Patents

Literature

277results about How to "Realize fine control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

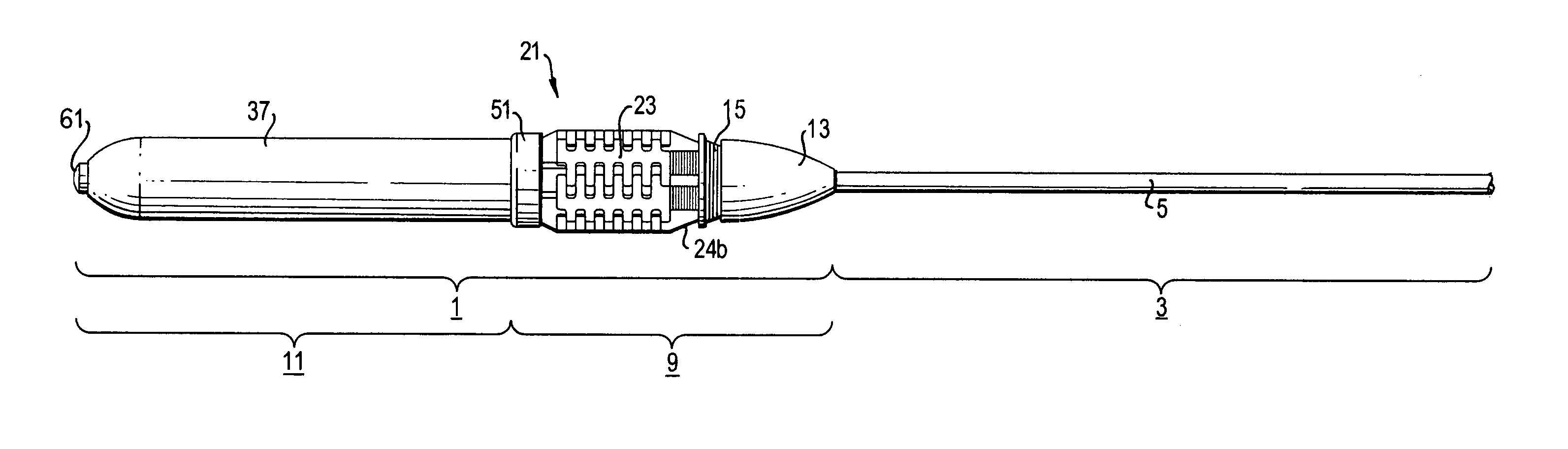

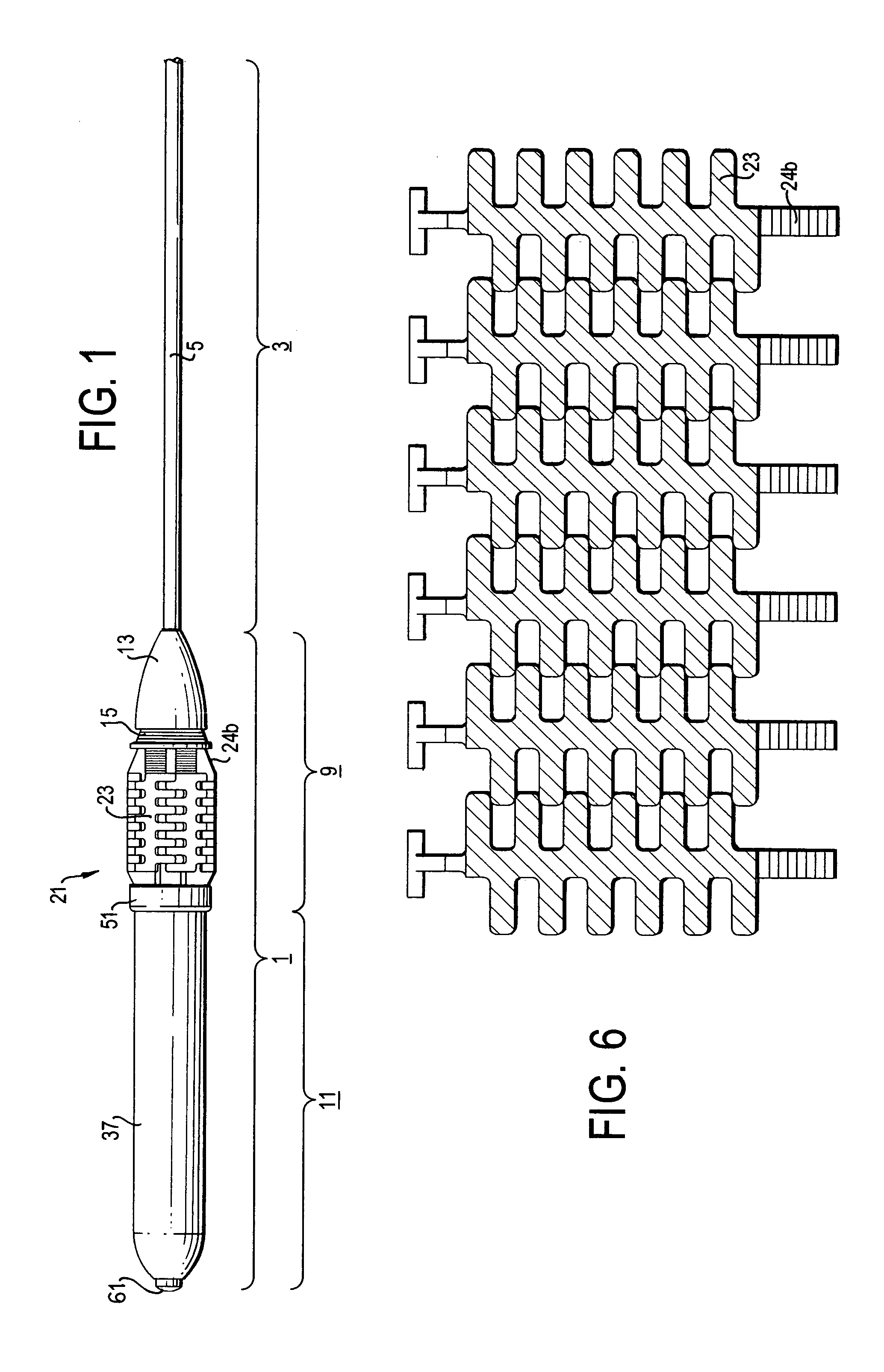

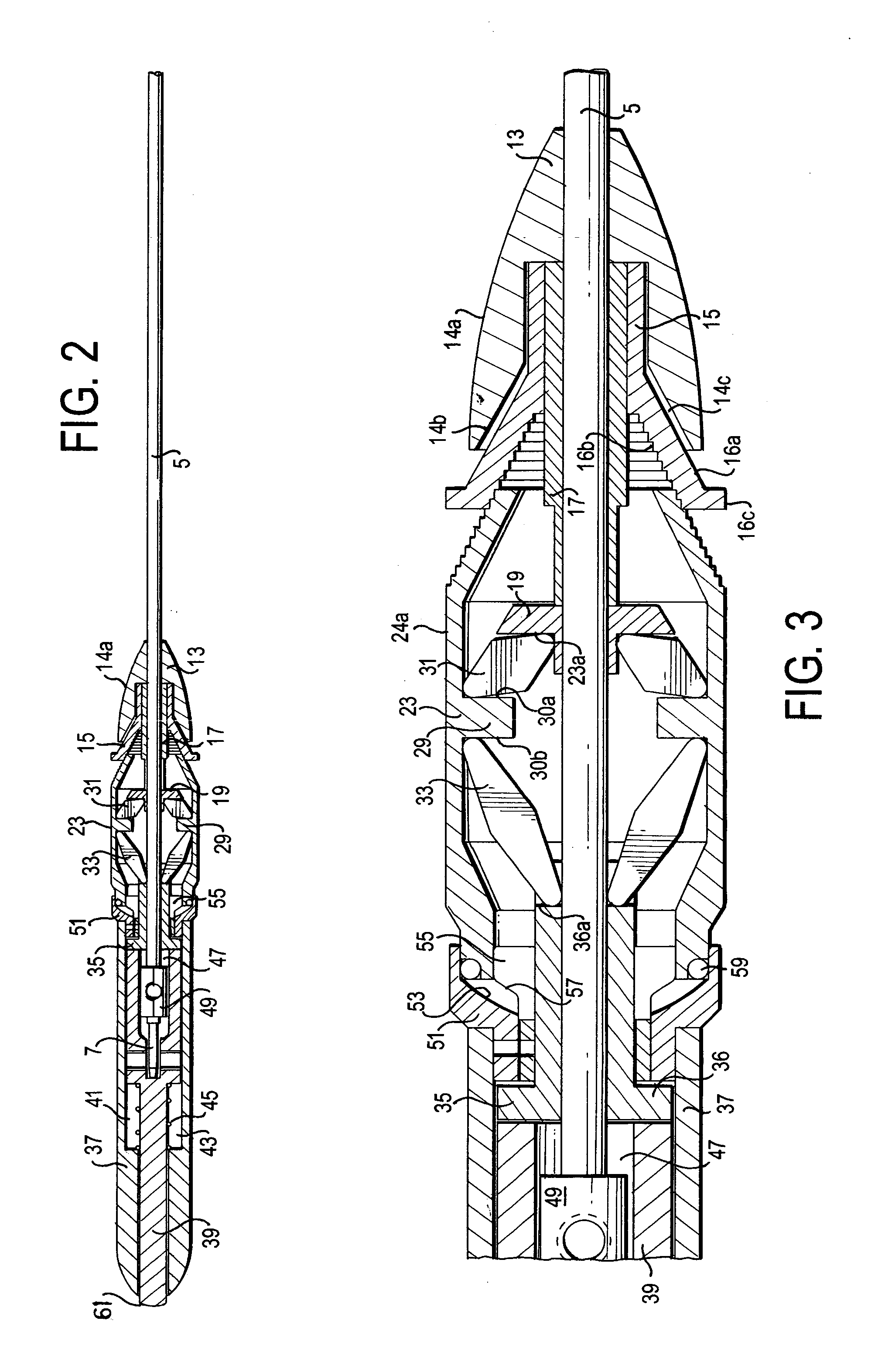

Actuating and locking mechanism for a surgical tool

InactiveUS7004957B1Less sensitiveRealize fine controlInfusion syringesIntravenous devicesSurgical operationRest position

An actuating mechanism for actuating a surgical tool of a surgical instrument including an actuating device having an actuator surface. The actuating device is operable by applying a force to substantially any part of the actuator surface for placing the actuating device in an actuated position from a rest position for actuating a surgical tool. The actuator surface comprises a radially collapsible cage having a plurality of interdigitating actuating pads. Each pad is movable in a radial direction.

Owner:SYCLIX

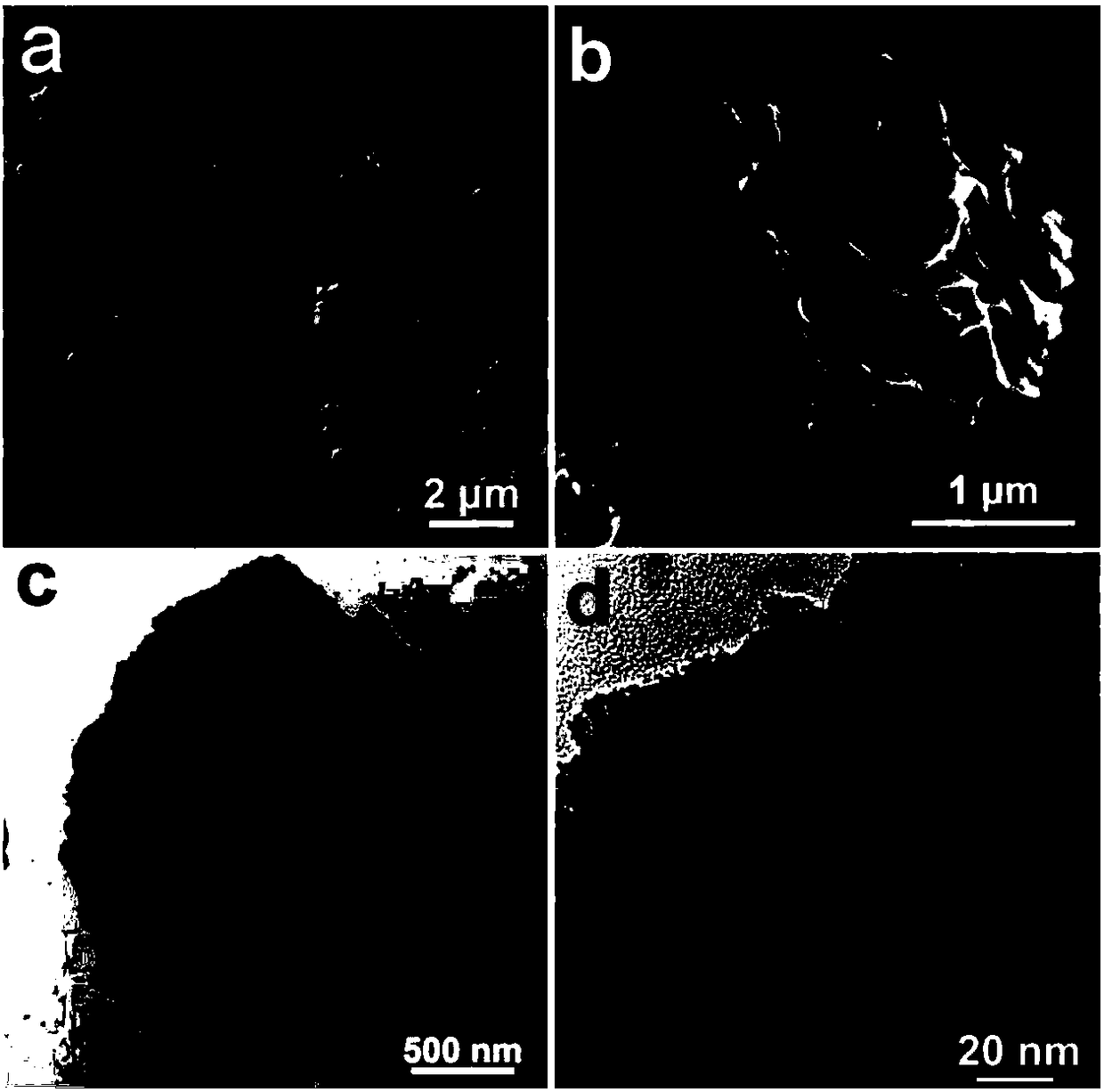

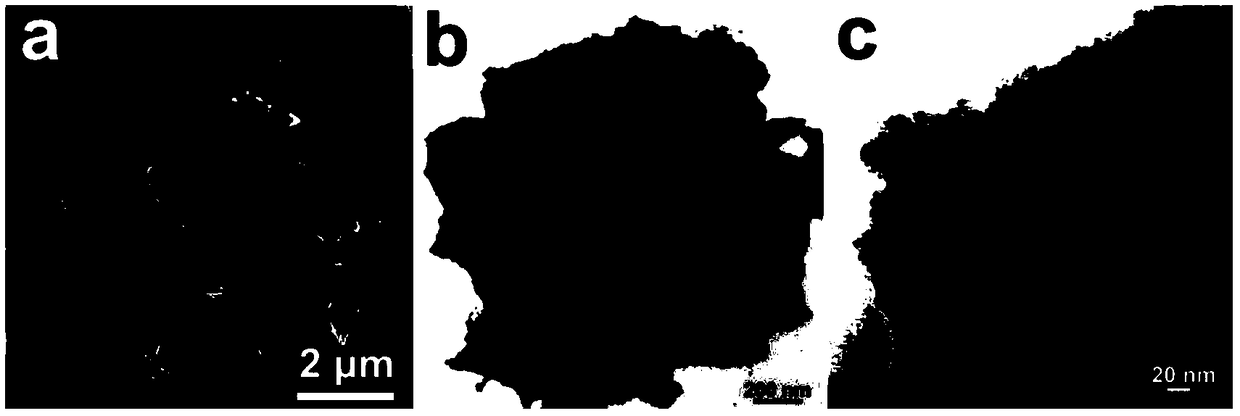

Three-dimensional compound structure based on three-dimensional MXene and general synthesis method thereof

ActiveCN108516528AReduce energy consumptionEasy to control versatilityNitrogen-metal/silicon/boron binary compoundsTitanium carbideSolventSolid phases

The invention discloses a general synthesis method of a three-dimensional compound structure based on three-dimensional MXene, and belongs to the field of nano materials. The three-dimensional compound structure is composed of a three-dimensional MXene load inorganic nano structure and is of a flower-like hierarchical porous structure. The method comprises the steps that an ultrasonic atomizer isadopted for atomizing mixed suspension liquid of three-dimensional MXene particles, metal salt and an auxiliary into aerosol micro-droplets, and under inert or reactive atmosphere, high-temperature fast drying is conducted to obtain the three-dimensional compound structure with controllable structure and size; or the three-dimensional MXene particles and metal salt or a nonmetallic compound are evenly mixed in solvent or in a solid-phase mode to obtain a mixture, and high-temperature calcination is conducted under the inert or reactive atmosphere to obtain the three-dimensional compound structure with controllable structure and size. By means of the three-dimensional compound structure based on the three-dimensional MXene, the problems of inorganic nano material particle aggregation, poorconductivity and two-dimensional MXene stacking can be solved, and thus a foundation is laid for preparation, processing and various aspects of application of a MXene-based high-performance functionalmaterial.

Owner:DALIAN UNIV OF TECH

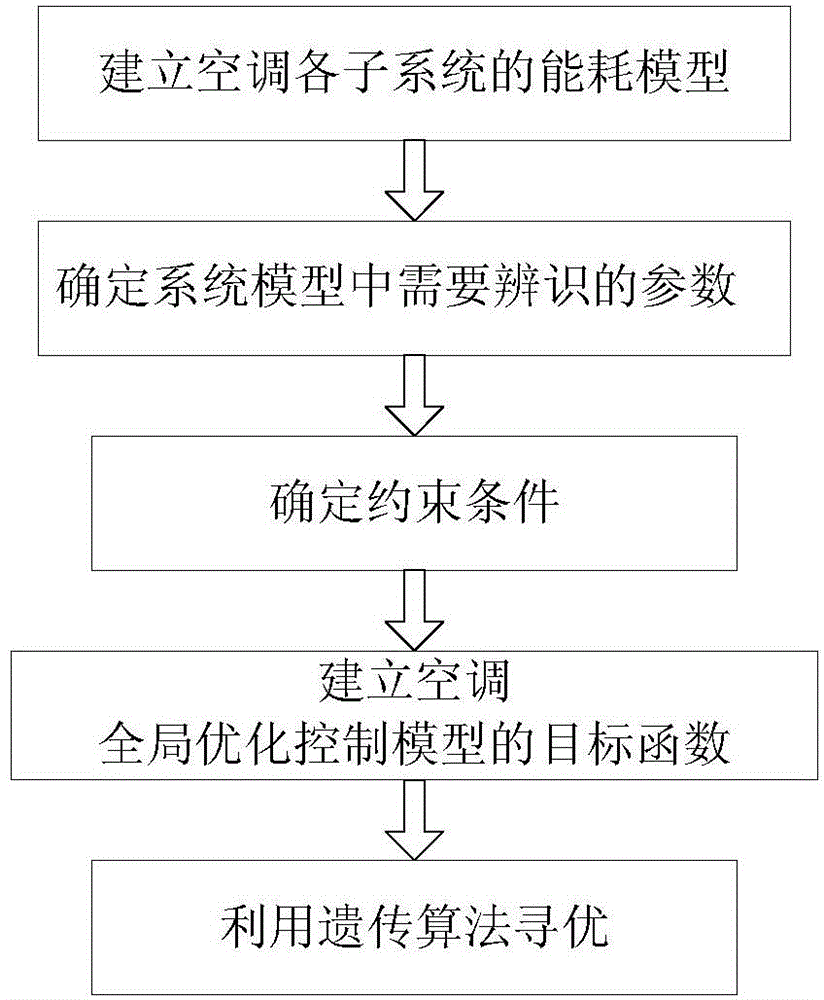

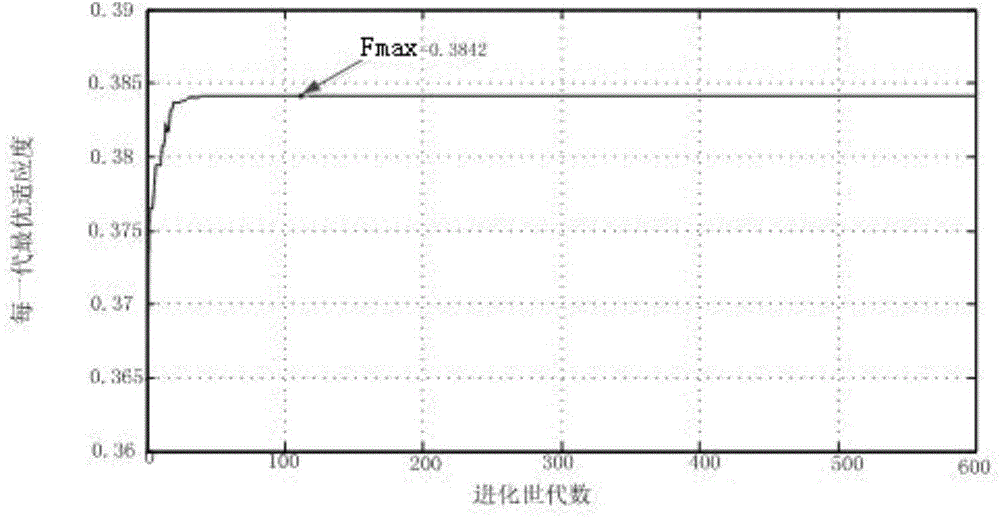

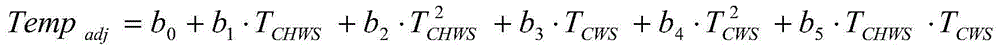

Central air conditioner fine control method

ActiveCN104613602AReduce power consumptionRealize fine controlMechanical apparatusSpace heating and ventilation safety systemsGenetics algorithmsGlobal optimization

The invention discloses a central air conditioner fine control method. The method includes the steps of establishing energy consumption models of all sub-systems of an air conditioner, determining parameters to be recognized in the models of all the sub-systems, determining constraint conditions, establishing a target function of a global optimization control model, and conducting optimizing through a genetic algorithm. Modeling is conducted for energy consumption of a central air conditioning system, and the power consumed when the central air conditioning system runs in a working state of the capacity smaller than the rated capacity is reduced through the genetic algorithm; through the cooperation of various control strategies, the all-directional air conditioner fine control is achieved, the energy conservation scheme is more comprehensive and exquisite, and the energy conservation effect is more remarkable.

Owner:HOHAI UNIV

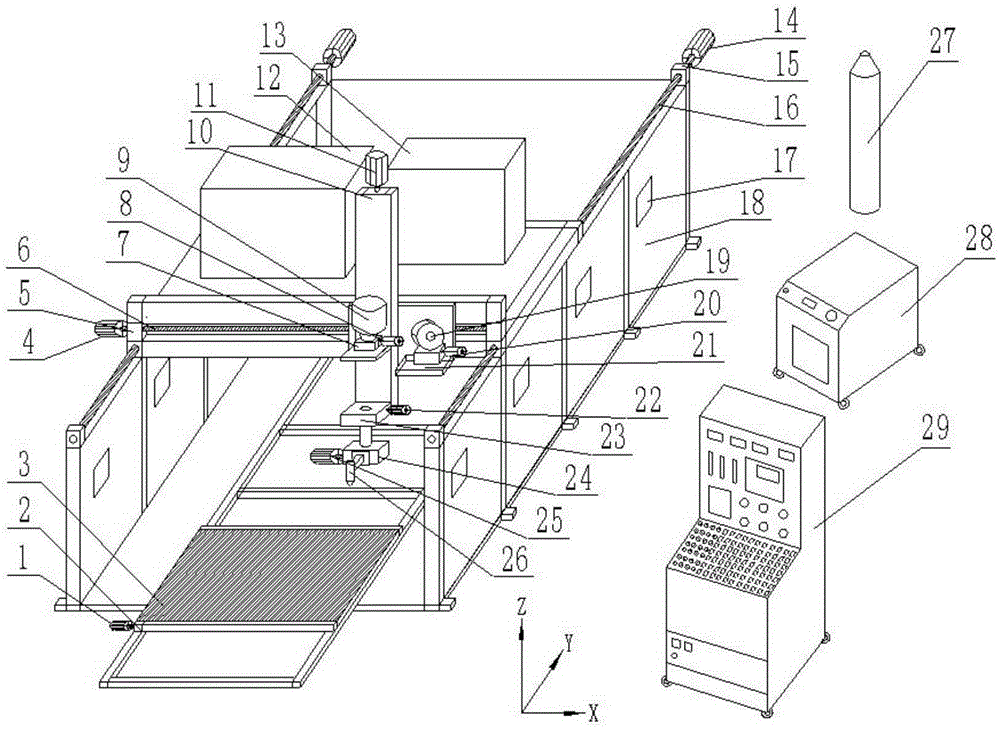

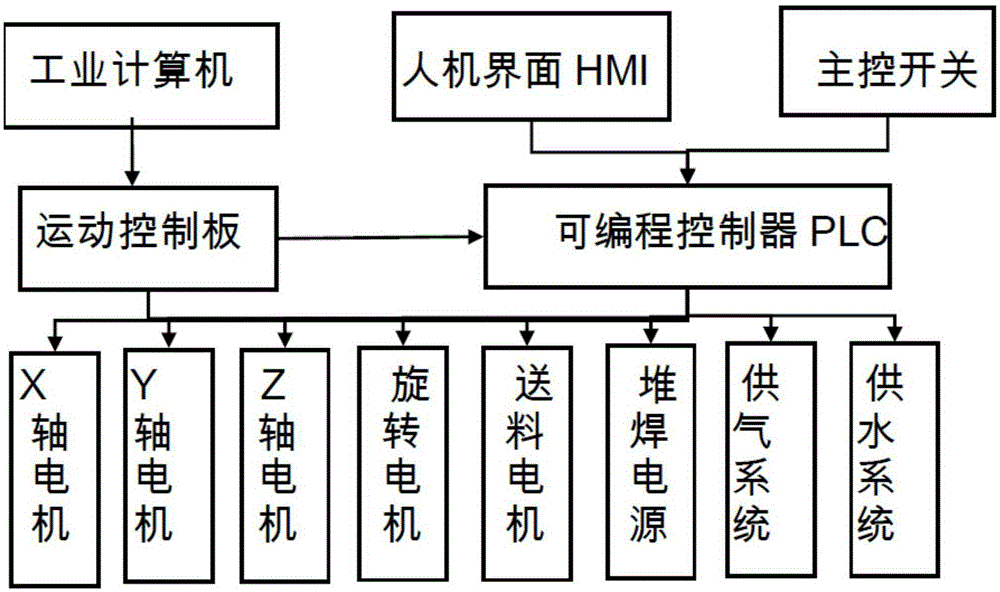

Gantry type high-power plasma arc 3D printing equipment and method

ActiveCN105234538AImprove printing efficiencyEasy to usePlasma welding apparatusHuman–machine interfaceDesign control

The invention discloses gantry type high-power plasma arc 3D printing equipment and a method. The printing equipment comprises a gantry type structure frame and elevated bearing walls, wherein a gantry platform of the frame is mounted at the upper ends of the elevated bearing walls at two sides. The printing equipment further comprises a printing machine head, a printing molding platform, an X-axle motion component, a Y-axle motion component, a Z-axle motion component, a powder feeding mechanism, an oscillator, a printing machine head rotating mechanism, a wire feeding device, a surfacing power supply and an electric cabinet. The printing method comprises the steps of three-dimensional modeling, layered slicing, process preparation and real-time printing. The plasma arc above 10kw is used for melting fed metal powder or wires to finish the 3D printing of large products under predesigned control programs, so that the 3D printing efficiency is greatly improved; the whole system adopts the full-digital control, and is provided with self-inspection and warning systems; and main process parameters are set by a human-computer interface, so that the use and the maintenance of operators are more convenient.

Owner:武汉高力热喷涂工程有限责任公司

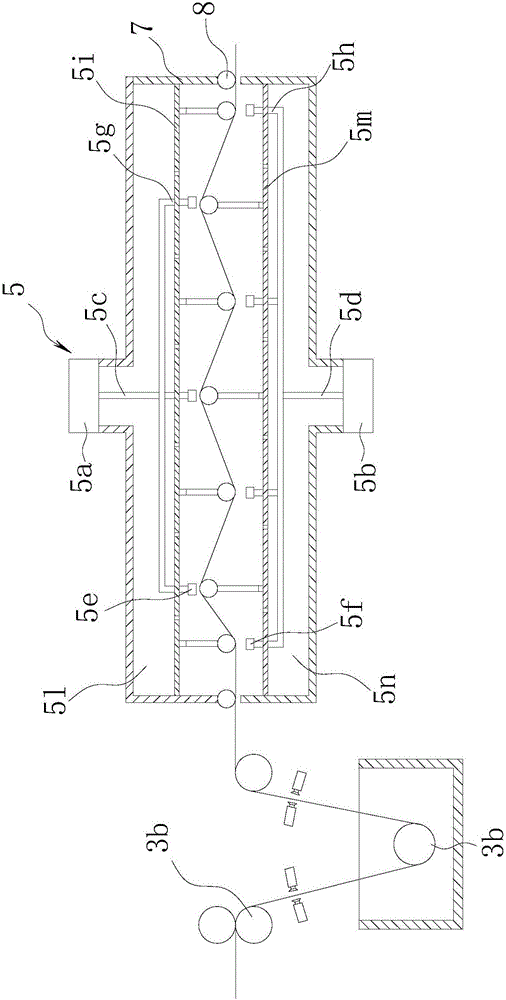

Device for removing copper powder on copper foil and application method of device

ActiveCN105689312ANot easy to damageNot easy to discountCleaning using liquidsHeating arrangementEngineeringCopper foil

The invention discloses a device for removing copper powder on a copper foil and an application method of the device, and belongs to the technical field of copper foil cleaning. The technical points of the device include that a cleaning mechanism and a plurality of drying mechanisms are arranged in order between an unwinding roll and a winding roll along a horizontal direction, and a copper foil orderly passes through the cleaning mechanism and all the drying mechanisms along the horizontal direction. Each drying mechanism is connected with a control unit, and is composed of a housing, a feeding hole and a discharge hole that are separately arranged in two sides of the housing, and an air-floating heating mechanism and a lifting heating mechanism that are arranged in the housing along a housing length direction. The present invention aims at providing the device, which is convenient to use and good in effect, for removing the copper power on the copper foil. The device is used for removing the copper powder on the copper foil.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

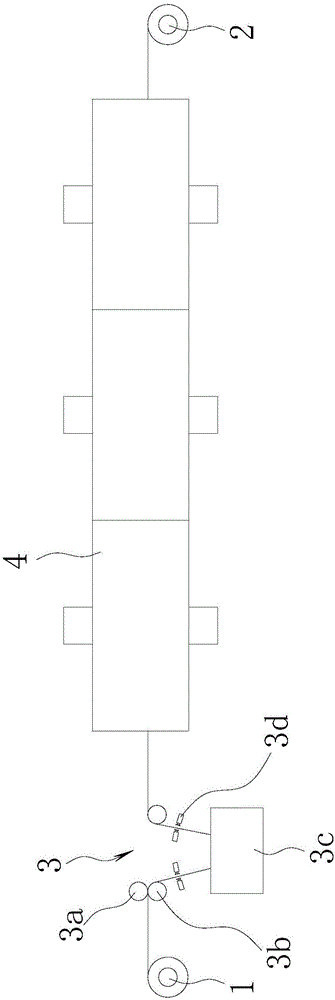

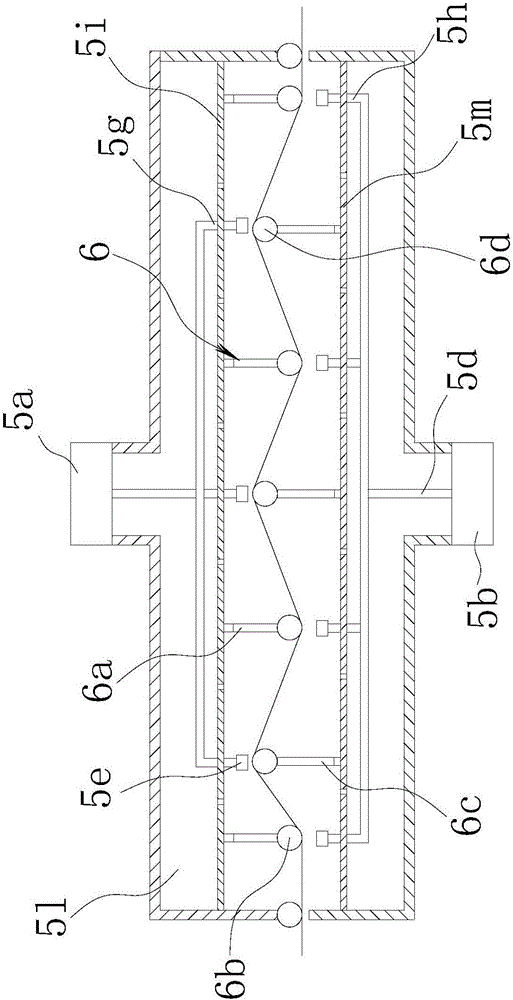

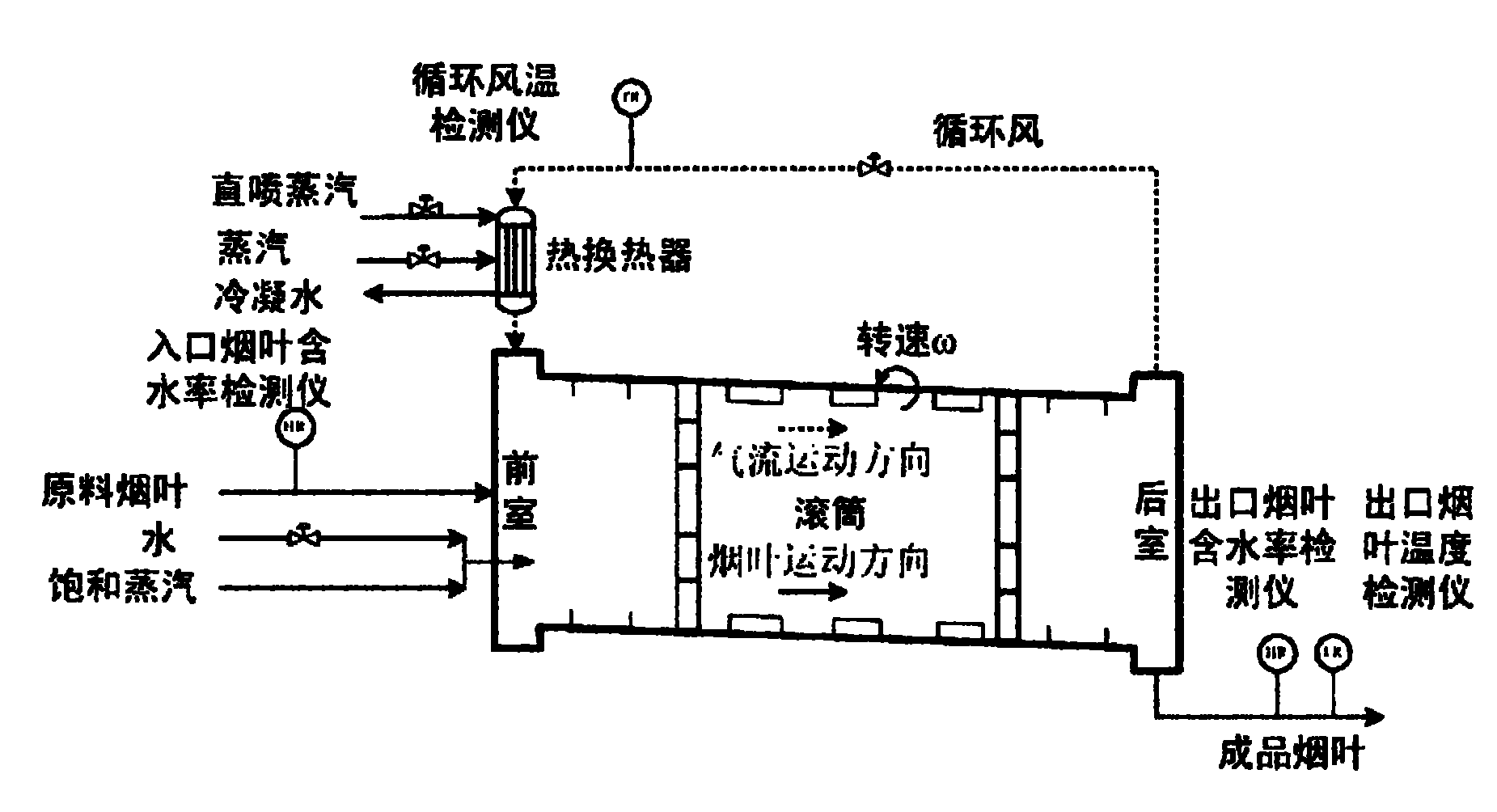

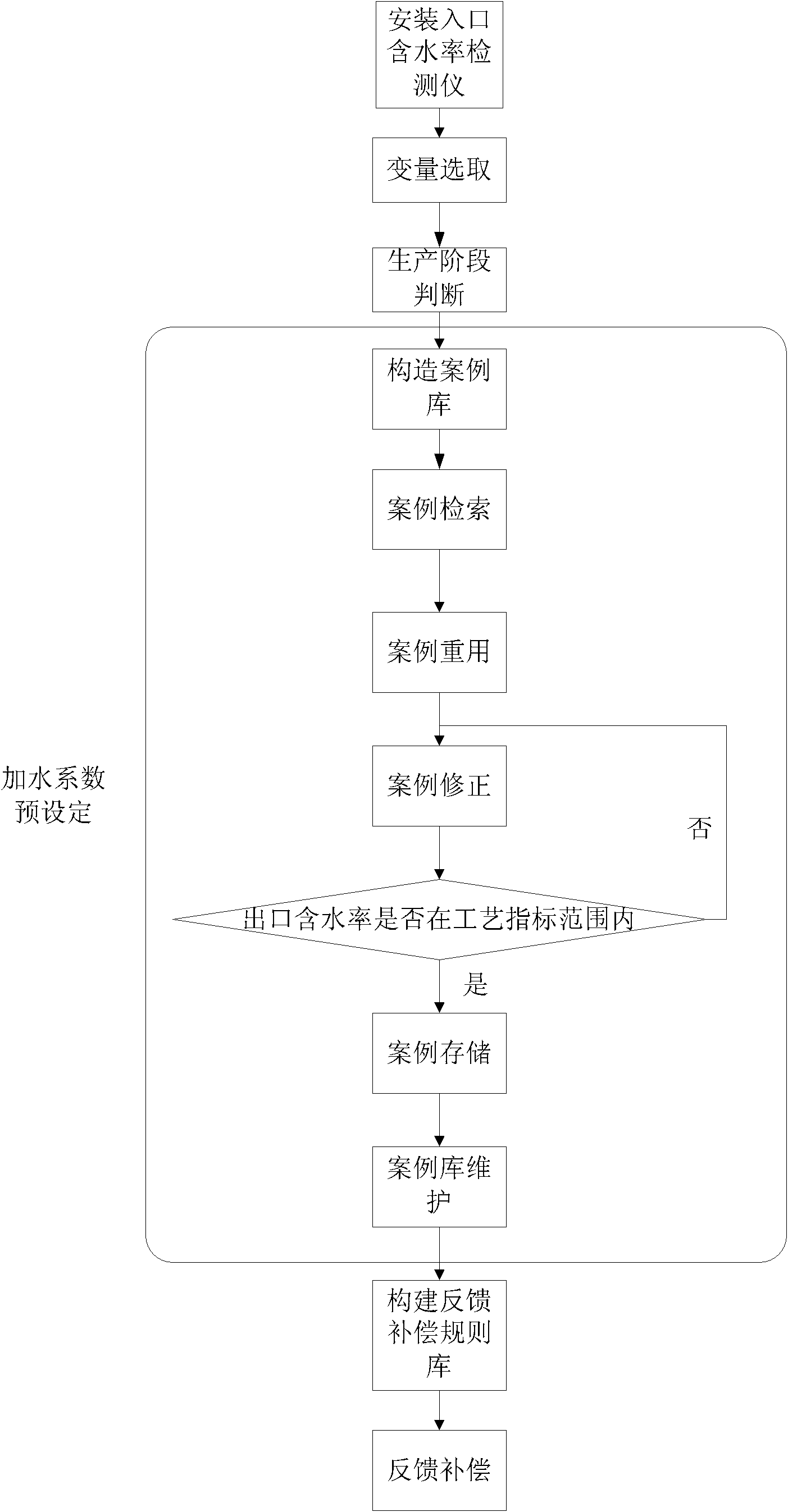

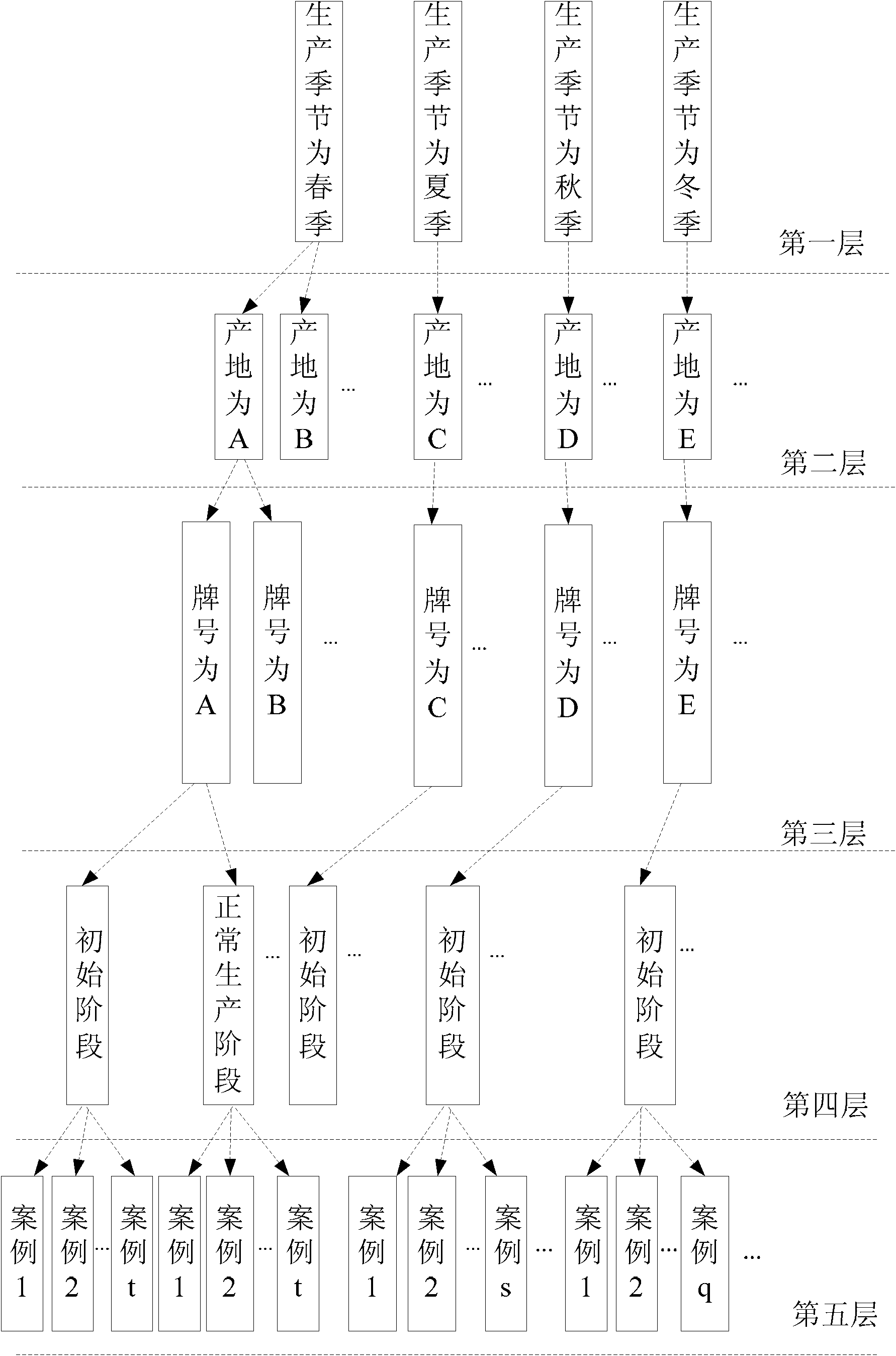

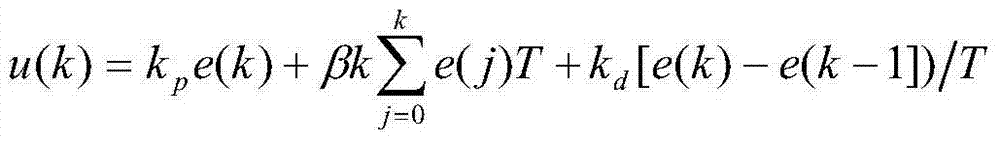

Case reasoning technology-based damping machine intelligent optimized control method

InactiveCN102486630ARealize fine controlReduce labor intensityTobacco preparationAdaptive controlProcess engineeringControl theory

The invention relates to a case reasoning technology-based damping machine intelligent optimized control method, which is characterized in that: a moisture detection instrument is added to an inlet of a damping machine and is used for detecting the moisture content of tobacco leaves at the inlet of the damping machine; a water charging coefficient is selected as a direct operating variable, watercharging flow rate sprayed out by a steam-water combined nozzle in the damping machine is used as an indirect operation variable, and the moisture content of tobacco leaves at an outlet of the damping machine is used as a controlled variable; whether the current production stage is a beginning stage, a normal production stage or an ending stage is judged according to tobacco leaves instantaneous flow rate, tobacco leaves accumulated flow rate and charging time information; the water charging coefficient is preset according to the production stage and the tobacco leaves production technical condition information to obtain a water charging coefficient preset value; a feedback compensation rule database is built according to the production technical requirement and an operating mode; and thewater charging coefficient preset value is compensated in a feedback way according to the feedback compensation rule database to obtain an optimized water charging coefficient setup value. The methodovercomes the control difficulties such as tobacco leaves loosening damping process nonlinearity and large time delay.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

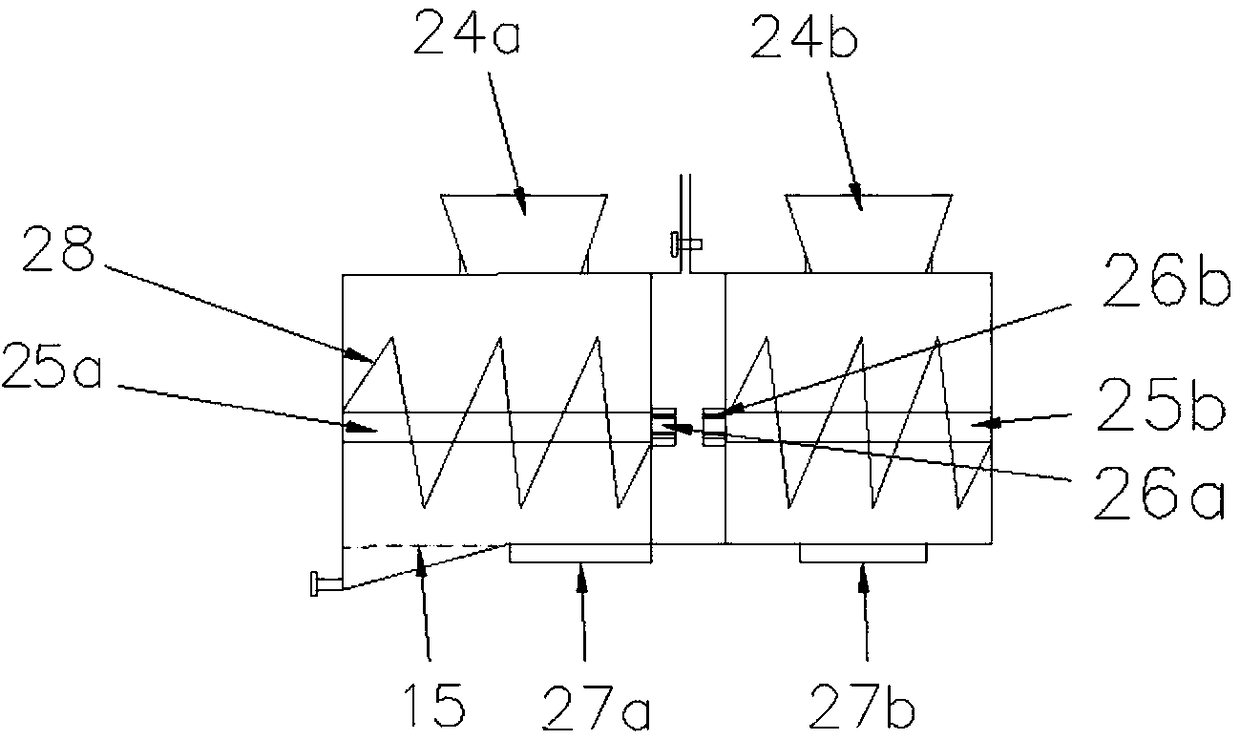

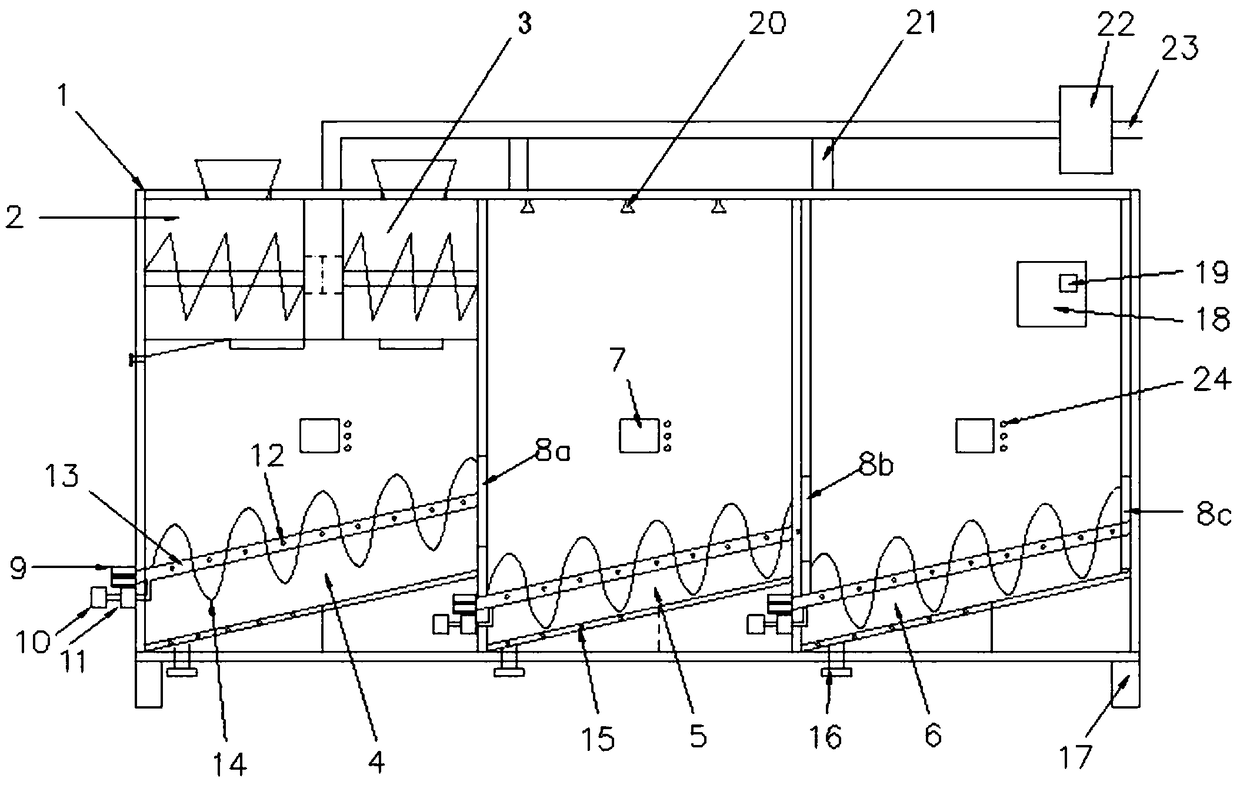

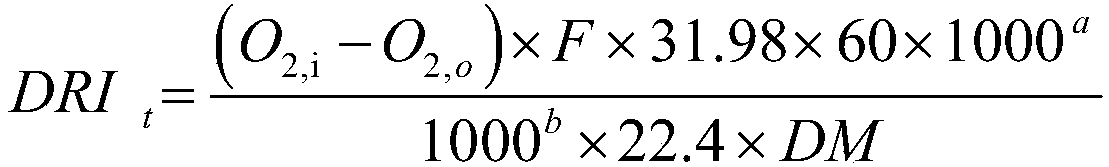

High-efficiency kitchen waste aerobic fermentation equipment

PendingCN109485475ARealize fine controlEffective fermentationBio-organic fraction processingOrganic fertiliser apparatusAutomatic controlAeration system

The invention discloses high-efficiency kitchen waste aerobic fermentation equipment. The equipment comprises a fermentation bin, a grinding and dehydrating system, a stirring and pushing system, a heating system, a biological deodorizing system, an aeration system, a water supply system and an automatic control system. According to the fermentation equipment, kitchen waste compost is divided intofour stages including grinding, heating, high temperature and curing, and parameters of the heating system, stirring system, aeration system and water supply system can be independently set in each stage, so that parameters in three bins can be finely controlled, and effective performance of fermentation can be favored; and the dynamic respiratory index DRI is applied in the kitchen waste fermentation equipment to serve as an index for measuring product maturity, and the quality of mature fertilizer can be finally guaranteed by the advanced monitoring method.

Owner:NANJING UNIV

Porous hydroxyapatite biological ceramic and preparation method thereof

InactiveCN102641523AHigh compressive strengthHigh pore penetration ratePharmaceutical delivery mechanismTissue regenerationFiberWater based

The invention discloses porous hydroxyapatite biological ceramic and a preparation method thereof. The porous hydroxyapatite biological ceramic has the aperture size and distribution, porosity, hole-through condition and hole surface suitable for growth of bone tissues and is provided with macro pores capable of accommodating grown new bones, and the pore wall of the ceramic is provided with rich lamellar pores, so that the ceramic has an effect of conducting the formed bones. The preparation method comprises the following steps of: setting the orientation, the diameter and the distribution density of macromolecular fibers in a mold in advance, and freezing and solidifying water-based hydroxyapatite slurry by using a directional temperature field, so that the hydroxyapatite powder granules are gathered and rearranged under push rejection of directionally grown ice crystal; and performing freeze drying on the obtained ice blank, sublimating the ice crystal, and sintering, so that fine control of a porous micro structure can be realized. The porous hydroxyapatite prepared by using the method has high hole-through rate and high porosity, and is suitable for growth of the bone tissues.

Owner:CENT SOUTH UNIV

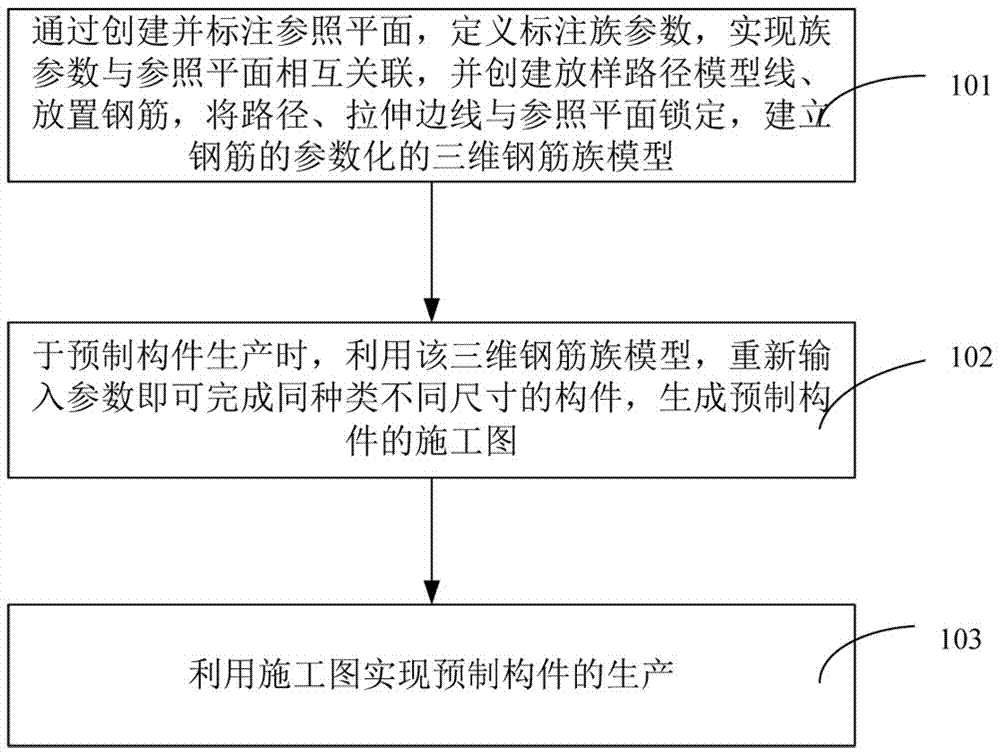

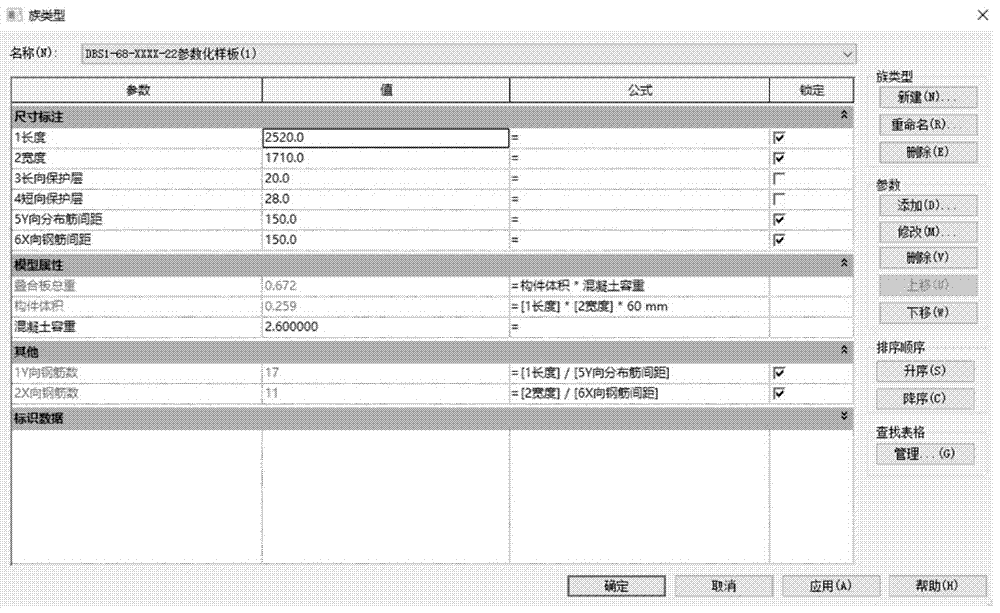

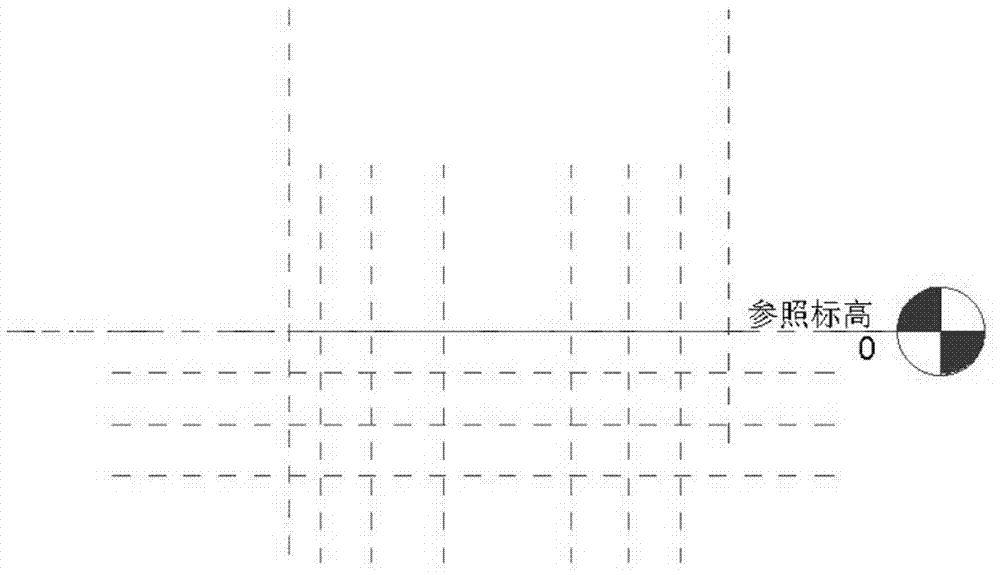

Production method and production system for parameterized steel bars applied to prefabricated components

ActiveCN107220462AImprove production and processing efficiencyRealize fine controlDesign optimisation/simulationSpecial data processing applicationsRebarProduction drawing

The invention discloses a production method and a production system for parameterized steel bars applied to prefabricated components. The production method includes: by means of establishing and labelling a reference plane and defining labelled family parameters, realizing interrelation between the family parameters and the reference plane, establishing lofting path model lines and steel bar placement, locking paths and extension edge lines with the reference plane, and establishing a parameterized three-dimensional steel bar family model for the steel bars; during production of the prefabricated components, by the aid of the three-dimensional steel bar family model, re-inputting parameters to complete size change of same types of the components, and generating a production drawing; by the aid of the production drawing, realizing large-scale and refined production for the prefabricated components. The production method and the production system have the advantages that shape and size of the needed steel bars can be generated quickly by only modifying a few parameters, refined controlling of the steel bars is realized, constraints of inflexible freehand sketching for the steel bars by AutoCAD (automatic computer-aided design) are ridded of, the parameters of the steer bars can be input into various steel bar fabricating facilities directly, and convenience is brought to production and fabrication.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

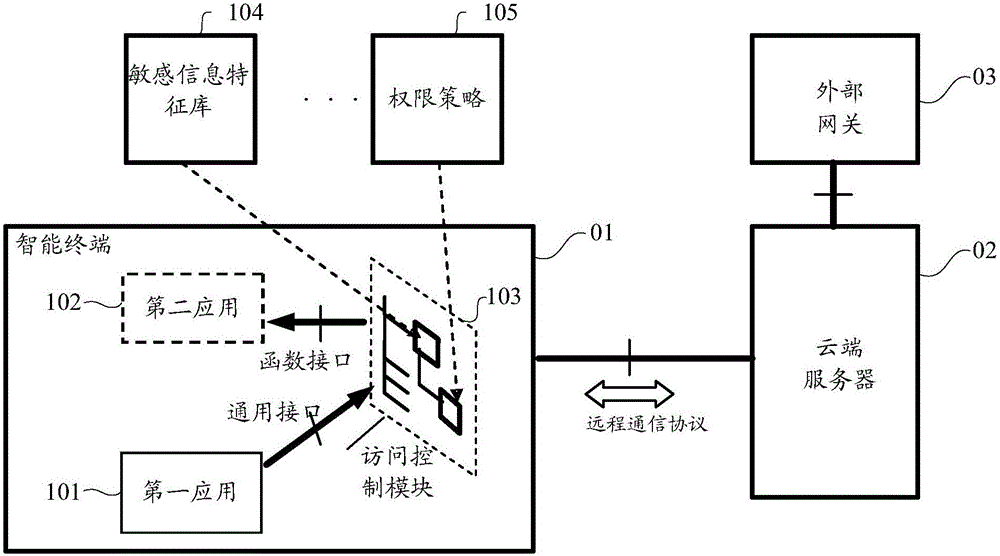

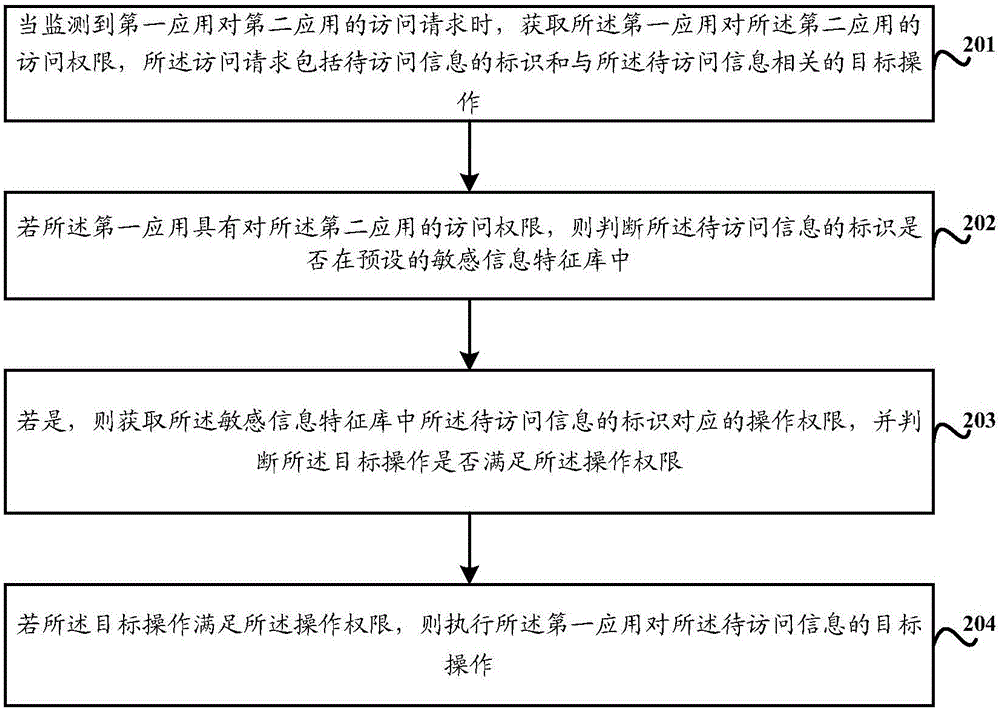

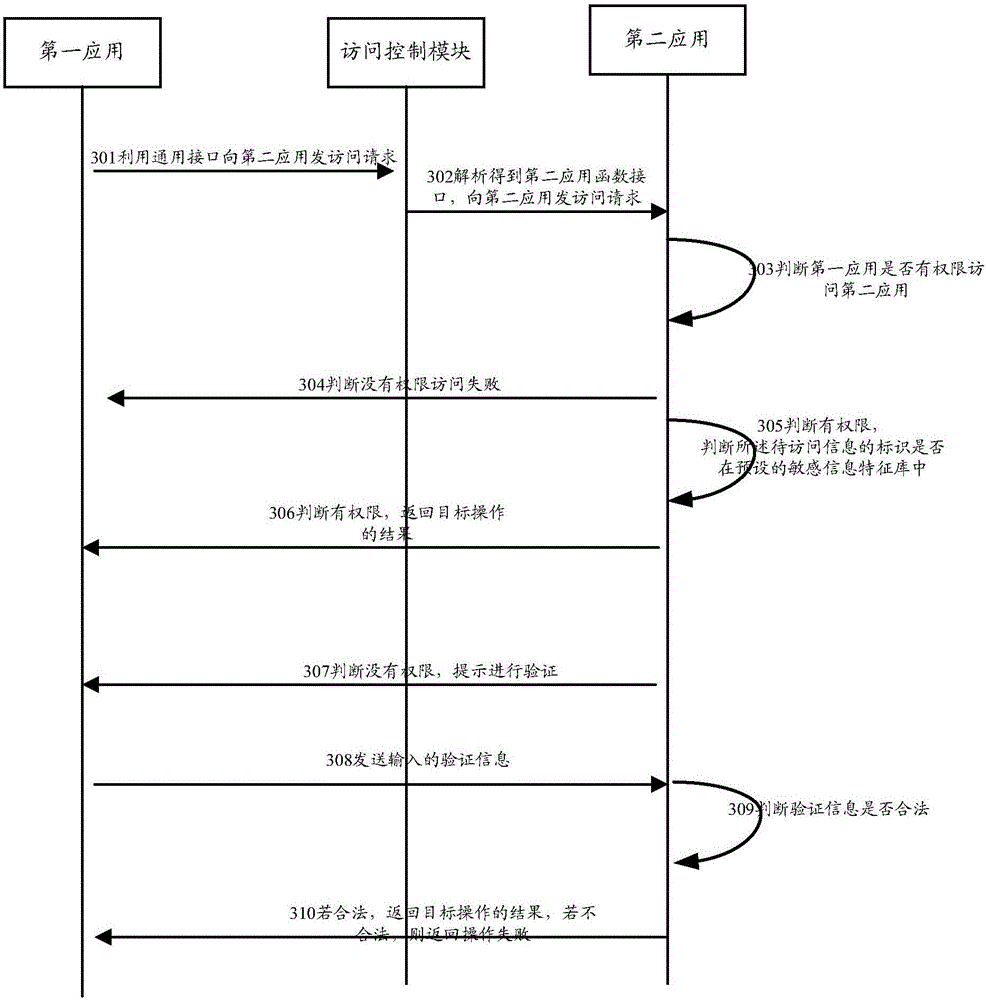

Secure accessing method and device

ActiveCN106330958APrevent unauthorized accessImprove securityTransmissionApplication softwareAccess method

The invention discloses a secure accessing method and device wherein the method comprises the following steps: obtaining the accessing right of a first application to a second application when an accessing request of the first application to the second application is monitored wherein the accessing request includes an identification mark of the to-be-accessed information and operations to targets associated with the to-be-accessed information; determining whether the information mark of the to-be-accessed information exists in a preset sensitive information characteristic database or not if the first application has the access right to the second application; if the information mark of the to-be-accessed information exists, obtaining the operation right to the information mark of the to-be-accessed information from the sensitive information characteristic database and determining whether the operations to relevant targets meet the operation right or not; and if the operations to relevant targets meet the operation right, allowing the first application to operate on the targets of the to-be-accessed information so as to solve the safety hazards that largely exist in the program accessing method in the prior art.

Owner:SHANGHAI CHUANGGONG COMM TECH

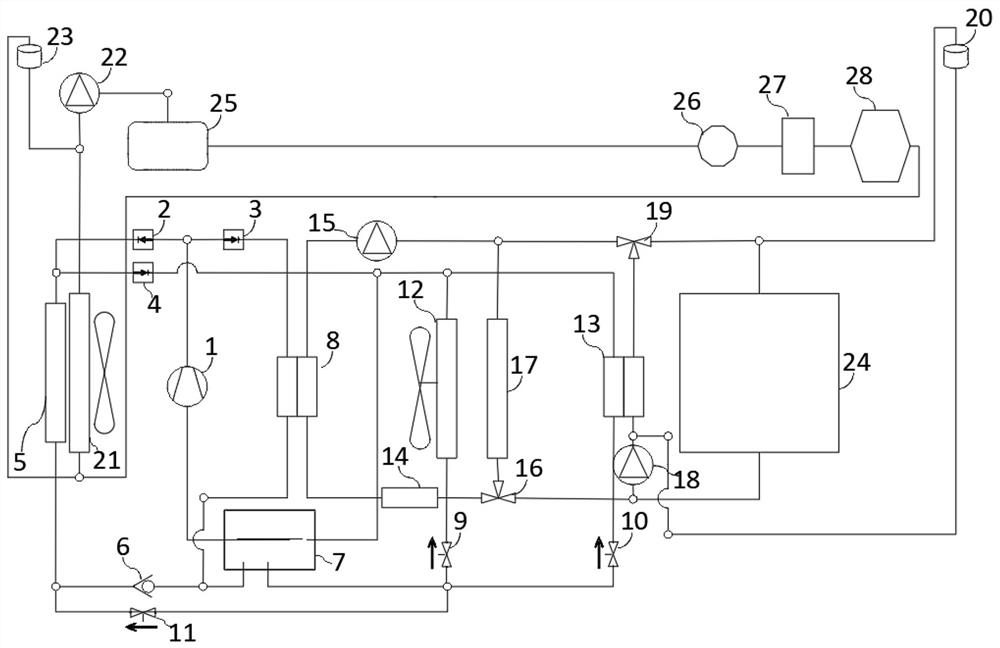

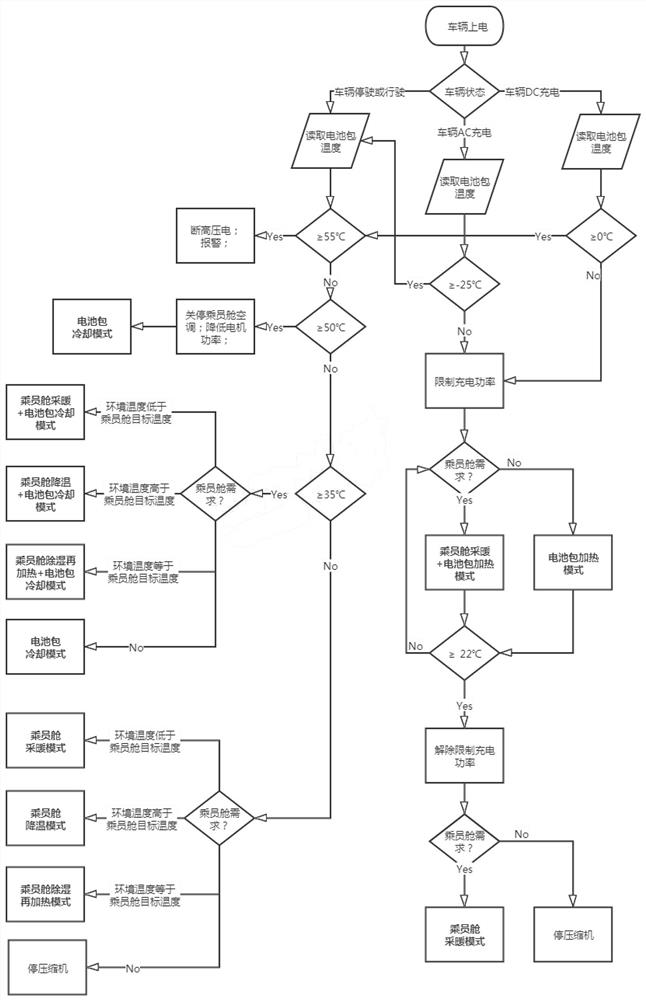

Whole-vehicle thermal management system of electric vehicle and control method of whole-vehicle thermal management system

PendingCN112848842ARealize managementImprove thermal management efficiencyAir-treating devicesElectric propulsion mountingElectrical batteryElectric cars

The invention discloses an electric vehicle thermal management system and a control method thereof, and relates to the technical field of electric vehicle thermal management. The system comprises a heat pump air conditioner loop, a battery pack heat management loop and a motor electric control cooling loop; in theheat pump air conditioner loopa heating loop is used for heating a passenger compartment and a battery pack of the electric automobile, and an electric heater is communicated with a water cooling condenser; the battery pack heat management loop is used for adjusting the temperature of a battery pack in the electric vehicle, and the battery pack heat management loop is communicated with the heating loop; and the motor electric control cooling loop is used for cooling a driving motor of the electric vehicle. The heat pump air conditioner loop, thebattery pack heat management loop and the heat management loop of the passenger compartment are integrated, the purpose of overall management of heat in the passenger compartment and the battery pack is achieved, and the heat management efficiency of the whole vehicle is improved.

Owner:广州高澜创新科技有限公司

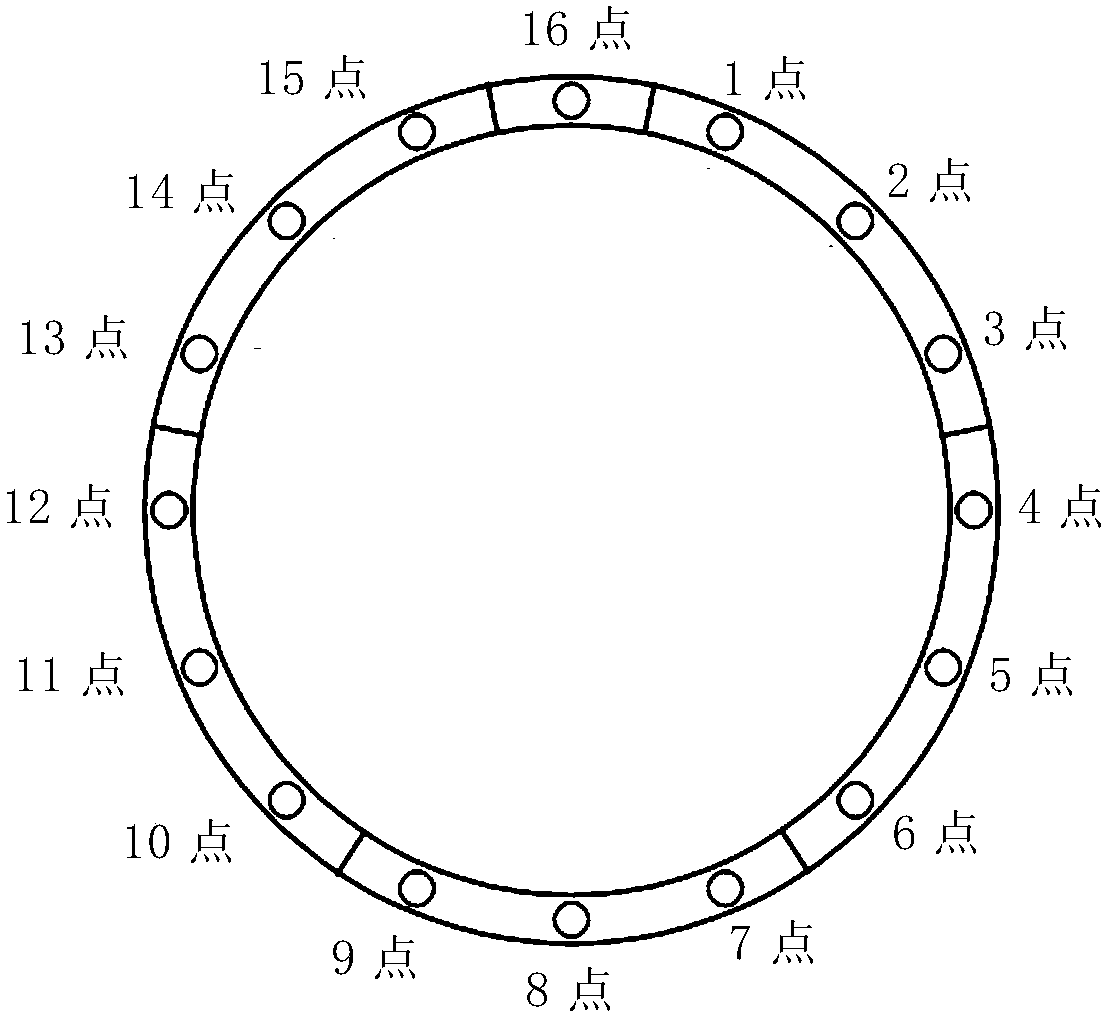

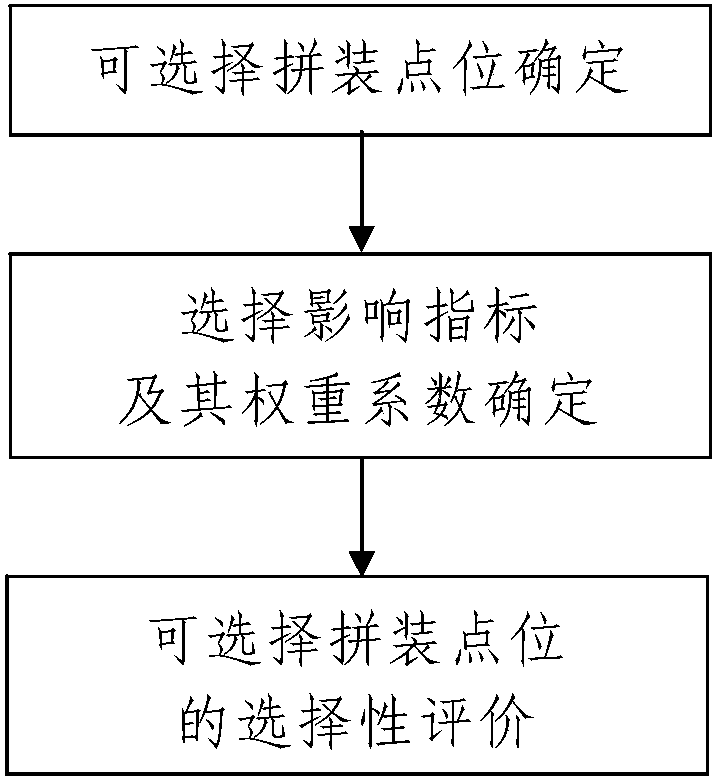

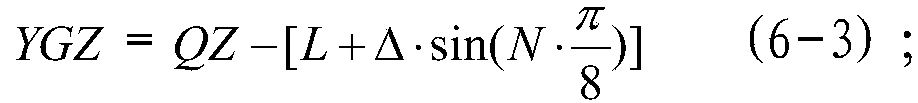

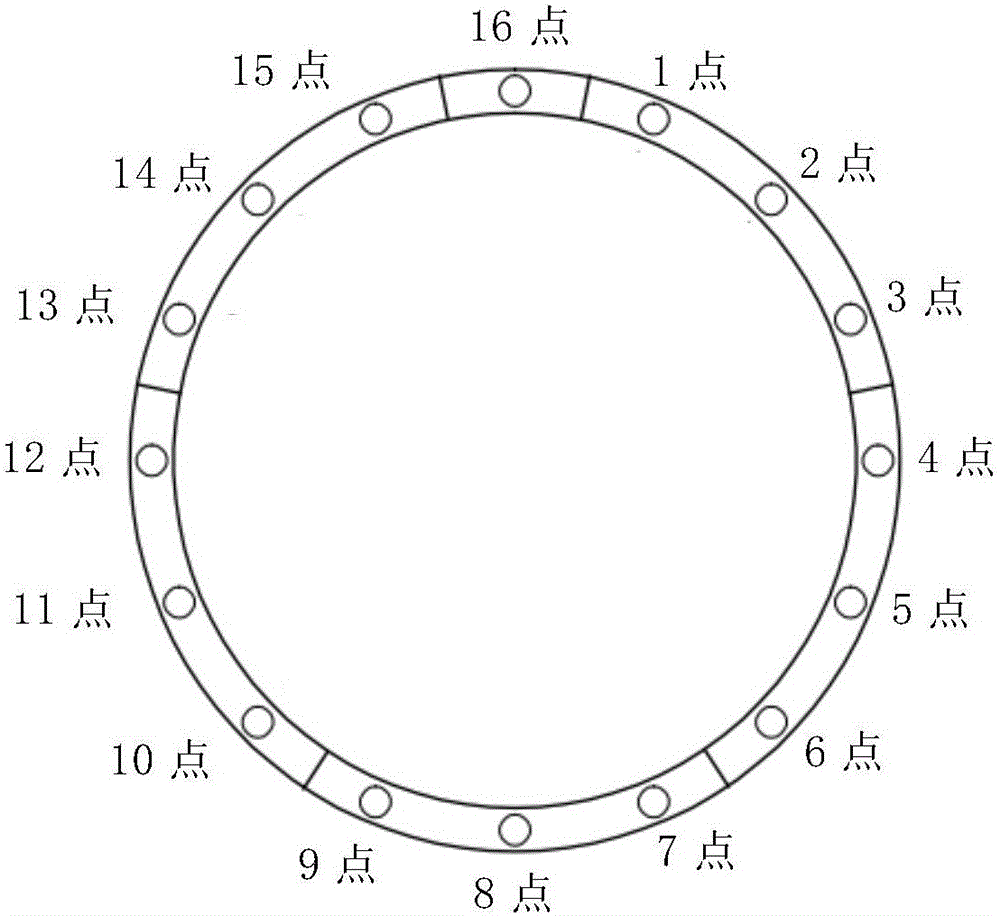

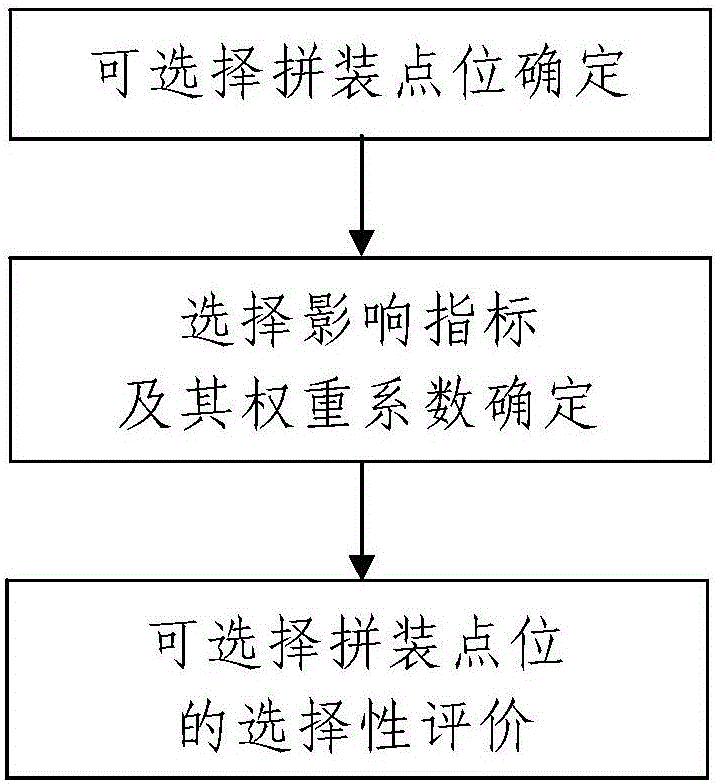

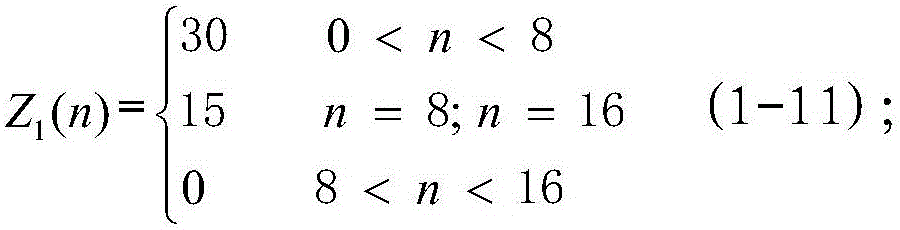

Shield general segment assembling point location determining method

ActiveCN107725067AThe method steps are simpleLow input costUnderground chambersResourcesWeight coefficientEngineering

The invention discloses a metro shield construction general segment assembling point location determining method. A shield tunneling machine is used for conducting shield tunneling construction on a construction tunnel along a tunnel central axis from back to front. After the shield tunneling construction is completed for one link, shield segment assembling construction is carried out. Before anylink of shield segment assembling construction is performed, first of all, segment assembling point locations of current shield segments are determined. Processes include the following steps that firstly, selectable assembling point locations are determined; secondly, selection influence indexes and weight coefficients of the selection influence indexes are determined, and the three selection influence indexes and the weight coefficients of the three selection influence indexes influencing segment assembling point location selection are determined separately; thirdly, the selectable assemblingpoint locations are selectively evaluated, wherein according to a weight coefficient method, the selection of all the selectable assembling point locations is evaluated separately, and the segment assembling point locations of the current shield segments are determined. The shield general segment assembling point location determining method is simple in step reasonable in design, convenient to achieve, good in using effect and capable of conveniently, fast and precisely determining the assembling point locations of the general segments.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

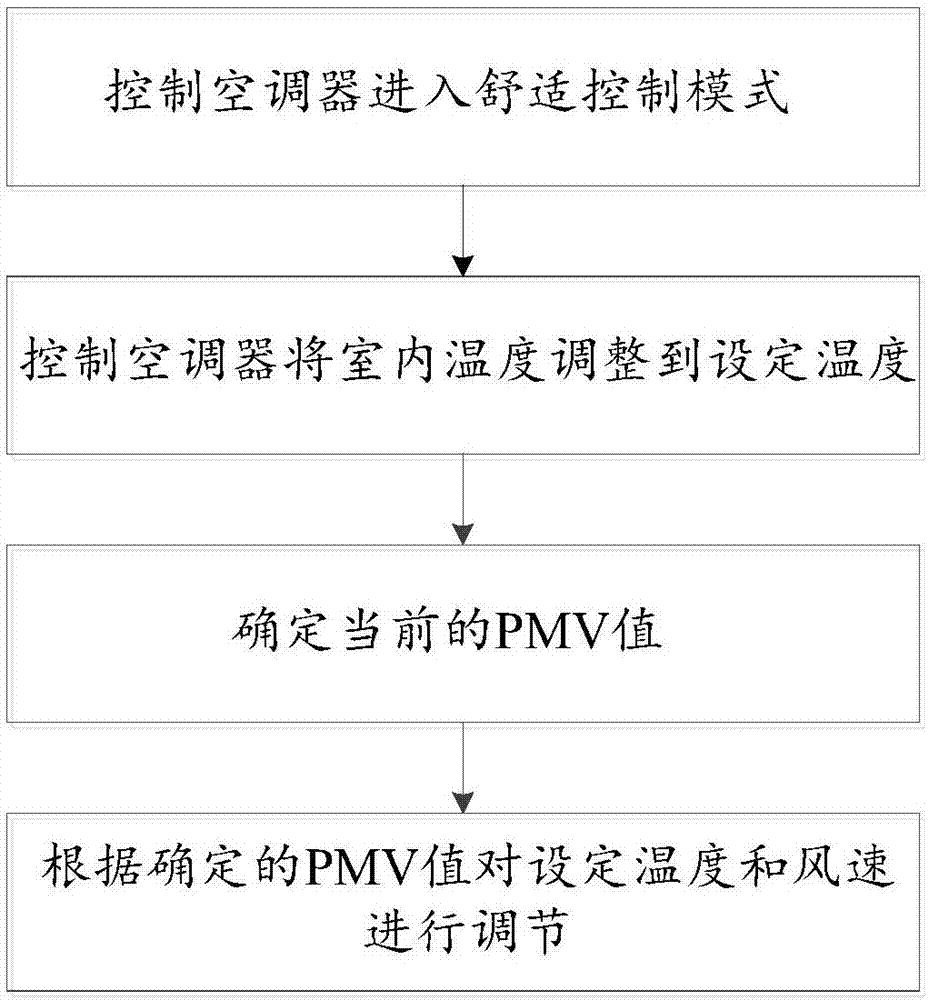

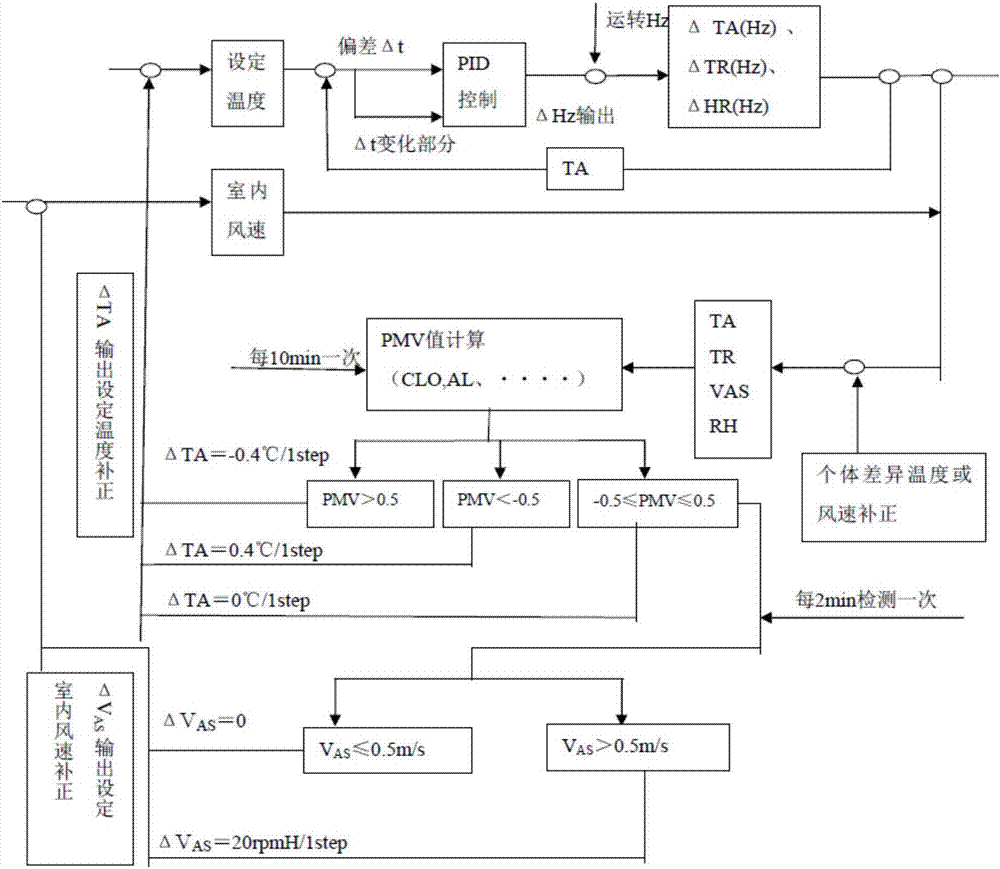

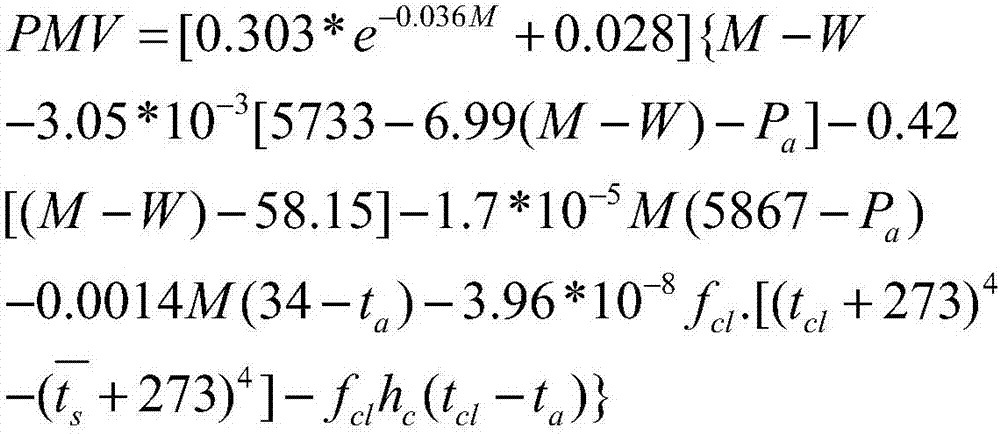

Control method of air conditioner

ActiveCN106871360AEnergy saving controlRealize energy-saving controlMechanical apparatusSpace heating and ventilation safety systemsEnergy consumptionControl mode

The invention discloses a control method of an air conditioner. The control method includes the steps that the air conditioner is controlled to operate in a comfort control mode; the air conditioner is controlled to adjust the indoor temperature to a set temperature; the current PMV value is determined; and the set temperature and the air speed are adjusted according to the determined PMV value. According to the control method of the air conditioner, the air conditioner can be made to meet the requirement of a user for comfort, and meanwhile, the air conditioner can operate in an energy saving mode, so that energy consumption is lowered.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +2

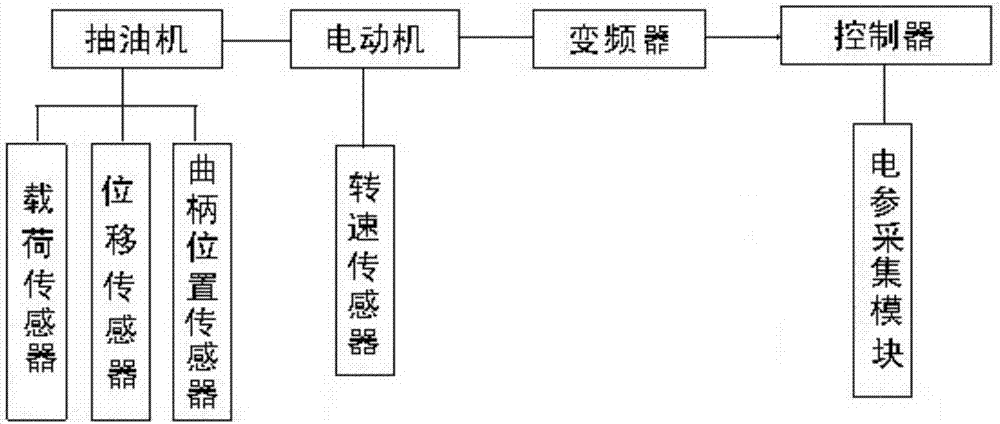

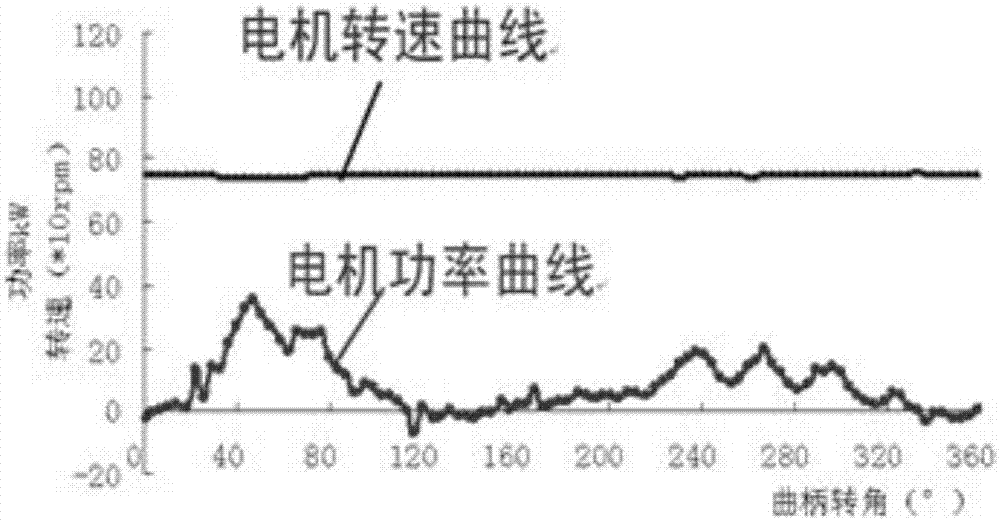

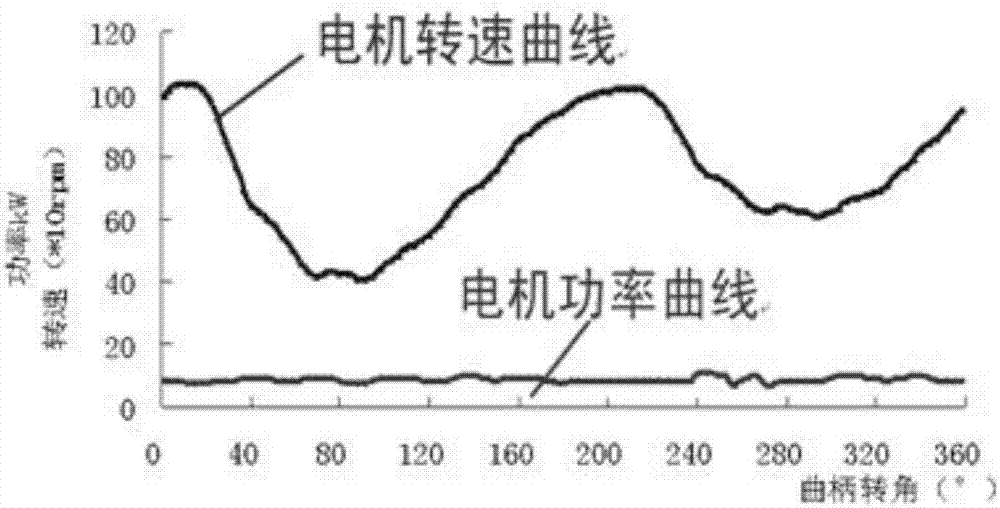

Control device and method for intermittent pumping of oil pumping unit without shutting down

ActiveCN106948796AMeet supply and production coordinationImprove operational efficiencyConstructionsFluid removalFrequency changerCrank

The invention provides a control device for intermittent pumping of an oil pumping unit without shutting down. The control device comprises a controller, a frequency converter, an electromotor and the oil pumping unit which are electrically connected in sequence. An electric parameter collecting module is arranged on the controller. A rotating speed sensor is arranged on the electromotor. A load sensor, a displacement sensor and a crank position sensor are arranged on the oil pumping unit. For a low-liquid-amount and intermittent liquid outlet well, the control device provides the most reasonable control method according to the actual liquid outlet situation to meet supply-production coordination of the oil well, so that fine control is achieved, the operation efficiency of an oil well system is improved, energy consumption is lowered, automatic, safe and unattended intermittent pumping operation of a well field is achieved, and the problems of large management difficulty and time and labor consuming of site manual intermittent pumping are solved.

Owner:PETROCHINA CO LTD

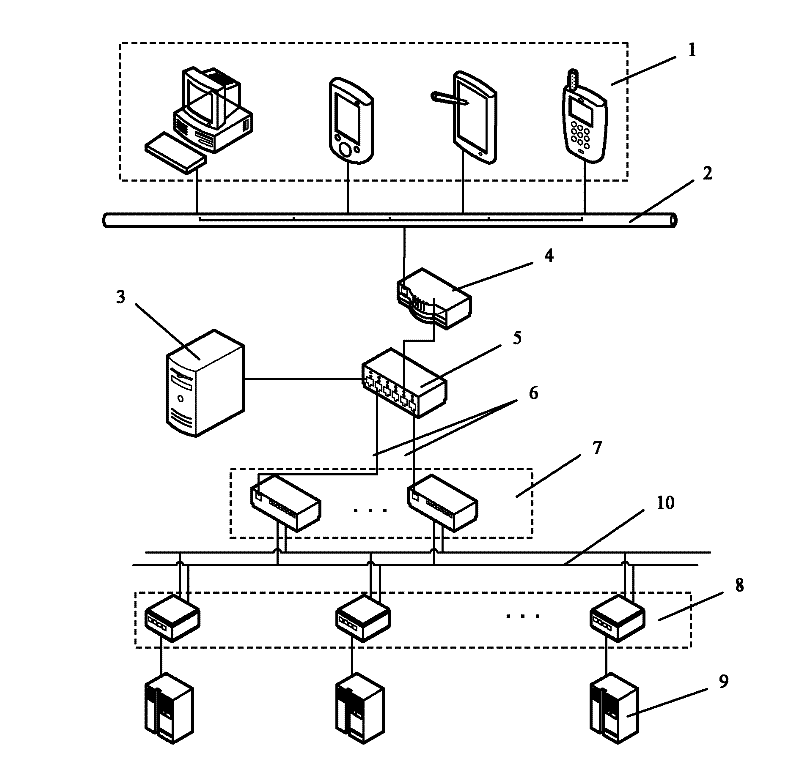

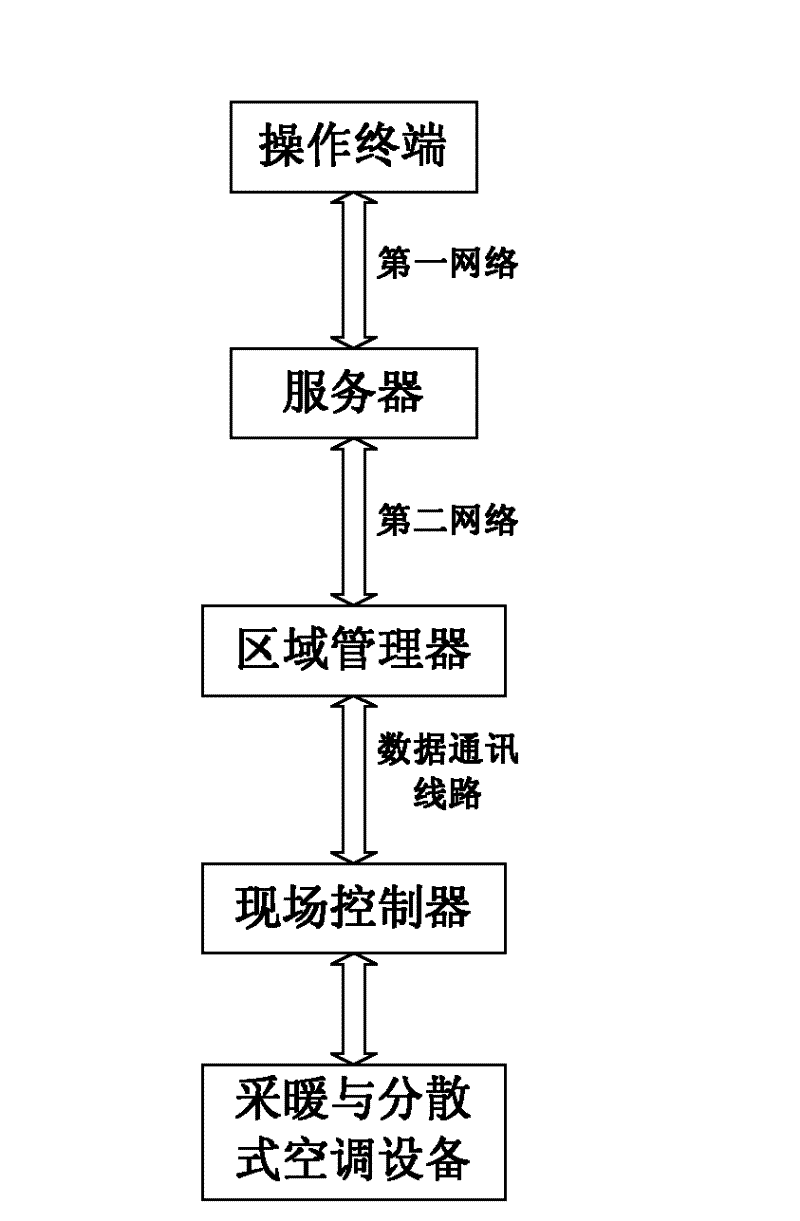

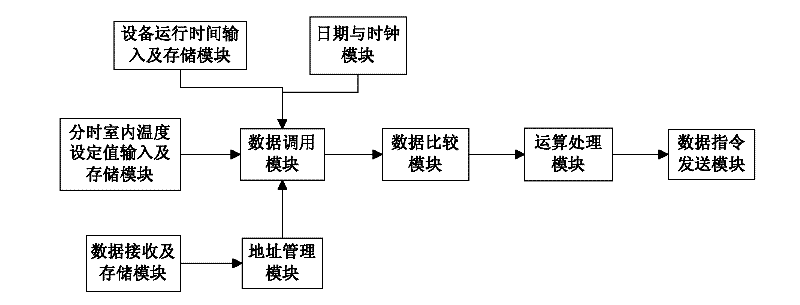

Heating and decentralized air-conditioning system for teaching or office building and control method

ActiveCN102411346ARealize fine controlAvoid wastingProgramme total factory controlRoom temperatureEngineering

The invention discloses a heating and decentralized air-conditioning system for a teaching or office building and a control method; in the system, an operation terminal is connected with a server through a first network; the server is connected with a regional manager group through a second network; all regional managers are connected with all on-site controllers in corresponding on-site controller groups through data communication lines; all the on-site controllers are arranged in all the rooms of the teaching or office building; all the on-site controllers are connected with radiators in the rooms; radiator electric two-way valves are arranged on hot water inlet pipes of the radiators; the method comprises the steps that: centralized control is realized by networking, so that heat supply, room temperature as well as heating and decentralized air-conditioning of all the rooms in the teaching or office building are controlled in real time, the heating or refrigeration speed is high, the automation of heating and decentralized air-conditioning of the teaching or office building can be effectively improved, the purpose of energy saving is achieved, and heating or refrigeration are truly realized.

Owner:GUANGZHOU YUANZHENG INTELLIGENCE TECH

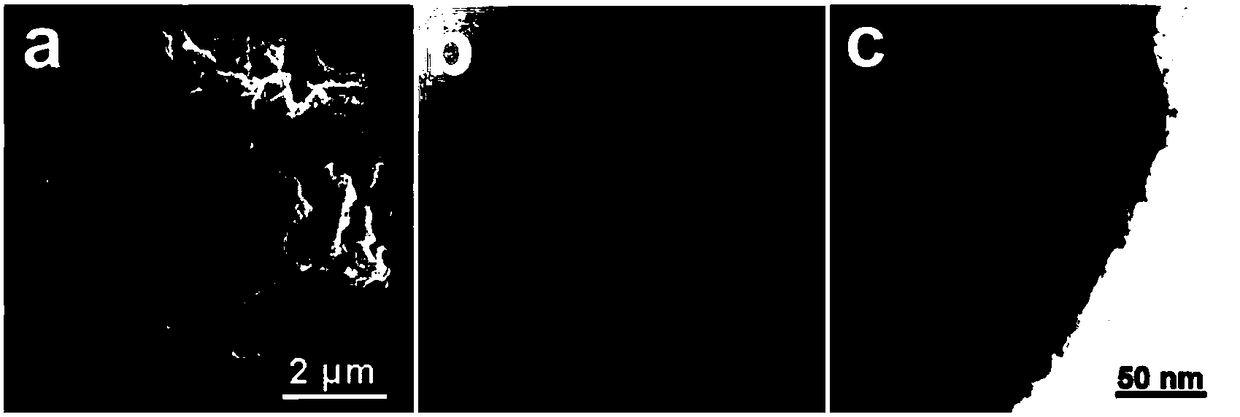

Sodium ion battery cathode material based on MXene and pseudocapacitance transition metal oxide nano composite structure, and synthetic method

ActiveCN110061228AImprove conductivityFull performance of magnificationMaterial nanotechnologyCell electrodesNano structuringSodium-ion battery

The invention discloses a sodium ion battery cathode material based on an MXene and pseudocapacitance transition metal oxide nano composite structure, and a synthetic method, and belongs to the technical field of new materials. The sodium ion battery cathode material consists of a carbon coated MXene two-dimensional nano sheet uniformly loaded with pseudocapacitance transition metal oxide nano particles on the surface, and has a two-dimensional nano structure. The synthetic method comprises the steps of dissolving MXene, a carbon source precursor and metal salt in water, adding absolute ethylalcohol and ammonia water to prepare a suspension, performing stirring, reaction, separation and washing to obtain a mixture, and performing calcination treatment in a high-temperature furnace under inert gas shield to obtain the carbon coated MXene two-dimensional nano sheet cathode material uniformly loaded with the pseudocapacitance transition metal oxide nano particles on the surface. The structure and the component of the cathode material are adjustable. The synthetic method is simple in technology, low in energy consumption, easy to control, green and environment-friendly, has the universality, and can be used for large-scale industrial popularization and application; and the obtained cathode material represents high specific capacity, excellent cycling stability and excellent rate capability in a sodium ion battery.

Owner:DALIAN UNIV OF TECH

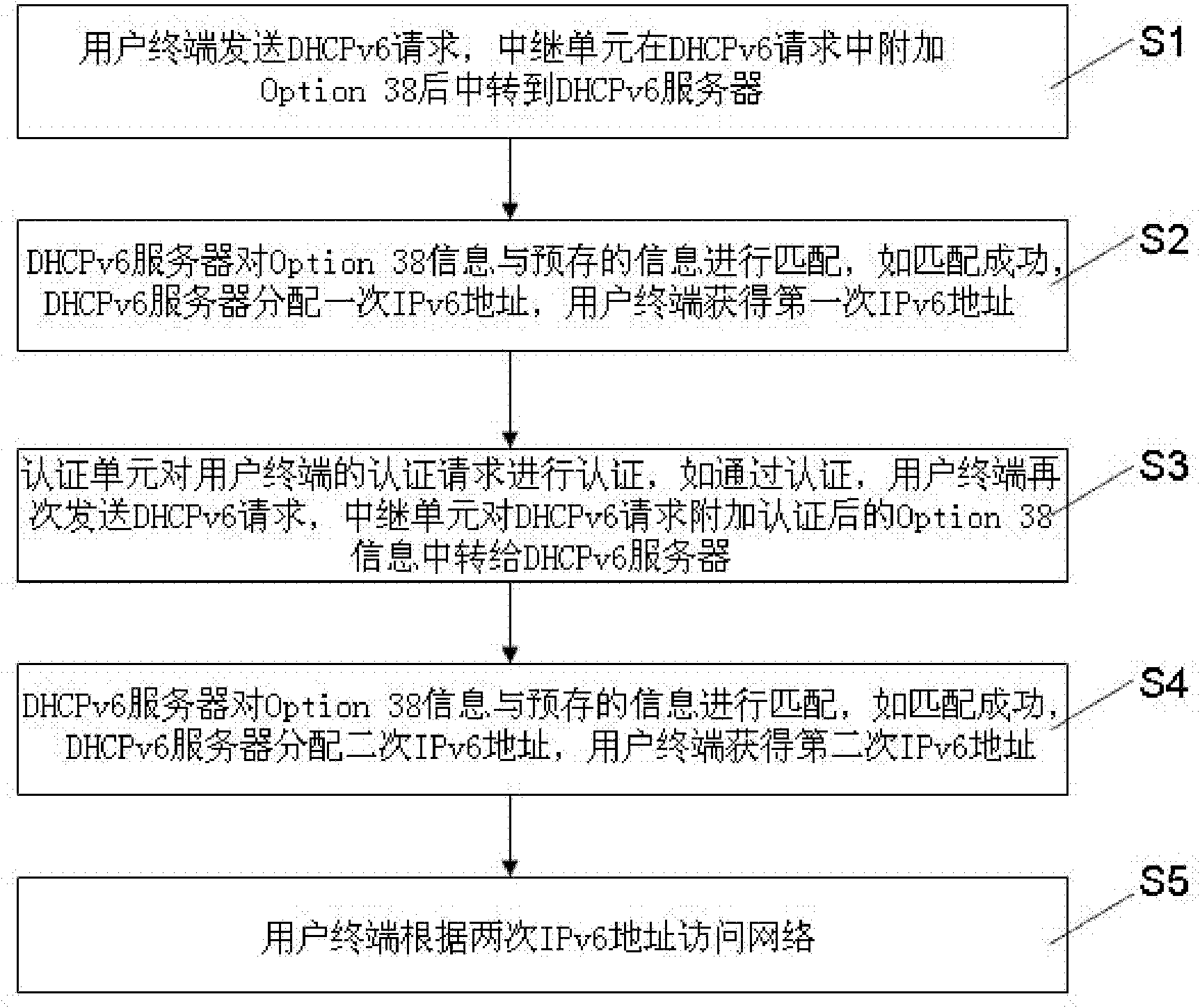

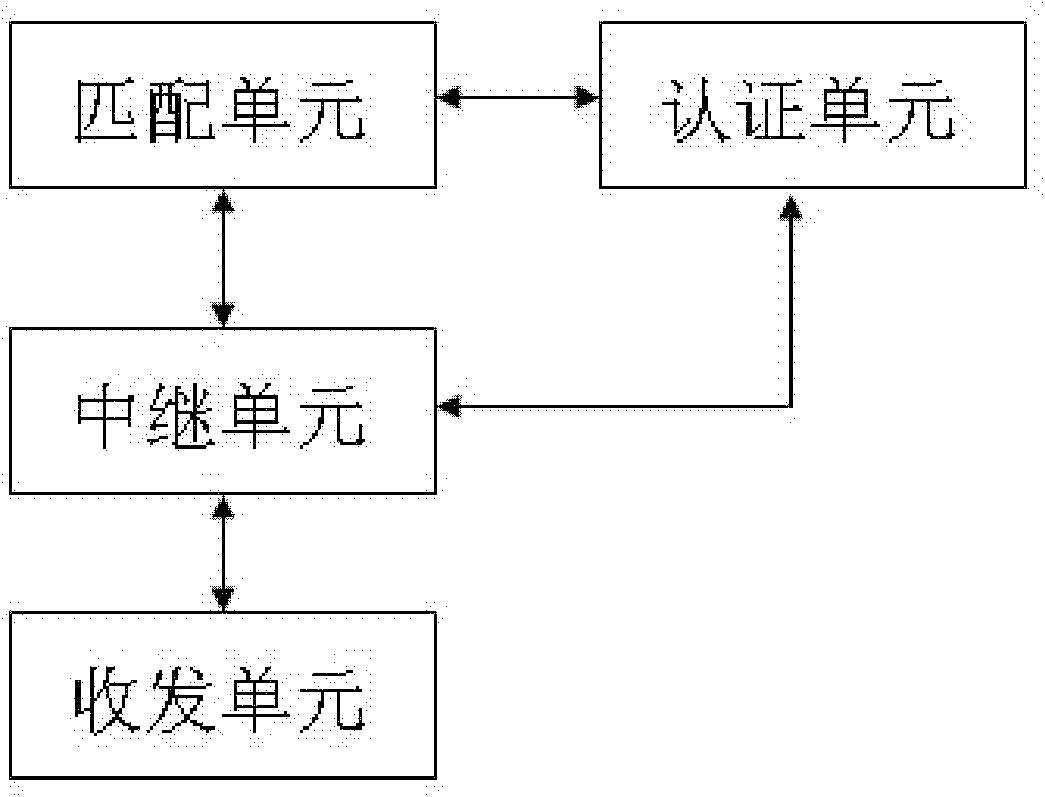

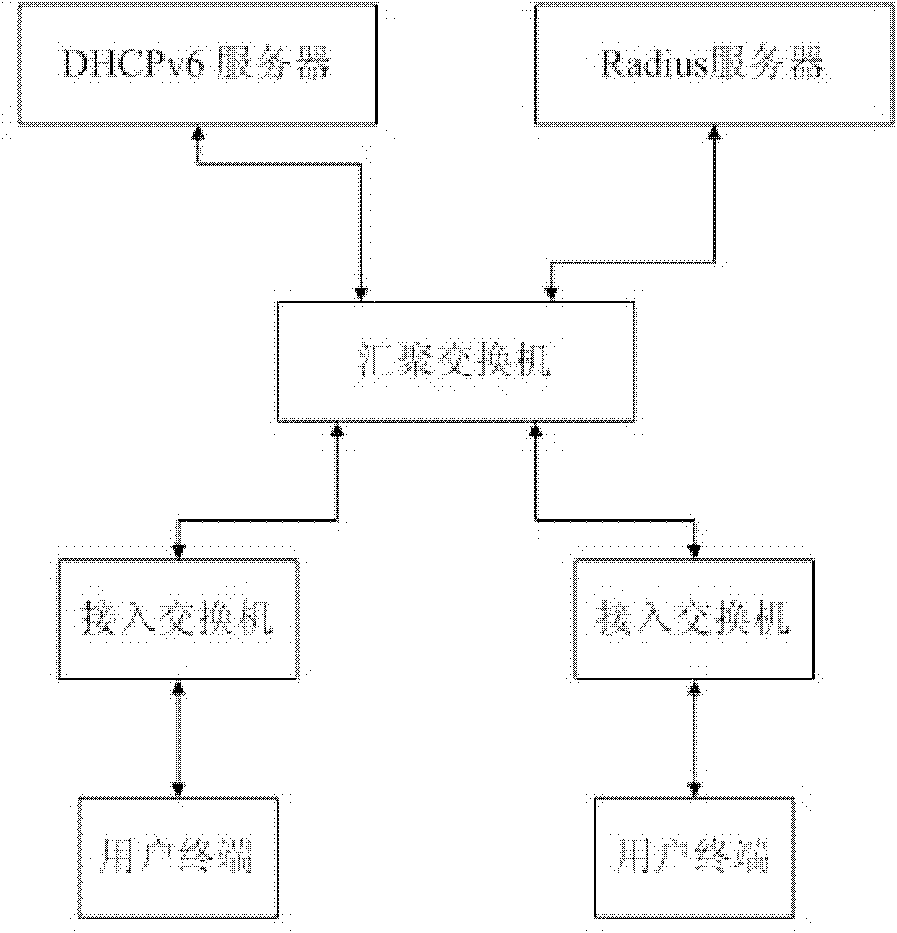

Method and system for controlling access right of internet users

InactiveCN102404346ASafe and convenient access methodRealize fine controlTransmissionSecure authenticationInternet users

The invention discloses a method and a system for controlling access right of internet users; when a user terminal applies IP (internet protocol) for DHCPv6 (Dynamic Host Configuration Protocol version 6) server, different Option 38 information is additionally added in a DHCPv6 request according to a 802.1x authenticated state of the user, the DHCPv6 server distributes IPv6 address after matching Option 38 information, and the user terminal accesses a network through access right configured by a switchboard on a convergence layer according to different IPv6 addresses obtained before and after authentication. In the invention, by utilizing the convenience of the DHCPv6 and a safety certificate mechanism of the 802.1x, an illegal user terminal is prevented from accessing the network and the right of a legal terminal user can be precisely controlled after the legal terminal user passes through the authentication.

Owner:北京神州数码云科信息技术有限公司

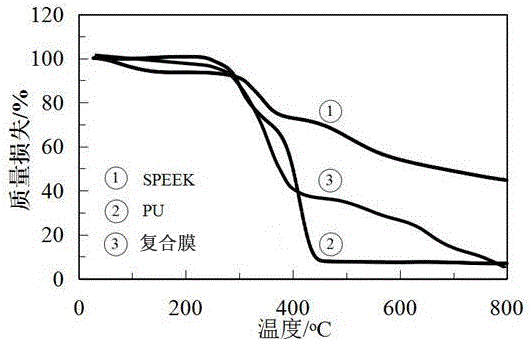

Preparation method of phosphoric acid-doped layer by layer self-assembly polymer composite film

ActiveCN106356546AImprove mechanical propertiesImprove proton conductivityFuel cellsPolymer sciencePhosphoric acid

The invention belongs to the technical field of fuel cells, and particularly relates to a preparation method of a phosphoric acid-doped layer by layer self-assembly polymer composite film. The preparation method comprises the following steps of firstly preparing an SPEEK (Sulfonated Polyether Ether Ketone) homogeneous phase water solution; putting a glass sheet into a PU (Poly Urethane) solution for soaking; taking the glass sheet out; soaking into deionized water; taking out, and blowing to realize no water on the surface; re-soaking in the SPEEK homogeneous phasewater solution; then soaking in the deionized water; blowing to realize no water on the surface; completing layer by layer self-assembly of PU and SPEEK; repeating for 170 to 200 times to obtain a (SPEEK / PU) 170 to 200 self-assembly film; after soaking a glass sheet carrying the (SPEEK / PU) 170 to 200 self-assembly film into a hydrofluoric acid solution for 10min, taking the (SPEEK / PU) 170 to 200 self-assembly film out; soaking the (SPEEK / PU) 170 to 200 self-assembly film into a PA water solution, and obtaining the phosphoric acid-doped (SPEEK / PU) 170 to 200 self-assembly film. According to the preparation method of the phosphoric acid-doped layer by layer self-assembly polymer composite film provide by the invention, a layer by layer self-assembly technology is utilized, so that a high-temperature proton exchange film with a layer by layer self-assembly structure, high proton conductivity, a favorable mechanical property and stabilityis prepared based on a polycation polymer and a polyanion polymer.

Owner:NORTHEASTERN UNIV

Method for determining duct piece splicing point position of universal ring for subway shield construction

ActiveCN105673041AThe method steps are simpleLow input costData processing applicationsUnderground chambersWeight coefficientEngineering

The invention discloses a method for determining a duct piece splicing point position of a universal ring for subway shield construction. The method comprises the following steps: performing shield tunneling construction on a constructed tunnel from back to front along the central axis of the tunnel by adopting a shield tunneling machine; after a ring of the shield tunneling construction is completed, performing shield duct piece splicing construction; before any ring of shield duct piece splicing construction, determining the duct piece splicing point position of shield duct pieces of the current ring first, wherein the method for determining the duct piece splicing point position comprises the following processes: firstly, determining selectable splicing point positions; secondly, determining selection influence indexes and weight coefficients thereof: respectively determining the three selection influence indexes which influence the selection of the duct piece splicing position point and the weight coefficients thereof; thirdly, performing selectivity evaluation on the selectable splicing position points: respectively evaluating the selectivity of each selectable splicing position point according to a weight coefficient method, and determining the duct piece splicing point position of the current shield duct piece. The method disclosed by the invention is simple in step, reasonable in design, convenient to implement and good in using effect, and can determine the splicing point position of the duct pieces of the universal ring easily, conveniently and accurately.

Owner:CHINA RAILWAY FIRST GRP CO LTD

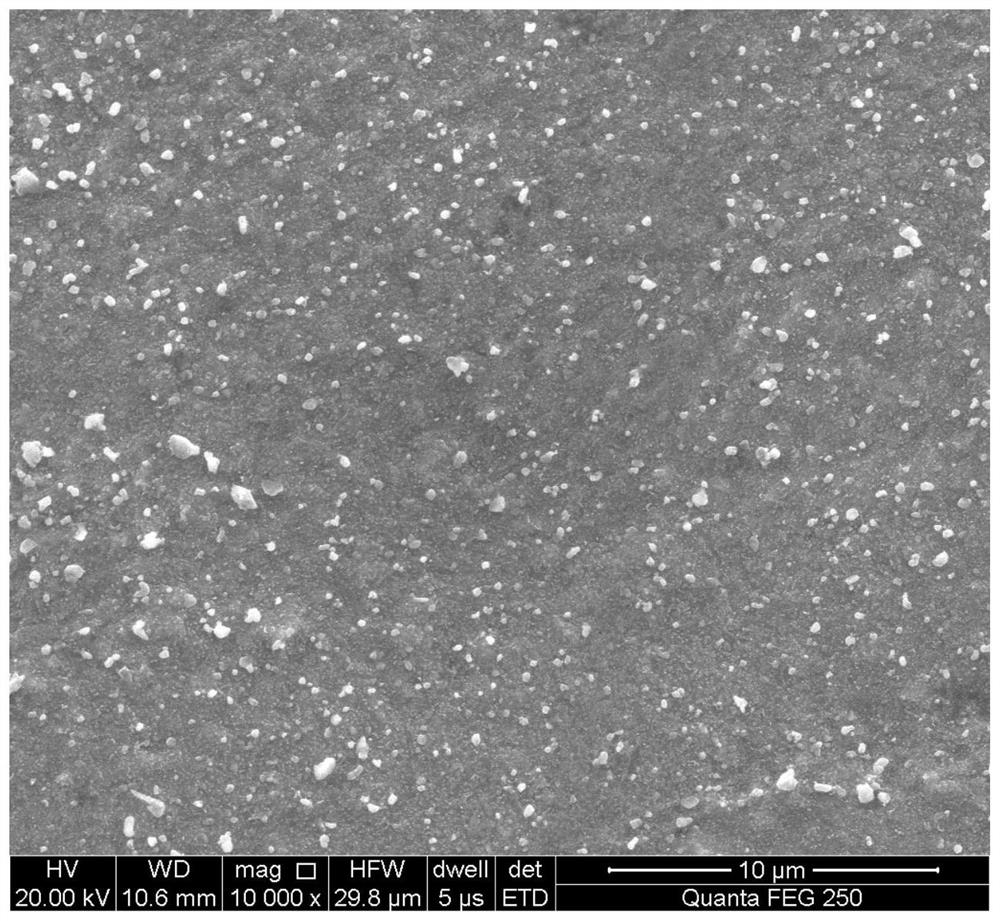

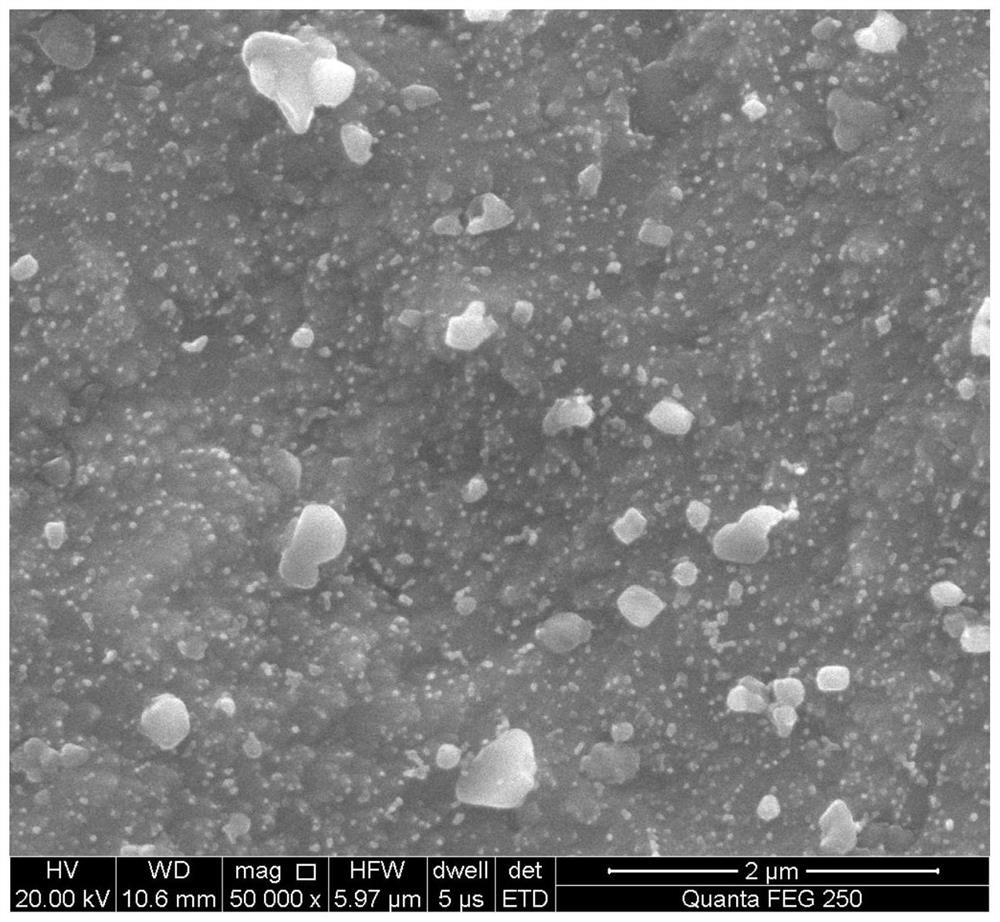

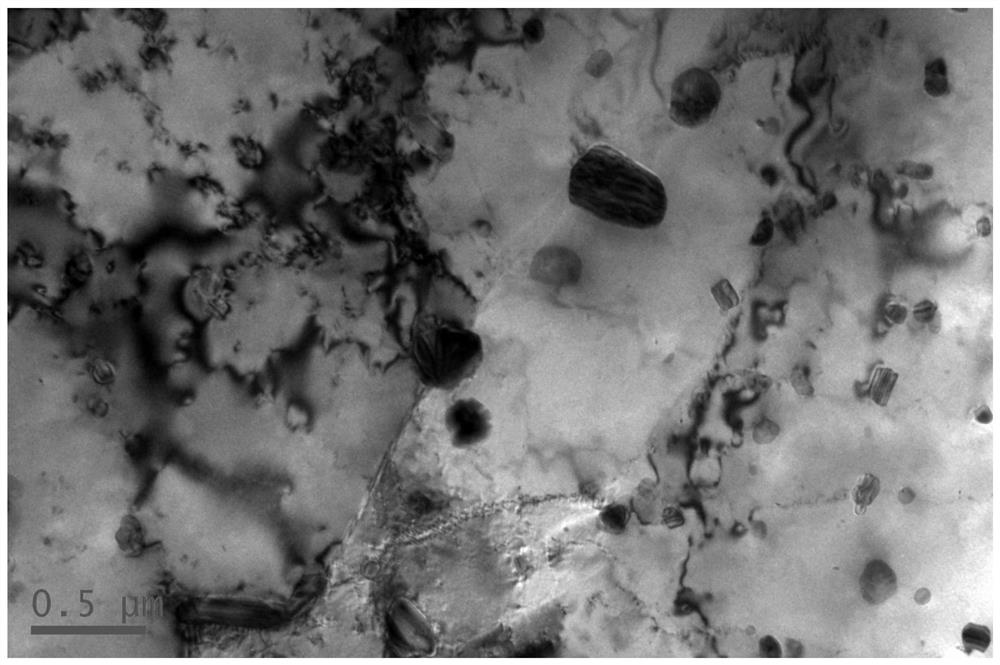

Method for simultaneously improving strength and electric conductivity of Cu-Cr-Nb alloy

The invention relates to a method for simultaneously improving the strength and electric conductivity of a Cu-Cr-Nb alloy. The alloy comprises the components with percent by weight: 0.5-5.0% of Cr, 0.5-5.0% of Nb, 0.01-1.00% of M and the balance copper, wherein M is at least three components selected from RE, B, P, Si, Ca, Zr, Li, Mg, Ti, Ni, Fe, Sn and Mn; and RE is at least one component selected from Ce, La, Y, Pr, Nd, Sm and Sc. The Cu-Cr-Nb-M alloy is prepared through powder formation and thermo-mechanical treatment. Under the combined action of microalloying, rapid solidification, rapiddensification and the thermo-mechanical treatment, the microscopic structure of the alloy is regulated; and under the synergistic action of various strengthening mechanisms, the strength of the alloyis improved, and the comprehensive performance of the alloy is improved. The size of the second phase in the alloy prepared by using the method is smaller than or equal to 0.50 micrometer; the secondphase is uniformly distributed; the room-temperature tensile strength of the alloy is equal to or higher than 450 Mpa; and the electric conductivity is equal to or higher than 80% IACS. The tensile strength is equal to or higher than 95 MPa at the high temperature of 700 DEG C; and it is achieved that the electric conductivity and the strength of the Cu-Cr-Nb alloy are simultaneously improved andwell matched.

Owner:CENT SOUTH UNIV

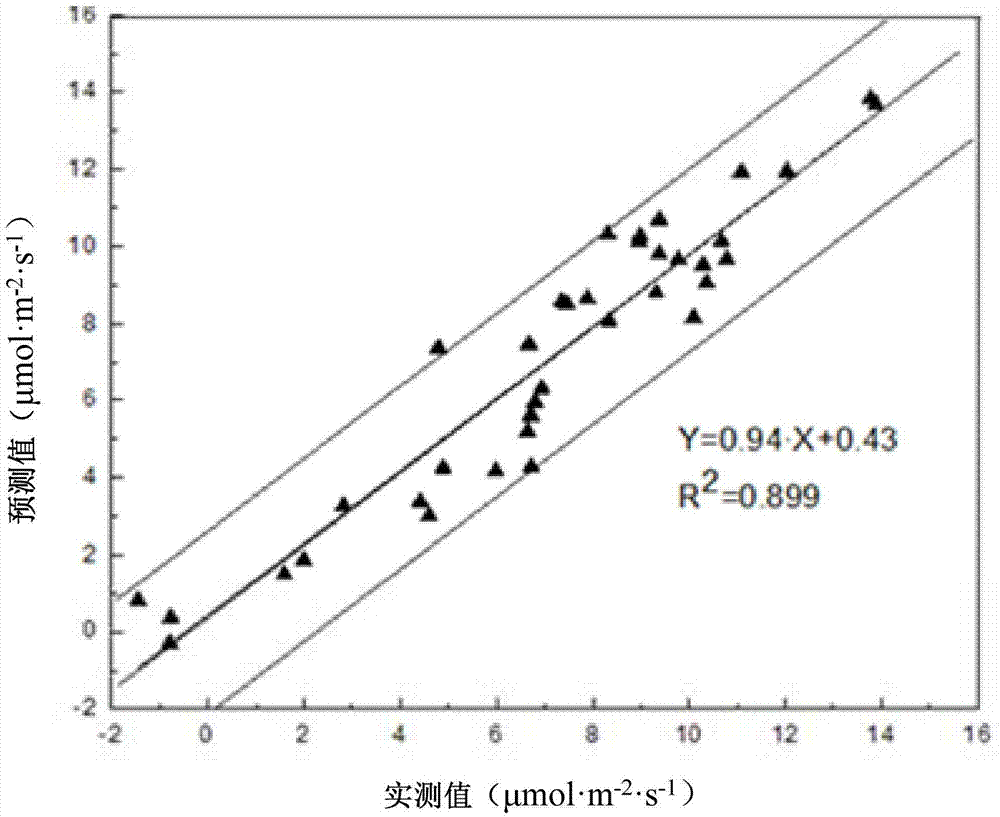

CO2 gas fertilizer fine regulation and control method and device used for solar greenhouse

ActiveCN103605385ARealize fine controlImprove overall utilizationControlling ratio of multiple fluid flowsHorticulture methodsDevice MonitorGreenhouse crops

A CO2 gas fertilizer fine regulation and control method and a device which are used for a solar greenhouse are provided. The device monitors environment information and crop growth information of the greenhouse in real time; and through a photosynthetic rate prediction model based on a BP neural network, the optimal CO2 gas fertilizer quantity demanded is determined and the value of the photosynthetic rate is predicted, and therefore fine regulation and control of CO2 concentration is achieved. According to the invention, the fact that a CO2 gas fertilizer in the solar greenhouse needs to be finely supplied in dependence on crop growth demands is achieved, the quality of greenhouse crops is improved, the yield of the greenhouse crops is risen, and environmental pollution caused by excessive application of the CO2 gas fertilizer is avoided.

Owner:CHINA AGRI UNIV

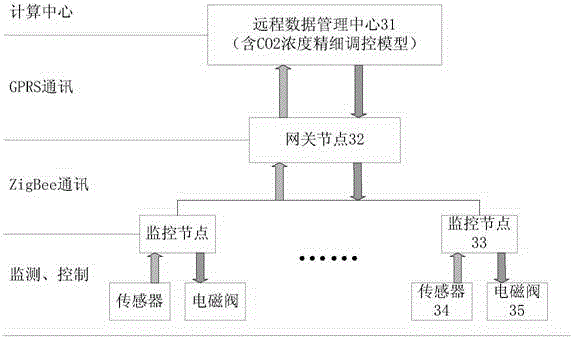

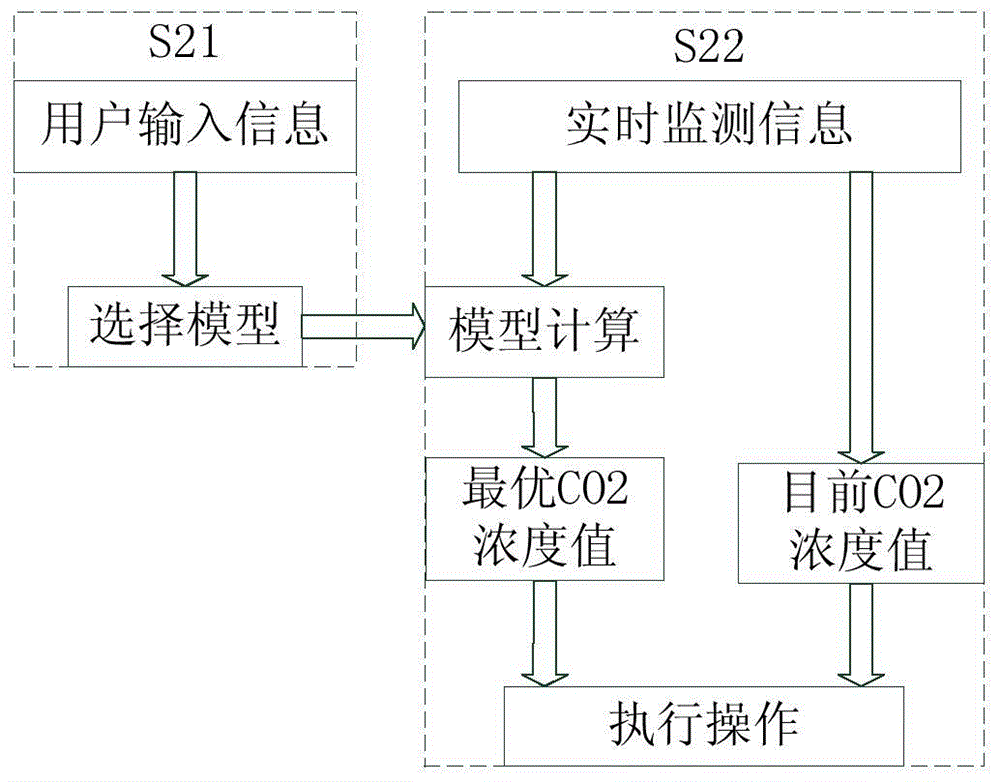

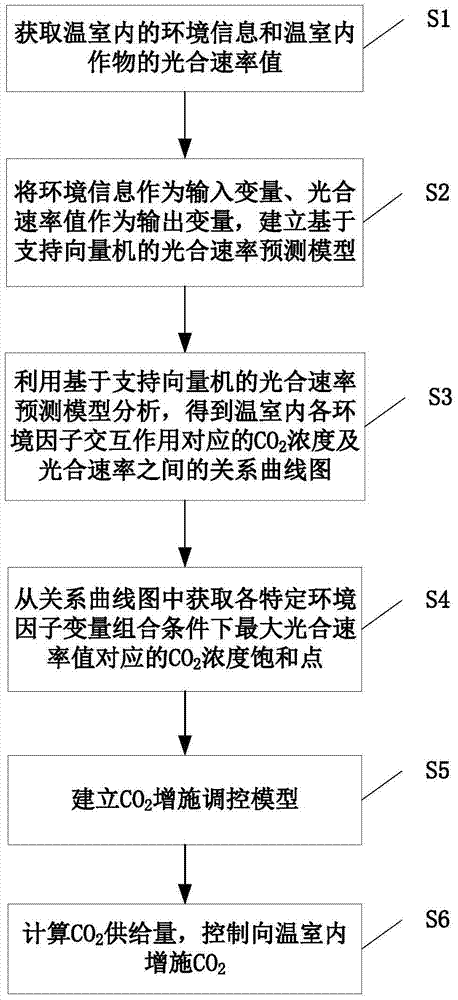

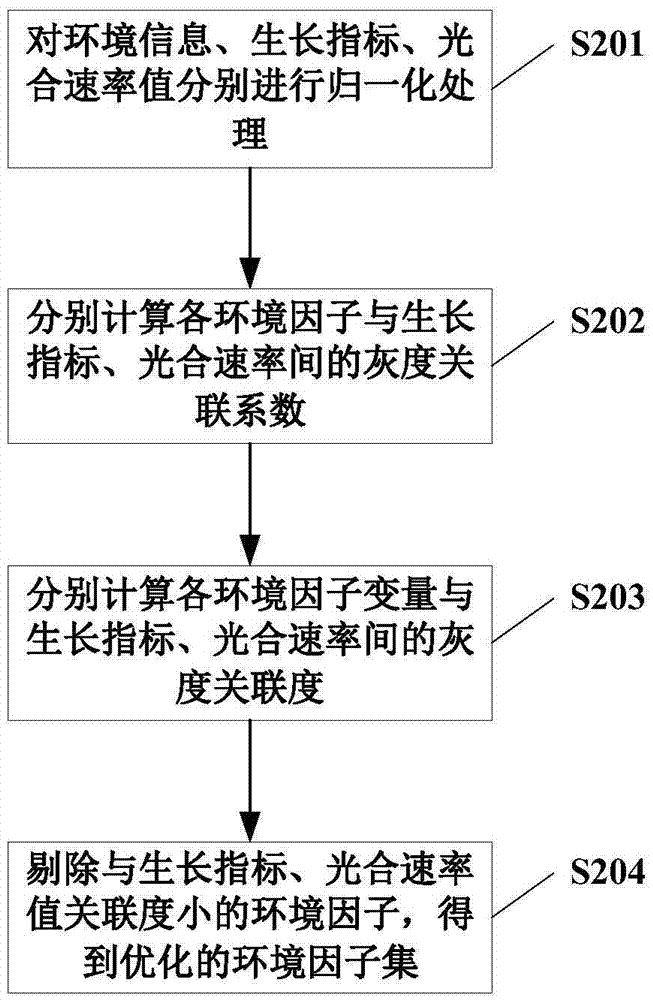

Greenhouse CO2 gas fertilizer increasing method, device and system

InactiveCN105446142AImprove photosynthesis efficiencyIncrease productionAdaptive controlGreenhouseExecution control

The invention relates to a greenhouse CO2 gas fertilizer increasing method, device and system. The method comprises the following steps that: environment information and the photosynthetic rate value of crops in a greenhouse are acquired; with the environmental information and the photosynthetic rate value respectively adopted as an input variable and an output variable, an SVM-based photosynthetic rate prediction model can be established; a relation curve graph between CO2 concentration and photosynthetic rate under the interaction effect of various environmental factors can be obtained through analysis; a CO2 concentration saturation point corresponding to a maximum photosynthetic rate value under combined conditions of specific environmental factor variables is obtained from the relation curve graph; a CO2 increase adjustment and control model is established; and CO2 supply quantity is calculated, and CO2 is increased in the greenhouse under control. The device comprises a data acquisition unit, a photosynthetic rate prediction model establishment unit, an analysis and processing unit, a CO2 increase calculation unit and an execution control unit. With the CO2 gas fertilizer increasing method, device and system of the invention adopted, optimal CO2 supply quantity can be calculated fast and accurately, and fine adjustment and control of CO2 gas fertilizer increase can be realized, and the photosynthetic efficiency and yield of the crops can be improved.

Owner:CHINA AGRI UNIV

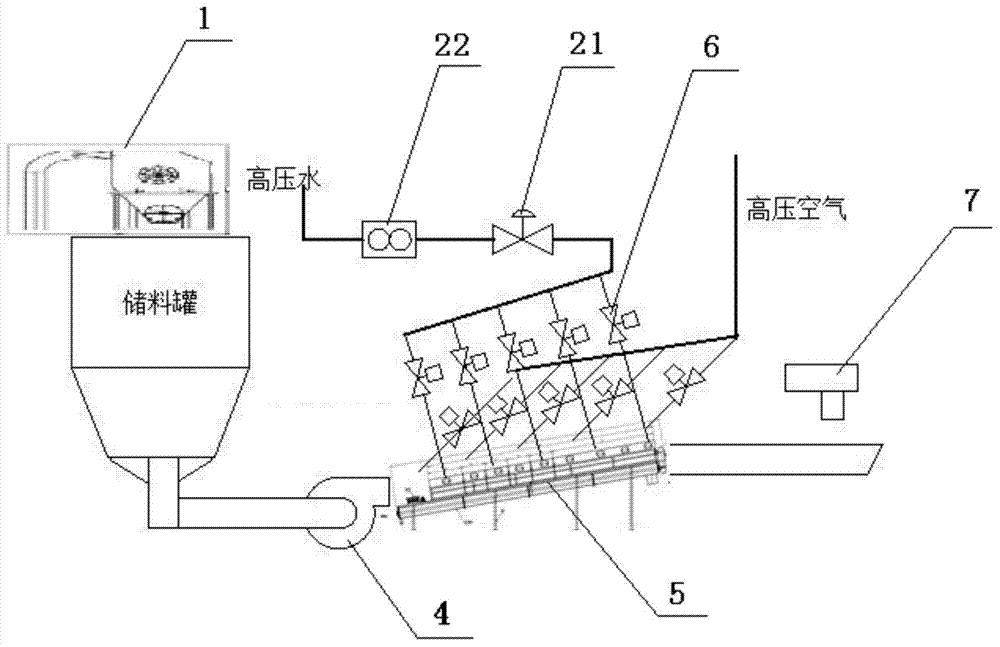

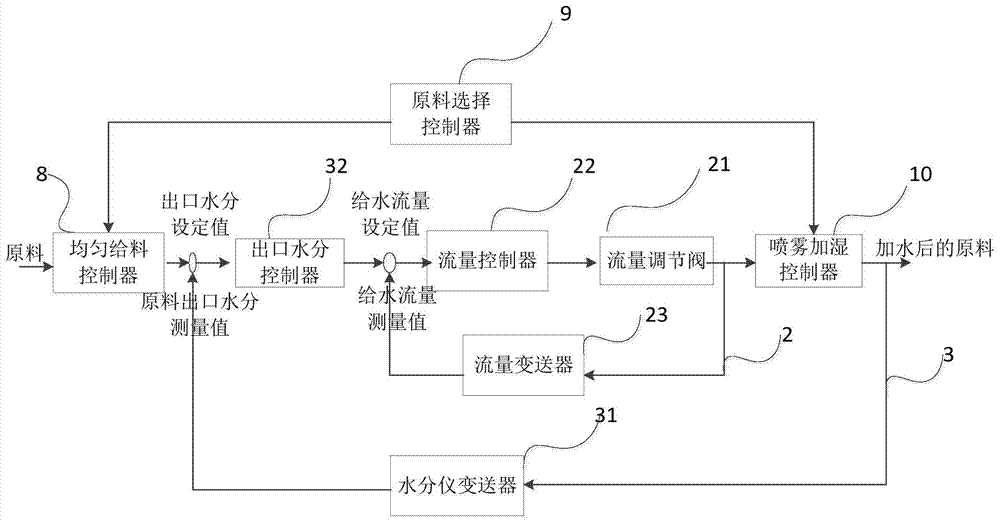

Uniform-feeding, atomizing, humidifying and water control system

ActiveCN104273646ARealize fine controlAchieving Automatic Stability ControlTobacco treatmentControl objectiveControl system

The invention provides a uniform-feeding, atomizing, humidifying and water control system. A water cascade control model comprising an outlet water control loop and a feed water flow control loop is built, the outlet water control loop is a main ring, and outlet water of a screw feeder is a control object of the main ring; the feed water flow control loop is an auxiliary ring, and feed water flow is a control object of the auxiliary ring. The water cascade control model utilizes the outlet water of the screw feeder as a control objective. The outlet water control loop utilizes difference between the final raw material outlet water measuring value and the set target value as input, output value of the water outlet control loop is converted as the set value of the feed water flow control loop, and the feed water flow control loop utilizes the difference between the set value and the feed water flow measuring value as input, and control value is outputted to a flow regulating valve via operation. Water added into the raw materials is controlled by a closed loop, and outlet water content of the screw feeder is automatically and stably controlled.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

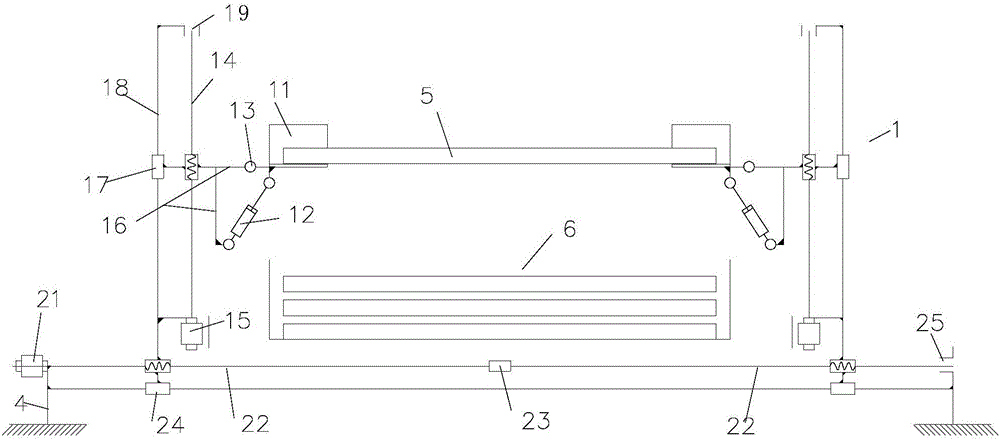

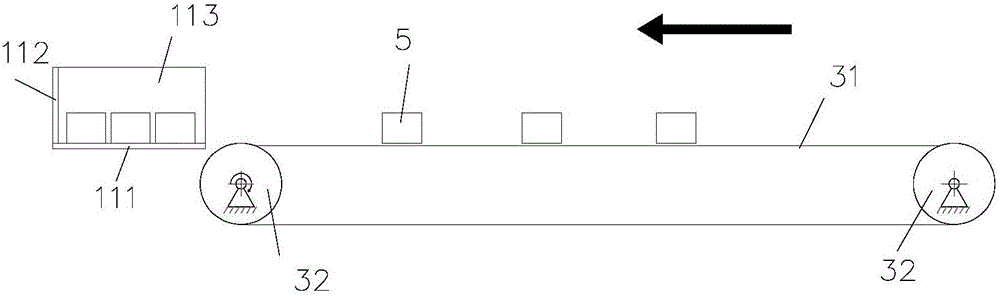

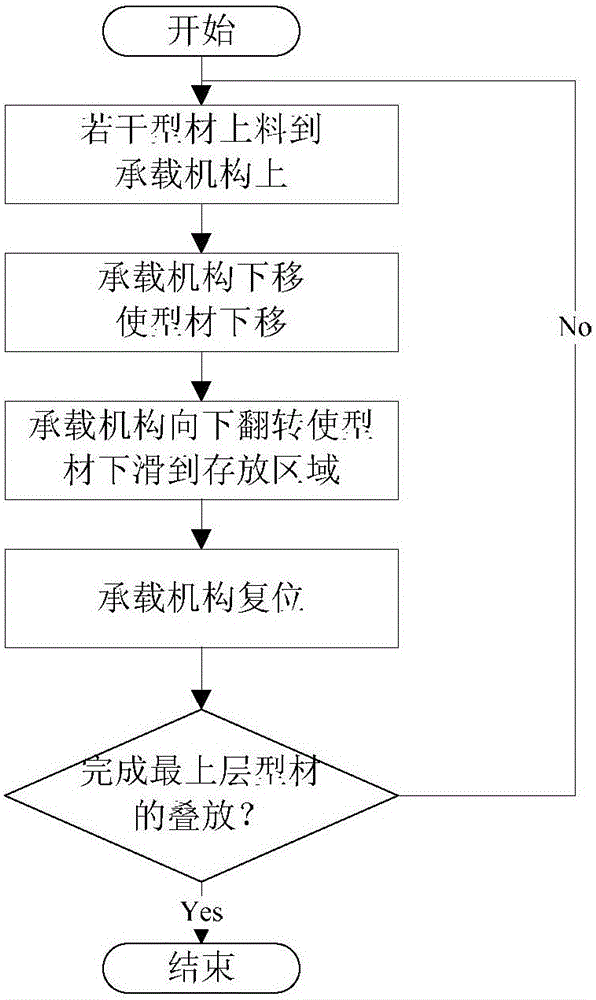

Full-automatic profile stacking equipment and method

Owner:FOSHAN UNIVERSITY

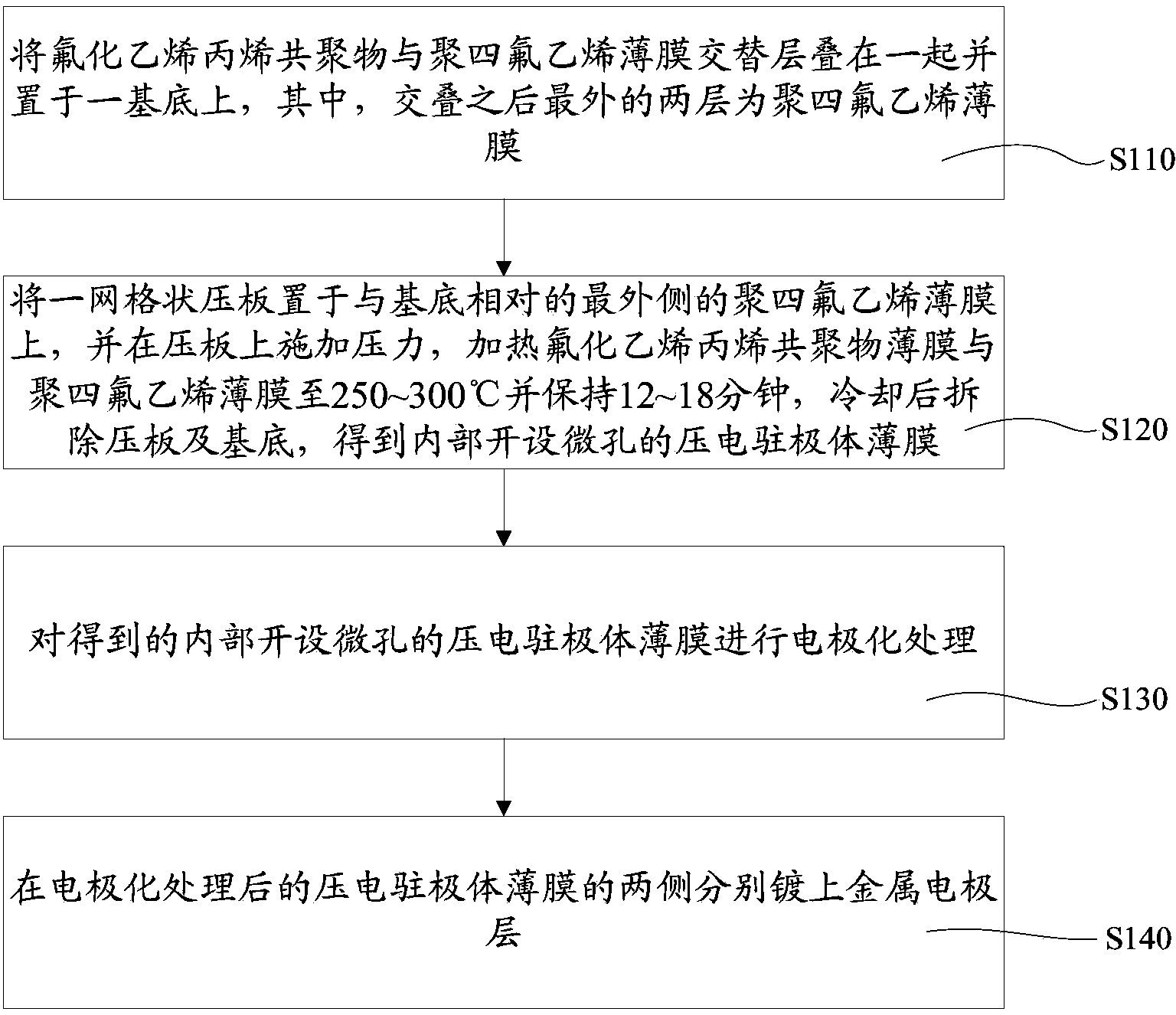

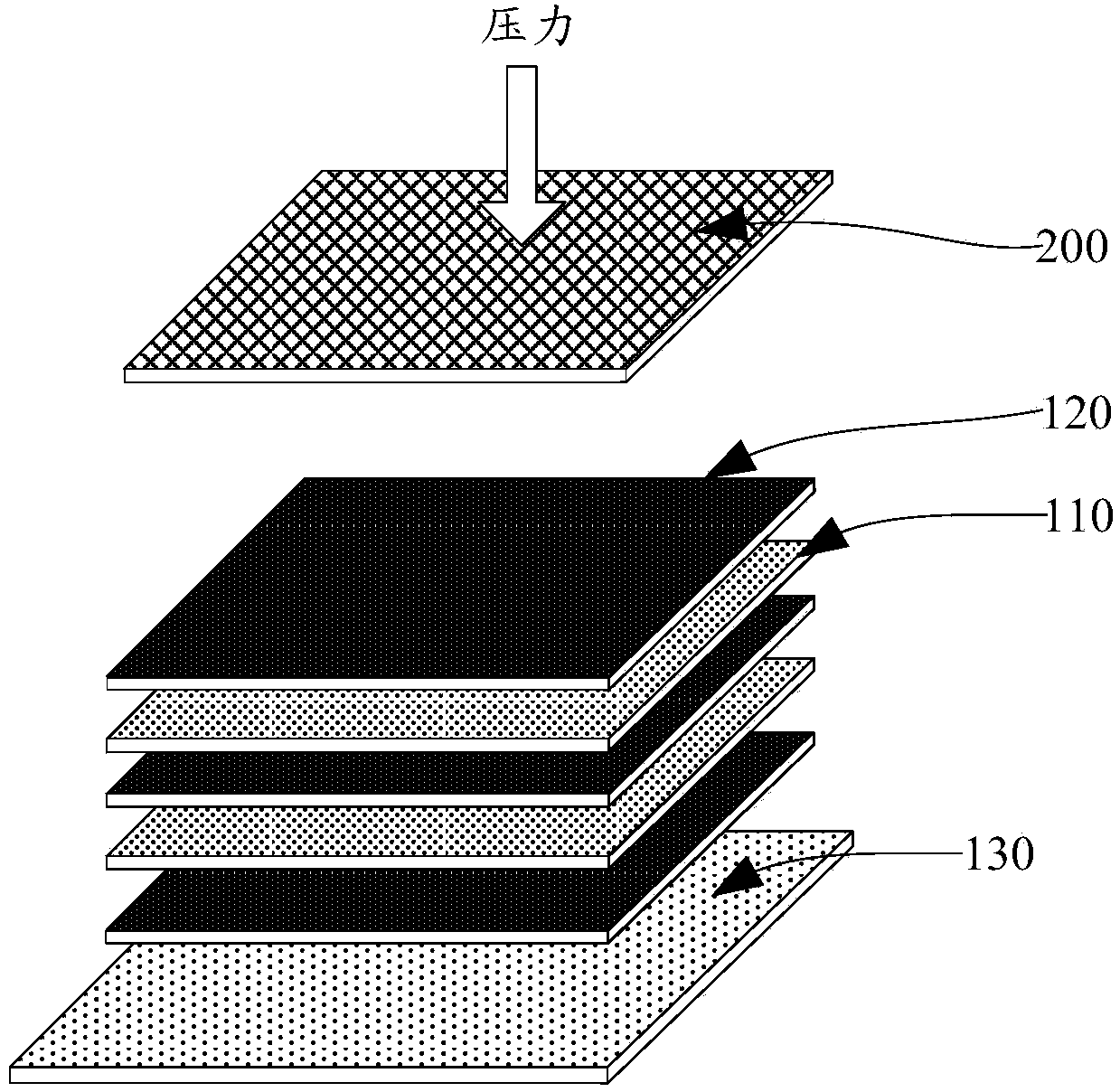

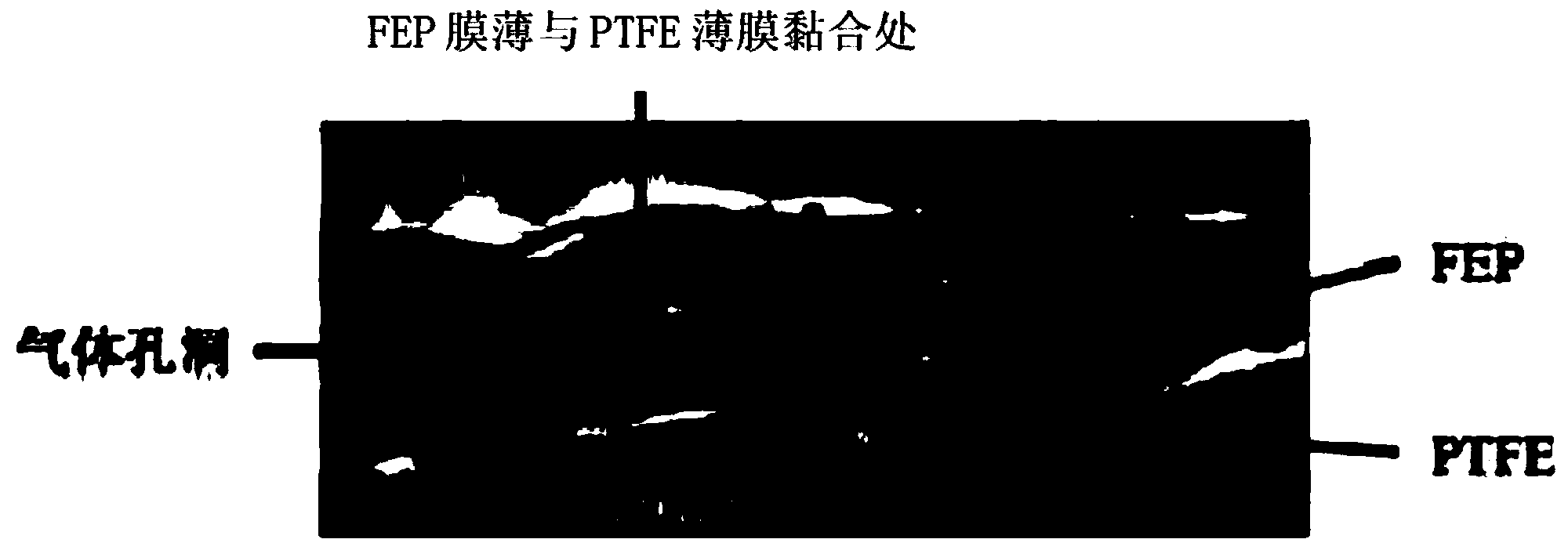

Piezoelectric electret film and producing method thereof

InactiveCN104044327ARealize fine controlPracticalSynthetic resin layered productsLaminationFerroelectretFluorinated ethylene propylene

The invention relates to a producing method of a piezoelectric electret film, and the producing method is as follows: fluorinated ethylene propylene copolymer films and polytetrafluoroethylene films are alternately laminated together, and then placed on a substrate, after the alternate lamination, two outermost layers are the polytetrafluoroethylene films; a latticed pressing plate is arranged on an outermost layer t polytetrafluoroethylene film opposite the substrate, pressure is applied to the pressing plate, the alternately laminated structure of the fluorinated ethylene propylene copolymer films and the polytetrafluoroethylene films is heated, after cooling, the pressing plate and the substrate are removed to obtain the piezoelectric electret film provided with micropores in the middle. In the production process of the piezoelectric electret film, through selection of latticed pressing plates with different specifications, such as regulation of mesh net opening mesh number, wire diameter, shape and other parameters and thermal bonding process parameter of the pressing plates, the fine adjustment of microporous structure of the piezoelectric electret film can be realized, and the producing method is strong in practicability, and can be widely popularized and applied. In addition, the invention also relates to the piezoelectric electret film produced by the producing method.

Owner:深圳市明鑫高分子技术有限公司

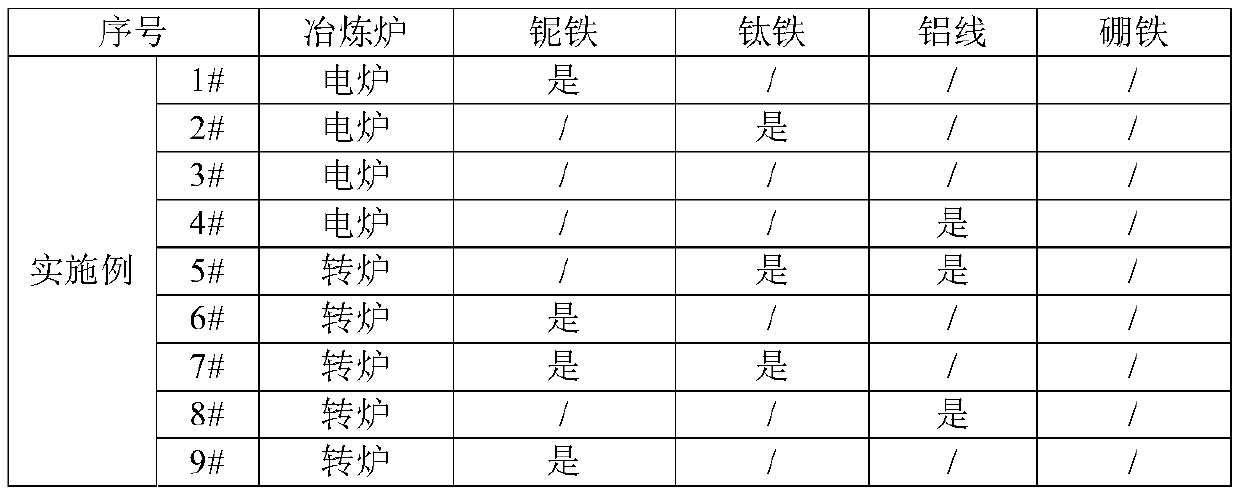

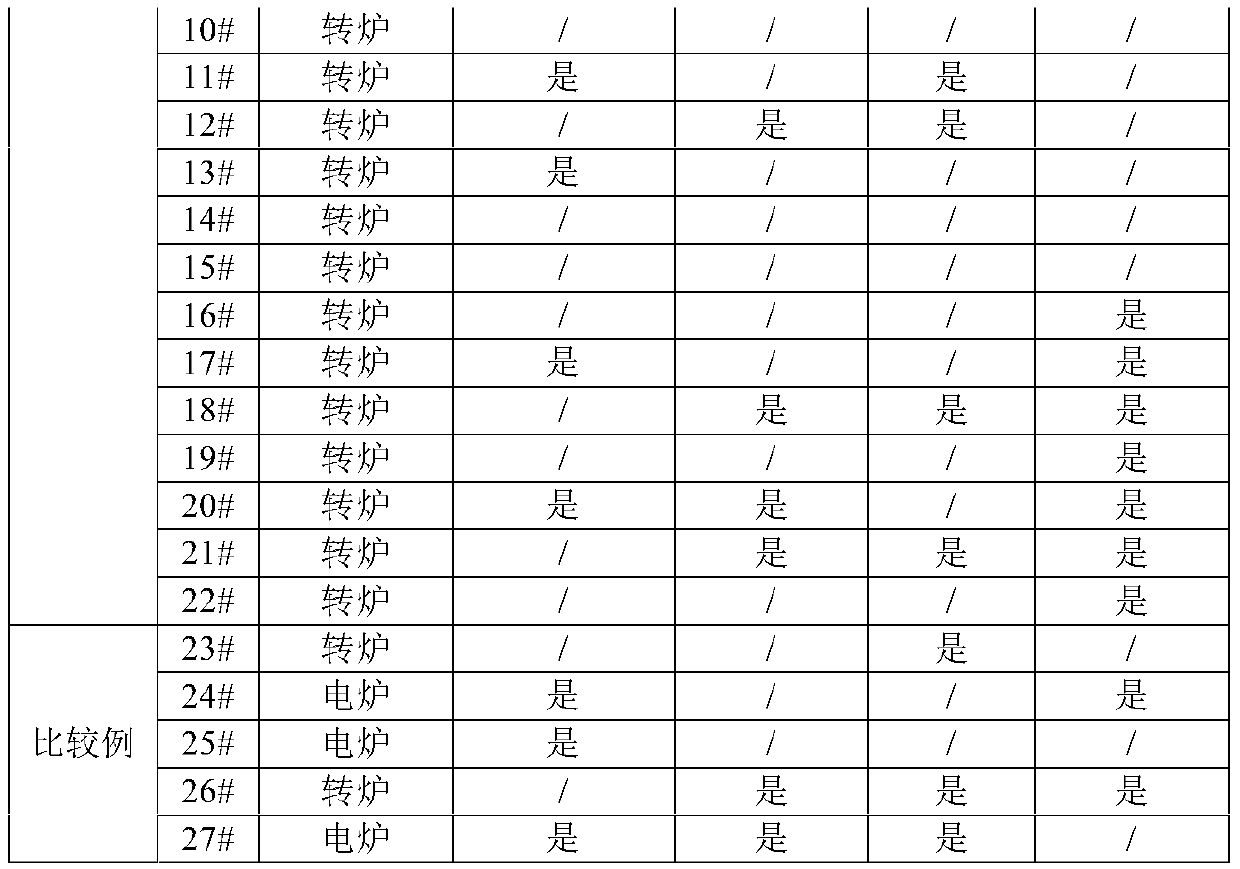

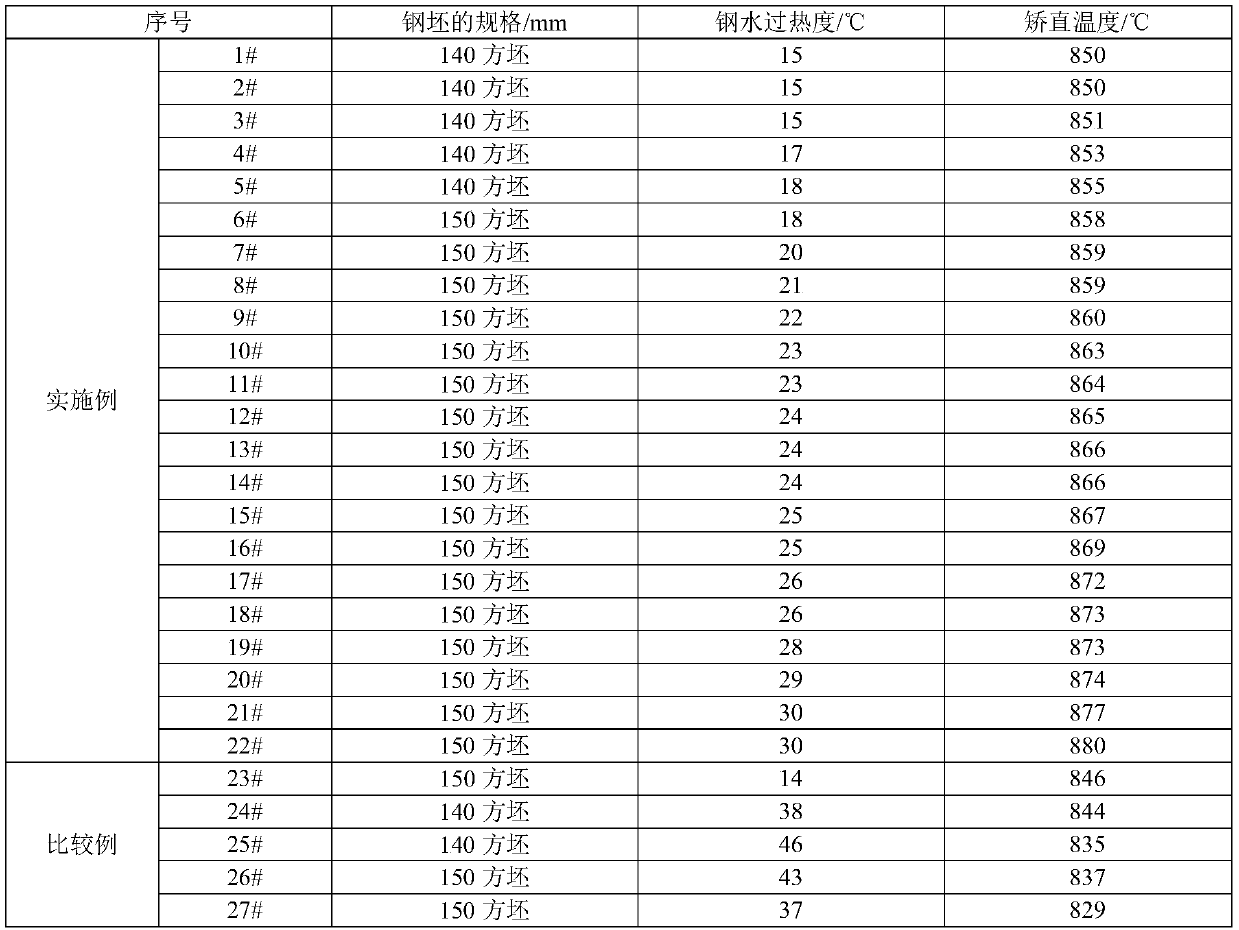

High-strength steel bar and production method thereof

ActiveCN110129675ARealize fine controlImproved resistance to external disturbancesFurnace typesHeat treatment furnacesTemperature controlChemical composition

The invention discloses a high-strength steel bar and a production method thereof. The high-strength steel bar comprises the chemical components of 0.15-0.32% of C, 0.5-1.9% of Si+Mn, 1.1-2.1% of Mn+Cr+Mo+Ni, 0.02-0.8% of V, 0.01-0.3% of at least one of Nb, Ti and Al and the balance Fe and inevitable impurities; and Mn=(2.5-3.5)Si, Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Cu+Ni) / 15<=0.56%. The production method ofthe high-strength steel bar comprises the steps of smelting, continuous casting, temperature control rolling and temperature control cooling, wherein the superheat temperature of molten steel subjected to continuous casting is 15-30 DEG C, the heating temperature is 1200-1250 DEG C, in addition, the molten steel stays in a furnace for 60-120 min, the rolling start temperature is 1000-1150 DEG C,the finish rolling temperature is 850-950 DEG C, and the temperature of the steel when the steel is fed onto a cooling bed is 800-920 DEG C.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

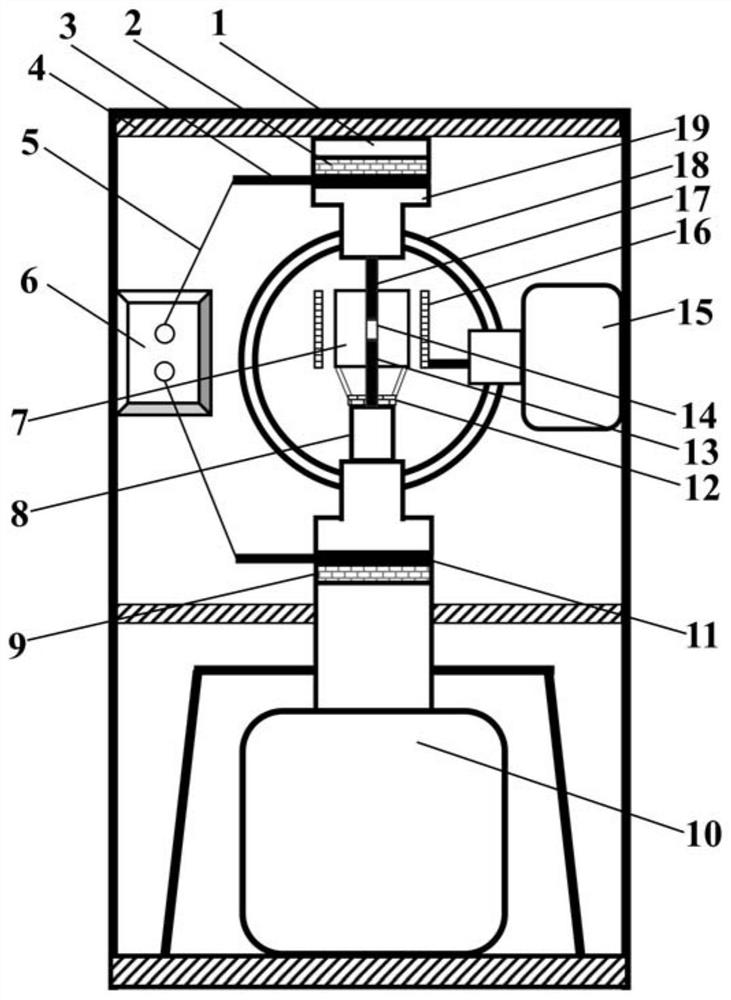

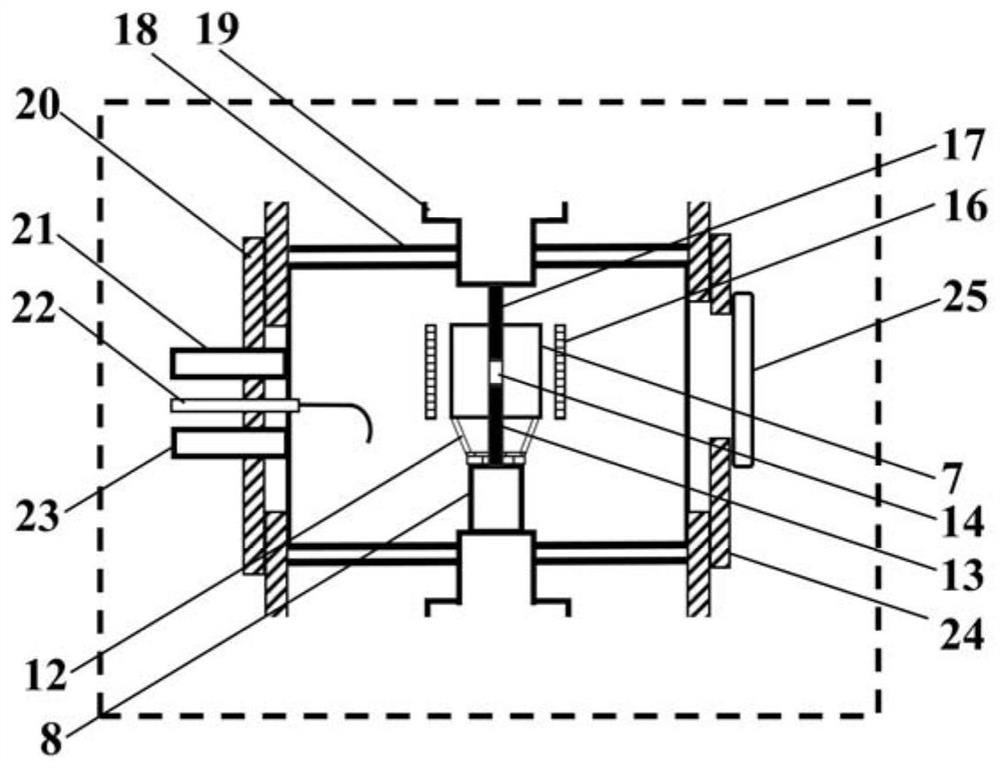

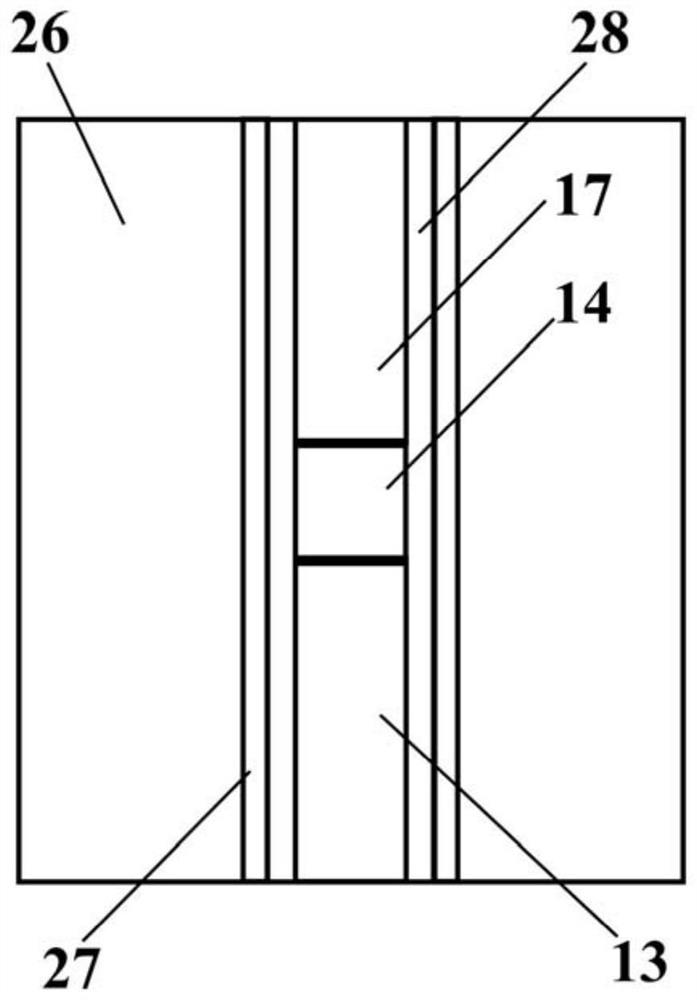

Pressure-assisted induction heating vacuum atmosphere flash sintering device

InactiveCN111981847AGood conductivity at room temperatureOvercome inherent shortcomingsMaintainance of heating chambersCharge treatment typeSystem pressurePumping vacuum

The invention relates to the field of new material preparation, and provides a pressure-assisted induction heating vacuum atmosphere flash sintering device. The pressure-assisted induction heating vacuum atmosphere flash sintering device comprises a furnace body, a pressure system, a flash sintering system, an induction heating system, a cooling system and a vacuum system. The pressure system comprises an upper pressing head and a movable lower pressing head. An upper electrode and a lower electrode are arranged on the end portions of the upper pressing head and the lower pressing head correspondingly and provide pressure for flash sintering samples. The flash sintering system provides a flash sintering circuit. The induction heating system provides heating and heat preservation. The furnace body is cooled by the cooling system. The furnace body is vacuumized by the vacuum system. The inherent defects in a traditional flash sintering technology are overcome, flash sintering power sources can be flexibly selected according to the electrical properties of materials obtained after flash sintering to cause thermal runaway, thus, the density level and microstructures of the samples arefinely adjusted and controlled to the maximum degree, and the device has universality for metal and ceramic materials; and pressure assisting of the flash sintering process can be easily achieved, andnew preparation means can be provided for the research field.

Owner:UNIV OF SCI & TECH BEIJING

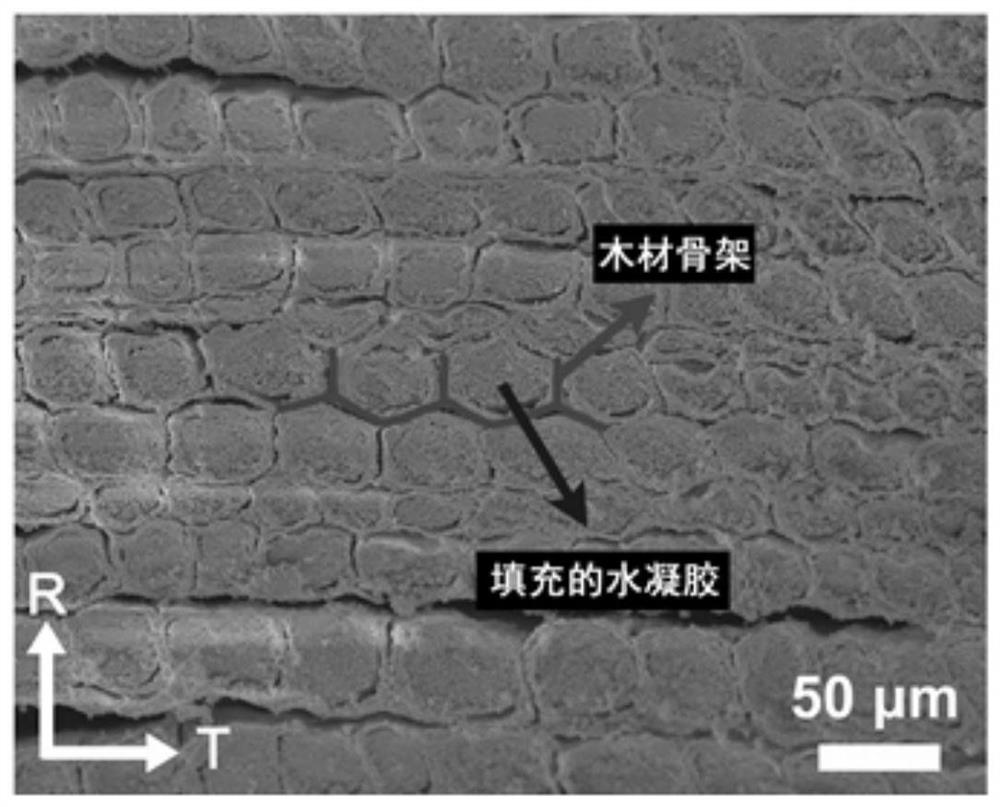

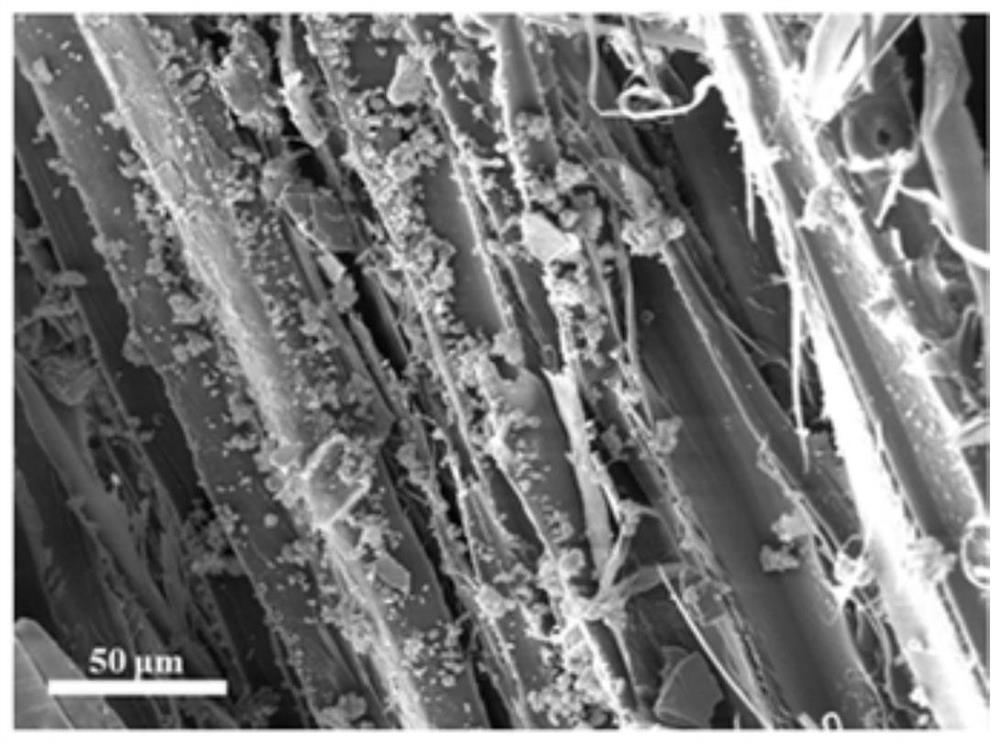

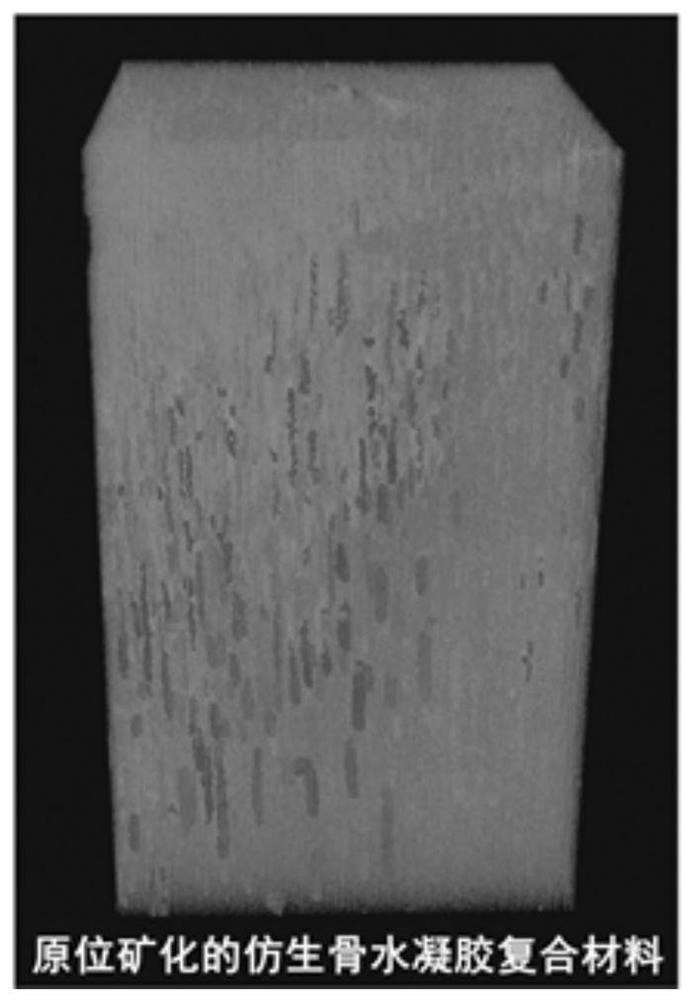

In-situ mineralized bionic bone hydrogel composite material with oriented structure as well as preparation method and application thereof

ActiveCN112402695APromote new bone growthGood osseointegration and mechanical stabilityTissue regenerationProsthesisOsteoblast adhesionMacromolecule

The invention relates to an in-situ mineralized bionic bone hydrogel composite material with an oriented structure as well as a preparation method and application thereof, which comprises a natural plant fiber template, natural polymer hydrogel directionally filled in the natural plant fiber template and hydroxyapatite directionally deposited in the natural plant fiber template. The hydrogel composite material has a three-dimensional porous structure and is anisotropic, which overcomes the problem of uneven distribution of hydroxyapatite particles in the hydrogel matrix; the material has super-strong tensile strength, compression strength, bending strength and toughness, and the mechanical properties are matched with those of hard bone tissues. The material is beneficial to induce pre-osteoblast adhesion and osteogenic differentiation, promote new bone growth, has good osseointegration and mechanical stability, and is suitable for large-area hard bone tissue repair; in addition, the material has adjustable surface activity, and fine adjustment and control of the structure and the surface can be achieved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

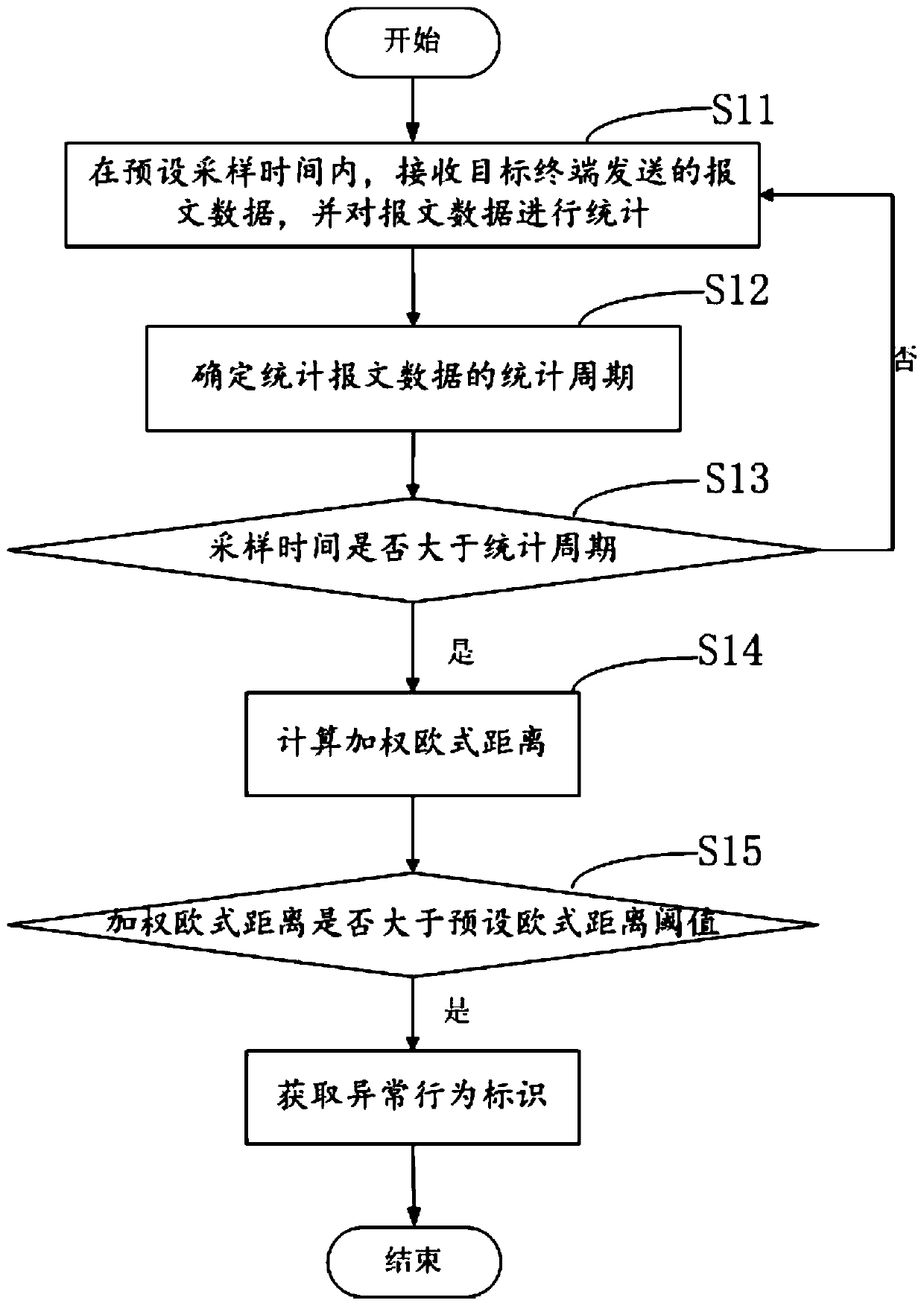

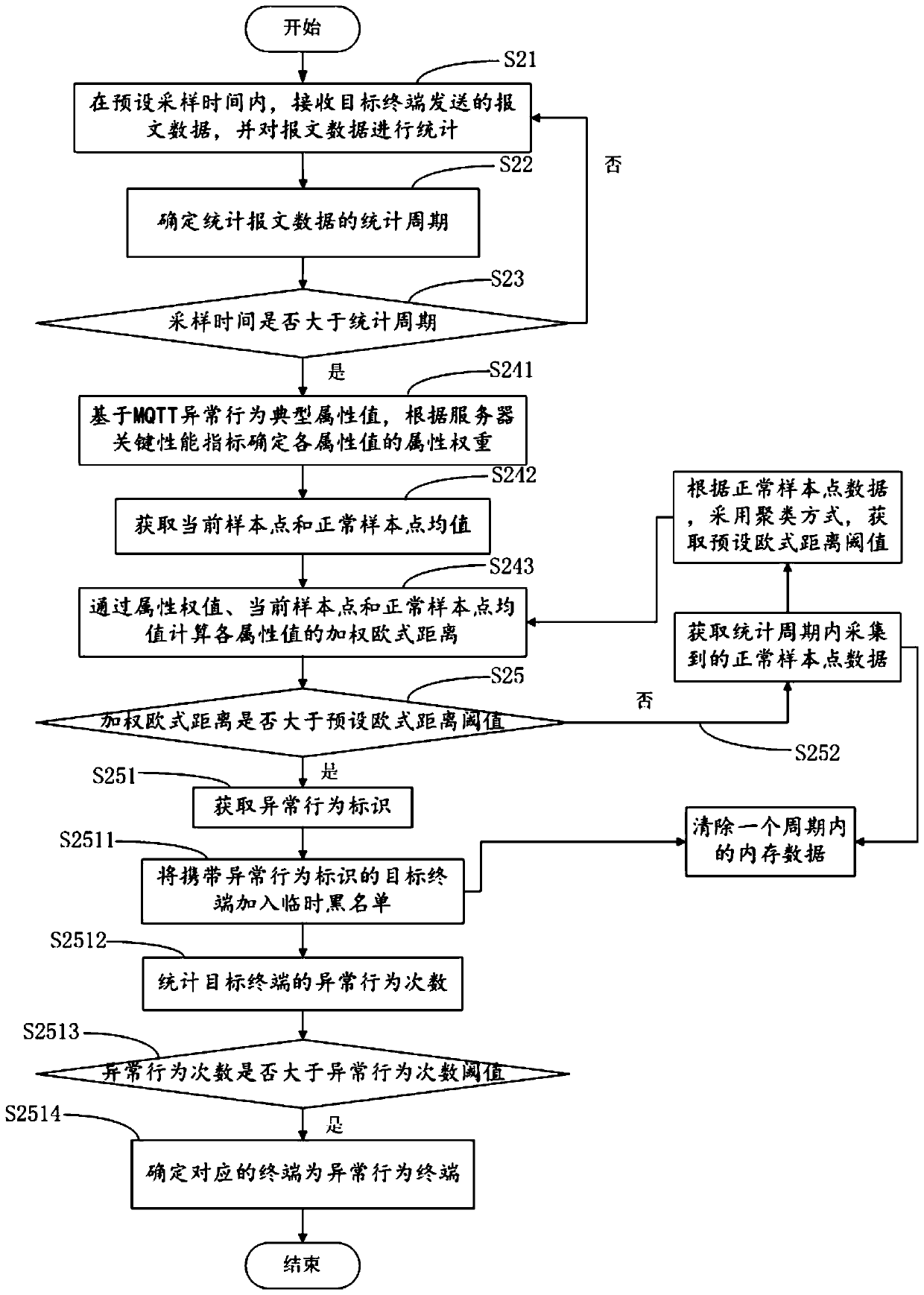

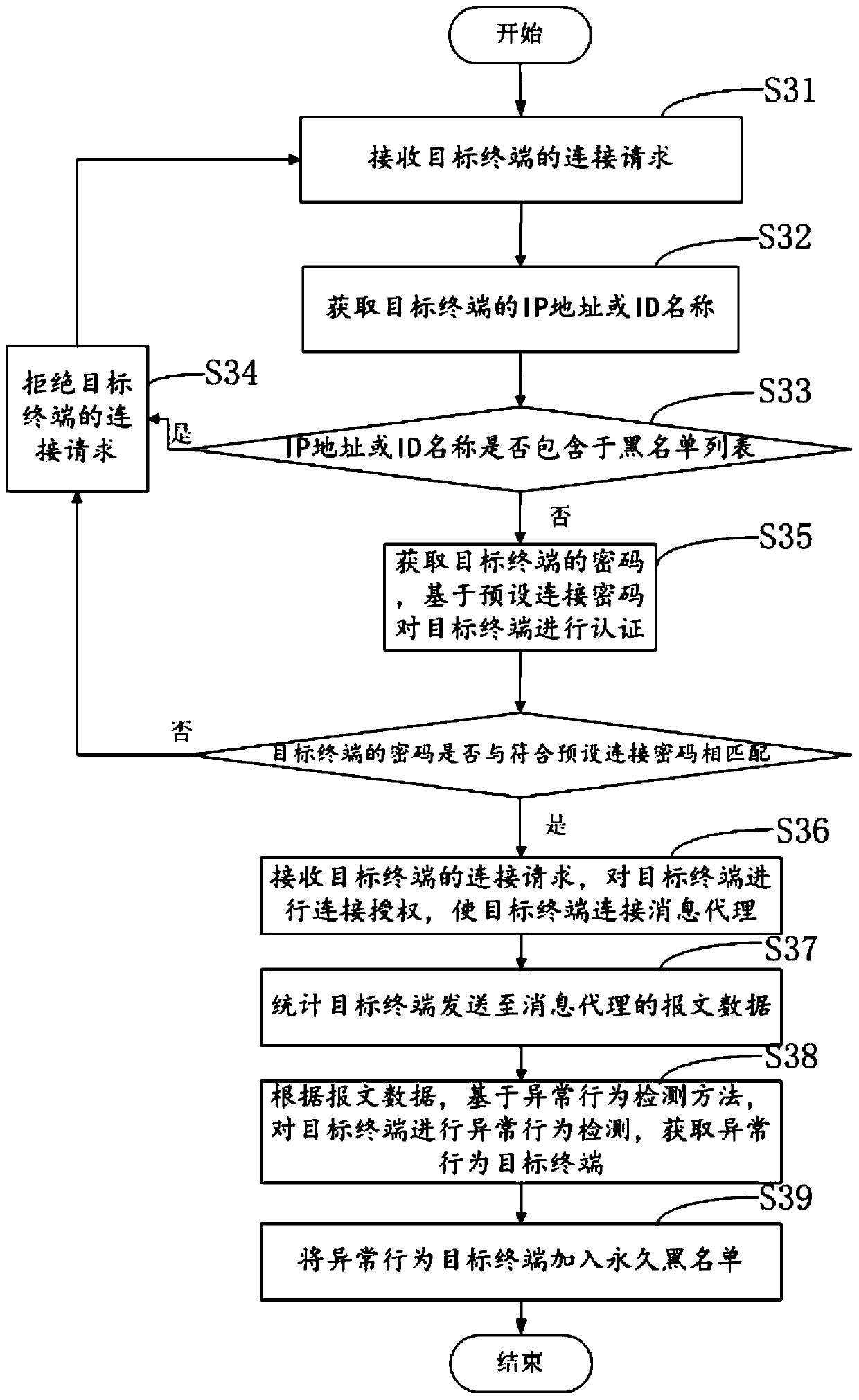

Security defense and abnormity detection method, device and system based on MQTT message queue

The invention relates to a security defense and abnormity detection method, device and system based on an MQTT message queue. The invention belongs to the technical field of shortcut message queue application in Internet of Things. The method comprises the following steps that in preset sampling time, message data sent by a target terminal is received, the message data sent by the target terminal in one period are counted, the weighted Euclidean distance of the statistical result of the message data is calculated, whether the target terminal is an abnormal behavior terminal or not is judged by comparing the weighted Euclidean distance with a preset Euclidean distance threshold value, and the abnormal behavior terminal can be detected and obtained in time. According to the security defense method, blacklist screening, client authentication, client authorization, message issuing and abnormal detection are set in the connection process of the target terminal and the message agent, and the abnormal behavior detection method is called to safely filter the abnormal client, so that the whole message interaction process is safely and finely controlled.

Owner:杨鲲

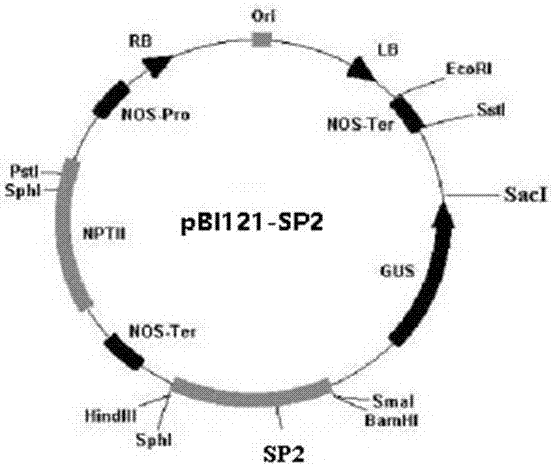

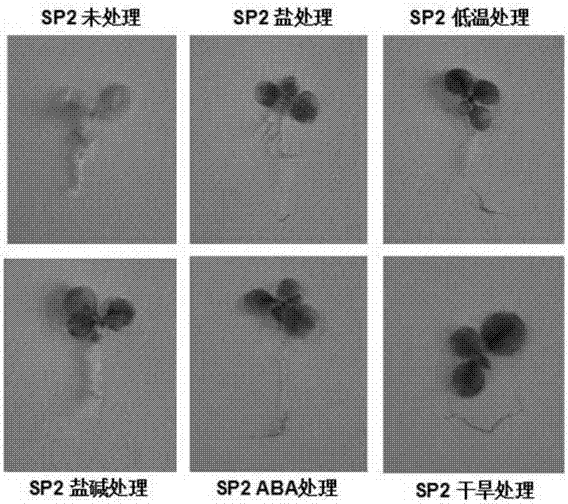

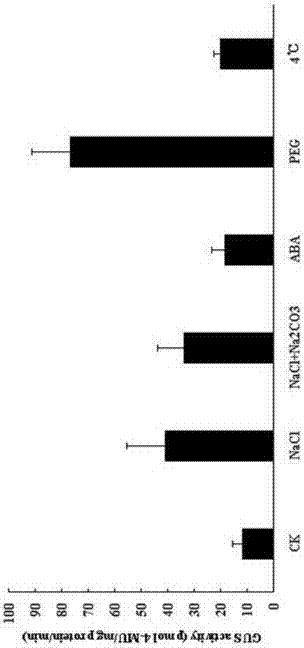

Plant drought-induced artificial synthesis promoter SP2 and application thereof

InactiveCN107164374ARealize fine controlPlant peptidesVector-based foreign material introductionEuryhalineReporter gene

The invention discloses a soybean-induced promoter SP2 and belongs to the construction of artificial synthesis promoters. The soybean-induced promoter SP2 is formed by taking G-box, ABRE, ABF, SORLIP1, CCA1 and E2F as basic cis elements, repeatedly connecting all the elements in series for four times, spacing every two elements through a random sequence of nine bases and then connecting a design fragment and a 35S key promoter Core-CaMV-35S, and is called SP2. The identification on the expression situation of an SP2 promoter-driven reporter gene GUS in transgenic tobaccos shows that the promoter SP2 can be induced by drought, salt, saline, ABA and low-temperature stress and is extremely sensitive to drought stress. The soybean-induced promoter SP2 disclosed by the invention can be directly applied to crop transgenic resistance seed breeding.

Owner:JILIN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com