Abrupt slope bare rock drilling platform and technology in huge reservoir

A drilling platform and steep slope technology, applied in the field of bridge engineering, can solve problems such as pile offset or slurry leakage, large steel input, and platform instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

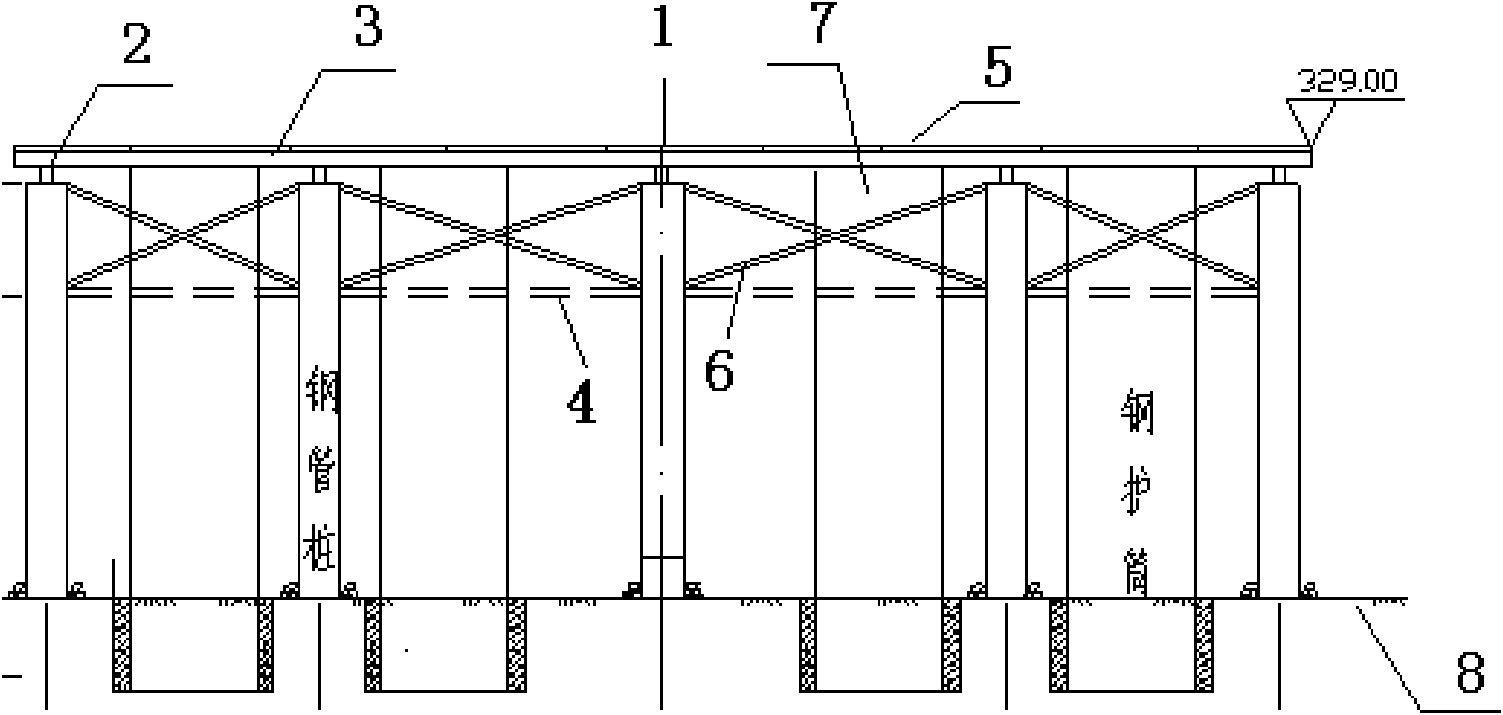

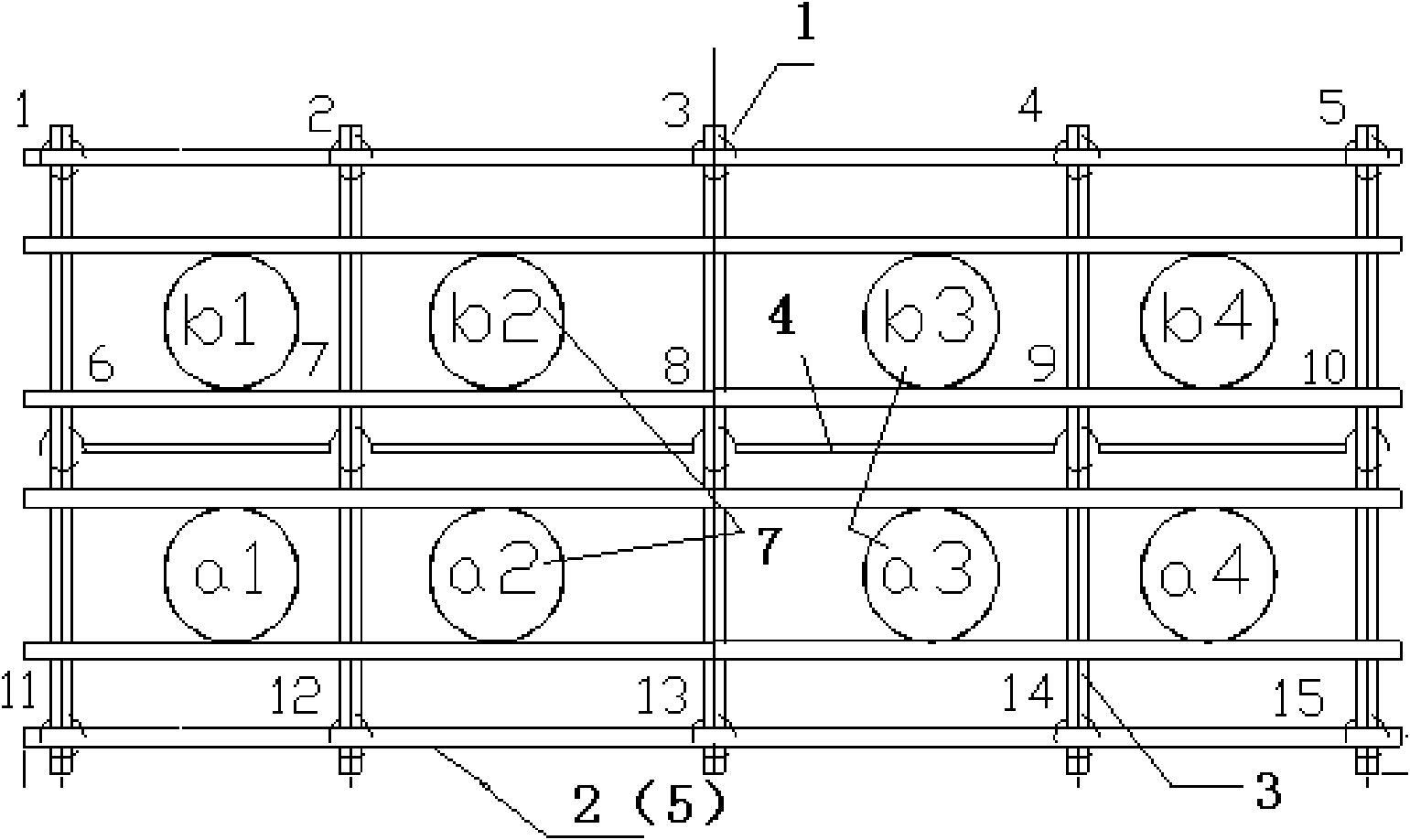

[0027] Such as figure 1 As shown, the steep slope bare rock drilling device in the deep reservoir area includes a steel pipe pile 1, a beam 2, a longitudinal beam 3, a scissor brace 6 and a steel casing 7. The vertical and horizontal distances of the steel pipe piles 1 are on the river bed, and the vertical and horizontal distances of the steel pipe piles 1 are connected by parallel joints 4, longitudinal scissor braces and horizontal scissor braces; there is a steel casing 7 in the space surrounded by the four steel pipe piles 1, The height direction of the steel casing 7 is parallel to the steel pipe pile 1. The pile foundation steel casing 7 has a diameter of Φ280cm, and the steel casing is rolled from an A3 steel plate with a thickness of 14mm.

[0028] Platform construction process and technology

[0029] 1. Steel pipe pile construction

[0030] 1.1. Construction procedure of steel pipe piles

[0031] Set up a simple platform→locate the steel pipe pile group→vibrate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com