Waste incineration system and method based on selective catalytic denitration plasma integration

A plasma and catalytic denitrification technology, applied in the field of waste incineration, can solve the problems that threaten the human living environment and produce nitrogen oxides, and achieve the effects of low environmental risk, low toxicity and low concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention.

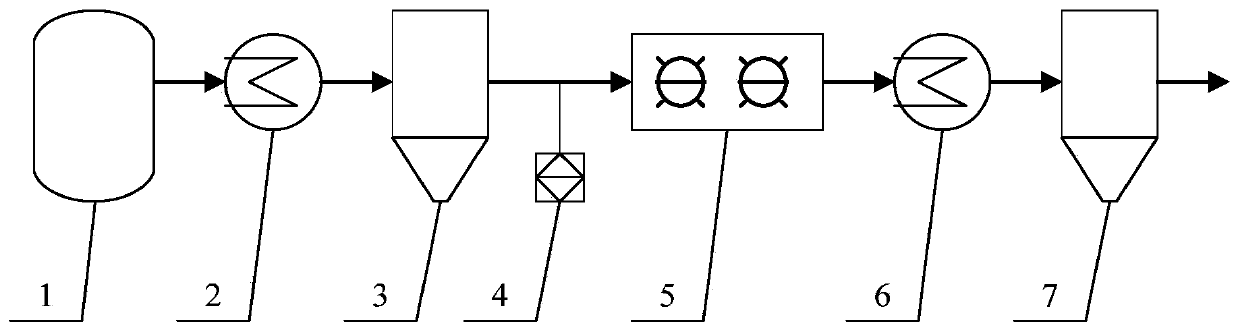

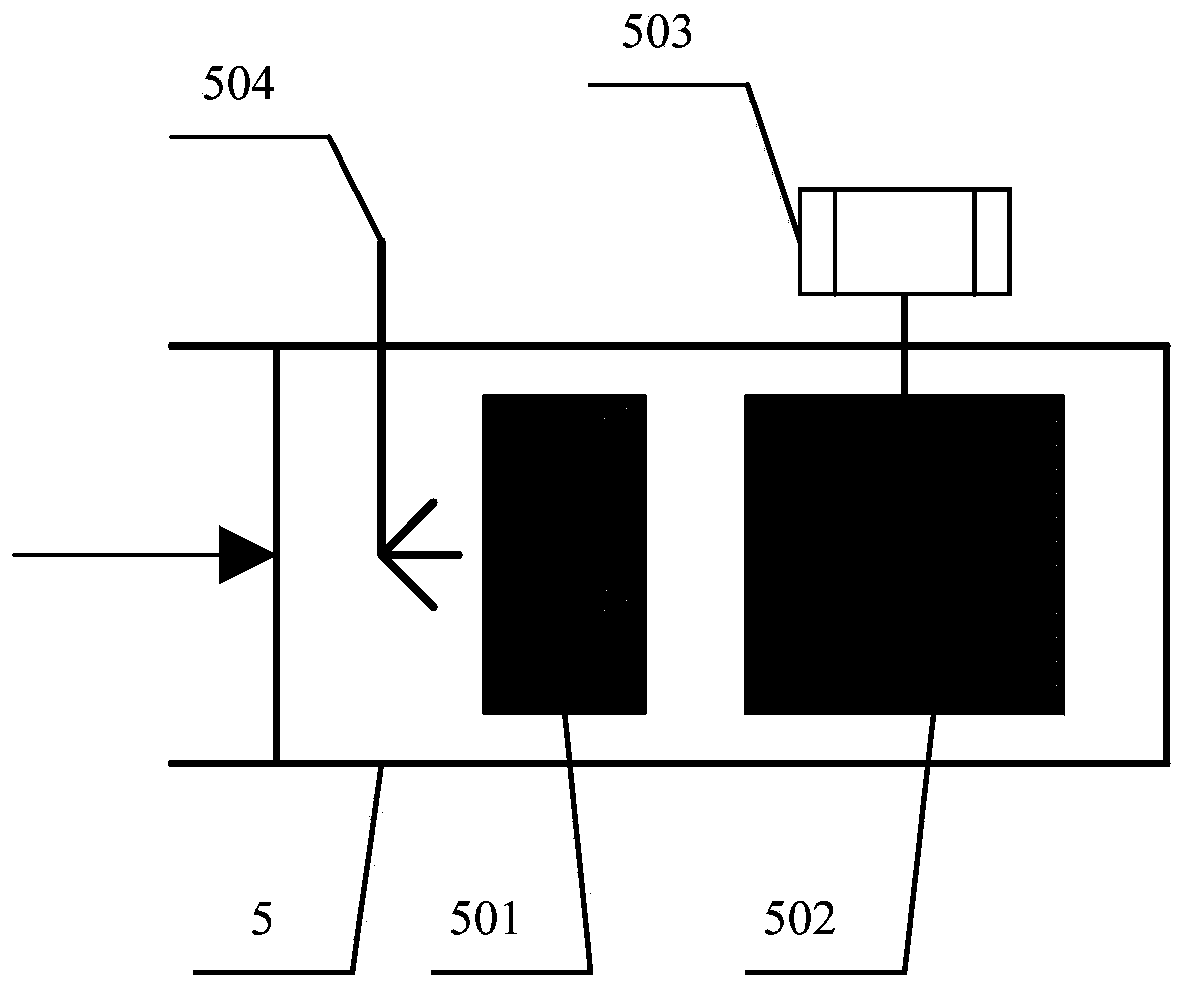

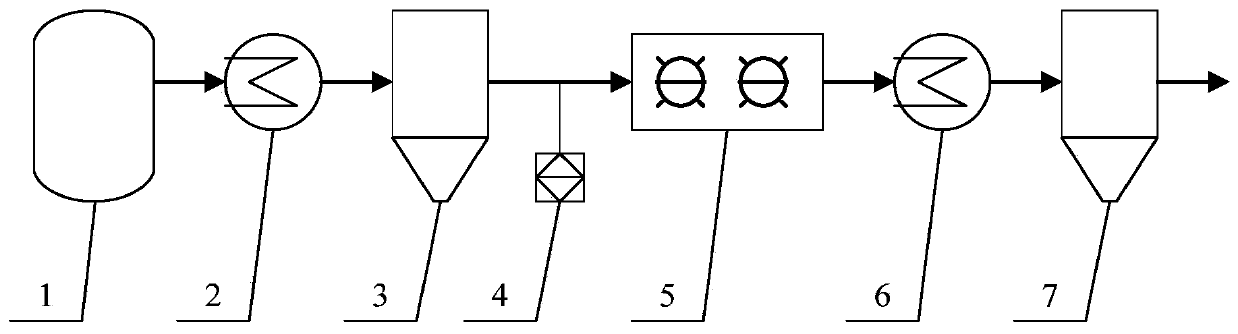

[0030] like figure 1 As shown, the present invention is based on a selective catalytic denitrification plasma integrated waste incineration system, including a waste incinerator 1, a high temperature heat exchanger 2, a high temperature dust collector 3, a temperature sensor 4, and a selective catalytic denitrification plasma integrated device 5 , low temperature heat exchanger 6, flue gas purification device 7.

[0031] The smoke outlet of the garbage incinerator 1 is connected to the high-temperature heat exchanger 2, and the high-temperature flue gas discharged from the garbage incinerator 1 is cooled through the high-temperature heat exchanger 2, and the flue gas outlet of the high-temperature heat exchanger 2 is Connected with the high-temperature dust collector 3, the high-temperature dust collector removes mos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com