High-temperature high-pressure tubular-flow erosion corrosion experiment device

A high-temperature, high-pressure, erosion-corrosion technology, applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as difficult erosion-corrosion mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

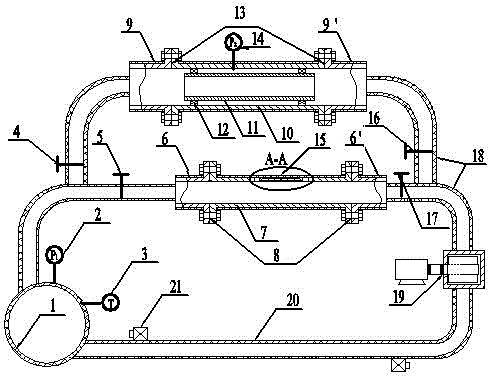

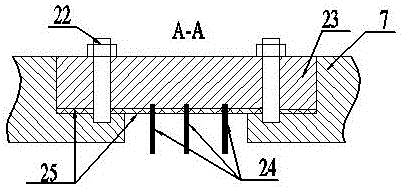

[0016] Referring to the accompanying drawings, the present invention proposes a high-temperature and high-pressure pipe-flow erosion corrosion test device, which mainly includes: a high-temperature autoclave 1, a first pressure gauge 2, a thermometer 3, a first valve 4, a second valve 5, a first, The second joint 6 and 6', the sample test pipe 7, the first flange 8, the third and fourth joints 9 and 9', the physical test pipe 10, the physical pipe 11, the first corrosion-resistant sealing ring 12, the second Flange 13, second pressure gauge 14, sample tank 15, third valve 16, fourth valve 17, heat insulation layer 18, magnetic pump 19, infusion tube 20, ultrasonic flowmeter 21, bolt 22, cover plate 23, test Sample 24, the second corrosion-resistant sealing ring 25, wherein the high-temperature autoclave 1 is used to provide fluid with a certain temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com