Printed circuit board capable of realizing high-speed signal transmission and making method

A printed circuit board, high-speed signal technology, applied in the direction of printed circuit manufacturing, printed circuit, circuit substrate materials, etc., can solve the problems of few applications, low signal test coverage, etc., achieve high-speed signal transmission, solve limitations, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

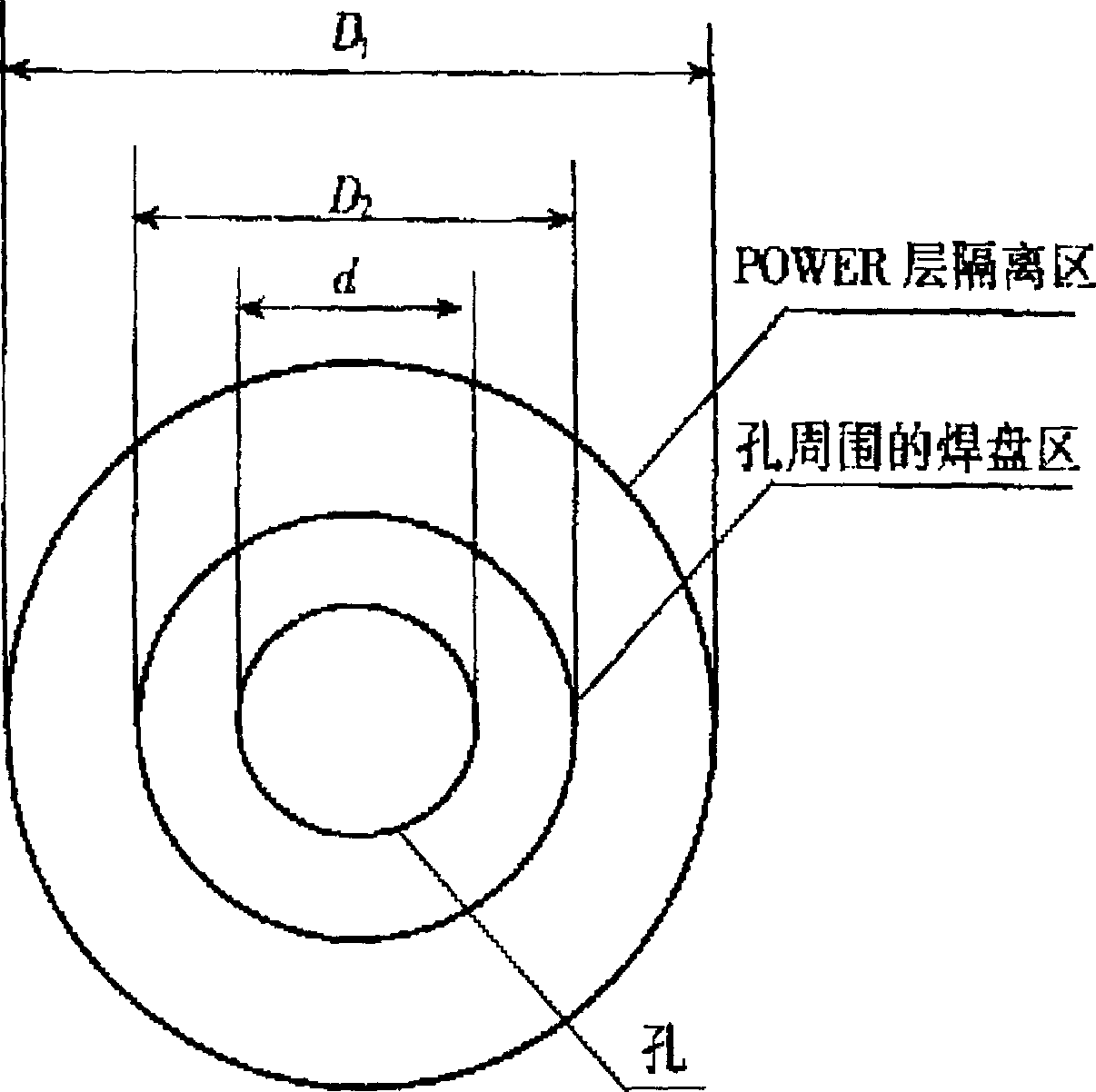

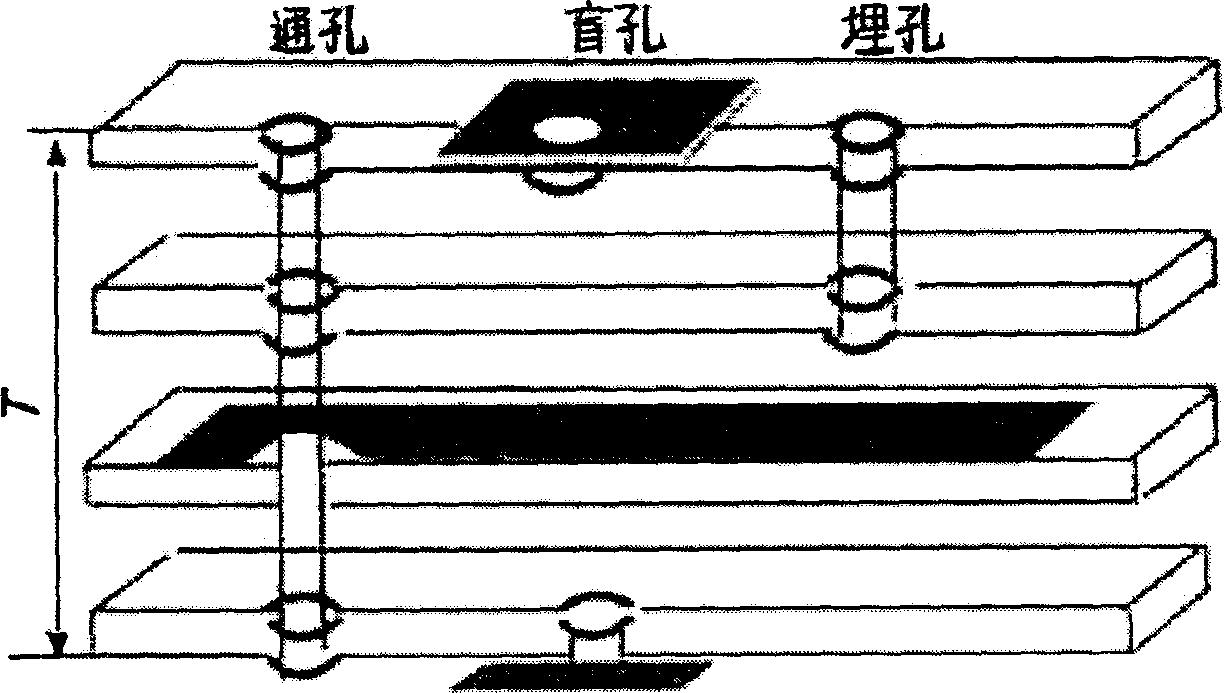

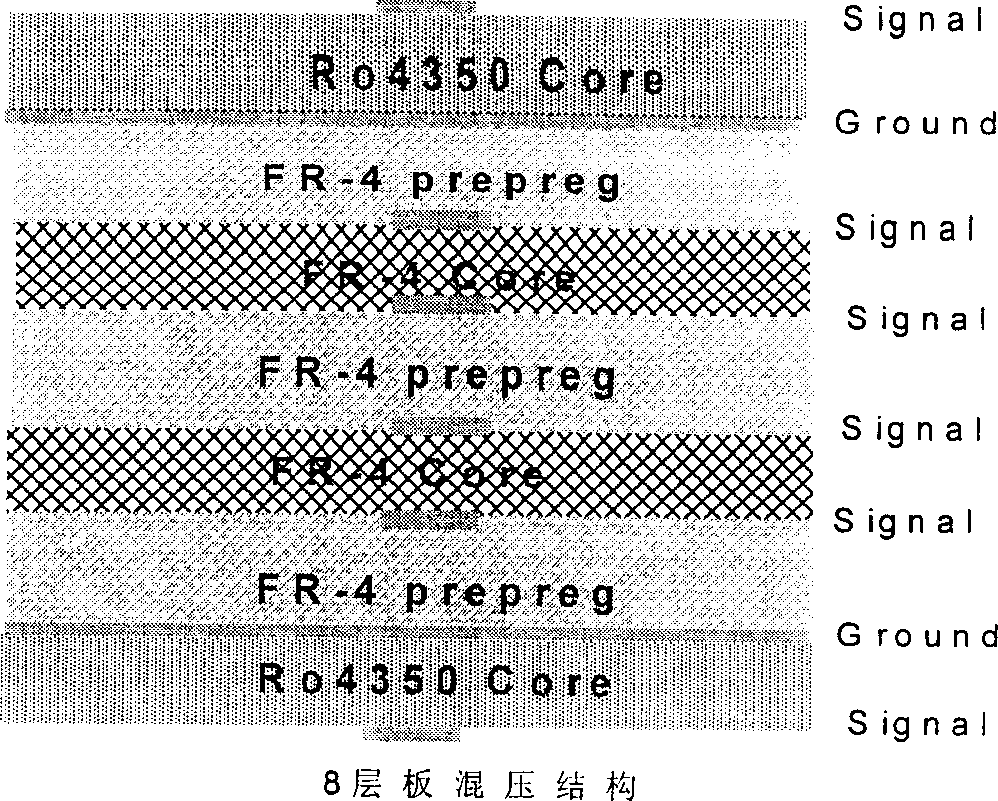

[0060] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 Generally, the high-speed signal transmission line on the PCB is only partial, and some layers of the PCB may not use high-grade materials, but the use price is relatively low, and the performance of the transmission signal is more common than ordinary materials such as FR4 to form multiple inner layers of the circuit board. , comprehensive signal quality requirements, simulation results and costs, and the maturity of the manufacturer's process, the plate mixed pressure technology can be used. Compared with the usual structure, the mixed pressure structure has more flexibility in terms of cost, performance, and availability. and adaptability, such as image 3 As shown, in order to realize the high-speed signal special board ROGERS4350 and the eight-layer board mixed structure of common board FR4: the two outer layers are made of ROGERS4350 special board that can transmit high-speed signals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com