Patents

Literature

73results about How to "Reduced scour wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas-blowing and slag-gathering spray gun for assisting slag-off of molten iron and using method of spray gun

ActiveCN103114177AReduce wear rateReduce wearCharge manipulationCasting cleaning apparatusSlagEngineering

The invention discloses a gas-blowing and slag- gathering spray gun for assisting slag-off of molten iron and a using method of the spray gun. The gas-blowing and slag-gathering spray gun comprises a gun barrel, wherein the gun barrel is provided with an opening end and a closed end; spray ports are symmetrically formed on the barrel wall, close to the closed end, of the gun barrel based on the middle axis of the gun barrel; the middle axes of the spray ports are vertical to the middle axis of the gun barrel; and the ratio of the inner diameters of the spray ports to the inner diameter of the gun barrel is (0.35-0.70):1. The gas-blowing and slag-accreting spray gun has the characteristics of being simple in structure, long in service life, stable in gas-blowing and slag-accreting operation and the like. The gas-blowing and slag-gathering spray gun disclosed by the invention is combined with the using method of the spray gun, so that the molten iron slag gathering degree can be improved, the bare area of the molten iron is increased, the erosive wear to the molten iron tank wall is small, the slag-off iron loss is low and the slag-off time is short.

Owner:武汉钢铁有限公司

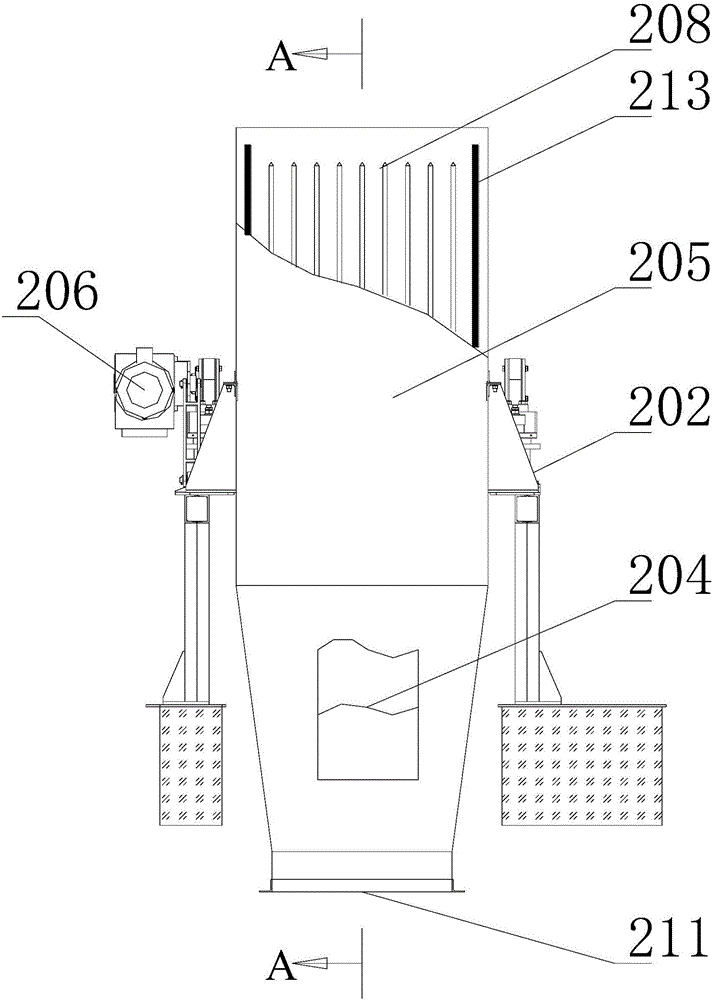

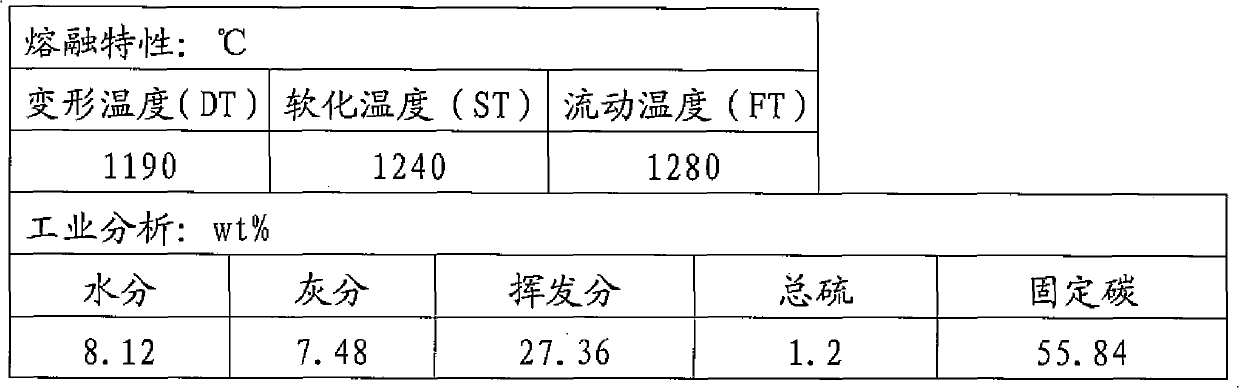

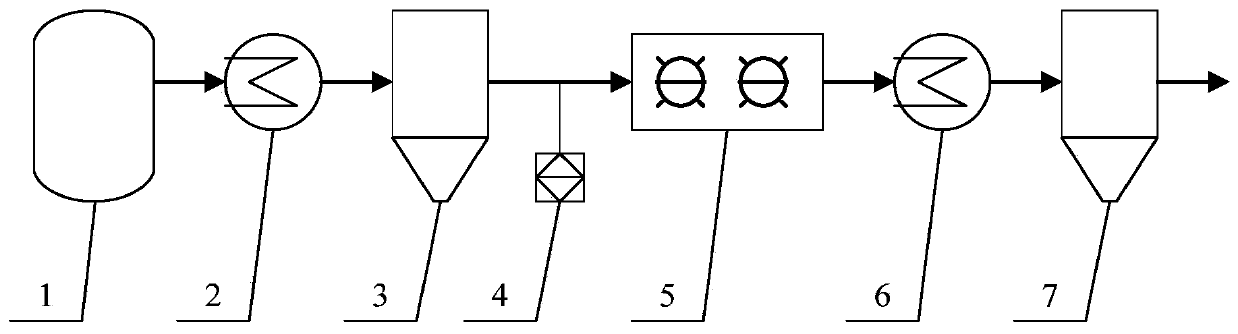

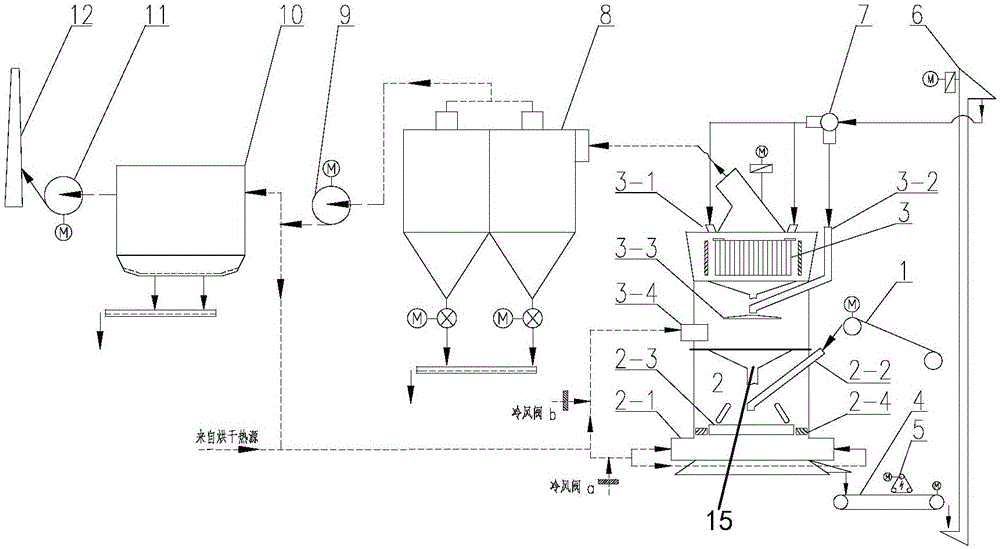

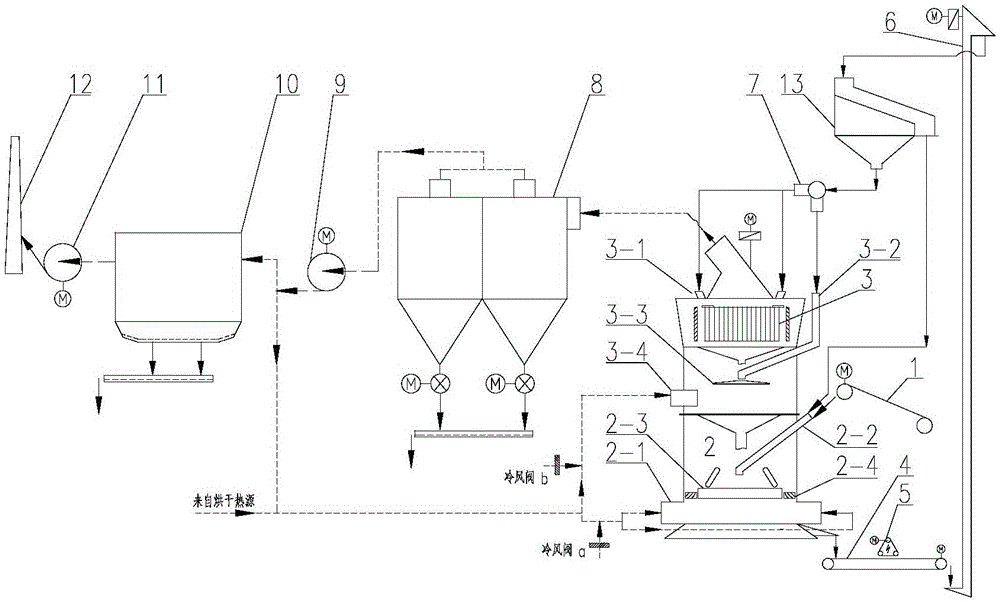

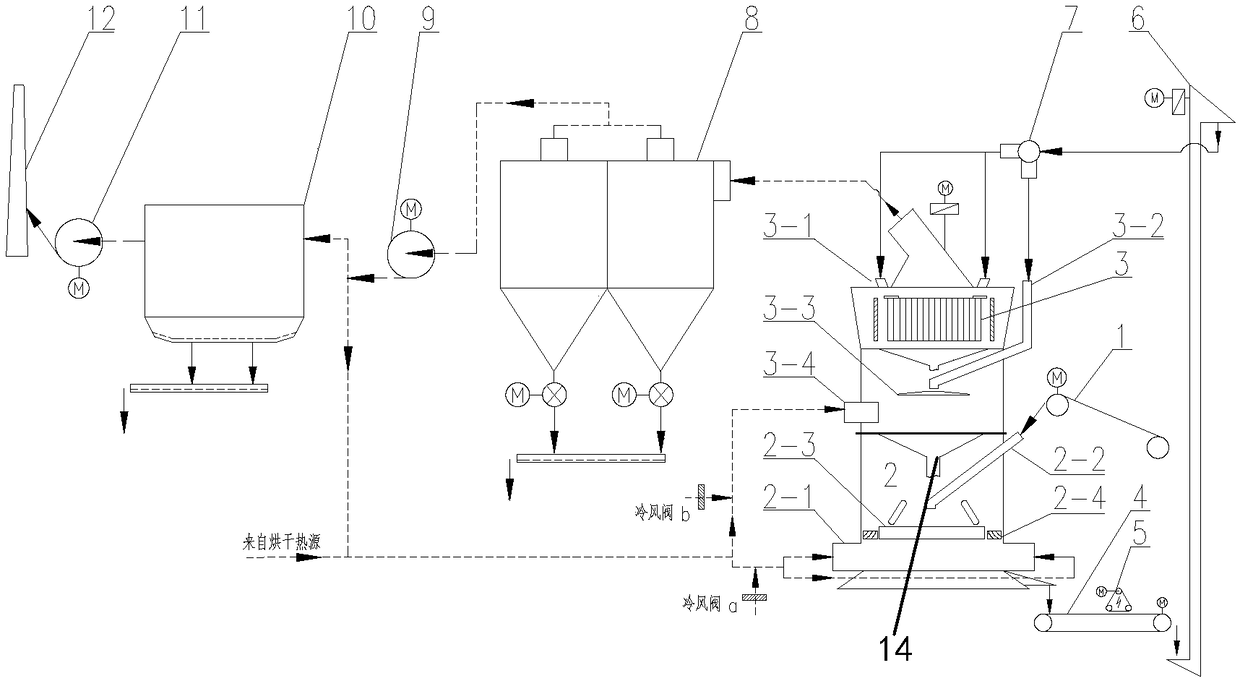

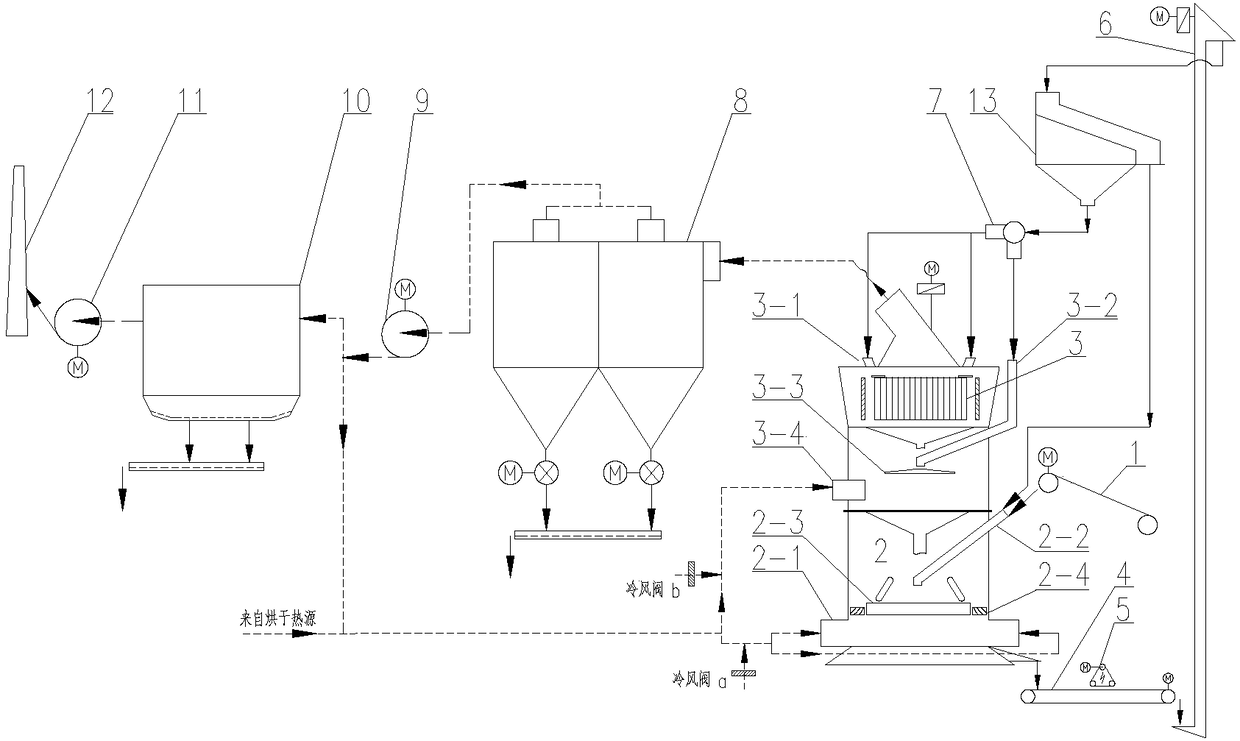

Method of large-proportion coal slime blending combustion of circulating fluidized bedboiler

ActiveCN105953257AIncrease the amount of blendingImprove efficiencyLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationFluidized bedProcess engineering

The invention discloses a method of large-proportion coal slime blending combustion of a circulating fluidized bedboiler. The method comprises the steps of (1) coal slime screening; (2) coarse slime unloading; (3) coarse slime airing and drying; (4) conveying of humidity-qualified coarse slime to a coal handling system; (5) coal conveying of the coal handling system; (6) coal feeding of the circulating fluidized bedboiler; and (7) combustion of fuel coal in the circulating fluidized bedboiler. The method of large-proportion coal slime blending combustion of the circulating fluidized bedboiler has the advantages that after low bed pressure operational optimization is implemented, the boiler efficiency reaches up to 91.9% and is increased by 1.9% when compared with a design value, the vibration of a material return device is effectively controlled, and the abrasion of a boiler heating surface is reduced; by means of implementation of low oxygen combustion optimization, the cost can be reduced by 4,800,000 RMB annually, and the standard coal can be saved by approximately 5,120 tons annually; and the generation of part of nitric oxide can be inhibited from the angle of combustion, and the urea usage amount of an SNCR system can be reduced.

Owner:INNER MONGOLIA JINGTAI POWER GENERATION

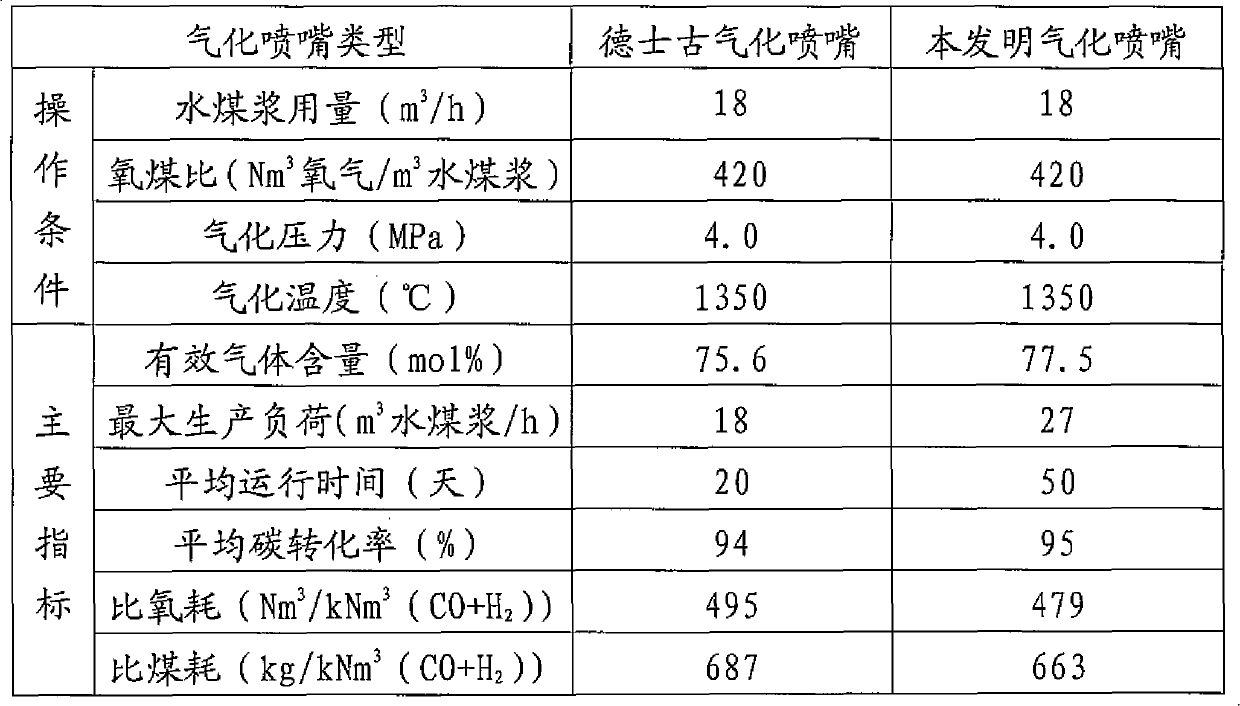

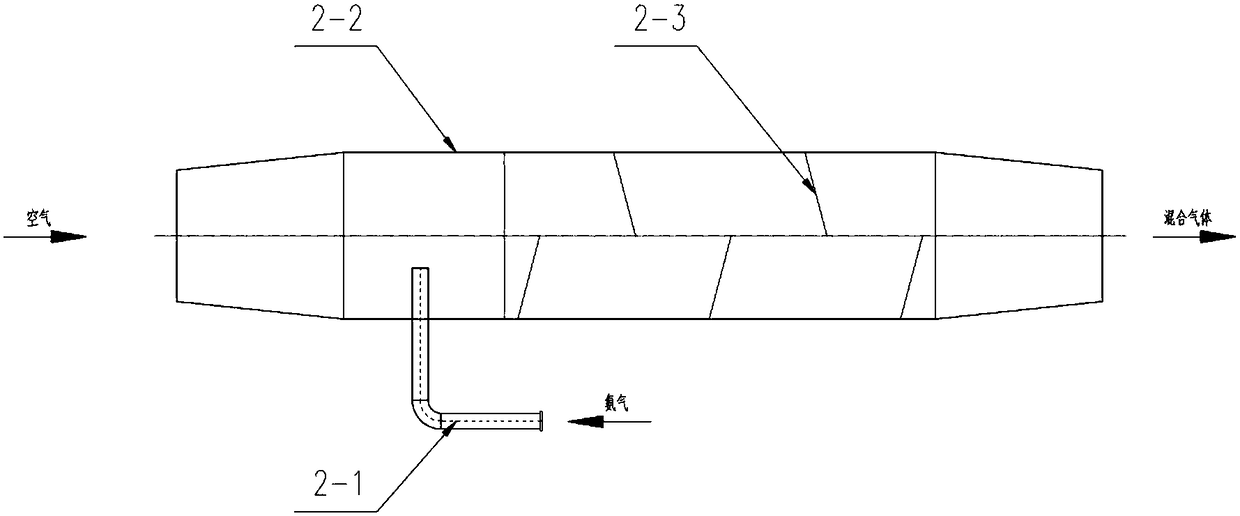

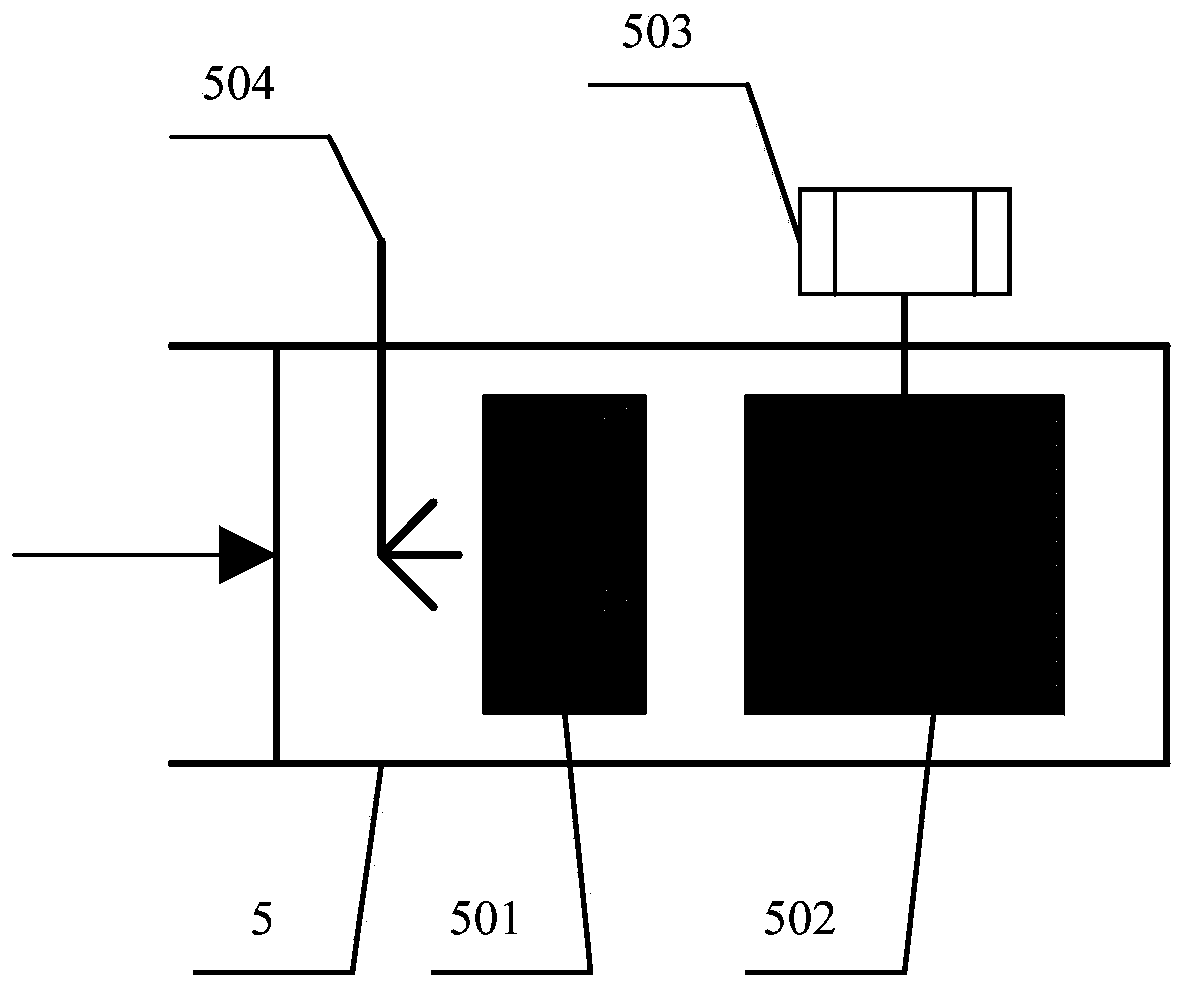

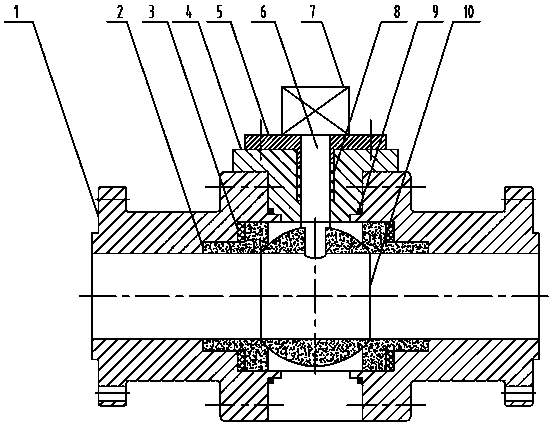

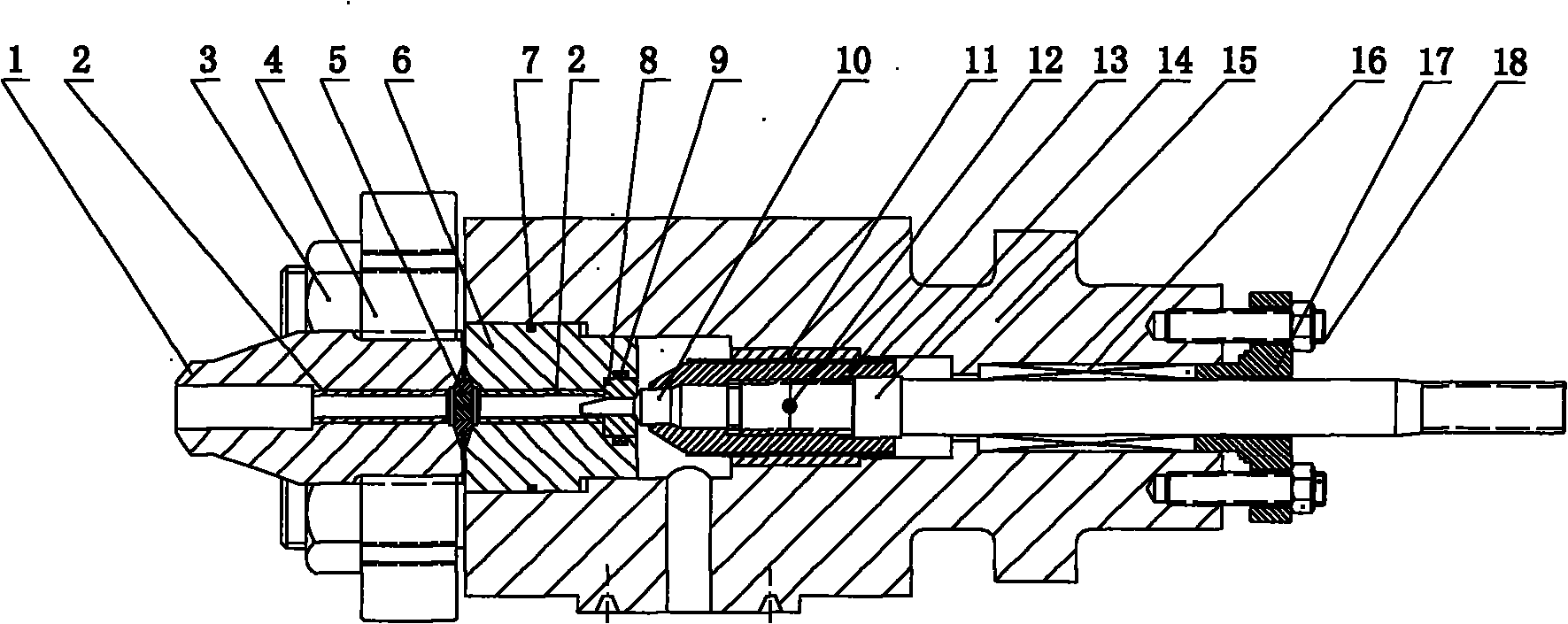

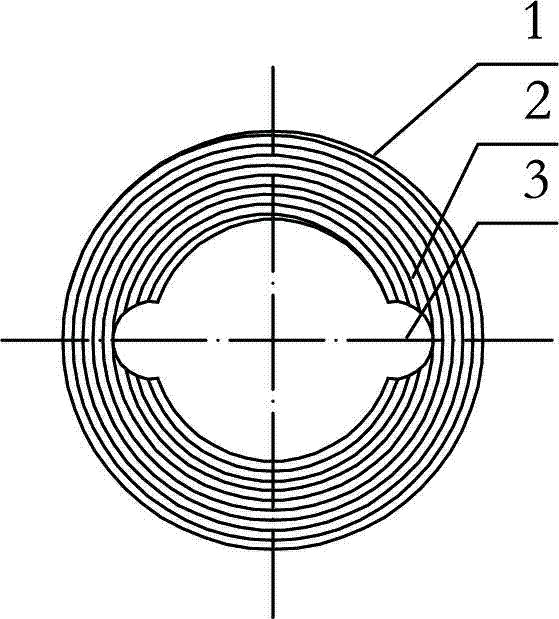

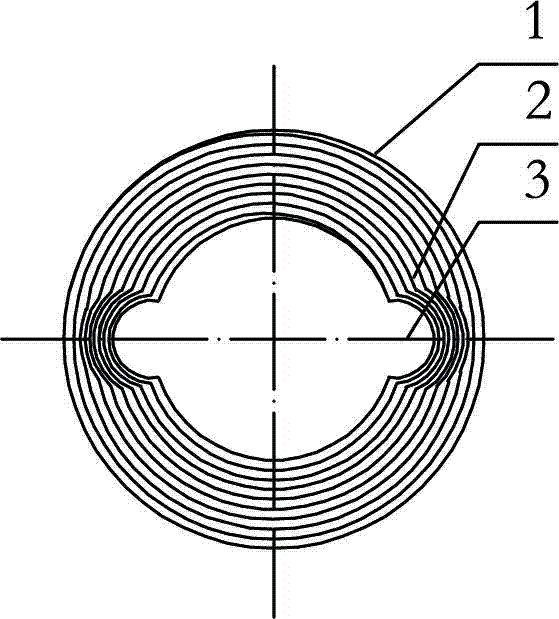

A gasification nozzle

InactiveCN102260533AImprove premix atomization effectWell mixedLiquid spraying apparatusGranular/pulverulent flues gasificationEpoxyCoal water

A gasification nozzle, which comprises a central oxygen nozzle, a coal-water slurry nozzle and an epoxy nozzle that are concentrically arranged from the inside to the outside, wherein the end section of the central oxygen nozzle is relative to the inner diameter of the end section of the coal-water slurry nozzle. The shrinkage is 20mm-100mm; the inclination angle of the epoxy nozzle is 20°-50°; the inclination angle of the outer side of the coal-water slurry nozzle is 30°-70°, and the inclination angle of the inner side is 30°-80°; the center The outside inclination angle of the oxygen nozzle is 30°-70°; a first locator is arranged in the epoxy channel, and a second locator is arranged in the coal-water slurry channel, and the top of the first locator is in the shape of a swirl sheet, so The included angle between the top and the feeding direction of oxygen is 20°-60°. When the gasification nozzle of the invention is used for gasification, the gasification effect of the coal-water slurry is better, the maximum production load of the gasification nozzle is increased, and the service life of the gasification nozzle is longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

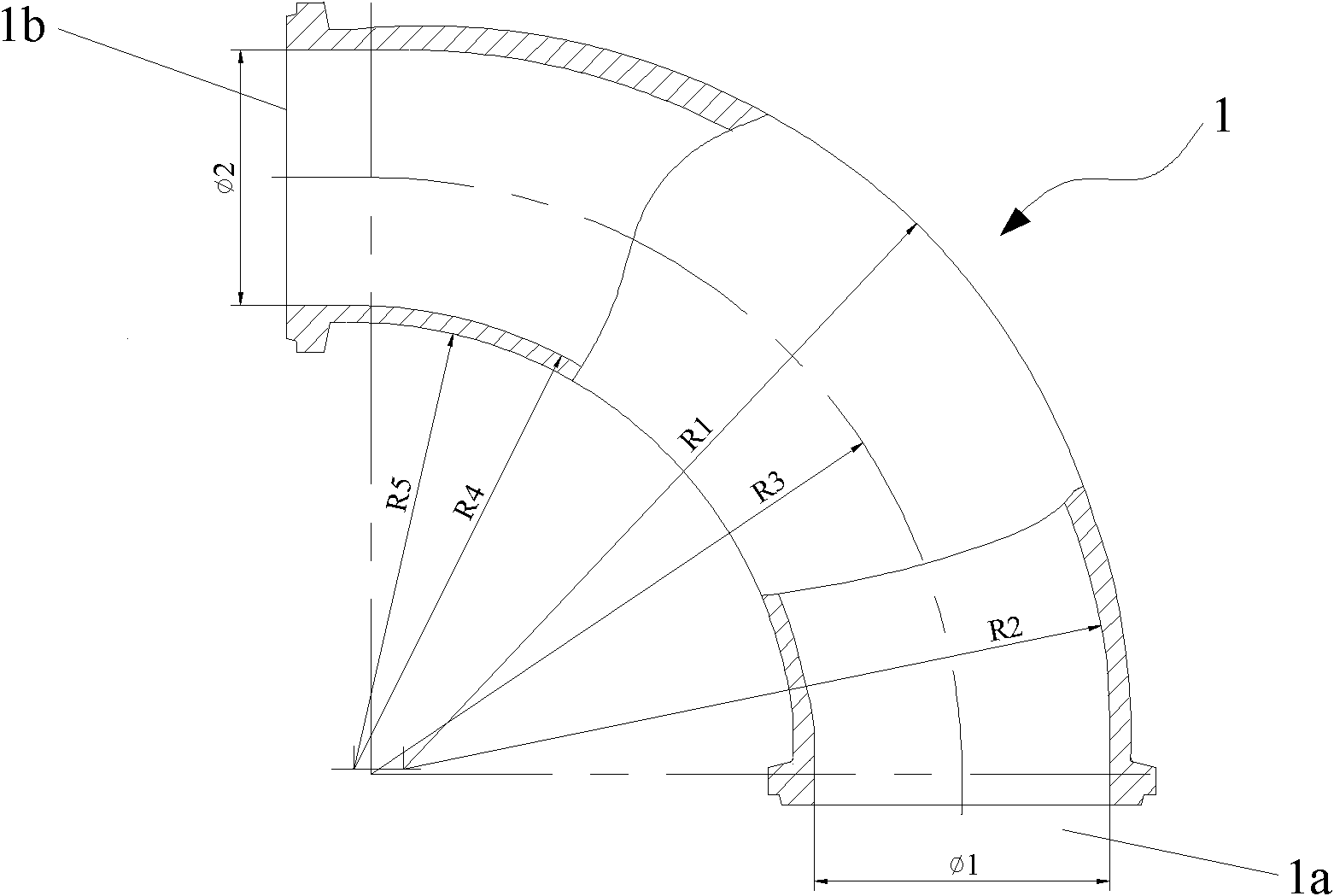

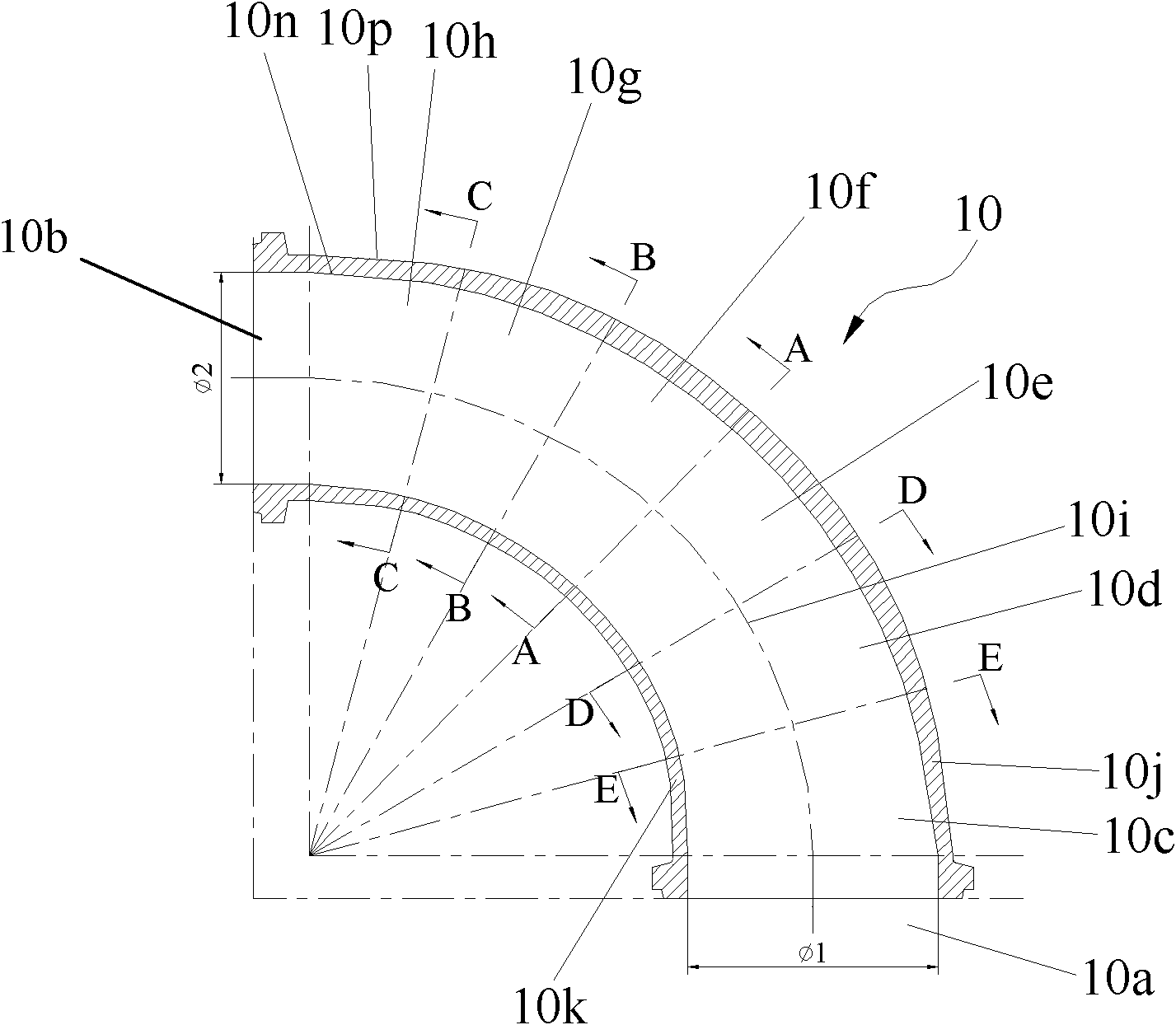

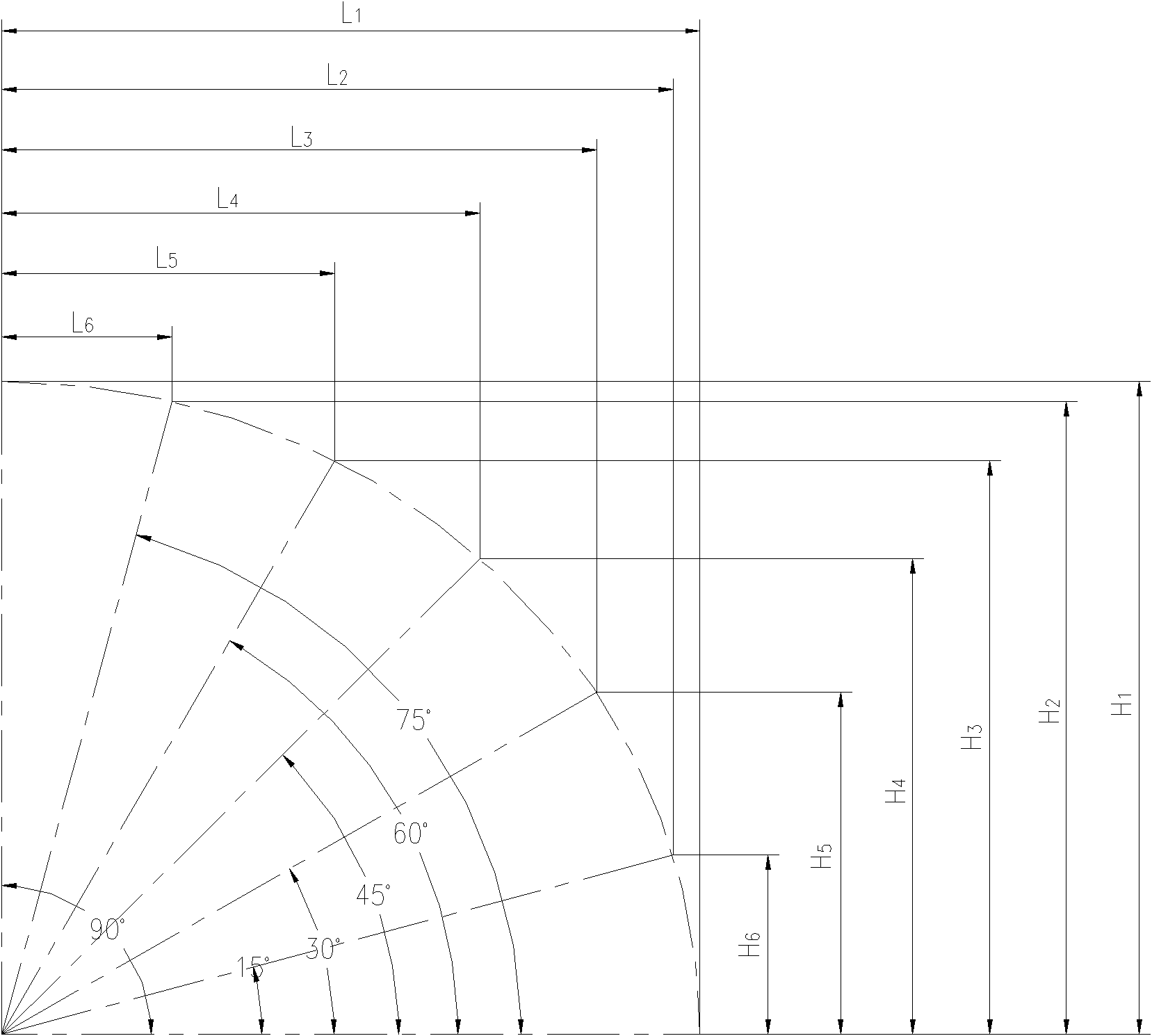

Reducing bent pipe and pumping equipment with same

ActiveCN102109077ASmall pressure lossReduce shockPumpsPositive-displacement liquid enginesEngineeringPiping

The invention provides a reducing bent pipe and pumping equipment with the same, and integrally relates to the field of material conveying. The reducing bent pipe is used in a fluid transportation piping, comprises an input end and an output end, and is characterized in that the radius of curvature of the reducing bent pipe increases from the input end to the output end. As the bending and the reducing degree of the reducing bent pipe are optimally designed, impact of transported materials on the reducing bent pipe can be effectively reduced, and the service life of the reducing bent pipe canbe prolonged.

Owner:ZOOMLION HEAVY IND CO LTD

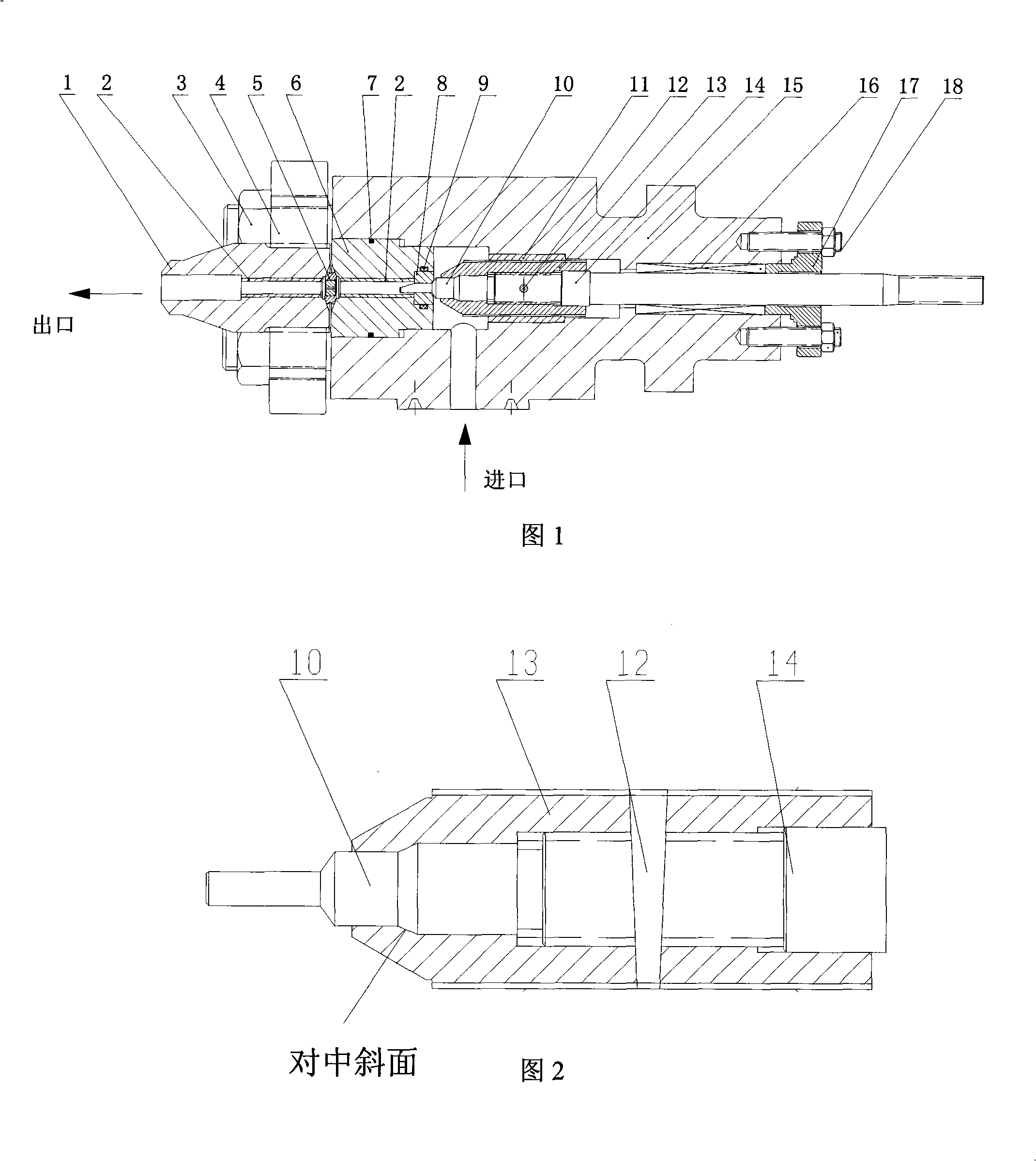

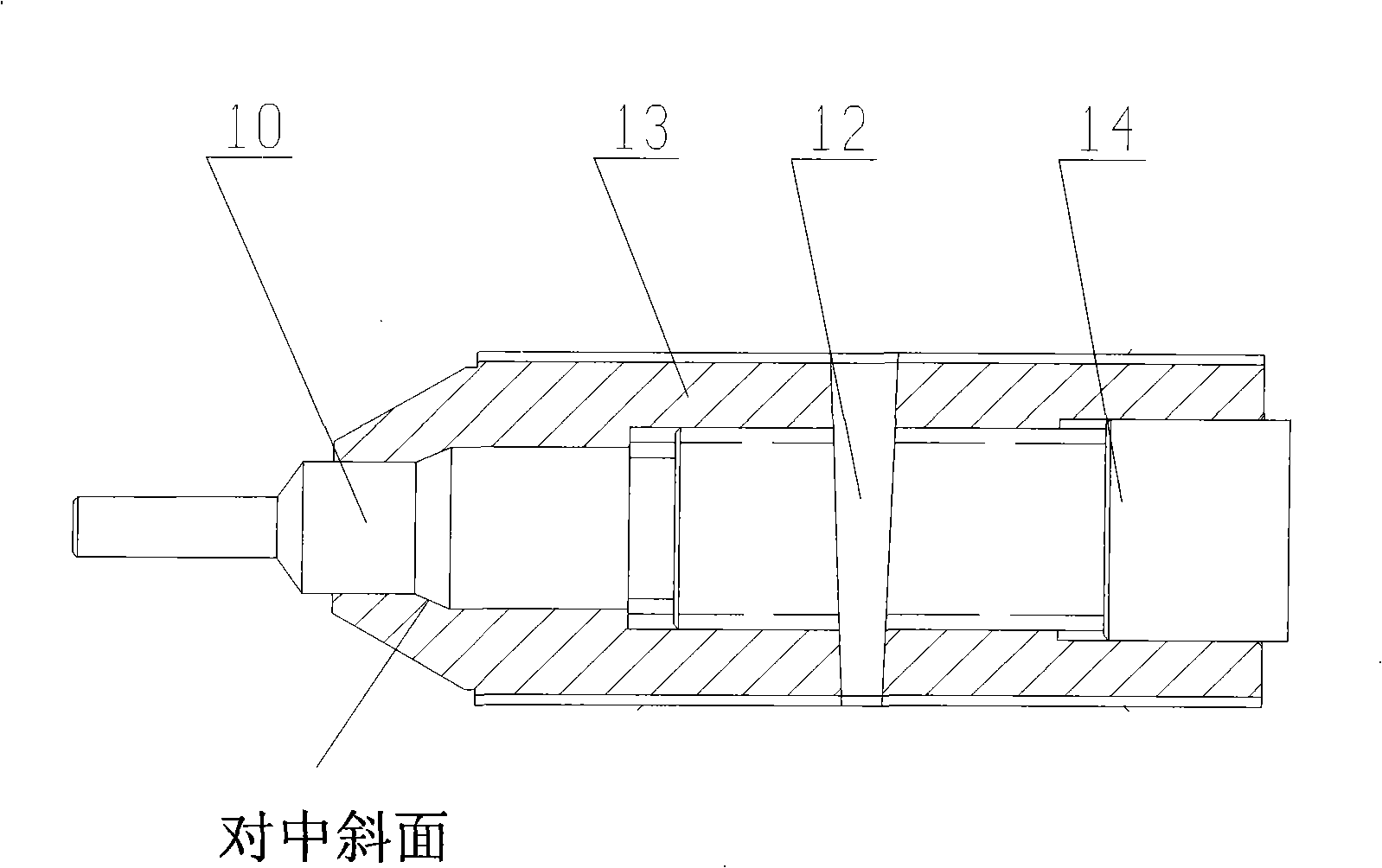

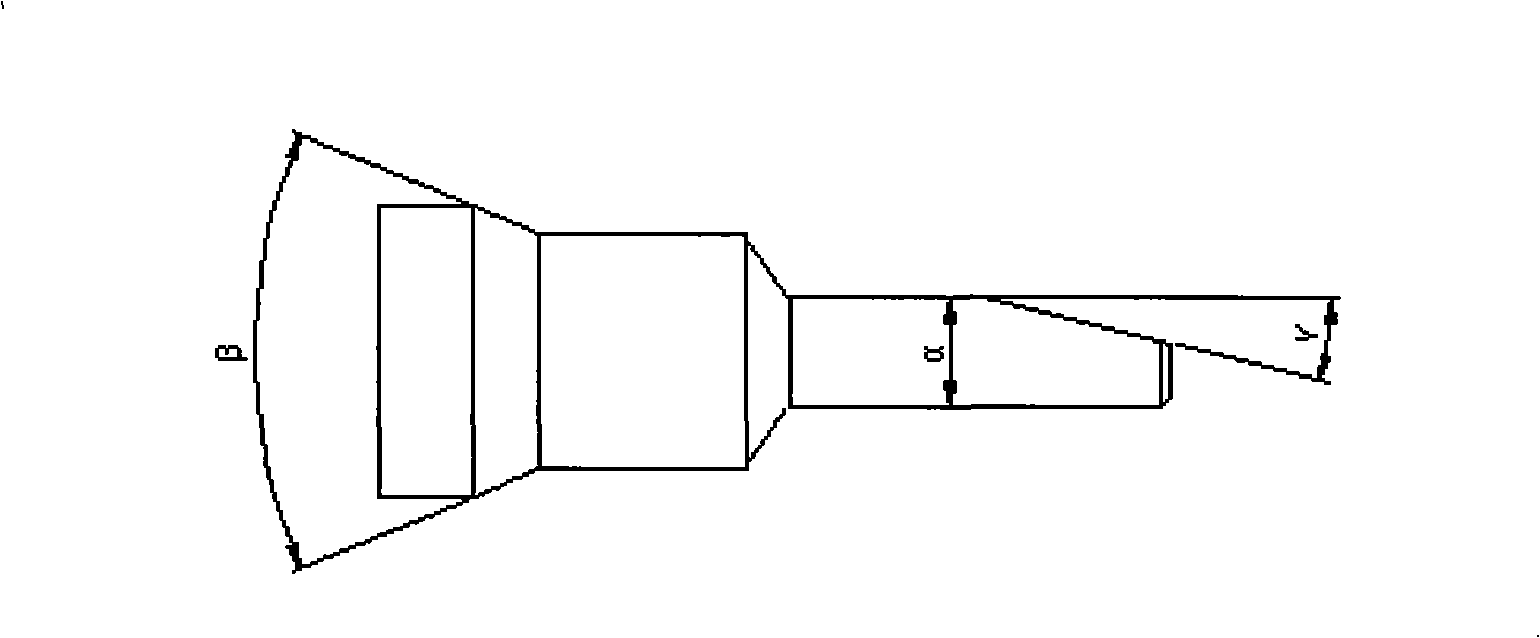

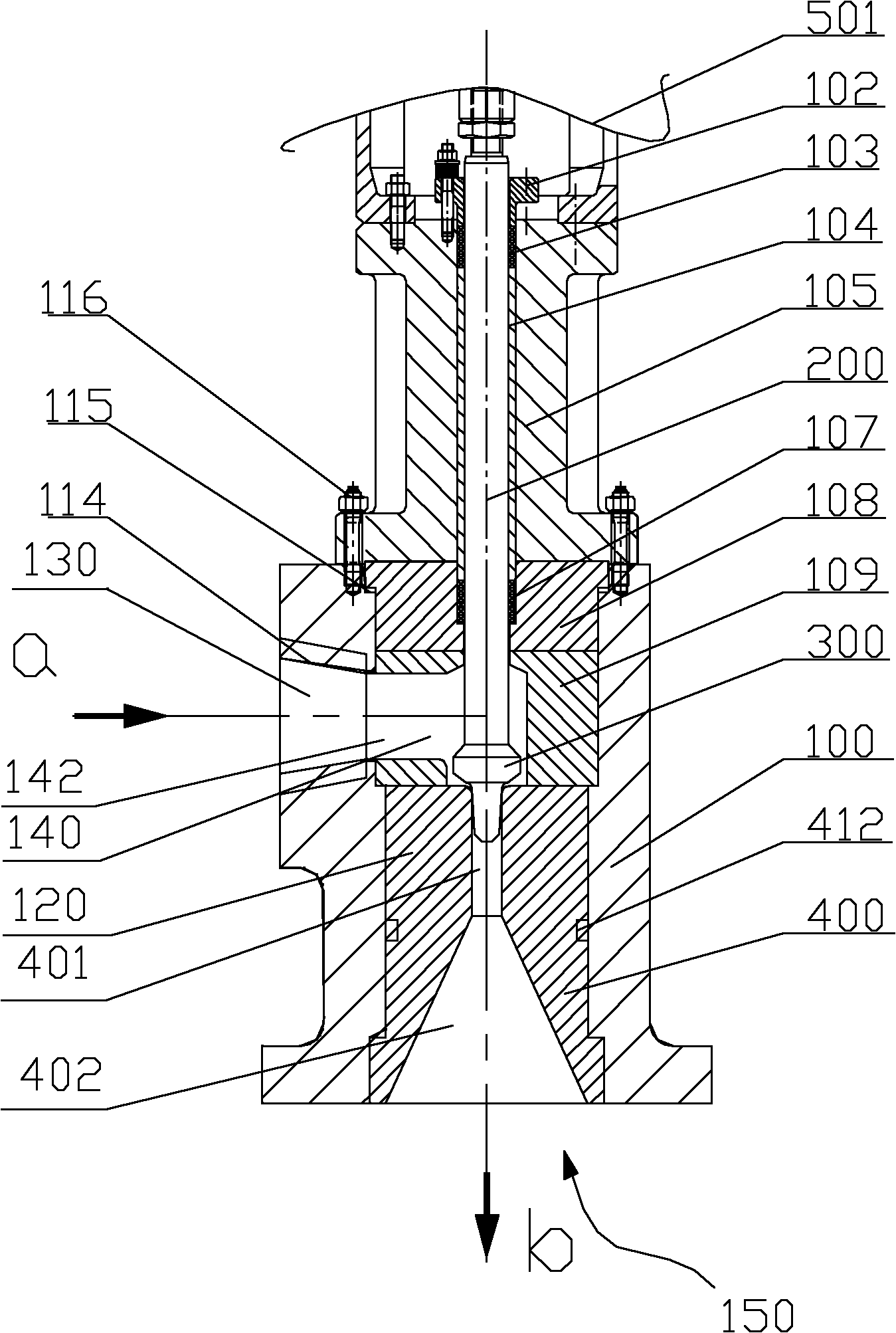

High-temperature high-pressure difference pressure-reducing valve

InactiveCN101403448ASimple structureExtended service lifeSpindle sealingsValve members for heating/coolingControl systemEngineering

The invention relates to a high temperature high pressure difference reducing valve, which is characterized in that the reducing valve comprises a valve body, a valve seat, and a valve core which is positioned in the valve seat and can move up and down in the valve seat; the valve core is fixedly connected with a valve rod by a thread and a pin; the valve rod is positioned in the valve body, sealed from the outside world by sealing packing and a packing gland, and can move up and down; the lower part of the valve seat is provided with a bush, a throttle orifice and a flange which is connected with the outer part; and a medium enters into a valve cavity from the side direction, and flows out from the tail end after flowing through a channel composed of the valve core and the valve seat, and the throttle orifice at the downstream of the valve seat,. Compared with the prior art, the high temperature high pressure difference reducing valve can reduce the pressure of materials with high temperature and high solid content, controls the pressure of systems and the liquid position of high-pressure tanks, not only can reduce the pressure and generate required large pressure reduction but also can carry out appropriate flow control; more importantly, the high temperature high pressure difference reducing valve can prevent harsh erosive wear formed by the high-speed flow of medium flow with high solid content under large pressure difference to the materials.

Owner:SHANGHAI RES INST OF CHEM IND +2

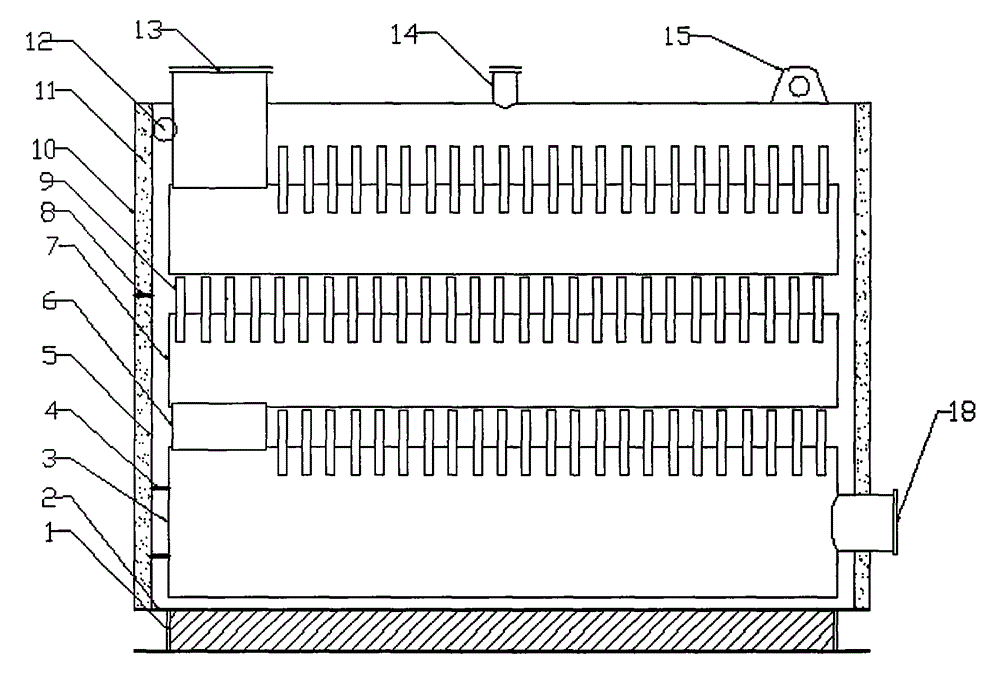

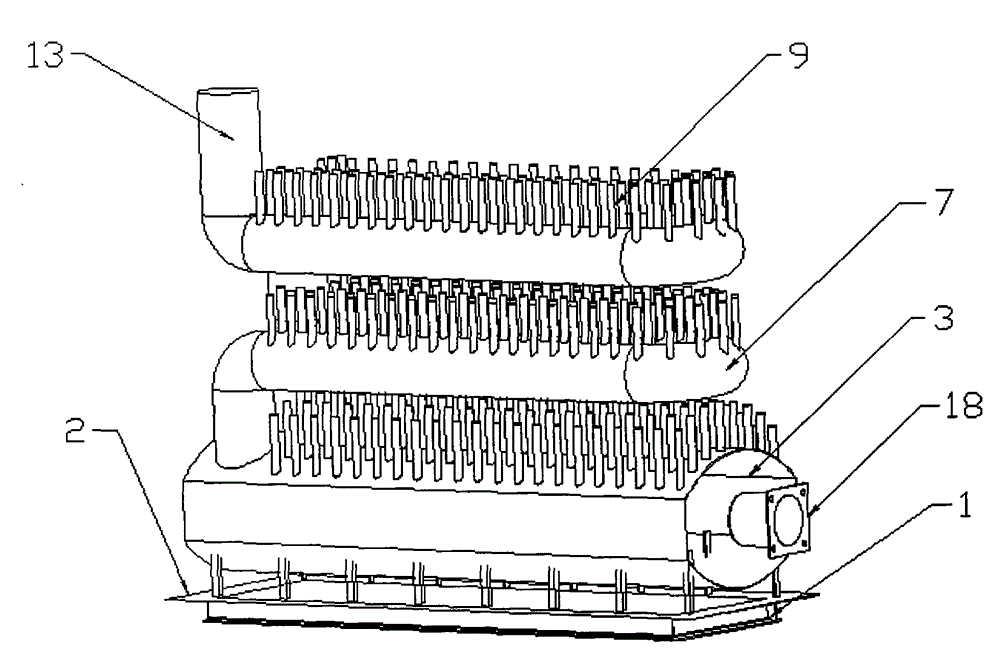

High-efficiency energy-saving normal-pressure horizontal super-conducting gas boiler

InactiveCN104913498AReduced scour wearReasonable reduction in flow rateIndirect heat exchangersCombustion technology mitigationCombustion chamberEngineering

The invention discloses a high-efficiency energy-saving normal-pressure horizontal super-conducting gas boiler, comprising an inner drum, an outer drum, an elbow, a flue, a heat pipe, a water inlet and outlet pipe and a discharge pipe; the inner drum is arranged in the outer drum, a pull nail is arranged between the inner drum and the outer drum, and a burner opening is formed in the inner drum; the flue is of a structure connected by the elbow, the heat pipe is arranged on the flue, and a flue outlet is connected to the flue; the outer drum, the flue and the heat pipe are all arranged in a packaging plate embedded with perlites; a proper amount of super-conducting heat pipes are welded and distributed in a plurality of smoke chambers, a super-conducting heat pipe technology is not only applicable for the tail waste heat recycling, but also is reasonably applicable for the boiler combustion chamber structure, so the hearth radiation and convective heat transfer area is increased and the heat efficiency is improved; in addition, the smoke flow rate is reduced reasonably by the continuous 90-degrees turning design of the flue, the erosion corrosion to the super-conducting heat pipes is reduced, thereby prolonging the service life of the heat pipes and the boiler.

Owner:安徽天晋超导科技有限公司

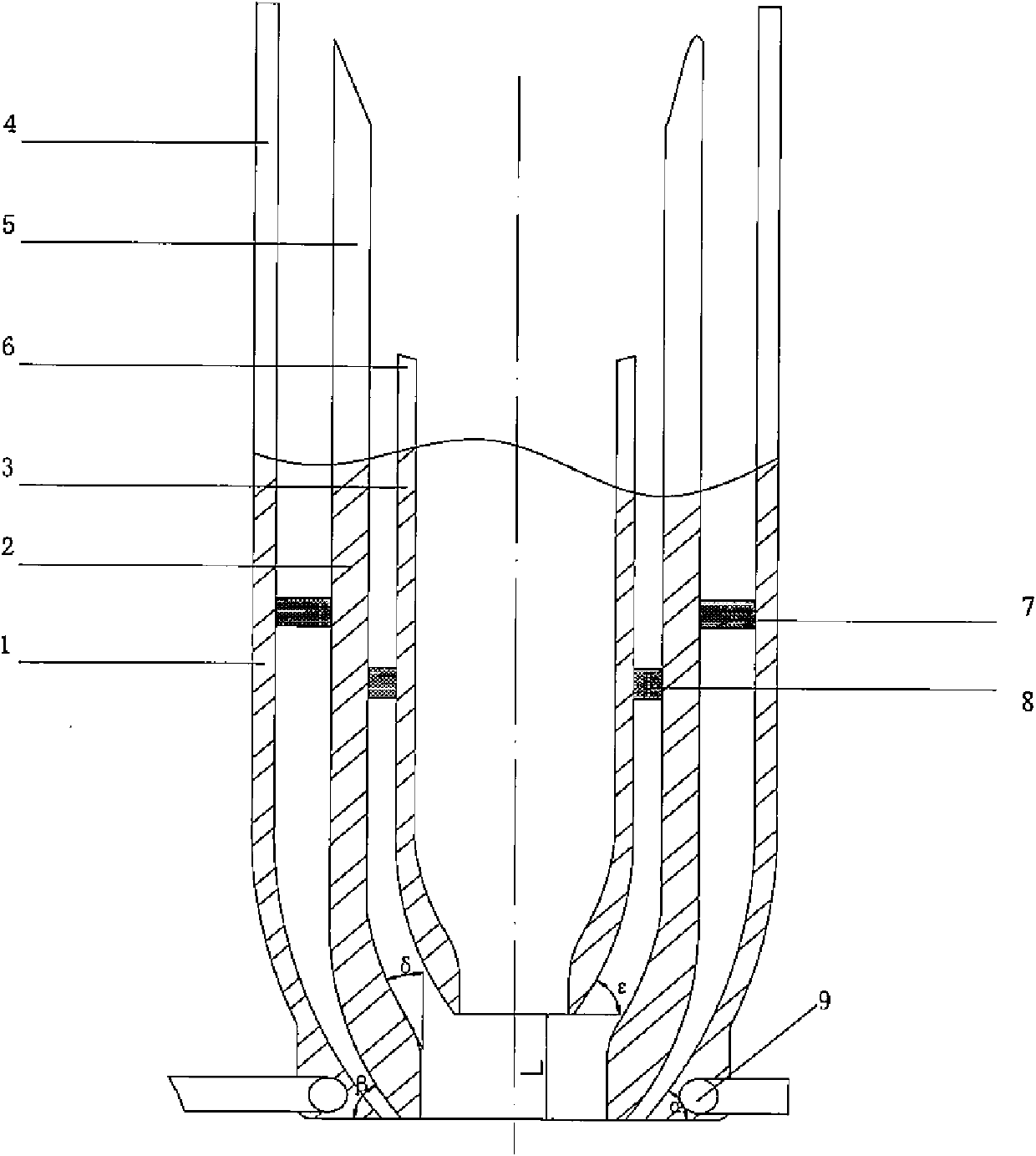

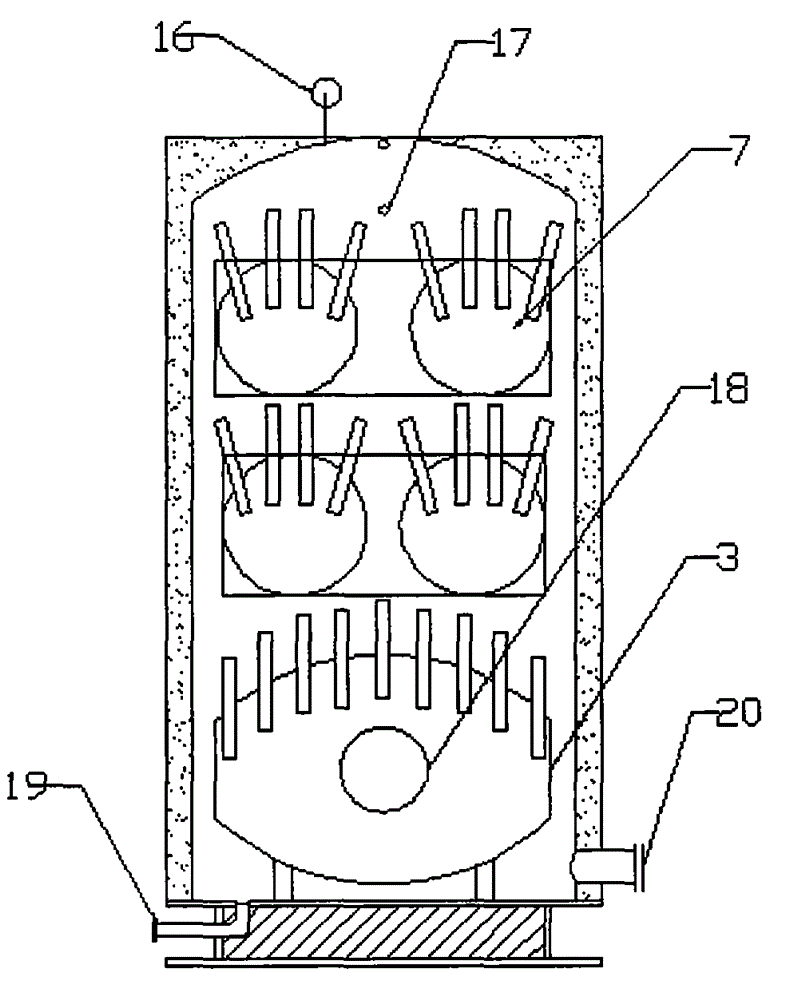

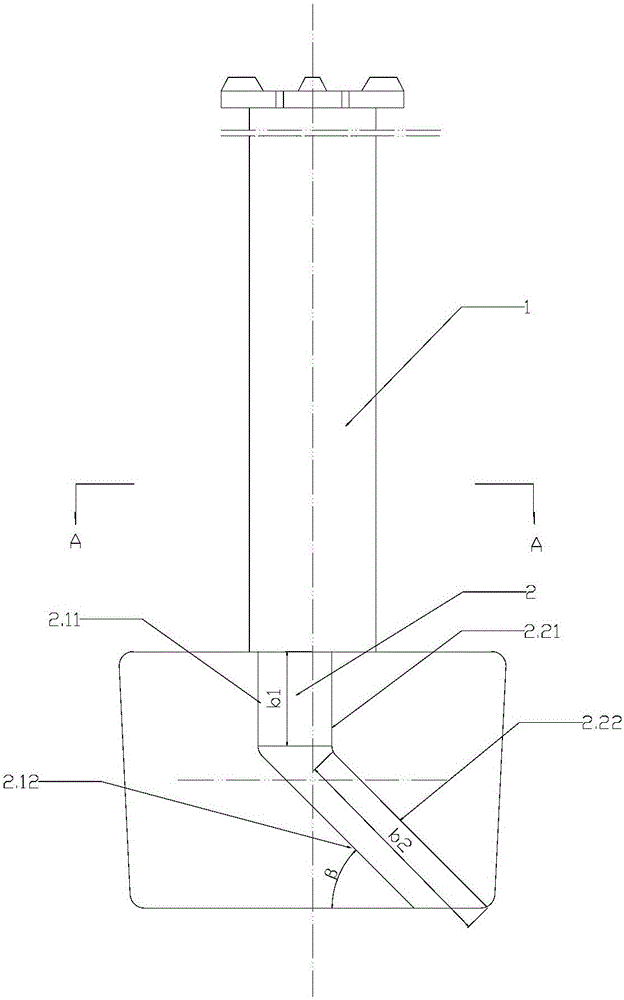

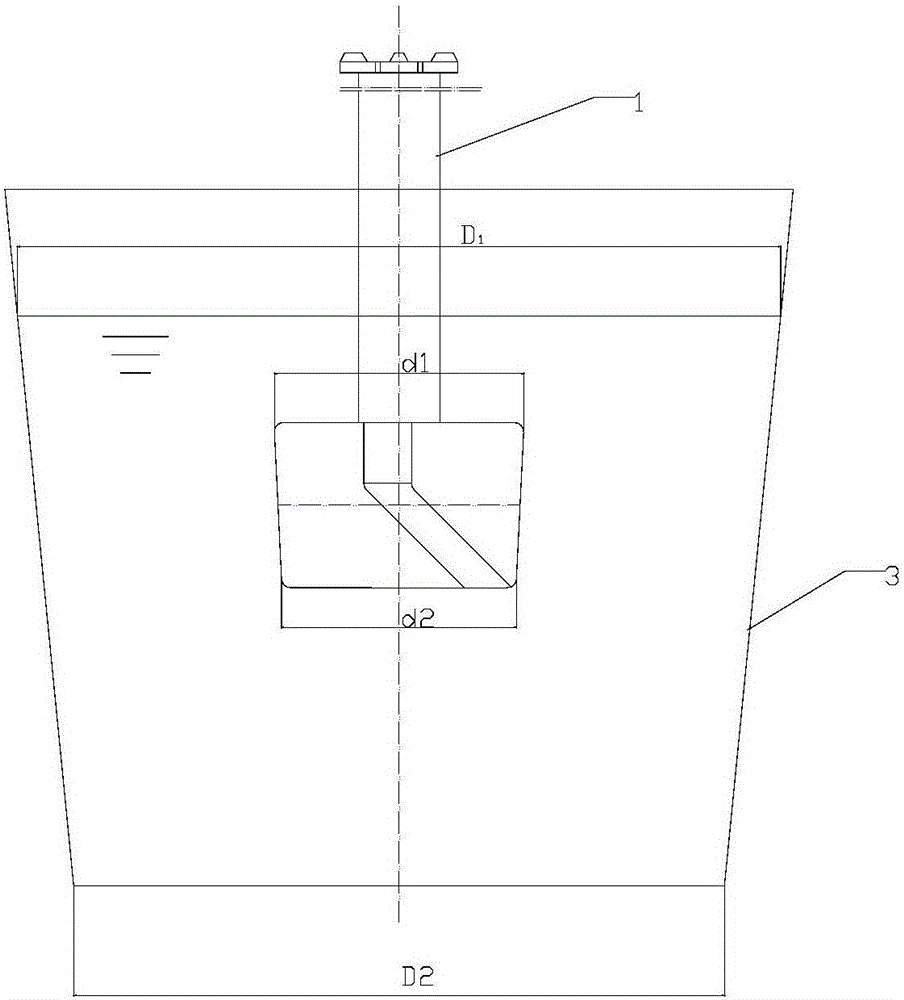

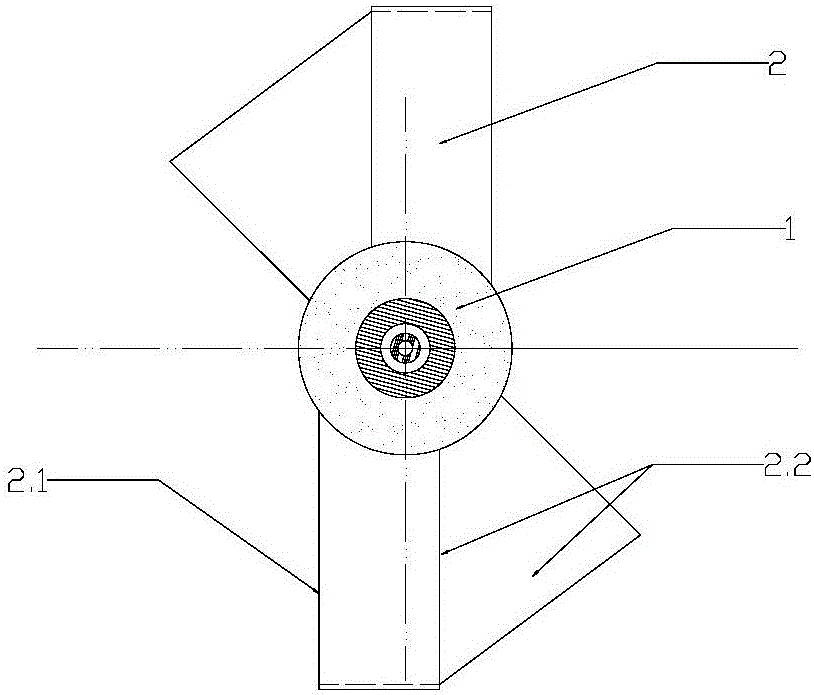

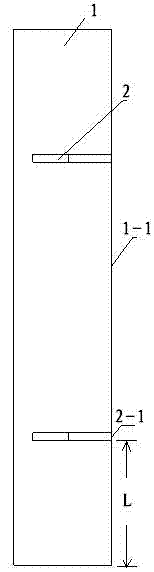

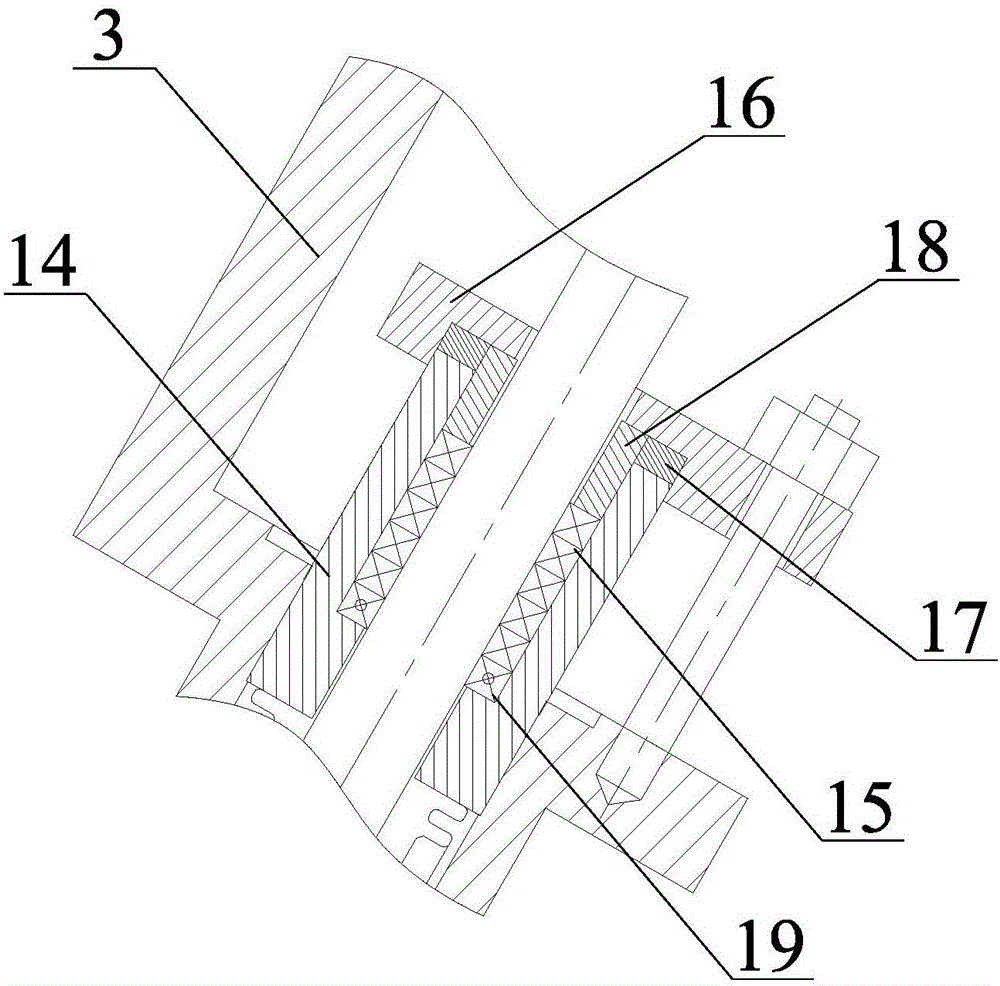

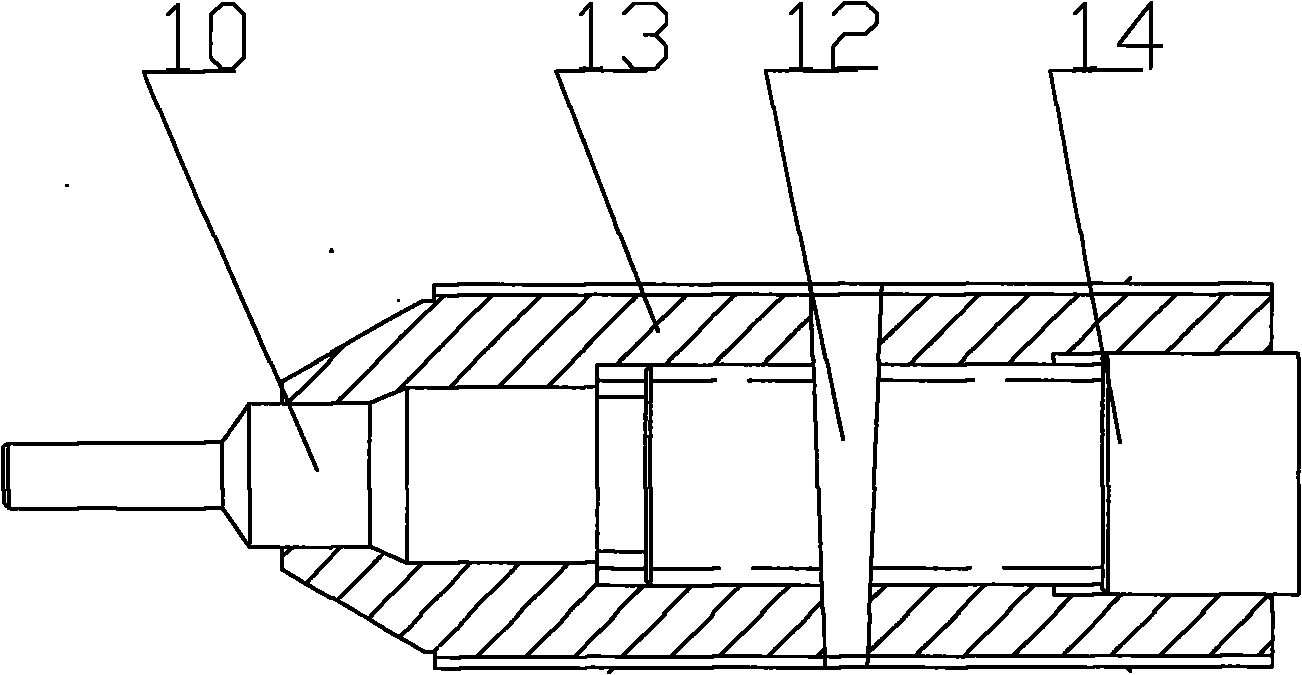

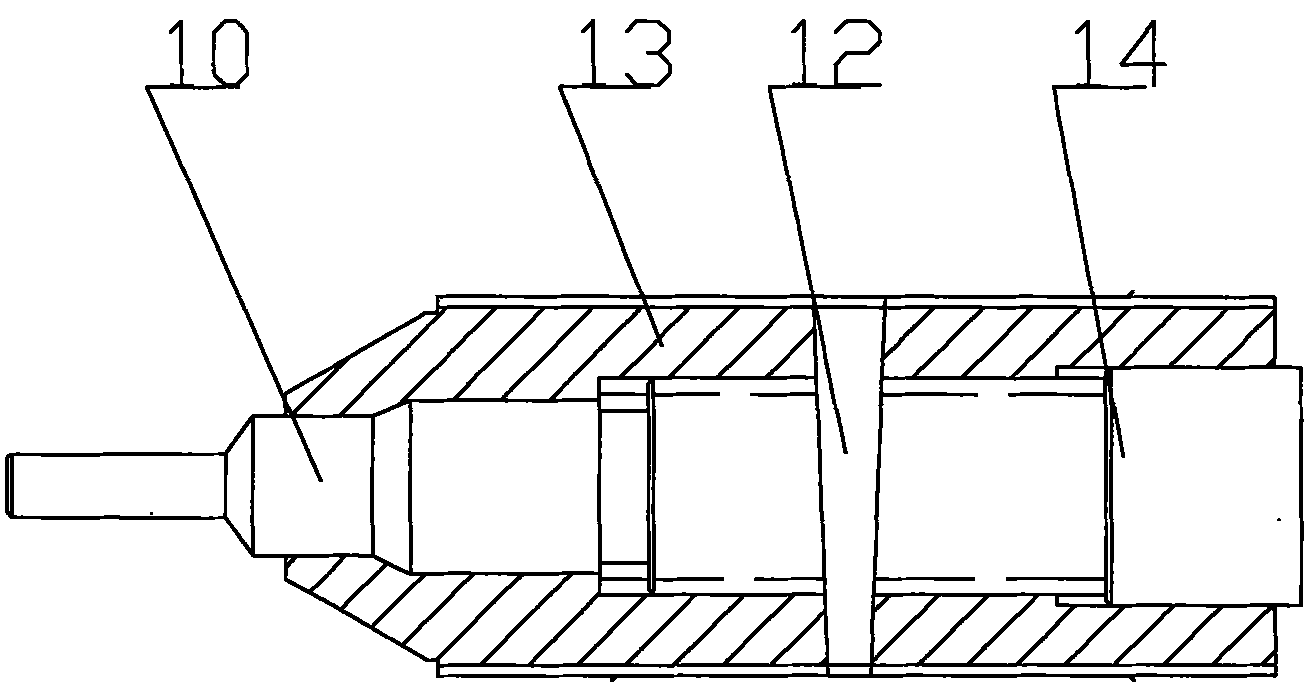

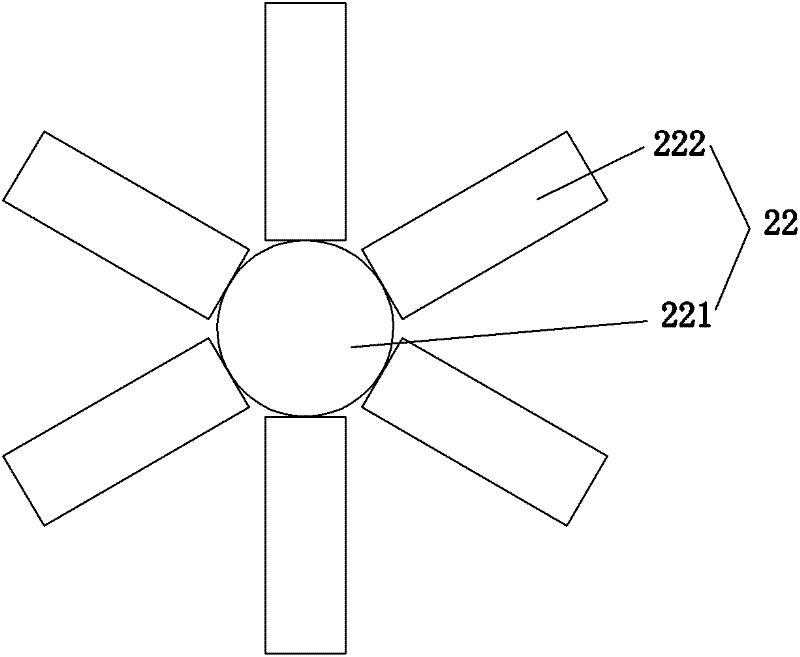

Stirrer used for molten iron mechanical stirring and efficient mixing desulphurization

The invention discloses a stirrer used for molten iron mechanical stirring and efficient mixing desulphurization. The stirrer is composed of a stirring shaft and stirring blades. Each stirring blade comprises an iron meeting face and an iron opposing face, wherein the iron meeting face is composed of an upper vertical face section of the iron meeting face and a lower forerake face section of the iron meeting face, the iron opposing face is composed of an upper vertical face section of the iron opposing face and a lower forerake face section of the iron opposing face, the width b1 of the upper vertical face section of the iron meeting face and the width b1 of the upper vertical face section of the iron opposing face are both 0.25-0.35 time the diameter d of a stirrer impeller, and the width b2 of the lower forerake face section of the iron meeting face and the width b2 of the lower forerake face section of the iron opposing face are both 0.35-0.65 time the diameter d of the stirrer impeller. The stirrer used for molten iron mechanical stirring and efficient mixing desulphurization can achieve the comprehensive purposes of expanding the stirring and mixing zone of a desulfurizer, prolonging the entraining and floating-upward circulating stroke of the desulfurizer in molten iron, improving the mixing and dispersing degree of desulfurizer particles and the desulphurization efficiency of the molten iron, and prolonging the service life of the stirrer in the practical production.

Owner:武汉钢铁有限公司

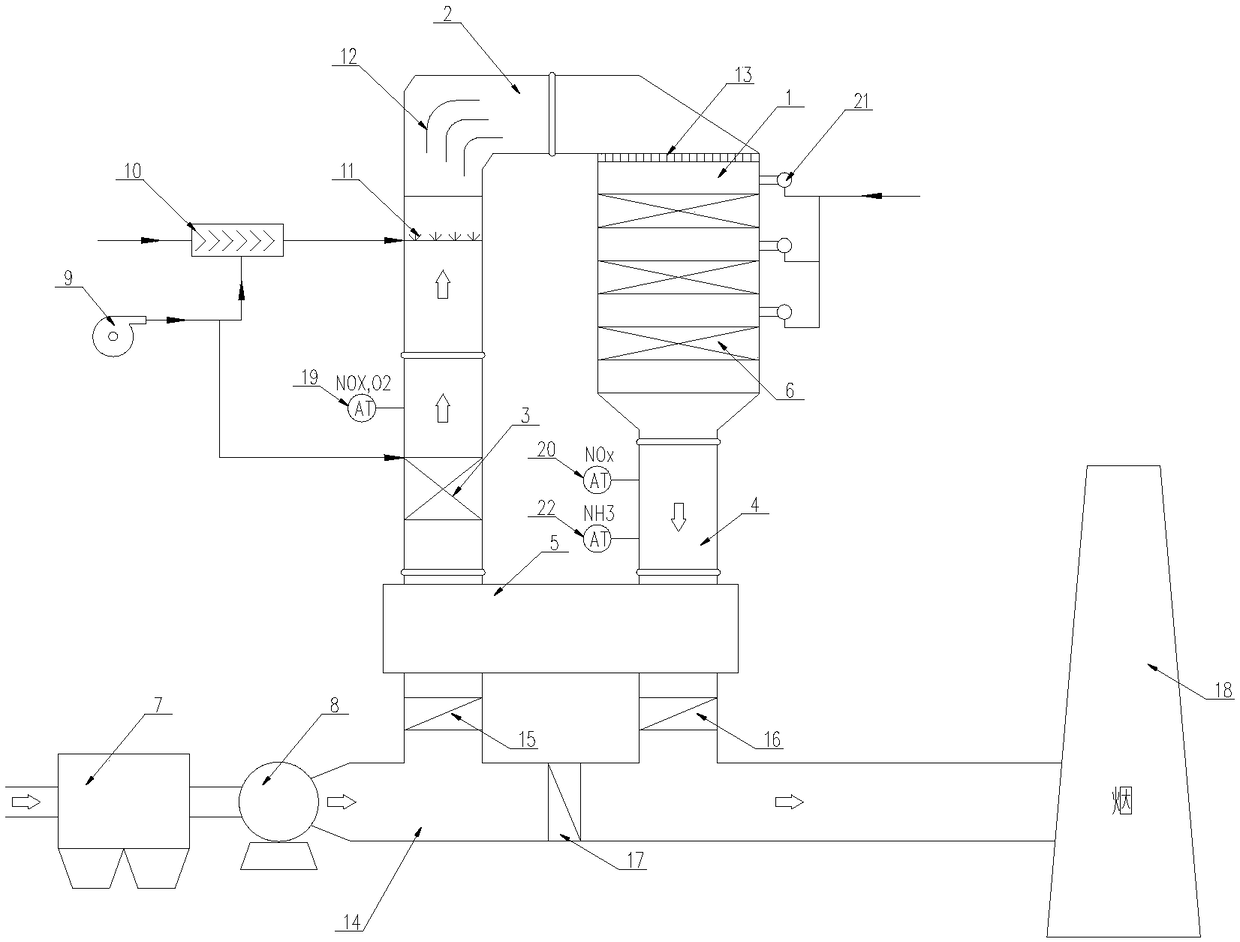

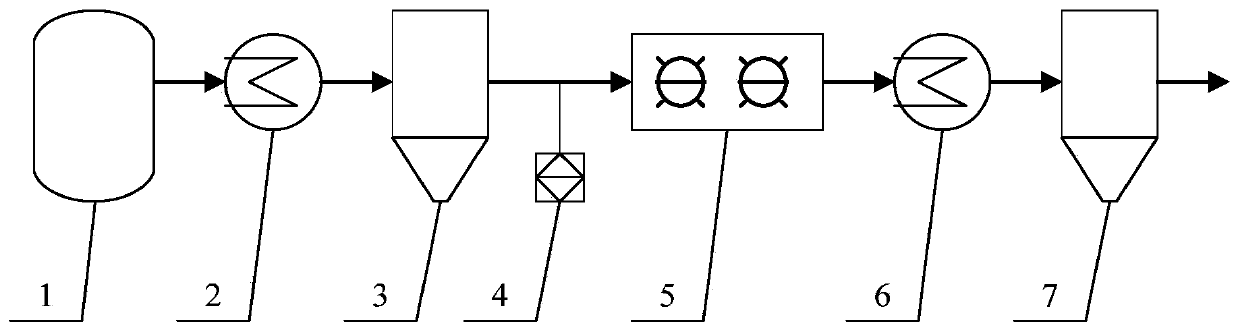

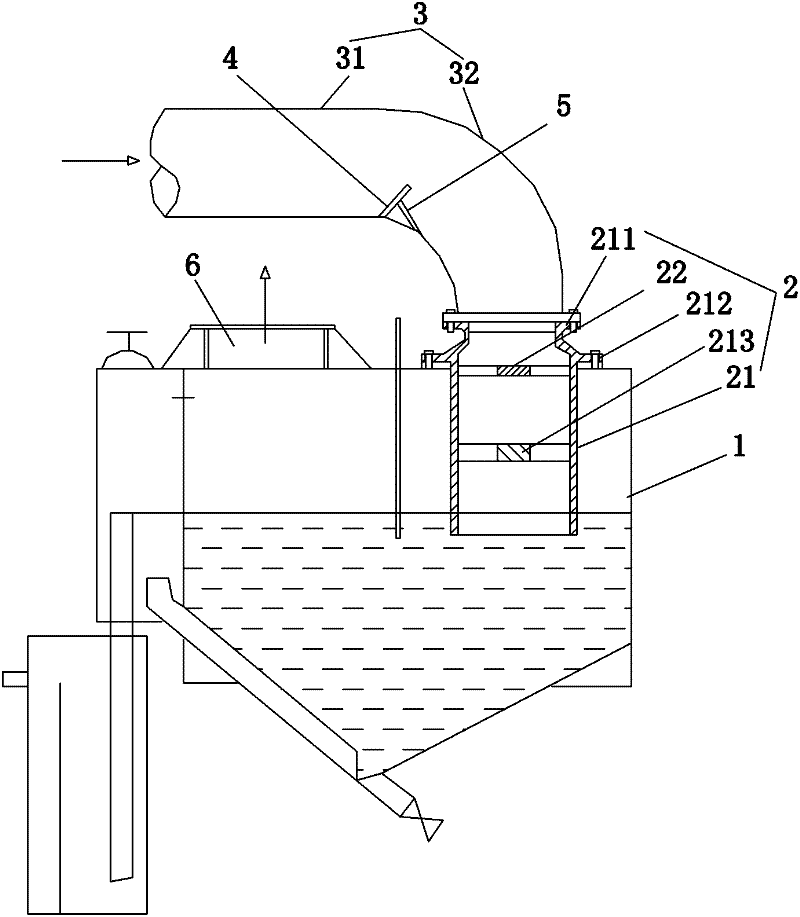

Flue gas denitration device and denitration method

PendingCN108283888AReduced scour wearReduce volumeGas treatmentElectrostatic separationExhaust valveInlet valve

The invention discloses a flue gas denitration device. The method mainly comprises a smoke dust introducing device, a flue, an air heat exchanger, a flue gas mixing pipeline, a selective catalytic reduction (SCR) reactor and a chimney; an air inlet pipeline and an air exhaust pipeline are arranged on the flue; the air heat exchanger is arranged between the air inlet pipeline and the air exhaust pipeline; the air inlet pipeline and the air exhaust pipeline between the air heat exchanger and the flue are respectively provided with an air inlet valve and an air exhaust valve; a bypass valve is arranged on the flue between the air inlet pipeline and the air exhaust pipeline; and the air inlet pipeline above the air heat exchanger is sequentially provided with a flue heater and an ammonia spraying grid. According to invention, the SCR reactor is arranged behind an electrostatic precipitator of a sintering machine, so that the scouring and abrasion of dust on a catalyst are reduced, the service life of the catalyst is improved; flue gas entering the air heat exchanger before denitration is preheated by the air heat exchanger, so that the thermal efficiency of the system is improved.

Owner:易能环境技术有限公司

Material blocking plate and lifting machine with same

ActiveCN102785895AReduce useless workReduce working power consumptionConveyorsMetal layered productsWear resistantBlock effect

The invention discloses a material blocking plate and a lifting machine with the material blocking plate. The material blocking plate comprises a baffle, wherein two guide plates are arranged on the baffle in parallel; the guide plates adopt ladder-shaped bodies; and wear-resistant layers are formed on the upper surface of the baffle and the outer surfaces of the guide plates. The lifting machine comprises a housing, a discharge port of the lifting machine, a hopper and the material blocking plate, wherein the material blocking plate comprises the baffle; the lower part of the guide edge of one of the guide plates mounted on the baffle is flush with one side surface of the baffle; the side surface is the outer side surface of the baffle; the surface opposite to the outer surface of the baffle is the inner side surface of the baffle; the inner side surface of the baffle is obliquely welded onto the discharge port of the lifting machine through a first welding seam; and the two end surfaces of the baffle are fixedly welded with the two side surfaces of the housing through a second welding seam and a third welding seam respectively. Compared with the prior art, the material blocking effect is good, the service life is more than 2 years and the working power consumption is low.

Owner:GUANGXI YUFENG CEMENT

Pressure reducing valve and use thereof as well as fluid conveying system

ActiveCN102011882ASimple structureAvoid wear and tearEqualizing valvesSafety valvesControl systemEngineering

The invention relates to a pressure reducing valve and use thereof as well as a fluid conveying system. The pressure reducing valve comprises a valve body, a valve cavity, a valve rod and a valve element, wherein, the valve body is provided with a lateral inlet and a lower outlet; the lateral inlet, the valve cavity and an outlet channel form a fluid channel; the valve rod extends in the valve body and can move along the longitudinal axis of the valve rod, and the valve rod is provided with a first end and a second end; the valve element is provided with a valve element connecting part which is positioned on the upper end of the valve element and is fixedly connected or bonded with the first end of the valve rod, a valve element middle part and a valve head positioned on the lower end of the valve element; the diameter D1 of the valve element middle part is more than the diameter d1 of the outlet channel; and at least one part of the valve head can be accommodated in the outlet channel and can move along the longitudinal axis direction of the outlet channel. The pressure reducing valve has the advantages of simple structure and applicability to a high solid content material decompression and control system, and is easy to maintain.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Novel photo-thermal power generation fused salt valve capable of avoiding residues

InactiveCN106051175AEasy maintenanceSimple structureSpindle sealingsLift valveInlet channelMolten salt

The invention discloses a novel photo-thermal power generation fused salt valve capable of avoiding residues. The novel photo-thermal power generation fused salt valve is a Y-shaped valve and comprises a valve body, a valve rod, a support, a hand wheel, a medium inlet channel and a medium outlet channel. The valve body and the support are integrally formed and integrally forged. A valve rod cavity is formed in the valve body, the valve rod extends into the valve rod cavity and is sleeved with a corrugated pipe in an embedded manner, and the corrugated pipe is located in the valve rod cavity. A packing box is arranged above the corrugated pipe, the valve rod is sleeved with the packing box in an embedded manner, a packing ring is placed in the packing box and is tightly pressed through a packing gland above the packing ring, and the packing gland is connected with the valve body through a bolt. The angle alpha formed between the medium inlet channel and the horizontal plane ranges from 10 degrees to 20 degrees, and the angle beta formed between the medium outlet channel and the horizontal plane ranges from 10 degrees to 20 degrees. The fused salt valve is simple in structure, good in sealing performance and convenient and rapid to operate; during work, no leakage happens, safety and reliability are achieved, and the service life is longer; and when a fused salt system stops operating, the situation that due to the fact that fused salt is left and solidified in the valve, the valve is blocked is avoided.

Owner:陈金环

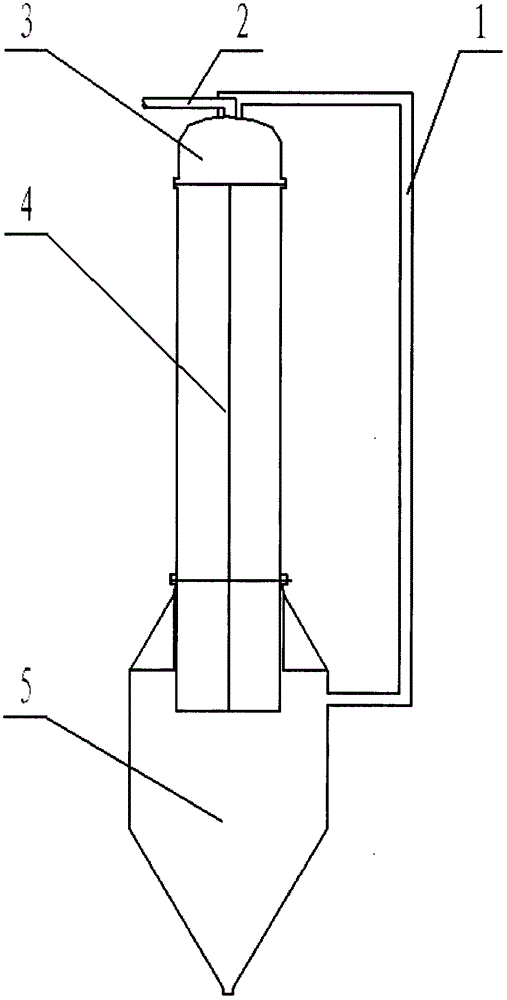

High-temperature cyclone separation type three-waste co-combustion furnace

InactiveCN104197338APrevent reverse stringingImprove combustion efficiencyIncinerator apparatusCycloneCombustor

The invention discloses a high-temperature cyclone separation type three-waste co-combustion furnace which comprises a combustion furnace and a separator communicated with an ash outlet of the combustion furnace. The combustion furnace is provided with a secondary air device, a combustor and a spiral coal feeder, a smoke outlet is formed in the upper portion of the separator, and a waste gas premixing device is installed on the side portion of the combustion furnace. An air distributing device is installed on the bottom of the combustion furnace, and an igniter and an air inlet are installed in the lower portion of the air distributing device. A central cylinder stretching downwards is arranged at the smoke outlet in the top of the separator, the lower end face of the central cylinder and the central line of the ash outlet are on the same horizontal plane, and a gas outlet pipe is connected to the smoke outlet in the top of the separator. A discharge port is formed in the bottom of the separator, the discharge port is communicated with a material return port in the lower portion of the combustion furnace through a material return pipe formed by sequentially connecting a first vertical section, a horizontal section, a second vertical section and an inclined section, the first vertical section is connected with the discharge port, the bottom end of the inclined section is connected with the material return port formed in the lower portion of the combustion furnace, and a material return device is arranged at the connecting position of the first vertical section and the horizontal section.

Owner:山东福源节能服务有限公司

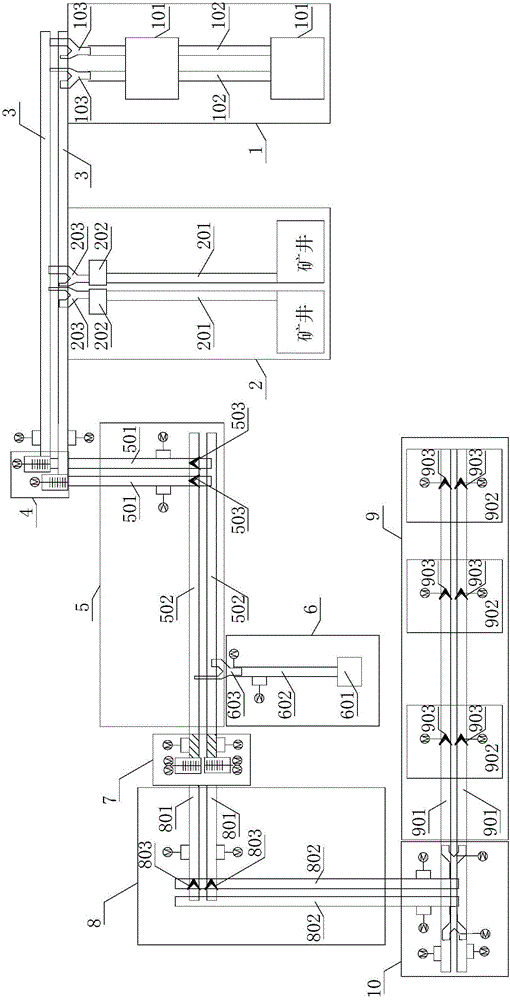

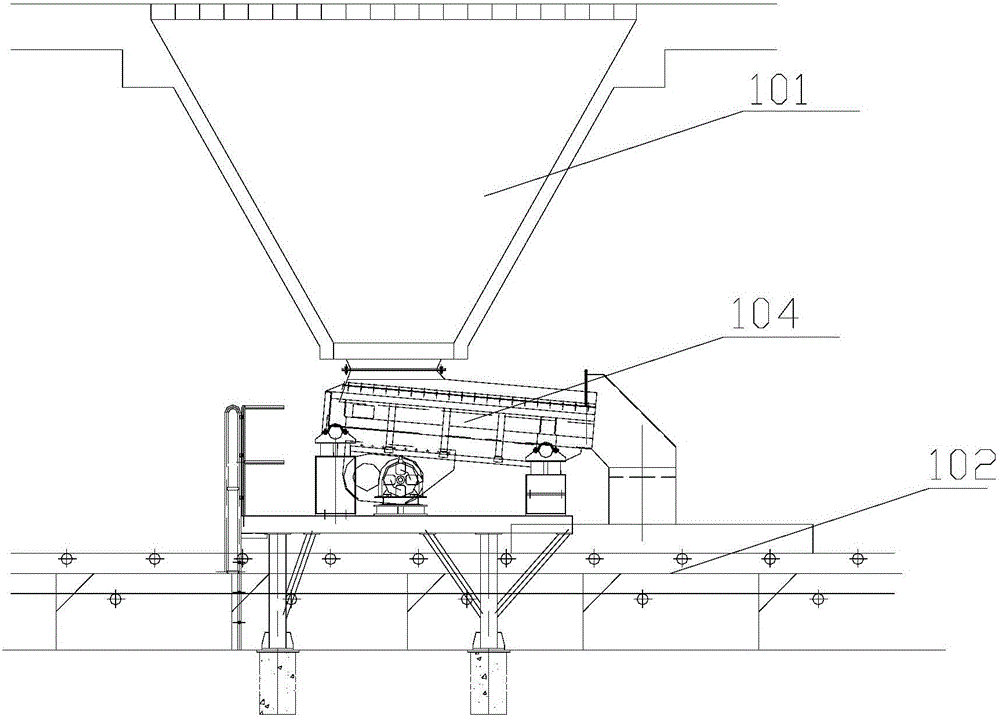

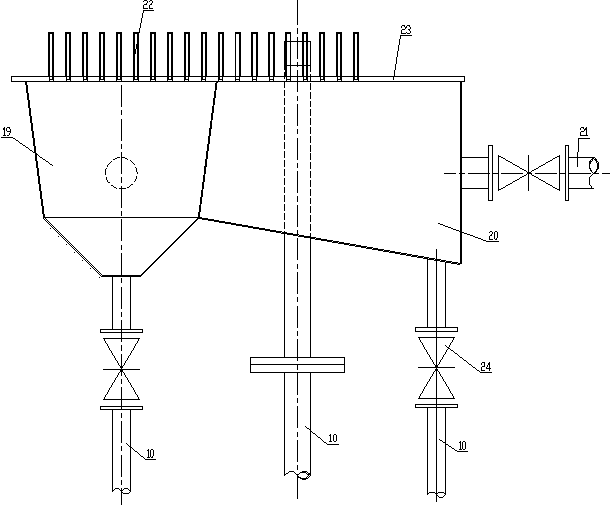

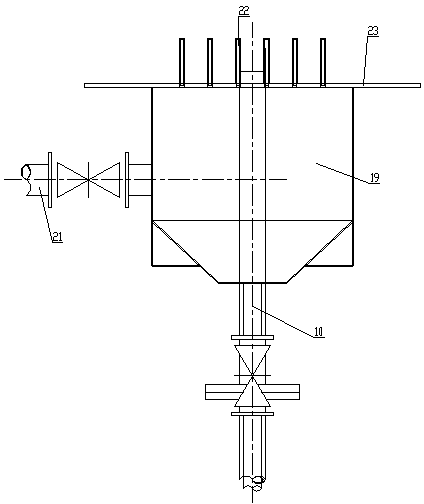

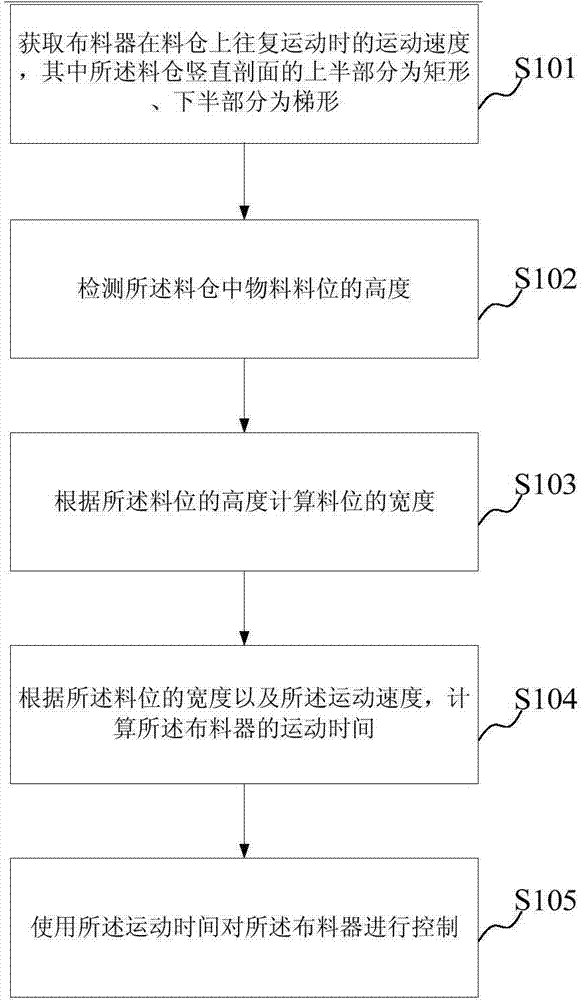

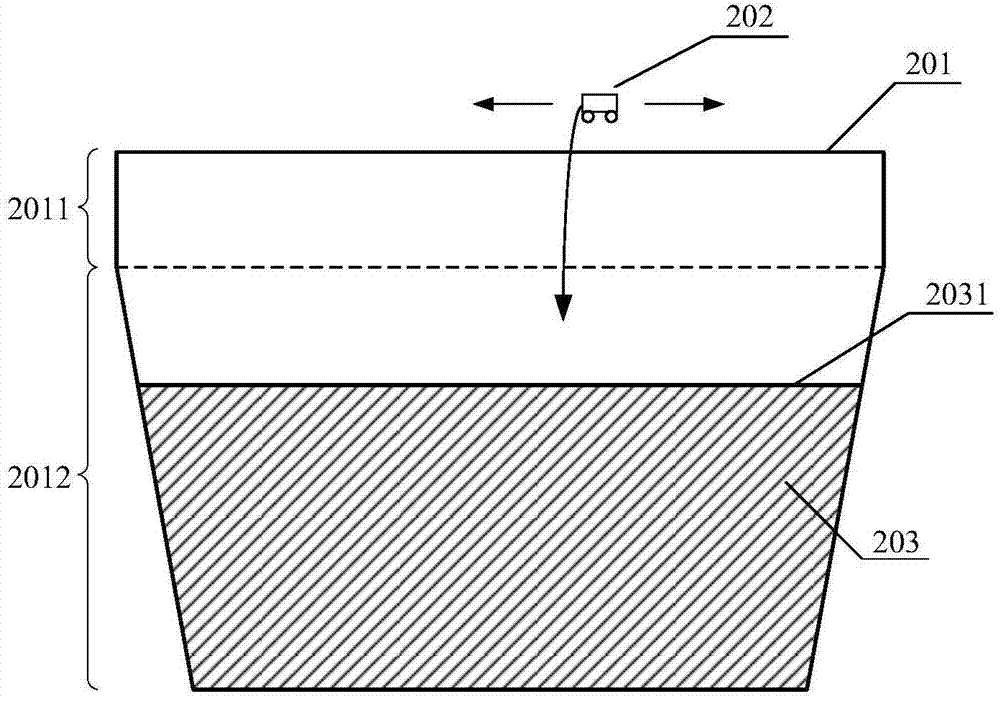

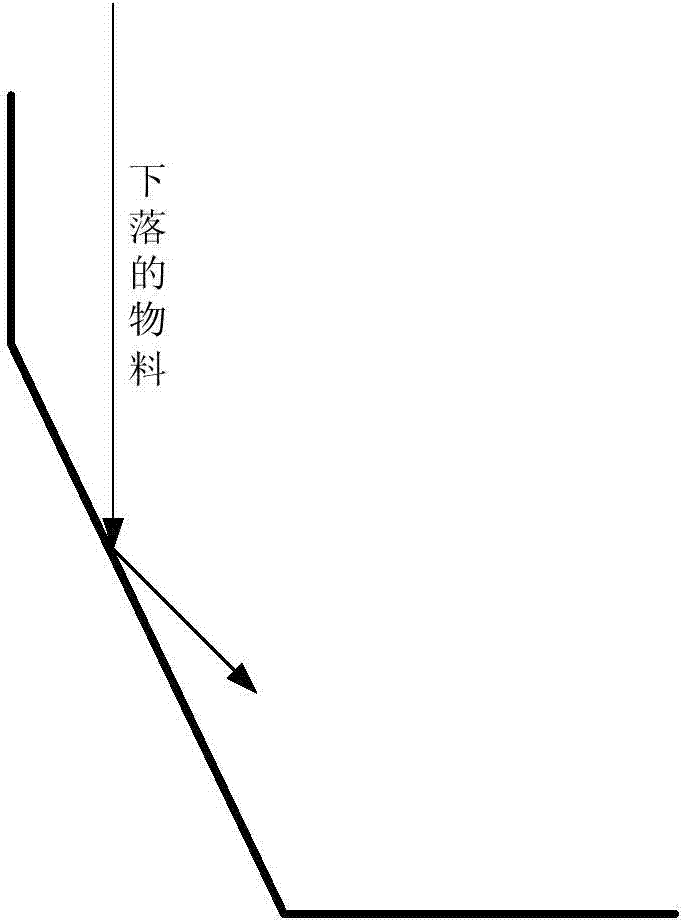

Method and device for controlling distributing device

ActiveCN104495412AImprove uniformityReduced scour wearLoading/unloadingRange of motionReciprocating motion

An embodiment of the invention provides a method and a device for controlling a distributing device. The method comprises the following steps of acquiring the movement speed of the distributing device when the distributing device moves on a bin in a reciprocating manner; detecting the height of materials in the bin; calculating the width of the materials according to the height of the materials; calculating the movement time of the distributing device according to the width of the materials and the movement speed; and controlling the distributing device according to the movement time. An upper half portion of a vertical section of the bin is rectangular, and a lower half portion of the vertical section of the bin is trapezoidal. The movement range of the distributing device is adjusted according to the height of the materials in the bin, the distributing device always moves in the range of the width of the materials, so that the materials can always directly drop on a material surface of the bin and cannot collide with a side wall of the bin, the possibility that the wall of the bin is eroded and worn by the materials is reduced, the possibility of breakage of mixture particles is reduced, the flatness of the material surface can also be ensured, and the uniformity of cloth in a downstream working procedure is improved.

Owner:HUNAN CHANGTIAN AUTOMATION ENG CO LTD +1

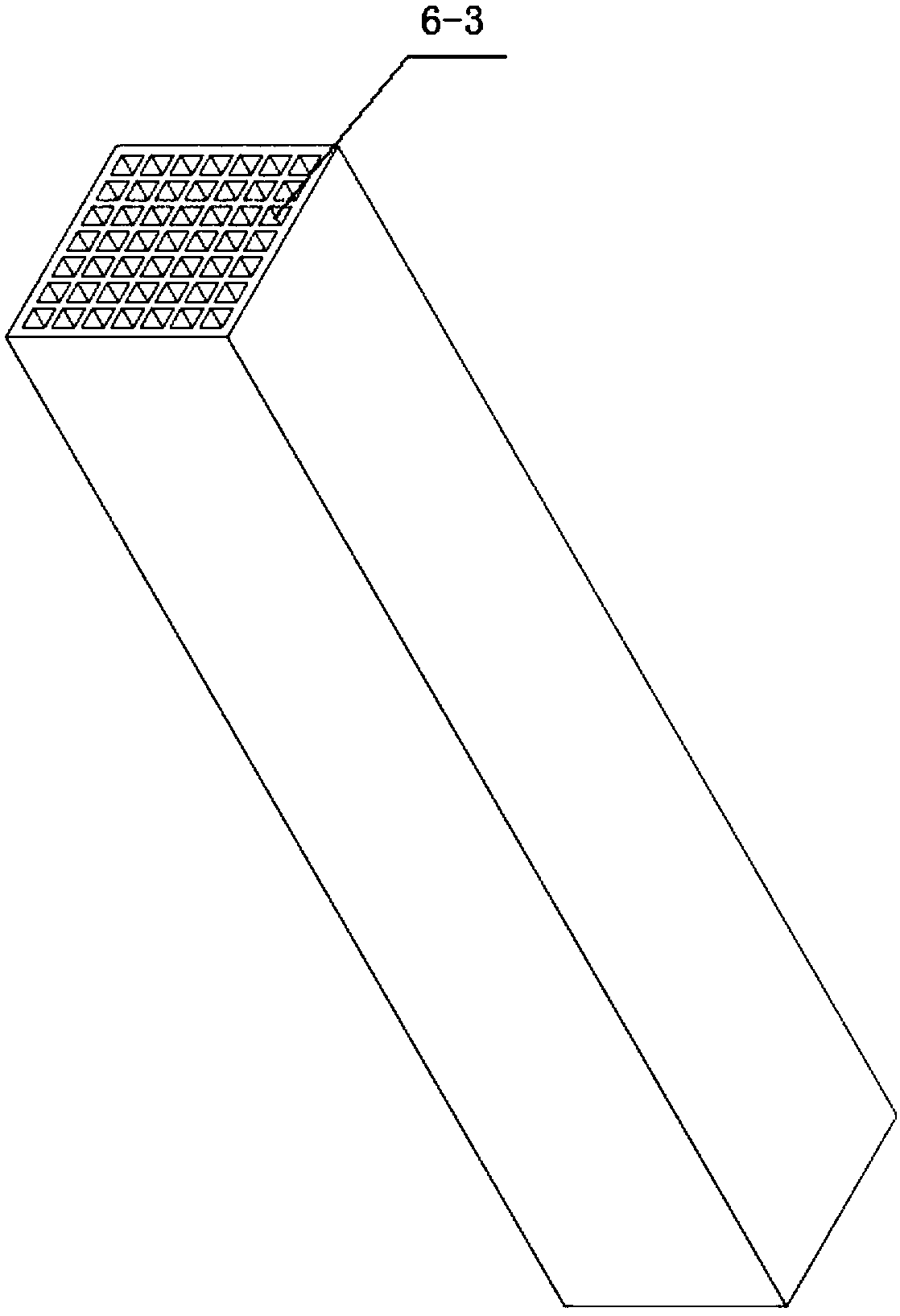

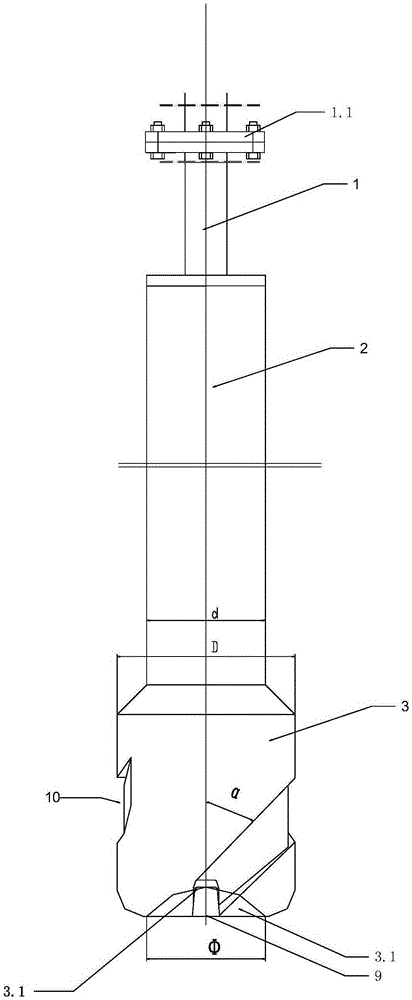

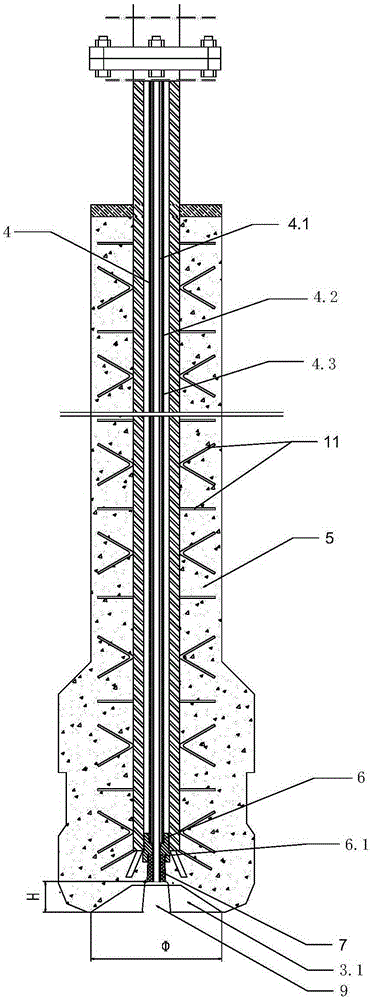

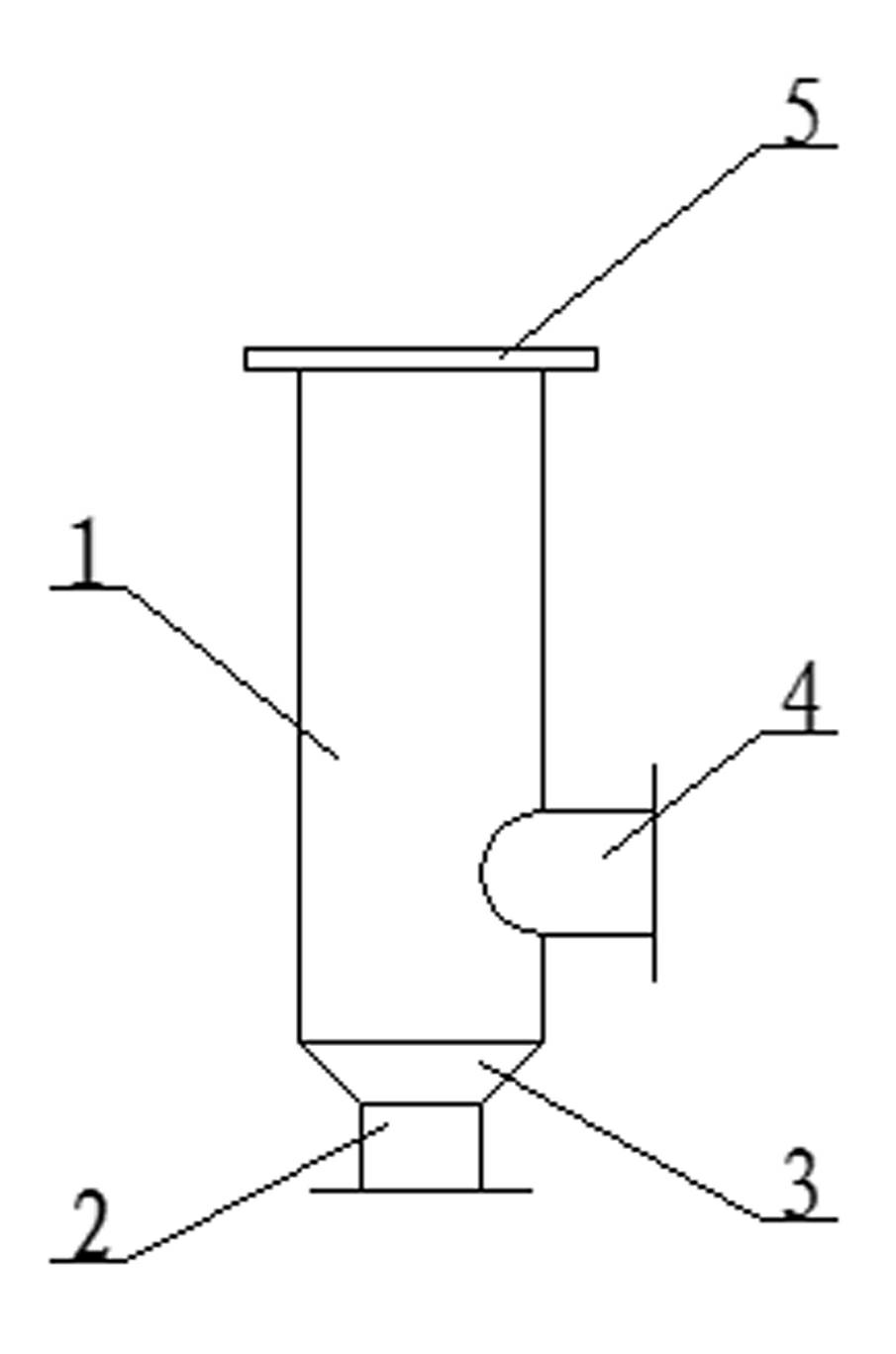

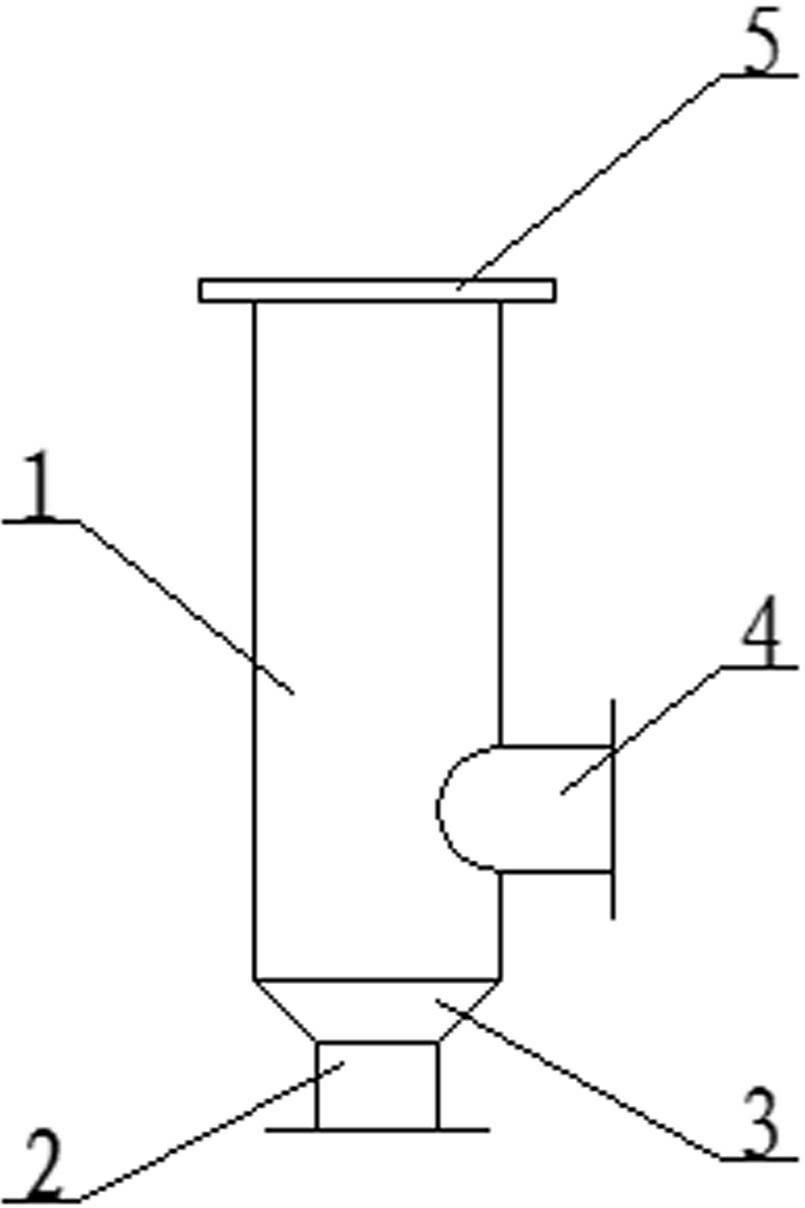

Anti-blocking molten iron blowing desulfurization spray gun with multi-strand cyclone dispersion function

InactiveCN105331773AGuarantee unimpededGuaranteed sealing performanceLiquid spraying apparatusCycloneRefractory

The invention discloses an anti-blocking molten iron blowing desulfurization spray gun with a multi-strand cyclone dispersion function. The anti-blocking molten iron blowing desulfurization spray gun is composed of a connection section, a gun body section and a blowing section, wherein the connection section is composed of a connection flange and a composite gun core in sequence, and the outer walls of the gun body section and the blowing section are a refractory material gun lining formed through pouring a refractory material; and a gun body outer diameter D of the blowing section is greater than a gun body outer diameter d of the gun body section, the composite gun core sequentially comprises an inner insertion tube, a main tube and a reinforcing tube from the inside to the outside, an inner insertion tube connector is installed on the inner wall of the bottom end of the reinforcing tube, the bottom end surface of the inner insertion tube is level with the bottom end surface of a graphite blowing tube, and wrapped with the refractory material gun lining to form a spray gun nozzle, and grooves are formed at the nozzle. According to the invention, the inherent shortages of poor reaction kinetics performance and high blocking frequency of a nozzle existing in a conventional spray gun are effectively solved through said structural design and optimization for the related structural dimensions; and meanwhile, the anti-damage capacity of the blowing section and the gun body section of the spray gun is effectively reinforced, and the purpose of prolonging the service life of the spray gun is achieved.

Owner:武汉钢铁有限公司

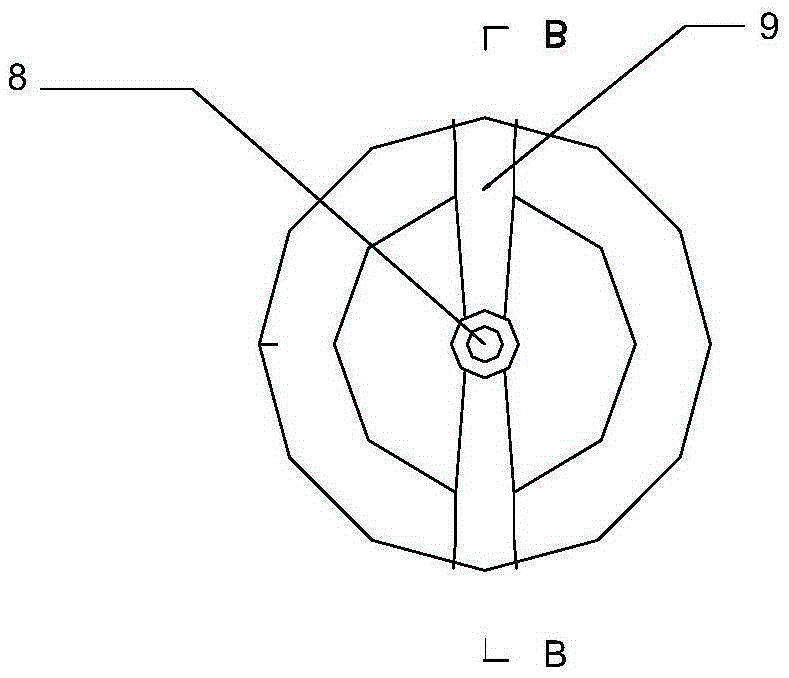

Waste incineration system and method based on selective catalytic denitration plasma integration

PendingCN110030570ASynthesis does not happenReduce concentrationGas treatmentLighting and heating apparatusChemical reactionFlue gas

The invention discloses a waste incineration system and method based on selective catalytic denitration plasma integration. The waste incineration system comprises a waste incinerator, a high-temperature heat exchanger, a high-temperature dust collector, a selective catalytic denitration plasma integration device, a low-temperature heat exchanger and a flue gas purification device. Dust collectedby the high-temperature dust collector does not contain low-temperature synthesized dioxins, and the toxicity is small. Flue gas dust formed after high-temperature dust removal is low in concentration, abrasion to a SCRCP device catalyst is small, pollution is also small, the service life of the catalyst is prolonged and chemical reaction efficiency is improved. Within the low-temperature synthesis temperature interval of 200-400 DEG C of the dioxins, the flue gas dust concentration is low, the quantity of dust catalysts required for dioxin low-temperature synthesis is decreased, the concentration of flue gas carbon granules and carbonaceous organic materials is low, matter required for dioxin low-temperature synthesis lacks, and the dioxin low-temperature synthesis amount is greatly reduced.

Owner:GUILIN UNIV OF AEROSPACE TECH

Economizer hopper of coal-fired boiler in power plant

InactiveCN101721860AImprove dust collection efficiencyImprove dust collection effectDispersed particle separationAir preheaterSystems design

The invention discloses an economizer hopper of a coal-fired boiler in a power plant. In a reversing chamber of the economizer hopper of the coal-fired boiler, one to five stages of herringbone guide plates are arranged along the horizontal direction, or two to seven stages of T-shaped guide plates are arranged along the vertical direction; the nasal tip of the reversing chamber of the economizer hopper is additionally provided with a guide plate; the outlet of the bottom of a dust hopper is provided with a blocking valve; the outlet of the blocking valve is connected with an ash storage hopper; and the outlet of the ash storage hopper is provided with a blocking valve. The dust collecting efficiency of the economizer hopper is greatly improved; and the ash content of the flue gas entering an air preheater is effectively reduced. The economizer hopper has high operability and obvious effect, can reduce or thoroughly manage ash fouling in the air preheater so as to alleviate or avoid the low-temperature corrosion of the air preheater and reduce the cost of cleaning the ash fouling of the air preheater. The economizer hopper has the advantage of simple process flow, less equipment and easy implementation. The method is applicable to the reform design of the equipment which has been put into operation, and is also applicable to the system design of new equipment.

Owner:BEIJING JIAOTONG UNIV

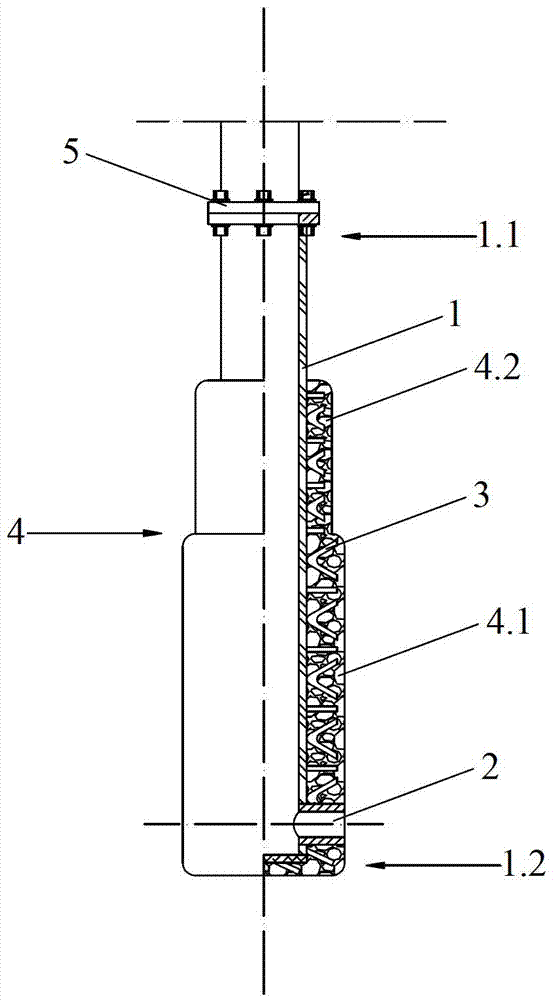

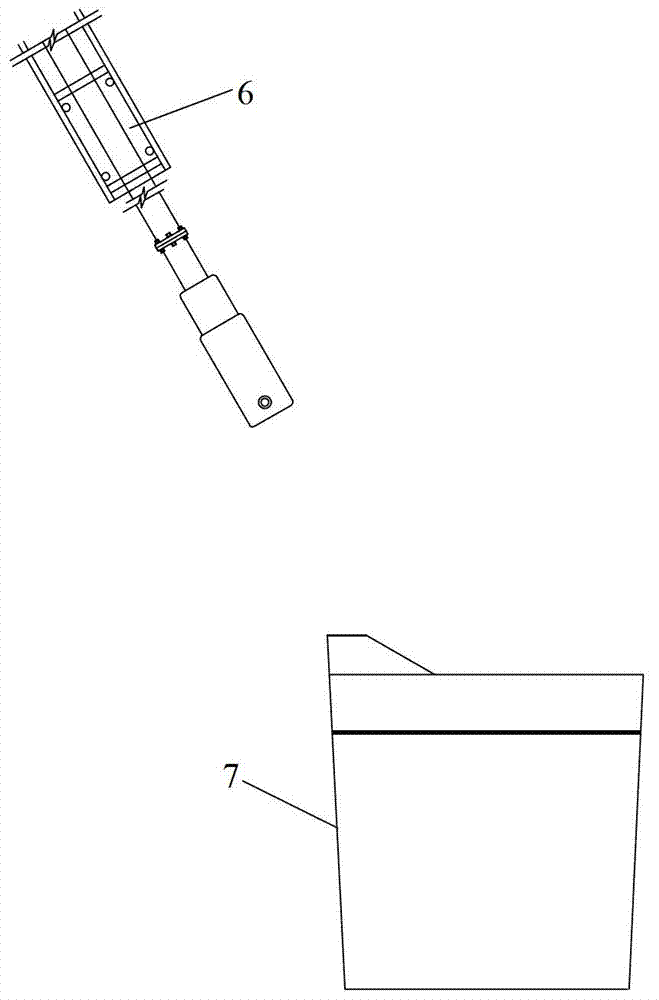

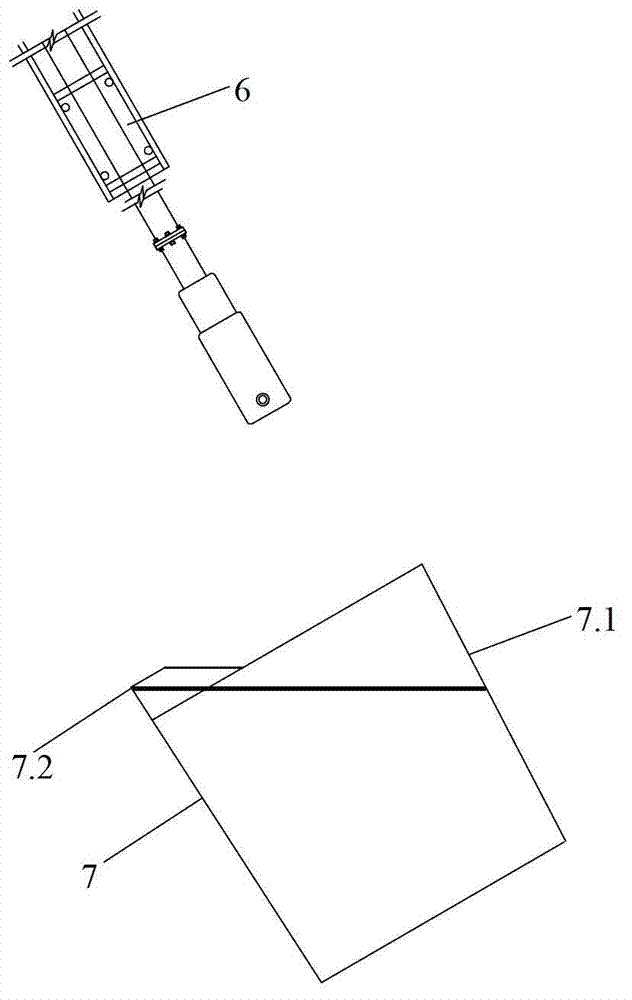

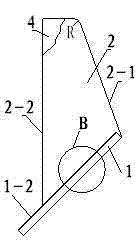

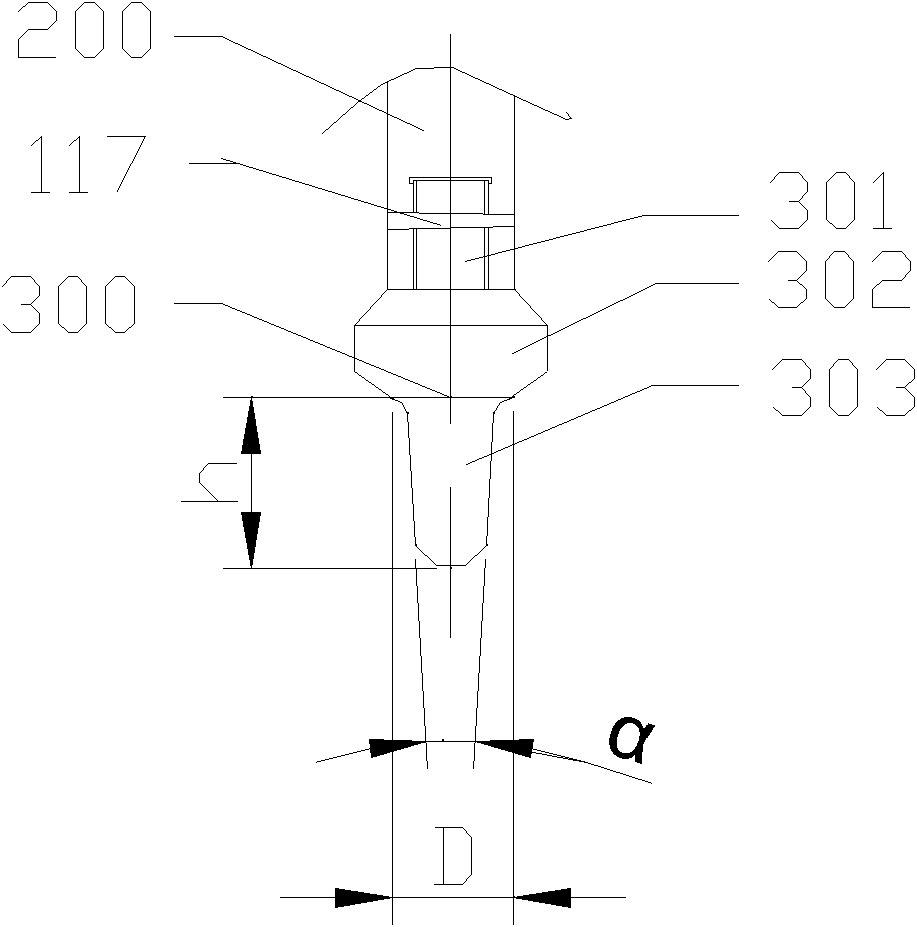

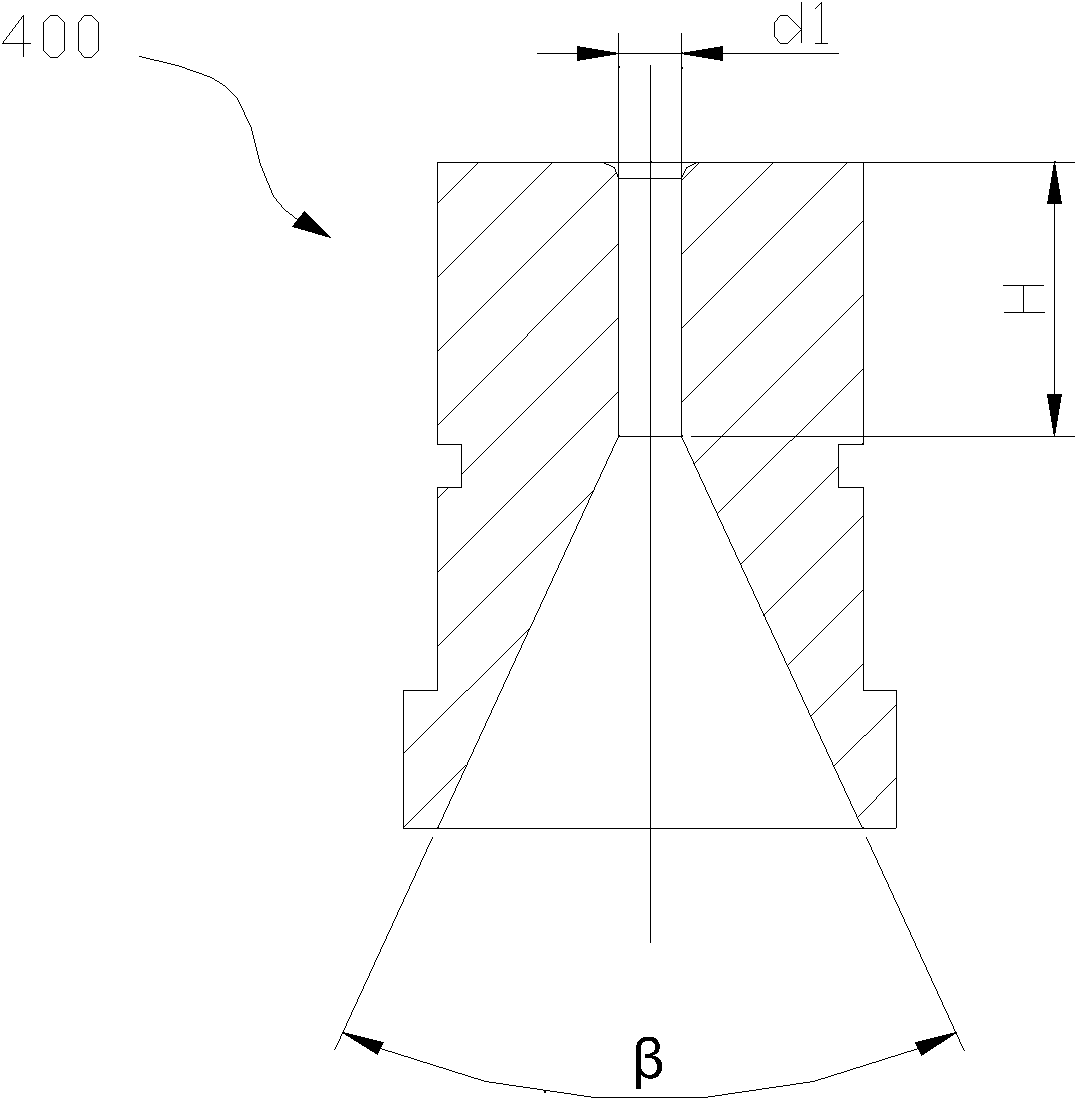

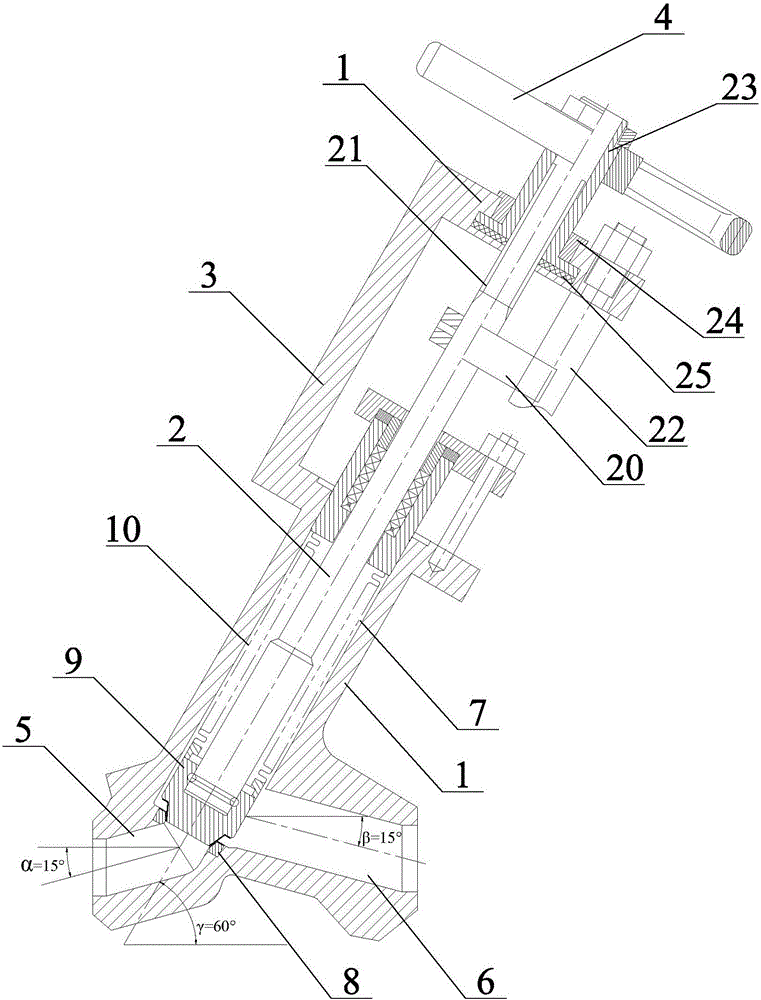

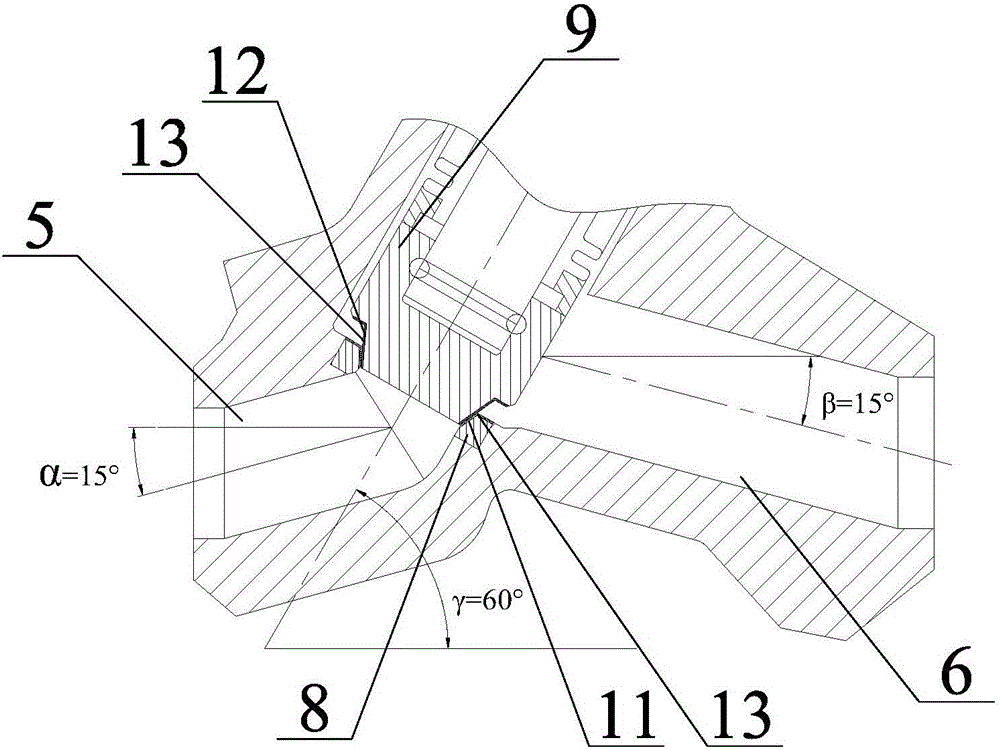

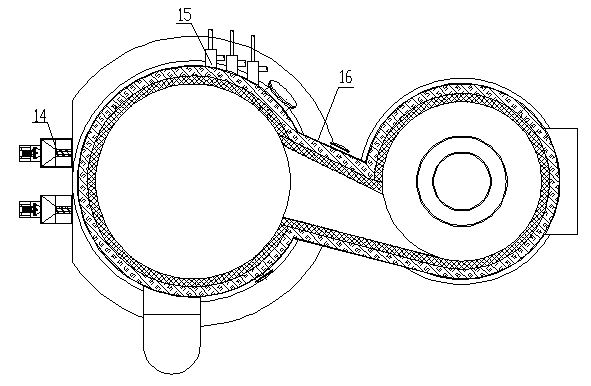

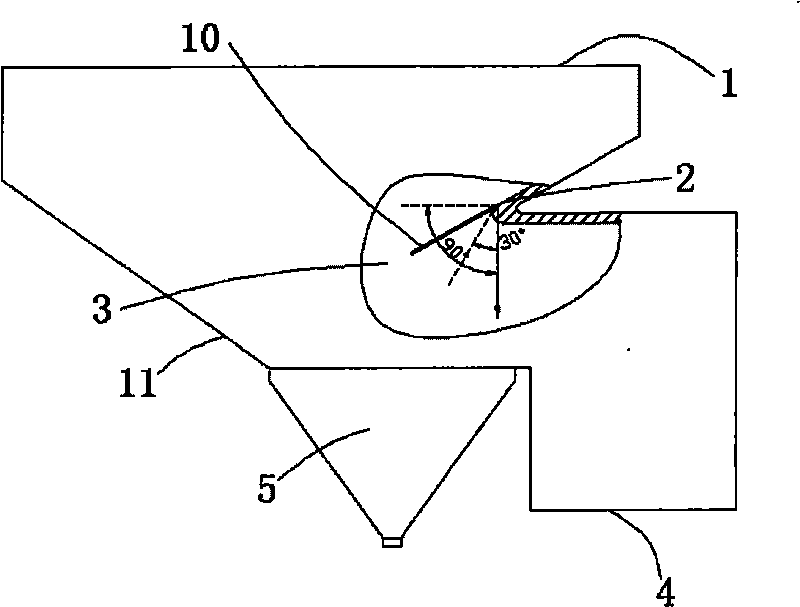

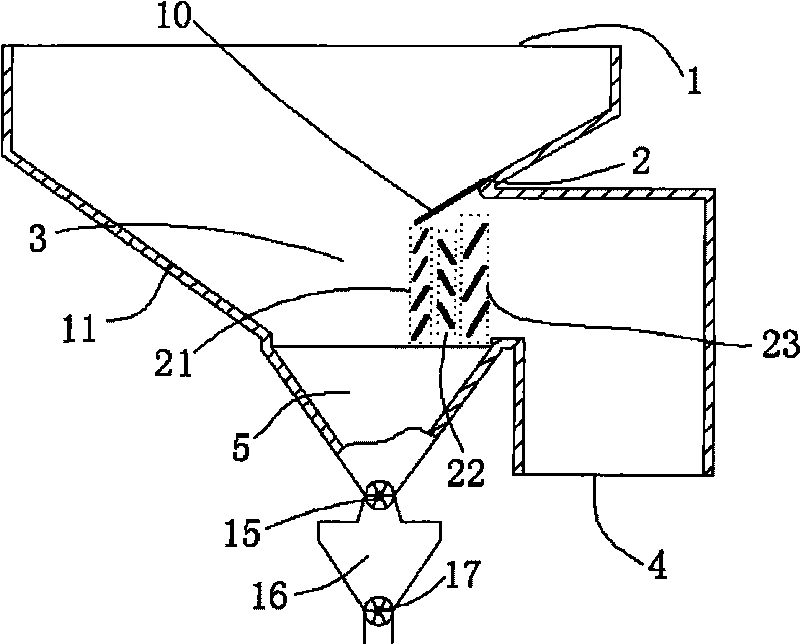

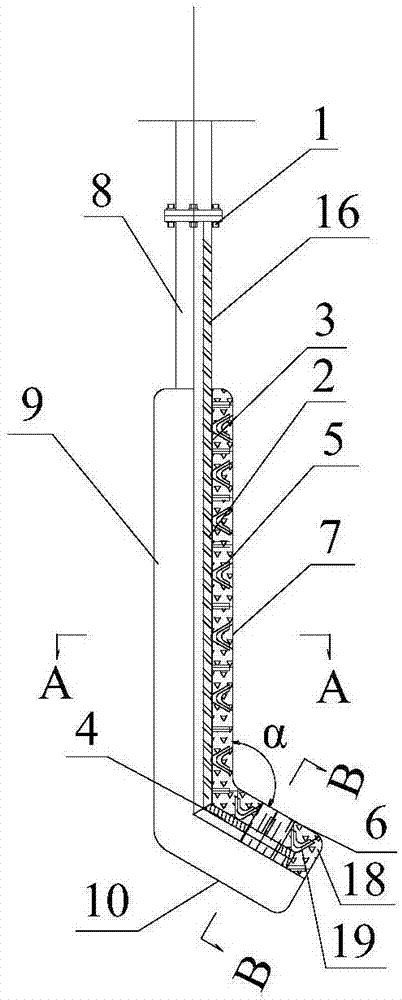

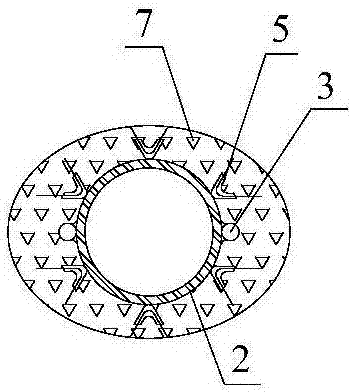

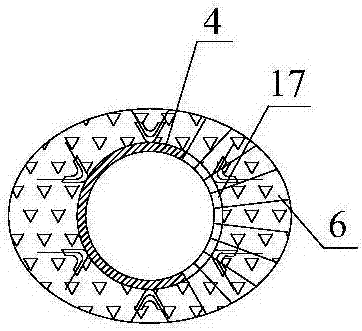

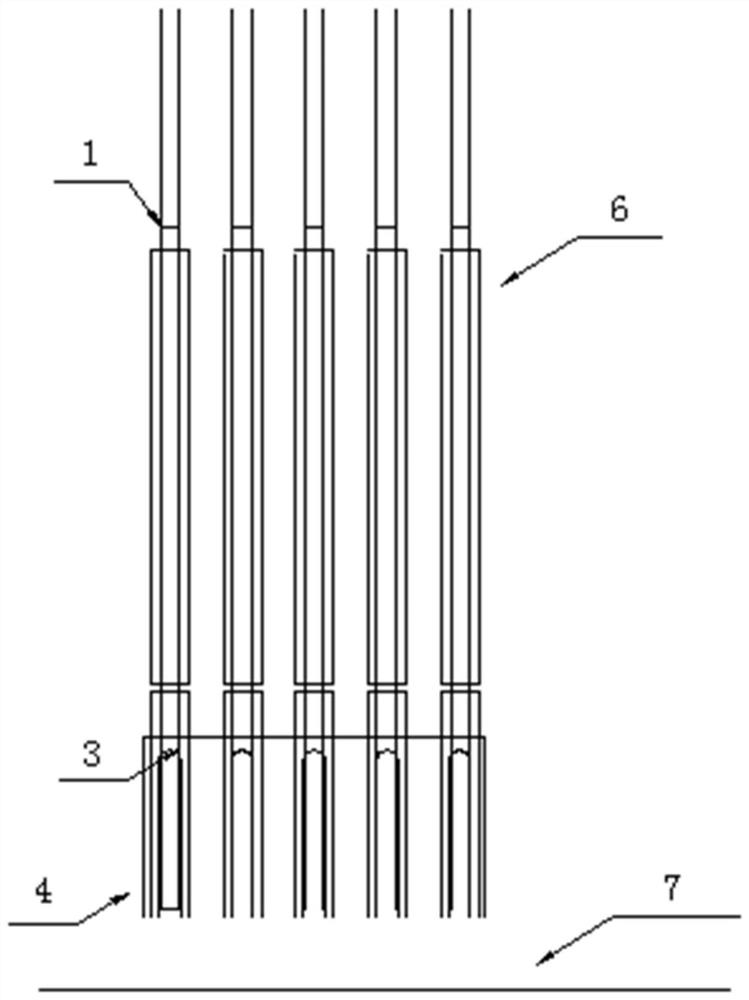

Top oblique insert type spray gun, preparation method and using method for air blowing slag accretion

The invention discloses a top oblique insert type spray gun for air blowing slag accretion. A connecting section comprises a metal connecting pipe and a connecting part, a gun body section comprises a metal main pipe, a gun body section refractory castable lining and a gun body section V-shaped anchoring part, and a nozzle section comprises a metal spray pipe, a nozzle section refractory castable lining and a nozzle section V-shaped anchoring part. The metal spray pipe and the metal main pipe are in welded communication, and an included angle alpha formed by the metal spray pipe and the metal main pipe is greater than 0 degree and less than 180 degrees. A diffuse type nozzle facing to the molten iron surface during air blowing is arranged in the nozzle section refractory castable lining, and a through hole which corresponds to the diffuse type nozzle and communicates with the diffuse type nozzle in the radial direction is formed in the side wall of the upper half portion of the metal spray pipe in the radial direction. Advantages of the top gun air blowing auxiliary deslagging technology and advantages of the molten iron jar air brick ventilation auxiliary deslagging technology are highly gathered, all kinds of disadvantages existing in conventional top gun air blowing or air brick ventilation are fully overcome, and the comprehensive purposes of reducing deslagging iron losses, shortening deslagging time, prolonging the service life of a molten iron jar and the air blowing slag accretion spray gun and lowering deslagging process cost are realized.

Owner:武汉钢铁有限公司

Ceramic ball valve high in corrosion resistance and erosive abrasion resistance

InactiveCN103968101AReduced scour wearGuaranteed tightnessPlug valvesValve housingsElectric power systemEngineering

The invention discloses a ceramic ball valve high in corrosion resistance and erosive abrasion resistance. Two valve bodies are in linkage with a valve cover, and the two valve bodies and the valve cover are sealed through an O-type gasket. Stepped valve seats are installed in the centers of the inner sides of the two valve bodies respectively. Shoulders of the stepped valve seats and the inner sides of the valve bodies are fixedly matched through resilience gaskets. The inner sides of the valve seats and an arch gap valve ball form a surface contact seal. Graphite packing is embedded into the circumferential gap of the connection between a valve rod and the valve cover and fixedly pressed through bolts by a packing gland. One end of the valve rod is inserted into the arch gap valve ball to be positioned, the other end of the valve rod is connected with an execution mechanism, the execution mechanism drives the arch gap valve ball to rotate through the valve rod, and the arch gap valve ball is a valve ball of a nonsymmetrical structure. The ceramic ball valve can be applied to multi-phase flow abrasion working conditions of coal chemical industries, petrochemical industries and electric power systems and is excellent in high temperature resistance and abrasion resistance, long in service life, good in comprehensive performance, capable of meeting the using requirements in the multi-phase flow harsh erosive abrasion environment and broad in application prospect.

Owner:ZHEJIANG SCI-TECH UNIV

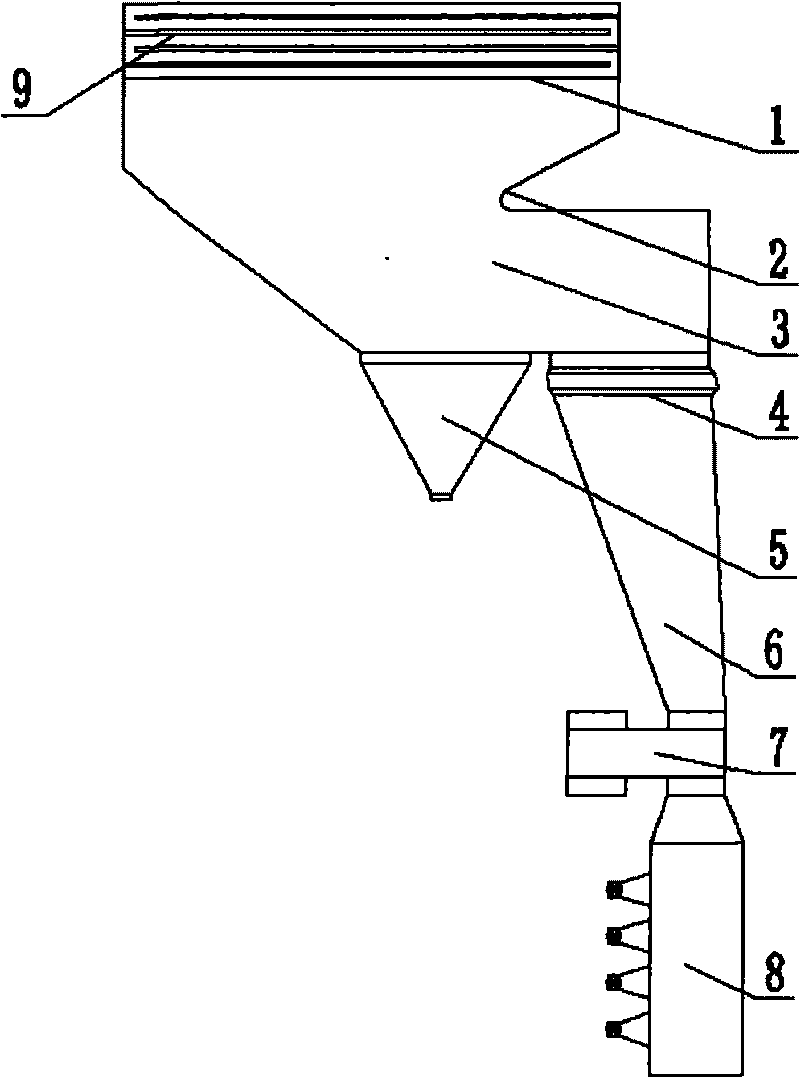

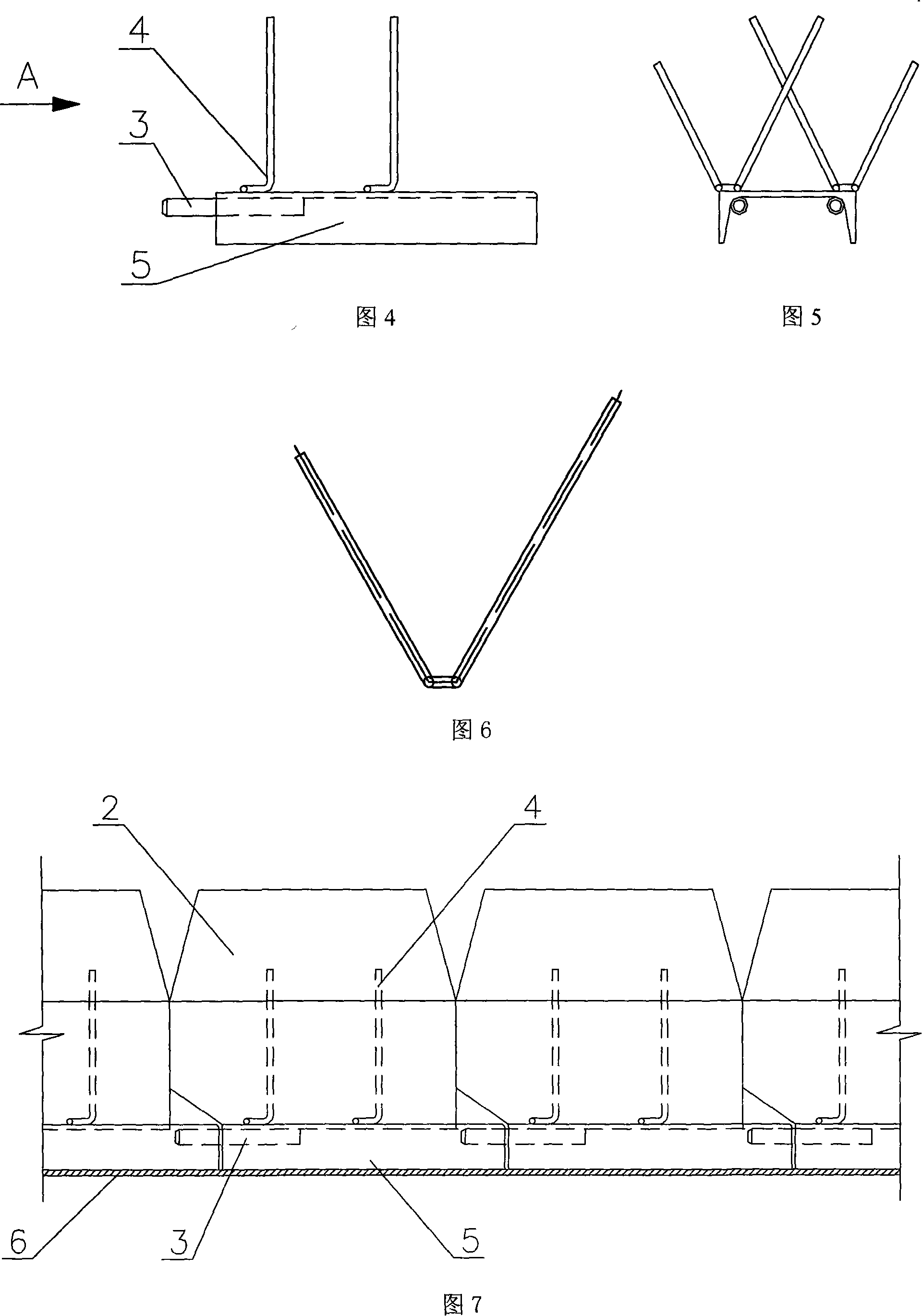

Material grinding system

ActiveCN106423414AReduce material transportation energy consumption and unit product energy consumptionSystem resistance is smallGrain treatmentsEngineeringIron removal

The invention relates to the field of material grinding systems, in particular to a vertical mill grinding system used for preparing raw materials or concrete. The vertical mill grinding system comprises a feeding device, a vertical mill, an efficient separator, a ground material conveying device, an iron removal device, an elevator, a material distributing device, a rotoclone collector, a circulating fan, a dust collector, an exhaust fan and a chimney. According to the vertical mill grinding system, the efficient separator and the vertical mill are of an integrated structure, and the system has the advantages of being reasonable in structural style and compact in arrangement; the efficient separator is provided with an upper material scattering device and a lower material scattering device, materials can enter the upper material scattering device and the lower material scattering device for material scattering and dispersing, material concentration of the upper region of the separator can be lowered, and the separation efficiency can be improved. In addition, the efficient separator integrates material drying, material roughing classification and material concentration classification functions, so that the equipment investment is reduced, and the burdens of enterprises are lowered.

Owner:NANJING KISEN INT ENG

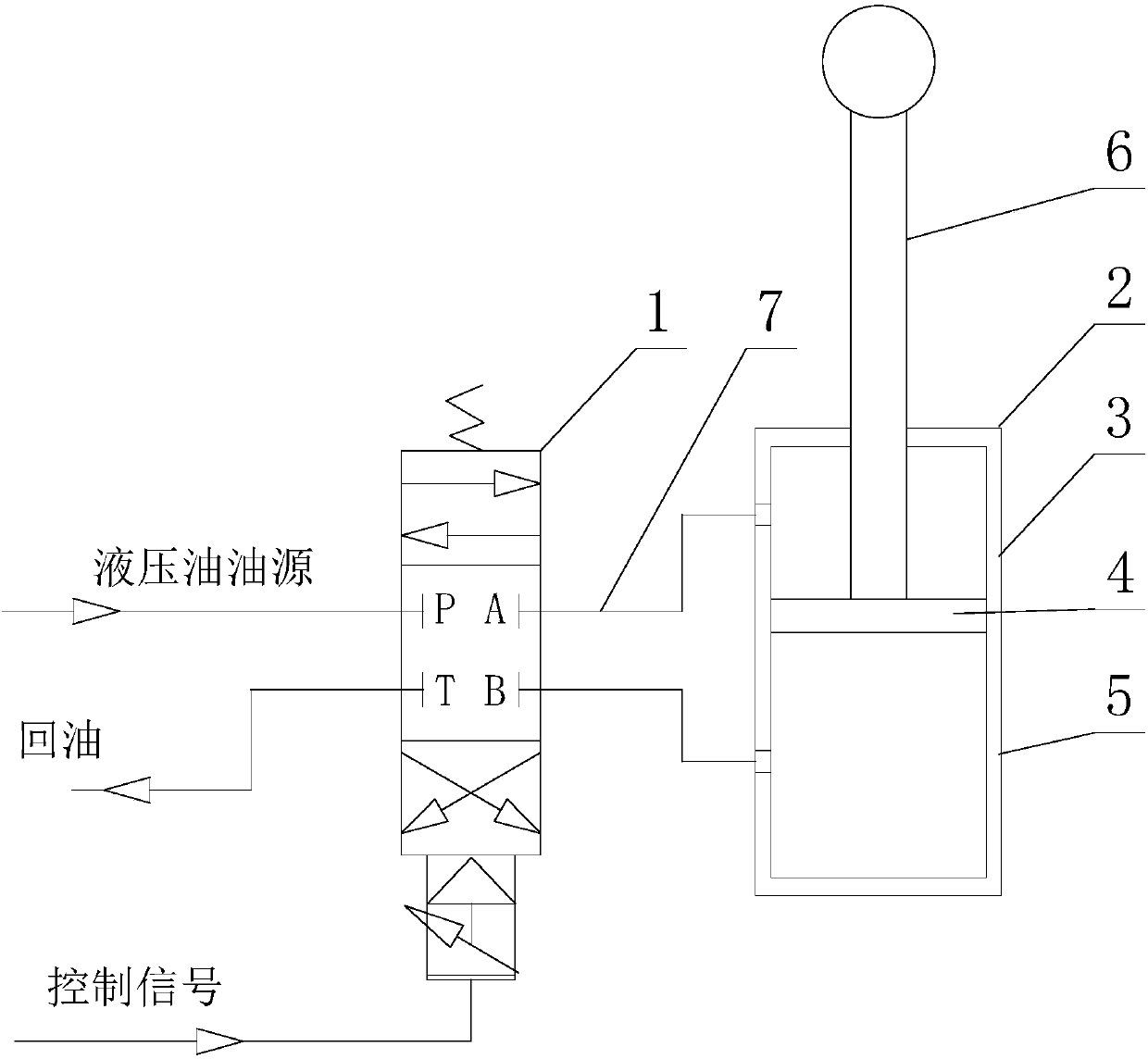

Novel hydraulic servo-motor system and adopted control method

PendingCN107939457AQuality improvementLow costMachines/enginesFluid-pressure actuatorsInterior spaceCylinder block

The invention discloses a novel hydraulic servo-motor system and an adopted control method. The system comprises a hydraulic control valve and a hydraulic servo-motor. The hydraulic servo-motor is only composed of a cylinder body, a piston and a piston rod. The piston is arranged in the cylinder body, and an internal space of the cylinder body is divided into two cavities by the piston. The pistonrod is fixed to the piston. The system further comprises two oil holes formed in the cylinder body; and one oil hole communicates with one of the cavities, and the other oil hole communicates with the other cavity. The hydraulic control valve is provided with two or more control oil openings. The two oil holes are connected with the different control oil openings of the hydraulic control valve through separate oil pipes correspondingly. The flowing directions of hydraulic oil of the two control oil openings can be switched. The control method is adopted for the novel hydraulic servo-motor system. The hydraulic servo-motor system and the control method are high in quality, low in cost and great in universality.

Owner:成都新华控制工程有限公司

High-temperature high-pressure difference pressure-reducing valve

InactiveCN101403448BAvoid scourGood for fault sealingSpindle sealingsValve members for heating/coolingControl systemEngineering

The invention relates to a high temperature high pressure difference reducing valve, which is characterized in that the reducing valve comprises a valve body, a valve seat, and a valve core which is positioned in the valve seat and can move up and down in the valve seat; the valve core is fixedly connected with a valve rod by a thread and a pin; the valve rod is positioned in the valve body, sealed from the outside world by sealing packing and a packing gland, and can move up and down; the lower part of the valve seat is provided with a bush, a throttle orifice and a flange which is connectedwith the outer part; and a medium enters into a valve cavity from the side direction, and flows out from the tail end after flowing through a channel composed of the valve core and the valve seat, and the throttle orifice at the downstream of the valve seat,. Compared with the prior art, the high temperature high pressure difference reducing valve can reduce the pressure of materials with high temperature and high solid content, controls the pressure of systems and the liquid position of high-pressure tanks, not only can reduce the pressure and generate required large pressure reduction but also can carry out appropriate flow control; more importantly, the high temperature high pressure difference reducing valve can prevent harsh erosive wear formed by the high-speed flow of medium flow with high solid content under large pressure difference to the materials.

Owner:SHANGHAI RES INST OF CHEM IND +2

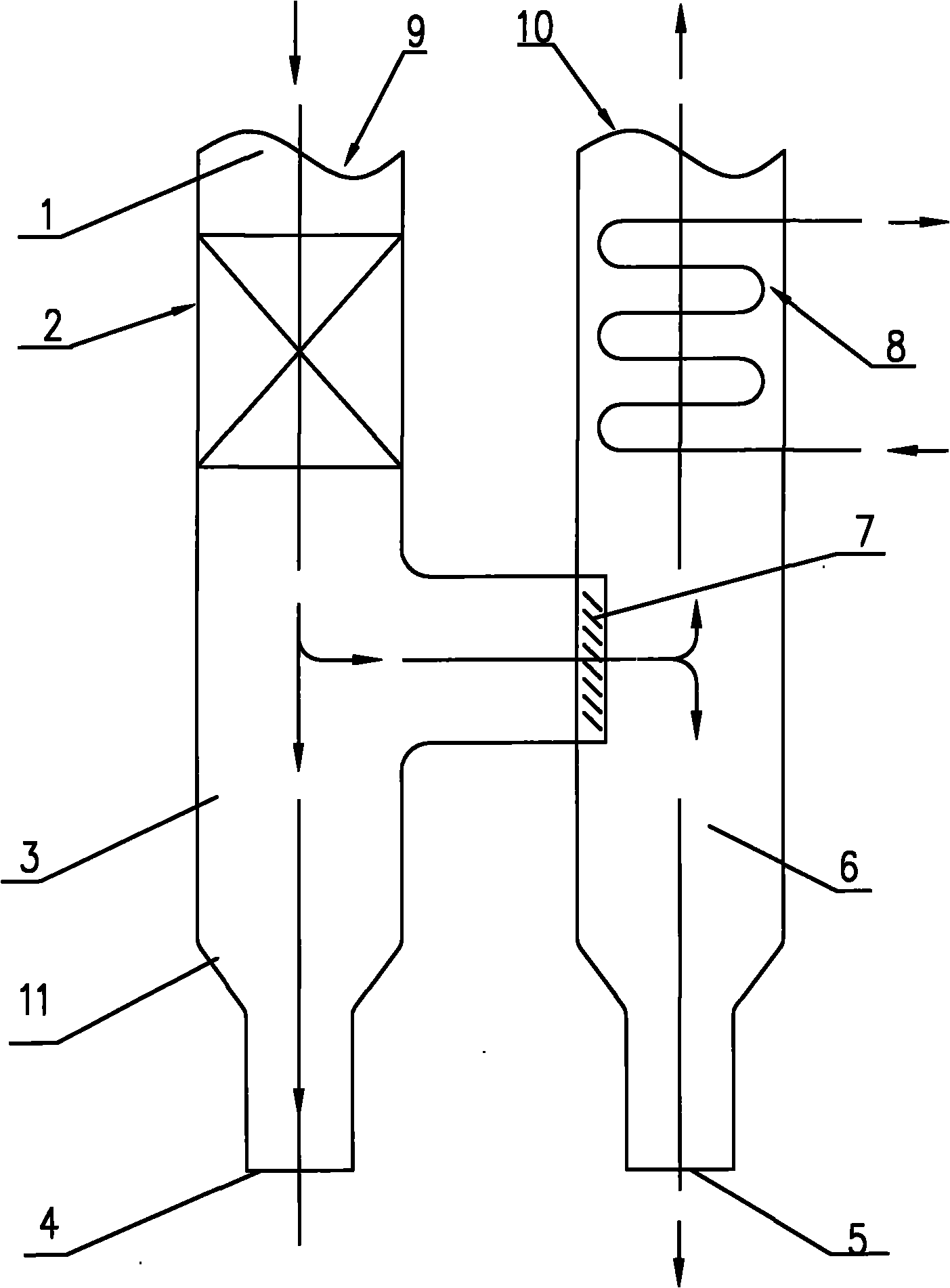

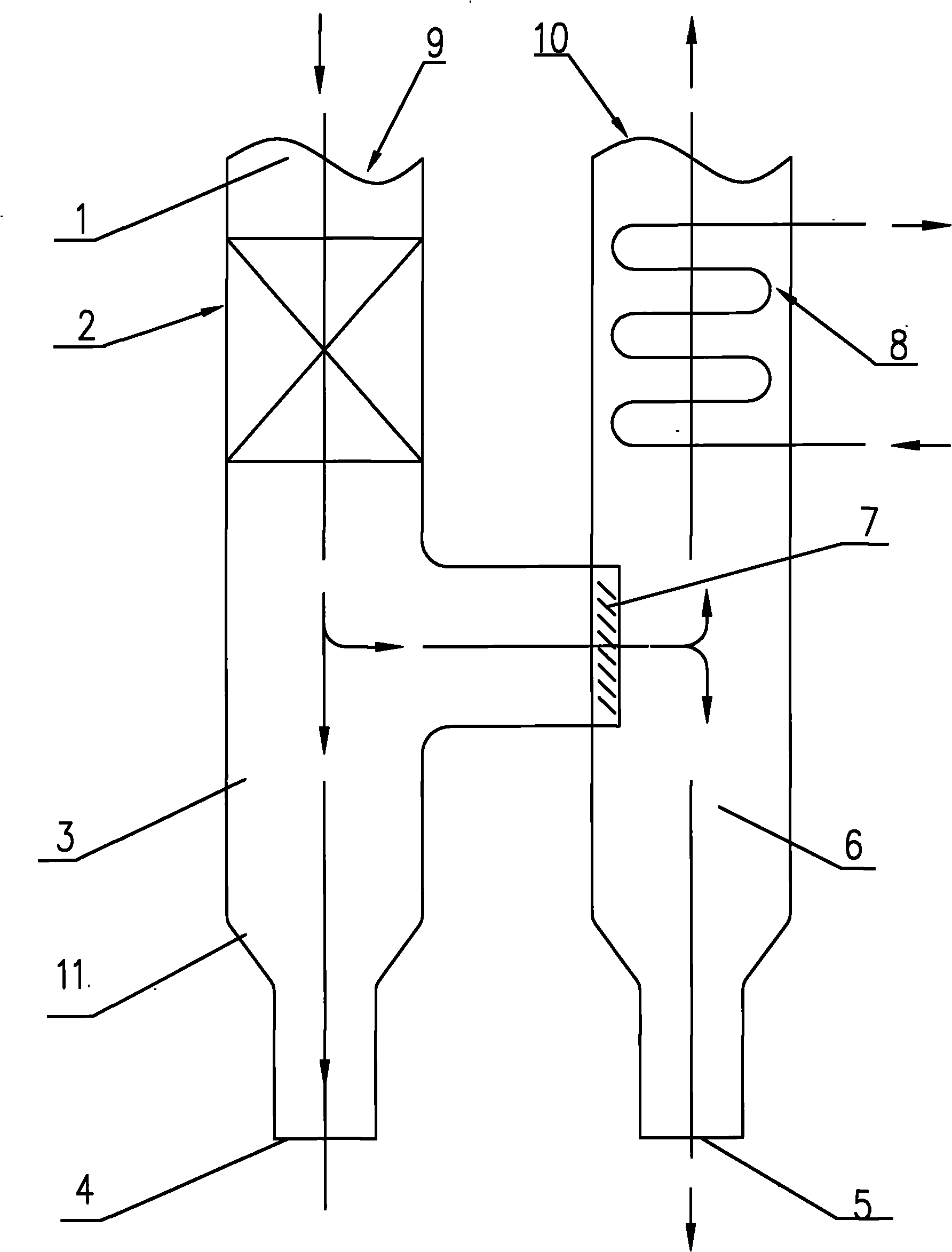

Waste heat recovery device

InactiveCN101963460AReduce mineral dust contentAutomatic temperature adjustmentEnergy industryWaste heat treatmentWaste heat recovery unitFlue gas

The invention discloses a waste heat recovery device. The device comprises a pre-evaporator, a primary ash settlement room, a secondary ash settlement room and a superheater, wherein the pre-evaporator and the primary ash settlement room are communicated with a flue; the secondary ash settlement room is communicated with the primary ash settlement room; the superheater is arranged in the secondary ash settlement room; the upper part of the primary ash settlement room is provided with a flue gas inlet; the lower part of the primary ash settlement room is provided with a primary ash discharge hole; the upper part of the secondary ash settlement room is provided with a flue gas outlet; the lower part of the secondary ash settlement room is provided with a secondary ash discharge hole; the superheater is arranged at the flue gas outlet; and an ash separator used for reducing a gas flow speed and separating ash is arranged between the primary ash settlement room and the secondary ash settlement room. The waste heat recovery device can separate ash from the flue gas very well, stabilize the temperature of the flue gas, and uniformize and stabilize a gas passing through the surface of the superheater so as to reduce local erosive wear of a heating surface of the superheater caused by the flue gas and avoid the explosion of a pipe.

Owner:JIANGNAN BOILERS & PRESSURE VESSELS ZHANGJIAGANG

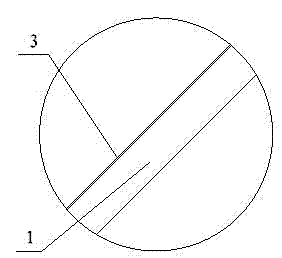

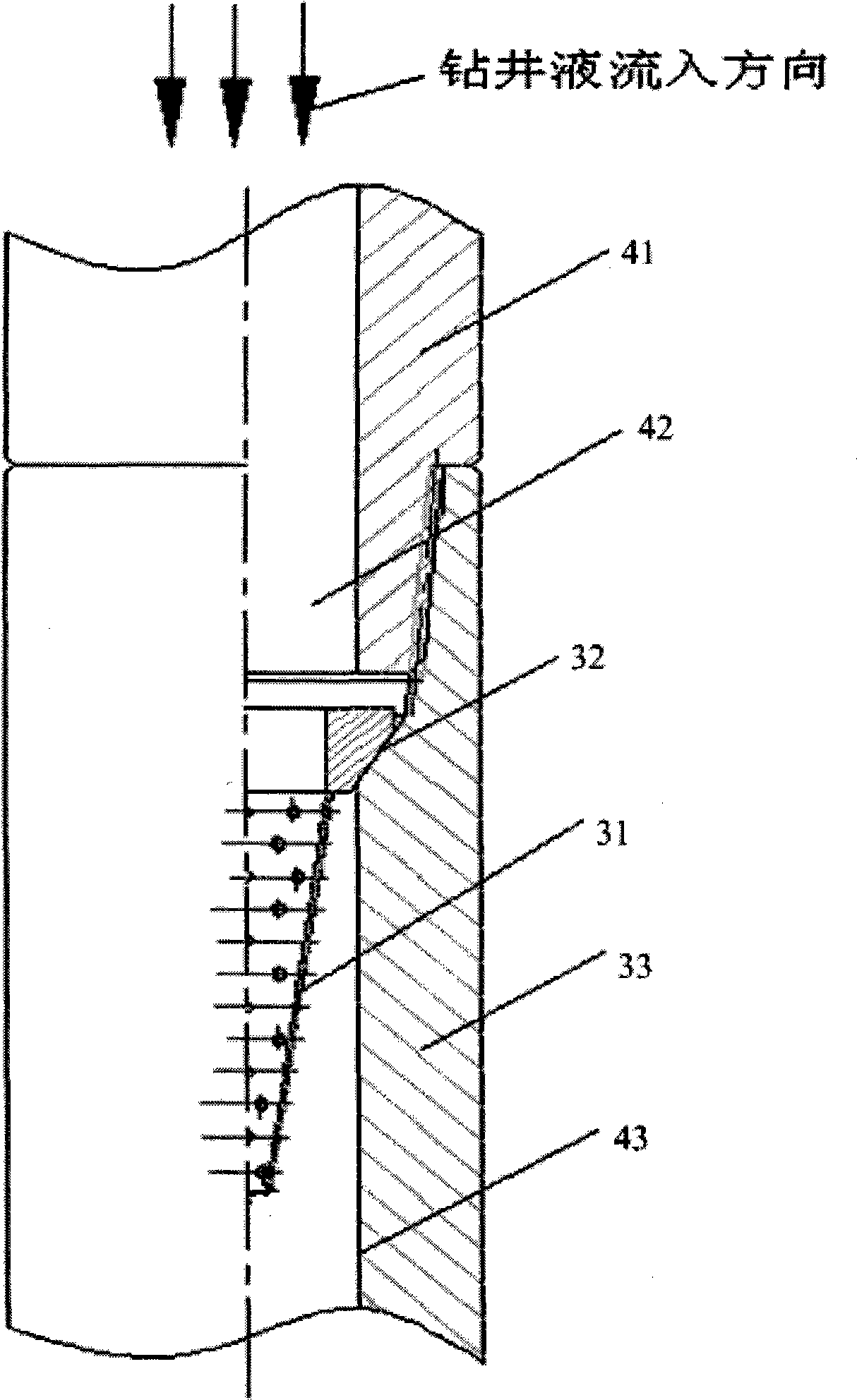

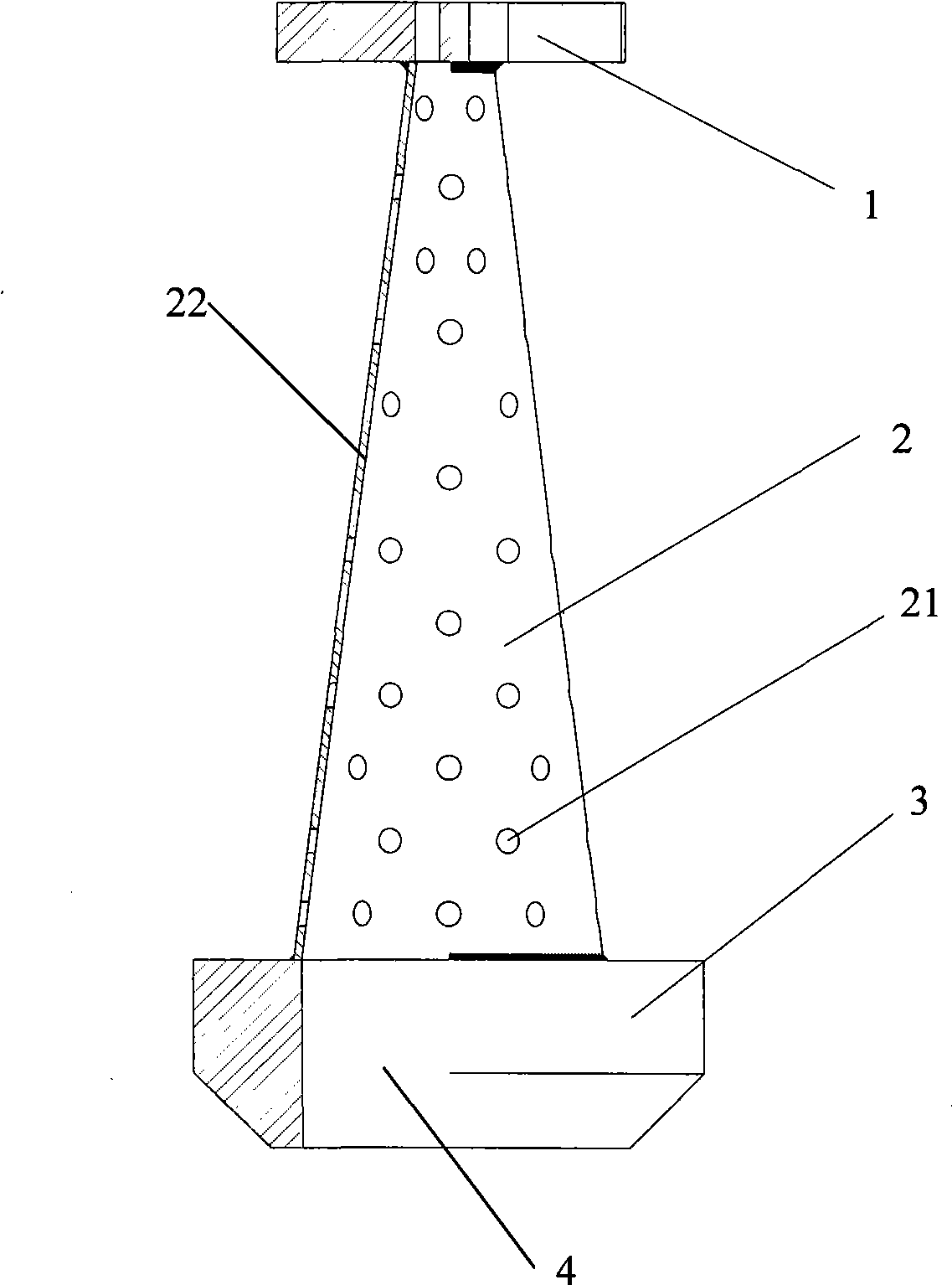

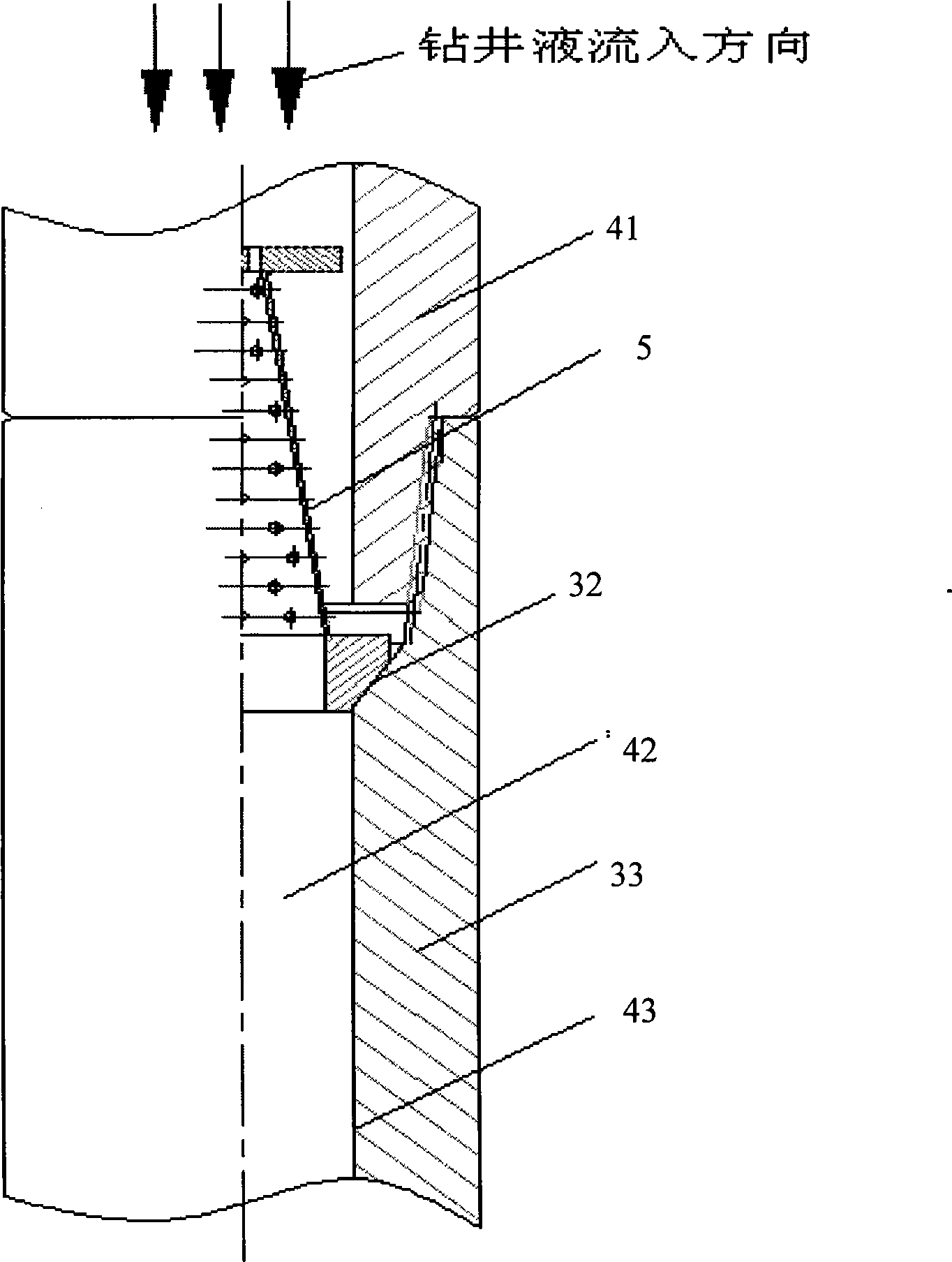

Drilling tool filter screen for realizing protection of internal wall of drilling tool

InactiveCN101530692AReduce accidentsGuaranteed filtering effectEarth drilling toolsDrill bitsWell drillingPetroleum

The invention relates to a drilling tool filter screen for realizing protection of the internal wall of a drilling tool. The drilling tool filter screen is arranged at the upper part of a small end of the internal thread of the drilling tool and an opening thereof faces downward; the drilling tool filter screen adopts a mode that drilling fluid flows into an inner cavity of the filter screen by filter holes on the filter screen from the outer part of the filter screen to filter impurities. The drilling tool filter screen for protecting the internal wall of the drilling tool guarantees that the impurities in the drilling fluid are filtered, simultaneously can protect the internal wall of the drilling tool effectively, reduce drilling tool accidents caused by washing out and abrasion of the drilling fluid to the internal wall of the drilling tool, prolong the service life of the drilling tool and can be widely applied to fields of drilling operation of petroleum gas.

Owner:张继川

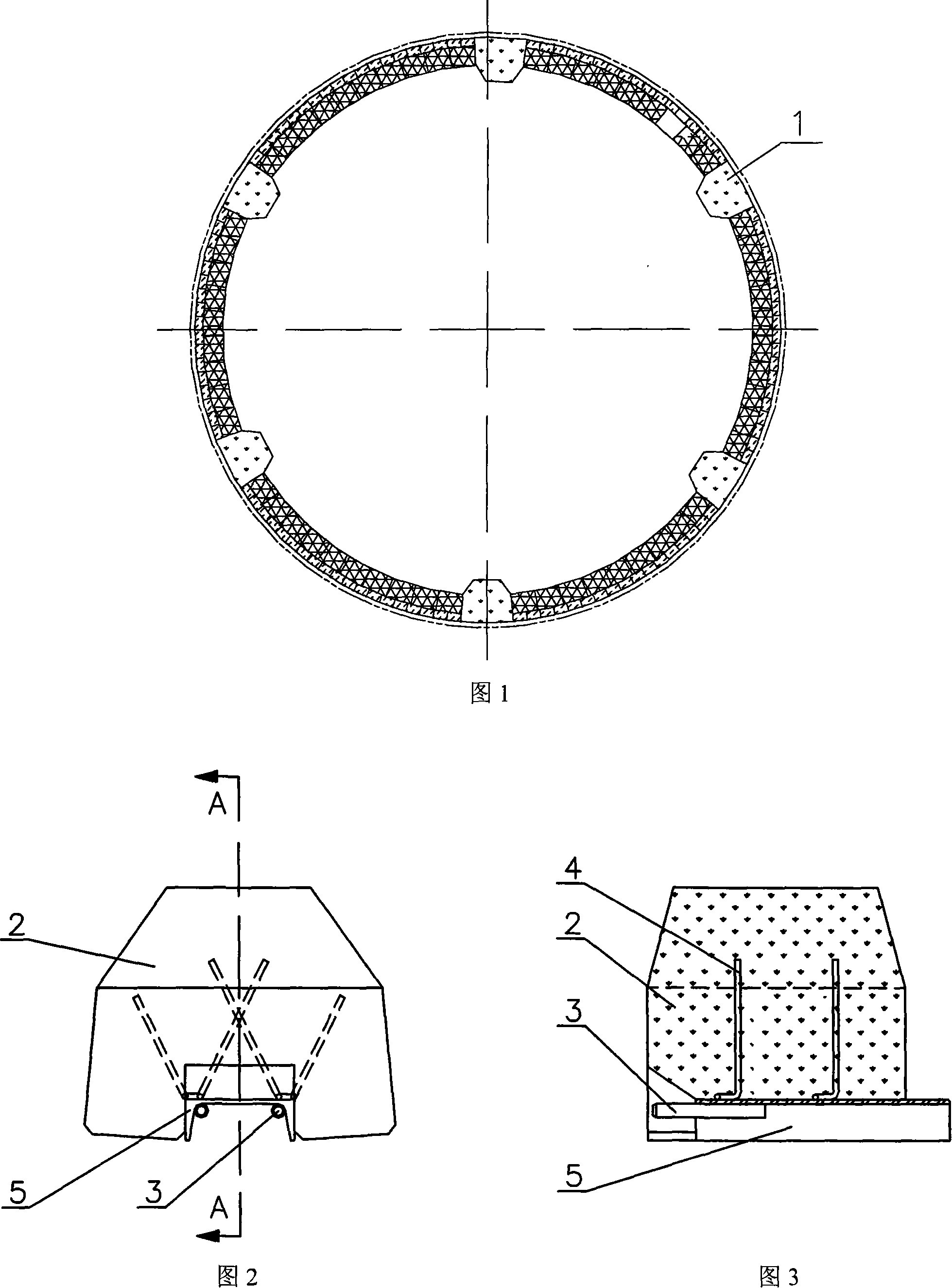

Rotary kiln inside lining refractory materials injecting brick with novel structure

ActiveCN101135541AImprove integritySolve the problem that small size specifications need to be combinedFurnace componentsRotary drum furnacesBrickRefractory

The invention relates to a novel structure of rotary kiln lining refractory spreading brick. Its characteristic: there is metal structural frame in the spreading brick, the castable refractory. Is poured at the metal structural frame to form spreading brick and is welded on the rotary kiln drum body by the metal structural frame, in the rotary kiln length direction, inter-adjacent spreading bricks are connected to form one piece as a whole by mosaic rod on the metal structural frame.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Material Grinding System

ActiveCN106423414BReduce concentrationReduce the burden onGrain treatmentsIron removalMaterial scattering

Owner:NANJING KISEN INT ENG

Falling-film evaporator balance device

InactiveCN105854323AReduce flow rateReduce differential pressureEvaporator accessoriesVapor liquidEngineering

A falling-film evaporator balance device comprises: a pressure balance tube, a pipeline, an upper head, a heating tube and a vapor-liquid separation chamber, wherein the lower end of the heating tube is disposed in the vapor-liquid separation chamber, the upper head is disposed on the heating tube, the pressure balance tube is connected between the upper head and the vapor-liquid separation chamber, and the pipeline is mounted on the upper head. Pressure between the upper head and vapor-liquid separation chamber in the evaporator is balanced, reducing erosive wear of a heating tube bundle of the evaporator from material.

Owner:LIUZHOU ELEVEN METALLURGICAL MACHINERY MFG

Erosive wear resistant pipeline elbow

InactiveCN102401207AReduced scour wearGuaranteed service lifePipe protection against damage/wearSiphonsWear resistantEngineering

The invention relates to an erosive wear resistant pipeline elbow, which comprises a pipe body, a feeding pipe and a discharge pipe, wherein the feeding pipe is connected to one end of the pipe body and is coaxial with the pipe body; the discharge pipe is connected to the side wall of the pipe body and forms a certain included angle with the pipe body; the diameters of the feeding pipe and the pipe body are different; and the feeding pipe is connected with the pipe body through a transition pipe. The flow rate of a sand-containing liquid material fed into the pipeline elbow by the feeding pipe is reduced by a concentric reducing pipe, and the material is accumulated under the coordination of a blind plate, so that the subsequent material is prevented from directly scouring the inner wall of the pipe body of the pipeline elbow, the erosive wear resistance of the pipeline elbow is effectively improved and the service life of the pipeline elbow is prolonged.

Owner:JINJIANG TAIXING CHEM IND CO LTD

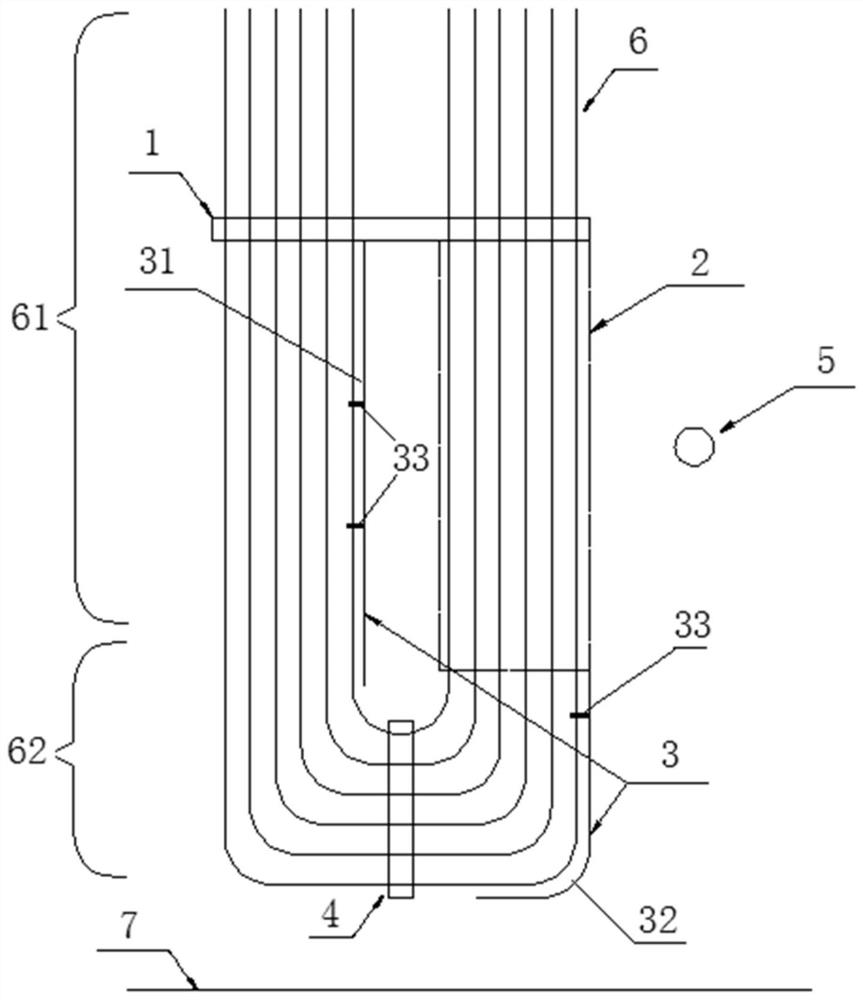

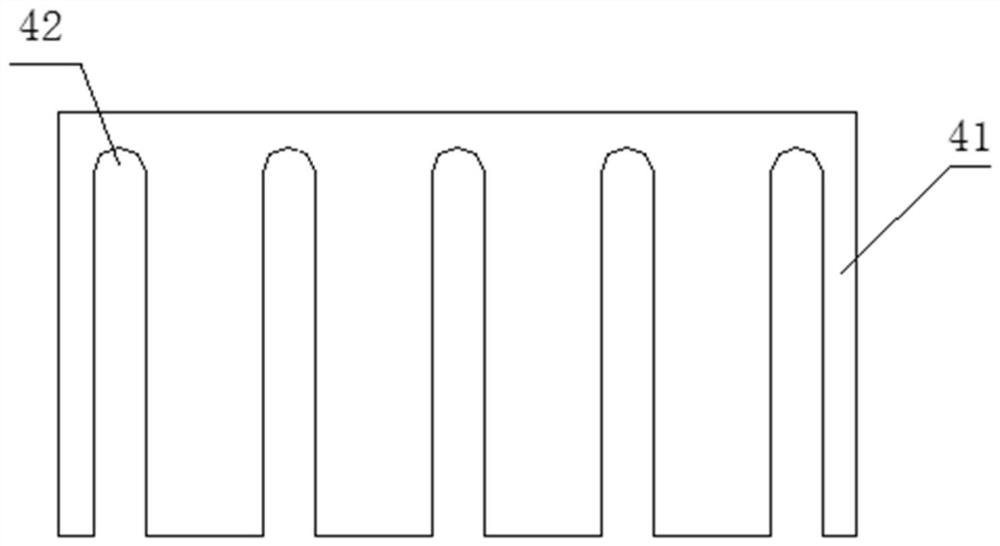

Anti-abrasion device for high-temperature reheater

PendingCN113137596AReduced scour wearReduce maintenance workloadSteam superheatersSteam boilersStructural engineeringPipe

The invention relates to an anti-abrasion device for a high-temperature reheater. The device is used for conducting anti-abrasion treatment on a metal pipe on the heated surface of the high-temperature reheater nearby a soot blower and comprises a hole-shaped pipe clamp, an anti-abrasion box and anti-abrasion covers which are arranged on the metal pipe of the heated surface of the high-temperature reheater. The metal pipe comprises a plurality of furnace pipes which are arranged side by side at equal intervals. Each furnace pipe comprises a U-shaped bent pipe section and a vertical pipe section arranged above the U-shaped bent pipe section. The anti-abrasion box covers the vertical pipe section close to one side of the soot blower. The anti-abrasion covers comprise the straight anti-abrasion cover and the 90-degree anti-abrasion cover, the straight anti-abrasion cover covers the furnace pipe on the innermost circle of the side, close to the soot blower, of the vertical pipe section, and the top of the straight anti-abrasion cover is welded to the bottom of the hole-shaped pipe clamp. The 90-degree anti-abrasion cover is arranged on the furnace pipe, close to the outermost circle of the soot blower, of the U-shaped bent pipe section in a covering mode, the top of the 90-degree anti-abrasion cover is welded to the bottom of the anti-abrasion box, and the anti-abrasion cover is fixed to the corresponding furnace pipe through an anti-abrasion cover butt strap. Compared with the prior art, the anti-abrasion device for the high-temperature reheater has the advantages of reducing the unit maintenance workloads, prolonging the service life of the metal pipe and the like.

Owner:HUANENG POWER INT INC

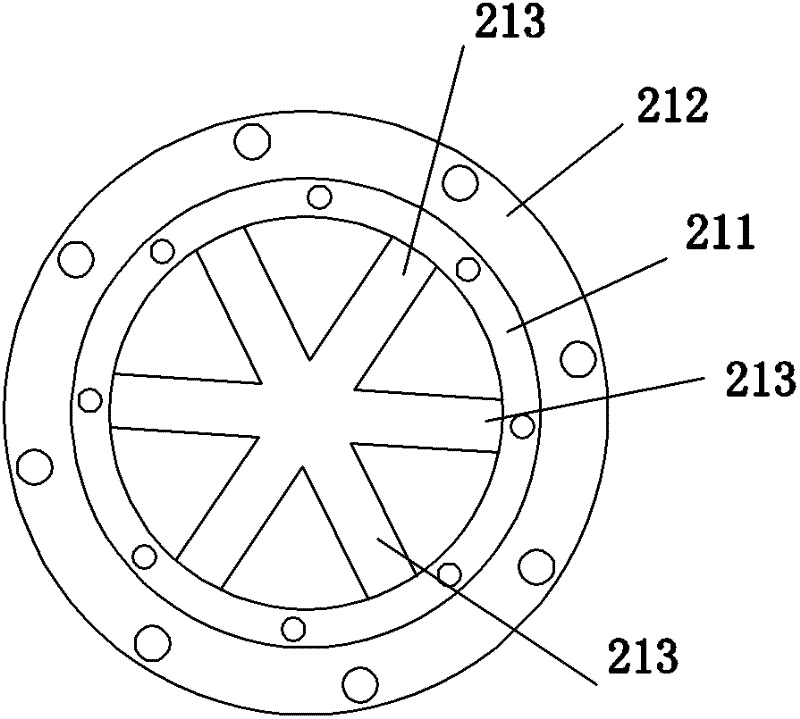

Gas scrubbers for gas generators

ActiveCN102295959AEase the blockageReduced scour wearGas purification by liquid washingCombustible gas productionEngineeringDistributor

A gas-washing device for a gas producer comprises a gas-washing box; a distributor is disposed at a coal gas inlet of the gas-washing box; a coal gas inlet pipe is connected with the upper end of the distributor; the invention is characterized in that: the distributor comprises a distributor body and a reinforcing rib plate; the distributor body is a cylinder; at least two separating ribs are disposed on the inner wall of the cylinder and are arranged staggeredly as a matrix in the cross section of the cylinder; the separating ribs divides the cylinder cavity into at least four identical sector gas-introducing channels; the reinforcing rib plate comprises a round center plate and bar-shaped plates uniformly and divergently distributed at the periphery of the center plate; the reinforcing rib plate is fixed above the inner wall of the distributor body and the separating ribs; the size of the reinforcing rib plate fits the inner wall of the cylindrical cylinder body. The gas-washing device for a gas producer of the invention is washing resistant, has a long life, and has uniform gas flow distribution.

Owner:ANHUI HUAIHUA

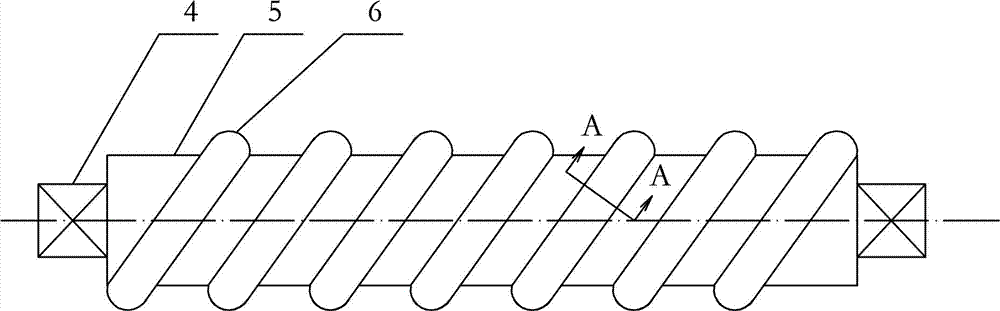

Production method of guide bearing

The invention discloses a production method of guide bearing. The guide bearing is produced according to the following process: equal altitude spiral hump is formed on the outer circumferential surface of the cylindrical core mold base, which is corresponded with the spiral sink shape of the inner wall of the guide bearing; coating the release agent on the surface of the core mold; modified resin impregnated fiber cloth is rolled up on the core mold which coating the release agent by using the tube winding machine; putting the fiber cloth rolled core mold in the forming cavity of the guide bearing of the pressing machine horizontally, hotpressing the core mold so that forming; fixing the fiber cloth layer of the outside surface of the core mold, then rotating the core mold, so that the core mold is rotated out by the superficial thread action of the equal altitude spiral hump to obtain a hot shell the spiral sink of which is provided with a hard and smooth internal surface; and last processing the shell, produce the guide bearing. Utilizing the guide bearing by the method, so the fiber cloth at the guide bearing sink cannot be destroyed, and sink is provided with a hard and smooth internal surface, the strength of the guide bearing is high, the service life is long, the production hours is short, pass-rate of production is high, manufacturing cost is low.

Owner:铁岭市建烨水泵部件制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com