Control device and method for intermittent pumping of oil pumping unit without shutting down

A technology of a control device and a control method, which is applied to earth-moving drilling, production of fluids, wellbore/well components, etc., can solve problems such as injury to personnel and livestock, impact on production, wax deposition on the inner wall of oil pipes, etc. The effect of improving operation efficiency and fine control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

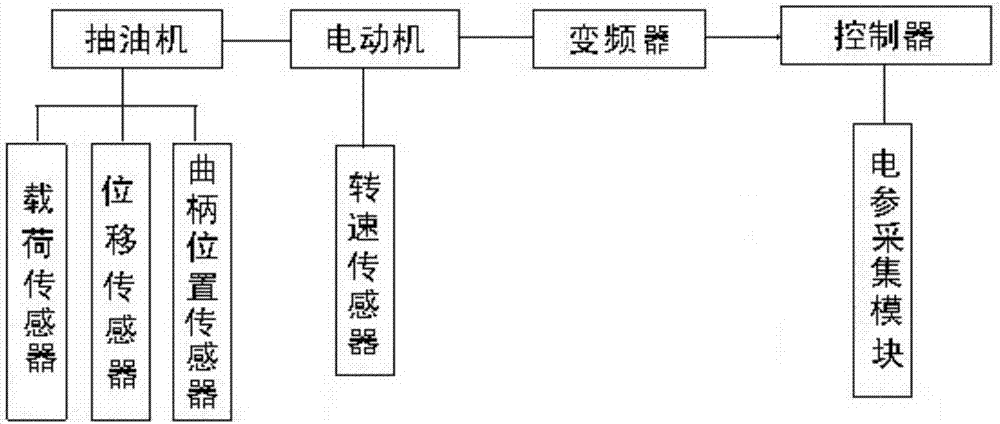

[0040] In order to overcome the problems existing in the remote automatic intermittent pumping control of oil wells, this embodiment provides a method such as figure 1 The shown oil pumping unit non-stop pumping control device includes a controller 1, a frequency converter 2, a motor 3 and a pumping unit 4 that are electrically connected in sequence. The controller 1 is provided with an electric parameter acquisition module 5, and the The motor 3 is provided with a speed sensor 6 , and the pumping unit 4 is provided with a load sensor 7 , a displacement sensor 8 and a crank position sensor 9 .

[0041] The working principle of the non-stop pumping control device for this pumping unit provided by the present invention is as follows:

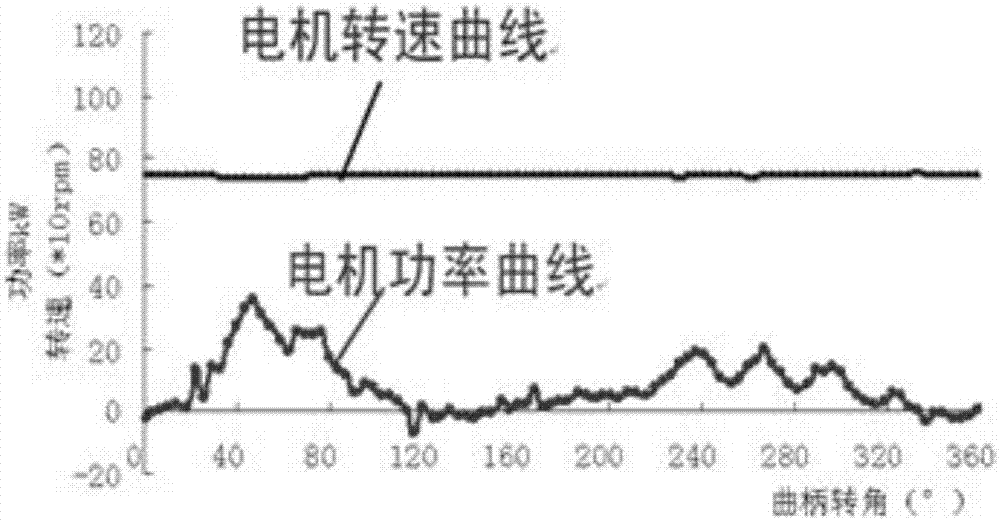

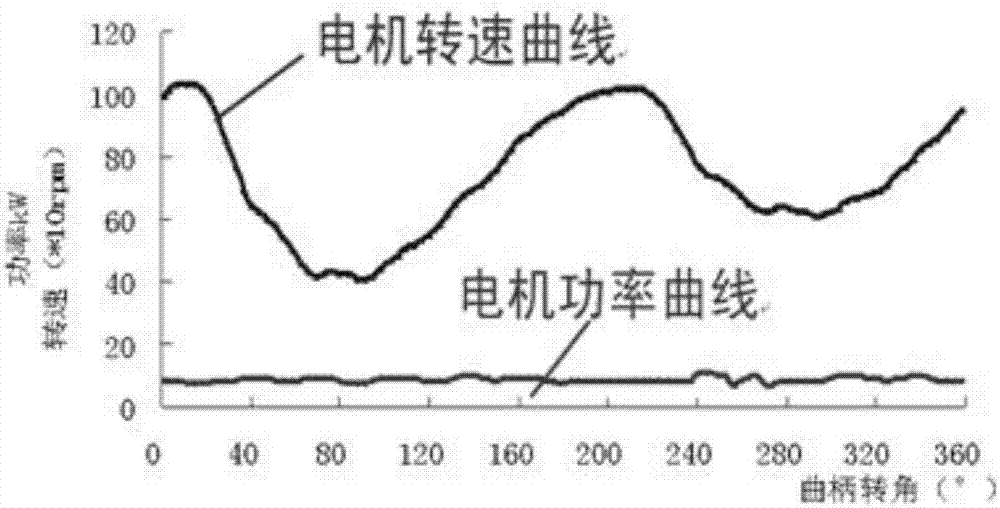

[0042] The rotational speed sensor 6, the load sensor 7, the displacement sensor 8 and the crank position sensor 9 send the motor speed, the load, displacement and crank position data of the pumping unit to the controller through wireless transmis...

Embodiment 2

[0046] On the basis of Example 1, this embodiment provides a control method for intermittent pumping without stopping the pumping unit. For wells with low fluid volume and intermittent fluid output, the most reasonable control method is given according to the actual fluid output to meet the requirements of oil wells. Supply and production coordination, at least including the following steps:

[0047] Step 1) According to the liquid production rate of the oil well, judge the cumulative stoppage time of the oil well in one day;

[0048] When the production of the oil well is ≤1t / d, the accumulative shutdown time of the oil well is 12 hours a day;

[0049]When the production of the oil well is 1t / d~1.5t / d, the accumulative pumping stop time of the oil well is 8 hours a day;

[0050] When the production of oil well is 1.5t / d~2t / d, the accumulative shutdown time of oil well is 6 hours a day.

[0051] Step 2) Preliminarily take half an hour as a working cycle of a pumping unit. Ac...

Embodiment 3

[0069] This embodiment provides a pumping unit non-stop pumping control method:

[0070] First, according to the fluid production of the oil well, determine which of the following conditions the oil well belongs to:

[0071] When the production of the oil well is ≤1t / d, the accumulative shutdown time is 12 hours;

[0072] When the oil well production is 1t / d~1.5t / d, the accumulative pumping stop time is 8 hours;

[0073] When the oil well production is 1.5t / d~2t / d, the accumulative shutdown time is 6 hours.

[0074] Taking liquid production less than 1t / d as an example, the accumulative pumping stop time is 12 hours, with half an hour as a cycle, the well is opened for 15 minutes and swings for 15 minutes. Given the initial state value, open the well for 15 minutes and swing for 15 minutes. By judging the fullness of the dynamometer of the polished rod, when the fullness of the dynamometer is less than the limit value (adjustable parameters), such as when the fullness is les...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com