Technology for preparing cement by dry carbide slag method

A dry calcium carbide and process technology, which is applied in the field of making cement from waste carbide slag by dry method and reducing pollution, can solve the problems of low amount of calcium carbide slag added, difficult operation control, low economic benefit, etc., to increase market competitiveness, Improved accuracy and high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

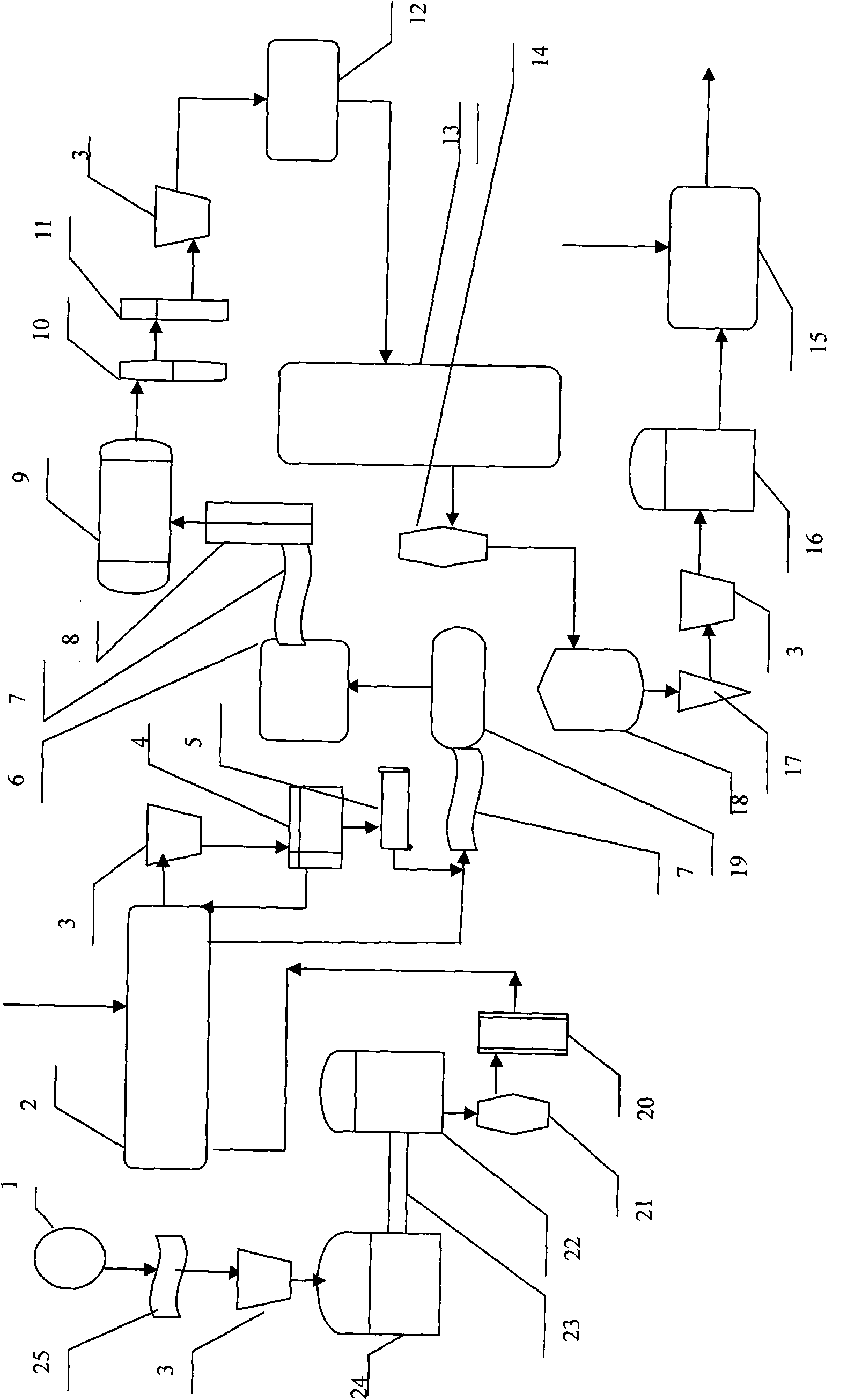

[0020] Attached below figure 1 The present invention is described in detail.

[0021] refer to figure 1 , present embodiment 1 comprises the steps of following order: a kind of dry calcium carbide slag dry process cement production process, utilizes dry process acetylene process to discharge the dry calcium carbide slag powder that moisture content is 5~8% from generator 1 through pipe chain machine 25, bucket lifting The machine 3 is transported into the calcium carbide slag storehouse 24 for storage, and the dry calcium carbide slag powder stored in the storehouse is sent to the carbide slag steel warehouse 22 through the pipe conveyor 23, and the dry calcium carbide slag powder in the warehouse is passed through the frequency conversion feeder 21 at the bottom of the warehouse. The control of the feeder 20 and the unloading of the drying mill 2 grind the qualified black raw meal through the chain conveyor 7, and carry out preliminary mixing and drying in the drying pipe 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com