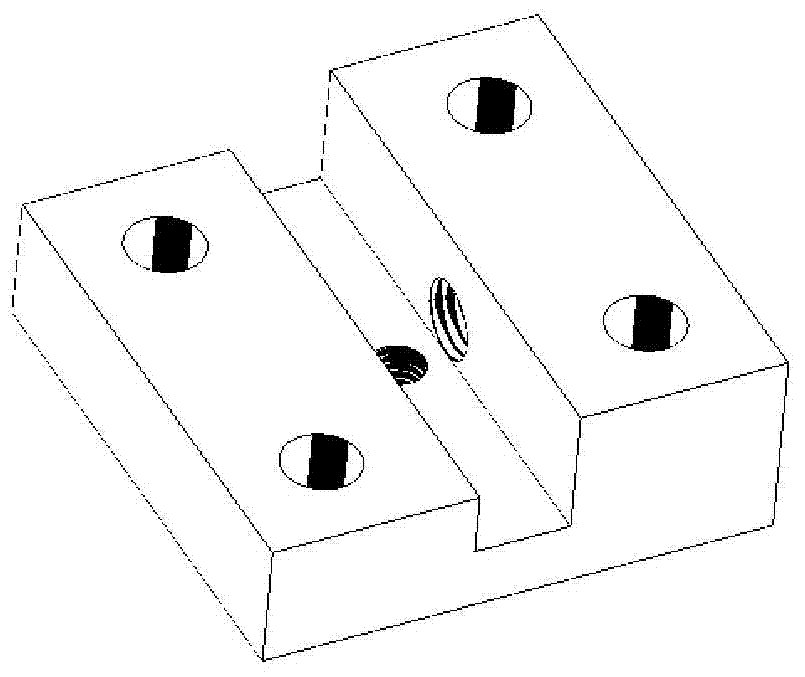

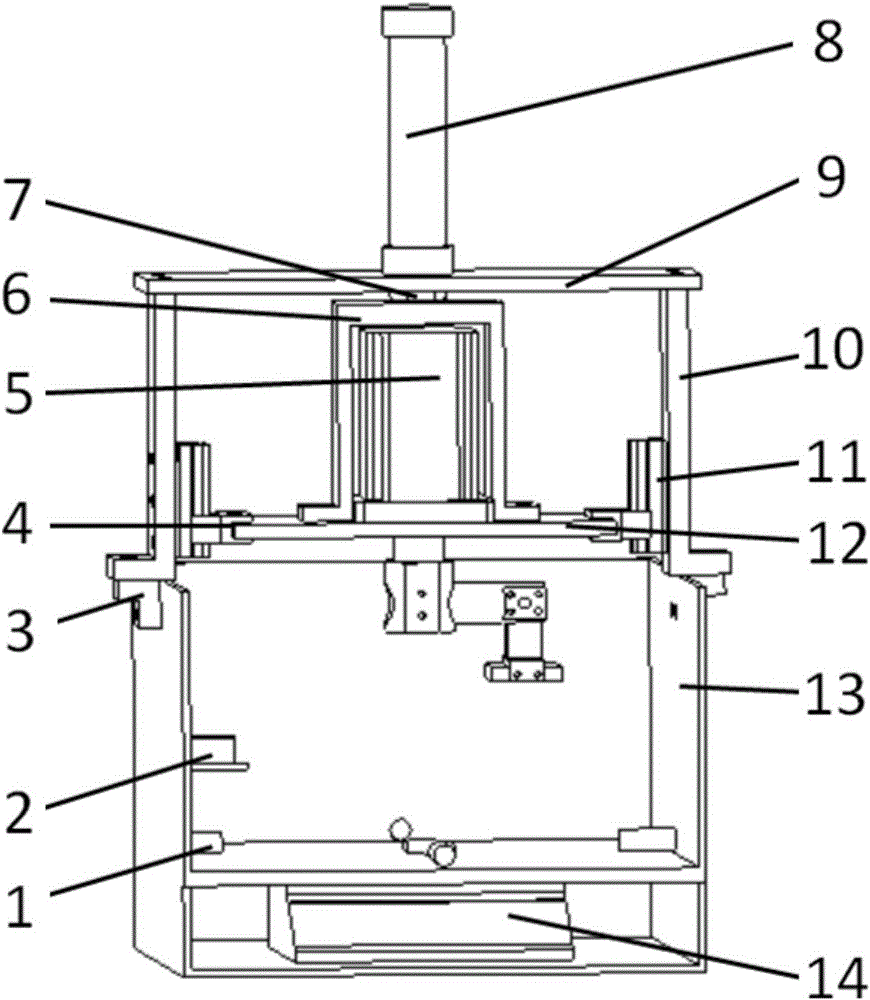

Erosion-corrosion experiment device for simulating spray splashing area

InactiveCN104849198AClarify the law of actionWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceElectricityTemperature control

The invention discloses an erosion-corrosion experiment device for simulating a spray splashing area. The experiment device is supported by a base and comprises a lifting system, a sample clamping system, a power system, an injection system, an ultraviolet illumination aging system, an electrochemical testing system and a temperature control system, wherein a hydraulic lifting frame is fixedly arranged on the base and is controlled to ascend or descend by a pedal or a pressure relief knob; the sample clamping system and the power system are mounted on the hydraulic lifting frame; a medium groove is formed in one side of the hydraulic lifting frame; the sample clamping system is arranged inside the medium groove; the upper part of the medium groove is sleeved by a sealing cover, and the sealing cover and the medium groove are sealed through a rubber sealing ring. According to the erosion-corrosion experiment device, the influence on a material erosion-corrosion behavior caused by factors such as wave impact strength, impact period, sand content, oxygen content, temperature and illumination can be researched, the failure process of an ocean spray splashing area structure is accurately simulated, and the defects of a conventional material erosion-corrosion research device for simulating a splashing area are overcome.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

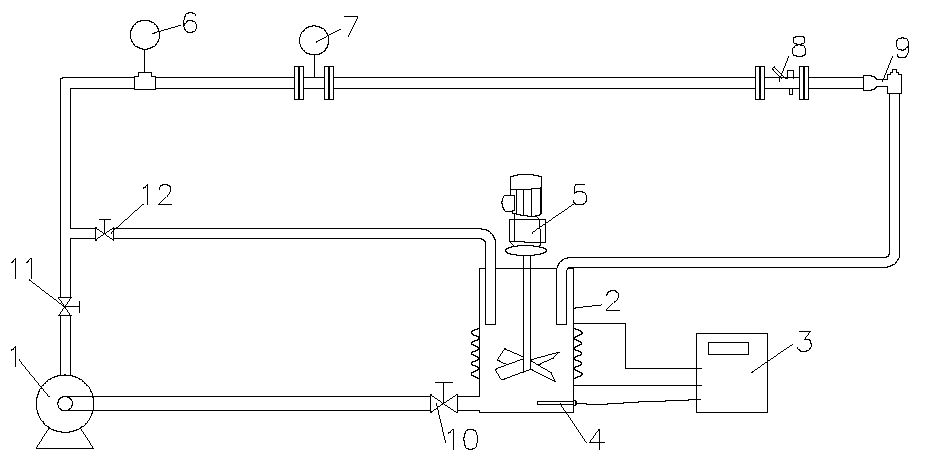

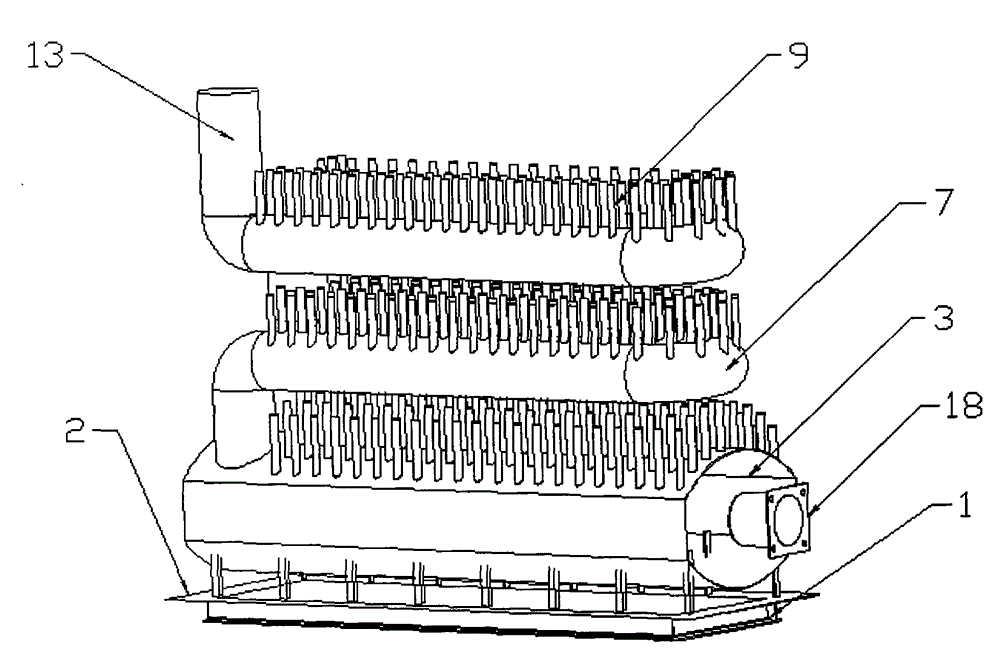

Multiphase flow erosion local corrosion testing apparatus

InactiveCN103234894AReduce volumeSimple structureWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceMaterial ErosionEngineering

The invention relates to a multiphase flow erosion local corrosion testing apparatus. The testing apparatus comprises an ore pulp pump, a slurry tank, a stirrer, a pressure gage, an electromagnetic flowmeter, a pipe flow erosion pipe section, a jet flow erosion pipe section, a thermocouple and a low temperature constant temperature circulator. The testing apparatus is characterized in that the stirrer is arranged above the slurry tank, the thermocouple is mounted in the slurry tank and is connected with the low temperature constant temperature circulator, the bottom end of the slurry tank is connected with the ore pulp pump through a feed pipe, a ball valve is installed on the feed pipe, an outlet pipe of the ore pulp pump is provided with a first stop valve and is divided into two paths through the stop valve, one path returns to the slurry tank after passing through a second stop valve, and the other path returns to the slurry tank after passing through the pressure gage, the electromagnetic flowmeter, the pipe flow erosion pipe section and the jet flow erosion pipe section. According to the invention, characteristics of pipe flow and jet flow erosion-corrosion testing machines are combined, pipe flow erosion and jet flow erosion local corrosion tests can be simultaneously or individually carried out, and the testing apparatus has the characteristics of a small size, a simple structure, low manufacturing cost and good operationality.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

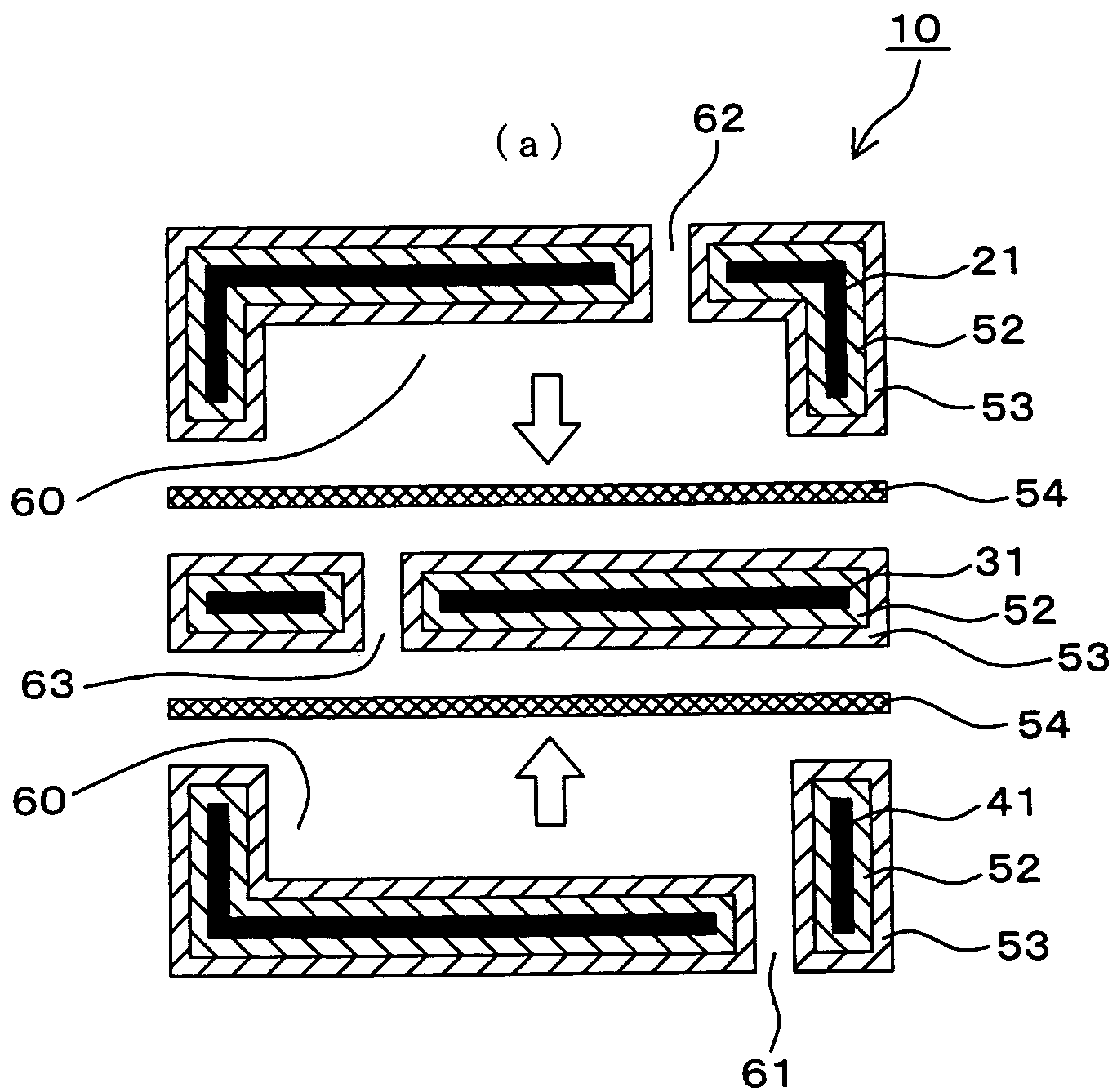

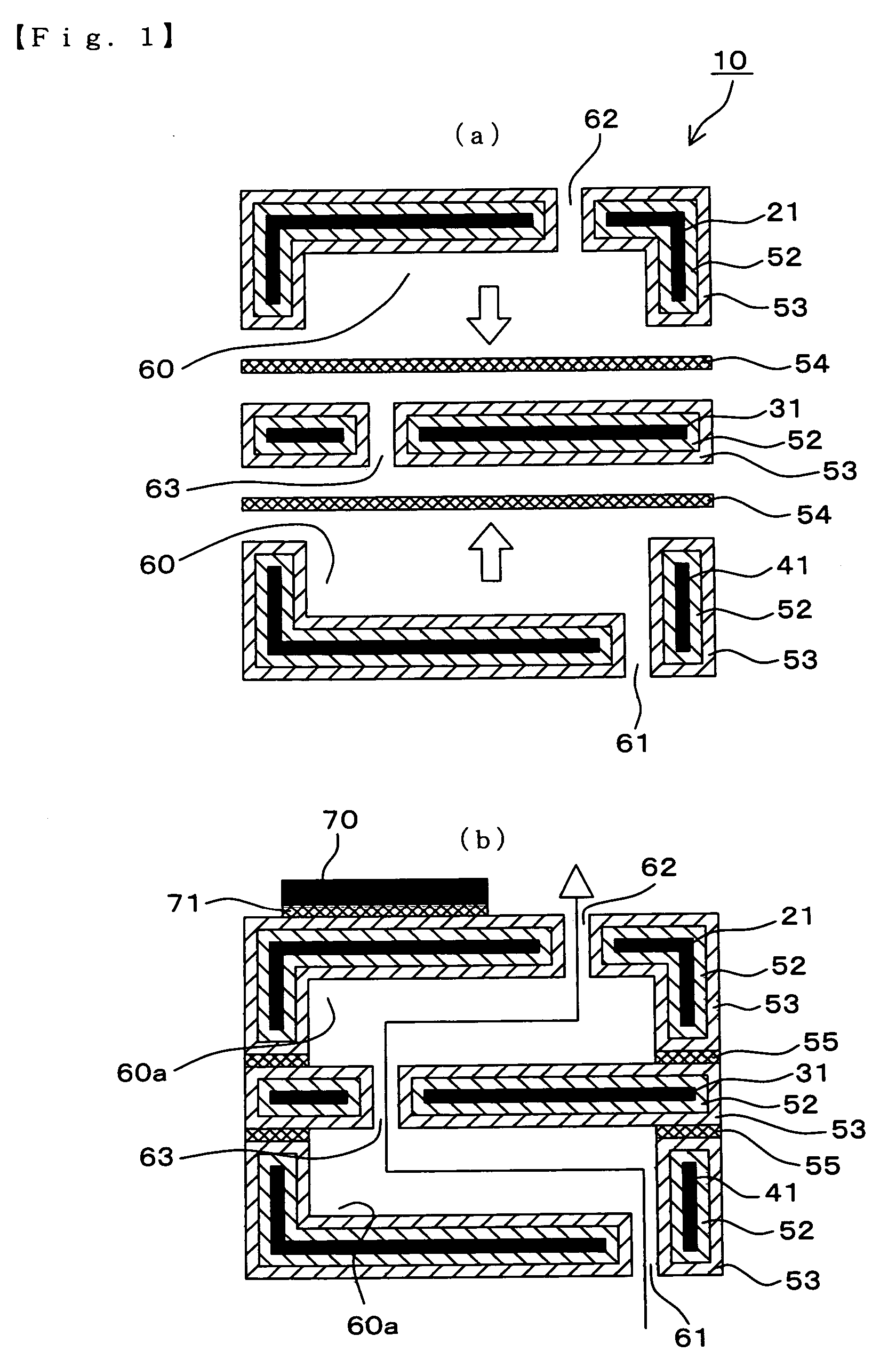

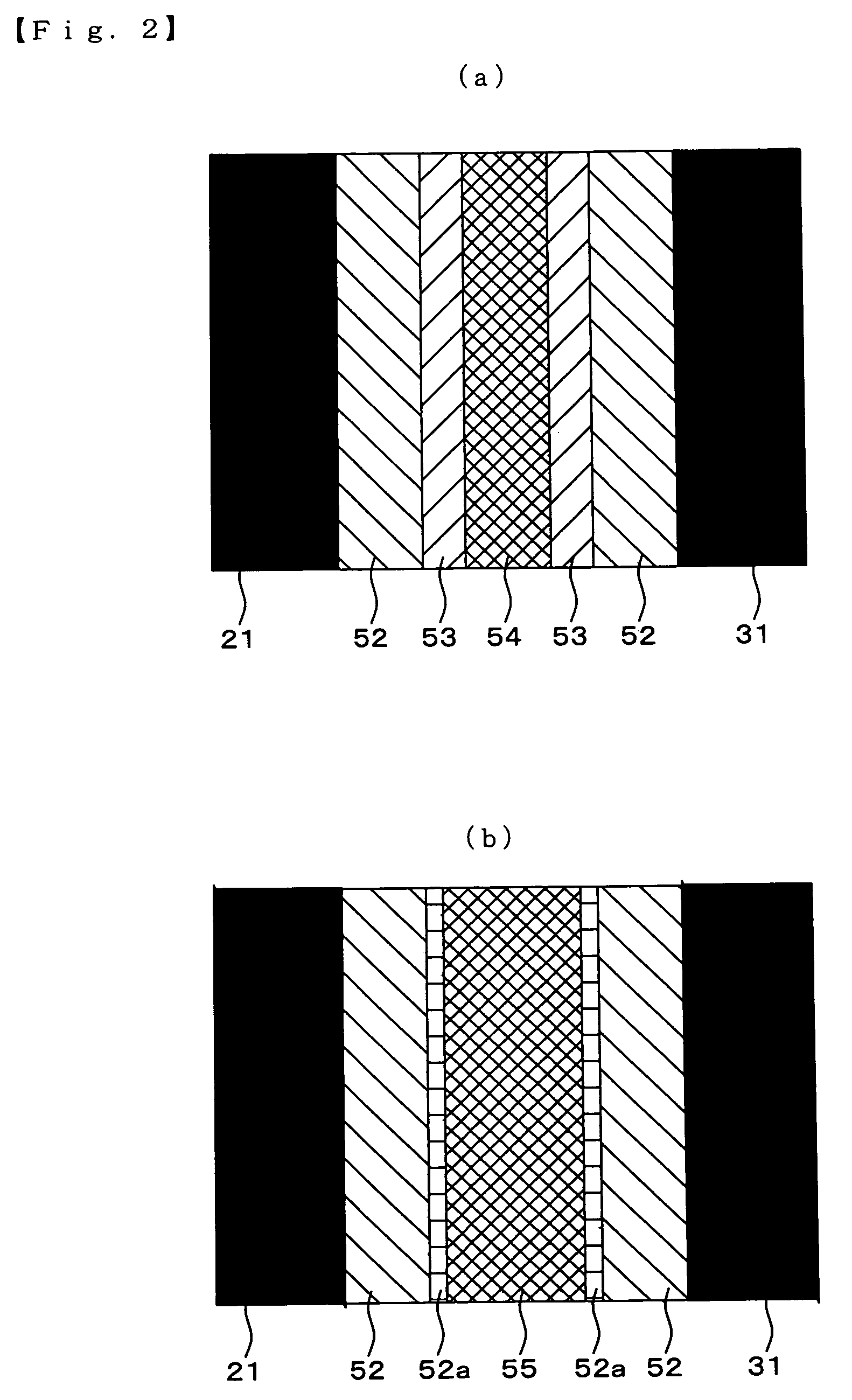

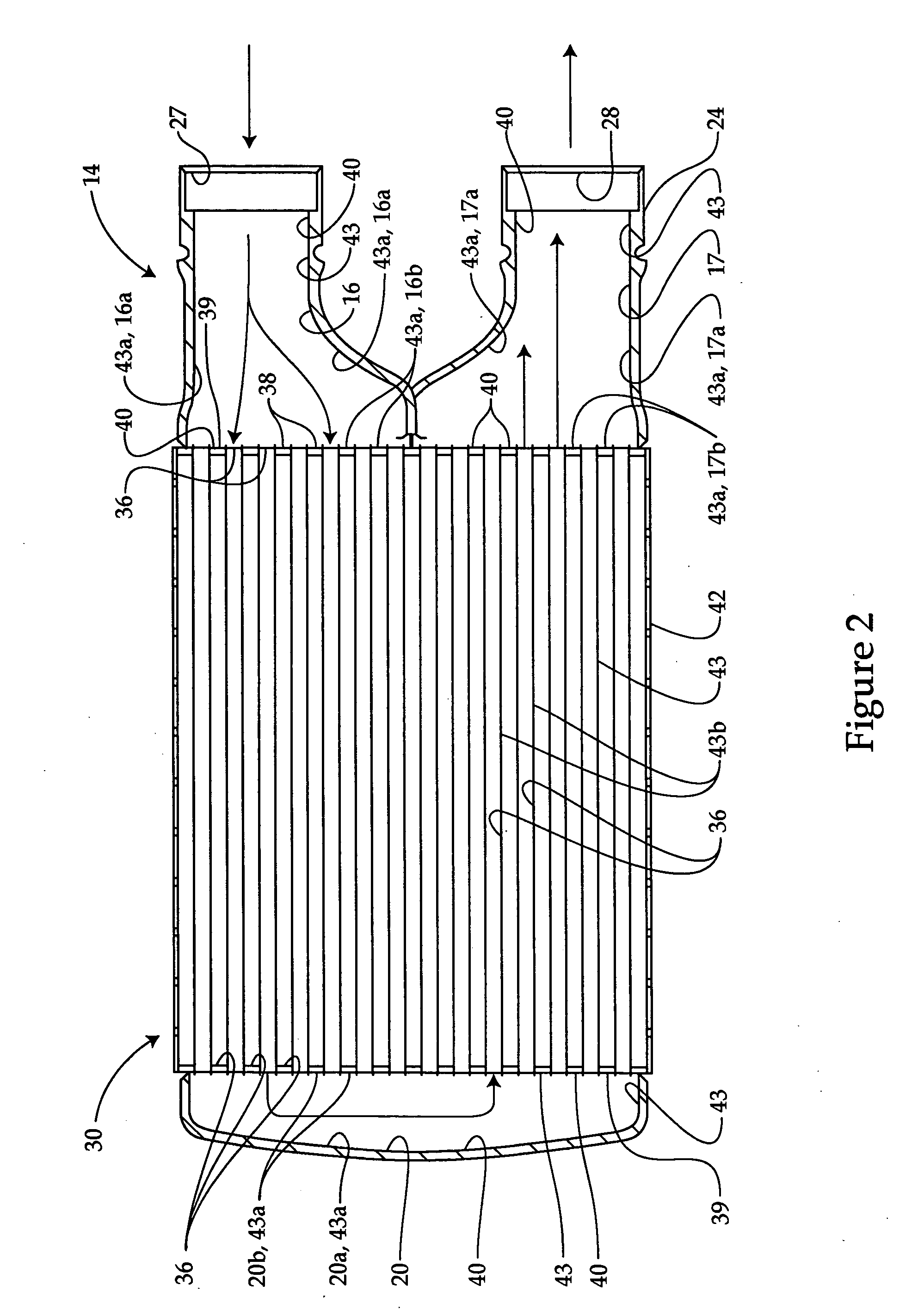

Heat sink and method for its production

ActiveUS20050063161A1High trafficIncrease pressureSemiconductor/solid-state device detailsSolid-state devicesEtchingMaterial Erosion

The present invention provides a liquid-cooling type heat sink which has a high pressure-resistibility and is resistible against the corrosion or erosion-corrosion or electrolytic etching, and a method for its production. The heat sink of the present invention comprises plural base members 21, 31 and 41, the base member being each in plate or block-shape, the base member each having paths 60 shaped on one or both sides of surfaces thereof, and the base members being bonded to each other, wherein a communicating flow path 60a including path 60, through holes 61, 62, and 63, is formed for a cooling medium to flow in and out. The base members are bonded to each other with a solder layer 54 made of Au—Sn alloy or Sn, while a coating layer of Au 53 is formed on each of the inner surfaces of the bonded base members. At the time of making a bond between the base members, the coating layer of Au 53 and the solder layer 54 are diffused to each other, resulting in formation of a bond layer of alloy 55 containing at least 91 wt % of Au and at most 9 wt % of Sn.

Owner:TECNISCO +1

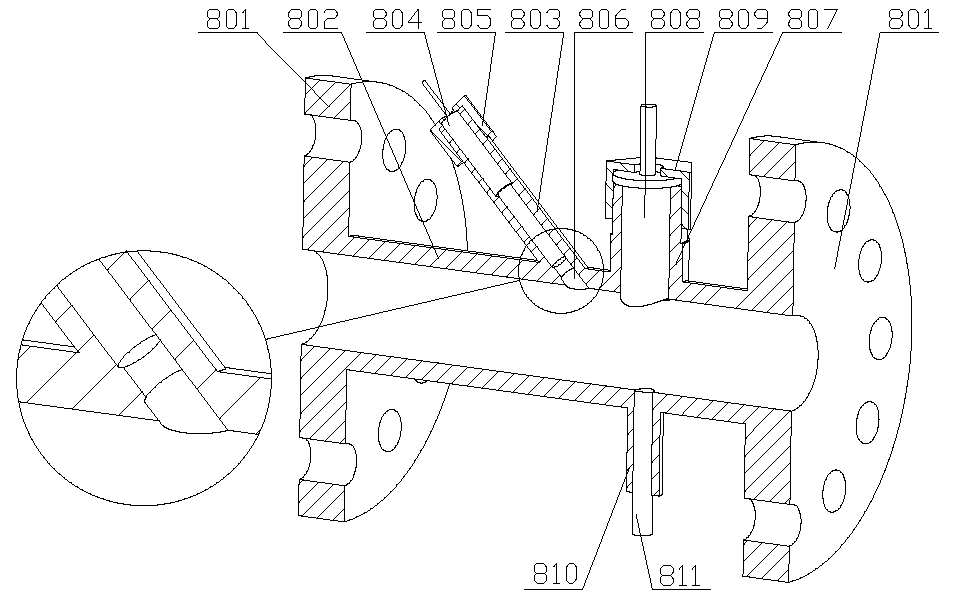

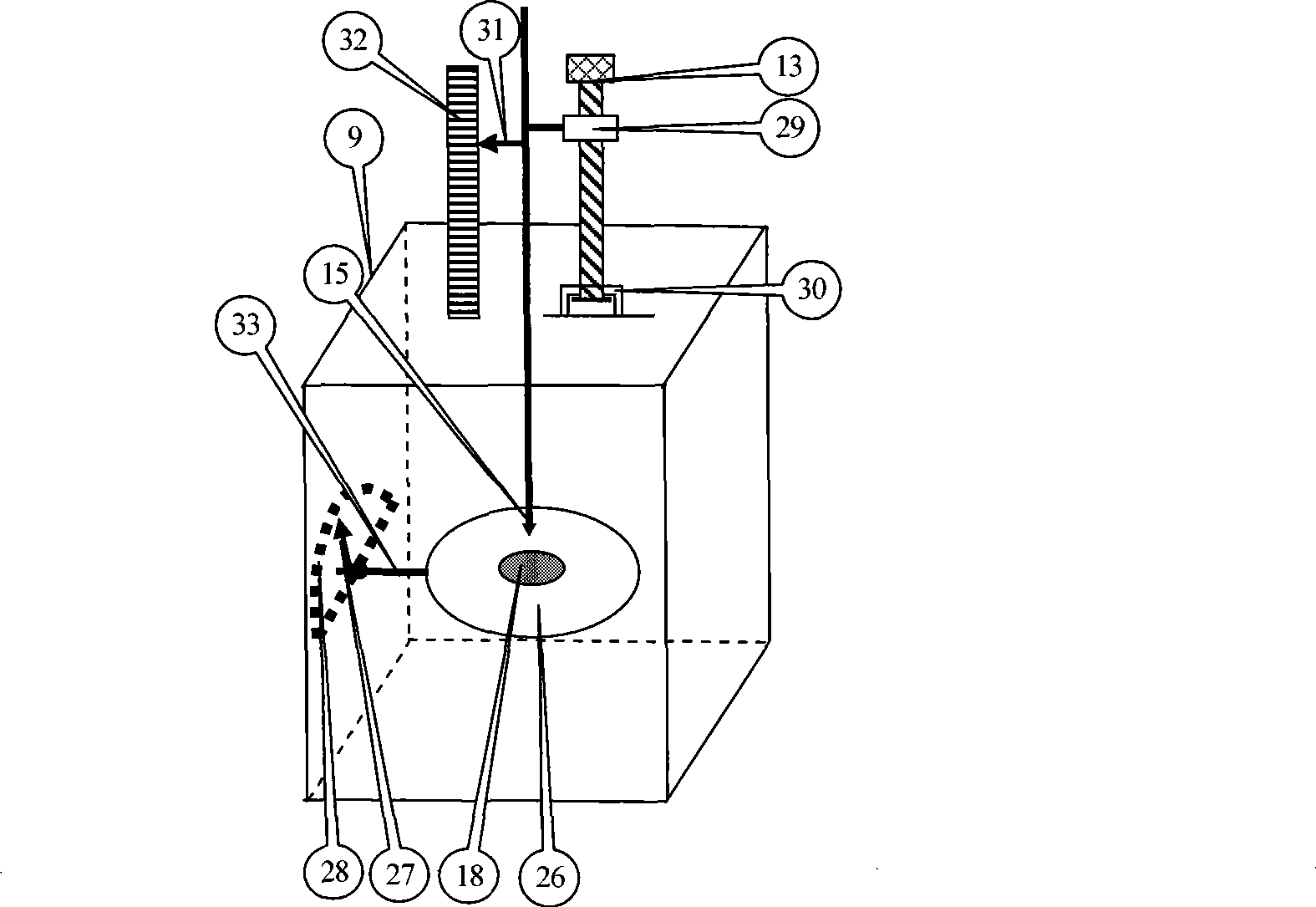

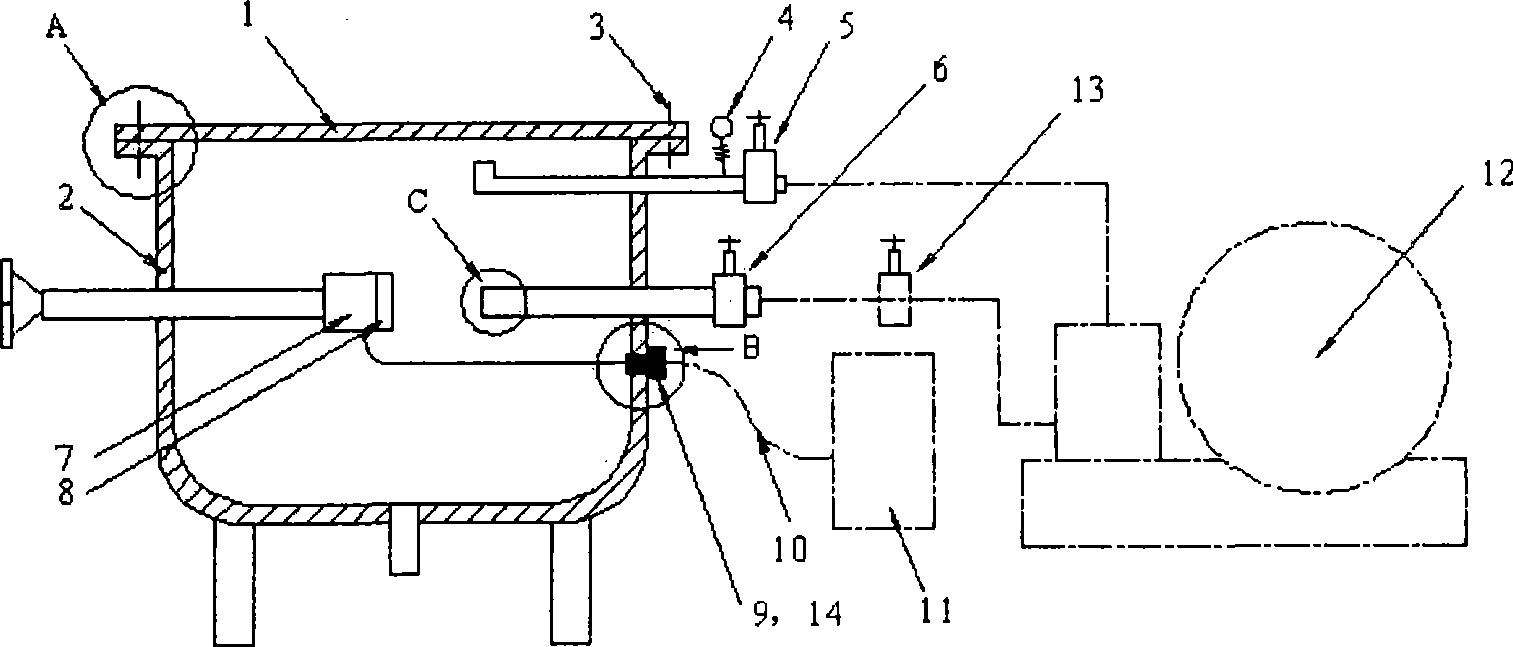

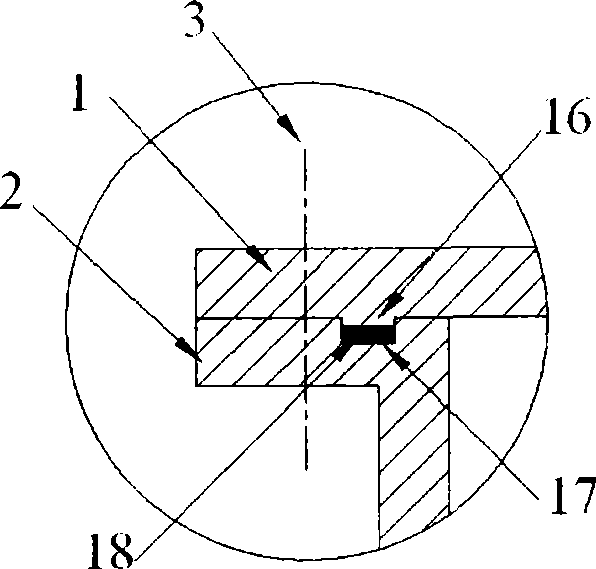

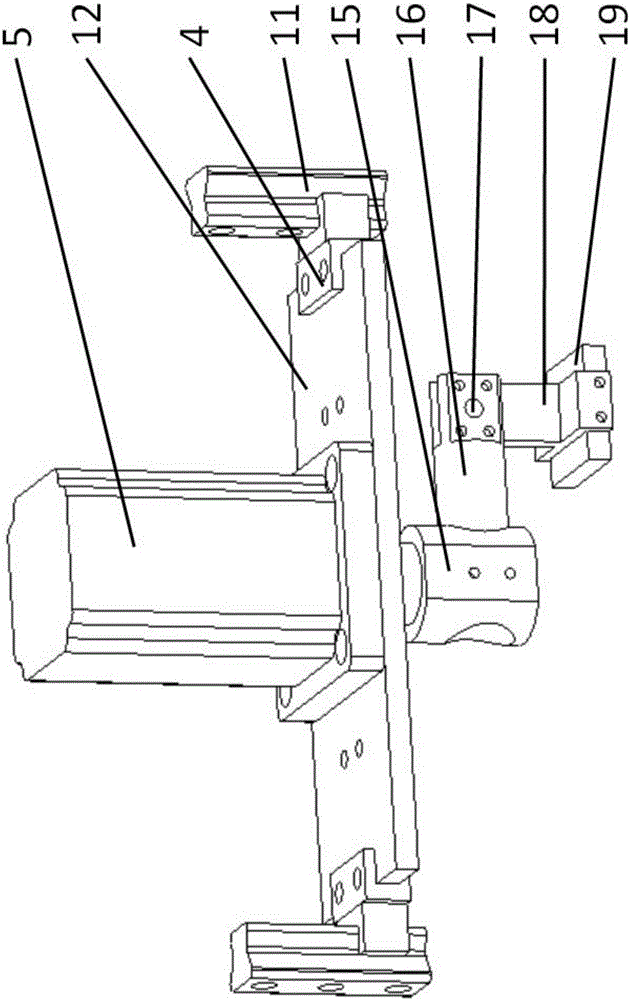

Jetting type liquid-solid double-phase scouring corrosion experiment apparatus

InactiveCN101382477AReduce pulsationWith angle of attackWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceFrequency changerDouble phase

The invention relates to an erosion-corrosion device, in particular to a jet type liquid-solid dual-phase fluid erosion-corrosion experimental device which solves the problems in the prior art that the adjustment of an attack angle is relatively difficult and the experimental period is long as well as the problem of real-time measurement of electrochemical parameters and the like. The experimental apparatus is provided with an ejector pump, a nozzle, a nozzle chamber and an electrochemical test system, and adopts the cam pump of a motor drive provided with a transducer as the ejector pump, wherein, an attack angle adjustment device used for adjusting the attack angle of samples is arranged in the nozzle chamber, the pipeline where the nozzle locates is connected with a jet distance adjustment device. The device adopts the cam pump as the ejector pump to realize the smooth conveying of media containing bigger solid phase particles, utilizes the cam pump of the motor drive provided with the transducer to control the flow speed; and the nozzle chamber is provided with the samples which can control the attack angle and the jet distance, the samples can fulfill the electrochemical measurement. The device can control the flow speed, attack angle and the temperature of the media, and fulfill the electrochemical measurement.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

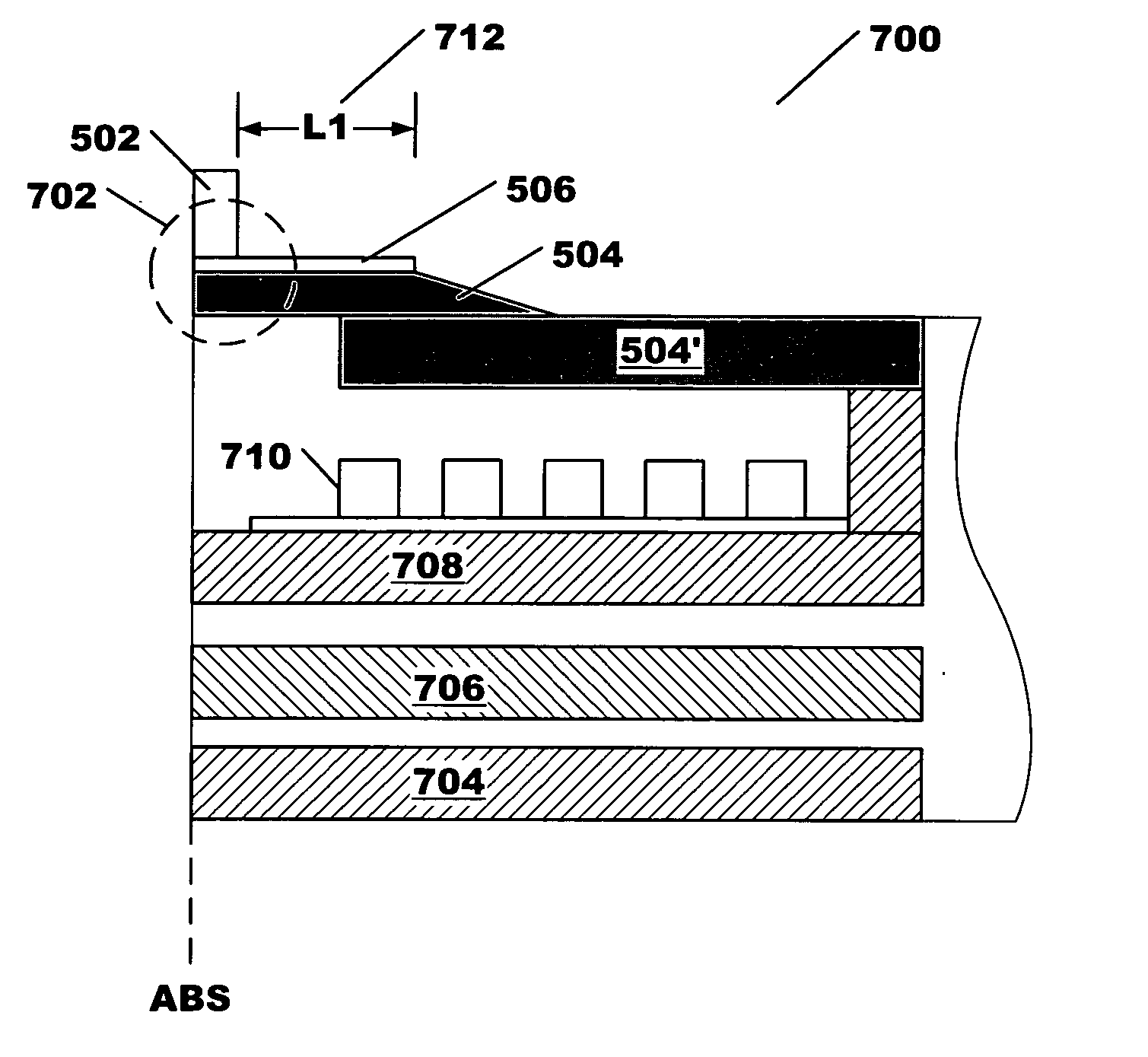

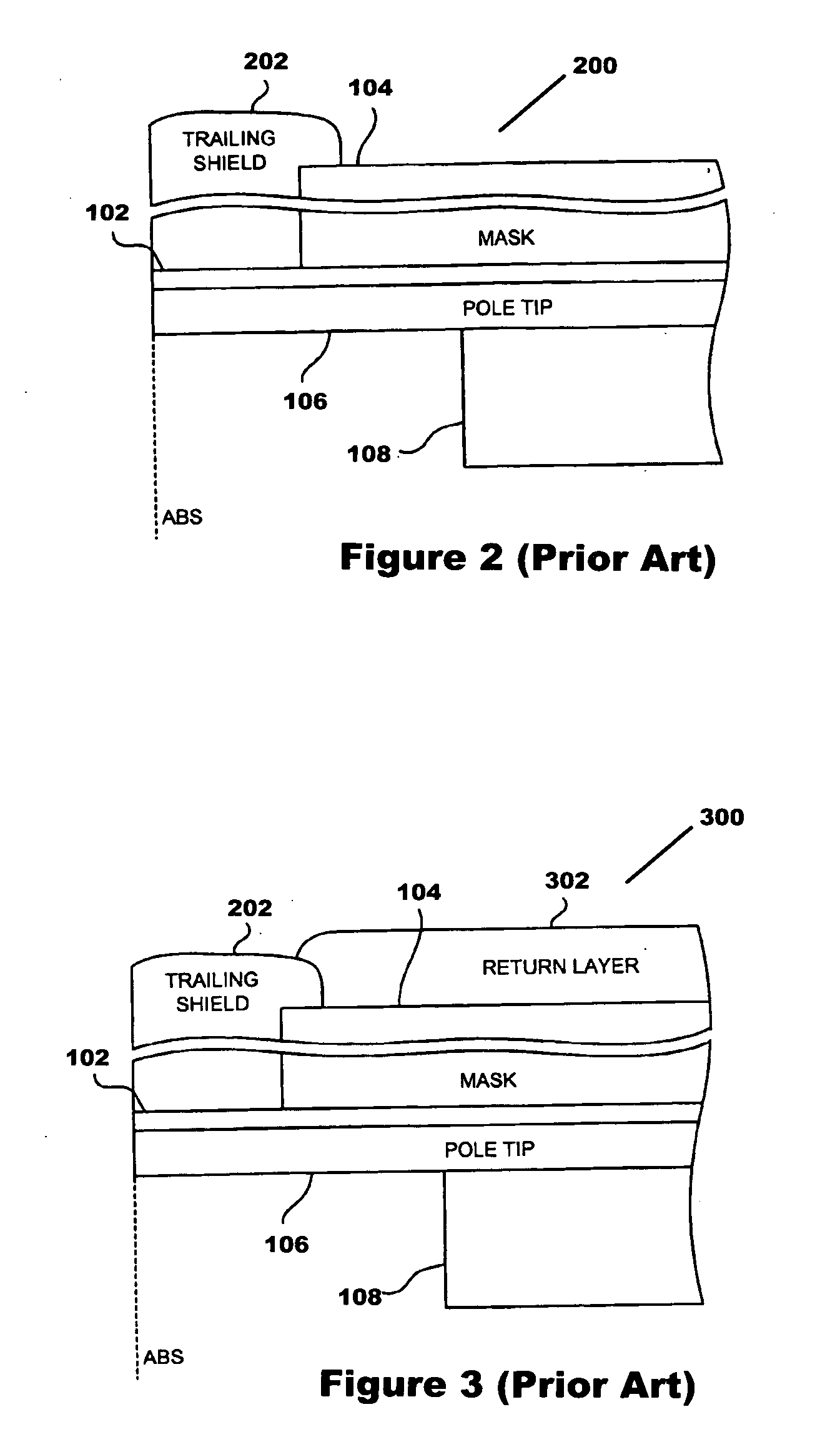

Structure and method for reduced corrosion of auxiliary poles during the fabrication of perpendicular write heads

InactiveUS20070247749A1Reduce corrosionManufacture head surfaceElectrical transducersMaterials scienceErosion corrosion

A method and structure for reducing corrosion during the manufacture of perpendicular write heads is disclosed. Auxiliary pole structures (otherwise known as trailing shields and wrap around shields) are susceptible to corrosion due to their iron containing composition and small dimensions. The impact of corrosion can be reduced by utilizing a gap material comprising an upper surface of noble metals, which extends from underneath the auxiliary pole and is exposed to the same corrosive environment during processing. The area of the exposed gap material is limited to optimize corrosion protection.

Owner:WESTERN DIGITAL TECH INC

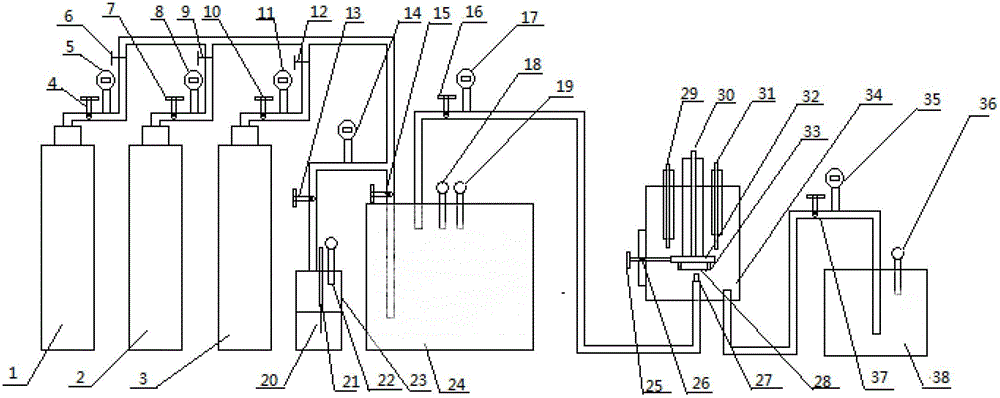

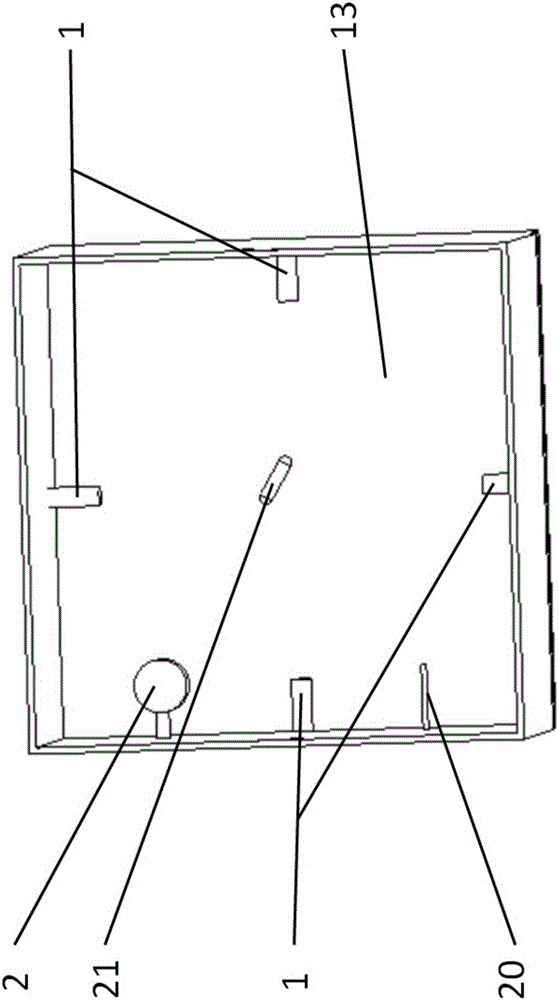

Loop test device for imitating gas phase erosion corrosion of natural gas

ActiveCN102980823ADeficiencies of changing flushing circuits with low flow ratesEasy to controlWeather/light/corrosion resistanceInvestigating abrasion/wear resistancePilot systemGas phase

The invention discloses a loop test device for imitating gas phase erosion corrosion of natural gas, and belongs to the technical field of imitating experiment devices. The loop test device for imitating gas phase erosion corrosion of natural gas is suitable for imitating conditions of medium components, humidity, flow speed and the like of natural gas gathering pipelines during the actual operation process, and is especially suitable for simulating the erosion corrosion situation caused by the flowing of gases containing trace moisture and corrosion media and having high-speed flowing in natural gas pipes, and testing electrochemistry and corrosion behaviors. The device is composed of three parts including a control system, a test system and a recovery system, wherein the control system comprises a high-pressure air bottle, a high-pressure kettle, a high-pressure flow meter, a regulating valve, a stop valve, an electric heater, a humidity probe, a pressure probe and pipelines; the test system comprises the high-pressure kettle, a three-electrode system, a rotary working bench, a test sample jig and a pressure probe; and the recovery system comprises a recovery tank, a regulating valve, a high-pressure flowmeter and a pressure probe. The device can well imitate the erosion corrosion situation of parts including pipe walls, elbows, tee joints and reducing parts by high-flow-speed wet gases under natural gas intra-pipe environment, can test electrochemistry signals, and has important significances for the research on erosion corrosion behavior rules under the natural gas intra-pipe environment as well as main influence factors of the erosion corrosion behavior rules.

Owner:UNIV OF SCI & TECH BEIJING

Multifunctional base injection type cavitation corrosion test device

InactiveCN101451940AEasy to adjustAchieve corrosiveInvestigating abrasion/wear resistanceMaterial ErosionMetallic materials

The invention belongs to a multifunctional submerged jet type cavitation test device in the fields of cavitation erosion resistance and erosion corrosion resistance of metal materials, a detachable upper end cover arranged closely is provided on top of a tank, a pressure valve and a pressure release valve are arranged on a side wall of the sealed tank, a nozzle is detachably arranged on an inner end of the tank of the same tube of the pressure valve, a testing bracket and a testing sample wafer are arranged on the other side wall of the sealed tank, a plug screw and a traverse education through hole for testing thereon are arranged at a lower part of the same side wall of the sealed tank and the pressure valve, the traverse and the education through hole are sealed through sealant; a pressure gauge is arranged on an upper part of the sealable tank matching with the pressure release valve; the plug screw and the sealed tank are sealed through a seal ring. The device is reliable in structure theory, low in manufacturing cost, handy in working use, precise in experiment effect, long in service life and reduced in energy consumption.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

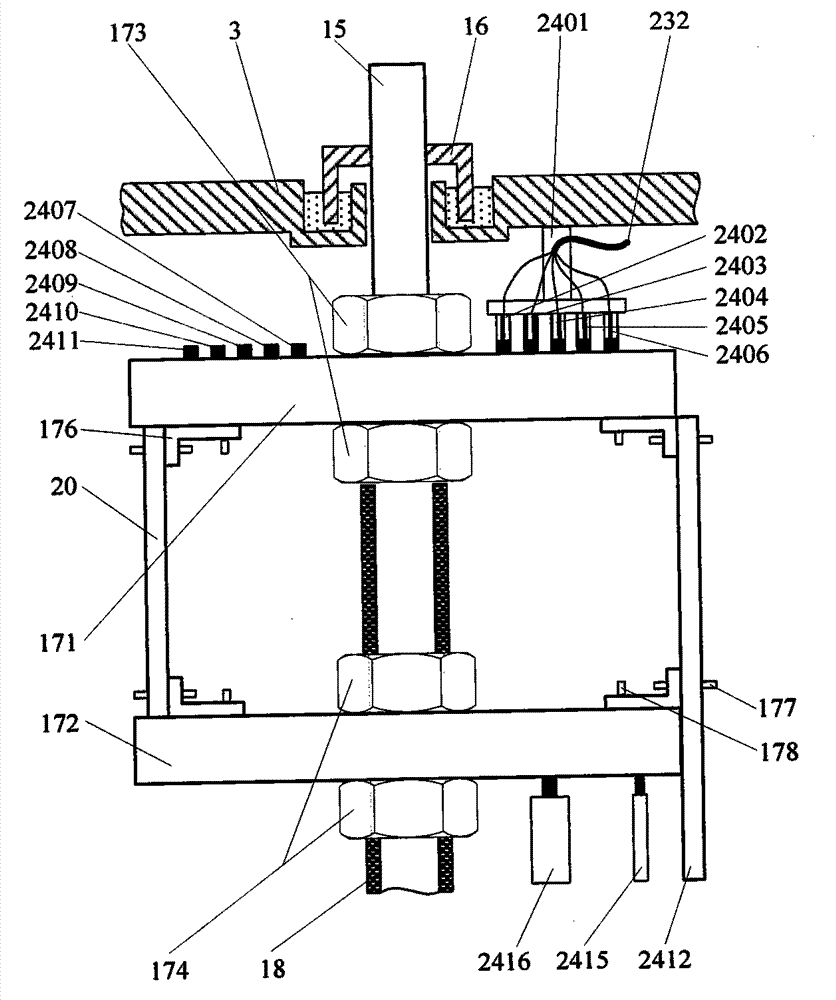

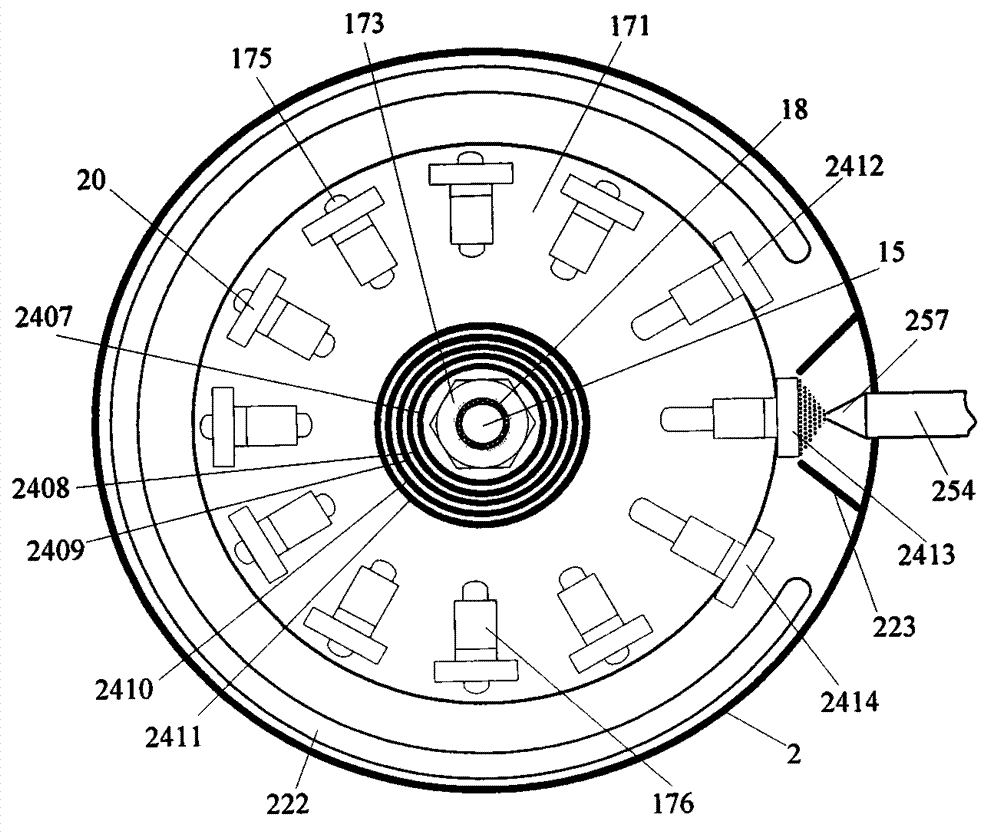

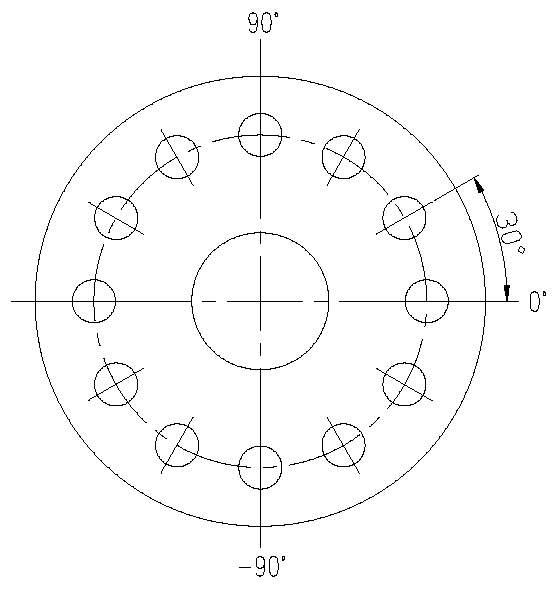

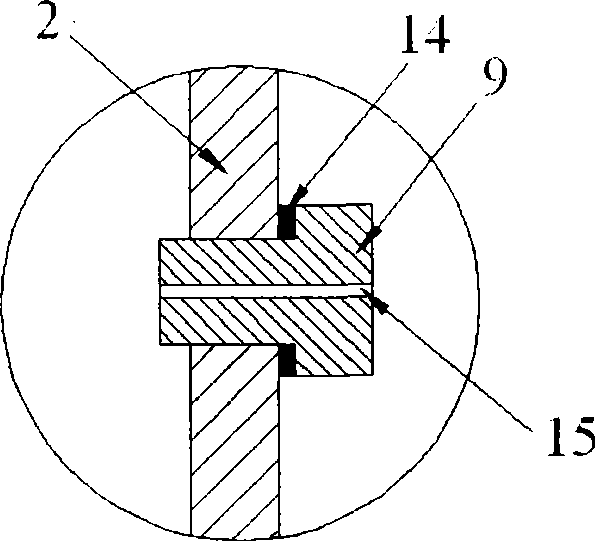

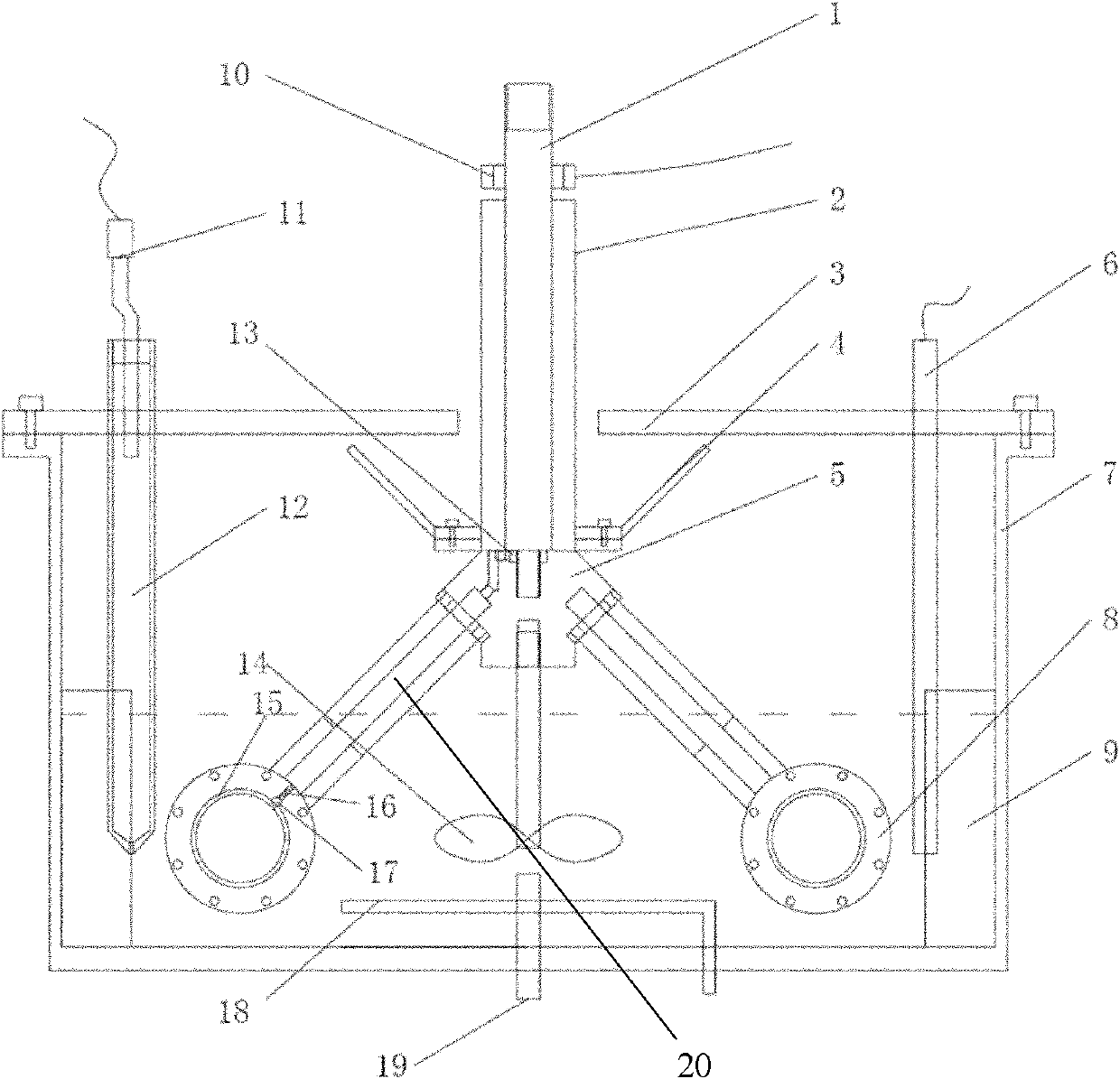

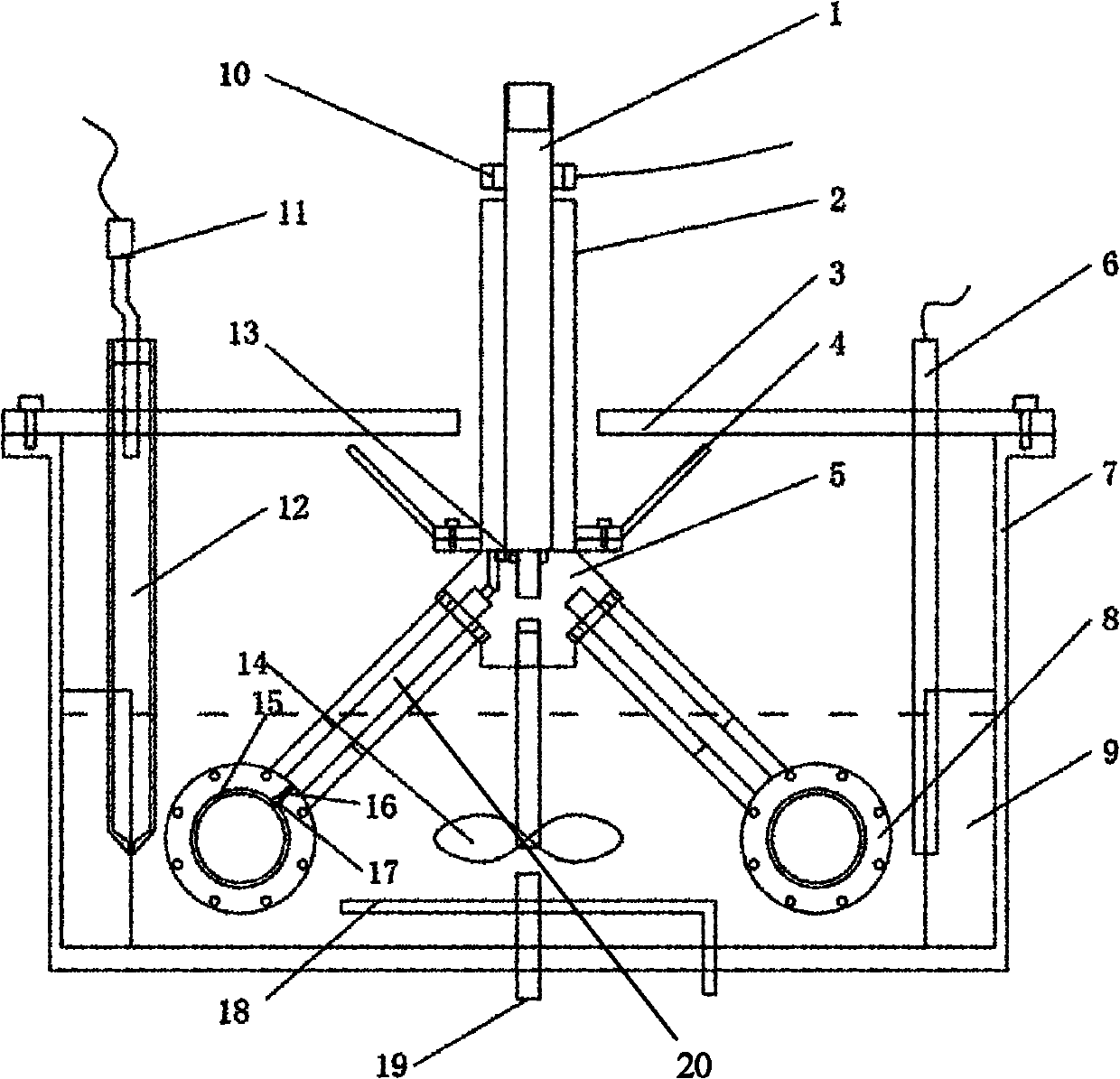

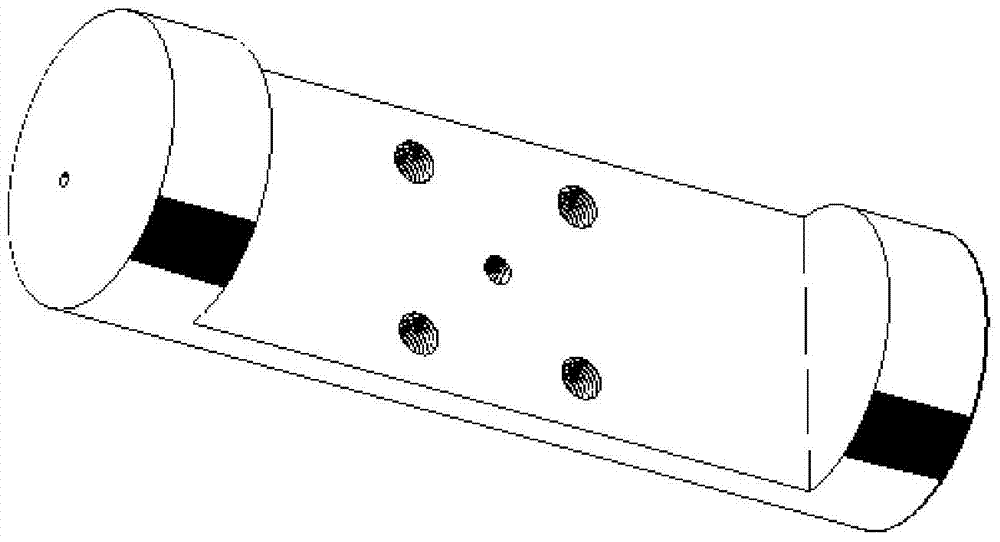

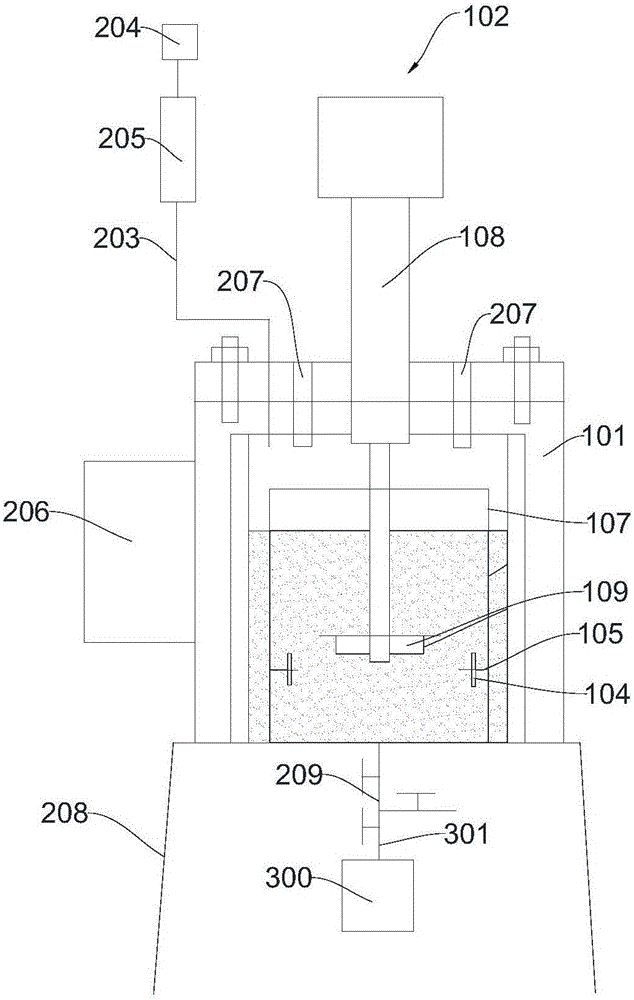

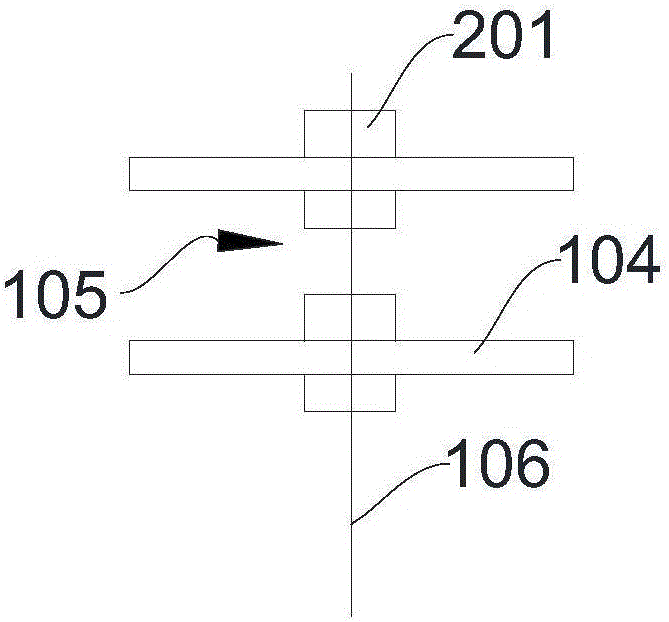

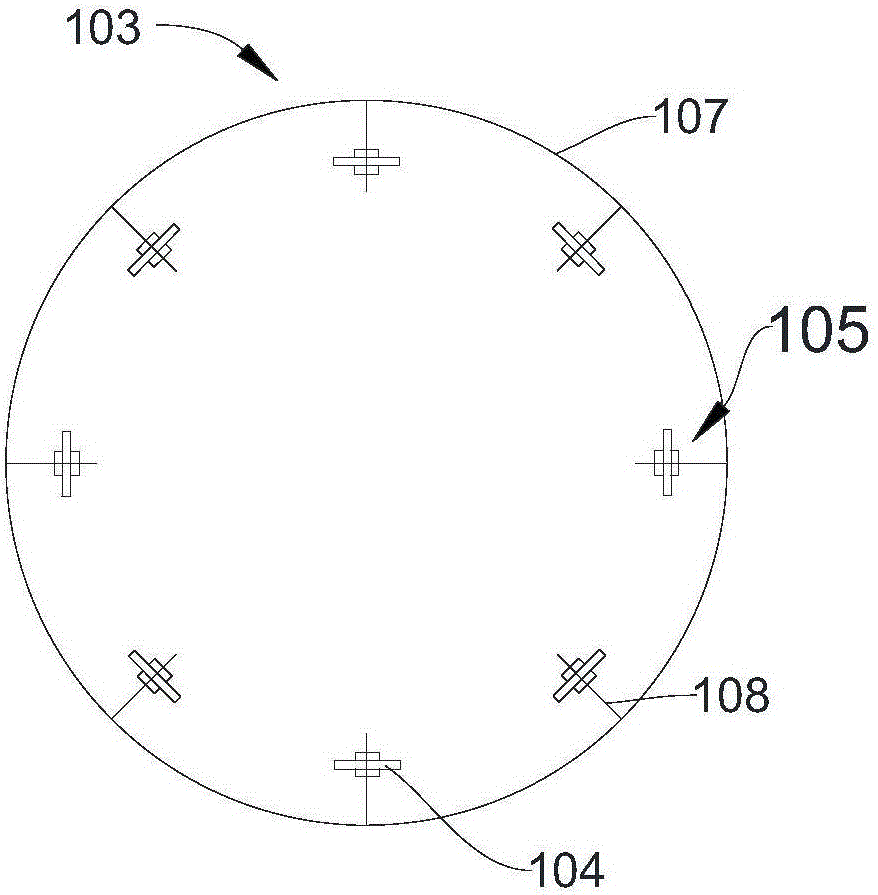

Rotary test device for simulating erosion corrosion on inner wall of pipeline

InactiveCN102564936AHigh simulationAchieving Axial Erosion Corrosion BehaviorWeather/light/corrosion resistanceMaterial ErosionSlurry

The invention relates to the field of an erosion corrosion device and particularly provides a rotary test device for simulating the erosion corrosion on an inner wall of a pipeline, and overcomes the defects that the conventional rotary erosion corrosion test device cannot simulate the erosion corrosion on the inner wall of the pipeline well and a pipe flow type erosion corrosion test device is high in manufacturing cost. The rotary test device disclosed by the invention is provided with a rotating shaft, a slurry tank, a sample clamp and an annular sample. A carbon brush is arranged at the upper part of the rotating shaft and is connected with electrochemical test equipment; the rotating shaft is connected with an output end of a motor which is provided with a frequency converter; the lower part of the rotating shaft extends to a place above slurry in the slurry tank; the rotating shaft is connected with the sample clamp through a rotary joint; and the annular test is mounted on the test clamp. The rotary test device disclosed by the invention combines the advantages of the conventional rotary erosion corrosion test device with the conventional pipe flow type erosion corrosion test device, so that axial erosion corrosion behaviors on the inner wall of the pipe are researched in a rotated condition. According to the rotary test device disclosed by the invention, the flow speed, the medium component and the temperature can be controlled, and real-time electrochemical parameter measurement and zero gravity measurement can be realized simultaneously.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

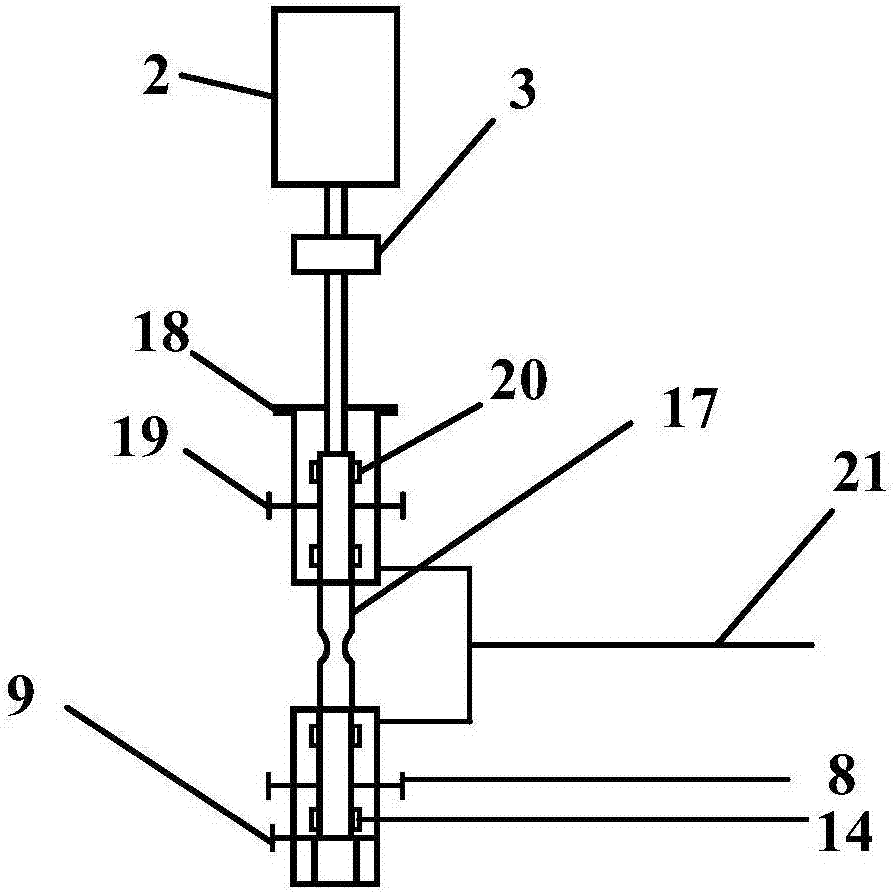

Injection type erosion corrosion testing device

ActiveCN103543077APrecise measurement of electrochemical informationTest environment factors are controllableWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceMetallic materialsAuxiliary electrode

The invention discloses an injection type erosion corrosion testing device and belongs to the field of metal material corrosion prevention. Polytetrafluoroethylene plastic serves as a pipeline loop material. The device comprises a constant-temperature liquid storage box, an erosion chamber, a stirring chamber, a circulating pump, a pipeline loop, a nozzle, a semi-cylindrical sample table and a clamp, wherein the circulating pump is connected in series with a frequency converter to change the operating frequency of a pump body so as to realize zero-order speed change; an electromagnetic flow meter is arranged on the pipeline loop at the rear section of the circulating pump and is used for monitoring flow in real time; a gear is arranged inside the stirring chamber; an external speed-regulating motor is installed for driving the gear to stir a fluid so as to ensure that solid particles in the fluid are uniformly suspended; a clamping device comprises the semi-cylindrical sample table and the clamp; an erosion angle of the fluid is changed by rotating the sample table. A reference electrode and an auxiliary electrode are arranged in the erosion chamber, the reference electrode, the auxiliary electrode and a sample clamped by the clamp form a three-electrode system which is externally connected with an electrochemical working station and a computer, and real-time dynamic electrochemical measurement at different fluid speeds, angles and temperatures can be realized by accurate control.

Owner:UNIV OF SCI & TECH BEIJING

Corrosion testing device capable of simulating complex environment and testing method thereof

ActiveCN105891094AGuaranteed accuracyEnsure scientificWeather/light/corrosion resistanceTemperature controlGas composition

The invention discloses a corrosion testing device capable of simulating the complex environment and a testing method thereof. The device comprises a dynamic high-temperature autoclave system, a medium circulation system and a gas mixing system which can be used for conducting corrosion tests on a sample; the medium circulation system cooperates with the dynamic high-temperature autoclave system so that the medium in the testing environment can be replaced or circulated, and thus the solution medium or flow velocity under the actual working condition is simulated; the gas mixing system is communicated with and cooperate with the dynamic high-temperature autoclave system to simulate the gas composition and pressure environment required by the tests; the dynamic high-temperature autoclave system is internally provided with a medium temperature controller which is used for simulating the temperature under the actual working condition. According to the testing device, multiple types of testing parameters are considered comprehensively, an expansion interface is provided, multiple types of actual working conditions can be effectively simulated, corrosion performance evaluation and research of multiple types of materials, such as stress corrosion, uniform corrosion, erosion corrosion, pitting corrosion, crevice corrosion, electrochemical corrosion, coating corrosion resistance evaluation and corrosion inhibitor efficiency evaluation, in the complex environment are completed, and correctness and scientificity of the test result are guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Chromium 23 nickel 6 ferrite-austenitic stainless steel pipe and fabrication process thereof

ActiveCN101353769AEasy to useHigh tensile strengthRoll mill control devicesWork treatment devicesChemical industryManufacturing technology

The invention relates to a Cr 23 Ni 6 ferrite-austenitic stainless steel which is manufactured from stainless steel materials containing components by weight percentage as follows: 22 percent to 24 percent of Cr, 5 percent to 7 percent of Ni, 3 percent to 4 percent of Mo, 0.15 percent to 0.25 percent of N, less than or equal to 0.03 percent of C and 1 percent to 2 percent of Mn, and the rest is Fe. The manufacturing technology of the Cr 23 Ni 6 ferrite-austenitic stainless steel of the invention is characterized in that: in hot piercing process, the hot piercing temperature is controlled to be 1150 DEG C to 1200 DEG C; the prior compression coefficient of a piercing plug is controlled to be 5 percent; the reduction of roller waist is controlled to be 12 percent and the ovality is controlled to be 1.08 to 1.11; in cold drawing / cold rolling process, cold deformation quantity is controlled to be below 50 percent; in heat treatment process, the solid solution temperature of products is controlled to be 1080 DEG C to 1100 DEG C and the solid solution temperature of finished products is controlled to be 1050 DEG C to 1100 DEG C. The Cr 23 Ni 6 ferrite-austenitic stainless steel has good chloride stress corrosion resistance, good pit corrosion resistance, high tensile strength and yield strength and good corrosion fatigue resistance and erosion corrosion resistance, and is widely used in the fields such as petroleum industry, chemical industry, natural gas industry and marine shipping and the like.

Owner:上上德盛集团股份有限公司

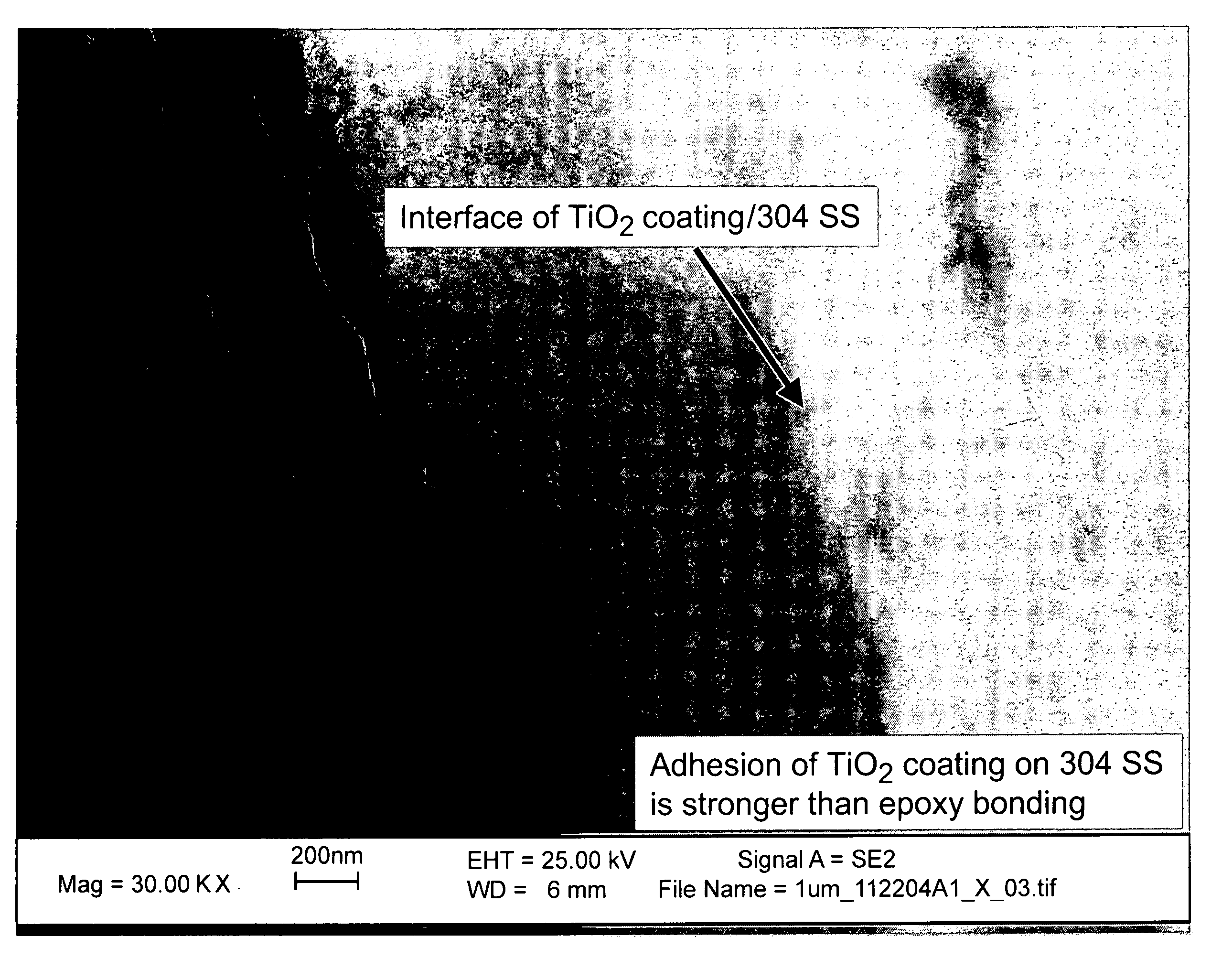

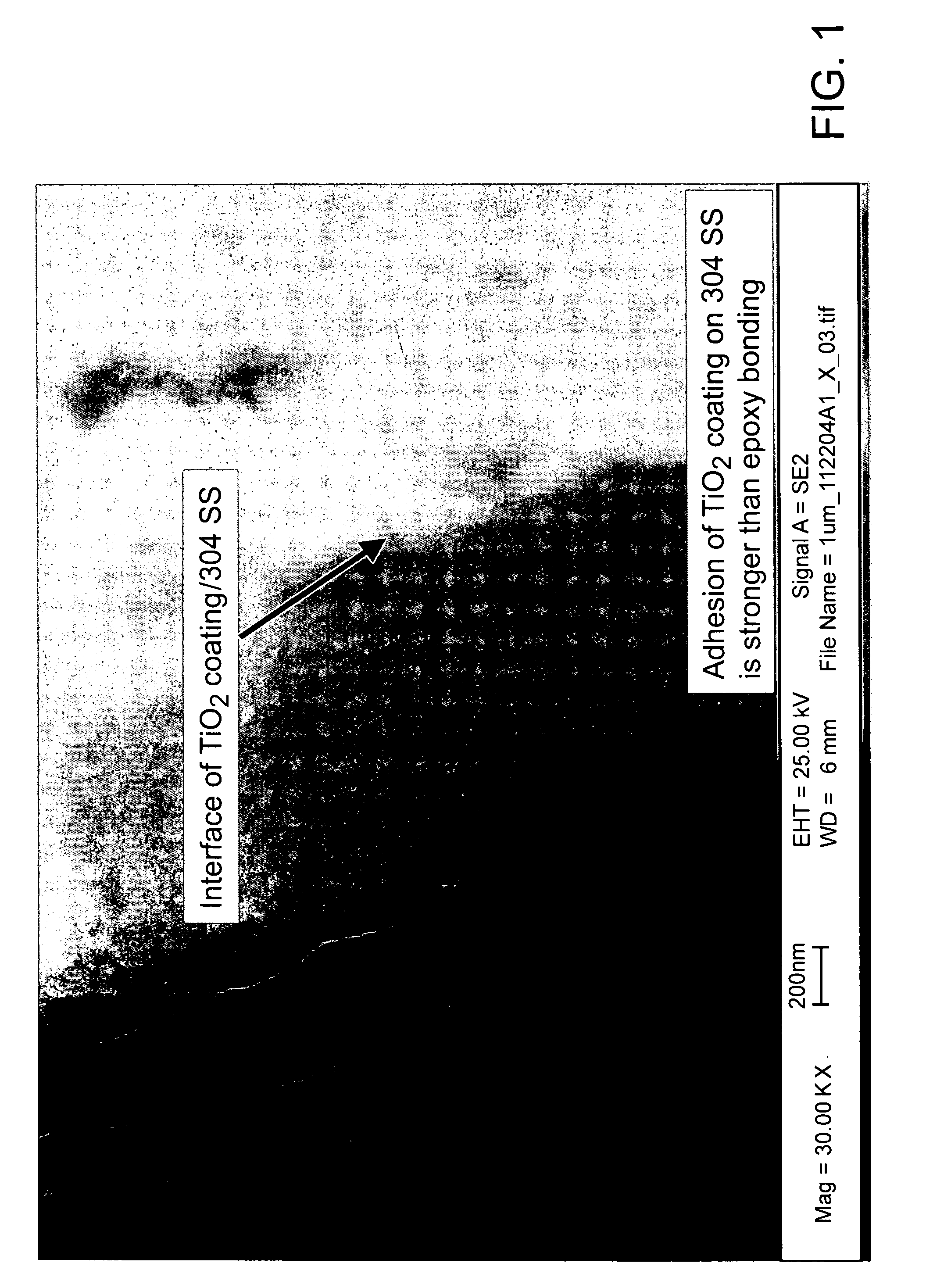

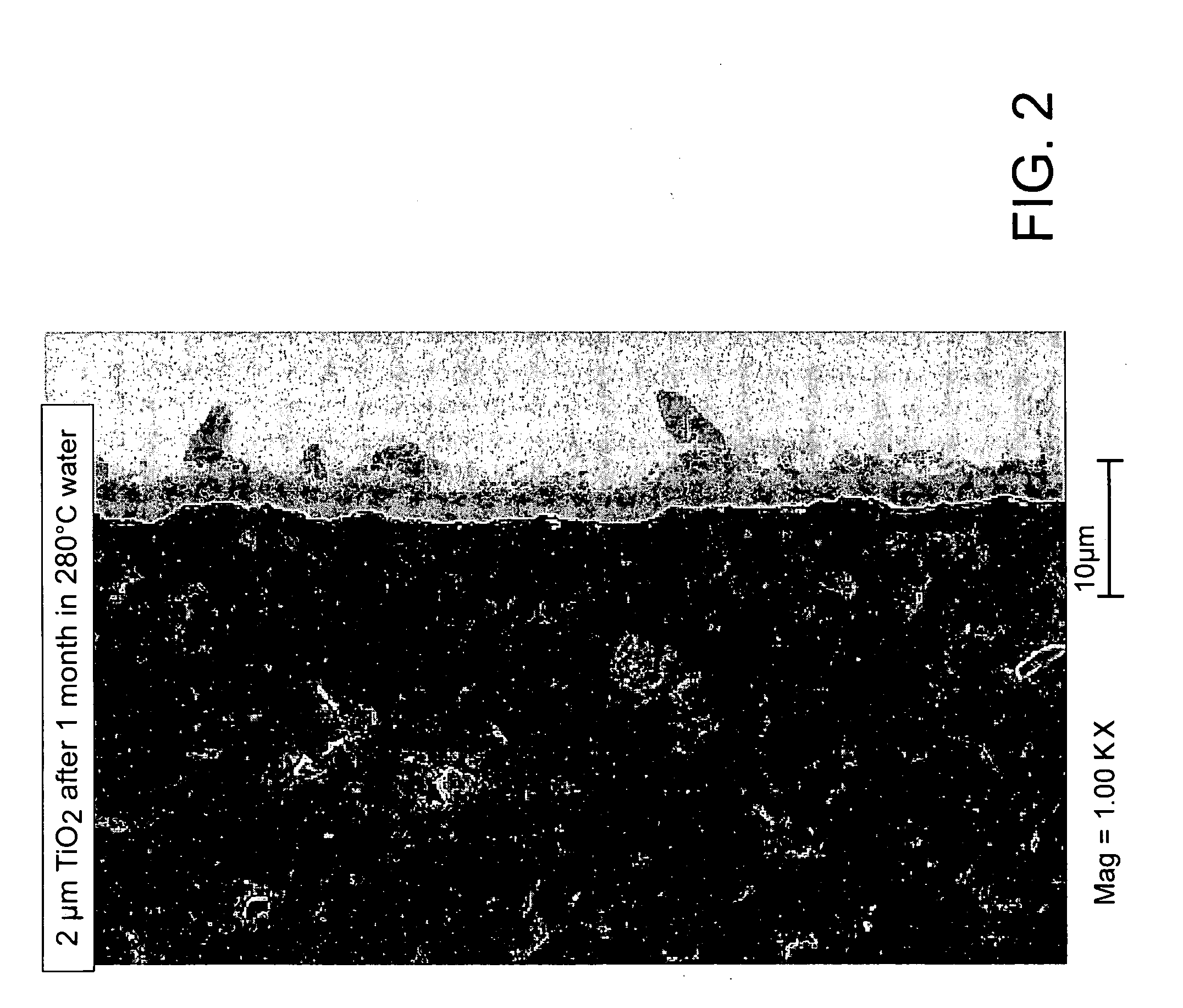

Protective coating applied to metallic reactor components to reduce corrosion products into the nuclear reactor environment

InactiveUS20090046825A1Reduce corrosionReduce and eliminate potentialMolten spray coatingVacuum evaporation coatingNuclear reactionCobalt

An insulating coating is applied to the metallic components in a nuclear reactor water environment to decrease and / or mitigate general corrosion and erosion-corrosion of the reactor component's metallic surfaces. Preferably, the coating is a 0.1 micron to 0.3 mm thin layer of an oxide coating such as titania (TiO2), zirconia (ZrO2), tantala (Ta2O5), Al2O3, CeO2 or similar oxides; or a thin layer of the metal, such as Ti, Zr, Ta, Hf, Ce, Al, which will oxidize in the reactor water environment. The applied coating provides a protective layer between the component surfaces and the reactor water environment. By reducing and / or eliminating the potential for corrosion on reactor metallic components, the coating eliminates or minimizes the potential for activated corrosion products to contaminate the reactor water. The coating is especially beneficial for nickel-alloy based metals that contribute significant cobalt-related corrosion products, and will also be effective on austenitic stainless steel components.

Owner:GE HITACHI NUCLEAR ENERGY AMERICAS

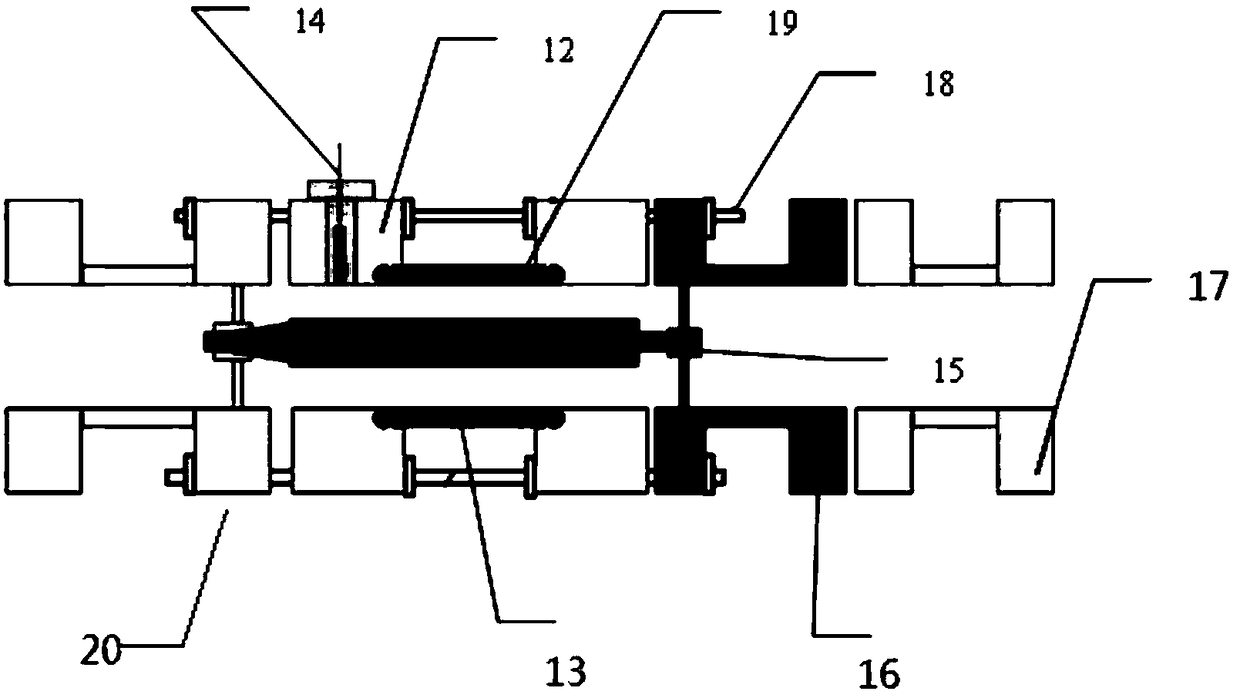

Jet type stress-erosion corrosion test device

PendingCN109975153AWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMaterial ErosionAir pump

The invention relates to a jet type stress-erosion corrosion test device. The device comprises a liquid storage tank, a circulating system, a test piece mounting and stress loading mechanism; the testdevice is characterized in that a heater is arranged in the liquid storage tank and used for heating a test solution in the tank; the circulating system is provided with a water pump, an air pump andan air-liquid mixer; the water pump is used for sucking the test solution in the tank into the air-liquid mixer, the air pump is connected to the air-liquid mixer, the air-liquid mixer communicates with a nozzle through a pipeline, a sand storage tank is arranged on the pipeline at the front end of the nozzle, and the particle content entering the pipeline is controlled through an adjusting valve; a temperature sensor and a flowmeter for measuring the temperature and flow of a transmission medium input into the pipeline from the air-liquid mixer are arranged at an upstream of a sand storage tank mounting place; the heater power is adjusted according to the reading of the temperature sensor, the rotating speeds of the water pump and the air pump are controlled according to the reading of the flowmeter, thereby controlling the jet velocity. The evaluation research on the stress-erosion corrosion performance test and the corrosion mechanism of the metal material, the nonmetallic material, the composite material and the stress erosion corrosion resistant coating can be performed.

Owner:TIANJIN UNIV

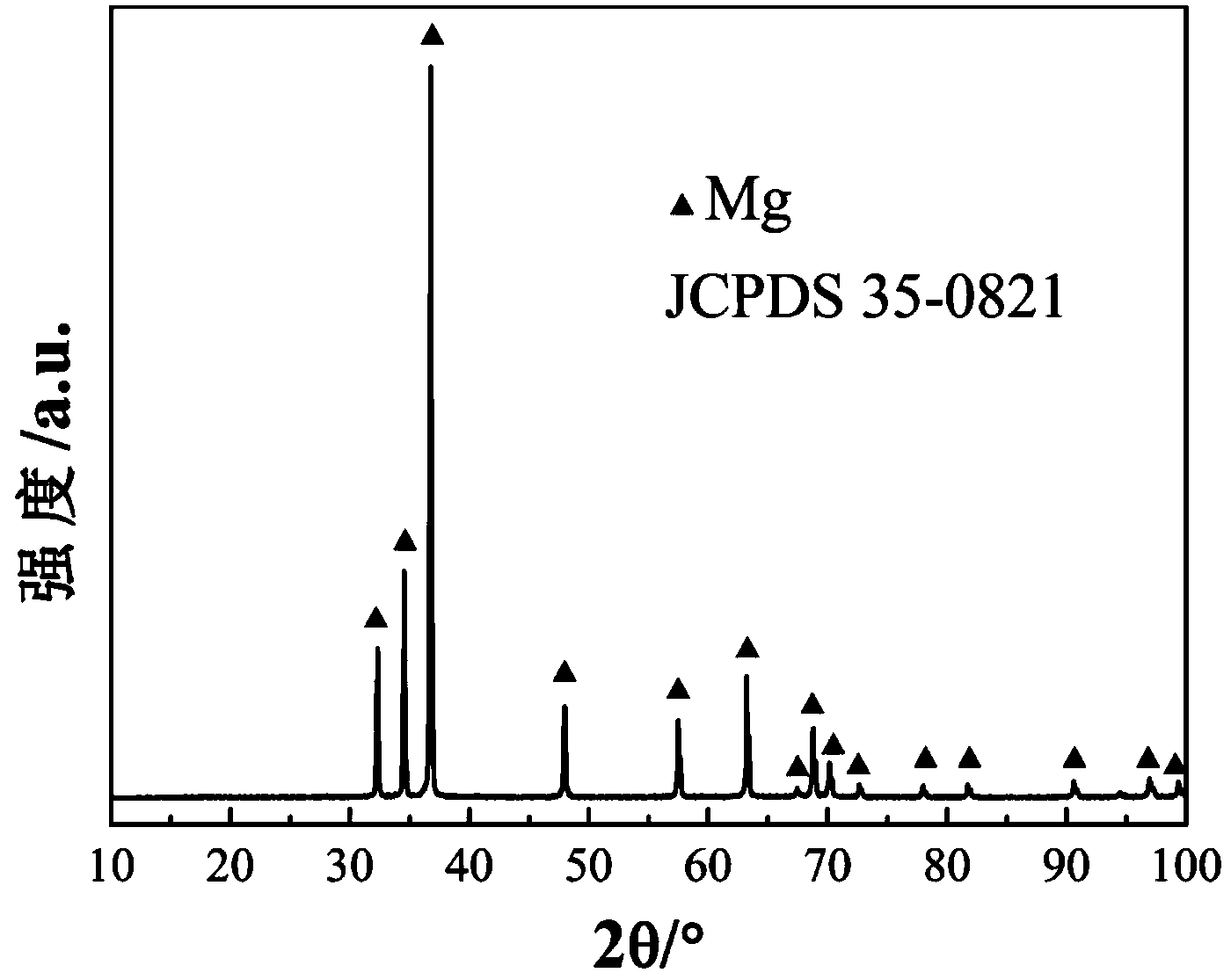

Biomedical degradable Mg-Zn-Zr-Sc alloy and preparation method thereof

ActiveCN103882274AImprove corrosion resistanceImprove mechanical propertiesAlloyBiological materials

The invention provides a biomedical degradable Mg-Zn-Zr-Sc alloy and a preparation method thereof. The alloy comprises the following components in percentage by mass: greater than or equal to 0.5% and less than or equal to 2% of Zn, greater than or equal to 0.3% and less than or equal to 0.8% of Zr, greater than 0% and less than or equal to 10% of Sc, and the balance of Mg. By utilizing the characteristics of favorable compatibility and high degradability of Mg in organisms, the Zn, Zr and Sc are reasonably added to further regulate and optimize the mechanical properties and corrosion resistance of Mg; and the alloy is prepared by a casting technique with lower cost. The Mg-Zn-Zr-Sc alloy does not have precipitated phase, and thus, is beneficial to inhibiting the couple corrosion, so the corrosion mode is uniform corrosion; the alloy has excellent corrosion resistance and favorable mechanical properties, and can be used in the fields of degradable bone plates, bone nails, vessel interventional therapy stents and other biological materials.

Owner:UNIV OF SCI & TECH BEIJING

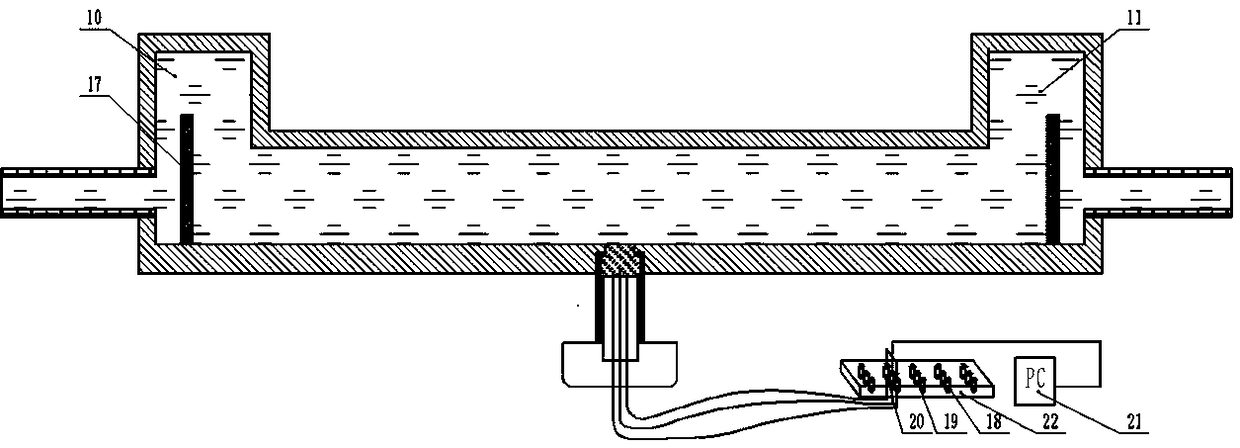

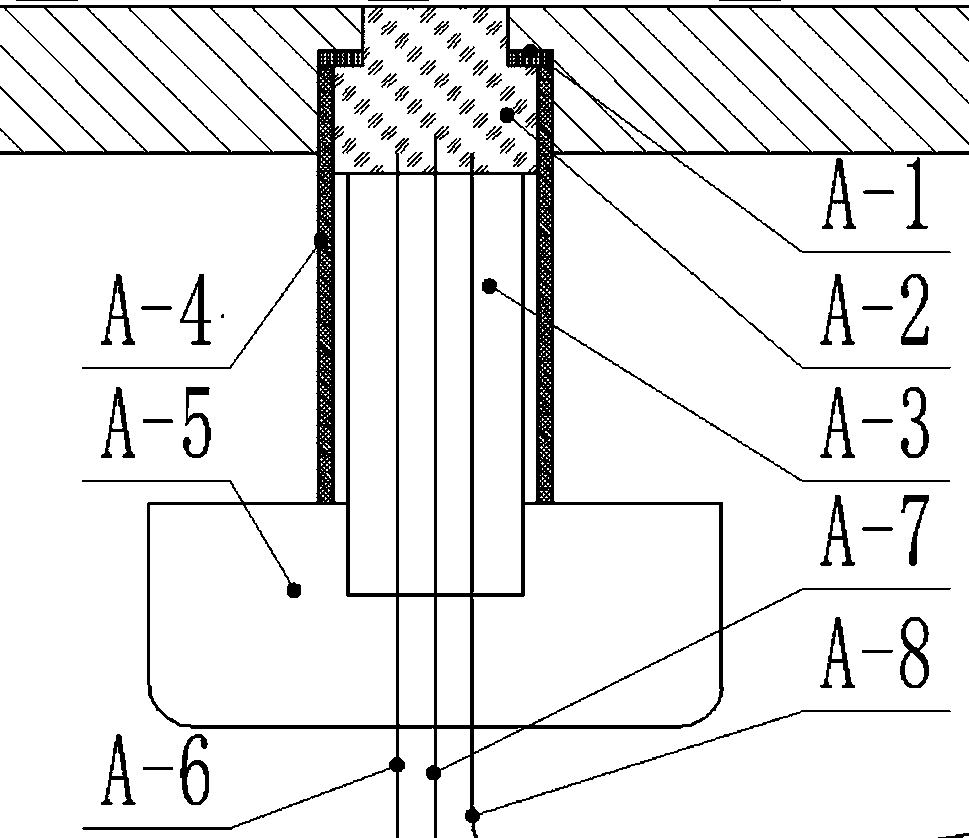

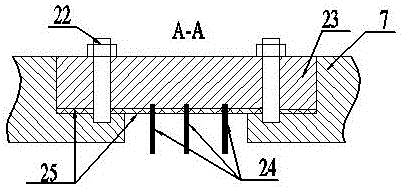

Multichannel erosion-corrosion test system and method

PendingCN109238901AQuick Conversion MeasurementsShorten experiment timeWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceAuxiliary electrodeEngineering

The invention relates to a multichannel erosion-corrosion test system and method. A technical scheme is as follows: connecting each of three electrode wires in a test sample with an electrode installation opening in a test conversion plate; respectively arranging a work installation hole, a reference installation hole and an auxiliary electrode installation hole at each row of the test conversionplate so as to be correspond to three electrode wires in the sample one to one, wherein the upper part of the test conversion plate is connected with the electrode wire of an electrochemical work station through a metal pin so as to guarantee the information transmission between the to-be-tested electrode and the electrochemical work station, thereby realizing the fast conversion measurement of corrosion conditions of multiple test samples when the samples are located at different flow velocity and different tube type conditions of the same system. The system disclosed by the invention has theadvantages the erosion-corrosion conditions under different flow velocity conditions under the same system and the same medium can be measured, the experimental time is greatly saved, and the samplecorrosion results can be contrasted and analyzed under the condition of guaranteeing the system error, thereby realizing multi-channel and independently-worked single-phase flow or gas liquid two-phase flow erosion-corrosion test.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

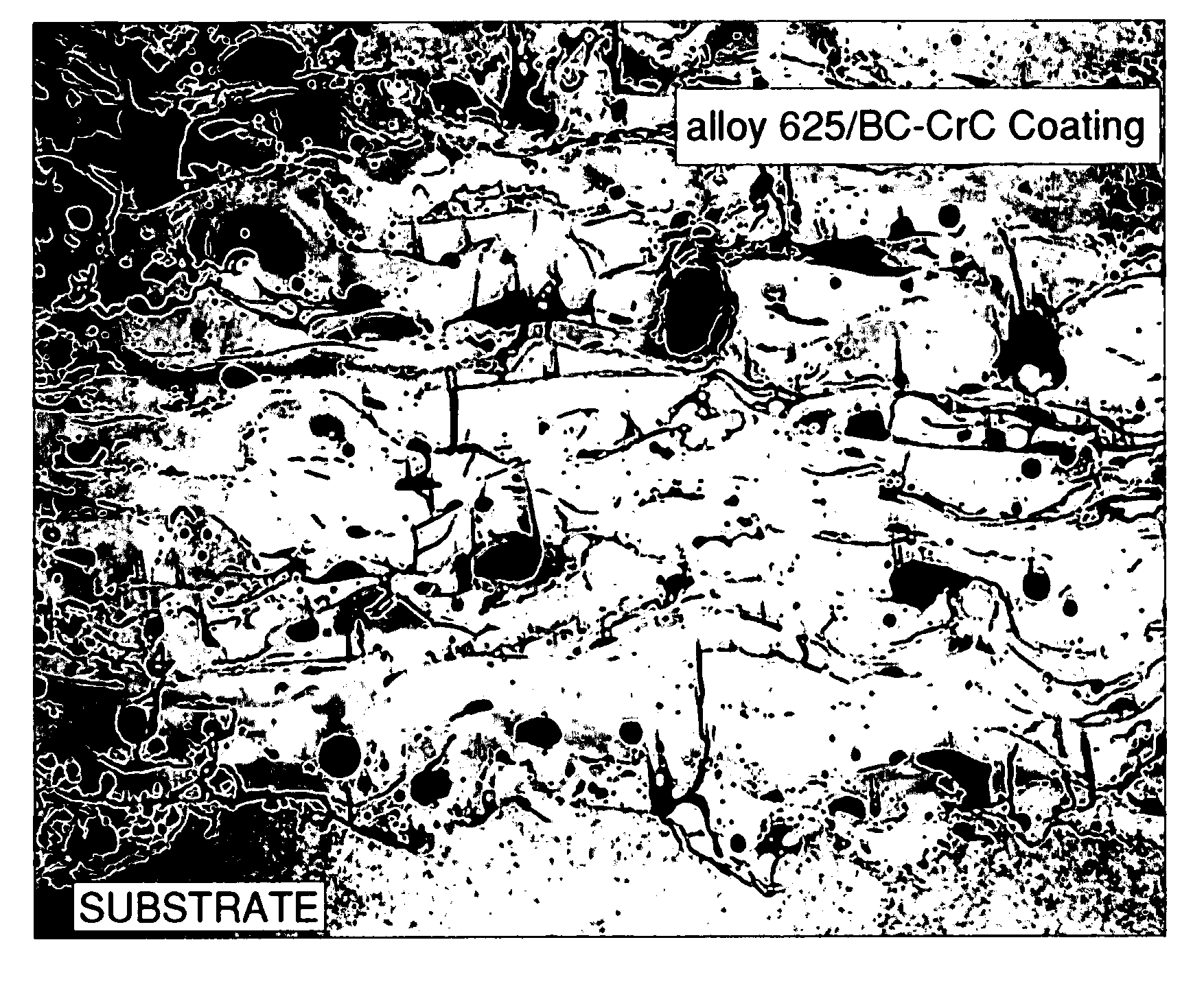

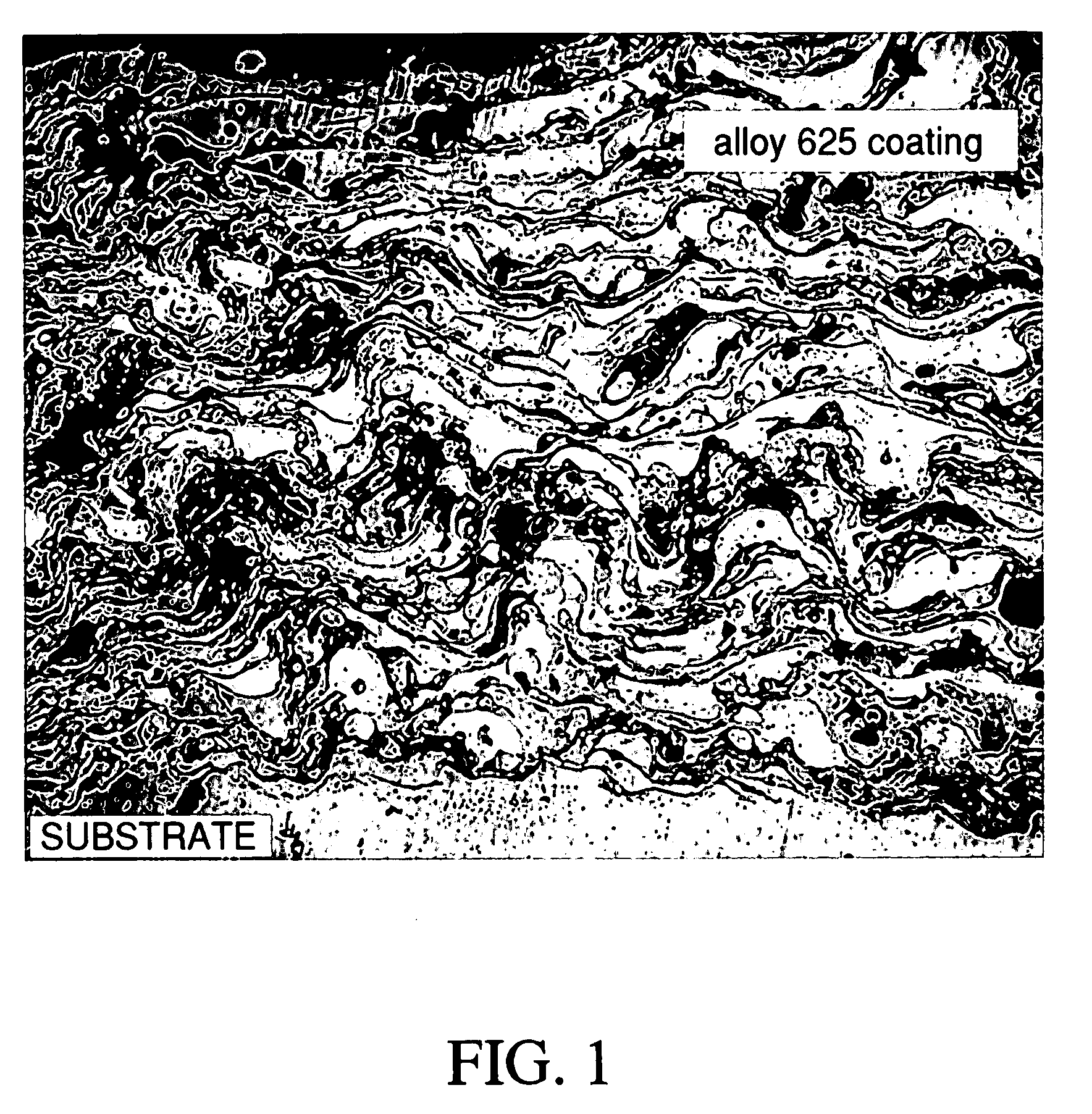

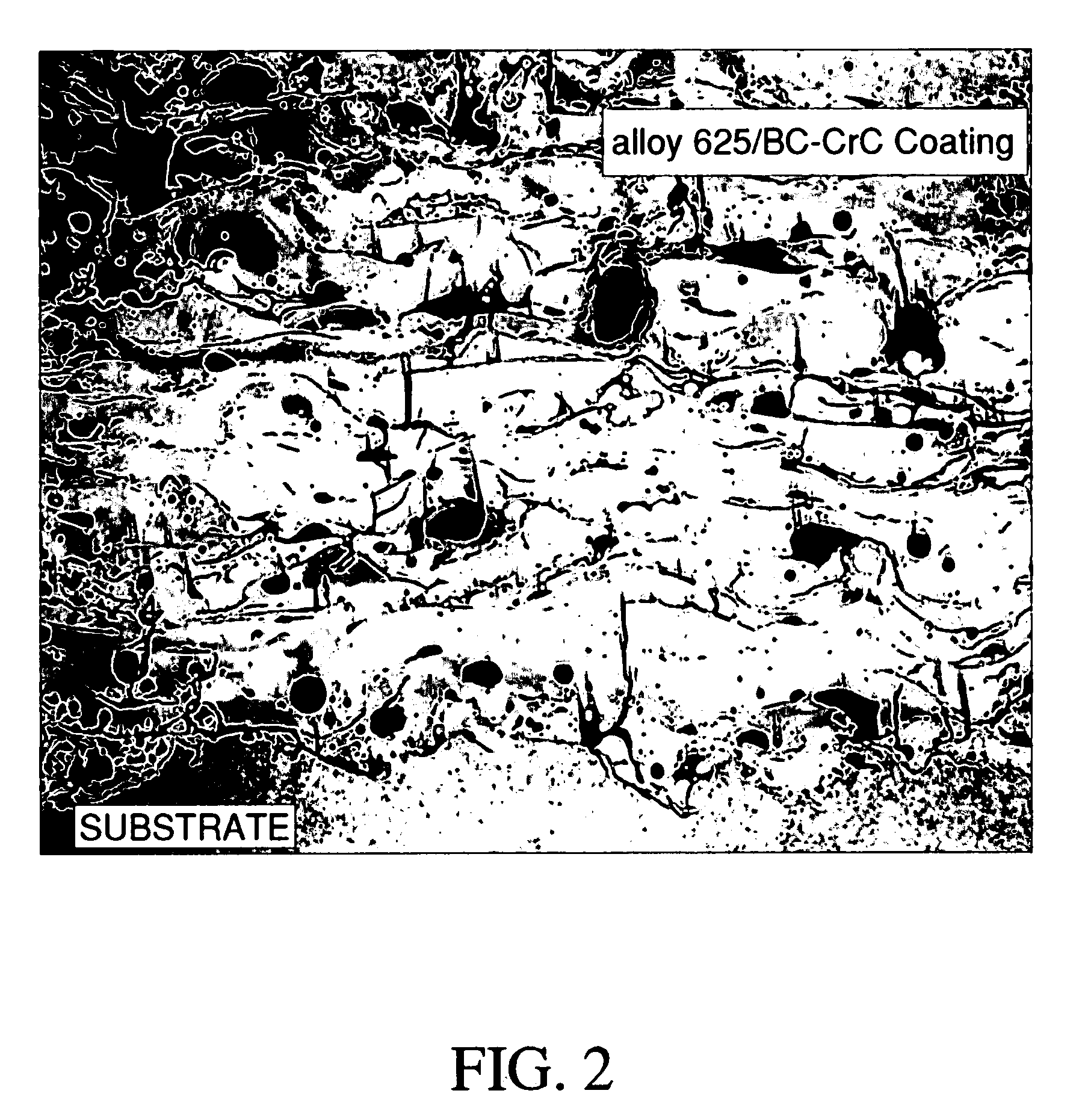

Composite wires for coating substrates and methods of use

ActiveUS20080098926A1Improve adhesionImprove wear resistanceSpark gapsLiquid surface applicatorsChromium carbideThermal spraying

A composite wire for producing a wear resistant and corrosion resistant coating on a substrate by thermal spraying, spray and fuse, or welding techniques are disclosed. The physical properties of the coating are particularly suited for high-temperature erosion-corrosion environments. The resultant coating exhibits good hardness, toughness, and bonding characteristics. The composite wire comprises a metallic outer sheath and an inner core containing boron carbide and chrome carbide.

Owner:INTEGRATED GLOBAL SERVICES

High-temperature high-pressure tubular-flow erosion corrosion experiment device

A high-temperature high-pressure tubular-flow erosion corrosion experiment device mainly includes: a high-temperature high-pressure kettle, a first pressure meter, a temperature meter, a sample test tube, an actual object test tube, a sample trough, a magnetic pump, a liquid transporting pipe, and an ultrasonic flow rate meter. The high-temperature high-pressure kettle is used for providing a fluid at certain temperature and under certain pressure. The actual object test tube is connected to a third joint and a fourth joint of the liquid transporting pipe through a second flange. An actual object tube is fixed in the actual object test tube through a first corrosion-resistant sealing ring. The sample test tube is connected to a first joint and a second joint of the liquid transporting pipe through a first flange. The sample trough, in which a sample is hung, is formed in the sample test tube. The magnetic pump is used for providing power to the experiment device for driving fluid circulation. The ultrasonic flow rate meter is used for testing the speed of the circulated fluid. The whole experiment device is made of corrosion-resistant alloy and a heat insulation layer covers external walls of all parts, so that temperature loss is avoided. The device is suitable for drilling production engineering of petroleum and natural gas.

Owner:SOUTHWEST PETROLEUM UNIV

Corrosion sensor

InactiveUS20070163892A1Weather/light/corrosion resistanceVolume/mass flow measurementElectrochemistrySensor system

A corrosion sensor having a fuse box having a plurality of corrosions fuses having different electrochemical activities, wherein the corrosion sensor is to monitor in-situ corrosion is discolsed. The corrosion sensor system having (a) a corrosion sensor having fuse box having a corrosion fuse having an eletrochemical activity, wherein the corrosion sensor is to monitor in-situ corrosion, and (b) an electronic module connected to the corrosion sensor for monitoring and storing potential and current data to allow for analysis of corrosion of the corrosion fuses is also disclosed. In addition, a method of monitoring corrosion by exposing a corrosion sensor having a corrosin fuse to an environment and determining a rate at which the corrosion fuse is corroded by the environment is disclosed.

Owner:HONEYWELL INT INC

High temperature and high pressure gas, liquid and solid phase erosion corrosion test device and method

InactiveCN109856036ANo erosionFree combinationWeather/light/corrosion resistanceCirculator pumpMetallic materials

Owner:CHINA PETROLEUM ENG & CONSTR

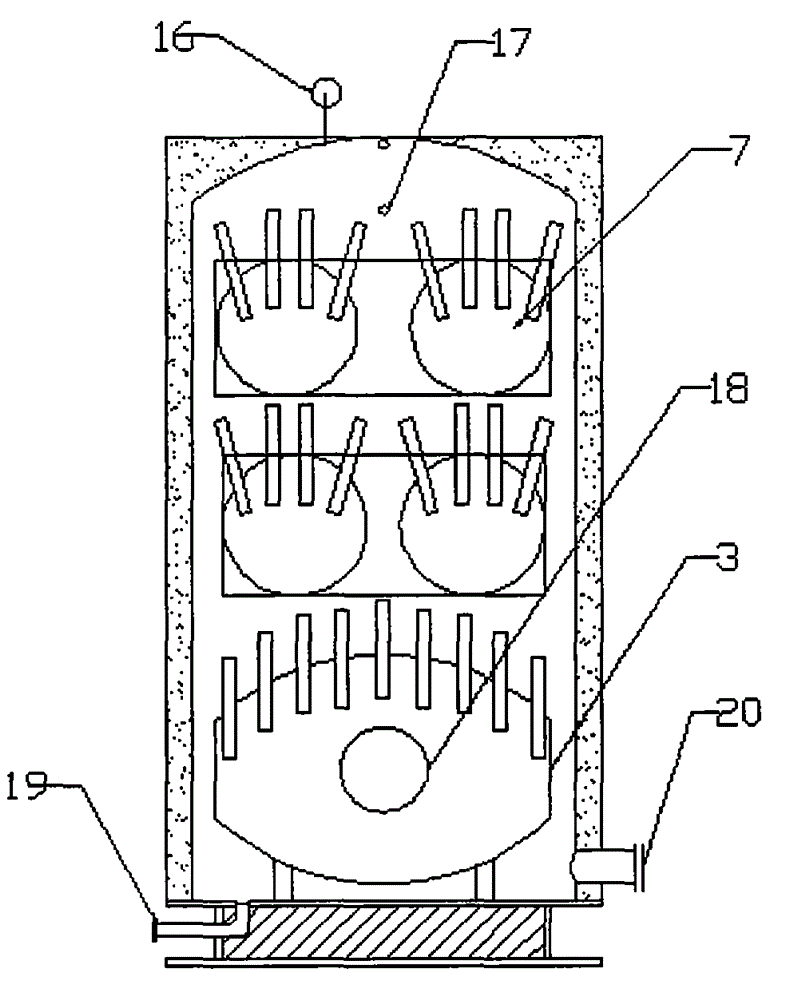

Erosion-corrosion abrasion test table

InactiveCN105259067ASimple structureCompact structureWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceMaterial ErosionEngineering

The invention provides an erosion-corrosion abrasion test table, which comprises a sample control mechanism and a liquid cavity (13) used for containing experiment liquid, wherein a part of the sample control mechanism can enter the liquid cavity (13); a part of the sample control mechanism can also fix a sample (19) and change the space posture of the sample (19). The erosion-corrosion abrasion test table can be used for performing multi-aspect regulation and control on the located environment of the sample; in addition, the space posture of the sample, the depth, the environment temperature, the liquid flow speed and the like can be precisely regulated and controlled on line.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

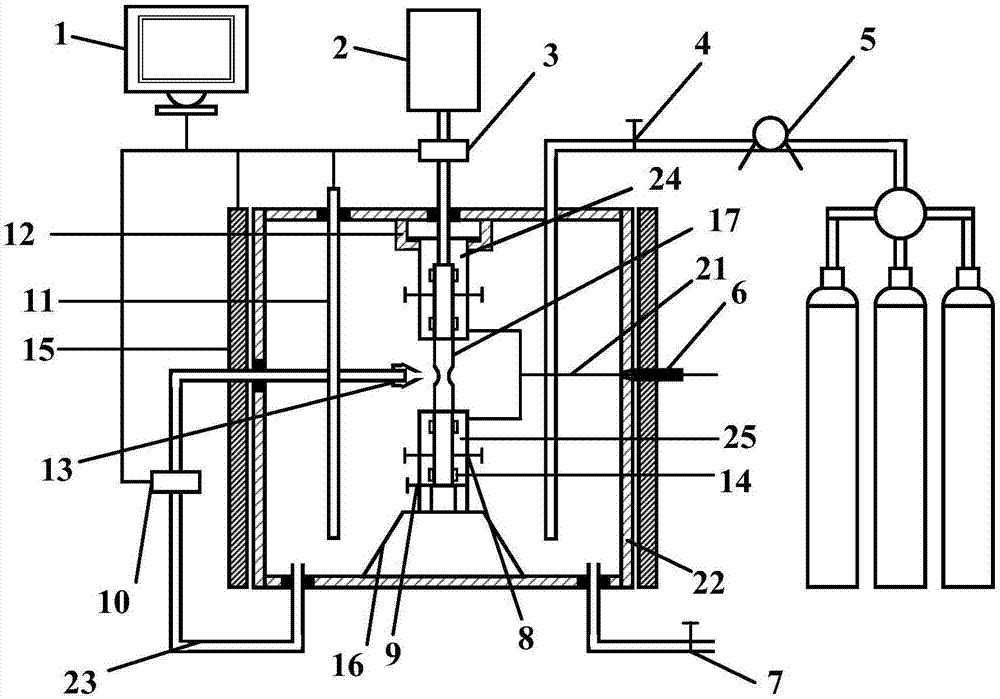

High-temperature and high-pressure erosion-corrosion fatigue testing device

ActiveCN107290229ASimulation is accurateSimple and Precise ExperimentMaterial strength using steady bending forcesGas cylinderEngineering

The invention relates to a high-temperature and high-pressure erosion-corrosion fatigue testing device applied to the field of material experimental science. The testing device comprises a high-temperature and high-pressure kettle, wherein a sample clamping mechanism is mounted in the high-temperature and high-pressure kettle; the high-temperature and high-pressure kettle is a cylindrical tank body, a sealed erosion circulating loop is connected to one side of the high-temperature and high-pressure kettle, an erosion pump is connected to the sealed erosion circulating loop, a nozzle is connected to a water outlet of the erosion pump and corresponds to a sample in the sample clamping mechanism, and a high-speed erosion-corrosion environment is formed on the sample by fluid in the high-temperature and high-pressure kettle by virtue of the erosion pump; a temperature pressure sensor is arranged in the high-temperature and high-pressure kettle, and the erosion pump and the temperature pressure sensor are respectively connected with a computer through cables; and the high-temperature and high-pressure kettle is connected with a high-pressure gas cylinder through a pipeline and a booster pump. The high-temperature and high-pressure erosion-corrosion fatigue testing device can be used for simulating and testing the fatigue performance of drilling equipment and a well completion production pipeline under an erosion effect.

Owner:SOUTHWEST PETROLEUM UNIV

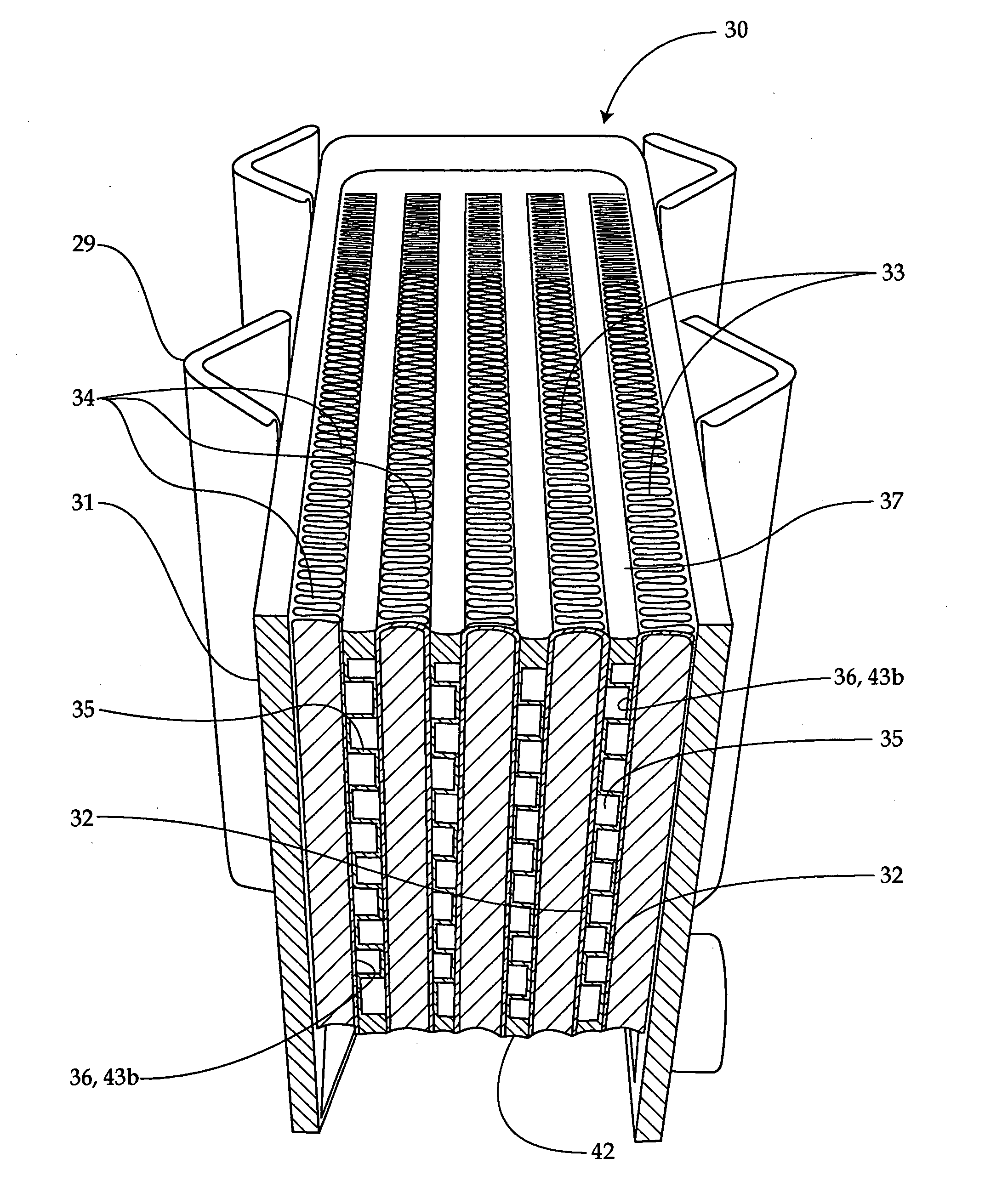

Fluid-handling apparatus with corrosion-erosion coating and method of making same

Inlet surfaces of a fluid-handling apparatus, such as a heat exchanger, are often prone to corrosion and erosion due to the high velocities of incoming fluid. The present disclosure includes a fluid-handling apparatus with a plurality of wetted surfaces of which a first portion is corrosion-erosion prone and a second portion is non-corrosion-erosion prone. The first portion is coated with a corrosion-erosion coating that is harder than the first portion. Less than all of the wetted surfaces are coated.

Owner:CATERPILLAR INC

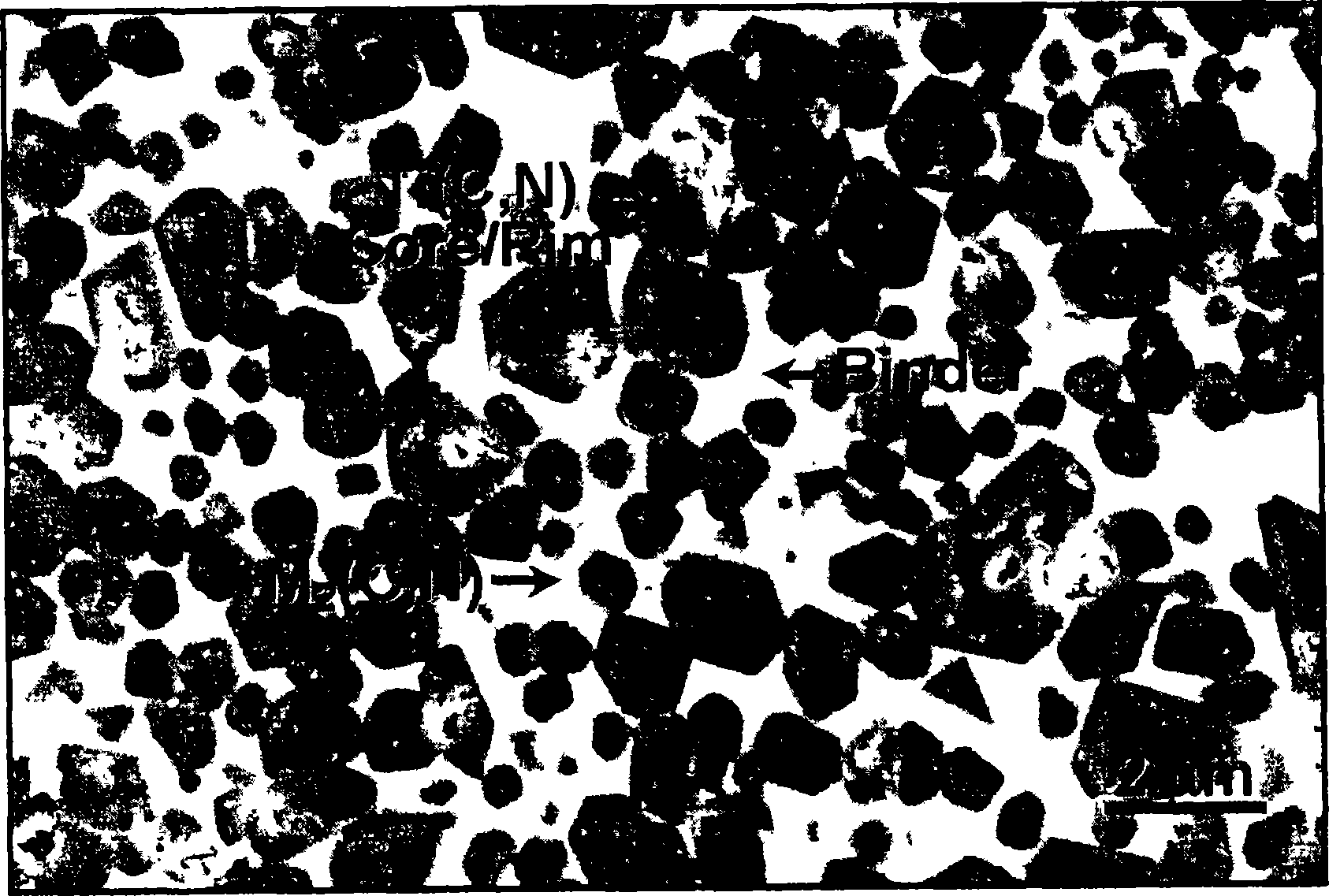

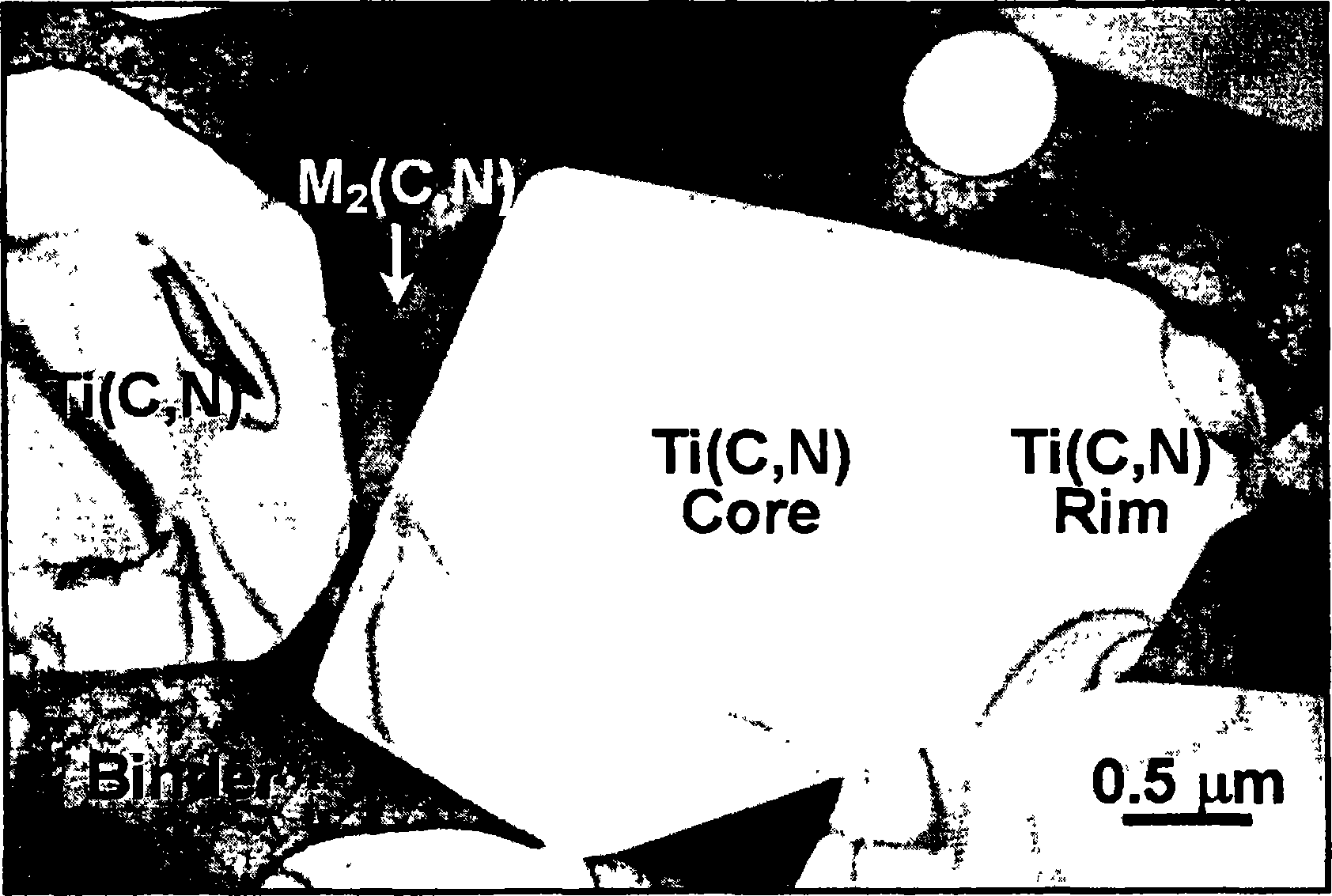

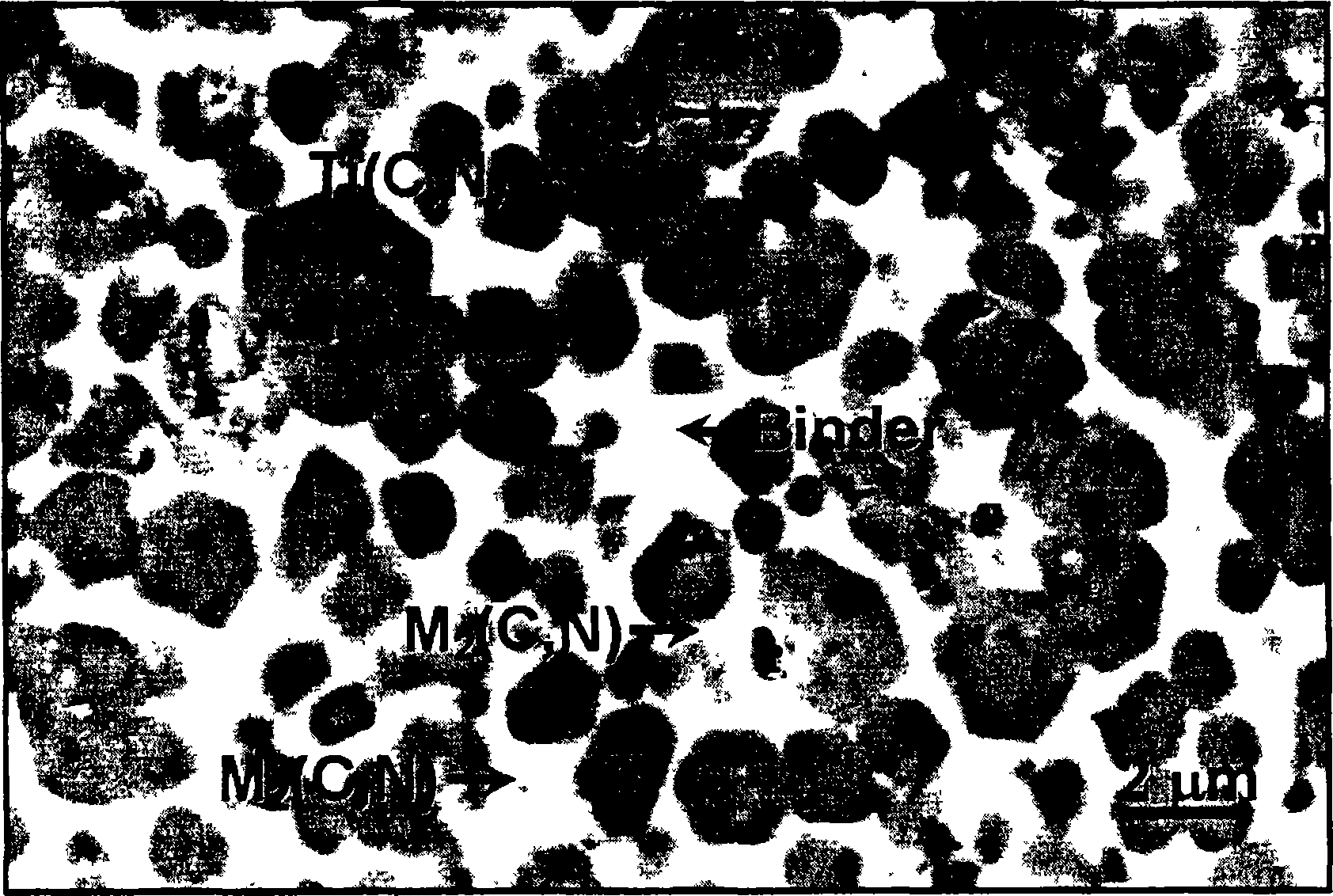

Advanced erosion-corrosion resistant boride cermets

A cermet composition represented by the formula (PQ)(RS) comprising: a ceramic phase (PQ) and binder phase (RS) wherein, P is at least one metal selected from the group consisting of Group IV, Group V, Group VI elements, Q is boride, R is selected from the group consisting of Fe, Ni, Co, Mn and mixtures thereof, S comprises at least one element selected from Cr, Al, Si and Y.

Owner:EXXON RES & ENG CO

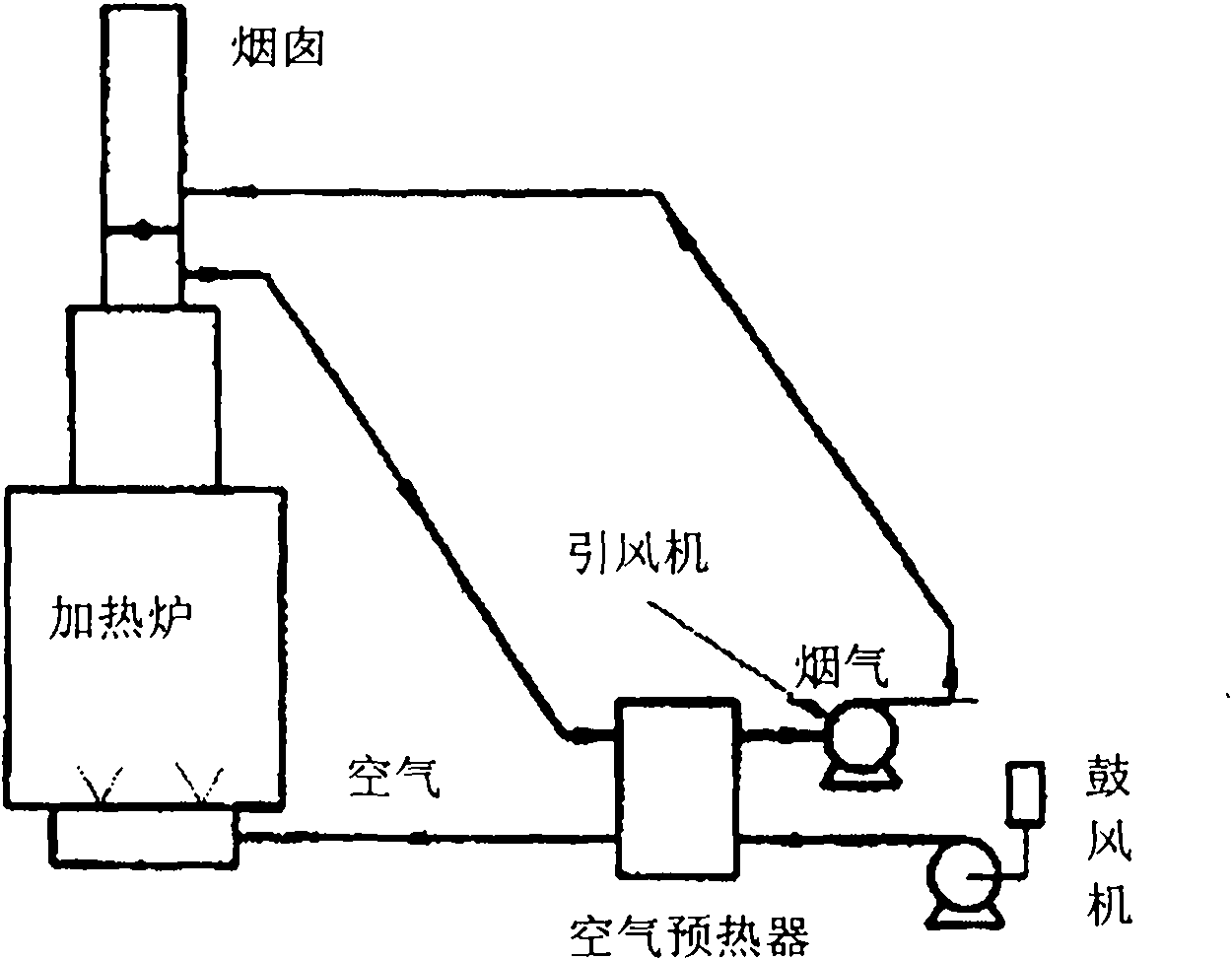

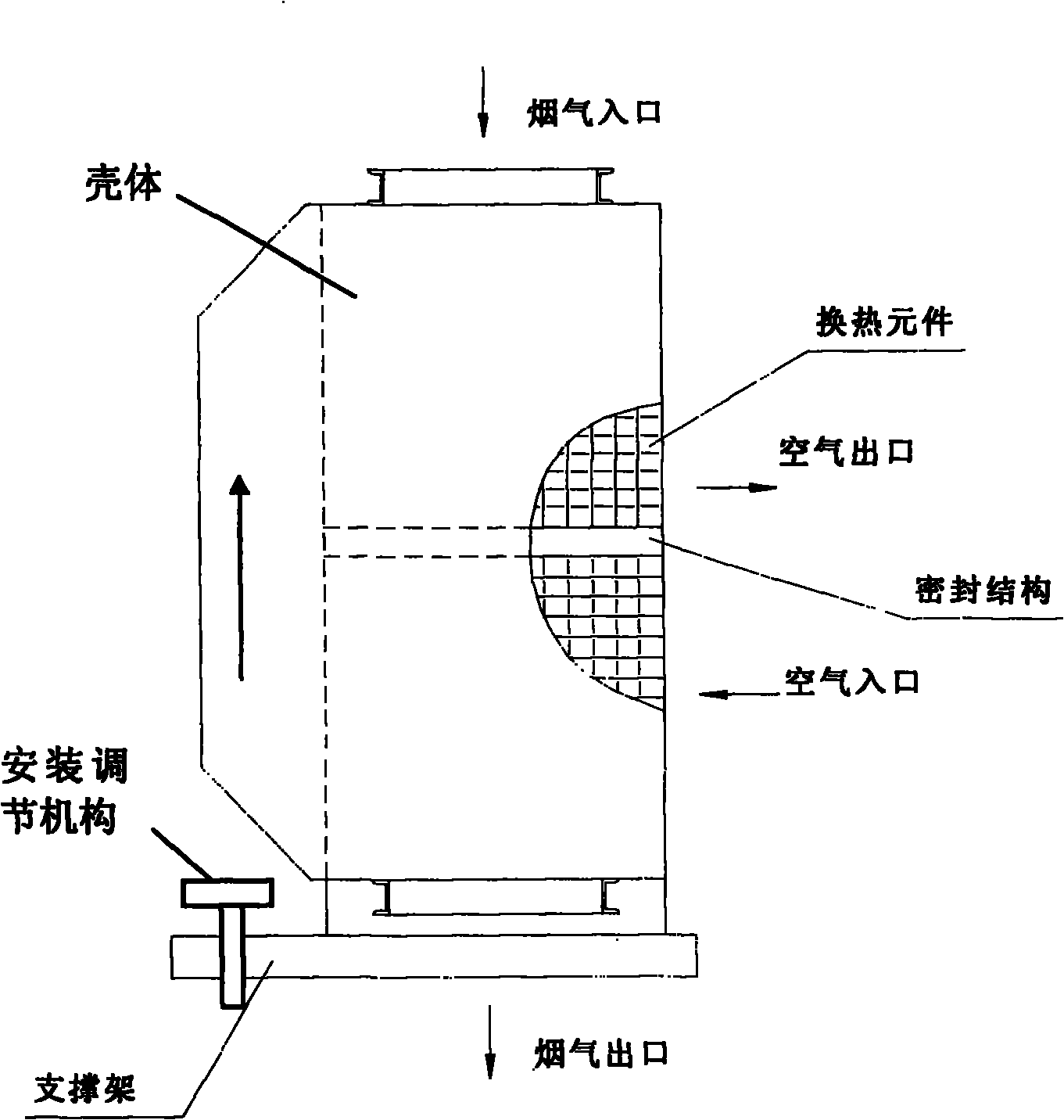

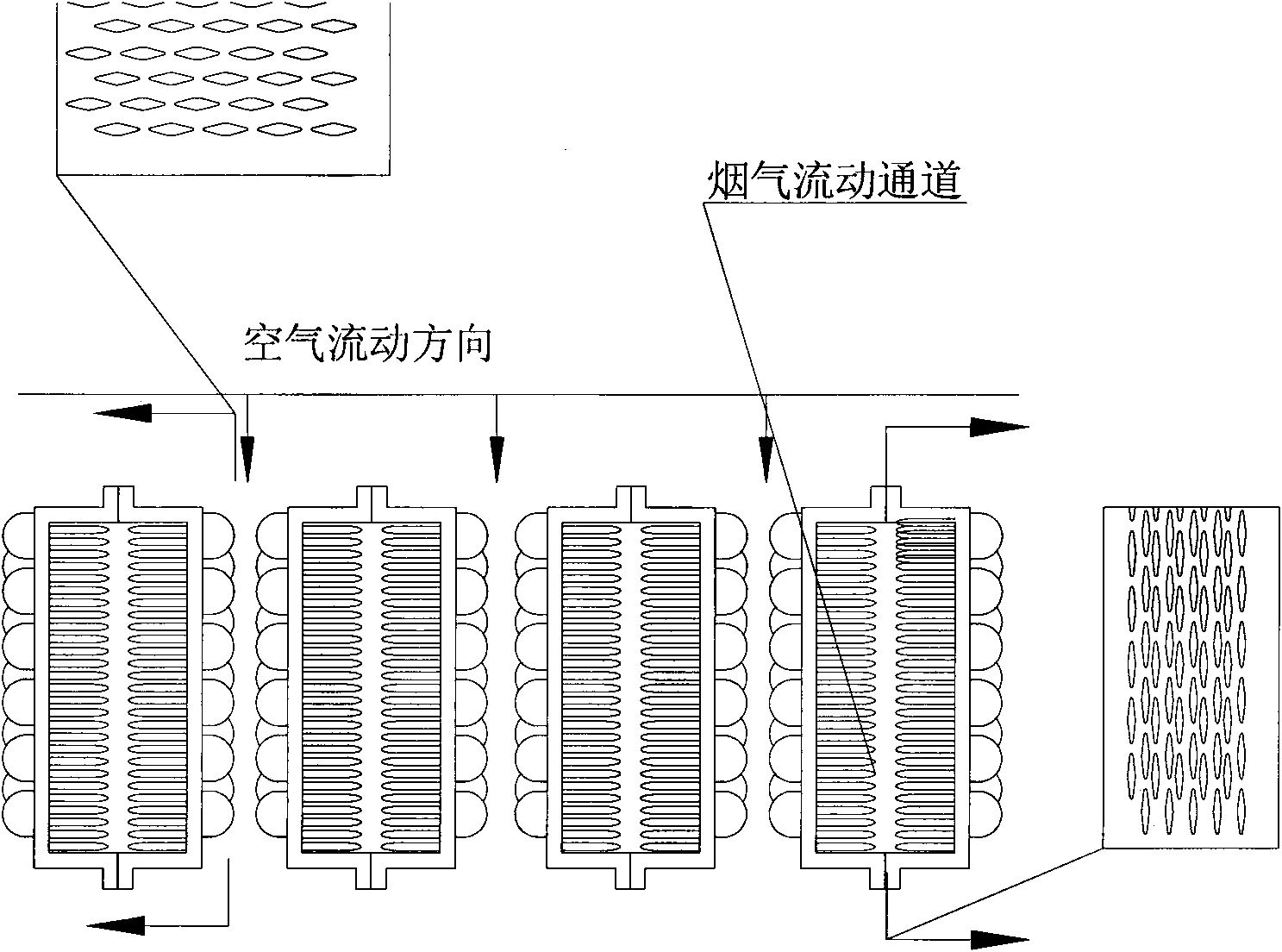

Anti-failure structure for cast iron air preheater and key process thereof

InactiveCN101858604AExtend the life cycleReduce maintenance costsCombustion processCorrosion preventionAir preheaterCrack resistance

The invention relates to an anti-failure structure for a cast iron air preheater and a key process thereof, which can slow down failures such as thermal stress cracking, stress corrosion cracking, erosion corrosion, deformed sealing leakage and the like. A major structure comprises a shell, an elastic sealing system and cast iron fin-plate heat exchange elements, and the anti-failure structure is characterized in that: sponge type metal wires are filled in a flue gas inlet end to enlarge heat-exchange areas, protect fins against the erosion of flue gas, obstruct granular impurities in the flue gas, homogenize inlet airflow and replace and clean conveniently; a primary seal between two flows consists of a concave-convex groove, a wavelike elastic leaf metal on the groove bottom and heated expansion bars filled in the groove, a planar auxiliary seal and a sliding sleeve auxiliary seal in the middle of a fin plate are arranged additionally to form a set of high-elasticity and fluctuation-resisting compound seal system; a gradient area type flow channel for supplementing the increase and decrease in the two flows enables the pressure of both sides of the fin plate to be balanced and maintains kinetic energy; and the manufacturing process for arc corners and the fin plate at the periphery of the flow channel improves the performance of heat deformation cracking resistance and erosion resistance of the cast iron air preheater. New products are particularly suitable for preheating air in heating furnaces.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Method and apparatus for testing high temperature fluid erosion corrosion resistance of material

InactiveCN106248514ARealize simulationStrong practical application guiding significanceWeighing by removing componentWeather/light/corrosion resistanceMaterial ErosionTest material

The invention provides a method and apparatus for testing the high temperature fluid erosion corrosion resistance of a material, and belongs to the field of experiments. The method for testing the high temperature fluid erosion corrosion resistance of the material comprises the following steps: selecting at least one metal material, and placing the at least one metal material in a flowing experiment flow medium, wherein an angle between the at least one metal material and the flow direction of the experiment fluid medium is adjustable, and the temperature and the speed of the experiment fluid medium are adjustable. The apparatus for testing the high temperature fluid erosion corrosion resistance of the material comprises a box body, a stirring driver and a material mounting rack, the box body is used for accommodating the high temperature experiment fluid medium and can be sealed, the stirring driver can drive the experiment flow medium to flow, the material mounting rack is used for mounting the test material, and the test material is placed in the experiment flow medium. The method and the apparatus can fully simulate erosion corrosion of the practical high temperature fluid to environment in order to objectively evaluate the high temperature fluid erosion corrosion resistance of the metal material.

Owner:SINOPEC ENG GRP CO LTD

Electrochemical pipeline erosion corrosion testing device

ActiveCN109444236AEnables electrochemical measurementsEasy to analyzeMaterial electrochemical variablesTest efficiencyMaterial Erosion

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

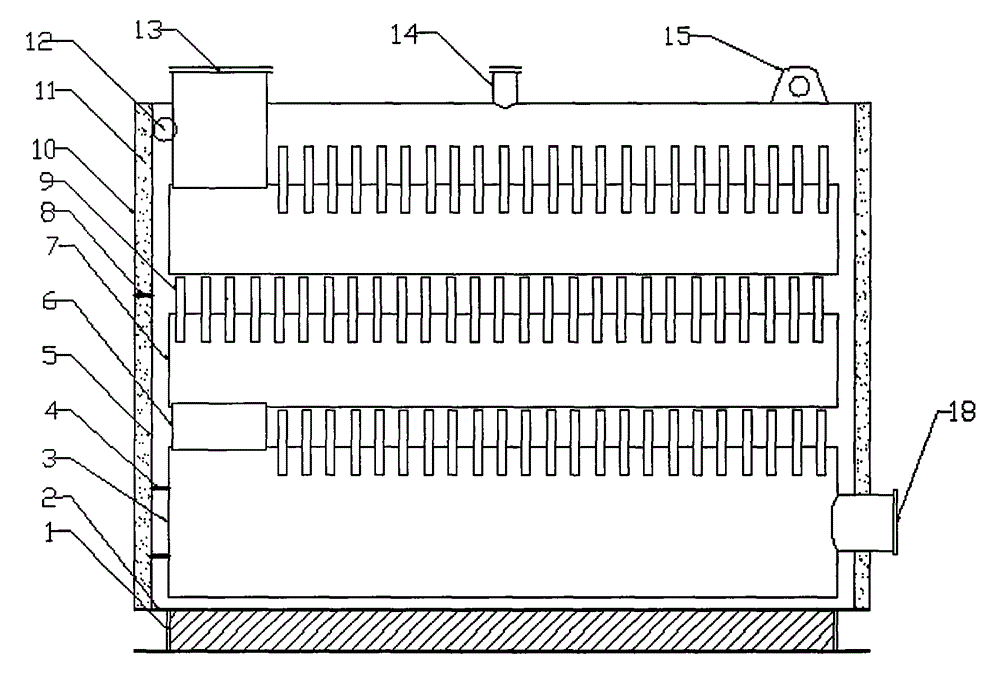

High-efficiency energy-saving normal-pressure horizontal super-conducting gas boiler

InactiveCN104913498AReduced scour wearReasonable reduction in flow rateIndirect heat exchangersCombustion technology mitigationCombustion chamberEngineering

The invention discloses a high-efficiency energy-saving normal-pressure horizontal super-conducting gas boiler, comprising an inner drum, an outer drum, an elbow, a flue, a heat pipe, a water inlet and outlet pipe and a discharge pipe; the inner drum is arranged in the outer drum, a pull nail is arranged between the inner drum and the outer drum, and a burner opening is formed in the inner drum; the flue is of a structure connected by the elbow, the heat pipe is arranged on the flue, and a flue outlet is connected to the flue; the outer drum, the flue and the heat pipe are all arranged in a packaging plate embedded with perlites; a proper amount of super-conducting heat pipes are welded and distributed in a plurality of smoke chambers, a super-conducting heat pipe technology is not only applicable for the tail waste heat recycling, but also is reasonably applicable for the boiler combustion chamber structure, so the hearth radiation and convective heat transfer area is increased and the heat efficiency is improved; in addition, the smoke flow rate is reduced reasonably by the continuous 90-degrees turning design of the flue, the erosion corrosion to the super-conducting heat pipes is reduced, thereby prolonging the service life of the heat pipes and the boiler.

Owner:安徽天晋超导科技有限公司

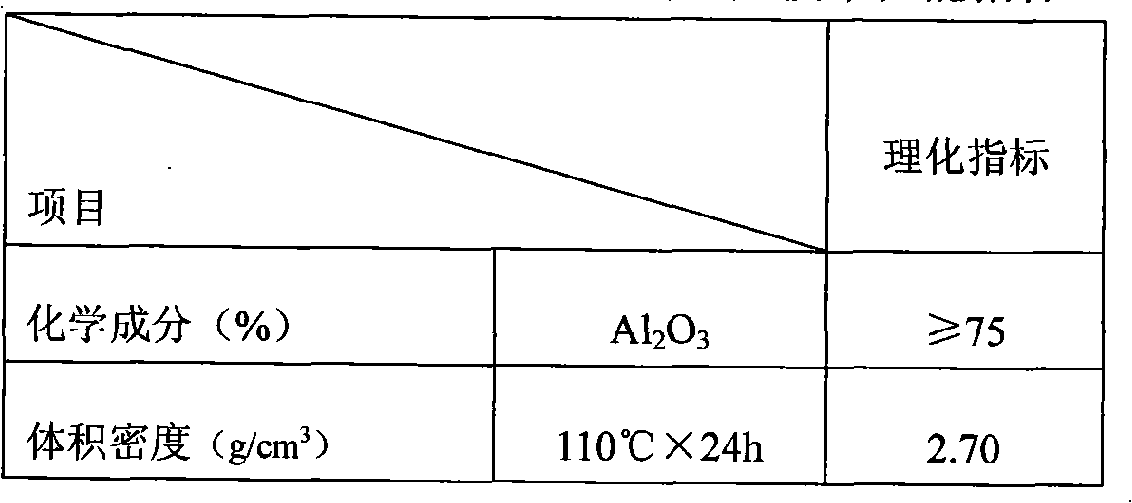

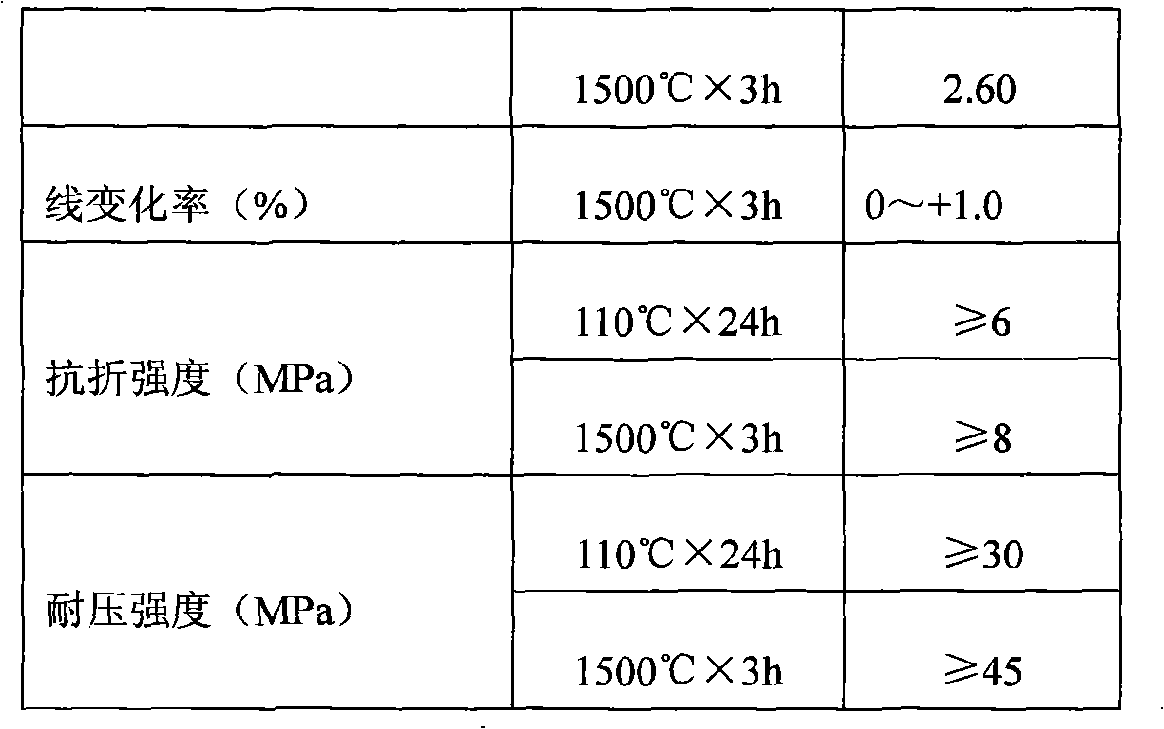

Ladle kerb casting material and ladle kerb preparation method thereof

The invention relates to ladle kerb casting material and a ladle kerb preparation method by the ladle kerb casting material. The casting material comprises the following components in weight percentage: 60-82% of ladle lining waste having a grain size of 1-8mm, 10-20% of bauxite grain size of 0.044-1mm, 2-10% of silicon dioxide superfine(less than or equal to 0.02mum), 5-10% of magnesium oxide fine powder grain size of 0.044-0.088 and 0.01-1% of sodium polyphosphate. The preparation method comprises ladle kerb lining waste selecting, crushing, mixing evenly and adding water while stirring, casting, maintaining, baking and the like. The waste ladle kerb casting material is recycled by the preparation method so that the production cost of the fireproof materials and the steel-making cost can be obviously reduced, the economic benefit is improved and the social meaning of protecting environment and saving energy can be realized; the ladle kerb prepared by the ladle kerb casting material has the advantages of good high-temperature volume stability, enough common / medium / high temperature strength, strong anti-slag corrosion and anti erosion-corrosion, thus satisfying the requirements for maintaining the normal running of the ladles.

Owner:HENAN GENGSHENG REFRACTORIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com