Patents

Literature

941results about How to "Solve difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

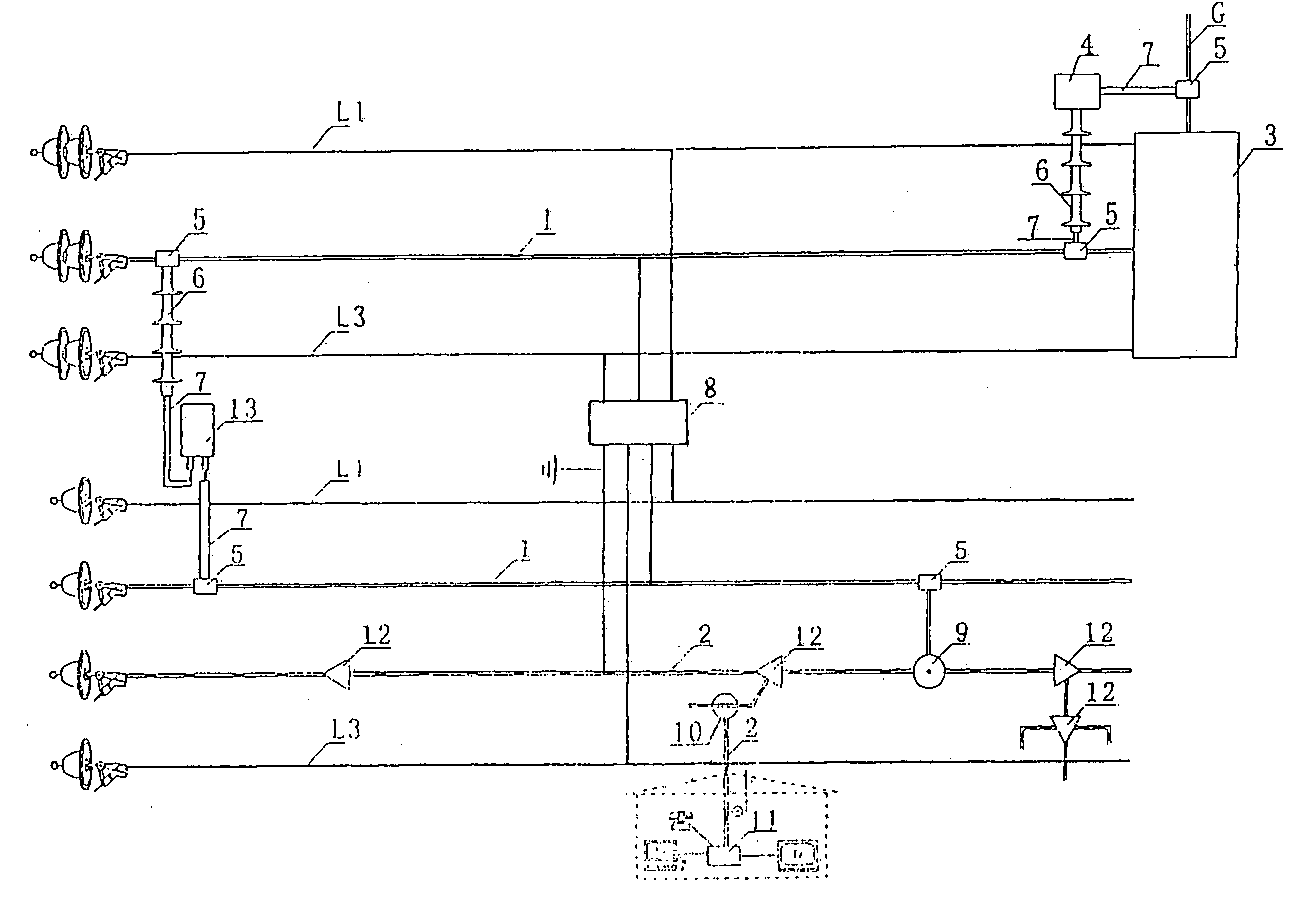

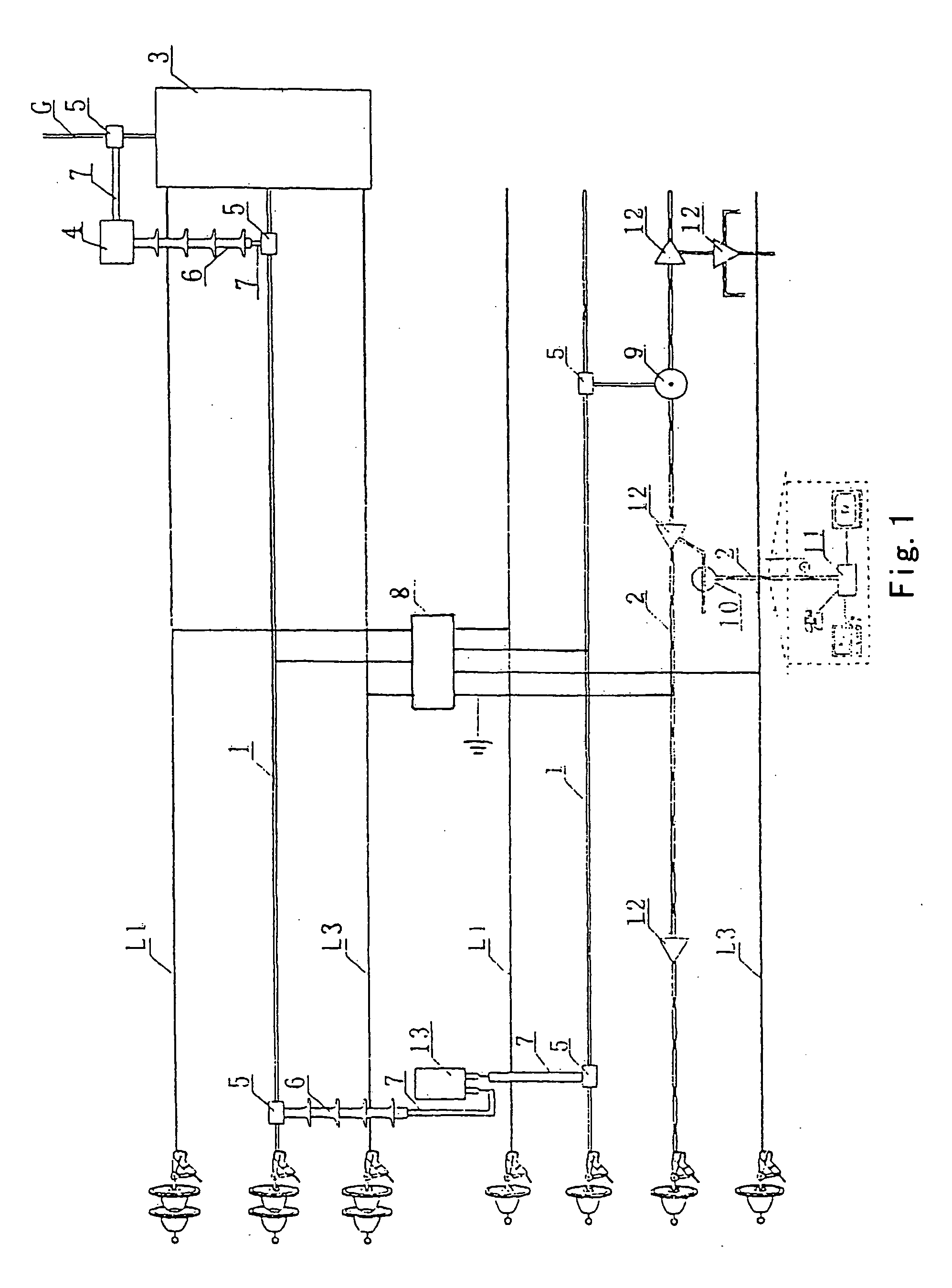

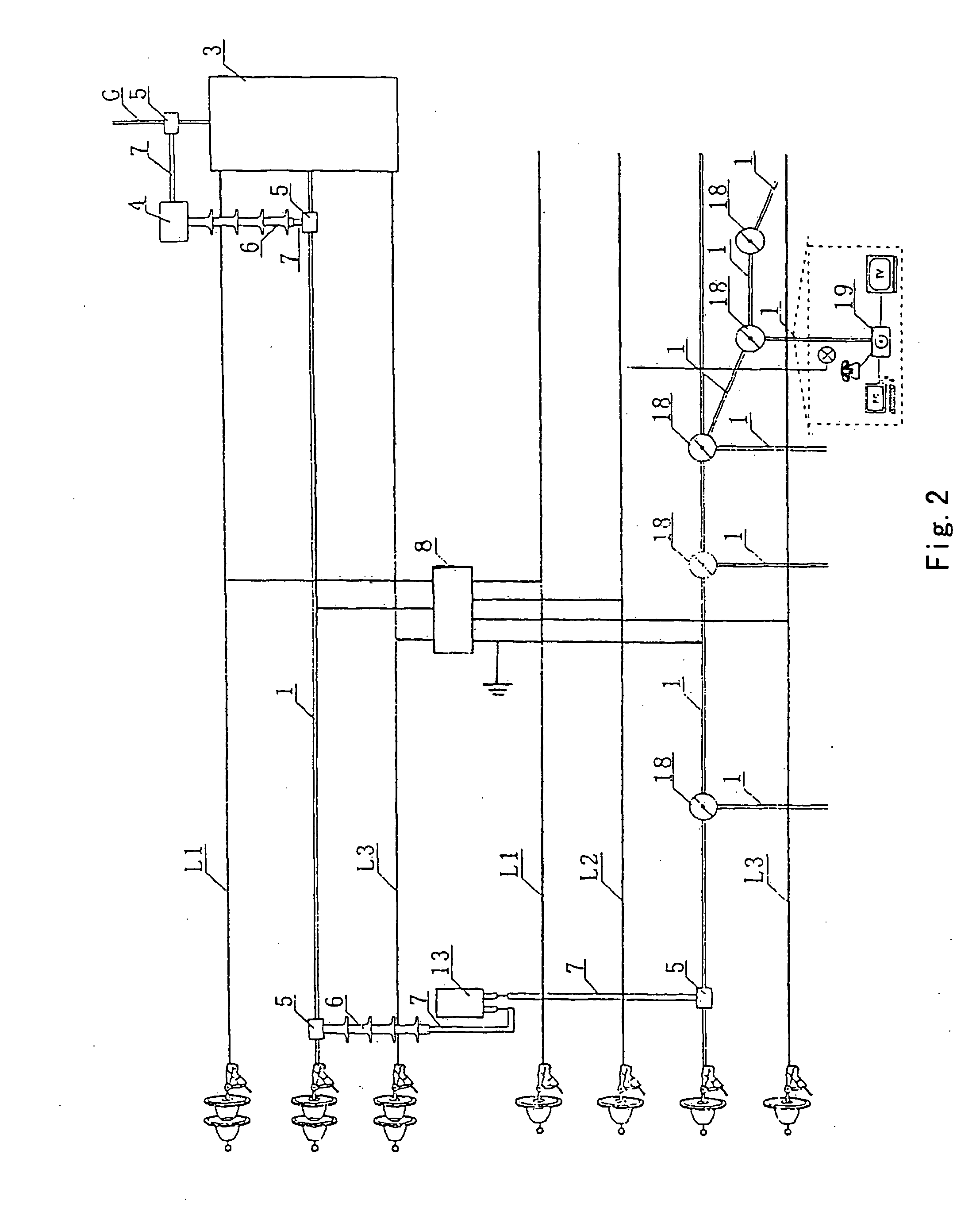

Broadband access transmission network integrating the functions of electric power network, telecommunication network, tv network and internet

InactiveUS20050030118A1Easy to implementConvenient maintain/administrationPulse modulation television signal transmissionOne-port networksElectric power transmissionModem device

A broadband access transmission network integrating the functions of electric power network, communication network, TV network and Internet relates to network transmission. It includes a broadband transmission network of 10 KV power distribution network and a broadband transmission network of low-voltage power distribution network. These two transmission networks are connected via distribution transformers and optical fiber connectors. The broadband transmission network of 10 KV power distribution network is composed of optical compound power lines, wires, transformer substations, machine rooms, taps, insulating jackets, insulating waterproofing outer jackets and optical fiber connectors. The broadband transmission network of low-voltage power distribution network is composed of optical compound power lines, coaxial cable compound power lines, taps, insulating jackets, optical access points, distributors, modems and two-way amplifiers. The invention can perform high-speed broadband communication and power transmission on the same compound wires. It utilizes the existing power network sufficiently and prevents the cost of rebuilding the communication network, cable TV network and Internet, and can simultaneously perform building, operating, maintaining and managing of these networks.

Owner:WANG DEGING

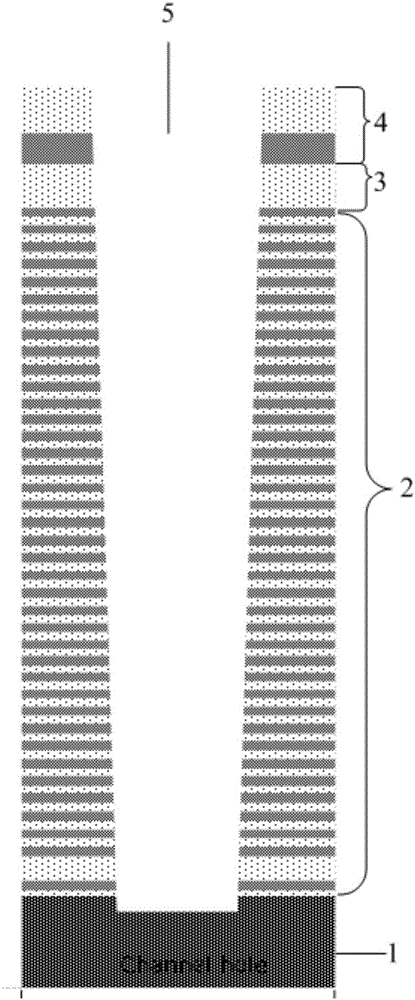

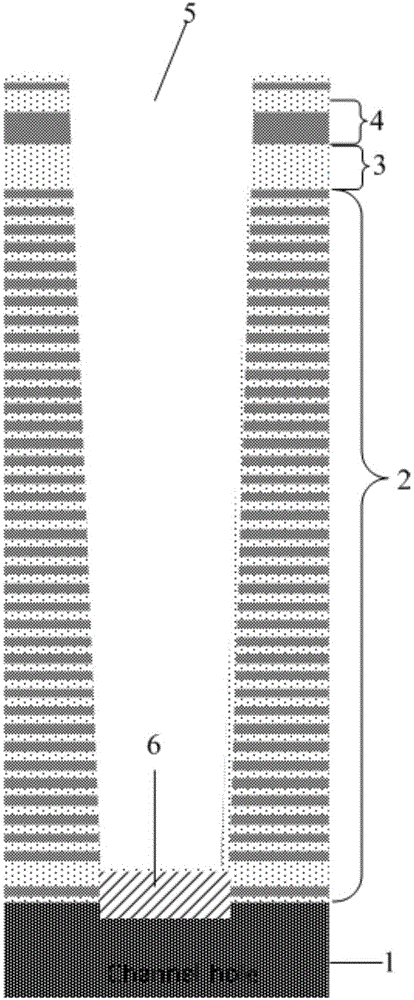

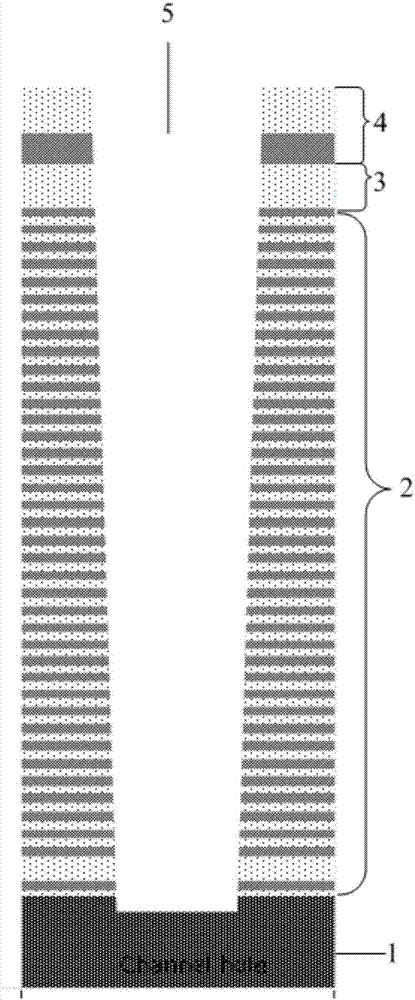

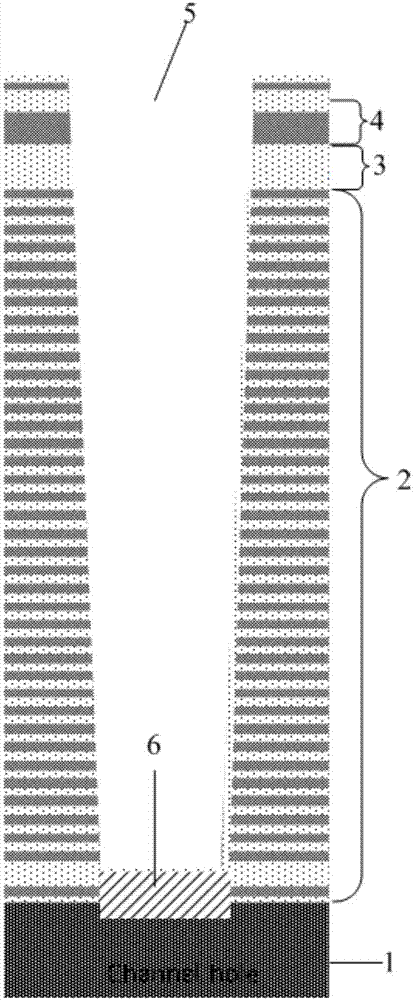

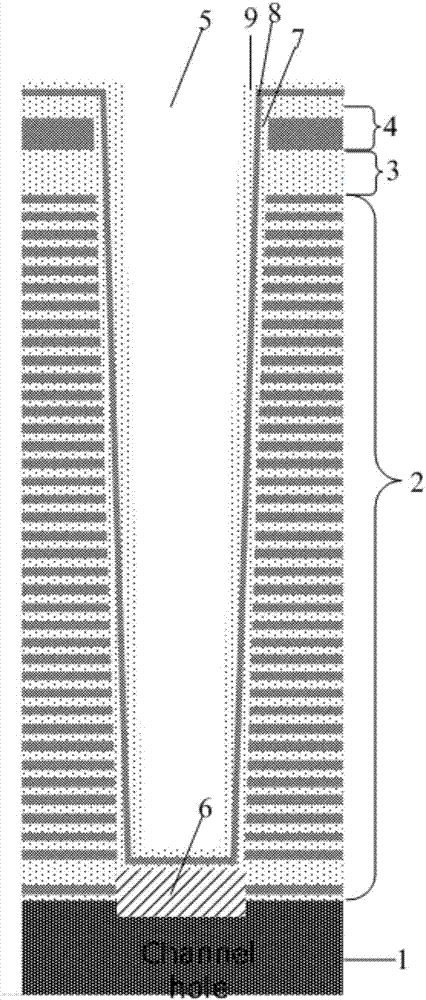

Three-dimensional memory and formation method of channel pore structure thereof

ActiveCN106653684AReduce the difficulty of manufacturing processLow manufacturing process costSemiconductor/solid-state device manufacturingGeomorphologyWidth ratio

The embodiment of the invention discloses a three-dimensional memory and a formation method of a channel pore structure thereof. According to the method, the channel pore structure in the three-dimensional memory is formed through a twice through-hole formation technology of a first through hole and a second through hole, so that the process difficulty and cost of the channel pore structure are greatly reduced, the problems of high process difficulty and high cost caused by ultrahigh through hole depth-to-width ratio under the same caliber are solved, and meanwhile the manufacturing process difficulty and cost of the three-dimensional memory are also reduced.

Owner:YANGTZE MEMORY TECH CO LTD

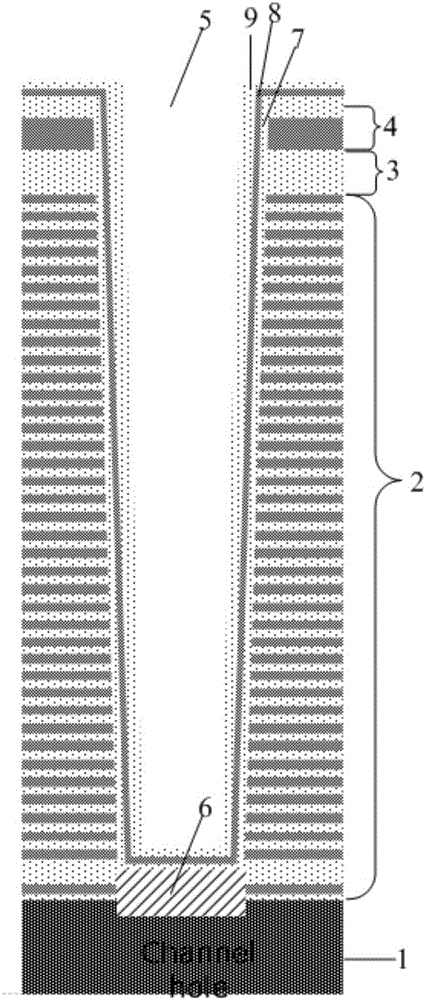

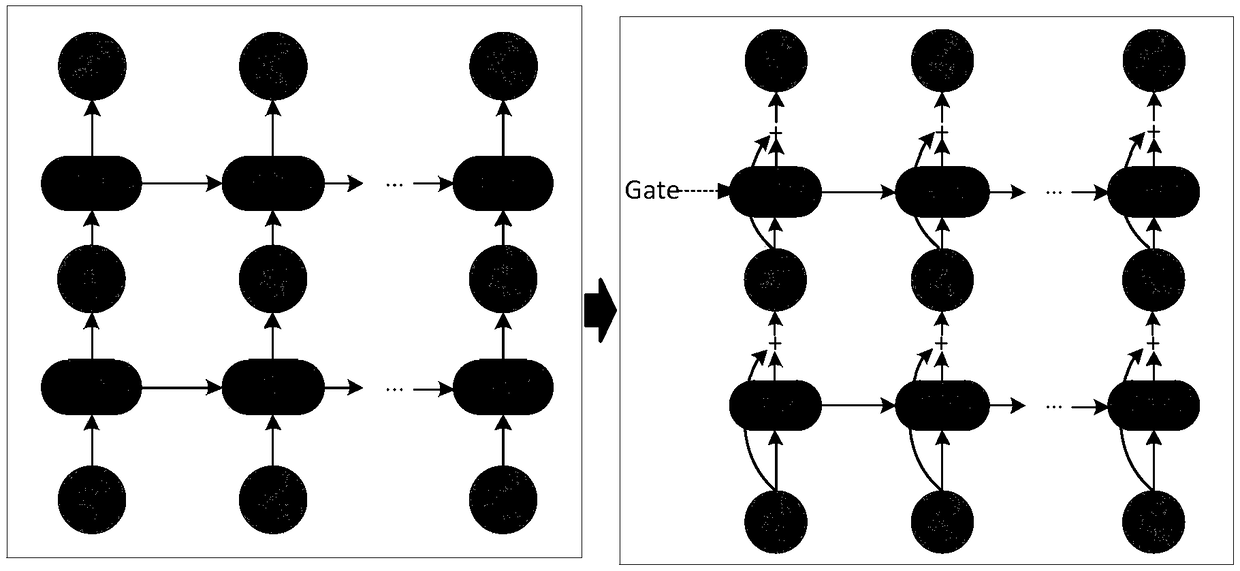

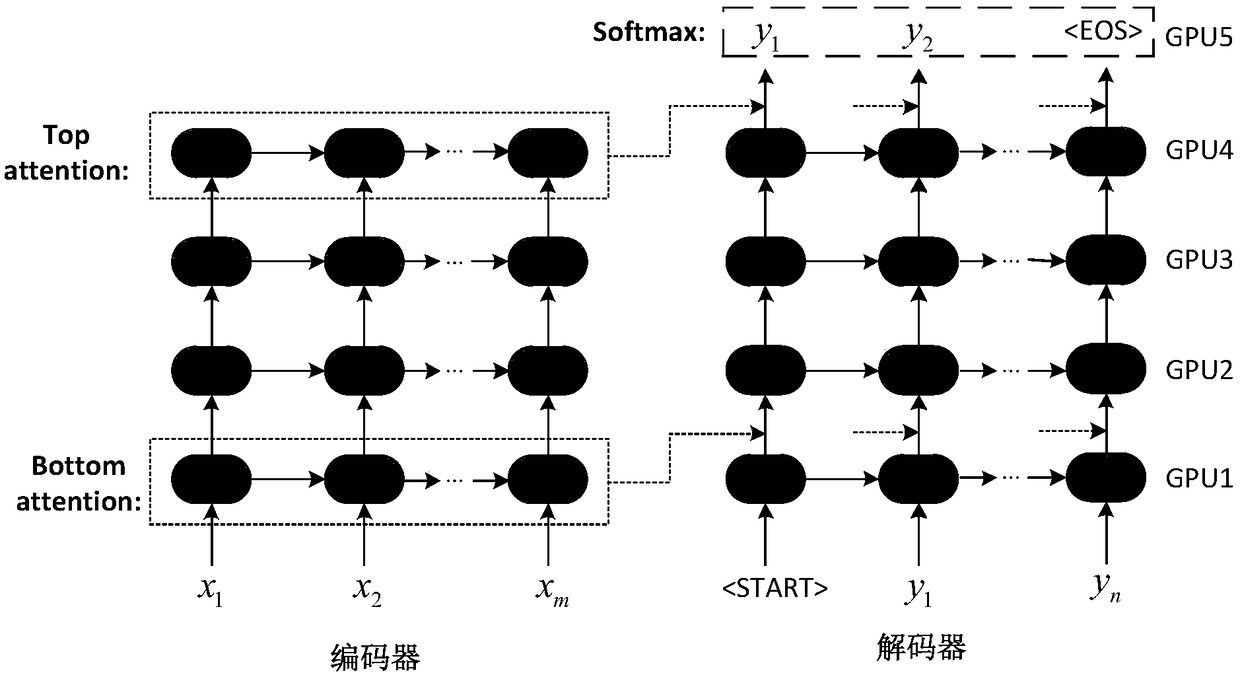

Decoding method based on deep neural network translation model

ActiveCN108647214ASolve complexitySolve difficultyNatural language translationNeural architecturesDecoding methodsModel translation

The invention relates to the field of the language processing, and provides a decoding method based on a deep neural network translation model. The problems of high model training complexity, large training difficulty and slow decoding speed in a machine translation model are solved. The specific implementation way of the method comprises the following steps: performing word segmentation processing on the to-be-translated sentence to obtain source language vocabulary; step two, performing word alignment on the linguistic data in a preset translation model glossary by using an automatic alignment tool so as to obtain a target language word aligned to the source language vocabulary; and step three, determining a target-side dynamic glossary of the to-be-translated sentence based on the target language word obtained in the step two, and using the sentence decoded by using a column searching method as the output of the translation model according to the pre-constructed translation model, wherein the translation model is the deep neural network based on the threshold residual mechanism and the parallel attention mechanism. Through the decoding method disclosed by the invention, the model translation quality is improved, and the mode coding speed is improved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI +1

Three-dimensional memory and formation method for channel hole structure of three-dimensional memory

ActiveCN106920772AReduce the difficulty of manufacturing processLow manufacturing process costSolid-state devicesSemiconductor/solid-state device manufacturingWidth ratioEngineering

Embodiments of the invention disclose a three-dimensional memory and a formation method for a channel hole structure of the three-dimensional memory. By implementing two times of a through hole formation process of a first through hole and a second through hole, the channel hole structure in the three-dimensional memory is formed, so that the process difficulty and cost of the channel hole structure can be greatly lowered; the problem of high process difficulty and high cost caused by overhigh depth-to-width ratio of the through holes under the same caliber are solved; and meanwhile, the manufacturing process difficulty and cost of the three-dimensional memory are lowered.

Owner:YANGTZE MEMORY TECH CO LTD

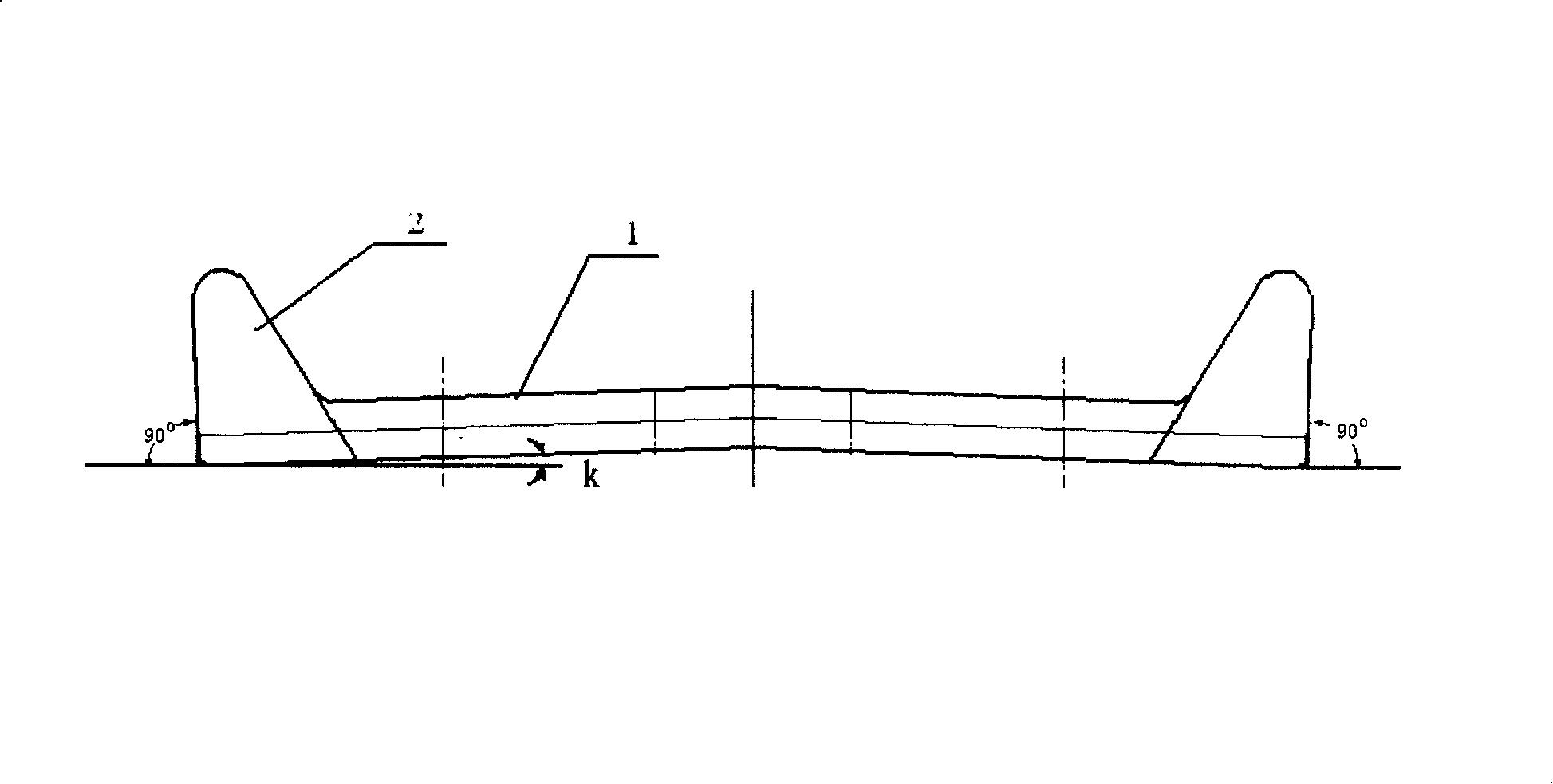

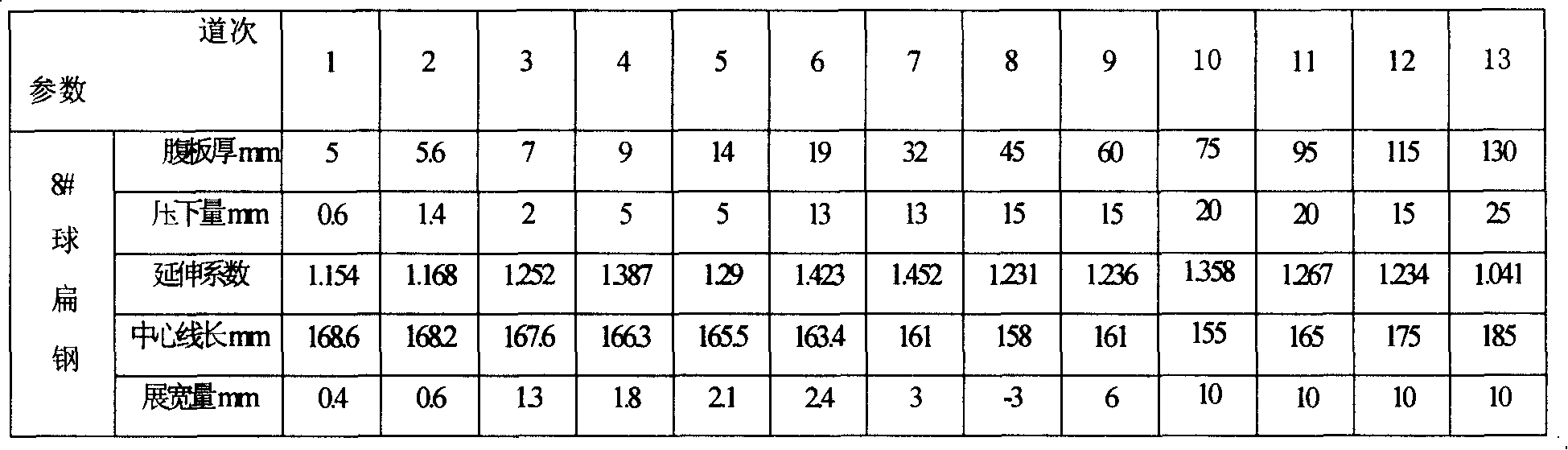

Bulb steel production technology

InactiveCN101190442ASmall fluctuations in section sizeSmall fluctuations in the size of the arcRollsMetal rolling arrangementsIron productionCompression ratio

The invention discloses a ball flat iron production technique, comprising steps of billet, heating, symmetrical rolling, straightening and dissection. The invention is characterized in that the dissection process is carried out after the processes of symmetric rolling and straightening; hole shapes in all the passages of a rolling mill are constituted by two ball flat iron hole shapes which are symmetrically identical. By adopting the technique of symmetric rolling, the invention solves the problems that existing large and medium rolling mills can not produce small ball flat irons with symmetrical rolling and dissection technology. The invention has the advantages of the small size fluctuation of profiles when producing, particularly the small size fluctuation of width, thickness, ball filling and the lower arc of the ball flat iron, rollers subject to uniform forces, easy control in rolling process, greatly reducing the scraping, the rolling mark and the waves of the product by 50% to 70%, improving the quality of the product, enlarging the types of rolled products, leading large profiled bar rolling mill to produce small ball flat iron, enlarging the profile of the billet, large corresponding compression ratio, improving the comprehensive performance of the products, etc.

Owner:ANGANG STEEL CO LTD

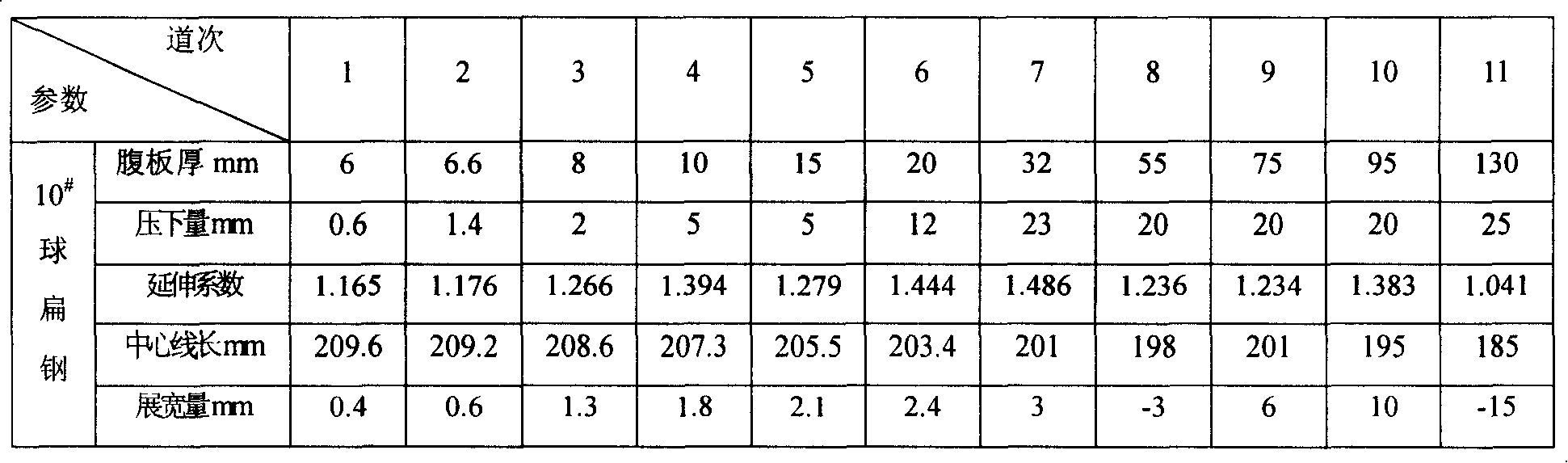

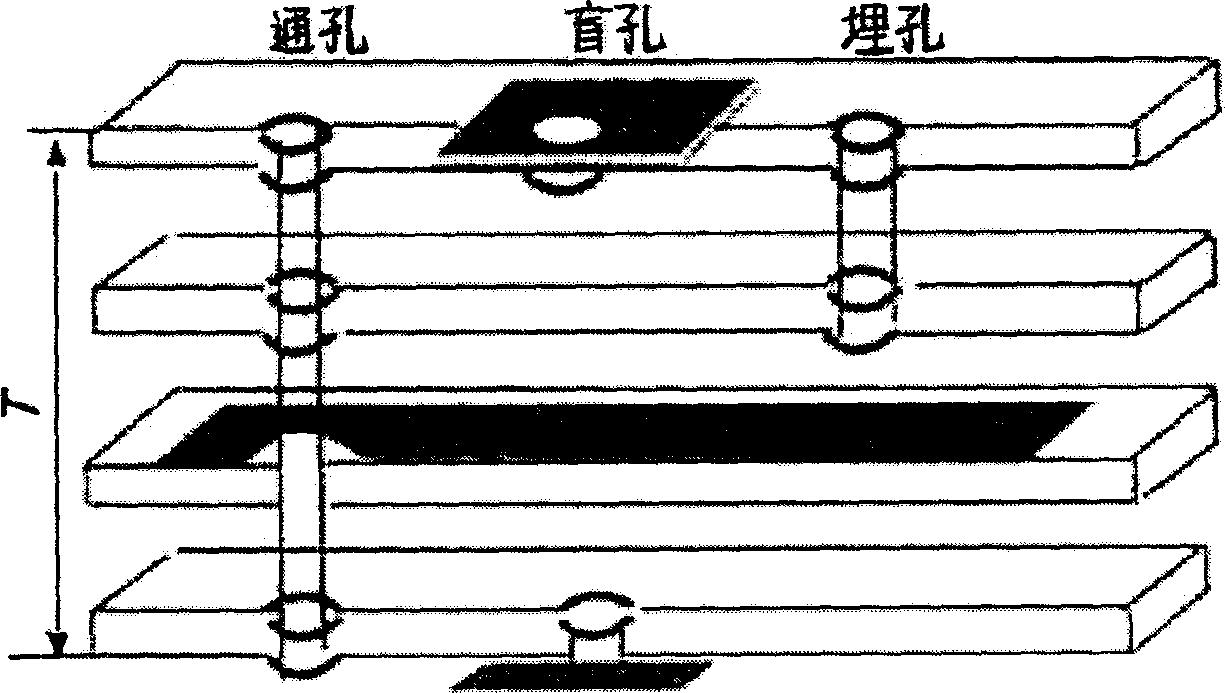

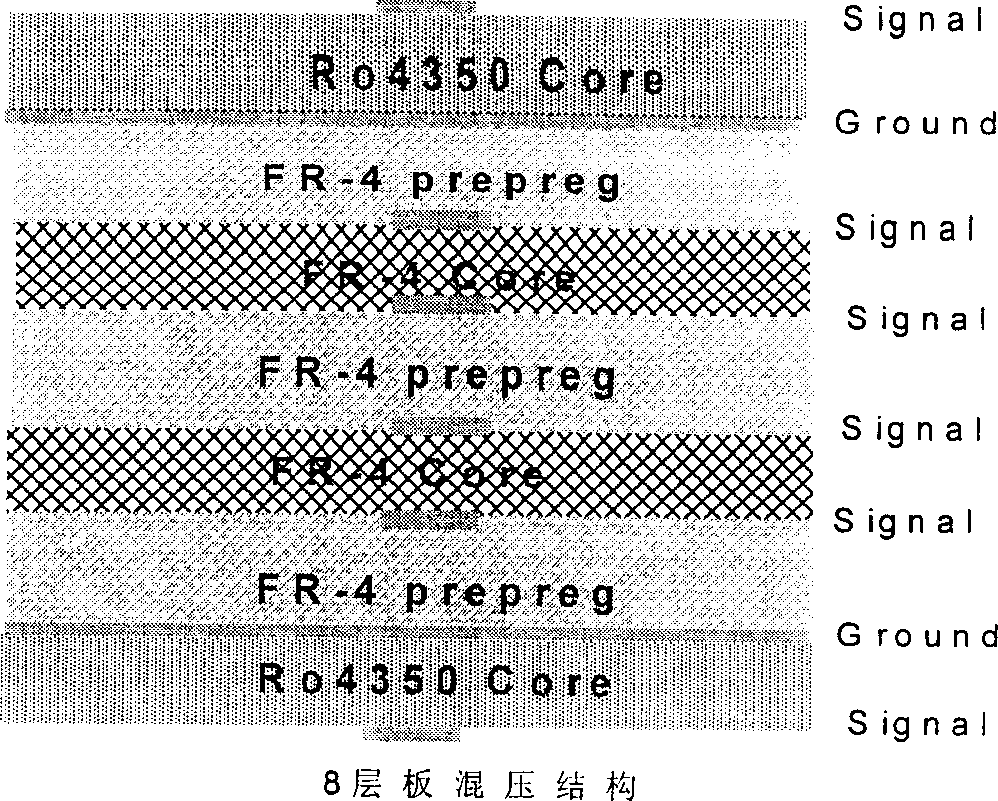

Printed circuit board capable of realizing high-speed signal transmission and making method

InactiveCN1852633ALow costOvercome limitationsCircuit susbtrate materialsMultilayer circuit manufactureCopper foilTransmission quality

The disclosed printing circuit board (PCB) is composed of two outer layers and one inner layer. The outer layer is made from plate of capable of transmitting signal in high speed; and the inner layer is made from general plate. Method for fabricating PCB includes following steps: carrying blackening / browning treatment; superimposing and pressing prepreg and outer copper foil together so as to form multilayer half finished board; drilling holes on multilayer board, plating via holes, using negative plate imaging and etching to prepare needed ducting lines in each core plate in inner layer; obtaining lines on outer layer so as to produce multilayer PCB in hybrid plates; back drilling technical holes in order to take out STUB with no connection and no attribute on end part of via holes. Features of the PCB are: high-speed signal transmission in low cost, high reliability, guaranteeing rate of good quality of PCB produced, and transmission quality of high-speed signal.

Robot forklift with simple and convenient positioning function

ActiveCN105752888ASolve the problem of not being able to walk arbitrarily on the groundSolve the costLifting devicesPosition/course control in two dimensionsLinear motionDrive wheel

The invention relates to a robot forklift with a simple and convenient positioning function. The robot forklift is characterized by comprising a forklift body chassis, a driving wheel, follow-up wheels, forklift body stand columns, a forklift body control box, a positioning control device, a platform lifting device and a horizontal goods storing and taking device, wherein the driving wheel and the follow-up wheels are mounted under the forklift body chassis; the forklift body stand columns are mounted at side ends of the forklift body chassis and perpendicular to the forklift body chassis; the forklift body control box is mounted on a forklift body; the positioning control device comprises a positioning device for goods pallets on goods shelves, and a positioning device for discretionary object points on the ground. According to the robot forklift disclosed by the invention, the horizontal goods storing and taking device is mounted in lifting sliding chutes, and when the direction of the linear motion in a front-rear direction of the robot forklift is maintained to be constant, the horizontal movement of wheels is replaced by the horizontal movement of sliding plates, and the longitudinal positioning of the goods shelves is realized, so that not only is the horizontal deviation correcting problem solved, but also the longitudinal deviation correcting problem is also solved, and the extraction speed of goods is effectively increased.

Owner:普智联科(深圳)有限公司

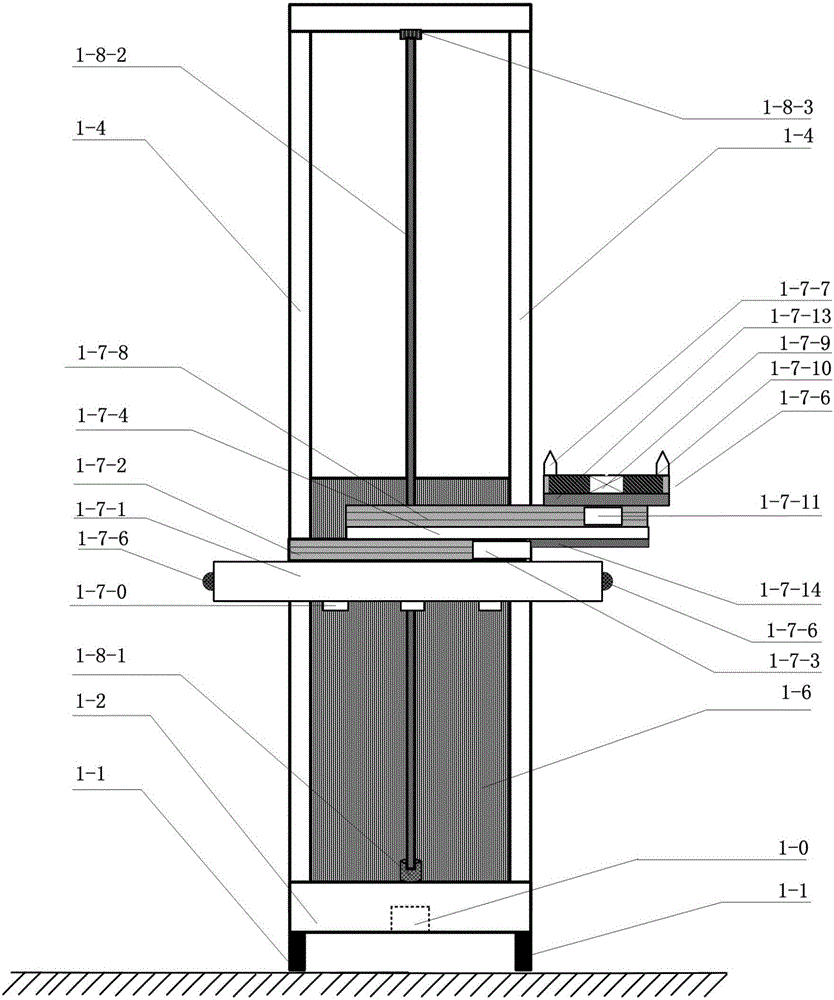

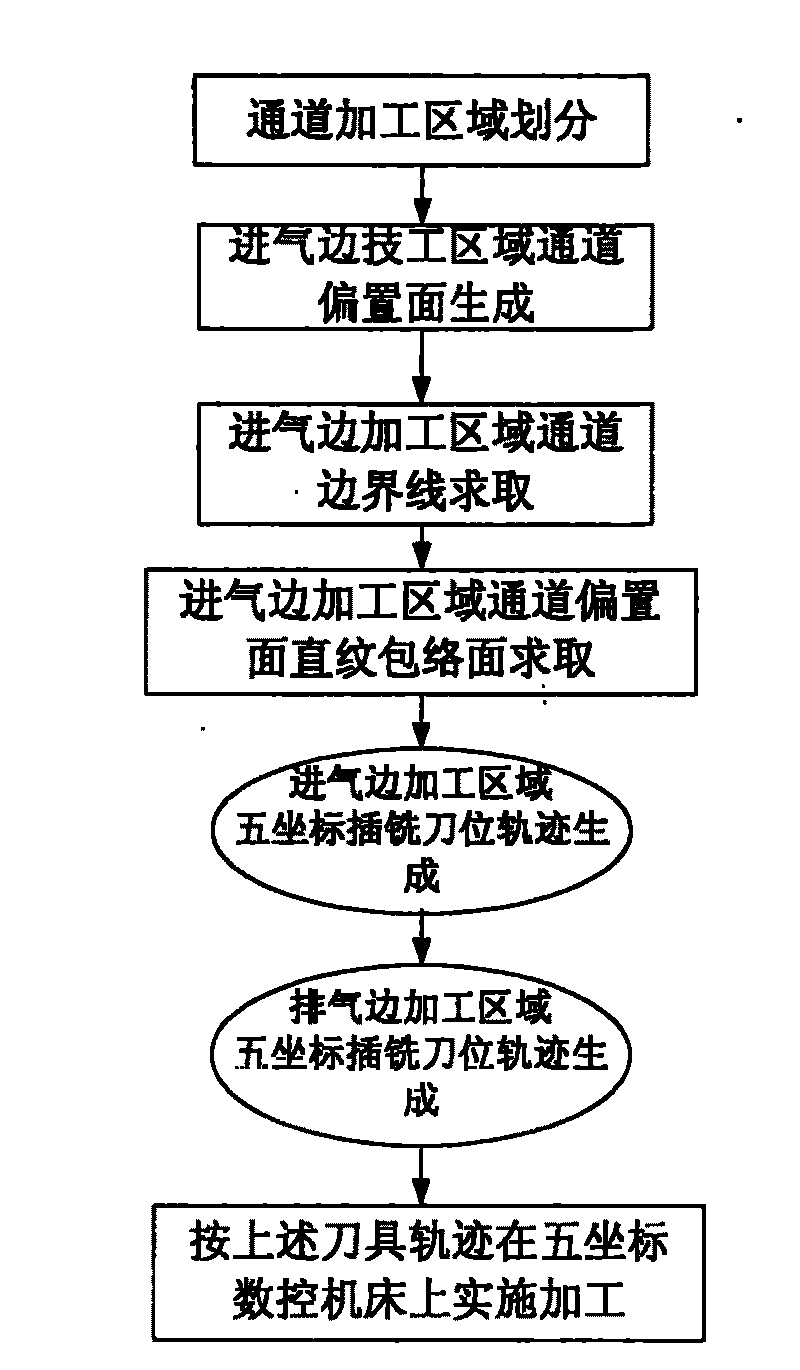

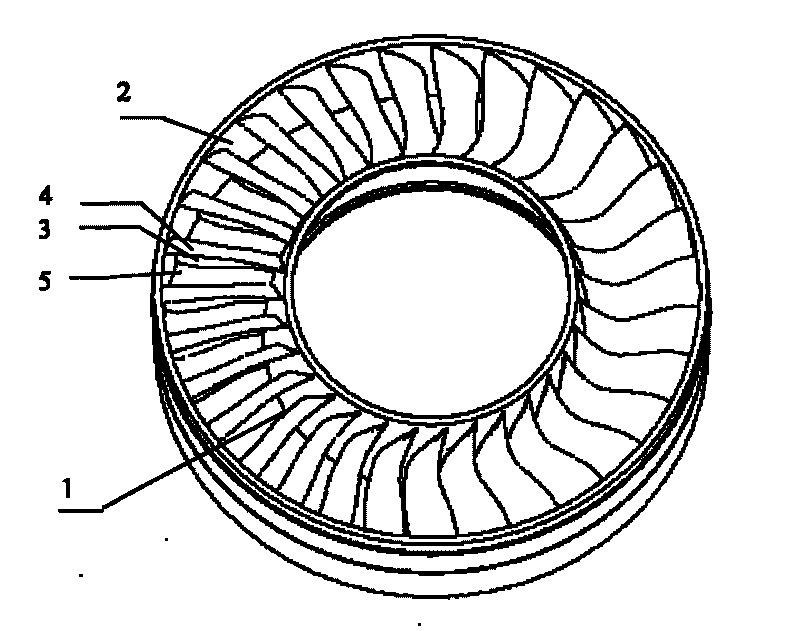

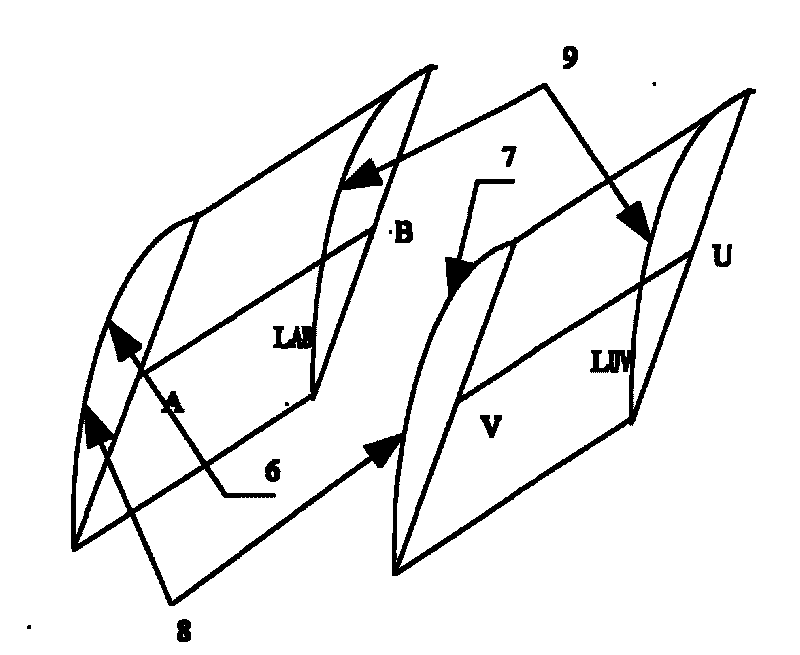

Five-coordinate plunge milling machining method of closed type bladed disc

InactiveCN101708559ARealize five-axis plunge millingAvoid interferenceWorkpiecesMilling equipment detailsNumerical controlMilling cutter

The invention discloses a five-coordinate plunge milling machining method of a closed type integral bladed disc, comprising the steps of: dividing machining areas of a passage of the machined closed type bladed disc; respectively generating passage offset surfaces in an air edge machining area and an air-exhaust edge machining area; solving a boundary line of the passage; generating straight-grain enveloping surfaces of the passage offset surfaces of the closed type integral bladed disc; respectively obtaining plunge milling cutter spacing orbits of the air edge machining area and the air-exhaust edge machining area so as to obtain the plunge milling cutter spacing orbits of the passage of the closed type integral bladed disc; and finally conducting plunge milling on the closed type integral bladed disc on a five-coordinate numerical control machine according to the obtained plunge milling cutter spacing orbits. The invention prevents the cutter interference when the closed type integral bladed disc is machined, solves the technical problems of great programming difficulty, multiple constraint conditions, the complex solving process of the cutter spacing orbits, and the like in the machining process and effectively realizes the five-coordinate plunge milling machining of the closed type integral bladed disc.

Location positioning method applied to LED display apparatus

ActiveCN105094740AFind quicklyFind exactlyInput/output processes for data processingLED displayImage resolution

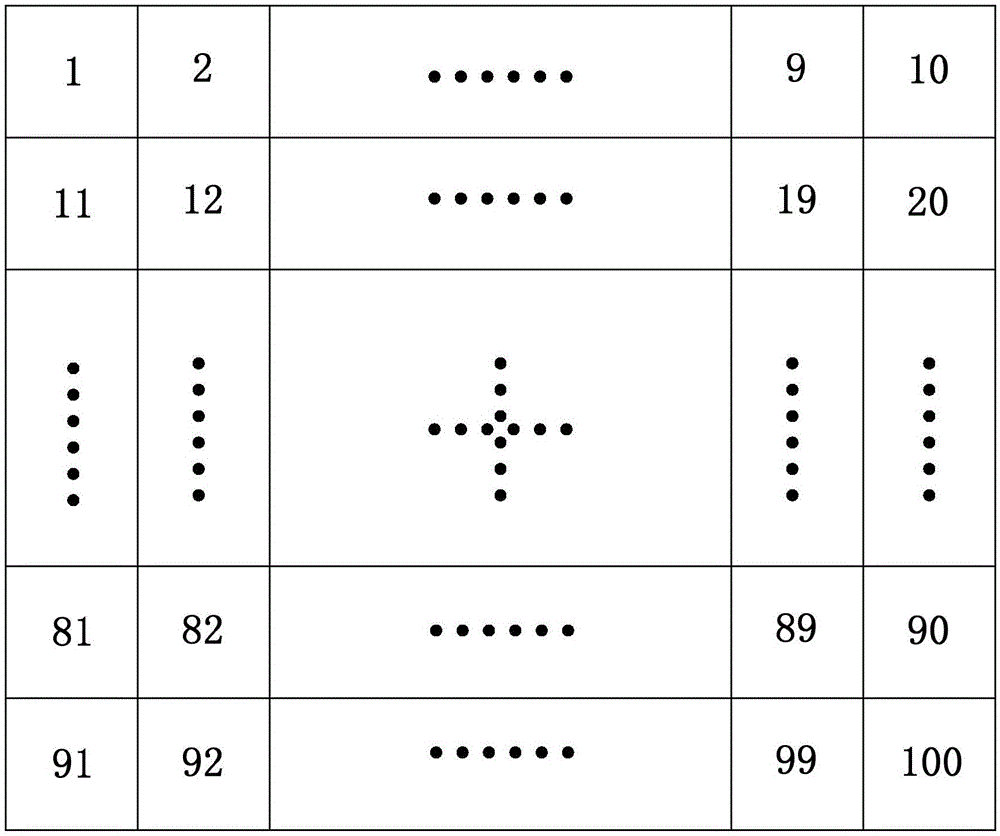

The invention provides a location positioning method applied to an LED display apparatus, which comprises: (a) acquire location information and resolution ratio information of a plurality of physics splicing units of the LED display apparatus; (b) generate distribution diagrams of a plurality of virtual splicing units, give different numbers respectively to the plurality of virtual splicing units and the numbers are corresponding to the plurality of the physical splicing unit groups one by one; (c) provide image for positioning consistent with the resolution ratio of the LED display apparatus and send the image for positioning to the LED display apparatus in order to enable the plurality of physics splicing unit groups to respectively display the numbers that are the same with the virtual splicing units, for observing display effects by users; and (d) respond to user input operation to select a virtual splicing unit that has the same number with the target physics splicing unit group from the plurality of virtual splicing units, so as to positioning a target physics splicing unit group. Thus, unique location on the LED display apparatus is positioned rapidly; and the positioning to an LED lamp point, lamp plate or box body is realized.

Owner:XIAN NOVASTAR TECH

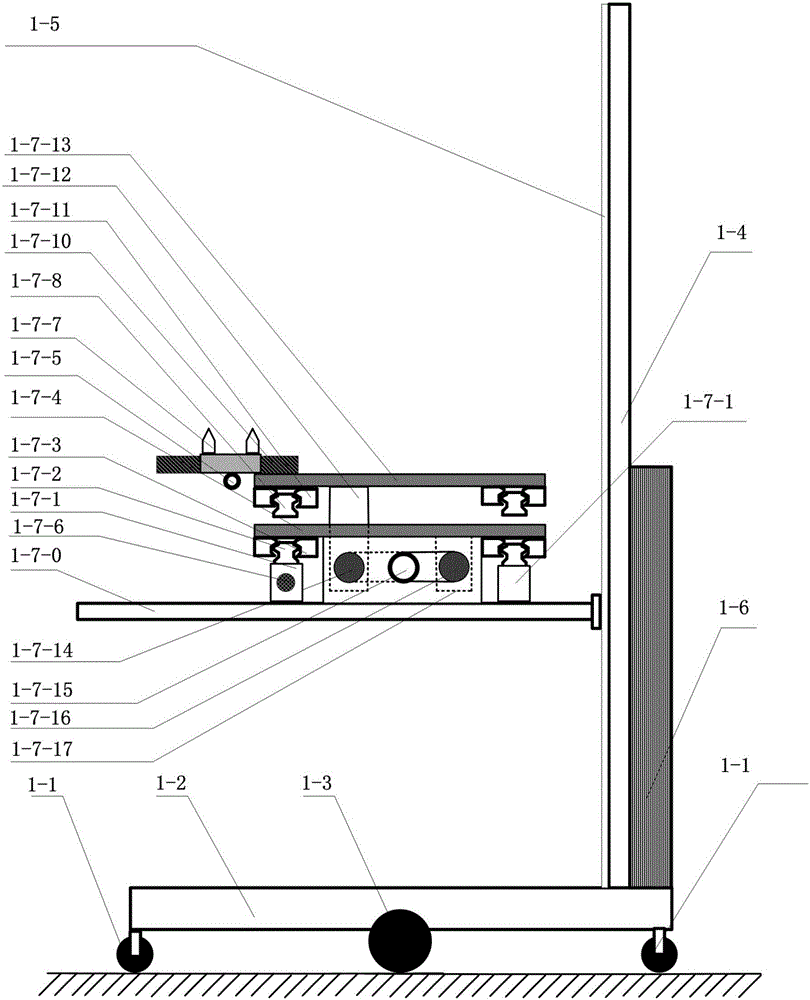

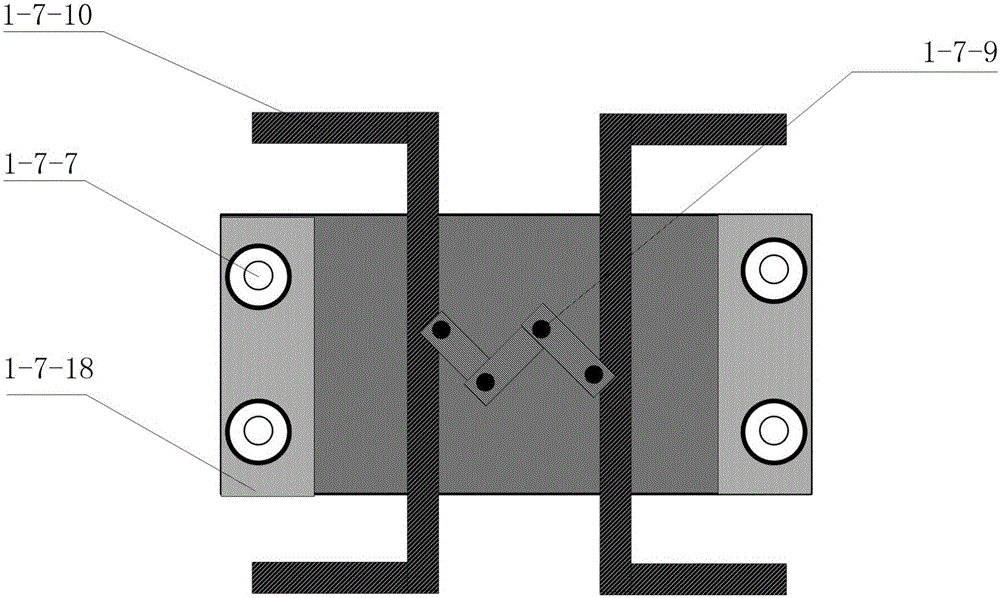

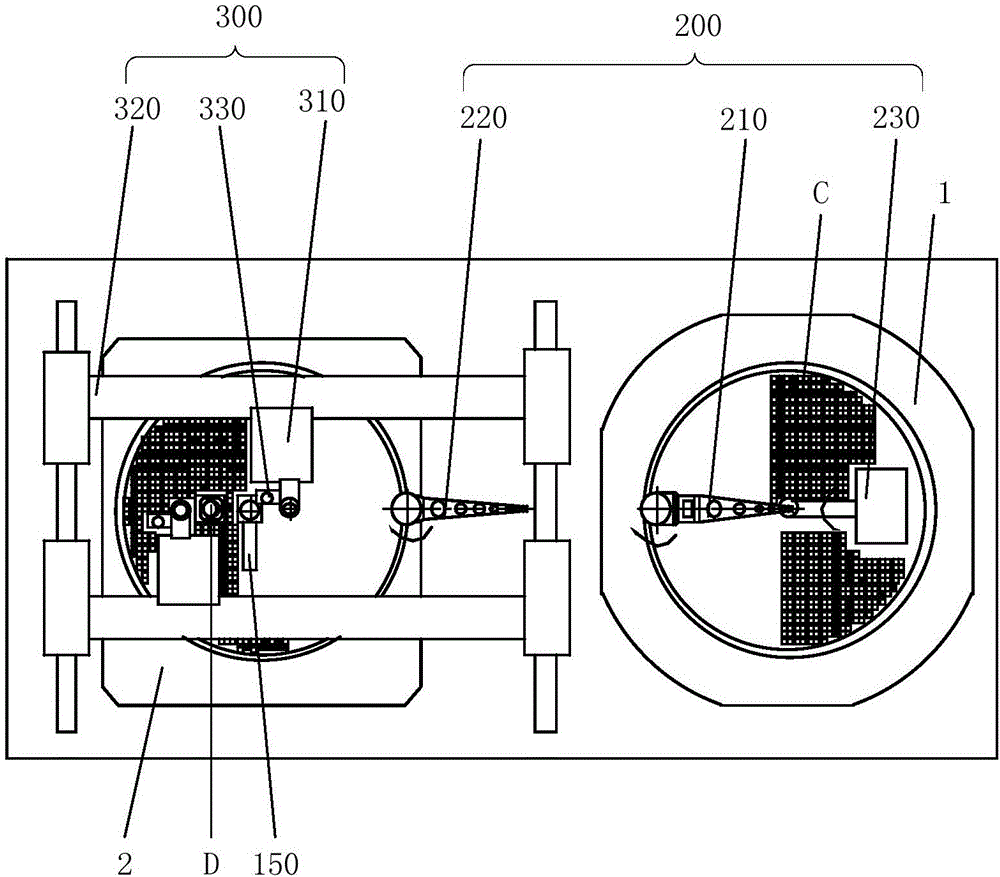

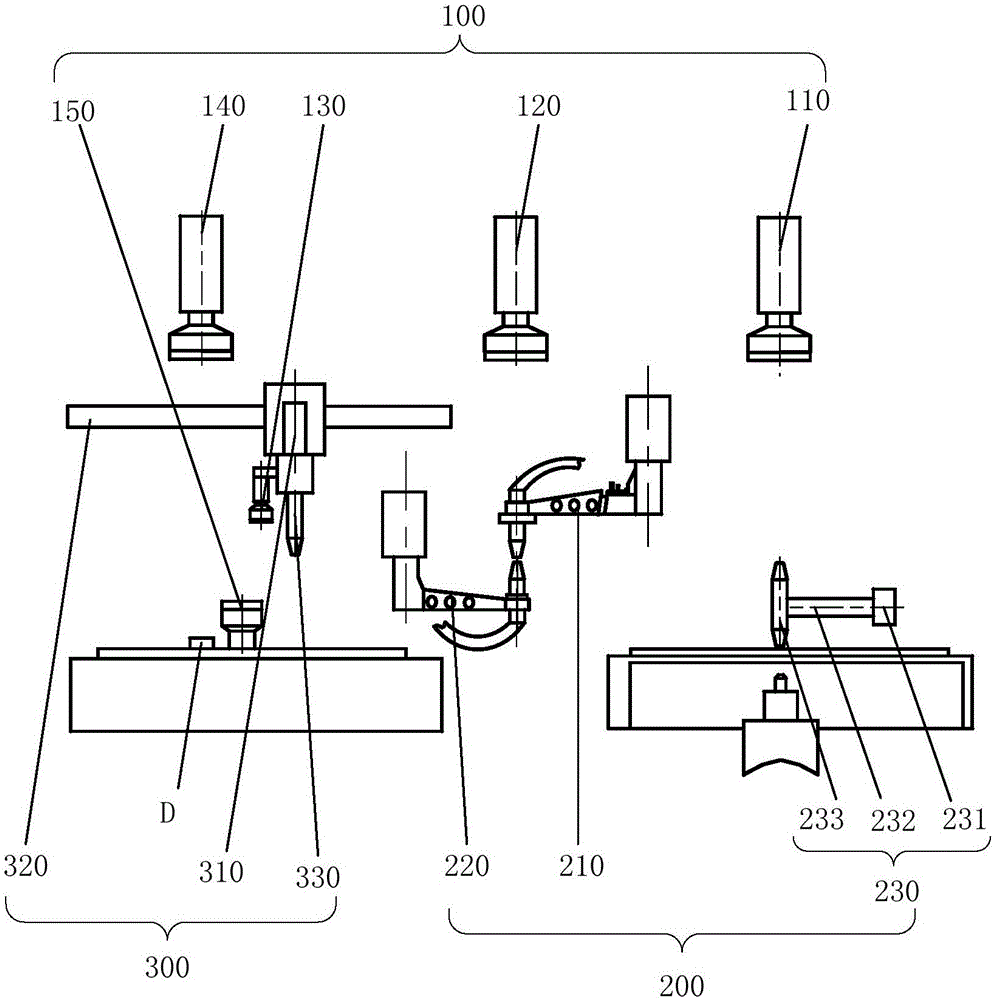

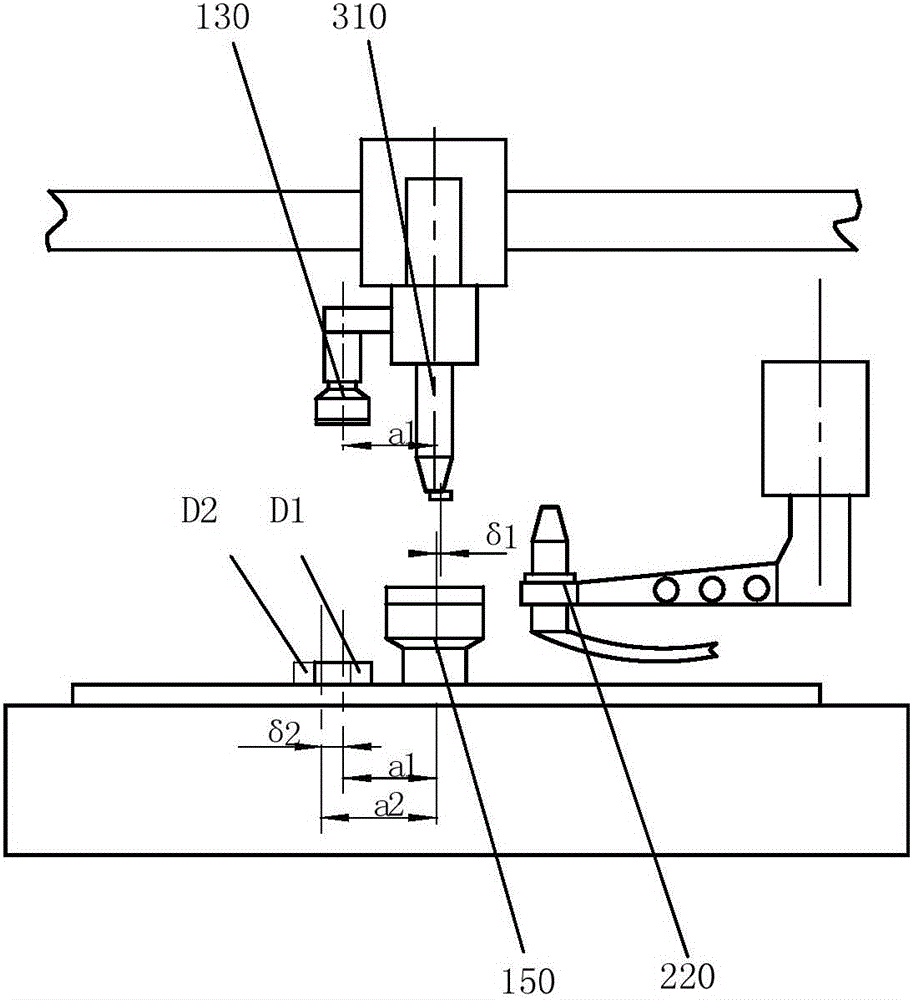

Chip bonding device

ActiveCN106373914AImprove efficiencyHigh precisionSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDie bonding

The invention relates to a chip bonding device comprising a first work platform, a second work platform, a visual sense detection and feedback module, a chip transmission module and a bonding module. The visual sense detection and feedback module is used for compensating position and angle deviation of chips during chip transmission processes; the chip transmission module comprises a first chip grabbing unit and a second chip grabbing unit; the first chip grabbing unit is used for picking up the chips from the first work platform according to feedback provided via a chip detection and feedback module, and the chips are conveyed to the second chip grabbing unit; the bonding module comprises a bonding head, a bonding head motion mechanism and a bonding head attracting rod; the bonding head motion mechanism and the bonding head attracting rod are used for picking up the chips from the second chip grabbing unit according to feedback provided via the visual sense detection and feedback module, then the chips are conveyed to a bonding position, and the bonding head is used for chip bonding operation. According to the chip bonding device, chip bonding efficiency and precision are improved via chip position information detection and feedback provided by the visual sense detection and feedback module.

Owner:CETC BEIJING ELECTRONICS EQUIP

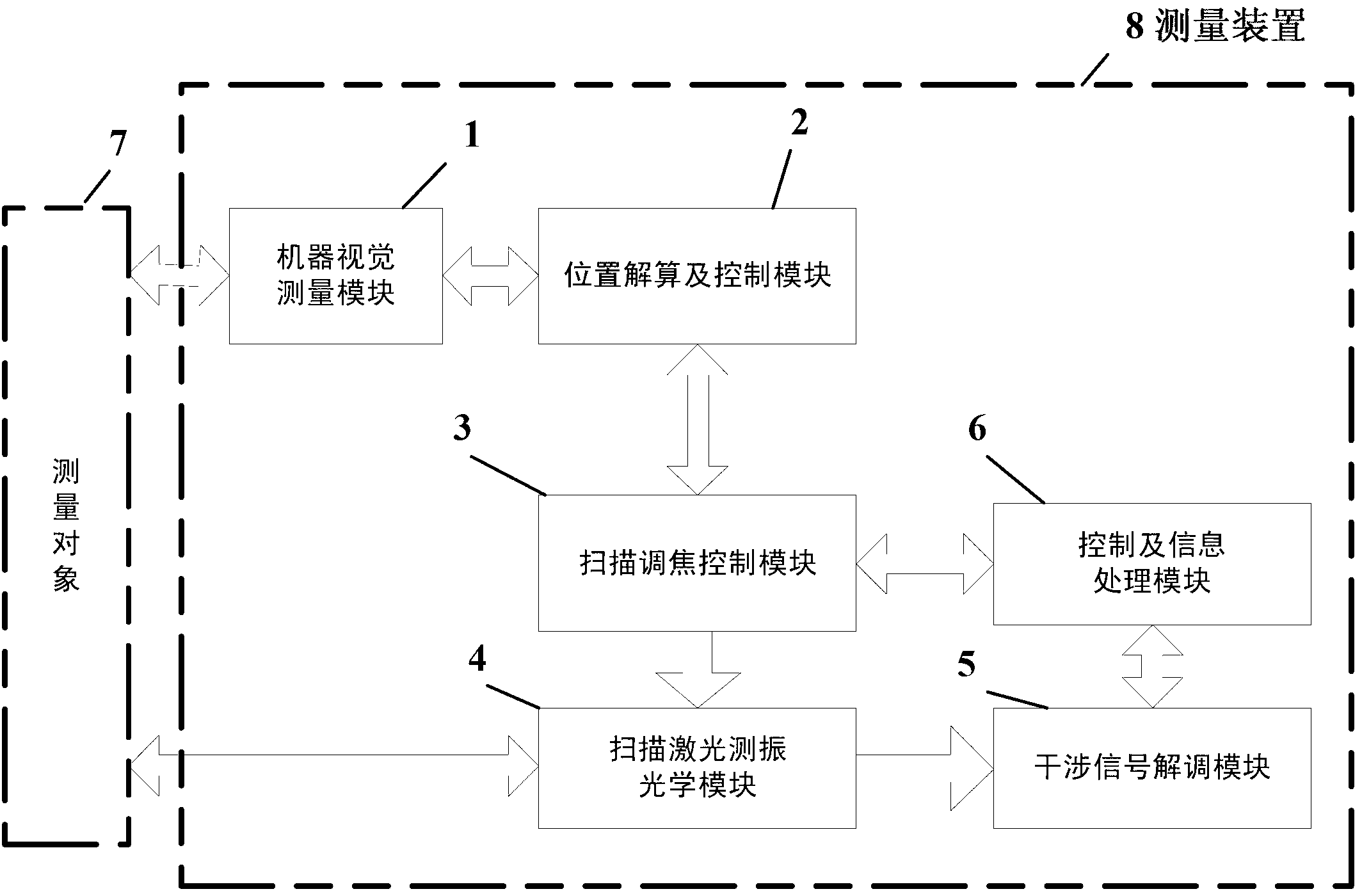

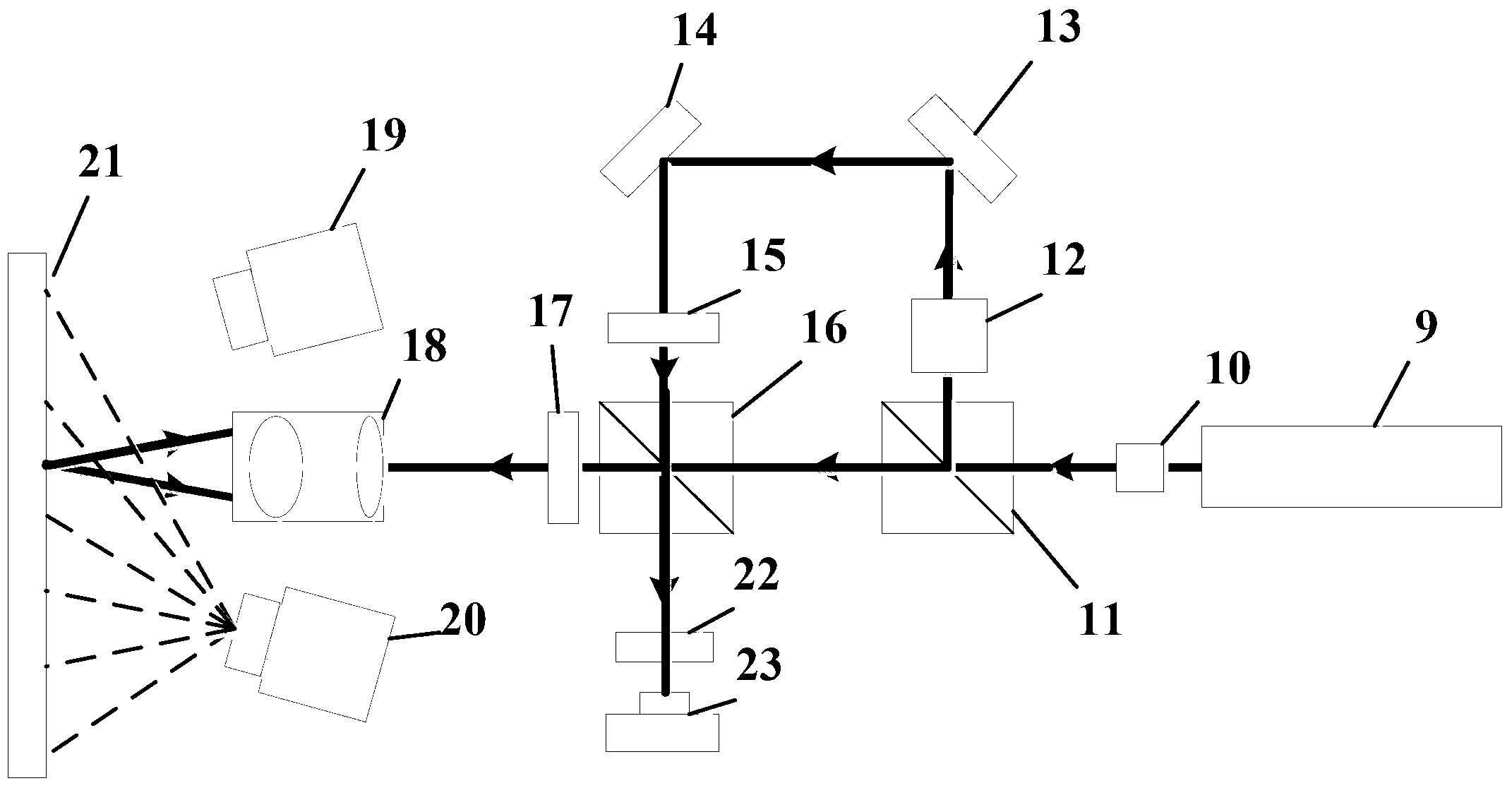

Machine vision synchronous focusing scanning type laser vibration measuring device

ActiveCN103308149AAchieve synchronous fetchResolution timeSubsonic/sonic/ultrasonic wave measurementUsing optical meansVibration measurementInformation processing

The invention relates to a machine vision synchronous focusing scanning type laser vibration measuring device and belongs to the technical field of precision measurement of impact and vibration. The device is composed of a machine vision measuring unit, a position resolving and control unit, a scanning focusing control unit, a scanning laser vibration measurement optical assembly, an interference signal demodulation unit and a control and information processing unit. Synchronous focusing of the device is finished through the machine vision measuring unit to achieve correlation management of measured space coordinates and focusing information of the scanning type laser vibration measuring device. The machine vision synchronous focusing scanning type laser vibration measuring device is simple in structure and convenient to operate, facilitates measurement and control, can effectively improve impact and vibration measuring accuracy, achieves synchronous focusing through the machine vision measuring unit and improves scanning vibration measuring speed and accuracy.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

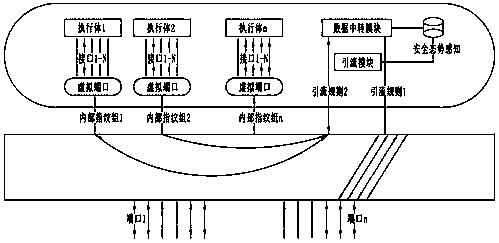

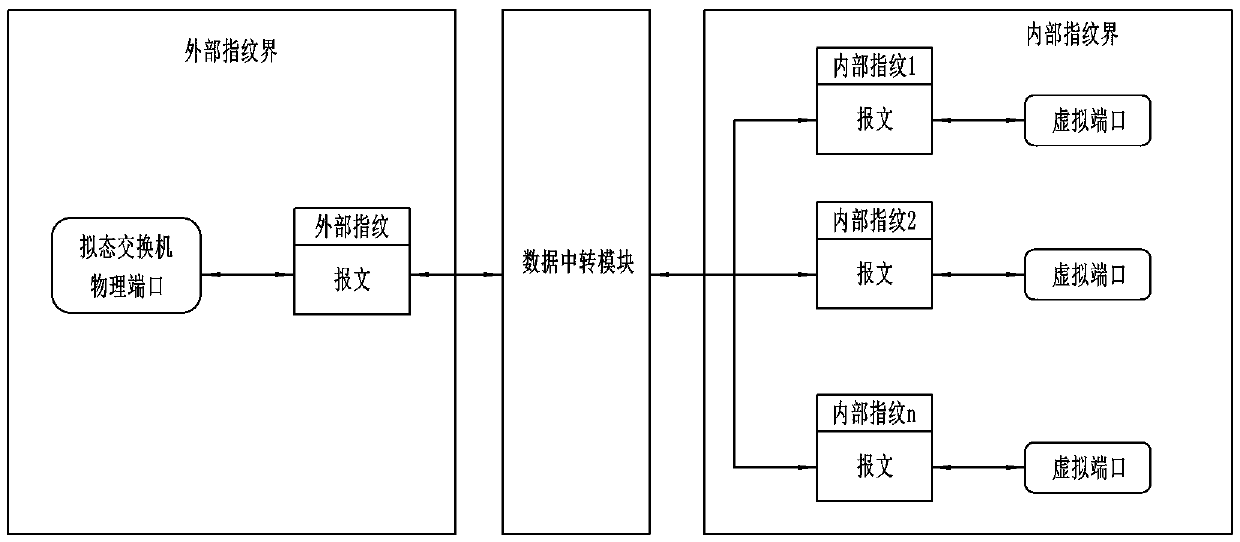

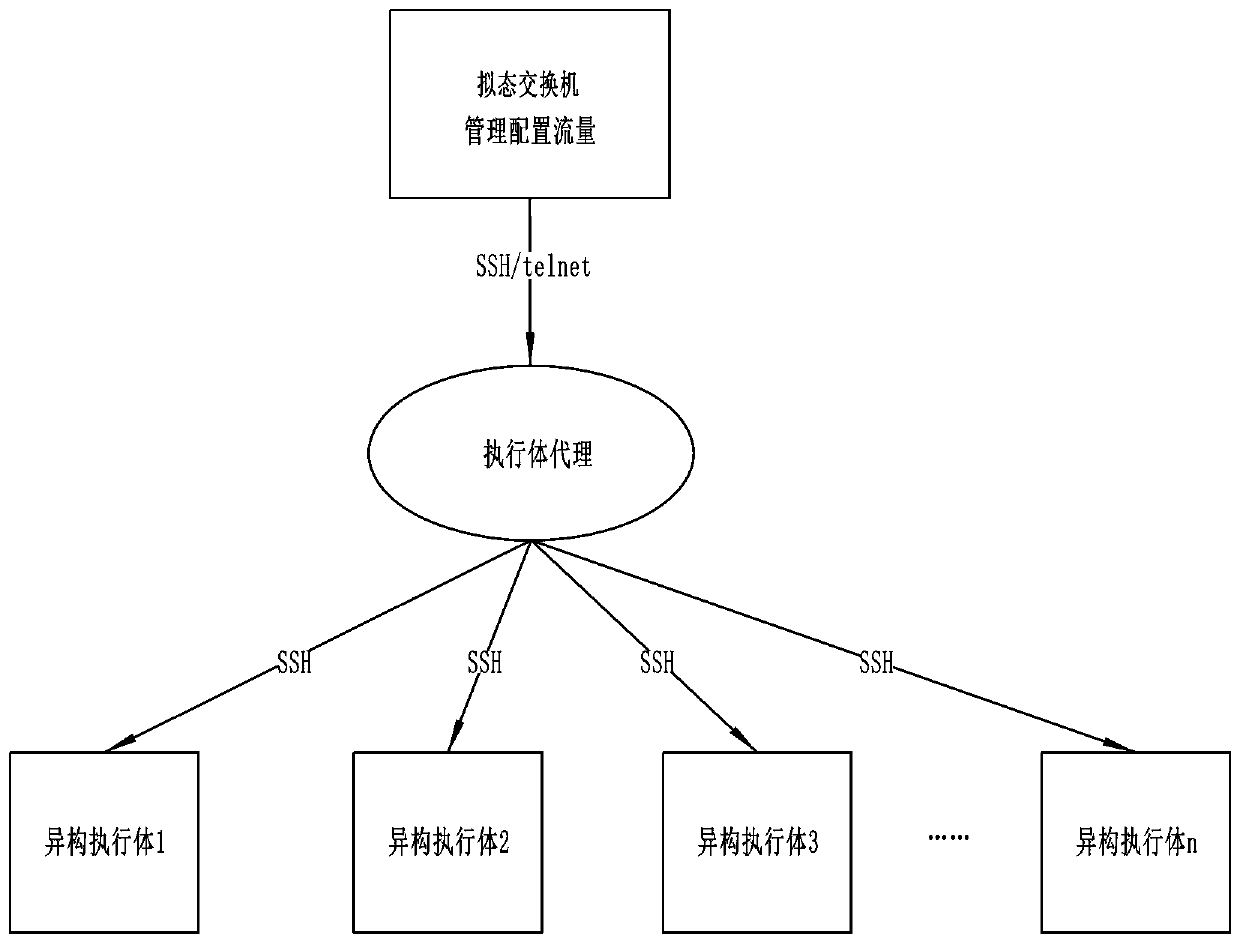

Mimic switch safety flow control device and method

ActiveCN110247928AImprove securityIncrease attack difficultyNetworks interconnectionTraffic volumeFingerprint

The invention provides a mimic switch safety flow control device and method. The device comprises a security situation awareness module, a drainage module and a data transfer module, and the method for controlling the security flow by using the device comprises the following steps that step 1, the security situation awareness module selects features of a security flow message to be controlled and formulates a security strategy; step 2, the drainage module obtains safety flow message characteristics from a mimicry switch physical port or a heterogeneous executor virtual port, and formulates a dynamic drainage strategy according to the message characteristics; and step 3, the data transfer module completes analysis of the message and then forwards the message to a mimicry switch physical port or a heterogeneous executor virtual port. The mimic switch safety flow control method solves the problems that in mimic switch flow forwarding, message distribution, fingerprint conversion and distribution assignment links are large in development difficulty and too low in efficiency, and the attack difficulty of attackers is greatly increased.

Owner:河南信大网御科技有限公司 +1

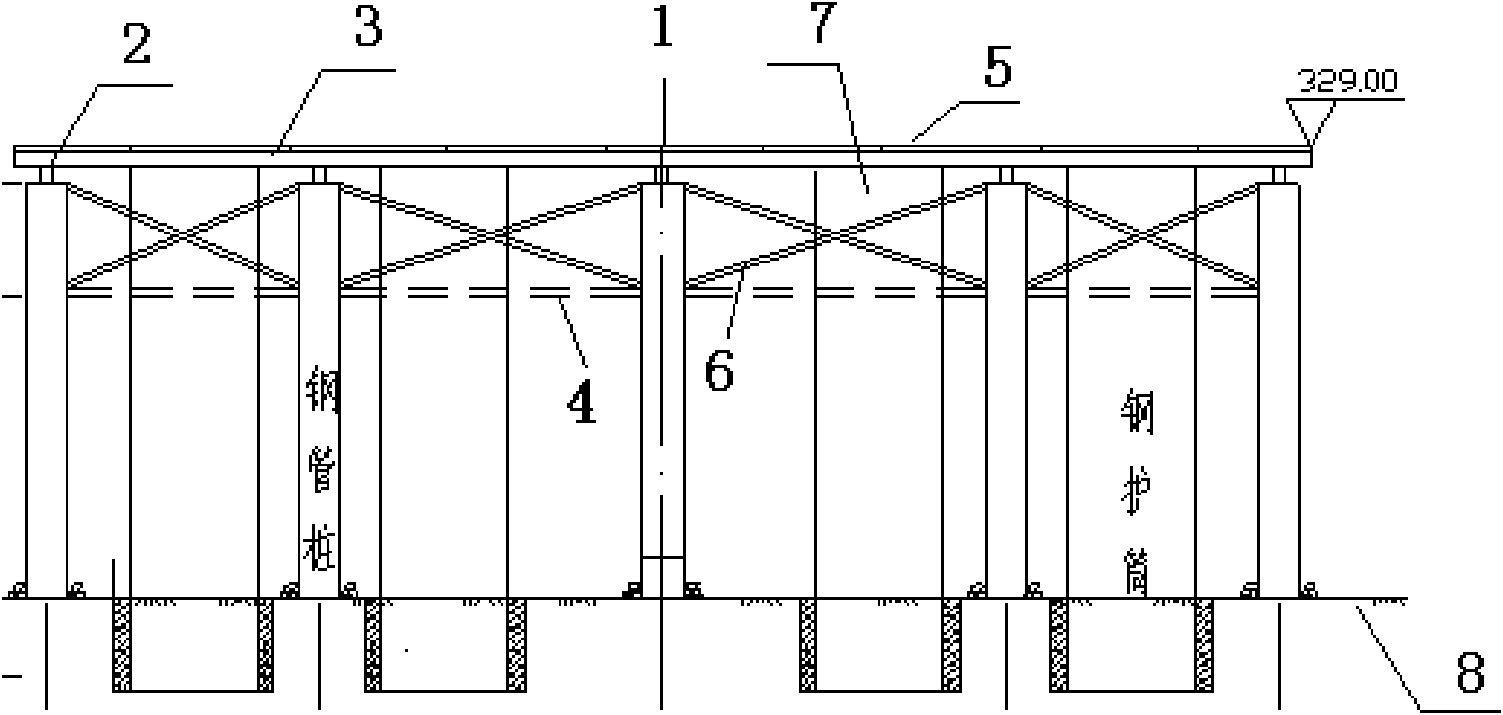

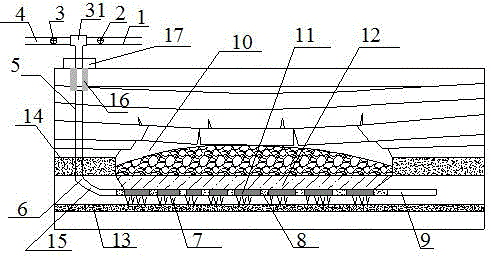

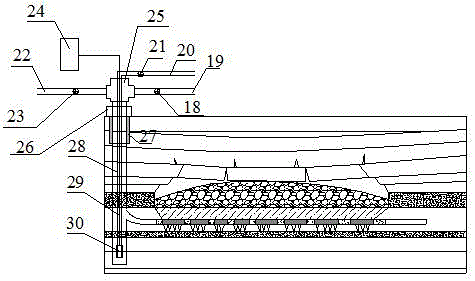

Abrupt slope bare rock drilling platform and technology in huge reservoir

ActiveCN101666081AGuaranteed stabilityFix stability issuesArtificial islandsUnderwater structuresBridge engineeringSteep slope

The invention relates to bridge engineering, in particular to an abrupt slope bare rock drilling platform and a technology in a huge reservoir and used for bridge construction. The invention is characterized in that an abrupt slope bare rock drilling device in a huge reservoir comprises steel pipe piles, a cross beam, a longitudinal beam, cross struts and a steel casing, wherein the steel pipe piles are arranged on the riverbed in a longitudinal and transverse spacing manner; the longitudinal and transverse spaces of the steel pipe piles are connected through a braced plane frame, the longitudinal cross strut and the transverse cross strut; the space surrounded by the four steel pipe piles is internally provided with the steel casing the height direction of which is parallel to the steel pipe piles; and the diameter of the pile foundation steel casing is 280cm, and the steel casing is made by rolling an A3 steel plate with the thickness of 14mm. The construction technology of the platform has 14 steps, and the invention provides the abrupt slope bare rock drilling platform and the technology in the huge reservoir, which can ensure the platform safety, easily heighten or lower the steel pipe piles, ensure the accurate in-position of a drilling machine and the pile foundation verticality, and is convenient to controlling the axial plane position of the pile foundation.

Owner:中交二公局第六工程有限公司

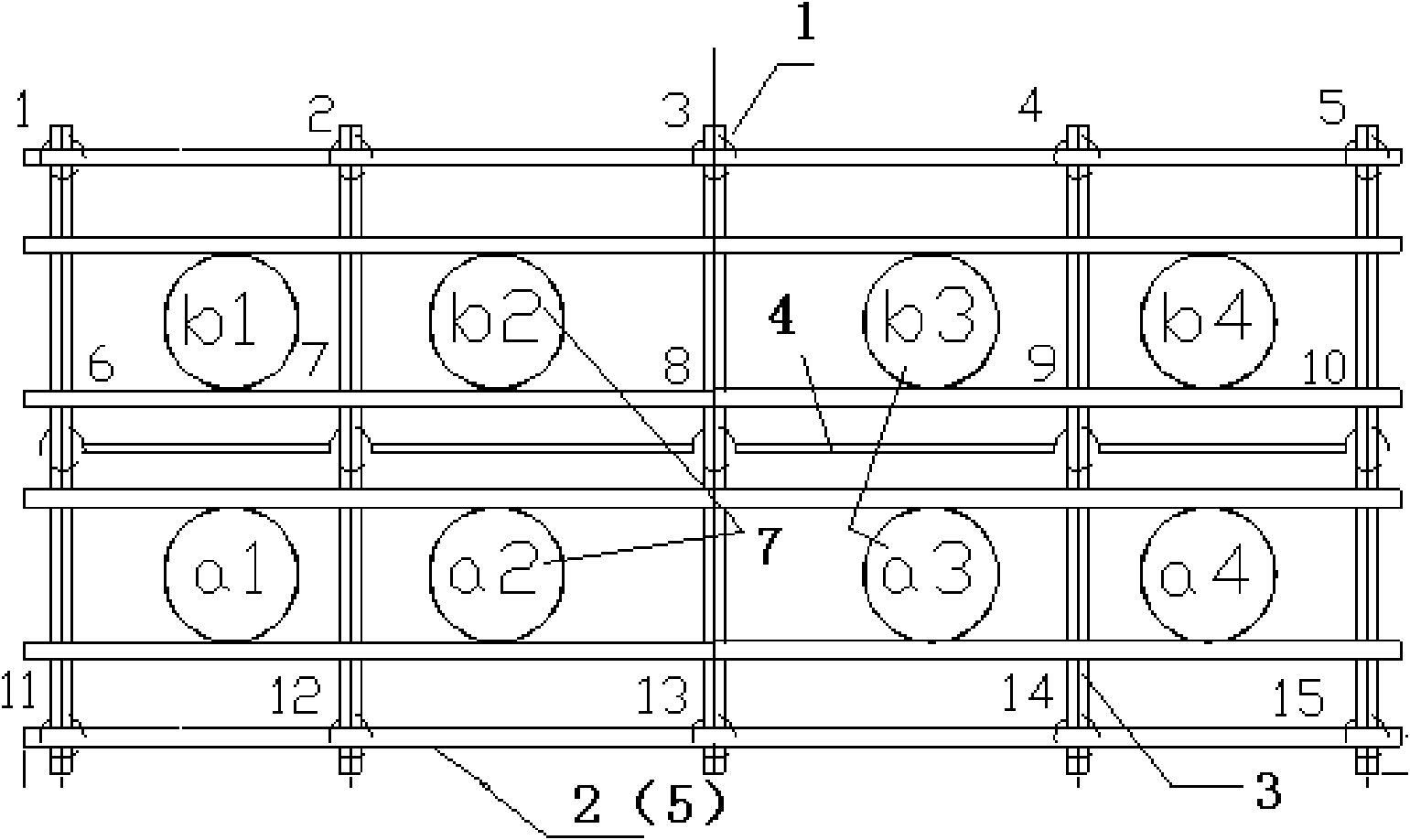

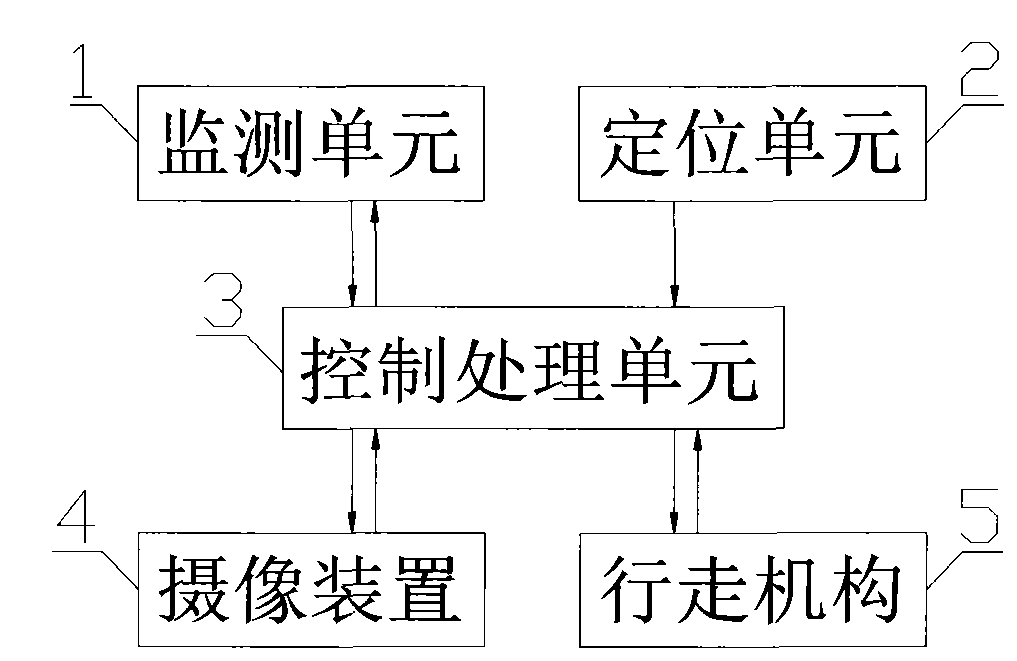

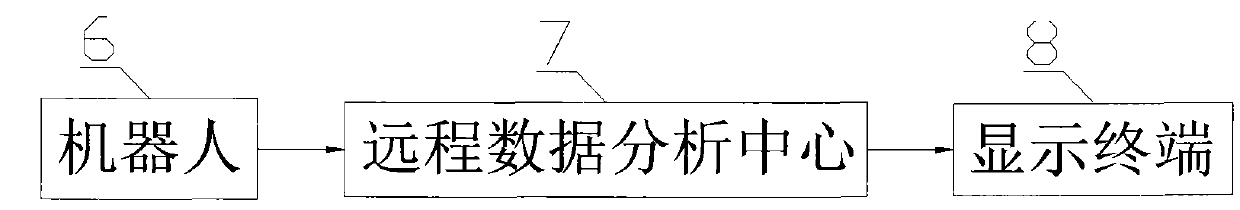

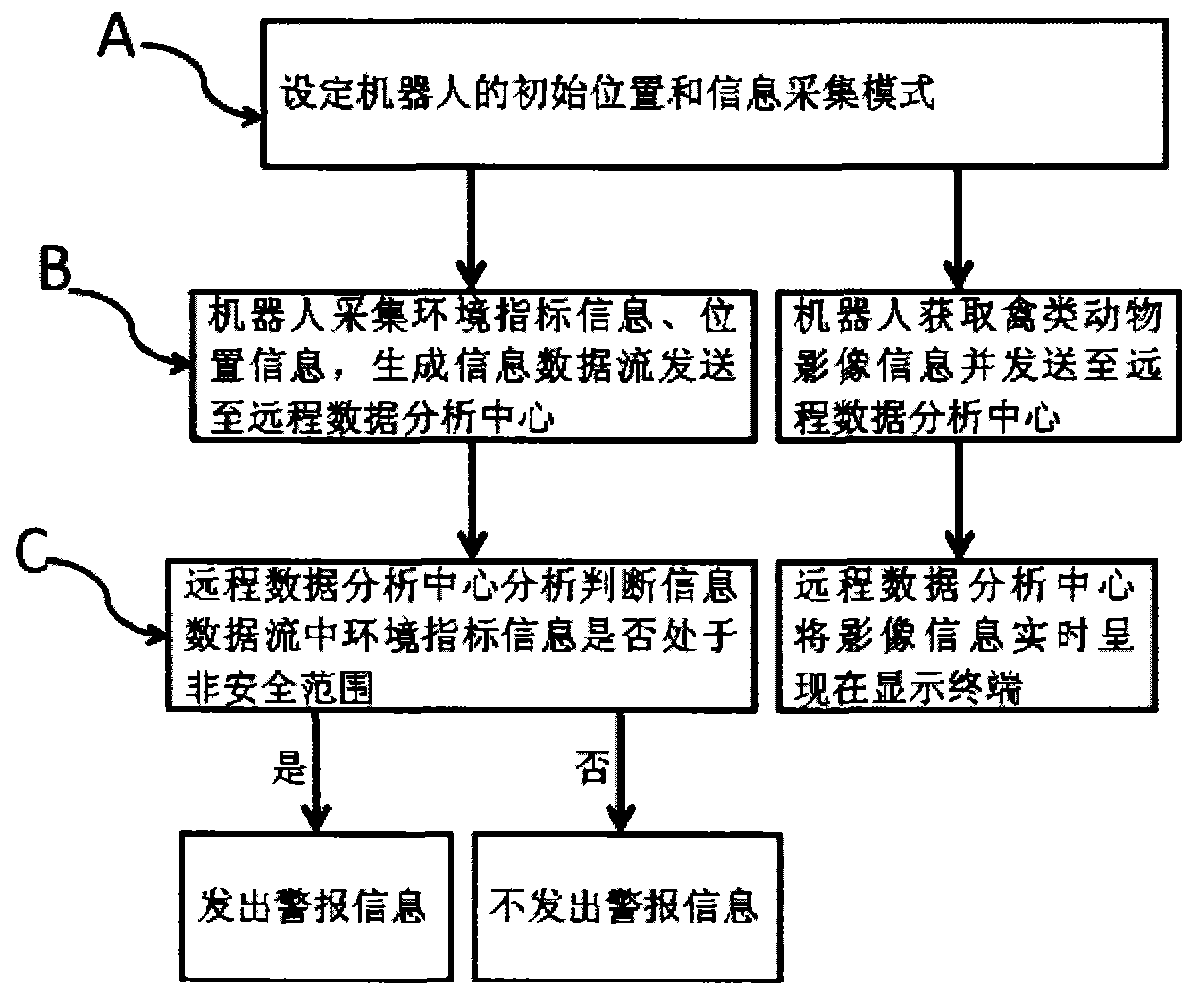

Robot for poultry house environment monitoring and monitoring method and system thereof

InactiveCN103995509AIncrease the amount of sample dataHigh precisionMeasurement devicesProgramme total factory controlMonitoring systemEngineering

The invention discloses a robot for poultry house environment monitoring and a monitoring method and system comprising the robot. The robot for poultry house environment monitoring comprises a monitoring unit, a positioning unit, a control processing unit, a photographic device and a walking mechanism. The invention further provides the poultry house environment monitoring system comprising the robot and the method for conducting monitoring with the application of the system. According to the robot, the system and the method, the number of monitoring positions inside a poultry house can be increased, so that the data size of environment monitoring samples is improved, and the problem that monitoring accuracy is poor in the prior art is solved.

Owner:BEIJING HUAKE SHUNENG TECH DEV

Composite decorative material with flexibility and production process thereof

The invention discloses a composite decorative material with flexibility and a production process thereof. The composite decorative material with flexibility comprises a flexible base layer, a flexible sand textured coating layer and a stain-resistant protective finish layer. The flexible sand textured coating layer and the stain-resistant protective finish layer are arranged on the flexible base layer in sequence; the flexible sand textured coating layer comprises water, cellulose ether, a film forming additive, an antifreeze, a flexible latex, natural color sand, composite rock slices, a pH adjustment agent and a defoamer. Due to the adoption of the mode, the multifunctional decorative material which is developed according to the building and the decoration surface is convenient to construct, has good weather resistance, can be designed, cut and spliced randomly and can be adhered by special adhesive to achieve various simulate stone and brick effects. Due to the adoption of the composite decorative material with flexibility, the load of the wall can be greatly reduced, the wall of each square meter is about 1 / 3 the weight of the wall bricks, and the problems of high-altitude construction difficulty and safety can be solved.

Owner:史丹龙涂料(常州)有限公司

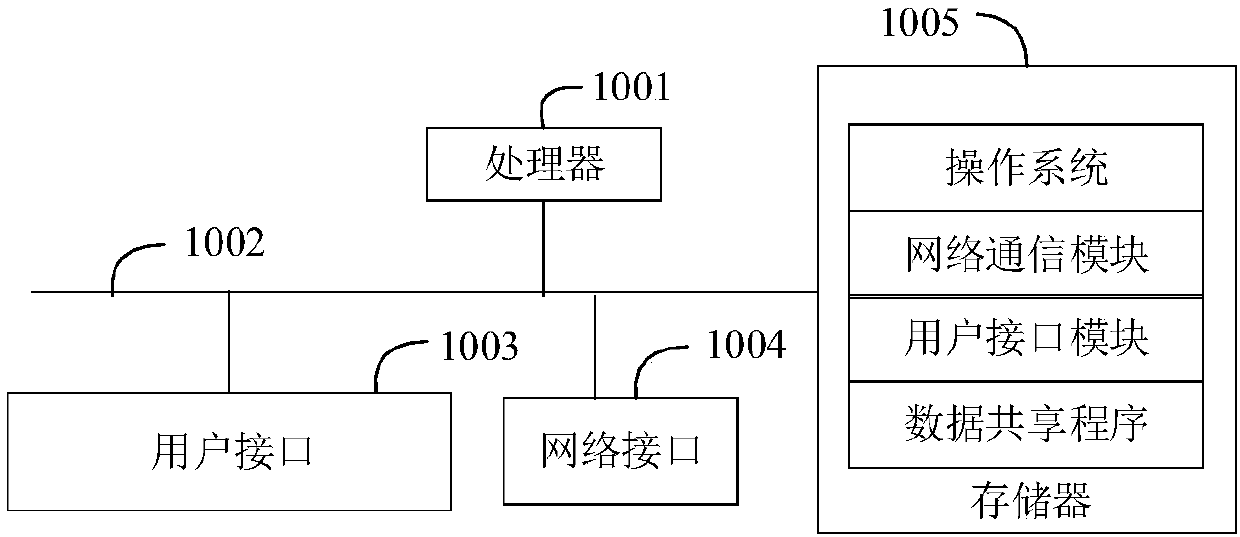

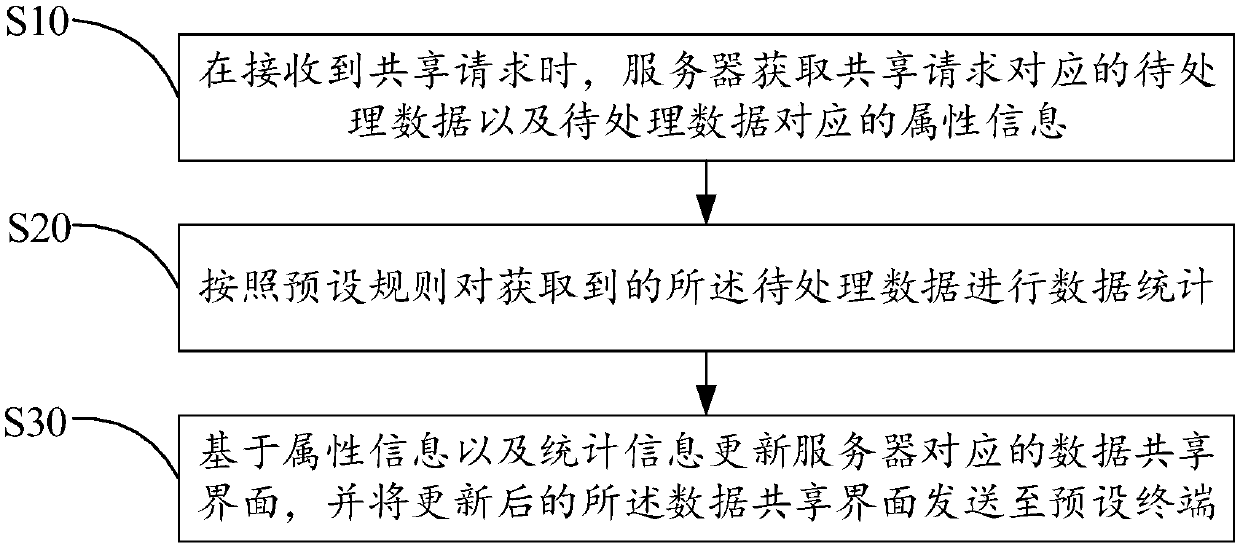

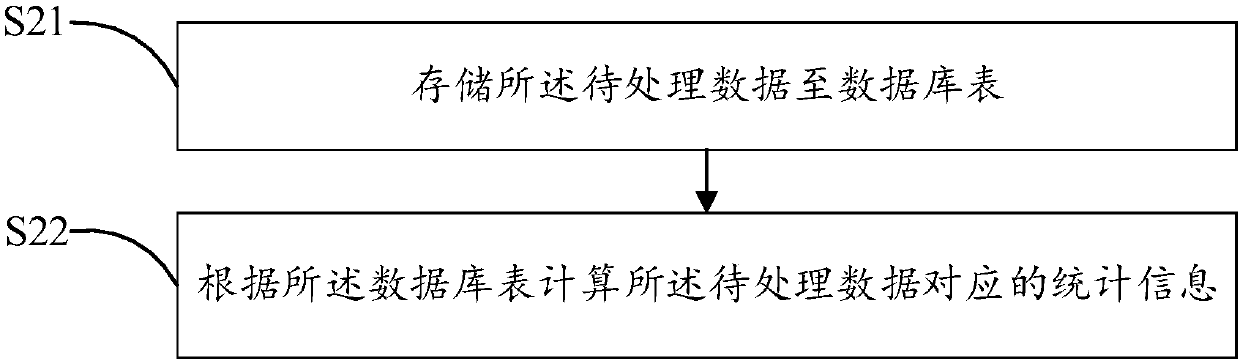

Data sharing method and device and computer readable storage medium

ActiveCN107623714AImprove interaction efficiencyIntegrity guaranteedTransmissionData sharingDistributed computing

The invention discloses a data sharing method, which comprises the following steps: when receiving a data sharing request, through a server, obtaining data to be processed corresponding to the data sharing request and attribute information corresponding to the data to be processed; carrying out data statistics on the obtained data to be processed according to preset rules to obtain statistical information corresponding to the data to be processed; and updating a data sharing interface corresponding to the server based on the attribute information and the statistical information, and sending the updated data sharing interface to a preset terminal. The invention also discloses a data sharing device and a computer readable storage medium. Data sharing can be realized only by uploading the data to be processed to the server when carrying out data sharing in the server without redeveloping customized database table interfaces during data interaction every time, thereby simplifying flow of data interaction and improving data interaction efficiency.

Owner:PING AN TECH (SHENZHEN) CO LTD

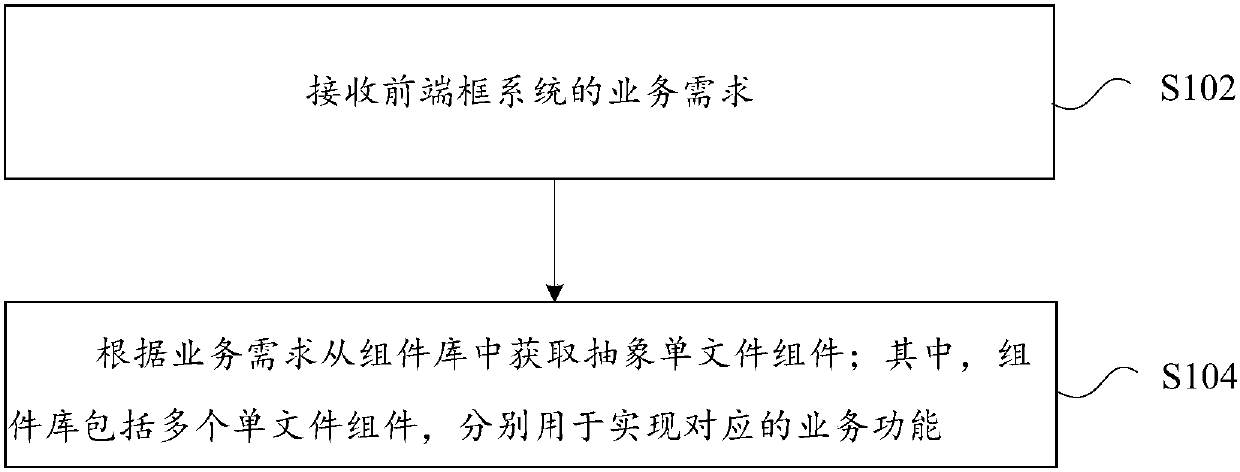

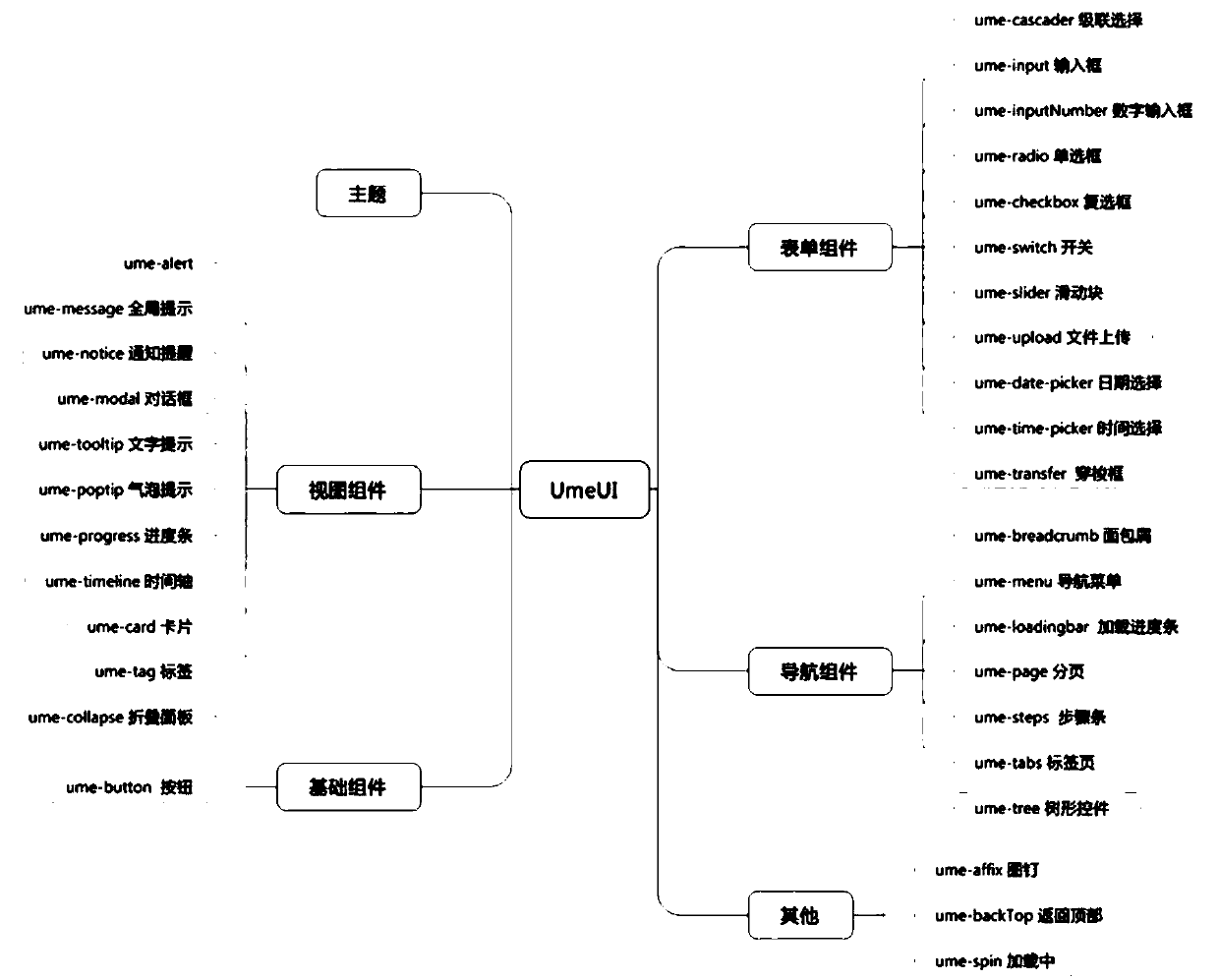

Component library implementing method and device

Owner:MOBILE TECH COMPANY CHINA TRAVELSKY HLDG

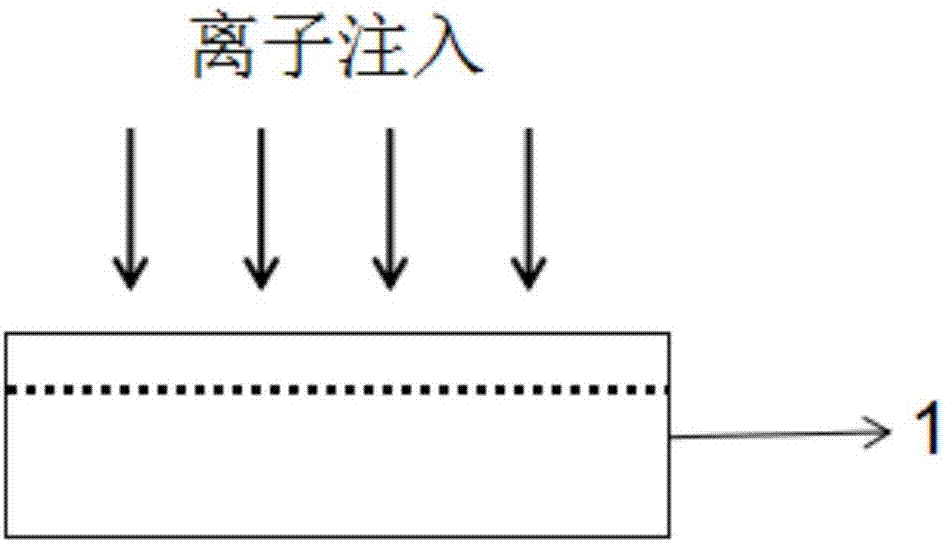

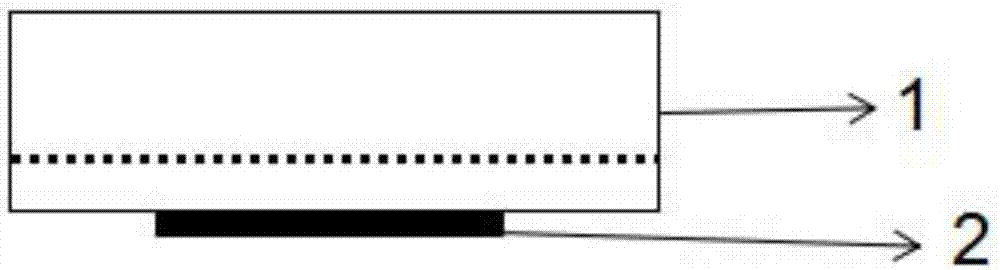

Preparation method for film bulk acoustic wave resonator

ActiveCN107508569ATroubleshoot difficult-to-graph problemsSolve the strength problemImpedence networksThin-film bulk acoustic resonatorResonant cavity

The invention relates to the technical field of a film bulk acoustic wave resonator and specifically relates to a preparation method for the film bulk acoustic wave resonator. According to the method, wafer bonding is carried out through adoption of polymer; SiO<2> hydrophilic bonding frequently used by a traditional ion injection stripping method is replaced; an electrode covered by the polymer can be patterned according to a design of the film bulk acoustic wave resonator. The polymer has fluidity, so the polymer can be flattened under the effect of pressure in a wafer bonding process; and the patterned electrode can be nested into the polymer and the stripping of LiNbO<3> single crystal film is not influenced, so the problem that the electrode is difficult to pattern in a bonding transfer process of the single crystal film is solved. The polymer is taken as an acoustic reflection layer of the film bulk acoustic wave resonator, the problem that an air resonant cavity is low in structure strength and a Bragg acoustic reflection cavity is high in preparation difficulty is solved, a preparation technology of a device is simple, and the prepared device is high in structure strength.

Owner:成都芯仕成微电子有限公司

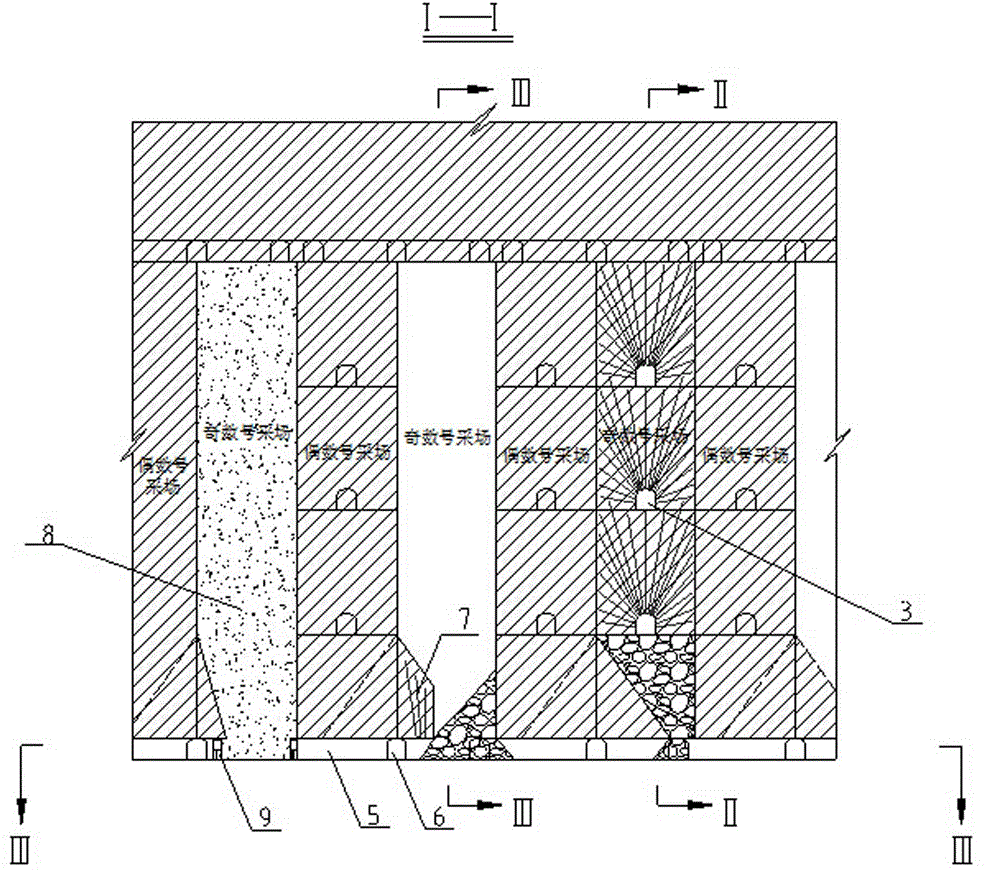

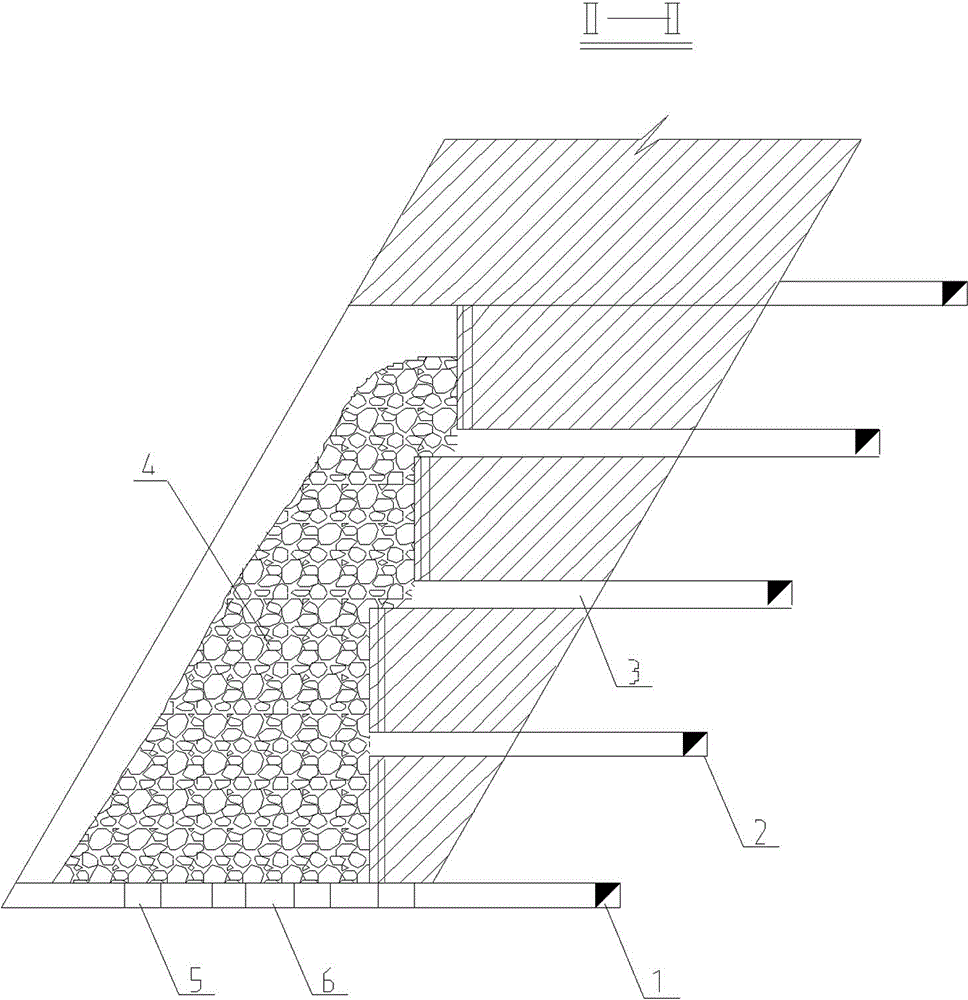

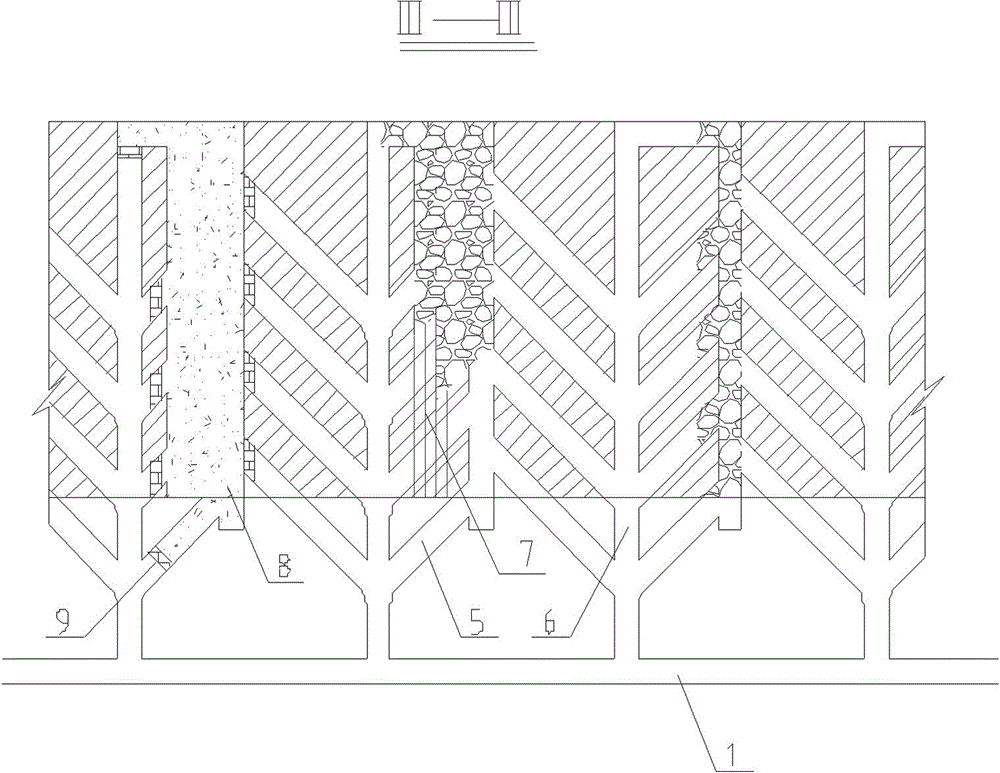

Large-structure sublevel drilling stage ore removal mining method with delayed filling

ActiveCN104863592AReduce labor intensityImprove stope production capacityUnderground miningSurface miningResource recoveryStructure of the Earth

The invention relates to a large-structure sublevel drilling stage ore removal mining method with delayed filling. The mining method comprises stoping in stopes and bottom structure recovery which are carried out synchronously in a crossed manner, and comprises the following steps: step 1, stoping in odd-numbered stopes, wherein the stoping manner is sublevel drilling stage ore removal, and mined out space I is not filled immediately; step 2, stoping in 1 / 2 bottom structures I corresponding to the odd-numbered stopes, and filling ore rooms and the mined out space I, corresponding to the 1 / 2 bottom structures I, of the ore rooms after stoping is finished; step 3, stoping in even-numbered stopes, wherein mined out space II is not filled immediately; step 4, stoping in 1 / 2 bottom structures II corresponding to ore pillars, and filling the ore pillars and the mined out space II, corresponding to the 1 / 2 bottom structures II, of the ore pillars after stoping is finished. The mining method has the advantages that the mining-cutting work amount is reduced greatly; the production capacity of a single stope is high; the efficiency is high; workers' labor intensity is low; production, dispatching and management are simple. Moreover, stoping of the main ore in a stope and recovery of ore in the bottom structure of the stope are realized synchronously in a crossed manner, and the stoping operation is safe, so that the resource recovery rate is high.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST +1

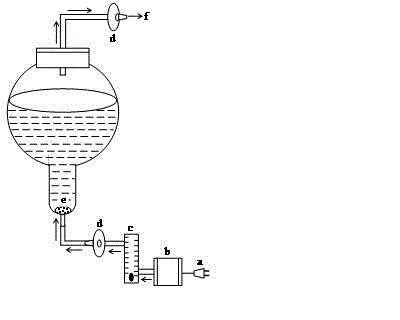

Method for culturing adventitious roots of oplopanax elatus Nakai by utilizing bioreactor

InactiveCN103141394AUniform fluidityReduce shear forcePlant tissue cultureHorticulture methodsOplopanax elatusSugar

The invention discloses a method for culturing adventitious roots of oplopanax elatus Nakai by utilizing a bioreactor. The method comprises the steps of: injecting 4L of an MS culture medium in the 5L airlift bioreactor and adding 3-4mg / L of IBA (Iso Butyl Alcohol) and 40-50g / L of white sugar, wherein the pH is 5.8; injecting air at 75-100mL / min; and inoculating 20-40g of adventitious root explants, and culturing for 40-50 days in dark, so as to obtain a large number of adventitious roots of the oplopanax elatus Nakai. The total phenols content in each obtained adventitious root of the oplopanax elatus Nakai is higher than that in the root and the stem of cultivated oplopanax elatus Nakai with two or five growth years and the polysaccharide content in the adventitious roots is approximate to that in the root of the cultivated oplopanax elatus Nakai with the two growth years. The method is capable of accelerating the multiplication rate, so as to obtain a large number of explants within a short period. The bioreactor is used for cultivation, the cost of the culture medium can be reduced, the labor intensity and the production cost can be lowered, the problems that currently the wild oplopanax elatus Nakai plants are endangered and the artificial cultivation difficulty o the oplopanax elatus Nakai plants is high are solved and a new approach is provided for the commercialized production.

Owner:YANBIAN UNIV

Method for cultivating Anji white tea in Jiaodong area

The invention discloses a method for cultivating Anji white tea in the Jiaodong area, which is characterized by including procedures of selecting and preparing a nursery, performing cutting, performing cuttage, putting a shed for shading, managing the nursery, seedling lifting and the like. By the method, the problem that seedlings of Anji white tea are unable to adapt to northern climate, low in survival rate, high in management difficulty and the like after introduction to the Jiaodong area is solved, and the method is applicable to propagation and cultivation of Anji white tea in the Jiaodong area.

Owner:QINGDAO YUANHE TEA

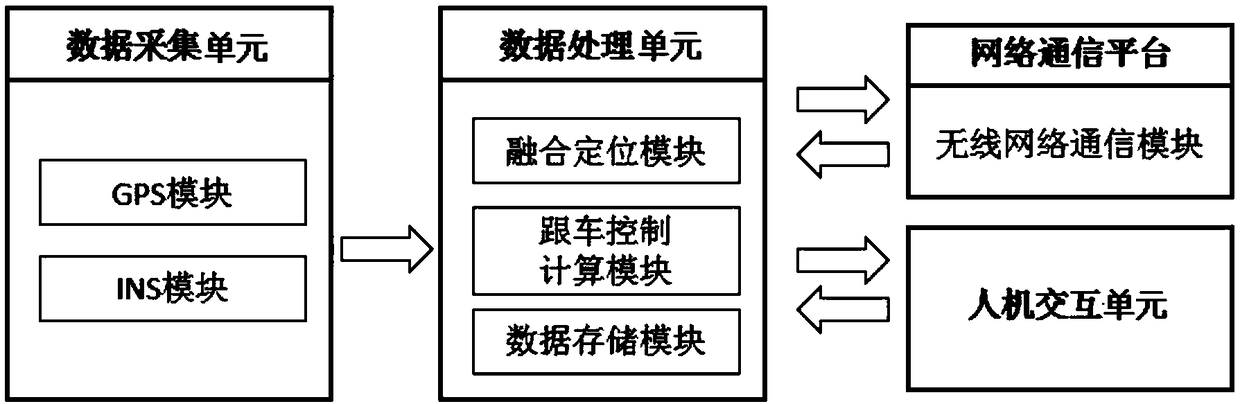

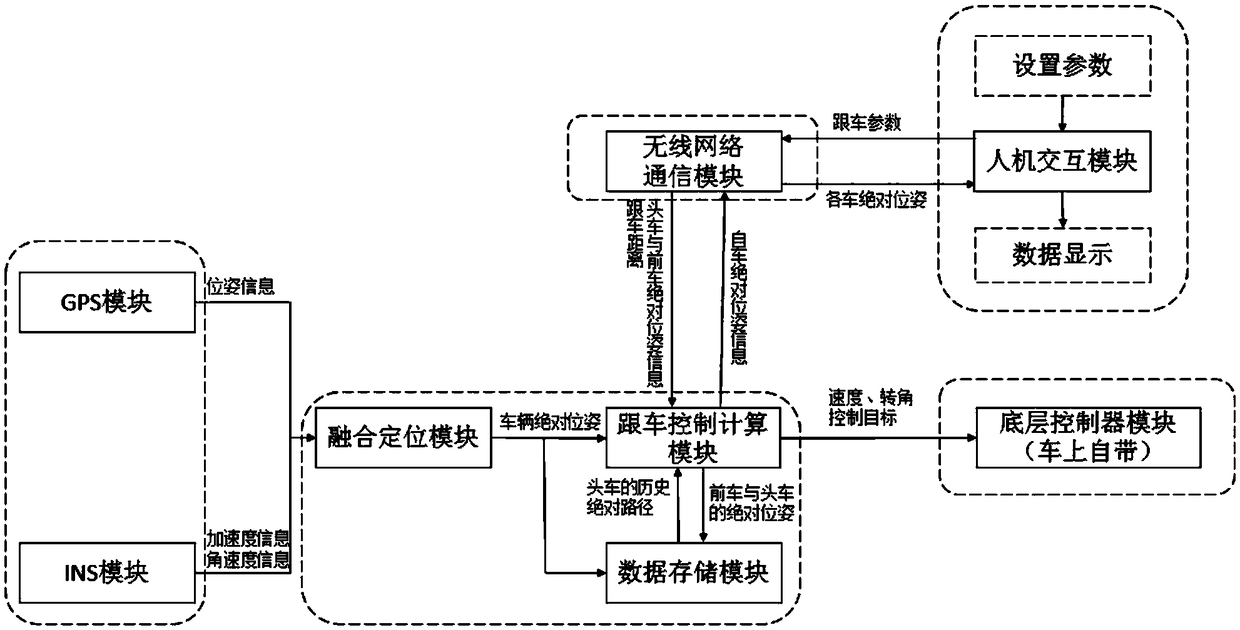

Motorcade autonomous car following system, portable device and method

InactiveCN108616810ARealize autonomous follow-up drivingResolution frequencyRoad vehicles traffic controlParticular environment based servicesTurn angleRouting table

The invention provides a motorcade autonomous car following system, a portable device and a method; the system comprises the following parts: a GPS module in a data acquisition unit is used for gathering vehicle positioning information, and an inertial navigation module in the data acquisition unit is used for gathering vehicle acceleration information and angular velocity information; a fusion positioning module in a data processing unit is used for fusing the GPS information and inertial navigation information in real time, thus obtaining a self-vehicle absolute pose; a car following controlcalculation module is used for planning an absolute route according to the self-vehicle absolute pose information, front vehicle absolute pose information and a head vehicle history route, updating an absolute route table, and calculating to obtain a vehicle target velocity and direction turning angle for vehicle control. The system and method can realize combined positioning via the GPS module and the INS module, are high in positioning precision, high in data refreshing frequency, and cannot be affected by illumination and weather environment factors, thus effectively improving the autonomous car following system precision and reliability. The device is portable and easy to construct, and low in cost.

Owner:SHANGHAI JIAO TONG UNIV +1

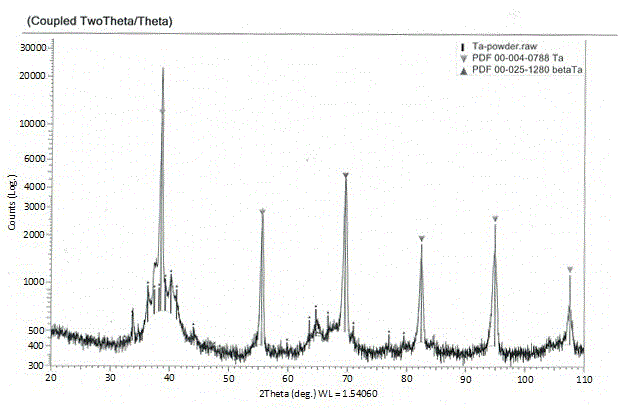

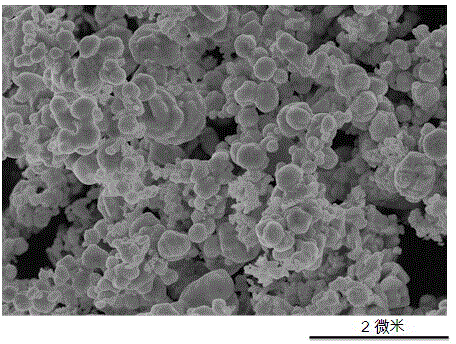

Connecting method for sintering/welding titanium-steel dissimilar metal

ActiveCN103480846ALittle controllabilityEffective thickness controlWelding/soldering/cutting articlesWelding apparatusExpansion factorTitanium

The invention discloses a connecting method for sintering / welding titanium-steel dissimilar metal. The differences of physical properties of the titanium and the steel which are dissimilar metal are large, and the titanium and the steel are hard to connect through conventional methods. According to the connecting method, firstly, the titanium or titanium alloy, V-Cu gradient alloy powder C1, C2 and C3 and stainless steel are placed in a die one by one to be pressed in advance, and secondly, the die is placed in a sintering device to be sintered in a spark plasma mode, wherein the V-Cu gradient alloy powder C1, C2 and C3 are composed of mixed powder which is formed by mixing a plurality of kinds of metal powder according to different proportions, and the expansion factor gradient of the V-Cu gradient alloy powder C1, the expansion factor gradient of the V-Cu gradient alloy powder C2 and the expansion factor gradient of the V-Cu gradient alloy powder C3 are matched with one another. The titanium or the titanium alloy and the stainless steel are directly connected and formed at a time in a sintering mode, the method of spark plasma sintering is particularly suitable for sintering molding of V-Cu gradient connectors of the titanium and the stainless steel, and a titanium-steel dissimilar metal sintering / welding connector can have a high mechanical property.

Owner:NANJING UNIV OF SCI & TECH

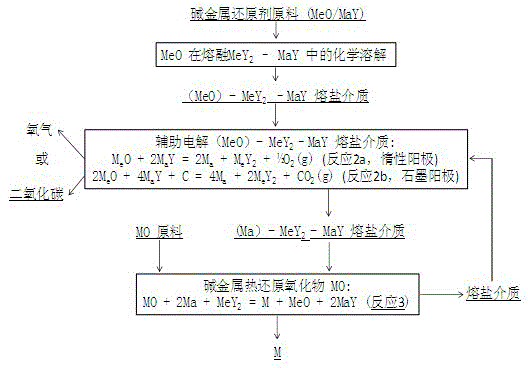

Method for preparing metal through continuous reduction in molten salt medium

InactiveCN105274576ASustainable useReduce manufacturing costMaterials preparationAlkaline earth metal

The present invention relates to a metal material preparation method, particularly to a method for preparing a metal through continuous reduction in a molten salt medium. According to the method, a molten alkali metal and alkaline earth metal mixing halide MaY-MeY2 is adopted as the flux of a molten salt medium, an alkaline earth metal oxide MeO / alkaline metal halide MaY mixture capable of being dissolving in the flux of the molten salt medium is used to replace an alkaline metal so as to be adopted as a reduction agent, the specifically-selected MeO / MaY mixture is added to the molten MaY-MeY2 flux to form a MeO-MaY-MeY2 molten salt, the molten salt medium is subjected to electrolysis to decompose the MeO dissolved in the medium so as to finally obtain the Ma-MaY-MeY2 molten salt medium, an oxide MO is added to the formed Ma-MaY-MeY2 molten salt medium under the support of the electrolysis process performing under the conditions, and the alkali metal Ma instantly performs thermal reduction on the added oxide MO so as to prepare the metal M. According to the present invention, the disadvantages of complex operation and danger of the direct alkali metal reduction agent adding in the traditional thermal reduction are overcome; the excessive use of the alkali metal reduction agent is solved, and the continuous production can be achieved; and the cost is low, and the energy consumption is low.

Owner:AUYONG ADVANCED MATERIALS TECH SHANGHAI CO LTD

Method for synergetic extraction of coal bed gas in caving type gob area and lower coal bed

ActiveCN106089291ASolution areaSolution rangeConstructionsFluid removalEnvironmental engineeringCoal

The invention discloses a method for synergetic extraction of coal bed gas in a caving type gob area and a lower coal bed. The method comprises the steps that firstly, a mine is explored, a horizontal well is constructed from the ground to a base plate of the gob area, carbon dioxide is compressed into the well for cleaning, and coal bed gas extraction is carried out; when the extraction amount of coal bed gas in unit time drops to 20%-40% of Qi, running and stopping circulate, the extraction pressure is reduced, and the re-extraction process is carried out again; when the extraction amount drops to be below 20% of Qi, carbon dioxide is injected for replacement, and extraction is carried out again; when the extraction amount drops to be below 20% of Q1 again, the horizontal well and a coal and rock strata of the lower coal bed are subjected to fracture, and coal bed gas discharge and extraction are carried out; when the extraction amount drops to be below 20% of Q2, supercritical carbon dioxide replacement is carried out; and when the extraction amount drops to 10% of Q2 through extraction, extraction is stopped. By means of the method, synergetic extraction of coal bed gas in the carving type gob area and coal bed gas near a low coal seam is achieved, cost is reduced, and the coal bed gas resource is extracted to the greatest extent.

Owner:TAIYUAN UNIV OF TECH

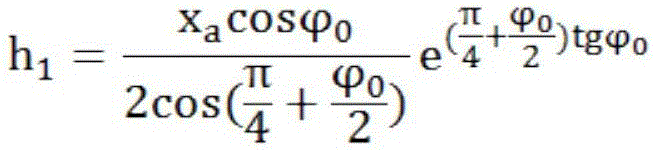

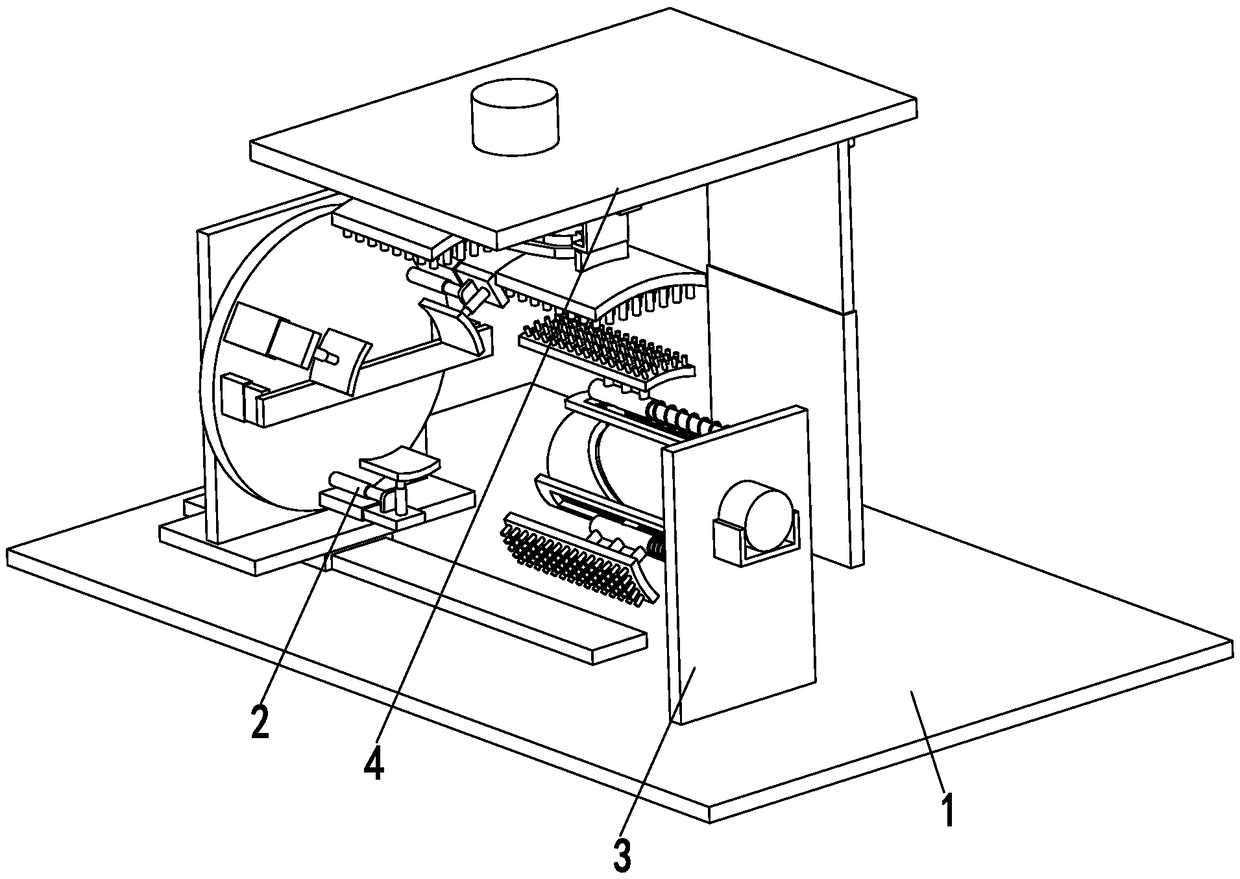

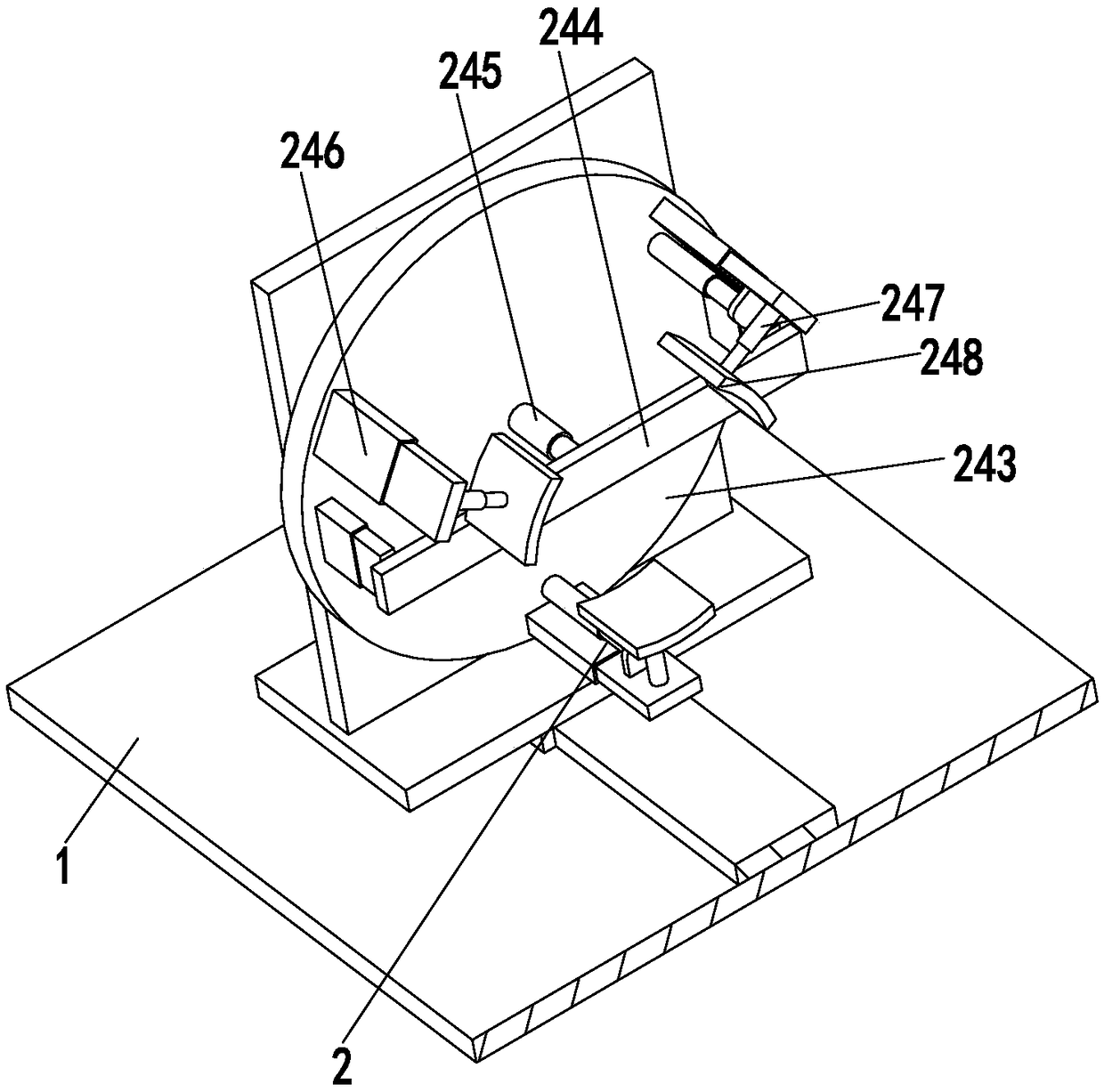

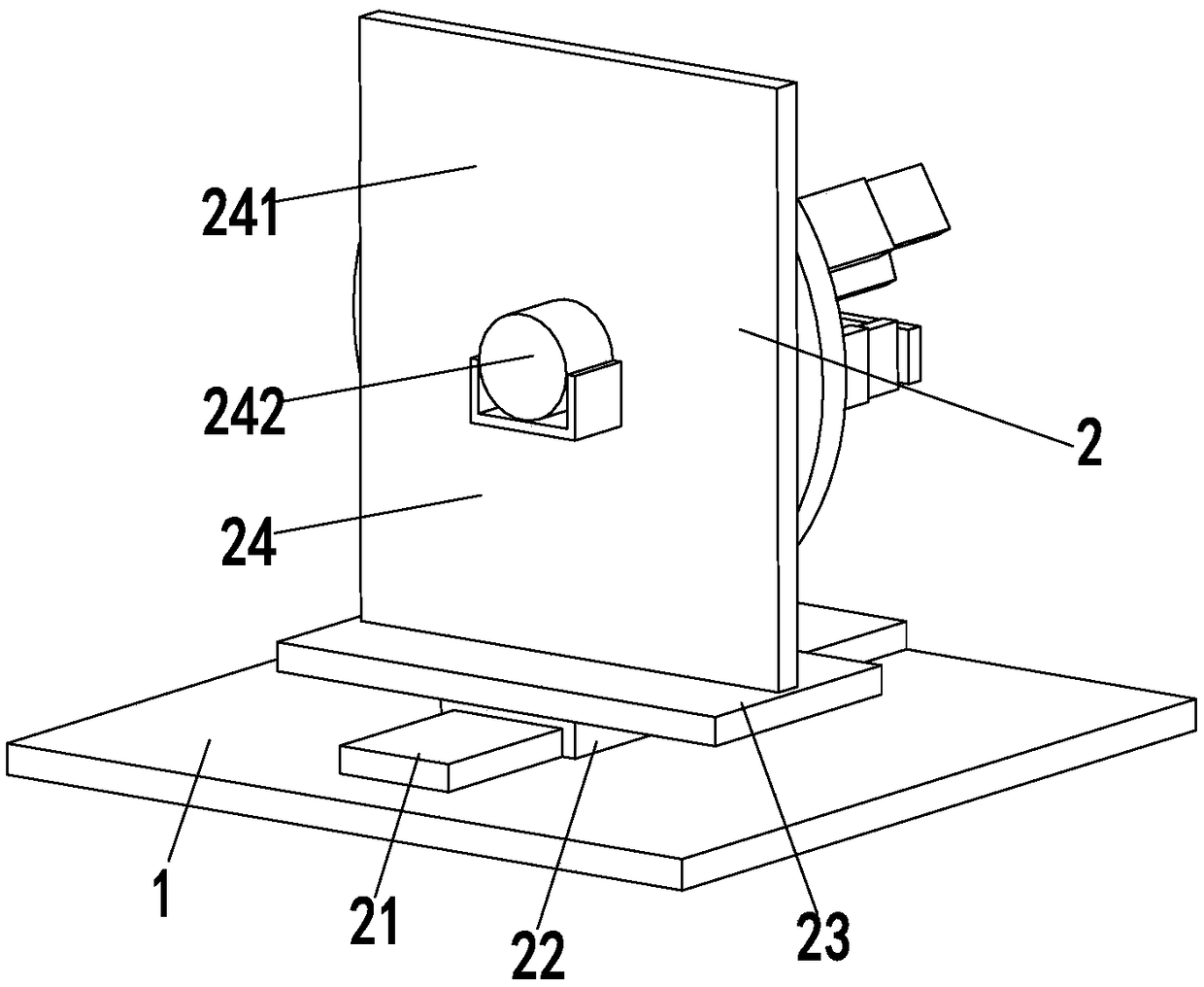

Workpiece grinding machine of numerical-control electric spark machine tool

InactiveCN108789046ASolve the costSolve labor intensityGrinding carriagesGrinding drivesNumerical controlEngineering

The invention relates to a workpiece grinding machine of a numerical-control electric spark machine tool. The workpiece grinding machine of the numerical-control electric spark machine tool comprisesa base plate, a fixing device, an inner wall grinding device and an outer wall grinding device. The fixing device and the inner wall grinding device are sequentially installed on the base plate from left to right. The outer wall grinding device is installed on the back side of the base plate. The inner wall grinding device comprises a fixing plate, a rotating motor, a rotating column, sliding blocks, limiting frames, telescopic rods, springs, adjusting air cylinders and first steel wire brushes. The outer wall polishing device comprises a lifting frame, a rotating motor, a rotating column, a cam, connection sliding blocks, connection frames, guide rails and second steel wire brushes. The workpiece grinding machine of the numerical-control electric spark machine tool can solve the problemsthat in an existing annular workpiece grinding process, the labor cost is high, the labor intensity is high, the work efficiency is low, the grinding difficulty is large, and the adjustability is poor; the automatic grinding function on the annular workpiece can be achieved; and the workpiece grinding machine of the numerical-control electric spark machine tool has the advantages of being low in labor cost, low in labor intensity, high in work efficiency, small in polishing difficulty, good in adjustability and the like.

Owner:浙江芊荷科技有限公司 +1

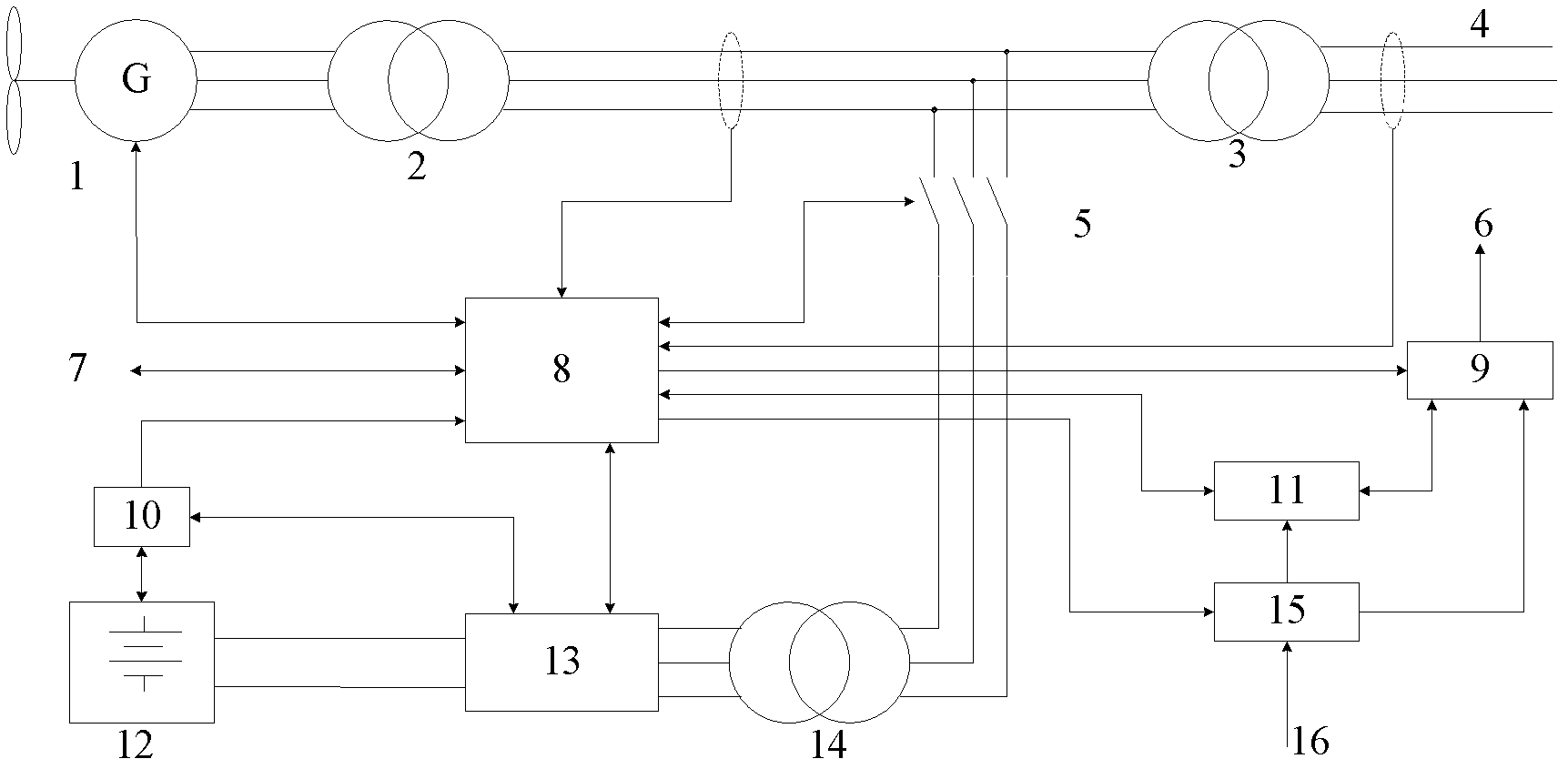

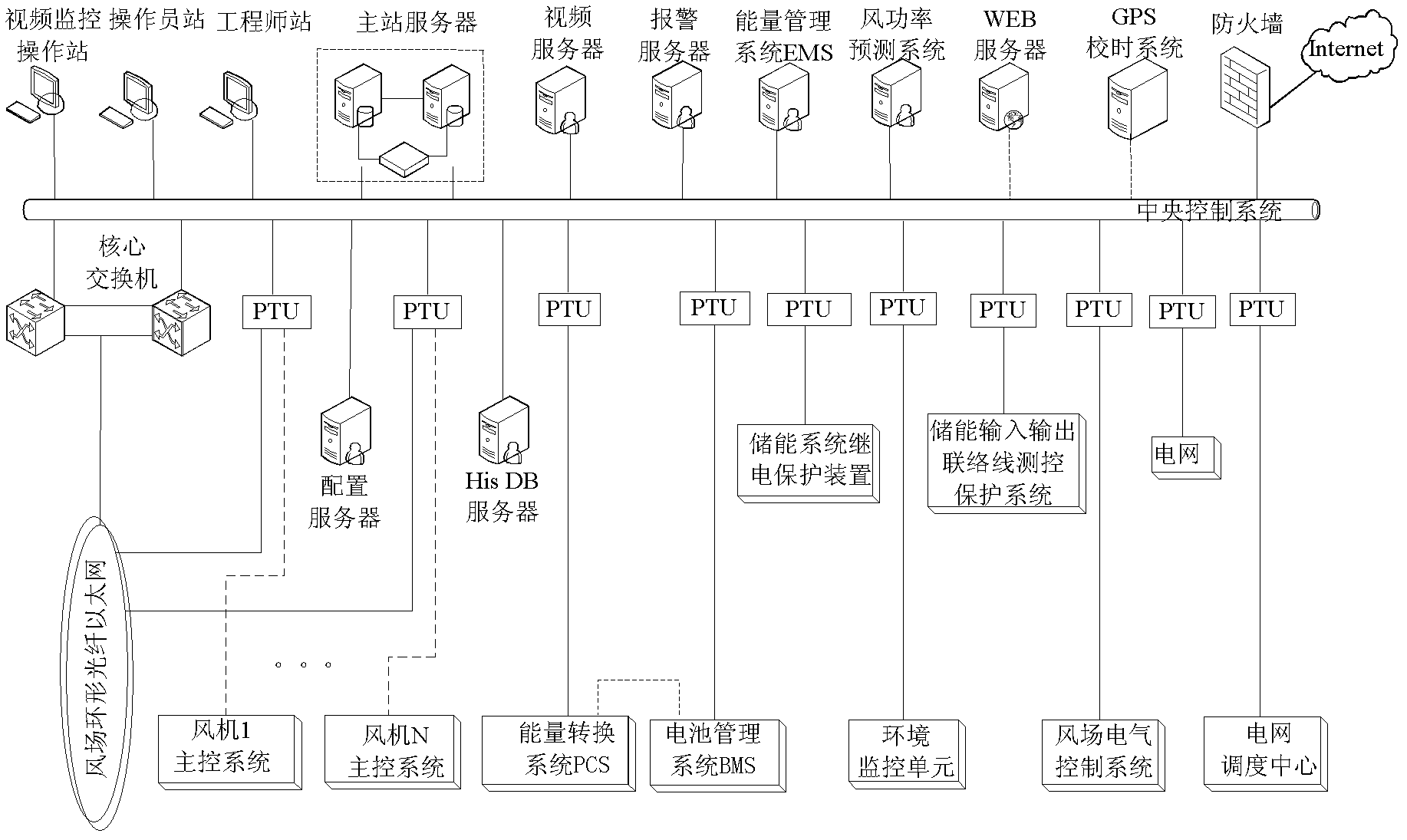

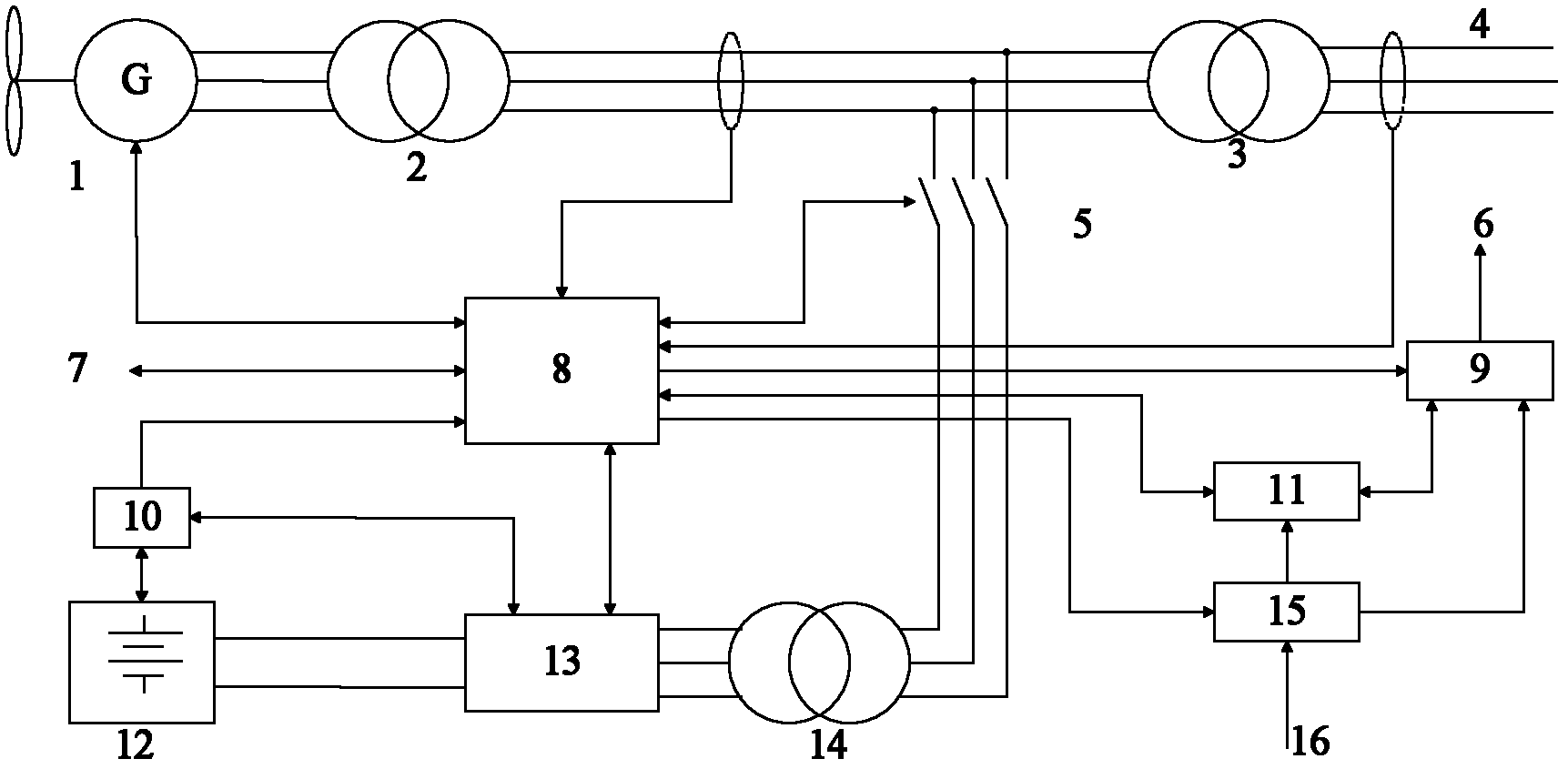

Central-control-system-based energy storage type wind power plant

ActiveCN102496948AEfficient and safe fully integrated integrated controlSolving large scaleElectrical storage systemEnergy storagePower qualityScheduling function

The invention relates to the technical field of control over wind power plants with energy storage systems, and discloses a central-control-system-based energy storage type wind power plant. The energy storage system is added on the basis of the conventional wind power plant. A central control system integrates the monitoring of an energy storage battery system, an energy conversion system, fans of the whole plant, a booster station and box type transformers of the whole plant. A power grid scheduling interface is arranged to realize totally integrated control over the energy storage type wind power plant. A central control system platform realizes a power prediction function, an energy management function, a power grid direct scheduling function and an entire-wind power plant low-voltage ride through function. A problem about the grid connection of conventional wind power generation is solved, the quality of grid-connected electric energy of the wind power generation is improved, and the real-time performance, accuracy and safety of the control over the energy storage type wind power plant are improved.

Owner:BEIJING HUADIAN TIANREN ELECTRIC POWER CONTROL TECH

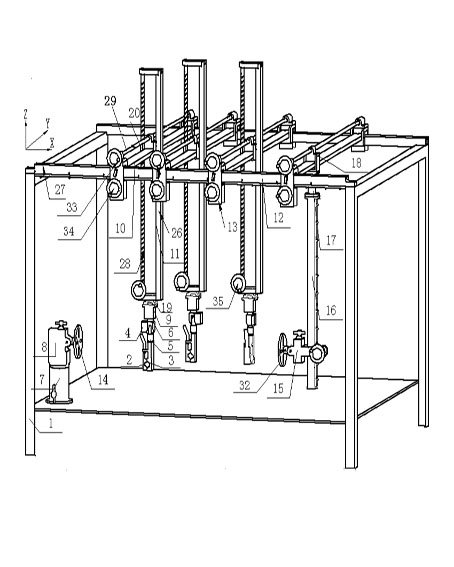

Flexible clamp for pipe fitting welding and adjusting method thereof

InactiveCN102000935AAvoid misalignmentExpand the scope of useWelding/cutting auxillary devicesAuxillary welding devicesPipe fittingEngineering

The invention discloses a flexible clamp for pipe fitting welding between multi-section pipe fittings and between a pipe fitting and a flange, and an adjusting method thereof. The bottom of a base bracket is provided with a fixed end flange around Z-axis angle adjusting mechanism and a fixed end flange around Y-axis angle adjusting mechanism connected with an equant chute flange plate rotating mechanism; a top Y-direction displacement regulating mechanism, a vertical Z-direction displacement regulating mechanism and a top X-direction displacement regulating mechanism for regulating the pipe fittings and a flange Y-direction displacement regulating mechanism for regulating the flange are arranged on the upper part of the base bracket; and each mechanism is adjusted to make a positioning mechanism rotate around the X, Y and Z directions. The invention can be rapidly and accurately adjusted and positioned so as to clamp the pipe fittings according to diversified space trends of different pipe fittings, and a set of clamp can adapt to welding a series of pipe fitting sections in different specifications.

Owner:JIANGSU UNIV OF SCI & TECH

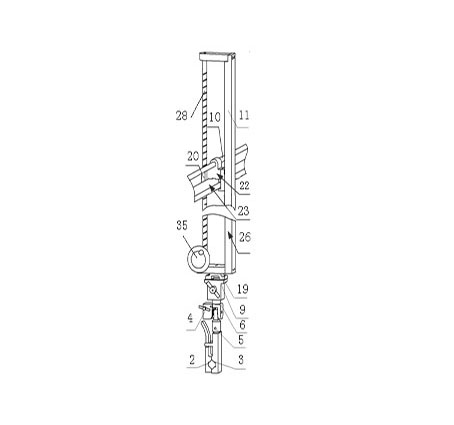

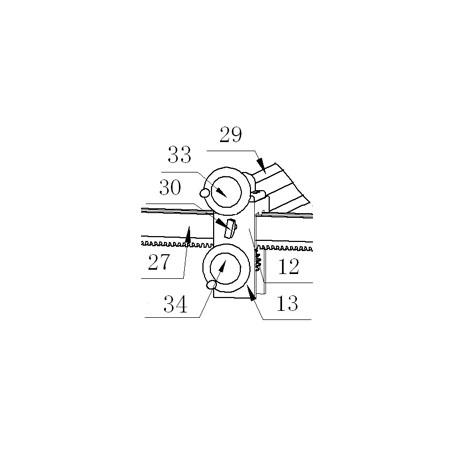

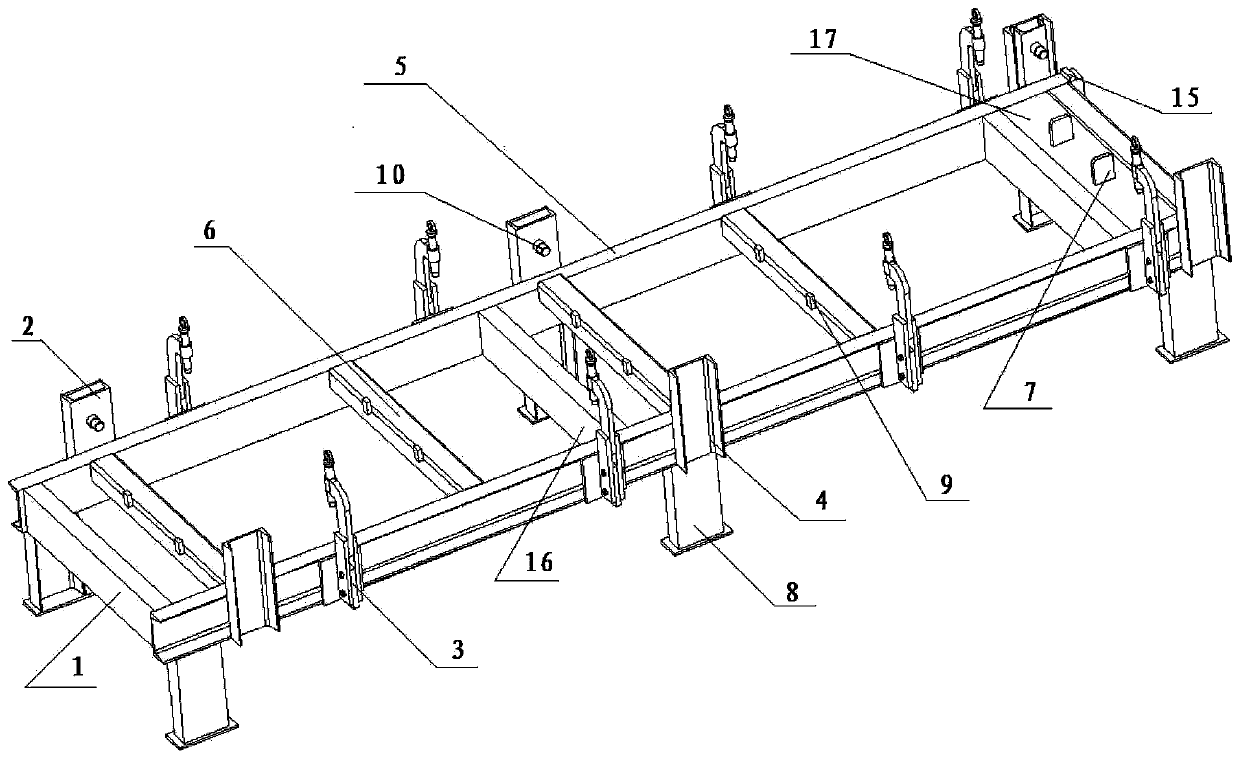

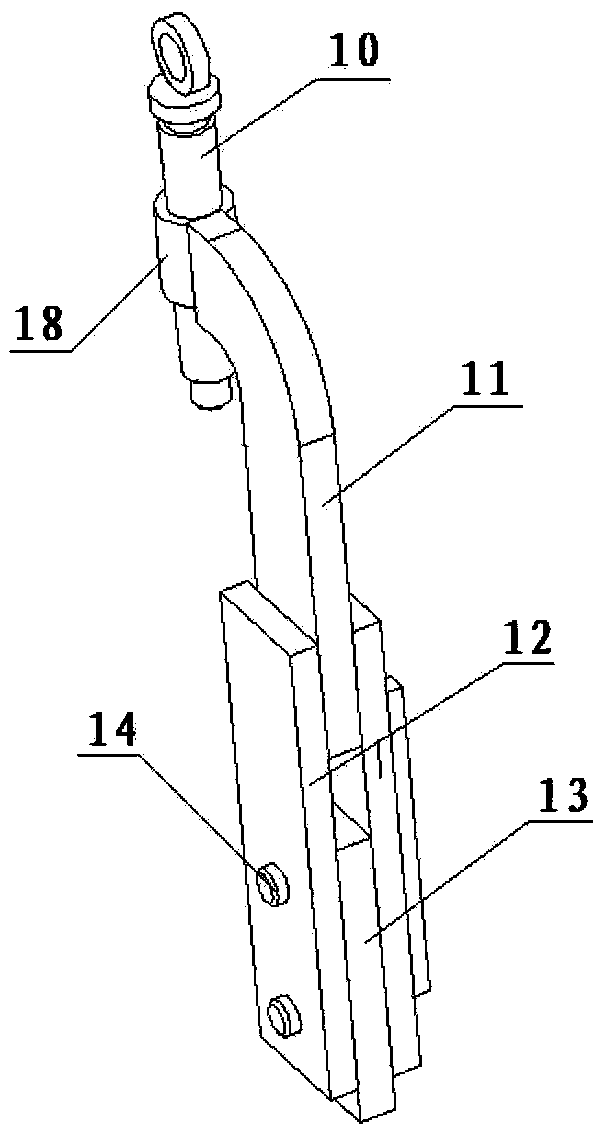

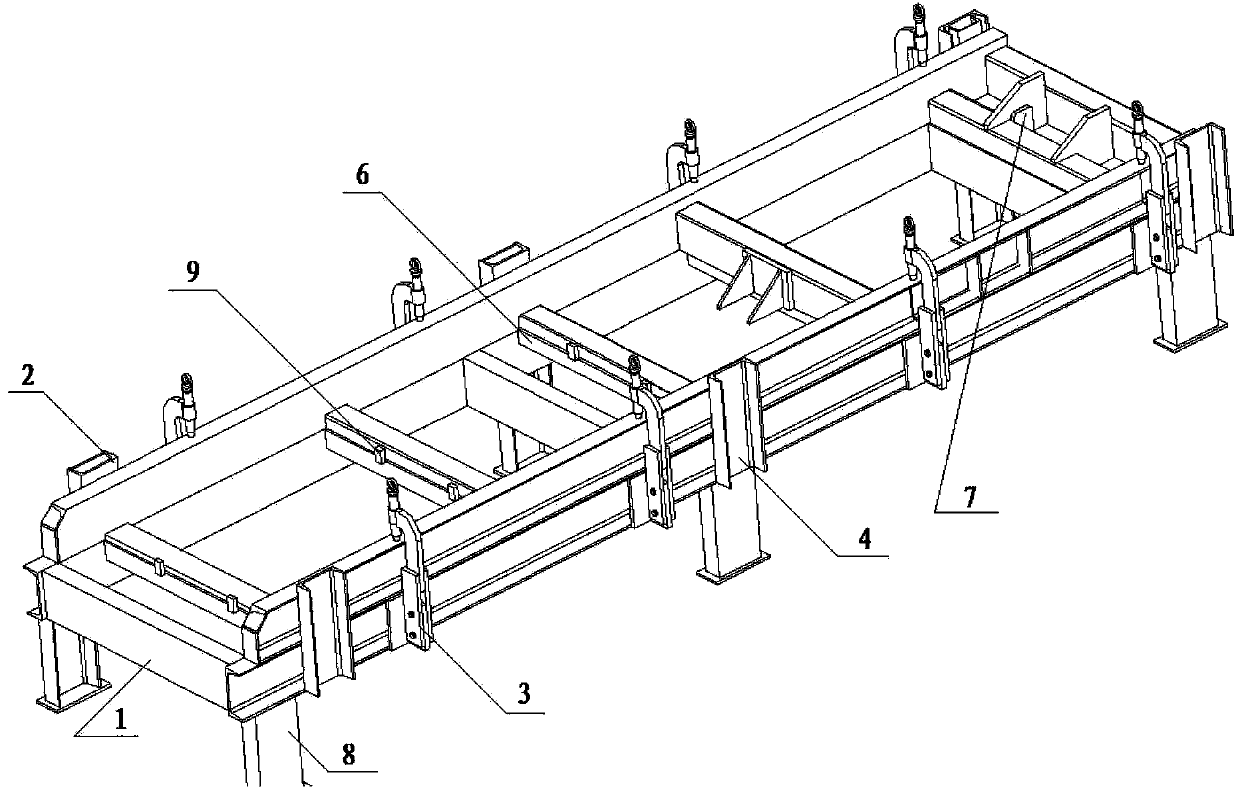

Carriage longitudinal beam tailor welding tool

ActiveCN103418965ASave adjustment timeHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesEngineering

The invention relates to a carriage longitudinal beam tailor welding tool. The carriage longitudinal beam tailor welding tool comprises a fixing frame and a first stand column which is fixed on the edge of one side of the fixing frame, wherein the edge of the other side of the fixing frame is fixedly connected with the lower portion of a second stand column, a regulating rod is fixed on the edge of the position, between the first stand column and the second stand column, of the fixing frame, and a base plate is fixedly connected with the surface of one end of the fixing frame. The carriage longitudinal beam tailor welding tool has the advantages that a part to be welded is accurately located and reliably clamped, so that the part to be welded is conveniently assembled and welded, and structural accuracy of the part to be welded is improved.

Owner:广西玉柴专用汽车有限公司

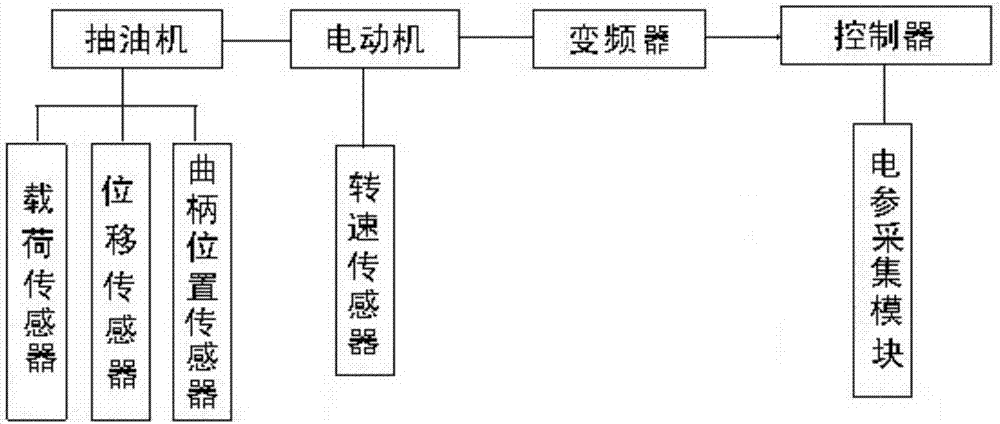

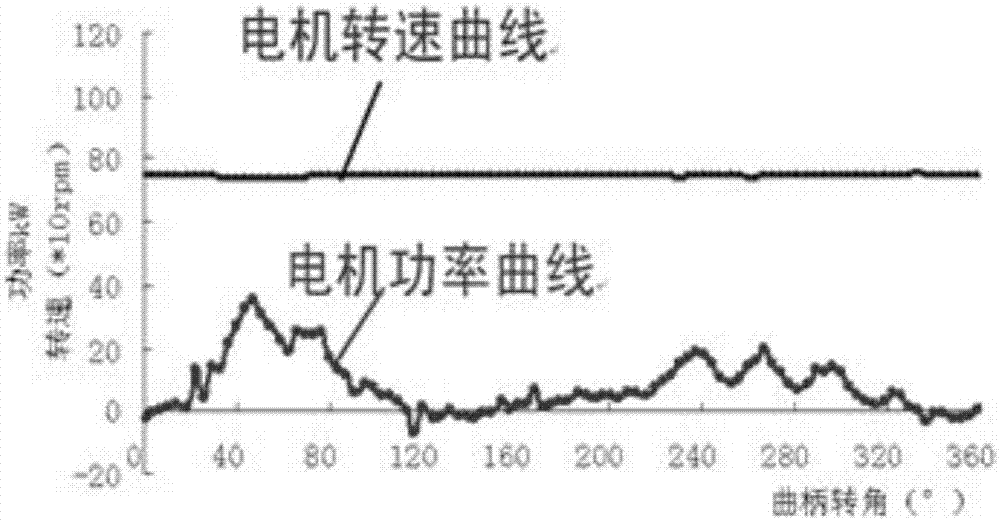

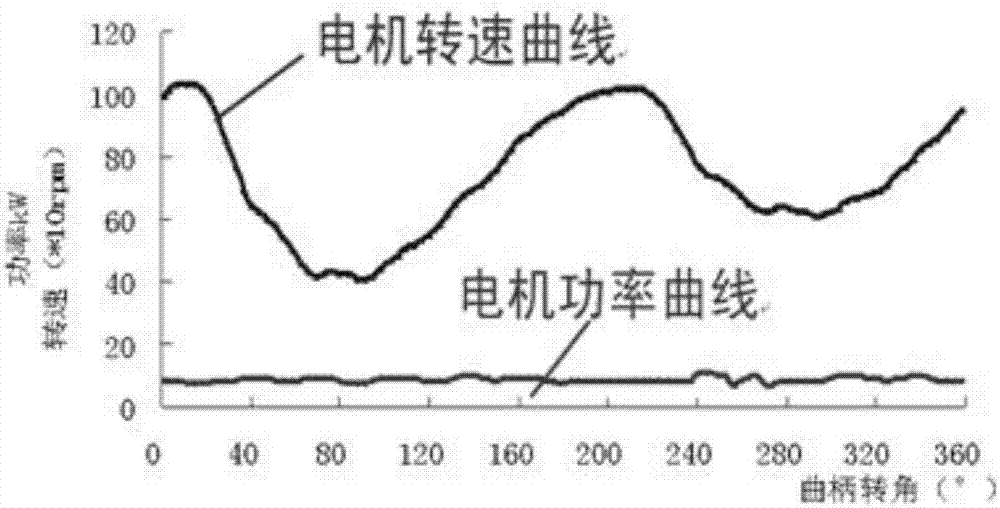

Control device and method for intermittent pumping of oil pumping unit without shutting down

ActiveCN106948796AMeet supply and production coordinationImprove operational efficiencyConstructionsFluid removalFrequency changerCrank

The invention provides a control device for intermittent pumping of an oil pumping unit without shutting down. The control device comprises a controller, a frequency converter, an electromotor and the oil pumping unit which are electrically connected in sequence. An electric parameter collecting module is arranged on the controller. A rotating speed sensor is arranged on the electromotor. A load sensor, a displacement sensor and a crank position sensor are arranged on the oil pumping unit. For a low-liquid-amount and intermittent liquid outlet well, the control device provides the most reasonable control method according to the actual liquid outlet situation to meet supply-production coordination of the oil well, so that fine control is achieved, the operation efficiency of an oil well system is improved, energy consumption is lowered, automatic, safe and unattended intermittent pumping operation of a well field is achieved, and the problems of large management difficulty and time and labor consuming of site manual intermittent pumping are solved.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com