Economizer hopper of coal-fired boiler in power plant

A technology for coal-fired boilers and economizers, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of low dust collection efficiency of an economizer ash hopper, and achieve the effect of avoiding the phenomenon of secondary dust. Significantly, the effect of improving dust collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

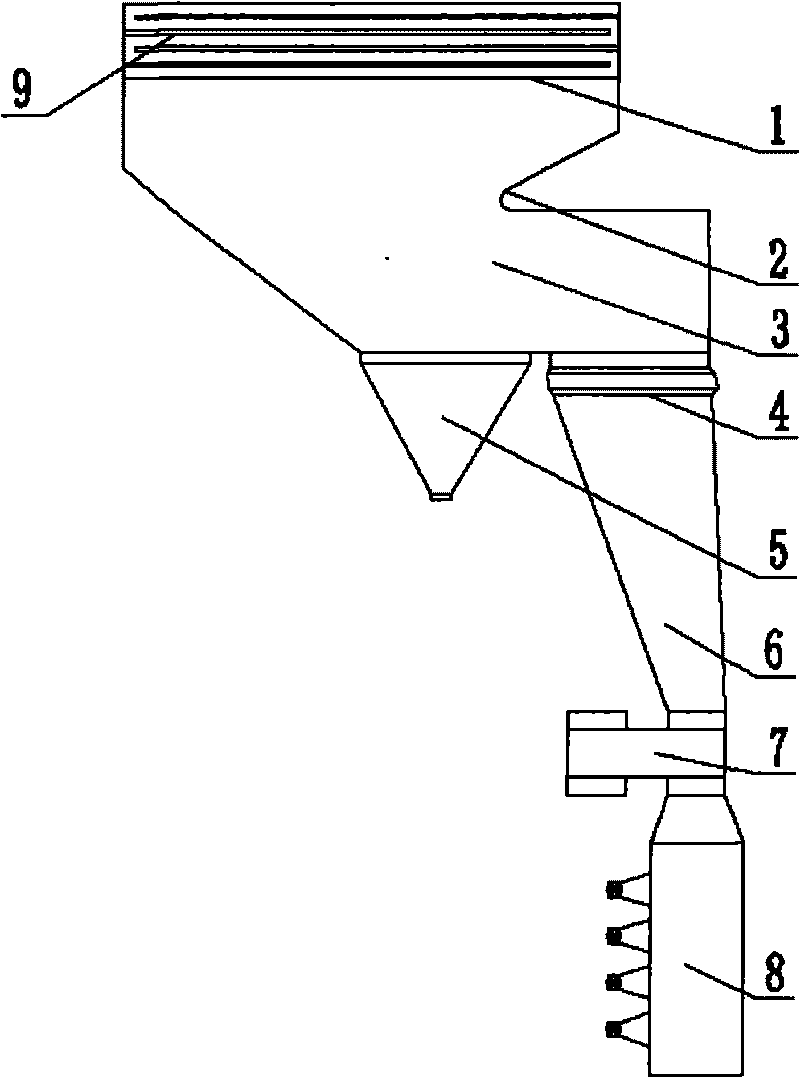

Method used

Image

Examples

Embodiment 1

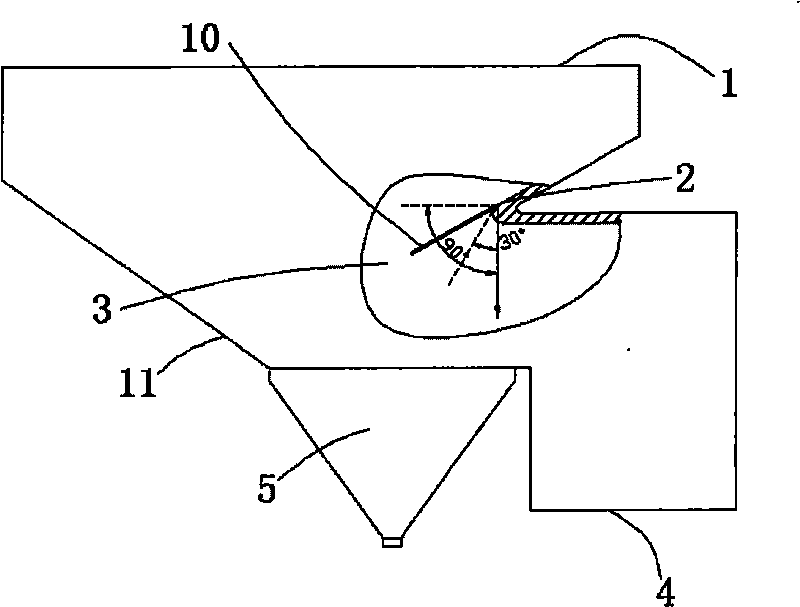

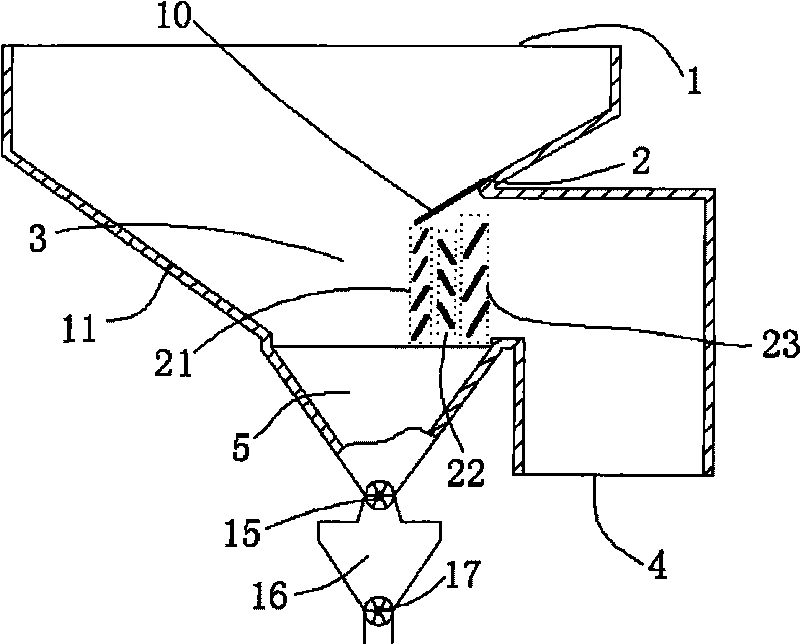

[0029] Such as image 3 , Figure 4 As shown, this embodiment presents a new ash hopper structure of the economizer. A deflector is installed in the steering chamber 3 of the ash hopper of the economizer. The shape of the deflector is rectangular, and the A-level Deflector 21, B-level baffle 22, and C-level baffle 23, including 4 pieces of A-level, 3 pieces of B-level, and 3 pieces of C-level. The two ends of the deflector in the length direction are connected with the walls on both sides of the economizer ash hopper. The material of the deflector is Q345, the thickness is 8mm, the distance between A and B grades is 200mm, the distance between B and C grades is 200mm, and the distance between A grade and B grade The board spacing is 700mm, and the C-level board spacing is 900mm. The included angle between the deflectors of grade A and C (odd-numbered grades) and the horizontal direction of the flue gas flow is 60 degrees, and the angle between the deflectors of grade B (even...

Embodiment 2

[0032] Such as Figure 5 , Figure 6As shown, this embodiment presents another new economizer ash hopper structure. A deflector is installed in the turning chamber of the economizer ash hopper, and a D-level deflector is installed in the turning chamber along the vertical direction. 31. E-level deflector 32, F-level deflector 33, G-level deflector 34, H-level deflector 35, a total of 5 levels of deflectors, of which, D-level 2 pieces, E-level 3 pieces, F-level 2 pieces, 3 pieces of G grade, 2 pieces of H grade, the two ends of the deflector in the length direction are connected with the walls on both sides of the economizer ash hopper, the material of the deflector is manganese steel, the thickness is 8mm, and the distance between all the plates is 1046mm. Class D, Class E, Class F, and Class G have the same structure of rectangular plate louvers; Class G has a trapezoidal plate louver structure because it is set in the ash hopper with a tetrahedral structure. The angle bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com